Page 1

Instruction Manual

February 2015

MR95 Series Pressure Regulators

MR95 Series

P1757

TYPE MR95L

P1753

TYPE MR95H

PRESSURE REDUCING REGULATORS

Figure 1. Typical MR95 Series Pressure Regulators

www.fisherregulators.com

D103587X012

Page 2

MR95 Series

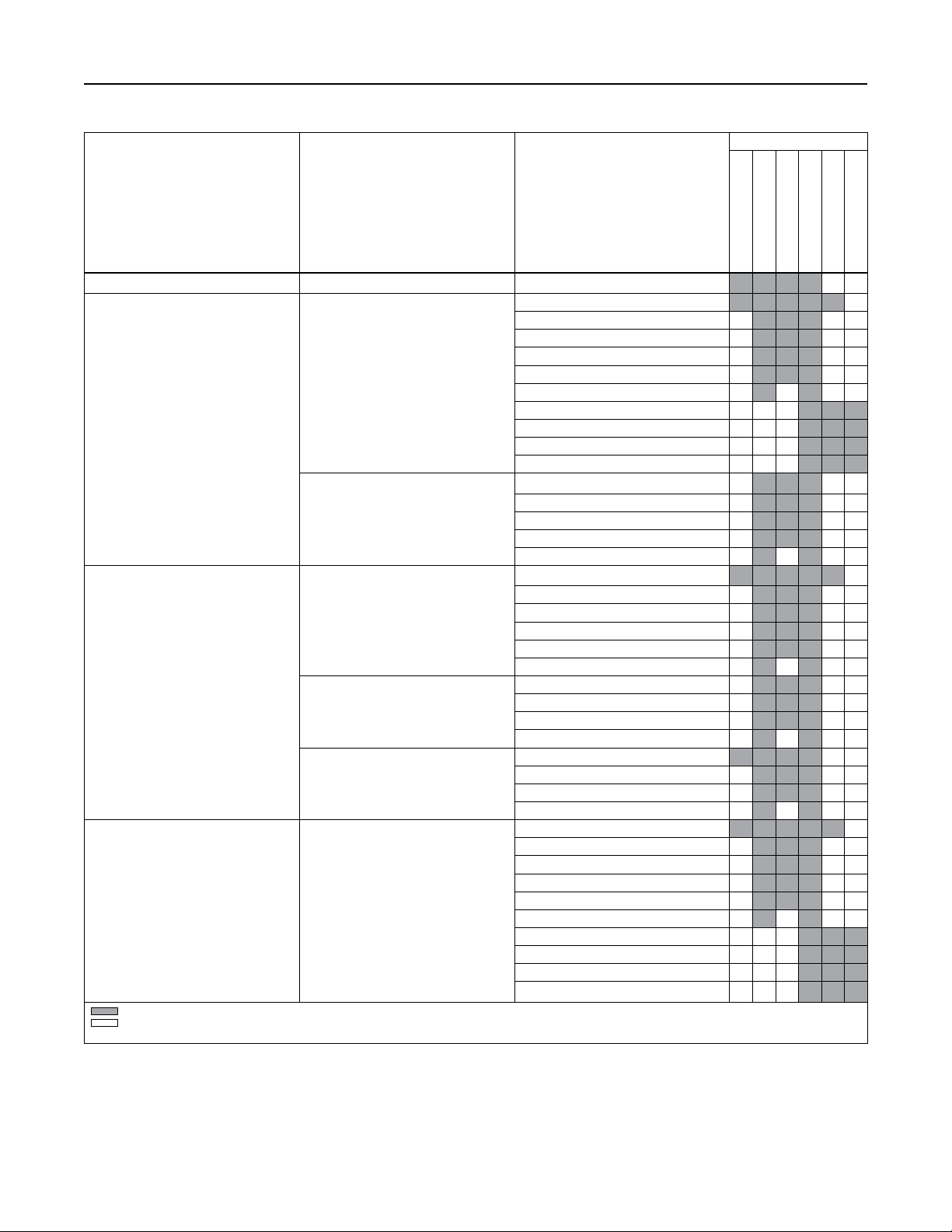

Specications

This section lists the specications for the MR95 Series regulators. Factory specication such as type, maximum

inlet pressure, maximum temperature, maximum outlet pressure, spring range, orice size and seat material are

stamped on the nameplate fastened on the regulator at the factory.

Available Constructions

Type MR95L: Low pressure regulator for 2 to

30 psig / 0.14 to 2.1 bar outlet pressures

Type MR95H: High pressure regulator for 5 to

150 psig / 0.34 to 10.3 bar outlet pressures

Type MR95HP: High pressure regulator for

15 to 400 psig / 1.0 to 27.6 bar outlet pressures

(soft-seated)

Maximum Temperature Ranges of Diaphragm and

Seat Materials

Fluorocarbon (FKM)

Ethylenepropylene (EPDM)

Peruoroelastomer (FFKM)

Polytetrauoroethylene (PTFE)

Stainless steel (SST)

(1)(2)

MATERIAL TEMPERATURE RANGE

Nitrile (NBR)

Neoprene (CR)

Type MR95HT: High pressure/high temperature

regulator for 15 to 300 psig / 1.0 to 20.7 bar outlet

pressures (metal seat) and up to 650°F / 343°C

Type MR95LD: Low pressure differential

regulator for 2 to 30 psi / 0.14 to 2.1 bar

differential pressures

Type MR95HD: High pressure differential

regulator for 5 to 150 psi / 0.34 to 10.3 bar

Maximum Temperature Ranges of Body Materials

BODY AND SPRING CASE MATERIAL TEMPERATURE RANGE

Gray Cast Iron

Stainless steel

Aluminum-Bronze

WCC Steel

LCC Steel

Monel

Hastelloy® C

(4)

(4)

®

differential pressures

Body and Orice Sizes

1/4 NPT body: 0.284 in. / 7.22 mm orice

1/2 in. / DN 15 body: 0.416 in. / 10.56 mm orice

3/4 and 1 in. / DN 20 and 25 Body Sizes:

0.631 in. / 16.02 mm orice

1-1/2 and 2 in. / DN 40 and 50 Body Sizes

(not available for Types MR95L and MR95LD):

1.142 in. / 29 mm orice

End Connection Styles

NPT, SWE and Welded and Integral CL150 RF,

CL300 RF, CL600 RF and PN 16/25/40 RF;

all sizes are fabricated with slip-on anges

(for welded end connections) and are 14 in.

face- to- face (EN anged-356 mm face-to-face)

See Tables 1 and 2

Maximum Cold Working Pressures of Body Size

and Materials

(1)

See Table 4

Outlet and Differential Pressure Ranges

(1)

See Table 3

Pressure Registration

Internal or External

Shutoff Classication Per ANSI/FCI 70-3-2004

Metal Seats: Class IV

Elastomer Seats: Class VI or better

PTFE: Class IV

Flow and Sizing Coefcients

Relief Sizing Coefcients for MR95 Series

Regulators with Reduced Flow Orices

See Table 6

Pressure Setting Adjustment

Adjusting screw:

Standard for Types MR95L, MR95H, MR95HP

and MR95HT only

Handwheel:

Standard for Types MR95LD and MR95HD

Optional for 1/2 in. / DN 15 body size of

Types MR95L, MR95H, MR95HP and MR95HT

Tee handle:

Optional for other body sizes (except 1/2 in. /

DN 15) of Types MR95L, MR95H, MR95HP

and MR95HT

Approximate Weights

MR95H Series:

1/4 NPT body: 5 lbs / 2.3 kg

1/2 in. / DN 15 body: 10 lbs / 4.5 kg

3/4 and 1 in. / DN 20 and 25 Body Sizes:

22 lbs / 10 kg

1-1/2 and 2 in. / DN 40 and 50 Body Sizes:

55 lbs / 25 kg

MR95L Series:

1/4 NPT body: 7 lbs / 3.2 kg

1/2 in. / DN 15 body: 15 lbs / 6.8 kg

3/4 and 1 in. / DN 20 and 25 Body Sizes:

35 lbs / 16 kg

See Table 5

1. The pressure/temperature limits in this Instruction Manual and any applicable standard or code limitation should not be exceeded.

2. Pressure and/or the body end connection may decrease these maximum temperatures.

3. Fluorocarbon (FKM) is limited to 200°F / 93°C hot water.

4. Meets API 614 requirements (with Stainless steel trim).

Monel® is a mark owned by Special Metals Corporation.

Hastelloy® C is a mark owned by Haynes International, Inc.

2

-40 to 180°F / -40 to 82°C

(3)

(4)

-40 to 180°F / -40 to 82°C

0 to 300°F / -18 to 149°C

20 to 275°F / -7 to 135°C

0 to 425°F / -18 to 218°C

-40 to 400°F / -40 to 204°C

-40 to 650°F / -40 to 343°C

-20 to 406°F / -29 to 208°C

-20 to 650°F / -29 to 343°C

-40 to 650°F / -40 to 343°C

-40 to 550°F / -40 to 288°C

-40 to 550°F / -40 to 288°C

-40 to 550°F / -40 to 288°C

-40 to 500°F / -40 to 260°C

(1)(2)

Page 3

MR95 Series

WARNING

!

Failure to follow these instructions or

to properly install and maintain this

equipment could result in an explosion,

re and/or chemical contamination

causing property damage and personal

injury or death.

Fisher® regulators must be installed,

operated and maintained in accordance

with federal, state and local codes, rules

and regulations and Emerson Process

Management Regulator Technologies,

Inc. (Emerson™) instructions.

If the regulator vents gas or a leak

develops in the system, service to

the unit may be required. Failure

to correct trouble could result in a

hazardous condition.

Installation, operation and maintenance

procedures performed by unqualied

personnel may result in improper

adjustment and unsafe operation. Either

condition may result in equipment

damage or personal injury. Only a

qualied person shall install or service

the MR95 Series regulator.

Introduction

Scope of the Manual

2 and 400 psig / 0.14 and 27.6 bar. Types MR95LD

and MR95HD are small-size, large-capacity,

differential pressure regulators. The differential

pressure range is from 2 to 150 psi / 0.14 to 10.3 bar.

Typical MR95 Series regulators are shown in Figure 1.

Pressure Reducing Regulators

Type MR95L—Pressure reducing regulator suitable

for controlling many gases and liquids. Gray Cast Iron,

Steel, Stainless steel, Hastelloy® C and Monel® bodies

are available. Outlet pressure range is from 2 to

30 psig / 0.14 to 2.1 bar with three different springs

available. Body sizes are available from 1/4 NPT and

1/2 through 1 in. / DN 15 through 25 with a variety

of end connections. The standard orice sizes are

0.284, 0.416 and 0.631 in. / 7.22, 10.56 and 16.02 mm

diameter, dependent on body sizes.

Type MR95H—Basically the same as Type MR95L,

but permits higher outlet pressure ranges from

15 to 150 psig / 1.0 to 10.3 bar for the 1/4 NPT and

1/2, 3/4 and 1 in. / DN 15, 20 and 25 sizes. Also

available in 1-1/2 and 2 in. / DN 40 and 50 sizes with a

1.142 in. / 29 mm orice to give outlet pressure ranges

from 5 to 150 psig / 0.34 to 10.3 bar.

Type MR95HP—Basically the same as Type MR95H,

but permits even higher outlet pressure ranges from

15 to 400 psig / 1.0 to 27.6 bar.

Type MR95HT—Basically the same as Type MR95H,

but permits higher outlet pressures at higher

temperatures. Outlet pressure ranges are available

from 15 to 300 psig / 1.0 to 20.7 bar and temperatures

up to 650°F / 343°C.

This manual provides instructions for the installation,

adjustment, maintenance and parts ordering for

MR95 Series pressure regulators. These regulators

are usually shipped separately for line or panel

mounting or installed on other equipment. Instructions

and parts lists for other equipment are found in

separate manuals.

Product Description

MR95 Series regulators are suitable for steam, air,

gas, water, oil and similar uids. Types MR95L,

MR95H, MR95HP and MR95HT are direct-operated

pressure reducing regulators for pressure control

requiring constant outlet pressures between

Monel® is a mark owned by Special Metals Corporation.

Hastelloy® C is a mark owned by Haynes International, Inc.

Differential Pressure Regulators

Type MR95LD—Small-size, large-capacity, differential

pressure regulators. Typical applications include use

on testing xtures, wash tanks, sterilizers, steam

tables, fuel lines and plant air supplies. Gray Cast

Iron, Steel, Stainless steel, Hastelloy® C and Monel®

bodies are available. Differential pressure range is

from 2 to 30 psi / 0.14 to 2.1 bar with three different

spring ranges.

Type MR95HD—Basically the same as Type MR95LD,

but permits higher differential pressure ranges from

5 to 150 psi / 0.34 to 10.3 bar with seven different

spring ranges.

3

Page 4

MR95 Series

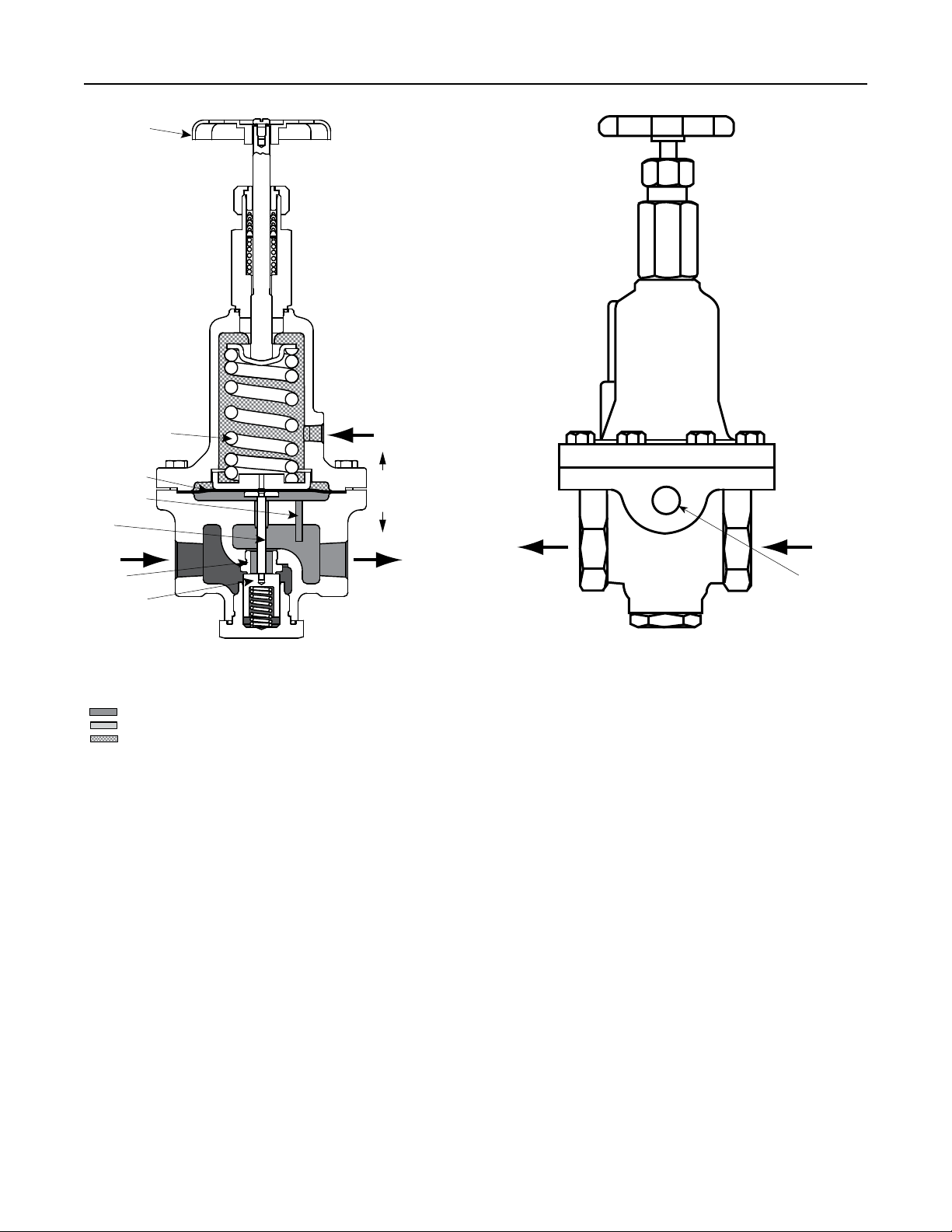

ADJUSTING SCREW

CONTROL SPRING

DIAPHRAGM

PITOT TUBE

STEM

VALVE PLUG

CONTROL LINE TAP

FRONT AND INTERNAL VIEW OF

TYPE MR95H WITH INTERNAL

PRESSURE REGISTRATION

INLET PRESSURE

OUTLET PRESSURE

ATMOSPHERIC PRESSURE

SPRING

GASKET

TYPE MR95H WITH 2 METAL DIAPHRAGMS (ALSO TYPICAL OF

TYPES MR95HT AND MR95L EXCEPT FOR TYPE MR95L WITH 1/4 NPT

BODY SIZE, 2 to 6 psi / 0.14 to 0.41 bar RANGE)

METAL DIAPHRAGMS

Figure 2. MR95 Series Operational Schematics

Principle of Operation

For Types MR95H, MR95L,

MR95HP and MR95HT

Pressure Reducing Regulators

Types MR95L, MR95H, MR95HP and MR95HT

(see Figure 2) are direct-operated regulators

and use spring force to regulate outlet pressure.

BACK VIEW OF

1/2 IN. / DN 15 TYPE MR95H

WITH EXTERNAL

PRESSURE REGISTRATION

SPRING

TYPE MR95L (1/4 NPT, 2 to 6 psi / 0.14 to 0.41 bar RANGE)

WITH METAL DIAPHRAGM

SIDE AND INTERNAL VIEW OF

3/4 TO 2 IN. / DN 20 TO 50

TYPE MR95H WITH EXTERNAL

PRESSURE REGISTRATION

(ALSO TYPICAL OF TYPE MR95L,

1/2 TO 2 IN. / DN 15 TO 50 BODY SIZES)

METAL DIAPHRAGM

GASKET

Downstream pressure is registered either internally

through the body or externally through a control

line to the under side of the diaphragm. When the

downstream pressure is at or above the set pressure,

the disk is held against the orice and restricting

ow through the regulator. When demand increases,

downstream pressure drops slightly allowing the spring

to extend, moving the stem down and the disk away

from the orice. This allows uid ow through the body

to the downstream system.

4

Page 5

Type 95HD Differential Pressure Reducing Regulator

M1006

October 2006

Type 95HD

HANDWHEEL

CONTROL SPRING

PRESSURE A*

(SPRING CASE

LOADING

PRESSURE)

MR95 Series

DIAPHRAGM

PITOT TUBE

STEM

ORIFICE

VALVE PLUG

TYPE MR95HD WITH INTERNAL PRESSURE REGISTRATION

INLET PRESSURE

OUTLET PRESSURE

LOADING PRESSURE

*PRESSURE A MAY BE SUPPLIED BY ANOTHER PRESSURE SYSTEM OR A MANUAL LOADING REGULATOR.

FRONT AND INTERNAL VIEW OF

Figure 2. MR95 Series Operational Schematics (continued)

For Types MR95LD and MR95HD

Differential Pressure Regulators

Types MR95LD and MR95HD regulators maintain

a differential pressure between the loading supply

pressure and the downstream pressure of the regulator.

See Figure 2. The design of the regulator isolates the

diaphragm and pressure response chamber from the

main ow stream. The downstream pressure (outlet

pressure) is registered under the diaphragm through

the pitot tube or registration hole. If the downstream

pressure increases, pressure under the diaphragm

PRESSURE A*

SPRING SETTING =

PRESSURE B

PRESSURE B

(OUTLET

PRESSURE)

TYPE MR95HD WITH EXTERNAL PRESSURE REGISTRATION

BACK VIEW OF

also increases. This force overcomes the spring

compression and loading supply pressure, allowing

the stem to rise. The valve plug spring forces the valve

plug closer to the orice. Flow through the regulator

is reduced so that downstream pressure returns to

the desired differential level. When the downstream

pressure decreases, the opposite action takes place.

Pressure under the diaphragm decreases. The valve

stem pushes the valve plug downward, opening the

ow stream and increasing the uid ow through the

regulator. Downstream pressure rises back to the

desired differential level.

CONTROL LINE TAP

5

Page 6

MR95 Series

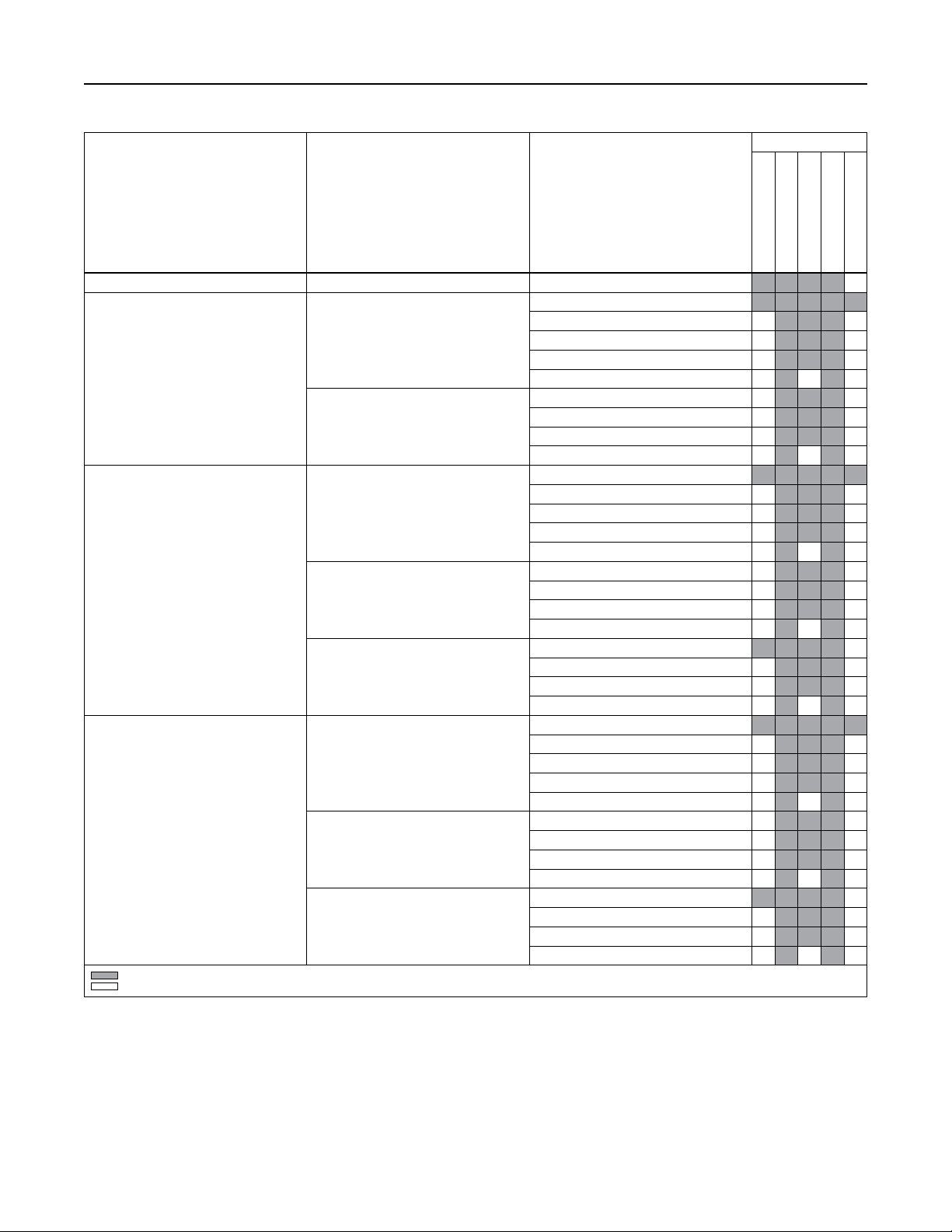

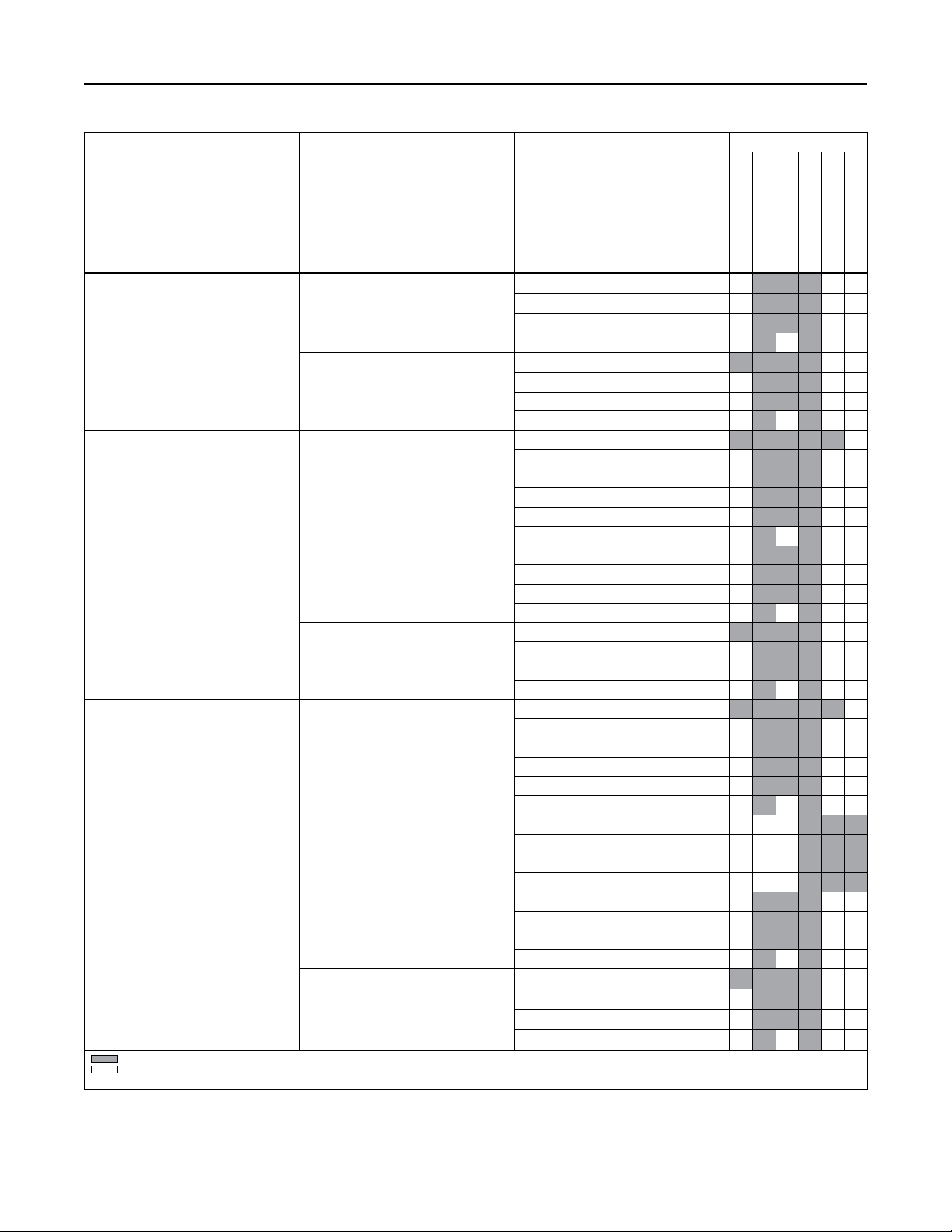

Table 1. Types MR95L and MR95LD Regulators Body Constructions

BODY SIZE BODY CONSTRUCTION END CONNECTION

1/4 NPT Without Control Line and Gauge Port NPT

Without Control Line and Gauge Port

1/2 in. / DN 15

With Control Line but Without Gauge Port

Without Control Line and Gauge Port

3/4 in. / DN 20

1 in. / DN 25

- Shaded areas indicate that the construction is available.

- Blank areas indicate that you need to contact your local Sales Ofce for the availability of the constructions.

With Control Line but Without Gauge Port

With Gauge Port but Without Control Line

Without Control Line and Gauge Port

With Control Line but Without Gauge Port

With Gauge Port but Without Control Line

NPT

SWE

Welded CL150 RF

Welded CL300 RF

Welded PN 16/25/40 RF

NPT

Welded CL150 RF

Welded CL300 RF

Welded PN 16/25/40 RF

NPT

SWE

Welded CL150 RF

Welded CL300 RF

Welded PN 16/25/40 RF

NPT

Welded CL150 RF

Welded CL300 RF

Welded PN 16/25/40 RF

NPT

Welded CL150 RF

Welded CL300 RF

Welded PN 16/25/40 RF

NPT

SWE

Welded CL150 RF

Welded CL300 RF

Welded PN 16/25/40 RF

NPT

Welded CL150 RF

Welded CL300 RF

Welded PN 16/25/40 RF

NPT

Welded CL150 RF

Welded CL300 RF

Welded PN 16/25/40 RF

BODY MATERIAL

Gray Cast Iron

LCC or WCC Steel

CF8M Stainless Steel

®

®

CF3M Stainless Steel

C

or Hastelloy

Monel

Monel® is a mark owned by Special Metals Corporation.

Hastelloy® C is a mark owned by Haynes International, Inc.

6

Page 7

Table 2. Types MR95H, MR95HD, MR95HT and MR95HP Regulators Body Constructions

BODY SIZE BODY CONSTRUCTION END CONNECTION

1/4 NPT Without Gauge Port and Control Line NPT

Without Control Line and Gauge Port

1/2 in. / DN 15

With Control Line but Without Gauge Port

Without Gauge Port and Control Line

3/4 in. / DN 20

With Control Line but Without Gauge Port

With Gauge Port but Without Control Line

1 in. / DN 25 Without Gauge Port and Control Line

- Shaded areas indicate that the construction is available.

- Blank areas indicate that you need to contact your local Sales Ofce for the availability of the constructions.

1. Gray cast iron body material is available for Types MR95H and MR95HD only.

NPT

SWE

Welded CL150 RF

Welded CL300 RF

Welded CL600 RF

Welded PN 16/25/40 RF

Integral CL150 RF

Integral CL300 RF

Integral CL600 RF

Integral PN 16/25/40 RF

NPT

Welded CL150 RF

Welded CL300 RF

Welded CL600 RF

Welded PN 16/25/40 RF

NPT

SWE

Welded CL150 RF

Welded CL300 RF

Welded CL600 RF

Welded PN 16/25/40 RF

NPT

Welded CL150 RF

Welded CL300 RF

Welded PN 16/25/40 RF

NPT

Welded CL150 RF

Welded CL300 RF

Welded PN 16/25/40 RF

NPT

SWE

Welded CL150 RF

Welded CL300 RF

Welded CL600 RF

Welded PN 16/25/40 RF

Integral CL150 RF

Integral CL300 RF

Integral CL600 RF

Integral PN 16/25/40 RF

MR95 Series

BODY MATERIAL

C

(1)

Gray Cast Iron

LCC or WCC Steel

®

or Hastelloy

®

CF8M Stainless Steel

CF3M Stainless Steel

Monel

Aluminum-Bronze

Monel® is a mark owned by Special Metals Corporation.

Hastelloy® C is a mark owned by Haynes International, Inc.

- continued -

7

Page 8

MR95 Series

Table 2. Types MR95H, MR95HD, MR95HT and MR95HP Regulators Body Constructions (continued)

BODY SIZE BODY CONSTRUCTION END CONNECTION

With Control Line but Without Gauge Port

1 in. / DN 25

With Gauge Port but Without Control Line

Without Gauge Port and Control Line

1-1/2 in. / DN 40

With Control line but Without Gauge Port

With Gauge Port but Without Control Line

Without Gauge Port and Control Line

2 in. / DN 50

With Control Line but Without Gauge Port

With Gauge Port but Without Control Line

- Shaded areas indicate that the construction is available.

- Blank areas indicate that you need to contact your local Sales Ofce for the availability of the constructions.

1. Gray cast iron body material is available for Types MR95H and MR95HD only.

NPT

Welded CL150 RF

Welded CL300 RF

Welded PN 16/25/40 RF

NPT

Welded CL150 RF

Welded CL300 RF

Welded PN 16/25/40 RF

NPT

SWE

Welded CL150 RF

Welded CL300 RF

Welded CL600 RF

Welded PN 16/25/40 RF

NPT

Welded CL150 RF

Welded CL300 RF

Welded PN 16/25/40 RF

NPT

Welded CL150 RF

Welded CL300 RF

Welded PN 16/25/40 RF

NPT

SWE

Welded CL150 RF

Welded CL300 RF

Welded CL600 RF

Welded PN 16/25/40 RF

Integral CL150 RF

Integral CL300 RF

Integral CL600 RF

Integral PN 16/25/40 RF

NPT

Welded CL150 RF

Welded CL300 RF

Welded PN 16/25/40 RF

NPT

Welded CL150 RF

Welded CL300 RF

Welded PN 16/25/40 RF

BODY MATERIAL

(1)

Gray Cast Iron

LCC or WCC Steel

CF8M Stainless Steel

C

®

or Hastelloy

®

Aluminum-Bronze

CF3M Stainless Steel

Monel

Monel® is a mark owned by Special Metals Corporation.

Hastelloy® C is a mark owned by Haynes International, Inc.

8

Page 9

MR95 Series

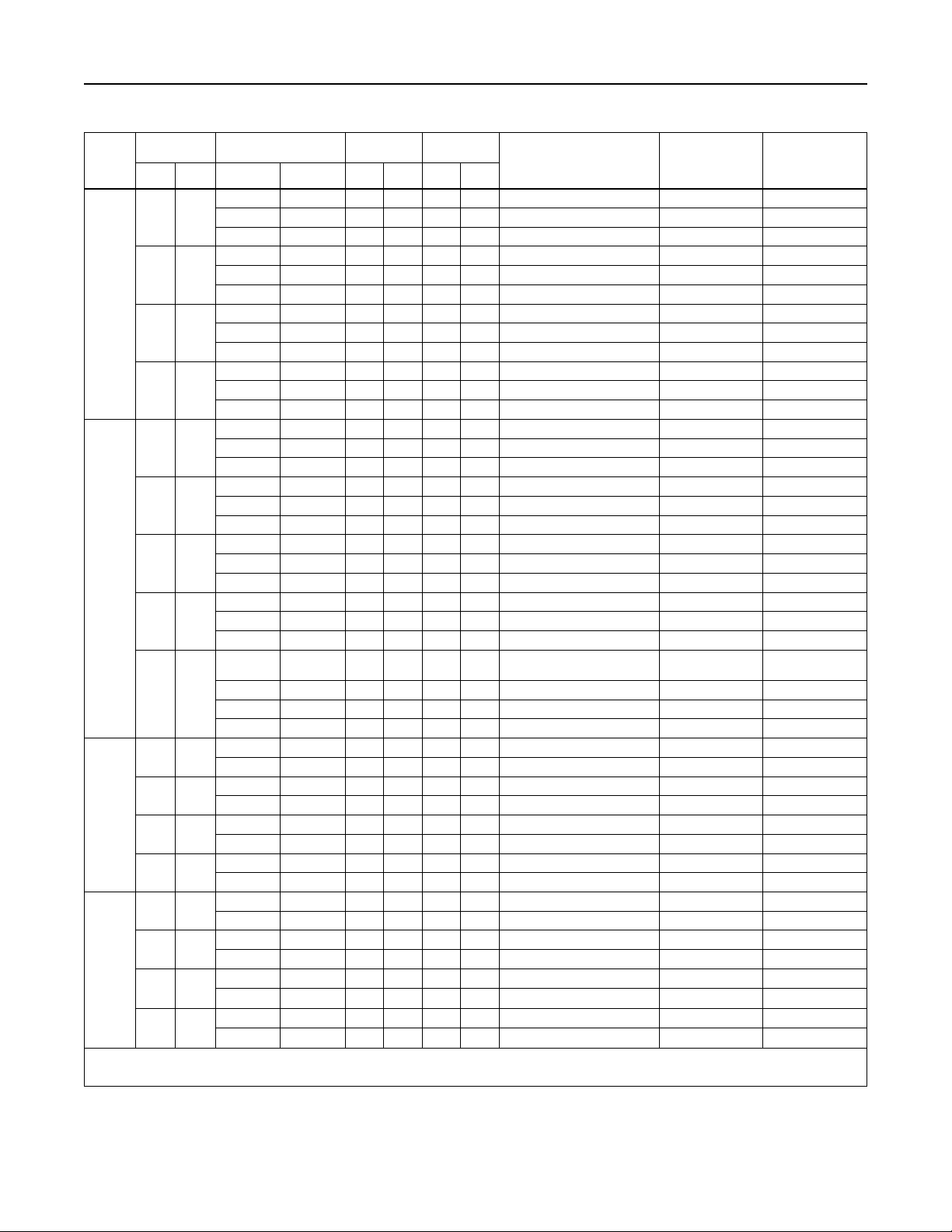

Table 3. MR95 Series Outlet and Differential Pressure Ranges and Spring Information

TYPE

BODY SIZE

OUTLET OR DIFFERENTIAL

PRESSURE RANGE

In. DN psi/psig bar In. mm In. mm

2 to 6 0.14 to 0.41 0.148 3.76 2.00 50.8 Zinc-plated steel 1E392527022 Yellow

1/4 - - - -

5 to 15 0.34 to 1.0 0.170 4.32 2.00 50.8 Zinc-plated steel ERAA01888A0 Green

13 to 30 0.90 to 2.1 0.207 5.26 1.94 49.2 Powder-coated steel ERAA01889A0 Red

2 to 6 0.14 to 0.41 0.207 5.26 2.50 63.5 Powder-coated steel ERCA04288A0 Yellow

MR95L

and

MR95LD

1/2 15

3/4

and 1

and 25

5 to 15 0.34 to 1.0 0.234 5.94 2.60 65.9 Powder-coated steel ERAA01910A0 Green

13 to 30 0.90 to 2.1 0.283 7.19 2.44 62.0 Powder-coated steel ERAA01911A0 Red

2 to 6 0.14 to 0.41 0.306 7.77 4.00 102 Powder-coated steel 1E398927022 Yellow

20

5 to 15 0.34 to 1.0 0.343 8.71 4.00 102 Powder-coated steel 1E399027142 Green

13 to 30 0.90 to 2.1 0.406 10.31 4.00 102 Powder-coated steel 1E399127162 Red

2 to 6 0.14 to 0.41 0.306 7.77 4.00 102 Powder-coated Stainless steel 1E3989X0052 Yellow

3/4

20

and 1

and 25

5 to 15 0.34 to 1.0 0.375 9.53 3.88 98.6 Stainless steel 1K762537022 Unpainted

13 to 30 0.90 to 2.1 0.437 11.1 4.00 102 Stainless steel 11A8269X012 Unpainted

15 to 30 1.0 to 2.1 0.148 3.76 2.00 50.8 Zinc-plated steel 1E392527022 Yellow

1/4 - - - -

25 to 75 1.7 to 5.2 0.170 4.32 2.00 50.8 Zinc-plated steel ERAA01888A0 Green

70 to 150 4.8 to 10.3 0.207 5.26 1.94 49.2 Powder-coated steel ERAA01889A0 Red

15 to 30 1.0 to 2.1 0.207 5.26 2.50 63.5 Powder-coated steel ERCA04288A0 Yellow

1/2 15

25 to 75 1.7 to 5.2 0.234 5.94 2.60 65.9 Powder-coated steel ERAA01910A0 Green

70 to 150 4.8 to 10.3 0.283 7.19 2.44 62.0 Powder-coated steel ERAA01911A0 Red

15 to 30 1.0 to 2.1 0.306 7.77 4.00 102 Powder-coated steel 1E398927022 Yellow

3/4

20

MR95H

and

MR95HD

and 1

3/4

and 1

and 25

and 25

25 to 75 1.7 to 5.2 0.343 8.71 4.00 102 Powder-coated steel 1E399027142 Green

70 to 150 4.8 to 10.3 0.406 10.31 4.00 102 Powder-coated steel 1E399127162 Red

15 to 30 1.0 to 2.1 0.306 7.77 4.00 102 Powder-coated Stainless steel 1E3989X0052 Yellow

20

25 to 75 1.7 to 5.2 0.375 9.53 3.88 98.6 Stainless steel 1K762537022 Unpainted

70 to 150 4.8 to 10.3 0.437 11.1 4.00 102 Stainless steel 11A8269X012 Unpainted

5 to 80 0.34 to 5.5 0.500 12.7 6.50 165 Powder-coated steel ERCA04290A0

1-1/2

40

and 2

and 50

60 to 120 4.1 to 8.3 0.562 14.3 6.56 167 Powder-coated steel ERAA01893A0 Light Gray

100 to 140 6.9 to 9.7 0.594 15.1 6.56 167 Enamel-coated steel ERAA01894A0 Yellow

120 to 150 8.3 to 10.3 0.625 15.9 6.57 167 Powder-coated steel 1P7888X0022 Black

1/4 - - - -

1/2 15

MR95HT

3/4

and 1

and 25

1-1/2

and 2

and 50

1/4 - - - -

1/2 15

MR95HP

3/4

and 1

and 25

1-1/2

and 2

and 50

1. For Types MR95LD and MR95HD regulators, the pressure ranges indicate the differential pressure that can be obtained with the indicated spring. The differential pressure

(spring setting) is added to the spring case loading pressure to determine the actual outlet pressure.

2. Springs meet NACE MR0175-2002 and NACE MR0103 requirements only for applications in which the spring is not exposed to the sour gas

15 to 100 1.0 to 6.9 0.192 4.88 2.00 50.8 Inconel

80 to 300 5.5 to 20.7 0.281 7.14 2.00 50.8 Inconel

15 to 100 1.0 to 6.9 0.281 7.14 2.50 63.5 Inconel

80 to 300 5.5 to 20.7 0.375 9.53 2.60 66.0 Inconel

15 to 100 1.0 to 6.9 0.437 11.1 4.08 104 17-4 PH Stainless steel ERCA04295A0 Unpainted

20

80 to 300 5.5 to 20.7 0.562 14.3 4.08 104 17-4 PH Stainless steel ERCA04296A0 Unpainted

15 to 100 1.0 to 6.9 0.625 15.9 6.70 170 17-4 PH Stainless steel

40

60 to 260 4.1 to 17.9 0.812 20.6 6.70 170 17-4 PH Stainless steel ERCA04298A0 Unpainted

15 to 100 1.0 to 6.9 0.192 4.88 2.00 50.8 Inconel

80 to 400 5.5 to 27.6 0.281 7.14 2.00 50.8 Inconel

15 to 100 1.0 to 6.9 0.281 7.14 2.50 63.5 Inconel

80 to 400 5.5 to 27.6 0.375 9.53 2.60 66.0 Inconel

15 to 100 1.0 to 6.9 0.437 11.1 4.08 104 17-4 PH Stainless steel ERCA04295A0 Unpainted

20

80 to 400 5.5 to 27.6 0.562 14.3 4.08 104 17-4 PH Stainless steel ERCA04296A0 Unpainted

15 to 100 1.0 to 6.9 0.625 15.9 6.70 170 17-4 PH Stainless steel ERCA04297A0 Unpainted

40

60 to 300 4.1 to 20.7 0.812 20.6 6.70 170 17-4 PH Stainless steel ERCA04298A0 Unpainted

(1)

SPRING WIRE

DIAMETER

SPRING FREE

LENGTH

SPRING

MATERIAL

(2)

®

®

®

®

SPRING PART

NUMBER

Black with

Light Blue Stripe

ERCA04292A0 Unpainted

ERCA04291A0 Unpainted

ERCA04294A0 Unpainted

ERCA04293A0 Unpainted

ERCA04297A0 Unpainted

®

®

®

®

ERCA04292A0 Unpainted

ERCA04291A0 Unpainted

ERCA04294A0 Unpainted

ERCA04293A0 Unpainted

SPRING

COLOR

®

Inconel

is a mark owned by Special Metals Corporation.

9

Page 10

MR95 Series

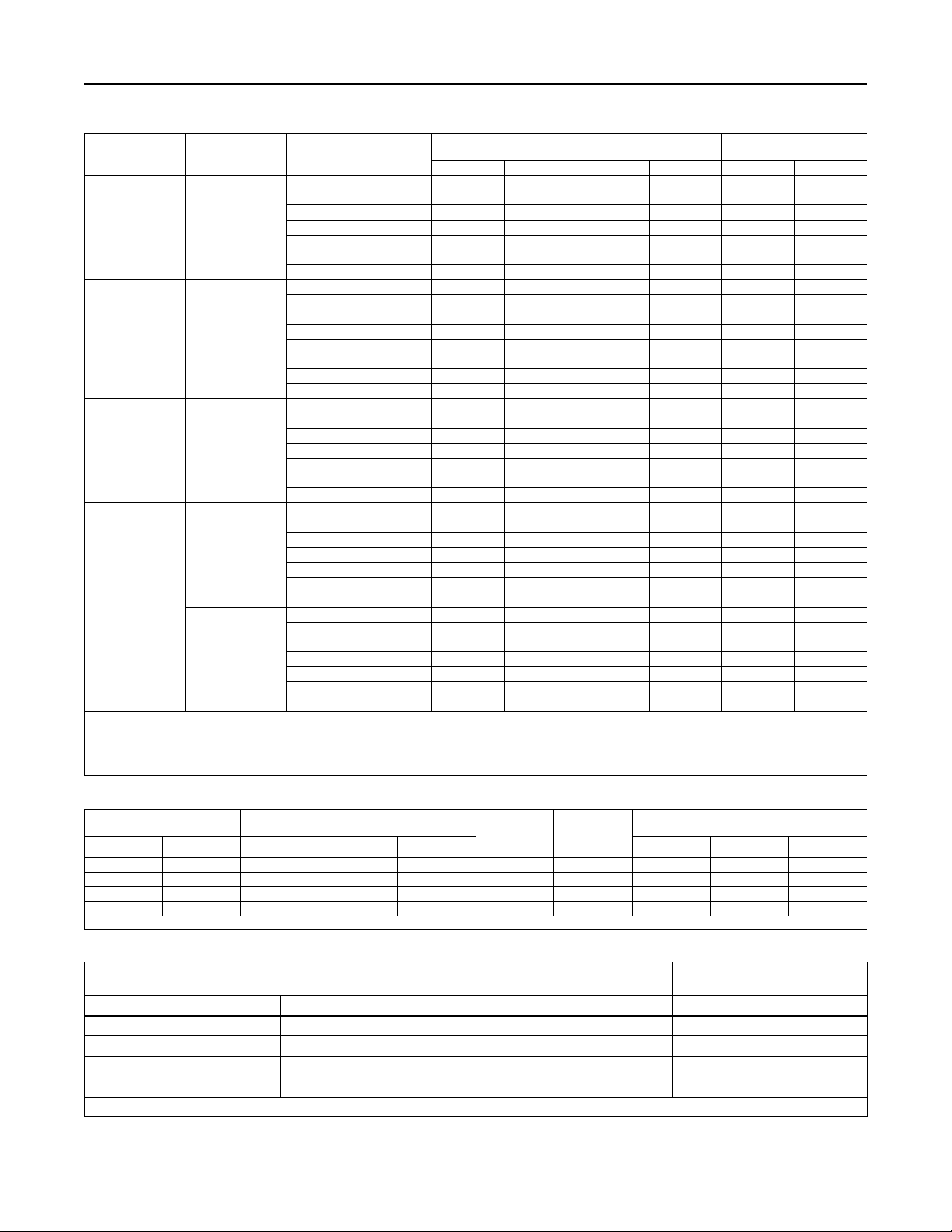

Table 4. Maximum Cold Working Pressures of Body Size and Material

TYPE BODY SIZE BODY MATERIAL

MAXIMUM INLET

PRESSURE

MAXIMUM OUTLET

PRESSURE

(1)(2)

MAXIMUM SPRING CASE

PRESSURE

psig bar psig bar psig bar

Gray cast iron 250 17.2 50 3.4 50 3.4

WCC Steel 300 20.7 125 8.6 125 8.6

MR95L and

MR95LD

All available

(3)

sizes

LCC Steel 300 20.7 125 8.6 125 8.6

CF8M Stainless steel 300 20.7 125 8.6 125 8.6

CF3M Stainless steel 300 20.7 125 8.6 125 8.6

Monel

Hastelloy

®(4)

® C(4)

300 20.7 125 8.6 125 8.6

300 20.7 125 8.6 125 8.6

Gray cast iron 250 17.2 250 17.2 250 17.2

WCC Steel 300 20.7 300 20.7 300 20.7

LCC Steel 300 20.7 300 20.7 300 20.7

MR95H and

MR95HD

All available

(3)

sizes

CF8M Stainless steel 300 20.7 300 20.7 300 20.7

CF3M Stainless steel 300 20.7 300 20.7 300 20.7

Aluminum-Bronze

Monel

Hastelloy

®(4)

® C(4)

300 20.7 300 20.7 300 20.7

(4)

300 20.7 300 20.7 300 20.7

300 20.7 300 20.7 300 20.7

WCC Steel 1000 68.9 600 41.4 300 20.7

LCC Steel 1000 68.9 600 41.4 300 20.7

MR95HP

All available

(3)

sizes

CF8M Stainless steel 1000 68.9 550 37.9 300 20.7

CF3M Stainless steel 1000 68.9 550 37.9 300 20.7

Aluminum-Bronze

Monel

Hastelloy

®(4)

® C(4)

1000 68.9 550 37.9 300 20.7

(4)

1000 68.9 550 37.9 300 20.7

1000 68.9 550 37.9 300 20.7

WCC Steel 600 41.4 600 41.4 300 20.7

LCC Steel 600 41.4 600 41.4 300 20.7

1/4 NPT and

1/2 to 1 in. /

DN 15 to 25

MR95HT

CF8M Stainless steel 600 41.4 550 37.9 300 20.7

CF3M Stainless steel 600 41.4 550 37.9 300 20.7

Aluminum-Bronze

Monel

Hastelloy

®(4)

® C(4)

600 41.4 550 37.9 300 20.7

(4)

600 41.4 550 37.9 300 20.7

600 41.4 550 37.9 300 20.7

WCC Steel 600 41.4 450 31.0 300 20.7

LCC Steel 600 41.4 450 31.0 300 20.7

1-1/2 and 2 in. /

DN 40 and 50

CF8M Stainless steel 600 41.4 450 31.0 300 20.7

CF3M Stainless steel 600 41.4 450 31.0 300 20.7

Monel

Hastelloy

®

®

C 600 41.4 450 31.0 300 20.7

600 41.4 450 31.0 300 20.7

Aluminum-Bronze 600 41.4 450 31.0 300 20.7

1. The pressure/temperature limits in this Instruction Manual and any applicable standard or code limitation should not be exceeded.

2. The pressure limits given are based on the body size and body materials only. Actual pressure limits of the assembled regulator may decrease and vary depending on the temperature,

body end connection, diaphragm, seat and/or trim material of the regulator.

3. See Tables 1 and 2 for all available body sizes.

4. Not available for 1/4 NPT body size.

Table 5. Types MR95LD and MR95HD Flow and Sizing Coefficient

BODY SIZE

In. DN C

1/4 - - - - 1.1 37 1.85 33.6 0.74 0.715 0.62 0.86

1/2 15 2.9 103 5.15 35.5 0.79 0.797 0.70 0.89

3/4 and 1 20 and 25 6.0 221 11.05 36.8 0.88 0.857 0.68 0.94

1-1/2 and 2 40 and 50 18.1 700 35.00 38.7 0.88 0.945 0.65 0.94

2

Km = F

L

Table 6. Relief Sizing Coefficients for MR95 Series Regulators with Reduced Flow Orifices

In. DN C

1/4 - - - - 28 28

1/2 15 70 67

3/4 and 1 20 and 25 156 156

1-1/2 and 2 40 and 50 482 475

1. The reduced ow orice option offers similar ow capacity as the equivalent 95 Series conguration.

®

is a mark owned by Special Metals Corporation.

Monel

Hastelloy® C is a mark owned by Haynes International, Inc.

10

WIDE-OPEN COEFFICIENT

(FOR RELIEF SIZING)

v

BODY SIZE

C

C

g

C

s

1

K

m

WIDE-OPEN COEFFICIENT FOR

MR95 SERIES REDUCED FLOW OPTION

g

IEC SIZING COEFFICIENT

X

T

F

D

(1)

WIDE-OPEN COEFFICIENT FOR

LEGACY 95 SERIES

C

g

F

L

Page 11

BLOCK

VALV E

MR95 Series

PLANT AIR

ATMOSPHERE

TYPE 67CFR REGULATOR

(INLET) VENT

TYPE MR95LD REGULATOR (ALSO TYPICAL OF TYPE MR95HD)

Figure 3. Differential Pressure Regulator Installation Schematics

Installation

WARNING

!

Personal injury or system damage

may result if this regulator is installed,

without appropriate overpressure

protection, where service conditions

could exceed the limits given in the

Speci cations section and/or regulator

nameplate. Refer to Overpressure

Protection section for recommendations

on how to prevent service conditions

from exceeding those limits.

Additionally, physical damage to the

regulator may result in personal injury

or property damage due to escaping of

accumulated gas. To avoid such injury

and damage, install the regulator in a

safe location.

Under enclosed conditions or indoors,

escaping gas may accumulate and be an

explosion hazard. In this case, the vent

should be piped outdoors.

For regulator constructions with a

spring case vent, the vent should be

kept open to permit free ow of gas

to the atmosphere. Protect openings

against entrance of rain, snow, insects

or any other foreign material that may

plug the spring case vent or vent line.

(OUTLET) VENT

Before installing the regulator:

• Unpack the regulator and remove the protective

shipping plugs from the end connections of

the body and the pressure connection in the

spring case.

• Check the regulator and make sure it has not

been damaged or collected foreign material

during shipping.

• Remove any debris or dirt in the tubing and

the pipeline.

• Apply pipe compound to the external pipe thread

for NPT bodies or use appropriate gaskets for

anged bodies.

• Make sure gas ow through the regulator is in the

same direction as the arrow on the body.

On 1-1/2 or 2 in. / DN 40 or 50 Types MR95H, MR95HP

and MR95HT regulators, the spring case vent is tapped

so a vent line can be connected to provide venting to a

remote location. On 1/4 NPT, 1/2, 3/4 and 1 in. / DN 15,

20 and 25 Types MR95H, MR95HP and MR95HT body

sizes, the tapped vent option is available on request.

Protect the exposed end of the vent pipe with a weather

and insect resistant vent assembly. Periodically check

all vents and remote vent lines to ensure that they

are unobstructed.

On Types MR95LD and MR95HD regulators, the

loading pressure is connected to the 1/4 NPT

connection in the spring case.

11

Page 12

MR95 Series

Overpressure Protection

WARNING

!

Personal injury, equipment damage or

leakage due to escaping accumulated gas

or bursting of pressure-containing parts

may result if this regulator is:

• Overpressured

• Installed where service conditions

could exceed the limits given in the

Specications section and on the

appropriate nameplate

• Where conditions exceed any ratings of

adjacent piping or piping connections

To avoid such injury or damage, provide

pressure-relieving or pressure-limiting

devices to prevent service conditions from

exceeding those limits.

The Types MR95H and MR95HD regulators have an

outlet pressure rating equal to the inlet pressure rating.

The Types MR95L, MR95LD, MR95HP and MR95HT

regulators have an outlet pressure rating lower than

the inlet pressure rating.

The recommended pressure limitations are

stamped on the regulator nameplate. Some type of

overpressure protection is needed if the actual inlet

pressure exceeds the maximum operating outlet

pressure rating. Provide external overpressure

protection if the regulator inlet pressure is greater than

the safe working pressure of downstream equipment.

Common methods of external overpressure protection

include relief valves, monitoring regulators, shutoff

devices and series regulation.

Regulator operation below the maximum pressure

limitations does not preclude the possibility of damage

from external sources or from debris in the pipeline. If

the regulator is exposed to an overpressure condition,

inspect it for any damage that may have occurred.

Startup

Note

The Specications section and Tables 3

and 4 show the maximum inlet, the

differential and the outlet pressures for

specic constructions. Use pressure

gauges to monitor inlet pressure, outlet

pressure and any loading pressure

during startup.

1. Check that proper installation is completed

and downstream equipment has been

properly adjusted.

2. Make sure all block and vent valves are closed.

3. Decompress the control spring by turning the

adjusting screw (for Types MR95L, MR95H,

MR95HP and MR95HT) or handwheel (for

Types MR95LD and MR95HD) counterclockwise.

4. Slowly open the valves in the following order:

a. Loading supply and control line valve(s), if used

b. Inlet block valve

c. Outlet block valve

5. Set the regulator to the desired outlet (control)

pressure according to the Adjustment procedure.

Adjustment

WARNING

!

To avoid personal injury, property

damage or equipment damage caused

by bursting of pressure containing parts

or explosion of accumulated gas, never

adjust the control spring to produce an

outlet pressure higher than the upper

limit of the outlet pressure range for that

particular spring. If the desired outlet

pressure is not within the range of the

control spring, install a spring of the

proper range.

The factory setting of the regulator can be varied

within the pressure range stamped on the nameplate.

Follow the following procedures for the proper

adjustment of the outlet (control) spring. If the spring

range was changed, be sure to change the stamped

spring range on the nameplate.

All MR95 Series regulator springs can be backed off

to provide zero outlet. Recommended outlet pressure

ranges available, maximum inlet pressures and color

codes of the respective springs are shown in Tables 3

and 4.

12

Page 13

MR95 Series

Types MR95L, MR95H, MR95HP

and MR95HT

Key numbers are referenced in Figure 6, 8 or 9.

1. Loosen the jam nut (key 17).

2. Turn the adjusting screw (key 15) clockwise to

increase outlet pressure or counterclockwise to

decrease it.

3. Monitor the outlet pressure with a test gauge

during the adjustment.

4. Tighten the jam nut (key 17) to maintain the

desired setting.

Types MR95LD and MR95HD

Key numbers are referenced in Figure 7 or 10.

1. Turn handwheel (key 38) clockwise to increase

outlet pressure or counterclockwise to decrease it.

2. Monitor the outlet pressure with a test gauge

during the adjustment.

Shutdown

1. Close the upstream block valve to the regulator inlet.

2. Close the downstream block valve to the

regulator outlet.

3. Vent the downstream pressure by slowly opening

the bleed valve between the regulator and the

downstream shutoff valve. Without changing

regulator spring adjustment, all pressure between

the upstream and downstream shutoff valves

will be released through the bleed valve, since

the Type MR95L, MR95H, MR95HP or MR95HT

regulator opens in response to the decreased outlet

pressure. For Types MR95L, MR95H, MR95HP

and MR95HT regulators, skip steps 4, 5 and 6. For

Types MR95LD and MR95HD continue steps 4

through 6.

4. Close the block valve to the loading pressure.

5. Vent loading pressure slowly to release pressure

in the spring case.

6. Vent inlet pressure slowly (through the bleed

valve) to release all remaining pressure in

the regulator.

Maintenance

WARNING

!

To avoid personal injury, property damage

or equipment damage caused by sudden

release of pressure or explosion of

accumulated gas, do not attempt any

maintenance or disassembly without

rst isolating the regulator from system

pressure and relieving all internal

pressure from the regulator.

To avoid possible personal injury from

spring or pressure-loaded actuator, make

certain the adjusting screw is completely

backed off and the spring case pressure

is vented prior to disassembly. Otherwise,

the spring load or loading pressure could

forcefully eject the spring case.

Regulators that have been disassembled

for repair must be tested for proper

operation before being returned to

service. Only parts manufactured by

Emerson™ should be used for repairing

Fisher® regulators.

Due to normal wear or damage that may

occur from external sources, this regulator

should be inspected and maintained

periodically. The frequency of inspection

and replacement of parts depends upon

the severity of service conditions or the

requirement of local, state and federal

rules and regulations.

Due to normal wear that may occur, inspect the

parts periodically and replace if necessary. The

frequency of inspection depends on the severity of

service conditions or the requirements of state and

federal laws.

Replace parts such as the O-rings, gaskets, diaphragm

and packing as necessary. Always apply lubricants as

the regulator is being reassembled. Suitable lubricants

are shown in the assembly drawings.

The regulator does not have to be taken out of the

pipeline to be disassembled. All key numbers are

referenced in Figures 4 to 10.

13

Page 14

MR95 Series

Replacement or Maintenance of Orice

and Valve Plug

If it appears that the valve does not shut off tightly, the

orice and valve plug could be worn out or damaged.

Proceed as follows to check and/or replace them.

1. Shut down the regulator. Refer to Shutdown section

for the proper procedure.

2. Unscrew the valve plug guide (key 5) from the

body (key 1). The valve plug spring (key 26) and

the valve plug (key 4) will normally come out of the

body along with the valve plug guide. On 1-1/2 or

2 in. / DN 40 or 50 body size regulators, the stem

(key 6) will also come out of the regulator body.

3. Inspect the seating surface of the valve plug (key 4),

make sure that the elastomer, PTFE or polished

metal surface of the valve plug is not damaged. Also

inspect the external O-ring (key 4c) on the valve

plug of Type MR95HP. Replace the valve plug

assembly if damage is noted.

4. Inspect the seating edge of the orice (key 3).

If damage is noted, unscrew the orice from

the body (key 1) and replace it with a new part.

Reference Table 8 for proper torque values.

5. Reassemble the regulator in the reverse order of

the above steps. When installing the valve plug

guide (key 5), coat the threads and sealing surface

with sealant to ensure an adequate metal-to-metal

seal. Reference Table 8 for proper torque values.

Flange Cap Screw Torque Inspection

Retorquing of spring case cap screws may be

necessary for some MR95 Series regulators after a

period of use. Retorque the cap screws as follows:

1. Shut down the regulator. Refer to Shutdown

section for the proper procedure.

2. Retighten the cap screws (key 16) in a crisscross

pattern. See Table 8 for proper torque values.

3. Follow the Startup section to repressurize

the regulator.

4. Refer to the Replacement of Diaphragm section

as needed.

Replacement of Diaphragm

When the regulator does not respond to differential or

downstream pressure changes, if uid leaks or vents

to the spring case (pressure reducing regulators) or

the loading pressure seems to leak to the downstream

piping (differential pressure regulators), the diaphragm

could be worn out or ruptured. Inspect/replace the

diaphragm as follows:

CAUTION

Metal diaphragms have thin sharp

edges. To avoid hand cuts, be careful

when handling the diaphragm and

particularly the diaphragm edge.

1. Shut down the regulator. Refer to “Shutdown”

section for the proper procedure.

2. For Types MR95L, MR95H, MR95HP and

MR95HT—loosen the jam nut (key 17) and turn

the adjusting screw (key 15) counterclockwise to

remove all spring compression.

For Types MR95LD and MR95HD—turn the

handwheel (key 38) counterclockwise to remove

all spring compression.

CAUTION

Provide adequate support to the spring

case when disassembling MR95 Series

regulator installed in a vertical

installation or other application where

the spring case is not oriented upward.

Without adequate support, the spring

case may fall and cause physical injury

when the cap screws are loosened.

3. Remove the cap screws (key 16) from the

diaphragm casing. Lift the entire spring case

(key 2) off of the body (key 1).

4. Remove the upper spring seat (key 9) and

regulator spring (key 11). For Types MR95H,

MR95HP and MR95HT with body sizes 1-1/2 and

2 in. / DN 40 and 50 skip steps 5 and 6.

5. For Type MR95HD and 1/4 NPT to 1 in. /

DN 25 body sizes of Types MR95H, MR95HP

and MR95HT—remove the lower spring seat (key 8).

For Types MR95L and MR95LD—remove the

diaphragm head assembly (key 21, lower spring

seat and diaphragm head threaded together).

6. Remove the diaphragm(s) (key 12) and examine

for damage. Replace if damage is noted. See

Table 7 for the required number of diaphragm(s).

Proceed to step 9.

7. For body sizes 1-1/2 and 2 in. / DN 40 and 50,

remove the diaphragm and diaphragm head. The

diaphragm head can only be disassembled for the

14

Page 15

MR95 Series

DIAPHRAGM (KEY 12)

GASKET (KEY 19)

TYPES MR95L AND MR95H METAL DIAPHRAGM

TYPES MR95LD AND MR95HD METAL DIAPHRAGM

Figure 4. Diaphragm Assembly for MR95 Series with 1/4 NPT and 1/2 to 1 in. / DN 15 to 25 Body Sizes

LOCKNUT (KEY 31)

LOCK WASHER (KEY 28)

LOWER SPRING SEAT (KEY 8)

DIAPHRAGM HEAD (KEY 21)

DIAPHRAGM (KEY 12)

DIAPHRAGM HEAD (KEY 21)

GASKET (KEY 45)

GASKET (KEY 19)

DIAPHRAGM (KEY 12)

GASKET (KEY 19)

LOCKNUT (KEY 31)

LOCK WASHER (KEY 28)

LOWER SPRING SEAT (KEY 8)

DIAPHRAGM HEAD (KEY 21)

DIAPHRAGM (KEY 12)

GASKET (KEY 29)

DIAPHRAGM HEAD (KEY 21)

GASKET (KEY 29)

PUSHER POST (KEY 10)

COMPOSITION DIAPHRAGM METAL DIAPHRAGM

PUSHER POST (KEY 10)

Figure 5. Diaphragm Assembly for MR95 Series with 1-1/2 and 2 in. / DN 40 and 50 Body Sizes

Table 7. Number of Diaphragms Required

BODY SIZE TYPE SPRING RANGE DIAPHRAGM MATERIAL NUMBER OF DIAPHRAGM

All ranges

2 to 6 psig / 0.14 to 0.41 bar Metal 1

All ranges

1/4 NPT

1/2 to 2 in. /

DN 15 to 50

MR95L and

MR95LD

MR95H,

MR95HD

and MR95HP

All types All ranges

All ranges except 2 to 6 psig / 0.14 to 0.41 bar Metal 2

1-1/2 and 2 in. / DN 40 and 50 sizes. Disassemble

it for inspection of the diaphragm (key 12) and

two small diaphragm gaskets (key 29) or O-ring

(key 45). Remove the locknut (key 31) from the

pusher post (key 10) and separate the assembly.

An O-ring is used to seal around the pusher post if

an elastomer diaphragm is used and the gaskets

are used with stainless steel diaphragm(s).

Ethylyne Propylene Diene (EPDM) 1

Neoprene (CR) 1

Fluorocarbon (FKM) 1

Metal 2

Ethylyne Propylene Diene (EPDM) 1

Fluorocarbon (FKM) 1

Neoprene (CR) 1

Metal 2

Ethylyne Propylene Diene (EPDM) 2

Fluorocarbon (FKM) 2

Neoprene (CR) 1

8. Remove the stem assembly (key 6) except for

regulator with 1/4 NPT body size. Inspect the

O-ring (not shown) from wear or damage. Replace

stem assembly if damage is noted.

9. With diaphragm(s) (key 12) removed, ensure

the pressure registration hole (pitot tube, key 20,

in 3/4 in. / DN 20 and larger body sizes) is

completely open and free of all obstructions.

15

Page 16

MR95 Series

Table 8. Torque Specifications

BODY SIZE SPRING CASE BOLT

In. DN FT-LBS N•m FT-LBS N•m FT-LBS N•m

1/4

1/2

3/4 and 1

1-1/2 and 2

1. Reduce spring case bolt’s torque by 30% when using Ethylenepropylene (EPDM) diaphragms.

- - - -

15

20 and 25

40 and 50

6 to 8

10 to 13

24 to 30

40 to 50

(1)

8 to 11

13 to 18

33 to 41

54 to 68

6 to 8

34 to 38

50 to 60

180 to 200

ORIFICE PLUG GUIDE

8 to 11

46 to 51

68 to 81

244 to 271

50 to 58

75 to 90

100 to 125

170 to 200

68 to 79

102 to 122

136 to 169

230 to 271

10. If the unit has metal diaphragms (see Figures 4

and 5):

a. (Applicable only for the lower diaphragm head

of Types MR95H, MR95HT and MR95HD, 1-1/2

and 2 in. / DN 40 and 50.) Find the pusher

post (key 10) and place on a surface with the

larger at surface down and the thread stem up

(metal diaphragm pusher post has a recessed

diameter in the bottom surface). Then, nd

one smaller composition gasket (key 29) and

t it over the threaded end of the pusher post.

Find and take one of the diaphragm heads and

slip it over the threaded end of the pusher post

with the chamfered side of the diaphragm head

toward the gasket. Take a second gasket and

place it over the threaded end of the pusher

post on top of the diaphragm head.

b. Replace one of the two large diaphragm gaskets

(key 19) on the surface of the body (key 1) that

will support the diaphragms (key 12). There will

be two diaphragms used per regulator, except

for Types MR95L and MR95LD, 1/4 NPT with

2 to 6 psi / 0.14 to 0.41 bar spring range setting

which use only one metal diaphragm (the

metal diaphragm is in between two diaphragm

gaskets). Another diaphragm gasket will be

placed on top of the second metal diaphragm.

The raised surfaces of the metal diaphragms

should be placed in the unit so that they are

facing toward the assembler (toward the spring)

except only when one metal diaphragm is

being used then the raised surface should be

facing down (towards the body). See Figure 2

as reference.

11. Reassemble in the reverse of the above

procedures. Lubricate the upper spring seat

(key 9) and the exposed threads of the adjusting

screw (key 15) with anti-seize lubricant. Install the

cap screws (key 16) in a crisscross pattern and

tighten to nger tight only.

12. To ensure proper slack in the diaphragm, install

the adjusting screw (key 15, for Types MR95L,

MR95H, MR95HP and MR95HT) or handwheel

(key 38, Types MR95LD and MR95HD), if

completely removed and turn it clockwise. This

allows proper positioning of the diaphragm

(key 12) to permit full travel of the valve plug

(key 4). Finish tightening the cap screws (key 16).

See Table 8 for proper torque values.

13. Complete reassembly procedures and turn the

adjusting screw (key 15) or handwheel (key 38)

to produce the desired outlet pressure. For

Types MR95L, MR95H, MR95HP and MR95HT,

tighten the jam nut (key 17) to maintain the

desired setting.

Replacement of Packing

(Types MR95LD and MR95HD only)

Leakage around the adjusting screw may indicate

worn packing material. Follow the instructions below to

replace the packing rings.

1. Shut down the regulator. Refer to “Shutdown”

section for the proper procedure.

2. Take out the machine screw (key 41) and lift off

the washer (key 44) and handwheel (key 38).

3. Unscrew the packing box (key 32). Unscrew the

packing nut (key 35) and the packing follower

(key 34) off of the adjusting screw (key 33).

4. Unscrew and pull the adjusting screw (key 33) out

through the bottom of the packing box (key 32).

5. Pull out the old packing (key 36) and replace it with

three new packing rings. Replace the packing box

gasket (key 37). Lubricate packing box gasket with

general purpose Polytetrauoroethylene (PTFE) or

lithium grease.

6. Reassemble the stufng box unit by returning

the adjusting screw (key 33) to the inside of the

stufng/packing box (key 32). Slip the packing

follower (key 34) onto the adjusting screw and

into the packing box. Screw on the packing nut

(key 35).

7. Put the stufng/packing box (key 32) back onto the

spring case (key 2). Set the handwheel (key 38) and

washer (key 44) on the adjusting screw (key 33) and

screw in the machine screw (key 41).

16

Page 17

MR95 Series

Parts Ordering

When corresponding with your local Sales Ofce about

this equipment, always reference the equipment serial

number or FS number that can be found on

the nameplate.

When ordering replacement parts, reference the key

number of each needed part as found in the following

parts list. Separate kits containing all recommended

spare parts are available.

Note

In this parts list, parts marked NACE

are intended for corrosion-resistant

service as detailed in the NACE

International Standard MR0175-2002

and/or MR0103.

Optional materials are available to meet

ANSI/NACE MR0175/ISO 15156, please

contact your local Sales Ofce for

special ordering instructions.

Parts List

Key Description Part Number

Parts Kit (included are keys 3, 4, 12, 19, 29,

45 and 63; not all parts are used for all types)

Types MR95H and MR95HP

Stainless steel diaphragm and plug

1/4 NPT Body RMR95HX0012

1/2 in. / DN 15 Body RMR95HX0042

3/4 and 1 in. / DN 20 and 25 Body Sizes RMR95HX0072

1-1/2 and 2 in. / DN 40 and 50 Body Sizes RMR95HX0102

Neoprene (CR) diaphragm and

Nitrile (NBR)/Brass Disk

1/4 NPT Body RMR95HX0022

1/2 in. / DN 15 Body RMR95HX0052

3/4 and 1 in. / DN 20 and 25 Body Sizes RMR95HX0082

1-1/2 and 2 in. / DN 40 and 50 Body Sizes RMR95HX0112

Neoprene (CR) diaphragm and

Nitrile (NBR)/416 Stainless steel Disk

1/4 NPT Body RMR95HX0032

1/2 in. / DN 15 Body RMR95HX0062

3/4 and 1 in. / DN 20 and 25 Body Sizes RMR95HX0092

1-1/2 and 2 in. / DN 40 and 50 Body Sizes RMR95HX0122

Type MR95L

Stainless steel diaphragm and plug

1/4 NPT Body RMR95LX0012

1/2 in. / DN 15 Body RMR95LX0042

3/4 and 1 in. / DN 20 and 25 Body Sizes RMR95LX0072

Neoprene (CR) diaphragm and

Nitrile (NBR)/Brass Disk

1/4 NPT Body RMR95LX0022

1/2 in. / DN 15 Body RMR95LX0052

3/4 and 1 in. / DN 20 and 25 Body Sizes RMR95LX0082

Neoprene (CR) diaphragm and

Nitrile (NBR)/416 Stainless steel Disk

1/4 NPT Body RMR95LX0032

1/2 in. / DN 15 Body RMR95LX0062

3/4 and 1 in. / DN 20 and 25 Body Sizes RMR95LX0092

*Recommended spare part

1. NACE MR0175-2002 and MR0103.

2. See Type MR95 Reduced Orice Part Numbers table on page 30 for reduced orices

that change Type MR95 Cv values to equivalent Type 95 Cv values.

Hastelloy® C is a mark owned by Haynes International, Inc.

Monel® is a mark owned by Special Metals Corporation.

Key Description Part Number

Parts Kit (included are keys 3, 4, 12, 19, 29,

45 and 63; not all parts are used for

all types) (continued)

Type MR95HT, Stainless Diaphragm and Plug

1/4 NPT Body RMR95HTX012

1/2 in. / DN 15 Body RMR95HTX022

3/4 and 1 in. / DN 20 and 25 Body Sizes RMR95HTX032

1-1/2 and 2 in. / DN 40 and 50 Body Sizes RMR95HTX042

1 Body See Following Tables

2 Spring Case See Following Tables

3* Orice

Metal-to-metal seat

Types MR95L, MR95LD, MR95H and MR95HD

1/4 NPT Body Size

416 Stainless steel GF04856X022

316 Stainless steel GF04856X032

Hastelloy

Monel

1/2 in. / DN 15 Body Size

416 Stainless steel GF04841X022

316 Stainless steel GF04841X032

Alloy 6 GF04841X062

Hastelloy

Monel

3/4 and 1 in. / DN 20 and 25 Body Sizes

416 Stainless steel GF04821X022

316 Stainless steel GF04821X032

Alloy 6 GF04821X062

Hastelloy

Monel

1-1/2 and 2 in. / DN 40 and 50 Body Sizes

416 Stainless steel GF04896X022

316 Stainless steel GF04896X032

Alloy 6 GF04896X062

Hastelloy

Monel

Type MR95HT

1/4 NPT Body Size

416 Stainless steel GF04856X022

316 Stainless steel GF04856X032

1/2 in. / DN 15 Body Size

416 Stainless steel GF04841X022

316 Stainless steel GF04841X032

Alloy 6 GF04841X062

3/4 and 1 in. / DN 20 and 25 Body Sizes

416 Stainless steel GF04821X022

316 Stainless steel GF04821X032

Alloy 6 GF04821X062

1-1/2 and 2 in. / DN 40 and 50 Body Sizes

416 Stainless steel GF04896X022

316 Stainless steel GF04896X032

Alloy 6 GF04896X062

Composition seat

Types MR95L, MR95LD, MR95H and MR95HD

1/4 NPT Body Size

Brass, Oxygen Service GF05038X012

316 Stainless steel, NACE

416 Stainless steel GF05038X022

Monel

1/2 in. / DN 15 Body Size

Brass, Oxygen Service GF05327X012

316 Stainless steel, NACE

416 Stainless steel GF05327X022

Monel

3/4 and 1 in. / DN 20 and 25 Body Sizes

Brass, Oxygen Service GF04822X012

316 Stainless steel, NACE

416 Stainless steel GF04822X022

Monel

1-1/2 and 2 in. / DN 40 and 50 Body Sizes

(Types MR95H and MR95HD only)

Brass, Oxygen Service GF05521X012

316 Stainless steel, NACE

416 Stainless steel GF05521X022

Monel

(2)

®

C GF04856X052

®

GF04856X042

®

C GF04841X052

®

GF04841X042

®

C GF04821X052

®

GF04821X042

®

C GF04896X052

®

GF04896X042

(1)

GF05038X032

®

GF05038X042

(1)

GF05327X032

®

GF05327X042

(1)

GF04822X032

®

GF04822X042

(1)

GF05521X032

®

GF05521X042

17

Page 18

MR95 Series

Key Description Part Number Key Description Part Number

3* Orice (continued)

(3)

Composition seat (continued)

Type MR95HP

1/4 NPT Body Size

316 Stainless steel, NACE

(1)

GF05038X032

416 Stainless steel GF05038X022

1/2 in. / DN 15 Body Size

316 Stainless steel, NACE

(2)

GF05327X032

416 Stainless steel GF05327X022

3/4 and 1 in. / DN 20 and 25 Body Sizes

316 Stainless steel, NACE

(1)

GF04822X032

416 Stainless steel GF04822X022

1-1/2 and 2 in. / DN 40 and 50 Body Sizes

316 Stainless steel, NACE

(1)

GF05521X032

416 Stainless steel GF05521X022

4* Valve Plug, Metal seat See Following Table

4* Disk Holder Assembly, Composition seat See Following Table

4a Disk Holder - - - - - - - - - - 4b Disk - - - - - - - - - - 4c O-ring (Type MR95HP only) - - - - - - - - - - 5 Valve Plug Guide

Types MR95L, MR95LD, MR95H and MR95HD

1/4 NPT Body Size

Brass, Oxygen Service GF05490X012

416 Stainless steel GF05490X022

316 Stainless steel, NACE

Hastelloy

Monel

®

C GF05490X052

®

GF05490X042

(1)

GF05490X032

1/2 in. / DN 15 Body Size

Brass, Oxygen Service GF05519X012

416 Stainless steel GF05519X022

316 Stainless steel, NACE

Hastelloy

Monel

®

C GF05519X052

®

GF05519X042

(1)

GF05519X032

3/4 and 1 in. / DN 20 and 25 Body Sizes

Brass, Oxygen Service GF04830X012

416 Stainless steel GF04830X022

316 Stainless steel, NACE

Hastelloy

Monel

®

C GF04830X052

®

GF04830X042

(1)

GF04830X032

1-1/2 and 2 in. / DN 40 and 50 Body Sizes

416 Stainless steel, Oxygen Service GF05510X022

316 Stainless steel, NACE

Hastelloy

Monel

®

C GF05510X052

®

GF05510X042

(1)

GF05510X032

Types MR95HP and MR95HT

1/4 NPT Body Size

416 Stainless steel GF05490X022

316 Stainless steel, NACE

(1)

GF05490X032

1/2 in. / DN 15 Body Size

416 Stainless steel GF05519X022

316 Stainless steel, NACE

(2)

GF05519X032

3/4 and 1 in. / DN 20 and 25 Body Sizes

416 Stainless steel GF04830X022

316 Stainless steel, NACE

(1)

GF04830X032

1-1/2 and 2 in. / DN 40 and 50 Body Sizes

416 Stainless steel GF05510X022

316 Stainless steel, NACE

(1)

GF05510X032

6 Stem/Stem Assembly

Types MR95L, MR95LD, MR95H and MR95HD

1/4 NPT Body Size

416 Stainless steel, Oxygen Service ERCA00638A0

316 Stainless steel

Standard ERCA00638A4

NACE

Hastelloy

Monel

(1)

, Types MR95L and MR95H only ERCA00638A1

®

C ERCA00638A3

®

ERCA00638A2

1/2 in. / DN 15 Body Size

416 Stainless steel

Without control line, Oxygen service ERCA00639A0

With control line ERAA01904A0

6 Stem/Stem Assembly (continued)

Types MR95L, MR95LD, MR95H and MR95HD (continued)

1/2 in. / DN 15 Body Size (continued)

316 Stainless steel

Standard ERCA00639A4

NACE

(1)

Without control line ERCA00639A1

With control line

Nitrile (NBR) seat ERAA01904A1

Fluorocarbon (FKM) seat ERAA01904A2

Hastelloy

Monel

®

C ERCA00639A3

®

ERCA00639A2

3/4 and 1 in. / DN 20 and 25 Body Sizes

416 Stainless steel

Without control line, Oxygen service ERCA00640A0

With control line ERAA01896A0

316 Stainless steel

Standard ERCA00640A4

NACE

(1)

Without control line ERCA00640A1

With control line

Nitrile (NBR) seat ERAA01896A1

Fluorocarbon (FKM) seat ERAA01896A2

Hastelloy

Monel

®

C ERCA00640A3

®

ERCA00640A2

1-1/2 and 2 in. / DN 40 and 50 Body Sizes

416 Stainless steel

Without control line, Oxygen service GF05507X022

With control line ERAA01906A0

316 Stainless steel

Standard GF05507X062

NACE

(1)

Without control line GF05507X032

With control line

Nitrile (NBR) seat ERAA01906A2

Fluorocarbon (FKM) seat ERAA01906A3

Hastelloy

Monel

®

C GF05507X052

®

GF05507X042

Type MR95HT

1/4 NPT Body Size

416 Stainless steel ERCA00638A0

316 Stainless steel ERCA00638A4

1/2 in. / DN 15 Body Size

416 Stainless steel ERCA00639A0

316 Stainless steel ERCA00639A4

3/4 and 1 in. / DN 20 and 25 Body Sizes

416 Stainless steel ERCA00640A0

316 Stainless steel ERCA00640A4

1-1/2 and 2 in. / DN 40 and 50 Body Sizes

416 Stainless steel, Oxygen Service GF05507X022

316 Stainless steel, Standard GF05507X062

Type MR95HP

1/4 NPT Body Size

416 Stainless steel ERCA00638A0

316 Stainless steel, NACE

(1)

ERCA00638A1

1/2 in. / DN 15 Body Size

416 Stainless steel

Without control line ERCA00639A0

With control line ERAA01904A0

316 Stainless steel, NACE

(1)

Without control line ERCA00639A1

With control line

Nitrile (NBR) seat ERAA01904A1

Fluorocarbon (FKM) seat ERAA01904A2

3/4 and 1 in. / DN 20 and 25 Body Sizes

416 Stainless steel

Without control line ERCA00640A0

With control line ERAA01896A0

316 Stainless steel, NACE

(1)

Without control line ERCA00640A1

With control line

Nitrile (NBR) seat ERAA01896A1

*Recommended spare part

1. NACE MR0175-2002 and MR0103.

2. NACE MR0175-2002.

3. See Type MR95 Reduced Orice Part Numbers table on page 30 for reduced orices

that change Type MR95 Cv values to equivalent Type 95 Cv values.

Hastelloy® C is a mark owned by Haynes International, Inc.

Monel® is a mark owned by Special Metals Corporation.

Fluorocarbon (FKM) seat ERAA01896A2

18

Page 19

MR95 Series

Key Description Part Number Key Description Part Number

6 Stem/Stem Assembly (continued)

Type MR95HP (continued)

1-1/2 and 2 in. / DN 40 and 50 Body Sizes

416 Stainless steel, Oxygen Service

Without control line GF05507X022

With control line ERAA01906A0

316 Stainless steel, NACE

(1)

Without control line GF05507X032

With control line

Nitrile (NBR) seat ERAA01906A2

Fluorocarbon (FKM) seat ERAA01906A3

6a Stem - - - - - - - - - - 6b Pusher Plate (1/4 NPT and 1/2 to 1 in. /

DN 15 to 25 Body Sizes only) - - - - - - - - - - 6b O-ring (1-1/2 and 2 in. /

DN 40 and 50 Body Sizes only) - - - - - - - - - - 6c O-ring (1/2 to 1 in. / DN 15 to 25 Body Sizes only) - - - - - - - - - - 7 Stem Guide Bushing

1/4 NPT Body Size

416 Stainless steel, Oxygen Service ERCA03695A0

316 Stainless steel, NACE

Hastelloy

Monel

®

C ERCA03695A3

®

ERCA03695A2

(1)

ERCA03695A1

1/2 in. / DN 15 Body Size

416 Stainless steel, Oxygen Service ERCA03694A0

316 Stainless steel, NACE

Hastelloy

Monel

®

C ERCA03694A3

®

ERCA03694A2

(1)

ERCA03694A1

3/4 to 2 in. / DN 20 to 50 Body Sizes

416 Stainless steel, Oxygen Service ERCA03668A0

316 Stainless steel, NACE

Hastelloy

Monel

®

C ERCA03668A3

®

ERCA03668A2

8 Lower Spring Seat, NACE

(1)

ERCA03668A1

(1)

Types MR95L, MR95LD, MR95H and MR95HD

1/4 NPT Body Size

Aluminum

(2)

1E392309012

Stainless steel 1E3923X0012

1/2 in. / DN 15 Body Size

Aluminum

(2)

1E395408012

Stainless steel 1E3954X0042

3/4 and 1 in. / DN 20 and 25 Body Sizes

Aluminum

(2)

1E398608012

Stainless steel 1E3986X0042

1-1/2 and 2 in. / DN 40 and 50 Body Sizes

Steel

(2)

1P787724152

Stainless steel 1P7877X0012

Types MR95HP and MR95HT

1/4 NPT Body Size

Steel

(2)

ERCA00453A0

Stainless steel ERCA00453A1

1/2 in. / DN 15 Body Size

Steel

(2)

ERCA00436A0

Stainless steel ERCA00436A1

3/4 and 1 in. / DN 20 and 25 Body Sizes

Steel

(2)

17B8733X012

Stainless steel 17B8733X022

1-1/2 and 2 in. / DN 40 and 50 Body Sizes

Steel

Stainless steel 1P7877X0012

9 Upper Spring Seat, NACE

(2)

1P787724152

(1)

Types MR95L, MR95LD, MR95H and MR95HD

1/4 NPT Body Size

Steel

(2)

ERCA00383A0

Stainless steel ERCA00383A1

1/2 in. / DN 15 Body Size

Steel

(2)

ERCA00823A0

Stainless steel ERCA00823A1

3/4 and 1 in. / DN 20 and 25 Body Sizes

Steel

(2)

1E398725072

Stainless steel 1E3987X0012

9 Upper Spring Seat, NACE

Types MR95L, MR95LD, MR95H and MR95HD (continued)

1-1/2 and 2 in. / DN 40 and 50 Body Sizes

Steel

(2)

1P787624092

Stainless steel 1P7876X0012

Types MR95HP and MR95HT

1/4 NPT Body Size

Steel

(2)

14B9950X012

Stainless steel 14B9950X022

1/2 in. / DN 15 Body Size

Steel

(2)

ERCA00382A0

Stainless steel ERCA00382A1

3/4 and 1 in. / DN 20 and 25 Body Sizes

Steel

(2)

ERCA00138A0

Stainless steel ERCA00138A1

1-1/2 and 2 in. / DN 40 and 50 Body Sizes

Steel

(2)

1P787624092

Stainless steel 1P7876X0012

10 Pusher Post, 1-1/2 and 2 in. / DN 40 and

50 Body Sizes only

Metal-to-metal seat

416 Stainless steel, Types MR95H,

MR95HD and MR95HT only GF05509X022

316 Stainless steel, Types MR95H,

MR95HD and MR95HT only GF05509X032

Hastelloy

MR95HD only GF05509X052

Monel

®

C, Types MR95H and

®

, Types MR95H and

MR95HD only GF05509X042

Composition seat

416 Stainless steel, Oxygen Service

Types MR95H, MR95HD and MR95HP only GF05549X022

316 Stainless steel, NACE

Types MR95H, MR95HD and MR95HP only GF05549X032

Monel

®,

Types MR95H and MR95HD only GF05549X042

11 Control Spring, NACE

12* Diaphragm See Following Table

13 Nameplate - - - - - - - - - - 14* Diaphragm Protector, PTFE, NACE

Types MR95L and MR95LD

1/4 NPT Body Size 11A5126X012

1/2 in. / DN 15 Body Size 11A5127X012

3/4 and 1 in. / DN 20 and 25 Body Sizes 11A5128X012

Types MR95H, MR95HP and MR95HD

1/4 NPT Body Size 11A5129X012

1/2 in. / DN 15 Body Size 11A5130X012

3/4 and 1 in. / DN 20 and 25 Body Sizes 11A5131X012

1-1/2 and 2 in. / DN 40 and 50 Body Sizes 11A5527X012

15 Adjusting Screw, NACE

Square Head Adjustment

1/4 NPT Body Size GF05533X012

1/2 in. / DN 15 Body Size GF05553X012

3/4 and 1 in. / DN 20 and 25 Body Sizes GF05543X012

1-1/2 and 2 in. / DN 40 and 50 Body Sizes GF05522X012

Stainless steel Square Head Adjustment

1/4 NPT Body Size GF05533X022

1/2 in. / DN 15 Body Size GF05553X022

3/4 and 1 in. / DN 20 and 25 Body Sizes GF05543X022

1-1/2 and 2 in. / DN 40 and 50 Body Sizes GF05522X022

Sealed Square Head Adjustment

1/2 in. / DN 15 Body Size GF05553X012

3/4 and 1 in. / DN 20 and 25 Body Sizes GF05543X012

1-1/2 and 2 in. / DN 40 and 50 Body Sizes GF05522X012

Handwheel Adjustment

1/2 in. / DN 15 Body Size ERAA02331A0

16 Cap Screw, NACE

Types MR95L and MR95LD

1/4 NPT Body Size

Steel (10 required) ERCA00651A0

Stainless steel (10 required) ERCA00651A1

1/2 in. / DN 15 Body Size

(1)

(continued)

(1)

(1)(2)

See Table 3

(1)

(1)(2)

(1)(2)

Steel (10 required) ERCA00100A0

Stainless steel (10 required) ERCA00100A1

*Recommended spare part

1. NACE MR0175-2002 and MR0103.

2. Part meets NACE requirements only for applications in which the part is not exposed to sour gas.

Hastelloy® C is a mark owned by Haynes International, Inc.

Monel® is a mark owned by Special Metals Corporation.

19

Page 20

MR95 Series

Key Description Part Number Key Description Part Number

16 Cap Screw, NACE

(1)(2)

(continued)

Types MR95L and MR95LD (continued)

3/4 and 1 in. / DN 20 and 25 Body Sizes

Steel (12 required) GF05446X012

Stainless steel (12 required) GF05446X022

Types MR95H and MR95HD

1/4 NPT Body Size

Steel (6 required) ERCA04149A0

Stainless steel (6 required) ERCA04149A1

1/2 in. / DN 15 Body Size

Steel (8 required) ERCA00100A0

Stainless steel (8 required) ERCA00100A1

3/4 and 1 in. / DN 20 and 25 Body Sizes

Steel (8 required) GF05446X012

Stainless steel (8 required) GF05446X022

1-1/2 and 2 in. / DN 40 and 50 Body Sizes

Steel (8 required) ERCA00601A0

Stainless steel (8 required) ERCA00601A3

Types MR95HP and MR95HT

1/4 NPT Body Size

Steel (6 required) ERCA04149A2

Stainless steel (6 required) ERCA04149A3

1/2 in. / DN 15 Body Size

Steel (8 required) ERCA00100A2

Stainless steel (8 required) ERCA00100A3

3/4 and 1 in. / DN 20 and 25 Body Sizes

Steel (8 required) GF05446X032

Stainless steel (8 required) GF05446X042

1-1/2 and 2 in. / DN 40 and 50 Body Sizes

Steel (8 required) ERCA00601A2

Stainless steel (8 required) ERCA00601A3

17 Jam Nut, NACE

(1)(2)

Square Head Adjustment

1/4 NPT Body Size ERCA00652A0

1/2 in. / DN 15 Body Size ERCA00380A0

3/4 and 1 in. / DN 20 and 25 Body Sizes GF05453X012

1-1/2 and 2 in. / DN 40 and 50 Body Sizes ERCA00633A0

Stainless steel Square Head Adjustment

1/4 NPT Body Size ERCA00652A1

1/2 in. / DN 15 Body Size ERCA00380A1

3/4 and 1 in. / DN 20 and 25 Body Sizes GF05453X022

1-1/2 and 2 in. / DN 40 and 50 Body Sizes ERCA00633A1

Sealed Square Head Adjustment

1/2 in. / DN 15 Body Size ERCA00380A0

3/4 and 1 in. / DN 20 and 25 Body Sizes GF05453X012

1-1/2 and 2 in. / DN 40 and 50 Body Sizes ERCA00633A0

Tee Handle Adjustment

1/4 NPT Body Size ERCA00652A0

3/4 and 1 in. / DN 20 and 25 Body Sizes GF05453X012

1-1/2 and 2 in. / DN 40 and 50 Body Sizes ERCA00633A0

Handwheel Adjustment

1/2 in. / DN 15 Body Size ERCA00380A0

18 Nameplate Drive Screw, Stainless steel

(4 required) ERAA01884A0

19* Diaphragm Gasket

(2 required for pressure loaded spring case)

For 302 Stainless steel Diaphragm

Types MR95L and MR95LD

1/4 NPT Body Size ERCA00655A0

1/2 in. / DN 15 Body Size ERCA00491A0

3/4 and 1 in. / DN 20 and 25 Body Sizes ERCA00556A0

Types MR95H and MR95HD

1/4 NPT Body Size 1E393104022

1/2 in. / DN 15 Body Size ERCA00485A0

3/4 and 1 in. / DN 20 and 25 Body Sizes ERCA00510A0

1-1/2 and 2 in. / DN 40 and 50 Body Sizes ERCA00526A0

19* Diaphragm Gasket (continued)

(2 required for pressure loaded spring case) (continued)

For 302 Stainless steel Steam Service, Monel

and Hastelloy

®

C Diaphragms (continued)

®

Types MR95L and MR95LD

1/4 NPT Body Size ERCA00655A1

1/2 in. / DN 15 Body Size ERCA00491A1

3/4 and 1 in. / DN 20 and 25 Body Sizes ERCA00556A1

Types MR95H, MR95HT and MR95HD

1/4 NPT Body Size 1E3931X0012

1/2 in. / DN 15 Body Size ERCA00485A1

3/4 and 1 in. / DN 20 and 25 Body Sizes ERCA00510A1

1-1/2 and 2 in. / DN 40 and 50 Body Sizes ERCA00526A1

For Stainless steel Oxygen Service Diaphragm

Type MR95L

1/4 NPT Body Size ERCA00655A2

1/2 in. / DN 15 Body Size ERCA00491A2

3/4 and 1 in. / DN 20 and 25 Body Sizes ERCA00556A2

Type MR95H

1/4 NPT Body Size 1E3931X0022

1/2 in. / DN 15 Body Size ERCA00485A2

3/4 and 1 in. / DN 20 and 25 Body Sizes ERCA00510A2

1-1/2 and 2 in. / DN 40 and 50 Body Sizes ERCA00526A2

20 Pitot Tube (for constructions without control line)

1/4 NPT Body Size

Copper, Oxygen Service ERCA04393A0

304 Stainless steel ERCA04393A1

316 Stainless steel, NACE

Hastelloy

Monel

®

C ERCA04393A4

®

ERCA04393A3

(1)

ERCA04393A2

1/2 in. / DN 15 Body Size

Copper, Oxygen Service ERCA04277A0

304 Stainless steel ERCA04277A1

316 Stainless steel, NACE

Hastelloy

Monel

®

C ERCA04277A4

®

ERCA04277A3

(1)

ERCA04277A2

3/4 and 1 in. / DN 20 and 25 Body Sizes

Copper, Oxygen Service GF05550X012

304 Stainless steel GF05550X022

316 Stainless steel, NACE

Hastelloy

Monel

®

C GF05550X052

®

GF05550X042

(1)

GF05550X032

1-1/2 and 2 in. / DN 40 and 50 Body Sizes

Copper, Oxygen Service ERCA00381A0

304 Stainless steel ERCA00381A1

316 Stainless steel, NACE

Hastelloy

Monel

®

C ERCA00381A4

®

ERCA00381A3

21 Diaphragm Head Assembly, NACE

(1)

ERCA00381A2

(1)

(Types MR95L and MR95LD only)

1/4 NPT Body Size

Aluminum/Steel

(2)

ERCA00641A0

Stainless steel ERCA00641A1

1/2 in. / DN 15 Body Size

Aluminum/Steel

(2)

ERCA00642A0

Stainless steel ERCA00642A1

3/4 and 1 in. / DN 20 and 25 Body Sizes

Aluminum/Steel

(2)

ERCA00643A0

Stainless steel ERCA00643A1

21a Diaphragm Head - - - - - - - - - - 21b Lower Spring Seat - - - - - - - - - - 21c Screw - - - - - - - - - - 21 Diaphragm Head, 1-1/2 and 2 in. /

DN 40 and 50 Sizes (2 required)

Plated Steel ERCA00578A0

316 Stainless steel, NACE

Oxygen Service ERCA00578A1

Hastelloy

Monel

®

C, Types MR95H and MR95HD only ERCA00578A3

®

, Types MR95H and MR95HD only ERCA00578A2

(1)

and

*Recommended spare part

1. NACE MR0175-2002 and MR0103.

2. Part meets NACE requirements only for applications in which the part is not exposed to sour gas.

Hastelloy® C is a mark owned by Haynes International, Inc.

Monel® is a mark owned by Special Metals Corporation.

20

Page 21

MR95 Series

Key Description Part Number Key Description Part Number

22 Adjusting Screw Assembly

Tee Handle Adjustment

1/4 NPT Body Size, NACE

(1)(2)

ERAA01707A0

3/4 and 1 in. / DN 20 and 25 Body Sizes ERAA01716A0

1-1/2 and 2 in. / DN 40 and 50 Body Sizes ERAA01694A0

23 Handwheel ERAA02088A0

26 Inner Valve Spring

1/4 NPT Body Size

302 Stainless steel, Oxygen Service ERCA04280A0

Inconel

®

, NACE

(1)

ERCA04281A0

1/2 in. / DN 15 Body Size

302 Stainless steel, Oxygen Service ERCA04282A0

Inconel

®

, NACE

(1)

ERCA04283A0

3/4 and 1 in. / DN 20 and 25 Body Sizes

302 Stainless steel, Oxygen Service ERCA04284A0

Inconel

®

, NACE

(1)

ERCA04285A0

1-1/2 and 2 in. / DN 40 and 50 Body Sizes

302 Stainless steel, Oxygen Service ERCA04286A0

Inconel

®

, NACE

(1)

ERCA04287A0

27 Inner Valve Base, 1-1/2 to 2 in. / DN 40 to 50

416 Stainless steel ERCA00376A1

316 Stainless steel, NACE

Hastelloy

Monel

®

C ERCA00376A4

®

ERCA00376A3

(1)

ERCA00376A2

Brass, Oxygen Service ERCA00376A0

27 Inner Valve Base Assembly, 1-1/2 and 2 in. /

DN 40 and 50, Type MR95HP only

Nitrile (NBR) Seat

416 Stainless steel ERAA01909A0

316 Stainless steel, NACE

(1)

ERAA01909A1

Fluorocarbon (FKM) Disk

416 Stainless steel ERAA01909A3

316 Stainless steel, NACE

(1)

ERAA01909A2

29* Gasket (2 required)

For 1-1/2 and 2 in. / DN 40 and 50 only

302 Stainless steel Diaphragm

Types MR95H and MR95HD ERCA00579A0

302 Stainless steel Diaphragm, Oxygen Service

Type MR95H ERCA00579A2

302 Stainless steel Steam Service,

Monel

®

and Hastelloy® C Diaphragm

Types MR95H, MR95HT and MR95HD ERCA00579A1

31 Locknut, Steel, 1-1/2 to 2 in. / DN 40 to 50 only 1P788724122

32 Stufng Box

Handwheel Adjustment (standard)

1/4 NPT Body Size ERAA02699A0

1/2 to 1 in. / DN 15 to 25 Body Sizes ERAA01655A0

1-1/2 and 2 in. / DN 40 and 50 Body Sizes ERAA01662A0

Handwheel Adjustment with Stainless steel Trim

1/4 NPT Body Size ERAA02699A1

1/2 to 1 in. / DN 15 to 25 Body Sizes ERAA01655A1

1-1/2 and 2 in. / DN 40 and 50 Body Sizes ERAA01662A1

33 Adjusting Screw

1/4 NPT Body Size ERAA01631A0

1/2 in. / DN 15 Body Size ERAA02333A0

3/4 and 1 in. / DN 20 and 25 Body Sizes ERAA01673A0

1-1/2 and 2 in. / DN 40 and 50 Body Sizes ERAA01677A0

34 Packing Follower

Handwheel Adjustment (standard)

1/4 NPT Body Size ERAA01632A0

1/2 to 2 in. / DN 15 to 50 Body Sizes 1K884924092

Handwheel Adjustment with Stainless steel Trim

1/4 NPT Body Size ERAA01632A0

1/2 to 2 in. / DN 15 to 50 Body Sizes 1K8849X0012

35 Stufng Box Nut

Handwheel Adjustment ERAA01633A0

Handwheel Adjustment with Stainless steel Trim ERAA01633A1

36 Packing (3 required)

1/4 NPT Body Size ERAA01634A0

1/2 to 2 in. / DN 15 to 50 Body Sizes ERAA01657A0

*Recommended spare part

1. NACE MR0175-2002 and MR0103.

2. Part meets NACE requirements only for applications in which the part is not exposed to sour gas.

Hastelloy® C is a mark owned by Haynes International, Inc.

Inconel® is a mark owned by Special Metals Corporation.

Monel® is a mark owned by Special Metals Corporation.

37* Stuff Box Gasket