Page 1

SYSTEM OVERVIEW

Home

Description: -48V DC @ up to 16,800 amperes Power System.

This power system is designed to power a load while charging a positive grounded

battery. This power system is capable of operating in a batteryless installation or off

battery for maintenance purposes. This power system is designed for operation with the

positive output grounded.

The N

Bay), and 801

system containing rectifiers, intelligent control, metering, monitoring, and distribution.

This power system consists of the following components.

• Power Bays

• Distribution Bays

SAG582140001

System Application Guide

Spec. No. 582140001 (Model 801

ETSURE™ 801NLDB (208V Input Power Bay), 801NLEB (380V/480V Input Power

NL-B (Distribution Bay) DC Power System is a complete integrated power

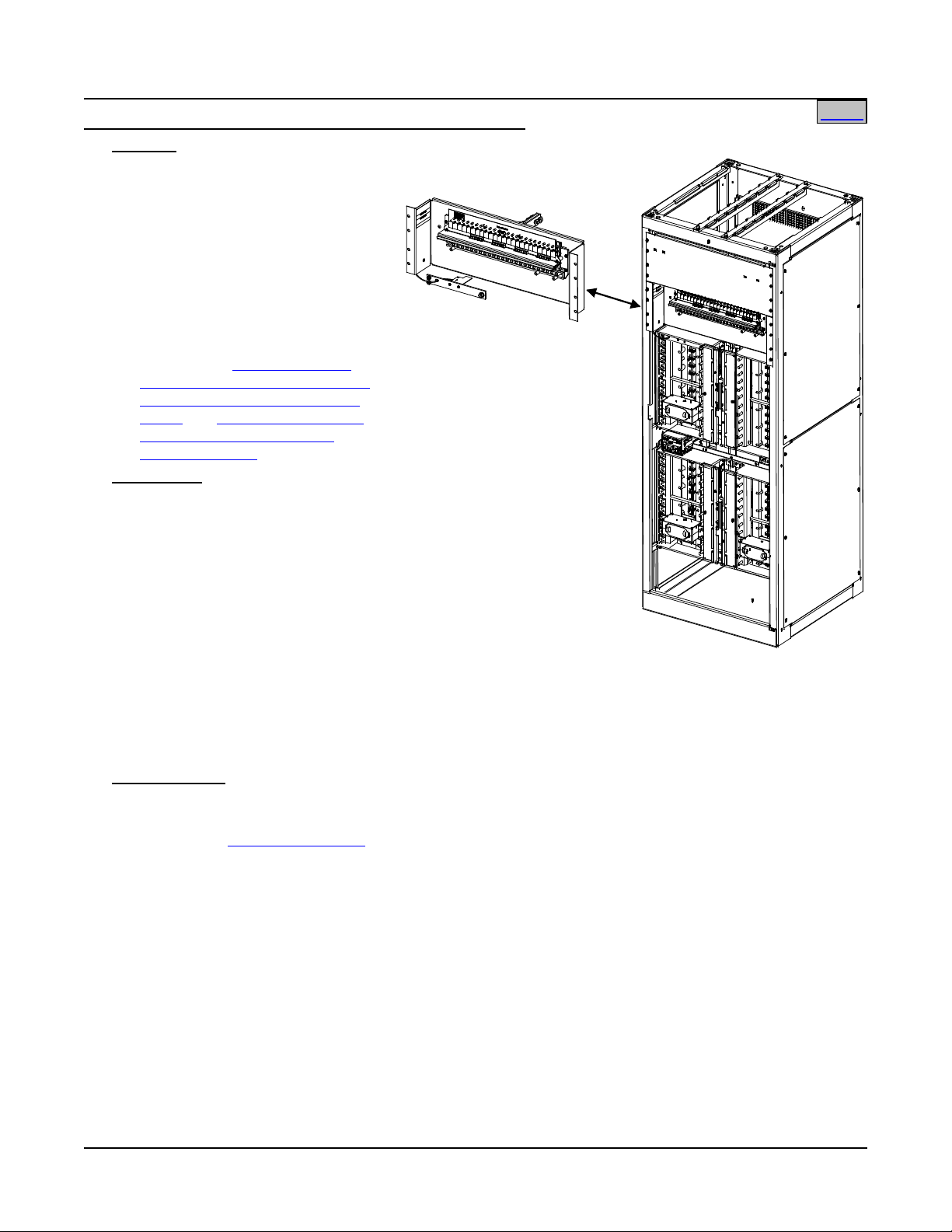

The system consists of one (1) Primary Power Bay and up to six (6) Secondary

Power Bays.

Each Power Bay can be equipped with up

to twenty-four (24) Rectifier Modules.

Each Power Bay contains a Monitor and

Control Panel. In the Primary Power Bay,

this panel houses the Meter-Control-Alarm

(MCA) assembly. This panel in the Primary

Power Bay also houses the optional LMS

Main CPU circuit card of the integrated

LMS Monitoring System. In a Secondary

Power Bay, this panel can be equipped

with an optional LMS Expansion CPU

circuit card. (The optional LMS Monitoring

System provides a higher level of

monitoring and controlling capabilities to

the power system.)

The Monitor and Control Panel in both

Primary and Secondary Power Bays

contain a seven-slot card cage to house

MCA alarm relay circuit cards, MCA

input/output (I/O) circuit cards, and optional

LMS I/O circuit cards. (If a Secondary

Power Bay is to be equipped with optional

LMS I/O circuit cards, it must also be

equipped with the LMS Expansion CPU

circuit card.)

The system consists of one (1) to eight (8)

Distribution Bays.

Each Distribution Bay provides four (4)

distribution buses.

Each distribution bus accepts a choice of

218-type circuit breakers and TPL-type

fuses.

A Distribution Bay may also be equipped

with an optional distribution panel which

accepts a choice of TPS/TLS-type

NLDB, 801NLEB, 801NL-B)

Issue AN, June 4, 2014

Power Bay

Page 1 of 115

This document is property of Emerson Network Power, Energy Systems, North America, Inc. and contains confidential and proprietary information owned by Emerson Network Power, Energy

Systems, North America, Inc. Any copying, use, or disclosure of it without the written permission of Emerson Network Power, Energy Systems, North America, Inc. is strictly prohibited.

Page 2

SAG582140001 System Application Guide

Home

Issue AN, June 4, 2014 Spec. No. 582140001 (Model 801

NLDB, 801NLEB, 801NL-B)

fuseholders or Bullet Nose-type circuit breakers.

• Rectifier Modules

The Rectifier Modules provide load power, battery float current, and battery recharge

current during normal operating conditions.

• MCA (Meter-Control-Alarm)

The MCA controls the operation of the Rectifier Modules and provides power system

control, metering, monitoring, and alarm functions.

MCA Local Control Panel: This panel is located on the front of the Primary Power

Bay and contains a keypad, display, and indicators for local MCA user interface.

MCA Relay Circuit Card: Each MCA relay circuit card provides six (6) sets of

Form-C relay contacts for customer external alarms. These relays are user

programmable for various power system alarms. Up to sixteen (16) MCA relay circuit

cards can be installed in the Primary

and Secondary Power Bays. The

Primary Power Bay is factory

equipped with two (2) MCA relay

circuit cards.

MCA I/O Circuit Cards: The MCA

I/O circuit cards provide analog

inputs/outputs and binary inputs. Up

to sixteen (16) MCA I/O circuit cards

can be installed in the Primary and

Secondary Power Bays.

• Optional Integrated

LMS Monitoring System

The LMS Monitoring System consists

of an LMS Main CPU circuit card,

optional LMS Expansion CPU circuit

cards, optional LMS I/O circuit cards,

optional LMS Expansion Cabinet,

and optional LMS Expansion

Assemblies.

The LMS Main CPU circuit card is

mounted in the Primary Power Bay.

Each Secondary Power Bay that is to

be equipped with optional LMS I/O

circuit cards must contain an LMS

Expansion CPU circuit card. LMS

Expansion Cabinets and LMS

Expansion Assemblies are available

that mount into customer racks and

equipment.

The LMS Monitoring System is

factory integrated within each Power

Bay, and requires no additional

customer interconnections within the

Power Bay. Simple cable

connections between Power and

Distribution Bays complete the

interbay connections required.

Separate analog, binary, and relay circuit cards do not have to be supplied for power

system monitoring. Analog, binary, relay, and temperature circuit cards can be

Distribution Bay

Page 2 of 115

This document is property of Emerson Network Power, Energy Systems, North America, Inc. and contains confidential and proprietary information owned by Emerson Network Power, Energy

Systems, North America, Inc. Any copying, use, or disclosure of it without the written permission of Emerson Network Power, Energy Systems, North America, Inc. is strictly prohibited.

Page 3

System Application Guide SAG582140001

Home

Spec. No. 582140001 (Model 801

NLDB, 801NLEB, 801NL-B) Issue AN, June 4, 2014

provided to monitor equipment external to the power system.

The LMS input circuit cards monitor a variety of analog, binary, and

temperature points external to the system. An LMS relay output circuit card is also

available which provides programmable relays. These relays may be used for

external alarms, or to control other equipment.

The LMS Monitoring System can be accessed via a local port, a modem port (when

optional modem is ordered), an optional TL1 port, and an Ethernet port (for Telnet

access, optional Web access, optional SNMP access, optional TL1 access, and

Email alarm reporting).

The LMS Monitoring System collects data from the power system and the input circuit

cards monitoring external points. The data collected is used for alarm processing

and reporting, and to provide statistics.

The LMS Monitoring System is capable of reporting alarm conditions to a remote

terminal, pager, Email address, via SNMP traps over Ethernet when the SNMP

option is ordered, or via TL1 (over Ethernet) when the 'TL1 over Ethernet' option is

ordered. TL1 is also available via a serial connection in 'direct mode'. For remote

terminal or pager notification, the LMS Main CPU circuit card must be equipped with

the optional modem. Two types of alarm reporting mechanisms are provided,

System Alarm Reporting and Individual User Alarm Reporting.

Refer to SAG586505000 for further LMS information. The SAG can be accessed via

the CD (Electronic Documentation Package) furnished with your system.

• Applications

ETSURE™ 801NLDB and 801NLEB is capable of interfacing with Vortex

The N

®

Power

Systems (VPS).

ETSURE™ 801NLDB and 801NLEB is capable of interfacing with legacy power

The N

systems.

Refer to the wiring diagrams in the Installation Instructions (Section 6016). Refer

also to Lists 64, 65, 66, and 67.

Page 3 of 115

This document is property of Emerson Network Power, Energy Systems, North America, Inc. and contains confidential and proprietary information owned by Emerson Network Power, Energy

Systems, North America, Inc. Any copying, use, or disclosure of it without the written permission of Emerson Network Power, Energy Systems, North America, Inc. is strictly prohibited.

Page 4

SAG582140001 System Application Guide

Home

Issue AN, June 4, 2014 Spec. No. 582140001 (Model 801

NLDB, 801NLEB, 801NL-B)

Family: N

ETSURE™

Spec. No.: 582140001

Model: 801

801

801

NLDB (208V Input Power Bay)

NLEB (380V/480V Input Power Bay)

NL-B (Distribution Bay)

Input Voltage Nominal 380/480 volts AC, three phase, 50/60 Hz, with an operating

range of 260 to 530 volts. Acceptable input frequency range is 45 to 65

Hz.

or

Nominal 208 volts AC, three phase, 50/60 Hz, with an operating range of

176 to 264 volts. Acceptable input frequency range is 45 to 65 Hz.

Output Voltage: -48 Volts DC

Output Capacity:

System: 16,800 Amperes, maximum

(Other configurations are available. For higher amperage configurations,

contact Emerson Network Power.)

Power Bay: 2400 Amperes, maximum

Rectifier Module: 100A / -48V

Distribution Bay: 6000 Amperes, maximum

Distribution Bus: 1500 Amperes, maximum

(four Distribution Buses

per Distribution Bay)

Optional Distribution Panel: 500 Amperes, maximum

(Bullet Nose Circuit

Breakers and/or TLS/TPS

Fuses) (one optional

Distribution Panel per

Distribution Bay)

Agency Approval: Model 801

NL-B (Distribution Bay): Listed UL 1801, NEBS

Model 801NLEB (Power Bay): Listed UL 1950, NEBS

Model 801NLDB (Power Bay):

Lists (All): Listed UL 1950

Lists (0B, 05, 13, 21, 50,

63, 64, 65, 66, 67, 70, 71): NEBS

Framework Type: Seismic Rated (Zone 4) Box Framework

Power Bay:

Width: 24.375 Inches

Depth: 30 Inches

Height: 84 Inches

Access: Front and Rear Access for Installation and Maintenance, Front for

Operation.

Distribution Bay:

Width: 31.375 Inches

Depth: 30 Inches

Height: 84 Inches

Access: Front and Rear Access for Installation and Maintenance, Front for

Operation.

Maximum Number of

Power Bays per System: 7

Page 4 of 115

This document is property of Emerson Network Power, Energy Systems, North America, Inc. and contains confidential and proprietary information owned by Emerson Network Power, Energy

Systems, North America, Inc. Any copying, use, or disclosure of it without the written permission of Emerson Network Power, Energy Systems, North America, Inc. is strictly prohibited.

Page 5

System Application Guide SAG582140001

Home

Spec. No. 582140001 (Model 801

NLDB, 801NLEB, 801NL-B) Issue AN, June 4, 2014

Maximum Number of

Distribution Bays per System: 8

Control: Microprocessor

Color: Gray

Environment: 0°C to +40°C (+32°F to +104°F)

Configurations: Plant is designed for centralized configuration with customer supplied

Main Battery Termination Bars (MBTB’s). Emerson Network Power

Services has standard MBTB’S in 4000, 6000, 10000, and 16000

ampere capacities. The ultimate plant capacity is determined by the

capacity of the MBTB’S.

Plant can be configured for distribution applications by bay-to-bay

cabling up to 9600 amperes.

Page 5 of 115

This document is property of Emerson Network Power, Energy Systems, North America, Inc. and contains confidential and proprietary information owned by Emerson Network Power, Energy

Systems, North America, Inc. Any copying, use, or disclosure of it without the written permission of Emerson Network Power, Energy Systems, North America, Inc. is strictly prohibited.

Page 6

SAG582140001 System Application Guide

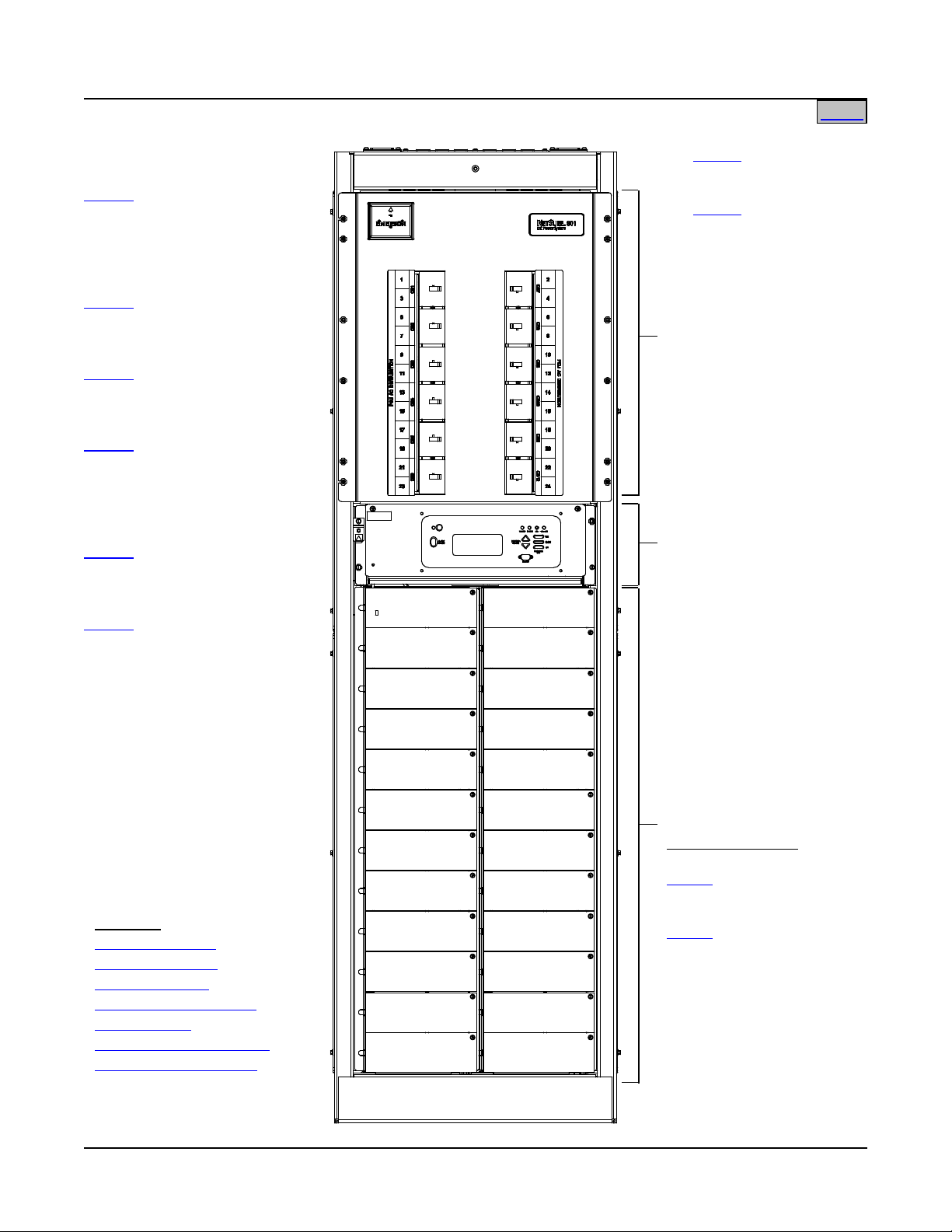

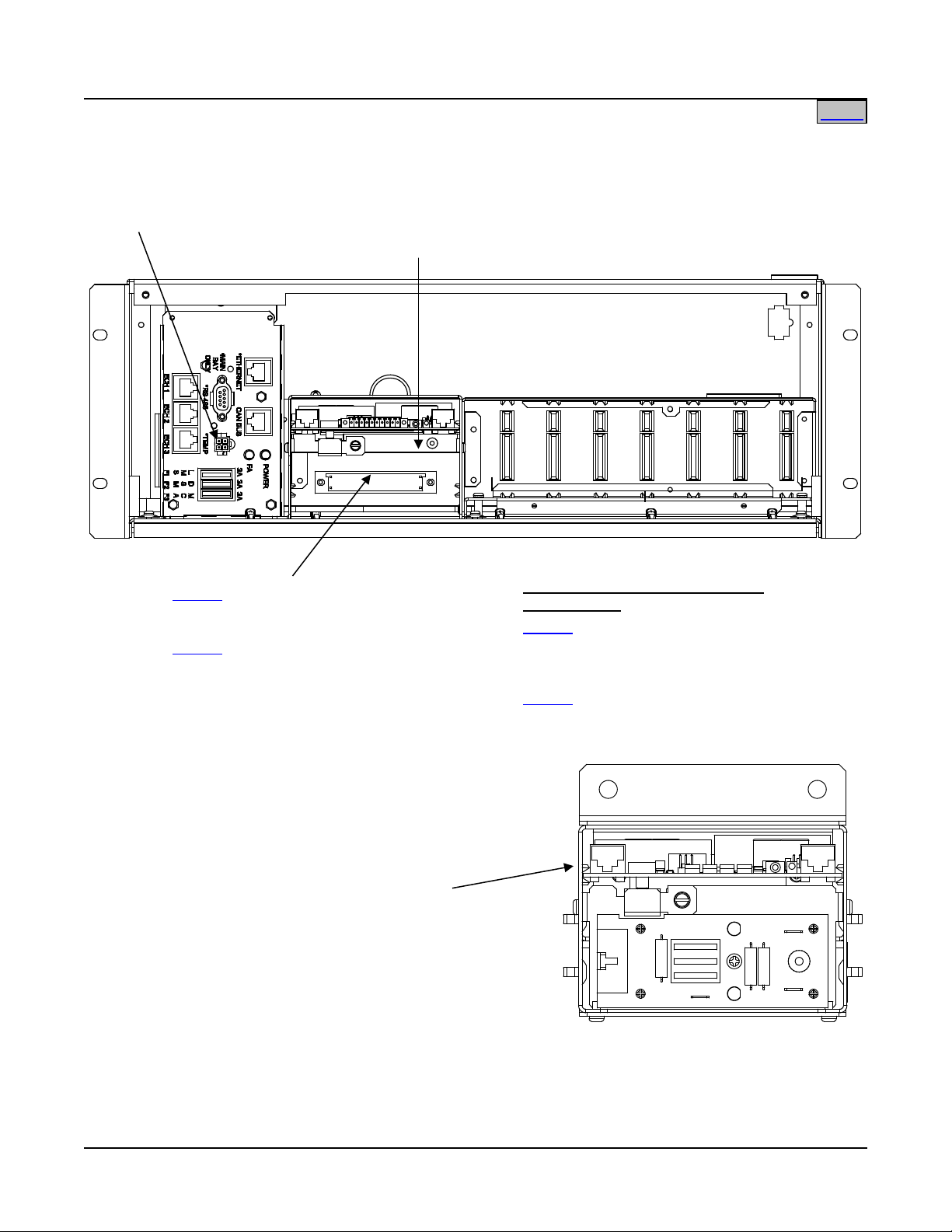

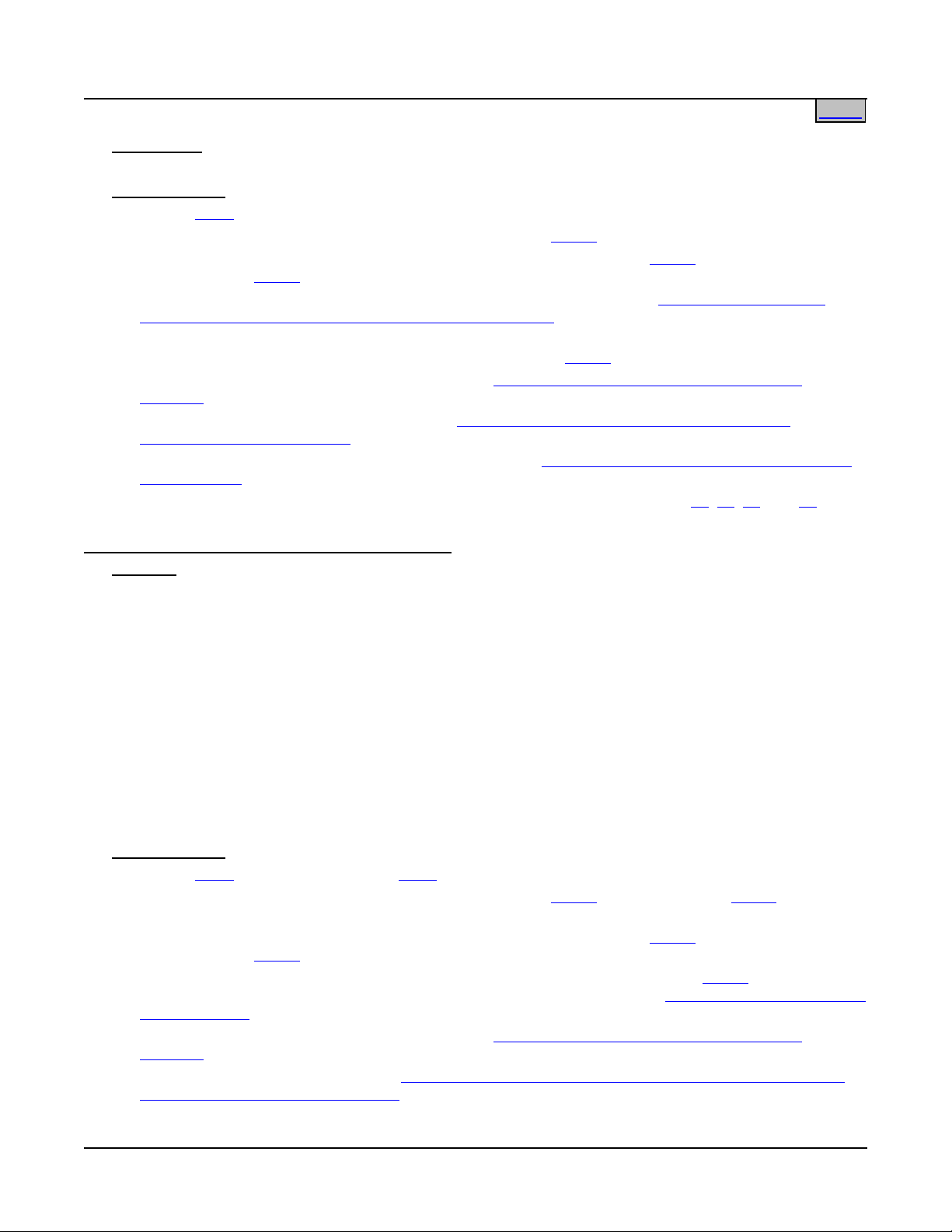

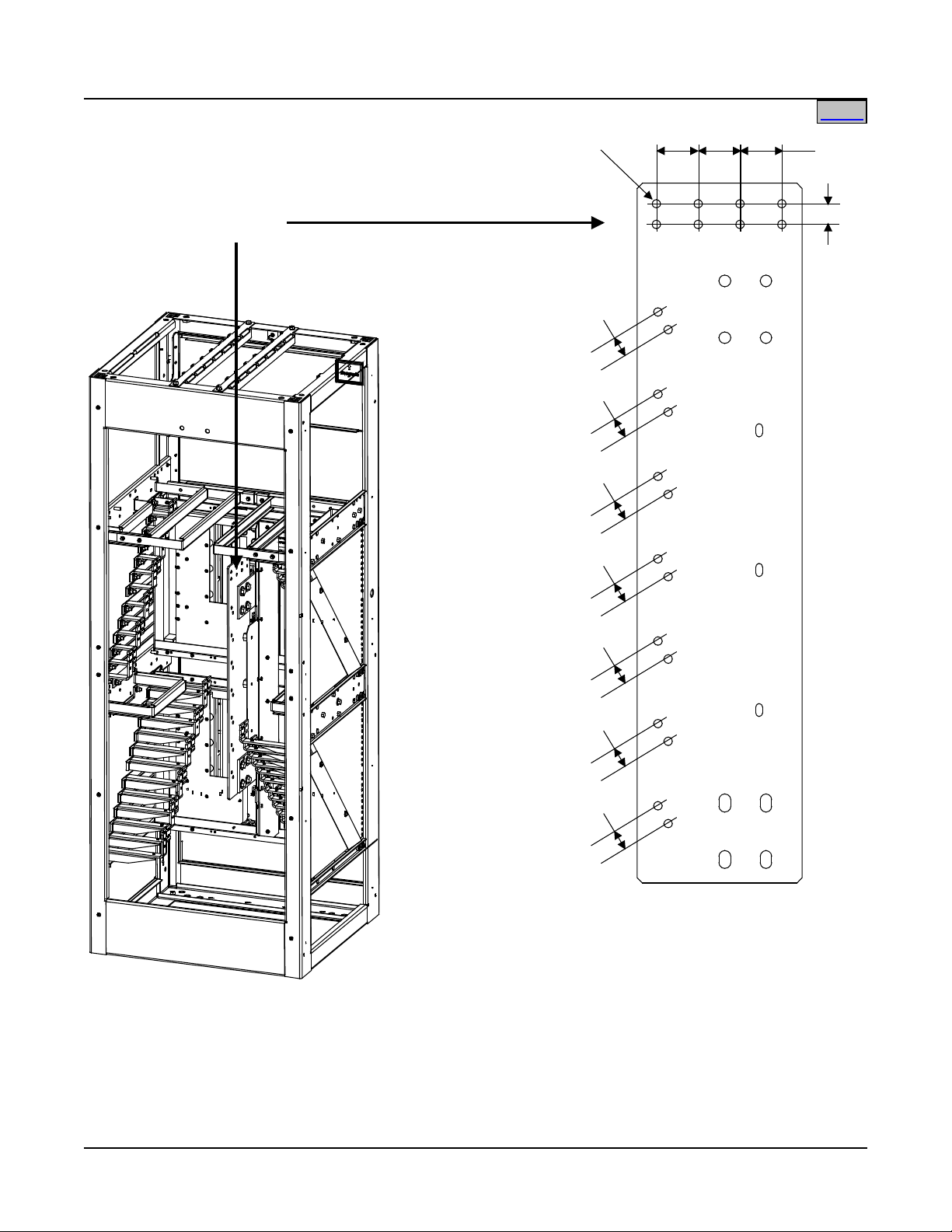

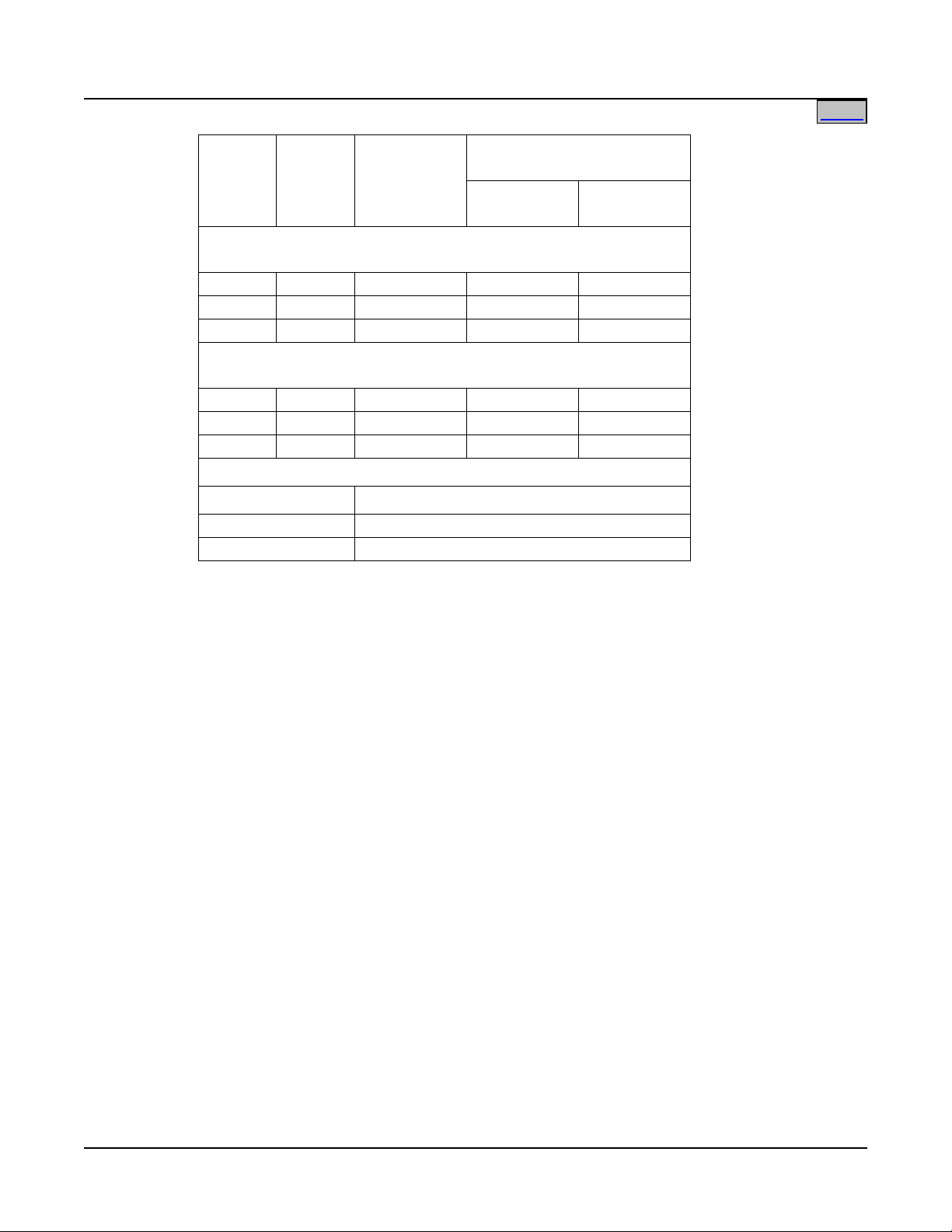

List 04: Primary Power Bay

List 05:

List 06:

List 12:

List 13:

List 14

(see Monitor and

Control Diagram)

Front View

See Also

Home

AC Input Termination Panel

and Optional AC Input

Breakers

List 0A: 380/480VAC

List 0B

Rectifier Module

Mounting Positions

List 21

List 22

Issue AN, June 4, 2014 Spec. No. 582140001 (Model 801

NLDB, 801NLEB, 801NL-B)

582140001 Power Bays

Plant Input

(2 AC Input Feeds)

(Includes Circuit

Breakers, One per Two

Rectifier Modules)

Primary Power Bay

(12 or 24 AC Input

Feeds)

Primary Power Bay

(6 Input Feeds)

480V only.

Secondary Power Bay

(2 AC Input Feeds)

(Includes Circuit

Breakers, One per Two

Rectifier Modules)

Secondary Power Bay

(12 or 24 AC Input

Feeds)

: Secondary Power Bay

(6 Input Feeds)

480V only.

: 208VAC Plant

Input

System Overview

Table of Contents

List Descriptions

Accessory Descriptions

Specifications

Physical Size Information

Related Documentation

This document is property of Emerson Network Power, Energy Systems, North America, Inc. and contains confidential and proprietary information owned by Emerson Network Power, Energy

Systems, North America, Inc. Any copying, use, or disclosure of it without the written permission of Emerson Network Power, Energy Systems, North America, Inc. is strictly prohibited.

Page 6 of 115

: Rectifier Module

(208VAC Input)

: Rectifier Module

(380/480VAC

Input)

Page 7

System Application Guide SAG582140001

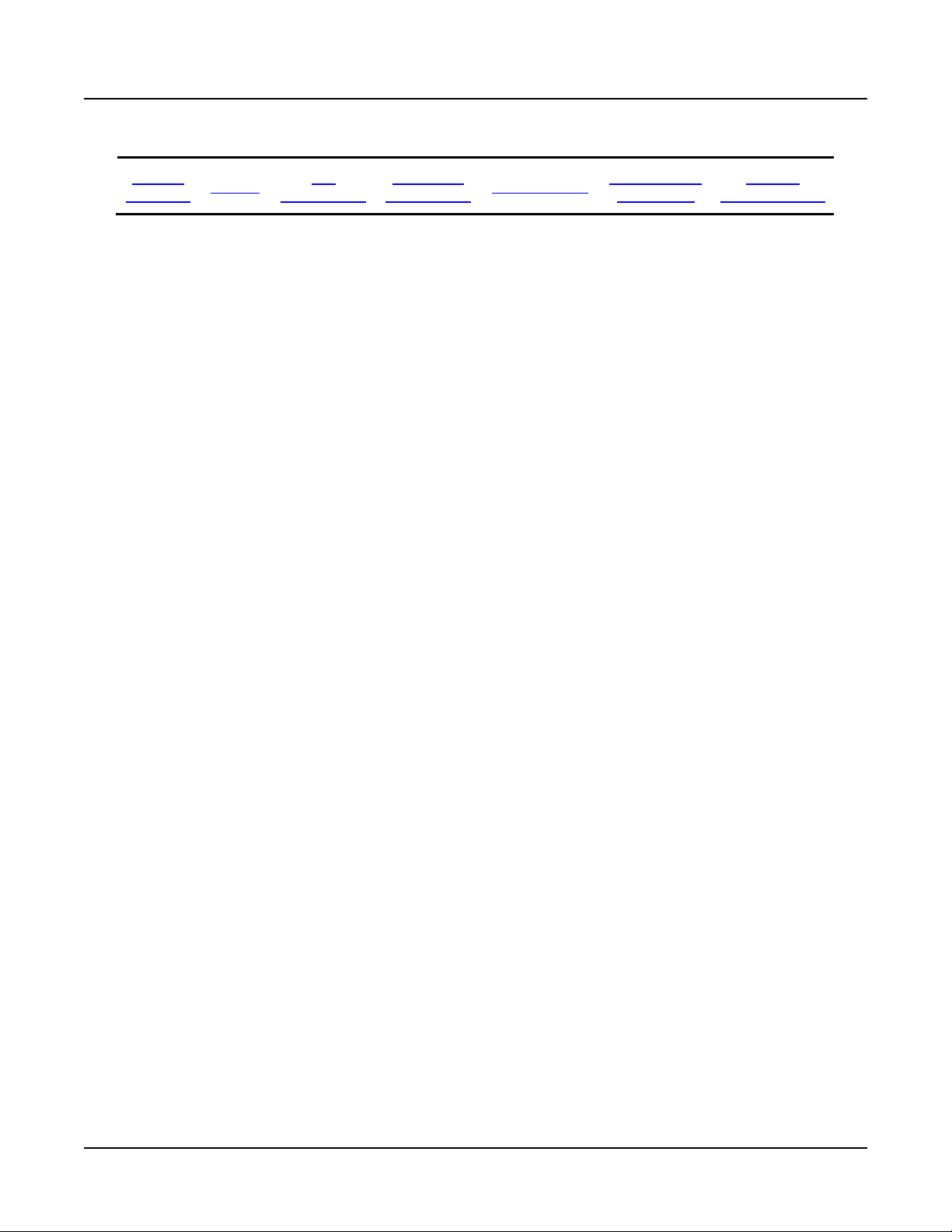

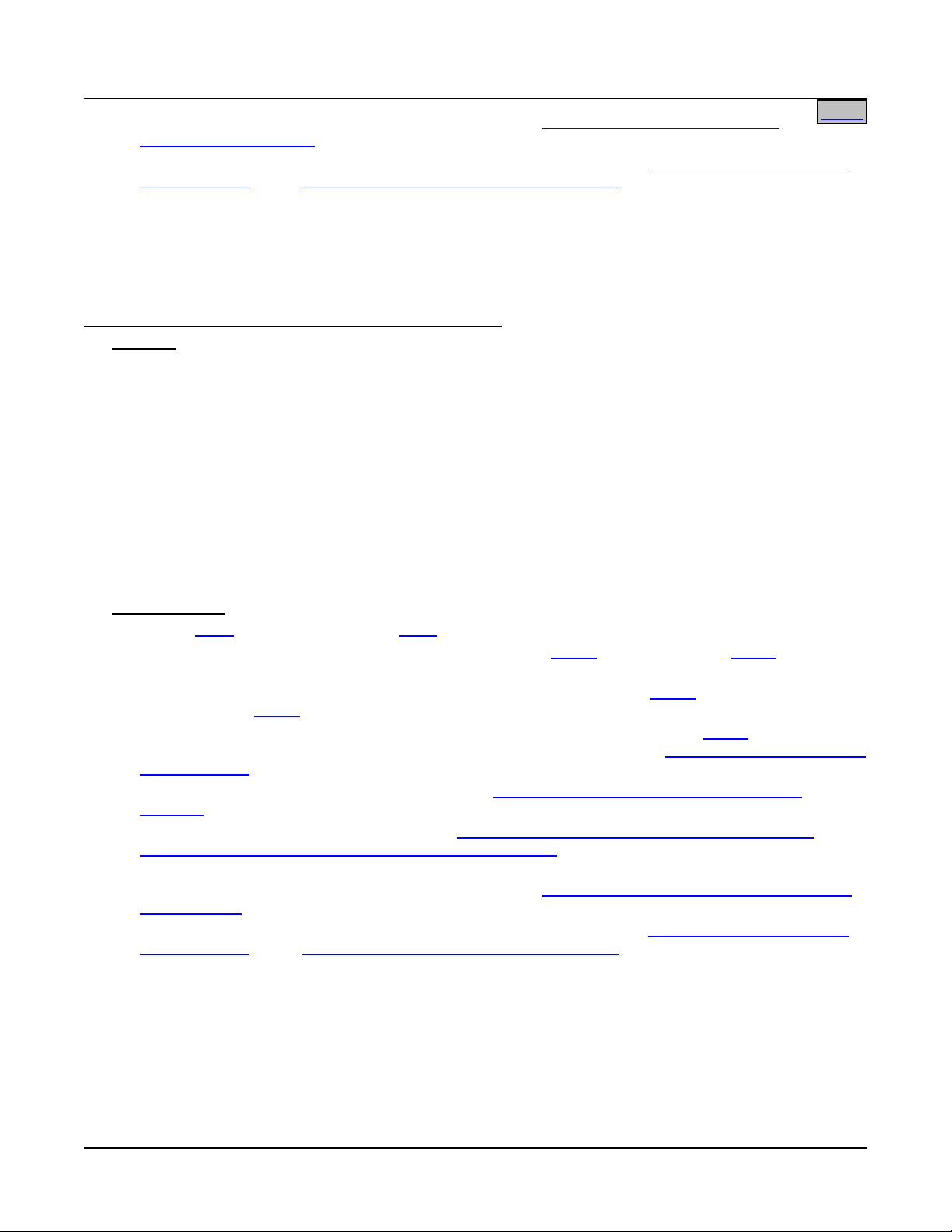

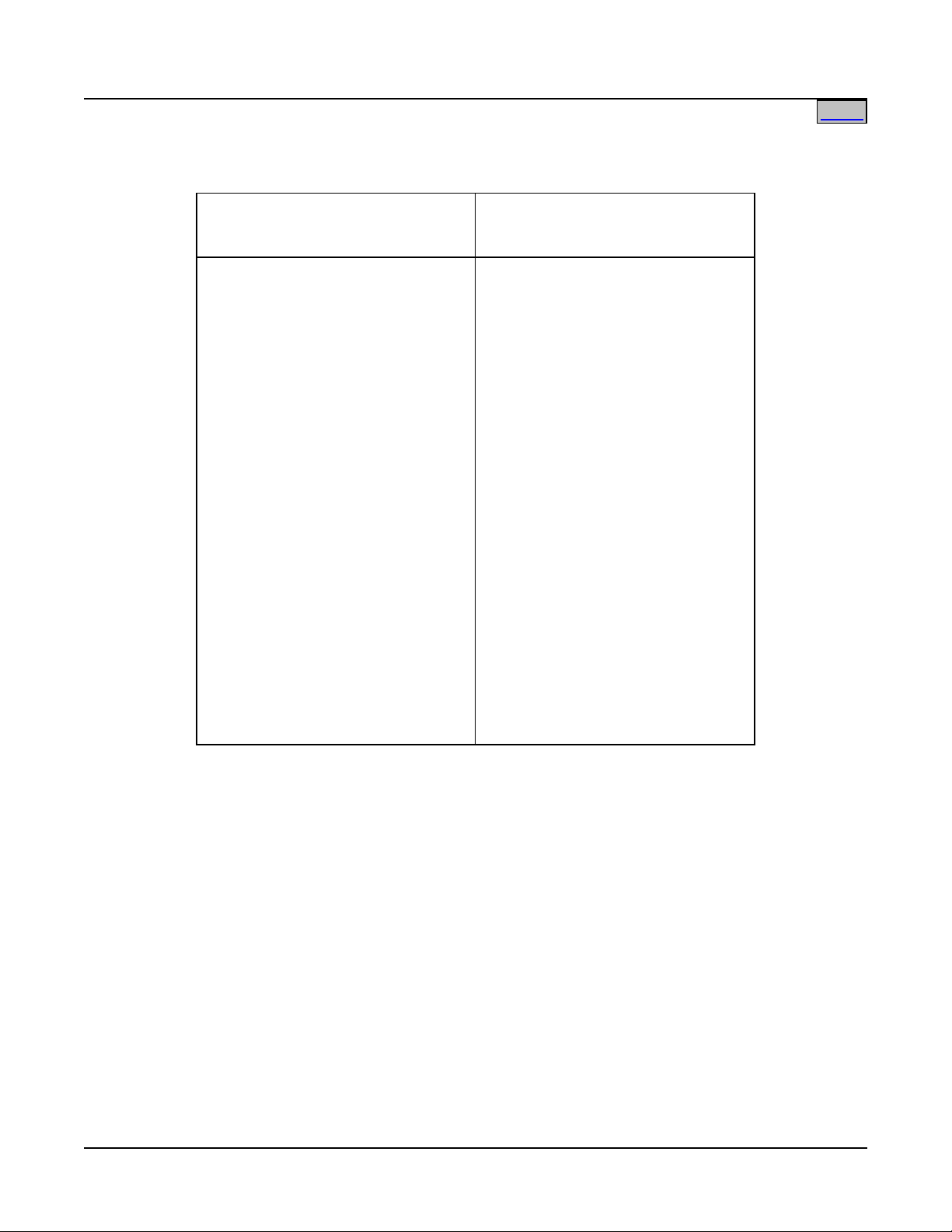

List 16: Distribution Bay

Distribution Bus

(see

Devices

ACCESSORY

DESCRIPTIONS

Section for

distribution

options)

Distribution Bus

(see

Devices

ACCESSORY

DESCRIPTIONS

Section for

distribution

options)

Distribution Bus

Distribution

in

ACCESSORY

DESCRIPTIONS

Section for

distribution

options)

Distribution Bus

Distribution

in

ACCESSORY

DESCRIPTIONS

Section for

ion

options)

(see Monitor and

Control Diagram)

Blank Panel

or

List 0C:

Front View

Home

Spec. No. 582140001 (Model 801

NLDB, 801NLEB, 801NL-B) Issue AN, June 4, 2014

582140001 Distribution Bays

Bullet

Fuse/Circuit

Breaker Panel

(see

(see

Devices

distribut

Devices

Distribution

in

Distribution

in

This document is property of Emerson Network Power, Energy Systems, North America, Inc. and contains confidential and proprietary information owned by Emerson Network Power, Energy

Systems, North America, Inc. Any copying, use, or disclosure of it without the written permission of Emerson Network Power, Energy Systems, North America, Inc. is strictly prohibited.

Page 7 of 115

Front door removed in

illustration for clarity.

Page 8

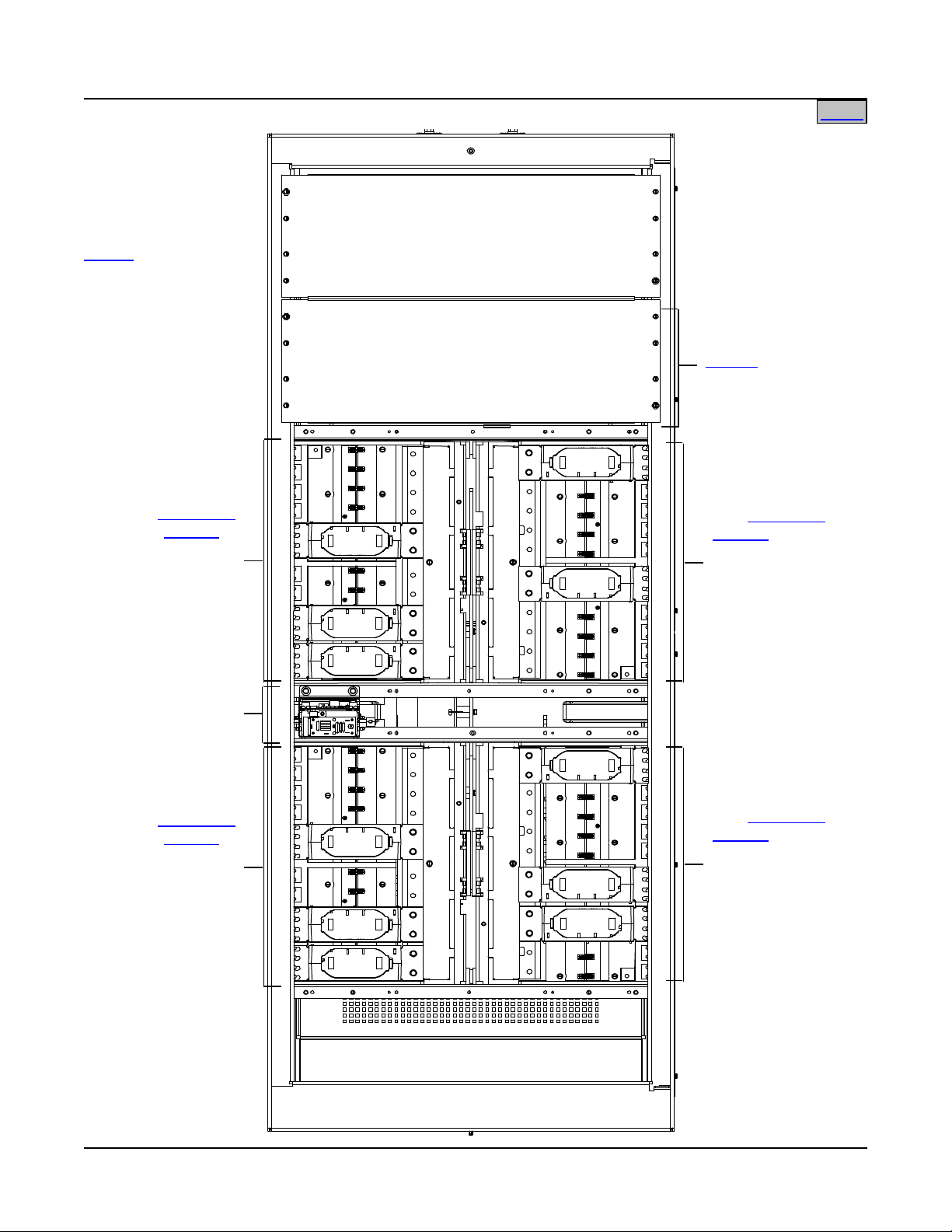

SAG582140001 System Application Guide

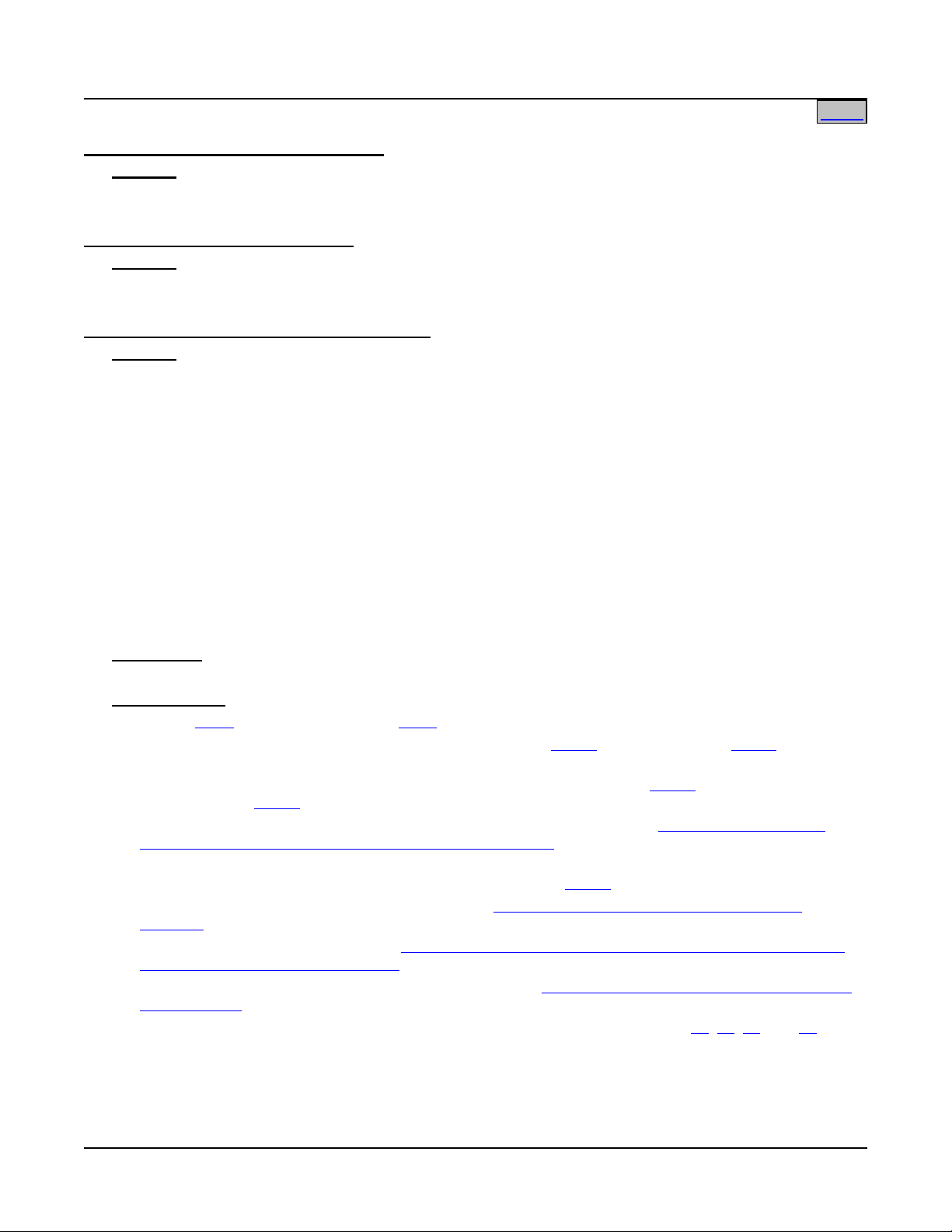

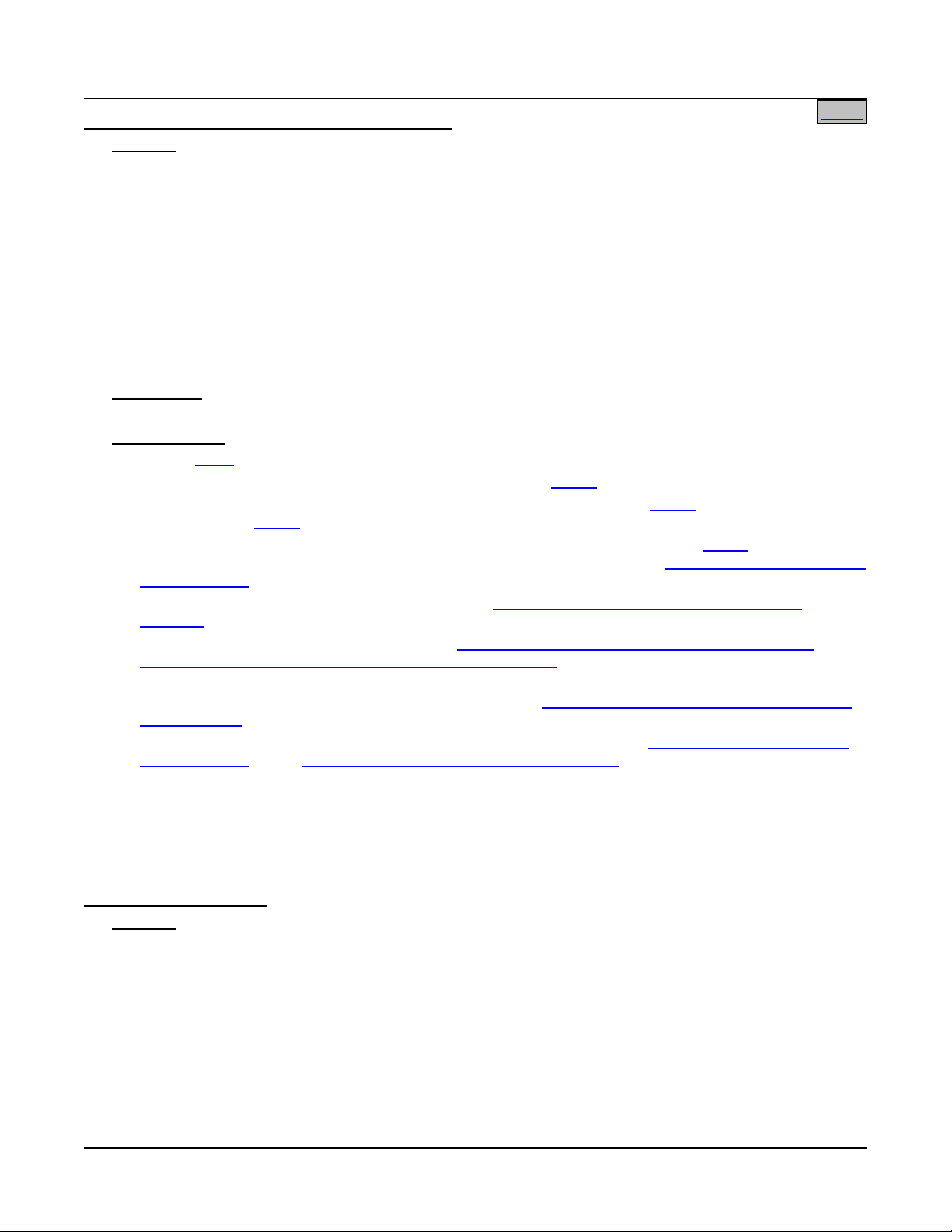

List 50: Optional LMS Main CPU

List 63:

Refer to SAG586505000

for additional LMS options.

Available MCA Input/Output (I/O)

Circuit Cards

List 70:

List 71:

P/O List 4 and 5: MCA Circuit Card

P/O List 12 and 13:

P/O Lists 16:

ROUTER Circuit Card

Front View

Battery Charge Temperature

Compensation Probe Connector

Home

Issue AN, June 4, 2014 Spec. No. 582140001 (Model 801

NLDB, 801NLEB, 801NL-B)

582140001 Power Bays Monitor and Control Diagram

(Primary Bay)

ROUTER Circuit Card

(Secondary Bay)

5821400

01

Circuit Card

or

Optional LMS Expansion

CPU Circuit Card

MCA Customer Alarm

MCA Analog Input/Output

Relay Circuit Card (Six [6]

Form-C Contacts)

and Binary Input Circuit

Card

Distribution Bays Monitor and Control Diagram

This document is property of Emerson Network Power, Energy Systems, North America, Inc. and contains confidential and proprietary information owned by Emerson Network Power, Energy

Systems, North America, Inc. Any copying, use, or disclosure of it without the written permission of Emerson Network Power, Energy Systems, North America, Inc. is strictly prohibited.

Page 8 of 115

Page 9

System Application Guide SAG582140001

Spec. No. 582140001 (Model 801

NLDB, 801NLEB, 801NL-B) Issue AN, June 4, 2014

TABLE OF CONTENTS

System

Overview

Picture

List

Descriptions

Accessory

Descriptions

Specifications

Physical Size

Information

Related

Documentation

SYSTEM OVERVIEW ................................................................................................................................................. 1

582140001 Power Bays ....................................................................................................................................... 6

582140001 Distribution Bays .............................................................................................................................. 7

582140001 Power Bays Monitor and Control Diagram .................................................................................... 8

582140001 Distribution Bays Monitor and Control Diagram .......................................................................... 8

TABLE OF CONTENTS ............................................................................................................................................. 9

LIST DESCRIPTIONS .............................................................................................................................................. 11

List 0A: 380/480VAC Plant Input Voltage ..................................................................................................... 11

List 0B: 208VAC Plant Input Voltage ............................................................................................................ 11

List 04: Primary Power Bay (2 AC Input Feeds) ........................................................................................... 11

List 05: Primary Power Bay (12 or 24 AC Input Feeds) ................................................................................ 12

List 06: Primary Power Bay (6 AC Input Feeds) ........................................................................................... 12

List 12: Secondary Power Bay (2 AC Input Feeds) ...................................................................................... 13

List 13: Secondary Power Bay (12 or 24 AC Input Feeds) ........................................................................... 14

List 14: Secondary Power Bay (6 AC Input Feeds) ...................................................................................... 15

List 16: Distribution Bay ................................................................................................................................ 15

List 21: Rectifier Module, 208V Input ............................................................................................................ 16

List 22: Rectifier Module, 380/480V Input ..................................................................................................... 16

List 24: Rectifier Module, 380/480V Input ..................................................................................................... 16

List 50: Optional LMS Main CPU Circuit Card (Primary Power Bay) ............................................................ 16

List 63: Optional LMS Expansion CPU Circuit Card (Secondary Power Bays) ............................................ 17

List 64: Interface Kit to a Spec. No. 582121900 Power System equipped with a DGU ................................ 17

List 65: Interface Kit to a Spec. No. 582121901 Power System equipped with an LMS1000 ...................... 18

List 66: Interface Kit to a Vortex Power System without a DGU or LMS1000 .............................................. 18

List 67: Interface Kit to a Model 1231H Legacy Power System with 1-8 Rectifiers ...................................... 18

List 70: Additional MCA Six (6) Output Form-C Relay Circuit Card .............................................................. 19

List 71: MCA I/O Circuit Card P/N 524550 .................................................................................................... 19

List 0C: 24 Position Bullet-Nose Circuit Breaker/Fuse Panel ....................................................................... 20

ACCESSORY DESCRIPTIONS ............................................................................................................................... 21

Seismic Anchor Kit, P/N 545387 ...................................................................................................................... 21

Seismic Anchor Isolation Kit, P/N 545388 ...................................................................................................... 21

Main Battery Termination Bars (MBTB’s) ....................................................................................................... 21

Distribution Device and Load Lug Locations ................................................................................................. 21

Distribution Devices .......................................................................................................................................... 25

218 Circuit Breaker Assemblies ..................................................................................................................... 25

TPL Fuses and Fuseholder Assemblies ........................................................................................................ 29

Bullet Nose-Type Circuit Breakers and Bullet Nose-Type Fuseholders e/w TLS/TPS Fuses ....................... 32

Optional Bullet Nose-Type 10-Position GMT Fuse Module for List C ............................................................ 37

Replacement Alarm, Reference, and Control Fuses ...................................................................................... 38

Fuseblock Located in Bay’s Left Center ........................................................................................................ 38

Input and Alarm Fuse on Optional Bullet Nose-Type 10-Position GMT Fuse Module, P/N 509128 ............. 39

Wiring Components .......................................................................................................................................... 40

Load Distribution Wire Sizes and Lugs Selection (Distribution Bay) ............................................................. 40

Power Bay DC Output Cable Sizes and Lugs Selection ................................................................................ 44

Distribution Bay DC Input Cable Sizes and Lugs Selection ........................................................................... 46

Power Bay Frame Grounding Wire Sizes and Lugs Selection ...................................................................... 48

Distribution Bay Frame Grounding Wire Sizes and Lugs Selection ............................................................... 49

Page 9 of 115

This document is property of Emerson Network Power, Energy Systems, North America, Inc. and contains confidential and proprietary information owned by Emerson Network Power, Energy

Systems, North America, Inc. Any copying, use, or disclosure of it without the written permission of Emerson Network Power, Energy Systems, North America, Inc. is strictly prohibited.

Page 10

SAG582140001 System Application Guide

Issue AN, June 4, 2014 Spec. No. 582140001 (Model 801

NLDB, 801NLEB, 801NL-B)

AC Input (12 or 24 AC Input Feeds) Wire and Conduit Sizes, Branch Circuit Protection, and Lugs

Selection Lists 5 and 13 ................................................................................................................................. 50

AC Input (6 AC Input Feeds) Wire and Conduit Sizes, Branch Circuit Protection, and Lugs

Selection Lists 6 and 14 ................................................................................................................................. 53

AC Input (2 AC Input Feeds) Wire and Conduit Sizes, Branch Circuit Protection, and Lugs

Selection Lists 4 and 12 ................................................................................................................................ 59

External Alarm, Reference, and Control Wire Sizes - Power Bays ............................................................... 62

Optional Battery Charge Temperature Compensation Probe for Digital Compensation ........................... 63

Replacement/Additional MCA Network Cable ................................................................................................ 64

Replacement/Additional LMS Network Cable ................................................................................................. 64

Replacement Modules and Circuit Cards ....................................................................................................... 65

SPECIFICATIONS .................................................................................................................................................... 66

1. System ........................................................................................................................................................... 66

1.1 DC Operating Voltage .............................................................................................................................. 66

1.2 Environmental Ratings ............................................................................................................................. 66

1.3 Compliance Information ........................................................................................................................... 67

1.4 Local Controls and Indicators ................................................................................................................... 67

2. Distribution Bay ............................................................................................................................................ 67

2.1 DC Ratings ............................................................................................................................................... 67

3. Rectifier Module (Model R48-5800, Spec. No. 1R485800) ......................................................................... 68

3.1 DC Output Ratings ................................................................................................................................... 68

3.2 AC Input Ratings ...................................................................................................................................... 71

3.3 Environmental Ratings ............................................................................................................................. 71

3.4 Standard Features .................................................................................................................................... 74

4. Rectifier Module (Model R48-5800L, Spec. No. 1R485800L)..................................................................... 78

4.1 DC Output Ratings ................................................................................................................................... 78

4.2 AC Input Ratings ...................................................................................................................................... 81

4.3 Environmental Ratings ............................................................................................................................. 81

4.4 Standard Features .................................................................................................................................... 84

5. Rectifier Module (Model R48-5800E Spec. No. 1R485800E) ..................................................................... 88

5.1 DC Output Ratings ................................................................................................................................... 88

5.2 AC Input Ratings ...................................................................................................................................... 91

5.3 Environmental Ratings ............................................................................................................................. 91

5.4 Standard Features .................................................................................................................................... 94

6. MCA ................................................................................................................................................................ 98

6.1 Standard Features .................................................................................................................................... 98

7. Optional LMS Monitoring System ............................................................................................................. 109

PHYSICAL SIZE INFORMATION .......................................................................................................................... 110

Floor Hole Drilling Pattern Dimensions - Power Bays ................................................................................. 110

Floor Hole Drilling Pattern Dimensions - Distribution Bays ....................................................................... 110

Overall Dimensions - Primary and Secondary Power Bays ........................................................................ 111

Overall Dimensions - Distribution Bays ........................................................................................................ 112

Overall Dimensions – Optional Battery Charge Digital Temperature Compensation Probes P/N

107021 (25 feet) and P/N 106824 (100 feet) ................................................................................................... 113

RELATED DOCUMENTATION .............................................................................................................................. 114

REVISION RECORD .............................................................................................................................................. 115

Page 10 of 115

This document is property of Emerson Network Power, Energy Systems, North America, Inc. and contains confidential and proprietary information owned by Emerson Network Power, Energy

Systems, North America, Inc. Any copying, use, or disclosure of it without the written permission of Emerson Network Power, Energy Systems, North America, Inc. is strictly prohibited.

Page 11

System Application Guide SAG582140001

Home

Spec. No. 582140001 (Model 801

NLDB, 801NLEB, 801NL-B) Issue AN, June 4, 2014

LIST DESCRIPTIONS

List 0A: 380/480VAC Plant Input Voltage

Features

♦ Specifies 380/480VAC Plant Input Voltage.

List 0B: 208VAC Plant Input Voltage

Features

♦ Specifies 208VAC Plant Input Voltage.

List 04: Primary Power Bay (2 AC Input Feeds)

Features

♦ Provides common equipment for one (1) Power Bay rated for up to 2400 amperes.

♦ Mounted in a 7'0"H x 24.375"W x 30"D seismic rated (Zone 4) box framework.

♦ Provides twenty-four (24) Rectifier Module mounting positions.

♦ Provides an AC input termination panel that accepts two (2) AC input branch circuits, one (1) per twelve

(12) Rectifier Module mounting positions. A 60A AC input circuit breaker rated for 65kA interrupting

capacity is provided for each pair of rectifier positions in the List B Bay. A 30A AC input circuit breaker

rated for 22kA interrupting capacity is provided for each pair of rectifier positions in the List A Bay.

♦ Provides the MCA Assembly and Local MCA Control Panel.

♦ Provides mounting for optional LMS Main CPU circuit card.

♦ Provides a seven-slot card cage for mounting MCA customer alarm relay circuit cards, MCA I/O circuit

cards, and/or optional LMS I/O circuit cards. Two (2) MCA customer alarm relay circuit cards furnished,

providing twelve (12) Form-C relay contacts

♦ Side cover panels are factory installed on both sides of the bay.

Restrictions

Only one (1) Primary Bay per power system required.

Ordering Notes

1) Specify List A (380/480VAC Input) or List B (208VAC Input).

2) Order up to twenty-four (24) Rectifiers Modules per bay per List 21 (208VAC Input) or List 22

(380/480VAC Input).

3) Order additional MCA customer alarm relay circuit card(s) as required per List 70, and optional MCA I/O

circuit cards per List 71.

4) Order a Battery Charge Temperature Compensation Probe as required per Optional Battery Charge

Temperature Compensation Probe for Digital Compensation in the ACCESSORY DESCRIPTIONS

section.

5) Order optional LMS Monitor and LMS options as required per List 50, and SAG586505000.

6) Order “Power Bay DC Output” lugs as required per Power Bay DC Output Cable Sizes and Lugs

Selection in the ACCESSORY DESCRIPTIONS section.

7) Order “AC Input” lugs as required per AC Input (Dual AC Input Feeds) Wire and Conduit Sizes, Branch

Circuit Protection, and Lugs Selection in the ACCESSORY DESCRIPTIONS section.

8) Order “Power Bay Frame Grounding” lugs as required per Power Bay Frame Grounding Wire Sizes and

Lugs Selection in the ACCESSORY DESCRIPTIONS section.

9) If the system is to be connected to an existing system with an MCA, refer to List 64, 65, 66, and 67.

Page 11 of 115

This document is property of Emerson Network Power, Energy Systems, North America, Inc. and contains confidential and proprietary information owned by Emerson Network Power, Energy

Systems, North America, Inc. Any copying, use, or disclosure of it without the written permission of Emerson Network Power, Energy Systems, North America, Inc. is strictly prohibited.

Page 12

SAG582140001 System Application Guide

Home

Issue AN, June 4, 2014 Spec. No. 582140001 (Model 801

NLDB, 801NLEB, 801NL-B)

List 05: Primary Power Bay (12 or 24 AC Input Feeds)

Features

♦ Provides common equipment for one (1) Power Bay rated for up to 2400 amperes.

♦ Mounted in a 7'0"H x 24.375"W x 30"D seismic rated (Zone 4) box framework.

♦ Provides twenty-four (24) Rectifier Module mounting positions.

♦ Provides an AC input termination panel that accepts twenty-four (24) AC input branch circuits [one (1) per

Rectifier Module mounting position] or twelve (12) AC input branch circuits [one (1) per two Rectifier

Module mounting positions]. The bay ships with the 12 Feed option installed.

♦ Provides the MCA Assembly and Local MCA Control Panel.

♦ Provides mounting for optional LMS Main CPU circuit card.

♦ Provides a seven-slot card cage for mounting MCA customer alarm relay circuit cards, MCA I/O circuit

cards, and/or optional LMS I/O circuit cards. Two (2) MCA customer alarm relay circuit cards furnished,

providing twelve (12) Form-C relay contacts.

♦ Side cover panels are factory installed on both sides of the bay.

Restrictions

Only one (1) Primary Bay per power system required.

Ordering Notes

1) Specify List A (380/480VAC Input) or List B (208VAC Input).

2) Order up to twenty-four (24) Rectifiers Modules per bay per List 21 (208VAC Input) or List 22

(380/480VAC Input).

3) Order additional MCA customer alarm relay circuit card(s) as required per List 70, and optional MCA I/O

circuit cards per List 71.

4) Order a Battery Charge Temperature Compensation Probe as required per Optional Battery Charge

Temperature Compensation Probe for Digital Compensation in the ACCESSORY DESCRIPTIONS

section.

5) Order optional LMS Monitor and LMS options as required per List 50, and SAG586505000.

6) Order “Power Bay DC Output” lugs as required per Power Bay DC Output Cable Sizes and Lugs

Selection in the ACCESSORY DESCRIPTIONS section.

7) Order “AC Input Ground” lugs as required per AC Input (Individual/Twin AC Input Feeds) Wire and

Conduit Sizes, Branch Circuit Protection, and Lugs Selection in the ACCESSORY DESCRIPTIONS

section.

8) Order “Power Bay Frame Grounding” lugs as required per Power Bay Frame Grounding Wire Sizes and

Lugs Selection in the ACCESSORY DESCRIPTIONS section.

9) If the system is to be connected to an existing system with an MCA, refer to List 64, 65, 66, and 67.

List 06: Primary Power Bay (6 AC Input Feeds)

Features

♦ Provides common equipment for one (1) Power Bay rated for up to 2400 amperes.

♦ Mounted in a 7'0"H x 24.375"W x 30"D seismic rated (Zone 4) box framework.

♦ Provides twenty-four (24) Rectifier Module mounting positions.

♦ Provides an AC input termination panel that accepts six (6) AC input branch circuits [one (1) per four

Rectifier Module mounting positions].

♦ Provides the MCA Assembly and Local MCA Control Panel.

♦ Provides mounting for optional LMS Main CPU circuit card.

♦ Provides a seven-slot card cage for mounting MCA customer alarm relay circuit cards, MCA I/O circuit

cards, and/or optional LMS I/O circuit cards. Two (2) MCA customer alarm relay circuit cards furnished,

providing twelve (12) Form-C relay contacts.

Page 12 of 115

This document is property of Emerson Network Power, Energy Systems, North America, Inc. and contains confidential and proprietary information owned by Emerson Network Power, Energy

Systems, North America, Inc. Any copying, use, or disclosure of it without the written permission of Emerson Network Power, Energy Systems, North America, Inc. is strictly prohibited.

Page 13

System Application Guide SAG582140001

Home

Spec. No. 582140001 (Model 801

NLDB, 801NLEB, 801NL-B) Issue AN, June 4, 2014

♦ Side cover panels are factory installed on both sides of the bay.

Restrictions

Only one (1) Primary Bay per power system required. 480V only.

Ordering Notes

1) Specify List A (480VAC Input).

2) Order up to twenty-four (24) Rectifiers Modules per bay per List 22 (380/480VAC Input).

3) Order additional MCA customer alarm relay circuit card(s) as required per List 70, and optional MCA I/O

circuit cards per List 71.

4) Order a Battery Charge Temperature Compensation Probe as required per Optional Battery Charge

Temperature Compensation Probe for Digital Compensation in the ACCESSORY DESCRIPTIONS

section.

5) Order optional LMS Monitor and LMS options as required per List 50, and SAG586505000.

6) Order “Power Bay DC Output” lugs as required per Power Bay DC Output Cable Sizes and Lugs

Selection in the ACCESSORY DESCRIPTIONS section.

7) Order “AC Input Ground” lugs as required per AC Input Wire and Conduit Sizes, Branch Circuit

Protection, and Lugs Selection in the ACCESSORY DESCRIPTIONS section.

8) Order “Power Bay Frame Grounding” lugs as required per Power Bay Frame Grounding Wire Sizes and

Lugs Selection in the ACCESSORY DESCRIPTIONS section.

9) If the system is to be connected to an existing system with an MCA, refer to List 64, 65, 66, and 67.

List 12: Secondary Power Bay (2 AC Input Feeds)

Features

♦ Provides common equipment for one (1) Power Bay rated for up to 2400 amperes.

♦ Mounted in a 7'0"H x 24.375"W x 30"D seismic rated (Zone 4) box framework.

♦ Provides twenty-four (24) Rectifier Module mounting positions.

♦ Provides an AC input termination panel that accepts two (2) AC input branch circuits, one (1) per twelve

(12) Rectifier Module mounting positions. A 60A AC input circuit breaker rated for 65kA interrupting

capacity is provided for each pair of rectifier positions in the List B Bay. A 30A AC input circuit breaker

rated for 22kA interrupting capacity is provided for each pair of rectifier positions in the List A Bay.

♦ Includes a Router Assembly for bay communication to the MCA in the Primary Power Bay.

♦ Provides mounting for optional LMS Expansion CPU circuit card.

♦ Provides a seven-slot card cage for mounting MCA customer alarm relay circuit cards, MCA I/O circuit

cards, and/or optional LMS I/O circuit cards.

♦ MCA Network bay interconnect cable provided (Qty. 1 P/N 514642).

Ordering Notes

1) Specify List A (380/480VAC Input) or List B (208VAC Input).

2) Order up to twenty-four (24) Rectifiers Modules per bay per List 21 (208VAC Input) or List 22

(380/480VAC Input).

3) Order additional MCA customer alarm relay circuit card(s) as required per List 70, and optional MCA I/O

circuit cards per List 71.

4) Order optional LMS Expansion CPU circuit card and LMS options as required per List 63, and

SAG586505000. Also order additional LMS Network cables as required per Replacement/Additional LMS

Network Cables.

5) Order “Power Bay DC Output” lugs as required per Power Bay DC Output Cable Sizes and Lugs

Selection in the ACCESSORY DESCRIPTIONS section.

6) Order “AC Input” lugs as required per AC Input (Dual AC Input Feeds) Wire and Conduit Sizes, Branch

Circuit Protection, and Lugs Selection in the ACCESSORY DESCRIPTIONS section.

Page 13 of 115

This document is property of Emerson Network Power, Energy Systems, North America, Inc. and contains confidential and proprietary information owned by Emerson Network Power, Energy

Systems, North America, Inc. Any copying, use, or disclosure of it without the written permission of Emerson Network Power, Energy Systems, North America, Inc. is strictly prohibited.

Page 14

SAG582140001 System Application Guide

Home Home

Issue AN, June 4, 2014 Spec. No. 582140001 (Model 801

NLDB, 801NLEB, 801NL-B)

7) Order “Power Bay Frame Grounding” lugs as required per Power Bay Frame Grounding Wire

Sizes and Lugs Selection in the ACCESSORY DESCRIPTIONS section.

8) If a different length LMS and/or MCA Network cable is required, order per Replacement/Additional LMS

Network Cables and/or Replacement/Additional MCA Network Cables. Refer to the Installation

Instructions (Section 6016) for Network cabling requirements.

9) Side cover panels are not provided. When bays are placed next to each other, the side cover panels

from the ‘inside’ side of the Primary Power Bay are moved to the ‘outside’ side of the last Secondary

Power Bay. In installations where a Secondary Power Bay is placed by itself, order (4) P/N 535092 side

cover panels.

List 13: Secondary Power Bay (12 or 24 AC Input Feeds)

Features

♦ Provides common equipment for one (1) Power Bay rated for up to 2400 amperes.

♦ Mounted in a 7'0"H x 24.375"W x 30"D seismic rated (Zone 4) box framework.

♦ Provides twenty-four (24) Rectifier Module mounting positions.

♦ Provides an AC input termination panel that accepts twenty-four (24) AC input branch circuits [one (1) per

Rectifier Module mounting position] or twelve (12) AC input branch circuits [one (1) per two Rectifier

Module mounting positions]. The bay ships with the 12 Feed option installed.

♦ Includes a Router Assembly for bay communication to the MCA in the Primary Power Bay.

♦ Provides mounting for optional LMS Expansion CPU circuit card.

♦ Provides a seven-slot card cage for mounting MCA customer alarm relay circuit cards, MCA I/O circuit

cards, and/or optional LMS I/O circuit cards.

♦ MCA Network bay interconnect cable provided (Qty. 1 P/N 514642).

Ordering Notes

1) Specify List A (380/480VAC Input) or List B (208VAC Input).

2) Order up to twenty-four (24) Rectifiers Modules per bay per List 21 (208VAC Input) or List 22

(380/480VAC Input).

3) Order additional MCA customer alarm relay circuit card(s) as required per List 70, and optional MCA I/O

circuit cards per List 71.

4) Order optional LMS Expansion CPU circuit card and LMS options as required per List 63, and

SAG586505000. Also order additional LMS Network cables as required per Replacement/Additional LMS

Network Cables.

5) Order “Power Bay DC Output” lugs as required per Power Bay DC Output Cable Sizes and Lugs

Selection in the ACCESSORY DESCRIPTIONS section.

6) Order “AC Input Ground” lugs as required per AC Input (Individual/Twin AC Input Feeds) Wire and

Conduit Sizes, Branch Circuit Protection, and Lugs Selection in the ACCESSORY DESCRIPTIONS

section.

7) Order “Power Bay Frame Grounding” lugs as required per Power Bay Frame Grounding Wire Sizes and

Lugs Selection in the ACCESSORY DESCRIPTIONS section.

8) If a different length LMS and/or MCA Network cable is required, order per Replacement/Additional LMS

Network Cables and/or Replacement/Additional MCA Network Cables. Refer to the Installation

Instructions (Section 6016) for Network cabling requirements.

9) Side cover panels are not provided. When bays are placed next to each other, the side cover panels

from the ‘inside’ side of the Primary Power Bay are moved to the ‘outside’ side of the last Secondary

Power Bay. In installations where a Secondary Power Bay is placed by itself, order (4) P/N 535092 side

cover panels.

Page 14 of 115

This document is property of Emerson Network Power, Energy Systems, North America, Inc. and contains confidential and proprietary information owned by Emerson Network Power, Energy

Systems, North America, Inc. Any copying, use, or disclosure of it without the written permission of Emerson Network Power, Energy Systems, North America, Inc. is strictly prohibited.

Page 15

System Application Guide SAG582140001

Home

Spec. No. 582140001 (Model 801

NLDB, 801NLEB, 801NL-B) Issue AN, June 4, 2014

List 14: Secondary Power Bay (6 AC Input Feeds)

Features

♦ Provides common equipment for one (1) Power Bay rated for up to 2400 amperes.

♦ Mounted in a 7'0"H x 24.375"W x 30"D seismic rated (Zone 4) box framework.

♦ Provides twenty-four (24) Rectifier Module mounting positions.

♦ Provides an AC input termination panel that accepts six (6) AC input branch circuits [one (1) per four

Rectifier Module mounting positions].

♦ Includes a Router Assembly for bay communication to the MCA in the Primary Power Bay.

♦ Provides mounting for optional LMS Expansion CPU circuit card.

♦ Provides a seven-slot card cage for mounting MCA customer alarm relay circuit cards, MCA I/O circuit

cards, and/or optional LMS I/O circuit cards.

♦ MCA Network bay interconnect cable provided (Qty. 1 P/N 514642).

Restrictions

480V only.

Ordering Notes

1) Specify List A (480VAC Input).

2) Order up to twenty-four (24) Rectifiers Modules per bay per List 22 (380/480VAC Input).

3) Order additional MCA customer alarm relay circuit card(s) as required per List 70, and optional MCA I/O

circuit cards per List 71.

4) Order optional LMS Expansion CPU circuit card and LMS options as required per List 63, and

SAG586505000. Also order additional LMS Network cables as required per Replacement/Additional LMS

Network Cables.

5) Order “Power Bay DC Output” lugs as required per Power Bay DC Output Cable Sizes and Lugs

Selection in the ACCESSORY DESCRIPTIONS section.

6) Order “AC Input Ground” lugs as required per AC Input (Individual/Twin AC Input Feeds) Wire and

Conduit Sizes, Branch Circuit Protection, and Lugs Selection in the ACCESSORY DESCRIPTIONS

section.

7) Order “Power Bay Frame Grounding” lugs as required per Power Bay Frame Grounding Wire Sizes and

Lugs Selection in the ACCESSORY DESCRIPTIONS section.

8) If a different length LMS and/or MCA Network cable is required, order per Replacement/Additional LMS

Network Cables and/or Replacement/Additional MCA Network Cables. Refer to the Installation

Instructions (Section 6016) for Network cabling requirements.

9) Side cover panels are not provided. When bays are placed next to each other, the side cover panels

from the ‘inside’ side of the Primary Power Bay are moved to the ‘outside’ side of the last Secondary

Power Bay. In installations where a Secondary Power Bay is placed by itself, order (4) P/N 535092 side

cover panels.

List 16: Distribution Bay

Features

♦ Provides common equipment for one (1) Distribution Bay rated for up to 6000 amperes.

♦ Mounted in a 7'0"H x 31.375"W x 30"D seismic rated (Zone 4) box framework.

♦ Provides forty-eight (48) distribution device mounting positions.

♦ Provides four (4) buses of distribution. Each bus contains an MCA monitoring circuit card; which can be

set for no group designation, Group A designation, or Group B designation.

♦ Includes a Router Assembly for bay communication to the MCA in the Primary Power Bay.

♦ MCA Network bay interconnect cable provided (P/N 514644).

Page 15 of 115

This document is property of Emerson Network Power, Energy Systems, North America, Inc. and contains confidential and proprietary information owned by Emerson Network Power, Energy

Systems, North America, Inc. Any copying, use, or disclosure of it without the written permission of Emerson Network Power, Energy Systems, North America, Inc. is strictly prohibited.

Page 16

SAG582140001 System Application Guide

Home

Issue AN, June 4, 2014 Spec. No. 582140001 (Model 801

NLDB, 801NLEB, 801NL-B)

Ordering Notes

1) Order distribution fuse and/or circuit breaker devices as required per Distribution Devices in the

ACCESSORY DESCRIPTIONS section.

2) Order load distribution lugs as required per Load Distribution Wire Sizes and Lugs Selection (Distribution

Bay) in the ACCESSORY DESCRIPTIONS section.

3) Order “Distribution Bay DC Input” lugs as required per Distribution Bay DC Input Cable Sizes and Lugs

Selection in the ACCESSORY DESCRIPTIONS section.

4) Order “Distribution Bay Frame Grounding” lugs as required per Distribution Bay Frame Grounding Wire

Sizes and Lugs Selection in the ACCESSORY DESCRIPTIONS section.

5) Order one (1) “Twenty-Four (24) Position Bullet-Nose Circuit Breaker/Fuse Panel” per Distribution Bay as

required per List C.

6) If a different length MCA Network cable is required, order per Replacement/Additional MCA Network

Cables. Refer to the Installation Instructions (Section 6016) for Network cabling requirements.

7) Side cover panels are factory installed on one side of the bay. In installations where a Distribution Bay is

placed by itself, order (2) P/N 528633 side cover panels for the other side.

List 21: Rectifier Module, 208V Input

Features

♦ Model R48-5800L, Spec. No. 1R485800L, 100A / 48 volt rectifier module.

Restrictions

For use in List B bays only.

Ordering Notes

1) Order List 21 Rectifier Modules as required. Each Power Bay holds up to twenty-four (24) Rectifier

Modules.

List 22: Rectifier Module, 380/480V Input

Features

♦ Model R48-5800, Spec. No. 1R485800, 100A / 48 volt rectifier module.

Restrictions

For use in List A bays only.

Ordering Notes

1) Order List 22 Rectifier Modules as required. Each Power Bay holds up to twenty-four (24) Rectifier

Modules.

List 24: Rectifier Module, 380/480V Input

Features

♦ Model R48-5800e, Spec. No. 1R485800e, 100A / 48 volt rectifier module.

Restrictions

For use in List A bays only. Requires that the system Router software is version 2.5.0.0 or higher.

Ordering Notes

Order List 24 Rectifier Modules as required. Each Power Bay holds up to twenty-four (24) Rectifier Modules.

List 50: Optional LMS Main CPU Circuit Card (Primary Power Bay)

Features

♦ Provides the LMS Monitoring System.

♦ Refer to SAG586505000 for further information.

Page 16 of 115

This document is property of Emerson Network Power, Energy Systems, North America, Inc. and contains confidential and proprietary information owned by Emerson Network Power, Energy

Systems, North America, Inc. Any copying, use, or disclosure of it without the written permission of Emerson Network Power, Energy Systems, North America, Inc. is strictly prohibited.

Page 17

System Application Guide SAG582140001

Home

Spec. No. 582140001 (Model 801

NLDB, 801NLEB, 801NL-B) Issue AN, June 4, 2014

Restrictions

The LMS Monitoring System Main CPU circuit card is mounted in the Primary Power Bay only.

Ordering Notes

1) Order the optional LMS Monitor if increased monitoring capabilities are required. Order the LMS Main

CPU circuit card (List 50) for the Primary Power Bay. Order the LMS Expansion CPU circuit card (List 63)

for Secondary Power Bays that are to be equipped with LMS I/O circuit cards.

2) Order additional LMS Network cables as required per Replacement/Additional LMS Network Cables.

Note that an LMS Network cable is factory provided with List 63.

3) This List option only provides the LMS CPU circuit card for the Primary Power Bay, additional LMS

options must be ordered separately per SAG586505000.

List 63: Optional LMS Expansion CPU Circuit Card (Secondary Power Bays)

Features

♦ Allows LMS I/O cards to be installed in Secondary Power Bays.

♦ LMS Network bay interconnect cable provided (Qty. 1 P/N 514639).

Restrictions

The LMS Monitoring System Expansion CPU circuit cards are mounted in Secondary Power Bays (required

only if LMS I/O circuit cards are to be installed in the same bay).

Ordering Notes

1) Order the LMS Expansion CPU circuit card for Secondary Power Bays that are to be equipped with LMS

I/O circuit cards.

List 64: Interface Kit to a Spec. No. 582121900 Power System equipped with a DGU

Features

♦ Provides the following...

LMS Dual MCA Interface Software Option

LMS Gateway Software Option

P/N 526843 50’ LMS Dual MCA Option Cable

P/N 548009 50’ LMS Gateway Port Cable

♦ LMS Dual MCA Interface Software Option enables the Spec. No. 582140001 Power System to be

integrated with an existing Power System. Specifically, List 64 allows the MCA in Spec. No. 582140001

to interface with the MCA in a Spec. No. 582121900 via the LMS in Spec. No. 582140001. Refer to the

LMS documentation for further information.

♦ LMS Gateway Software Option allows the LMS to emulate a “dumb” RS-232 asynchronous terminal

interface. Specifically, List 64 enables user input through either a local or remote LMS port to be directed

to a DGU connected to the LMS Gateway port. Refer to the LMS documentation for further information.

Restrictions

Operation of Energy Management is disabled with this option installed.

The Gateway port is provided via the port located on the front of the LMS CPU circuit card installed in the

Spec. No. 582140001 Primary Bay.

Ordering Notes

1) Order as required.

Page 17 of 115

This document is property of Emerson Network Power, Energy Systems, North America, Inc. and contains confidential and proprietary information owned by Emerson Network Power, Energy

Systems, North America, Inc. Any copying, use, or disclosure of it without the written permission of Emerson Network Power, Energy Systems, North America, Inc. is strictly prohibited.

Page 18

SAG582140001 System Application Guide

Home

Issue AN, June 4, 2014 Spec. No. 582140001 (Model 801

NLDB, 801NLEB, 801NL-B)

List 65: Interface Kit to a Spec. No. 582121901 Power System equipped with an LMS1000

Features

♦ Provides the following...

LMS Dual MCA Interface Software Option

P/N 506153 LMS Expansion CPU Card

P/N 514641 150’ Echelon Cable

P/N 526843 50’ LMS Dual MCA Option Cable

♦ LMS Dual MCA Interface Software Option enables the Spec. No. 582140001 Power System to be

integrated with an existing Power System. Specifically, List 65 allows the MCA in Spec. No. 582140001

to interface with the MCA in Spec. No. 582121901 via the LMS in Spec. No. 582140001. Refer to the

LMS documentation for further information.

Restrictions

Operation of Energy Management is disabled with this option installed.

The Main LMS CPU card in 582121901 must be replaced with the Expansion LMS CPU card (P/N 506153)

provided with List 65.

Ordering Notes

1) Order as required.

List 66: Interface Kit to a Vortex Power System without a DGU or LMS1000

Features

♦ Provides the following...

LMS Dual MCA Interface Software Option

P/N 526843 50’ LMS Dual MCA Option Cable

♦ LMS Dual MCA Interface Software Option enables the Spec. No. 582140001 Power System to be

integrated with an existing Power System. Specifically, List 66 allows the MCA in Spec. No. 582140001

to interface with the MCA in a Vortex Power System via the LMS in Spec. No. 582140001. Refer to the

LMS documentation for further information.

Restrictions

Operation of Energy Management is disabled with this option installed.

Ordering Notes

1) Order as required.

List 67: Interface Kit to a Model 1231H Legacy Power System with 1-8 Rectifiers

Features

♦ Provides the following...

LMS Gateway Software Option

P/N 548009 50’ LMS Gateway Port Cable

Two (2) P/N 506336 LMS 4-Input Universal Analog Cards

One (1) P/N 506334 LMS 8-Input Binary Card

♦ LMS Gateway Software Option allows the LMS to emulate a “dumb” RS-232 asynchronous terminal

interface. Specifically, List 67 enables user input through either a local or remote LMS port to be directed

to a DGU (in the legacy plant) connected to the LMS Gateway port. Refer to the LMS documentation for

further information.

♦ The analog and binary DGU I/O cards provide monitoring of the legacy system’s rectifiers

Restrictions

LMS Channels must be configured.

Ordering Notes

1) Order as required.

Page 18 of 115

This document is property of Emerson Network Power, Energy Systems, North America, Inc. and contains confidential and proprietary information owned by Emerson Network Power, Energy

Systems, North America, Inc. Any copying, use, or disclosure of it without the written permission of Emerson Network Power, Energy Systems, North America, Inc. is strictly prohibited.

Page 19

System Application Guide SAG582140001

Home

Spec. No. 582140001 (Model 801

NLDB, 801NLEB, 801NL-B) Issue AN, June 4, 2014

List 70: Additional MCA Six (6) Output Form-C Relay Circuit Card

Features

♦ Provides six relays each with one set of Form-C relay contacts.

♦ These relays are used for alarm applications and can be programmed by the user.

♦ Refer to the "Specifications" section of this document for further information.

♦ Plugs into any slot in 7-position card cage in Primary and Secondary Power Bays.

♦ User maps relay closure to any or multiple programmable alarm functions.

Restrictions

Relay contacts rated for 2A at 30 volts DC.

The system may contain up to 16 MCA Relay circuit cards.

Ordering Notes

1) Order one (1) List 70 relay circuit card for every six (6) customer relay contacts to be provided by the

MCA.

List 71: MCA I/O Circuit Card P/N 524550

Features

♦ Provides 1 analog input, 1 analog output (for remote plant output current monitoring), and 4 binary inputs.

♦ Refer to the "Specifications" section of this document for further information.

♦ Plugs into any slot in 7-position card cage in Primary and Secondary Power Bays.

Restrictions

The system may contain up to 16 MCA I/O circuit cards.

Only one (1) P/N 524550 card can be installed per bay.

Analog input and output rating = 0-50mv DC.

Binary input rating = dry contact.

Analog inputs should be protected by a 49.9 ohm resistor.

Recommended to use current limiting resistors to protect binary input wiring.

Ordering Notes

1) Order optional MCA I/O circuit cards as required.

2) Use of the “Alternate Current Limit” feature requires that an MCA I/O circuit card be installed.

Page 19 of 115

This document is property of Emerson Network Power, Energy Systems, North America, Inc. and contains confidential and proprietary information owned by Emerson Network Power, Energy

Systems, North America, Inc. Any copying, use, or disclosure of it without the written permission of Emerson Network Power, Energy Systems, North America, Inc. is strictly prohibited.

Page 20

SAG582140001 System Application Guide

Home

Optional List C

Bullet Nose Device Panel

Front door removed in

illustration for clarity.

Issue AN, June 4, 2014 Spec. No. 582140001 (Model 801

NLDB, 801NLEB, 801NL-B)

List 0C: 24 Position Bullet-Nose Circuit Breaker/Fuse Panel

Features

♦ Provides twenty-four (24) Bullet

Nose Device positions.

♦ Accepts a choice of TLS/TPS-type

fuseholders, Bullet Nose-Type

circuit breakers, or Bullet NoseType GMT Fuse Modules.

♦ The List C Fuse/Circuit Breaker

Panel is equipped with one (1)

shunt for all distribution positions for

MCA load current measurements.

♦ Refer also to Bullet Nose-Type

Circuit Breakers and Bullet NoseType Fuseholders e/w TLS/TPS

Fuses and Optional Bullet Nose-

Type 10-Position GMT Fuse

Module for List C.

Restrictions

Each Distribution Bay can be equipped

with only one (1) List C panel.

The List C Circuit Breaker/Fuse Panel

requires distribution position #12 in the

Bus #1 Distribution Panel.

Current monitoring for the List C

Fuse/Circuit Breaker Panel is for the

complete panel. Circuit Breakers

and/or fuses are not individually

monitored.

When installed, the bay can be loaded with up to (47) 218 Circuit Breakers or (23) TPL Fuses and (24) Bullet

Nose Circuit Breakers or TLS/TPS Fuses.

The List C Circuit Breaker/Fuse Panel is rated for a maximum continuous load of 500 amps.

The total load combination of List C and Distribution Panel #1 cannot exceed 1500A.

Ordering Notes

1) Order as required.

2) Also order distribution fuses, circuit breakers, and/or Bullet Nose-Type 10-Position GMT Fuse Modules as

required per Distribution Devices in the ACCESSORY DESCRIPTIONS section.

This document is property of Emerson Network Power, Energy Systems, North America, Inc. and contains confidential and proprietary information owned by Emerson Network Power, Energy

Systems, North America, Inc. Any copying, use, or disclosure of it without the written permission of Emerson Network Power, Energy Systems, North America, Inc. is strictly prohibited.

Page 20 of 115

Page 21

System Application Guide SAG582140001

Home

Spec. No. 582140001 (Model 801

NLDB, 801NLEB, 801NL-B) Issue AN, June 4, 2014

ACCESSORY DESCRIPTIONS

Seismic Anchor Kit, P/N 545387

Features

Provides four (4) Relay Rack Seismic Mounting Anchors, P/N 216821200.

Ordering Notes

1) Order Seismic Anchor Kit, P/N 545387, as required.

Seismic Anchor Isolation Kit, P/N 545388

Features

Provides four (4) bushings, P/N 124866 (one per seismic anchor) and one (1) insulator, P/N 112490.

Ordering Notes

1) Order Seismic Isolation Anchor Kit, P/N 545388, as required.

Main Battery Termination Bars (MBTB’s)

Plant is designed for centralized configuration with customer supplied Main Battery Termination Bars

(MBTB’s). Emerson Network Power Services has standard MBTB’S in 4000, 6000, 10000, and 16000

ampere capacities. The ultimate plant capacity is determined by the capacity of the MBTB’S. Refer to the

EA3434-41xx Series MBTB’s drawings.

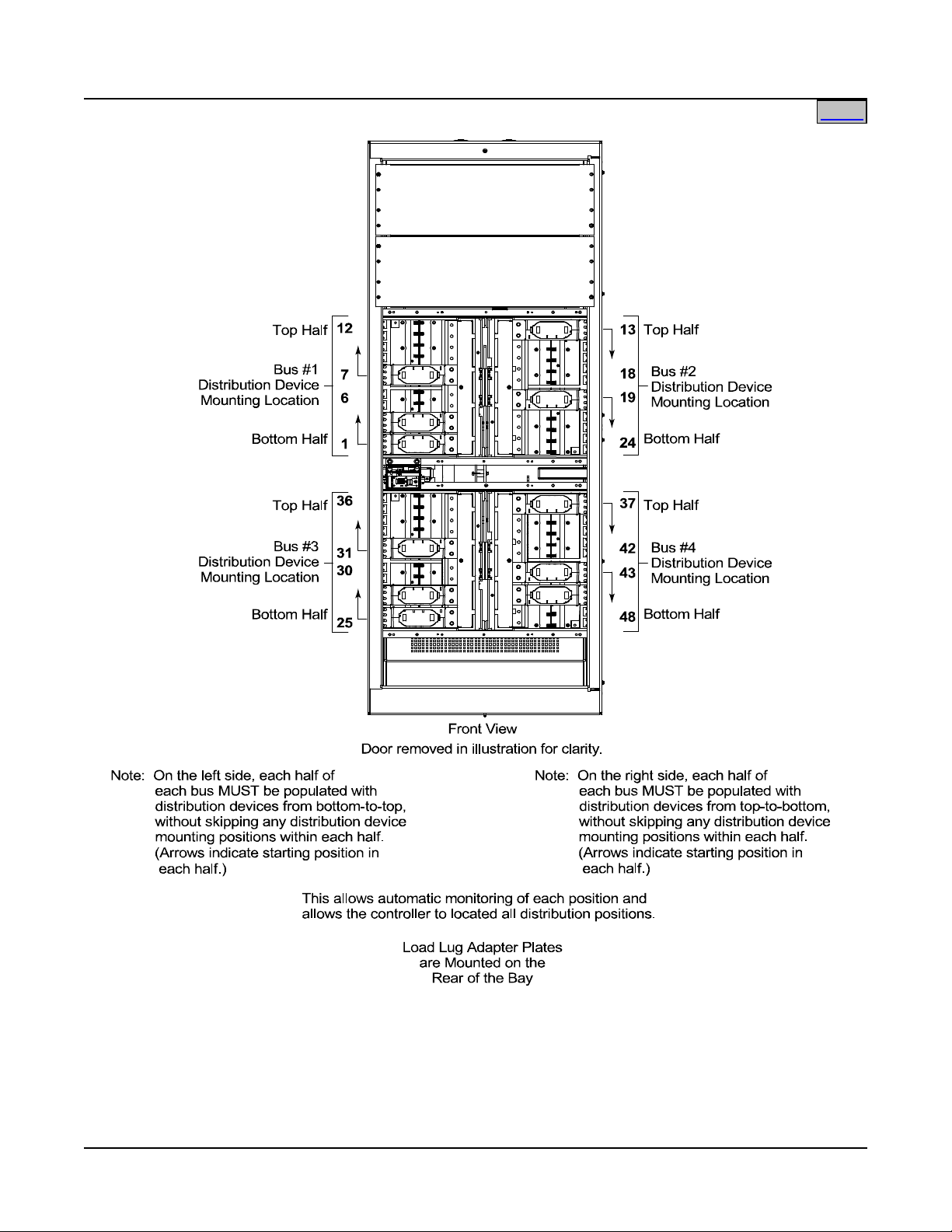

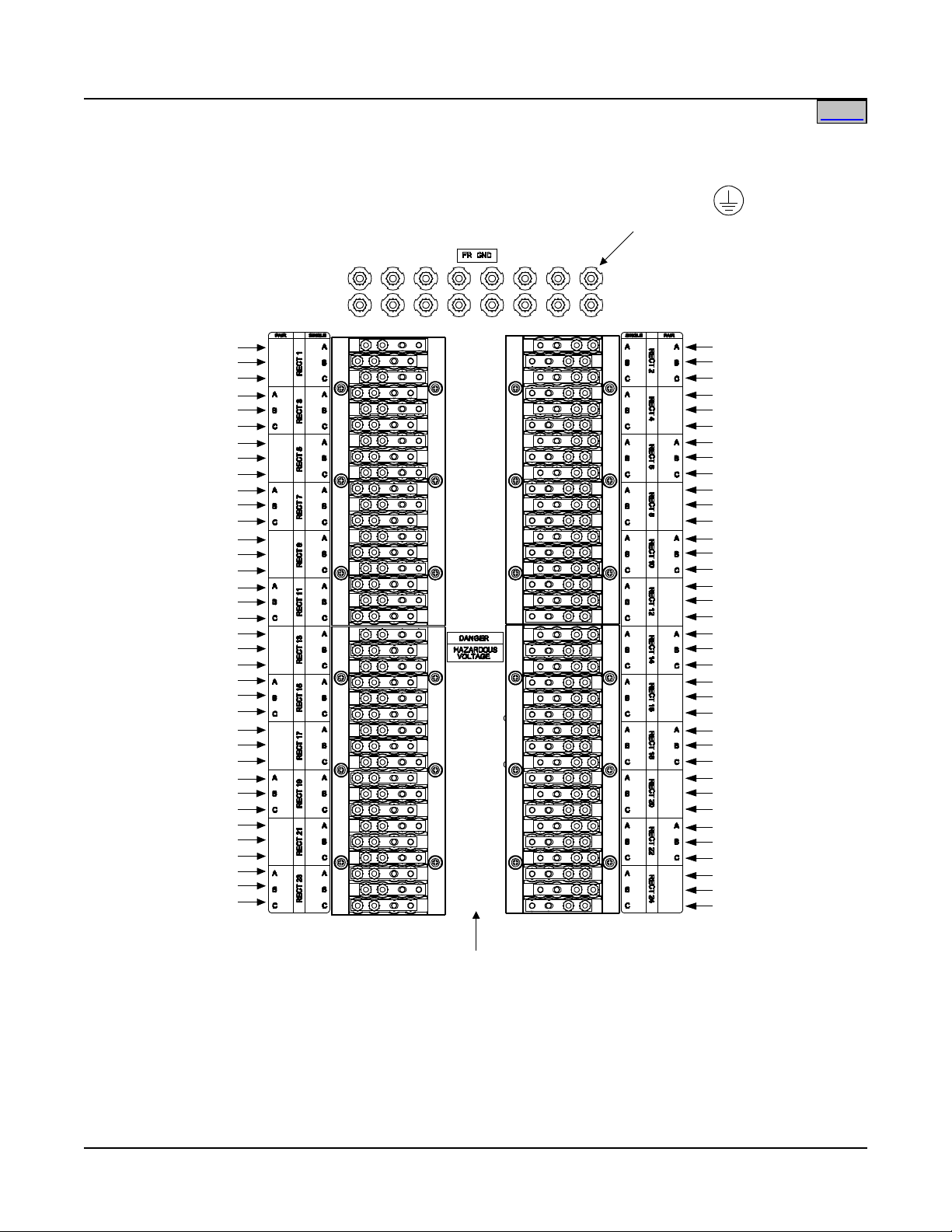

Distribution Device and Load Lug Locations

Each Distribution Bay has four (4) distribution buses. Each distribution bus has twelve (12) fuse/circuit

breaker device mounting positions. Note that the various fuse/circuit breaker devices require different number

of mounting positions, as detailed in the following sections. Note also that each distribution bus is divided into

half, and each half MUST be populated with distribution devices as shown in the following illustration, without

skipping any distribution device mounting positions within each half. This allows automatic monitoring of each

position and allows the controller to located all distribution positions. The load side of each fuse/circuit

breaker mounting position is bused to the rear of the bay. Each fuse/circuit breaker device requires a load lug

adapter plate kit that mounts to the appropriate load side busbars at the rear of the bay (except 1-pole

devices). Load return leads are terminated outside the bay to customer provided return busbars. See

following illustration.

Page 21 of 115

This document is property of Emerson Network Power, Energy Systems, North America, Inc. and contains confidential and proprietary information owned by Emerson Network Power, Energy

Systems, North America, Inc. Any copying, use, or disclosure of it without the written permission of Emerson Network Power, Energy Systems, North America, Inc. is strictly prohibited.

Page 22

SAG582140001 System Application Guide

Home

Issue AN, June 4, 2014 Spec. No. 582140001 (Model 801

NLDB, 801NLEB, 801NL-B)

Page 22 of 115

This document is property of Emerson Network Power, Energy Systems, North America, Inc. and contains confidential and proprietary information owned by Emerson Network Power, Energy

Systems, North America, Inc. Any copying, use, or disclosure of it without the written permission of Emerson Network Power, Energy Systems, North America, Inc. is strictly prohibited.

Page 23

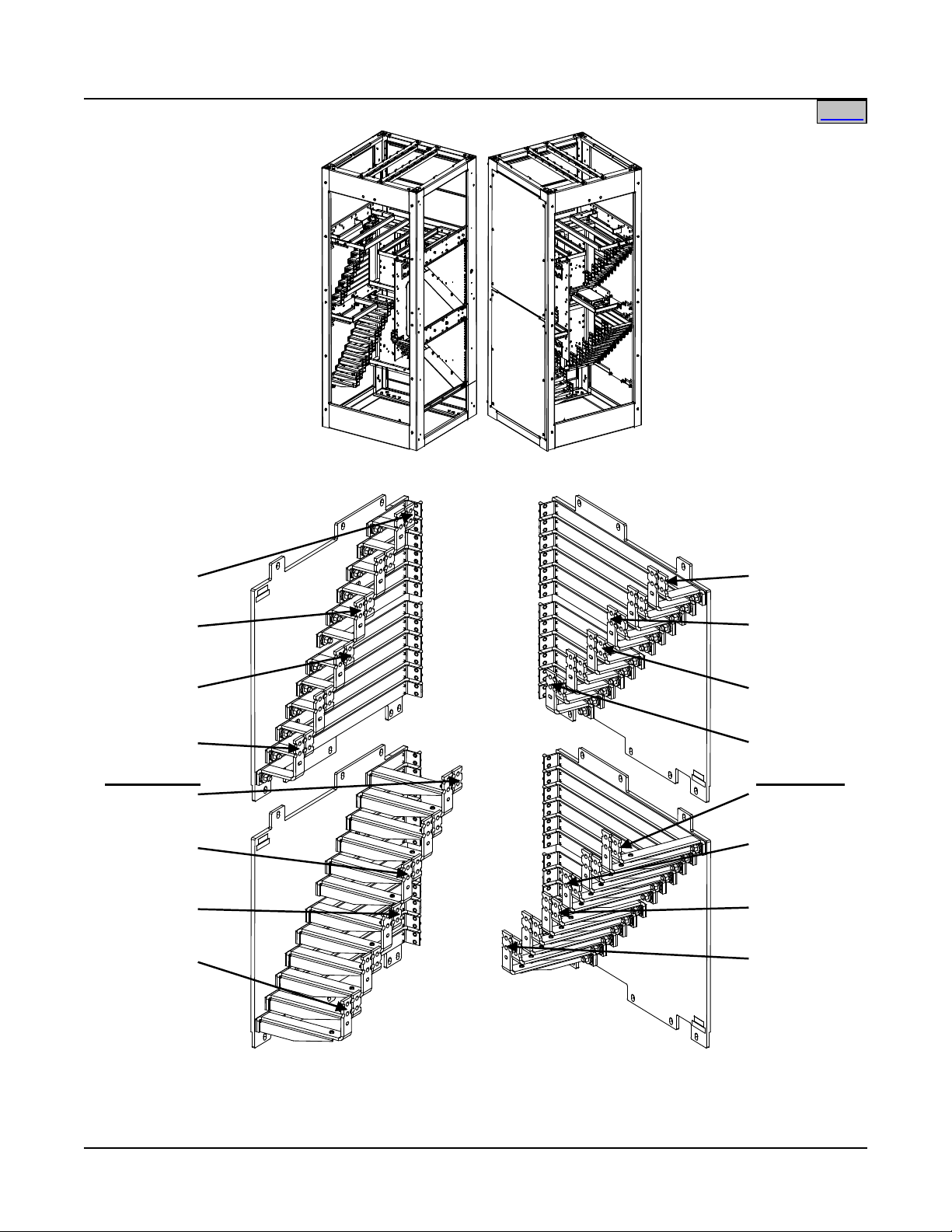

System Application Guide SAG582140001

to Distribution:

Bus #2

Position #24

to Distribution:

Bus #2

Position #19

to Distribution:

Bus #2

Position #18

to Distribution:

Bus #2

Position #13

to Distribution:

Bus #4

Position #48

to Distribution:

Bus #4

Position #43

to Distribution:

Bus #4

Position #42

to Distribution:

Bus #4

Position #37

to Distribution:

Bus #1

Position #1

to Distribution:

Bus #1

Position #6

to Distribution:

Bus #1

Position #7

to Distribution:

Bus #1

Position #12

to Distribution:

Bus #3

Position #25

to Distribution:

Bus #3

Position #30

to Distribution:

Bus #3

Position #31

to Distribution:

Bus #3

Position #36

Rear cover panels removed in illustration for clarity.

Rear View

Rear View

Home

Spec. No. 582140001 (Model 801

NLDB, 801NLEB, 801NL-B) Issue AN, June 4, 2014

Page 23 of 115

This document is property of Emerson Network Power, Energy Systems, North America, Inc. and contains confidential and proprietary information owned by Emerson Network Power, Energy

Systems, North America, Inc. Any copying, use, or disclosure of it without the written permission of Emerson Network Power, Energy Systems, North America, Inc. is strictly prohibited.

Page 24

SAG582140001 System Application Guide

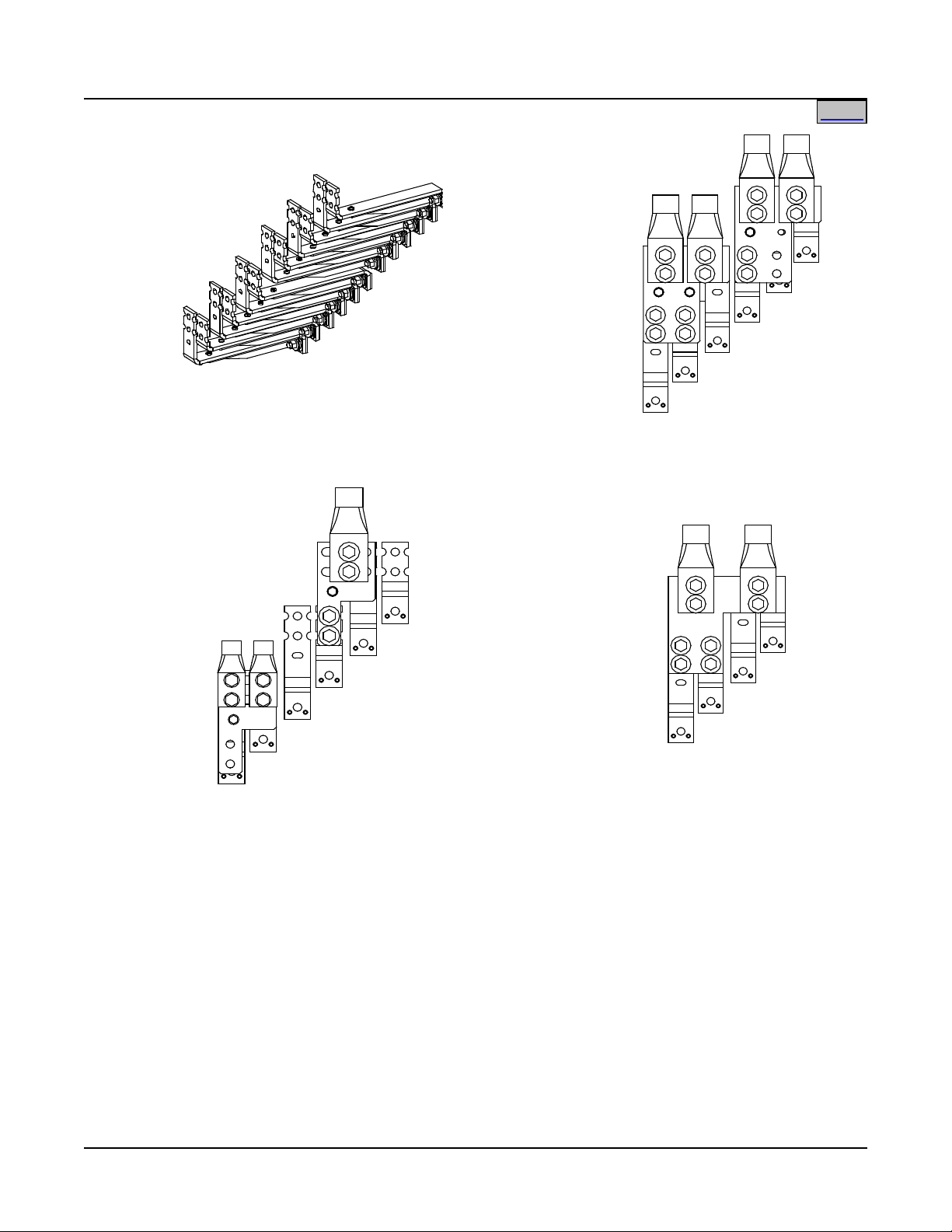

Notes:

1. Lug adapter accepts a maximum of (2) 750 kcmil or (4) 350 kcmil lugs.

2. Lug adapter accepts a maximum of (4) 750 kcmil lugs.

3. Lugs are not part of the kit, shown for illustration only.

4. Bay busbars are not part of the kit, shown for illustration only.

5. Two (2) kits shown for illustration of the kit installed on busbars with tops

even with each other and staggered.

6. Maximum lug width (without using an adapter plate) is 1.250 inches.

2-Position

Lug Adapter Kit

P/N 529132

(see Notes 1, 3, 4, 5)

3-Position

Lug Adapter Kit

P/N 529131

(see Notes 2, 3, 4, 5)

4-Position

Lug Adapter Kit

P/N 534420

(see Notes 2, 3, 4)

1-Position Devices

(Load Busbars with NO

Lug Adapters Installed)

(see Note 6)

Home

Issue AN, June 4, 2014 Spec. No. 582140001 (Model 801

NLDB, 801NLEB, 801NL-B)

This document is property of Emerson Network Power, Energy Systems, North America, Inc. and contains confidential and proprietary information owned by Emerson Network Power, Energy

Systems, North America, Inc. Any copying, use, or disclosure of it without the written permission of Emerson Network Power, Energy Systems, North America, Inc. is strictly prohibited.

Page 24 of 115

Page 25

System Application Guide SAG582140001

Home

Spec. No. 582140001 (Model 801

NLDB, 801NLEB, 801NL-B) Issue AN, June 4, 2014

Distribution Devices

See Distribution Device and Load Lug Locations at the beginning of this section for illustrations of distribution

device and load lug mounting locations.

218 Circuit Breaker Assemblies

Features

♦ Each circuit breaker assembly is equipped with a shunt for MCA load current measurements.

♦ Bolts into bay's distribution device mounting positions.

♦ Load lug busbars and adapter plates provide 3/8" clearance holes on 1" centers for installation of

customer provided two-hole lugs.

Restrictions

Load should not exceed 80% of device rating.

Refer to Table 1 for required distribution bus mounting positions.

Each distribution bus is divided into half. Each half MUST be populated with distribution devices as shown in

the illustrations at the beginning of this section, without skipping any distribution device mounting positions

within each half.

Four (4) position devices can only be installed in the 1st four or last four positions within each half of a

distribution bus. This is because the lug adapter plate for four (4) position devices can only be installed in

positions starting with the load busbar tops even with each other (not staggered).

Divide distribution equally between rows.

Refer to the illustrations in this section for lug and wire size restrictions.

Load return leads are terminated outside the bay to customer provided return busbars.

Ordering Notes

1) Order circuit breaker assemblies and load lug adapter kits per Table 1. Load lug adapter kits also contain

the necessary hardware to mount the circuit breakers. For 1-pole circuit breakers, also order circuit

breaker hardware kit P/N 558709. This hardware is used to mount the circuit breaker.

2) See Table 10 for recommended load distribution wire sizes and lugs.

Page 25 of 115

This document is property of Emerson Network Power, Energy Systems, North America, Inc. and contains confidential and proprietary information owned by Emerson Network Power, Energy

Systems, North America, Inc. Any copying, use, or disclosure of it without the written permission of Emerson Network Power, Energy Systems, North America, Inc. is strictly prohibited.

Page 26

SAG582140001 System Application Guide

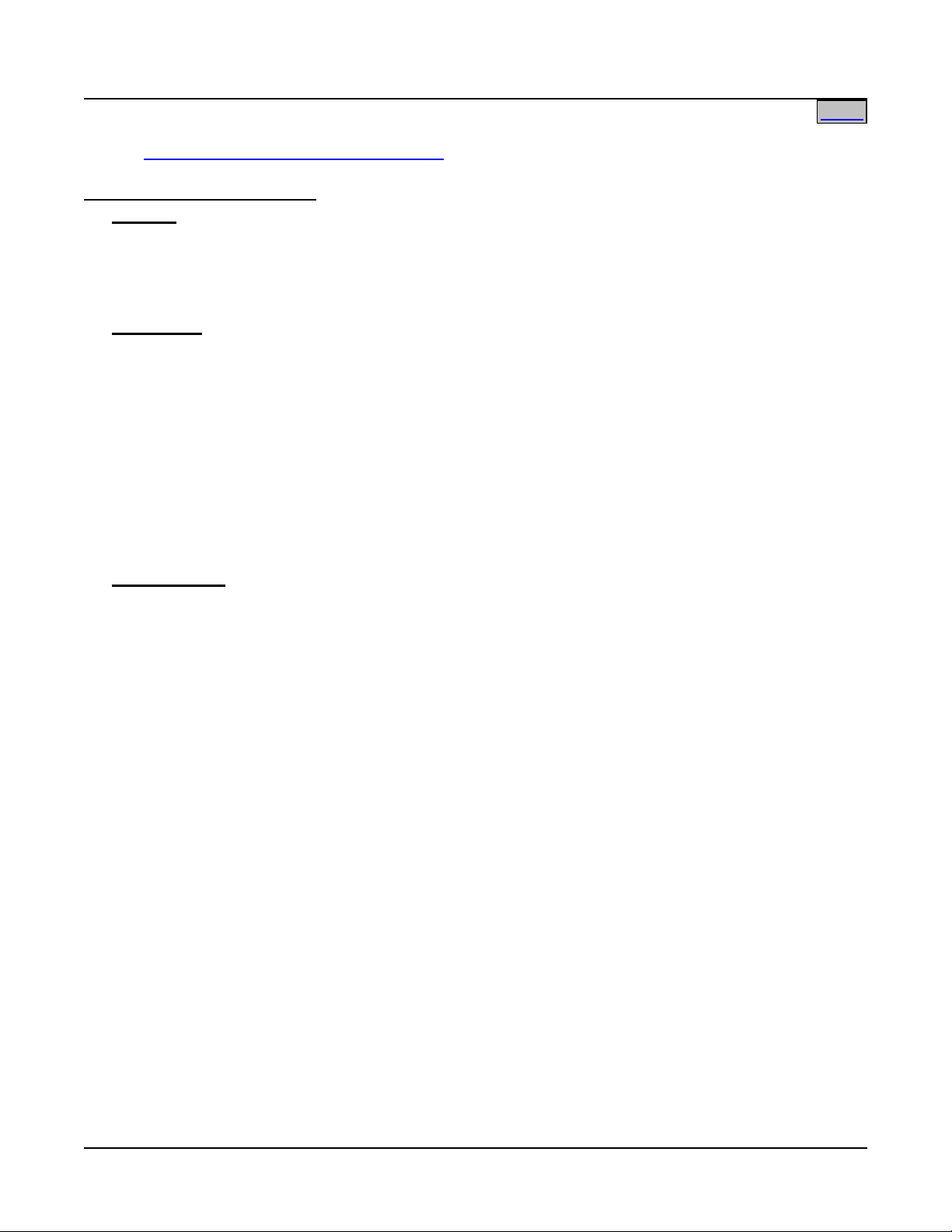

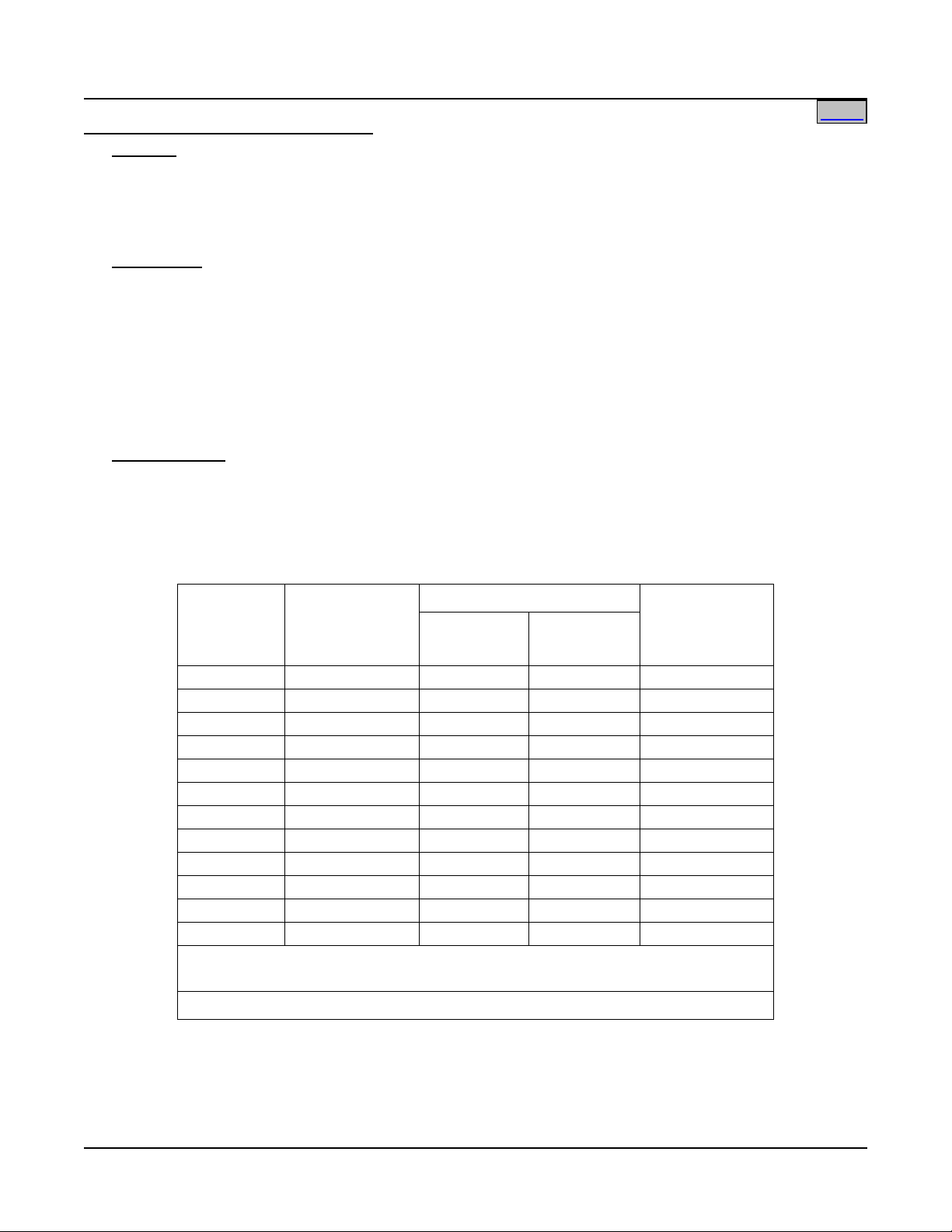

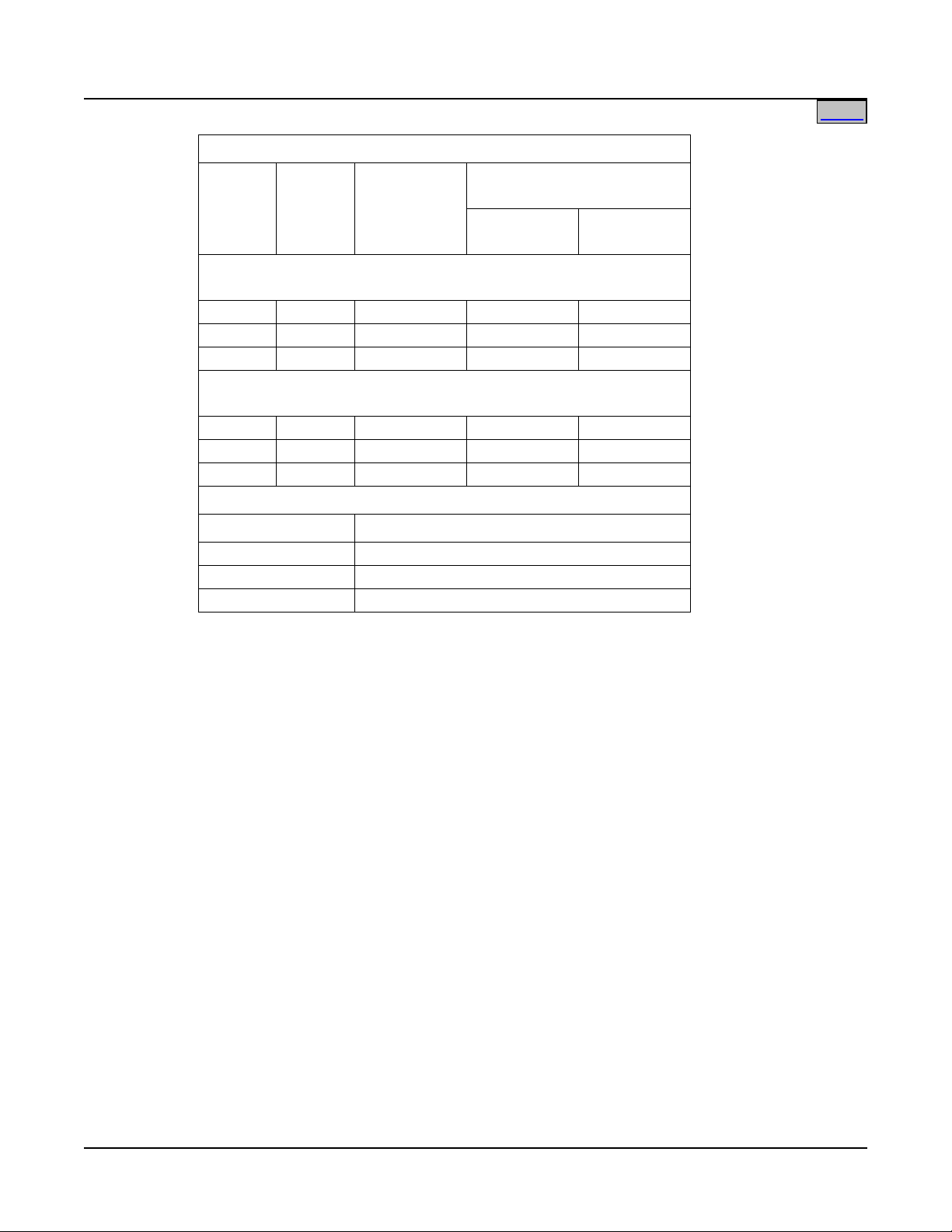

200 1 1

513774

513775

not required

225 1 1

513776

513777

not required

250 1 1

513778

513779

not required

300 2 2

513780

513781

529132

350 2 2

513782

513783

529132

400 2 2

513784

513785

529132

450 3 3

513786

513787

529131

500 3 3

513788

513789

529131

600 3 3

513790

513791

529131

800 4 4

513792

513793

534420

Home

Issue AN, June 4, 2014 Spec. No. 582140001 (Model 801

NLDB, 801NLEB, 801NL-B)

Circuit Breaker

Ampere

Rating

No.

of

Poles

Required

Distribution Bus

Mounting

Positions

Electrical Trip1

(White Handle)

Part Number

Electrical/

Mechanical Trip

(Black Handle)

Lug Adapter Kit

Part Number

2

(Qty 1)

100 1 1 513766 513767 not required

125 1 1 513768 513769 not required

150 1 1 513770 513771 not required

175 1 1 513772 513773 not required

See Table 10 for recommended load distribution wire sizes and lugs.

Circuit Breaker Alarm Operation:

1

Provides an alarm during an electrical trip condition only.

2

Provides an alarm during an electrical or manual trip condition.

Table 1

218 Circuit Breaker Assemblies

This document is property of Emerson Network Power, Energy Systems, North America, Inc. and contains confidential and proprietary information owned by Emerson Network Power, Energy

Systems, North America, Inc. Any copying, use, or disclosure of it without the written permission of Emerson Network Power, Energy Systems, North America, Inc. is strictly prohibited.

Page 26 of 115

Page 27

System Application Guide SAG582140001

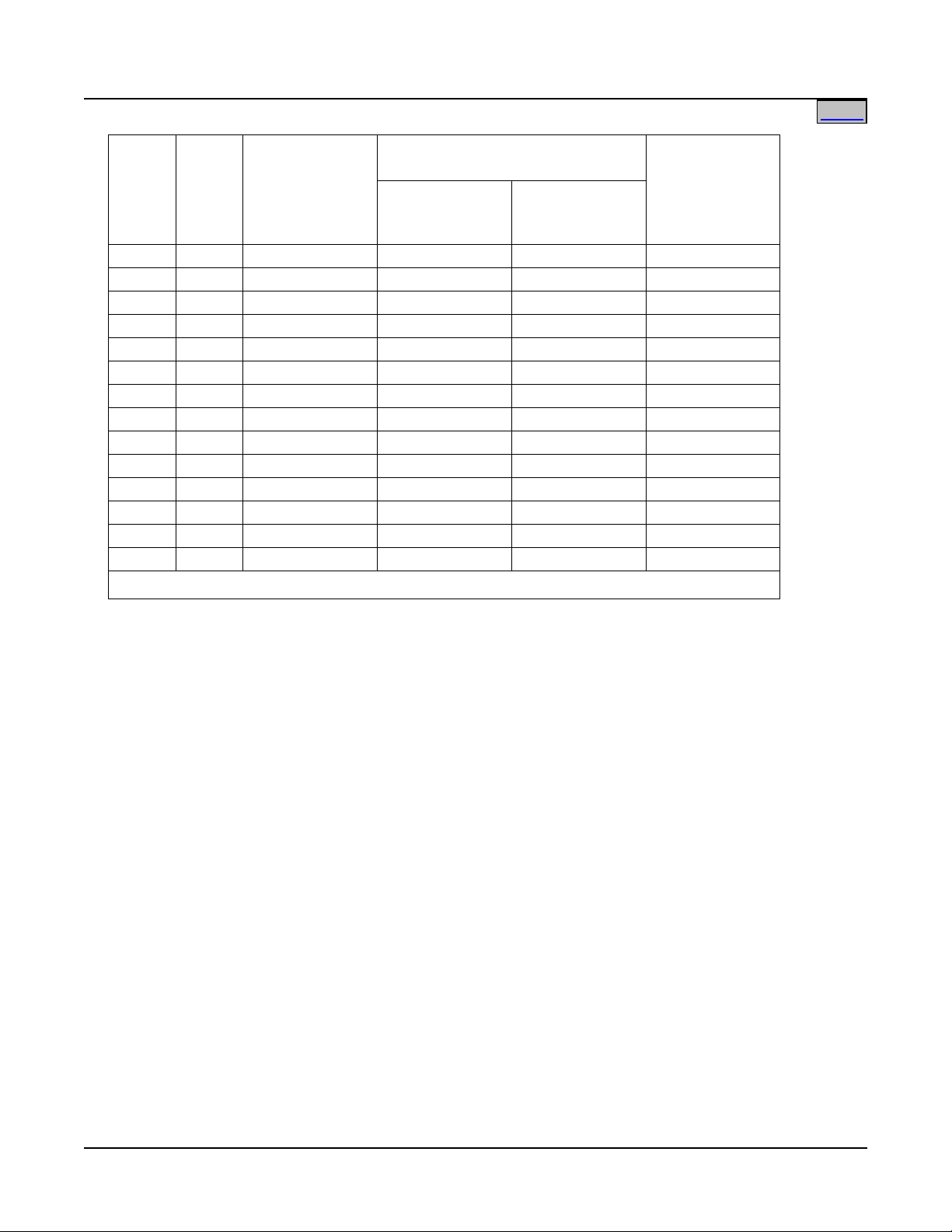

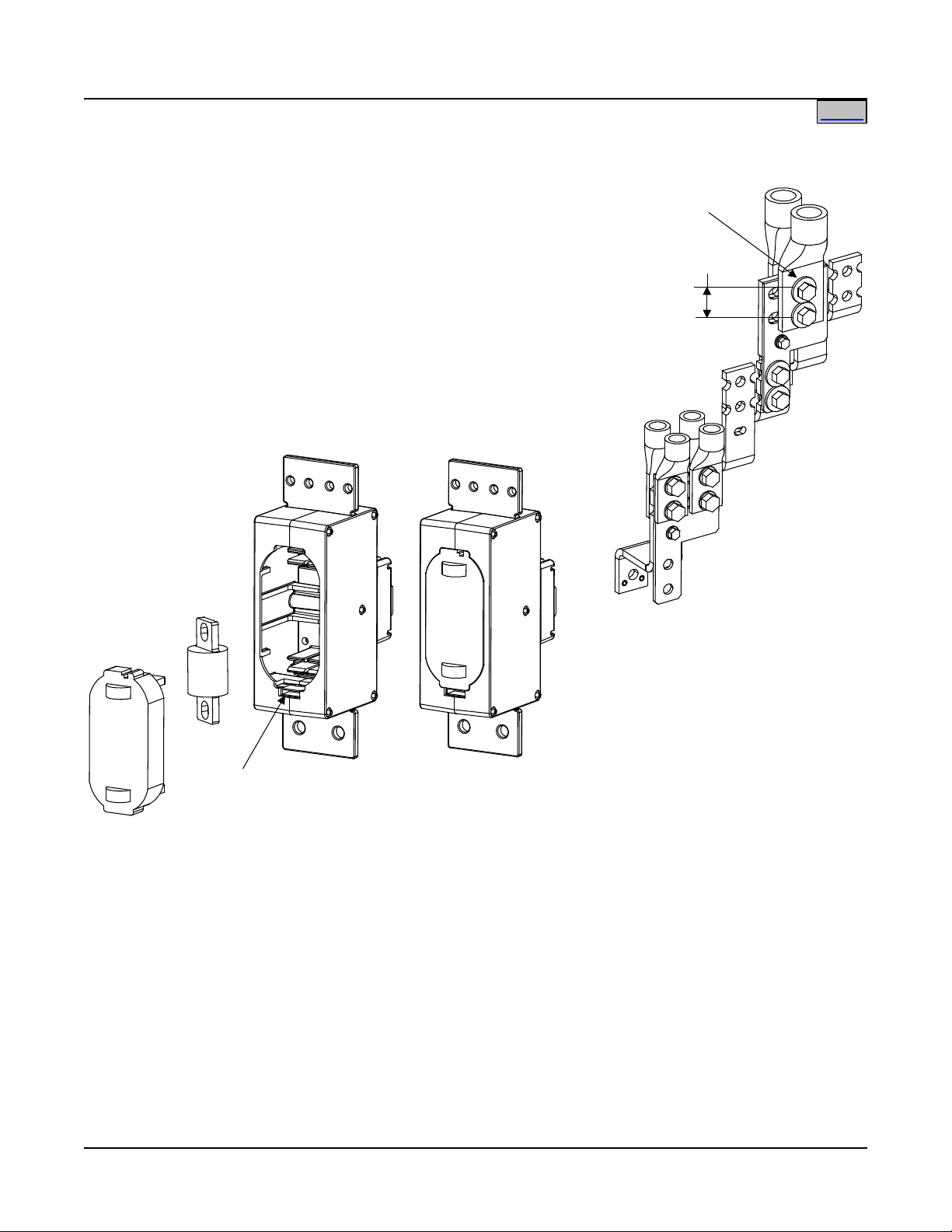

1-Pole 218 Circuit

Breakers Assemblies

2-Pole 218 Circuit

Breaker Assemblies

NO LUG ADAPTER

KIT REQUIRED

Lug Adapter Kit

2-Position

Lug Adapter Kit

P/N 529132

(see Notes 1, 2, 3, 4)

Lug Adapter Kit

3/8" Clearance Hole

1.000"

Notes:

1. Lug adapter accepts a maximum of (2) 750 kcmil or (4) 350 kcmil lugs.

2. Lugs are not part of the kit, shown for illustration only.

3. Bay busbars are not part of the kit, shown for illustration only.

4. Two (2) kits shown for illustration of the kit installed on busbars with tops

even with each other and staggered.

Home

Spec. No. 582140001 (Model 801

NLDB, 801NLEB, 801NL-B) Issue AN, June 4, 2014

This document is property of Emerson Network Power, Energy Systems, North America, Inc. and contains confidential and proprietary information owned by Emerson Network Power, Energy

Systems, North America, Inc. Any copying, use, or disclosure of it without the written permission of Emerson Network Power, Energy Systems, North America, Inc. is strictly prohibited.

Page 27 of 115

Page 28

SAG582140001 System Application Guide

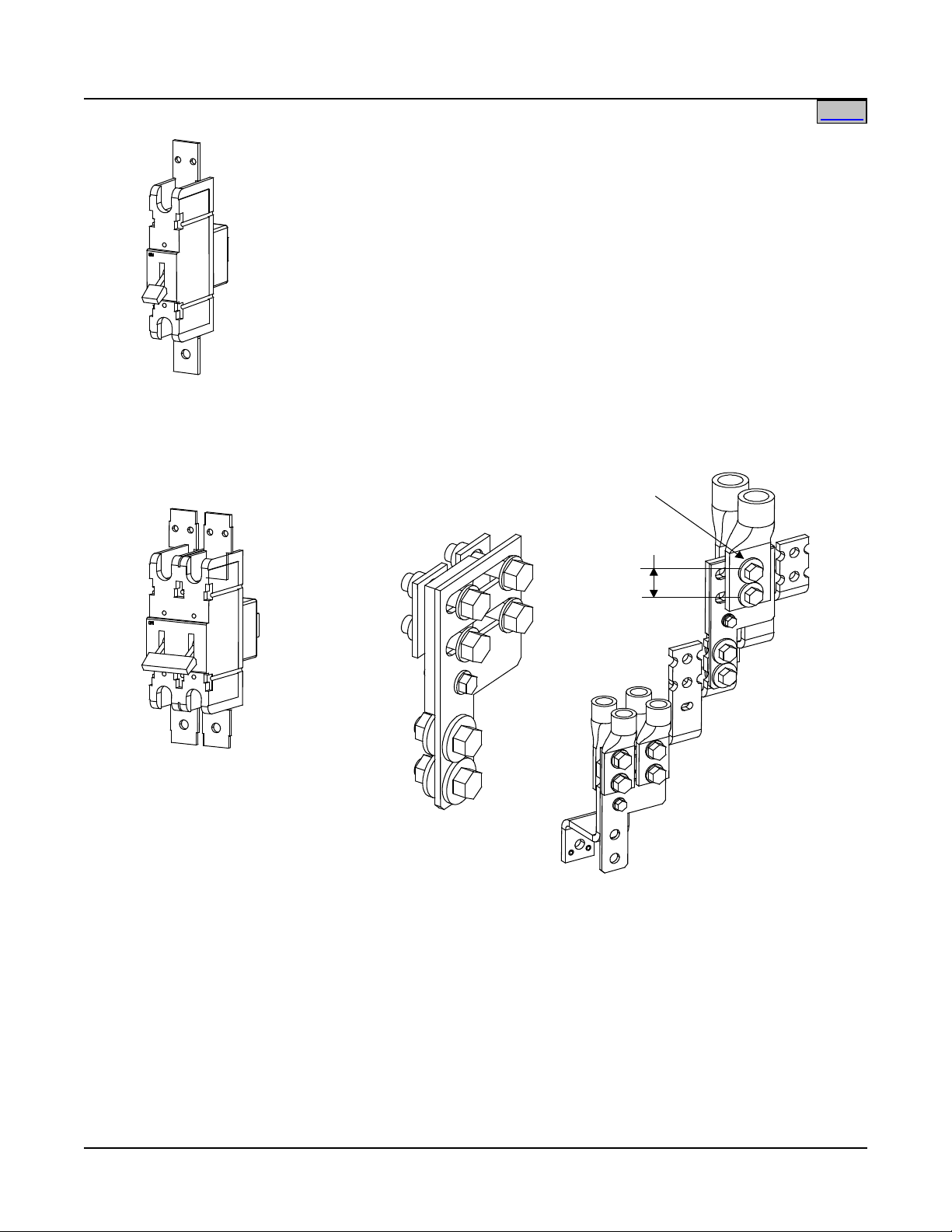

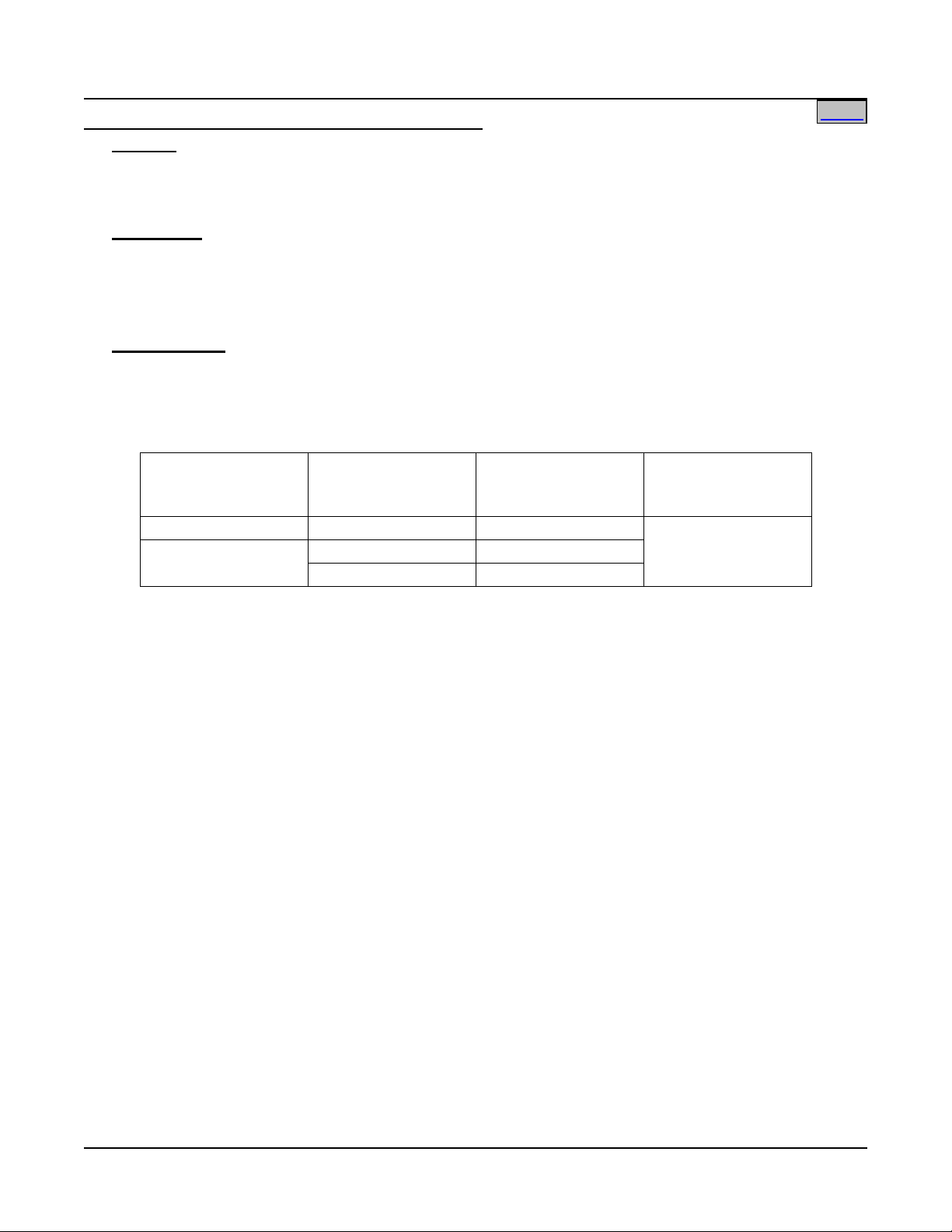

4-Pole 218 Circuit

Breaker Assemblies

3-Pole 218 Circuit

Breaker Assemblies

3-Position

Lug Adapter Kit

P/N 529131

(see Notes 1, 2, 3, 4)

Lug Adapter Kit

3/8"

Clearance

Hole

1.000"

4-Position

Lug Adapter Kit

P/N 534420

(see Notes 1, 2, 3, 5)

Lug Adapter Kit

3/8"

Clearance

Hole

1.000"

Notes:

1. Lug adapter accepts a maximum of (4) 750 kcmil lugs.

2. Lugs are not part of the kit, shown for illustration only.

3. Bay busbars are not part of the kit, shown for illustration only.

4. Two (2) kits shown for illustration of the kit installed on busbars with tops

even with each other and staggered.

5. Can only be installed in positions starting with

busbar tops even with each other (not staggered).

Home

Issue AN, June 4, 2014 Spec. No. 582140001 (Model 801

NLDB, 801NLEB, 801NL-B)

This document is property of Emerson Network Power, Energy Systems, North America, Inc. and contains confidential and proprietary information owned by Emerson Network Power, Energy

Systems, North America, Inc. Any copying, use, or disclosure of it without the written permission of Emerson Network Power, Energy Systems, North America, Inc. is strictly prohibited.

Page 28 of 115

Page 29

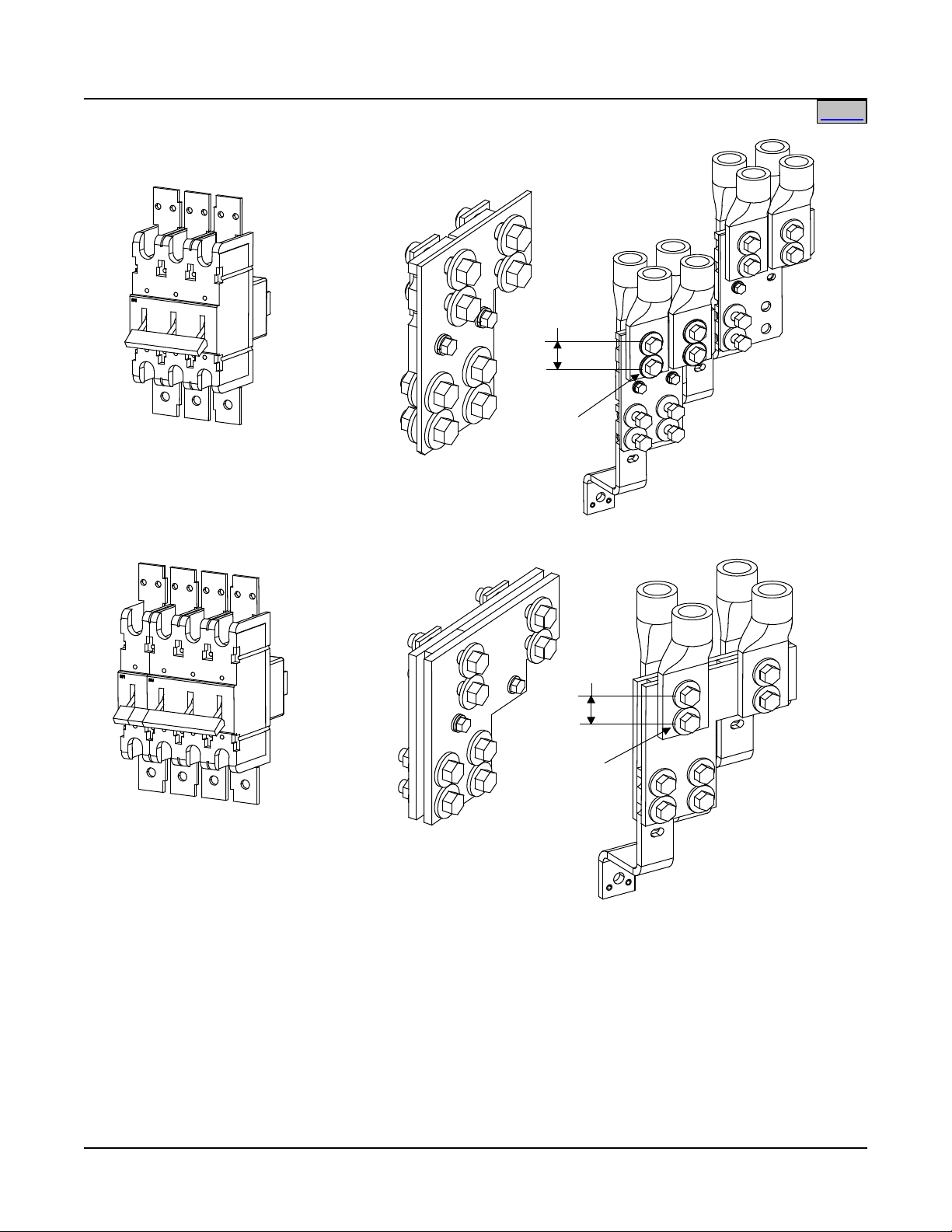

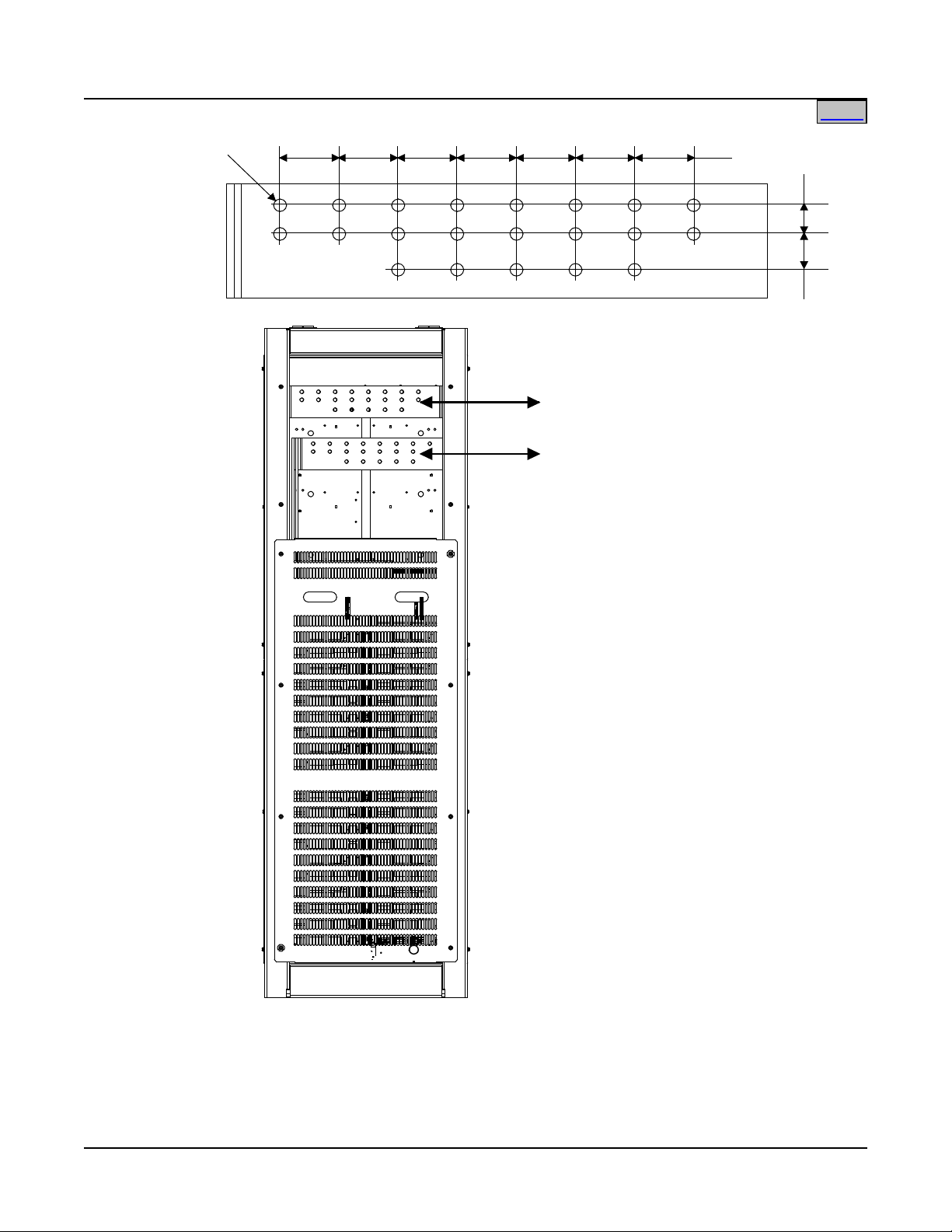

System Application Guide SAG582140001

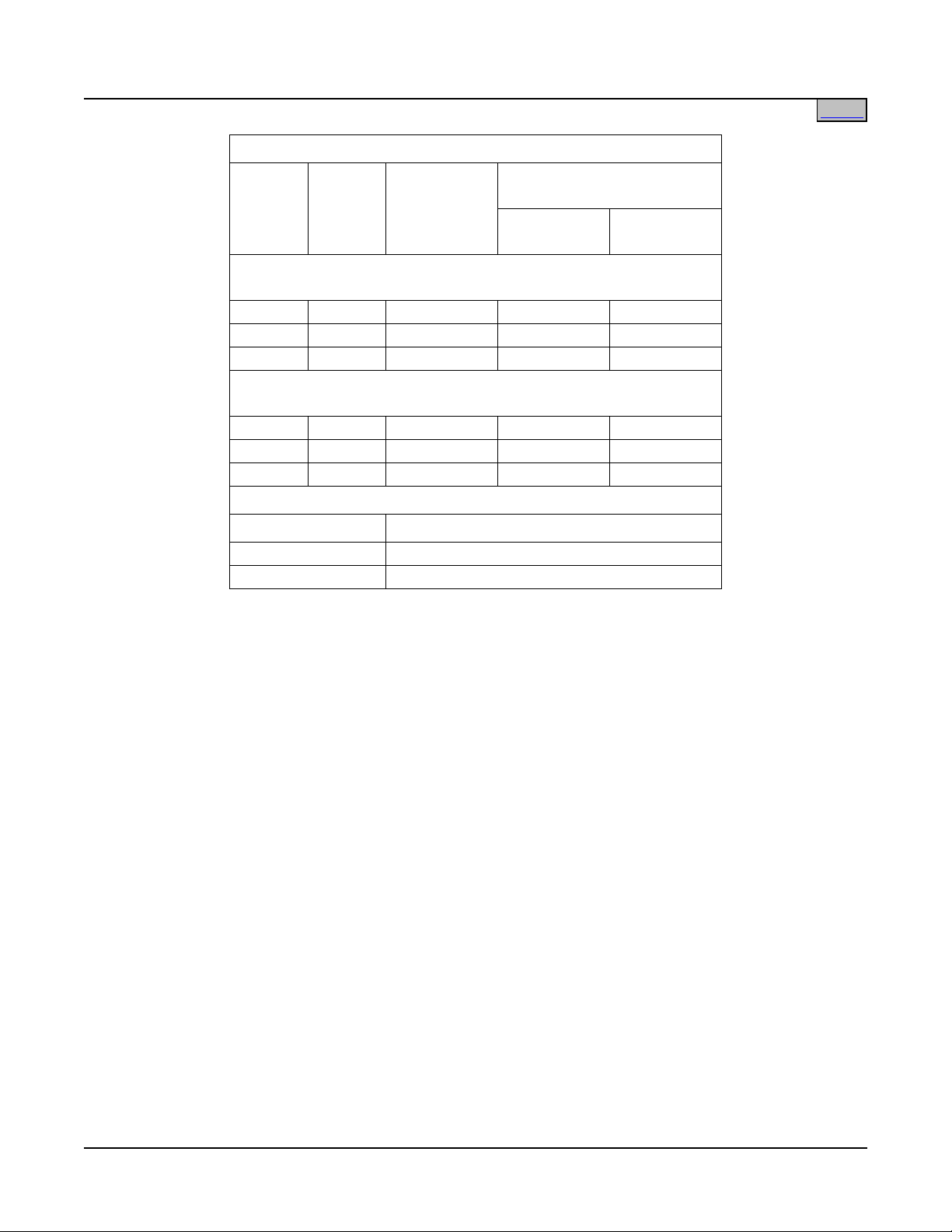

70

2

248251500

514403

529132

80

2

248252000

514403

529132

100

2

248252600

514403

529132

150

2

248253300

514403

529132

200

2

248254000

514403

529132

225

2

248254500

514403

529132

250

2

248255000

514403

529132

300

2

248255700

514403

529132

400

2

248257000

514403

529132

500

2

248258000

514403

529132

600

2

248259000

514403

529132

800

3

102901

514404

529131

Home

Spec. No. 582140001 (Model 801

NLDB, 801NLEB, 801NL-B) Issue AN, June 4, 2014

TPL Fuses and Fuseholder Assemblies

Features

♦ Each fuseholder assembly is equipped with a shunt for MCA load current measurements.

♦ Bolts into bay's distribution device mounting positions.

♦ Load lug busbars and adapter plates provide 3/8" clearance holes on 1" centers for installation of

customer provided two-hole lugs.

Restrictions

Load should not exceed 80% of device rating.

Refer to Table 2 for required distribution bus mounting positions.