Page 1

Emerson Network Power® MPH2™ Rack PDU

User Manual

Page 2

Table of Content

Important Safety Instructions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Safety Symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.0 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.1 General Characteristics. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.2 Model Types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.3 Appearance and Components. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.3.1 Controls and Indicators—RPC2

1.3.2 LED Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

1.3.3 On-board LCD Controls and Indicators. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

1.3.4 Power Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

1.3.4.1 Branch Overcurrent Protection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

1.3.5 Hard-Wired Connection Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

™ . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.0 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2.1 Attaching Input Power Cords—Hard-wired Models Only . . . . . . . . . . . . . . . . . . . . . . . . . 11

2.1.1 Attaching Input-power Cords without Conduit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2.1.2 Attaching Input-power Cords with Conduit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

2.2 Tool-less Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

2.3 Installing a MPH2 in an Emerson® Rack. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

2.3.1 Mounting Hardware and Tools Required . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

2.3.2 Mounting the Vertical MPH2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

2.3.3 Mounting the Horizontal MPH2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

2.3.4 Mounting Horizontal MPH2 on Vertical Frame Member with Aluminum Extrusions . . . . . 17

2.3.5 Rack Grounding strap . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

2.3.6 Recommended Electrical-backup Protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

2.4 Connecting Rack Equipment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

2.5 Installing Optional Items . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

2.5.1 RPC Basic Display Module Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

2.5.1.1 Included Hardware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

2.5.2 Temperature/Humidity Sensor Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Emerson® MPH2™ User Manual i

Page 3

3.0 Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

3.1 Controls and Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

3.2 View Input-level Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

3.2.1 Communication Link with RPC2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

3.3 View MPH2 System Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

3.3.1 System and Screen Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

3.3.2 Reboot the On-board LCD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

3.3.3 Restore System Defaults . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

3.3.4 Determine IP Address, MAC Address and Firmware Version . . . . . . . . . . . . . . . . . . . . . 32

3.3.5 Adjust the Contrast of the On-board LCD. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

3.3.6 Adjust the Orientation of the On-board LCD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

3.4 View Active Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

3.4.1 Silence an Audible Alarm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

3.5 View Branch-level Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

3.6 View Receptacle-level Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

3.7 View Sensor Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

3.8 Opening and Closing Circuit Breakers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

4.0 Emerson® MPH2 Rack PDU Specifications. . . . . . . . . . . . . . . . . . . . . . . 41

5.0 Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

5.1 Additional Troubleshooting by Plug Type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

ii Emerson® MPH2™ User Manual

Page 4

List of Figures

Figure 1-1: Vertical MPH2 Rack PDU Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Figure 1-2: Horizontal MPH2 Rack PDU Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Figure 1-3: MPH2 major monitoring and management features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Figure 1-4: Branch and receptacle identification—Units with no monitoring (Type B models). . . . . . . . . . . . . . . . . 8

Figure 1-5: Branch and receptacle identification—Units with individually-monitored

and managed receptacles (Type C, R and M models) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Figure 1-6: Circuit breaker branch identification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Figure 2-1: Disassembly to install an input-power cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Figure 2-2: Re-assembly to install an input power cable in conduit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Figure 2-3: Tool-less mounting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Figure 2-4: Installing vertical MPH2 in an Emerson rack . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Figure 2-5: Installing horizontal MPH2 in an Emerson rack. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Figure 2-6: Installing horizontal MPH2 in a rack with aluminum extrusions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Figure 2-7: Rack grounding-strap connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Figure 2-8: RPC BDM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Figure 2-9: Inserting the spring nut into a T-slot. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Figure 3-1: On-board LCD and control keys . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Figure 3-2: Input-level information (main screen) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Figure 3-3: Configuration in-progress wheel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Figure 3-4: System information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Figure 3-5: System-info and Screen-option icons . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Figure 3-6: Reboot Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Figure 3-7: Restore Defaults selected on Reboot Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Figure 3-8: Restore Defaults? confirmation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Figure 3-9: IP address, MAC address, and firmware information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Figure 3-10: Adjust LCD contrast. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Figure 3-11: Alarm list . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Figure 3-12: Branch information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Figure 3-13: Receptacle list . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Figure 3-14: Receptacle information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Figure 3-15: Sensor list . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Figure 3-16: Sensor information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Figure 3-17: Turning Off or resetting a circuit breaker . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Emerson® MPH2™ User Manual iii

Page 5

List of Tables

Table 2-1: Hard-wired models—Connection terminal ratings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Table 2-2: Terminal tightening torque. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Table 2-3: Ground-strap wire gauge by MPH2 rating. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Table 2-4: Upstream circuit breaker rating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Table 3-1: Factory-default settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Table 5-1: Receptacle LED Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Table 5-2: Line LED Troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Table 5-3: Active Line LEDs and Branch Voltage Phasing by Plug Type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

iv Emerson® MPH2™ User Manual

Page 6

Important Safety Instructions

!

!

!

Important Safety Instructions

SAVE THESE INSTRUCTIONS

This safety sheet contains important safety instructions. Read all safety, installation and operating

instructions before installing the Emerson Network Power MPH2 rack power-distribution unit (PDU).

Adhere to all warnings on the unit and in this safety sheet. Follow all instructions.

• The MPH2 Rack PDU is designed for information technology equipment. The MPH2 Rack PDU is not

intended for use with life support or other designated critical devices. If uncertain about its intended

application, consult your local dealer or Emerson representative.

• Maximum load must not exceed the rating shown on the MPH2 Rack PDU nameplate.

• The rated line voltage must not exceed 240VAC for connection to AC power distribution systems with

an isolated or high-impedance ground.

• Operate the MPH2 Rack PDU in an indoor environment only in the appropriate ambient temperature

range:

• 32°F to 140°F (0°C to 60°C) for 24A or less input models.

• 32°F to 122°F (0°C to 50°C) for 40A and 48A input models without case ventilation.

• 32°F to 140°F (0°C to 60°C) for 40A and 48A input models with case ventilation.

• Install the MPH2 Rack PDU in a clean environment, free of conductive contaminants, moisture,

flammable liquids, gases and corrosive substances.

• The MPH2 Rack PDU must be installed in a restricted-access location. A restricted-access location is

an area where access is possible only through the use of a tool or lock and key or other means of

security, and is controlled by the authority responsible for the location.

• The MPH2 Rack PDU has no user-serviceable parts. Under no circumstances attempt to gain internal

access due to the risk of electric shock or burn.

• Refer any unexpected behavior or unusual fault conditions to your local dealer, Emerson

representative or Emerson Network Power Applications Engineering.

• Emerson recommends powering only devices with safety agency approval from the MPH2 Rack PDU.

• For permanently connected MPH2 Rack PDUs (hard-wired versions), a readily accessible disconnect

device must be incorporated external to the equipment.

• For MPH2 Rack PDUs with integral plugs, the socket/ outlet must be installed near the equipment and

must be easily accessible.

WARNING

Opening or removing end caps from an MPH2 Rack PDU may expose personnel to lethal voltages

within the rack PDU. Observe all cautions and warnings. Failure to do so may result in serious

injury or death. MPH2 Rack PDU units contain no user-serviceable parts. For service or technical

support, contact Emerson Network Power Applications Engineering or your local Emerson

representative. Do not attempt to service this product yourself.

CAUTION

Connecting an MPH2 Rack PDU to a power supply with an incorrect rating in voltage or amperes

may damage the connected equipment and your MPH2 Rack PDU. For questions about the power

supply connections, contact Emerson Network Power Applications Engineering or your local

Emerson representative.

CAUTION

Ensure that the ratings of the electric circuit of each connected device meets the specified rating at

each branch and receptacle.

Emerson® MPH2™ User Manual 1

Page 7

Important Safety Instructions

!

!

CAUTION

All configuration steps must be completed before attempting to start equipment connected to the

MPH2 Rack PDU.

NOTE

For power management purposes, record the receptacle where each piece of equipment is

connected. Receptacles on the MPH2 Rack PDU have a numeric designation. The MPH2 Rack

PDU identifies the receptacles with numbers and are grouped by branch with a letter referring to

the proper circuit breaker.

EUROPEAN UNION

Notice to European Union Customers: Disposal of Old Appliances

This product uses components that are dangerous for the environment, such as

electronic cards and other electronic components. Any component that is removed

must be taken to specialized collection and disposal centers. If this unit must be

dismantled, this must be done by a specialized center for collection and disposal

of electric and electronics appliances or other dangerous substances. This product

has been supplied from an environmentally aware manufacturer that complies with

the Waste Electrical and Electronic Equipment (WEEE) Directive 2002/96/EC. The

“crossed-out wheelie bin” symbol at right is placed on this product to encourage

you to recycle wherever possible.

Please be environmentally responsible and recycle this product through your

recycling facility at its end of life. Do not dispose of this product as unsorted municipal waste. Follow local

municipal waste ordinances for proper disposal provisions to reduce the environmental impact of waste

electrical and electronic equipment (WEEE).

For information regarding the scrapping of this equipment, go to http://www.eu.emersonnetworkpower.com

(“Products session” or “Contact us” session) or call Emerson’s worldwide technical support at:

• 00 80011554499 (toll free number)

• +39 0298250222 (toll number based in Italy)

ROHS Compliance

The MPH2 Rack PDU modules comply with the Restriction of Hazardous Substances directive (ROHS),

prohibiting use of six hazardous materials manufacturing of electronics, including lead-free solder.

FCC Compliance

This unit complies with the limits for a Class A device pursuant to Part 15 of the FCC Rules. Operation is

subject to the following two conditions:

This device may not cause harmful interference, and

This device must accept any interference received, including interference that may cause undesired

operation.

NOTE

This equipment has been tested and found to comply with the limits for a Class A digital device,

pursuant to Part 15 of the FCC Rules. These limits are designed to provide reasonable protection

against harmful interference when the equipment is operated in a commercial environment. This

equipment generates, uses and can radiate radio frequency energy and, if not installed and used

in accordance with the instruction manual, may cause harmful interference to radio

communications.

Operation of this equipment in a residential area is likely to cause harmful interference that the

user must correct, including the expense of all corrective modifications.

2Emerson

®

MPH2™ User Manual

Page 8

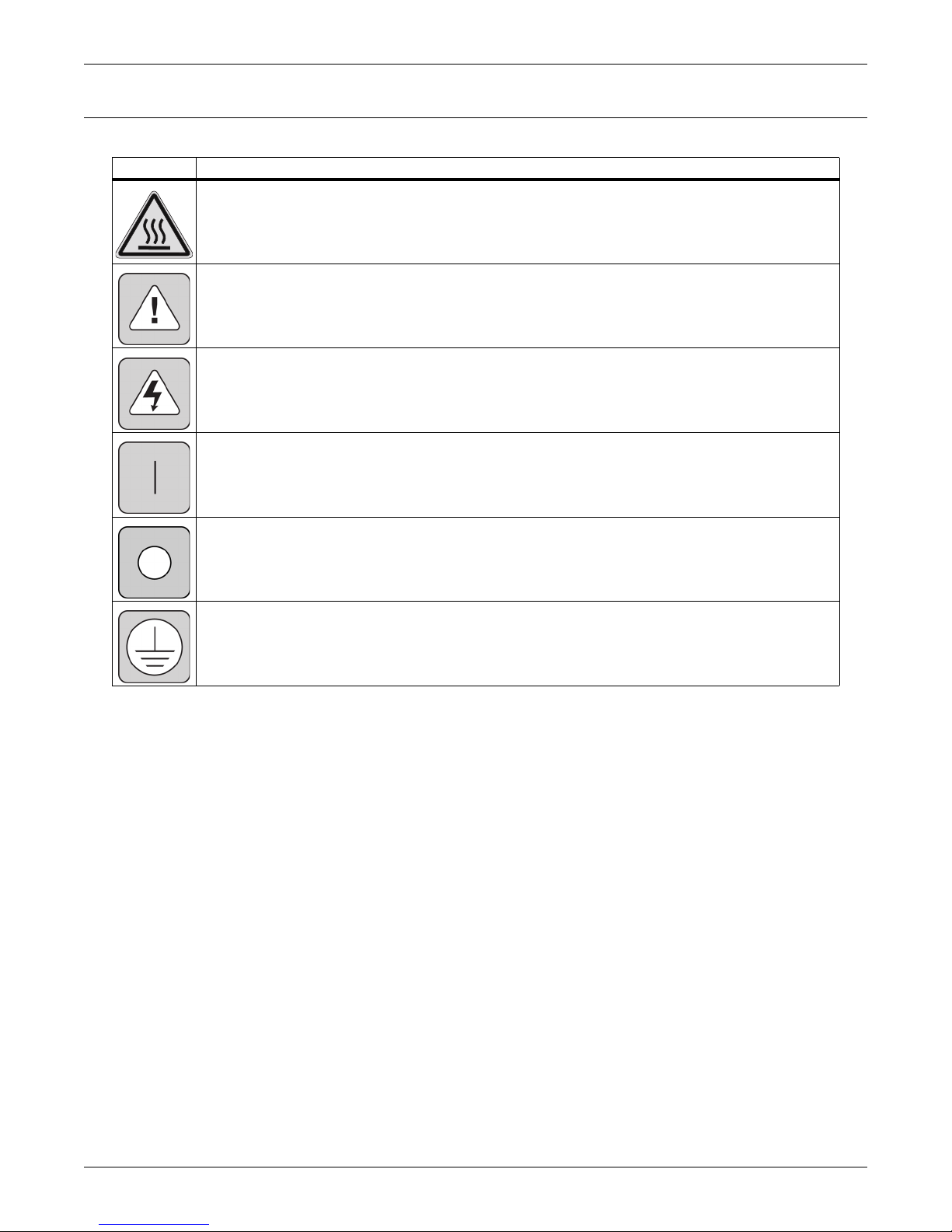

Safety Symbols

Safety Symbols

The following symbols may appear within the documentation or on the product.

Symbol Meaning

High Temperature

Alerts the user where the enclosure temperature may exceed 158°F (70°C) while operating under highambient temperature and at maximally rated load.

Instructions

Signifies the presence of important operating and maintenance (servicing) instructions in the literature

accompanying the appliance.

Dangerous Voltage

Warns about the presence of uninsulated dangerous voltage within the product’s enclosure that may be

of sufficient magnitude to constitute a risk of electric shock to persons.

Power On

Indicates the principal On/Off switch is in the On position.

Power Off

Indicates the principal On/Off switch is in the Off position.

Protective Grounding Terminal

Indicates a terminal that must be connected to earth ground before any other connections to the

equipment may be made.

Emerson® MPH2™ User Manual 3

Page 9

1.0 Introduction

The Emerson Network Power® MPH2™ is the most intelligent, high-availability line of managed rack PDUs.

It offers remote monitoring and control capabilities as well as environmental sensors with multiple power

input selections and output configurations.

Metering Levels

Four types of MPH2 are available that offer metering of all electrical information including input, branch

and receptacle levels, as well as integration with environmental sensors. The available information varies

by type of MPH2. See 1.2 - Model Types, page 7 for descriptions.

Mounting

Rack PDUs are available for mounting in vertical and horizontal configurations in standard racks or

network enclosures.

Because the power cord is connected at the end of the vertical-mount (0-U) MPH2 models, the rack PDUs

may be oriented to accommodate top or bottom cable-entry into the rack.

Locking Receptacles - IEC Type Only

Locking receptacles are available on models with IEC receptacles. The locking feature requires optional

locking power cords to be installed on devices powered by the MPH2.

Introduction

The receptacles require no modification to function properly with non-locking power cords.

Overcurrent Protection

All MPH2 Rack PDU units with input current rating of 30 A and higher feature 100% rated

hydraulic-magnetic breakers. For all UL-listed models, the maximum cord and plug-connected loading is

limited to 80% continuous loading, as required by UL in accordance with the National Electric Code.

Low-profile circuit breakers are used on all MPH2 0-U Rack PDUs with two or three branch circuits.

Standard-profile circuit breakers are used on MPH2 horizontal models and on certain vertical models that

have 6 branch circuits or have a 240 VAC rating. Each type of circuit breaker is a flush-mount, rocker style

(see Figure 3-17).

Integrated Monitoring and Management

The factory-installed Emerson RPC2™ communications module permits managing the MPH2 Rack PDU

over a secure Web page and SNMP-based network management system. The RPC2 permits

interconnecting up to 4 rack PDUs in a Rack-PDU array configuration for monitoring and management.

NOTE

Do not interconnect RPC-1000 with RPC2 Rack PDUs in an array. They are incompatible and will

not interoperate.

NOTE

Refer to the RPC2 communications module user manual, SL-20841, for detailed instructions on

installing and using the RPC2 module. The document is available at Emerson’s Web site:

http://www.emersonnetworkpower.com

4Emerson

®

MPH2™ User Manual

Page 10

Introduction

A rack PDU can be monitored locally through its on-board LCD, through a Web interface or through an

optional display module, either the RPC BDM (Part# RPCBDM-1000). The display module connects

directly to the RPC2 communications module and may be moved between operating MPH2 units. It can be

hand-held, mounted in or on the rack or mounted on a wall near the rack PDU it is monitoring.

Multiple MPH2 Rack PDUs can be managed with these software applications:

• Avocent

• Avocent DSView

• Emerson’s Trellis

• Liebert

• Liebert SiteScan

®

Rack Power Manager software

™

management software

™

Real-Time Infrastructure Optimization platform software

®

Nform®, which adds group-based receptacle management

®

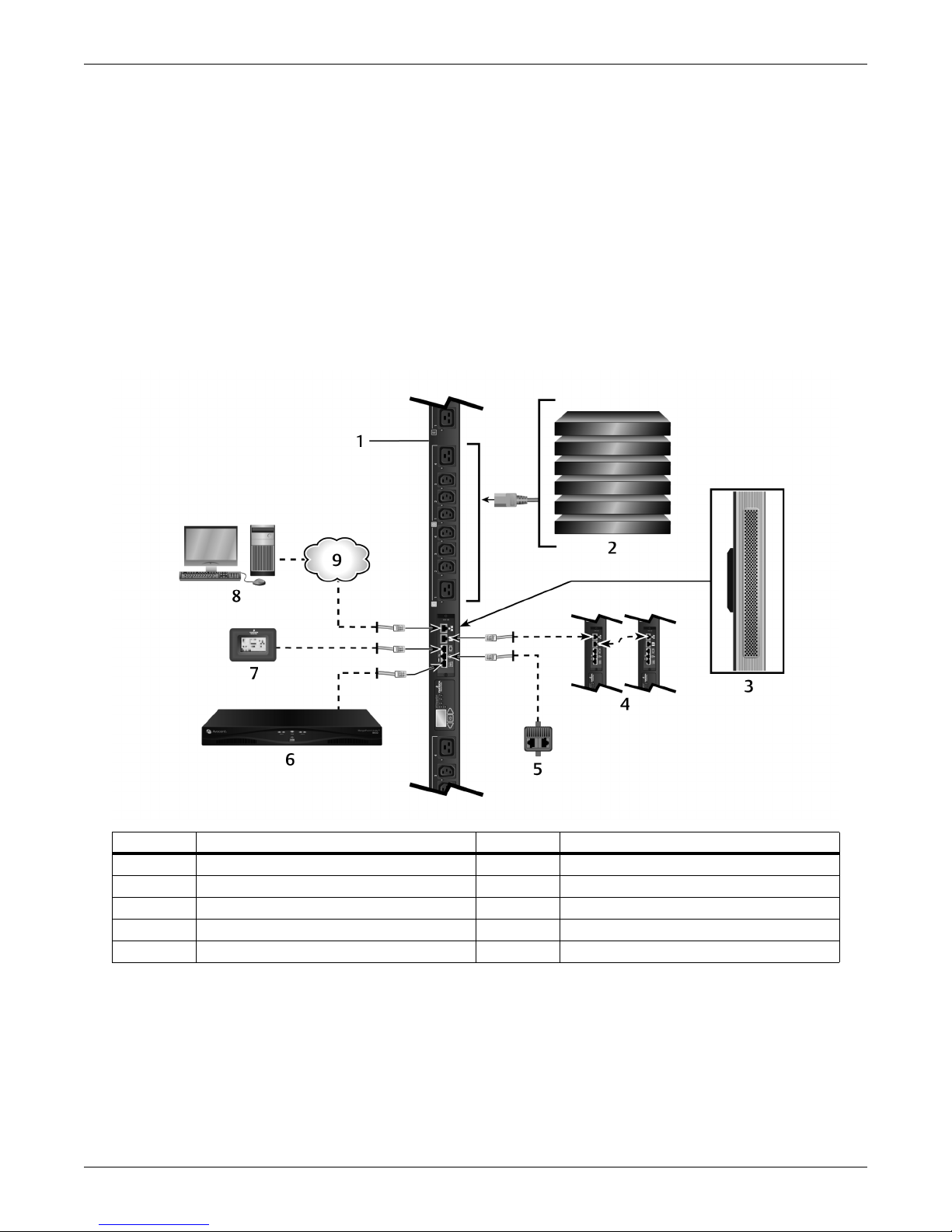

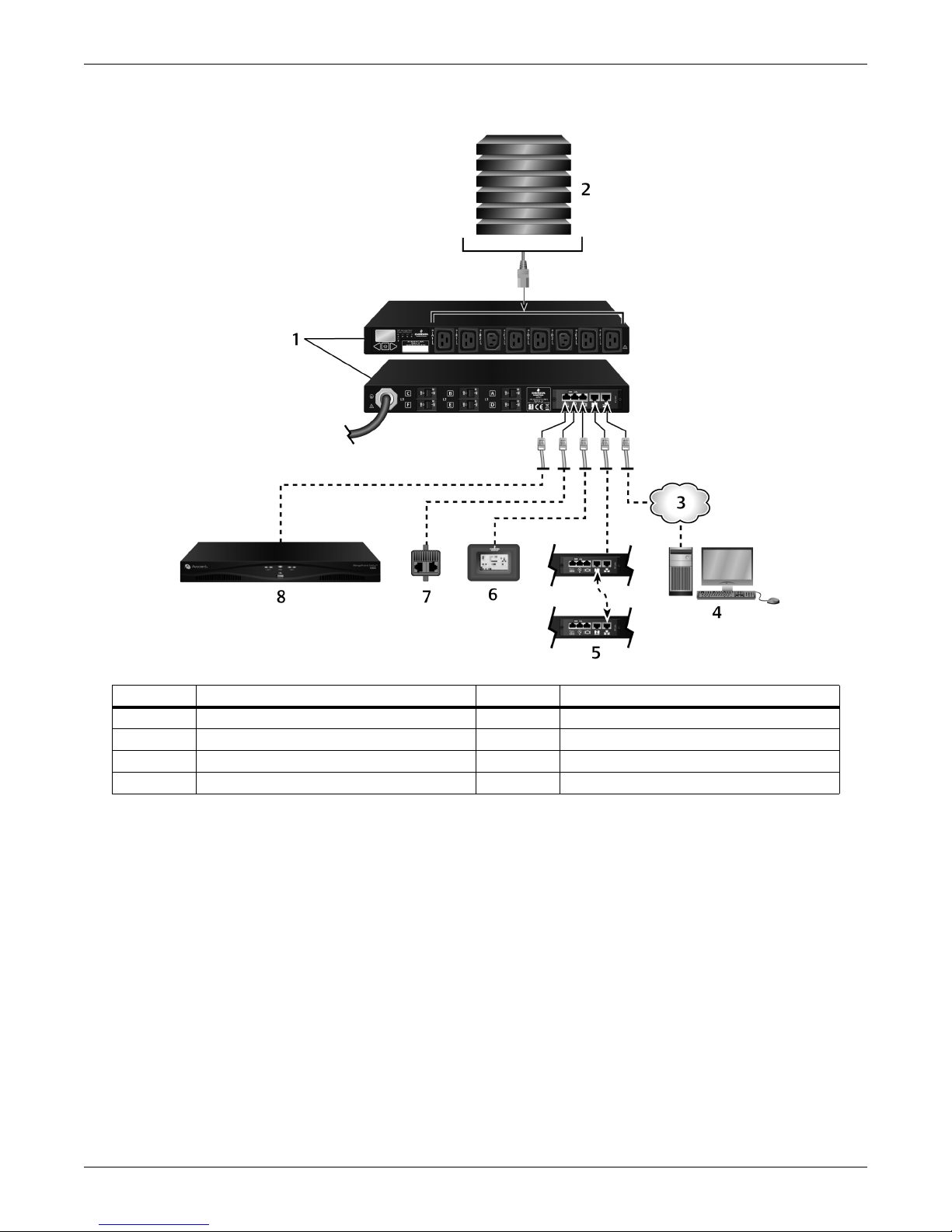

Figure 1-1 Vertical MPH2 Rack PDU Configuration

Number Description Number Description

1 Vertical MPH2 Rack PDU 6 Serial appliance

2 Connected equipment 7 RPC basic display module (BDM)

3 Case ventilation, both sides (Optional) 8 Monitoring station

4 Rack PDU array 9 Network connection (10 MB/100 MB/1 GB)

5 Sensors—integrated and modular

Emerson® MPH2™ User Manual 5

Page 11

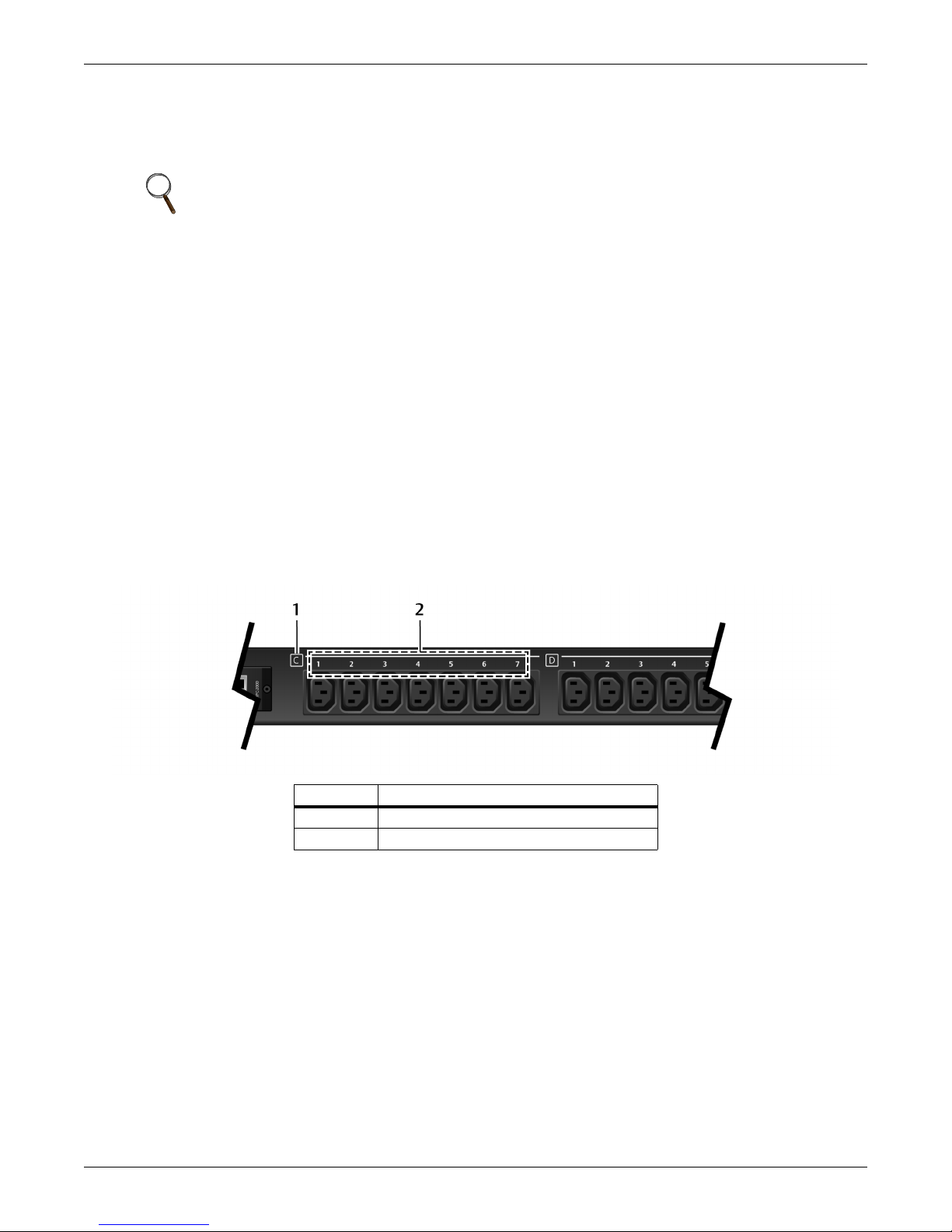

Figure 1-2 Horizontal MPH2 Rack PDU Configuration

Introduction

Number Description Number Description

1 Horizontal MPH2 Rack PDU 5 Rack PDU array

2 Connected equipment 6 RPC basic display module (BDM)

3 Network connection (10 MB/100 MB/1 GB) 7 Sensors—integrated and modular

4 Monitoring station 8 Serial appliance

1.1 General Characteristics

• Input ampacities include 16 A or 32 A for European Union versions and 12 A to 48 A for

North-American versions.

• Single-phase and three-phase.

• Input voltages include 100-120 VAC, 120/208 VAC, 200-240/415 VAC.

• Receptacle types include NEMA 5-20, IEC 60320 C13 and IEC 60320 C19

• Input connection supports a highly flexible fixed power cord or hard-wired connection to user

accessible terminal block.

6Emerson

®

MPH2™ User Manual

Page 12

Introduction

1.2 Model Types

There are four types of MPH2 Rack PDU. All models provide power distribution and include input and

branch metering.

• Type B—Rack PDU metered: Provides metering of input and branches.

• Type C—Rack PDU metered, receptacle-switched: Provides metering of input and branches and

individual on/off control of each receptacle.

• Type M—Receptacle-metered: Provides metering of input, branches and receptacles.

• Type R—Receptacle-metered, receptacle-switched: Provides metering of input, branches and

receptacles. Provides individual on/off control of each receptacle.

1.3 Appearance and Components

1.3.1 Controls and Indicators—RPC2

The MPH2 Rack PDU is monitored and managed by the factory-installed RPC2 communications module.

This manual presents information about the MPH2’s functions and features. For details on operating the

MPH2 through the RPC2 communications module, refer to the RPC2 user manual, SL-20841. The

document is available at Emerson’s Web site: http://www.emersonnetworkpower.com

The RPC2 is installed near the middle of the MPH2 Rack PDU. The central location eases connections

whichever orientation is required for network cabling.

The RPC2’s Web-based interface provides system-operating measurements, sensor readings (optional)

and basic unit information including firmware version, unit rating, model number and serial number.

Figure 1-3 MPH2 major monitoring and management features

™

Number Description Number Description

1 Serial port 5 Array link/management port

2USB port 6Network port

3 Sensor port 7 Access to Reset button

4 Display port

Emerson® MPH2™ User Manual 7

Page 13

Introduction

1.3.2 LED Indicators

The MPH2 Rack PDU also has LEDs that indicate receptacle and branch status and system information.

The LEDs flash, pulse or change colors to indicate an event or alarm condition (for details on how LEDs

respond to events and alarms, refer to 5.0 - Troubleshooting.

NOTE

Units with a “B” as the fourth character in the model name (MPHBxxxx) do not have LEDs at their

receptacles. The branch and receptacle LED behavior in 5.0 - Troubleshooting and elsewhere in

this document does not apply to these units.

Receptacles on units with an “M” as the fourth character in the model name (MPHMxxxx) cannot

be turned off. Refer to the description of branch and receptacle LED behavior in 5.0 -

Troubleshooting.

1.3.3 On-board LCD Controls and Indicators

Emerson’s MPH2 has an integrated, on-board LCD that can be used to view information about the rack

PDU. The information available depends on the type of MPH2. For additional information about the

on-board LCD, refer to 3.0 - Operation.

1.3.4 Power Components

The component location and type depend on the model of the MPH2 Rack PDU. For example, units

with a “B” as the fourth character in the model name do not have LEDs at their receptacles; see Figures 1-

4, 1-5 and 1-6.

Figure 1-4 Branch and receptacle identification—Units with no monitoring (Type B models)

Number Description

1 Branch identification

2 Receptacle identification

8Emerson

®

MPH2™ User Manual

Page 14

Introduction

Figure 1-5 Branch and receptacle identification—Units with individually-monitored

and managed receptacles (Type C, R and M models)

Number Description

1 Branch identification

2 Receptacle identification

3

Receptacle-status LED (See 5.0 -

Troubleshooting, page 42.)

1.3.4.1 Branch Overcurrent Protection

Models having more than 16-A input-current rating are equipped with branch overcurrent protection. The

branch circuit breaker is a UL 489-listed breaker with a flush-mount, rocker-style actuator. This protects

each receptacle group against overload and short circuit by interrupting the fault current flowing in the

line-to-line, line-to-neutral and line-to-PE conductors of the branch circuits. The branch circuit breaker

ratings apply over the full, rated operating temperature and frequency.

The flush-mount breakers guard against accidental trips that could interrupt power to the connected load.

Manually tripping a breaker requires a small, flat blade, such as a screw driver (see Figure 3-17).

Low-profile circuit breakers are used on all MPH2 Rack PDUs with two or three branch circuits less than

240-V rating in a line-neutral configuration. Standard-profile circuit breakers are used on MPH2 Rack

PDUs with six branch circuits or have a 240-VAC rating. Each type of circuit breaker is a rocker style (see

Figure 1-6).

The branch circuit breaker labeling (A, B, C and so on) shows which receptacles are protected by each

specific breaker. Receptacles on Branch A are protected by the circuit breaker labeled A. Three-phase

PDUs may also have labeling showing the phase associated with each circuit breaker.

NOTE

The branch circuit breaker is not designed to be used as a disconnect device for the connected

load.

Emerson® MPH2™ User Manual 9

Page 15

Figure 1-6 Circuit breaker branch identification

Number Description

1 Low-profile circuit breaker

2 Standard-profile circuit breaker

3 Branch identification

Introduction

1.3.5 Hard-Wired Connection Features

Emerson’s MPH2 Rack PDU may be equipped with either a factory-installed input power cord or

hard-wired connections. The hard-wired connection will be at one end of the unit. A terminal block in the

hard-wired connection compartment is coded to aid in making the connections. A collar secures the input

wire, keeping the strain off the terminal block connections. See Figure 2-1.

10 Emerson® MPH2™ User Manual

Page 16

Installation

2.0 Installation

An MPH2 Rack PDU can be installed in an Emerson rack on the frame members using factory-supplied

hardware. The unit can be installed on the face or the side of frame members. The unit can be mounted so

that the power cord exits either the top or bottom of the rack.

NOTE

Follow all local and national electrical codes, standards and recommended practices.

Disconnect Required for Hard-Wired MPH2 Units

A readily-accessible input-power disconnect device must be installed near the MPH2 Rack PDU.

Input Power Location for MPH2 Units with Factory-Installed Power Cords

The input-power socket or outlet must be installed near the MPH2 and must be easily accessible.

2.1 Attaching Input Power Cords—Hard-wired Models Only

MPH2s with integral power cords need no assembly before installation. Units with hard-wired input power

require attachment of input-power cords. See Table 2-1 for wire sizing.

Hard-wired models may be wired with or without conduit.

2.1.1 Attaching Input-power Cords without Conduit

1. Remove the end cap. It is held in place with two T10 Torx screws.

2. Slide the terminal block cover off.

3. Loosen the strain-relief collar. It is held in place with two Phillips head PH1 screws.

4. Strip the insulation from the individual wires as required to fit into the terminal block.

Recommended stripping length for MPH2 units rated less than 32 A is 9 mm; for MPH2s rated 40 A or

higher, 11 mm.

5. Slip the power cord through the hole in the end cap and through the strain-relief collar.

6. Loosen the terminal block screws.

7. Insert the wires into the terminal block according to the labeling inside the MPH2; tighten each terminal

block screw after inserting a wire. Refer to Table 2 -2 for tightening torque.

8. Tighten the strain-relief collar around the input power cord. The cord’s outer insulation covering should

extend through the bracket.

Emerson® MPH2™ User Manual 11

Page 17

9. Replace the terminal block cover by either sliding it on or snapping it into place.

10. Reattach the end cap to the MPH2 with the two screws removed in Step 1.

Figure 2-1 Disassembly to install an input-power cable

Installation

Number Description Number Description

1 Cover plate 4 Terminal-block labels

2 Terminal-block screws 5 Strain-relief collar w/Phillips-head screws

3 Terminal blocks 6 End cap (attached with 2 screws)

2.1.2 Attaching Input-power Cords with Conduit

1. Remove the end cap. It is held in place with two T10 Torx screws.

2. Slide the terminal block cover off.

3. Loosen the strain-relief collar. It is held in place with four nuts (see Figure 2-1).

4. Strip the insulation from the individual wires as required to fit into the terminal block.

Recommended stripping length for MPH2 units rated less than 32 A is 9 mm; for MPH2s rated 40 A or

higher, 11 mm.

5. Slip the stripped wires through the conduit connector, through the metal end plate and into the terminal

block connection box.

6. Loosen the terminal block screws.

7. Insert the wires into the terminal block according to the labeling inside the MPH2; tighten each terminal

block screw after inserting a wire. Refer to Table 2 -2 for tightening torque.

8. Install the cover plate, by either sliding it on or snapping it into place and sliding it firmly against the

main body of the MPH2.

9. Install the cover plate, by either sliding it on or snapping it into place and pressing it against the cover

plate.

10. Attach the metal end plate to the MPH2 with four screws provided in the kit.

12 Emerson® MPH2™ User Manual

Page 18

Installation

11. Slide the conduit into the conduit connector.

12. Tighten the conduit connector until it grips the conduit and crimps it securely.

Figure 2-2 Re-assembly to install an input power cable in conduit

Number Description Number Description

1 Cover plate 5 Strain-relief collar w/Phillips-head screws

2 Terminal-block screws 6 Metal end plate (attached with 4 screws)

3 Terminal blocks 7 Conduit connector (field-supplied)

4 Terminal-block labels 8 Conduit (cable not shown)

Table 2-1 Hard-wired models—Connection terminal ratings

MPH2 Rating

≤32 A >32 A

Conductor Cross-Section Solid, Minimum

Conductor Cross-Section Solid, Maximum

Conductor Cross-Section Stranded, Minimum

0.2 mm

6mm

0.2 mm

²

²

²

Conductor Cross-Section Stranded, Maximum 4 mm²

Conductor Cross-Section, AWG/kcmil, Minimum 24 20

Conductor Cross-Section, AWG/kcmil, Maximum 10 6

Conductor Cross-Section Stranded, with Ferrule

without Plastic Sleeve, Minimum

Conductor Cross-Section Stranded, with Ferrule

without Plastic Sleeve, Maximum

Conductor Cross-Section Stranded, with Ferrule

with Plastic Sleeve, Minimum

Conductor Cross-Section Stranded, with Ferrule

with Plastic Sleeve, Maximum

0.25 mm

0.25 mm

4mm

4mm

²

²

²

²

0.5 mm

16 mm

0.5mm

10 mm

0.5 mm

10 mm

0.5 mm

10 mm

²

²

²

²

²

²

²

²

Emerson® MPH2™ User Manual 13

Page 19

Table 2-2 Terminal tightening torque

Tightening Torque

Minimum 0.6 Nm (4.4 lb-in.) 1.5 Nm (13.3 lb-in.)

Maximum 0.8 Nm (7.1 lb-in.) 1.8 Nm (15.9 lb-in.)

2.2 Tool-less Mounting

For tool-less mounting, attach the mounts to the rear of the MPH2 Rack PDU, then hang it in the rack as

shown in Figure 2-3. Torque the screw attaching the mounting button 17 lb-in. (2 Nm).

NOTE

Brackets are not supplied. A range of brackets for Emerson and other manufacturers’ racks are

available as accessories.

Figure 2-3 Tool-less mounting

Installation

MPH2 Rating

≤32 A >32 A

Number Description

1

2 Button mount

3 Insert button mount into keyhole slot.

Torx screw

(tighten torque 17 lb-in. (2 Nm)

14 Emerson® MPH2™ User Manual

Page 20

Installation

2.3 Installing a MPH2 in an Emerson® Rack

2.3.1 Mounting Hardware and Tools Required

Factory-supplied

• 2 mounting brackets

• 2 mounting buttons

•4 spring nuts

Field-supplied

For mounting a vertical MPH2

• Phillips #2 screwdriver

For mounting a horizontal MPH2:

• Flat-blade screwdriver

• Torx screwdriver TX30

• Torque wrench

2.3.2 Mounting the Vertical MPH2

The vertical MPH2 can be installed on a vertical or horizontal frame member in the rack.

1. Determine where in the Emerson rack the PDU will be installed.

2. Attach a bracket to each end of the PDU.

3. If mounting on horizontal frame members, attach the brackets in-line, Figure 2-4.

- or -

If mounting on a vertical frame member, attach the brackets at a right angle to the PDU.

4. Insert two spring nuts into the appropriate T-slot on the frame member, Figure 2-4. Position the spring

nuts to accommodate screws inserted through slots in the brackets. To move the spring nuts, press

down on each with a small, pointed object and slide each into position.

5. Hold the PDU in place and attach the top of the unit to the rack with tool-less fasteners, Figure 2-4.

Emerson® MPH2™ User Manual 15

Page 21

6. Tighten the screws, applying 46 lb-in (5.2 Nm).

7. Repeat Steps 4 through 6 for the lower bracket on the lower end of the PDU.

Figure 2-4 Installing vertical MPH2 in an Emerson rack

2.3.3 Mounting the Horizontal MPH2

The horizontal MPH2 is installed on a vertical frame member in the rack.

1. Choose a position in the rack for the PDU and install 4 cage nuts into the respective slots, Figure 2-5.

Installation

2. Hold the MPH2 PDU over the desired mounting holes (now with the cage nuts), and route the input

cable through the rack as desired.

3. Insert screws and use a Torx T30 screwdriver to tighten all of them. Leave the screws slightly loose for

the time being, Figure 2-5.

4. Once all the screws are installed, tighten them completely using 35.4 lb-in (5.2 Nm).

Figure 2-5 Installing horizontal MPH2 in an Emerson rack

16 Emerson® MPH2™ User Manual

Page 22

Installation

2.3.4 Mounting Horizontal MPH2

on Vertical Frame Member with Aluminum Extrusions

1. Choose a position in the rack for the PDU and install 4 spring nuts into the groove, Figure 2-6.

2. Use a level to check if the horizontal plane is maintained.

3. Set the distance to match the holes on the PDU, and hold the MPH2 PDU over the desired position

(now with the spring nuts).

4. Route the input cable through the rack as desired.

5. Insert screws and use a Torx T30 screwdriver to tighten all of them, Figure 2-6. Leave the screws

slightly loose for the time being.

6. Once all the screws are installed, tighten them completely using 35.4 lb-in (5.2 Nm).

Figure 2-6 Installing horizontal MPH2 in a rack with aluminum extrusions

Emerson® MPH2™ User Manual 17

Page 23

Installation

2.3.5 Rack Grounding strap

NOTE

Ensure that the safety-earth connection at the input-power-source receptacle

is made before any equipment is connected to Emerson’s MPH2 Rack PDU.

Units with factory-attached input-power cords have an grounding conductor internal to the case. The rack

grounding strap establishes the same ground reference between the MPH2 Rack PDU and the rack.

NOTE

The grounding strap may be used with MPH2 Rack PDUs that have integral input-power cords and

units that have hard-wired input-power cords. The strap supplements the internal grounding

conductor of the integral power-supply cord.

The grounding strap may be particularly useful when the rack is on a raised floor.

Table 2-3 Ground-strap wire gauge by

Wire Size

Rating

12 A 14 AWG — —

16 A 12 AWG

24 A 10 AWG — —

32 A —

40 A 6 AWG — —

48 A 6 AWG — —

NA, UL Listed EU, CE Marked WW

2

4.0 mm

2

6.0 mm

MPH2 rating

12 AWG or 4.0 mm

—

2

1. Insert a spring nut into the rack frame near the grounding point on the MPH2 (see Figure 2-3 for

inserting the spring nut).

2. Attach a ground wire to the rack with a screw, washer and lock washer. The screw is secured to the

rack’s frame with a spring nut.

3. Use a second field-supplied screw, washer and lock washer to secure the ground wire to the MPH2.

The connection point is marked with an earth-ground symbol (see Figure 2-7).

18 Emerson® MPH2™ User Manual

Page 24

Installation

Figure 2-7 Rack grounding-strap connection

Number Description Number Description

1 Ground-wire connection screw, M6 x 12 4 Lock washer

2 Washer 5

3 Ground-wire connector (to MPH2) 6 Ground-wire connector (to rack)

Ground-wire connection on MPH2

(location may vary)

Emerson® MPH2™ User Manual 19

Page 25

2.3.6 Recommended Electrical-backup Protection

A field-provided external circuit breaker must be installed upstream of the MPH2 Rack PDU. The circuit

breaker must be sized according to the input rating of the PDU. The circuit breaker rating must meet the

values in Tab le 2-4.

The external circuit breaker serves as the primary input power disconnect for the MPH2.

Table 2-4 Upstream circuit breaker rating

Maximum Input

Current Per Pole

12 A 15 A (NA)

16 A

24 A 30 A (NA)

32 A 32 A (EU, WW)

40 A 50 A (NA)

48 A 60 A (NA)

63 A 63 A (EU, WW)

Rated Current

of Upstream CB

20 A (NA)

16 A (EU, WW)

2.4 Connecting Rack Equipment

Installation

NOTE

Circuit breakers on Emerson’s MPH2 Rack PDU are opened at the factory. The open circuit

breakers help protect against high inrush current when input power is first connected.

To mitigate in-rush currents:

• Close the branch circuit breakers after all receptacle loads are connected.

–or –

• For MPH2-C and MPH2-R models, turn the receptacle off before connecting the load.

Once the MPH2 Rack PDU has been installed in the rack, the unit is ready for connection of equipment

that will be powered by the unit or used for monitoring.

Verify that the equipment to be connected meet these requirements:

• Input power requirements of each load do not exceed the MPH2 receptacle ratings.

• Input power cords meet or exceed the rating of the MPH2 receptacles and are fully-engaged.

• Total equipment power consumption will not overload the MPH2 Rack PDU.

To connect devices to an MPH2 Rack PDU:

1. Make sure that input power is installed in accordance with national and local electric codes.

2. Verify that all devices to be connected are shut down and unplugged from input power sources.

3. If the MPH2 Rack PDU will be monitored over a network, connect an Ethernet cable to the LAN port on

the RPC2.

4. Route the devices’ power cables to the MPH2 Rack PDU, following proper procedures and good

practices, such as segregating power cables from control cables and keeping cable bends to

recommended angles.

5. Verify that the branch circuit breakers on the MPH2 Rack PDU are open.

20 Emerson® MPH2™ User Manual

Page 26

Installation

6. Connect the devices’ input power cables to the MPH2 Rack PDU.

7. Record where each piece of rack equipment is connected, using the branch and receptacle numbers

8. Post the connection information on or near the rack and at any remote monitoring location.

9. Connect input power to the MPH2 Rack PDU. On Types R, C and M models, the receptacle LEDs

10. Verify that input power is present and the line-status LEDs are illuminated green and steady state. If

11. Close the branch circuit breakers. The receptacle LEDs are lit green and steady-state. If any LEDs are

12. Turn on the connected devices one at a time and verify that each is operating properly.

13. Ensure that the specified ratings found on the MPH2 Rack PDUs name plate are not exceeded.

NOTE

All C13 and C19 receptacles on MPH2 Rack PDUs are locking receptacles. Locking requires use

of special power cords, which may be factory-installed on the equipment or is available from

Emerson.

If non-locking power cords are used, the power cords should be secured through other methods to

prevent unintended power interruption.

on the MPH2 Rack PDU.

pulse RED indicating that the branch circuit breakers are open.

any LEDs are not lit or are blinking, refer to Table 5-2 - Line LED Troubleshooting, page 39.

not lit or are blinking, refer to Table 5-1 - Receptacle LED Troubleshooting, page 38.

14. Monitor and control the MPH2 Rack PDU as detailed in the RPC2 user manual, SL-20841, available at

www.emersonnetworkpower.com

2.5 Installing Optional Items

The following items may be added to an MPH2 Rack PDU system but are not required.

• RPC Basic Display Module

• Liebert

2.5.1 RPC Basic Display Module Installation

The RPC Basic Display Module (BDM) provides local display of parametric data, including electrical status,

temperature and humidity for all connected MPH2 Rack PDUs. Display information is accessed via a

navigation switch on the BDM. The RPC BDM is connected by cable to the MPH2 Rack PDU, allowing the

user to install the display to suit the local reading requirements. A 6.5-ft. (2-m) cable and general mounting

provisions are provided. A single display can be used for up to four rack PDUs connected in a Rack PDU

Array

The RPC BDM can be mounted in the rack with either the included hardware or with a cable tie through the

slot on the back of the module. Either method permits moving the BDM to a different place in the same

rack or to another rack.

2.5.1.1 Included Hardware

• RPC BDM, 1

®

SN temperature/humidity sensors

™

.

• Spring Nut M5, 1

• Spacer Sleeve, 1

• Mounting Button, 1

•M5 Screw, 1

• Cable Clip, 1

Emerson® MPH2™ User Manual 21

Page 27

Figure 2-8 RPC BDM

Installation

Number Description

1 Scan switch

2 RJ-45 communication and power input port

To install an RPC BDM in a rack:

1. Determine the mounting location on the frame member where the RPC BDM will be installed.

2. Insert a spring nut into a T-slot and flip it so that it is square in the slot as shown in Figure 2-9.

Figure 2-9 Inserting the spring nut into a T-slot

3. Insert the MPH2 Rack PDU screw into the spacer sleeve.

4. Insert the MPH2 Rack PDU screw into the spring nut and tighten securely with a flat-head screwdriver.

5. Hang the RPC BDM on the screw with the hooded mounting slot on the back of the RPC BDM.

6. Connect the RPC BDM to the RPC2 with an Ethernet cable.

7. Be certain to connect the cable to the correct port on the RPC2.

22 Emerson® MPH2™ User Manual

Page 28

Installation

2.5.2 Temperature/Humidity Sensor Installation

Optional Liebert® SN temperature/humidity sensors are available to assist in monitoring conditions in the

rack. Liebert SN sensors are designed for installation in Emerson racks without tools, but each may be

placed in any area to monitor temperature and humidity levels. Each connects to the RPC2

communications module, which makes readings available to other monitoring methods.

To install a sensor in a rack:

1. Insert the sensor bracket base into one end of the sensor support.

2. Snap the sensor into the other end of the sensor support.

3. Choose where in the rack to install the sensor assembly.

NOTE

Emerson recommends placing the sensor in the area of the rack that is likely to be warmest. That

location helps determine extreme conditions that can cause equipment damage.

4. Hold the sensor bracket on a T-slot on the Emerson rack frame where the sensor will be placed.

5. Insert the included quarter-turn fastener through the rectangular hole in the sensor bracket base and

into the T-slot.

6. Turn the fastener clockwise 90 degrees, a quarter of a turn.

7. Route the sensor cable to the RPC2 communications module and insert it into the card’s external

sensor port.

NOTE

For more information, see the RPC2 user manual, SL-20841, available at Emerson’s Web site,

http://www.emersonnetworkpower.com

Emerson® MPH2™ User Manual 23

Page 29

3.0 Operation

Emerson’s MPH2 Rack PDU may be monitored and managed by the factory-installed RPC2

communications module. This manual presents information about the MPH2’s functions and features.

Refer to the RPC2 user manual, SL-20841, for details on using the RPC2 communications module to

monitor and manage the MPH2. The document shipped with the MPH2 Rack PDU and is available at

Emerson’s Web site, http://www.emersonnetworkpower.com

The MPH2’s on-board LCD and the Web-based interface display system operating measurements, as well

as readings from optional Liebert SN temperature or temperature/humidity sensors. The RPC2

communications module and on-board LCD also display basic information about the MPH2 Rack PDU,

such as firmware version, unit rating, model number and serial number.

LEDs on the MPH2 and an audible alarm also assist in monitoring performance with alerts about events

and alarm conditions. The keys under the on-board LCD are used to navigate to various information and to

silence alarms.

3.1 Controls and Indicators

The MPH2 Rack PDU also has LEDs that indicate receptacle and branch status and system information.

LEDs flash, pulse or change colors to indicate an event or alarm condition (for details on how LEDs

respond to events and alarms, refer to 5.0 - Troubleshooting.

Operation

NOTE

Units with a “B” as the fourth character in the model name (MPHBxxxx) do not have LEDs at their

receptacles. The branch and receptacle LED behavior in 5.0 - Troubleshooting and elsewhere in

this document does not apply to these units.

Receptacles on units with an “M” as the fourth character in the model name (MPHMxxxx) cannot

be turned Off. LEDs at receptacles on these models are always either on continuously or flashing

when input power is present.

Figure 3-1 On-board LCD and control keys

Number Description

1 On-board LCD

2 Line-input-status LEDs

3 Right-arrow key

4 Select key

5 Left-arrow key

24 Emerson® MPH2™ User Manual

Page 30

Operation

3.2 View Input-level Information

The MPH2’s main screen is displayed by the on-board LCD when the rack PDU is first powered up. The

input-level information is the main screen, Figure 3-2.

NOTE

After 5 minutes of no activity (no key pressed), the on-board LCD returns to

the main screen.

NOTE

During a firmware upgrade:

• The Line-input status LEDs flash red and green, and the rack PDU

continues receiving and distributing power without interruption.

Figure 3-2 Input-level information (main screen)

Number Description Number Description

1 Input-level metered information icon 7 Receptacle icon

2 Bar graph of input current 8 Sensor icon

3 Link icon 9 Alarm icon

4 Input voltage 10 % Amperes used until alarm threshold.

5 Voltage phase 11 Unit identification (always shows unit 1)

6 Information icon

Emerson® MPH2™ User Manual 25

Page 31

3.2.1 Communication Link with RPC2

When power is cycled to the MPH2, it takes a few moments to establish communication and load the

configuration information from RPC2, such as receptacle labels and IP and MAC addresses.

When configuration changes (such as turning-on/off a receptacle) require that the LCD screen update, the

configuration wheel appears and spins, Figure 3-3, to indicate that navigation is unavailable while

configuration is in-progress.

Figure 3-3 Configuration in-progress wheel

Operation

Number Description

1 Configuration wheel

26 Emerson® MPH2™ User Manual

Page 32

Operation

3.3 View MPH2 System Information

1. Use the arrow keys to highlight the information icon, .

2. Press .

The MPH2 model number, serial number, firmware version, power rating and number of receptacles

display, Figure 3-4.

Figure 3-4 System information

NOTE

The firmware version and other information in the figure are an examples only.

3.3.1 System and Screen Options

On the system-information screen is a menu of icons that provides access to further system options,

network information, and LCD-screen options, Figure 3-5.

Figure 3-5 System-info and Screen-option icons

Number Description

1 Reboot/Restore-defaults icon

2 Flip screen orientation icon

3 Adjust screen contrast icon

4 System network icon

5 Up-to-previous-level icon

Emerson® MPH2™ User Manual 27

Page 33

3.3.2 Reboot the On-board LCD

1. Use the arrow keys to highlight the information icon, , and press .

2. Use an arrow key to highlight the reboot/restore-defaults icon, , and press .

The Reboot Options display, Figure 3-6.

Figure 3-6 Reboot Options

Operation

3. Use the arrow keys to highlight an up/down arrow at the bottom-left, and press to highlight Reboot.

4. Use the arrow keys to highlight the play button, , and press .

The Reboot? confirmation displays.

5. Use the arrow keys to highlight an up/down arrow, and press to highlight Yes / Reboot Now.

6. Press .

The system reboots.

28 Emerson® MPH2™ User Manual

Page 34

Operation

3.3.3 Restore System Defaults

Table 3 -1 describes the factory-default settings.

1. Use the arrow keys to highlight the information icon, , and press .

2. Use an arrow key highlight the reboot/restore-defaults icon, , and press .

The Reboot Options display, Figure 3-6.

Figure 3-7 Restore Defaults selected on Reboot Options

3. Use the arrow keys to highlight an up/down arrow at the bottom-left, and press

to highlight Restore Defaults.

4. Use the arrow keys to highlight the play button, , and press .

The Restore Defaults? confirmation displays, Figure 3-8.

5. Use the arrow keys to highlight an up/down arrow, and press to highlight Yes/ Reboot to Default.

6. Press .

The system-default settings are restored.

Figure 3-8 Restore Defaults? confirmation

Emerson® MPH2™ User Manual 29

Page 35

The default settings described in Table 3-1 apply only to MPH2, are set at time of manufacture and are

applied when “Restore to Factory Defaults” is initiated via RPC2 clients.

NOTE

For detailed information about settings and about network- and protocolrelated default settings for RPC2, see SL-20841. The document is available at

Emerson’s Web site: http://www.emersonnetworkpower.com

Table 3-1 Factory-default settings

Level Settings Default Value Units

MPH2 or

PDU

Branch

User Assigned Label

Asset Tag 1 <empty> — All

Asset Tag 2 <empty> — All

Overcurrent Alarm Threshold 45 % All

Overcurrent Warning

Threshold

Undercurrent Alarm Threshold 0 % All

Unbalanced Load Alarm

threshold

Software Over Current

Protection (SWOCP)

User Assigned Label Branch <alpha> — All

Asset Tag 1 <empty> — All

Asset Tag 2 <empty> — All

Overcurrent Alarm Threshold 95 % All

Overcurrent Warning

Threshold

Undercurrent Alarm Threshold 0 % All

SWOCP Disabled — R

Rack PDU

<alpha>

40 % All

0%

Disabled — R

90 % All

Models

Affected Notes

—All

All

3-phase

• RackPDU is default value the first time

only.

• Allowed characters include

alphanumeric, space,

and ~!#$_+`-={}|[]\\:;'?,.\/%^&*()@

• % calculated from maximum inputcurrent rating on nameplate.

• Default values are recommended for

dual-corded server applications.

% difference calculated between any two

phases.

Conditionally applies to unlocked and

unloaded receptacles only.

Allowed characters include

alphanumeric, space,

and ~!#$_+`-={}|[]\\:;'?,.\/%^&*()@

% calculated from CB rating. Refer to

nameplate for maximum branch current

rating.

Conditionally applies to all unlocked and

unloaded receptacles only for this

branch.

Operation

30 Emerson® MPH2™ User Manual

Page 36

Operation

Table 3-1 Factory-default settings (continued)

Level Settings Default Value Units

Receptacle

<number>

90 % M,R

Disabled — C,R

Receptacle

User Assigned Label

Asset Tag 1 <empty> — All

Asset Tag 2 <empty> — All

Overcurrent Alarm Threshold 95 % M,R

Overcurrent Warning

Threshold

Undercurrent Alarm Threshold 0 % M,R

Power Up State Restore — C,R

Power On Delay 0 seconds C,R

Power Cycle Delay 8 seconds C,R

Post On Delay 0 seconds C,R

Post Off Delay 0 seconds C,R

Software Over Temperature

Protection (SWOTP)

SWOTP Delay 10 seconds C,R

SWOTP Scope Local — C,R

Criticality Critical — C,R

Locked/Unlocked Unlocked — C,R

Models

Affected Notes

—All

Allowed characters include

alphanumeric, space,

and ~!#$_+`-={}|[]\\:;'?,.\/%^&*()@

Configurable per receptacle.

% calculated from maximum receptacle

current rating on nameplate.

Restore returns receptacle power state

to last programmed state after expiration

of Power On Delay.

The delay timing begins after

measurement stability is achieved.

A Power Cycle turns off power to the

receptacle for the specified delay.

Delay before RPC2 issues command to

power on receptacle.

Delay before RPC2 issues command to

power off receptacle.

• Unconditionally applies regardless of

locked/unlocked and loaded/unloaded

status.

• At least one temperature sensor is

required.

Delay required for persistent overtemperature alarm condition before

SWOTP triggered.

• Local = affects only PDU connected to

the temperature sensor that triggered

SWOTP.

• Array = affects all PDUs regardless of

temperature sensor that triggered

SWOTP.

Affects power control when a member of

a receptacle group.

Affects authorization to manage power

control and behavior of SWOCP.

Emerson® MPH2™ User Manual 31

Page 37

3.3.4 Determine IP Address, MAC Address and Firmware Version

1. Use the arrow keys to highlight the information icon, , and press .

2. Use an arrow key to highlight the network icon, , and press .

The IP address, MAC address, firmware, date and time display, Figure 3-9.

Figure 3-9 IP address, MAC address, and firmware information

Operation

Number Description

1 IP address

2 MAC address

3 Agent firmware type and version

NOTE

The firmware version and other information in the figure are examples only.

32 Emerson® MPH2™ User Manual

Page 38

Operation

3.3.5 Adjust the Contrast of the On-board LCD

NOTE

Contrast adjustment may help improve LCD-screen legibility in a

high-temperature environment.

The on-board LCD is factory-set to be easily viewed in lighting conditions found in most work places. The

contrast can be changed.

1. Press any key to activate the LCD.

2. Use the arrow keys to highlight the information icon, , and press

3. Use the arrow keys to highlight the contrast icon, , and press .

4. Use the arrow keys to highlight an up/down arrow, and press to increase or decrease contrast.

Refer to the pattern, Figure 3-10, to determine when the contrast is acceptable.

5. When the contrast is satisfactory, highlight and press to return to the system-information

screen.

NOTE

These steps also apply to the RPC BDM.

Figure 3-10 Adjust LCD contrast

Emerson® MPH2™ User Manual 33

Page 39

3.3.6 Adjust the Orientation of the On-board LCD

Because mounting of the MPH2 in the rack may vary, the on-board LCD may be “flipped” to change the

screen orientation for viewing ease.

1. Press any key to activate the LCD.

2. Use the arrow keys to highlight the information icon, , and press .

3. Use the arrow keys to highlight the flip-orientation icon, , and press .

The screen “flips” orientation.

4. Highlight and press to return to the input-level screen.

NOTE

These steps also apply to the RPC BDM.

3.4 View Active Alarms

NOTE

The most-recent alarms are at the top of the list.

Operation

1. Use the arrow keys to highlight the alarm icon, , and press .

A list of active alarms on the MPH2 displays, Figure 3-11.

2. Use the arrow keys to highlight an up/down arrow, and press to highlight an alarm.

3. Highlight the play button, , and press .

The alarm details display.

Figure 3-11 Alarm list

3.4.1 Silence an Audible Alarm

To silence an audible alarm, press any of the three navigation keys below the LCD.

See 5.0 - Troubleshooting for details about how the LED interface signifies events and alarms.

34 Emerson® MPH2™ User Manual

Page 40

Operation

3.5 View Branch-level Information

1. At the input-level (main) screen, highlight the unit-identification number, , and press .

The branch letters display along the bottom-left, Figure 3-12.

2. Use the arrow keys to highlight the letter of the branch to view, and press .

Information about the selected branch displays, Figure 3-12.

• To display more details about the selected branch, highlight the information icon, , and press .

• To return to the previous level view, highlight and press .

Figure 3-12 Branch information

Number Description

1 Branch-level information icon

Branch circuit-breaker status icon

2

3 Branches (two shown, A and B)

I = closed circuit breaker

O = open circuit breaker

Emerson® MPH2™ User Manual 35

Page 41

3.6 View Receptacle-level Information

1. At the input-level (main) screen, highlight the receptacle icon, , and press .

The receptacle list displays, Figure 3-13.

Figure 3-13 Receptacle list

Operation

2. Use the arrow keys to highlight an up/down arrow at the bottom-left, and press to highlight a

receptacle.

3. Highlight the play button, , and press .

The receptacle information displays, Figure 3-14. The receptacle numbers display along the bottomleft, and the number of the selected receptacle number flashes.

4. To view a different receptacle, highlight the number of the receptacle, and press .

• To display more details about the selected receptacle,

highlight the information icon, , and press .

• To return to the previous level view, highlight and press .

36 Emerson® MPH2™ User Manual

Page 42

Operation

Figure 3-14 Receptacle information

Number Description

1 Receptacle-level information icon

2

3

Receptacle identification:

1 = MPH2 #1

A = Branch A

1 = Receptacle #1

Receptacle list (receptacle #1 of 5 is

selected)

Emerson® MPH2™ User Manual 37

Page 43

3.7 View Sensor Information

1. At the input-level (main) screen, highlight the sensor icon, , and press .

A list of the sensors, in the order of their identification number, displays, Figure 3-15.

NOTE

The default label is the sensor’s serial number, but can be changed through

the Web interface.

Figure 3-15 Sensor list

Operation

Number Description

Sensors connected to the MPH2. (two

1

temperature sensors and one humidity

sensor in the example)

2. Use the arrow keys to highlight an up/down arrow at the bottom-left, and press to highlight a

receptacle.

38 Emerson® MPH2™ User Manual

Page 44

Operation

3. Highlight the play button, , and press .

The sensor information displays, similar to that shown in Figure 3-16, which shows

humidity-sensor information:

• Percentage and severity of humidity.

• Sensor identification and label (serial number).

NOTE

The default label is the sensor’s serial number, but can be changed through

the Web interface.

Figure 3-16 Sensor information

Emerson® MPH2™ User Manual 39

Page 45

3.8 Opening and Closing Circuit Breakers

MPH2 Rack PDU feature circuit breakers to protect either branches or individual receptacles, depending

on the model. Low-profile circuit breakers are used on all MPH2 Rack PDUs with two or three branch

circuits. Standard-profile circuit breakers are used on MPH2 Rack PDUs with six branch circuits or have a

240VAC rating.

Both types of circuit breakers are flush-mount, rocker-style breakers. The circuit breakers are designed to

prevent accidental trips. To manually trip a circuit breaker to the Off position, insert a flat-blade screwdriver

or similar tool into the slot on the breaker as shown in Figure 3-17. To reset the breaker, press the end

nearest ON until it clicks into place.

Figure 3-17 Turning Off or resetting a circuit breaker

Operation

Number Description

1 Low-profile breaker switch

2 Standard-profile breaker switch

Flat-blade screw driver.

3

4 Press here to reset low-profile breaker.

5

To trip breaker (low- or standard-profile),

press screw driver into slot.

Push top of breaker switch in to reset

standard-profile breaker.

40 Emerson® MPH2™ User Manual

Page 46

Emerson® MPH2 Rack PDU Specifications

4.0 Emerson® MPH2 Rack PDU Specifications

0-U 1-U 2-U

Input Power Configurations;

Vary by Model and Region

Single-Phase Input; CE-Mark

240 VAC, 16 A; also UL-listed 3.7 kW

230 V, 32 A 7.3 kW

Three-Phase Input; CE-Mark

230/400 V, 16 A 11 kW

230/400 V, 32 A 22 kW

Single-Phase Input; UL-Listed

120 VAC, 12 A 1.4 kW

120 VAC, 16 A 1.9 kW

120 VAC, 24 A 2.9 kW

208 VAC, 24 A 4.9 kW

Three-Phase Input; UL-Listed

120/208 VAC, 24 A 8.6 kW

120/208 VAC, 40 A 14.4 kW

120/208 VAC 48 A; 240/415 VAC, 24 A 17.3 kW

Input Wiring Options 10-ft. (3-m) Non-Detachable Power

Supply Cord

Hard-Wired Terminal Block

Receptacle Options NEMA 5-15; NEMA 5-20; IEC 320C13; IEC 320 C19

Number of Receptacles, Maximum 48 12 24

Power Consumption, Maximum 7.5 W

Measurement Accuracy

Current: ±1.5% + 0.01 A from 1% to 10% of unit rating;

±1% +0.01 A from >10% to 125% of unit rating

Insulation

Dielectric Electric Strength

Overcurrent Protection UL489-Listed, CSA, TUV, CCC Overcurrent Circuit Breaker,

Operating Temperature Range, °F (°C) 32-A or Less Input Models: 32 to 140 (0 to 60)

Storage Temperature Range, °F (°C) -13 to 185 (-25 to 85)

Humidity,%

Altitude, ft. (m)

Mounting Factory-Installed Tool-less Brackets

Width x Depth, in. (mm) Low-profile: 2.2 x 1.96

Units, Length, in. (mm) 13.1 - 72.2 (333 - 1833) 19 (482.6) 19 (482.6)

Safety Standards

(Vary by Model and Region)

EMC Standards

(Vary by Model and Region)

Note: A temporary loss of touch-key functionality may occur for sufficiently large radiofrequency fields induced through the power-supply cord.

Agency Approvals

(Vary by Model and Region)

40-A and 48-A Input Models without case ventilation: 32 to 122 (0 to 50)

40-A and 48-A Input Models with case ventilation: 32 to 140 (0 to 60)

Universal Mounting Bracket

(56 x 50)

Standard: 2.2 x 2.7

(56 x 70)

IEC 60950-1:2005 (Second Edition) + Amendment 1:2009

CSA C22.2 NO. 60950-1-07 (2nd Edition) + Amendment 1:2009

UL 60950-1 (2nd Edition) + Amendment 1:2009

IECEE CB Full Certification Scheme

FCC Class A, Part 15, Industrial

EN55022:2006+A1:2007, Class A, Industrial

EN55024:1998+A1:2001+A2:2003, Class A, Industrial

IEC61000-3-2:2014 (ed.3), IEC61000-3-3:2013 (ed.3)

IEC61000-4-2/3/4/5/6/8/11

UL, cUL, CE, BV, CB, RoHS, REACH, WEEE

10-ft. (3-m) Non-Detachable Power Supply Cord

Voltage: ±1% +0.1 VAC

Class I, Reinforced SELV

Tested up to 4242 VDC

20 A, 5000 A A.I.C

10 to 90 non-condensing

6562 (2000)

Factory-installed, Right-angle Mounting Brackets

1.73 x 9.84 (44 x 250) 3.46 x 9.84 (88 x 250)

Emerson® MPH2™ User Manual 41

Page 47

5.0 Troubleshooting

NOTE

Per UL 60950-1 2nd Ed. ITE safety-standard requirements, the current ratings of UL Listed

models are 80% of input-plug, branch-circuit-breaker and receptacle maximum current ratings.

Table 5-1 Receptacle LED Troubleshooting

LED Indication

(One or All LEDs)

State/

Flash Speed

Green Steady On —

Green Fast — Receptacle Identification

Off NA — Voltage Off Check receptacle power control settings.

Green Slow — Overcurrent Warning

Red Fast

Red

(All LEDs)

Green

(All LEDs)

Red

(All LEDs)

Pulse — Branch Circuit Breaker Open

Slow — Branch Overcurrent Warning

Fast Branch Overcurrent Alarm

Audible

Alarm Condition Status/Recommended ActionColor

Input-voltage-supported

Receptacle Powered-on

Overcurrent Alarm

Undercurrent Alarm

Normal Operation

Remote user is requesting receptacle identification.

The LED should stop flashing after 10 seconds.

Check for changing load conditions.

Check overcurrent warning threshold settings.

Check for changing load conditions.

Check overcurrent alarm threshold settings.

Check for removal of load.

Check undercurrent alarm threshold settings.

Check for changing load conditions; confirm circuit

breaker actuator is closed. If open, correct loading

condition before pressing circuit breaker actuator

closed again.

Note: On single-phase, switched-receptacle models,

this may indicate that the input-power line and

neutral are swapped if there is no power to the unit.

Check for changing load conditions.

Check overcurrent warning threshold settings.

Check for changing load conditions.

Check overcurrent alarm threshold settings.

Troubleshooting

42 Emerson® MPH2™ User Manual

Page 48

Troubleshooting

Table 5-2 Line LED Troubleshooting

LED Indication

(One or All LEDs)

State/

Flash Speed

Green Steady On — None

Off NA — Voltage Off

Red Steady On Line Undervoltage Alarm

Red Fast Overcurrent Alarm

Green Slow — Overcurrent Warning

Red Fast Undercurrent Alarm

Green/Red Fast — Firmware Update

Audible

Alarm Condition Status/Recommended ActionColor

Normal Operation

Note: Depending on plug type, not all LEDs may be lit,

see Table 5-3.

Confirm that the LED is active per Table 5-3.

Check power source and input plug’s receptacle

wiring.

Check receptacle power control settings.

Check power source for power quality problem. If the

MPH2 uses 3-phase power, a single low-voltage

phase may cause one or more undervoltage alarms.

The undervoltage alarm is factory-set to -10% of the

minimum input voltage range on the nameplate; it

cannot be changed.

Check for changing load conditions.

Check overcurrent alarm threshold settings.

Check for changing load conditions.

Check overcurrent warning threshold settings.

Check for removal of load.

Check undercurrent alarm threshold settings.

Firmware updated in-progress. LCD does not display

information. If the update fails or aborts, the indication

continues until firmware update is successful.

Emerson® MPH2™ User Manual 43

Page 49

Troubleshooting

5.1 Additional Troubleshooting by Plug Type

Table 5 -3 describes the line LEDs active by plug type. Depending on the type of plug, not all of the line

LEDs may be lit. The table also describes the branch circuits/receptacle-type and corresponding

input-power voltage phases

Table 5-3 Active Line LEDs and Branch Voltage Phasing by Plug Type

Pole/Wire

Plug Type

NEMA 5-15P 1P3W L1-N

NEMA 5-20P 1P3W L1-N

NEMA L5-20P 1P3W L1-N

NEMA L5-30P 1P3W L1-N L1-N

NEMA L6-20P 2P3W L1-L2

NEMA L6-30P 2P3W L1-L2 L1-L2

NEMA L14-30P 2P4W L1-N L1-L2 L1-L2

NEMA L15-20P 3P4W L1-L2 L2-L3 L3-L1

NEMA L15-30P 3P4W L1-L2 L2-L3 L3-L1

NEMA L21-20P

NEMA L21-30P

NEMA L22-30P 3P5W L1-N L2-N L3-N L1-N L2-N L3-N

CS8365C 50A 3P4W L1-L2 L2-L3 L3-L1 L1-L2 L2-L3 L3-L1

IEC 60309 1P3W 16A 1P3W L1-N

IEC 60309 1P3W 32A 1P3W L1-N L1-N

IEC 60309 3P5W 16A 3P5W L1-N L2-N L3-N

IEC 60309 3P5W 32A 3P5W L1-N L2-N L3-N L1-N L2-N L3-N

IEC 60309 3P4W 60A 3P4W L1-L2 L2-L3 L3-L1 L1-L2 L2-L3 L3-L1

Config.

3P5W L1-L2 L2-L3 L3-L1

3P5W L1-N + L1-L2 L2-N + L2-L3 L3-N + L3-L1

3P5W L1-L2 L2-L3 L3-L1

3P5W L1-N L2-L3 L2-L3

.

Receptacle

Types

NEMA

5-20

C13/C19 L1 L2 L3 A B C D E F

LEDs

Active Branch Voltage Phasing

IEC

44 Emerson® MPH2™ User Manual

Page 50

Page 51

Technical Support / Service

Web Site

www.liebert.com

Monitoring

liebert.monitoring@emerson.com

800-222-5877

Outside North America: +00800 1155 4499

Single-Phase UPS & Server Cabinets

liebert.upstech@emerson.com

800-222-5877

Outside North America: +00800 1155 4499

Three-Phase UPS & Power Systems

800-543-2378

Outside North America: 614-841-6598

Environmental Systems

800-543-2778

Outside the United States: 614-888-0246

Locations

United States

1050 Dearborn Drive

P.O. Box 29186

Columbus, OH 43229

Europe

Via Leonardo Da Vinci 8

Zona Industriale Tognana

35028 Piove Di Sacco (PD) Italy

+39 049 9719 111

Fax: +39 049 5841 257

Asia

7/F, Dah Sing Financial Centre

108 Gloucester Road, Wanchai

Hong Kong

852 2572220

Fax: 852 28029250

While every precaution has been taken to ensure the accuracy and completeness of this literature, Liebert Corporation assumes no responsibility and disclaims

all liability for damages resulting from use of this information or for any errors or omissions.

© 2016 Liebert Corporation

All rights reserved throughout the world.

Specifications subject to changewithout notice.

® Liebert is a registered trademark of Liebert Corporation. All names referred to are trademarks or registered trademarks of their respective owners.

Emerson Network Power

Liebert

www.emersonnetworkpower.com

SL-20860_REV4_4-16

590-1330-501C

Loading...

Loading...