Page 1

026-1720 Rev 4 06-APR-2010

MultiFlex ESR Installation and

Operation Manual

Page 2

Page 3

Computer Process Controls, Inc.

1640 Airport Road Suite #104

Kennesaw, GA 31044

Phone 770-425-2724

Fax 770-425-9319

ALL RIGHTS RESERVED

The information contained in this manual has been carefully checked and is believed

to be accurate. However, Computer Process Controls, Inc. assumes no responsibility

for any inaccuracies that may be contained herein. In no event will Computer Process

Controls, Inc. be liable for any direct, indirect, special, incidental, or consequential

damages resulting from any defect or omission in this manual, even if advised of the

possibility of such damages. In the interest of continued product development, Computer Process Controls, Inc. reserves the right to make improvements to this manual,

and the products described herein, at any time without notice or obligation.

FCC COMPLIANCE NOTICE

This device complies with Class B of Part 15 of the FCC Rules.

Page 4

Page 5

Table of Contents

1 INTRODUCTION.......................................................................................................................................................... 1

1.1. M

ULTIFLEX ESR AND ESR-8 BOARD DIFFERENCES ................................................................................................... 1

1.1. RS-485 I/O Network................................................................................................................................................. 1

1.1. Center-Tapped Transformer.................................................................................................................................... 1

1.1. Molex Connectors (Board P/N 810-1398)............................................................................................................... 1

1.1. Hand-Held Terminal (HHT) .................................................................................................................................... 1

1.1. Snap-Track Mounting .............................................................................................................................................. 1

1.2. M

ULTIFLEX ESR MOLEX CONNECTOR BOARD (DISCONTINUED) ............................................................................... 2

2 INSTALLATION........................................................................................................................................................... 2

2.1. P

ANEL MOUNTING AND HEAT DISSIPATION ................................................................................................................ 2

2.2. S

NAP-TRACK INSTALLATION........................................................................................................................................ 2

3 WIRING.......................................................................................................................................................................... 2

3.1. P

OWER.......................................................................................................................................................................... 2

3.2. V

ALVE WIRING............................................................................................................................................................. 3

3.2.1. Molex Connector (Discontinued) Board Wiring................................................................................................... 3

4 SETTING THE TERMINATING RESISTANCE JUMPERS ................................................................................. 4

5 SETTING THE NETWORK ADDRESS AND BAUD RATE .................................................................................. 4

6 SOFTWARE OVERVIEW........................................................................................................................................... 5

6.1. P

ROGRAMMING E2 VERSION 2.21 AND ABOVE ........................................................................................................... 6

6.2. S

TEP 1: ADD A MULTIFLEX ESR................................................................................................................................. 6

6.3. S

TEP 2: ADD A STANDARD CIRCUIT............................................................................................................................. 7

6.4. S

TEP 3: ASSOCIATE THE MULTIFLEX ESR......................................................................................................... .......... 7

6.5. S

TEP 4: SET UP THE STANDARD CIRCUIT .................................................................................................................... 8

6.6. S

TEP 5: SET UP THE MULTIFLEX ESR....................................................................................................................... 10

7 VALVE ZEROING ...................................................................................................................................................... 12

7.1. S

TEP 1......................................................................................................................................................................... 12

7.2. S

TEP 2......................................................................................................................................................................... 12

8 HAND-HELD TERMINAL........................................................................................................................................ 12

8.1. O

VERVIEW .................................................................................................................................................................. 12

8.2. S

CREENS ..................................................................................................................................................................... 13

8.2.1. Main Screen ........................................................................................................................................................ 13

8.2.2. Output Status Screens ......................................................................................................................................... 13

8.2.3. Alarm Status Screens .......................................................................................................................................... 13

8.2.4. Main Select Screen.............................................................................................................................................. 14

8.2.5. Valve Configuration Screens .............................................................................................................................. 14

8.2.6. Network Screen................................................................................................................................................... 14

VALVE SPECIFICATIONS TABLES............................................................................................................................15

E

MERSON FLOW CONTROLS STEPPER VALVES...................................................................................................................15

S

PORLAN (PARKER) STEPPER VALVES................................................................................................................................15

MultiFlex ESR I&O Manual Table of Contents • v

Page 6

1Introduction

8

3

7

24VAC CT 75 VAC Power Input

Valve Connectors (8)

I/O Network Input

Termination Jumpers

Network Address Switches

General Status LED

1

5

2

3

4

6

7

8

HHT Jack

TX and RX LEDs

9

10

Open LED (8)

Close LED (8)

9

10

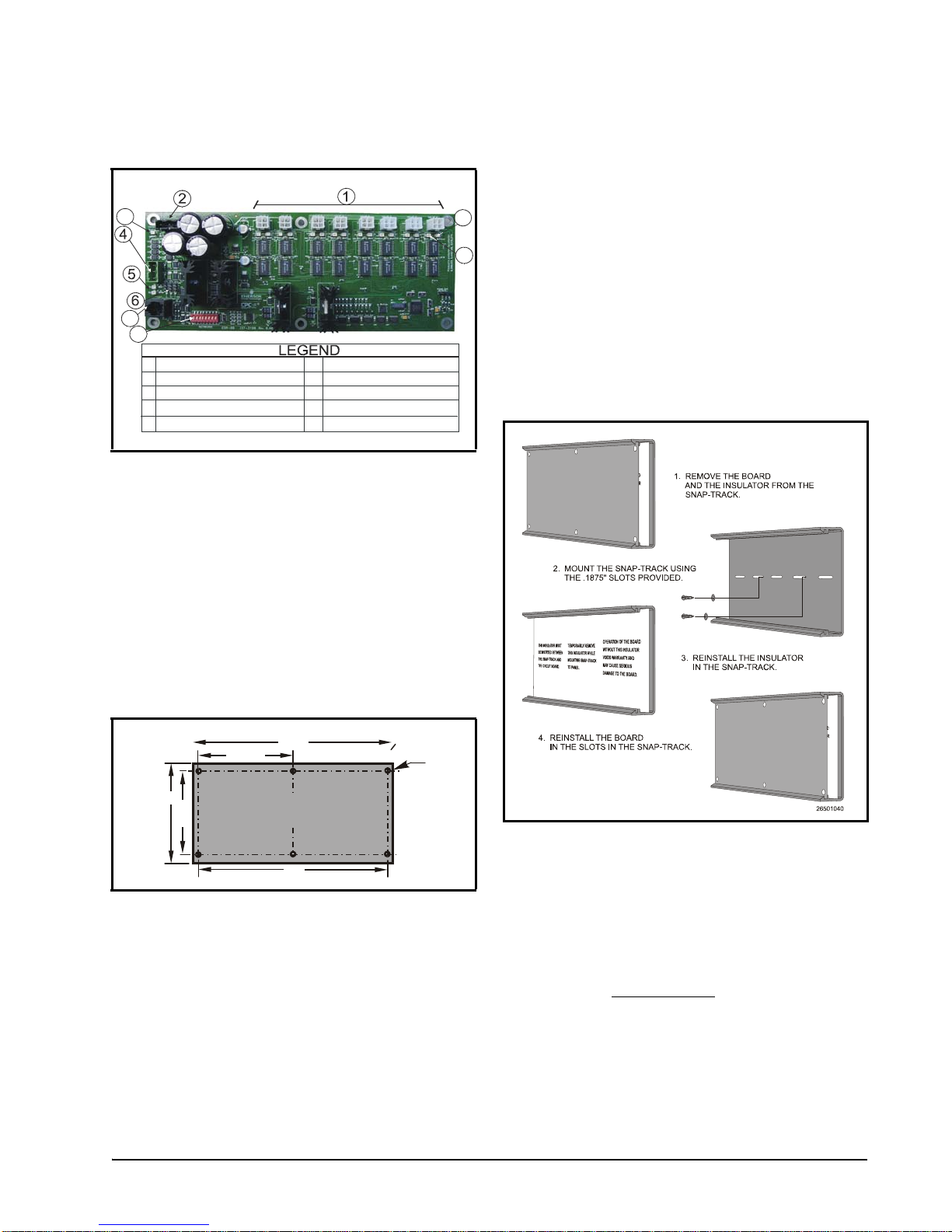

1.1. MultiFlex ESR and ESR-8 Board

Differences

The MultiFlex ESR Valve Regulator board (P/N

810-3199), shown in (Figure 1-1), is an RS-485

I/O Network electronic stepper valve regulator

capable of driving up to eight stepper motor

valves, which are typically used to control temperature.

RS-485 I/O Network

The MultiFlex ESR communicates with the E2

directly over the RS-485 I/O network, unlike the

previous version of the board, which communicated with the controller over the Echelon network.

Center-Tapped Transformer

For power, a Class 2, 80VA 24VAC centertapped transformer is required for each MultiFlex ESR board. (Previous board versions did

not require a center-tapped power source.)

Molex Connectors (Board P/N 810-1398)

The discontinued MultiFlex ESR board’s valve

outputs are four-contact molex connectors

instead of the screw terminals. Valve cables having a four-contact molex connector are plugged

directly into the board. This board has been discontinued and replaced with the new MultiFlex

ESR board version (P/N 810-3199).

Hand-Held Terminal (HHT)

Figure 1-1 - MultiFlex ESR Board Layout

When controlling ECT Flow valves, the MultiFlex ESR will detect overcurrent, open wire,

stuck valve situations, and generate the appropriate alarms. For non-ECT Flow valves, the MultiFlex ESR will only detect overcurrent situations

and generate an alarm. (See Section 8.2.3.,

Alarm Status Screens for details on alarm

descriptions.)

Set configuration parameters, setpoints, and failsafe conditions of each valve with the HHT. By

using the HHT, each valve output can be set separately with a valve step rate and the total number of steps from closed to fully open.

Snap-Track Mounting

The MultiFlex ESR board fits into the standard

CPC 4" I/O board snap-track for mounting.

The MultiFlex ESR uses suction side variableposition evaporator regulators (ESRs) to vary

evaporator pressure for an entire circuit and is an

alternative to mechanical EPR control.

The MultiFlex ESR receives input data from a

CPC E2 controller (via the I/O Network) and

then regulates the stepper valves according to

the data from the E2.

1 • MultiFlex ESR I&O Manual 026-1720 Rev 4 06-APR-2010

Page 7

1.2. MultiFlex ESR Molex Connec-

24VAC CT 75 VAC Power Input

Valve Connectors (8)

I/O Network Input

Termination Jumpers

Network Address Switches

General Status LED

1

5

2

3

4

6

7

8

HHT Jack

TX and RX LEDs

8

3

7

9

10

Open LED (8)

Close LED (8)

9

10

3.5”

4.00”

10.00"

4.75”

TYP 2 PL

MULTIFLEX ESR BOARD

WEIGHT: 9.4 OZ.

O 0.220”

TYP 6 PL

9.5”

tor Board (Discontinued)

Figure 1-2 - MultiFlex ESR Molex Connector Board Layout Discontinued (P/N

810-3198)

2 Installation

that enclosure with the MultiFlex ESR, you may

need to ventilate the enclosure by installing air

circulation fans or other devices to aid in heat

dissipation.

2.2. Snap-Track Installation

Boards not supplied with an enclosure are supplied with a snap-track for easy installation. The

insulation sheet and I/O board must be removed

from the track before the track is mounted. The

snap-track is mounted using the 0.1875” mounting slots. Figure 2-2 shows this installation procedure:

The MultiFlex ESR control board is designed to

be located in a central location, preferably near

the valves it is driving. Figure 2-1 shows the

mounting dimensions of the MultiFlex ESR

board:

Figure 2-1 - MultiFlex ESR Board Dimensions

2.1. Panel Mounting and Heat Dissipation

The MultiFlex ESR can generate a substantial

amount of heat when it draws up to a maximum

of 80 VA during operation. The MultiFlex ESR

is rated for a maximum ambient temperature of

65°C (150°F); therefore, depending on the size

of the enclosure and what other devices are in

MultiFlex ESR Molex Connector Board (Discontinued) Installation • 2

Figure 2-2 - MultiFlex ESR Snap-Track Installation

3 Wiring

3.1. Power

Each MultiFlex ESR board requires a Class 2,

80VA 24VAC center-tapped

power. The power connector (labeled J12) is

located in the top left corner of the board.

transformer for

Page 8

CPC transformer (P/N 640-0080) is a multi-

WIRING FOR 640-0080, 80VA Transformer

SECONDARY SIDE

Use 24VAC Center-Tapped Transformer

PRIMARY SIDE

240 208

C

120

(

N

E

U

T

R

A

L

)

(

H

O

T

)

120/208/240 VAC

L2

L1

Three-conductor non-shielded cables

are the recommended wire

for connecting between the

center-tapped transformer

and I/O boards.

Power Wiring Types:

14 AWG Belden 9495

18 AWG Belden 9493

24V CT 24V

AC1

GND

AC2

AC1

AC2

24VAC Center-Tapped

Earth ground the

GND (center-tapped)

terminal of each board

GND

BLU

R BLK

W

Wire Color Legend on

Each Valve Connector (8)

ECT Flow

Stepper Valve

MultiFlex ESR Board w/ Eight

Screw Terminal Connectors

(P/N 810-3199)

Stepper Valve

Harness

WHITE

BLACK

RED

BLUE

Match wire colors to

silk screen legend on

board terminals

tapped primary transformer that may be used

with the MultiFlex ESR board.

Refer to Figure 3-1 and follow the instructions

below for transformer power wiring:

1. Connect the three wires from the secondary

side of the transformer to the power connector. The AC should be run with a minimum of

18 AWG wire up to 10 feet, 16 AWG up to 20

feet, or 14 AWG up to 30 feet.

2. Connect 24VAC to AC1 and AC2.

3. Connect the center tap (CT) of the transformer to the GND center terminal of the power

connector.

4. Attach an additional 14 AWG or larger wire

from the center GND terminal to solid earth

ground. Keep the wire as short as possible, 6"

or less is preferred, and should be completed

for each board.

the cable and cable harnesses that are supplied

with the valves.

Figure 3-2 - Valve Connector Wi re Color Indicator

Figure 3-1 - Power Wiring - Center -Tapped Transformer

3.2. Valve Wiring

The stepper valves are wired to the board by

connecting the stepper valve harness to one of

the eight screw terminal connectors along the

top of the board (Figure 3-3) and matching the

wire colors to the legend on the connectors. Use

3 • MultiFlex ESR I&O Manual 026-1720 Rev 4 06-APR-2010

Figure 3-3 - ECT Flow Valve and New Board W iring Diagram

For Sporlan valves, match all wire colors except

the green wire. Instead, connect the green wire

to the silk screen blue wire legend (Figure 3-2).

3.2.1. Molex Connector (Discontinued)

Board Wiring

The stepper valves are wired to the board by

connecting the stepper valve molex connector to

one of the eight molex connectors along the top

of the board (Figure 3-4). Use the cable and

cable harnesses that are supplied with the valves.

NOTE: A valve cable harness may not be longer than 150 feet.

Page 9

Figure 3-4 - ECT Flow Valve and Old Board Wiring

RS485 I/O NET

NO TERMINATION

(Jumpers in the

DOWN position)

JP2 JP3

JP4

TERMINATION

(Jumpers in the

UP position)

JP2

JP3

JP4

For retrofits or stepper valve harnesses without a

mating molex connector, use the MultiFlex ESR

adapter cable (P/N 335-3275). Crimp-type

waterproof splices should be used to make the

connections.

For Sporlan valves used with these discontinued

boards, match all wire colors except the blue

wire. Instead, connect the blue wire to the Sporlan green wire.

proper terminating resistance jumper settings for

the MultiFlex ESR board.

Figure 4-1 - Daisy Chain Termination Jumper Settings

For more information about network configuration and termination, see the I/O Network wiring

section in your site controller’s user manual.

CAUTION: Always have the JP1 jumper

(located on the far right side of the board

opposite the Termination jumpers) set to the

Normal

correctly.

position, or the board will not operate

4 Setting the Terminat-

ing Resistance Jumpers

All MultiFlex ESR boards have a set of terminating resistance jumpers (one jumper for each

wire lead). These jumpers are labeled JP2, JP3,

and JP4 on the MultiFlex ESR board.

Set the termination jumpers UP (JP2, JP3, JP4)

if at either end of a daisy chain. Otherwise, set

jumpers DOWN.

The purpose of the jumpers is to indicate the two

ends, or termination points, of the segment. On a

daisy chain, one device at the beginning and one

device on the end must be terminated by placing

all three termination jumpers in the UP position.

All other devices on the daisy chain must be set

to the DOWN position. Figure 4-1 shows the

5 Setting the Network

Address and Baud Rate

Set the network address on the first five rockers

of the dip switch (labeled S1) on the MultiFlex

ESR board. Set the network baud rate using

rockers 6 and 7.

Valve Wiring Setting the Terminating Resistance Jumpers • 4

Page 10

Figure 5-1 - Network Address Settings

S1

Set the network address

using the first 5 rockers

of dip switch S1.

Valid address range 1-31.

2345678

1

ON

2345678

1

ON

2345678

1

ON

2345678

1

ON

BOARD 1 BOARD 2 BOARD 3 BOARD 4

2345678

1

ON

2345678

1

ON

2345678

1

ON

2345678

1

ON

BOARD 5

BOARD 6 BOARD 7 BOARD 8

2345678

1

ON

2345678

1

ON

2345678

1

ON

2345678

1

ON

BOARD 9 BOARD 10 BOARD 11 BOARD 12

2345678

1

ON

2345678

1

ON

2345678

1

ON

2345678

1

ON

BOARD 13 BOARD 14 BOARD 15 BOARD 16

2345678

1

ON

2345678

1

ON

2345678

1

ON

2345678

1

ON

BOARD 17 BOARD 18 BOARD 19 BOARD 20

2345678

1

ON

2345678

1

ON

2345678

1

ON

BOARD 21 BOARD 22 BOARD 23

2345678

1

ON

BOARD 24

2345678

1

ON

2345678

1

ON

2345678

1

ON

2345678

1

ON

BOARD 25 BOARD 26 BOARD 27 BOARD 28

2345678

1

ON

BOARD 29

2345678

1

ON

2345678

1

ON

BOARD 30

BOARD 31

Figure 5-2 - Baud Rate Settings

6 Software Overview

The MultiFlex ESR board is intended to interface closely with E2’s Standard Circuit application. Once a valve on the MultiFlex ESR board

has been associated with a Standard Circuit, the

Standard Circuit assumes control of the valve’s

position. The Standard Circuit must be specifically configured to control a MultiFlex ESR

5 • MultiFlex ESR I&O Manual 026-1720 Rev 4 06-APR-2010

valve so that the advanced capabilities provided

with the MultiFlex ESR will be enabled.

Valve Rescaling

The Standard Circuit has an enhanced control

strategy when it is configured to control a MultiFlex ESR valve. As with previous ESR control,

a PID algorithm is used to position the valve

during refrigeration mode in order to maintain

the circuit temperature setpoint. In addition, a

minimum and maximum valve percentage may

be specified. When this is used, the PID output

(0-100%) is rescaled to a control range between

the minimum and maximum valve percentage

parameters. This may be useful in situations

where the valve is slightly oversized and tends to

continuously overshoot the temperature setpoint.

Pulldown Mode

A new Standard Circuit control state named

Pulldown has been added. The Pulldown state is

optional and is, by default, disabled. When

enabled, the Standard Circuit will go into Pulldown following a defrost cycle or a case wash.

Also, if a door switch is configured and refrigeration mode is temporarily suspended due to the

door opening (such as with a walk-in box), a

Pulldown will be initiated when the door closes.

The Pulldown mode simply forces the valve to a

fixed position, as specified with the Pulldown

Percent parameter. The circuit will stay in Pulldown until the case temperature reaches the setpoint or the maximum time allowed in Pulldown

has been exceeded. The maximum time in Pulldown defaults to zero, which disables the Pulldown mode. By setting this to a valid time (up to

2 hours), Pulldown mode will be enabled.

Valve Failsafe

The Standard Circuit has additional valve failsafe capability. If a control failure occurs, such

as a loss of the control temperature sensor, the

valve will be instructed to go to a failsafe position. As with previous ESR control, the valve

may be configured to go to a fixed position, as

specified by the Temp Fail EEPR % parameter.

However, a ne w Valve Daily A verage Position is

now being calculated for MultiFlex ESR and

Page 11

ECT Flow valves. The valve may be configured

to go to this position during periods of control

failure. The Valve Daily Average Position is

determined by averaging the position of the

valve only during the refrigeration state. While

in Defrost or other circuit states, the average

position will not be updated. At midnight of each

new day, the Valve Daily Average Position is

updated to reflect the average position calculated

throughout the previous day. In addition, if a

communication failure occurs, the valve will be

instructed to go to a different failsafe position

(Comm Fail EEPR %) or for ECT Flow valves,

the Valve Daily Average Position may be used.

Lead Circuit

When a MultiFlex ESR circuit is defined as the

lead circuit in its associated Suction Group and

suction float has been enabled, the Standard Circuit will suspend normal PID control of the

valve while in the refrigeration state. Instead, the

Standard Circuit will force the valve to full open.

By doing this, the associated Suction Group will

be able to float the suction setpoint to the highest

possible value, while still maintaining the circuit

temperature setpoint.

Valve Alarms

When a Standard Circuit is associated with a

MultiFlex ESR valve, it also processes alarms

associated with that valve, including Stuck

Valve, Fault Wire, and Fault Overload. Stuck

Valve and Fault Wire are only ECT Flow valve

alarms.

3. Associate MultiFlex ESR - Assign the Multi-

Flex ESR to standard circuit(s) so the valve on

the board is associated or "mapped" to a circuit,

which will enable valve control. The association

creates auto hookup of circuit valve control and

alarm parameters between the circuit and the

MultiFlex ESR application. This association

should be completed prior to Step 4 - Standard

Circuit Setup to minimize the set up of standard

circuit(s) for MultiFlex ESR.

4. Standard Circuit Setup - A Standard Circuit

application must be set up as normal, (with all

case types, setpoints, and other parameters

defined) except

egy; the Temperature Control Strategy must be

set up as LINE UP(MFLEXESR)/DEF.

5. MultiFlex ESR Setup - Physical properties of

the valves connected to the MultiFlex ESR will

need to be specified in the MultiFlex ESR application in the E2 software.

the Temperature Control Strat-

6.2. Step 1: Add a MultiFlex ESR

A. Add Number of Boards

A MultiFlex ESR board must be added to the E2

in the same manner that an 8RO or a 16AI is

added in the network setup of the controller . This

is done from the Connected I/O screen of the E2

(Figure 6-1):

6.1. Programming E2 Version 2.21

and Above

Successful installation of a MultiFlex ESR

requires you to perform five main programming

steps in the E2 software:

1. Add MultiFlex ESR Board(s) - The E2 refriger-

ation controller must be programmed to communicate and utilize the MultiFlex ESR board(s) on

the network.

2. Add Standard Circuit(s) - The circuit must first

be added in the E2 before a circuit can be set up

and associated with the MultiFlex ESR board.

Programming E2 Version 2.21 and Above Software Overview • 6

Figure 6-1 - Connected I/O Screen

1. Press

Page 12

2. Press

3. Press the down arrow key until the MultiFlex

ESR field is highlighted.

4. Enter the number of MultiFlex ESRs connected to the E2 and press

5. Press to save changes and exit the

screen.

cally connected and can communicate. This auto

hookup of circuit valve control and alarm

parameters between the circuit and the MultiFlex ESR application minimizes the set up of

standard circuit(s) for MultiFlex ESR (Step 4).

T o access the MultiFlex ESR Association screen

from the Home screen:

6.3. Step 2: Add a Standard Circuit

Before a standard circuit can be set up and associated with the board, you must first add the circuit in the E2 from the Add Application screen.

1. Press

2. Press

3. Choose Standard Circuit from the list

(Press F4 for look-up) and use the arrow keys

to move to the How Many? field. Enter the

number of circuits you wish to add and press

1. Press

2. Press

3. Use the arrow keys to highlight the circuit

you wish to edit, and press

Figure 6-3 - Associations Screen

Figure 6-2 - Add Application Screen

6.4. Step 3: Associate the MultiFlex

ESR

Each standard circuit controls a single valve. In

this step, you must associate or "map" the valve

on the MultiFlex ESR board to a particular circuit. When a valve on the MultiFlex ESR board

is associated with a circuit, the two are automati-

7 • MultiFlex ESR I&O Manual 026-1720 Rev 4 06-APR-2010

The Circuit column displays all configured stan-

dard circuits in the E2. The MFlex ESR Appl

column displays a list of all MultiFlex ESR

applications in the E2 (press F4 to choose which

MultiFlex ESR board to associate with the circuit). The Valve column, selectable between 1

and 8 for the valve number, displays the valve

number the circuit is connected to.

NOTE: A valve may be associated to only one

circuit. Multiple valves cannot be assigned to a

single circuit.

Page 13

6.5. Step 4: Set Up the Standard

Circuit

The MultiFlex ESR works in conjunction with a

Standard Circuit application in E2 to control

case circuit temperature. Each Standard Circuit

application should be programmed as documented in the E2’s installation guide or the E2’s

user manual and/or online help.

To specify that the case circuit is going to be

controlled by a valve on a MultiFlex ESR board,

there are three important screens in the Standard

Circuit application that you will need to alter. To

edit a Standard Circuit application:

A. General Setup Screen

1. Press

2. Press - CIRCUITS.

3. If more than one circuit has been added, the

Circuits Summary page will open, displaying

all circuits in the E2. Use the arrow keys to

highlight the circuit you wish to edit, and

press

4. From that circuit’s Status screen, press

- SETUP.

NOTE: Use the F1 and F2 keys to scroll

between screens.

Figure 6-4 - General Setup Screen

Under the General Setup screen (C1 tab), the

Temp Ctrl Strat field tells the E2 what method

of control will be used. This field should be set

to LINE UP(MFLEXESR)/DEF to indicate a

MultiFlex ESR will control temperature.

NOTE: To see all available options, view

screens in the Full Options mode. Press

in E2 to turn Full Options mode ON.

+

B. Setpoints Setup Screen

Step 4: Set Up the Standard Circuit Software Overview • 8

Figure 6-5 - Setpoints Setup Screen

Page 14

Under the Setpoints Setup screen (C3 tab), the

TR field sets the throttling range of the MultiFlex ESR temperature control. The throttling

range is the number of degrees between a 0%

and 100% valve aperture in the Proportional

mode of PID control. In most cases, the default

value (10°F) is sufficient. If a different TR is

desired, enter it here.

C. Additional Setup Screen: MultiFlex ESR

Under the More Setup screen (C0 tab), set the

following parameters described in Table 6-1.

comm failure. When CommFailDefrost is set to

DISABLE, the advisory priority and type can be

configured: The following two advisory parameters will appear:

• AdvPrior - lets the user set the priority of

the Notice or Alarm logged if a defrost is

disabled due to a MultiFlex ESR comm failure.

• AdvTyp - lets the user select between

Notice or Alarm to be logged for the event

described above.

NOTE: There are multiple screens under the

CO: MORE tab. Use F1 and F2 to toggle

between available screens under this tab.

Figure 6-6 - More Tab: Additional MultiFlex ESR Setup Screen

Temp Fail EEPR % - Failsafe setting that is

used exclusively when the valve type (Valve

Mfg) under the MultiFlex ESR Valves Setup

screen is set to Other. The value set in this field

will be the position the valve goes to if the case

temperature sensor fails or the MultiFlex ESR

board goes offline. This failsafe setting is always

available.

CommFailDefrost - If set to ENABLE

(default), the scheduled defrost will occur if the

board is in comm failure (offline). If set to DIS-

ABLE, the circuit will disable any scheduled

defrost if the MultiFlex ESR board containing

the valve for this circuit is in comm failure (offfline). An advisory will be logged if a scheduled

defrost is disabled due to a MultiFlex ESR

Standard

Circuit Valve

Parameters

Min Valve % The minimum percentage the valve

can go to during refrigeration control. The valve will go to 0% (fully

closed) during defrost regardless of

what the minimum valve % has been

set to.

Max Valve % The maximum percentage the valve

can open during refrigeration control.

Pulldown % The percentage the valve will be

open during the pulldown period after defrost.

Max Pulldown Tm The maximum amount of time the

valve will remain in pulldown following a defrost. If exceeded, the

valve will resume PID control. Pulldown will terminate earlier than the

max pulldown time if the case temperature reaches setpoint.

Table 6-1 - MultiFlex ESR Valve Parameters - E2 More Tab

Description

9 • MultiFlex ESR I&O Manual 026-1720 Rev 4 06-APR-2010

Page 15

Standard

Circuit Valve

Parameters

Temp Fail EEPR % The MultiFlex ESR uses the value set

Temp Fail Use

Avg %

Comm Fail EEPR % The MultiFlex ESR uses the value set

Comm Fail Use

Avg %

CommFailDefrost If enabled (default), the scheduled

Table 6-1 - MultiFlex ESR Valve Parameters - E2 Mor e Tab

in this field if the case temperature

sensor fails. This feature is always

available.

If an ECT Flow valve has been selected, the MultiFlex ESR will have

the option to use the daily average

valve % if the case temperature sensor fails. This option is only available

when valve type is set to ECT Flow.

in this field if a communication failure with the board occurs. This feature is always available.

If an ECT Flow valve has been selected, the MultiFlex ESR will have

the option to use the Daily Average

Valve % if a communication failure

with the board occurs. This option is

only available when the valve type is

set to ECT Flow.

defrost will occur if the board is offline (comm fail). If disabled, and the

MultiFlex ESR board containing the

valve associated with this circuit is in

comm fail, the standard circuit will

skip any scheduled defrost and an advisory will be generated. Additionally, two configurable advisory

parameters will appear.

Description

ESR and press

number next to it. The MultiFlex ESR Sum-

mary screen will open.

Figure 6-7 -MultiFlex ESR Summary Scre en

4. If more than one MultiFlex ESR is listed,

choose the one you wish to edit, and press

, or simply enter the

5. From the status screen, press - SETUP.

NOTE: Use the F1 and F2 keys to scroll

between screens.

6.6. Step 5: Set Up the MultiFlex

ESR

Before setting up the MultiFlex ESR evaporator

stepper regulator, you must have completed

steps 1-4 so that the MultiFlex ESR boards are

added and configured correctly in your Standard

Circuit applications. In this step, you must specify the type of valves being used and (if necessary) the specifics of the valve such as step rate

and maximum number of steps.

To edit a MultiFlex ESR application:

1. Press

2. Press - Configured Applications.

3. Use the arrow keys to highlight MultiFlex

Step 5: Set Up the MultiFlex ESR Software Overview • 10

A. General Setup Screen

The General Setup screen is where general prop-

erties of the MultiFlex ESR application are specified. The only field on this screen you will edit

is the Name field. If you wish to assign a name

to this MultiFlex ESR application, enter it in this

field; otherwise, move to the Valves Setup

screen.

Page 16

Figure 6-8 - General Properties Screen

B. Valves Setup Screen

The Valves Setup screen (C4 tab) allows you to

specify the type of valve connected to each output on the MultiFlex ESR board:

it, define the following fields:

OvrClose% The Over Close Percentage is the

percentage of the MaxStep parameter that

the valve will attempt to close past its 0%

limit for defrost. This will ensure the valve is

fully closed when the circuit associated with

the valve goes into defrost.

For example, when a valve with an Over

Close Percentage of 5% and a Maximum

Steps value of 800 is called upon to over

close (i.e., defrost), the valve will travel to

the step that it counts as 0% and then attempt

to close 40 more steps. By doing this, any

error that may cause the valve to be slightly

open at 0% will be eliminated.

It is recommended that this value be set to

5% for all Emerson Flow Control valves. For

more information, refer to the Valve

Specifications tables at the end of this

manual.

Figure 6-9 -Valves Setup Screen

Enter specifics about the valves that are

connected to the MultiFlex ESR.

All valves on this screen are listed in eight rows

numbered one (#1) through eight (#8). The

number on each row corresponds to the similarly

numbered point on the MultiFlex ESR. For each

MultiFlex ESR point that has a valve attached to

Step Rate The Step Rate field corresponds to

the valve manufacturer’s recommended step

rate in steps-per-second. The default, 50

steps per second, is the correct step rate for

the ESR 12 and ESR 20 valves. If using

different types of valves, refer to the Valve

Specifications tables at the end of this

manual and enter the rate listed for your

valve type.

MaxStep

The MaxStep field is where you must

enter the total number of steps the valve

travels between fully closed (0%) and fully

open (100%). This is a physical property of

the valve. Refer to the Valve Specifications

tables at the end of this manual to determine

the total number of valve steps.

11 • MultiFlex ESR I&O Manual 026-1720 Rev 4 06-APR-2010

Page 17

Valve Mfg If you have already associated the

valve and circuit, select the valve type in the

appropriate field. Press the F4 button to

choose the type of valve used. If this field is

set to ECT Flow, the following options will

be available:

• Stuck Valve alarm - the valve is not moving

in response to commands:

Based on characteristics for this valve type,

this feature offers a high probability that if

the valve becomes stuck, a Stuck Valve

alarm will be generated.

• Open Wire alarm - at least one drive winding

of the valve is disconnected or has an open

coil (no current flow was detected).

• Over Current alarm - available if the Valve

Mfg field is either set to ECT Flow or

Other, the valve driver is reporting an over

current condition possibly caused by a

shorted driver winding.

facturer (Valve Mfg) is set to Other and the

valve harness becomes disconnected while the

MultiFlex ESR board is attempting to control,

zero the valve after the disconnect is resolved.

7.1. Step 1

To zero the valve, first configure the Step Rate

and Max Step parameters for the valve type. The

configuration can be done with either the E2

controller or CPC’s hand-held terminal (HHT).

For the parameters to be configured with the E2,

the HHT must be unplugged and disconnected

from the MultiFlex ESR board.

The Max Step parameter is the total number of

control steps for the valve from 0-100%, but the

physical valve may have a step range that is substantially larger than the Max Step parameter.

This is why the valve must be zeroed at initial

start-up.

7.2. Step 2

NOTE: All alarms attempt to auto reset continuously every 10 minutes after the alarm was

first detected.

7Valve Zeroing

During the installation process of the valves or

when a valve is replaced, the valve(s) must be

zeroed before the MultiFlex ESR board can

begin controlling.

The zeroing process closes the valve twice the

number of Max Steps and should sufficiently

"zero" ECT valves. For Sporlan and other valve

manufacturers that have a full travel much

greater than Max Steps, this process may need to

be repeated one or two more times to fully zero

the valve. Once the valve has been zeroed, the

process will not need to be repeated unless the

valve has been replaced or driven open beyond

its control range by a device other than the MultiFlex ESR board. Note that if the valve manu-

After the configuration of Step Rate and Max

Step parameters for the valve, disconnect the

power plug from the MultiFlex ESR board, then

reconnect the power plug to reapply power to the

MultiFlex ESR board. When power has been

reapplied to the board, all valves will begin to

close and the Close LED (located on the right

side under the valve connector on the MultiFlex

ESR board) will illuminate. After the valve

closes the Max Step parameter number of steps,

the valve will begin to open and the Open LED

(located on the left side under the valve connector on the MultiFlex ESR board) will illuminate.

The moment any Open LED illuminates, disconnect power from the board. Then reconnect

the power plug to reapply power to the MultiFlex ESR board.

8 Hand-Held Terminal

8.1. Overview

The hand-held terminal (HHT) connector is

located on the lower left side of the board and is

Step 1 Valve Zeroing • 12

Page 18

labeled as J2. The HHT allows each valve output

MULTIFLEX ESR

810-3198

VER:1.11F01

( PRESS )

V1:C 48% 0V:100%

V2:0 98% 0V: 5%

V3:I NA

V4:I 48%

V1: VALVE OK

V2: FAULT STUCK

V3: FAULT WIRE

V4: FAULT OVLD

to be set separately with a valve step rate and the

total number of steps from closed to fully open.

The HHT is able to indicate the position status of

each valve. The failsafe condition of each valve

can be set with the HHT.

However, once the HHT is removed, the settings

will go back to the values programmed at the E2

if online.

Valves may be manually positioned with the

HHT, which overrides control from the E2 controller . Fully closing and fully opening any valve

can be accomplished with a minimal number of

keystrokes.

points have not been configured (the MultiFlex ESR

board is using factory defaults for valve configurations).

8.2.2. Output Status Screens

The third and fourth screens will show the state

of all valves. Valves 1 - 4 are seen on one screen

and continue with 5 - 8 on the next. These

screens will allow an override to be placed on

the valve’s position.

Figure 8-2 - Output Status Screen

The HHT can be used to fully open the valve

(override to 100%) for brazing during the valve

installation process or evacuation of the system.

8.2. Screens

8.2.1. Main Screen

The HHT will display the following home or

main screen:

Figure 8-1 - Main Screen

NOTES: Press F1 at any time to return to the

Home screen. Use arrows to select fields and

scroll.

Possible internal failures or communication bus

problem messages:

• FAIL: FLASH/CLK - Either the flash executable

code has changed or the hardware clock is not functioning properly.

• FAIL: I/O NET - Unable to communicate with the

I/O Network.

• FAIL: USER CFG - The MultiFlex ESR board set-

Also shown are status indicators:

• I - Valve is idle

• O - Valve is opening

• C - Valve is closing

•A - Alarm

OV and its value will not appear unless the valve

has been overridden. Once the HHT has been

removed, all overrides will be erased.

8.2.3. Alarm Status Screens

The alarm screens provide information about

alarms that have been generated during operation of the valve.

Figure 8-3 - Alarm Status Screen

Possible alarm states:

• VALVE OK - Normal val ve operation. Valve is

ready for commands.

• FAULT STUCK - The valve is not moving or responding to commands: Based on characteristics for

this valve type, this feature offers a high probability

that if the valve becomes stuck, a Stuck Valve alarm

13 • MultiFlex ESR I&O Manual 026-1720 Rev 4 06-APR-2010

Page 19

will be generated.

SELECT: 1

2. NET CONFIG

1. VALVE CONFIG

VALVE:1 Other

MAX STEPS: 800

RATE: 50 OvrCls

Fail%: 100 5%

DIP Settings:

Address: 1

Baud : 9600

• FAULT WIRE - At least one drive winding is disconnected or has an open coil (no current flow was

detected).

• FAULT OVLD - The valve driver is reporting a

shorted driver winding.

8.2.4. Main Select Screen

The seventh screen (or accessed by pressing F2

on the HHT) will allow the user to select what

sub-system should be accessed. (Defaults to 1.)

For Valve, choose the type of valve being used.

Set to ECT Flow for ECT valve types or Other

for any other type of valve.

Max Steps is the total number of steps the valve

travels between fully closed (0%) and fully open

(100%).

Rate corresponds to the step rate of the valve (in

steps per second). The default, 50 steps per second, is the correct step rate for the ESR 12 and

ESR 20 valves.

OvrCls is the Over Close percentage that will be

used when setting a valve to 0% for defrost.

Figure 8-4 - Main Select/Configuration Screen

8.2.5. Valve Configuration Screens

The Option 1 screen will enable the user to view

valve configurations and to make temporary

changes to the settings. However, once the HHT

is removed, the settings will go back to the values programmed at the E2 if online. (Defaults

are Flow Control’s ESR 12 and ESR 20 valves.)

Figure 8-5 - Valve Configuration Screens

Use the up and down arrows to select the desired

valve (1-8). Use the right arrow to select the desired fields.

Fail % is the failsafe output percentage to use if

communications are lost with the E2.

8.2.6. Network Screen

The Option 2 screen will show the network settings for the MultiFlex ESR controller. There are

no editable fields on this screen. This display is a

reflection of the dip switch settings:

Figure 8-6 - DIP Switch Settings Screen

NOTE: This Network screen can also be

accessed by pressing the down arrow key once

from the Home screen.

• Valve: 1 - can be set to Other or ECT Flow

• Max Steps - can be set from 1-10000. Default is 800.

• Rate - can be set from 20-500. Default is 50.

• OvrCls - can be set from 0-20. Default is 5.

• Fail % - can be set from 0-100. Default is

100.

Screens Hand-Held Terminal • 14

Page 20

Valve Specifications Tables

Emerson Flow Controls Stepper Valves

TYPE ESR 12 ESR 20 ESVB

10-20 Ton

Voltage 12 VDC

24 VDC

12 VDC

24 VDC

12 VDC

24 VDC

ESVB (4)

1-4 Ton

12 VDC

24 VDC

ESV (4)

12 VDC

24 VDC

Control Suction Suction Liquid Liquid Liquid

Step Rate 50 50 50 50 (30 ok) 30

Max Steps 500/800

(1) 800 800 384 360 (2)

OverClose5%5%5%5%5%

Total Watts 10 10 10 3.4 12.8

Phase

(3)

Resistance

29 ohms

115 ohms

29 ohms

115 ohms

29 ohms

116 ohms

84 ohms

336 ohms

23.5 ohms

95 ohms

Hysteresis 0 0 0 0 0

Motor Bipolar Bipolar Bipolar Bipolar Unipolar

ESR, CC100

CCB

ESR, CC100

CCB

CC100

CCB

CC100

CCB

CC100

CCB

products

Notes:

(1) 500 steps for valves manufactured before year 2001. Identify using date code bef ore 0100 (e.g., 0052, 9902, 9848, or brass body size

~2" vs. ~2

(2) DO NOT exceed max steps of 384 for this valve.

(3) Shown for 12V and 24V motors, +/- 10% at 75°F.

(4) For ESV replacement with ESVB: 1. Swap the Flow Control colors RED and BLUE. 2. Cap off the YELLOW wire.

1/4" for 800 steps.

Sporlan (Parker) Stepper Valves

TYPE CDS-8 CDS-16

CDS-17

Voltage 12 VDC 12 VDC 12 VDC 12 VDC

Control Suction Suction Suction Suction

Step Rate 200 200 200 200

Max Steps 3064 6386 1596 3193/6386

OverClose 5% 10% 10% 10%

Total Watts 10 4 5.7 4

Phase (3)

75 ohms 75 ohms 72 ohms 75 ohms

Resistance

Hysteresis 0 0 0 0

Motor Bipolar Bipolar Bipolar Bipolar

ESR, CC100

CCB

ESR, CC100

CCB

products

15 • MultiFlex ESR I&O Manual 026-1720 Rev 4 06-APR-2010

SEI/EEV CDS-9

CC100

CCB

ESR, CC100

CCB

Page 21

Loading...

Loading...