Page 1

Installation Manual

MMI-20027478, Rev AE

Micro Motion™ 5700 Transmitters with

Configurable Inputs and Outputs

All Installation Types (Integral, 4-Wire, and 9-Wire)

September 2020

Page 2

Safety messages

Safety messages are provided throughout this manual to protect personnel and equipment. Read each safety message carefully

before proceeding to the next step.

Safety and approval information

This Micro Motion product complies with all applicable European directives when properly installed in accordance with the

instructions in this manual. Refer to the EU declaration of conformity for directives that apply to this product. The EU declaration

of conformity, with all applicable European directives, and the complete ATEX Installation Drawings and Instructions are available

on the internet at www.emerson.com or through your local Micro Motion support center.

Information affixed to equipment that complies with the Pressure Equipment Directive, can be found on the internet at

www.emerson.com.

For hazardous installations in Europe, refer to standard EN 60079-14 if national standards do not apply.

Other information

Full product specifications can be found in the product data sheet. Troubleshooting information can be found in the configuration

manual. Product data sheets and manuals are available from the Micro Motion web site at www.emerson.com.

Return policy

Follow Micro Motion procedures when returning equipment. These procedures ensure legal compliance with government

transportation agencies and help provide a safe working environment for Micro Motion employees. Micro Motion will not accept

your returned equipment if you fail to follow Micro Motion procedures.

Return procedures and forms are available on our web support site at www.emerson.com, or by phoning the Micro Motion

Customer Service department.

Emerson Flow customer service

Email:

• Worldwide: flow.support@emerson.com

• Asia-Pacific: APflow.support@emerson.com

Telephone:

North and South America

United States 800-522-6277 U.K. and Ireland 0870 240 1978 Australia 800 158 727

Canada +1 303-527-5200 The Netherlands +31 (0) 70 413

Mexico +52 55 5809 5300 France +33 (0) 800 917

Argentina +54 11 4809 2700 Germany 0800 182 5347 Pakistan 888 550 2682

Brazil +55 15 3413 8000 Italy +39 8008 77334 China +86 21 2892 9000

Chile +56 2 2928 4800 Central & Eastern +41 (0) 41 7686

Peru +51 15190130 Russia/CIS +7 495 995 9559 South Korea +82 2 3438 4600

Europe and Middle East Asia Pacific

New Zealand 099 128 804

6666

India 800 440 1468

901

Japan +81 3 5769 6803

111

Egypt 0800 000 0015 Singapore +65 6 777 8211

Oman 800 70101 Thailand 001 800 441 6426

Qatar 431 0044 Malaysia 800 814 008

Kuwait 663 299 01

South Africa 800 991 390

Saudi Arabia 800 844 9564

UAE 800 0444 0684

2

Page 3

Installation Manual Contents

MMI-20027478 September 2020

Contents

Chapter 1 Before you begin........................................................................................................5

1.1 About this document...................................................................................................................5

1.2 Hazard messages.........................................................................................................................5

1.3 Related documentation............................................................................................................... 5

Chapter 2 Planning.................................................................................................................... 7

2.1 Installation checklist.................................................................................................................... 7

2.2 Additional considerations for retrofitting existing installations.................................................... 8

2.3 Power requirements.................................................................................................................... 9

Chapter 3 Mounting and sensor wiring.................................................................................... 11

3.1 Mounting and sensor wiring for integral-mount transmitters.....................................................11

3.2 Mounting transmitters...............................................................................................................11

3.3 Wire a remote-mount transmitter to the sensor........................................................................ 15

3.4 Ground the meter components................................................................................................. 18

3.5 Rotate the transmitter on the sensor (optional)......................................................................... 19

3.6 Rotate the user interface on the transmitter (optional)..............................................................20

3.7 Rotate the sensor wiring junction box on a remote-mount transmitter (optional)......................21

Chapter 4 Wiring the channels................................................................................................. 23

4.1 Available channels..................................................................................................................... 23

4.2 Access the wiring channels........................................................................................................ 23

4.3 Wire the mA Output.................................................................................................................. 24

4.4 Wire the mA/HART Output........................................................................................................ 26

4.5 Wire the Frequency Output....................................................................................................... 28

4.6 Wire the Discrete Output...........................................................................................................32

4.7 Wire the RS-485 output............................................................................................................. 35

4.8 Wire the mA Input..................................................................................................................... 35

4.9 Wire the Discrete Input..............................................................................................................36

4.10 Wire the Frequency Input........................................................................................................ 37

4.11 Wire Channels A and D for SIS applications.............................................................................. 38

Chapter 5 Wiring the power supply..........................................................................................43

Chapter 6 Wire the printer....................................................................................................... 45

Chapter 7 Power up the transmitter.........................................................................................47

Chapter 8 Configuring the transmitter with Guided Setup........................................................49

Chapter 9 Using the display controls........................................................................................ 51

Chapter 10 Available service port connection............................................................................. 53

Appendix A Wire the 5700 to the 3100 transmitter..................................................................... 55

Installation Manual 3

Page 4

Contents Installation Manual

September 2020 MMI-20027478

4 Micro Motion 5700 Transmitters with Configurable Inputs and Outputs

Page 5

Installation Manual Before you begin

MMI-20027478 September 2020

1 Before you begin

1.1 About this document

This manual provides information on planning, mounting, wiring, and initial setup of the

5700 transmitter. For information on full configuration, maintenance, troubleshooting, or

service of the transmitter, see the configuration and use manual.

The information in this document assumes that users understand basic transmitter and

sensor installation, configuration, and maintenance concepts and procedures.

1.2 Hazard messages

This document uses the following criteria for hazard messages based on ANSI standards

Z535.6-2011 (R2017).

DANGER

Serious injury or death will occur if a hazardous situation is not avoided.

WARNING

Serious injury or death could occur if a hazardous situation is not avoided.

CAUTION

Minor or moderate injury will or could occur if a hazardous situation is not avoided.

NOTICE

Data loss, property damage, hardware damage, or software damage can occur if a

situation is not avoided. There is no credible risk of physical injury.

Physical access

NOTICE

Unauthorized personnel can potentially cause significant damage and/or misconfiguration

of end users' equipment. Protect against all intentional or unintentional unauthorized use.

Physical security is an important part of any security program and fundamental to

protecting your system. Restrict physical access to protect users' assets. This is true for all

systems used within the facility.

1.3 Related documentation

You can find all product documentation on the product documentation DVD shipped with

the product or at www.emerson.com.

See any of the following documents for more information:

• Micro Motion 5700 Product Data Sheet

Installation Manual 5

Page 6

Before you begin Installation Manual

September 2020 MMI-20027478

• Micro Motion 5700 Transmitters with Configurable Inputs and Outputs: Configuration and

Use Manual

• Coriolis Flow Meter with Micro Motion Model 5700 Transmitters Safety Manual for Safety

Instrumented Systems (SIS)

• Micro Motion 5700 Transmitters with a Marine Bunker Transfer Package: Application

Manual

• Sensor installation manual

6 Micro Motion 5700 Transmitters with Configurable Inputs and Outputs

Page 7

Installation Manual

MMI-20027478 September 2020

Planning

2 Planning

2.1 Installation checklist

□ If possible, install the transmitter in a location that will prevent direct exposure to

sunlight. The environmental limits for the transmitter may be further restricted by

hazardous area approvals.

□ If you plan to mount the transmitter in a hazardous area:

WARNING

— Verify that the transmitter has the appropriate hazardous area approval. Each

transmitter has a hazardous area approval tag attached to the transmitter

housing.

— Ensure that any cable used between the transmitter and the sensor meets the

hazardous area requirements.

— For ATEX/IECEx installations, strictly adhere to the safety instructions

documented in the ATEX/IECEx approvals documentation available on the

product documentation DVD shipped with the product or at www.emerson.com.

□ Verify that you have the appropriate cable and required cable installation parts for your

installation. For wiring between the transmitter and sensor, verify the maximum cable

length does not exceed 1,000 ft (305 m).

□ Ensure that you use the following cables for the different connections:

— A shielded, twisted-pair instrument cable with drain for all I/O connections

— A twisted-pair shielded cable for the RS-485 (Channel E) connection

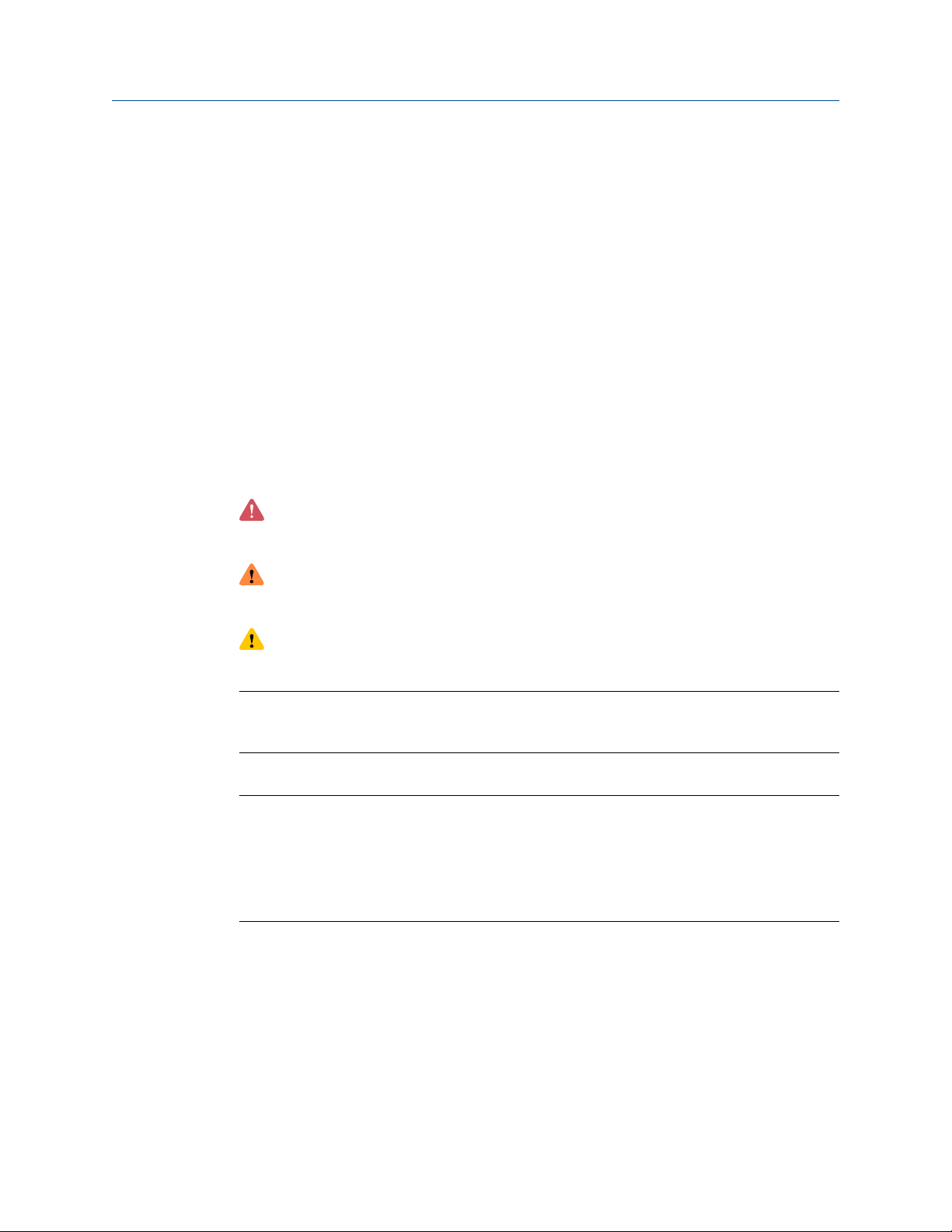

□ You can mount the transmitter in any orientation as long as the conduit openings or

transmitter display do not point upward.

Installing the transmitter with the conduit openings or transmitter display facing

upward risks condensation moisture entering the transmitter housing, which could

damage the transmitter.

Following are examples of possible orientations for the transmitter.

Preferred orientation

Alternate orientations

□ Mount the meter in a location and orientation that satisfies the following conditions:

— Allows sufficient clearance to open the transmitter housing cover. Install with 8 in

(203 mm) to 10 in (254 mm) clearance at the wiring access points.

Installation Manual 7

Page 8

Planning Installation Manual

September 2020 MMI-20027478

— Provides clear access for installing cabling to the transmitter.

— Provides clear access to all wiring terminals for troubleshooting.

2.2 Additional considerations for retrofitting existing installations

□ The transmitter installation may require 3 in (76 mm) to 6 in (152 mm) of additional

wiring for the input/output and power connections. This length would be in addition to

the currently installed wiring. Confirm you have the additional wiring necessary for the

new installation.

□ Before removing the existing transmitter, be sure to record the configuration data for

the currently installed transmitter. At initial startup of the newly installed transmitter,

you will be prompted to configure the meter via a guided setup.

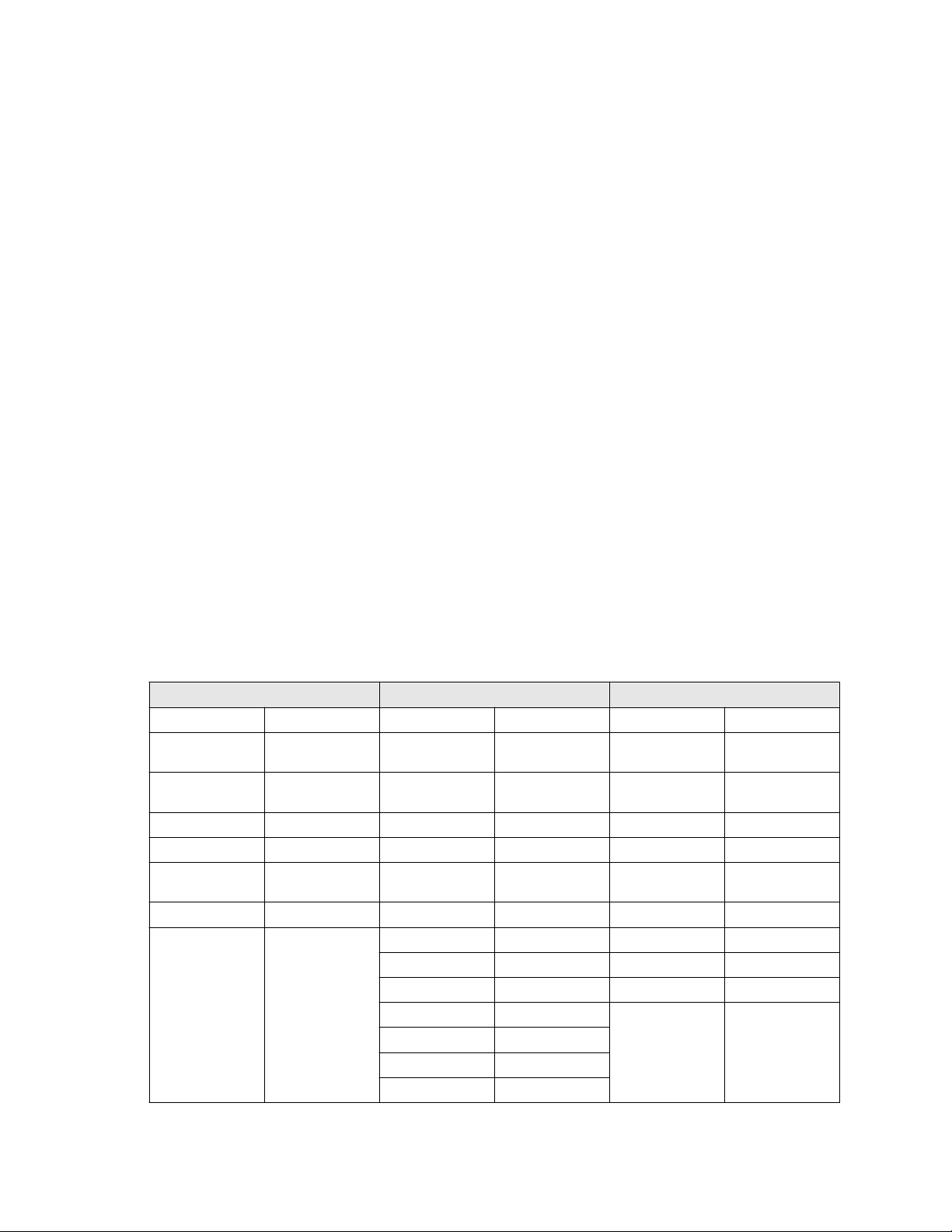

Record the following information (if applicable):

Variable Setting

Tag

Mass flow units

Volume flow units

Density units

Temperature units

Channel configuration

mA Outputs 1 — Power (Internal or External):

— Source:

— Scaling (LRV, URV):

— Fault Action:

mA Outputs 2 (optional) — Power (Internal or External):

— Source:

— Scaling (LRV, URV):

— Fault Action:

Frequency Outputs (optional) — Power (Internal or External):

— Source:

— Scaling (LRV, URV):

— Fault Action:

— Dual output:

8 Micro Motion 5700 Transmitters with Configurable Inputs and Outputs

Page 9

Installation Manual

Planning

MMI-20027478 September 2020

Variable Setting

Discrete Outputs (optional) — Power (Internal or External):

— Source:

— Scaling (LRV, URV):

— Fault Action:

Discrete Input (optional) — Power (Internal or External):

— Source:

— Scaling (LRV, URV):

— Fault Action:

RS-485 Address:

Calibration parameters (for 9-wire installations only)

Flow calibration factor FCF (Flow Cal or Flow Calibration Factor):

Density calibration factors — D1:

— D2:

— K1:

— K2:

— TC:

— FD:

2.3 Power requirements

Self-switching AC/DC input, automatically recognizes supply voltage:

• 85 to 240 VAC, 50/60 Hz, 6 watts typical, 11 watts maximum

• 18 to 100 VDC, 6 watts typical, 11 watts maximum

Note

For DC power:

• Power requirements assume a single transmitter per cable.

• At startup, the power source must provide a minimum of 1.5 amps of short-term

current per transmitter and not pull voltage below 18 VDC.

• Length and conductor diameter of the power cable must be sized to provide 18 VDC

minimum at the power terminals, at a load current of 0.7 amps.

Cable sizing formula

M = 18V + (R x L x 0.7A)

• M: minimum supply voltage

• R: cable resistance

• L: cable length (in Ω/ft)

Installation Manual 9

Page 10

Planning Installation Manual

September 2020 MMI-20027478

Typical power cable resistance at 68 °F (20.0 °C)

Wire gauge Resistance

14 AWG 0.0050 Ω/ft

16 AWG 0.0080 Ω/ft

18 AWG 0.0128 Ω/ft

20 AWG 0.0204 Ω/ft

2.5 mm

1.5 mm

1.0 mm

0.75 mm

0.50 mm

2

2

2

2

2

0.0136 Ω/m

0.0228 Ω/m

0.0340 Ω/m

0.0460 Ω/m

0.0680 Ω/m

2.3.1 Maximum cable lengths between sensor and transmitter

The maximum cable length between the sensor and transmitter that are separately

installed is determined by cable type.

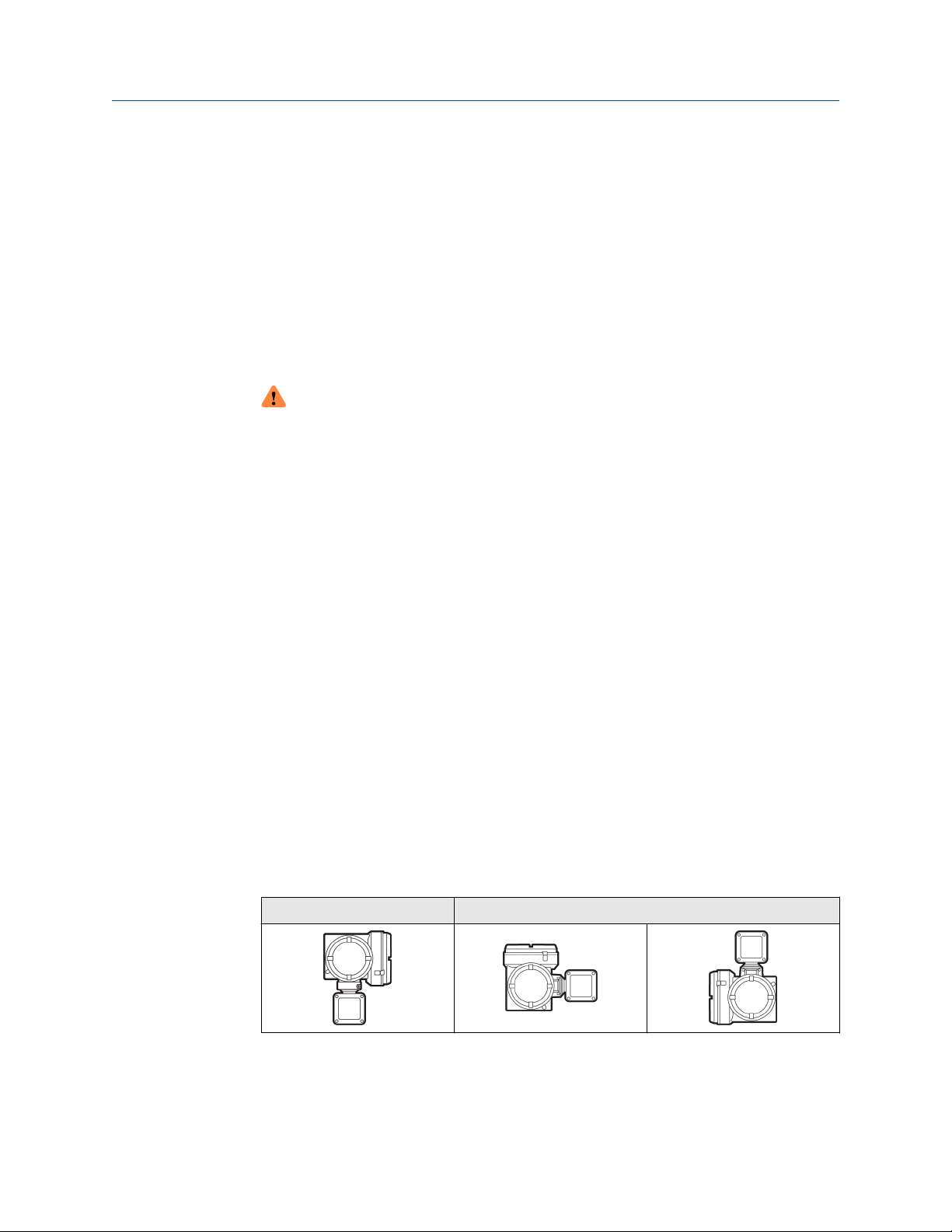

Cable type Wire gauge Maximum length

Micro Motion 4-wire remote

mount

Micro Motion 9-wire remote

mount

User-supplied 4-wire VDC 22 AWG (0.326 mm²) 300 ft (91 m)

Not applicable • 1,000 ft (305 m) without

Ex-approval

• 500 ft (152 m) with IIC

rated sensors

• 1,000 ft (305 m) with IIB

rated sensors

Not applicable 60 ft (18 m)

VDC 20 AWG (0.518 mm²) 500 ft (152 m)

VDC 18 AWG (0.823 mm²) 1,000 ft (305 m)

RS-485 22 AWG (0.326 mm²)

or larger

1,000 ft (305 m)

10 Micro Motion 5700 Transmitters with Configurable Inputs and Outputs

Page 11

Installation Manual Mounting and sensor wiring

MMI-20027478 September 2020

3 Mounting and sensor wiring

3.1 Mounting and sensor wiring for integralmount transmitters

There are no separate mounting requirements for integral transmitters, and no need to

connect wiring between the transmitter and the sensor.

3.2 Mounting transmitters

There are two options available for mounting transmitters:

• Mount the transmitter to a wall or flat surface.

• Mount the transmitter to an instrument pole.

3.2.1

Mounting the transmitter to a wall or flat surface

Prerequisites

• Micro Motion recommends 5/16-18 (8 mm–1.25) fasteners that can withstand the

process environment. Micro Motion does not supply bolts or nuts as part of the

standard offering (general purpose bolts and nuts are available as an option).

• Ensure that the surface is flat and rigid, does not vibrate, or move excessively.

• Confirm that you have the necessary tools, and the mounting kit shipped with the

transmitter.

Procedure

1. Attach the mounting bracket to the transmitter and tighten the screws to 80 in lbf

(9.04 N m) to 90 in lbf (10.17 N m).

Installation Manual 11

Page 12

Mounting and sensor wiring Installation Manual

September 2020 MMI-20027478

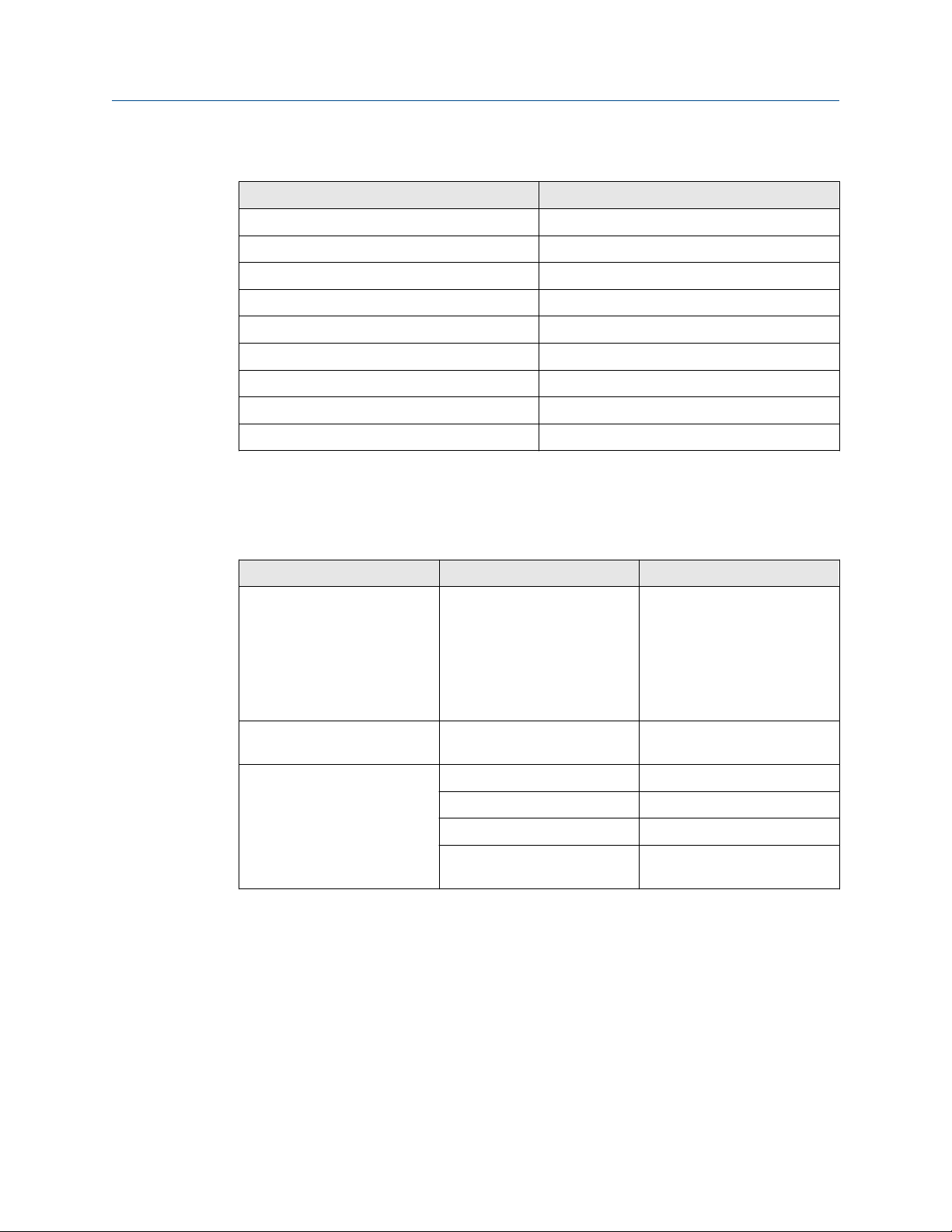

Figure 3-1: Mounting bracket to an aluminum transmitter

Figure 3-2: Mounting bracket to a stainless steel transmitter

2. For wall-mount installations, secure the mounting bracket to the prepared surface.

12 Micro Motion 5700 Transmitters with Configurable Inputs and Outputs

Page 13

Installation Manual Mounting and sensor wiring

MMI-20027478 September 2020

Figure 3-3: Wall-mounting bracket and dimensions for an aluminum

transmitter

A. 2.8 in (71 mm)

B. 2.8 in (71 mm)

Figure 3-4: Wall-mounting bracket and dimensions for a stainless steel

transmitter

A. 7.51 in (190.8 mm)

B. 3.67 in (93.2 mm)

Installation Manual 13

Page 14

Mounting and sensor wiring Installation Manual

September 2020 MMI-20027478

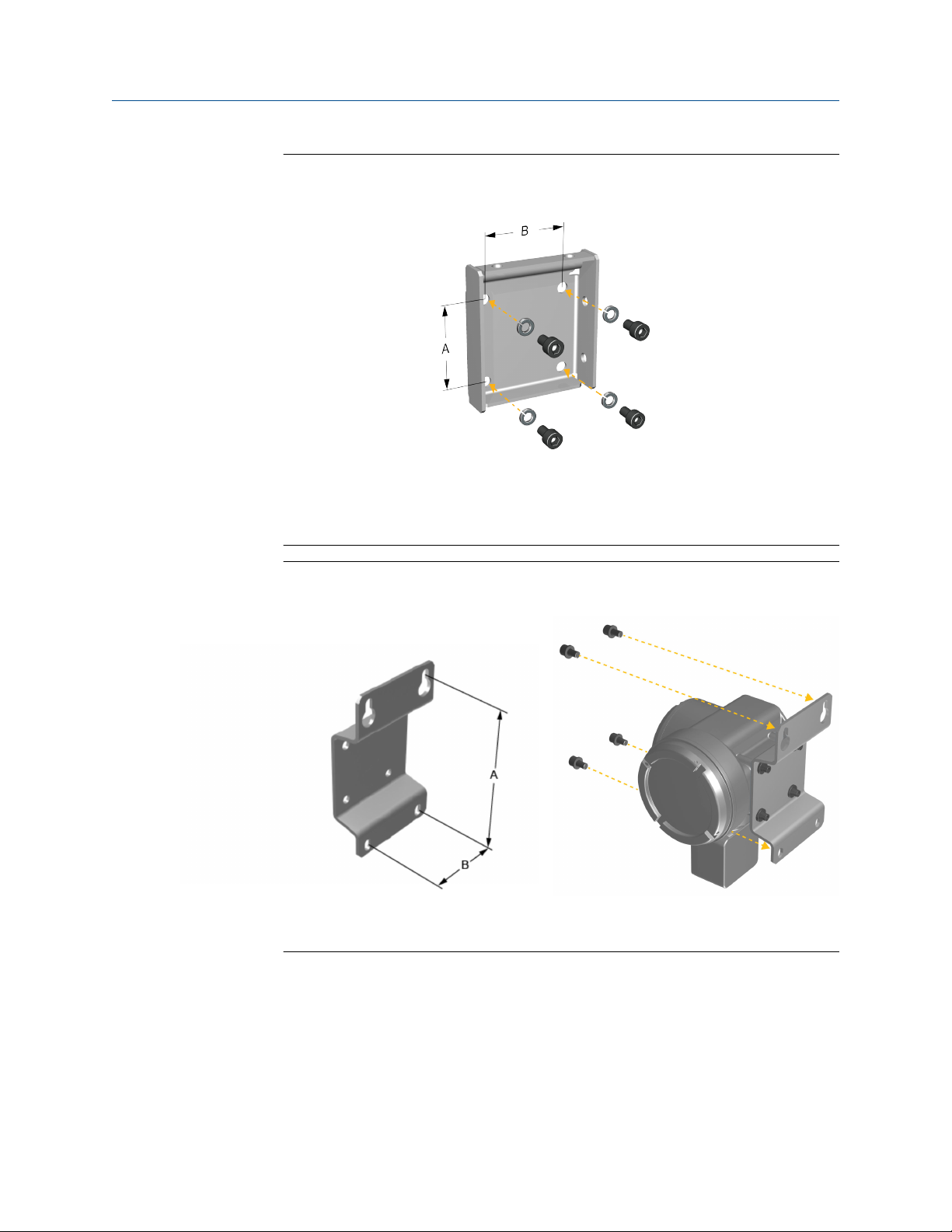

3. For aluminum transmitters, place and attach the transmitter-mounting bracket to

the mounting bracket secured to the wall or instrument pole.

Figure 3-5: Attaching and securing an aluminum transmitter to the mounting

bracket

3.2.2

Tip

To ensure the mounting bracket holes are aligned, insert all attachment bolts into

place before tightening.

Mount the transmitter to a pole

Prerequisites

• Ensure that the instrument pole extends at least 12 in (305 mm) from a rigid base and

is no more than 2 in (51 mm) in diameter.

• Confirm that you have the necessary tools, and the instrument-pole mounting kit

shipped with the transmitter.

Procedure

For pole-mount installations, attach the U-bolt mounting piece to the instrument pole.

14 Micro Motion 5700 Transmitters with Configurable Inputs and Outputs

Page 15

Installation Manual Mounting and sensor wiring

MMI-20027478 September 2020

Figure 3-6: Pole-mounting bracket attachment for an aluminum transmitter

Figure 3-7: Pole-mounting bracket attachment for a stainless steel transmitter

3.3 Wire a remote-mount transmitter to the sensor

Use this procedure to wire a 4-wire or 9-wire remote-mount transmitter to the sensor.

Prerequisites

• Prepare the 4-wire cable as described in the sensor documentation.

Installation Manual 15

Page 16

Mounting and sensor wiring Installation Manual

September 2020 MMI-20027478

• Prepare the 9-wire cable as described in the Micro Motion 9-Wire Flow Meter Cable

Preparation and Installation Guide.

• Connect the cable to the sensor-mounted core processor or junction box as described

in the sensor documentation. You can access all product documentation on the

documentation DVD shipped with the product or at www.emerson.com.

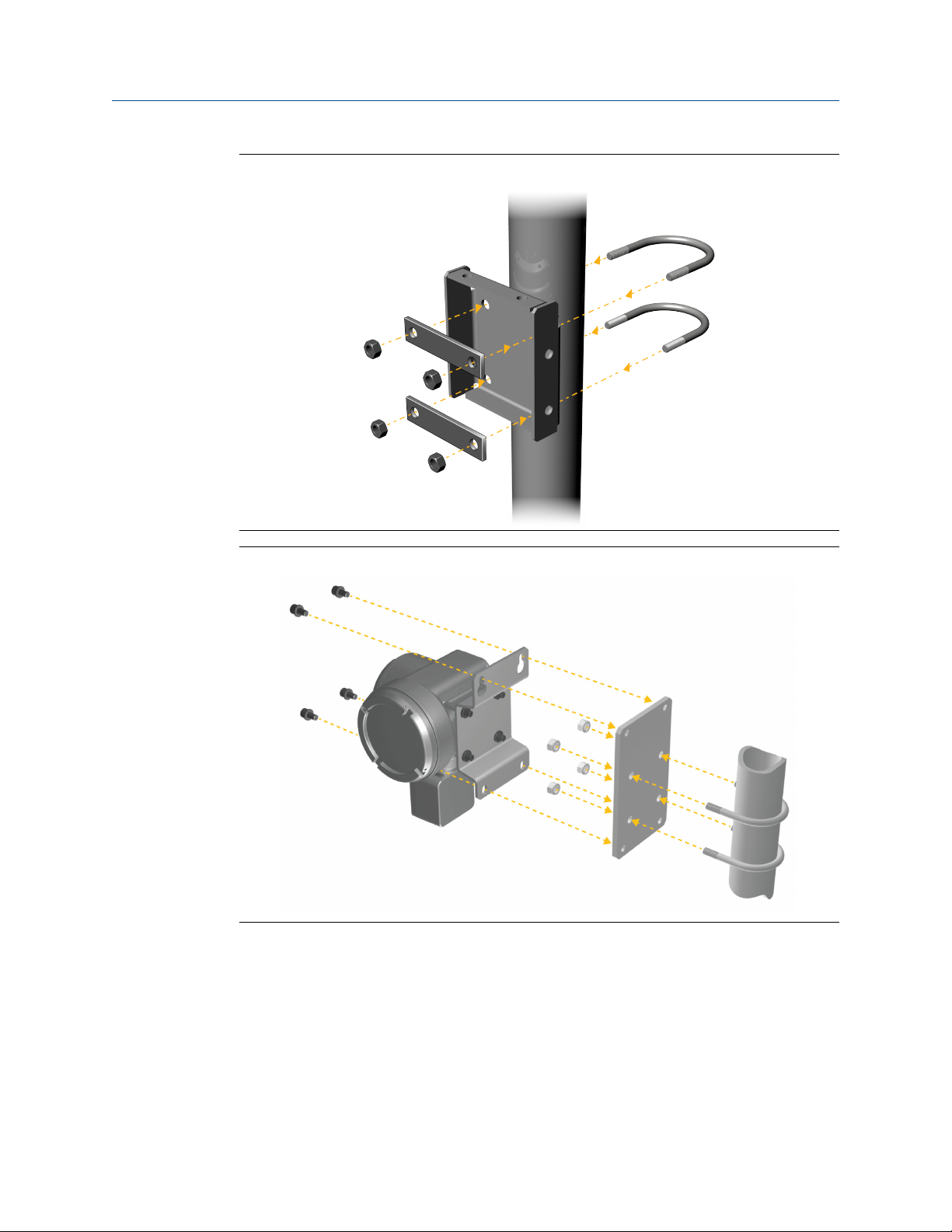

Procedure

1. Remove the transmitter-to-sensor wiring compartment cover to reveal the terminal

connections.

Figure 3-8: Removal of the transmitter-to-sensor wiring compartment cover

2. Feed the sensor wiring cable into the transmitter wiring compartment.

Figure 3-9: Sensor wiring feedthrough

3. Connect the sensor wires to the appropriate terminals.

16 Micro Motion 5700 Transmitters with Configurable Inputs and Outputs

Page 17

Installation Manual Mounting and sensor wiring

MMI-20027478 September 2020

Important

Terminate the 4-wire cable drain wires only at the sensor/core processor end of the

cable. See the sensor installation manual for more detail. Do not connect the 4-wire

cable drain wires to the ground screw located inside the 5700 junction box.

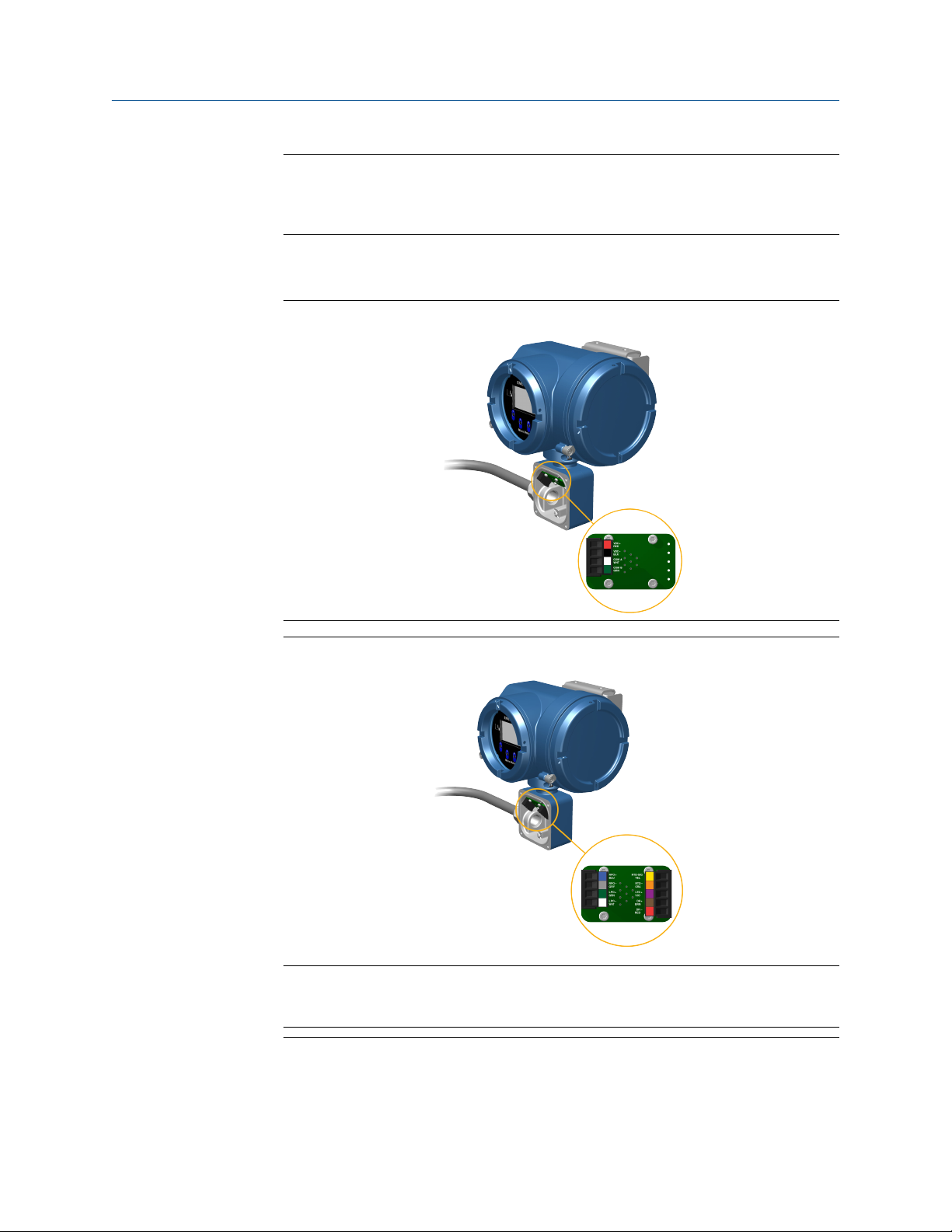

• See Figure 3-10 for 4-wire terminal connections.

• See Figure 3-11 for 9-wire terminal connections.

Figure 3-10: 4-wire transmitter-to-sensor wiring connections

Figure 3-11: 9-wire transmitter-to-sensor wiring connections

Note

Connect the 4 drain wires in the 9-wire cable to the ground screw located inside the

junction box.

4. Replace the transmitter-to-sensor wiring compartment cover and tighten the

screws to 14 in lbf (1.58 N m) to 15 in lbf (1.69 N m).

Installation Manual 17

Page 18

Mounting and sensor wiring Installation Manual

September 2020 MMI-20027478

3.4 Ground the meter components

In 4-wire or 9-wire remote installations, the transmitter and sensor are grounded

separately.

Prerequisites

NOTICE

Improper grounding could cause inaccurate measurements or meter failure.

WARNING

Failure to comply with requirements for intrinsic safety in a hazardous area could result

in an explosion causing death or serious injury.

Note

For hazardous area installations in Europe, refer to standard EN 60079-14 or national

standards.

If national standards are not in effect, adhere to the following guidelines for grounding:

• Use copper wire, 14 AWG (2.08 mm2) or larger wire size.

• Keep all ground leads as short as possible, less than 1 Ω impedance.

• Connect ground leads directly to earth, or follow plant standards.

Procedure

1. Ground the sensor according to the instructions in the sensor documentation.

2. Ground the transmitter according to applicable local standards, using the

transmitter’s internal or external ground screw.

• The earth ground terminal is located inside the power wiring compartment.

• The external ground screw is located on the side of the transmitter located

below the transmitter tag.

18 Micro Motion 5700 Transmitters with Configurable Inputs and Outputs

Page 19

Installation Manual Mounting and sensor wiring

MMI-20027478 September 2020

3.5 Rotate the transmitter on the sensor (optional)

In integral installations, you can rotate the transmitter on the sensor up to 360º in 45º

increments.

Procedure

1. Using a 4 mm hex key, loosen and remove the clamp securing the transmitter head

in place.

Figure 3-12: Removal of the sensor clamp

2. Gently lift the transmitter straight up, and rotate the transmitter to the desired

position.

You can rotate the transmitter to any of the eight positions, but a stop exists that

will not allow a full 360° rotation.

Figure 3-13: Rotation of the transmitter head

3. Gently lower the transmitter onto the base, confirming that the transmitter is in a

locked position.

Installation Manual 19

Page 20

Mounting and sensor wiring Installation Manual

September 2020 MMI-20027478

4. Replace the clamp in its original position and tighten the cap screw. Torque to 28 in

lbf (3.16 N m) to 30 in lbf (3.39 N m).

Figure 3-14: Re-attachment of the sensor clamp

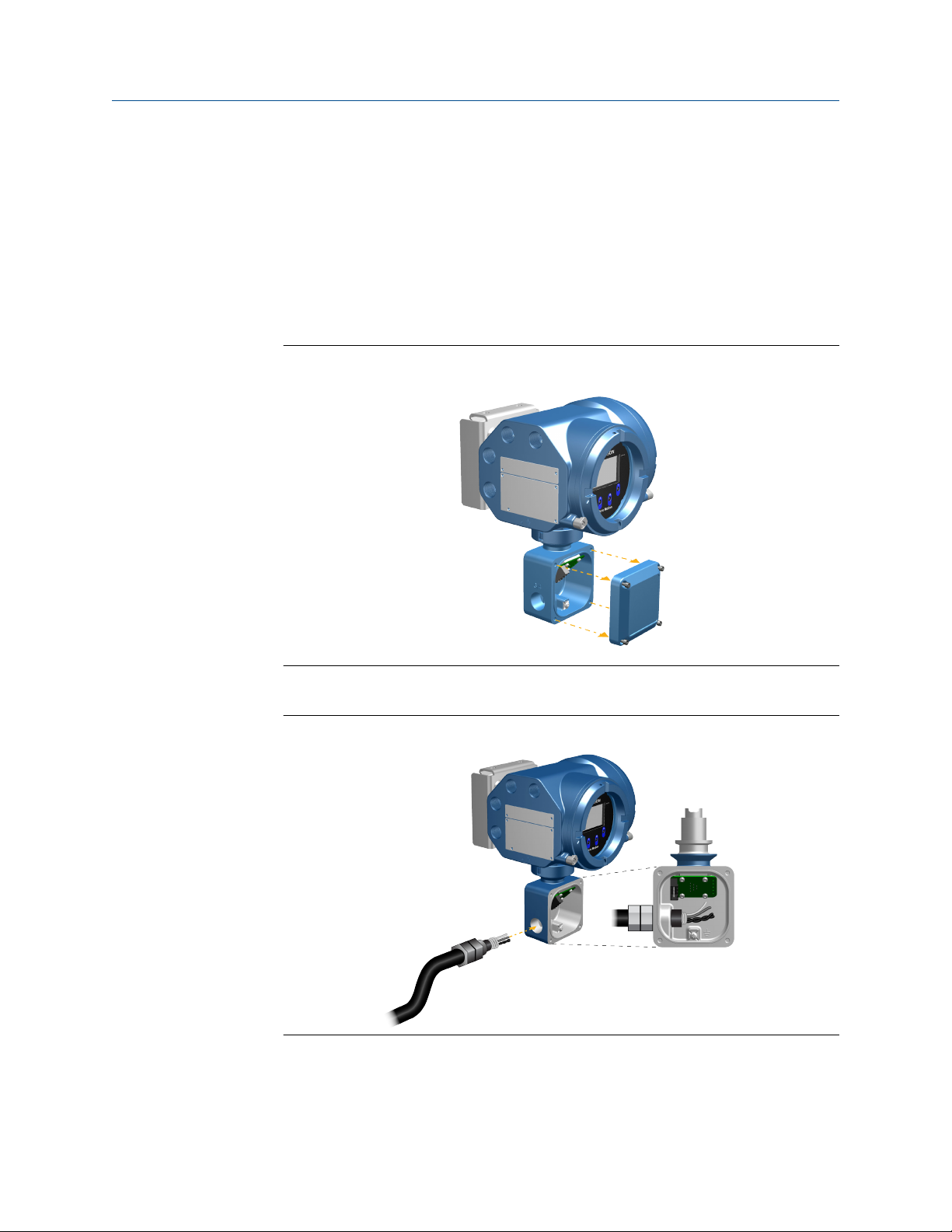

3.6 Rotate the user interface on the transmitter (optional)

The user interface on the transmitter electronics module can be rotated 90°, 180°, or 270°

from the original position.

Figure 3-15: Display components

A. Transmitter housing

B. Sub-bezel

C. Display module

D. Display screws

E. End-cap clamp

F. Cap screw

G. Display cover

20 Micro Motion 5700 Transmitters with Configurable Inputs and Outputs

Page 21

Installation Manual Mounting and sensor wiring

MMI-20027478 September 2020

Procedure

1. Shut off power to the unit.

WARNING

If the transmitter is in a hazardous area, wait five minutes after disconnecting the

power. Failure to do so could result in an explosion causing death or injury.

2. Loosen and rotate the end cap clamp so that it does not interfere with the cover.

3. Turn the display cover counterclockwise to remove it from the main enclosure.

4. Carefully loosen the captive display screws while holding the display module in

place.

5. Carefully pull the display module out of the main enclosure.

6. Rotate the display module to the desired position.

7. Gently press the display module back onto the connector.

8. Tighten display screws.

9. Place the display cover onto the main enclosure.

10. Turn the display cover clockwise until it is fully seated.

11. Replace the end-cap clamp by tightening the cap screw.

12. Restore power to the transmitter.

3.7 Rotate the sensor wiring junction box on a remote-mount transmitter (optional)

In remote-mount installations, you can rotate the sensor wiring junction box on the

transmitter plus or minus 180º.

Procedure

1. Using a 4 mm hex key, loosen and remove the clamp securing the sensor wiring

junction box in place.

Figure 3-16: Removal of the clamp

2. Gently rotate the junction box to the desired position.

Installation Manual 21

Page 22

Mounting and sensor wiring Installation Manual

September 2020 MMI-20027478

You can rotate the junction box plus or minus 180º to any position.

Figure 3-17: Rotation of the sensor wiring junction box

3. Gently set the junction box into its new position, confirming that the position is

locked.

4. Replace the clamp in its original position and tighten the cap screw. Torque to 28 in

lbf (3.16 N m) to 30 in lbf (3.39 N m).

Figure 3-18: Re-attachment of the clamp

22 Micro Motion 5700 Transmitters with Configurable Inputs and Outputs

Page 23

Installation Manual Wiring the channels

MMI-20027478 September 2020

4 Wiring the channels

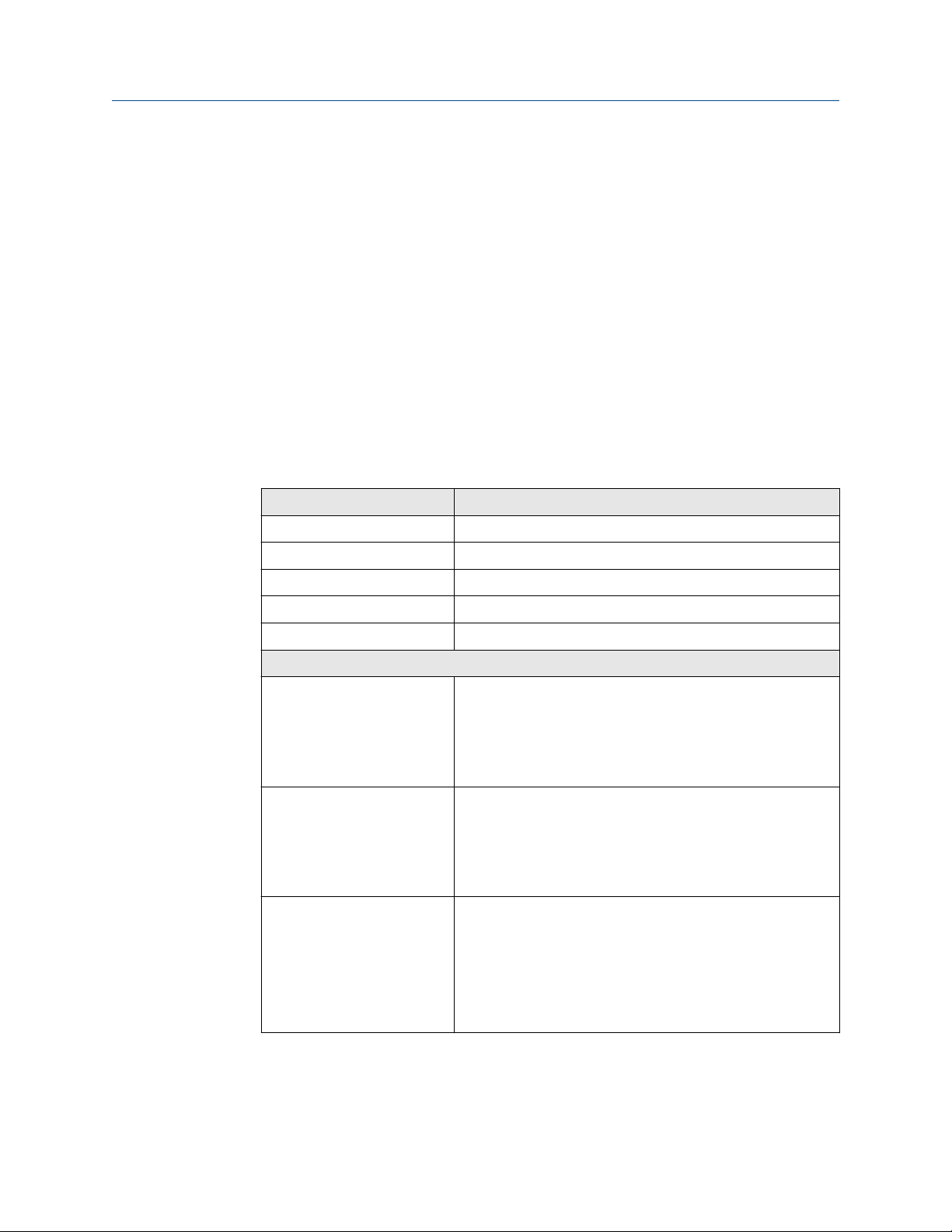

4.1 Available channels

Signal Channel A Channel B Channel C Channel D Channel E

Wiring

terminals

mA Inputs

and Outputs

Frequency

Outputs

Discrete

Outputs

Discrete

Inputs

Frequency

Inputs

(1) Frequency Output 2 can be mapped to Channel B or D. For multiple Frequency Outputs, use Frequency 1 on Channel C

and Frequency 2 on either Channel B or D.

1 2 3 4 5 6 7 8 9 10

mA Output 1

(HART)

mA Output 2 mA Output 3 mA Input RS-485

Frequency Output

(1)

2

Discrete Output 1 Discrete Output 2 Discrete Output 3

Frequency Output1Frequency Output

Discrete Input 1 Discrete Input 2

(1)

2

Frequency Input

4.2 Access the wiring channels

Procedure

1. Remove the wiring access cover to reveal the I/O wiring terminal block connectors.

Installation Manual 23

Page 24

A

Wiring the channels Installation Manual

September 2020 MMI-20027478

2. Confirm which transmitter channels are activated, or ON, and identify the type of

configuration you will be wiring to based on the options available.

Figure 4-1: Activated channel identification

A. Key to identify the activated input/outputs

3. Record the channel and wiring configuration on the label provided inside the

transmitter housing cover.

Figure 4-2: Channel and wiring configurations label

4.3 Wire the mA Output

Use this section to wire the mA Output in explosion-proof, nonincendive, or nonhazardous

installations.

Important

Meter installation and wiring should be performed only by suitably-trained personnel.

4.3.1

24 Micro Motion 5700 Transmitters with Configurable Inputs and Outputs

Wire the mA Output (internally powered)

Procedure

Wire to the appropriate output terminal and pins.

Page 25

A

D

C

B

A

E

D

C

B

Installation Manual Wiring the channels

MMI-20027478 September 2020

Figure 4-3: mA Output wiring (internally powered)

A. mA Output

B. Channel A, B, or C

C. 820 Ω maximum loop resistance

D. Signal device

4.3.2

Wire the mA Output (externally powered)

Procedure

Wire to the appropriate output terminal and pins.

Figure 4-4: mA Output wiring (externally powered)

A. mA Output

B. Channel A, B, or C

C. 5–30 VDC (maximum)

D. See Figure 4-5 for maximum loop resistance

E. Signal device

Installation Manual 25

Page 26

0

100

200

300

400

500

600

700

800

900

1000

1100

0 7.5 15.0 22.5 30.0

B

A

A

1

2

C

B

Wiring the channels Installation Manual

September 2020 MMI-20027478

Figure 4-5: Externally-powered mA Output: maximum loop resistance

A. Maximum resistance (Ω)

B. External supply voltage (V)

4.4 Wire the mA/HART Output

Use this section to wire the mA/HART Output in explosion-proof, nonincendive, or

nonhazardous installations.

Important

Meter installation and wiring should be performed only by suitably-trained personnel.

4.4.1

26 Micro Motion 5700 Transmitters with Configurable Inputs and Outputs

Wire the mA/HART Output (internally powered)

Procedure

Wire to the appropriate output terminal and pins.

Figure 4-6: mA/HART Output wiring (internally powered)

A. mA/HART Output

B. 250–600 Ω resistance

C. HART device

Page 27

A

1

2

D

C

B

0

100

200

300

400

500

600

700

800

900

1000

1100

0 7.5 15.0 22.5 30.0

B

A

Installation Manual Wiring the channels

MMI-20027478 September 2020

4.4.2 Wire the mA/HART Output (externally powered)

Procedure

Wire to the appropriate output terminal and pins.

Figure 4-7: mA/HART Output wiring (externally powered)

A. mA/HART Output

B. 5–30 VDC (maximum)

C. 250–600 Ω resistance (see Figure 4-8 for maximum loop resistance)

D. HART device

Figure 4-8: Externally-powered mA/HART Output: maximum loop resistance

A. Maximum resistance (Ω)

B. External supply voltage (V)

4.4.3

Installation Manual 27

Wire the mA/HART multidrop installation (internally or externally powered)

Procedure

See the following figure for information on wiring a mA/HART multidrop installation.

Page 28

B

A

C

E

D

F

I give up

Wiring the channels Installation Manual

September 2020 MMI-20027478

Figure 4-9: mA/HART multidrop wiring

A. 250–600 Ω resistance

B. HART-compatible host or controller

C. HART-compatible transmitter (internally powered)

D. 5700 transmitter (internally powered) mA/HART connections

E. SMART FAMILY™ transmitters

F. 24 VDC loop power supply required for external transmitter

4.5 Wire the Frequency Output

Use this section to wire the Frequency Output in explosion-proof, nonincendive, or

nonhazardous installations.

Important

Meter installation and wiring should be performed only by suitably-trained personnel.

4.5.1

Wire the Frequency Output (internally powered)

Use this procedure to wire the internally-powered Frequency Output for Channel B or C.

Procedure

Wire to the appropriate output terminal and pins.

28 Micro Motion 5700 Transmitters with Configurable Inputs and Outputs

Page 29

A

D

C

B

0

2

4

6

8

10

12

14

16

18

20

22

24

0 250 500 750 1000

A

B

Installation Manual Wiring the channels

MMI-20027478 September 2020

Figure 4-10: Frequency Output wiring (internally powered)

A. Frequency Output

B. Channel B or C

C. See Figure 4-11for output amplitude versus load resistance

D. Counter

Figure 4-11: Internally powered Frequency Output: output amplitude versus load

resistance [24 VDC (Nom) open circuit]

4.5.2

Wire the Frequency Output (externally powered)

Use this procedure to wire the externally-powered Frequency Output for Channel B or C.

Procedure

Installation Manual 29

Wire to the appropriate output terminal and pins.

A. Output amplitude (V)

B. Load resistor (Ω)

Page 30

A

B

E

D

C

A

7

8

C

B

Wiring the channels Installation Manual

September 2020 MMI-20027478

Figure 4-12: Frequency Output wiring (externally powered)

A. Frequency Output

B. Channel B or C

C. 5–30 VDC (maximum)

D. Current Limiting Resistor. Chose resistor to limit current below 500mA (maximum).

Current= C (VDC)/ D (ohms).

E. Counter

4.5.3

Wire the Frequency Output (internally powered) (Channel D)

Procedure

Wire to the appropriate output terminal and pins.

Figure 4-13: Frequency output wiring (internally powered)

A. Frequency Output

B. See Figure 4-14 for output amplitude versus load resistance

C. Counter

30 Micro Motion 5700 Transmitters with Configurable Inputs and Outputs

Page 31

0

2

4

6

8

10

12

14

16

18

20

22

24

0 2500 5000 7500 10000

A

B

A

7

8

D

C

B

Installation Manual Wiring the channels

MMI-20027478 September 2020

Figure 4-14: Internally powered Frequency Output: output amplitude versus load

resistance [24 VDC (Nom) open circuit]

A. Output amplitude (V)

B. Load resistor (Ω)

4.5.4

Wire the Frequency Output (externally powered Channel D)

Procedure

Wire to the appropriate output terminal and pins.

Figure 4-15: Frequency Output wiring (externally powered)

A. Frequency Output

B. 3–30 VDC (maximum)

C. 500 mA current (maximum)

Installation Manual 31

D. Signal device

Page 32

A

D

C

B

0

2

4

6

8

10

12

14

16

18

20

22

24

0 750 1500 2250 3000

A

B

Wiring the channels Installation Manual

September 2020 MMI-20027478

4.6 Wire the Discrete Output

Use this section to wire the Discrete Output in explosion-proof, nonincendive, or

nonhazardous installations.

Important

Meter installation and wiring should be performed only by suitably-trained personnel.

4.6.1 Wire the Discrete Output (internally powered)

Use this procedure to wire the internally-powered Discrete Output for Channel B or C.

Procedure

Wire to the appropriate output terminal and pins.

Figure 4-16: Discrete Output wiring (internally powered)

A. Discrete Output

B. Channel B or C

C. See Figure 4-17 for output amplitude versus load resistance

D. Counter

Figure 4-17: Internally powered Discrete Output: output amplitude versus load

resistance [24 VDC (Nom) open circuit]

32 Micro Motion 5700 Transmitters with Configurable Inputs and Outputs

A. Output amplitude (V)

B. Load resistor (Ω)

Page 33

A

B

E

D

C

A

7

8

C

B

Installation Manual Wiring the channels

MMI-20027478 September 2020

4.6.2 Wire the Discrete Output (externally powered)

Use this procedure to wire the externally-powered Discrete Output for Channel B or C.

Procedure

Wire to the appropriate output terminal and pins.

Figure 4-18: Discrete Output wiring (externally powered)

A. Discrete Output

B. Channel B or C

C. 3–30 VDC (maximum)

D. 500 mA current (maximum)

E. Counter

4.6.3

Wire the Discrete Output (internally powered Channel D)

Procedure

Wire to the appropriate output terminal and pins.

Figure 4-19: Discrete Output wiring (internally powered)

A. Discrete Output

B. See Figure 4-20 for output amplitude versus load resistance

C. Counter

Installation Manual 33

Page 34

0

2

4

6

8

10

12

14

16

18

20

22

24

0 2500 5000 7500 10000

A

B

A

7

8

D

C

B

Wiring the channels Installation Manual

September 2020 MMI-20027478

Figure 4-20: Internally powered Discrete Output: output amplitude versus load

resistance [24 VDC (Nom) Open Circuit]

A. Output amplitude (V)

B. Load resistor (Ω)

4.6.4

Wire the Discrete Output (externally powered Channel D)

Procedure

Wire to the appropriate output terminal and pins.

Figure 4-21: Discrete Output wiring (externally powered)

A. Discrete Output

B. 3–30 VDC (maximum)

C. 500 mA current (maximum)

34 Micro Motion 5700 Transmitters with Configurable Inputs and Outputs

D. Signal device

Page 35

A

AA

B

9

10

B

C

A

7

8

C

B

Installation Manual Wiring the channels

MMI-20027478 September 2020

4.7 Wire the RS-485 output

Use this section to wire the RS-485 output in explosion-proof, nonincendive, or

nonhazardous installations.

Procedure

Wire to the appropriate output terminal and pins.

Figure 4-22: RS-485 output wiring

A. RS-485 output

B. RS-485/A

C. RS-485/B

Note

The transmitter does not provide any RS-485 termination resistance.

4.8 Wire the mA Input

Use this section to wire the mA Input in explosion-proof, nonincendive, or nonhazardous

installations.

Important

Meter installation and wiring should be performed only by suitably-trained personnel.

4.8.1

Wire the mA Input (internally powered)

Procedure

Wire to the appropriate input terminal and pins.

Figure 4-23: mA Input wiring (internally powered)

A. mA Input

B. 100 Ω input resistance at Channel D

C. 4–20 mA Input device

Installation Manual 35

Page 36

A

7

8

C

B

D

A

C

B

Wiring the channels Installation Manual

September 2020 MMI-20027478

4.8.2 Wire the mA Input (externally powered)

Procedure

Wire to the appropriate input terminal and pins.

Figure 4-24: mA Input wiring (externally powered)

A. mA Input

B. 100 Ω input resistance at Channel D

C. 4–20 mA Input device

D. 30 VDC (maximum)

4.9 Wire the Discrete Input

Use this section to wire the Discrete Input in explosion-proof, nonincendive, or

nonhazardous installations.

Important

Meter installation and wiring should be performed only by suitably-trained personnel.

4.9.1

Wire the Discrete Input (internally powered)

Procedure

Wire to the appropriate input terminal and pins.

Figure 4-25: Discrete Input wiring (internally powered)

A. Discrete Input

B. Channel C or D

C. Switch

36 Micro Motion 5700 Transmitters with Configurable Inputs and Outputs

Page 37

A

C

B

A

D

B

C

7

8

Installation Manual Wiring the channels

MMI-20027478 September 2020

4.9.2 Wire the Discrete Input (externally powered)

Procedure

Wire to the appropriate input terminal and pins.

Figure 4-26: Discrete Input wiring (externally powered)

A. Discrete Input

B. Channel C or D

C. 30 VDC (maximum)

Note

• Maximum positive threshold is 3 VDC.

• Minimum negative threshold is 0.6 VDC.

4.10 Wire the Frequency Input

Use this section to wire the Frequency Input in explosion-proof, nonincendive, or

nonhazardous installations.

Important

Meter installation and wiring should be performed only by suitably-trained personnel.

4.10.1

Wire the Frequency Input (internally powered)

Procedure

Wire to the appropriate input terminal and pins.

Figure 4-27: Frequency Input wiring (internally powered)

A. Frequency Input

B. Frequency Input device

C. (Optional) 1–10 KΩ resistor/open collector

D. (Optional) 3–30 VDC

Installation Manual 37

Page 38

A

D

B

C

7

8

Wiring the channels Installation Manual

September 2020 MMI-20027478

4.10.2 Wire the Frequency Input (externally powered)

Procedure

Wire to the appropriate input terminal and pins.

Figure 4-28: Frequency Input wiring (externally powered)

A. Frequency Input

B. Frequency Input device

C. 1–10 KΩ resistance

D. 3–30 VDC

4.11 Wire Channels A and D for SIS applications

Use this procedure to wire Channels A and D for Safety Instrumented Systems (SIS)

applications.

Procedure

Use one of the following power options:

• Channel A active (internal) power and Channel D passive (external) power

• Channel A passive (external) power and Channel D passive (external) power

38 Micro Motion 5700 Transmitters with Configurable Inputs and Outputs

Page 39

Installation Manual Wiring the channels

MMI-20027478 September 2020

Figure 4-29: Channel A active (internal) and Channel D passive (external) power

A. Channel A mA Output

B. Channel D mA Input

C. Terminals

D. 820 ohm maximum loop resistance including 100 ohms (H) for mA Input (250–600 ohm

for HART communications)

E. Signal device

F. Terminal compartment

G. External to the 5700

H. 100 ohm input resistance

Installation Manual 39

Page 40

0

100

200

300

400

500

600

700

800

900

1000

1100

0 7.5 15.0 22.5 30.0

B

A

Wiring the channels Installation Manual

September 2020 MMI-20027478

Figure 4-30: Channel A passive (external) and Channel D passive (external) power

A. Channel A mA Output

B. Channel D mA Input

C. Terminals

D. Maximum loop resistance including 100 ohms (I) for mA Input — see Figure 4-31.

E. Signal device

F. 5–30 VDC (maximum)

G. Terminal compartment

H. External to the 5700

I. 100 ohm input resistance

Figure 4-31: Externally-powered mA/HART output: maximum loop resistance

40 Micro Motion 5700 Transmitters with Configurable Inputs and Outputs

A. Maximum resistance (Ω)

B. External supply voltage (V)

Page 41

Installation Manual Wiring the channels

MMI-20027478 September 2020

Note

The calculation for loop resistance must include 100 ohms for the mA Input.

Postrequisites

To configure your system for SIS applications, see the Coriolis Flow Meter with Micro Motion

Model 5700 Transmitters Safety Manual for Safety Instrumented Systems (SIS) and the Micro

Motion 5700 Transmitters with Configurable Inputs and Outputs: Configuration and Use

Manual.

Installation Manual 41

Page 42

Wiring the channels Installation Manual

September 2020 MMI-20027478

42 Micro Motion 5700 Transmitters with Configurable Inputs and Outputs

Page 43

Installation Manual Wiring the power supply

MMI-20027478 September 2020

5 Wiring the power supply

You can install a user-supplied switch in the power supply line.

Important

For compliance with the Low Voltage Directive 2014/35/EU (European installations), verify

that the transmitter is located in close proximity to a switch.

Procedure

1. Remove the wiring access cover.

2. Open the Power warning flap to locate the power terminals.

Figure 5-1: Location of power supply wiring terminals and equipment ground

A. Power supply wiring terminals (+ and -)

B. Equipment ground

3. Connect the power supply wires:

• For DC power: connect to terminals + and –.

• For AC power: connect to terminals L/L1 (line) and N/L2 (neutral).

4. Tighten the two screws holding the power connector in place.

5. Ground the power supply using the equipment ground, also under the Power

warning flap.

Installation Manual 43

Page 44

Wiring the power supply Installation Manual

September 2020 MMI-20027478

44 Micro Motion 5700 Transmitters with Configurable Inputs and Outputs

Page 45

Installation Manual Wire the printer

MMI-20027478 September 2020

6 Wire the printer

For configurations that will use tickets, wire a printer to the 5700.

Procedure

Wire the RS232-RS485 adapter terminals to the 5700 terminals.

Converter Terminals

K2 ADE • Wire the K2 ADE terminal 1 to Channel E, RS-485B, terminal

10

• Wire the K2 ADE terminal 2 to Channel E, RS-485A, terminal 9

K2 • Wire the K2 terminal 3 to Channel E, RS-485B, terminal 10

• Wire the K2 terminal 4 to Channel E, RS-485A, terminal 9

Figure 6-1: Wiring between the K2 terminals to the 5700 terminals

A. Transmitter with end-cap removed

Important

For a K2 ADE converter, use terminals 1 and 2 on the converter.

For more information, see RS485/RS232 adapter instructions supplied by the

manufacturer.

Installation Manual 45

Page 46

Wire the printer Installation Manual

September 2020 MMI-20027478

46 Micro Motion 5700 Transmitters with Configurable Inputs and Outputs

Page 47

Installation Manual Power up the transmitter

MMI-20027478 September 2020

7 Power up the transmitter

The transmitter must be powered up for all configuration and commissioning tasks, or for

process measurement.

Procedure

1. WARNING

If the transmitter is in a hazardous area, do not remove the housing cover while

the transmitter is powered up. Failure to follow these instructions can cause an

explosion resulting in injury or death.

Ensure that all transmitter and sensor covers and seals are closed.

2. Turn on the electrical power at the power supply.

The transmitter will automatically perform diagnostic routines. The transmitter is

self-switching and will automatically detect the supply voltage. When using DC

power, a minimum of 1.5 amps of startup current is required. During this period,

Alert 009 is active. The diagnostic routines should complete in approximately

30 seconds. The status LED will turn green and begin to flash when the startup

diagnostics are complete. If the status LED exhibits different behavior, an alert is

active.

Postrequisites

Although the sensor is ready to receive process fluid shortly after power-up, the

electronics can take up to 10 minutes to reach thermal equilibrium. Therefore, if this is the

initial startup, or if power has been off long enough to allow components to reach ambient

temperature, allow the electronics to warm up for approximately 10 minutes before

relying on process measurements. During this warm-up period, you may observe minor

measurement instability or inaccuracy.

Installation Manual 47

Page 48

Power up the transmitter Installation Manual

September 2020 MMI-20027478

48 Micro Motion 5700 Transmitters with Configurable Inputs and Outputs

Page 49

Installation Manual Configuring the transmitter with Guided Setup

MMI-20027478 September 2020

8 Configuring the transmitter with

Guided Setup

At initial startup of the transmitter, the guided configuration screen appears on the

transmitter display. This tool guides you through basic configuration of the transmitter.

The guided setup allows you to upload configuration files, set the transmitter display

options, configure channels, and review sensor calibration data.

Procedure

To access the guided setup screen from the display main menu, go to: Startup Tasks →

Guided Setup.

Installation Manual 49

Page 50

Configuring the transmitter with Guided Setup Installation Manual

September 2020 MMI-20027478

50 Micro Motion 5700 Transmitters with Configurable Inputs and Outputs

Page 51

Installation Manual Using the display controls

MMI-20027478 September 2020

9 Using the display controls

The transmitter display interface includes a display (LCD panel) and four optical switches –

left, up, down, and right arrow keys – used to access the display menus and navigate the

display screens.

Procedure

1. To activate an optical switch, block the light by holding your thumb or finger in

front of the opening.

You can activate the optical switch through the lens. Do not remove the transmitter

housing cover.

Important

The transmitter only detects one switch selection at a time. Be sure to place your

thumb or finger directly over a single optical switch, and ensure no other switches

are being obstructed.

Figure 9-1: Proper finger positioning for activating an optical switch

2. Use the arrow indicators on the display screen to identify which optical switch to

use to navigate the screen (see examples 1 and 2).

Important

When using the arrow keys, you must first activate the optical switch then release

the same switch by removing your finger from the glass to move up, down, right,

left or to make a selection. To enable auto-scroll when navigating up or down,

activate the appropriate switch and continue to hold for one second. Release the

switch when the desired selection is highlighted.

Installation Manual 51

Page 52

Using the display controls Installation Manual

September 2020 MMI-20027478

Figure 9-2: Example 1: Active arrow indicators on the transmitter display

Figure 9-3: Example 2: Active arrow indicators on the transmitter display

52 Micro Motion 5700 Transmitters with Configurable Inputs and Outputs

Page 53

Installation Manual Available service port connection

MMI-20027478 September 2020

10 Available service port connection

Use the service port connection to download or upload data from/to the transmitter.

To access the service port, you can use commonly-available USB hardware, such as a USB

drive, or USB cable.

WARNING

If the transmitter is in a hazardous area, do not remove the housing cover while the

transmitter is powered up. Failure to follow these instructions can cause an explosion

resulting in injury or death.

The service port connection is located under the Service Port warning flap at the wiring

access points.

Installation Manual 53

Page 54

Available service port connection Installation Manual

September 2020 MMI-20027478

54 Micro Motion 5700 Transmitters with Configurable Inputs and Outputs

Page 55

F3

C A

IEC 127-2

J3

DISC

OUT 3

T5A 250V

C A

F1

C A

IEC 127-2

J1

J4

MODEL 3300/350 0

TERMINAL

CONNECTION

DS1

T5A 250V

K3 K2 K1

A B C

'

(

)

DISC

OUT 2

IEC 127-2

F2 T5A 250V

J2

DS2

DISC

OUT 1

DS3

1 2 3 4 5 6 7 8 9 10

A14

C18

C16

C14

Installation Manual Wire the 5700 to the 3100 transmitter

MMI-20027478 September 2020

A Wire the 5700 to the 3100

transmitter

Prerequisites

• Set up the transmitter channel configuration to DO before wiring.

• Use active high and internal power.

• Use wire size 24 AWG (0,25 mm2) to 16 AWG (1,5 mm2).

Procedure

Tie the three ground pins of the 5700 together and then land on A14 of the 3100. The

ground pins are even numbers: 4, 6, and 8.

Example (see the following figure): Use relay 1 (C) and 2 (B) with Channels B and C, then

connect terminal 2 and 4 together from 5700 and land on A14.

Figure A-1: 5700 to 3100 - screw-type or solder-tail connector

This graphic sets Channel B, configured as DO1, to relay 1. If a different channel is assigned

to DO, wire any DO to any relay.

A. Relay 3, DO 3 pins 6 and 7, C18

B. Relay 2, DO 2 pins 5 and 6, C16

C. Relay 1, DO 1 pins 3 and 4, C14

D. Channel D

E. Channel C

F. Channel B

Installation Manual 55

Page 56

*MMI-20027478*

MMI-20027478

Rev. AE

2020

Micro Motion Inc. USA

7070 Winchester Circle

Boulder, Colorado USA 80301

T +1 303-527-5200

T +1 800-522-6277

F +1 303-530-8459

www.emerson.com

Micro Motion Asia

Emerson Automation Solutions

1 Pandan Crescent

Singapore 128461

Republic of Singapore

T +65 6363-7766

F +65 6770-8003

©

2020 Micro Motion, Inc. All rights reserved.

The Emerson logo is a trademark and service mark of Emerson Electric Co. Micro Motion, ELITE,

ProLink, MVD and MVD Direct Connect marks are marks of one of the Emerson Automation

Solutions family of companies. All other marks are property of their respective owners.

Micro Motion Europe

Emerson Automation Solutions

Neonstraat 1

6718 WX Ede

The Netherlands

T +31 (0) 318 495 555

T +31 (0) 70 413 6666

F +31 (0) 318 495 556

www.emerson.com/nl-nl

Micro Motion United Kingdom

Emerson Automation Solutions

Emerson Process Management Limited

Horsfield Way

Bredbury Industrial Estate

Stockport SK6 2SU U.K.

T +44 0870 240 1978

F +44 0800 966 181

Loading...

Loading...