Page 1

Unidrive SP

230V / 460V Servo Drive Systems

Page 2

Unidrive SP – Advanced Solutions Platform for Servo Motor Control

N1652

Control Techniques’ Unidrive SP delivers dynamic performance to operate a wide array of servo motor types and power

ratings. Snap-in SM option modules allow the addition of programming platforms, distributed or centralized control

architecture, I/O, communications and feedback to tailor the solution to specic application needs.

Optional keypad,

available as highbrightness LED or

multi-language LCD

with plain text

Modbus

communications port

for PC programming

and device interfacing

Drive identication

marker rail

SmartCard for

parameter, PLC

program storage

Terminal cover for DC

bus, low voltage power

supply and on board

EMC lter

Internal EMC lter with

easy disconnect

Power On / Drive

Status LED

Aluminium heatsink:

drive can be mounted on

a at surface, or through

panel mounted so that

the heat is dissipated

outside the enclosure*

3 universal SM option

module slots for

communications,

I/O, additional

feedback devices and

automation/motion

controllers*

Universal encoder

port supporting

Incremental, SinCos,

SSI, EnDAT and

HIPERFACE encoder

types

* Features and their locations vary on some drive sizes

E171230

2

Plug-in connections with

removable terminals*

Certificate No. EMS 54446

ISO 14001

ENVIROMENTAL

MANAGEMENT

003

Certificate No. Q 05176

ISO 9001

QUALITY

MANAGEMENT

003

www.controltechniques.com

Relay connections

Power connections

with removable

terminals*

Page 3

One Drive, Any Power, Any Motor

The Unidrive SP is a universal AC and Servo drive with

ratings from 0.5 to 2,900hp. This eld-proven drive

features dynamic servo performance with a wide array

of power, motor types and snap-in SM option modules

including programming/automation platforms, distributed

or centralized control, I/O, communications and feedback

to tailor the solution to your exact needs. (For full details

on the wide range of available option modules, please see

the Control Techniques SM Option Modules brochure.)

Panel Mount – Standard Drives

0.5 - 200hp (0.37kW to 132kW)

Unidrive SP Panel Mount drives are standard AC input, AC

output sizes for installation within a control panel. Optional

conduit boxes are available for wall mounting.

Performance Advantage

Servo Motor Control

Closed-loop servo motor control and power regeneration

control features in one drive

Dual Duty Ratings — Normal and Heavy

Provides cost-effective sizing choices for all applications

24Vdc Auxiliary Power Supply Input

Maintains control, network communications and position loop on

input AC power loss, minimizing system recovery time

Comprehensive Auto-Tune

Inertia monitoring and static auto-tune reduce startup time

Universal Feedback Interface

Supports 14 different types of feedback devices, including several

absolute encoders; multiple encoders can be connected to a

single drive with SM option modules

Ratings

Input

Voltage

200-240V,

1Ø

200-240V,

3Ø

380-480V,

3Ø

500-575V,

3Ø

500-690V,

3Ø

Normal Duty Heavy Duty

50

0.5 325

20

2 175 200

100 125 150

60

Horsepower Range

High-Resolution Analog Input

16-bit, 250µsec interface for high-performance applications;

two additional 10-bit analog inputs for lower level controls

Extensive Fieldbus Connectivity

ModbusRTU (Standard), Probus-DP (V1), Ethernet, DeviceNet,

CAN, CANOpen, EtherCAT, SERCOS, Interbus-S and CTNet/CTSync

optional via zero-space option modules; up to four eldbus

devices can connect to a single drive, eliminating the need for

expensive gateways

Universal SM Option Module Slots

Unidrive SP size 0 has two slots; Unidrive SP sizes 1 and up have

three option module slots; SM-Fieldbus, I/O and Application

modules t in any of the open module slots

Safe Torque Off Function

Conforms to IEC61800-5-1, SIL 3 and EN954-1 Category 3 for

machine safety and system cost reduction

SmartCard for Simple Set-up and Cloning

Easy-to-use card stores drive conguration for simple startup and

parameter cloning — supplied free with every Unidrive SP

Keypad Options

Choose no keypad, LED keypad or LCD keypad based on the

system design and operating environment

Drive-Mounted Brake Resistors

Unidrive SP sizes 0, 1 and 2 feature a drive-mounted brake resistor

option to reduce panel space requirements

www.controltechniques.com

3

Page 4

Automation Solutions

Unidrive SP programmable drives offer more compact, higher-performance and lower-cost solutions in machinery

automation applications. Over the past 20 years, Control Techniques has pioneered the embedding of programmable

automation, motion control and communications features within its drive products.

Featured SM Option Modules

To provide the best possible dynamic motor performance, the

following Control Techniques SM option modules contain a

high-performance microprocessor that allows the base drive

to be dedicated to shaft control as well as machine control.

SM-EZMotion

The SM-EZMotion option module and Control

Techniques’ FREE PowerTools Pro software

provide a user-friendly environment for

“out-of-the-box” conguration and motion

programming. The EZMotion approach is ideal for rapid

development of motion application solutions. The module

has four digital inputs and two digital outputs for high-speed

I/O operations.

SM-Applications Plus

SM-Applications Plus offers all of the features

of the SM-Applications Lite V2 module plus

Control Techniques’ CTNet network tool (see

below), RS485 serial port and high-speed I/O. The

SM-Applications Plus option module is programmed using

SyPTPro (System Programming Tool).

• Drive-to-drive communications: SM-Applications Plus

option modules include a high-speed, drive-to-drive

network called CTNet. This network is optimized for

intelligent drive systems offering exible peer-to-peer

communications. CTNet has the capability to connect to

remote I/O, operator panels, Mentor MP DC drives and PCs

providing the ability to perform true parallel multi-tasking.

• Control Techniques’ CTSync is also standard on the

SM-Applications Plus module, providing the drive clock

synchronization with <4µsec jitter.

• Inputs/Outputs: This module has two digital inputs and

two digital outputs for high-speed I/O operations such as

position capture and actuator ring.

SM-Applications Lite V2

The SM-Applications Lite V2 option module

provides programmable control for standalone

drive applications or when the drive is connected

to a centralized controller via I/O or eldbus. SM-

Applications Lite V2 may be programmed using Ladder Logic

with SyPTLite or can use the full automation and motion

control capabilities contained within SyPTPro, IEC 61131-3

software (see page 8 for more information).

•

Real-time control: The SM-Applications Lite V2 module

provides real-time access to all of the drive’s parameters

plus access to data from I/O and other drives. The module

uses a high-speed multi-tasking operating system with task

update times as low as 250µs. Tasks are synchronized to

the drive’s own control loops to give you the best possible

performance for drive control and motion.

SM-Register

The SM-Register option module is designed to

provide a exible, high-performance solution

for programmable motion requiring high-speed

registration features – ideal for applications such

as printing, packaging and cutting machinery.

Features include:

• Motion programming using PLCopen or Control

Techniques’ Advanced Position Controller (APC)

• Two fully independent registrations capture channels

• Storage for 256 events per channel, microseconds apart

• Pattern recognition

• Speed capacity in excess of 3000ft/min

• Ability to lter unwanted marks (i.e. splashes, dirt, text, etc.)

• Minimum and/or maximum pulse width

• Distance from previous edge

• Compensation for registration sensor throughput delay

• CTNet and CTSync functionality

4

www.controltechniques.com

Page 5

“Made-to-Order” Drive Configurations

Feature-rich Unidrive SP drives are optimized for servo applications requiring high peak torque, dynamic response, ease of use and

versatile integration features. Several core congurations are listed below to which feedback, communications or I/O option modules

can be added for custom solutions. All in all, there are over 10,000 possible Unidrive SP congurations allowing you to match your

specic application and development requirements. The following combination examples also offer the option of adding two

additional option modules.

Unidrive SP “Base.” With up to 14 different motor feedback

options, the base Unidrive SP can be easily controlled with

single- and multi-axis controllers, PLC’s and host controllers

for medium- to high-power applications. The analog torque

or velocity modes can be used with classic position controllers

using analog outputs and encoder inputs. The drive can be

controlled over a SERCOS or EtherCAT network with the

addition of an SM-SERCOS or SM-EtherCAT option module.

Drive set-up parameters can be easily stored on a credit

card -sized SmartCard. Simple sequencing logic can be

accomplished using the onboard Ladder editor. Conguration

and diagnostics is done using the FREE CTSoft software tool.

Unidrive SP “EZ” (Base drive + SM-EZMotion module).

With out-of-the-box motion control in less than ve minutes,

the Unidrive SP is the ultimate servo drive in terms of ease of

use and motion performance. Utilizing a familiar Windows®

interface, machine builders can use PowerTools Pro software

to quickly set up and program the Unidrive SP “EZ” to perform

almost any motion prole. Applications requiring camming,

indexing, electronic gearing, velocity and torque modes

can be accomplished through simple drag-and-drop, ll-

in-the-blank set-up. Real-time programs with “Basic-like”

command structured text can be used to program the machine

sequencing. The programming interface guides the user

through the drive, I/O and motion congurations. The drive

offers a standalone solution for many common indexing and

synchronized motion applications.

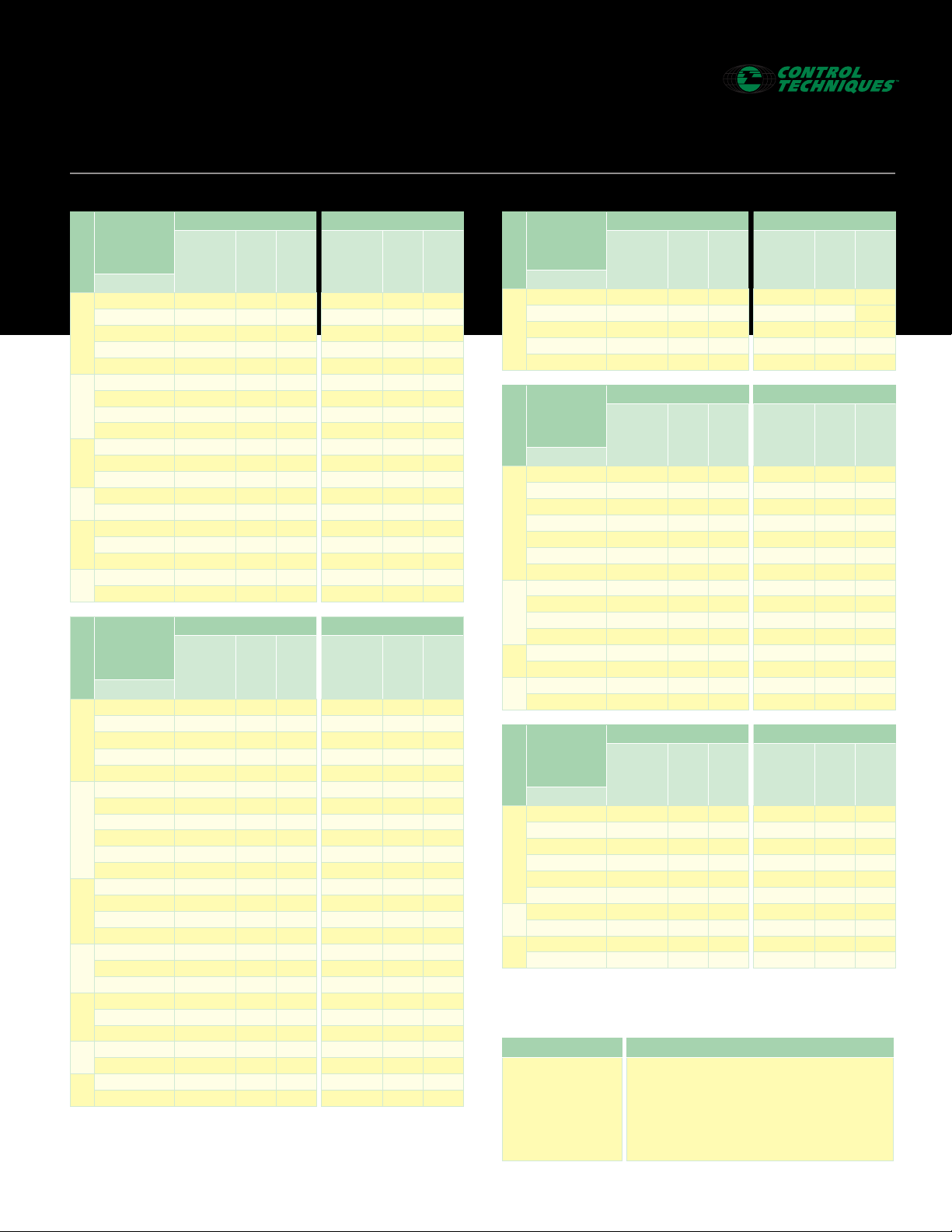

Product Styles

Unidrive SP Configuration

Control Hierarchy

Centralized Control System

Decentralized Control System

Hybrid

Standalone Applications

Motion Control Functionality

Velocity, Torque Mode

Position-Indexing

Synchronization, Electronic Gearing

CAMS

Programming Environment

Drag-and-Drop, Fill-in-the-Blank

Text Programming

PLC Open

IEC 61131 Programming

FREE Application Software

PowerTools Pro

SyPTPro

SyPTLite

CTSoft

CTScope

CTOPCServer

“Base” “EZ” “Plus”

ü

ü ü

ü ü

ü ü

ü

ü ü

ü ü

ü ü

ü

ü ü

ü

ü

ü

ü

ü

ü ü

ü ü ü

ü ü ü

Unidrive SP “Apps” (Base drive + SM-Applications Plus module). This

full-functionality machine control set-up is optimized for high-performance

machine cells requiring drive-to-drive networking and precision motion

control synchronization. SyPT Pro is an IEC61131-3 compliant software

development environment used to provide effective machine control,

motion and network communications. Ethernet and I/O connectivity

enable interfacing with other automation components and intellectual

property protection ensures your valuable knowledge remains secure.

www.controltechniques.com

5

Page 6

Motion Made Easy™ Solutions

“Motion Made Easy™ ”

Each step is congured using

simple check boxes, drop-down

selections and drag-and-drop

functionality. A straightforward

programming language allows

users to develop more complex

applications and advanced

sequencing by simply dragging

functions onto the work area and

dropping them in place.

PowerTools Pro Software for Unidrive SP EZMotion

PowerTools Pro software provides advanced motion control programming for Control

Techniques drives with internal motion controller. This FREE software enables users

to fully realize the power of our EZMotion motion controller. A familiar Microsoft®

Windows® interface provides operators and machine builders with the tools needed to

access everything they need for complete servo control — PLS, Queueing, High-Speed

Capture, Electronic Gearing, Event Assignments and more.

Developing motion applications with PowerTools Pro is a simple “ve-step, topdown” process. The ve steps are displayed in a familiar “explorer” bar (insert, left)

for easier navigation:

• Hardware

conguration

Assignments – Use “virtual wiring” to create programs right out of the box without

writing a single line of code. For example, the assignment screen (below) allows you to

drag-and-drop the desired machine function onto the digital inputs and outputs.

• Drive setup

• I/O setup

• Motion

• Programs

Indexes – Indexes are

easily set up by lling in the

screen’s blanks to create an

index prole. Select from

Incremental, Absolute,

Registration or Rotary Plus

and Minus types. “Position

Trac ker™” synchronization is

easily achieved using menu

selections. Choose the

time base of the index by

selecting either real-time or

synchronization with a master.

Microsoft and Windows are registered trademarks of Microsoft Corporation in the United States and other countries.

6

www.controltechniques.com

Page 7

Software Matched to Your Application Requirements

PowerTools Pro continued

Camming – Cams make set-up and programming of complex motion proles easy.

The use of real-time programs provides smooth transitions when switching between

cam proles on the y. Cam data is easily imported within PowerTools Pro and the cam

graphing tool features multiple interpolation types.

Network – Regardless of the eldbus

being used, setting up network communications is quick and easy. Fill-inthe-blank, drag-and-drop procedures

are used to set up communication.

PowerTools Pro’s diagnostics allow you

to monitor the data being sent and

received.

Sophisticated

motion routines

such as camming,

gearing or

multiple prole

summation

are easily

implemented with

PowerTools Pro

and Unidrive SP.

Typical Applications

Commander SK

Sensor

AC Motor

NT Motor

Master Axis

Encoder

Random Infeed – Smartbelt High-Speed Labeling

www.controltechniques.com

Unidrive SP

CTVue

Operator

Interface

www.controltechniques.com

7

Page 8

Flexible Automation Software

SyPTPro (Systems Programming Toolkit)

SyPTPro is a full-featured automation development

environment that can be used for developing tailored

solutions for single- or multiple-drive applications. The

programming environment fully supports three IEC 61131

languages: Function Block, Ladder Logic and Structured

Text. Motion control is congured using PLCopen motion

language, supporting multiple axes.

CTNet, a high-speed, deterministic drive-to-drive

network links the drives, SCADA and I/O together to form

a networked system, with SyPTPro managing both the

application programs and network communications.

Programming Flexibility

SyPTPro can be used with three programming languages

— Function Block diagram, Ladder Logic and Drive

Programming Language (DPL). The software offers a multitasking environment in which tasks are scheduled according

to the required speed of execution or triggered by events.

Function Block

Ladder Logic

SyPTPro is the ideal format for sequencing and I/O control

familiar to all PLC programmers. Using an SM-Applications

Plus module, over 5,000 rungs of logic may be stored

and executed. All normal Ladder Logic functions are

available plus high-level blocks for communications, word

manipulation, math operands and much more.

SyPTPro includes a library of more than 380 Function Blocks

for both simple and complex functions. In addition to the

dened Function Blocks, users can create User Dened

Function Blocks (UDFB). This feature allows users to create

special functions. It is also possible to use pre-dened

Function Blocks inside the UDFB. Intellectual property can

be protected by creating a UDFB that allows access only to

authorized source code users.

Drive Programming Language (DPL)

DPL is a structured text language as easy to use as BASIC,

incorporating many standard constructs such as IF-THENELSE and FOR-NEXT loops. DPL is ideal for initializing,

conguration and general programming of Control

Techniques drives. DPL may be mixed throughout the

program with the other graphical editors such as Ladder Logic.

PLCopen (Open Motion Programming)

PLCopen-style programming for motion control uses

industry-standard Function Blocks for motion control

resulting in reduced development time.

8

www.controltechniques.com

Page 9

Additional Software

CTOPC Server

OPC is the industry standard for connecting industrial

automation components to higher-level information systems

such as SCADA, MRP, ERP and others. Control Techniques’

CTOPC server is an OPC-compliant server that allows PCs to

communicate with Control Techniques drives via Ethernet,

CTNet, RS485 and USB. The OPC standard allows OPC clients

to browse data from an OPC server thus eliminating the

need for gateway data concentrators or proprietary drivers

and gateways. CTOPC server “serves” data to the various

OPC clients then polls data from all Control Techniques

components connected via Modbus RTU, Modbus TCP/IP or

CTNet.

CTSize

CTScope

This Windows®-based software utility is designed to trend/

trace parameter values on Control Techniques drives and option modules. CTScope has the look and feel of a traditional

hardware oscilloscope and can plot up to four channels of

data simultaneously. All channel data appears in single-scope

view for easy comparison and CTScope les can be saved for

future use.

CTSoft

This easy-to-use servo drive sizing software helps select the

optimum system in just six steps:

1. Select one of six pre-congured load types: Leadscrew,

Rack and Pinion, Conveyor, Cylinder, Feedroll and User

Dened.

2. Fill in the load details.

3. Enter the load’s motion prole, making use of prole-type

shortcuts or creating multi-segment proles.

4. Select speed reduction from Belt/Pulley, Gear/Gear,

Chain/Sprocket, or Gearbox for up to three separate

stages of reduction.

5. Select from all products or narrow the search to a specic

drive and/or motor.

The optimum motor/drive combination appears in the

Results tab.

www.controltechniques.com

Control Techniques’ free drive conguration tool can be used

to commission, optimize and monitor Unidrive SP “Base”

drives. CTSoft uses wizards to simplify commissioning,

manages data stored on the SmartCard and features robust

and graphical tools for monitoring and troubleshooting. The

status of the program can be monitored and the speed of the

motion reduced for commissioning and testing purposes.

9

Page 10

U

1 2 3 4 5 6 7 8

Power

CTScope

n

y

t

i

l

i

b

i

x

e

l

f

n

o

i

t

a

r

g

e

t

n

i

y

s

a

e

d

n

a

t

s

a

f

,

P

S

e

v

i

r

d

i

SM-APPS-LITE-V2

SmartCard

SM-APPS-PLUS

for relevence to each module and order codes

Software

SM-REGISTER

See the Software brochure

Applications with PLC or Motion Functionality

Operator Interface Options

HMI Operator Interface

SM-EZMOTION

Tools Pro

External Control

Windows 98,

NT 4.0, 2000,

XP, Vista 32 or

7-compatible PC

USB Port-to-Drive Serial Interface Cable

CT-USB-CABLE

LCD Keypad

LED Keypad

PLC

Multi-Axis Controller

MC464

LED Keypad

Memory device to

store and copy drive

parameters

SMARTCARD

Standard Options

Modbus RTU

CTOPCserver

Communications

SM-CANOPEN

SM-DEVICENET

SM-ETHERCAT

See the Options & Accessories

brochure for order codes

SM Option Modules

SM-ETHERNET:SM-CAN

EtherNet/IP, Modbus TCP/IP,

email, web server, simple

network time Protocol

Standard

5 Analog input/outputs

7 Digital input/outputs

1 Safe Torque Off

Remote panel or drive-

mount LCD multilingual

text keypad display to IP54

(NEMA 12)

SM-KEYPAD-PLUS

Interconnect Cable

See Options & Accessories brochure for order codes

SM-INTERBUS

SM-PROFIBUS-DP

SM-PROFINET

SM-SERCOS

Options

SM Option Modules Remote I/O

SM-I/O-32 (32 digital I/O)

SM-I/O-24V (protected)

SM-I/O-LITE

SM-I/O-PELV

SM-I/O-TIMER (Real-Time Clock)

SM-I/O-120V (120Vac I/O)

SM-I/O-PLUS

Drive mount LED

display to IP65

(NEMA 12)

Size 1 and up.

SM-KEYPAD

Input / Output

Drive mount LED

CTNet

HEALTHY

BUS ERR

COM RUN

INIT ERR

I/O RUN

I/O ERR

BECKHOFF

BK7200

See the Options & Accessories

brochure for order codes

display to IP65

(NEMA 12)

Size Zero.

KEYPAD-SP0

RTU

TCP/IP

24V

0V

PE PE

10

www.controltechniques.com

Page 11

BRO_USPSERVO_1107, Printed: November 11, 2013 10:48 AM

Dynamic Braking Options

Filters

OptionsStandard

Internal Zero-Space Braking Resistor Dynamic Brake Resistors

E-Stop or Cyclic Duty

Internal EMC

Filter

External EMC Filter

See the Options & Accessories

brochure for order codes

Feedback

Sincos Quadrature

Frequency/Direction

Clockwise/Counter Clockwise

Frame sizes 0 to 2.

See the Options & Accessories

brochure for order codes

Standard Options

Installation Accessories

See the Options & Accessories

brochure for order codes

SM Option Modules

SM-UNI-ENCODER*

SM-ENCODER-OUT**

SM-ENCODER-PLUS**

SM-RESOLVER

* Accepts and replicates incremental and

absolute feedback types. Recommended

for Servo and positioning applications

** For use with Induction motors and

incremental feedback devices.

DC Back-up Power Supply

AC Induction Open-loop

Vector Control

24Vdc Control

24VDC

Motor Control Modes

AC Induction Closed-loop

Vector Control

www.controltechniques.com

48-96Vdc Power

Servo Motor

Conduit Boxes

Available on sizes 1 to 6 for

wall-mount applications

See Options & Accessories brochure

for order codes

Linear Motor

Regenerative

Active Front End

10 min

11

Page 12

Motors to Match Your Application Needs

As

A.

As

A.

The Unidrive SP supports 14 feedback devices as standard

for awless operation with nearly any Servo motor or

actuator to t a wide range of motion control needs. Control

Techniques manufactures several matched motor solutions

for Unidrive SP Servo drives and supplies a wide range of

gear reducers, actuators and other motion products through

Control Techniques’ One Source program (see page 16).

Control Techniques drive-and-motor combinations provide an

optimized system in terms of ratings, performance, cost and

nameplate” data during the manufacturing process. This data

can be read by Control Techniques Servo drives and used to

automatically optimize the drive settings.

This feature simplies commissioning

and maintenance, ensures

consistent

performance

and saves

time.

ease of use. Some motors tted with high-resolution SinCos or

absolute encoders are pre-loaded with the motor “electronic

Servo Motor

HD Motors NT Motors XV Motors FM Motors MG Motors MH Motors

Product Matrix

Motor Family

Drive Voltage 230/460 230 230 230/460 230

Continuous Stall Torque

Flange IEC IEC, NEMA Metric IEC IEC, NEMA

Frame 55, 67, 89, 115mm 2, 3in

Inertia Low Low (high inertia opt.) Low, Medium Med. (high inertia opt.) Medium

Peak Torque

Base Speeds Up to 6000rpm Up to 5000rpm Up to 5000rpm Up to 6000rpm Up to 5000rpm

Brake Options YES

Connector Options

Feedback Options

Ingress Protection IP65 IP65, IP67, IP68 IP55, IP65 IP65 IP65

Approvals CE, RoHS CE, UL (RoHS opt.) CE, UL, RoHS CE, UL, RoHS CE, UL

Up to 166lb-in

(18.8Nm)

Up to 499lb-in

(56.4Nm)

Circular-style frame

mounted 90° and

rotatable

Incremental encod-

ers, optical SinCos

single & multi-turn,

inductive SinCos

single- & multi-turn

resolver, Hiperface

(SICK) and EnDAT

Up to 56lb-in

(6.3Nm)

Up to 144lb-in

(16.3Nm)

MS- or circular-style

frame mounted, MS

style on 40in lead,

ying leads, drive

connector terminated

leads (20ft max.)

Incremental

2048 line count,

inductive absolute,

resolver

Up to 101lb-in

(11.4Nm)

40, 60, 80,

130mm

Up to 301lb-in

(34Nm)

AMP Mat-n-Loc

on 1ft. lead (40-

80mm); MS-style

frame mounted

(130mm)

Incremental

2048 line count

Up to 1204lb-in

(136Nm)

55, 75, 95, 115, 142,

190, 250mm

Up to 3611lb-in

(408Nm)

™

Circular-style frame

mounted 90° and

rotatable; optional 90°

xed, vertical or mixed

Incremental encoders,

optical SinCos single &

multi-turn, inductive SinCos single- &

multi-turn, resolver,

Hiperface (SICK) and

EnDAT

Up to 162lb-in

(18.3Nm)

2, 3, 4in 3, 4, 6, 8in

Up to 3611

lb-in (54.9Nm)

MS-style frame mounted

Incremental 2048 line count

460

Up to 748lb-in

(84.9Nm)

Up to 1500lb-in

(182Nm)

Up to 4000rpm

sembled in the U.S.

12

sembled in the U.S.

www.controltechniques.com

Page 13

Selecting the Right Motor for the Right Drive

6

2020

56

59

7.5

7.5

22.5

Control Techniques drive-and-motor combinations provide

an optimized system in terms of ratings, performance, cost

and ease of use. Use Control Techniques’ FREE CTSelect

software to select system components or manually select

the system using the following steps.

1. Determine the application’s continuous and peak torque

requirements at various motor shaft speeds, then refer to

motor data tables and the visual-reference overview on

the facing page to help determine which motor family will

be most appropriate for the application.

2. Once the motor family is selected, refer to the Control

Techniques Servo Motors brochure to select a specic

motor that delivers the required torque and speed.

Make note of the continuous and peak current (Amps)

requirements of the selected motor.

3. Check the ratings tables on page 19 of this brochure to

select the drive model that delivers adequate continuous

and peak current for the selected motor.

4. Go to the Control Techniques Servo Motors brochure to

select motor power and feedback cables for the selected

drive/motor combination.

Check that the rotor inertia of the selected motor has a

ratio of <10 when calculated with the load inertia using

the following equation:

Load inertia / rotor inertia

Note: A gear reducer will reduce the load inertia based on

the following equation:

Reflected load inertia = load inertia / (gear ratio)

2

When specifying a motor system, be sure to consider such

factors as user-interface (HMI) options, braking resistors and

other options and accessories that will enhance the system’s

performance and value (see Options & Accessories brochure

for information and order codes).

Electronic Nameplates

Some motors tted with high-resolution SinCos or absolute

encoders are pre-loaded with the motor “electronic

nameplate” data during the manufacturing process. This

data can be read by Control Techniques’ Servo drives and

used to automatically optimize the drive settings. This

feature simplies commissioning and maintenance, ensures

consistent performance and saves time.

Example (using Control Techniques’ NT Motor family and Unidrive SP Servo drive family):

Step 1: The application requires 10 lb-in continuous torque.

The input voltage available is 230Vac.

Frame

Size

NT-207

NT-212

NT-320

110 100

NT Torque Range

7.5 18

12.5 37.5

20 56

Continuous Stall (lb-in) Peak (lb-in)

Step 2: The Control Techniques Servo Motors brochure lists

the NT-212 motor with 2.7A continuous torque and 6A peak.

NT Motor Specifications

Rated

Motor Model

NT-207 7.5 (.85) 1.7 3.6 11.1 39.1 5000 0.000094 (.106) 35 5.12 (.58) 3 (1.36)

NT-212 12.5 (1.4) 2.7 6 4.56 18.9 5000 0.000164 (.000018) 35 5.12 (.58) 4 (1.82)

NT-320 20 (2.2) 5.4 16.2 1.5 16.0 4000 0.000328 (.37) 29 3.50 (.40) 6 (2.72)

NT-320

medium inertia

NT-320 32 (3.6) 6.25 18.38 1.2 15.0 4000 0.000438 (.494) 36 4.73 (.53) 7.3 (3.31)

For complete information on Control Techniques’ Servo motor offering, refer to brochure number BRO-SRVOMTRS-1107.

Torque

lb-in (Nm)

18.0 (2.0) 5.4 16.2 1.5 16.0 4000 0.000558 (.63) 29 3.50 (.40) 6.9 (3.13)

Cont.

Stall

Current

Arms

Peak

Current

Arms

Motor

Resistance

Ohms

Motor

Inductance

mH

Step 3: Select the Unidrive SP drive with adequate current rating.

200-240Vac

+/- 10% 3Ø

(kW@220V,

hp@230V)

Frame Size

Order Code

SP0201 2.2 0.5 0.37 2.2 0.5 0.37

SP0202 3.1 0.75 0.55 3.1 0.75 0.55

0

SP0203 4 1 0.75 4 1 0.75

SP0204 5.7 1.5 1.1 5.7 1.5 1.1

SP0205 7.5 2 1.5 7.5 2 1.5

Normal Duty Heavy Dut y

Max

Continuous

Current (A)

Motor

Power

(hp)

Typical

Output

(kW)

Continuous

Current (A)

Max

Step 4: Select the appropriate power and feedback cables.

Max

Operating

Speed

rpm

Inertia

lb-in-sec

(kgm2)

2

Motor Ke

Vrms/krpm

Motor Kt

lb-in/Arms

(Nm/Arms)

Motor

Weight

lb (kg)

Motor

Power

(hp)

Typical

Output

(kW)

www.controltechniques.com

13

Page 14

Standard Features

SmartCard

The SmartCard is a memory device that is supplied with

every Unidrive SP and can be used to back-up parameter sets

and PLC programs and copy them from one drive to another.

• Parameter and program storage

• Simplify drive maintenance and commissioning

• Quick set-up for sequential build of machines

• Machine upgrades can be stored on a SmartCard and sent

to the customer for installation

Internal Dynamic Braking Resistors

During deceleration, the kinetic energy stored in the

spinning mass of the motor/load combination is converted

to electrical energy which recharges the drive’s DC bus.

Dynamic braking resistors provide a means of rapidly

dissipating that energy so that the drive does not fault from

the DC bus over voltage trip. The Ohmic value and power

rating of the braking resistor is a function of the drive type,

size and duty cycle of the application.

A zero-space braking resistor is available for heatsink

mounting on Unidrive SP frame sizes 0 to 2. These resistors

are designed for low-inertia loads commonly used in servo

type applications. For higher inertia loads, the heatsinkmounted resistor may not have enough braking capacity

and a larger external resistor may be required. No additional

thermal protection device is required with these heatsinkmounted resistor packages.

Frame

Size

0 70Ω 50W SM-HEATSINK-DBR0

1 75Ω 50W SM-HEATSINK-DBR1

2 37.5Ω 100W SM-HEATSINK-DBR2

DC

Resistance

Power

Rating Order Code

Unidrive SP-Compatible Encoders

Encoder Type

Quadrature incremental encoders with or without marker pulse

Quadrature incremental encoders with UVW commutation signals for

permanent magnet motors with or without marker pulse

Forward / reverse incremental encoders with or without marker pulse

Forward / reverse incremental encoders with UVW commutation signals

for permanent magnet motors with or without marker pulse

Frequency and direction incremental encoders with or without marker

pulse

Frequency and direction incremental encoders with UVW commutation

signals for permanent magnet motors with or without marker pulse

SinCos incremental encoders

Heidenhain sin/cos encoders with Endat comms for absolute position

Stegmann sin/cos encoders with Hiperface comms for absolute position

SinCos encoders with SSI comms for absolute position

SSI encoders (gray code or binary)

Endat comms only encoders

UVW commutation only encoders*

* This feedback device provides very low resolution feedback and should not be used for

applications requiring a high level of performance

(Drives larger than Size 2 do not have this option.)

14

www.controltechniques.com

Page 15

Options

The Unidrive SP provides application and system designers with an incredibly exible drive

platform which is easily modied by an extensive range of sophisticated snap-in SM option

modules for economical, space saving solutions. SM option modules install easily into any of

the three option slots on the Unidrive SP with no tools required. The I/O, feedback, motion

control, communication and application modules enable the Unidrive SP to provide an

optimized solution to meet your specic application requirements.

Option Description Order Code

Cloning and parameter

storage card

SMARTCARD

Conguration software CTSOFT

USB 485 communications cable CT-USB-CABLE

Base Drive

Conguration

and

Programming

Keypad to drive cable, 5ft SP-LCD-485-005

Keypad to drive cable, 10ft SP-LCD-485-010

Keypad to drive cable, 15ft SP-LCD-485-015

Keypad to drive cable, 25ft SP-LCD-485-025

Keypad to drive cable, 50ft SP-LCD-485-050

Keypad to drive cable

length in 5ft increments (max length

100ft)

, xxx is cable

SP-LCD-485-xxx

No keypad option Standard

LED keypad (SP size 1 to 6) SM-KEYPAD

Operator

Interface

LED keypad (SP size 0 only) KEYPAD-SP0

LCD keypad SM-KEYPAD-PLUS

Programmable HMI panels

See the Options &

Accessories brochure

Zero-space brake resistor Based on Drive

E-Stop duty braking resistor See page 13

Power

Accessories

Cyclic-duty braking resistor

Zero-space EMC lter Standard

External EMC lters

See the Options &

Accessories brochure

See the Options &

Accessories brochure

Ladder Logic and Function Blocks SYPT-LITE

Applications

Programming

Software

IEC 61131-3 (Ladder Logic,

Function Block, and text-based)

Motion Made Easy™

programming

SYPTPRO

POWERTOOLSPRO

Systems programming

(distributed control)

SM-APPS-PLUS

SM-Applications Plus

Programmable

SM Option

Modules

Systems programming

(centralized control)

SM-Applications Lite V2

System programming

and registration

SM-APPS-LITE-V2

SM-REGISTER

Dedicated motion control SM-EZMOTION

1 Can be ordered separately, but comes standard with Unidrive SP

2 Must be ordered separately

3 Provides an additional Modbus RTU port (in addition to one on drive)

4 Only one of these modules can be used in a Unidrive SP at a time

5 Available mid-2011

6 Where xxx is the length in feet in 5 foot increments up to 100ft

7 Requires an SM-Application module

1

2

2

Option Description Order Code

Modbus RTU follower Standard

Modbus RTU master SM-APPS-PLUS

Modbus RTU master SM-REGISTER

DeviceNet SM-DEVICENET

PROFIBUS DP SM-PROFIBUS-DP

PROFINET SM-PROFINET

Communications

SM Option

Modules

Ethernet (Modbus TCP/IP,

EtherNet IP)

INTERBUS-S SM-INTERBUS

CANopen SM-CANOPEN

SM-ETHERNET

CAN Interface SM-CAN

Ethernet (EtherCAT) SM-ETHERCAT

SERCOS SM-SERCOS

CTNet, CTSync SM-APPS-PLUS

CTNet, CTSync SM-REGISTER

2

Universal encoder feedback

SM-Universal Encoder Plus

Incremental encoder input

Feedback

SM Option

Modules

SM-Encoder Plus

Incremental encoder input and

output SM-Encoder Output

SM-UNI-ENCODER

SM-ENCODER-PLUS

SM-ENCODER-OUT

Plus

Resolver feedback SM-RESOLVER

Screw terminal connector SM-E TC

Extended analog and digital

I/O

SM-I/O-PLUS

Extra analog and digital I/O SM-I/O-LITE

Extended I/O SM-I/O-32

I/O SM Option

Modules

Extra I/O with Real-Time Clock/

Calendar

120/240 Vac I/O SM-I/O-120V

SM-I/O-TIMER

Double insulated extended I/O SM-I/O-PELV

Remote network I/O

See the Options &

Accessories brochure

+24 Vdc protected I/O SM-I/O-24V

Safe Torque Off (STO) Standard

Safety

4

Miscellaneous

High-speed

IEC 61800-5-2 functions

Conduit entry plates

SM-SAFETY

See the Options &

Accessories brochure

IP54 or IP55 cooling fans (Based on drive)

3

3

7

5

www.controltechniques.com

15

Page 16

Unidrive SP Additional Functionality

Unidrive SP Regenerative Mode

Unidrive SP can be congured to provide full four-quadrant

control of the power or drive system. In regenerative mode,

the Unidrive SP is capable of either supplying power to the

DC bus of the Unidrive controlling the motor or removing

power from the DC bus of the Unidrive SP controlling the

motor and returning it back to the supply.

• Unity or controllable input power factor

• Sinusoidal input current (low harmonic content)

Control Techniques engineers are experts at building

four-quadrant regenerative systems for use in many

applications where clean sinusoidal power can be put

back to the AC supply.

Unidrive SP Regenerative Solutions

Servo Motor

Positioning Using Closed-Loop Vector Motors

Unidrive SP motion programming platforms support closedloop vector motor positioning applications using “Motion

Made Easy,” PowerTools Pro software with the SM-EZMotion

option module, or using SyPTPro with the SM-Applications

option module. Many applications today can benet from

the advanced control capabilities, energy savings, cleanliness,

noise reduction and advanced communications that AC vector

motor positioning and the Unidrive SP can provide. Through

its One Source program, Control Techniques offers a wide

selection of closed-loop vector motors which feature an

economical incremental encoder and matched cabling. This

combination provides users with “plug-and-play” solutions

for hundreds of applications that can now be solved using

the latest AC motor and control technology to increase

performance while lowering overall costs.

Benefits

• Overcomes high-load inertia mismatches with use of larger

AC motors without the expense of large servo motors and/

or gear reducers

• Provides precise high-speed positioning when rapid accel/

decel rates are not required

• Eliminates environmental and maintenance issues

associated with hydraulic and pneumatic systems

• Plug-and-play eldbus integration into full-featured

control systems

• Integrated, scalable PLC functionality reduces panel space

and wiring costs

• Simplied programming, quick startup and advanced

diagnostics

• High-performance 2000-to-1 speed range

• Encoder-ready with cables

Control Techniques has the solution for any application requiring pure sinusoidal

regenerative output such as winder-to-winder or tensioner machines.

16

www.controltechniques.com

Control Techniques One Source Program

One Source provides access to key peripheral equipment

from world class suppliers. All products provided under this

program are only available with Emerson drive or soft starter

product/solutions.

For more information on

Control Techniques’ One Source

program, visit:

OneSource.cta@emerson.com

Page 17

Terminal Diagram

RS485

Pin # Function

1 120Ω Termination resistor

2 RX TX

3 Isolated 0V

4 +24V (100mA)

5 Isolated 0V

6 TX enable

7

RX\ TX\

RX\ TX\ (if termination resistors are

8

required, link to pin1)

Shell Isolated 0V

Control Terminals - Bottom Row

Pin # Function Description

21 0V Common

+24Vdc

22

Output

0V Common

23

24

Digital I/O 1

25

Digital I/O 2

26

Digital I/O 3

Digital Input 4

27

Digital Input 5

28

Digital Input 6

29

0V Common

30

Safe Torque

31

Off

41

Status Relay

Status Relay

42

Common for external

digital inputs

200mA max user supply

Common for external

digital inputs

0 to 24Vdc input, or 1

to 24Vdc, 240mA max

output digital I/O

0 to 24Vdc input, or 1

to 24Vdc, 240mA max

output digital I/O

0 to 24Vdc input, or 1

to 24Vdc, 240mA max

output digital I/O

0 to 24Vdc, 6kΩ digital

input

0 to 24Vdc, 6kΩ digital

input

0 to 24Vdc, 6kΩ digital

input

Common for external

digital inputs

0 to 24Vdc, 8µsec

typical/20µsec max

sample digital input

240Vac, 2A resistive

normally open

240Vac, 2A resistive

normally open

Power - Line/Motor

Pin # Function

PE Ground Connection

L1 Line In

L2 Line In

L3 Line In

U Motor Connection

V Motor Connection

W Motor Connection

GND Motor Ground

Connection shown for Size 1 unit

Bottom view

Power - DC Connections

Pin # Function

48V 48Vdc

- DC Bus

-DC

+DC + DC Bus

BR Brake Resistor

GND Ground

Connection shown for size 1 unit

Terminal locations may vary based on unit size

Control Terminals - Top Row

Pin # Function Description

1 0V Common

+24Vdc External

2

Input

3 0V Common

4 10Vdc source 10mA max reference supply

5 Analog Input 1+

6 Analog Input 1-

7 Analog Input 2

8 Analog Input 3

9 Analog Output 1

10 Analog Output 2

11 0V Common

Common for backup power

supply

60W, 24Vdc - Backup power

supply for control

Common for external analog

signals

±10Vdc 100kΩ - differential

analog input, non-inverting

input, 16 bit

±10Vdc 100kΩ - differential

analog input, inverting input,

16 bit

±10Vdc, 100kΩ or 0-20/

4-20mA, 200Ω single-ended

analog input 10 bit

±10Vdc, 100kΩ or 0-20/

4-20mA, 200Ω single-ended

analog input 10 bit, motor

thermistor input

±10Vdc or 0-20 / 4-20mA

single-ended analog output,

bi-polar, 10 bit

±10Vdc or 0-20 / 4-20mA

single-ended analog output,

bi-polar, 10 bit

Common for external analog

signals

Encoder

Signal Quadrature

Pin #

1 A Cos F

2 A/ Cosref F/

3 B Sin D, R

4 B/ Sinref D/, R/

5 Z Data Z

6 Z/ Data/ Z/

7 U n/c U

8 U/ n/c U/

9 V n/c V

10 V/ n/c V/

11 W Clock W

12 W/ Clock/ W/

13 +V +V +V

14 0V Common 0V Common 0V Common

15 Thermistor Thermistor Thermistor

ABS Pulse

www.controltechniques.com

17

Page 18

(448mm)

(162mm)

SP Control

Platform

Weight 3.3lbs

(368mm)

Size SP1

Weight 11lbs

(368mm)

(219mm)

Size SP2

Weight 15.5lbs

(368mm)

Size SP3

Weight 33lbs

(510mm)

Size SP4

Weight 66lbs

(820mm)

Size SP5

Weight 121lbs

(1131mm)

Size SP6

Weight 165.3lbs

Specifications and Dimensions

Specifications

Environment

Ambient Operating

Temperature

Cooling method Forced convection

Humidity 95% maximum non-condensing at 104 °F

Storage Temperature -40 to 122 °F (-40 to 50 °C)

Altitude 0 to 9,900ft (0 to 3000m). Derate 1% per 328ft

Vibration Tested in accordance with IEC 60068-2-6,

Mechanical Shock In accordance with IEC 60068-2-27

Enclosure NEMA 1 (IP 20), NEMA 12 (IP 54) through-panel

Electromagnetic

Immunity

Electromagnetic

Emissions

AC Supply

Requirements

Voltage 200 to 240Vac ±10%

Phase 3Ø (SP size Zero: 200 to 240V 1Ø or 3Ø)

Phase Imbalance 2% negative phase sequence (equivalent to 3%

Frequency 48 to 65Hz

Input Power Factor Displacement 0.97

Control

Carrier Frequency 3, 4, 6, 8, 12,16kHz - Panel Mount drives

Dimensions

(112mm)

www.controltechniques.com

18

32 to 104 °F (0 to 40 °C)

32 to 122 °F (0 to 50 °C) with derating

(40 °C)

(100m) between 3280ft (1000m) and 9,900ft

(3000m)

2-29, 2-64

mounting

In compliance with EN 61800-3 and

EN 61000-6-2, and complies with

EN61800-3 2nd environment with built-in lter

In compliance with EN61000-6-4 when the

recommended RFI lter is used and EMC

installation guidelines are followed

380 to 480Vac ±10%

500 to 575Vac ±10%

500 to 690Vac ±10%

voltage imbalance between phases)

3, 4, 6kHz - Free Standing and SPM drives

4.4in

17.6in

6.4in

6.1in

(155mm)

8.6in

14.5in

Size SP0

Weight 4.6lbs

(249.7mm)

9.8in

8.9in

(226mm)

2.4in

(62mm)

M

10 min

9.8in

(250mm)

10.2in

(260mm)

12.7in

(322mm)

14.5in

www.controltechniques.com

3.9in

(100mm)

8.6in

(219mm)

12.2in

(310mm)

14.5in

11.7in

(298mm)

Output Frequency 0 to 3000Hz (Open-loop)

Output Speed 0 to 40,000rpm (Closed-loop)

Frequency Accuracy ±0.01% of full scale

Frequency Resolution 0.001Hz

Analog Input 10 bit + sign (Qty 2); 16 bit + sign (Qty 1)

Serial

Communications

Braking DC injection braking (stopping and holding) and

Control Power Ride

Through

Protection

DC Bus

Undervoltage Trip

DC Bus

Overvoltage Trip

MOV Voltage

Transient Protection

Drive Overload Trip Current overload value is exceeded

Instantaneous

Overcurrent Trip

Phase Loss Trip DC bus ripple threshold exceeded

Overtemperature

Tri ps

Short Circuit Trip Protects against output phase to phase fault

Ground Fault Trip Protects against output phase to ground fault

Motor Thermal Trip Electronically protects the motor from

12.2in

(310mm)

20.1in

11.7in

(298mm)

resolution

2-wire RS485

4-wire RS232 or RS485 with SM-APPS module

Protocol is ANSI x 3.28-2.5-A4, or Modbus RTU

Baud rate 300 to 115,200

dynamic braking transistor standard.

Up to 1 second depending on inertia and decel

time

175 / 330 / 435Vdc (approximately

124 / 233 / 307Vac line voltage)

415 / 830 / 990Vdc (approximately 293 / 587 /

700Vac line voltage)

120 Joules, 1500Vdc clamping (line-to-line);

140 Joules, 1815Vdc clamping (line-to-ground)

Programmable for Normal Duty or Heavy Duty,

open-loop or closed-loop operation

225% of drive rated current

Drive heatsink, control board, and option

module(s) monitoring

overheating due to loading conditions

12.2in

(310mm)

44.5in

32.3in

11.7in

(298mm)

Page 19

Ratings

Normal Duty Heavy Dut y

Max

Motor

Continuous

Current (A)

Power

(hp)

Typical

Output

(kW)

Continuous

Current (A)

Max

Frame Size

200-240Vac

+/- 10% 3Ø

(kW@220V,

hp@230V)

Order Code

SP0201 2.2 0.5 0.37 2.2 0.5 0.37

SP0202 3.1 0.75 0.55 3.1 0.75 0.55

0

SP0203 4 1 0.75 4 1 0.75

SP0204 5.7 1.5 1.1 5.7 1.5 1.1

SP0205 7.5 2 1.5 7.5 2 1.5

SP1201 5.2 1.5 1.1 4.3 1 0.75

SP1202 6.8 2 1.5 5.8 1.5 1.1

1

SP1203 9.6 3 2.2 7.5 2 1.5

SP1204 11 3 3 10.6 3 2.2

SP2201 15.5 5 4 12.6 3 3

2

SP2202 22 7.5 5.5 17 5 4

SP2203 28 10 7.5 25 7.5 5.5

SP3201 42 15 11 31 10 7.5

3

SP3202 54 20 15 42 15 11

SP4201 68 25 18.5 56 20 15

4

SP4202 80 30 22 68 25 18.5

SP4203 104 40 30 80 30 20

SP5201 130 50 37 105 40 30

5

SP5202 154 60 45 130 50 37

Normal Duty Heavy Dut y

Max

Motor

Continuous

Current (A)

Power

(hp)

Typical

Output

(kW)

Continuous

Current (A)

Max

Frame Size

380-480Vac

+/- 10% 3Ø

(kW@400V,

hp@460V)

Order Code

SP0401 1.3 0.5 0.37 1.3 0.5 0.37

SP0402 1.7 0.75 0.55 1.7 0.75 0.55

0

SP0403 2.1 1 0.75 2.1 1 0.75

SP0404 3 1.5 1.1 3 1.5 1.1

SP0405 4.2 2 1.5 4.2 2 1.5

SP1401 2.8 1.5 1.1 2.1 1 0.75

SP1402 3.8 2 1.5 3 1.5 1.1

SP1403 5 3 2.2 4.2 2 1.5

1

SP1404 6.9 5 3 5.8 3 2.2

SP1405 8.8 5 4 7.6 5 3

SP1406 11 7.5 5.5 9.5 5 4

SP2401 15.3 10 7.5 13 7.5 5.5

SP2402 21 15 11 16.5 10 7.5

2

SP2403 29 20 15 25 15 11

SP2404 29 20 15 29 20

SP3401 35 25 18.5 32 25 15

3

SP3402 43 30 22 40 30 18.5

SP3403 56 40 30 46 30 22

SP4401 68 50 37 60 40 30

4

SP4402 83 60 45 74 50 37

SP4403 104 75 55 96 75 45

SP5401 138 100 75 124 100 55

5

SP5402 168 125 90 156 125 75

SP6401 205 150 110 180 150 90

6

SP6402 236 200 132 210 150 110

Motor

Power

(hp)

Motor

Power

(hp)

Typical

Output

(kW)

Typical

Output

(kW)

15

Frame Size

200-240Vac

+/- 10% 1Ø

(kw@220V,

hp@230V)

Order Code

Normal Duty Heavy Dut y

Max

Motor

Continuous

Current (A)

Power

(hp)

Typical

Output

(kW)

Continuous

Current (A)

Max

Motor

Power

(hp)

Typical

Output

(kW)

SP0201 2.2 0.5 0.37 2.2 0.5 0.37

SP0202 3.1 0.75 0.55 3.1 0.75 0.55

0

SP0203 4 1 0.75 4 1 0.75

SP0204 5.7 1.5 1.1 5.7 1.5 1.1

SP0205 7.5 2 1.5 7.5 2 1.5

500-575Vac

+/- 10% 3Ø

(kW@575V,

hp@575V)

Frame Size

Order Code

SP3501 5.4 3 3 4.1 2 2.2

SP3502 6.1 5 4 5.4 3 3

SP3503 8.4 7.5 5.5 6.1 5 4

3

SP3504 11 10 7.5 9.5 7.5 5.5

SP3505 16 15 11 12 10 7.5

SP3506 22 20 15 18 15 11

SP3507 27 25 18.5 22 20 15

SP4603* 36 30 22 27 25 18.5

SP4604* 43 40 30 36 30 22

4

SP4605* 52 50 37 43 40 30

SP4606* 62 60 45 52 50 37

SP5601* 84 75 55 63 60 45

5

SP5602* 99 100 75 85 75 55

SP6601* 125 125 90 100 100 75

6

SP6602 144 150 110 125

500-690Vac

+/- 10% 3Ø

(kW@690V,

hp@690V)

Frame Size

Order Code

SP4601 22 25 18.5 19 20 15

SP4602 27 30 22 22 25 18.5

SP4603 36 40 30 27 30 22

4

SP4604 43 50 37 36 40 30

SP4605 52 60 45 43 50 37

SP4606 62 75 55 52 60 45

SP5601 84 100 75 63 75 55

5

SP5602 99 125 90 85 100 75

SP6601 125 150 110 100 125 90

6

SP6602 144 175 132 125 150 110

Notes: Select model on actual motor full load current. *The same model can be used on a

575V or a 690V supply, and has two different output ratings. For example: At Normal

Duty, SP4603 is suitable for a 30hp output motor on a 575V supply and a 40hp output

motor on a 690V supply. Can be used on IT supplies - all voltages, Grounded delta

supplies - all voltages except 690V

Normal Duty Heavy D uty

Suitable for most

applications, current

overload of 110% for 165

seconds is available. Where

motor rated current is

less than the drive rated

continuous current, higher

overloads are achieved.

Normal Duty Heavy Dut y

Max

Motor

Continuous

Current (A)

Power

(hp)

Typical

Output

(kW)

Max

Continuous

Current (A)

Motor

Power

(hp)

125 90

Normal Duty Heavy Dut y

Max

Motor

Continuous

Current (A)

Power

(hp)

Typical

Output

(kW)

Max

Continuous

Current (A)

Motor

Power

(hp)

Suitable for demanding applications, current overload of 175%

for 40 seconds is available for frame size 0 - 5 in closed-loop,

150% for 60 seconds in open-loop, and size 0 single phase

current overload is 150% for 60 seconds. For frame size 6 current

overload of 150% for 60 seconds is available in closed-loop

and 129% for 97 seconds in open-loop. Where the motor rated

current is less than the drive rated continuous current higher

overloads (200% or greater) are achieved.

Typical

Output

(kW)

Typical

Output

(kW)

www.controltechniques.com

19

Page 20

............

............

............

Driving Technology...

AMERICAS

Toll-free: 1-800-893-2321

info.cta@emerson.com

Minneapolis Drive Center

Headquarters

T: 952 995 8000

Calgary Drive Center

T: 403 253 8738

Charlotte Application Center

T: 704 424 9811

Cleveland Drive Center

T: 216 901 2400

Grand Island

Americas Service Center

T: 716 774 1193

Los Angeles Application Center

T: 562 943 0300

Portland Drive Center

T: 503 266 2094

Providence Application Center

T: 401 392 4256

Toronto Application Center

T: 905 948 3402

Salt Lake City Application Center

T: 801 566 5521

LATIN AMERICAN & CARIBBEAN

REGION

Miami Sales Ofce

T: 305 818 8897

For current authorized distributors

or resellers, please check the Control

Techniques web site.

www.controltechniques.com

BRAZIL

São Paulo Application Center

T: +55 11 3618 6688

controltechniques.br@emerson.com

P/N BRO-USPSRVO-1107 08/11

*Operated by sister company,

®

Leroy Somer

AUSTRALIA

Melbourne Application Center

T: +613 973 81777

controltechniques.au@emerson.com

Sydney Drive Center

T: +61 2 9838 7222

controltechniques.au@emerson.com

AUSTRIA

Linz Drive Center

T: +43 7229 789480

controltechniques.at@emerson.com

BELGIUM

Brussels Drive Center

T: +32 1574 0700

controltechniques.be@emerson.com

CHINA

Shanghai Drive Center

T: +86 21 5426 0668

controltechniques.cn@emerson.com

Beijing Application Center

T: +86 10 856 31122 ext 820

controltechniques.cn@emerson.com

CZECH REPUBLIC

Brno Drive Center

T: +420 511 180111

controltechniques.cz@emerson.com

DENMARK

Copenhagen Drive Center

T: +45 4369 6100

controltechniques.dk@emerson.com

FRANCE*

Angoulême Drive Center

T: +33 5 4564 5454

controltechniques.fr@emerson.com

GERMANY

Bonn Drive Center

T: +49 2242 8770

controltechniques.de@emerson.com

Chemnitz Drive Center

T: +49 3722 52030

controltechniques.de@emerson.com

Darmstadt Drive Center

T: +49 6251 17700

controltechniques.de@emerson.com

GREECE*

Athens Application Center

T: +0030 210 57 86086/088

controltechniques.gr@emerson.com

HOLLAND

Rotterdam Drive Center

T: +31 184 420555

controltechniques.nl@emerson.com

HONG KONG

Hong Kong Application Center

T: +852 2979 5271

controltechniques.hk@emerson.com

............

www.controltechniques.com

MALAYSIA

Kuala Lumpur Drive Center

T: +603 5634 9776

controltechniques.my@emerson.com

INDIA

Chennai Drive Center

T: +91 44 2496 1123/

2496 1130/2496 1083

controltechniques.in@emerson.com

Pune Application Center

T: +91 20 2612 7956/2612 8415

controltechniques.in@emerson.com

New Delhi Application Center

T: +91 112 2581 3166

controltechniques.in@emerson.com

IRELAND

Newbridge Drive Center

T: +353 45 448200

controltechniques.ie@emerson.com

ITA LY

Milan Drive Center

T: +39 02575 751

controltechniques.it@emerson.com

Reggio Emilia Application Center

T: +39 02575 751

controltechniques.it@emerson.com

Vicenza Dri ve Center

T: +39 0444 933400

controltechniques.it@emerson.com

SOUTH KOREA

Seoul Application Center

T: +82 2 3483 1605

controltechniques.kr@emerson.com

REPUBLIC OF SOUTH AFRICA

Johannesburg Drive Center

T: +27 11 462 1740

controltechniques.za@emerson.com

Cape Town Application Center

T: +27 21 556 0245

controltechniques.za@emerson.com

RUSSIA

Moscow Application Center

T: +7 495 981 9811

controltechniques.ru@emerson.com

SINGAPORE

Singapore Drive Center

T: +65 6891 7600

controltechniques.sg@emerson.com

SLOVAKIA

Emerson A.S

T: +421 32 7700 369

controltechniques.sk@emerson.com

SPAIN

Barcelona Drive Center

T: +34 93 680 1661

controltechniques.es@emerson.com

Bilbao Application Center

T: +34 94 620 3646

controltechniques.es@emerson.com

Valencia Drive Center

T: +34 96 154 2900

controltechniques.es@emerson.com

SWEDEN*

Stockholm Application Center

T: +468 554 241 00

controltechniques.se@emerson.com

SWITZERLAND

Lausanne Application Center

T: +41 21 637 7070

controltechniques.ch@emerson.com

Zurich Drive Center

T: +41 56 201 4242

controltechniques.ch@emerson.com

TAIWAN

Taipei Application Center

T: +886 2 8161 7695

controltechniques.tw@emerson.com

THAILAND

Bangkok Drive Center

T: +66 2962 2092 99

controltechniques.th@emerson.com

TURKEY

Istanbul Drive Center

T: +90 216 4182420

controltechniques.tr@emerson.com

UAE*

Emerson FZE

T: +971 4 8118100

ct.dubai@emerson.com

UNITED KINGDOM

Telford Drive Center

T: +44 1952 213700

controltechniques.uk@emerson.com

© Control Techniques 2011. The information contained in this brochure is for guidance only and does not form part of any contract. The accuracy cannot be guaranteed

as Control Techniques has an ongoing process of development and reserves the right to change the specication of its products without notice. Printed in the USA

.

Loading...

Loading...