Emerson Neotecha NTB, Neotecha NTC, NEOTECHA SNB Series, NEOTECHA SNC Series Installation And Maintenance Instructions Manual

Page 1

NEOTECHA NTB-NTC BALL VALVES

INSTALLATION AND MAINTENANCE INSTRUCTIONS

Before installation these instructions must be fully read and understood

2 SAFETY

Please also read through these notes carefully.

2.1 General potential danger due to:

a. Failure to observe the instructions

b. Improper use

c. Insufficiently qualified personnel

2.2 Correct use

2.2.1 Area of application

Ball valves are bubble-tight shut-off industrial

1 GENERAL INFORMATION ON THE

INSTALLATION AND MAINTENANCE

INSTRUCTIONS

These instructions contain information on

how the valve should be safely installed and

operated in the prescribed manner. If any

problems are encountered during installation

or operation which cannot be resolved with

the aid of the installation and maintenance

instructions, please contact the supplier or

manufacturer for more information.

These installation and maintenance

instructions comply with the applicable

ENsafety standards.

When installing the fitting, the operator or

the person responsible for the design of

the installation must ensure that applicable

national regulations are complied with.

The manufacturer reserves all rights to

maketechnical changes and improvements

atany time.

The use of these installation and maintenance

instructions assumes that the user is qualified

to “Qualified Personnel” level. Operating staff

must be given appropriate training in the

operating and maintenance instructions.

valves that can be used for the isolation,

throttling and regulation of corrosive gases,

liquids, pastes and powder products in

pipelines, vessels, apparatus etc.

The surfaces of the of the body parts, together

with the ball or C-core that are in contact

with the medium are coated with PFA. Ball

seats and control orifice plates are available

in various material types and can be used to

suitthe medium.

2.2.2 Performance data

Nominal diameter range:

DIN-PN 16 and JIS10K

DN15 / 20 / 25 / 40 / 50 / 65 / 80 / 100 / 150

(ANSI 6” face-to-face with extension)

ANSI 150lbs½”, ¾”, 1”, 1½”, 2”, 2½”

(DIN face-to-face), 3”, 4”, 6”

Pressure range:

16bar (0.1 mbar vacuum)

Test pressure = 1.5 x PN = 24bar

Temperature range:

-40°C to 180°C

Emerson.com/FinalControl © 2017 Emerson. All Rights Reserved. VCIOM-01973-EN 15/02

Page 2

NEOTECHA NTB-NTC BALL VALVES

INSTALLATION AND MAINTENANCE INSTRUCTIONS

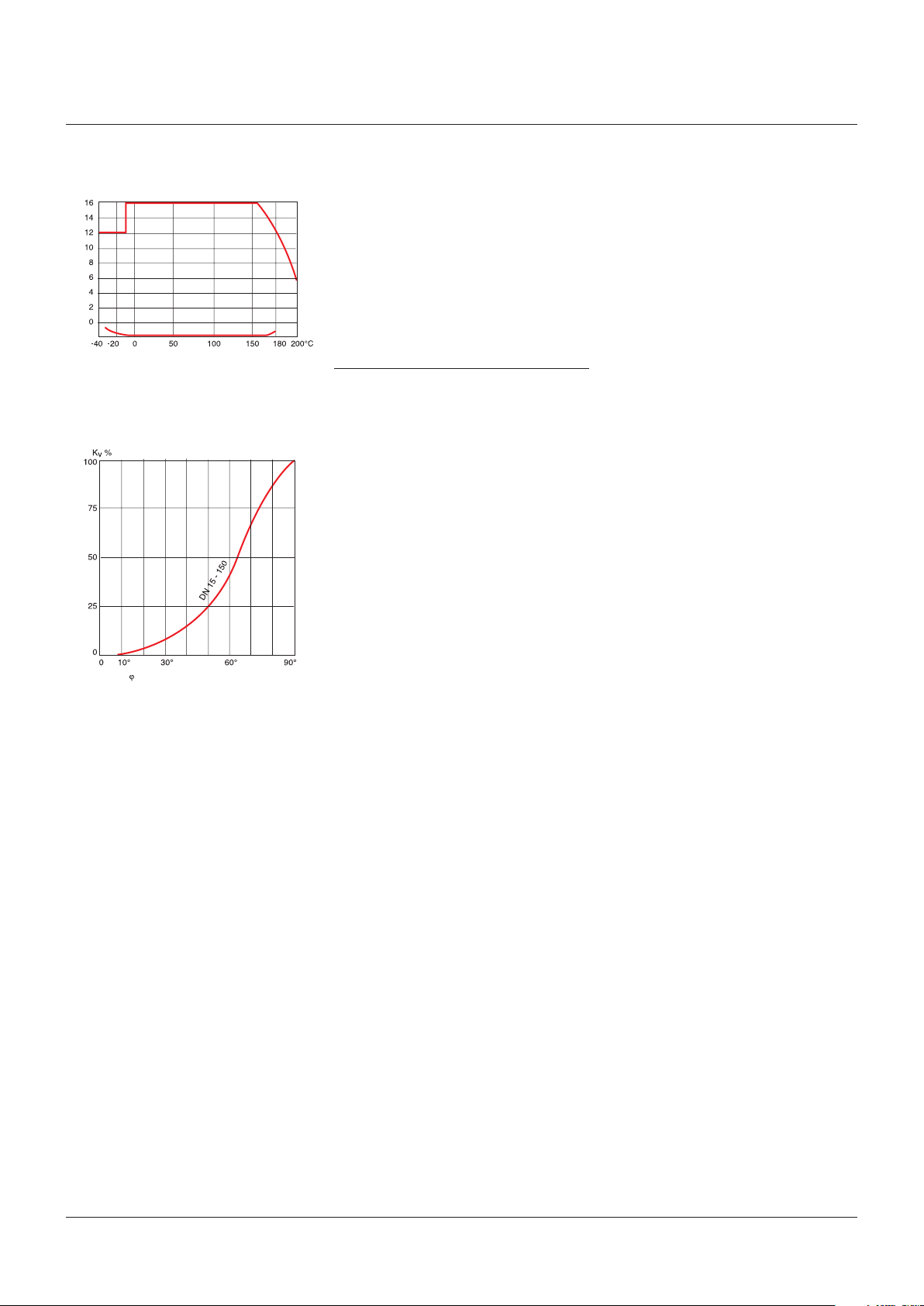

2.2.3 Pressure-temperature diagram for

NTB-NTC ball valves

bar

Vacuum

0.1 mbar

2.2.4 Flow characteristic for NTC control valves

(without control orifice plate)

Angular

position

2.2.5 Usage restrictions

Before the valve is installed, a check should be

made on the extent to which the coating of the

surfaces is resistant to the intended medium.

The same applies to stainless steel valves with

no additional coating. Refer to appropriate

literature or consult the manufacturer or

distributor for advice on this.

2.2.6 Modification prohibition

Mechanical modifications to the valves or the

use of other manufacturer’s parts for repair

purposes are not permissible, as otherwise

safety is no longer guaranteed. Repair work

must only be carried out by the manufacturer’s

trained personnel. The manufacturer and

supplier will accept no liability in the event

ofmisuse.

2.2.7 Warning about foreseeable misuse

Valves and their accessories (e.g. operating

elements) must not be misused as

climbingaids.

2.2.8 Duty to comply with the instructions

foroperation, maintenance and servicing

These instructions form part of the delivery

package and must be easily accessible to the

user. They should be protected from soiling

andkept in a suitable place.

3 SOURCES OF DANGER

3.1 External chemical effects

The valve body is either made of stainless steel

or is coated with a 2-part polyester paint. The

coating can be attacked externally by strong

solvents, leading to corrosion of the body.

If damage of this nature occurs, the effects

on the environment should be investigated

and the damage to the coating made good

in accordance with the manufacturer’s data.

Stainless steel valve bodies are not suitable

foruse with chlorine gas.

3.2 Mechanical

When using hand levers and handwheels,

it should be ensured that there is sufficient

clearance everywhere for the operator’s

hands,so that there is no risk of trapping.

3.3 Electrical

If static charges can lead to explosions,

the valve must be earthed by means of

the appropriate earthing accessory. As an

alternative, valves with electrically conductive

linings are available. For more information,

please contact the supplier or manufacturer.

3.4 Thermal

The operating temperature of the valve can

be up to a maximum of 200°C. Suitable

precautions should be taken to protect against

burns due to high or freezing temperatures.

In particular, insulated gloves should be worn

when using the hand lever, for example. In case

of fire, the mechanical strength of the PTFE

seals is no longer guaranteed above 200°C.

2

Page 3

NEOTECHA NTB-NTC BALL VALVES

INSTALLATION AND MAINTENANCE INSTRUCTIONS

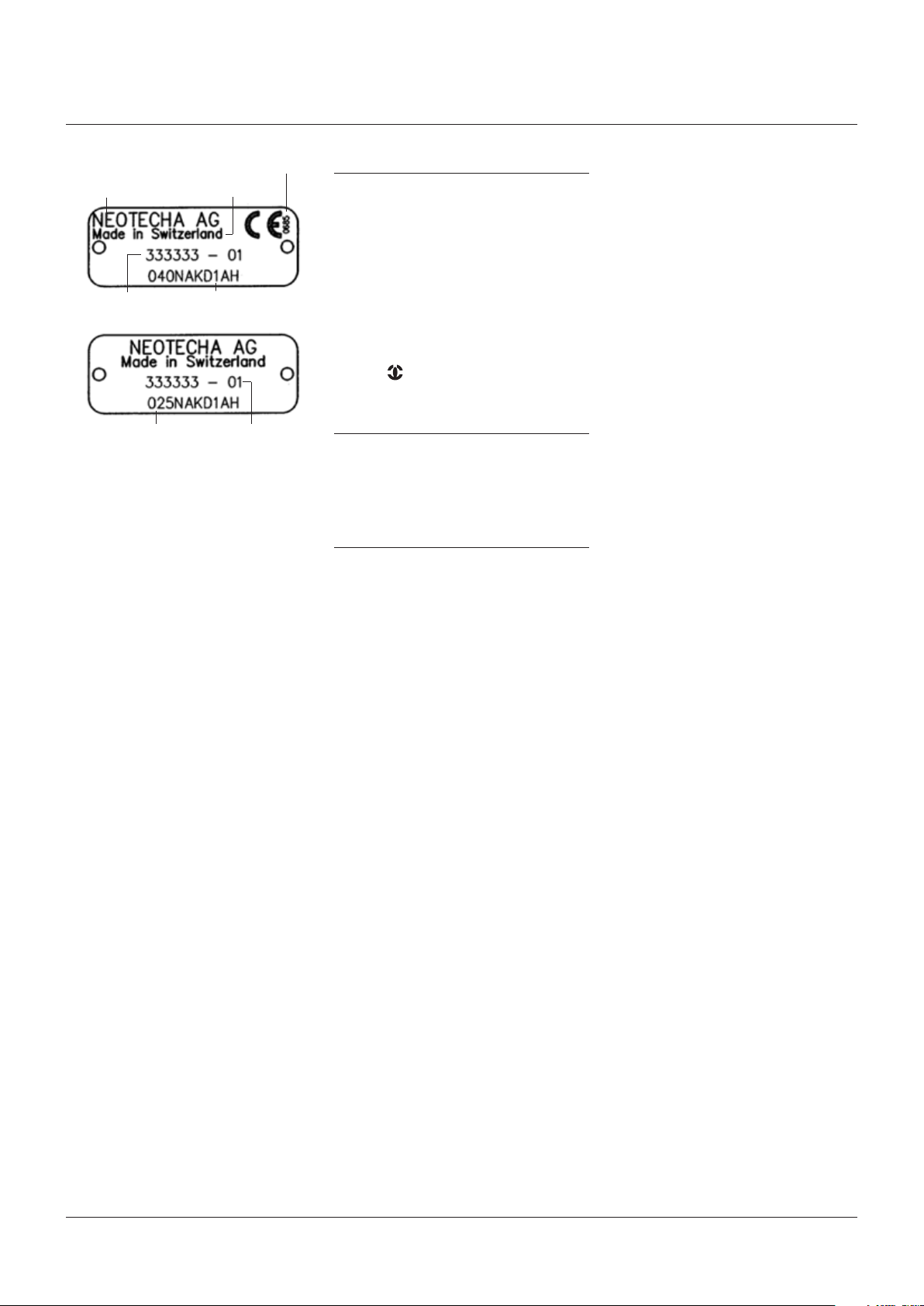

Number of the

notified body

Manufacturer Origin

Serial number Manufacturer’s code

Ball valve type

3.5 Requirements for the operator

This means people who are familiar with the

erection, installation, commissioning, operation

and maintenance of the product and have

appropriate qualifications relating to their

activities and functions, such as e.g.:

- Instruction in and duty to comply with all

installation-related, regional and internal

works regulations and requirements.

- Training or instruction in accordance with the

Safety Standards for personal care and use of

appropriate safety equipment and protective

workgear, like e.g. personal protection

equipment (insulated gloves or similar),

suitable for the operating conditions.

Furthermore, these people must have read

andunderstood these instructions.

3.6 Transport/storage

The valve is delivered with protective covers

which should protect against soiling and

mechanical effects. For this reason, the

protective covers should only be removed

immediately prior to installation.

The ball valve is shipped in the closed position.

3.7 Transport and storage conditions

- Transport and storage temperature

-20°C to +65°C.

- Protect against external force(impact,

shock,vibration).

- Do not damage the coating.

- In damp storage areas, a drying agent

or heating is required to protect against

condensation.

- Store the ball valve in a slightly open position.

3.8 Handling prior to installation

- On versions with protective covers,

only remove these immediately prior

toinstallation!

- Protect against the effects of weather,

e.g.dampness (or else use a drying agent).

- Proper treatment prevents damage.

Year of manufacture

4 IDENTIFICATION

Each ball valve is fitted with a rating plate giving

information on valve type and origin. When

ordering spare parts this information should

becarefully noted down each time.

Ball valves in the size range DN 15 to DN 25

have a standard rating plate with no CE mark.

Ball valves in the size range DN 40 to DN 150

are provided with a rating plate with a CE mark.

Additional identification on the valve in

accordance with DIN19, such as: DN, PN,

manufacturer’s logos of the Neotecha AG

company . The identification of the valve

body material is cast onto the valve.

5 DIMENSIONS AND WEIGHTS

Please refer to the product documentation

for any dimensions that are not contained in

the installation and maintenance instructions

andfor ball valve weights.

6 INSTALLATION

6.1 Installation in the pipeline

Fit the ball valve in the pipeline, ensuring that

the sealing surfaces on the faces of the flanges

are not damaged. The NTB ball valve can be

installed independently of the direction of

flow. On the other hand, the NTC can only be

installed in one direction, i.e. the arrow on the

side of the valve must point in the direction of

flow. Adequate clearance should be ensured

around the ball valve, so that it can be operated

and maintained easily.

The mounting flanges of the pipeline in which

the valve is to be installed must be aligned

axially and laterally, in order to prevent the

valve body being subjected to additional

stresses. Fit suitable flange packings, provided

that they are called for: then the fixing bolts

are inserted. Tightening the bolts in stages is

essential for an equal distribution of the of the

initial stress force of the clamping bolts.

The specified tightening torques must not

beexceeded.

The flanges must meet the following

requirements: cleaned and undamaged

matingsurface.

Flange packings are not required with flanges

with flat sealing surfaces. Additional packings

may possibly be required with rubberized

flanges.

3

Page 4

NEOTECHA NTB-NTC BALL VALVES

INSTALLATION AND MAINTENANCE INSTRUCTIONS

6.2 Dimensions of the mounting flanges for NTB-NTC ball and C valves DIN-PN 16

DIMENSIONS

DN D Tk n x d

mm inches mm mm mm

15 ½” 95 65 4 x 14

20 ¾” 105 75 4 x 14

25 1” 115 85 4 x 14

40 1½” 150 110 4 x 18

50 2” 165 125 4 x 18

65 2½” 185 145 4 x 18

80 3” 200 160 8 x 18

100 4” 220 180 8 x 18

150* 6” 279 241 8 x 22

* DN150 ball valve only as ANSI 6” version available

6.3 Dimensions of the mounting flanges for NTB-NTC valves ANSI B 16.10class150 (lbs)

DIMENSIONS

DN D Tk n x d

mm inches mm mm mm

15 ½” 89 60.3 4 x 16

20 ¾” 98 70.0 4 x 16

25 1” 108 79.5 4 x 16

40 1½” 127 98.5 4 x 16

50 2” 152 120.5 4 x 19

65 2½” 185 145.0 4 x 19

80 3” 190 152.5 4 x 19

100 4” 229 190.5 8 x 19

- 6” 279 241.0 8 x 22

6.4 Dimensions of the mounting flanges for NTB-NTC ball and C valves JIS-10K

6.5 Installation options

Ball valves can be equipped with various means

of operation e.g. with hand lever, handwheel,

electrical, pneumatic or hydraulic drive, or with

a drive linked to a position controller for NTC

control valves. The hand levers are supplied

complete with a notched plate which allows the

lever to be latched either in the end positions

only (version ZE) or in the end positions and

additionally in various intermediate positions

(version Z). In addition, the hand lever can be

provided with limit switches which indicate

“open” or “closed”.

For installation in exposed places, shaft

extensions in various lengths are available

forall sizes.

6.6 Bolted joints in the pipeline

All flange bolts must be used, even on

low-pressure systems. The specified tightening

toques for the bolts must always be adhered to.

6.7 Body variants

NTB and NTC ball valves have the same body

dimensions. The face-to-face and mounting

flange dimensions of the ball valve bodies

varyaccording to the various standards.

When used as an end of the line valve, it must

be secured in such a way that access to the

isolating valve is restricted when in service.

It should also be noted that when a valve is

used as the end valve of a pressurized system,

a dummy flange must be assembled.

DIMENSIONS

DN D Tk n x d

mm inches mm mm mm

15 ½” 95 70 4 x 15

20 ¾” 100 75 4 x 15

25 1” 125 90 4 x 19

40 1½” 140 105 4 x 19

50 2” 155 120 4 x 19

65 2½” 175 140 4 x 19

80 3” 185 150 8 x 19

100 4” 210 175 8 x 19

- 6” 279 241 8 x 22

* Ball valves DN150 only as ANSI 6” version available

4

Page 5

NEOTECHA NTB-NTC BALL VALVES

INSTALLATION AND MAINTENANCE INSTRUCTIONS

6.7.1 Face-to-face body dimensions for NTB-NTC ball valves

FACE-TO-FACE BODY DIMENSIONS

DN DIN-PN 16 ANSI-150lbs JIS-10K

mm inches mm mm mm

15 ½” 130 108 130

20 ¾” 150 117 150

25 1” 160 127 160

40 1½” 200 165 200

50 2” 230 178 230

65 2½” 290 290 (DIN dimension) 290

80 3” 310 203 310

100 4” 350 229 350

150 6” 480

ANSI-dim. 229

withextension

6.8 Step-by-step valve installation

1. Check that the distance between flanges matches the face-to-face dimension of the ball valve.

Before installing the valve, spread the mounting flanges apart sufficiently using a suitable tool.

2. Remove the protective caps and position the ball valve in the pipeline. When installing a

Cvalve, check that the arrow points in the direction of flow.

3. Insert the fixing bolts.

4. Tighten the flange bolts hand-tight as the tool holding the flanges apart is gradually removed.

Make sure that the flanges remaincorrectly aligned.

5. Tighten all flange bolts in opposite pair sequence. Refer to following table for tightening

torques.

267 480

ANSI-dim. 229

withextension

6.9 Recommended tightening torques for mounting flange bolts

6.9.1 Recommended tightening torques for NTB-NTC ball valves DIN-PN 16 and JIS-10K

RECOMMENDED TORQUES

DN

mm inches Nm

15 ½” 4 x M12 A2-70 10

20 ¾” 4 x M12 A2-70 15

25 1” 4 x M12 A2-70 20

40 1½” 4 x M16 A2-70 27

50 2” 4 x M16 A2-70 45

65 - 4 x M16 A2-70 60

80 3” 8 x M16 A2-70 60

100 4” 8 x M16 A2-70 45

- 6” 8 x M20 A2-70 85

Bolts

metric Class

Torque

6.9.2 Recommended tightening torques for NTB-NTC ball valves ANSI B 16.10class150 (lbs)

RECOMMENDED TORQUES

DN

mm inches

15 ½” ½” B7 9

20 ¾” ½” B7 13

25 1” ½” B7 18

40 1½” ½” B7 21

50 2” ⅝” B7 41

65 - ⅝” B7 52

80 3” ⅝” B7 52

100 4” ⅝” B7 38

- 6” ¾” B7 68

Bolts

UNC lbf·ft

Class

Torque

5

Page 6

NEOTECHA NTB-NTC BALL VALVES

INSTALLATION AND MAINTENANCE INSTRUCTIONS

6.10 Final checks

- Checking the ball position as far as the

fullyopen position.

- Cleaning and flushing the pipeline before

thefirst closure.

- Repeated opening and closing of the ball

valve, to ensure unrestricted movement

ofball and control shaft.

7 NOTES ON DANGERS DURING

INSTALLATION, OPERATION

ANDMAINTENANCE

Safe operation of the valve is only guaranteed

ifit has been correctly installed, commissioned

and maintained by qualified personnel

(see“Qualified Personnel”), taking into account

the warning information of these installation

and maintenance instructions.

In addition, compliance with the general

installation and safety regulations for the

pipeline or plant construction, together

with the correct use of tools and protective

equipment, must be ensured. The installation

and maintenance instructions must be

strictly followed when any work is carried

out on the valve or when handling the valve.

Non-observance can result in injuries or

damage to property. When the valve is used

as a final termination, a safety measure e.g.

a blank or dummy flange is recommended

when carrying out maintenance work. When

the valve is installed as an end of line valve,

theinformation given in DIN EN294 point 5

must be observed.

9 USE

9.1 Operation - general

NTB series ball valves should only be used

in the fully open or fully closed position, as

they are not designed for flow regulation.

Intermediate settings can result in turbulence,

leading to vibrations in the pipeline system

which then generates noise. If the flow has to

be regulated, an NTC series C valve should

be used. This type can also be fitted with

various control orifice plates. Refer to the flow

characteristic diagram for NTC control valves.

Operating:

Clockwise to close.

Counter clockwise to open.

9.2 Operation with hand lever

Neotecha ball valves and C valves are

supplied with a hand lever as standard, unless

anything different has been provided (except

DN150-6” -too high a torque). The hand lever

should always be fitted on the ball valve and

only removed when necessary for maintenance

purposes. When the hand lever points in the

direction of the pipeline, the ball valve is fully

open; when the hand lever is at right angles

to the pipeline, the valve is fully closed. The

hand lever should be turned clockwise to

closethevalve.

Nominal diameters 15 to 100 (½” to 4”)

Hand lever with notched plate with 10°

divisions, range 90°

Operating element: detent lever

8 COMMISSIONING

8.1 General commissioning

Before commissioning, the information relating

to material, pressure and temperature should

be compared with the installation diagram of

the pipeline system.

Tools for increasing the lever or handwheel

torque are not allowed.

Any debris left in the pipeline and valves

(dirt,welding beads, etc.) will inevitably

leadtoleakage.

Before each commissioning of a new system or

re-commissioning of a system after repair or

modification, it must be ensured that:

- All installation and assembly work has

been completed in accordance with the

regulations.

- Commissioning is only undertaken by

“Qualified Personnel”.

- The valve is in the correct operating position.

- New protective equipment is installed or

existing protective equipment repaired.

The hand lever and detent lever must not be

modified. The locking function is otherwise

adversely affected. Damaged hand levers

shouldbe exchanged.

9.3 Operation with drive

Thanks to its modular method of construction,

the NTB-NTC ball valve can be converted to

anautomatic drive at any time. In this case

it may be necessary to remove the ball valve

fromthe pipeline.

When drives or gear units are used, the

instructions of the particular manufacturer

areapplicable.

6

Page 7

NEOTECHA NTB-NTC BALL VALVES

INSTALLATION AND MAINTENANCE INSTRUCTIONS

10 SERVICING AND MAINTENANCE

No routine maintenance or lubrication is

required. However, for systems with high

temperatures, an inspection for leakage at

the flanges should be carried out shortly after

installation. The large difference between

the temperature related expansions of PTFE

and some metals can result in cold flow.

Tightening the bolts once again will eliminate

this problem. This process may possibly have to

be repeated several times. We recommend that

the valve is operated at least once a month.

11 CAUSE AND REMEDY OF OPERATING

FAULTS

If the valve function or operating action is

faulty, a check should be made to ensure that

the assembly and installation work has been

carried out and completed in accordance with

the installation and maintenance instructions.

The information relating to material, pressure,

temperature and direction of flow should be

compared with the installation diagram of the

pipeline system. Furthermore, a check should

be made on whether the installation conditions

correspond to the technical data given in the

data sheet or on the rating plate.

The safety regulations must always

beobservedwhen troubleshooting.

Repair work must only be carried out by

themanufacturer’s trained personnel.

ATTENTION!

Check that the pipe is depressurized and drained.

With corrosive, inflammable, aggressive or toxic

media, ventilate the pipeline system.

- Only allow assembly work to be carried out

byqualified personnel.

- Almost fully close the valve (note position

ofthe flat sections of the control shaft).

- Loosen all flange bolts and withdraw

themuntil the valve can be removed.

- Spread the flanges apart using a suitable

tooland withdraw the valve.

13 SPARE PARTS

Always provide the information in accordance

with the rating plate fitted on the mounting

flange when ordering seals and other

spareparts.

14 DISPOSAL

Hand in the correctly cleaned valve to the

scrapmaterial recycling plant.

Badly cleaned valves can cause severe burning

ofthe hands and other parts of the body.

If the valve is passed on to a third party, the

manufacturer no longer guarantees the valve.

12 DECOMMISSIONING

Removal of the valve for repair or servicing is

often carried out carelessly, as the valve has to

be repaired or replaced in any case. However, it

is recommended that the valve is removed with

care, without damaging the PTFE, so that the

possible cause of damage can be determined

after removal.

7

Page 8

Neither Emerson, Emerson Automation Solutions, nor any of their affiliated entities assumes responsibility for the selection, use or maintenance of any product.

Responsibility for proper selection, use, and maintenance of any product remains solely with the purchaser and end user.

Neotecha is a mark owned by one of the companies in the Emerson Automation Solutions business unit of Emerson Electric Co. Emerson Automation Solutions, Emerson

and the Emerson logo are trademarks and service marks of Emerson Electric Co. All other marks are the property of their respective owners.

The contents of this publication are presented for informational purposes only, and while every effort has been made to ensure their accuracy, they are not to be

construed as warranties or guarantees, express or implied, regarding the products or services described herein or their use or applicability. All sales are governed by

our terms and conditions, which are available upon request. We reserve the right to modify or improve the designs or specifications of such products at any time without

notice.

Emerson.com/FinalControl

Loading...

Loading...