Page 1

Reference Manual

IP2013, Rev BA

February 2012

Mobrey MSP422

Ultrasonic Liquid Level Transmitter

Mobrey MSP422

www.mobrey.com

Page 2

Page 3

Reference Manual

NOTICE

Rev BA , Rev BA

February 2012

Mobrey MSP422

Mobrey MSP422 Ultrasonic

Liquid Level Transmitter

Read this manual before working with the product. For personal and system safety, and for

optimum product performance, make sure you thoroughly understand the contents before

installing, using, or maintaining this product.

The products described in this document are NOT designed for nuclear-qualified

applications.

This device complies with part 15 of the FCC rules. Operation is subject to the following two

conditions: (1) This device may not cause harmful interference, and (2) this device must

accept any interference received, including interference that may cause undesired

operation.

www.mobrey.com

Page 4

Page 5

Reference Manual

Rev BA , Rev BA

February 2012

Mobrey MSP422

Table of Contents

SECTION 1

Introduction

SECTION 2

Transmitter Overview

SECTION 3

Installation

Safety Messages. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Manual Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Customer Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Product Recycling/Disposal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Theory of Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Components of the Transmitter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Safety Messages. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Before You Install . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

General Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Mechanical Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Mounting Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Liquid Surface Conditions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

In-tank Effects. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Mounting the Transmitter Above the Liquid Surface . . . . . . . . . . . 3-5

Electrical Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

Cabling the Transmitter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

After Completing the Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

Lightning / Surge Protection and Other Loop Devices . . . . . . . . . . 3-8

SECTION 4

Starting up

Safety Messages. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Power Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Before Programming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

MSP422 Menu Map . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

Programming The MSP422. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

Display Units. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

First Measurements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

Setting the Bottom Reference . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

Setting 4 mA and 20 mA Levels . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

Setting the Output Damping. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-7

Selecting the Action on Alarm Condition . . . . . . . . . . . . . . . . . . . . 4-8

Setting 4 mA and 20 mA Levels Using Ranging. . . . . . . . . . . . . . . 4-9

Learn About Echoes From False Targets. . . . . . . . . . . . . . . . . . . 4-10

Final Checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-11

Power Failure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-11

www.mobrey.com

Page 6

Mobrey MSP422

Reference Manual

IP2013, Rev BA

February 2012

SECTION 5

Service and

Troubleshooting

APPENDIX A

Reference Data

APPENDIX B

Product Certifications

Safety Messages. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Servicing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

Diagnostics for The MSP422. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

General Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

Error Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-1

Temperature and Pressure Ratings. . . . . . . . . . . . . . . . . . . . . . . . . . .A-2

Load Limitations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-2

Dimension Drawings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-3

Safety Messages. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B-1

Manufacturing Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B-2

European Union Directive Information. . . . . . . . . . . . . . . . . . . . . . . . .B-2

Non-hazardous Location Certifications . . . . . . . . . . . . . . . . . . . . . . . .B-2

American and Canadian Certifications. . . . . . . . . . . . . . . . . . . . . .B-2

TOC--2

Page 7

Reference Manual

IP2013, Rev BA

February 2012

Mobrey MSP422

Section 1 Introduction

Safety Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 1-1

Manual Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 1-2

Customer Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 1-2

SAFETY MESSAGES Procedures and instructions in this manual may require special precautions to

ensure the safety of the personnel performing the operations. Infor mation that

raises potential safety issues is indicated by a warning symbol ( ). Refer to

the safety messages listed at the beginning of each section before performing

an operation preceded by this symbol.

Failure to follow these installation guidelines could result in death or serious

injury.

• Make sure only qualified personnel perform the installation.

• Use the equipment only as specified in this manual. Failure to do so may

impair the protection provided by the equipment.

Explosions could result in death or serious injury.

• The Mobrey MSP422 is only for use in a non-hazardous location

Electrical shock could cause death or serious injury.

• Use extreme caution when making contact with the leads and terminals.

Any substitution of non-recognized parts may jeopardize safety. Rep air, e.g. substitution

of components etc., may also jeopardize safety and is under no circumstances allowed.

www.mobrey.com

Page 8

Reference Manual

IP2013, Rev BA

Mobrey MSP422

February 2012

MANUAL OVERVIEW This manual provides installation, configur ation, and maintenance info rmation

for the Mobrey MSP422 ultrasonic level transmitter.

Section 2: Transmitter Overview

Section 3: Installation

Section 4: Starting up

Section 5: Service and Troubleshooting

Appendix A: Reference Data

Appendix B: Product Certifications

CUSTOMER SUPPORT For the latest customer support information, visit www.mobrey.com, and then

click on the quick links Mobrey Service or Product Support.

Individuals who handle products exposed to a hazardous substance can avoid injury if they

are informed of, and understand, the hazard. If the product being returned was exposed to a

hazardous substance as defined by OSHA, a copy of the required Material Safety Data

Sheet (MSDS) for each hazardous substance identified must be included with the returned

goods.

PRODUCT

RECYCLING/DISPOSAL

Recycling of equipment and packaging should be taken into consideration.

The product and packaging should be disposed of in accordance with local

and national legislation.

1-2

Page 9

Reference Manual

Distance

Level

Bottom Reference

IP2013, Rev BA

February 2012

Mobrey MSP422

Section 2 Transmitter Overview

Theory of Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .page 2-1

Components of the Transmitter . . . . . . . . . . . . . . . . . . . . page 2-2

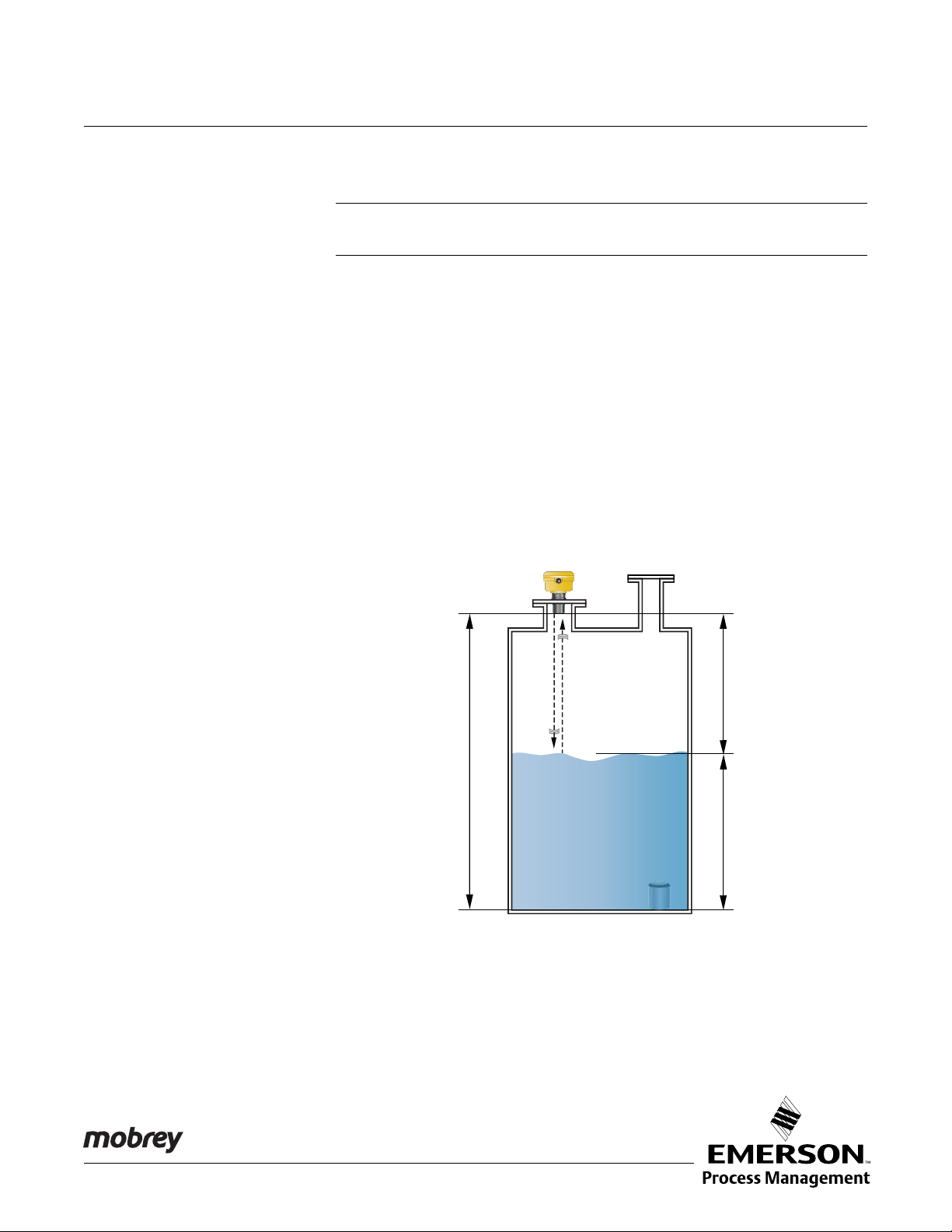

THEORY OF OPERATION The Mobrey MSP422 ultrasonic level transmitter is designed to be mounted

above a liquid and uses ultrasonic pulses to continuously measure the

distance to the liquid surface. The microprocessor-controlled electronics

measures the time delay between the transmitting and the receiving of the

reflected signals to calculate the distance (Figure 2-1).

When programmed with the bottom reference of the application – usually the

bottom of a tank – the MSP422 computes the liquid depth (level) and outputs

a 4–20 mA signal proportional to that level.

An LCD screen inside the enclosure displays the selected measurement.

Programming of the MSP422 is achieved using the integral push-buttons

inside the enclosure and the menu system shown on the LCD screen.

Figure 2-1. Typical Applica tio n

Using a Mobrey MSP422

Transmitter

The MSP422 may be mounted in a non-hazardous areas only.

www.mobrey.com

Page 10

Mobrey MSP422

M20

Conduit

Thread

Transmitter Face

2-in. Mounting

Thread

Electronics

Housing

MSP422 FEATURES

Supplied With:

1 x Cable Gland and Dust Cap

Reference Manual

IP2013, Rev BA

February 2012

COMPONENTS OF THE

TRANSMITTER

Figure 2-2. The Mobrey MSP

Series Transmitters

The Mobrey MSP422 has a housing containing advanced electronics for

signal processing, and terminals for connecting the external power supply.

The electronics produces an ultrasonic signal from the transmitter face.

It is a two-wire, loop-powered transmitter; the two wires are used for both

24 Vdc power supply connections and the 4–20 mA an alo g outpu t si gn a l.

A two-core, shielded/screened cable is required (not supplied).

A comprehensive specification for the Mobrey MSP422 is in the section

“Specifications” on page A-1.

2-2

Page 11

Reference Manual

IP2013, Rev BA

February 2012

Mobrey MSP422

Section 3 Installation

Safety Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 3-1

Before Yo u Install . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .page 3-2

Mechanical Installation . . . . . . . . . . . . . . . . . . . . . . . . . . .page 3-3

Electrical Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 3-7

SAFETY MESSAGES Procedures and instructions in this section may require special precautions to

ensure the safety of the personnel performing the operations. Infor mation that

raises potential safety issues is indicated by a warning symbol ( ). Please

refer to the following safety messages before performing an operation

preceded by this symbol.

Explosions could result in death or serious injury:

• The Mobrey MSP422 is only for use in a non-hazardous location

Failure to follow safe installation and servicing guidelines could result in death or

serious injury:

Make sure only qualified personnel perform the installation.

Use the equipment only as specified in this manual. Failure to do so may impair the

protection provided by the equipment.

Do not perform any service other than those contained in this manual unless you are

qualified.

Process leaks could result in death or serious injury.

Make sure that the transmitter is handled carefully.

High voltage that may be present on leads could cause electrical shock:

Avoid contact with leads and terminals.

Make sure the main power to the Mobrey MSP422 transmitter is off and the lines to any

other external power source are disconnected or not powered while wiring.

www.mobrey.com

Page 12

Mobrey MSP422

BEFORE YOU INSTALL The MSP422 is used for level measurement.

The transmitter must be installed in a location where it is protected from

ultraviolet radiation to prevent long term degradation of the plastics used

e.g. shrouded from direct sunlight.

It is important to correctly position the transmitter for reliable ultrasonic level

measurement. For maximum accuracy and stability of the level measurement

reading, the transmitter should always be shrouded from direct sunlight and

radiated heat.

The transmitter may be site-tuned to deal with most application conditions, but

it is recommended that the following guidelines be adopted where relevant.

NOTE:

The Mobrey MSP422 is designed to be mounted in a non-metallic fitting or

flange. The use of metallic fittings/flanges is not recommended.

General Considerations Guidelines:

a) Installation must be carried out by suitably trained personnel in

accordance with the applicable code of practice.

Reference Manual

IP2013, Rev BA

February 2012

b) If the equipment is likely to come into contact with aggressive substances,

it is the responsibility of the user to take suitable precautions that prevent

it from being adversely affected, thus ensuring that the type of protection

is not compromised.

Aggressive Substances are acidic liquids or gases that may attack met als

or solvents that may affect polymeric materials.

Suitable Precautions are regular checks as part of routine inspections, or

establishing, from the material's datasheet, that it is resistant to specific

chemicals.

c) The equipment must only be cleaned with a damp cloth.

d) The equipment is not intended to be repaired by the user and is to be

replaced by an equivalent unit. Repairs should only be carried out by the

manufacturer or approved repairer.

e) The transmitter is Double Insulated, and therefore Protective Earthing is

not required.

f) To maintain protection against the possible spread of fire, the supply to

the equipment must be limited to 3.75 Amps by a fuse or other mean s

g) Note that if the equipment is used in a manner not specified by the

manufacturer, the protection afforded by the equipment may be impaired.

h) The transmitter complies with the European Directive for Electro Magnetic

Compatibility (EMC) Class B. To ensure electro-magnetic compatibility in

any member state, it should not be installed in a reside ntial area.

3-2

NOTE:

It is not advisable to mount the transmitter in close proximity to a source of

electrical noise such as a variable-speed drive, or other high-powered

electrical device.

Page 13

Reference Manual

IP2013, Rev BA

February 2012

MECHANICAL

INSTALLATION

Mobrey MSP422

Mounting

Considerations

Guidelines:

a) The transmitter should be mounted above the liquid surface using the

2-inch thread provided, but not closer than 12 in. (0,3 m) to the surface.

The transmitter does not detect any liquid surface closer than

12 in. (0,3 m) to the transmitter face. (See "Mounting the Transmitter

Above the Liquid Surface" on page 3-5).

Optional flanges and bracket kits are available to help mounting.

b) The transmitter should be mounted vertically to ensure a good echo from

the liquid surface. The beam half angle of the transmitter is 6 degrees.

(See Figure 3-1 on page 3-4).

c) Obstructions in the tank, or well, may generate echoes which can be

confused with the real liquid surface echo. Obstructions within the beam

angle generate strong false echoes. Wherever possible, the transmitter

should be positioned to avoid false echoes.

d) To avoid detecting unwanted objects in the tank or well , it is advisable to

maintain a distance of at least 1.3 in. from the ce nter line of the transmitter

for every foot (11 cm per meter) range to the obstruction.

e) No false echoes are generated if the transmitter is located near the side of

the tank or well, and the wall is smooth and free of protrusions. However,

there will still be a reduction in the echo size. It is recommended that the

transmitter be mounted no closer than 12 in . (0,3 m ) to the wall to avoid a

large reduction in the echo size.

f) If the transmitter is mounted in an enclosed tank with a domed top, avoid

mounting the transmitter in the center of the tank roof because this could

act as a parabolic reflector and create unwanted echoes.

g) Avoid applications where heavy condensation could fo rm on the

transmitter face.

h) If the transmitter is mounted in a stand-off or nozzle, the transmitter face

should protrude at least 0.2 in. (5 mm) into the tank. If this is not possible,

see "Mounting the Transmitter Above the Liquid Surface" on page 3-5).

i) If the transmitter is used in environments where direct sunlight can cause

high surface temperatures on exposed instruments, a sun-shade is

recommended.

3-3

Page 14

Mobrey MSP422

Max. 3°

C

Use Non-metallic

Fitting / Flange

C =1.3 in./ft. (11 cm/m)

C Min. = 12 in. (0,3 m)

6° Beam

Half Angle

Figure 3-1. Min And Max

Distances From Tank Wall

Reference Manual

IP2013, Rev BA

February 2012

Liquid Surface

Conditions

Guidelines:

a) Foaming liquids can reduce the size of the returned echo beca use foam is

a poor ultrasonic reflector. Mount an ultrasonic tran smitter ove r an area of

clear liquid, such as near the inlet to a tank or well. In extreme conditions,

or where this is not possible, the transmitter may be mounted in a vented

stilling tube provided that the inside measurement of the stilling tube is at

least 4 in. (100 mm) and is smooth and free from joints or protrusions. It is

important that the bottom of the stilling tube stays covered to prevent the

ingress of foams.

b) Avoid mounting the transmitter directly over any inlet stream.

In-tank Effects Guidelines:

a) Stirrers or agit ators can cause a vortex. Moun t the transmitter of f-center of

any vortex to maximize the return echo.

b) If stirrer blades become uncovered, they create echoes as they pass

through the ultrasonic beam. The transmitter can learn to ignore these

false echoes (see "Learn About Echoes From False Targets" on

page 4-10).

c) In tanks with rounded or conical bottoms, mount the transmitter off-center .

If needed, a perforated reflector plate can be installed on the tank bottom

directly under the transmitter center line to ensure a satisfactory return

echo.

d) Avoid detecting pump casings, as the liquid falls away, by not mounting

the transmitter directly above pumps. If this is not possible, fine-tuning of

the transmitter on-site may be required.

3-4

Page 15

Reference Manual

IP2013, Rev BA

February 2012

Mobrey MSP422

Mounting the Transmitter

Above the Liquid Surface

A 2-in. thread is provided to mount the transmitter. The thread form is either

2-in. BSPT or 2-in. NPT, and is clearly marked on the hexagon of the

transmitter body.

NOTE:

The Mobrey MSP422 is designed to be mounted in a non-metallic fitting or

flange. The use of metallic fittings/flanges is not recommended.

To help installation, flange accessories and bracket kits are available from

Mobrey.

Procedure:

1. Ensure that the transmitter is perpendicular to the liquid surface to

maximize the return echo size.

2. Check that the maximum liquid level will not enter the 12-in. (0,3 m)

blanking zone of the transmitter.

3. When installing in a tank with a nozzle or stand-off

(Figure 3-2 on page 3-6):

a) Use PTFE tape on the screw thread (Figure 3-2 on page 3-6).

b) Lower transmitter into the tank through the process connection.

c) Turn the transmitter until it is properly secured in the process

connection (Figure 3-2 on page 3-6).

d) Tighten to a torque of 1.5 lbf.ft (2 Nm) using the hexagon. Do not use

the transmitter housing to tighten.

NOTE:

If the transmitter face does not protrude into the vessel, note the dimensions

in Table 3-1 for Figure 3-2, and ensure that the nozzle/vessel weld is smooth

and free from internal weld beads or other projections.

4. When installing using a bracket kit (Figure 3-3 on page 3-6):

a) Attach bracket to the disc using the 3 screws provided.

b) Attach bracket and disc to a support. The combined weight of bracket

and disc is 16 oz (0,5 kg). For transmitter weight, see "Specifications"

on page A-1.

c) Use PTFE tape on the screw thread of the transmitter

(Figure 3-2 on page 3-6).

d) Insert the transmitter into the disc.

e) Tighten to a torque of 1.5 lbf.ft (2 Nm) using the hexagon. Do not use

the transmitter housing to tighten.

NOTE:

The bracket kit contains a stainless steel angle bracket and PVC threaded

disc, which may be used to mount the transmitter on a support over the liquid

surface. The bracket and disc dimensions are in Figure A-4 on page A-4.

3-5

Page 16

Mobrey MSP422

PTFE

L

D

Tighten To A To rqu e Of 1 .5 lb f.ft (2 Nm)

Using The Hexagon. Do Not Use The

Housing To Tighten

Use Non-metallic

Fitting / Flange

No. 4X 13 Long Self Tap

Screw (3 Positions)

Carbon Steel (Zinc Plated)

PVC Disc

Stainless Steel Bracket

Note: Combined weight of bracket

and disc is 16 oz (0,5 kg)

Figure 3-2.

Mounting The Mobrey MSP422

Using A Nozzle/Stand-off

Reference Manual

IP2013, Rev BA

February 2012

NOTE:

If the transmitter face does not protrude into the vessel, note the dimensions

in Table 3-1 for Figure 3-2, and always ensure that the nozzle/vessel weld is

smooth and free from internal weld beads or other projections.

Table 3-1. Nozzle Diameter

Size (D) and Max Length (L)

Figure 3-3.

Mounting the Mobrey MSP422

Using a Bracket Kit

Nozzle Diameter Size (D) Maximum Nozzle Length (L)

DN50 (2 in.) 4 in. (100 mm)

DN80 (3 in.) 6.3 in. (160 mm)

DN100 (4 in.) 6.3 in. (160 mm)

DN125 (5 in.) 11.8 in. (300 mm)

3-6

Page 17

Reference Manual

Min. 12 Vdc

0.15 to 0.31 in.

(Ø4 to 8 mm)

Twisted-pair, Screened

Min. 0.22 mm

2

(24 SWG / 23 AWG)

Max. 1.5 mm

2

(16 SWG / 18 AWG)

+12 to 30 Vdc

0 Vdc

Max. 3000 m (9750 ft.)

T1: 24 Vdc

T2: 0 Vdc

IP2013, Rev BA

February 2012

Mobrey MSP422

ELECTRICAL

INSTALLATION

NOTE!

The MSP422 is not intrinsically safe certified, and is therefore for use in

non-hazardous (Ordinary Location) installations only.

Cabling the Transmitter The Mobrey MSP422 is a two-wire, loop-powered transmitter requiring an

external 24 Vdc power supply. There is one M20x1.5 cable entry. A suitable

conduit system or cable gland must be used to keep the weather-proof rating.

To cable the transmitter:

1. Make sure that the power supply is switched off.

2. Remove the cover of the transmitter housing.

3. Pull the cable through the cable gland /conduit.

4. Wire the transmitter as shown in Figure 3-4.

5. Connect the cable screen (shield) to ground at one end only.

6. Replace the cover, tighten the cable gland.

Figure 3-4. MSP422 Wiring

After Completing the

Wiring

To maintain the weather-proof rating and hazardous area protection of the

transmitter, ensure all cable glands, blanking plugs, and seals are in good

condition.

Check that the cover seal is in good condition, and not twisted or misaligned

in the seal location groove. When replacing the cover, tighten the three cover

screws evenly to exert uniform pressure on the cover seal.

3-7

Page 18

Mobrey MSP422

Reference Manual

IP2013, Rev BA

February 2012

Lightning / Surge

Protection and Other

Loop Devices

If the area is prone to lightning strike s or vo ltage surges, a suppressor device

may be installed between the transmitter and the control unit.

If an additional loop-powered device or sepa rately powered device is included

in the two-wire loop, the transmitter must receive a minimum voltage of

12 Vdc at 21 mA loop current. (See "Load Limitations" on pag e A-2).

3-8

Page 19

Reference Manual

IP2013, Rev BA

February 2012

Mobrey MSP422

Section 4 Starting up

Safety Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 4-1

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .page 4-2

Programming The MSP422 . . . . . . . . . . . . . . . . . . . . . . . . page 4-4

Final Checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .page 4-11

Power Failure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 4-11

SAFETY MESSAGES Procedures and instructions in this section may require special precautions to

ensure the safety of the personnel performing the operations. Infor mation that

raises potential safety issues is indicated by a warning symbol ( ). Refer to

the safety messages listed at the beginning of each section before performing

an operation preceded by this symbol.

Explosions could result in death or serious injury:

• The Mobrey MSP422 is only for use in a non-hazardous location

Failure to follow safe installation and servicing guidelines could result in death or

serious injury:

Make sure only qualified personnel perform the installation.

Use the equipment only as specified in this manual. Failure to do so may impair the

protection provided by the equipment.

Do not perform any service other than those contained in this manual unless you are

qualified.

www.mobrey.com

Page 20

Reference Manual

IP2013, Rev BA

Mobrey MSP422

February 2012

OVERVIEW The Mobrey MSP422 ultrasonic level transmitter is operated from a menu of

parameters, each held in a specific memory location within the transmitter.

The memory locations may be pictured as a matrix, and navigated for

programming the instrument using

The Integral Display Menu structure is shown in Figure 4-1 on pag e4-3.

The transmitter is pre-programmed at the factory with a value in each

parameter location so that when the power is first applied, the transmitter

gives a sensible reading.

This section details the local programming using the push-buttons provided

inside the transmitter.

and steps.

Power Up When the power is turned on, the transmitter takes several seconds to

initialize. The display will run a set-up routine, first illuminating all display

characters, and then showing the software revision number. Finally, a full set

of zeros is displayed while the microprocessor identifies the correct return

echo. After these checks are complete, the display indicates the live

measurement based upon the factory default values in memory.

On a new instrument aimed at a good targ et, the transmitter calcul ates a level

reading based upon the default value for the bottom reference.

The transmitter is now ready to be set-up with details of the application.

The transmitter may be programmed prior to, or after, installation. All

programmed data is retained in the transmitter memory after the power is

turned off.

Before Programming Important notes to help you program the transmitter:

a) Do not allow rain, or water , to enter the transmitter dur ing programming or

the circuit boards may be damaged.

b) See the instructions below on how to use the push-buttons to navigate

through the programming menu and select or enter application data.

c) Push the buttons firmly, but not too hard, to avoid damaging the circuit

boards. Also, to avoid entering incorrect data, do not push the buttons too

fast.

d) Holding down the green button

e) Pressing the red button

the previous level in the menu (see Figure 4-1 on page 4-3).

Note, however , if the red button

has been made or new data has been entered (i.e. stop ped flashi ng), this

option selection / new data will automatically be saved (see Figure 4-1).

at certain locations in the menu returns you to

scrolls through any option list.

is pressed after a menu option selection

4-2

Page 21

Reference Manual

IP2013, Rev BA

February 2012

MSP422 Menu Map

Figure 4-1. MSP422 Menu Map

Mobrey MSP422

4-3

Page 22

Mobrey MSP422

Reference Manual

IP2013, Rev BA

February 2012

PROGRAMMING

THE MSP422

Refer the Integral Display menu on a card tucked between the housing and

body, and in Figure 4-1 on page 4-3.

Display Units The display units are indicated by the position of the decimal point in the

displayed PV value:

Units Display

m 8.000

ft. 26.24

in. 314.9

Default values are as follows:

MSP422-B28: m

MSP422-N28: ft.

NOTE:

See Figure 4-1 on page 4-3 for a map of the programming menu structure

showing how to access all the menu options and return to the PV display.

To change the display units:

a) Start from the PV display (see the note above.)

b) Hold down the blue button

c) The display units will then change according to the following sequence:

MSP422-B28: Metres to Feet, Feet to Inches, and Inches to Metres.

MSP422-N28: Feet to Inches, Inches to Metres, and Metres to Feet.

d) Continue to hold down the blue button

unit in the above sequence after every three seconds.

e) Confirm the display units by releasing the blue button

The same units must be used when programming in the bottom reference and

the 4 and 20 mA points.

for 10 seconds, but do not release it yet.

to change to the next display

.

4-4

The 4–20 mA output may be set to operate over all or just a part of the total

measuring range. There is no limit on the minimum span o f the current output,

although a span below 4 in. (100 mm) is not recommended.

The 4 mA level may be set above or below the 20 mA level to suit the

monitoring or control equipment.

NOTE:

The MSP422 measures and calculates in metres. The display units are

derived as a last operation using a pre-programmed conversion factor.

Page 23

Reference Manual

Distance-to-target

Depth (Level)

Bottom Reference

IP2013, Rev BA

February 2012

Mobrey MSP422

First Measurements With the transmitter installed and display units selected, the display will show

what the instrument calculates as the liquid depth (level). This value is

calculated by the microprocessor as being the difference between the

distance-to-target being measured and the default value for the datum or

bottom reference (b.rEF).

Figure 4-2. Bottom Reference

Before changing any of the default values, press the blue button

to change

the PV display to indicate distance-to-target, as measured by the transmitter

from the transmitter face. This value is shown alternately with the text “diSt”

to indicate the display is in distance mode. The calculation can be checked

against a manual measurement if required.

NOTE:

A useful feature at this stage is that the transmitter can be used as an

electronic tape measure. With an empty tank or vessel, the transmitter will

read the distance to the bottom of the tank. This distance can be noted and

later used when setting b.rEF.

Press the blue button

again to get to the echo size. This is a scale of 0 to

100. (It is possible to record a value greater than 100). With the display in this

mode, the central “:” cursor will flash once for every echo received, which

under normal circumstances will be once per second.

NOTE:

It is useful at this point to check that the maximum echo size available is be ing

received. Adjust the position of the instrument until the highest echo size is

continually shown. In most applications, the signal strength will vary over a

wide range: 20 to 80.

Press the blue button

again to return to the original level reading and start

the calibration routine.

NOTE:

The output of the transmitter will vary during programming, as the various

default values are changed. The display will automatically revert to the level

or distance reading from any other display after a period of four minutes.

4-5

Page 24

Mobrey MSP422

Reference Manual

IP2013, Rev BA

February 2012

Setting the Bottom

Reference

Screen display: b.rEF

Defaults: 8.000 (m), 26.24 (ft.), 314.9 (in.)

NOTE:

See Figure 4-1 on page 4-3 for a map of the programming menu structure and

how to access all the menu options.

To change the bottom reference (b.rEF) setting:

a) If entering the menu system from the PV display, press the green button

to indicate the “b.rEF” menu option (see above note.)

b) Press the blue button

indicates the present b.rEF value.

c) If this value is correct, press the red button

button

d) Press the blue button

can be edited.

e) Press the green button

f) Press the blue button

indicate it can be edited.

g) Repeat steps (e) and (f) until the last digit is flashing, and edited as

required.

h) Press the blue button

digits should now be flashing.

i) If the new value is correct, press the red button

changes to the next menu option.

j) If the new value is incorrect, press the blue button

The “b.rEF” re-appears; re-start at step (b) or press

to get to the next menu option.

to enter the menu for b.rEF. The display

, and then press the green

to start editing. The first digit flashes to indicate it

repeatedly to edit the flashing digit.

to move to the next digit. The digit flashes to

to confirm the new b.rEF value. None of the

to save. The display

to exit to the menu.

for the next menu.

Setting 4 mA and 20 mA

Levels

Screen display: 4 and 20

4mA level defaults: 0.000 (m), 00.00 (ft.), 000.0 (in.)

20mA level defaults: 7.500 (m), 24.60 (ft.), 295.2 (in.)

The 4 mA level may be set above, or below, the 20 mA level to suit the

monitoring or control equipment.

NOTE:

To set the 4 and 20 mA levels by ranging the transmitter to a fixed target, such

as the level in the tank at any particular time, skip these menu options by

pressing the green button twice to get to the next menu option.

NOTE:

See Figure 4-1 on page 4-3 for a map of the programming menu structure and

how to access all the menu options.

To change the 4 mA value:

a) If entering the menu system from the PV display, press the green button

repeatedly until the “4” menu option is indicated (see above note.)

b) Press the blue button

indicates the present value of the 4 mA level.

to enter the menu for the 4 mA level. The display

4-6

Page 25

Reference Manual

IP2013, Rev BA

February 2012

Mobrey MSP422

c) If this value is correct, press the red button , and th en pre ss the green

button

d) Press the blue button

it can be edited.

e) Press the green button

f) Press the blue button

indicate it can be edited.

g) Repeat steps (e) and (f) until the last digit is flashing, and edited as

required.

h) Press the blue button

should now be flashing.

i) If the new value is correct, press the red button

changes to the next menu option.

j) If the new value is incorrect, press the blue button

The “4” re-appears; re-start at step (b) or press

NOTE:

See Figure 4-1 on page 4-3 for a map of the programming menu structure and

how to access all the menu options.

to get to the next menu option.

to start editing. The first digit will flash to indicate

repeatedly to edit the flashing digit.

to move to the next digit. The digit flashes to

to confirm the new 4 mA level. None of the digits

to save. The display

to exit to the menu.

for the next menu.

Setting the Output

Damping

To change the 20 mA value:

a) If entering the menu system from the PV display, press the green button

repeatedly until the “20” menu option is indicated (see above note.)

b) Press the blue button

to enter the menu for the 20 mA level. The

display indicates the present value of the 20 mA level.

c) If this value is correct, press the red button

button

d) Press the blue button

to get to the next menu option.

to start editing. The first digit flashes to indicate it

, and then press the green

can be edited.

e) Press the green button

f) Press the blue button

repeatedly to edit the flashing digit.

to move to the next digit. The digit flashes to

indicate it can be edited.

g) Repeat steps (e) and (f) until the last digit is flashing, and edited as

required.

h) Press the blue button

to confirm the new 20 mA level. None of the digits

should now be flashing.

i) If the new value is correct, press the red button

to save. The display

changes to the next menu option.

j) If the new value is incorrect, press the blue button

The “20” re-appears; re-start at step (b) or press

to exit to the menu.

for the next menu.

Screen display: d

Default: 10

The damping value is a time constant in seconds, and is applie d as smoothing

to the level reading and the output current. A new value may be entered up to

999 seconds. A larger value will have the effect of smoothing out rapid

changes of level, and smooth out the effects of turbulence and ripples on the

liquid surface. (It would be unusual to select a value greater than 30 seconds).

A value of zero may be edited, in which case no smoothing is applied to the

Current Output and transmitter readings immediately change the output.

4-7

Page 26

Mobrey MSP422

Reference Manual

IP2013, Rev BA

February 2012

NOTE:

The MSP422 transmits nominally at once per second. Therefore, a damping

time of zero will not necessarily give an immediate response.

NOTE:

See Figure 4-1 on page 4-3 for a map of the programming menu structure and

how to access all the menu options.

To change the output damping:

a) If entering the menu system from the PV display, press the green button

repeatedly until the “d” menu option is indicated (see above note.)

b) Press the blue button

present damping value.

c) If this value is correct, press the red button

get to the next menu option.

d) Press the blue button

can be edited.

e) Press the green button

f) Press the blue button

indicate it can be edited.

g) Repeat steps (e) and (f) until the last digit is flashing, and edited as

required.

h) Press the blue button

digits should now be flashing.

i) If the new value is correct, press the red button

changes to the next menu option.

j) If the new value is incorrect, press the blue button

The “d” re-appears; re-start at step (b) or press

to enter the menu “d”. The display indicates the

and then the green button to

to start editing. The first digit flashes to indicate it

repeatedly to edit the flashing digit.

to select the next digit. The digit flashes to

to confirm the new damping value. None of the

to save. The display

to exit to the menu.

for the next menu.

Selecting the Action on

Alarm Condition

4-8

Screen display: AL

Default: Hold

The transmitter signals an alarm condition if the target echo is lost for more

than 10 seconds.

There are three options for an alarm condition:

Hi The current on the two-wire loop will increase to 21 mA and remain

there until a correct target echo is recovered. The display flashes

alternately “LE” and the alarm action.

Hold The current will freeze at the value it was last reading and remain

there until a correct target echo is recovered. The display flashes

alternately “LE” and the last valid reading.

Lo The current on the two wire loop will decrease to 3.6 mA and remain

there until a correct target echo is recovered. The display flashes

alternately “LE” and the alarm action.

NOTE:

See Figure 4-1 on page 4-3 for a map of the programming menu structure and

how to access all the menu options.

Page 27

Reference Manual

IP2013, Rev BA

February 2012

Mobrey MSP422

To change from the default action of Hold:

a) If entering the menu system from the PV display, press the green button

repeatedly until the “AL” menu option is indicated (see above note.)

b) Press the blue button

present action setting.

c) If this action is correct, press the red button

get to the next menu option.

d) Press the blue button

can be edited.

e) Press the green button

f) Press the blue button

g) If the new action is correct, press the red button

changes to the next menu option.

h) If the new action is incorrect, press the blue button

The “AL” re-appears; re-start at step (b) or press

to enter the menu “AL”. The display indicate s the

and then the green button to

to start editing. The action flashes to indicate it

repeatedly to scroll through the actions.

to confirm an action. The flashing then stops.

to save. The display

to exit to the menu.

for the next menu.

Setting 4 mA and 20 mA

Levels Using Ranging

Screen display: S--4 and S-20

NOTE:

If the 4 and 20 mA levels are programmed as described above, th is menu can

be skipped; it overwrites previously entered data for them. Press the

green button to get to the final menu option, “Lrn”.

This is for setting the 4 mA or 20 mA levels by ranging the instrument to a

known target, e.g. the present level in a vessel.

NOTE:

See Figure 4-1 on page 4-3 for a map of the programming menu structure and

how to access all the menu options.

To change the 4 mA level:

a) If entering the menu system from the PV display, press the green button

repeatedly until the “S--4” menu option is indicated (see above note.)

b) Ensure the target is the 4 mA level and, with the display indicating that

level, press the blue button

.

c) The display indicates the present 4 mA level setting, not the new level

reading. If this setting is correct, press the red button

and then the green

button to get to the next menu option.

d) Press the blue button

to start editing. The display flashes alternately “4”

and the new level reading.

e) Press the blue button

to confirm the new level reading is the new 4 mA

level.

f) If the new 4 mA level is correct, press the red button

to save. The

display changes to the next menu option.

g) If the new 4 mA level is incorrect, press the blue button

to exit to the

menu. The menu option “S--4” re-appears; re-start at step (b) or press

for the next menu option.

4-9

Page 28

Mobrey MSP422

Reference Manual

IP2013, Rev BA

February 2012

NOTE:

See Figure 4-1 on page 4-3 for a map of the programming menu structure and

how to access all the menu options.

To change the 20 mA level:

a) If entering the menu system from the PV display, press the green button

repeatedly until the “S-20” menu option is indicated (see above note.)

b) Ensure the target is the 20 mA level and, with the display indicating that

level, press the blue button

c) The display indicates the present 20 mA level setting, not the new level

reading. If this value is correct, press the red button

button to get to the next menu option.

d) Press the blue button

“20” and the new level reading.

e) Press the blue button

20 mA level.

f) If the new 20 mA level is correct, press the red button

display changes to the next menu option.

g) If the new 20 mA level is incorrect, press the blue button

menu. The menu option “S-20” re-appears; re-start at step (b) or press

for the next menu option.

.

and then the green

to start editing. The display flashes alternately

to confirm the new level reading is the new

to save. The

to exit to the

Learn About Echoes

From False Targets

The MSP422 has an easy-to-use “Lrn” (Learn) routine that allows the

instrument to learn up to two false echoes, which can then be ignored in

future operations.

If the application is simple and there are no false echoes, press the green

button

to exit the integral display menu and return the instrument to

indicating the level reading on the display.

If an echo other than the true liquid surface echo is detected and an incorrect

level reading is indicated, the instrument can learn to ignore this false echo.

The “Lrn” routine may be used at any time, either during or af ter setting- up or

if a problem occurs later.

NOTE:

See Figure 4-1 on page 4-3 for a map of the programming menu structure and

how to access all the menu options.

To store a false target echo:

a) If entering the menu system from the PV display, press the green button

repeatedly until the “Lrn” menu option is indicated (see above note.)

b) Press the blue button

to enter the “Lrn” menu. The display indicates

“LrnX” where “X” (0, 1 or 2) is the number of stored false target echoes.

c) To exit to the menu at this stage, press the red button

and then the

green button to get to the next menu option.

d) To store a new false echo, hold the blue button down

for five seconds.

e) The display now alternately flashes “Lrn” and the false target position.

After four seconds, the false echo targ et position is stored and the disp lay

re-indicates “LrnX” alternating with the distance to the stored echo.

4-10

Page 29

Reference Manual

IP2013, Rev BA

February 2012

Mobrey MSP422

f) Press the red button to save this false echo and exit to the menu.

However , if this false echo shouldn't be saved, press the blue bu tto n

exit to the menu.

g) To store another false target echo, re-start from step (b).

h) Press the green button

NOTE:

If there are two false echoes stored (“Lrn2”), the transmitter will not allow

another echo to be stored until the memory is cleared (see next procedure.)

NOTE:

When a false echo is stored, the transmitter sets up a 'window' around the

false target and ignores any echo from that window, unless the echo received

from the liquid surface is larger than the stored false echo. There may be no

change in the transmitter output current while the liquid level moves through

this window, which is equivalent to a distance of 8 in. (20 cm).

to exit the menu and return to the PV display.

to

NOTE:

See Figure 4-1 on page 4-3 for a map of the programming menu structure and

how to access all the menu options.

To clear all the stored false echoes:

a) If entering the menu system from the PV display, press the green button

repeatedly until the “Lrn” menu option is indicated (see above note.)

b) Press the blue button

c) With the display indicating “LrnX”, press and hold the gree n bu tt on

ten seconds to clear the memory. The display then indicates “Lrn0”.

d) Press the red button

e) Press the green button

PV display .

FINAL CHECKS Final checks:

a) Check the display is reading correctly.

b) You may wish to check echo size again before re-fitting the enclosure lid.

c) Check that the cover seal is in place in the cover, and is good condition. It

should not be twisted or kinked in any way.

d) Carefully set the cover on the transmitter, and tighten the three cover

screws equally to seal the instrument.

e) Check that the cable gland is securely tightened and check sealing on the

cable sheath.

to enter the “Lrn” menu.

for

to exit to the menu.

to exit the menu system and change to the

POWER FAILURE All parameters are held in EPROM memory. In the event of a power failure, or

disconnection from the power supply, the transmitter will remember all of it's

last parameter values and will resume correct operation once power is

restored.

4-11

Page 30

Reference Manual

IP2013, Rev BA

February 2012

Mobrey MSP422

4-12

Page 31

Reference Manual

IP2013, Rev BA

February 2012

Mobrey MSP422

Section 5 Service and Troubleshooting

Safety Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 5-1

Servicing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .page 5-2

Diagnostics for The MSP422 . . . . . . . . . . . . . . . . . . . . . . .page 5-2

SAFETY MESSAGES Procedures and instructions in this section may require special precautions to

ensure the safety of the personnel performing the operations. Infor mation that

raises potential safety issues is indicated by a warning symbol ( ). Please

refer to the following safety messages before performing an operation

preceded by this symbol.

.

Explosions could result in death or serious injury.

• The Mobrey MSP422 is only for use in a non-hazardous location

Failure to follow safe installation and servicing guidelines could result in death or

serious injury.

Make sure only qualified personnel perform the installation.

Use the equipment only as specified in this manual. Failure to do so may impair the

protection provided by the equipment.

Do not perform any service other than those contained in this manual unless you are

qualified.

High voltage that may be present on leads could cause electrical shock.

Avoid contact with leads and terminals.

Make sure the main power to the Mobrey MSP422 transmitter is off, and the lines to any

other external power source are disconnected or not powered while wiring

the transmitter.

www.mobrey.com

Page 32

Reference Manual

IP2013, Rev BA

Mobrey MSP422

February 2012

SERVICING The only maintenance required is to occasionally check the transmitter face to

ensure it remains clean and check that the cover seal, wiring, and cable

glands are in good condition.

There are no spare parts for the Mobrey MSP422. If a problem persists,

contact Mobrey Measurement for advice.

DIAGNOSTICS FOR

THE MSP422

General

Troubleshooting

No Display

Check the power supply. Ensure there is a minimum of 12 Vdc at the

instrument terminals. Check that the cable insulation is not preventing contact

at the terminal block.

No Level Reading

Check that the instrument is ticking about once per second. If there is no

ticking, the instrument should be replaced.

Error Messages Flashing “LE” With “0000”

The transmitter is not receiving a return echo, which could mean the liquid

surface is poor or that it is beyond the range of 26 ft. (8 m) of the instrument.

Change the position of the transmitter or contact Mobrey Measurement for

information on longer range instruments

This means that the transmitter is not receiving a return echo, possibly

because the liquid surface is poor or beyond the range (26 ft./8 m) of the

instrument. Re-locate the instrument or contact Mobrey Measurement for

details of longer range instruments.

Flashing “LE” With Level Reading

This means that the transmitter is no longer receiving satisfactory echoes

from the liquid surface. This may be because of one of a variety of reasons,

for example, excessive foaming, turbulence, or ullage vapors.

5-2

First, check that the transmitter face is free from contamination and

condensation. The transmitter will operate with some condensation on the

face, but excessive condensation may cause operational problems. If the

vessel cannot be adequately vented to prevent condensatio n forming, cont act

Mobrey Measurement for alternative solutions.

Second, check that the instrument is still vertically aligned above the liquid

surface and check the echo received size. If the echo size is small (<3),

re-position the transmitter or modify the vessel for the transmitter to operate

above a more acceptable area of the liquid surface.

Lost echo (LE) is signalled when there has been no return echo for 10

seconds. Within the 10 seconds, the output will remain fixed. If, after the 10

seconds, no satisfactory has been received, the output will increase to the

current selected level and the display flashes alternately “LE” and the last

valid level reading.

If a satisfactory echo is received within the 10 seconds, a new output is

established and the LE timer is re-set.

Page 33

Reference Manual

IP2013, Rev BA

February 2012

Appendix A Reference Data

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page A-1

Temperature and Pressure Ratings . . . . . . . . . . . . . . . . . page A-2

Load Limitations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page A-2

Dimension Drawings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page A-3

SPECIFICATIONS

General

Product Mobrey MSP Series Ultrasonic Level Transmitters:

Level and Distance measurement

Measurement Principle Ultrasonic, time-of-flight

Measuring Performance

Measurement Range 1 to 26 ft. (0,3 to 8 m)

Level Resolution Better than 0.06 in. (1 mm)

Level Accuracy

Under Reference Conditions

Blanking Distance (Dead Zone) 12 in. (0,3 m)

Update Interval

Display / Configuration

Integral Display 4 digit display for live measurement and for configuration purposes

Display Units m, ft, or in,

Output Level

Output Units Set by Display Units selection

Configuration Tools Standard integral push-buttons with LCD

Electrical

External Power Supply 12 to 30 Vdc Loop-powered (two-wire)

Earthing None required

Current Output Analog 4–20 mA

Signal On Alarm

Saturation Levels

Cable Entry M20 x 1.5 conduit entry for a cable gland

Output Cabling Single twisted-pair and shielded, min. 0,22 mm

Materials of Construction

Wet-side Material PVDF

Body And Cover Material Glass-filled Nylon

Cover Seal Silicone rubber

Cover Screws 316 Stainless Steel

Transducer Body Seal EPDM

Mechanical

Mounting Thread Size 2-in. NPT, or 2-in. BSP. Optional flange accessories available

Weight of Transmitter 2.0 lb (0,9 kg)

Measuring

Temperature Compensation

(1)

± 0.2 in. (5 mm) for < 3.3 ft. (1 m),

± 0.5% of measured distance for > 3.3 ft. (1 m)

Display: 500 ms; Current Output: 200 ms

Low = 3.6 mA. High = 21 mA

Low = 3.8 mA. High = 20.5 mA

Automatic Integral temperature compensation

2

(24 AWG), max. 1,5 mm2 (15 AWG)

Mobrey MSP422

www.mobrey.com

Page 34

Mobrey MSP422

Pressure

psi (bar)

158

°F

(70

°C)

-4

°F (-20 °C)

-4 psi

(-0,25 bar)

44 psi

(3 bar)

OPERATIN G RANGE

The final rating may be limited by

flange selection

Temperature

°F (°C)

U (V)

R (Ohms)

0

30

1244

800

400

12 20

24

533

0

NOTE

R = Maximum Load Resistance

U = External Power Supply Voltage

Environment

Ambient Temperature

Process Temperature –4 to 158 °F (–20 to 70 °C)

Process Pressure –4 to 44 psi (–0,25 to 3,0 bar)

Ingress Protection IP 66

Electromagnetic Compatibility EN61326 (Class B)

Certifications CE-mark

(1) T emperature: 68 °F (20 °C), Pressure: 1013 mbar (atmospheric pressure), and Relative Humidity: 50%.

(2) See page A-2 onwards for approval temperature ranges.

(2)

–4 to 158 °F (–20 to 70 °C)

Reference Manual

IP2013, Rev BA

February 2012

TEMPERATURE AND

PRESSURE RATINGS

The process temperature/pressure rating depends on the design of the

transmitter in combination with the flange materials.

Figure A-1.

Process Temperature and

Pressure Diagram

LOAD LIMITATIONS The maximum load resistance can be determined from Figure A-2.

Figure A-2. Load Limitations

A-2

Page 35

Reference Manual

Note: Dimensions are in inches (mm)

Ø5.7 (Ø144)

5.3

(135)

2.6

(65)

2-in. Thread

2.36 (60) A/F Hexagon

M20 x 1.5

Cable Entry

MSP422

IP2013, Rev BA

February 2012

DIMENSION DRAWINGS

Figure A-3. Transmitter Dimensions (Nylon-filled Glass Housing)

Mobrey MSP422

A-3

Page 36

Mobrey MSP422

0.51

(13)

4.33

(110)

2.95

(75)

0.35

(9)

Ø

1

.0

2

(Ø

2

6)

0.26

(6

,

5)

TYP.

2.26

(57)

4.02

(102)

2.24

(57)

1.5

(38)

Note: Dimensions are in inches (mm)

SIDE VIEW

END VIEW

ACTUAL VIEW WITH

TRANSMITTER MOUNTED

2-in. NPT/BSPT

Threaded PVC Disc

No. 4X 13 Long Self Tap

Screw (3 Positions)

Carbon Steel (Zinc Plated)

Stainless Steel Bracket

Note: The combined weight of

bracket and disc is 16 oz. (0,5 kg)

Figure A-4. The 2-in. NPT/BSPT mounting bracket

Reference Manual

IP2013, Rev BA

February 2012

A-4

Page 37

Reference Manual

IP2013, Rev BA

February 2012

Mobrey MSP422

Appendix B Product Certifications

Safety Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page B-1

Manufacturing Location . . . . . . . . . . . . . . . . . . . . . . . . . . . page B-2

European Union Directive Information . . . . . . . . . . . . . . . page B-2

Non-hazardous Location Certifications . . . . . . . . . . . . . . page B-2

SAFETY MESSAGES Procedures and instructions in this section may require special precautions to

ensure the safety of the personnel performing the operations. Infor mation that

raises potential safety issues is indicated by a warning symbol ( ). Please

refer to the following safety messages before performing an operation

preceded by this symbol.

Explosions could result in death or serious injury:

The Mobrey MSP422 is only for use in a non-hazardous location

Failure to follow safe installation and servicing guidelines could result in death or

serious injury:

Make sure the transmitter is installed by qualified personnel and in accordance with

applicable code of practice.

Use the equipment only as specified in this manual. Failure to do so may impair the

protection provided by the equipment.

Do not perform any service other than those contained in this manual unless you are

qualified.

High voltage that may be present on leads could cause electrical shock:

Avoid contact with leads and terminals.

Make sure the main power to the transmitter is off and the lines to any other external

power source are disconnected or not powered while wiring the transmitter.

www.mobrey.com

Page 38

Mobrey MSP422

Reference Manual

IP2013, Rev BA

February 2012

MANUFACTURING

LOCATION

EUROPEAN UNION

DIRECTIVE

INFORMATION

NON-HAZARDOUS

LOCATION

CERTIFICATIONS

American and Canadian

Certifications

Mobrey Limited – Slough, Berkshire, United Kingdom

NOTE:

Refer to the housing label to identify the approv als for yo ur tran sm itt er. The

EC declaration of conformity for all applicable European directives for this

product can be obtained by contacting our local sales representative.

Pressure Equipment Directive (PED) (97/23/EC)

• The MSP422 is outside the scope of the PED Directive

Electro Magnetic Compatibility (EMC) (2004/108/EC)

• EN 61326-1:2006

NOTE:

Refer to the housing label to identify the approv als for yo ur tran sm itt er.

Factory Mutual (FM) Ordinary Location Certification

The transmitter has been examined and tested to determine that the design

meets basic electrical, mechanical, and fire protection requirements by FM, a

nationally recognized testing laboratory (NRTL) as accredited by the Federal

Occupational Safety and Health Administration (OSHA).

Canadian Standards As sociation (CSA) Ordinary Location Certification

The transmitter has been examined and tested to determine that the design

meets basic electrical, mechanical, and fire protection requirements by CSA,

a nationally recognized testing laboratory as accredited by the Standards

Council of Canada (SCC).

B-2

Page 39

Page 40

Reference Manual

IP2013, Rev BA

February 2012

Mobrey MSP422

The Emerson logo is a trade mark and service mark of Emerson Electric Co.

Rosemount is a registered trademark of Rosemount Inc.

Mobrey is a registered trademark of Mobrey Ltd.

All other marks are the property of their respective

We reserve the right to modify or improve the designs or specifications of product and services at any time without notice.

© 2012 Mobrey Ltd. All rights reserved.

International:

Emerson Process Management

Mobrey Ltd.

158 Edinburgh Avenue

Slough, Berks, SL1 4UE, UK

T +44 (0)1753 756600

F +44 (0)1753 823589

www.mobrey.com

IP2013 Rev BA 02/12

Americas:

Emerson Process Management

Rosemount Measurement

8200 Market Boulevard

Chanhassen MN 55317 USA

Tel (USA) 1 800 999 9307

Tel (International) +1 952 906 8888

Fax +1 952 906 8889

owners.

Loading...

Loading...