Page 1

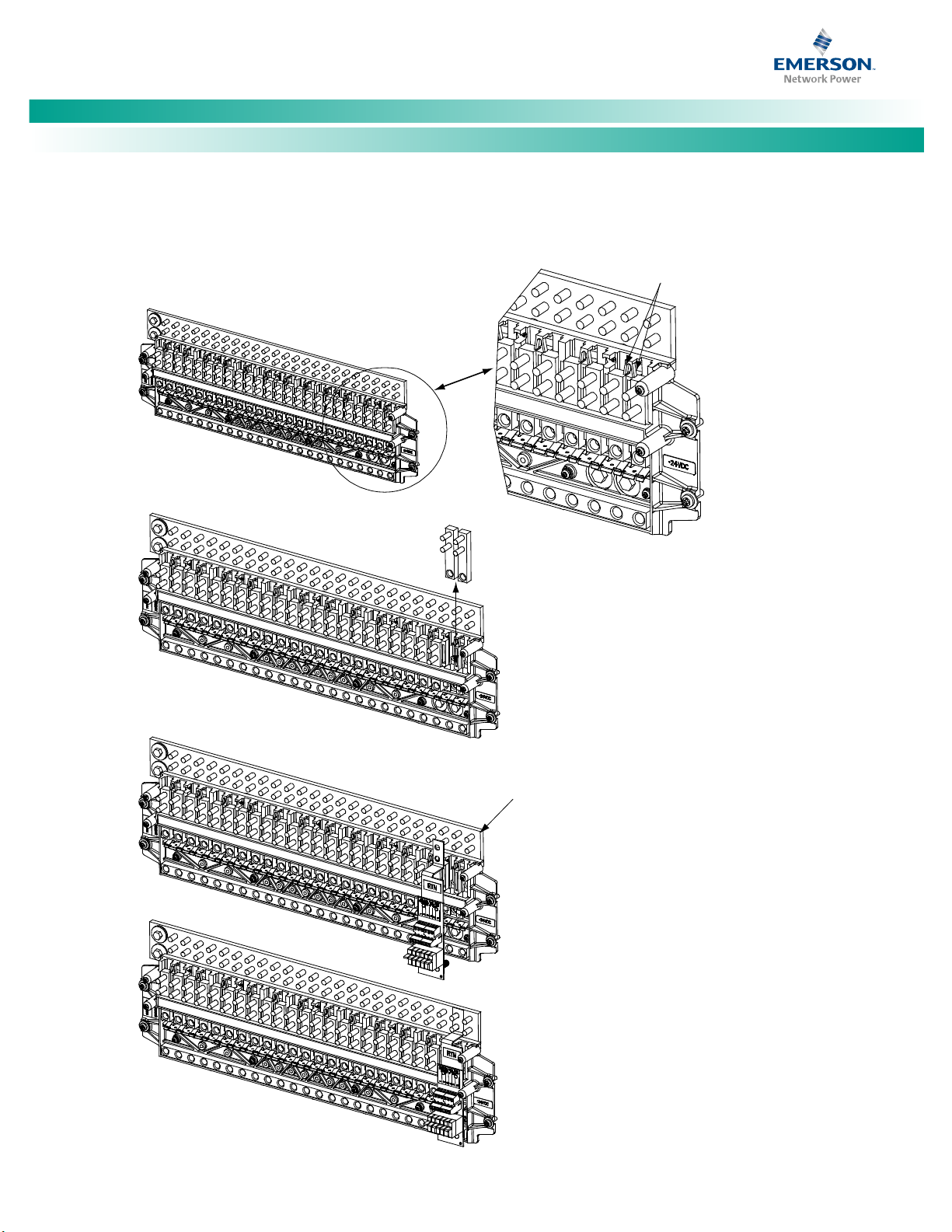

(E/W Spec. No. 588705000 Module Mounting Shelves)

(E/W Spec. No. 588705300 Module Mounting Shelves)

Main Bay Supplemental BayMain Bay Supplemental Bay

NetSure™ -48V DC Power System

Quick Start Guide, QS582127000 (Issue AC, December 10, 2013)

Specification Number: 582127000

Model Number: 721

NPBB

A Technical Manual from th

in Business-Critical Continu

s

rt

pe

x

e e

™

ty

i

Page 2

NetSure™ -48V DC Power System

Quick Start Guide, QS582127000 (Issue AC, December 10, 2013)

This page is intentionally blank.

Spec. No: 582127000 Code: QS582127000

Model No: 721NPBB Issue AC, December 10, 2013

Page 3

NetSure™ -48V DC Power System

[i]

Quick Start Guide, QS582127000 (Issue AC, December 10, 2013)

Table of Contents

Admonishments Used in this Document ................................................................................................................ ii

Important Safety Instructions .............................................................................................................................. iii

General Safety ........................................................................................................................................................iii

Voltages .................................................................................................................................................................iii

Battery ...................................................................................................................................................................iii

Personal Protective Equipment (PPE) .......................................................................................................................iv

Hazardous Voltage .................................................................................................................................................iv

Handling Equipment Containing Static Sensitive Components .................................................................................iv

Static Warning ...................................................................................................................................................... v

Customer Documentation Package ....................................................................................................................... 1

To Access Technical Documentation on the Web… .................................................................................................. 2

Physical Installation .............................................................................................................................................. 3

Install Distribution Devices.................................................................................................................................... 3

Make Jumper and Switch Settings ......................................................................................................................... 9

Electrical Connections ......................................................................................................................................... 10

Important Safety Instructions................................................................................................................................ 10

Make Frame Grounding Connections .................................................................................................................... 10

Make Nominal 208/240 Volts AC Input and Equipment Grounding Connections (if equipped) ................................ 10

Make Nominal 400 Volts DC Input and Equipment Grounding Connections (if equipped) ....................................... 18

Make External Interface Connections .................................................................................................................... 24

Make ACU+ Controller Ethernet Connection (if required) ....................................................................................... 41

Make Bay-to-Bay Communications Cable Connections .......................................................................................... 41

Installing Bay-to-Bay Busbars (582127000 List 1 with List 2 / List 3) ........................................................................ 41

Connecting Converter Output Cables 582127000 List 60....................................................................................... 45

Make Load Connections ........................................................................................................................................ 48

Make Battery Connections .................................................................................................................................... 56

List 93 Battery Tray ............................................................................................................................................... 63

Installing Rectifier or Converter Modules into Spec. No. 588705000 Module Mounting Shelves ........................... 63

Installing the Rectifier and Converter Modules into Spec. No. 588705300 Module Mounting Shelves ................... 65

Start and Check System ....................................................................................................................................... 67

NetPerform™ Optimization Services ................................................................................................................... 73

Spec. No: 582127000 Code: QS582127000

Model No: 721NPBB Issue AC, December 10, 2013

Page 4

NetSure™ -48V DC Power System

[ii]

DANGER!

if not avoided. (ANSI, OSHA)

WARNING!

serious injury if not avoided. This admonition is not used for situations that pose a risk on

equipment, software, data, or service. (ANSI)

CAUTION!

moderate injury if not avoided. (ANSI, OSHA) This admonition is not used for situations that pose a risk

only to equipment, data, or service, even if such use appears to be permitted in some of the applicable

standards. (OSHA)

ALERT!

data, or service. (ISO)

ALERT!

software corruption, data loss, or s

FIRE SAFETY!

locations of fire

SAFETY!

to a particular source of hazard or to fire safety. (ISO, ANSI, OSHA)

Quick Start Guide, QS582127000 (Issue AC, December 10, 2013)

Admonishments Used in this Document

Warns of a hazard the reader will be exposed to that will likely result in death or serious injury

D

an

g

er

Warns of a potential hazard the reader may be exposed to that could result in death or

W

ar

n

in

g

Warns of a potential hazard the reader may be exposed to that could result in minor or

ly to

Caution

A

lert

Alert

Fi

re Safet

S

afety

Alerts the reader to an action that must be avoided in order to protect equipment, software,

Alerts the reader to an action that must be performed in order to prevent equipment damage,

ervice interruption. (ISO)

Informs the reader of fire safety information, reminders, precautions, or policies, or of the

-fighting and fire-safety equipment. (ISO)

y

Informs the reader of general safety information, reminders, precautions, or policies not related

Spec. No: 582127000 Code: QS582127000

Model No: 721NPBB Issue AC, December 10, 2013

Page 5

NetSure™ -48V DC Power System

[iii]

Danger

Da

nger

Warning

Warnin

g

Dange

r

Dan

ger

Da

n

ge

r

Quick Start Guide, QS582127000 (Issue AC, December 10, 2013)

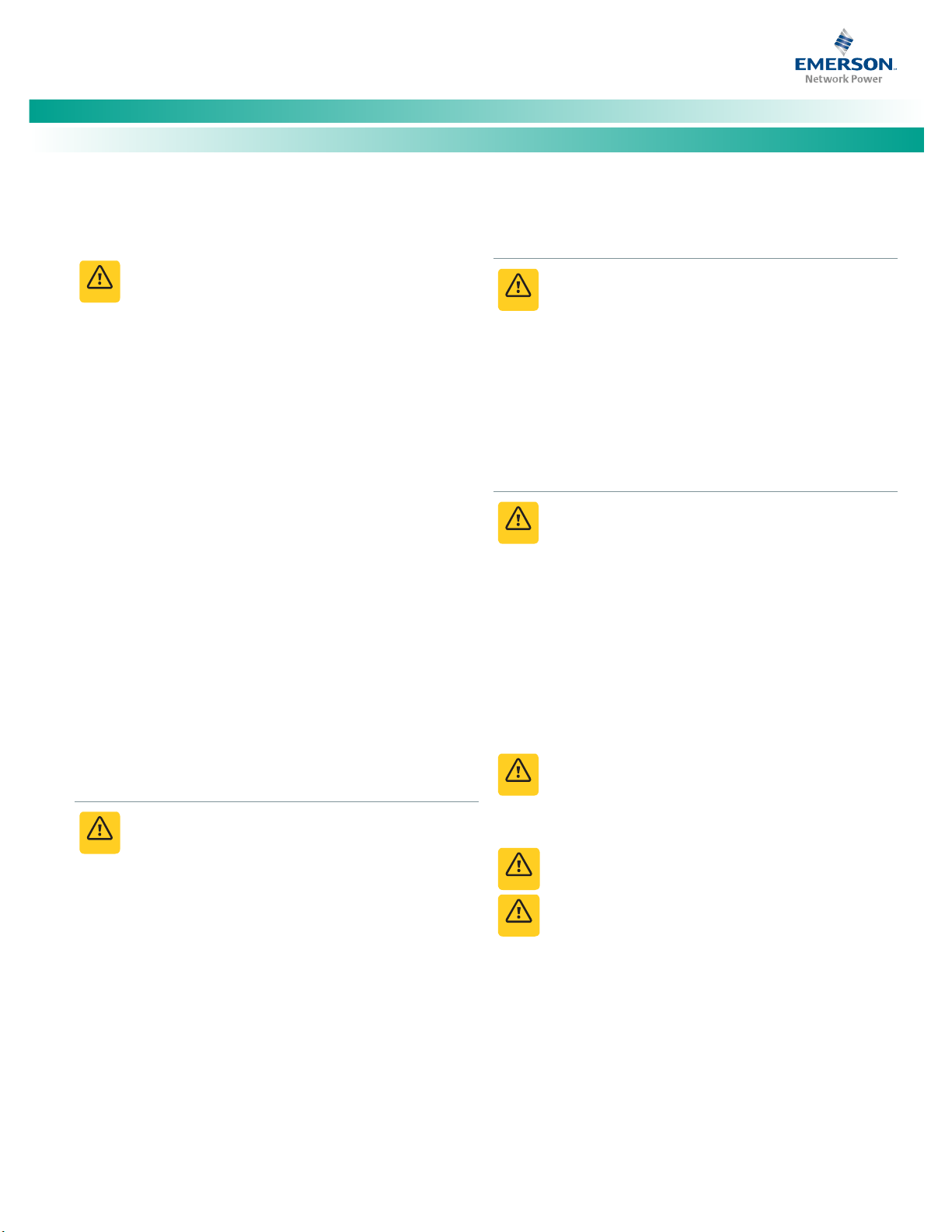

Important Safety Instructions

General Safety

DANGER!

YOU MUST FOLLOW APPROVED SAFETY PROCEDURES.

Performing the following procedures may expose you to

hazards. These procedures should be performed by

qualified technicians familiar with the hazards

associated with this type of equipment. These hazards

may include shock, energy, and/or burns. To avoid

these hazards:

a) The tasks should be performed in the order

indicated.

b) Remove watches, rings, and other metal objects.

c) Prior to contacting any uninsulated surface or

termination, use a voltmeter to verify that no

voltage or the expected voltage is present. Check

for voltage with both AC and DC voltmeters prior to

making contact.

d) Wear eye protection.

e) Use double insulated tools appropriately rated for

the work to be performed.

f) For 400V DC input systems, do not work on an

energized system without full arc flash and PPE

protection.

Voltages

AC Input Voltages

DANGER! This system may operate from AC input

voltage capable of producing fatal electrical shock. AC

input power must be completely disconnected from the

branch circuits wiring used to provide power to the

system before any AC electrical connections are made.

Follow local lockout/tagout procedures to ensure

upstream branch circuit breakers remain de-energized

during installation. DO NOT apply AC input power to

the system until all electrical connections have been

completed and checked.

DC Input Voltages

DANGER! This system may operate from 400V DC input

voltage capable of producing fatal electrical shock. DC

input power must be completely disconnected from the

branch circuits wiring used to provide power to the

system before any DC electrical connections are made.

Follow local lockout/tagout procedures to ensure

upstream branch circuit breakers remain de-energized

during installation. DO NOT apply DC input power to

the system until all electrical connections have been

completed and checked.

DC Output and Battery Voltages

DANGER! This system produces DC Power and may have

a battery source connected to it. Although the DC

voltage is not hazardously high, the rectifiers/converters

and/or battery can deliver large amounts of current.

Exercise extreme caution not to inadvertently contact or

have any tool inadvertently contact an output terminal

or battery terminal or exposed wire connected to an

output terminal or battery terminal. NEVER allow a

metal object, such as a tool, to contact more than one

termination or battery terminal at a time, or to

simultaneously contact a termination or battery

terminal and a grounded object. Even a momentary

short circuit can cause sparking, explosion, and injury.

DANGER! Follow local lockout/tagout procedures to

ensure DC branch circuit protection devices remain deenergized during installation at loads, as required.

Battery

WARNING! Correct polarity must be observed when

connecting battery leads.

WARNING! Special safety precautions are required for

procedures involving handling, installing, and servicing

batteries. Observe all battery safety precautions in this

manual and in the battery instruction manual. These

precautions should be followed implicitly at all times.

Spec. No: 582127000 Code: QS582127000

Model No: 721NPBB Issue AC, December 10, 2013

Page 6

NetSure™ -48V DC Power System

[iv]

W

a

rn

in

g

Danger

Danger

Dange

r

Alert

Alert

Quick Start Guide, QS582127000 (Issue AC, December 10, 2013)

WARNING! A battery can present a risk of electrical

shock and high short circuit current. Servicing of

batteries should be performed or supervised only by

properly trained and qualified personnel knowledgeable

about batteries and the required precautions.

The following precautions should be observed when

working on batteries:

• Remove watches, rings, and other metal objects.

• Eye protection should be worn to prevent injury

from accidental electrical arcs.

• Use certified and well maintained insulated tools.

Use double insulated tools appropriately rated for

the work to be performed. Ensure that wrenches

with more than one working end have only one end

exposed.

• Do not lay tools or metal parts on top of batteries.

• Disconnect charging source prior to connecting or

disconnecting battery terminals.

• Risk of explosion if battery is replaced with an

incorrect type or if polarity is reversed. When

replacing batteries, replace with the same

manufacturer and type, or equivalent.

• Dispose of used batteries according to the

instructions provided with the batteries. Do not

dispose of batteries in a fire. They may explode.

• ALWAYS FOLLOW THE BATTERY MANUFACTURER’S

RECOMMENDATIONS AND SAFETY INSTRUCTIONS.

In addition to the hazard of electric shock, gas produced

by batteries can be explosive and sulfuric acid can cause

severe burns. Do not open or mutilate batteries.

Released electrolyte is harmful to the skin and eyes, and

is toxic. If electrolyte comes into contact with skin, the

affected area should be washed immediately with large

amounts of water.

DANGER!

This equipment may be used in conjunction

with lead-acid batteries. Working near lead-acid

batteries is dangerous!

• Batteries contain sulfuric acid.

• Batteries generate explosive gases during normal

operation. Systems containing batteries should

never be installed in an airtight room or space.

Only install in a ventilated environment.

• Batteries are an energy source that can produce

high amounts of electrical current.

FOR THESE REASONS, IT IS OF CRITICAL IMPORTANCE

THAT YOU READ THESE INSTRUCTIONS AND FOLLOW

THEM EXACTLY.

WHEN WORKING WITH LEAD-ACID BATTERIES:

• Wear complete protection for eyes, face, hands,

and clothing. Examples are safety goggles or face

shield, a rubber apron and gloves.

• If battery acid enters your eye, immediately flush

your eye with running cold water for at least 15

minutes. Get medical attention immediately.

• If battery acid contacts skin or clothing, wash

immediately with soap and water.

ALERT! Performing maintenance and/or

troubleshooting procedures may interrupt power to the

loads, if battery reserve is not sufficient.

Personal Protective Equipment (PPE)

The following admonishments apply to 400V DC input systems.

DANGER! ARC FLASH AND SHOCK HAZARD.

Appropriate PPE and tools required when working on

this equipment. An appropriate flash protection

boundary analysis should be done determine the

“hazard/risk” category, and to select proper PPE.

This product is intended only for installation in a

Restricted Access Location.

Only authorized and properly trained personnel should

be allowed to install, inspect, operate, or maintain the

equipment.

Do not work on LIVE parts. If required to work or

operate live parts, obtain appropriate Energized Work

Permits as required by the local authority, per NFPA 70E

“Standard for Electrical Safety in the Workplace”.

Hazardous Voltage

DANGER! Hazard of electrical shock. More than one

disconnect may be required to de-energize the system

before servicing.

Handling Equipment Containing

Static Sensitive Components

ALERT! Installation or removal of equipment containing

static sensitive components requires careful handling.

Before handling any equipment containing static

sensitive components, read and follow the instructions

contained on the Static Warning Page.

Spec. No: 582127000 Code: QS582127000

Model No: 721NPBB Issue AC, December 10, 2013

Page 7

NetSure™ -48V DC Power System

[v]

Quick Start Guide, QS582127000 (Issue AC, December 10, 2013)

Static Warning

This equipment contains static sensitive components. The warnings listed below must be observed to prevent damage to these

components. Disregarding any of these warnings may result in personal injury or damage to the equipment.

1. Strictly adhere to the procedures provided in this document.

2. Before touching any equipment containing static sensitive components, discharge all static electricity from yourself by wearing

a wrist strap grounded through a one megohm resistor. Some wrist straps, such as Emerson Network Power Part Number

631810600, have a built-in one megohm resistor; no external resistor is necessary. Read and follow wrist strap manufacturer’s

instructions outlining use of a specific wrist strap.

3. Do not touch traces or components on equipment containing static sensitive components.

Handle equipment containing static sensitive components only by the edges that do not have connector pads.

4. After removing equipment containing static sensitive components, place the equipment only on conductive or anti-static

material such as conductive foam, conductive plastic, or aluminum foil. Do not use ordinary Styrofoam

5. Store and ship equipment containing static sensitive components only in static shielding containers.

6. If necessary to repair equipment containing static sensitive components, wear an appropriately grounded wrist strap, work on a

conductive surface, use a grounded soldering iron, and use grounded test equipment.

™

or ordinary plastic.

Spec. No: 582127000 Code: QS582127000

Model No: 721NPBB Issue AC, December 10, 2013

Page 8

NetSure™ -48V DC Power System

[vi]

Quick Start Guide, QS582127000 (Issue AC, December 10, 2013)

This page is intentionally blank.

Spec. No: 582127000 Code: QS582127000

Model No: 721NPBB Issue AC, December 10, 2013

Page 9

NetSure™ -48V DC Power System

[1]

Quick Start Guide, QS582127000 (Issue AC, December 10, 2013)

Customer Documentation Package

This document (QS582127000) provides Quick Start Instructions for NetSure™ -48V DC Power System Model 721NPBB, Spec. No.

582127000.

The complete Customer Documentation Package consists of…

NetSure

NetSure

USB Drive with All Customer Documentation

™

-48V DC Power System Installation Manual

• NetSure™ -48V DC Power System Quick Start Guide: QS582127000

• NetSure™ -48V DC Power System Quick Start Guide: QS582127000

™

ACU+ Controller User Manual

• NetSure™ ACU+ Controller User Instructions: UM1M820BNA (AC Input Voltage Systems) or UM1M820DNA400 (DC Input

Voltage Systems)

• Power System Quick Start Guide: QS582127000

• Power System Quick Start Guide: QS582127000

• Power System User Instructions: UM582127000

• Power System “System Application Guide”: SAG582127000

• Module Mounting Shelf Power Data Sheet: PD588705000

• Rectifier Instructions: UM1R483500E

• Converter Instructions: UM1C400483500E

• Module Mounting Shelf Power Data Sheet: PD588705300

• Rectifier Instructions: UM1R482000E3

• Converter Instructions: UM1C48241500

• Engineering Drawings

• Also provided on the USB drive is an ACU+ configuration drawing and the ACU+ configuration files loaded into the ACU+ as

shipped.

Spec. No: 582127000 Code: QS582127000

Model No: 721NPBB Issue AC, December 10, 2013

Page 10

NetSure™ -48V DC Power System

[2]

*

*

Quick Start Guide, QS582127000 (Issue AC, December 10, 2013)

To Access Technical Documentation on the Web…

To view and download technical documentation for your Emerson Network Power DC power products, please visit our secure partner

portal website, EnergyNet at www.EmersonEnergy.com.

Under Partner Login, click on “Request Account” to request access to this website. If you can’t remember your password, use the “Forgot

Password?” tool.

Once you log in, you arrive at the EnergyNet landing page

document you are looking for, use the request info button at the bottom of the screen.

For Users who require access to company specific documents, after logging into EnergyNet you will be

directed to a company specific landing page.

. Here you can search for product documentation. If you do not find the

Spec. No: 582127000 Code: QS582127000

Model No: 721NPBB Issue AC, December 10, 2013

Page 11

NetSure™ -48V DC Power System

[3]

Choose a mounting location

Secure the relay rack to the

floor

Securing the Relay Rack to the Floor in the

Mount the Power System

Mounting System Components in an Equipment Rack

Fuseho

lde

r As

sembly

Longer Sid

e

to the Bot

tom

Sh

ort

er Si

de

to the Top

Fuse Carrie

r

Fus

eholder Body

T

PS/TL

S Fus

e

Polariz

ing Keyway

Matches Key on

Bot

tom of Fuse Carrier

Fuse

holder

Assembly

E

xploded View

Fuseholder Assem

bly (P/N 117201) incl

udes

body & car

rier, alarm fuse, and a

larm fuse safety cover.

Ins

ert t

hese terminals

into cor

res

pond

ing

soc

ket

s

on

dist

rib

ution panel.

GM

T-X

Safety Fuse

Cover

(Repla

cement

P/N 24889870

0)

GMT-18/100A

Al

arm Fuse

(Replacement

P/N 248610301)

Quick Start Guide, QS582127000 (Issue AC, December 10, 2013)

Physical Installation

To do this…

See this in the Installation Instructions (IM582127000)

General Requirements in the INSTALLING THE

SYSTEM section.

INSTALLING THE SYSTEM section.

in the INSTALLING THE SYSTEM section.

Install optional lug adapter

busbar kits

Installing Optional Lug Adapter Busbar Kits, Part Nos.

534449 and 514714 in the INSTALLING THE

SYSTEM section.

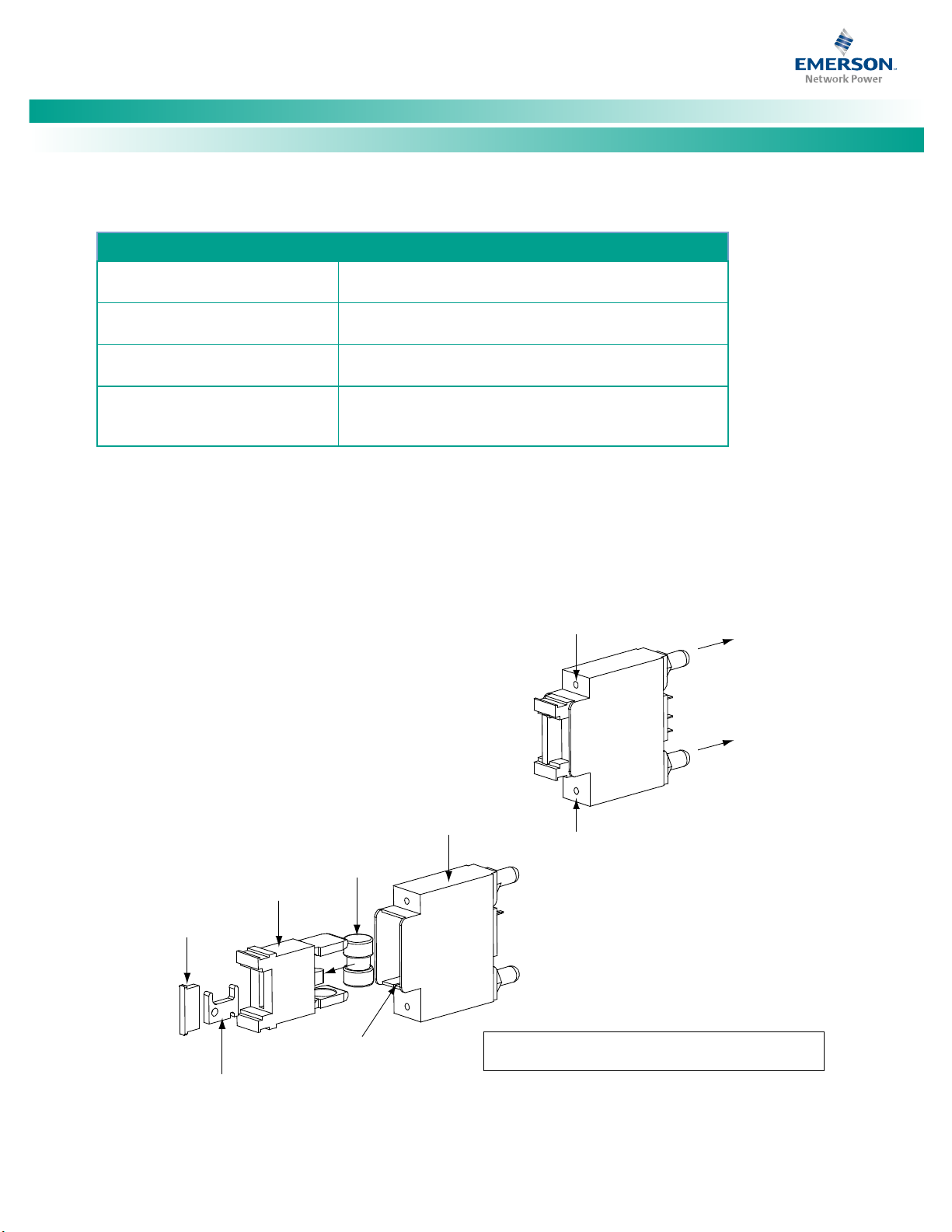

Install Distribution Devices

Load and battery distribution devices were factory-installed if ordered with the power system. If additional installation is required, refer

to Figure 1 through Figure 6. For detailed procedures, refer to Installing Circuit Breakers and Fuses in the INSTALLING THE SYSTEM section

of the Installation Instructions (IM582127000).

Figure 1. Installing a Bullet Nose Type Fuseholder and TPS/TLS Fuse

Spec. No: 582127000 Code: QS582127000

Model No: 721NPBB Issue AC, December 10, 2013

Page 12

NetSure™ -48V DC Power System

[4]

Insert these terminals

into corresponding sockets

on distribution panel.

Longer Side

to the Bottom

Shorter Side

to the Top

Lettering on

handle must be

right side up.

Turn off

before installing.

Quick Start Guide, QS582127000 (Issue AC, December 10, 2013)

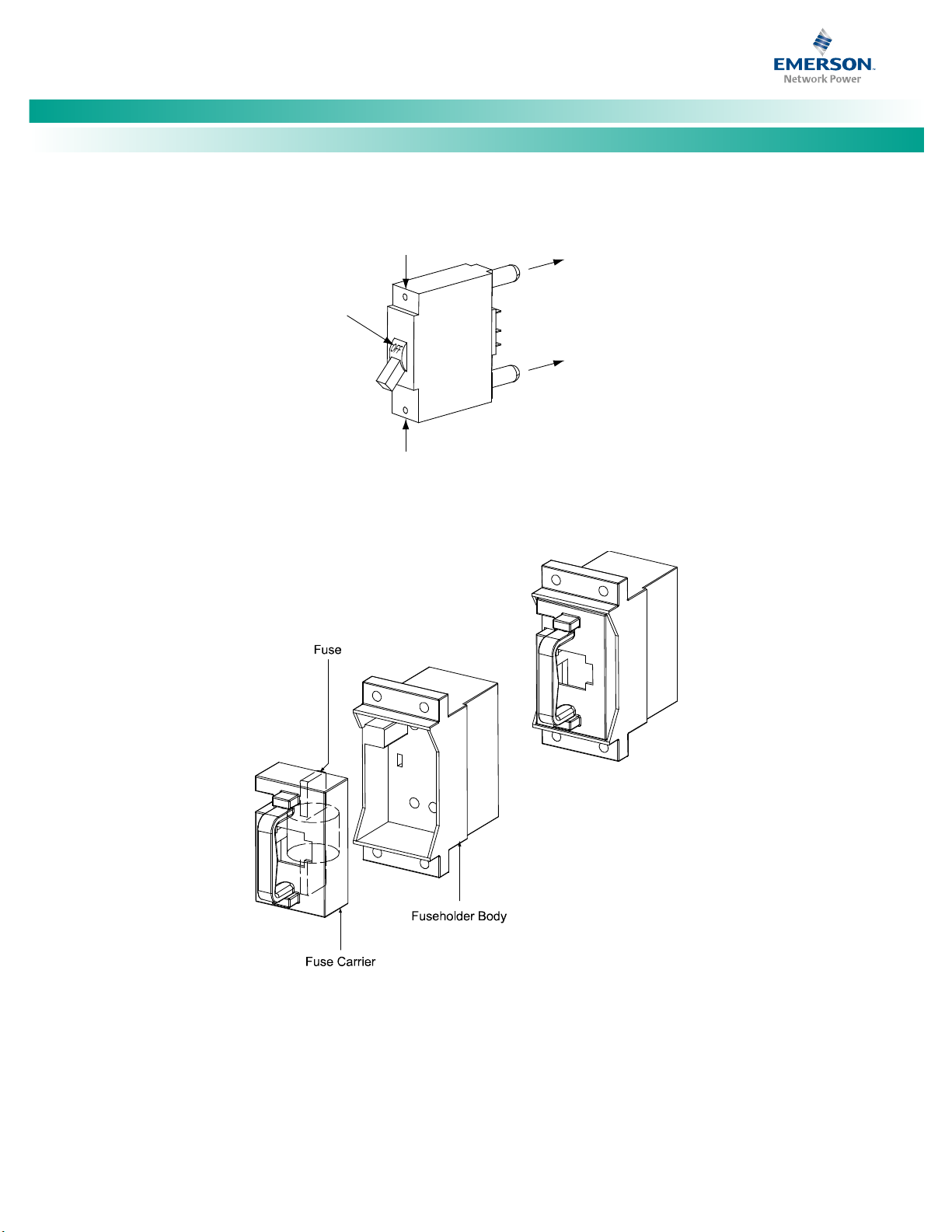

Figure 2. Installing a Bullet Nose Type Circuit Breaker

Figure 3. Installing a TPH Fuse

Spec. No: 582127000 Code: QS582127000

Model No: 721NPBB Issue AC, December 10, 2013

Page 13

NetSure™ -48V DC Power System

[5]

F

us

e C

ase

Open Fuse Case View

TPL F

use

Fuse

In

s

ta

ll

e

d i

n

Open Fuse C

as

e

(r

ear

vie

w)

Fuse Installed in

Closed Fuse Case

(rear view)

Fu

sebl

ock

(P/

N 51

6241)

GMT-18/100A Al

ar

m Fuse

(P/N 248610301) and

GMT-X Safety F

us

e

Cover

(P/N 248898700)

(Both ar

e

pr

ov

i

ded

w/ fusebloc

k

)

Quick Start Guide, QS582127000 (Issue AC, December 10, 2013)

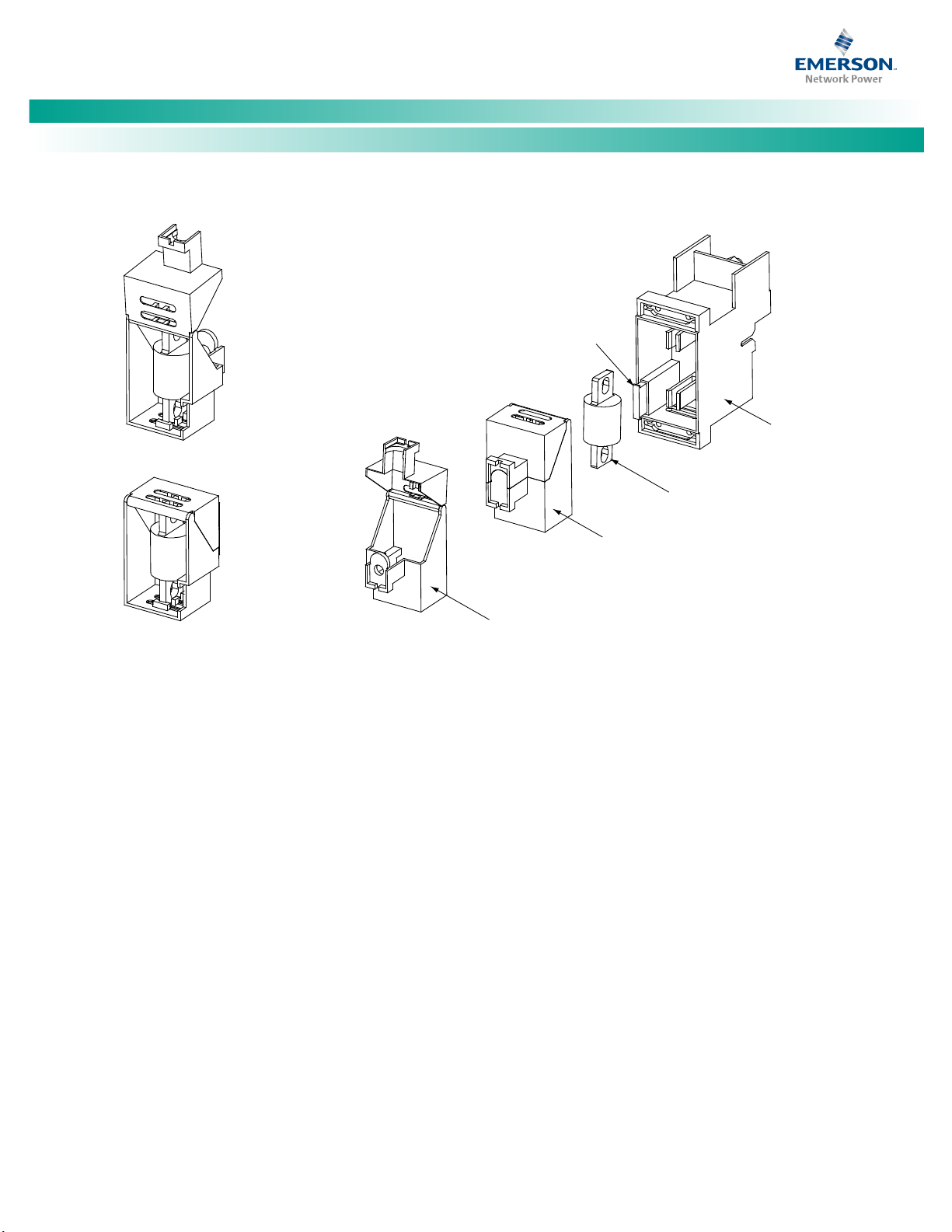

Figure 4. Installing TPL-B Fuses

Spec. No: 582127000 Code: QS582127000

Model No: 721NPBB Issue AC, December 10, 2013

Page 14

NetSure™ -48V DC Power System

[6]

Press in tabs to release

lug terminal busbars for

positions to be occupied

by GMT Fuse Block.

Remove two lug terminal busbars

for positions to be occupied

by GMT Fuse Block.

Plug in GMT Fuse Block and secure

at two locations on the RTN bar.

Torque to 72 in-lbs.

RTN Bar

GMT Fuse Block Installed View

1.

2.

3.

Quick Start Guide, QS582127000 (Issue AC, December 10, 2013)

Figure 5. Installing an Optional Bullet Nose Type 6-Position GMT Distribution Fuse Block

Spec. No: 582127000 Code: QS582127000

Model No: 721NPBB Issue AC, December 10, 2013

Page 15

NetSure™ -48V DC Power System

[7]

INSTALLING CIRCUIT BREAKER

A

Quick Start Guide, QS582127000 (Issue AC, December 10, 2013)

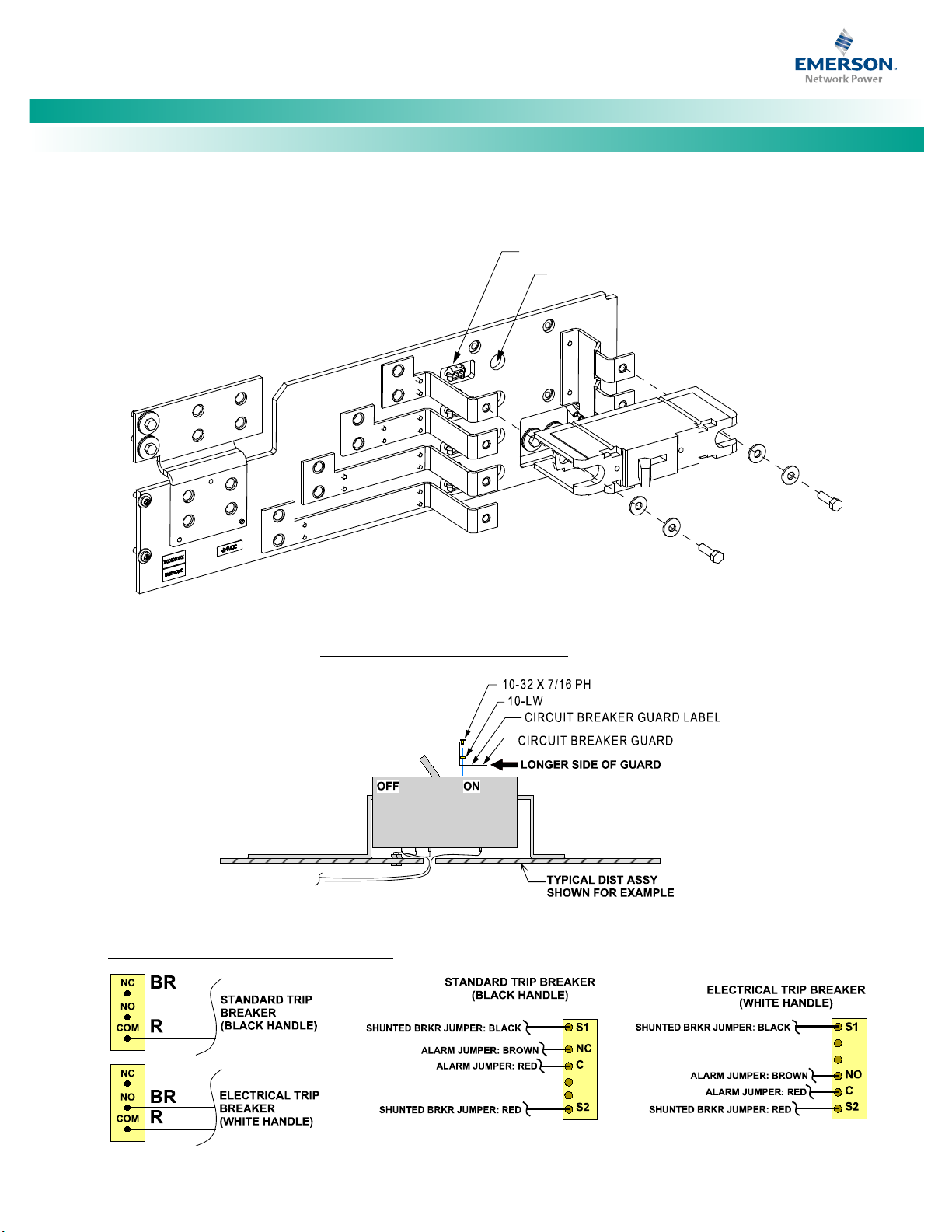

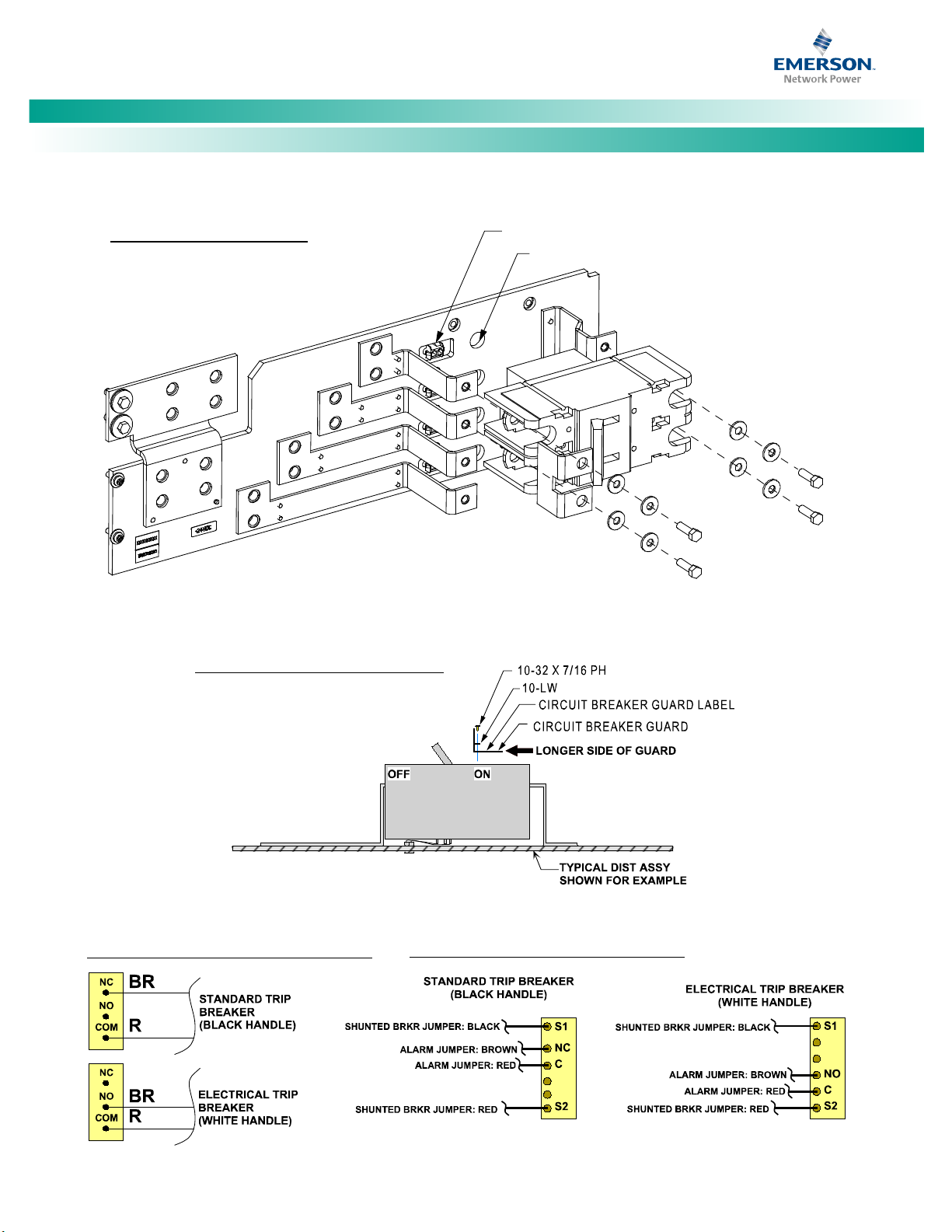

Figure 6. Installing a GJ/218 Circuit Breaker (1-Pole) (cont’d on next page)

Alarm jumper connector.

Holes to route shunt jumper through (if applicable).

ON

OFF

INSTALLING CIRCUIT BREAKER GUARD

LARM WIRING (BREAKERS W/OUT SHUNTS)

Apply anti-oxidizing compoun

surfaces before mounting circuit breakers.

ALARM WIRING (BREAKERS WITH SHUNTS)

d to

bar ma

bus

tin

4" H

1/

ard

ene

d

Fla

t Was

her

g

1/4" Belleville

Lock Washer

1/4-20 x 3/4” Bolt

(2 places)

Torque to 60 in-lbs.

Spec. No: 582127000 Code: QS582127000

Model No: 721NPBB Issue AC, December 10, 2013

Page 16

NetSure™ -48V DC Power System

[8]

Alarm jumper connectors.

A

Quick Start Guide, QS582127000 (Issue AC, December 10, 2013)

Figure 6. Installing a GJ/218 Circuit Breaker (2-Pole, 3-Pole, 4-Pole) (cont’d from previous page)

INSTALLING CIRCUIT BREAKER

2-pole breaker shown.

3-pole and 4-pole breakers similar.

Holes to route shunt jumper through (if applicable).

OFF

ON

Apply anti-oxidizing compound to busbar mating

surfaces before mounting circuit breakers.

INSTALLING CIRCUIT BREAKER GUARD

LARM WIRING (BREAKERS W/OUT SHUNTS)

Busbar

ALARM WIRING (BREAKERS WITH SHUNTS)

1/4" Hardened

Flat Washer

1/4" Belleville

Lock Washer

1/4-20 x 3/4” Bolt

(4 places / 2-pole brk,

6 places / 3-pole brk,

8 places / 4-pole brk)

Torque to 60 in-lbs.

Spec. No: 582127000 Code: QS582127000

Model No: 721NPBB Issue AC, December 10, 2013

Page 17

NetSure™ -48V DC Power System

[9]

Switch Settings:

Jumper Settings:

J

8 (Mai

n Bay Onl

y)

Se

lects to

power Co

ntrolle

r

from “Ba

ttery P

ower” or no

t.

No

Batt

ery

Pw

r

B

attery

Pwr

External I

nterna

l

J8

J10

J10 (

Main Bay

Only)

B

attery M

onitor

ing Exter

nal / In

ternal

(see TB1

-4 and TB1

-5 for

ex

ternal m

onitor

ing points

)

1

2

3

7

8

9

1

2

3

7

8

9

Shorting Jumper

Shorting Jumpe

r

1

1A

2A 3A

1B

2B 3

B

5

J1

J2

J

3

J

4

J8

TB2

TB1

TP1 T

P2 T

P3 T

P4

J10

J5

T

B1-4

: External Batt

ery

Moni

tor

ing

(-)

TB1-5: E

xt

er

nal

Ba

ttery Moni

toring

(+)

4-R

ow C

abi

net

Shown,

O

the

rs S

imilar

(Fro

nt D

oor

Removed in

Illu

str

ati

on fo

r Clarity)

Syst

em Interf

ac

e

Circ

uit Car

d

(

Mai

n Bay Only

)

Quick Start Guide, QS582127000 (Issue AC, December 10, 2013)

Make Jumper and Switch Settings

Various circuit cards installed in the system have switch and jumper settings.

All switch settings set the various circuit cards to operate properly with this system and have been factory set.

The jumpers located on the system interface circuit card are customer selectable. Refer to Figure 7 for jumper locations

and function. Refer to SETTING JUMPERS AND SWITCH OPTIONS in the Installation Instructions (IM582127000) for a complete

procedure.

Figure 7. System Interface Circuit Card Jumper Locations

Spec. No: 582127000 Code: QS582127000

Model No: 721NPBB Issue AC, December 10, 2013

Page 18

NetSure™ -48V DC Power System

[10]

Danger!

Connection to Relay Rack

the MAKING ELECTRICAL CONNECTIONS section.

Connection

NOTE THAT THIS SYSTEM MAY BE EQUIPPED WITH AC OR DC INPUTS.

THESE PROCEDURES APPLY TO SYSTEMS WITH AC INPUTS.

SPECIFICALLY, THESE PROCEDURES APPLY TO THE FOLLOWING EQUIPMENT:

D

a

n

g

e

r

Quick Start Guide, QS582127000 (Issue AC, December 10, 2013)

Electrical Connections

Important Safety Instructions

Adhere to the “Important Safety Instructions” presented at the front of this document.

Make Frame Grounding Connections

To do this…

Make Frame Grounding

Make Central Office Ground

See this in the Installation Instructions (IM582127000)

Relay Rack Grounding Connection (Frame Ground) in

Central Office Ground Connection in the MAKING

ELECTRICAL CONNECTIONS section.

Make Nominal 208/240 Volts AC Input and Equipment Grounding Connections (if equipped)

Refer to Nominal 208/240 Volts AC Input and Equipment Grounding Connections (if equipped) in the MAKING ELECTRICAL CONNECTIONS

section of the Installation Instructions (IM582127000) for a complete procedure.

• 582127000 List 40, 41, 42

• 588705000 List 22

• 588705000 List 31

• 588705000 List 32

• 588705300 List 3

The available AC input options for this system are:

AC Input Termination Assemblies

• The system can be equipped with an AC input termination assembly which provides a separate single phase AC input

connection for each rectifier position (582127000 List 40).

• The system can be equipped with an AC input termination assembly which provides a separate single phase AC input

connection for every two (2) rectifier positions (582127000 List 41).

• The system can be equipped with an AC input termination assembly which provides a separate three phase AC input connection

for every three (3) rectifier positions (582127000 List 42).

Direct AC Input Connections to the Module Mounting Shelves

• The system can be equipped with module mounting shelves that contain AC input terminal blocks which provide a separate

single phase AC input connection for each rectifier position (588705000 List 31).

• The system can be equipped with module mounting shelves that contain AC input terminal blocks which provide a separate

three phase AC input connection for every three (3) rectifier positions (588705000 List 32).

• The system can be equipped with module mounting shelves that contain AC input line cords (one for each rectifier module

position) (588705000 List 22).

• The system can be equipped with module mounting shelves that contain AC input cable assemblies which provide a separate

single phase AC input connection for every two (2) rectifier positions (588705300 List 3).

Spec. No: 582127000 Code: QS582127000

Model No: 721NPBB Issue AC, December 10, 2013

Page 19

[11]

Note:

(4

-R

o

w C

a

bi

ne

t

Sh

ow

n

,

O

t

he

rs

S

im

il

a

r)

F

ro

nt

D

oo

r

Re

mo

v

ed

in

Illu

st

r

at

io

n

fo

r C

l

ar

i

ty

A

C I

NP

U

T C

ON

N

EC

T

IO

NS

,

1 F

E

ED

PE

R

1 R

EC

T

IF

IE

R

, S

I

NG

LE

P

HA

SE

(

58

2

12

70

0

0 L

IS

T

40

)

N

OT

E

:

W

I

RI

NG

T

O A

F

IE

LD

I

NS

TA

L

LE

D

SH

EL

F

IS

DO

N

E A

T

TH

E R

E

AR

O

F

TH

E S

H

EL

F.

A

C W

i

re

w

ay

Co

ver

AC

W

ir

ew

a

y

C

ove

r

A

C I

n

pu

t

Con

nec

tor

Cover

I

nsi

de

Vi

e

w

Le

ft S

ide

Ins

ide

View

Rig

ht Si

de

G

ND G

ND

GND

GND

AC 2AC

1

P

CU 1

A

C 2A

C 1

PC

U 2

AC

2AC

1

PC

U 3

R

ECTI

FIE

R

(P

CU

)

AC

INP

UT FE

EDS

1 FE

ED P

ER

1 RECTI

FIE

R (P

CU

)

208

-24

0VA

C, 50

/60

Hz,

SING

LE P

HAS

E

SHE

LF 1

AC

2AC 1

P

CU 1

AC 2AC 1

PCU 2

AC

2AC 1

PCU 3

AC

2AC 1

PCU

1

AC 2A

C 1

PCU

2

AC 2AC

1

PCU 3

REC

TIF

IER (

PCU

) AC

INPU

T FEEDS

1

FEE

D PE

R 1 RE

CTIFIE

R (PCU)

208-24

0VAC, 50/

60H

z, S

ING

LE PH

ASE

S

HELF

3 SHE

LF 2

AC 2AC 1

PCU

1

AC 2AC

1

PCU 2

AC 2AC 1

P

CU 3

AC 2A

C 1

PCU 1

AC 2

AC 1

PCU 2

AC 2AC 1

PCU 3

RECTIF

IER (PCU

) AC INPU

T FEEDS

1

FEED PE

R 1 RECTI

FIER (P

CU)

208

-240VAC

, 50/60H

z, SING

LE PHASE

SHELF 5 SHE

LF 4

A

C 2AC

1

PC

U 4

A

C 2AC

1

P

CU 5

AC 2A

C 1

PCU

6

R

EC

TI

FI

ER (PCU

) AC I

N

PU

T

FE

ED

S

1 F

EED

PER 1

REC

TIF

IE

R (

PCU)

208

-24

0VA

C, 50

/60

Hz,

SING

LE P

HAS

E

S

HEL

F 1

AC 2A

C 1

P

CU 4

AC 2AC 1

PCU

5

AC 2A

C 1

PCU 6

AC 2A

C 1

PCU 4

AC 2

AC 1

P

CU 5

AC 2AC 1

PCU 6

R

ECTIFIER

(PC

U) AC

INP

UT F

EED

S

1 FEE

D PER

1 RE

CTI

FIE

R (PC

U)

208

-240VA

C, 50/60

Hz, SINGL

E PH

ASE

SHELF 2 S

HELF 3

AC 2A

C 1

PCU 4

AC 2

AC 1

PCU 5

AC 2AC 1

PCU

6

AC 2AC 1

PC

U 4

AC 2AC 1

PCU 5

AC 2AC 1

P

CU 6

R

ECTIFIE

R (PCU)

AC INPUT

FEEDS

1 F

EED PER 1

RECTIF

IER (PCU

)

208-2

40VAC,

50/60Hz

, SINGLE

PHASE

S

HELF 4 SHE

LF 5

L

ine t

o L

in

e:

Co

nne

ct Li

ne 1

to T

erm

inal

1.

Conn

ect

Lin

e 2 to

Ter

min

al 2

.

Lin

e to

Neu

tral

Conn

ect

Lin

e to

Term

ina

l 1.

Con

nec

t Neu

tra

l to

Term

ina

l 2.

W

ire S

ize

Cap

aci

ty: 1

0-2

4 AWG.

R

ecom

men

ded

Tor

que: 10

in-lbs

.

F

RAM

E GR

OUN

D

CO

NNE

CT

I

ON

Fo

ur 1

0-32

X 3/

4"

Stu

d

s a

nd

H

ar

d

war

e.

Reco

mme

nde

d tor

qu

e

:

23

i

n-

lb

s

.

FRAM

E GR

OUN

D

CO

NNECT

ION

Fou

r 10

-32

X 3/

4"

Studs a

nd H

a

rd

w

ar

e.

Re

com

men

ded t

orq

ue:

23

in

-l

bs

.

Rec

tif

i

er

Mo

d

ul

e (

P

CU

) M

o

un

ti

ng Sl

ots

S

he

l

f #

1

Re

ct

.

(

PC

U)

1

R

ec

t

.

(P

C

U)

2

R

ec

t.

(

P

CU

)

3

Re

c

t.

(

PC

U

)

4

R

e

ct

.

(P

C

U)

5

R

ec

t

.

(P

CU

)

6

R

ec

t.

(PCU)

1

R

ec

t.

(

PC

U)

2

R

e

ct

.

(

P

CU

)

3

Re

ct

.

(

P

CU

)

4

Re

ct.

(

P

CU

)

5

Re

ct.

(

P

CU

)

6

Re

ct.

(P

C

U)

1

Rect.

(P

CU)

2

Rec

t.

(PC

U)

3

R

e

ct

.

(PCU

)

4

Re

ct

.

(PC

U)

5

R

e

ct

.

(PCU

)

6

R

ect.

(PC

U)

1

Rect.

(PCU

)

2

Re

ct.

(P

CU)

3

Re

c

t.

(PC

U)

4

Re

c

t.

(PCU)

5

Re

c

t.

(PC

U)

6

Rec

t.

(

P

CU

)

1

R

ect

.

(

PC

U)

2

Rect

.

(

PCU)

3

Rect.

(PC

U)

4

Re

ct.

(P

CU)

5

Re

ct

.

(PCU

)

6

Sh

el

f

#2

Sh

e

lf

#

3

S

he

l

f #

4

S

hel

f #5

NetSure™ -48V DC Power System

Quick Start Guide, QS582127000 (Issue AC, December 10, 2013)

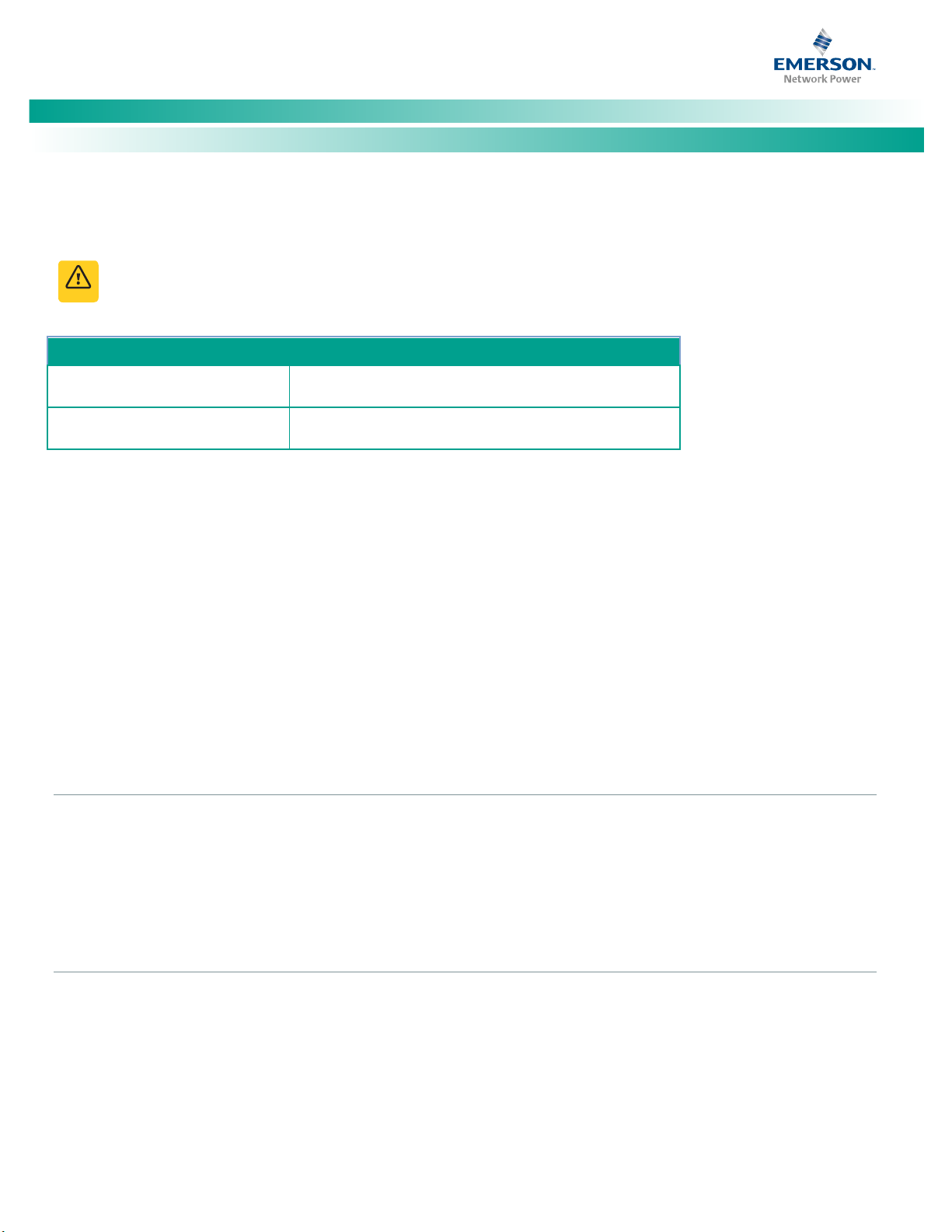

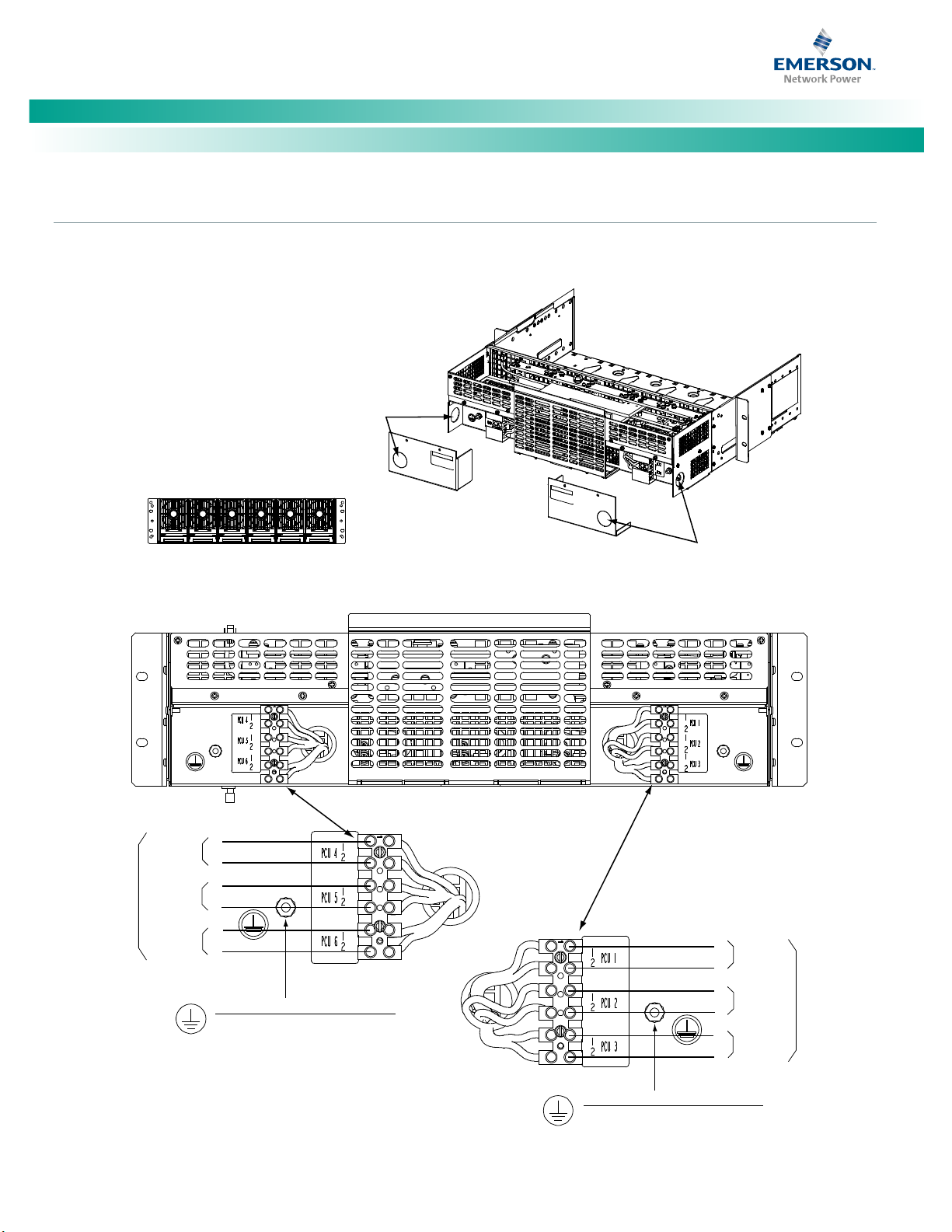

Connections to AC Input Termination Assemblies (582127000 List 40, 41, and 42)

Refer to Figure 8, Figure 9, or Figure 10.

Terminal blocks for a system with maximum possible rectifier shelves shown. Your system may have less terminal blocks then shown.

Figure 8. Nominal 208/240 Volts AC Input and Equipment Grounding Connections to AC Input Termination Assembly 582127000 List 40

(1 Feed per 1 Rectifier, Single Phase)

Spec. No: 582127000 Code: QS582127000

Model No: 721NPBB Issue AC, December 10, 2013

Page 20

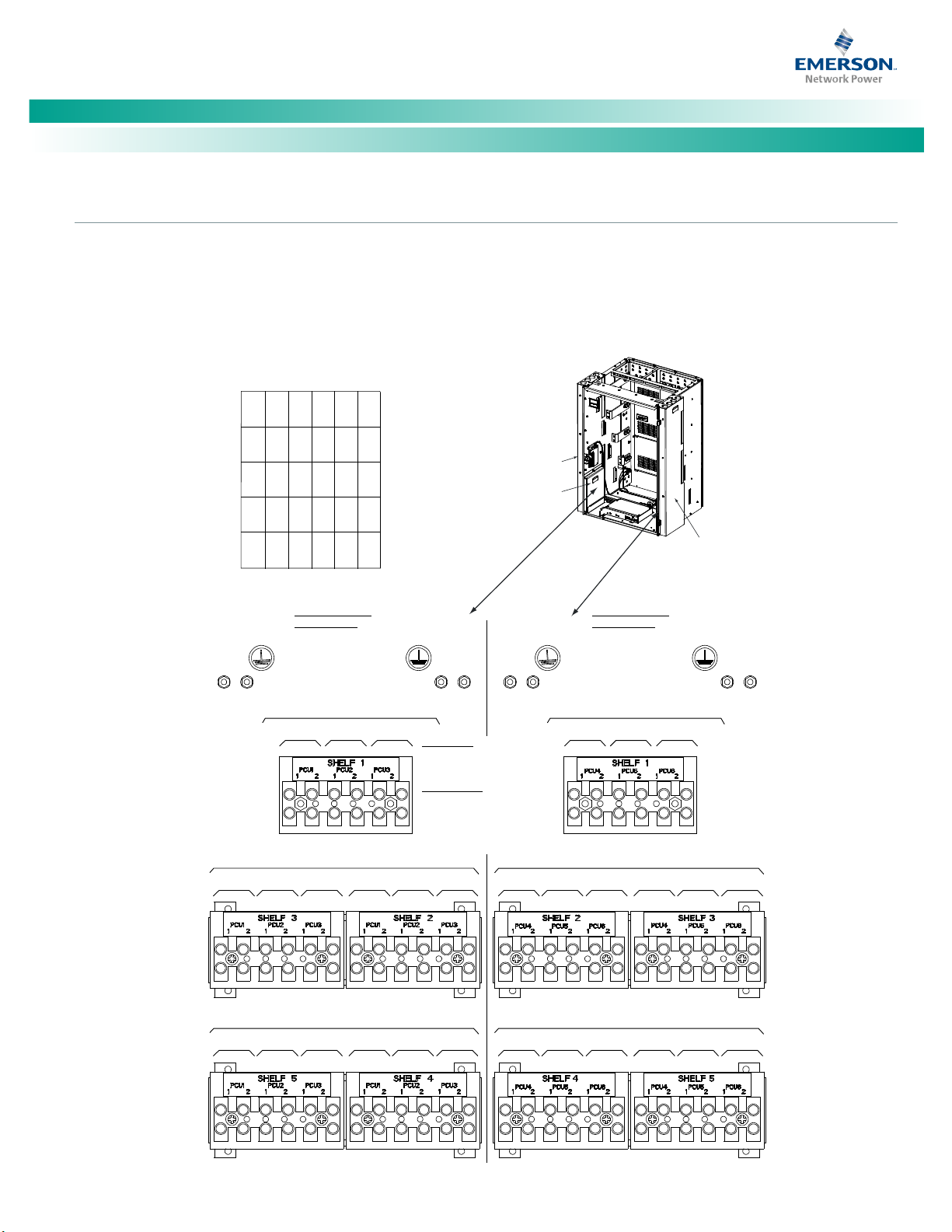

NetSure™ -48V DC Power System

[12]

(4-Row Cabinet Shown,

Others Similar)

Front Door Removed in

Illustration for Clarity

AC INPUT CONNECTIONS,

1 FEED PER 2 RECTIFIERS, SINGLE PHASE

(582127000 LIST 41)

Inside View

Left Side

Inside View

Right Side

NOTE:

WIRING TO A FIELD INSTALLED

SHELF IS DONE AT THE REAR

OF THE SHELF.

GND GND GND GND

AC 2AC 1

PCU 1

AC 2AC 1

PCU 2

AC 2AC 1

PCU 3

RECTIFIER (PCU) AC INPUT FEEDS

1 FEED PER 2 RECTIFIERS (PCU)

208-240VAC, 50/60Hz, SINGLE PHASE

SHELVES 1 AND 2

AC 2AC 1

PCU 4

AC 2AC 1

PCU 5

AC 2AC 1

PCU 6

RECTIFIER (PCU) AC INPUT FEEDS

1 FEED PER 2 RECTIFIERS (PCU)

208-240VAC, 50/60Hz, SINGLE PHASE

SHELVES 1 AND 2

AC 2AC 1

PCU 1

AC 2AC 1

PCU 2

AC 2AC 1

PCU 3

RECTIFIER (PCU) AC INPUT FEEDS

1 FEED PER 2 RECTIFIERS (PCU)

208-240VAC, 50/60Hz, SINGLE PHASE

SHELVES 3 AND 4

AC 2AC 1

PCU 4

AC 2AC 1

PCU 5

AC 2AC 1

PCU 6

RECTIFIER (PCU) AC INPUT FEEDS

1 FEED PER 2 RECTIFIERS (PCU)

208-240VAC, 50/60Hz, SINGLE PHASE

SHELVES 3 AND 4

AC Wireway

Cover

AC Wireway

Cover

AC Input

Connector Cover

FRAME GROUND

CONNECTION

Four 10-32 X 3/4"

Studs and Hardware.

Recommended torque:

23 in-lbs.

FRAME GROUND

CONNECTION

Four 10-32 X 3/4"

Studs and Hardware.

Recommended torque:

23 in-lbs.

Line to Line:

Connect Line 1 to Terminal 1.

Connect Line 2 to Terminal 2.

Line to Neutral

Connect Line to Terminal 1.

Connect Neutral to Terminal 2.

Wire Size Capacity: 6-14 AWG.

Recommended Torque: 18 in-lbs.

Rectifier Module (PCU) Mounting Slots

Shelf #1

Rect.

(PCU)

1

Rect.

(PCU)

2

Rect.

(PCU)

3

Rect.

(PCU)

4

Rect.

(PCU)

5

Rect.

(PCU)

6

Rect.

(PCU)

1

Rect.

(PCU)

2

Rect.

(PCU)

3

Rect.

(PCU)

4

Rect.

(PCU)

5

Rect.

(PCU)

6

Rect.

(PCU)

1

Rect.

(PCU)

2

Rect.

(PCU)

3

Rect.

(PCU)

4

Rect.

(PCU)

5

Rect.

(PCU)

6

Rect.

(PCU)

1

Rect.

(PCU)

2

Rect.

(PCU)

3

Rect.

(PCU)

4

Rect.

(PCU)

5

Rect.

(PCU)

6

Shelf #2

Shelf #3

Shelf #4

Quick Start Guide, QS582127000 (Issue AC, December 10, 2013)

Figure 9. Nominal 208/240 Volts AC Input and Equipment Grounding Connections to AC Input Termination Assembly 582127000 List 41

(1 Feed per 2 Rectifiers, Single Phase)

Spec. No: 582127000 Code: QS582127000

Model No: 721NPBB Issue AC, December 10, 2013

Page 21

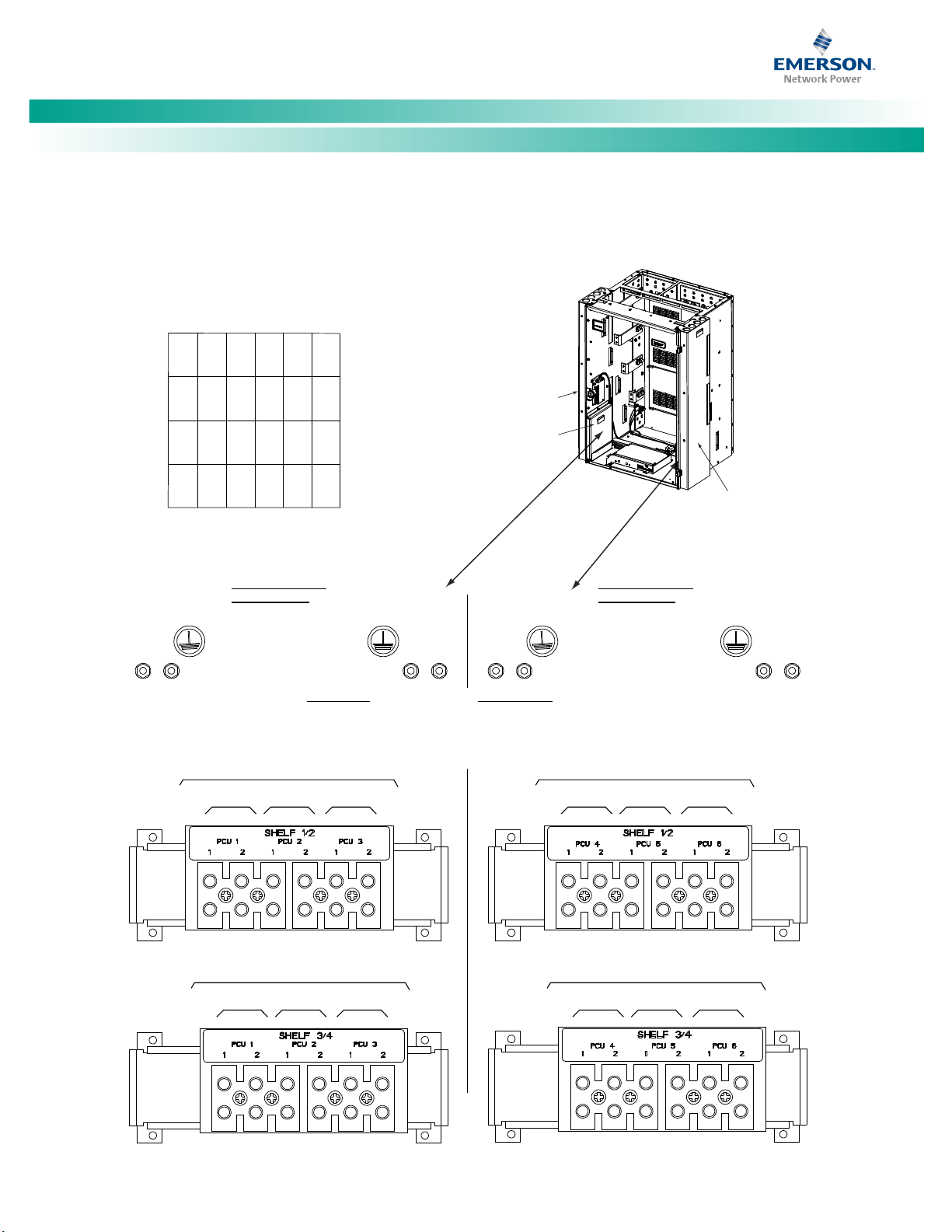

NetSure™ -48V DC Power System

[13]

(4-Row Cabinet Shown,

Others Similar)

Front Door Removed in

Illustration for Clarity

AC INPUT CONNECTIONS,

1 FEED PER 3 RECTIFIERS, THREE PHASE

(582127000 LIST 42)

Inside View

Left Side

Inside View

Right Side

NOTE:

WIRING TO AFIELD INSTALLED

SHELF IS DONE AT THE REAR

OF THE SHELF.

GND GND

GND GND

AC Wireway

Cover

AC Wireway

Cover

AC Input

Connector Cover

A B C

RECTIFIER (PCU) AC INPUT FEEDS

1 FEED PER 3 RECTIFIERS (PCU)

208-240VAC, 50/60Hz, THREE PHASE

SHELF 1 - PCUs #1 - #3

A B C

RECTIFIER (PCU) AC INPUT FEEDS

1 FEED PER 3 RECTIFIERS (PCU)

208-240VAC, 50/60Hz, THREE PHASE

SHELF 3 - PCUs #1 - #3

A B C

SHELF 2 - PCUs #1 - #3

A B C

RECTIFIER (PCU) AC INPUT FEEDS

1 FEED PER 3 RECTIFIERS (PCU)

208-240VAC, 50/60Hz, THREE PHASE

SHELF 5 - PCUs #1 - #3

A B C

SHELF 4 - PCUs #1 - #3

C B A

RECTIFIER (PCU) AC INPUT FEEDS

1 FEED PER 3 RECTIFIERS (PCU)

208-240VAC, 50/60Hz, THREE PHASE

SHELF 1 - PCUs #4 - #6

C B A

RECTIFIER (PCU) AC INPUT FEEDS

1 FEED PER 3 RECTIFIERS (PCU)

208-240VAC, 50/60Hz, THREE PHASE

SHELF 2 - PCUs #4 - #6

C B A

SHELF 3 - PCUs #4 - #6

C B A

RECTIFIER (PCU) AC INPUT FEEDS

1 FEED PER 3 RECTIFIERS (PCU)

208-240VAC, 50/60Hz, THREE PHASE

SHELF 4 - PCUs #4 - #6

C B A

SHELF 5 - PCUs #4 - #6

FRAME GROUND

CONNECTION

Four 10-32 X 3/4"

Studs and Hardware.

Recommended torque:

23 in-lbs.

FRAME GROUND

CONNECTION

Four 10-32 X 3/4"

Studs and Hardware.

Recommended torque:

23 in-lbs.

Wire Size Capacity: 6-14 AWG.

Recommended Torque: 18 in-lbs.

Rectifier Module (PCU) Mounting Slots

Shelf #1

Rect.

(PCU)

1

Rect.

(PCU)

2

Rect.

(PCU)

3

Rect.

(PCU)

4

Rect.

(PCU)

5

Rect.

(PCU)

6

Rect.

(PCU)

1

Rect.

(PCU)

2

Rect.

(PCU)

3

Rect.

(PCU)

4

Rect.

(PCU)

5

Rect.

(PCU)

6

Rect.

(PCU)

1

Rect.

(PCU)

2

Rect.

(PCU)

3

Rect.

(PCU)

4

Rect.

(PCU)

5

Rect.

(PCU)

6

Rect.

(PCU)

1

Rect.

(PCU)

2

Rect.

(PCU)

3

Rect.

(PCU)

4

Rect.

(PCU)

5

Rect.

(PCU)

6

Rect.

(PCU)

1

Rect.

(PCU)

2

Rect.

(PCU)

3

Rect.

(PCU)

4

Rect.

(PCU)

5

Rect.

(PCU)

6

Shelf #2

Shelf #3

Shelf #4

Shelf #5

Quick Start Guide, QS582127000 (Issue AC, December 10, 2013)

Figure 10. Nominal 208/240 Volts AC Input and Equipment Grounding Connections to AC Input Termination Assembly 582127000 List 42

(1 Feed per 3 Rectifiers, Three Phase)

Spec. No: 582127000 Code: QS582127000

Model No: 721NPBB Issue AC, December 10, 2013

Page 22

NetSure™ -48V DC Power System

[14]

Holes for 3/4"

Conduit Fitting

(AC Input)

Hol

es f

or 3/4"

C

ondu

it F

itting

(AC I

npu

t)

R

ear

Vie

w

Rear View

FRAME GROUND CONNECTION

ONE 10-32 X 3/4" STU

D

AN

D H

ARDWARE.

Recommended torque: 23 in-l

bs.

FRAME GROUND CONNECTION

ONE 10-32 X 3/4" STUD

AND HARDWARE.

Recommended torque: 23 in-lbs.

Re

ct

i

fi

er

M

od

ule

(PC

U) M

oun

ting Slots

(

f

ro

nt vi

ew)

Re

c

t.

(P

CU)

1

Re

ct.

(P

CU)

2

Re

ct.

(

PCU)

3

Re

ct.

(

PCU)

4

Rec

t.

(PCU)

5

Rect.

(PCU)

6

1

2

1

2

AC

IN

Rec

tifier

Modu

le 4

1

2

Rect

ifie

r

Module 5

Rectifier

Modul

e 6

AC

IN

Rectifier

Mod

ule 1

Rectifier

Module 2

Rectifier

Module 3

1

2

1

2

1

2

RECTIFIER (PCU) AC INPUT FEEDS

INDIVIDUAL RECTIFIER (PCU) FEED

208-240VAC, 50/6

0Hz, SINGLE PHASE

Wire Siz

e Capacity: 10-24 AWG.

Recommended Torque: 10 in-lbs.

Wire Size Capacity: 10-2

4 A

WG.

Recommended Torque: 10 in-lbs.

Quick Start Guide, QS582127000 (Issue AC, December 10, 2013)

Direct AC Input Connections to 588705000 List 31 Module Mounting Shelves

Refer to Figure 11.

Figure 11. Nominal 208/240 Volts AC Input Connections (Single-Phase) to a 588705000 List 31 Module Mounting Shelf

Spec. No: 582127000 Code: QS582127000

Model No: 721NPBB Issue AC, December 10, 2013

Page 23

NetSure™ -48V DC Power System

[15]

(ØA)

(ØB)

(ØC)

(

Ø

A

)

(

Ø

B

)

(

Ø

C

)

Holes for 3/4"

Conduit Fitting

(AC Input)

Holes for 3/4"

Conduit Fitting

(AC Input)

Rear View

Rear View

FRAME GROUND CONNECTION

ONE 10-32 X 3/4" STUD

AND HARDWARE.

Recommended torque: 23 in-lbs.

F

R

A

M

E

G

R

O

U

N

D

C

O

N

N

E

C

T

I

O

N

O

N

E

1

0

-

3

2

X

3

/

4

"

S

T

U

D

A

N

D

H

A

R

D

W

A

R

E

.

R

e

c

o

m

m

e

n

d

e

d

t

o

r

q

u

e

:

2

3

i

n

-

l

b

s

.

Rectifier Module (PCU) Mounting Slots

(front view)

Rect.

(PCU)

1

Rect.

(PCU)

2

Rect.

(PCU)

3

Rect.

(PCU)

4

Rect.

(PCU)

5

Rect.

(PCU)

6

AC IN

Feed 2

(Rectifier

Modules

4-6)

AC IN

Feed 1

(Rectifier

Modules

1-3)

1 (ØA) 2 (ØB) 3 (ØC) 1 (ØA ) 2 (ØB) 3 (ØC)

L1 L2

L1 L2

L1 L2

L1 L2

L1 L2

L1 L2

CONNECTIONS WITHIN THE SHELF

Mounting

Position

Rect 1

Rect 2

Rect 3

Rect 4

Rect 5

Rect 6

TB1, Terminal TB2, Terminal

RECTIFIER (PCU) AC INPUT FEEDS

1 FEED PER 3 RECTIFIERS (PCU)

208-240VAC, 50/60Hz, THREE PHASE

Wire Size Capacity: 6-14 AWG.

Recommended Torque: 18 in-lbs.

Wire Size Capacity: 6-14 AWG.

Recommended Torque: 18 in-lbs.

Quick Start Guide, QS582127000 (Issue AC, December 10, 2013)

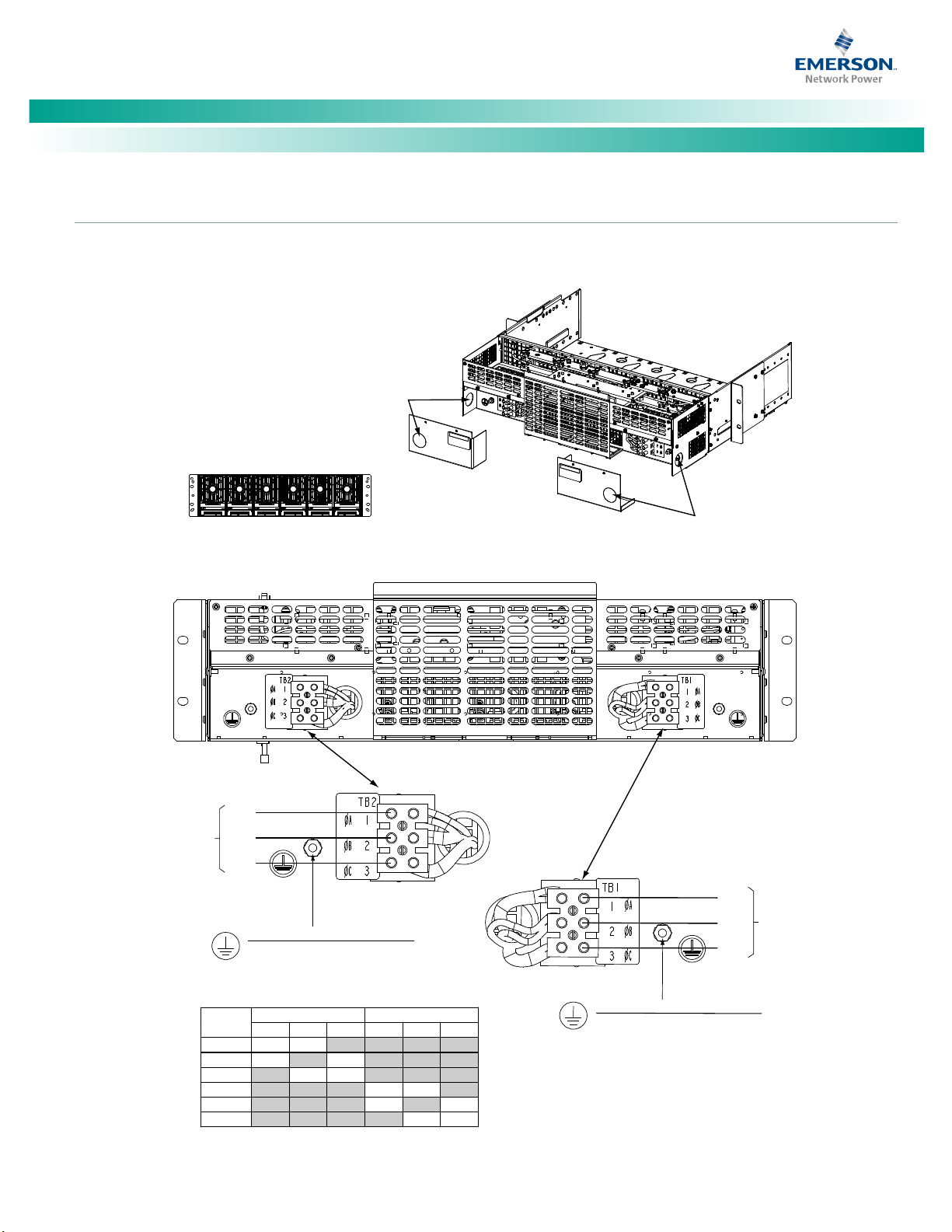

Direct AC Input Connections to 588705000 List 32 Module Mounting Shelves

Refer to Figure 12.

Figure 12. Nominal 208/240 Volts AC Input Connections (Three-Phase) to a 588705000 List 32 Module Mounting Shelf)

Spec. No: 582127000 Code: QS582127000

Model No: 721NPBB Issue AC, December 10, 2013

Page 24

NetSure™ -48V DC Power System

[16]

Re

cti

fier

Mod

ule

4

Rect

ifi

er

Modu

le 6

Rec

tifi

er

M

odu

le 5

Re

cti

fier

Mod

ule

1

Rectifier

Mo

dule 3

Re

cti

fie

r

Module

2

Rear

Vie

w

R

e

ct

if

i

er

Mo

d

ul

e

(PCU) Mounting Slots

(

fr

on

t

vi

ew

)

Re

ct

.

(PCU)

1

R

e

ct

.

(PCU)

2

Rect.

(PC

U)

3

Rect.

(P

C

U)

4

Rect.

(

P

CU

)

5

Rect.

(

PC

U)

6

RE

CTI

FIE

R (P

CU) AC INPUT FEED

S

INDIV

IDU

AL RE

CTI

FIE

R (PCU) FEED

20

8-24

0VA

C, 50/60Hz, SINGLE P

HAS

E

Quick Start Guide, QS582127000 (Issue AC, December 10, 2013)

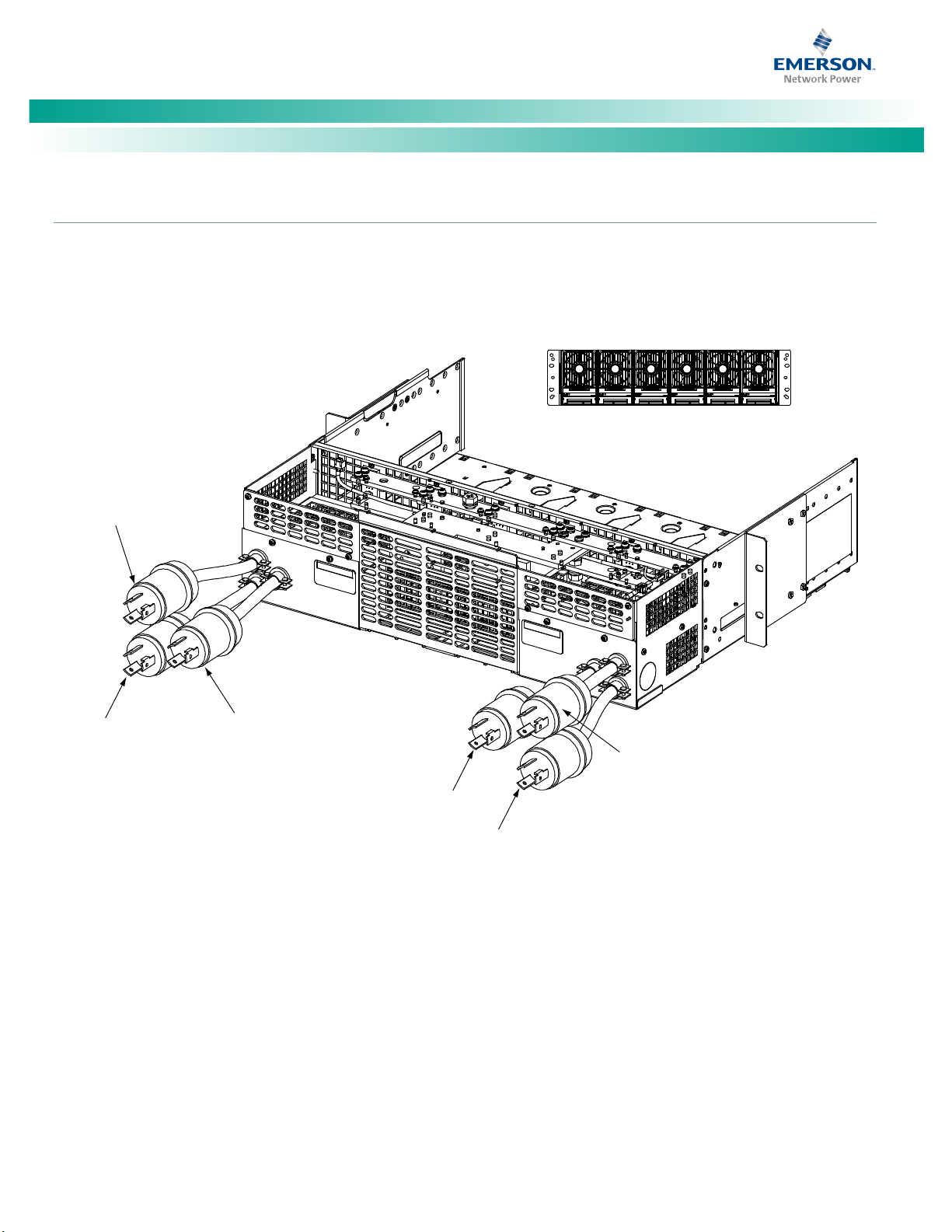

Direct AC Input Connections to 588705000 List 22 Module Mounting Shelves

Refer to Figure 13.

Figure 13. Nominal 208/240 Volts AC Input and Equipment Grounding Connections to Module Mounting Shelf 588705000 List 22

(Single Phase, Line Cords)

Spec. No: 582127000 Code: QS582127000

Model No: 721NPBB Issue AC, December 10, 2013

Page 25

NetSure™ -48V DC Power System

[17]

L2-N

Blue*

Ground

Green/Yellow*

L1

Brown*

* Color of AC Input

Cable Assembly Lead.

P/N 535232

P/N 547898

Nominal

120/208/240V

AC Input

AC Input Connector

(Cabinet Rear View)

AC input connections are made using the supplied

AC input cable assemblies connected here.

Rectifiers are numbered left to

right as viewed from the front.

AC Input for

Rectifier Positions

#5 and #6

AC Input for

Rectifier Positions

#1 and #2

AC Input for

Rectifier Positions

#3 and #4

Rear

Rear

Quick Start Guide, QS582127000 (Issue AC, December 10, 2013)

Direct AC Input Connections to 588705300 List 3 Module Mounting Shelves

Refer to Figure 14.

Figure 14. Nominal 120/208/240 Volts AC Input and Equipment Grounding Connections to Module Mounting Shelf 588705300 List 3

(Single Phase, Cable Assemblies)

Spec. No: 582127000 Code: QS582127000

Model No: 721NPBB Issue AC, December 10, 2013

Page 26

NetSure™ -48V DC Power System

[18]

NOTE THAT THIS SYSTEM MAY BE EQUIPPED WITH AC OR DC INPUTS.

THESE PROCEDURES APPLY TO SYSTEMS WITH DC INPUTS.

SPECIFICALLY, THESE PROCEDURES APPLY TO THE FOLLOWING EQUIPMENT:

Quick Start Guide, QS582127000 (Issue AC, December 10, 2013)

Make Nominal 400 Volts DC Input and Equipment Grounding Connections (if equipped)

Refer to Nominal 400 Volts DC Input and Equipment Grounding Connections (if equipped) in the MAKING ELECTRICAL CONNECTIONS section

of the Installation Instructions (IM582127000) for a complete procedure.

• 582127000 List 45, 46, 47

• 588705000 List 41

• 588705000 List 42

The available DC input options for this system are:

DC Input Termination Assemblies

• The system can be equipped with a DC input termination assembly which provides a separate DC input connection for each

converter position (582127000 List 45).

• The system can be equipped with a DC input termination assembly which provides a separate DC input connection for every

two (2) converter positions (582127000 List 46).

• The system can be equipped with a DC input termination assembly which provides a separate DC input connection for every

three (3) converter positions (582127000 List 47).

Direct DC Input Connections to the Module Mounting Shelves

• The system can be equipped with module mounting shelves that contain DC input terminal blocks which provide a separate DC

input connection for each converter position (588705000 List 41).

• The system can be equipped with module mounting shelves that contain DC input terminal blocks which provide a separate DC

input connection for every two (2) converter positions (588705000 List 42).

Spec. No: 582127000 Code: QS582127000

Model No: 721NPBB Issue AC, December 10, 2013

Page 27

NetSure™ -48V DC Power System

[19]

Note:

(4-Row Cabinet Shown,

Others Similar)

Front Door Removed in

Illustration for Clarity

DC INPUT CONNECTIONS,

1 FEED PER 1 CONVERTER

(582127000 LIST 45)

NOTE:

WIRING TO A FIELD INSTALLED

SHELF IS DONE AT THE REAR

OF THE SHELF.

DC Wireway

Cover

DC Wireway

Cover

DC Input

Connector Cover

Inside View

Left Side

Inside View

Right Side

GND GND

GND GND

Converter Module Mounting Slots

Shelf #1

Conv.1Conv.2Conv.3Conv.4Conv.5Conv.

6

Conv.1Conv.2Conv.3Conv.4Conv.5Conv.

6

Conv.1Conv.2Conv.3Conv.4Conv.5Conv.

6

Conv.1Conv.2Conv.3Conv.4Conv.5Conv.

6

Conv.1Conv.2Conv.3Conv.4Conv.5Conv.

6

Shelf #2

Shelf #3

Shelf #4

Shelf #5

Conv. 1

Conv. 2

Conv. 3

400VDC CONVERTER DC INPUT FEEDS

1 FEED PER 1 CONVERTER

SHELF 1

Conv. 1

Conv. 2

Conv. 3

Conv. 1

Conv. 2

Conv. 3

400VDC CONVERTER DC INPUT FEEDS

1 FEED PER 1 CONVERTER

SHELF 3

SHELF 2

+ - + - + -

+ - + - + -

+ - + - + -

Conv. 1

Conv. 2

Conv. 3

Conv. 1

Conv. 2

Conv. 3

400VDC CONVERTER DC INPUT FEEDS

1 FEED PER 1 CONVERTER

SHELF 5

SHELF 4

+ - + - + - + - + - + -

Conv. 4

Conv. 5

Conv. 6

400VDC CONVERTER DC INPUT FEEDS

1 FEED PER 1 CONVERTER

SHELF 1

Conv. 4

Conv. 5

Conv. 6

Conv. 4

Conv. 5

Conv. 6

400VDC CONVERTER DC INPUT FEEDS

1 FEED PER 1 CONVERTER

SHELF 2

SHELF 3

+ - + - + -

+ - + - + -

+ - + - + -

Conv. 4

Conv. 5

Conv. 6

Conv. 4

Conv. 5

Conv. 6

400VDC CONVERTER DC INPUT FEEDS

1 FEED PER 1 CONVERTER

SHELF 4

SHELF 5

+ - + - + - + - + - + -

CONV4

+ -

CONV5

+ -

CONV6

+ -

CONV4

+ -

CONV5

+ -

CONV6

+ -

CONV4

+ -

CONV5

+ -

CONV6

+ -

CONV4

+ -

CONV5

+ -

CONV6

+ -

CONV4

+ -

CONV5

+ -

CONV6

+ -

CONV1

+ -

CONV2

+ -

CONV3

+ -

CONV1

+ -

CONV2

+ -

CONV3

+ -

CONV1

+ -

CONV2

+ -

CONV3

+ -

CONV1

+ -

CONV2

+ -

CONV3

+ -

CONV1

+ -

CONV2

+ -

CONV3

+ -

Quick Start Guide, QS582127000 (Issue AC, December 10, 2013)

Connections to DC Input Termination Assemblies (582127000 List 45, 46, and 47)

Refer to Figure 15, Figure 16, or Figure 17.

Terminal blocks for a system with maximum possible converter shelves shown. Your system may have less terminal blocks then shown.

Figure 15. Nominal 400 Volts DC Input and Equipment Grounding Connections to DC Input Termination Assembly 582127000 List 45

(1 Feed per 1 Converter)

Spec. No: 582127000 Code: QS582127000

Model No: 721NPBB Issue AC, December 10, 2013

Page 28

[20]

(4-Row Cabinet Sh

o

wn

,

O

th

er

s

Si

mi

l

ar

)

F

r

on

t

Do

or

R

em

ov

e

d i

n

Illustration for Clarity

D

C I

N

PU

T C

O

NN

ECTIONS,

1 F

EE

D

PER 2 CONV

ER

T

ER

S

(

58

2

12

70

0

0 L

IS

T

46

)

In

sid

e Vi

ew

Lef

t Sid

e

Ins

ide V

iew

Ri

ght

Sid

e

NO

TE:

WIR

ING

TO A F

IEL

D IN

STA

LLED

SH

ELF

IS D

ONE

AT TH

E REA

R

OF

THE

SHEL

F.

G

ND GN

D

GN

D GN

D

D

C W

i

re

wa

y

C

o

ver

DC Wi

rew

ay

C

ove

r

DC In

put

Conne

c

to

r

Co

ve

r

Con

ver

ter M

odu

le M

oun

ting

Slo

ts

S

h

el

f #

1

Conv

.

1

C

o

nv

.

2

C

on

v.

3

Co

nv

.

4

C

o

nv

.

5

C

on

v.

6

Co

n

v.

1

C

o

nv

.

2

C

on

v.

3

Co

n

v.

4

C

o

nv

.

5

C

on

v.

6

C

on

v

.1C

o

nv

.2C

onv

.3C

onv

.4Conv.5C

on

v

.

6

Co

nv.

1

Con

v.

2

Con

v.3C

onv

.4C

onv.

5

Co

nv.

6

S

he

l

f #

2

S

hel

f #3

S

helf

#4

C

onv

. 1 Co

nv.

2 Conv. 3

400VD

C CON

VER

TER

DC I

NPUT

FEE

DS

1

FEED

PER

2 CO

NVERTERS

S

HELV

ES 1

AND

2

+ -

+ - + -

Co

nv. 1 Conv. 2

Conv. 3

400

VDC CON

VERTER D

C INPUT

FEEDS

1 FE

ED PER 2 C

ONVERT

ERS

SHEL

VES 3 AND 4

+ - + - + -

Conv. 4

Con

v. 5

Conv

. 6

40

0VD

C CONVERT

ER D

C IN

PUT

FEED

S

1 F

EED

PER 2

CON

VER

TERS

SHELVES 1

AND

2

+

- + - + -

Con

v. 4 Conv. 5

Conv. 6

400

VDC CONV

ERTER D

C INPUT F

EEDS

1 FEE

D PER 2 CO

NVERTERS

SHELVES 3 A

ND 4

+ - + -

+ -

CON

V 4

+ -

CONV 5

+

-

CO

NV 6

+ -

CONV 1

+

-

CO

NV 2

+ -

CON

V 3

+ -

CONV 4

+ -

C

ONV 5

+ -

CONV

6

+ -

CONV 1

+

-

CONV 2

+ -

CON

V 3

+ -

NetSure™ -48V DC Power System

Quick Start Guide, QS582127000 (Issue AC, December 10, 2013)

Figure 16. Nominal 400 Volts DC Input and Equipment Grounding Connections to DC Input Termination Assembly 582127000 List 46

(1 Feed per 2 Converters)

Spec. No: 582127000 Code: QS582127000

Model No: 721NPBB Issue AC, December 10, 2013

Page 29

NetSure™ -48V DC Power System

[21]

(4-Row Cabinet Shown,

Others Similar)

Front Door Removed in

Illustration for Clarity

DC INPUT CONNECTIONS,

1 FEED PER 3 CONVERTERS

(582127000 LIST 47)

Inside View

Left Side

Inside View

Right Side

NOTE:

WIRING TO A FIELD INSTALLED

SHELF IS DONE AT THE REAR

OF THE SHELF.

GND GND GND GND

DC Wireway

Cover

DC Wireway

Cover

DC Input

Connector Cover

400VDC CONVERTER DC INPUT FEEDS

1 FEED PER 3 CONVERTERS

SHELF 1: Conv. #1 - #3

400VDC CONVERTER DC INPUT FEEDS

1 FEED PER 3 CONVERTERS

SHELF 3: Conv. #1 - #3 SHELF 2: Conv. #1 - #3

Converter Module Mounting Slots

Shelf #1

Conv.1Conv.2Conv.3Conv.4Conv.5Conv.

6

Conv.1Conv.2Conv.3Conv.4Conv.5Conv.

6

Conv.1Conv.2Conv.3Conv.4Conv.5Conv.

6

Conv.1Conv.2Conv.3Conv.4Conv.5Conv.

6

Conv.1Conv.2Conv.3Conv.4Conv.5Conv.

6

Shelf #2

Shelf #3

Shelf #4

Shelf #5

+ -

+ - + -

400VDC CONVERTER DC INPUT FEEDS

1 FEED PER 3 CONVERTERS

SHELF 5: Conv. #1 - #3 SHELF 4: Conv. #1 - #3

+ - + -

400VDC CONVERTER DC INPUT FEEDS

1 FEED PER 3 CONVERTERS

SHELF 1: Conv. #4 - #6

400VDC CONVERTER DC INPUT FEEDS

1 FEED PER 3 CONVERTERS

SHELF 2: Conv. #4 - #6 SHELF 3: Conv. #4 - #6

+ -

+ - + -

400VDC CONVERTER DC INPUT FEEDS

1 FEED PER 3 CONVERTERS

SHELF 4: Conv. #4 - #6 SHELF 5: Conv. #4 - #6

+ - + -

SHELF 1 CONV4-6

SHELF 2 CONV4-6 SHELF 3 CONV4-6

SHELF 4 CONV4-6 SHELF 5 CONV4-6

SHELF 1 CONV1-3

SHELF 3 CONV1-3 SHELF 2 CONV1-3

SHELF 5 CONV1-3 SHELF 4 CONV1-3

Quick Start Guide, QS582127000 (Issue AC, December 10, 2013)

Figure 17. Nominal 400 Volts DC Input and Equipment Grounding Connections to DC Input Termination Assembly 582127000 List 47

(1 Feed per 3 Converters)

Spec. No: 582127000 Code: QS582127000

Model No: 721NPBB Issue AC, December 10, 2013

Page 30

NetSure™ -48V DC Power System

[22]

Hol

es

f

or

3/

4

"

Cond

ui

t

Fi

tt

i

ng

(I

npu

t)

Holes fo

r 3/

4"

Conduit Fi

tti

ng

(Input)

Rear View

Rear Vi

ew

Co

nve

rter Module Mount

ingSlot

s

(front view)

Con

v.1Co

nv.2C

onv.3Conv.

4

Conv

.5Co

nv.

6

Wire Size C

apacity: 10-20

AWG.

Recom

mended Torque: 10 in-

lbs.

FRAME GROUND CONNECTION

ONE 10-32 X 3/4" STUD

AND HARDWARE.

Recommended torque: 23 in-lbs.

FRAME GROUND CONNECTION

ONE 10-32 X 3/4" ST

UD

AND HARDWARE.

Recommended torque: 23 in-lbs.

+

-

+

-

400VDC

IN

Conve

rter

M

odu

le 4

Converter

Module 5

Converter

Mo

dule 6

Converter

Module 1

Converter

Module 2

Converter

Module 3

+

-

400VDC

IN

+

-

+

-

+

-

INDIVIDUAL 400VDC CONVERTER FEEDS

1

FEED PER CONVERTER

Quick Start Guide, QS582127000 (Issue AC, December 10, 2013)

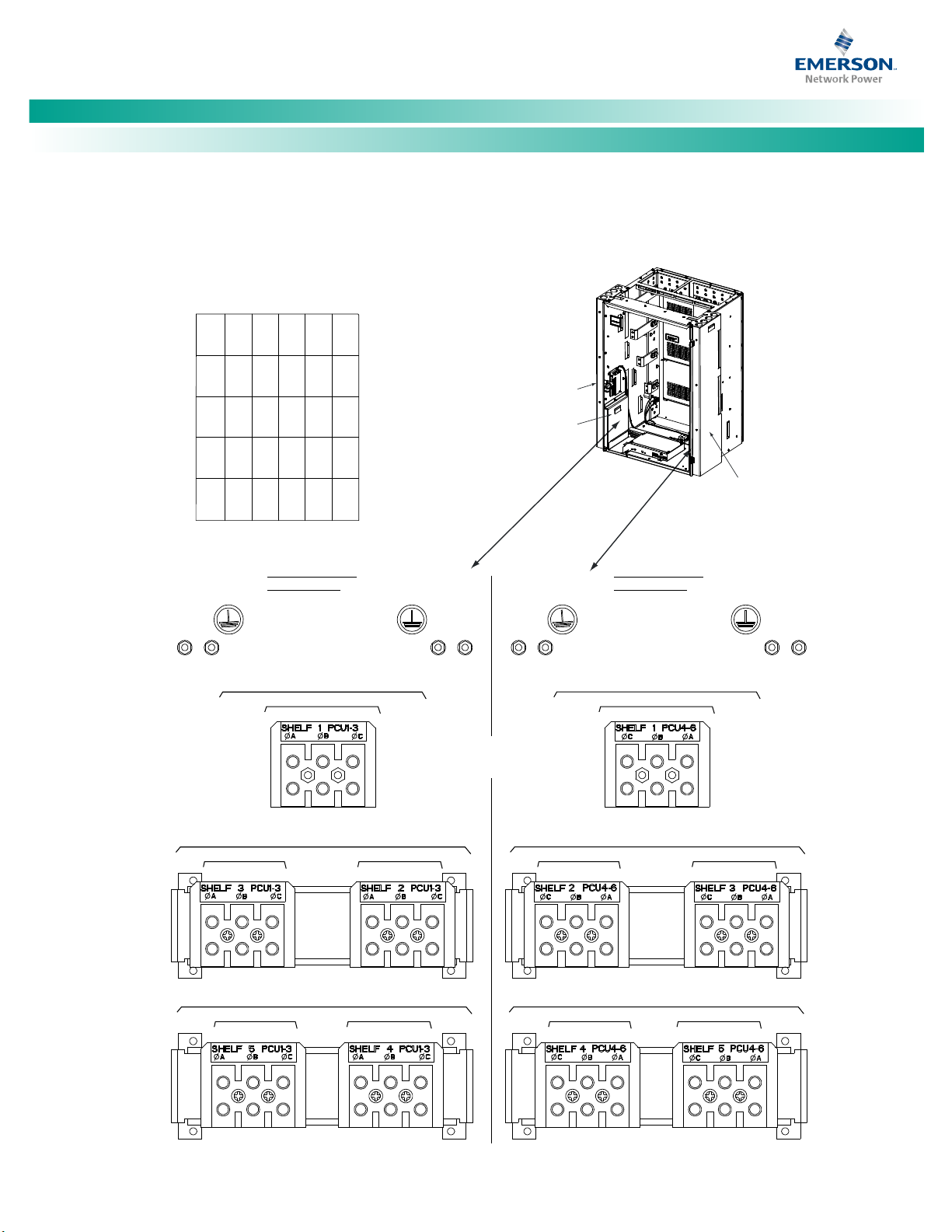

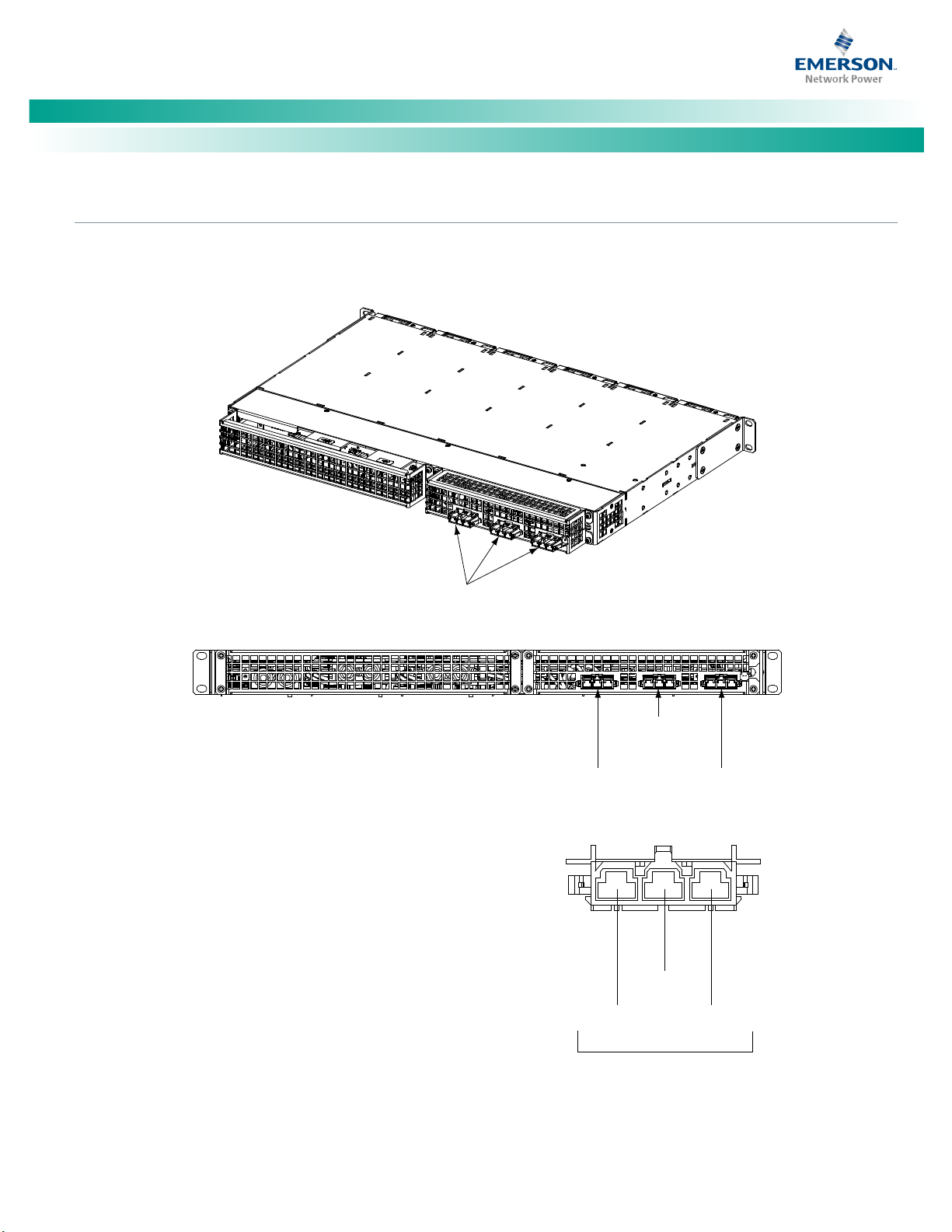

Direct DC Input Connections to 588705000 List 41 Module Mounting Shelves

Refer to Figure 18.

Figure 18. Nominal 400 Volts DC Input and Equipment Grounding Connections to Module Mounting Shelf 588705000 List 41

(1 Feed per 1 Converter)

Spec. No: 582127000 Code: QS582127000

Model No: 721NPBB Issue AC, December 10, 2013

Page 31

NetSure™ -48V DC Power System

[23]

Ho

le

s

fo

r

3/

4"

Conduit Fitting

(I

npu

t)

Re

ar V

iew

C

on

v

e

r

te

r M

odu

le Mo

unt

ing

Slo

ts

(f

ron

t vie

w)

C

onv.

1

Con

v.

2

Co

nv.

3

C

onv.

4

C

o

nv

.

5

Co

nv.

6

CONVERTER 400

VDC INPUT FEEDS

1 F

EED PER 3 CONVERTERS

+

-

+

-

H

oles

for

3/4

"

Con

dui

t Fi

ttin

g

(Inp

ut)

Rear View

FR

AME GROUND

CONNECT

ION

ONE 10

-32 X 3/4" S

TUD

AND HAR

DWARE.

Rec

ommended tor

que: 23 in-l

bs.

F

R

AME

G

ROUNDCO

NNECTIO

N

O

NE10-32X3/4

"ST

U

D

A

N

DHARDWARE

.

R

e

commendedtorque

:

23in-lbs.

400VD

C IN

Feed

2

(Conv

erter

M

odules

4-6)

400VD

C IN

Fe

ed 1

(

Conver

ter

Modu

les

1-3)

Wi

re S

ize

Ca

pac

ity

: 6-14 A

WG.

Re

co

mm

end

ed Torq

ue: 18 i

n-lbs.

Quick Start Guide, QS582127000 (Issue AC, December 10, 2013)

Direct AC Input Connections to 588705000 List 42 Module Mounting Shelves

Refer to Figure 19.

Figure 19. Nominal 400 Volts DC Input and Equipment Grounding Connections to Module Mounting Shelf 588705000 List 42

(1 Feed per 2 Converters)

Spec. No: 582127000 Code: QS582127000

Model No: 721NPBB Issue AC, December 10, 2013

Page 32

NetSure™ -48V DC Power System

[24]

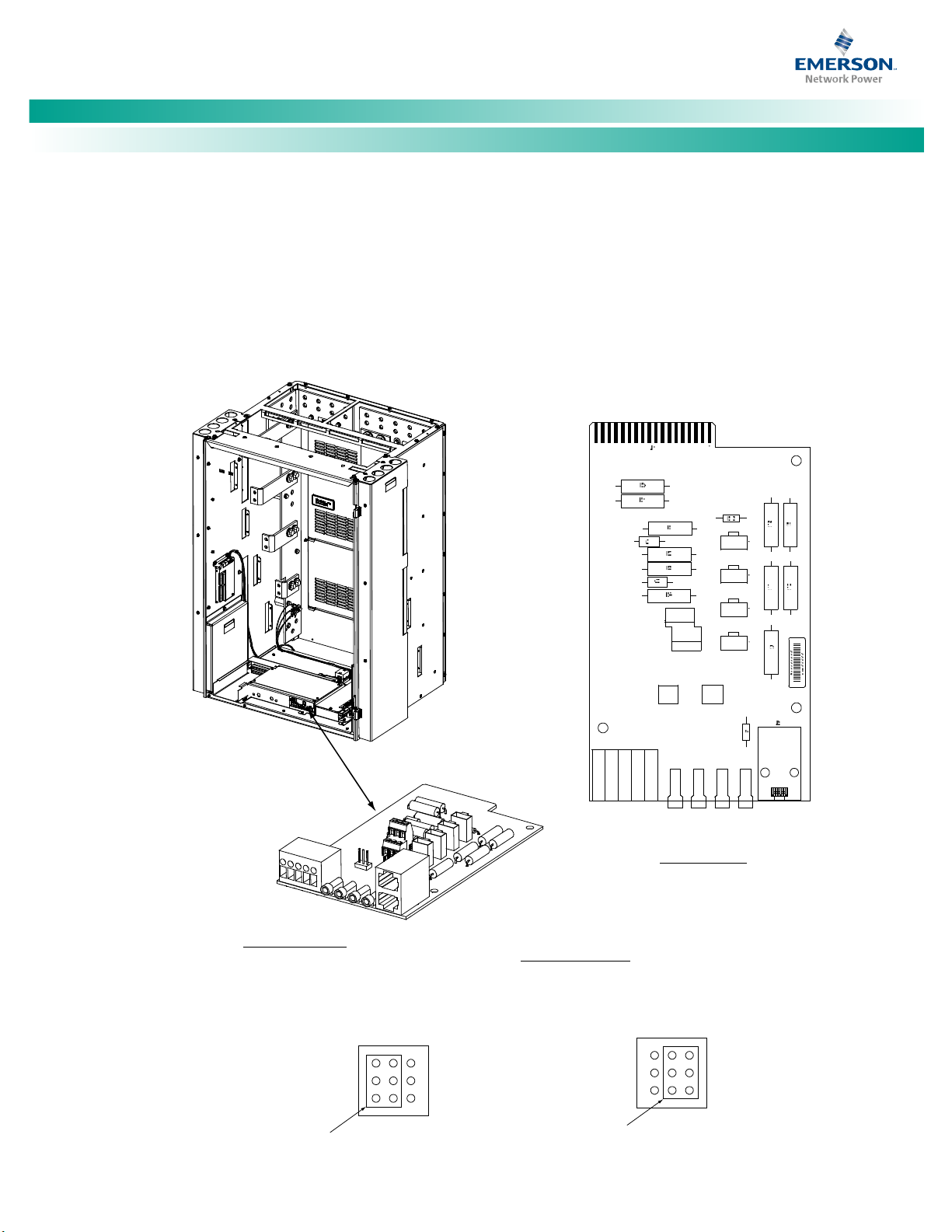

Optional SM-DU+ and

Shunt Interface Board

4-Row Cabinet Shown,

Others Similar

(Front Door Removed in

Illustration for Clarity)

System Interface

Circuit Card

IB2 (Main Bay Only)

(ACU+ Interface Board)

(located on inside side panel)

Optional EIB (Main Bay Only)

(ACU+ Extended Interface Board)

(located on inside side panel)

Quick Start Guide, QS582127000 (Issue AC, December 10, 2013)

Make External Interface Connections

Refer to External Alarm, Reference, Monitoring, and Control Connections in the MAKING ELECTRICAL CONNECTIONS section of the

Installation Instructions (IM582127000) for complete procedures.

Circuit Card Locations

Refer to Figure 20.

Figure 20. Circuit Card Locations

Spec. No: 582127000 Code: QS582127000

Model No: 721NPBB Issue AC, December 10, 2013

Page 33

NetSure™ -48V DC Power System

[25]

Quick Start Guide, QS582127000 (Issue AC, December 10, 2013)

System Interface Circuit Card

The System Interface Circuit Card provides connections for the following.

Refer to Figure 21.

• RS-485 (used for communication with SM modules)

• RS-232 (used for communication with a DPU)

• External Battery Monitoring (circuit card installed in Main Bay only)

• External System FA Signal (circuit card installed in Main Bay only)

• External Battery FA Signal (circuit card installed in Main Bay only)

• Battery Tray FA Signal

• Bay Voltage Monitoring Test Points

• Bay Load Shunt Monitoring Test Points

Spec. No: 582127000 Code: QS582127000

Model No: 721NPBB Issue AC, December 10, 2013

Page 34

NetSure™ -48V DC Power System

[26]

g

Card in Main Bay

in 1st Supplemental Bay

in 2nd Supplemental Bay

Quick Start Guide, QS582127000 (Issue AC, December 10, 2013)

Figure 21. System Interface Circuit Card Connections

J1

J2

TB2

RS485 Connection

TB2 1A: RS485+

TB2 2A: RS485-

RS232 Connection

TB2 1B: CGND

TB2 2B: TXD232

TB2 3B:RXD232

TB2 3A: Internally

used by system.

1B 2B 3B

TB2

1A 2 A 3A

J8

TB1

1

5

J3

J4

J10

J5

J1, J2, J3, J4

Distribution Panels FA Inputs

J8 (Main Bay Only)

Selects to power Controller

from “Battery Power” or not.

No

Battery

1

2

3

Shorting Jumper

J10 (Main Bay Only)

Battery Monitoring External / Internal

(see TB1-4 and TB1-5 for

external monitoring points)

External Internal

1

2

3

Pwr

Battery

Pwr

J8

7

8

9

7

8

9

TP1 TP2 TP3 TP4

TB1-1: Battery Tray FA

TB1-2: External Battery FA

TB1-4: External Battery Monitoring (-)

TB1-5: External Battery Monitoring (+)

System Interface

Spec. No: 582127000 Code: QS582127000

Model No: 721NPBB Issue AC, December 10, 2013

TB1-3: External System FA

TB1

TB1-2, TB1-3, TB1-4, TB1-5 Main Bay Only.

Wire Size Capacity: 22-12 AWG.

Recommended Torque: 3.0 in-lbs.

FA Signals: System voltage applied to the

terminal turns in an alarm.

System Interface Card

TP1 (+) and TP2 (-)

Bay Voltage

Monitoring

TP3 (+) and TP4 (-)

Bay Load

Shunt Monitoring

System Interface Card

Shorting Jumper

J5

CAN

J10

System Interface

Card in Last Bay

CAN termination plu

must be installed.

Page 35

NetSure™ -48V DC Power System

[27]

Digital Inputs

Programmable Relay Outputs

Note:

Quick Start Guide, QS582127000 (Issue AC, December 10, 2013)

IB2 (ACU+ Interface Board) Connections (if required) (Main Bay Only)

The IB2 (ACU+ Interface Board) provides connection points for

digital inputs, programmable relay outputs, and temperature

probes. The IB2 interface board is mounted inside the distribution

cabinet. Refer to Figure 20.

Digital Inputs and Programmable Relay Outputs

Digital input and relay output leads are connected to screw-type

terminal blocks located on the IB2. Recommended torque for

these connections is 2.2 in-lbs. Refer to Figure 22 for terminal

locations. Refer to Table 1and Table 2 for pin-out information.

Connect up to eight (8) digital inputs to the IB2. Note that you

must supply both paths for the digital input (either a positive or

negative signal and the opposite polarity return path). Observe

proper polarity. Refer to Figure 22 for terminal locations and Table

1 for pin-out information.

The digital inputs can be programmed to provide an alarm when

the signal is applied (HIGH) or removed (LOW). Refer to the ACU+

Instructions (UM1M820BNA or UM1M820DNA400) for

programming information.

Digital Input Ratings: Refer to the following.

a. Maximum Voltage Rating: 60V DC.

a. Active High: > 19V DC.

b. Active Low: < 1V DC.

The digital inputs may be preprogrammed for specific functions.

Refer to the configuration drawing (C-drawing) supplied with your

system for your system’s specific configuration.

The IB2 provides eight (8) programmable alarm relays with dry

Form-C contacts. Connect up to eight (8) relay outputs to the IB2.

Refer to Figure 22 for terminal locations and Table 2for pin-out

information.

Refer to the ACU+ Instructions (UM1M820BNA or

UM1M820DNA400) for programming information.

Relay Ratings: Refer to the following.

The relays may be preprogrammed for specific functions. Refer to

the configuration drawing (C-drawing) supplied with your system

for your system’s specific configuration.

Temperature Probes

Each temperature probe consists of two pieces that plug

together to make a complete probe. See SAG582127000 for

part numbers and descriptions.

Temperature probes are connected to the IB2 (ACU+ Interface

Board) and/or optional EIB (ACU+ Extended Interface Board)

mounted inside the distribution cabinet. See Figure 22 and Figure

24.

Up to two (2) temperature probes can be connected to the IB2. Up

to two (2) additional temperature probes can be connected to the

optional EIB. Any combination of the four (4) temperature probes

can be programmed to monitor ambient temperature and/or

battery temperature. A temperature probe set to monitor battery

temperature can also be used for the rectifier battery charge

temperature compensation feature, or the battery charge

temperature compensation feature can be programmed to use the

average or highest value of all battery temperature probes. The

battery charge temperature compensation feature allows the

controller to automatically increase or decrease the output voltage

of the system to maintain battery float current as battery

temperature decreases or increases, respectively. Battery life can

be extended when an optimum charge voltage to the battery with

respect to temperature is maintained. A temperature probe set to

monitor battery temperature can also be used for the BTRM

(Battery Thermal Runaway Management) feature. The BTRM

feature lowers output voltage when a high temperature condition

exists to control against battery thermal runaway.

The temperature sensor end of the probe contains a tab with a

5/16” clearance hole for mounting.

A temperature probe programmed to monitor battery

temperature should be mounted on the negative post of a battery

cell to sense battery temperature. A temperature probe used for

battery charge temperature compensation and/or BTRM (Battery

Thermal Runaway Management) should also be mounted on the