Page 1

026-1705 Rev 7 06-APR-2010

MultiFlex Condensing Unit Board

(CUB-II and CUB-TD) Installation and

Operation Manual

Page 2

Page 3

3240 Town Point Drive NW Suite 100

Kennesaw, GA 30144, USA

Phone: 770-425-2724

Fax: 770-425-9319

ALL RIGHTS RESERVED

The information contained in this manual has been carefully checked and is believed

to be accurate. However, Computer Process Controls, Inc. assumes no responsibility

for any inaccuracies that may be contained herein. In no event will Computer Process

Controls, Inc. be liable for any direct, indirect, special, incidental, or consequential

damages resulting from any defect or omission in this manual, even if advised of the

possibility of such damages. In the interest of continued product development, Computer Process Controls, Inc. reserves the right to make improvements to this manual,

and the products described herein, at any time without notice or obligation.

Page 4

Page 5

Page 6

Table of Contents

1 OVERVIEW OF THE MULTIFLEX CUB-II AND CUB-TD.................................................................................. 1

1.1. T

HE MULTIFLEX CUB-II.............................................................................................................................................. 1

1.2. T

HE MULTIFLEX CUB-TD........................................................................................................................................... 1

2 MOUNTING AND POWERING.................................................................................................................................. 2

2.1. S

NAP-TRACK INSTALLATION........................................................................................................................................ 2

2.2. T

HE PLUG-IN OUTPUT BOARD ..................................................................................................................................... 3

2.3. P

OWERING THE MULTIFLEX CUB BOARD ................................................................................................................... 3

2.3.1. Choosing Transformer Sizes ................................................................................................................................. 4

2.3.2. MultiFlex CUB Power Wiring............................................................................................................................... 4

2.3.2.1. New-Style MultiFlex CUB Boards (With Isolated Power Supply)....................... .. ............................. .............................. 5

2.3.2.2. Old-Style MultiFlex CUB Boards (No Isolated Power Supply)......................................................................................... 5

2.3.3. Wire Types and Maximum Distances.................................................................................................................... 6

3 THE I/O NETWORK .................................................................................................................................................... 7

3.1. W

IRING TYPES.............................................................................................................................................................. 7

3.1.1. Daisy Chains......................................................................................................................................................... 7

3.1.2. Network ID Numbers............................................................................................................................................. 7

3.1.2.1. Numbering the MultiFlex

CUB ................................................................................................................................................................................................... 8

3.1.3. Setting the Baud Rate............................................................................................................................................ 8

3.1.4. Setting the Terminating Resistance Jumpers ........................................................................................................ 8

4 CUB INPUT AND OUTPUT SETUP..................................................................... ...................................................... 9

4.1. T

HE INPUTS................................................................................................................................................................... 9

4.1.1. Connecting Sensors to the MultiFlex CUB........................................................................................................... 9

4.1.1.1. Wiring.......................................... ........................... ........................... ................................................................................. 9

4.1.1.2. Sensor Wiring Types .......................................................................................................................................................... 9

4.1.1.3. Input Type Dip Switches .................................................................................................................................................... 9

4.1.2. Power Connection............................................................................................................................................... 10

4.1.2.1. Current Ratings for On-Board Power Sources.................................................................................................................. 10

4.1.2.2. Powering Sensors Requiring 24VAC Off the Power Transformer.............................................. ..................................... 10

4.1.3. MultiFlex CUB Fixed Input Locations................................................................................................................ 10

4.2. T

HE OUTPUTS ............................................................................................................................................................. 11

4.2.1. Relay Output Ratings and Fuse Protection......................................................................................................... 12

4.2.2. Wiring Outputs to Points..................................................................................................................................... 12

4.2.3. MultiFlex CUB Fixed Outputs............................................................................................................................ 12

5 BOARD STATUS LEDS ............................................................................................................................................. 13

5.1. S

TATUS LED................................................................. .................................. ............................................................ 13

5.2. T

X AND RX LEDS....................................................................................................................................................... 13

5.3. C

ODE A AND CODE B LEDS ...................................................................................................................................... 13

5.4. R

ELAY OUTPUT LEDS................................................................................................................................................ 14

6 MULTIFLEX CUB-II AND CUB-TD SOFTWARE OVERVIEW......................................................... ............... 15

6.1. C

OMPRESSOR CONTROL.............................................................................................................................................. 15

6.1.1. Suction Pressure Compressor Control................................................................................................................ 15

6.1.2. Case Temperature Compressor Control............................................................................................................. 15

6.1.2.1. Pump Down .. ........................... ..................................................... .................................................................................... 15

6.1.2.2. Fallback Pressure Setpoints ............................. ........................... ...................................................................................... 15

vi • Table of Contents 026-1705 Rev 7 06-APR-2010

Page 7

6.2. CONDENSER FAN CONTROL ....................................................................................................................................... 16

6.2.1. Temperature Differential (TD) Strategy ............................................................................................................. 16

6.2.1.1. TD Control Fail-Safes..................... ........................... .. ........................... .......................................................................... 16

6.2.2. Pressure Control Strategy.................................................... .................................. ... .......................................... 16

6.2.3. Case Temperature Control.................................................................................................................................. 17

6.3. D

EFROST CONTROL .................................................................................................................................................... 17

6.3.1. Defrost Termination............................................................................................................................................ 17

6.4. S

ENSOR CONTROL ...................................................................................................................................................... 17

6.4.1. How Cut In/Cut Out Control Works .................................. ................................. ................................................ 17

6.4.2. Motor Room Temperature Control..................................................................................................................... 18

6.4.2.1. Exhaust Fan Control .................................................... ..................................................................................................... 18

6.4.2.2. Example of a Motor Room Zone Temperature Configuration ........ ........................... ...................................................... 18

6.5. ALARM CONDITIONS (SAFETY MODES) ..................................................................................................................... 19

6.5.1. High Discharge Trip Safety Mode...................................................................................................................... 19

6.5.2. Compressor Proof Fail Safety Mode .................................................................................................................. 19

6.5.3. Compressor Oil Failure Safety Mode................................................................. ................................................ 20

6.5.4. Phase Fail Mode................................................................................................................................................. 20

6.6. D

OOR SWITCHES AND CLEAN (WASH) SWITCHES ..................................................................................................... 20

6.6.1. Door Switches..................................................................................................................................................... 20

6.6.2. Clean (Wash) Switches........................................................................................................................................ 21

7 THE MULTIFLEX CUB E2/ EINSTEIN INTERFACE......................................................................................... 22

7.1. A

DDING/DELETING A CUB ........................................................................................................................................ 22

7.1.1. Adding a CUB......................................................................... ............................................................................ 22

7.1.2. Deleting a CUB................................................................................................................................................... 23

7.2. V

IEWING THE CUB STATUS SCREEN ......................................................................................................................... 23

7.2.1. Inputs and Setpoints............................................................................................................................................ 24

7.2.2. Sensor Control .................................................................................................................................................... 25

7.2.3. Outputs and Operational States.......................................................................................................................... 25

7.2.4. Defrost................................................................................................................................................................. 26

7.2.5. KW Usage ........................................................................................................................................................... 26

7.3. P

ROGRAMMING THE CUB USING THE E2 OR EINSTEIN FRONT PANEL..................................................................... 26

7.3.1. Screen 1: General ............................................................................................................................................... 27

7.3.2. Screen 2: Setpoints.............................................................................................................................................. 28

7.3.2.1. Temperature Differential (TD) ................................................................. ........................................................................ 30

7.3.2.2. Traditional Strategy ...................... .................................................................................................................................... 30

7.3.3. Screen 3: Inputs .................................................................................................................................................. 31

7.3.4. Screen 4: Aux Inputs........................................................................................................................................... 32

7.3.5. Screen 5: CUB Inputs ......................................................................................................................................... 32

7.3.6. Screen 6: Defrost ................................................................................................................................................ 34

7.3.7. Screen 7: Outputs................................................................................................................................................ 35

7.3.8. Screen 8: CUB Outputs....................................................................................................................................... 37

7.3.9. Screen 9: Sensor Control.................................................................................................................................... 38

7.3.10. Screen 10: Alarms............................................................................................................................................. 39

7.3.10.1. Oil Failure Alarm Setpoints............................................................................................................................................ 39

7.3.10.2. Discharge Pressure Alarm .............................................................................................................................................. 40

7.3.10.3. High/Low Suction Pressure Alarms ......... .. ........................... ......................................................................................... 41

7.3.10.4. Compressor Proof Alarms .............................................................................................................................................. 41

7.3.10.5. Phase Fail Shutdown....................................................................................................................................................... 42

7.3.10.6. Door Switch Alarms ....................................................................................................................................................... 42

7.3.10.7. Wash Active Alarms....................................................................................................................................................... 42

7.3.10.8. Case Temperature Alarms .............................................................................................................................................. 42

7.3.10.9. Suction Temperature Alarms.......................................................................................................................................... 43

7.3.10.10. TD Condenser Control Alarms..................................................................................................................................... 43

MultiFlex CUB-II and CUB-TD I&O Guide Table of Contents • vii

Page 8

8 THE MULTIFLEX CUB HAND-HELD INTERFACE........................................................................................... 44

8.1. CUB H

AND-HELD TERMINAL STATUS SCREENS ....................................................................................................... 44

8.1.1. Pressure Status.................................................................................................................................................... 44

8.1.2. Case Temp Status................................................................................................................................................ 44

8.1.3. Other Temperatures ............................................................................................................................................ 44

8.1.4. Input Summary Screen ........................................................................................................................................ 45

8.1.5. Outputs Summary Screen #1............................................................................................................................... 45

8.1.6. Outputs Summary Screen #2............................................................................................................................... 45

8.1.7. System Status....................................................................................................................................................... 45

8.1.8. Refrigeration Control Status............................................................................................................................... 45

8.2. A

LTERING CUB CONFIGURATION USING THE HAND-HELD TERMINAL.................................................................... 45

8.2.1. The Main Configuration Menu............................................................................................................................ 45

8.2.2. Navigation........................................................................................................................................................... 46

8.2.3. General Hand-Held Terminal Screens................................................................................................................ 46

8.2.3.1. Circuit Name......................................... ........................... ........................... ...................................................................... 46

8.2.3.2. Refrigerant Select................ ... .......................... ................................................................................................................. 47

8.2.3.3. Phase.................... ........................... .......................... ........................................................................................................ 47

8.2.3.4. Temp EU.................. ........................... ........................... .......................... ......................................................................... 47

8.2.3.5. Time and Date................................................................................................................................................................... 48

8.2.3.6. Daylight Savings Time ..................................................................................................................................................... 48

8.2.4. Setpoints Screens................................................................................................................................................. 48

8.2.4.1. Condenser Setpoints ......................................................................................................................................................... 49

8.2.4.2. TD Strat Info.......... ........................... ........................... ..................................................................................................... 49

8.2.4.3. TD Max............................................... ........................... .......................... ......................................................................... 49

8.2.4.4. Comb Method ........................................................... ........................... ............................................................................. 49

8.2.4.5. Min OFF/ON Times.......... ...................................................... .......................... ................................................................ 50

8.2.4.6. Condenser SPs .................................................................................................................................................................. 51

8.2.4.7. Condenser Fan 1 Setpoints ............................................................................................................................................... 51

8.2.4.8. Condenser Fan 2 Setpoints ............................................................................................................................................... 51

8.2.5. Alarm Setpoints Screens...................................................................................................................................... 52

8.2.5.1. Case Hi and Lo Temp ....................................................................................................................................................... 52

8.2.5.2. Phase Fail........ ...................................................... ........................... ................................................................................. 52

8.2.5.3. Shut Down On Proof......................................................................................................................................................... 52

8.2.5.4. Proof Failure ........ ........................... ..................................................... ............................................................................. 53

8.2.5.5. Oil Restart Delay .............................................................................................................................................................. 53

8.2.5.6. Digital Oil Failure............................................................................................................................................................. 53

8.2.5.7. High Discharge Alarm........................................................................... ........................................................................... 54

8.2.5.8. High Discharge Auto Resets............................................................................................................................................. 54

8.2.5.9. Door Switch.................. .......................... ........................... ........................... .................................................................... 54

8.2.5.10. Wash Switch ................................................................................................................................................................... 54

8.2.6. Defrost Setup Screens.......................................................................................................................................... 55

8.2.6.1. Defrost Type .......... .. ........................... .............................................................................................................................. 55

8.2.6.2. Fan Control .......... ................................................................................ ............................................................................. 55

8.2.6.3. Defrost Times ...................................................................... ........................... .................................................................. 56

8.2.6.4. Defrost Schedule Screens 1 and 2..................................................................................................................................... 56

8.2.7. Input Setup Screens............................................................................................................................................. 56

8.2.7.1. Input Setup ....................................................................................................................................................................... 56

8.2.8. Outputs Screens................................................................................................................................................... 58

8.2.9. Auxiliary Inputs Screens.................................................................... .................................................................. 58

8.2.9.1. Pulse KW Setup ..................................................... ........................... ............................................................................... 58

8.2.9.2. Analog KW Setup ............................................................................................................................................................ 58

8.2.9.3. Linear 1 and 2 Setup ......................................................................................................................................................... 58

8.2.10. Sensor Control Screens..................................................................................................................................... 59

8.2.10.1. Sensor Screen 1 (Name, Type) .......... ............................. ............................. .................................................................. 59

8.2.10.2. Sensor Screen 2 (Cut In/Out, Min ON/OFF).......... ............................. .. ............................. ............................................ 59

8.2.10.3. Sensor Screen 3 (Hi/Lo Alarm) ...................................................................................................................................... 60

viii • Table of Contents 026-1705 Rev 7 06-APR-2010

Page 9

8.2.10.4. Sensor Control Screen 4 (Alarm Priority, Comb Method)............................................................................................. 60

APPENDIX A: TD QUICK START ..................................... .................................. ........................................................ 62

APPENDIX B: CASE TYPE DEFAULTS ................................................................ ..................................................... 68

MultiFlex CUB-II and CUB-TD I&O Guide Table of Contents • ix

Page 10

Page 11

1 Overview of the Multi-

Flex CUB-II and CUB-TD

The MultiFlex CUB-II and CUB-TD boards

are “smart” input/output boards designed to control single condensing units. A single condensing unit is a self-contained compressor and

condenser bearing unit which controls refrigeration in a single case line-up or walk-in cooler.

The MultiFlex CUB-II controllers are capable of

commanding compressors, condensers, refrigeration, and defrost for a single condensing unit

using on-board I/O and control algorithms. The

CUB-TD controller is a more limited board that

controls only condensers, using a temperature

differential control strategy.

The MultiFlex’s I/O Points

The compact size of the MultiFlex allows

technicians to easily field-mount the MultiFlex

CUB-II and CUB-TD in a panel or enclosure

close to the single condensing unit, allowing for

easy local connection of sensors and transducers.

The board has 16 analog inputs (for connection

to vital input sources, such as suction pressure

transducers and case temperature sensors) and

eight relay outputs, rated 2.0 amps max, for activating and deactivating compressors, defrost,

and condenser fans.

Independent System Control

The MultiFlex CUB-II and CUB-TD controllers are equipped with software and an

enhanced processor, which gives them the capability of controlling independently without the

need of a central controller (such as CPC’ s E2 or

Einstein RX Refrigeration Controller). However,

the CUB-II and CUB-TD are designed to interface with an E2 or Einstein for purposes of displaying status on status screens, reporting

alarms, and recording logs. The CUB-II and

CUB-TD may be configured either with a CPC

Hand-Held T erminal (HHT) or through the E2 or

Einstein front panel.

1.1. The MultiFlex CUB-II

The MultiFlex CUB-II controllers are capable of handling all aspects of single condensing

unit control, including compressors, condensers,

refrigeration, and defrost, using on-board I/O

and control algorithms. The CUB-II is capable

of controlling one single-stage compressor,

refrigeration and scheduled/terminated defrost in

a case circuit with up to six temperature inputs,

and condenser control using either a control by

pressure strategy (activates up to two fans to

maintain a set discharge pressure) or temperature

differential strategy (activates up to four fans to

maintain a set difference between the ambient

temperature and the drop leg refrigerant temperature).

1.2. The MultiFlex CUB-TD

The MultiFlex CUB-TD is a “stripped” version of the MultiFlex CUB-II that includes only

an algorithm for temperature differential (TD)

condenser fan control. Up to four condensing

unit fans are cycled on and off as required to

meet compressor unit heat of rejection load. The

TD algorithm subtracts plenum air temperature

from the drop leg temperature and uses the difference between the two temperatures as a control value. If the difference is higher than the

setpoint, the fans are staged on. If the difference

is lower than the setpoint, the fans are staged off.

The temperature differential control capabilities of the CUB-TD are identical to those of a

CUB-II operating in temperature differential

mode, except the CUB-TD controls condensers

only. The CUB-TD only has inputs for reading

temperatures and outputs for controlling up to

four fans. For control of any other single condensing unit subsystem, a CUB-II will necessary.

The MultiFlex CUB-II Overview of the MultiFlex CUB-II and CUB-TD • 1

Page 12

2 Mounting and Power-

ing

The MultiFlex boards are usually mounted

by the refrigeration equipment manufacturer.

Therefore, the installer need only make the necessary connections between the boards and the

site controller(s).

In some instances, an installer may be

required to mount an I/O board. There are no

restrictions on the location of these boards; however, for ease of network configuration, it is recommended that the boards be located adjacent to

the E2 or Einstein. I/O boards may be mounted

without an enclosure, but they should be

mounted in a location that is not easily accessible to avoid tampering or damage.

2.1. Snap-Track Installation

MultiFlex boards not supplied in a custom

panel or other enclosure are supplied with a

snap-track for easy installation. The insulation

sheet and I/O board must be removed from the

track before the track is mounted. The snap-track

is mounted using the 0.1875” mounting slots.

Figure 2-1 shows this installation procedure.

2 • MultiFlex CUB-II and CUB-TD I&O Guide 026-1705 Rev 7 06-APR-2010

Figure 2-1 - MultiFlex Snap-Track Mounting

Figure 2-2 provides mounting dimensions

for the MultiFlex board.

Figure 2-2 - MultiFlex Board Dimensions

Page 13

2.2. The Plug-In Output Board

The additional board makes the MultiFlex

CUB boards considerably taller than the MultiFlex 16 and other CPC I/O boards. If you will be

mounting these boards in an enclosure, the board

will need at least 2.5” of clearance between the

baseboard and the panel door.

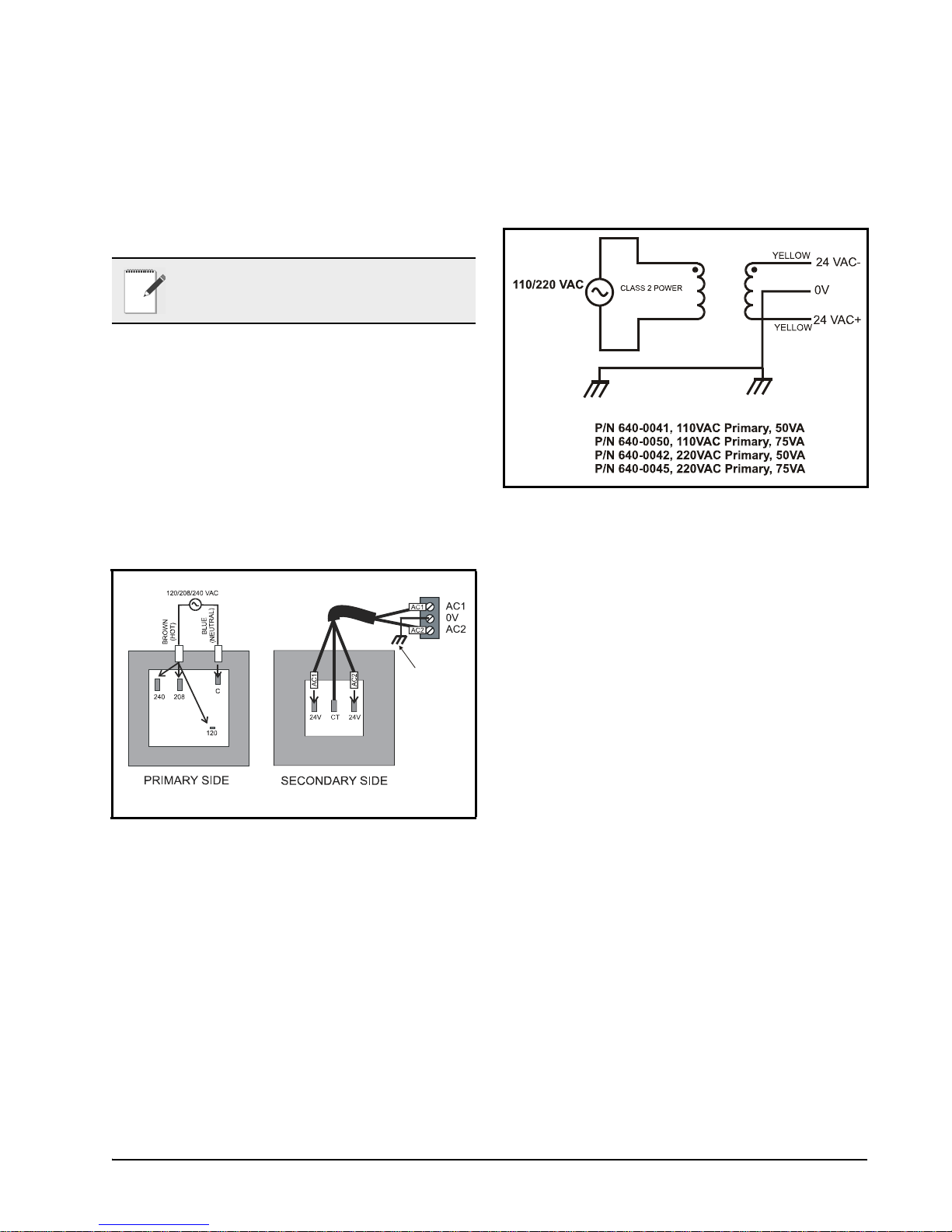

2.3. Powering the MultiFlex

CUB Board

WARNING: All models of MultiFlex require a

24V AC Class 2 input power source. The MultiFlex CUB-II requires the power source to be

non-center-tapped. Refer to Section 2.3.1.,

Choosing Transformer Sizes for center tap usage.

CPC supplies a wide variety of 24VAC transformers with varying sizes and either with or

without center taps. Table 2-1 shows the trans-

former sizes and whether they are center-tapped

or non-center-tapped.

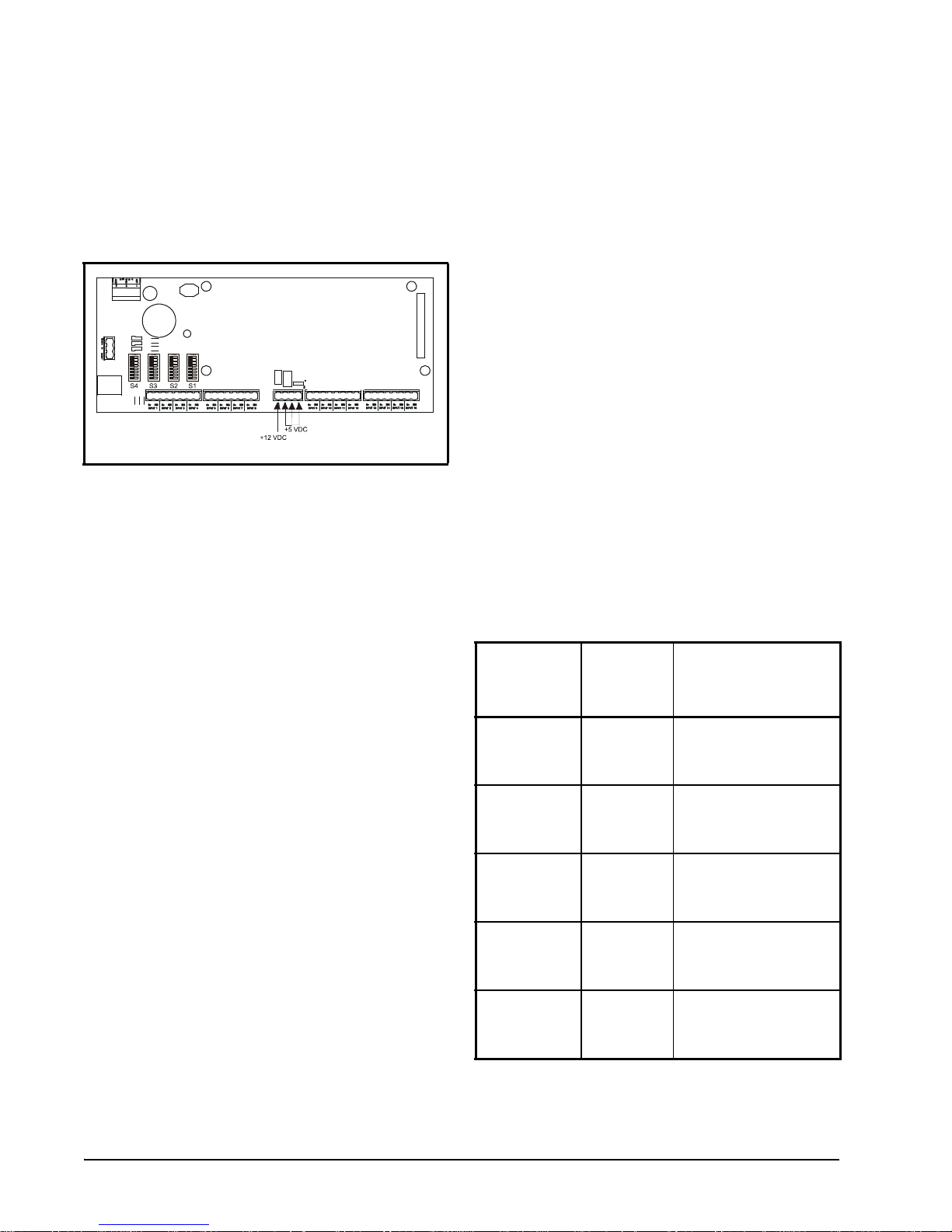

Figure 2-3 - Exploded View — MultiFlex CUB-II

The MultiFlex CUB has an output sub-board

that plugs to the top of the baseboard. Typically,

these boards are shipped with the output board

pre-installed on the board using stand-offs, so no

additional hardware setup should be necessary.

Xformer P/N VA Rating Primary Voltage Center Tap?

640-0041 50 VA 110 VAC No

640-0042 50 VA 220 VAC No

640-0056 56 VA Multi-tap (120/208/240 VAC) Yes

640-0050 75 VA 110 VAC No

640-0045 75 VA 220 VAC No

640-0080 80 VA Multi-tap (120/208/240 VAC) Yes

Table 2-1 - Transformers Compatible with Datalink Module

The Plug-In Output Board Mounting and Powering • 3

Page 14

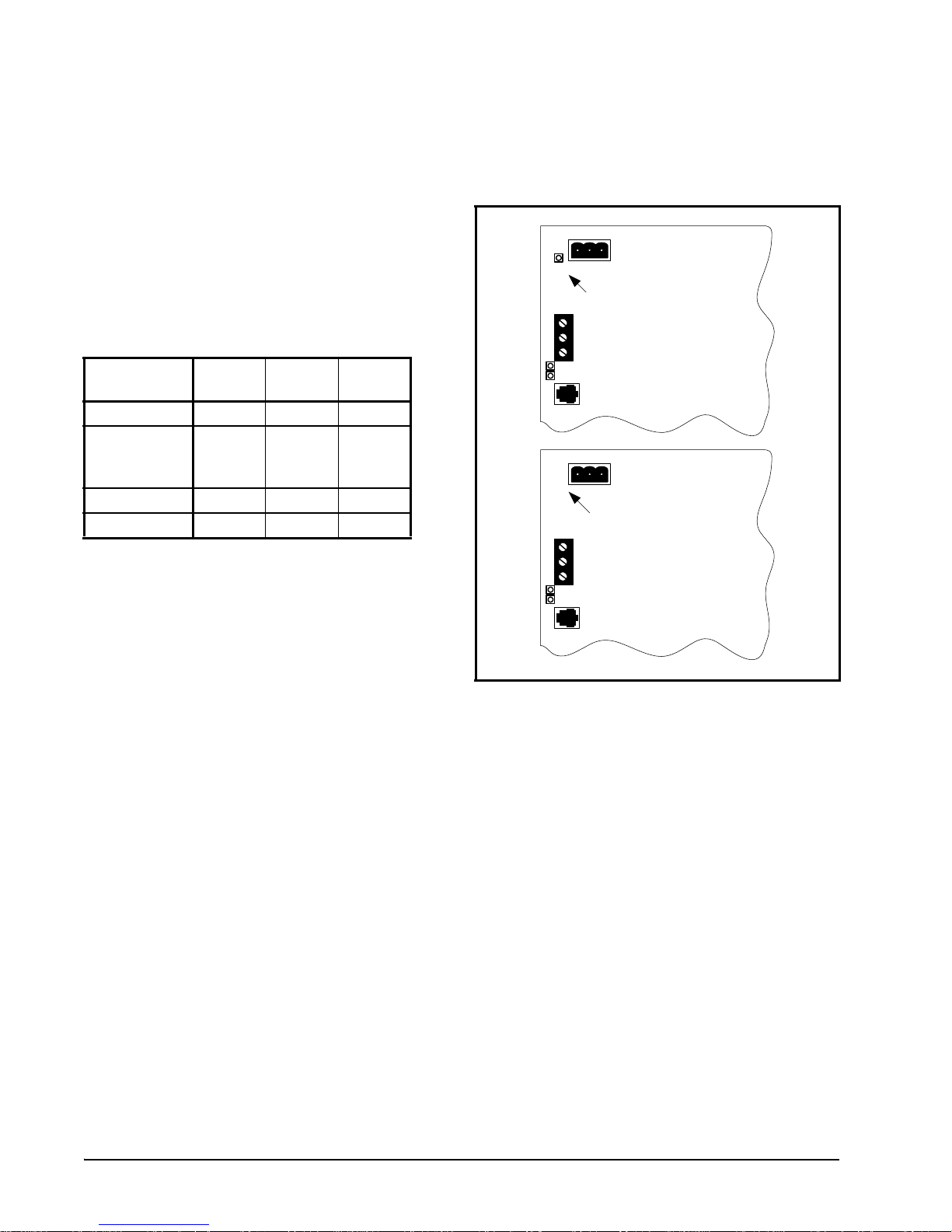

2.3.1. Choosing Transformer Sizes

POWER LED

New Style

MultiFlex Board

(Top Left Corner)

NO POWER LED

Old Style

MultiFlex Board

(Top Left Corner)

24 VAC

24 VAC

In most site installations, a single trans-

former will power multiple devices. Choose a

transformer with a VA rating large enough to

power all devices that will be attached to it.

Table 2-2 gives the VA ratings of the MultiFlex

CUB in conjunction with other MultiFlex

boards. Refer to your site controller’s manual for

VA ratings of the other I/O boards that may be

powered by one of these transformers.

Unit VA VAC Center-

Tapped?

MultiFlex 16 624Yes

MultiFlex 88,

88AO, 168,

and 168AO

MultiFlex RTU 15 24 NO

MultiFlex CUB 15 24 NO

Table 2-2 - Device Power Requirements

15 24 NO

A new-style MultiFlex board has a green

power LED located next to the 24VAC connection terminal in the upper right corner of the circuit board (see Figure 2-4 for reference).

2.3.2. MultiFlex CUB Power Wiring

The MultiFlex CUB boards do not use a center tap. Instead, the 0V terminal on the board

should be connected to a separate earth ground.

Important! The rules that must be followed when connecting a MultiFlex CUB

board to a transformer are different depending on whether you have a "new style" MultiFlex board with an isolated power supply (all

MultiFlex boards shipped after November 1,

2002) or an "old style" MultiFlex board (all

MultiFlex boards shipped before November

1, 2002).

Figure 2-4 - New-Style vs. Old-Style MultiFlex Board

If there is a green power LED next to the

connector, your MultiFlex is a new-style Multi-

Flex -- refer to Section 2.3.2.1., New-Style MultiFlex CUB Boards (With Isolated Power

Supply) for power wiring instructions.

If there is no green power LED next to the

connector, your MultiFlex is an old-style Multi-

Flex -- refer to Section 2.3.2.2., Old-Style MultiFlex CUB Boards (No Isolated Power Supply)

for power wiring instructions.

4 • MultiFlex CUB-II and CUB-TD I&O Guide 026-1705 Rev 7 06-APR-2010

Page 15

2.3.2.1. New-Style MultiFlex CUB Boards

Earth ground.

Use 14 AWG or

larger.

Keep as short

as possible.

Less

than six inches

is preferred.

(With Isolated Power Supply)

The new-style MultiFlex board can be con-

nected to any of the center-tapped transformers

mentioned in Table 2-2, provided the 0V termi-

nal of the board is connected to an earth ground.

NOTE: 14AWG or larger should be used for

earth ground and the length should be kept

short. Less than six inches is preferred.

A center-tapped transformer may power

both center-tapped and non-center-tapped

devices at the same time, as long as none of the

non-center-tapped MultiFlex boards are old-

style MultiFlex boards. If an old-style Multi-

Flex shares the same center-tapped transformer

as a device that uses the center tap, the old-style

MultiFlex will be damaged. Figure 2-5 shows

how to wire a non-center-tapped device to a cen-

ter-tapped transformer.

In addition, the MultiFlex CUB boards can

be powered by one of the 50VA or 75VA noncenter-tapped transformers listed in Table 2-1 on

page 3. Figure 2-6 shows how to wire the transformers to the MultiFlex boards.

Figure 2-6 - Non-Center-Tapped Transformer Wiring

2.3.2.2. Old-Style MultiFlex CUB Boards

(No Isolated Power Supply)

Figure 2-5 - Wiring Non-Center-Tapped MultiFlex Boards to

Transformers With a Center Tap

Like the new-style MultiFlex board, the oldstyle MultiFlex board can be connected to any of

the center-tapped transformers mentioned in

Table 2-2, provided you observe the following

three rules:

Rule 1: Ground the 0V terminal on the oldstyle MultiFlex board to an earth ground.

Do not connect the center tap of the transformer to the 0V terminal.

Rule 2: Do not power an old-style MultiFlex

non-center-tapped board with a transformer

that is also powering a center-tapped device.

This means you cannot connect an old-style

MultiFlex non-center-tapped board to a transformer that is powering a MultiFlex 16, 16AI,

8RO, 4AO, 8DO, or any previous generation

CPC board that uses center-tapped power. Doing

so will destroy the MultiFlex board.

Rule 3: The secondary of the transformer

must not be grounded on any side.

Powering the MultiFlex CUB Board Mounting and Powering • 5

Page 16

Verify that neither side of the transformer

secondary is connected to earth ground before

powering the old-style MultiFlex board. A

grounded secondary will damage the MultiFlex

board.

In addition, the old-style MultiFlex CUB

boards can be powered by one of the 50VA or

75VA non-center-tapped transformers listed in

Table 2-1 on page 3. Figure 2-6 shows how to

wire the transformers to the MultiFlex boards.

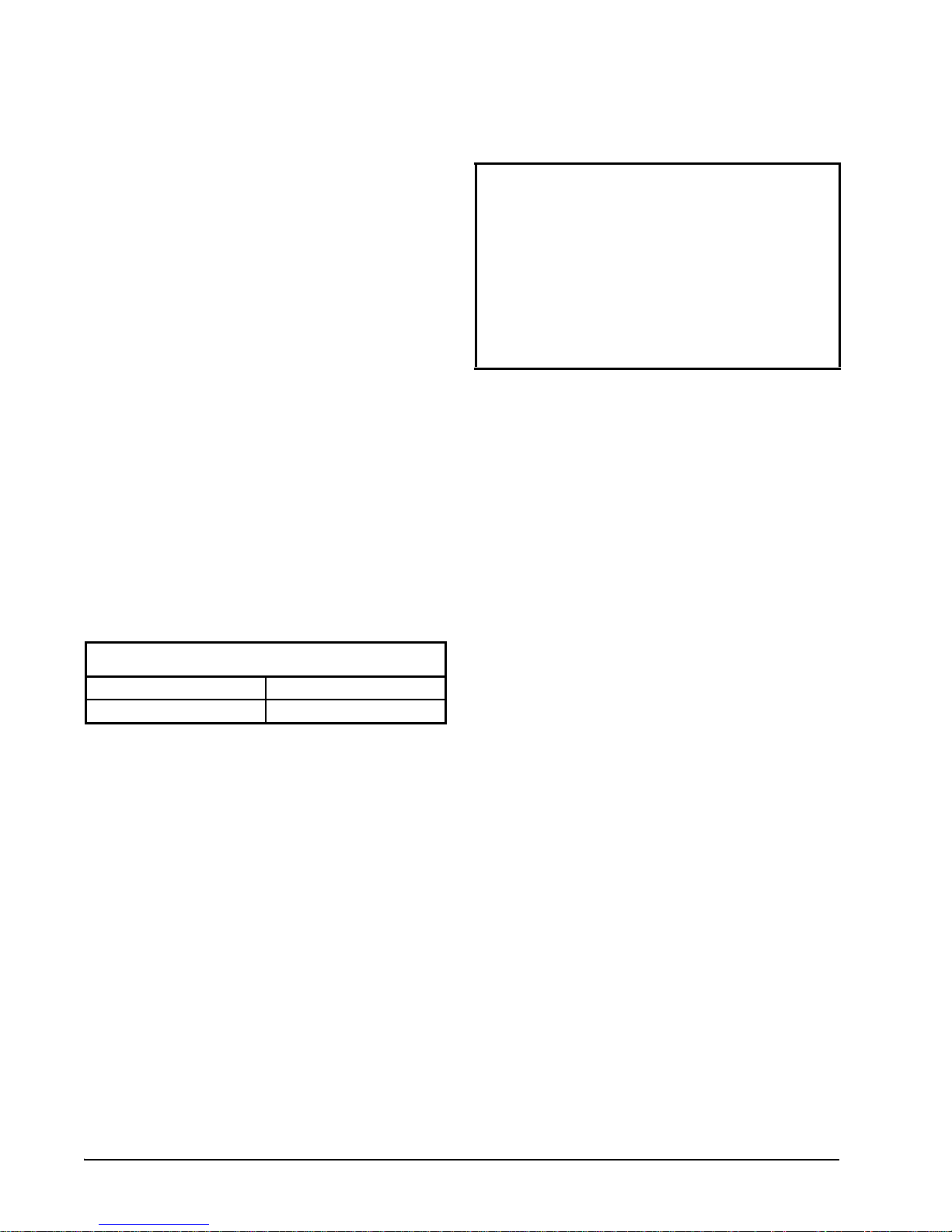

2.3.3. Wire Types and Maximum Dis-

tances

Use these formulas to determine if the wire

gauge you are using fits within specification:

14 AWG:

Feet = 1920/VA

18 AWG:

Feet = 739/VA

(VA is the total VA rating of the I/O board s)

For example, if you had an 80 VA load:

14 AWG: 24 ft

18 AWG: 9 ft (rounded down)

Figure 2-7 - Power Wire Lengths

For powering I/O boards, use only the listed

wire types from Table 2-3. Three-conductor non-

shielded cables are the recommended wire for

connecting between the center-tapped transformer and the I/O boards. Shielded cable should

not be used for power wiring. The center tap

should be wired with the third conductor to earth

ground at the controller. (Use 14AWG and keep

the length of wire short. Less than six inches is

preferred).

Power Wiring Types

14 AWG Belden 9495

18 AWG Belden 9493

Table 2-3 - Power W iring Types

The wire length from the transformer and the

number of boards connected to the same wire

determines the type wire gauge used. In most

cases, the distance between the I/O boards and

the transformer that supplies power to them is

not enough to be concerned with. But it is very

important not exceed this maximum wire length

or the boards will malfunction.

Sensors requiring 24VAC can be powered

from the same transformer powering the input

board as long as the resulting total load of both

the input board(s) and the sensor(s) connected to

the transformer does not exceed the transformer’s VA rating, and the sensors have an isolated power supply . If the sensors do not have an

isolated power supply, they could be damaged if

connected with center-tapped or grounded secondary transformers.

6 • MultiFlex CUB-II and CUB-TD I&O Guide 026-1705 Rev 7 06-APR-2010

Page 17

3The I/O Network

Although the MultiFlex CUB can operate as

a stand-alone controller, it relies on an E2, Einstein, or REFLECS unit for advanced features

such as remote dial-in/dial-out, logging, and

alarm control. All MultiFlex boards and controllers use an RS485 Network connection to communicate with an E2, Einstein, and REFLECS

site controllers. Technicians who are familiar

with CPC’s previous generation 16AI, 8IO, and

ARTC boards will find the network setup procedure for the MultiFlex CUB boards to be very

much the same.

3.1. Wiring Types

CPC specs Belden #8761 shielded twisted

pair cables for use as I/O Network wiring (or

Belden #82761 and Belden #88761 for plenum

installations).

If the recommended cable is not available in

your area, be sure the wiring meets or exceeds

the following specs:

put communication boards, and terminates at the

last input or output board on the network. A diagram of this network arrangement is shown in

Figure 3-1.

Figure 3-1 - I/O Network Configurations

3.1.2. Network ID Numbers

Each device on an RS485 segment has a net-

work dip switch that must be used to assign the

board a unique network ID number.

The network ID number makes a board

unique from other boards on the network of the

same type. This allows the site controller to find

it and communicate with it easily.

Shielded? Yes

Conductor Type Twisted Pair

Gauge 18 - 24 AWG

Capacitance between

signal wires

Capacitance between

signal and shield

Nominal Impedance 12050

Table 3-1 - RS485 I/O Network Wiring Specifications

31 pF/ft or less

59 pF/ft or less

3.1.1. Daisy Chains

The RS485 Input/Output (I/O) Network connects all input and output communication boards

together in a single open communications loop.

This loop, or “daisy chain,” connects the E2,

Einstein, or REFLECS to multiple input and out-

Boards of the same type should be numbered

in sequence, starting with one and continuing

with two, three, and so forth.

Wiring Types The I/O Network • 7

Page 18

3.1.2.1. Numbering the MultiFlex

CUB

The MultiFlex CUB is a unique board type

on the RS485 Network by the CPC controllers.

Each CUB that will be associated with an E2 or

Einstein must have a unique number from

1 to 31, which is configured by setting the first

five switches on dip switch bank S3.

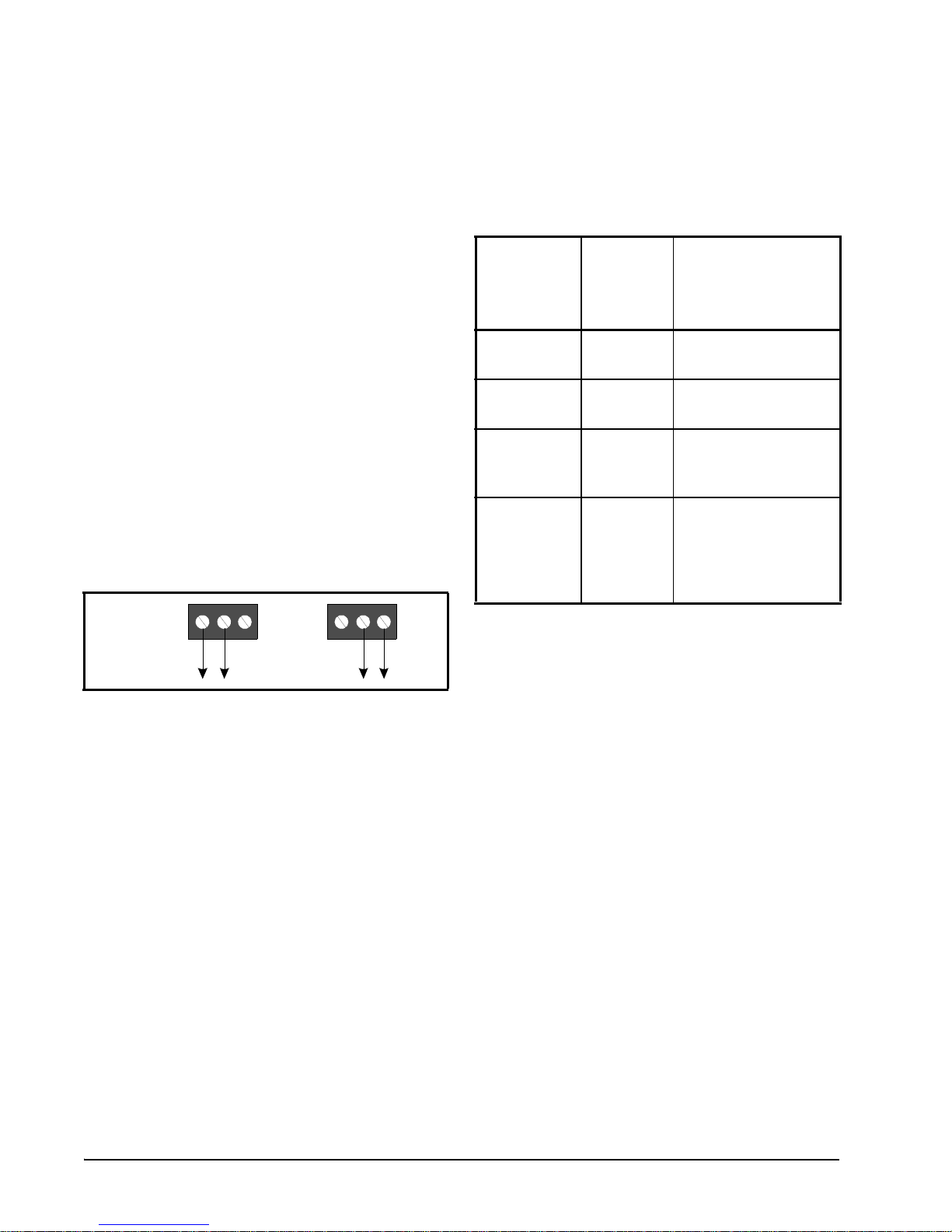

3.1.4. Setting the Terminating Resistance Jumpers

All MultiFlex boards and other RS485

devices have a set of terminating resistance

jumpers (one jumper for each wire lead). These

jumpers are labeled JP2, JP3, and JP4 on the

MultiFlex board.

The purpose of the jumpers is to indicate the

two ends, or termination points, of the segment.

On a daisy chain, one device at the beginning

and one device on the end must be terminated by

placing all three termination jumpers in the OUT

(toward the left edge of the board) position. All

other devices on the daisy chain must be set to

the IN (toward the center of the board) position.

Figure 3-3 shows the proper terminating resistance jumper settings for the E2, Einstein, and

for all I/O boards.

Figure 3-2 - CUB-II Baud Rate Switches

3.1.3. Setting the Baud Rate

All I/O boards have dip switches that determine the baud rate at which they communicate.

Currently, the baud rate dip switch in network

components may be set at either 9600 or 19200

baud. Either may be used — refer to your site

controller’s user manual for the baud rate recommendation (currently 9600 baud for REFLECS,

E2, and Einstein controllers).

On all MultiFlex boards, switches 6 and 7 on

S3 are used to set the baud rate. T o communicate

at 9600 baud, set switch #6 UP and #7 DOWN.

For 19200 baud, set switch #6 DOWN and #7

UP. Refer to Figure 3-2 for a visual look at how

the switches must be set.

8 • MultiFlex CUB-II and CUB-TD I&O Guide 026-1705 Rev 7 06-APR-2010

Figure 3-3 - I/O Network Termination Jumper Settings

Page 19

4 CUB Input and Output

Setup

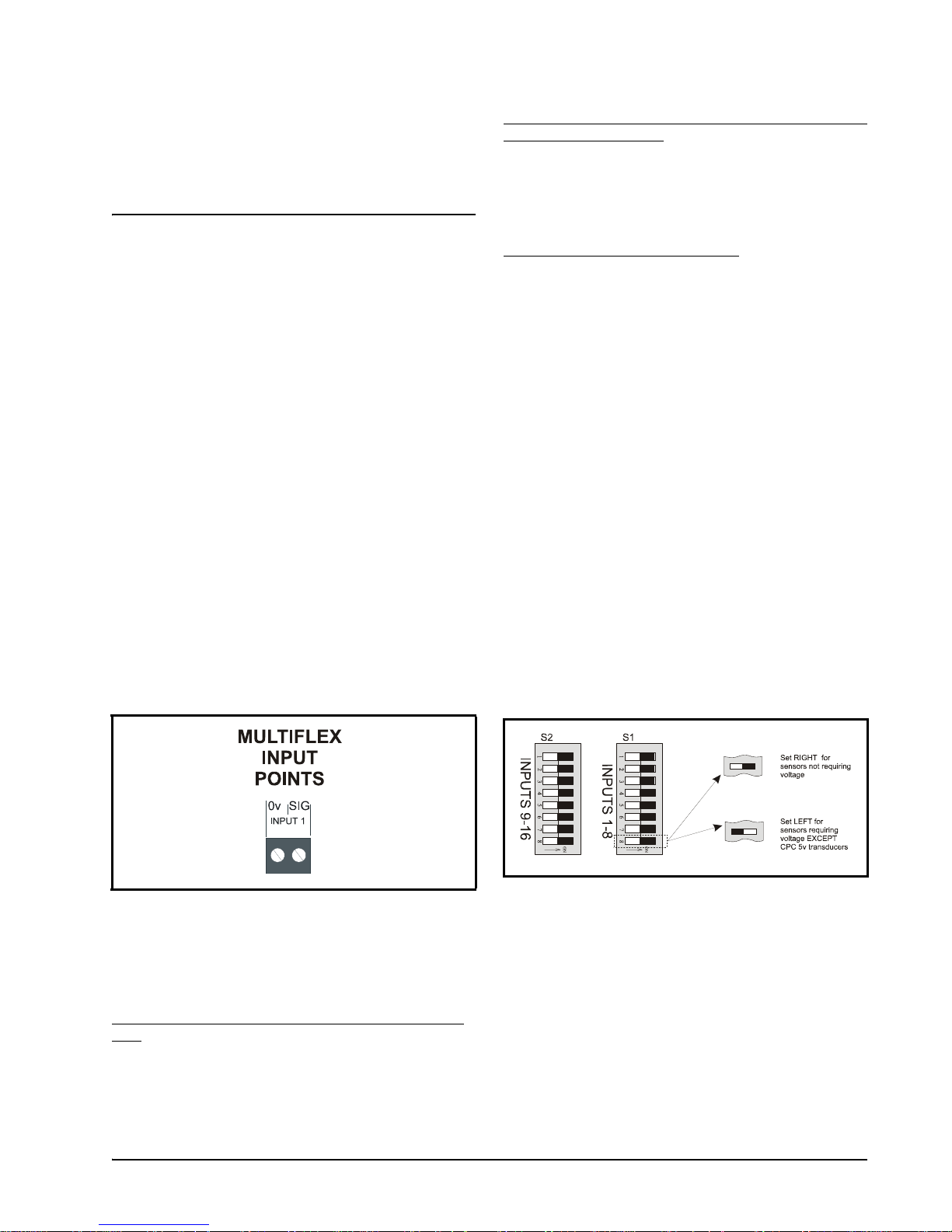

4.1. The Inputs

4.1.1. Connecting Sensors to the

MultiFlex CUB

Wiring an input to the input points on a Mul-

tiFlex board requires three steps:

1. Connect the sensor’s signal wires to the two

terminals of an input point.

2. Set the input type dip switch that corre-

sponds to the point being connected.

3. If necessary , connect the sensor to one of the

5V or 12V power terminals.

4.1.1.1. Wiring

An input point on a MultiFlex board consists

of two terminals, as shown in Figure 4-1. One of

these terminals, labeled SIG, reads the signal

from the sensor, while the other, labeled 0v is

where the sensor’s ground and/or cable shield

wire is connected.

All Pressure Transducers, Humidity Sensors, and Refrigeration Transducers

Pressure and refrigeration transducers and

humidity sensors are to be wired with shielded, 3

conductor, at least 22 GA wire (Belden #8771 or

equivalent).

Dewpoint and Light Level Sensors

These sensors are to be wired with shielded,

4 conductor at least 22 GA wire (Belden # 8729

or equivalent).

4.1.1.3. Input Type Dip Switches

Each MultiFlex input point has an input type

dip switch that must be set. Input type dip

switches are located in the switch banks labeled

S1 and S2.

The input type dip switch tells the input

board whether or not the sensor connected to the

point is a resistive type sensor. Generally, if the

sensor or transducer supplies its own voltage

signal to the point, the dip switch should be set

to the LEFT position. If the sensor uses variable

resistance and requires voltage to be supplied to

it from the input point, set the dip switch to the

RIGHT position. Dip switches for unused points

should be set to the RIGHT position.

Figure 4-1 - Input Board Points

4.1.1.2. Sensor Wiring Types

Specific wiring types are required for each

type of sensor used with E2, Einstein, or RMCC.

All Analog Temperature Sensors and Air Flow Sensors

Temperature and air flow sensors are to be

wired with shielded, 2 conductor, at least 22 GA

wire (Belden # 8761 or equivalent).

The Inputs CUB Input and Output Setup • 9

Figure 4-2 - Input Type Dip Switches for CUB Board

Page 20

4.1.2. Power Connection

If power is needed to operate the sensor, four

points are provided on the MultiFlex board that

supply DC power: one +12VDC point, and three

+5VDC points. See Figure 4-3 for the location

of these points.

Figure 4-3 - Input Board Power Sources

To connect to one of the DC power sources,

simply connect the sensor’s power wire to one of

the terminals.

A sensor that requires 24VAC can be pow-

ered off the MultiFlex’s own 24VAC power connection. T o connect to the 24VAC power source,

connect the sensor’s power wires to terminals

AC1 and AC2.

4.1.2.1. Current Ratings for On-Board

Power Sources

The maximum current that may be drawn

from the +12VDC terminal is 100 milliamps.

The maximum current that can be drawn from

all three +5VDC terminals COMBINED is 50

milliamps.

4.1.2.2. Powering Sensors Requiring

24VAC Off the Power Transformer

Some sensors that requires 24VAC can be

powered off the MultiFlex’s own 24VAC power

connection. To connect to the 24VAC power

source, connect the sensor’s power wires to terminals AC1 and AC2.

This can only be done with sensors that keep

the 24VAC signal isolated from its DC output

signal (such as CPC’s Dewpoint Probe). If the

output signal is not isolated from the 24VAC

input, you must use a separate transformer.

4.1.3. MultiFlex CUB Fixed Input Lo-

cations

The MultiFlex CUB supports a large number

of different types of input sources that might be

found on a single condensing unit’s pressure

control, condenser control, or refrigeration control systems. Because input locations are specified by the user in the system software, you can

connect inputs from the condensing unit to any

point on the CUB. However, to make setup easier, the CUB has assigned default sensor locations to a few of the inputs on the board.

Table 4-1 lists the inputs with assigned

defaults. If you choose to not use the defaults

listed, you may change any or all of them in the

system software (see Section 7.3.3., Screen 3:

Inputs and Section 8.2.7., Input Setup Screens).

CUB Input

Point

Number

1 Suction

2 Discharge

3 Oil Trans-

4 Case 1

16 Alarm

Label

Transducer

Transducer

ducer

Temp

Reset

Sensor to Connect

To This Point

0-100PSI Pressure

Transducer, measuring

suction pressure

0-500PSI Pressure

Transducer, measuring

discharge pressure

0-200PSI Pressure

Transducer, for measuring oil pressure

Discharge air temperature sensor for the

cooler or case lineup

Digital contact closure

(switch or push button)

to reset alarms

10 • MultiFlex CUB-II and CUB-TD I&O Guide 026-1705 Rev 7 06-APR-2010

Table 4-1 - CUB Default Inputs

Page 21

4.2. The Outputs

The MultiFlex CUB has eight relays that

energize and de-energize to control output loads.

Decision #1 is made by setting the fail-safe

switch. This is a bank of eight switches on the

plug-in output module. Each switch corresponds

to an output on the board (switch #1 = output #1,

etc.).

When setting up an output on one of these re-

lays, you must make two important decisions:

1. Do you want an ON command from your

controller to mean “energize the relay” or

“de-energize the relay,” and

2. When the relay is de-energized, as is the case

when the CUB goes offline or loses power,

do you want the contacts to be OPEN or

CLOSED?

HHT

Display

ON

OFF

ON

OFF

ON

OFF

Contact

State

CLOSED

OPEN

OPEN

CLOSED

CLOSED

OPEN

Equipment

State

ON

OFF

OFF

ON

OFF

ON

Fail Safe

ON UP N.C

OFF UP N.O

OFF UP N.C.

Decision #2 is made either by setting a fail-

safe jumper (for the MultiFlex CUB) or by wiring the load to either the N.O. or N.C. terminals

on the Form C contact (for the MultiFlex

16I8O).

T able 4-2 shows how the fail-safe s witch and

Form C contacts should be configured based on

how you want the output to perform during both

normal operation and during network/power

loss.

Set Failsafe Switch

To:

Form C Contacts

Used:

ON

OFF

ON

OFF

ON

OFF

Table 4-2 - Output Board Fail-Safe and Switch Settings

CLOSED

OPEN

OPEN

CLOSEDONOFF

CLOSED

OPEN

OFF

ON

ON

OFF

ON DOWN N.O

OFF DOWN N.C

OFF DOWN N.O

The Outputs CUB Input and Output Setup • 11

Page 22

4.2.1. Relay Output Ratings and Fuse

RELAY IS

CLOSED

ON POWE R

FAILURE

RELAY IS

OPEN ON

POWER

FAILURE

Protection

Each relay output on the MultiFlex Combination I/O boards is rated for up to 240 VAC

with a maximum current of 2 amps.

Table 4-1 lists the inputs with assigned

defaults. If you choose to not use the defaults

listed, you may change any or all of them in the

system software (see Section 7.3.7., Screen 7:

Outputs and Section 8.2.8., Outputs Screens).

Each relay is fused with a 2 amp fast-blow

5mm x 20mm fuse, Bussman GMA-2 or equivalent.

4.2.2. Wiring Outputs to Points

The MultiFlex CUB has Form C relay contacts. Figure 4-4 shows how to wire the threeterminal Form C contact.

One wire of the two-wire connection should

always be connected to the middle terminal. The

second wire must either be connected to the N.C.

terminal (if you want the path to be closed when

the relay is de-energized) or the N.O. terminal (if

you want the path to be open during power failure).

N.C. N.O. N.C. N.O.

Figure 4-4 - Form C Contact Wiring

CUB

Output

Point

Number

1 Compres-

2 Defrost Electric defrost heaters

3 Condenser

8 Alarm Out-

Table 4-3 - CUB Default Outputs

Label

sor

Fan #1

put

Device to Connect

To This Point

Compressor

or hot gas valve

Condenser fan (or 1st

condenser fan if multiple fans are present)

Digital contact closure

that is ON when an

alarm condition is

active in the condensing unit.

4.2.3. MultiFlex CUB Fixed Outputs

The MultiFlex CUB supports a large number

of different types of output devices that might be

found on a single condensing unit’s pressure

control, condenser control, or refrigeration control systems. Because output locations are specified by the user in the system software, you can

connect outputs from the condensing unit to any

point on the CUB. However, to make setup easier, the CUB has assigned default sensor locations to a few of the inputs on the board.

12 • MultiFlex CUB-II and CUB-TD I&O Guide 026-1705 Rev 7 06-APR-2010

Page 23

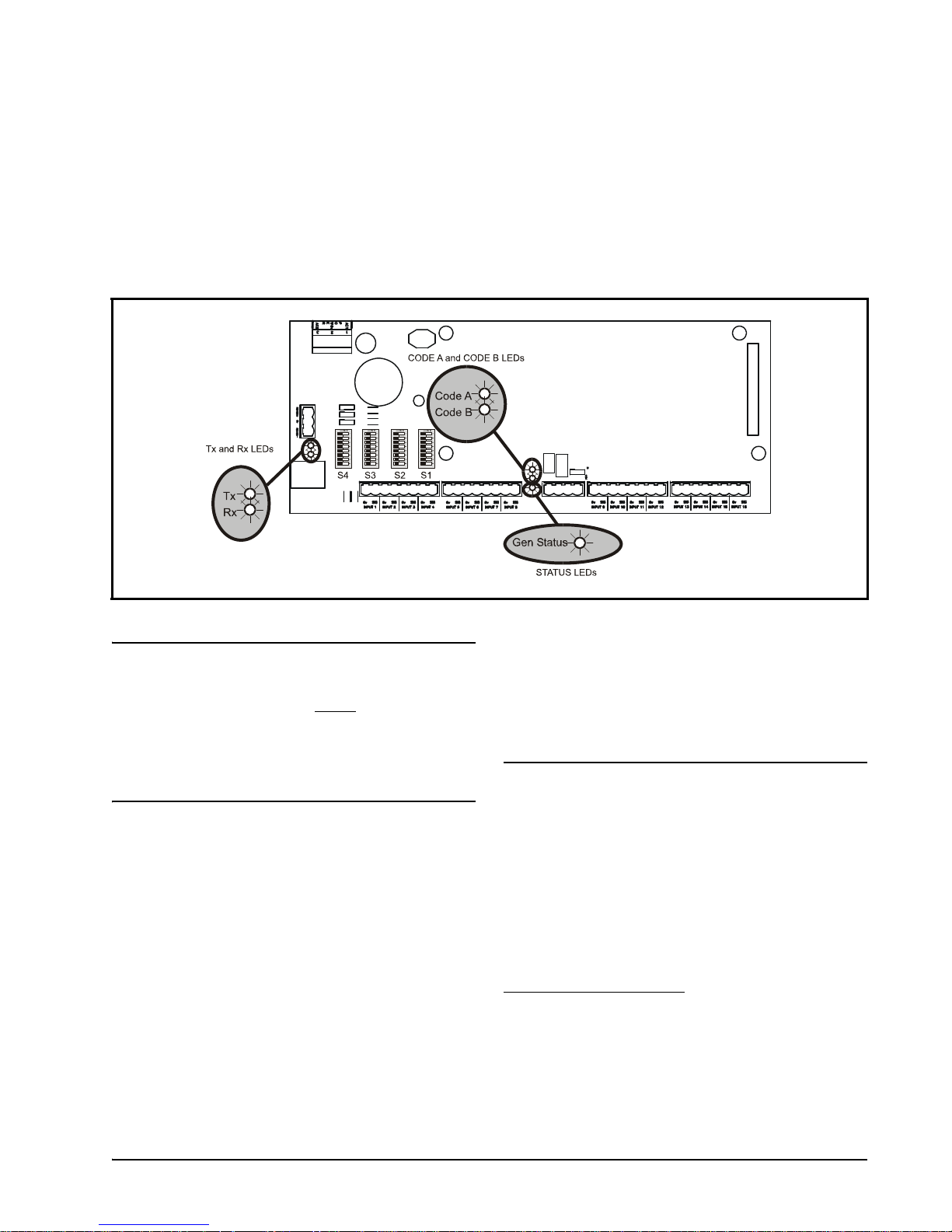

5 Board Status LEDs

When a MultiFlex board is powered up, you

will be able to determine the operating status of

the board by observing its status LEDs. Figure

5-1 shows the location of the MultiFlex’s status

LEDs.

Figure 5-1 - MultiFlex Status LED Locations

5.1. Status LED

The Status LED blinks green once per second to show that the board is powered and operational. If this light is dark, the board has likely

lost power.

5.2. Tx and Rx LEDs

The Tx and Rx LEDs indicate when the MultiFlex is sending or receiving messages on the

RS485 Network.

The Tx LED blinks once every time the MultiFlex sends a response to the E2, Einstein, or

REFLECS. The Rx LED blinks once when the

MultiFlex receives a message.

If the MultiFlex is connected to the network

and set up to communicate with the controller,

you should see these lights blinking regularly. If

they do not, there may be a problem with the network.

5.3. Code A and Code B LEDs

All MultiFlex models except the MultiFlex

16 have two LEDs labeled Code A and Code B.

These LEDs indicate failure conditions. When

these LEDs are OFF, there are no failures active.

When one or both of these LEDs are blinking,

there are failure conditions. The rate of blinking

indicates the type of failure:

Code A Failure Conditions

• Blinking fast (4 times/second) - There is a problem

with the flash memory or hardware clock on this

board. This generally means the board is bad and

must be replaced.

• Blinking slow (1 time/second) - The board is not re-

ceiving any messages addressed to it. This means ei-

Status LED Board Status LEDs • 13

Page 24

ther the I/O Network is down or it has not yet been

commissioned in the E2, Einstein, or REFLECS

Network Configuration screen.

Code B Failure Conditions

• Blinking 2 times/second - The battery on this board

that backs up the CUB configuration during power

failures has failed. If you see this light flashing, the

battery will need to be replaced to avoid loss of configuration.

Also, check the position of the Enable Battery jumper, located at the bottom right of the board just underneath the output plug-in board. If this jumper is

set to the DOWN position, move it to the UP position. This will enable the battery and should cause

the Code B light to stop flashing.

5.4. Relay Output LEDs

Each relay output point on a MultiFlex has

an indicator LED that shows the status of the

output. This LED is lit to show the output is ON,

and unlit to show the output is OFF.

The definition of ON and OFF in this case is

determined by the position of the fail-safe dip

switch (see Table 4-2). Therefore, if the output’s

switch is UP, a lit LED means the path is

CLOSED for N.C. contacts and OPEN for N.O.

contacts.

14 • MultiFlex CUB-II and CUB-TD I&O Guide 026-1705 Rev 7 06-APR-2010

Page 25

6 MultiFlex CUB-II and

CUB-TD Software Overview

The CUB-II is capable of controlling all vital

systems of a single condensing unit, including

compressors, condenser fans, evaporators and

case circuit systems. Extended logging and

alarm control capabilities require connection to

an E2 or Einstein RX refrigeration controller.

6.1. Compressor Control

Since a single condensing unit has a single

compressor, the MultiFlex CUB-II’s pressure

control strategy uses simple Cut In/Cut Out

strategy for activating and deactivating the compressor. The compressor may be controlled

either by suction pressure or case temperature.

setpoint plus one-half the deadband, the compressor will turn ON and will remain ON until

the case temperature falls below the setpoint

minus one-half the deadband.

NOTE: A suction transducer is required even

for temperature control and is used to prevent

the compressor from operating below the minimum suction pressure setpoint.

6.1.2.1. Pump Down

If the CUB-II is using the Temperature strategy, it also has the option of using a special

Pump Down mode to pump refrigerant out of the

evaporator coil when going from Refrigeration

to Idle or from Refrigeration to Defrost.

A Pump Down causes the refrigeration solenoid to shut while keeping the compressor ON.

The compressor will remain ON until the suction

pressure drops below a minimum setpoint (or

until a fail-safe time elapses).

6.1.1. Suction Pressure Compressor

Control

Using the Suction Pressure Control strategy ,

the CUB-II compares the suction pressure to a

set of Cut In/Cut Out setpoints. If the suction

pressure rises higher than the Cut In setpoint, the

compressor is activated and remains activated

until the suction pressure falls below the Cut Out

setpoint.

To prevent short-cycling of the compressor,

minimum ON and OFF times may be used in

this strategy.

6.1.2. Case Temperature Compres-

sor Control

Using the Case Temperature Control strategy, the CUB-II only activates the compressor

when refrigeration is necessary in the case. This

strategy uses a temperature setpoint and a deadband. When the case temperature is above the

Idle Pump Down With Door Switches

If a door switch is available and Idle Pump

Down mode is enabled, the CUB-II will do a

Pump Down every time a door switch is activated.

6.1.2.2. Fallback Pressure Setpoints

When in Temperature strategy, if the case

temperature sensors fail or the CUB-II is otherwise unable to determine the case circuit air temperature, the CUB-II will cease operating in

Case Temperature Compressor Control mode

and use fallback suction pressure Cut In/Cut Out

setpoints to control the compressor. This fallback mode operates exactly like the Suction

Pressure Compressor Control mode described in

Section 6.1.1.

The CUB-II will continue to operate using

the fallback pressure setpoints until a case temperature sensor value becomes available. The

CUB-II will then resume Temperature strategy

control.

Compressor Control MultiFlex CUB-II and CUB-TD Software Overview • 15

Page 26

6.2. Condenser Fan Control

6.2.1. Temperature Differential (TD)

Strategy

Temperature differential strategy attempts to

keep a minimum amount of difference between

the temperature of the refrigerant and the ambient temperature.

The CUB-II and CUB-TD temperature differential strategy uses drop leg temperature for the

refrigerant temperature and plenum temperature

for the ambient temperature. The formula for

determining the TD control value is:

TD = (dropleg temp) + (dropleg offset*) plenum temp.

* DropLeg Offset is a user-configured parameter to allow fine-tuning of the drop leg temperature measurement.

In TD condenser control operation, when the

TD rises above TD setpoint + (TD deadband /

2), an increase in fan capacity is called for. Similarly, when the TD drops below TD setpoint -

(TD deadband / 2), a decrease in fan capacity is

called for. TD can control up to four condenser

fans.

6.2.1.1. TD Control Fail-Safes

TD control operates as explained in Section

6.2.1. as long as plenum and drop leg tempera-

ture inputs are available and the drop leg temperature remains within a minimum/maximum

range configured by the user. Otherwise, TD

control uses various fail-safe modes to maintain

proper operation of condenser control.

Drop Leg Temperature Not Available

In the event drop leg temperature is not

available (due to probe failure), all fan stages

will be staged on.

Drop Leg Temperature Above Maximum Drop Leg

Setpoint

If the drop leg temperature (DropLeg Temp)

rises above the maximum drop leg temperature

setpoint (DropLeg Max), an increase will be

called for until DropLeg Temp drops below

DropLeg Max. This protects against the possibility of the DropLeg Temp rising too high as a

result of high plenum temperature.

Drop Leg Temperature Below Minimum Drop Leg

Setpoint

If the drop leg temperature drops below the

minimum drop leg temperature setpoint

(DropLeg Min) a decrease will be called for

until DropLeg Temp rises above DropLeg Min.

This protects against the possibility of the

DropLeg Temp falling too low as a result of low

plenum temperature.

Plenum Temperature Not Available

If plenum temperature is not available (due

to probe or communication failure), control will

be based on the DropLeg Min and Max setpoints.

6.2.2. Pressure Control Strategy

Pressure control strategy uses Cut In/Cut Out

setpoints for control based on discharge pressure. The CUB-II can control a maximum of two

fans using this strategy. This strategy is not

available in the CUB-TD.

Traditional strategy condenser fan control

simply compares the value of the discharge pressure transducer to a set of Cut In/Cut Out setpoints for each fan. If the discharge pressure

rises above the Cut In setpoint for a fan, that fan

will turn ON and will remain active until the discharge pressure falls below the fan’ s Cut Out setpoints.

Condenser fans may be programmed with a

minimum ON time to prevent short-cycling.

16 • MultiFlex CUB-II and CUB-TD I&O Guide 026-1705 Rev 7 06-APR-2010

Page 27

6.2.3. Case Temperature Control

Case temperature control supports using a

combination of up to six case temperature inputs

as the control input. The CUB-II also supports

multiple strategies for combining multiple case

temp inputs, including minimum temp, maximum temp, and average temp.

6.3. Defrost Control

The CUB-II controls scheduled defrosts for

its case circuit, and supports both electric and

off-cycle (or timed) defrost. Up to 12 daily

scheduled defrost times can be programmed in

the CUB-II memory. The CUB-II executes

defrost cycles at each scheduled time.

6.3.1. Defrost Termination

6.4.1. How Cut In/Cut Out Control

Works

Cut In/Cut Out setpoints work differently

depending upon whether the Cut In/Cut Out setpoint is higher.

Cut In Higher Than Cut Out

The CUB-II allows for defrost termination

based on temperature or suction pressure. Temperature termination can use either a digital

defrost sensor (or Klixon) or an analog termination sensor, whose value is compared to the termination setpoint. Suction pressure termination

will terminate a defrost cycle when the suction

pressure rises above a programmed suction pressure termination setpoint.

Defrost cycles may be programmed with a

minimum defrost time and a maximum defrost

time.

6.4. Sensor Control

The CUB-II provides for up to two generic

Cut In/Cut Out control algorithms for use in controlling subsystems related to the condensing

unit. Each sensor control application consists of

an input (or a set of inputs combined into a single value), a set of Cut In/Cut Out setpoints, and

a digital output that is controlled by comparing

the input to the setpoints.

Figure 6-1 - Cut In Setpoint Higher than Cut Out

When the Cut In setpoint is higher than the

Cut Out setpoint, the Sensor Control output turns

ON when the sensor input goes higher than the

Cut In setpoint. The Sensor Control output

remains ON until the input falls below the Cut

Out setpoint, at which time the output turns OFF .

(See Figure 6-1 for an illustration).

Typical uses for a sensor control application

on a CUB-II include: refrigerant leak detection,

motor room temperature control, and case lights.

Defrost Control MultiFlex CUB-II and CUB-TD Software Overview • 17

Page 28

Cut In Lower Than Cut Out

Figure 6-2 - Cut In Setpoint Lower Than Cut Out

When the Cut In setpoint is lower than the

Cut Out setpoint, the Sensor Control output turns

ON when the sensor input goes lower than the

Cut In setpoint. The Sensor Control output

remains ON until the input rises above the Cut

Out setpoint, at which time the output turns OFF .

(See Figure 6-2 for an illustration).

read this value into Global Data as SPARE

ANLG02. All other CUB-IIs that are assigned to

zone 2 will read SPARE ANLG02 as the motor

room temp.

6.4.2.1. Exhaust Fan Control

The CUB-II in each zone that is reading the

motor room temp may also use the input to perform Cut In/Cut Out control of a single output.

This can drive an exhaust fan or similar HVAC

device.

6.4.2.2. Example of a Motor Room Zone

Temperature Configuration

An example of how motor room temperature

zone control is shown in Figure 6-1. In this

example, there are two motor rooms with five

CUB-IIs each. Each motor room has an exhaust

fan that is controlled by the same CUB-II that

has the motor room temp probe. This fan is controlled entirely by the individual CUB-II.

6.4.2. Motor Room Temperature

Control

Part of the capabilities of sensor control

involves the control of temperature in a motor

room.

The CUB-II takes a “zone control” approach

to controlling motor room temperature. All the

CUB-IIs attached to a single E2 or Einstein can

be divided into up to four “zones” (physically,

up to four different motor rooms). In each zone,

one CUB-II must be set up with a sensor control

input designated as “Motor Room Temp.” This

temperature value is shared with E2 or Einstein’ s

Global Data handler, and passed back down

through Global Data to all CUB-IIs that share

the same zone number.

In an E2 or Einstein that has CUB-II boards

attached to it, the Global Data values SPARE

ANLG01 through SP ARE ANLG04 are reserved

for motor room temperatures in zones 1-4. If, for

example, a CUB-II in zone 2 has a “Motor Room

Temp” sensor control input, E2 or Einstein will

The motor room temperature for Zones 1 and

2 are passed to E2 or Einstein as the Global Data

values SPARE ANLG01 and SPARE ANLG02.

All the CUB-IIs in Zone 1 except the one with

the sensor will read the SPARE ANLG01 Global

Data value as their zone’s motor room temp, and

will display this value on their HHT status

screens.

WARNING: If you are using CUB-IIs, you

cannot use Global Data’s SPARE ANLG 01

through 04 inputs for any purpose other than

motor room temperature control. If you need to use

some of Global Data’s “Spare Analog” slots to share

values between E2s or Einsteins, use SPARE ANLG 05

through 08.

18 • MultiFlex CUB-II and CUB-TD I&O Guide 026-1705 Rev 7 06-APR-2010

Page 29

Resetting a High Discharge Trip

Resetting a high discharge trip safety mode

can be done manually by closing the Alarm

Reset input on the CUB-II or by resetting the

High Discharge Trip alarm in the E2 or Einstein

alarm log.

You can also program the CUB-II to autoreset when the discharge pressure falls below the

discharge trip setpoint minus a user-defined differential. This ensures the pressure will drop

well below the trip setpoint before re-starting the

compressor.

Figure 6-1 - Example of Zone Temperature Control Setup

6.5. Alarm Conditions (Safety

Modes)

When certain conditions are detected, the

CUB-II and CUB-TD operate in a special mode

(called Safety mode) in order to correct the condition or to prevent equipment, product, and/or

energy loss. Safety mode alarm conditions can

be reset two different ways:

1. Resetting the alarm in the E2 or Einstein Alarm Log will reset all active

Safety mode alarms.

2. Defining an alarm reset input on the

CUB-II, and then manually closing

the input will reset all active Safety

mode alarms.

6.5.1. High Discharge Trip Safety

Mode

When using auto-reset, you may also set a

maximum number of auto-reset attempts. The

CUB will only attempt an auto-reset if it has not

already auto-reset the CUB a number of times in

the past hour equal to the user-defined maximum. If CUB’s auto-reset maximum has already

been met, it will remain in High Discharge Trip

mode until it is manually reset.

6.5.2. Compressor Proof Fail Safety

Mode

If the CUB-II has a Compressor Proof input

configured, it can use this input to verify the

compressor is operating properly. Under normal

conditions, the CUB-II will expect the proof

input to mirror the state of the compressor at all

times (i.e., proof registers ACTIVE when the

compressor is ACTIVE, and INACTIVE when

the compressor is INACTIVE). If the proof input

does not mirror the value of the compressor state

for a period of time longer than a user-defined

period, the CUB-II will enter Proof Fail mode.

The CUB-II will always try to prevent the

condensing unit’ s dischar ge pressure from rising

above a user-defined setpoint, called the dis-

charge trip setpoint. If the discharge pressure

ever rises above this setpoint, the CUB will enter

the High Discharge Trip Safety mode. This will

lock the compressor OFF, and cause the Circuit

State of the CUB to display Rack Fail in the E2

or Einstein and HHT status screens.

Alarm Conditions (Safety Modes) MultiFlex CUB-II and CUB-TD Software Overview • 19

In Proof Fail mode, you may either choose to

program the CUB-II to shut down the compressor until the failure is cleared, or to keep

attempting to activate/deactivate the compressor

as normal.

Page 30

Resetting a Compressor Proof Failure

Resetting a Compressor Proof Failure Safety

mode can be done manually by closing the

Alarm Reset input on the CUB or by resetting

the Compressor Proof Fail alarm in the E2 or

Einstein alarm log.

You can also program the CUB-II to autoreset when the proof input state indicates the

compressor is physically behaving as commanded. When using auto-reset, you may also

set a maximum number of auto-reset attempts.

The CUB-II will only attempt an auto-reset if it

has not already auto-reset the CUB-II a number

of times in the past hour equal to the userdefined maximum. If CUB-II’s auto-reset maximum has already been met, it will remain in

Compressor Proof Fail mode until it is manually

reset.

6.5.3. Compressor Oil Failure Safety

Mode

6.5.4. Phase Fail Mode

If a phase fail checking device is present onsite, the CUB-II can be programmed to shut

down multiple-phase devices it controls.

To enable phase protection, a digital phase

fail checking device must be connected to one of

the CUB-II’s physical inputs. When this input

signifies a phase failure has occurred, the CUBII immediately shuts down the compressor, the

condenser fans, and the defrost output. CUB-II

will lock these devices OFF until the phase failure is over.

NOTE: CUB-II will not lock out evaporator

fans when a phase fail occurs, because these

are single-phase devices.

6.6. Door Switches and Clean

The CUB-II can monitor compressor oil

pressure using either an oil pressure transducer

or a digital oil pressure switch. When a low oil

pressure condition occurs, CUB-II can be programmed to lock the compressor OFF to prevent

equipment damage.

Resetting an Oil Failure

Resetting an Oil Fail Safety mode can be

done manually by closing the Alarm Reset input

on the CUB or by resetting the “Oil Failure”

alarm in the E2 or Einstein alarm log.

You can also program the CUB-II to autoreset when the oil failure input state indicates the

oil pressure has returned to normal. When using

auto-reset, you may also set a maximum number

of auto-reset attempts. The CUB-II will only

attempt an auto-reset if it has not already autoreset the CUB-II a number of times in the past

hour equal to the user-defined maximum. If

CUB-II’s auto-reset maximum has already been

met, it will remain in Oil Fail mode until it is

manually reset.

(Wash) Switches

The MultiFlex CUB-II has special modes of

operation to accommodate use of freezer door

switches and clean (or wash) switches.

6.6.1. Door Switches

If the CUB-II is controlling refrigeration in a

walk-in freezer or other case type that has a door

switch equipped, the CUB-II may be programmed to shut off the compressor and fans

when the door is open. The CUB-II will lock the

compressor and case fans OFF until the door is

closed, at which time it will resume normal

refrigeration control.

The CUB-II may be programmed with an

alarm time and a fail-safe time. If the door is

open longer than the alarm time, the E2 or Einstein controlling the CUB-II will generate an

alarm to warn store personnel that the door has

been left open. If the door is open longer than the

fail-safe time, the CUB-II will resume refrigeration to prevent product loss.