Page 1

Installation Manual

P/N 20001700, Rev. C

November 2007

Micro Motion

®

Model 1700 and

Model 2700 Transmitters

Installation Manual

Page 2

©2007, Micro Motion, Inc. All rights reserved. ELITE and ProLink are registered trademarks, and MVD and MVD Direct

Connect are trademarks of Micro Motion, Inc., Boulder, Colorado. Micro Motion is a registered trade name of Micro Motion,

Inc., Boulder, Colorado. The Micro Motion and Emerson logos are trademarks and service marks of Emerson Electric Co. All

other trademarks are property of their respective owners.

Page 3

Contents

Chapter 1 Before You Begin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.2 Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.3 Flowmeter components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1.4 Transmitter type, installation type, and outputs option board . . . . . . . . . . . . . . . . . . . 2

1.5 Transmitter installation procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.6 Flowmeter documentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.7 Micro Motion customer service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Chapter 2 Installing the Transmitter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.2 Installation architecture . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.3 Determining an appropriate location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.3.1 Environmental requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.3.2 Hazardous area classifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.3.3 Power source . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.3.4 Maximum cable lengths . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.3.5 Accessibility for maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.4 Mounting the transmitter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.4.1 Integral installations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2.4.2 4-wire remote or remote core processor with remote

transmitter installations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2.4.3 9-wire remote installations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

2.5 Mounting the remote core processor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

2.6 Grounding the flowmeter components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

2.7 Supplying power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

2.8 Rotating the display. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Chapter 3 Wiring the Transmitter to the Sensor. . . . . . . . . . . . . . . . . . . . . . . 19

3.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

3.2 Cable types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

3.2.1 4-wire cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

3.2.2 9-wire cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

3.3 Wiring for 4-wire remote installations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

3.4 Wiring for 9-wire remote installations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

3.5 Wiring for remote core processor with remote transmitter installations. . . . . . . . . . . 23

Chapter 4 Output Wiring – Model 1700/2700 Analog Transmitters . . . . . . . . . . 29

4.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

4.2 Output terminals and output types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

4.3 Output wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Installation Manual iii

Page 4

Contents

Chapter 5 Output Wiring – Model 1700/2700 Intrinsically Safe Transmitters . . . 33

5.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

5.2 Output terminals and output types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

5.3 Safe area output wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

5.3.1 Safe area mA output wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

5.3.2 Safe area frequency/discrete output wiring . . . . . . . . . . . . . . . . . . . . . . . 36

5.4 Hazardous area output wiring. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

5.4.1 Hazardous area safety parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

5.4.2 Hazardous area mA output wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

5.4.3 Hazardous area frequency/discrete output wiring . . . . . . . . . . . . . . . . . . 39

Chapter 6 Output Wiring – Model 2700 Configurable I/O Transmitters . . . . . . . 41

6.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

6.2 Channel configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

6.3 mA output wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

6.4 Frequency output wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

6.5 Discrete output wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

6.6 Discrete input wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Chapter 7 Output Wiring – Model 2700 FOUNDATION fieldbus and PROFIBUS-PA

Transmitters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

7.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

7.2 F

7.3 PROFIBUS-PA wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

OUNDATION fieldbus wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Appendix A Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

A.1 Functional specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

A.1.1 Electrical connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

A.1.2 Input/output signals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

A.1.3 Digital communication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

A.1.4 Power supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

A.1.5 Environmental requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

A.1.6 Ambient temperature effect . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

A.1.7 EMC compliance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

A.2 Hazardous area classifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

A.2.1 UL and CSA. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

A.2.2 ATEX and IECEx . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

A.3 Performance specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

A.4 Physical specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

A.4.1 Housing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

A.4.2 Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

A.4.3 Interface/display. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

A.4.4 Weight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

A.4.5 Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

iv Micro Motion® Model 1700 and 2700 Transmitters

Page 5

Chapter 1

WARNING

WARNING

CAUTION

Before You Begin

1.1 Overview

This chapter provides an orientation to the use of this manual. This manual describes the procedures

required to install the following Model 1700 and 2700 transmitters:

• Model 1700 or Model 2700 with analog outputs option board

• Model 1700 or Model 2700 with intrinsically safe analog outputs option board

• Model 2700 with configurable input/outputs option board

• Model 2700 with F

• Model 2700 with PROFIBUS-PA option board

If you do not know what transmitter you have, see Section 1.4 for instructions on identifying the

transmitter type from the model number on the transmitter’s tag.

Note: Installation information for Model 1500 transmitters or Model 2500 transmitters is provided in

a separate manual. See the manual for your transmitter.

OUNDATION fieldbus

™

option board

Installing the Transmitter Output Wiring – AnalogSensor WiringBefore You Begin

1.2 Safety

Safety messages are provided throughout this manual to protect personnel and equipment. Read each

safety message carefully before proceeding to the next step.

Improper installation in a hazardous area can cause an explosion.

For information about hazardous applications, refer to the approval documentation,

shipped with the transmitter or available from the Micro Motion web site.

Hazardous voltage can cause severe injury or death.

Make sure power is disconnected before installing transmitter.

Improper installation could cause measurement error or flowmeter failure.

Follow all instructions to ensure transmitter will operate correctly.

Installation Manual 1

Page 6

Before You Begin

1.3 Flowmeter components

The Model 1700 or 2700 transmitter is one component in your Micro Motion flowmeter. Other major

components include:

• The sensor, which provides measurement functions

• The core processor, which provides memory and processing functions

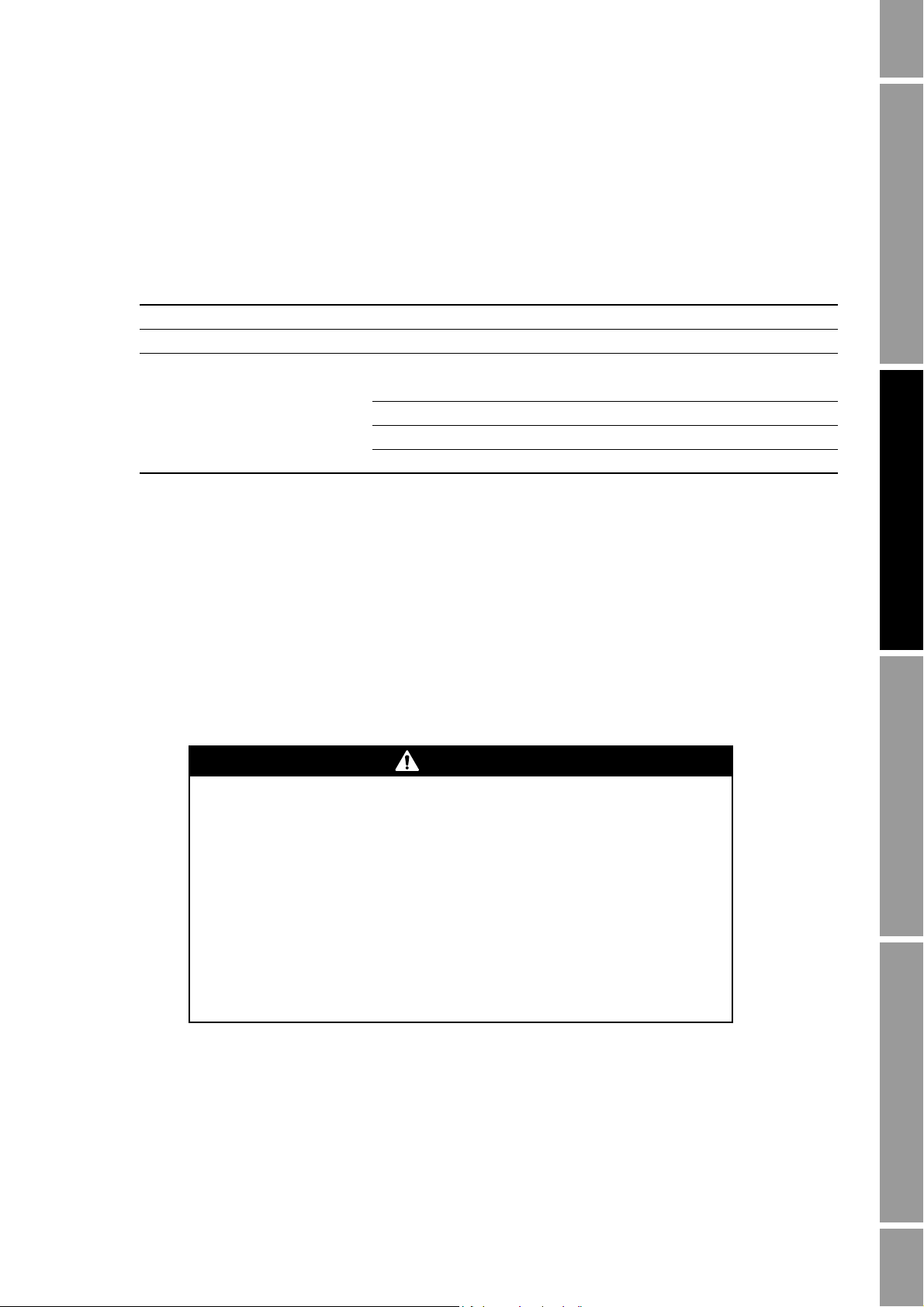

1.4 Transmitter type, installation type, and outputs option board

To install the transmitter, you must know your transmitter type, installation type, and outputs option

board. This section provides information on obtaining this information. The codes described below

match the codes that were used to order your transmitter.

1. Obtain the transmitter's model number, which is provided on a tag attached to the side of the

transmitter.

• Model 1700 transmitters have a model number of the form

1700xxxxxxxxxx.

• Model 2700 transmitters have a model number of the form

2. The fifth character in the model number (

xxxxXxxxxxxxxx) represents the installation type

that was ordered:

• R = remote (4-wire remote installation)

• I = integral (transmitter mounted on sensor)

• C = transmitter/core processor assembly (9-wire remote installation)

• B = remote core processor with remote transmitter

Note: For more information on installation type, see Figure 2-1.

3. The eighth character in the model number (

xxxxxxxXxxxxxx) represents the outputs option

board.

• A = transmitter with analog outputs option board (one mA, one frequency, one RS-485)

• B = transmitter with configurable input/outputs option board, default output configuration

(two mA, one frequency)

• C = transmitter with configurable input/outputs option board, customized output

configuration

• D = transmitter with intrinsically safe analog outputs option board

• E = transmitter with intrinsically safe (FISCO compliant) F

option board

• N = transmitter with non-incendive (FNICO compliant) F

option board

• G = transmitter with PROFIBUS-PA outputs option board

2700xxxxxxxxxx.

OUNDATION fieldbus outputs

OUNDATION fieldbus outputs

Note: The remaining characters in the model number describe options that do not affect transmitter

installation.

The following examples illustrate use of the model number to determine transmitter type, installation

type, and output board type:

•

1700RxxAxxxxxx = Model 1700 remote transmitter with analog outputs option board

•

2700CxxDxxxxxx = Model 2700 transmitter/core processor assembly with intrinsically safe

outputs option board

2 Micro Motion® Model 1700 and 2700 Transmitters

Page 7

Before You Begin

1.5 Transmitter installation procedures

To install the transmitter, the following procedures are required:

• Install the transmitter – see Chapter 2

• Wire the transmitter to the sensor – see Chapter 3

• Wire the transmitter outputs:

- For Model 1700 or 2700 analog outputs transmitters, see Chapter 4.

- For Model 1700 or 2700 intrinsically safe analog outputs transmitters, see Chapter 5.

- For Model 2700 configurable I/O transmitters, see Chapter 6.

- For Model 2700 F

Chapter 7.

1.6 Flowmeter documentation

Table 1-1 lists documentation sources for other required information. Documents can be obtained in

PDF form from the Micro Motion web site (www.micromotion.com/documentation).

Table 1-1 Flowmeter documentation resources

Topic Document

Sensor installation Installation manual shipped with sensor

Core processor installation (if mounted

remotely from sensor and transmitter)

Transmitter configuration, transmitter

startup and use, and transmitter

troubleshooting

OUNDATION fieldbus and PROFIBUS-PA outputs transmitters, see

This document

Series 1000 and 2000 Transmitter Configuration and

Use Manual

or

Model 2700 Transmitter with F

Installation and Operation Manual

or

Model 2700 Transmitter with PROFIBUS-PA

Installation and Operation Manual

OUNDATION Fieldbus

Installing the Transmitter Output Wiring – AnalogSensor WiringBefore You Begin

Installation Manual 3

Page 8

Before You Begin

1.7 Micro Motion customer service

For technical assistance, phone the Micro Motion Customer Service department:

• In the U.S.A., phone 800-522-MASS (800-522-6277) (toll free)

• In Canada and Latin America, phone +1 303-527-5200 (U.S.A.)

•In Asia:

- In Japan, phone 3 5769-6803

- In other locations, phone +65 6777-8211 (Singapore)

•In Europe:

- In the U.K., phone 0870 240 1978 (toll-free)

- In other locations, phone +31 (0) 318 495 555 (The Netherlands)

Customers outside the U.S.A. can also email Micro Motion customer service at

International.MMISupport@EmersonProcess.com.

4 Micro Motion® Model 1700 and 2700 Transmitters

Page 9

Chapter 2

Installing the Transmitter

2.1 Overview

This chapter describes how to install Micro Motion Model 1700 and 2700 transmitters. The following

general steps are required:

• Determine the location of the transmitter and other flowmeter components (see Section 2.3)

• Mount the transmitter (see Section 2.4)

• Mount the core processor, if required (see Section 2.5)

• Ground the flowmeter components (see Section 2.6)

• Supply power to the flowmeter (see Section 2.7)

• Rotate the display, if desired and the transmitter has a display (see Section 2.8)

Installing the Transmitter Output Wiring – AnalogSensor WiringBefore You Begin

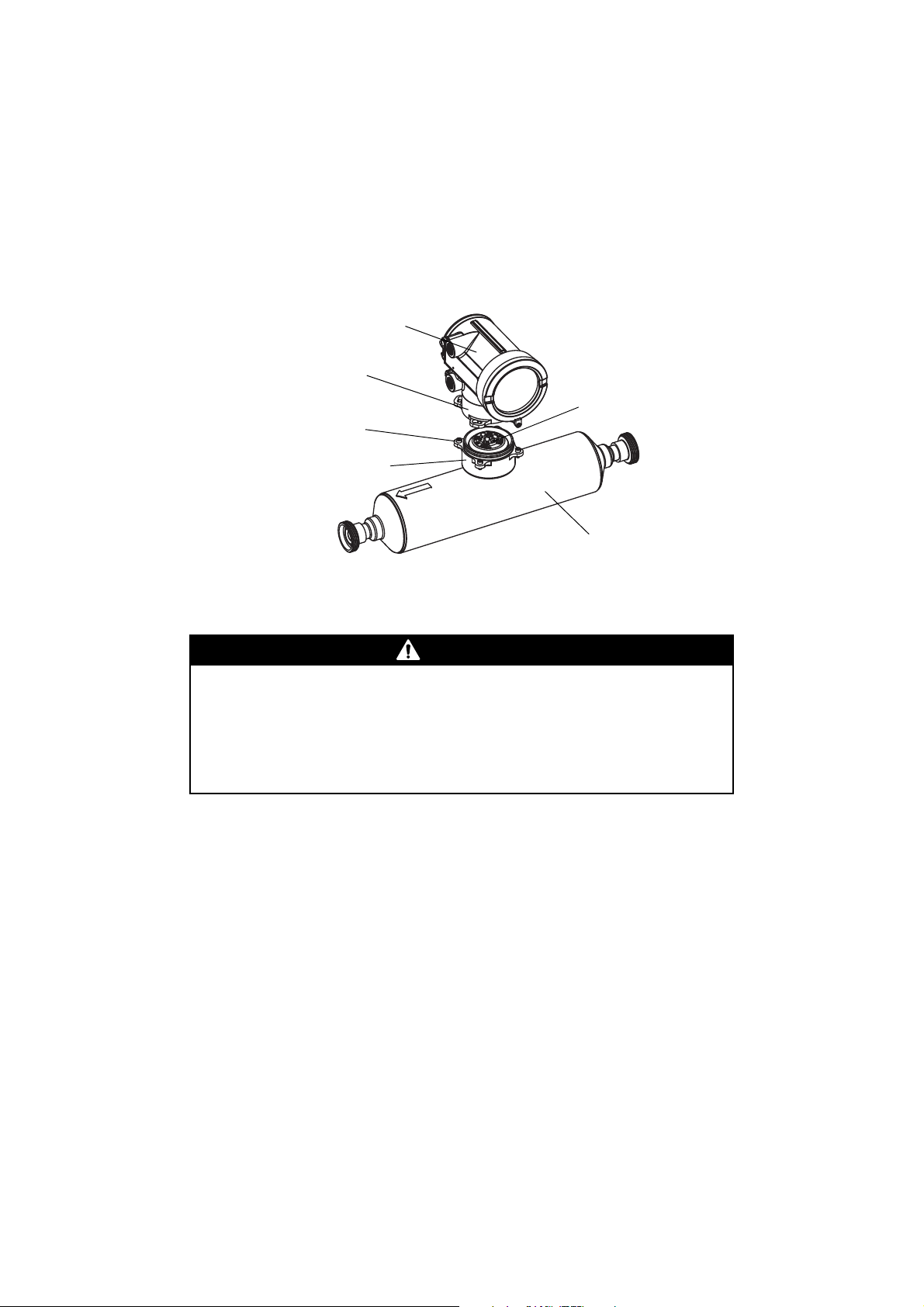

2.2 Installation architecture

Your flowmeter installation will match one of the architectures shown in Figure 2-1. Mounting, sensor

wiring, and grounding requirements depend on this architecture. Your installation type should be

consistent with the installation type specified in your transmitter model number (see Section 1.4).

Installation Manual 5

Page 10

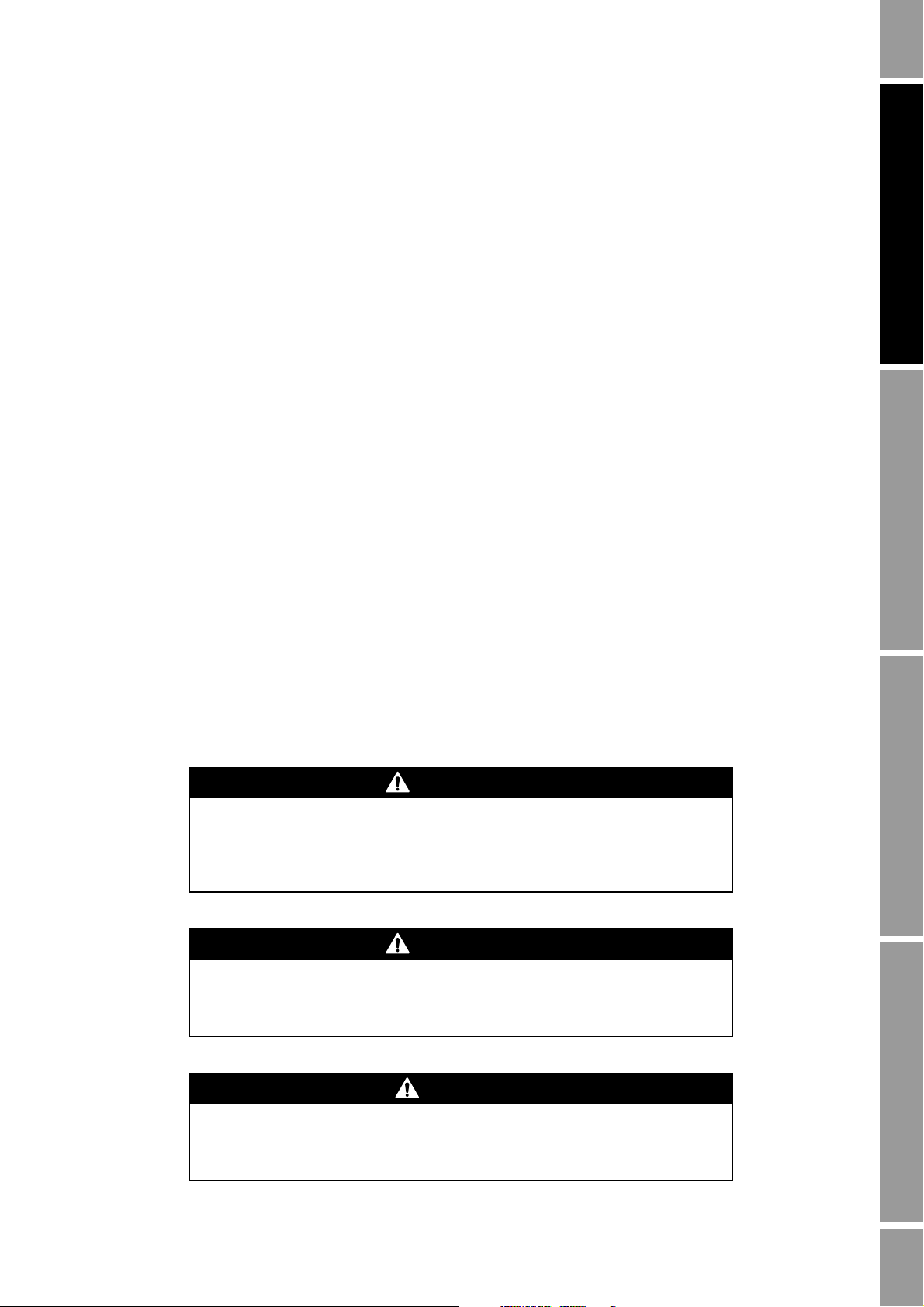

Transmitter

Sensor

Junction box

9-wire cable

9-wire remote

Core

processor

4-wire remote

Transmitter

Sensor

Core processor

4-wire cable

Transmitter

Sensor

Core processor

Integral

Remote core processor with

remote transmitter

4-wire cable

9-wire cable

Sensor

Junction box

Transmitter

Core

processor

Installing the Transmitter

Figure 2-1 Installation types

6 Micro Motion® Model 1700 and 2700 Transmitters

Page 11

Installing the Transmitter

2.3 Determining an appropriate location

To determine an appropriate location for the transmitter, you must consider the environmental

requirements of the transmitter and core processor, hazardous area classification, location of power

source, cable lengths, accessibility for maintenance, and visibility of the display (if the transmitter is

equipped with a display).

2.3.1 Environmental requirements

The transmitter’s environmental requirements include temperature, humidity, and vibration.

Temperature limits

Install the transmitter in an environment where ambient temperature is between –40 and +140 °F

(–40 and +60 °C). If possible, install the transmitter in a location that will prevent direct exposure to

sunlight.

Different ambient temperature requirements may apply when installing the transmitter in a hazardous

area. Refer to the approval documentation shipped with the transmitter or available on the Micro

Motion web site.

Humidity limits

Installing the Transmitter Output Wiring – AnalogSensor WiringBefore You Begin

Install the transmitter in an environment where relative humidity is between 5 and 95%,

non-condensing at 140 °F (60 °C).

Vibration limits

The transmitter meets IEC 68.2.6, endurance sweep, 5 to 2000 Hz, 50 sweep cycles at 1.0 g.

2.3.2 Hazardous area classifications

If you plan to mount the transmitter in a hazardous area:

• Verify that the transmitter has the appropriate hazardous area approval. Each transmitter has a

hazardous area approval tag attached to the transmitter housing.

• Ensure that any cable used between the transmitter and the sensor meets the hazardous area

requirements.

For more information about hazardous area classifications and requirements, see Section A.2.

2.3.3 Power source

Connect the transmitter to an AC or DC voltage source. The transmitter automatically recognizes the

source voltage.

AC power requirements

If you are using AC power, the following requirements apply:

• 85–265 VAC

•50/60 Hz

• 6 watts typical, 11 watts maximum

Installation Manual 7

Page 12

Installing the Transmitter

MinimumSupplyVoltage 18V CableResistance CableLength× 0.5 A×()+=

MinimumSupplyVoltage 18V 0.0080 ohms/ft 350 ft× 0.5A×()+=

MinimumSupplyVoltage 19.4V=

MinimumSupplyVoltage 18V CableResistance CableLength× 0.5A×()+=

DC power requirements

Note: These requirements assume a single transmitter per cable. Connecting multiple transmitters to

a single cable should be avoided.

If you are using DC power, the following requirements apply:

• 18–100 VDC

• 6 watts typical, 11 watts maximum

• At startup, the transmitter power source must provide a minimum of 1.5 amps of short-term

current per transmitter.

• Length and conductor diameter of the power cable must be sized to provide 18 VDC minimum

at the power terminals, at a load current of 0.5 amps. To size the cable, refer to Table 2-1 and

use the following formula as a guideline:

Table 2-1 Typical power cable resistances at 68 °F (20 °C)

Gauge Resistance

14 AWG 0.0050 Ω/foot

16 AWG 0.0080 Ω/foot

18 AWG 0.0128 Ω/foot

20 AWG 0.0204 Ω/foot

2,5 mm

1,5 mm

1 mm

0,75 mm

0,5 mm

(1) These values include the resistance of both high and low conductors in a cable.

Example

(1)

2

2

2

2

2

0,0136 Ω/meter

0,0228 Ω/meter

0,0340 Ω/meter

0,0460 Ω/meter

0,0680 Ω/meter

The transmitter is mounted 350 feet from a DC power supply. If you want to use 16 AWG

cable, calculate the required voltage at the DC power supply as follows:

8 Micro Motion® Model 1700 and 2700 Transmitters

Page 13

Installing the Transmitter

CAUTION

2.3.4 Maximum cable lengths

This requirement does not apply to integral installations (see Figure 2-1). For other installation types

(see Figure 2-1), maximum cable length between flowmeter components depends on the installation

type and the cable type. Refer to Figure 2-1, then see Table 2-2.

Table 2-2 Maximum cable lengths

Cable type Wire gauge Maximum length

Micro Motion 9-wire Not applicable 60 feet (20 meters)

Micro Motion 4-wire Not applicable 1000 feet (300 meters)

User-supplied 4-wire

• Power wires (VDC) 22 AWG (0,35 mm

• Signal wires (RS-485) 22 AWG (0,35 mm2) or larger 1000 feet (300 meters)

2.3.5 Accessibility for maintenance

Ensure that the transmitter is mounted in a location and orientation that will allow easy access to the

terminals and to the display (if your transmitter has a display).

2

) 300 feet (90 meters)

2

20 AWG (0,5 mm

18 AWG (0,8 mm2) 1000 feet (300 meters)

) 500 feet (150 meters)

Installing the Transmitter Output Wiring – AnalogSensor WiringBefore You Begin

2.4 Mounting the transmitter

You can mount the transmitter in any orientation as long as the conduit and wiring openings do not

point upward. If possible, mount the transmitter so that there is at least 8–10″ (200–250 mm)

clearance at the rear of the housing to enable operator access to the wiring and power compartments.

For transmitter dimensions, see Appendix A.

Condensation or excessive moisture entering the transmitter could damage

the transmitter and result in measurement error or flowmeter failure.

To reduce the risk of measurement error or flowmeter failure:

• Ensure the integrity of gaskets and O-rings.

• Grease the O-rings every time the transmitter housing or core processor

housing is opened and closed.

• Do not mount the transmitter with the conduit openings pointing upward.

• Install drip legs on conduit or cable.

• Seal the conduit openings.

• Fully tighten the transmitter cover.

Installation Manual 9

Page 14

Installing the Transmitter

CAUTION

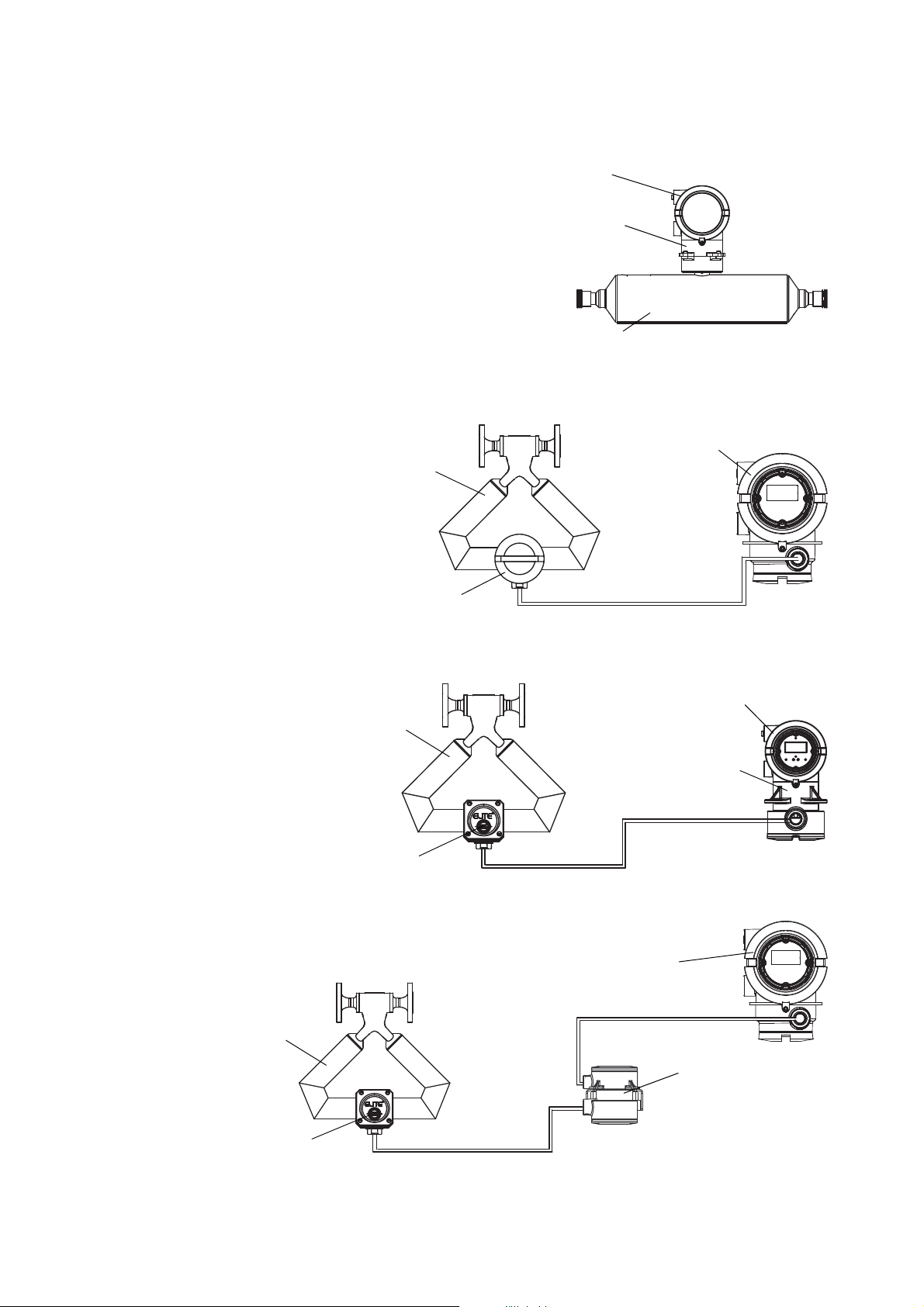

Base

Core processor

Transmitter

Sensor

Transition ring

4 X Cap screws (4 mm)

2.4.1 Integral installations

If you chose an integral installation (see Figure 2-1), there are no special mounting instructions for the

transmitter.

You can rotate an integrally mounted transmitter up to 360° in 90° increments, to one of four possible

positions on the core processor base. See Figure 2-2.

Figure 2-2 Rotating the transmitter

Damaging the wires that connect the transmitter to the core processor can

cause measurement error or flowmeter failure.

To reduce the risk of damaging the wires, do not move the transmitter more than a

few inches from the core processor. When reassembling the flowmeter, ensure that

the wires will not be bent or pinched in the housing.

To rotate the transmitter on the core processor:

1. Loosen each of the four cap screws (4 mm) that fasten the transmitter to the base.

2. Rotate the transmitter counter-clockwise so that the cap screws are in the unlocked position.

3. Gently lift the transmitter straight up, disengaging it from the cap screws. Do not disconnect or

damage the wires that connect the transmitter to the core processor.

4. Rotate the transmitter to the desired orientation, and align the slots with the cap screws. Do not

pinch or stress the wires.

5. Gently lower the transmitter onto the base, inserting the cap screws into the slots.

6. Rotate the transmitter clockwise so that the cap screws are in the locked position.

7. Tighten the cap screws, torquing to 20 to 30 in-lbs (2,3 to 3,4 N-m).

10 Micro Motion® Model 1700 and 2700 Transmitters

Page 15

Installing the Transmitter

CAUTION

Mounting bracket

(wall mount)

Mounting bracket

(pipe mount)

Note: If possible, maintain 8–10″ (200–250 mm) clearance

at the rear of the transmitter.

Twisting the core processor will damage the sensor.

To reduce the risk of damaging the sensor, do not allow the core processor

to rotate.

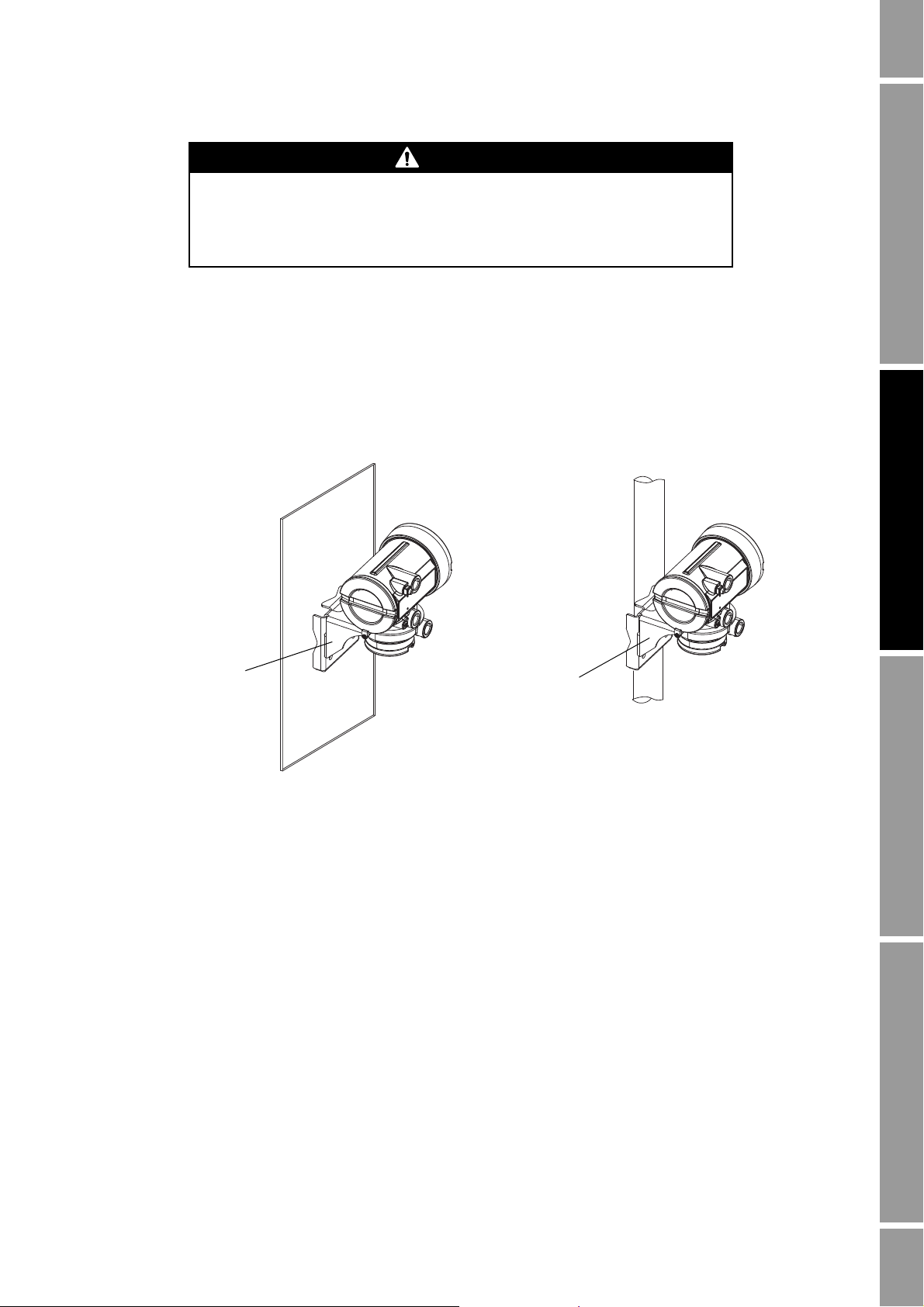

2.4.2 4-wire remote or remote core processor with remote transmitter installations

If you chose the 4-wire remote or the remote core processor with remote transmitter installation (see

Figure 2-1), see Figure 2-3 for a diagram of the mounting bracket supplied with the transmitter. Both

pipe mounting and wall mounting are shown. Ensure that the transmitter is mounted and oriented in a

way that will allow easy access to the terminals and to the display (if your transmitter has a display).

Figure 2-3 4-wire remote – Wall mount or pipe mount

Installing the Transmitter Output Wiring – AnalogSensor WiringBefore You Begin

To mount the transmitter:

1. Identify the components shown in Figure 2-4. For dimensions, see Appendix A.

2. If desired, re-orient the transmitter on the bracket.

a. Remove the junction end-cap from the junction housing.

b. Loosen each of the four cap screws (4 mm) inside the junction housing.

c. Rotate the bracket so that the transmitter is oriented as desired.

d. Tighten the cap screws, torquing to 30 to 38 in-lbs (3 to 4 N-m).

e. Replace the junction end-cap.

3. Attach the mounting bracket to an instrument pole or wall. For pipe mount, two user-supplied

U-bolts are required. Contact Micro Motion to obtain a pipe-mount installation kit if required.

Installation Manual 11

Page 16

Installing the Transmitter

Ground screw

Mounting bracket

Main enclosure

Junction housing

Mating connector

socket

Mating connector

Junction end-cap

4 X Cap screws

(4 mm)

Conduit opening

for 4-wire cable

Mounting bracket

(wall mount)

Mounting bracket

(pipe mount)

Note: If possible, maintain 8–10″ (200–250 mm) clearance

at the rear of the transmitter.

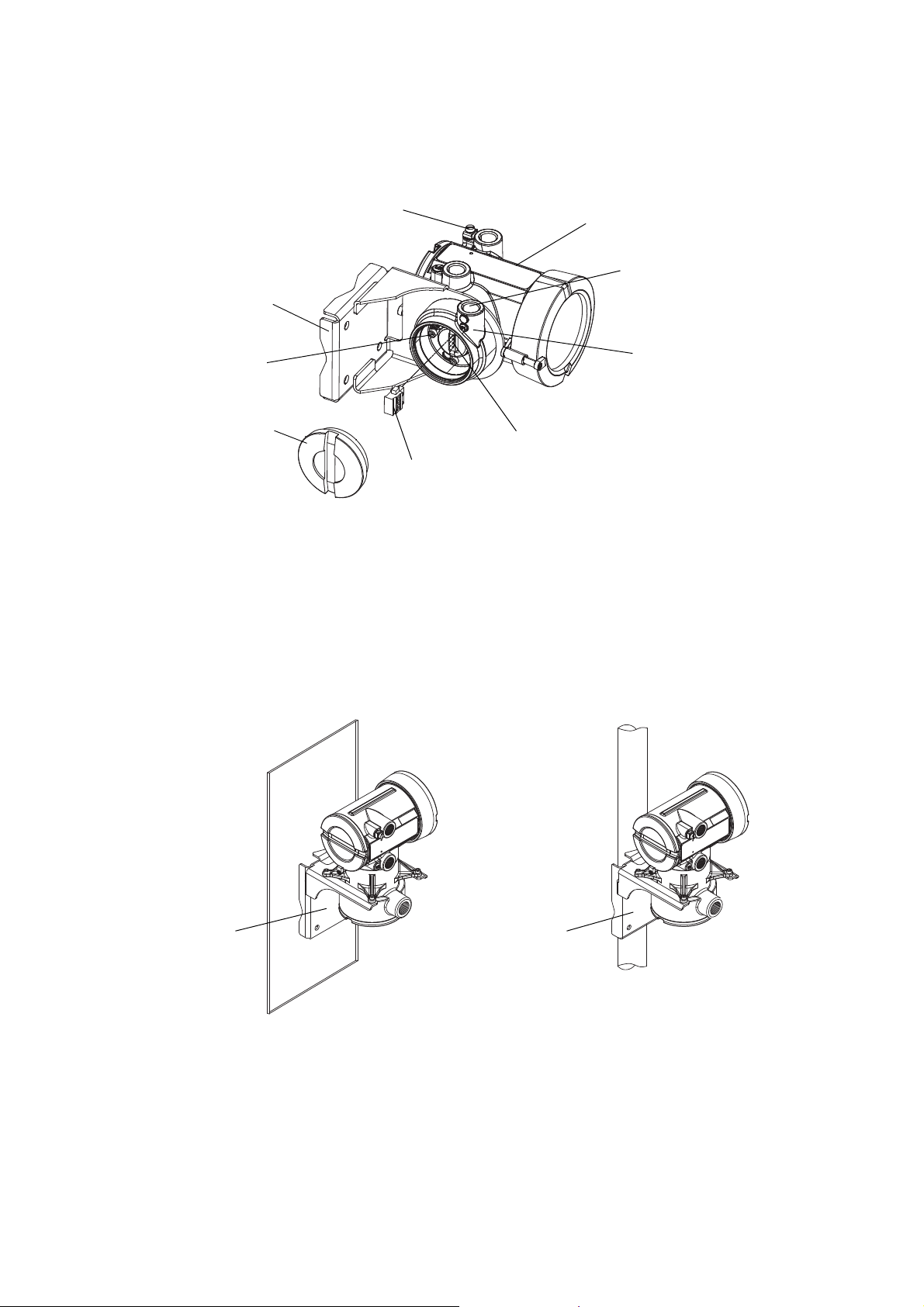

Figure 2-4 Transmitter components – 4-wire remote or remote core processor with

remote transmitter installations

2.4.3 9-wire remote installations

If you chose a 9-wire remote installation (see Figure 2-1), see Figure 2-5 for a diagram of the

mounting bracket supplied with the transmitter/core processor assembly. Ensure that the transmitter is

mounted and oriented in a way that will allow easy access to the terminals and to the display (if your

transmitter has a display).

Figure 2-5 9-wire remote – Wall mount or pipe mount

12 Micro Motion® Model 1700 and 2700 Transmitters

Page 17

Installing the Transmitter

End-cap

Mounting bracket

Core processor housing

Transmitter

Core processor

4 × Cap screws (4 mm)

Conduit opening

for 9-wire cable

To mount the transmitter/core processor assembly:

1. Identify the components shown in Figure 2-6. For dimensions, see Appendix A.

2. If desired, re-orient the transmitter on the bracket.

a. Loosen each of the four cap screws (4 mm).

b. Rotate the bracket so that the transmitter is oriented as desired.

c. Tighten the cap screws, torquing to 30 to 38 in-lbs (3 to 4 N-m).

3. Attach the mounting bracket to an instrument pole or wall. For pipe mount, two user-supplied

U-bolts are required. Contact Micro Motion to obtain a pipe-mount installation kit if required.

Figure 2-6 Transmitter/core processor assembly – Exploded view

Installing the Transmitter Output Wiring – AnalogSensor WiringBefore You Begin

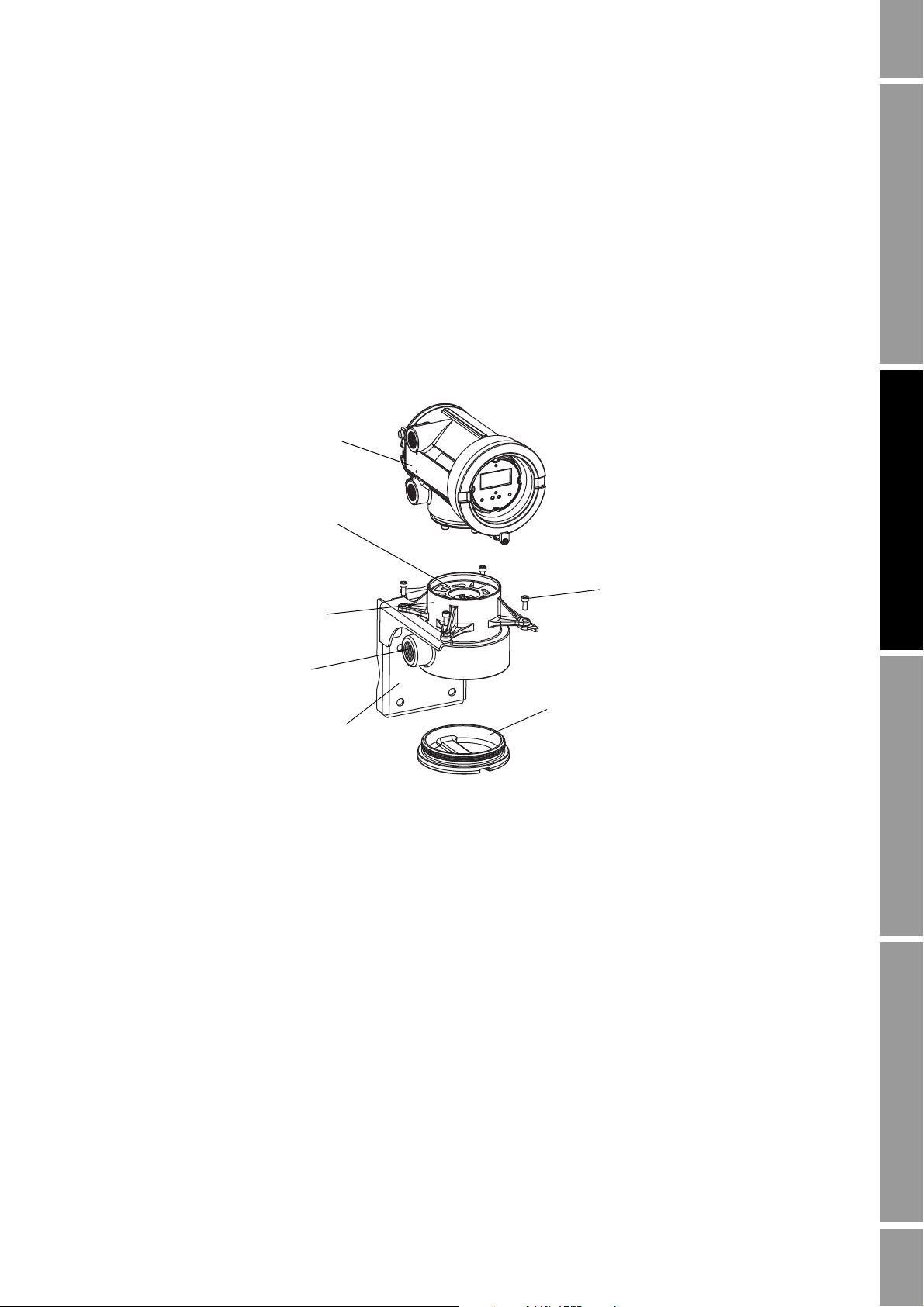

2.5 Mounting the remote core processor

Note: This step is required only for remote core processor with remote transmitter installations (see

Figure 2-1). If you have an integral installation, 4-wire remote installation, or 9-wire remote

installation, go to Section 2.6.

If you chose the remote core processor with remote transmitter installation (see Figure 2-1), see

Figure 2-3 for a diagram of the mounting bracket supplied with the transmitter. Both pipe mounting

and wall mounting are shown.

Installation Manual 13

Page 18

Installing the Transmitter

Mounting bracket

(wall mount)

Mounting bracket

(pipe mount)

End-cap

Mounting bracket

Core processor lid

Core processor housing

Conduit opening

for 4-wire cable

Conduit opening

for 9-wire cable

4 × Cap screws (4 mm)

Figure 2-7 Remote core processor – Wall mount or pipe mount

To mount the core processor:

1. Identify the components shown in Figure 2-8. For dimensions, see Appendix A.

2. If desired, reorient the core processor housing on the bracket.

a. Loosen each of the four cap screws (4 mm).

b. Rotate the bracket so that the core processor is oriented as desired.

c. Tighten the cap screws, torquing to 30 to 38 in-lbs (3 to 4 N-m).

3. Attach the mounting bracket to an instrument pole or wall. For pipe mount, two user-supplied

U-bolts are required. Contact Micro Motion to obtain a pipe-mount installation kit if required.

Figure 2-8 Remote core processor components

14 Micro Motion® Model 1700 and 2700 Transmitters

Page 19

Installing the Transmitter

CAUTION

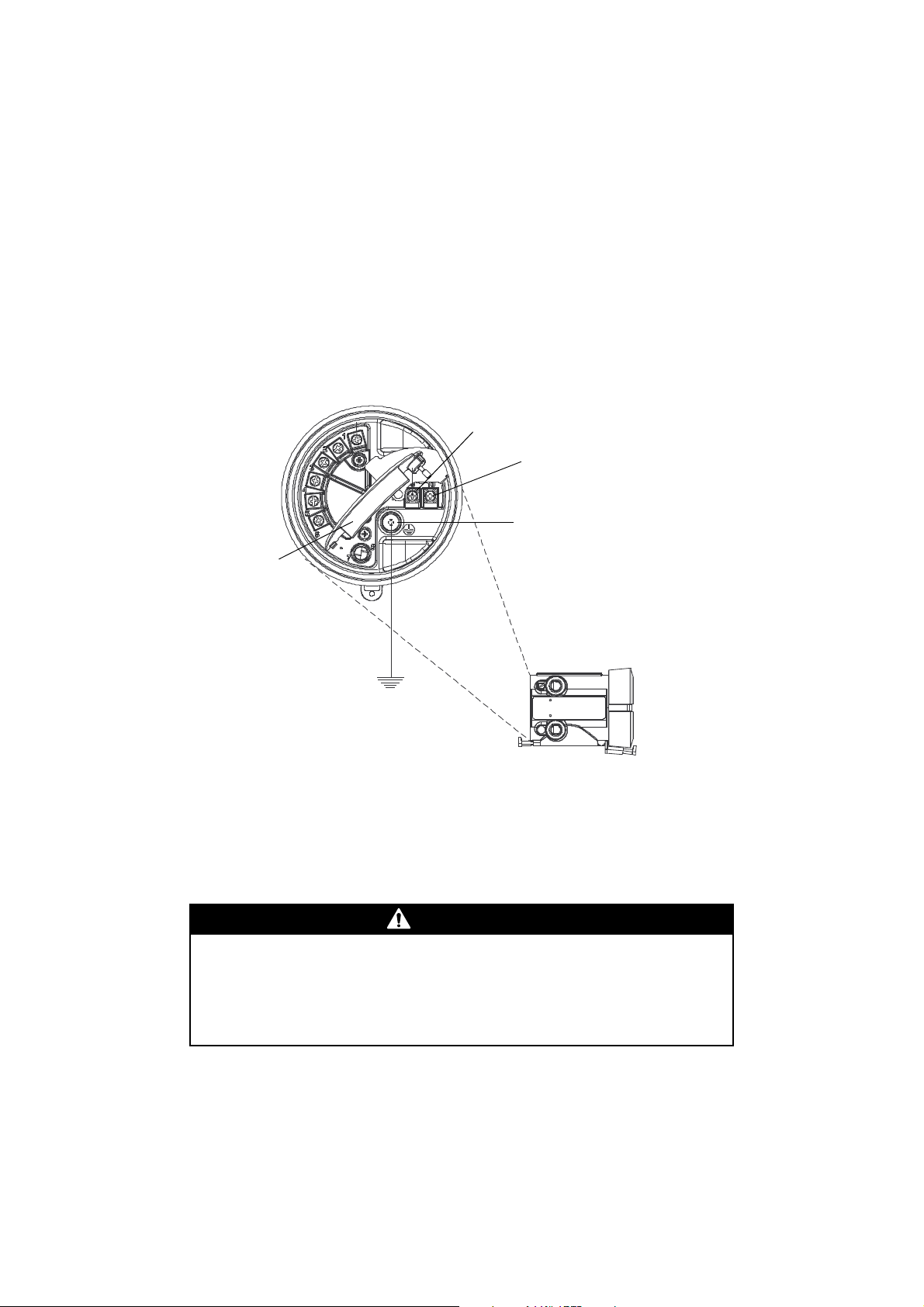

2.6 Grounding the flowmeter components

Grounding requirements depend on the installation type (see Figure 2-1

each flowmeter component are listed in Table 2-3.

Improper grounding could cause measurement error.

To reduce the risk of measurement error:

• Ground the transmitter to earth, or follow ground network requirements for the

facility.

• For installation in an area that requires intrinsic safety, refer to Micro Motion

approval documentation, shipped with the transmitter or available from the Micro

Motion web site.

• For hazardous area installations in Europe, refer to standard EN 60079-14 if

national standards do not apply.

If national standards are not in effect, follow these grounding guidelines:

• Use copper wire, 14 AWG (2,5 mm

). Grounding methods for

2

) or larger wire size, for grounding.

Installing the Transmitter Output Wiring – AnalogSensor WiringBefore You Begin

• Keep all ground leads as short as possible, less than 1 Ω impedance.

• Connect ground leads directly to earth, or follow plant standards.

Table 2-3 Grounding methods for flowmeter components

Installation

architecture Components Grounding method

Integral Sensor / core processor /

transmitter

4-wire remote Sensor / core processor

9-wire remote Sensor / junction box See sensor documentation.

Remote core

processor with

remote

transmitter

assembly

Transmitter Ground according to applicable local standards, using either the

Transmitter / core

processor assembly

Sensor See sensor documentation.

Core processor Ground according to applicable local standards, using either the internal

Transmitter Ground according to applicable local standards, using either the

Ground via piping, if possible (see sensor documentation). Otherwise,

ground according to applicable local standards using either the

transmitter’s internal or external ground screw.

See sensor documentation.

transmitter’s internal or external ground screw.

Ground according to applicable local standards, using either the

transmitter’s internal or external ground screw, or the core processor’s

internal ground screw.

or external ground screw.

transmitter’s internal or external ground screw.

Installation Manual 15

Page 20

Installing the Transmitter

WARNING

Equipment

ground

9

10

Warning flap

2.7 Supplying power

In all installations, power must be provided to the transmitter. Refer to Section 2.3.3 for information

on the transmitter’s power supply requirements.

A user-supplied switch may be installed in the power supply line. For compliance with low-voltage

directive 2006/95/EC (European installations), a switch in close proximity to the transmitter is

required.

Connect the power supply to terminals 9 and 10, under the Warning flap. Terminate the positive (line)

wire on terminal 10 and the return (neutral) wire on terminal 9. Ground the power supply using the

equipment ground, also under the Warning flap. See Figure 2-9.

Figure 2-9 Wiring the transmitter power supply

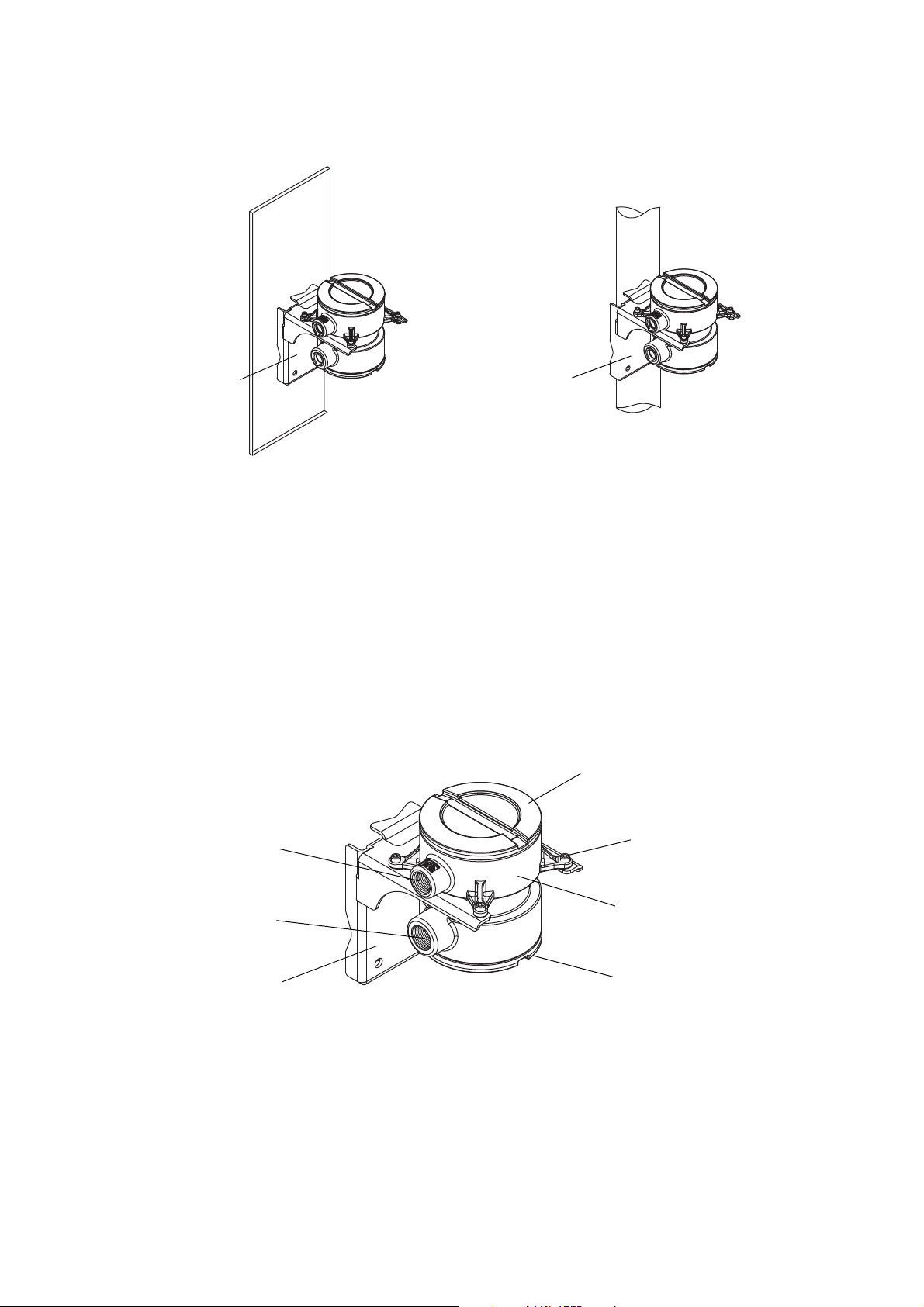

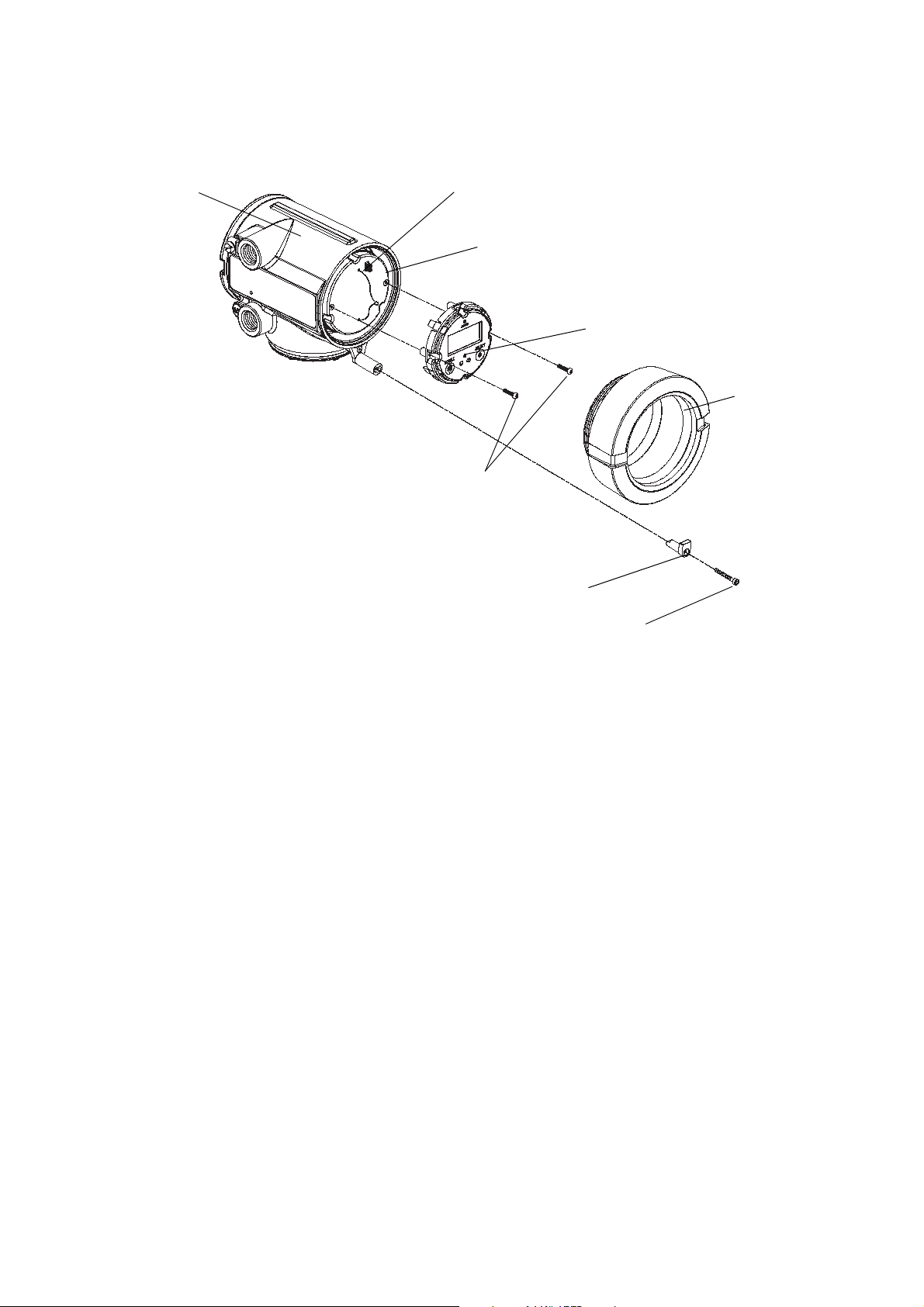

2.8 Rotating the display

If your transmitter has a display, you can rotate the display on the transmitter up to 360° in

90° increments.

Removing the display cover in explosive atmospheres while the power is on

can cause an explosion.

To reduce the risk of an explosion, before removing the display cover in explosive

atmospheres, be sure to shut off the power and wait five minutes.

16 Micro Motion® Model 1700 and 2700 Transmitters

Page 21

Installing the Transmitter

WARNING

Using a dry cloth to clean the display cover can cause static discharge,

which could result in an explosion in an explosive atmosphere.

To reduce the risk of an explosion, always use a damp cloth to clean the display

cover in an explosive atmosphere.

To rotate the display, follow the instructions below:

1. Power down the transmitter.

2. Remove the end-cap clamp by removing the cap screw. See Figure 2-10.

3. Turn the display cover counterclockwise to remove it from the main enclosure.

4. Carefully loosen (and remove if necessary) the semicaptive display screws while holding the

display module in place.

5. Carefully pull the display module out of the main enclosure until the sub-bezel pin terminals

are disengaged from the display module.

Note: The display pins may come out of the board stack with the display module. If this happens,

simply remove the pins and reinstall them.

Installing the Transmitter Output Wiring – AnalogSensor WiringBefore You Begin

6. Rotate the display module to the desired position.

7. Insert the sub-bezel pin terminals into the display module pin holes to secure the display in its

new position.

8. If you have removed the display screws, line them up with the matching holes on the

sub-bezel, then reinsert and tighten them.

9. Place the display cover onto the main enclosure. Turn the display cover clockwise until it is

snug.

10. Replace the end-cap clamp by reinserting and tightening the cap screw.

11. Restore power to the transmitter.

Installation Manual 17

Page 22

Installing the Transmitter

Display cover

Display screws

Display module

Main enclosure

Sub-bezel

Pin terminals

Cap screw

End-cap clamp

Figure 2-10 Display components

18 Micro Motion® Model 1700 and 2700 Transmitters

Page 23

Chapter 3

CAUTION

Wiring the Transmitter to the Sensor

3.1 Overview

This chapter describes how to connect Micro Motion Model 1700 and 2700 transmitters to a Micro

Motion sensor.

Note: If you have an integral installation, this step is not required. Continue with wiring the

transmitter outputs (Chapters 4–7).

Wiring requirements between the sensor and transmitter depend on the installation type (see

Figure 2-1

).

• If you have a 4-wire remote transmitter installation, review the information on 4-wire cable in

Section 3.2, then follow the instructions in Section 3.3.

• If you have a 9-wire remote transmitter installation, review the information on 9-wire cable in

Section 3.2, then follow the instructions in Section 3.4.

• If you have a remote core processor with remote transmitter installation, review the

information on both 4-wire and 9-wire cable in Section 3.2, then follow the instructions in

Section 3.5.

Large electromagnetic fields can interfere with flowmeter communication

signals.

Improper installation of cable or conduit can cause measurement error or flowmeter

failure. To reduce the risk of measurement error or flowmeter failure, keep cable or

conduit away from devices such as transformers, motors, and power lines which

produce large electromagnetic fields.

Installing the Transmitter Output Wiring – AnalogSensor WiringBefore You Begin

3.2 Cable types

This section describes the types of 4-wire cable and 9-wire cable that can be used for wiring the

transmitter to the sensor.

Installation Manual 19

Page 24

Wiring the Transmitter to the Sensor

Core processor

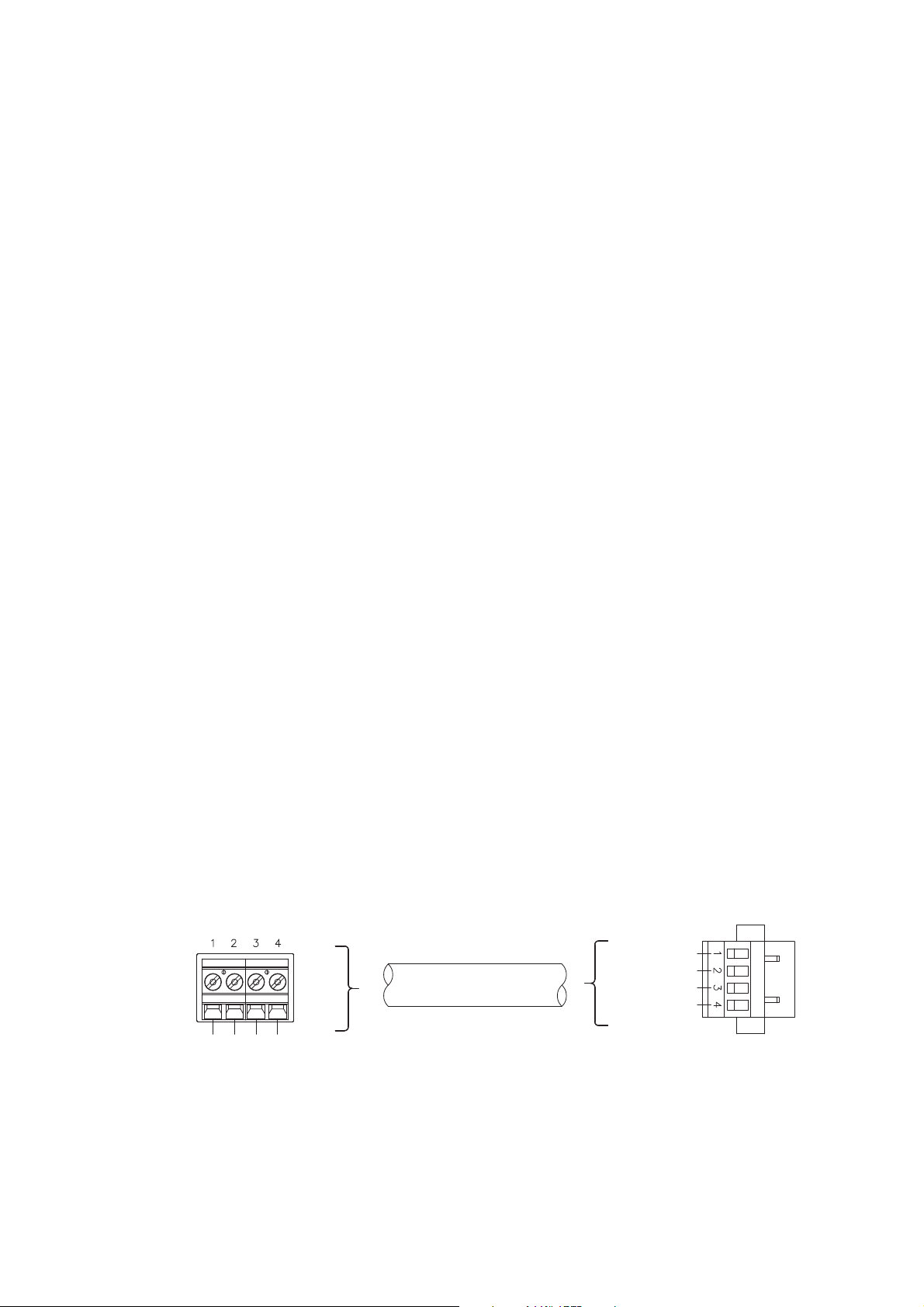

terminals

4-wire cable Mating connector

(transmitter)

Maximum cable length: see Table 2-2

VDC+

VDC–

RS-485A

RS-485B

User-supplied or

factory-supplied cable

VDC+ (Red)

VDC– (Black)

RS-485A (white)

RS-485B (Green)

3.2.1 4-wire cable

Micro Motion offers two types of 4-wire cable: shielded and armored. Both types contain shield

drain wires.

User-supplied 4-wire cable must meet the following requirements:

• Twisted pair construction

• The gauge requirements as described in Table 2-2

• The applicable hazardous area requirements, if the core processor is installed in a hazardous

area (see the approval documentation shipped with the transmitter or available on the Micro

Motion web site)

3.2.2 9-wire cable

Micro Motion offers three types of 9-wire cable: jacketed, shielded, and armored. Refer to Micro

Motion’s 9-Wire Flowmeter Cable Preparation and Installation Guide for detailed descriptions of

these cable types and for assistance in selecting the appropriate cable for your installation.

3.3 Wiring for 4-wire remote installations

To connect the cable, follow the steps below.

1. Prepare the cable as described in the sensor documentation.

2. Connect the cable to the core processor as described in the sensor documentation.

3. To connect the cable to the transmitter:

a. Identify the wires in the 4-wire cable. The 4-wire cable supplied by Micro Motion consists

of one pair of 18 AWG (0,75 mm

VDC connection, and one pair of 22 AWG (0,35 mm

2

) wires (red and black), which should be used for the

2

) wires (green and white), which

should be used for the RS-485 connection.

b. Connect the four wires from the core processor to terminals 1–4 on the mating connector

of the transmitter. See Figures 3-1, 3-2, and 3-3. Never ground the shield, braid, or drain

wire(s) at the transmitter.

Figure 3-1 4-wire cable between enhanced core processor and transmitter

20 Micro Motion® Model 1700 and 2700 Transmitters

Page 25

Wiring the Transmitter to the Sensor

Core processor terminals 4-wire cable Mating connector

(transmitter)

Maximum cable length: see Table 2-2

VDC+

(Red)

VDC–

(Black)

RS-485B

(Green)

RS-485A

(White)

VDC+

VDC–

RS-485A

RS-485B

User-supplied or

factory-supplied cable

Mating connector

Match wire colors as shown in

Figures 3-1 and 3-2

Transmitter

Feed 4 wires from sensor

through the conduit

opening and connect them

to the mating connector

Figure 3-2 4-wire cable between standard core processor and transmitter

Figure 3-3 Wiring to the mating connector

Installing the Transmitter Output Wiring – AnalogSensor WiringBefore You Begin

Installation Manual 21

Page 26

Wiring the Transmitter to the Sensor

CAUTION

Brown

Red

Green

White

Blue

Gray

Orange

Violet

Ye l l o w

Black

(Drains from all

wire sets)

Plug and

socket

Mounting screw

Blue

Gray

Orange

Red

Green

White

Brown

Violet

Yellow

Ground screw

Black

9-wire cable from sensor Core processor (on transmitter)

3.4 Wiring for 9-wire remote installations

If you chose a 9-wire remote installation (see Figure 2-1), a 9-wire cable must be used to connect the

junction box on the sensor to the core processor on the transmitter/core processor assembly.

Allowing the shield drain wires to contact the sensor junction box can cause

flowmeter errors.

Do not allow the shield drain wires to contact the sensor junction box.

To connect the cable, follow the steps below:

1. Refer to Micro Motion’s 9-Wire Flowmeter Cable Preparation and Installation Guide for

instructions on cable shielding and preparation:

• At the sensor end, follow the instructions for your cable type.

• At the transmitter end, follow the instructions for your cable type with an MVD

transmitter.

2. To connect the wires, refer to Micro Motion’s 9-Wire Flowmeter Cable Preparation and

Installation Guide and follow the instructions for your sensor with an MVD transmitter.

Additional information for connecting the wires at the transmitter is provided below:

a. Identify the components shown in Figure 2-6.

b. Remove the end-cap.

c. Insert the 9-wire cable through the conduit opening.

d. Connect the wires to the plugs supplied with the transmitter.

e. Insert the plugs into the sockets inside the lower conduit ring. See Figure 3-4.

Figure 3-4 9-wire cable between sensor and core processor (on transmitter)

3. Ground the cable.

22 Micro Motion® Model 1700 and 2700 Transmitters

Page 27

Wiring the Transmitter to the Sensor

CAUTION

If using jacketed cable:

a. Ground the shield drain wires (the black wire) only on the core processor end, by

connecting it to the ground screw inside the lower conduit ring. Never ground to the core

processor’s mounting screw. Never ground the shield drain wires at the sensor junction

box.

If using shielded or armored cable:

a. Ground the shield drain wires (the black wire) only on the core processor end, by

connecting it to the ground screw inside the lower conduit ring. Never ground to the core

processor’s mounting screw. Never ground the shield drain wires at the sensor junction

box.

b. Ground the cable braid on both ends, by terminating it inside the cable glands.

4. Ensure integrity of gaskets, grease all O-rings, then close the junction box housing and core

processor end-cap, and tighten all screws.

Damaging the wires that connect the transmitter to the sensor can cause

measurement error or flowmeter failure.

Installing the Transmitter Output Wiring – AnalogSensor WiringBefore You Begin

To reduce the risk of measurement error or flowmeter failure, when closing the

housings on the sensor and core processor, make sure that the wires are not

caught or pinched.

3.5 Wiring for remote core processor with remote transmitter installations

This task includes two subtasks:

• Subtask 1: Wiring the remote core processor to the transmitter (4-wire cable)

• Subtask 2: Wiring the sensor to the remote core processor (9-wire cable)

Subtask 1: Wire the remote core processor to the transmitter

1. Use one of the following methods to shield the wiring from the core processor to the

transmitter:

• If you are installing unshielded wiring in continuous metallic conduit that provides

360° termination shielding for the enclosed wiring, go to Subtask 1, Step 6.

• If you are installing a user-supplied cable gland with shielded cable or armored cable,

terminate the shields in the cable gland. Terminate both the armored braid and the shield

drain wires in the cable gland. Go to Subtask 1, Step 6.

• If you are installing a Micro Motion-supplied cable gland at the core processor housing:

- Refer to Figure 3-5 to identify the cable gland to use for the 4-wire cable conduit

opening.

- Prepare the cable and apply shielded heat shrink to the cable (see Figure 3-6). The

shielded heat shrink provides a shield termination suitable for use in the gland when

using cable whose shield consists of foil and not a braid. Proceed to Subtask 1, Step 2.

- With armored cable, where the shield consists of braid, prepare the cable as described

below, but do not apply heat shrink. Proceed to Subtask 1, Step 2.

Installation Manual 23

Page 28

Wiring the Transmitter to the Sensor

Cable gland

• Used with 4-wire conduit

opening

Cable gland

•3/4″–14 NPT

• Used with 9-wire conduit opening

Cable glands

•1/2″–14 NPT or M20 × 1.5

• Used with transmitter

4 1/2 in

(114 mm)

3/4 in

(19 mm)

7/8 in

(22 mm)

7/8 in

(22 mm)

Shielded heat shrink

Gland body

Gland nut

Gland clamping insert

Figure 3-5 Cable glands

2. Remove the cover from the core processor housing.

3. Slide the gland nut and the clamping insert over the cable.

Figure 3-6 Micro Motion cable gland and heat shrink

4. For connection at the core processor housing, prepare shielded cable as follows (for armored

cable, omit steps d, e, f, and g):

a. Strip 4 1/2 inches (114 mm) of cable jacket.

b. Remove the clear wrap that is inside the cable jacket, and remove the filler material

between the wires.

c. Remove the foil shield or braid and drain wires from the insulated wires, leaving 3/4 inch

(19 mm) of foil or braid exposed, and separate the wires.

d. Wrap the shield drain wire(s) around the exposed foil twice. Cut off the excess wire. See

Figure 3-7.

24 Micro Motion® Model 1700 and 2700 Transmitters

Page 29

Wiring the Transmitter to the Sensor

Figure 3-7 Wrapping the shield drain wires

e. Place the shielded heat shrink over the exposed shield drain wire(s). The tubing should

completely cover the drain wires. See Figure 3-8.

f. Without burning the cable, apply heat (250 °F or 120 °C) to shrink the tubing.

Figure 3-8 Applying the heat shrink

Installing the Transmitter Output Wiring – AnalogSensor WiringBefore You Begin

g. Position gland clamping insert so the interior end is flush with the heat shrink.

h. Fold the cloth shield or braid and drain wires over the clamping insert and approximately

1/8 inch (3 mm) past the O-ring. See Figure 3-9.

Figure 3-9 Folding the cloth shield

i. Install the gland body into the core processor housing conduit opening. See Figure 3-10.

Installation Manual 25

Page 30

Wiring the Transmitter to the Sensor

CAUTION

Power supply +

(Red wire)

Power supply –

(Black wire)

RS-485A

(White wire)

RS-485B

(Green wire)

Core processor housing internal ground screw

• For connections to earth ground (if core processor cannot be grounded via sensor

piping and local codes require ground connections to be made internally)

• Do not connect shield drain wires to this terminal

Figure 3-10 Gland body and core processor housing

5. Insert the wires through the gland body and assemble the gland by tightening the gland nut.

6. Identify the wires in the 4-wire cable. The 4-wire cable supplied by Micro Motion consists of

one pair of 18 AWG (0,75 mm

2

) wires (red and black), which should be used for the VDC

connection, and one pair of 22 AWG (0,35 mm

used for the RS-485 connection. Connect the four wires to the numbered slots on the core

processor, matching corresponding numbered terminals on the transmitter. See Figure 3-11.

Figure 3-11 Connecting the wires at the core processor

2

) wires (green and white), which should be

7. Reinstall and tighten the core processor housing cover.

26 Micro Motion® Model 1700 and 2700 Transmitters

Twisting the core processor will damage the equipment.

Do not twist the core processor.

Page 31

Wiring the Transmitter to the Sensor

CAUTION

Brown

Red

Green

White

Blue

Gray

Orange

Violet

Ye l l o w

Black

(Drains from all

wire sets)

Plug and

socket

Mounting screw

Blue

Gray

Orange

Red

Green

White

Brown

Violet

Yellow

Ground screw

Black

9-wire cable from sensor Core processor

8. At the transmitter, connect the four wires from the core processor to terminals 1–4 on the

mating connector of the transmitter. See Figure 3-2. Never ground the shield, braid, or shield

drain wire(s) at the transmitter. Refer to Figure 2-4.

Subtask 2: Wiring the sensor to the remote core processor

Allowing the shield drain wires to contact the sensor junction box can cause

flowmeter errors.

Do not allow the shield drain wires to contact the sensor junction box.

1. Refer to Micro Motion’s 9-Wire Flowmeter Cable Preparation and Installation Guide for

instructions on cable shielding and preparation:

• At the sensor end, follow the instructions for your cable type.

• At the core processor end, follow the instructions for your cable type with an MVD

transmitter.

2. To connect the wires, refer to Micro Motion’s 9-Wire Flowmeter Cable Preparation and

Installation Guide and follow the instructions for your sensor with an MVD transmitter.

Additional information for connecting the wires at the core processor is provided below:

a. Identify the components shown in Figure 2-8.

b. Remove the end-cap.

c. Insert the 9-wire cable through the conduit opening.

d. Connect the wires to the plugs supplied with the core processor.

e. Insert the plugs into the sockets inside the lower conduit ring. See Figure 3-12.

Figure 3-12 9-wire cable between sensor and core processor

Installing the Transmitter Output Wiring – AnalogSensor WiringBefore You Begin

3. Ground the cable.

Installation Manual 27

Page 32

Wiring the Transmitter to the Sensor

CAUTION

If using jacketed cable:

a. Ground the shield drain wires (the black wire) only on the core processor end, by

connecting it to the ground screw inside the lower conduit ring. Never ground to the core

processor’s mounting screw. Never ground the cable at the sensor junction box.

If using shielded or armored cable:

a. Ground the shield drain wires (the black wire) only on the core processor end, by

connecting it to the ground screw inside the lower conduit ring. Never ground to the core

processor’s mounting screw. Never ground the cable at the sensor junction box.

b. Ground the cable braid on both ends, by terminating it inside the cable glands.

4. Ensure integrity of gaskets, grease all O-rings, then close the junction box housing and core

processor end-cap, and tighten all screws.

Damaging the wires that connect the transmitter to the sensor can cause

measurement error or flowmeter failure.

To reduce the risk of measurement error or flowmeter failure, when closing the

housings on the sensor and core processor, make sure that the wires are not

caught or pinched.

28 Micro Motion® Model 1700 and 2700 Transmitters

Page 33

Chapter 4

Output Wiring – Model 1700/2700

Analog Transmitters

4.1 Overview

This chapter explains how to wire outputs for Model 1700 or 2700 transmitters with the analog

outputs option board (output option code A).

Note: If you do not know what outputs option board is in your transmitter, see Section 1.4.

It is the user’s responsibility to verify that the specific installation meets the local and national safety

requirements and electrical codes.

4.2 Output terminals and output types

Table 4-1 describes the outputs and communication protocols available for the Model 1700 or 2700

analog transmitter.

Installing the Transmitter Output Wiring – AnalogSensor WiringBefore You Begin

Table 4-1 Terminals and output types

Terminals Model 1700 output type Model 2700 output type Communication

1 & 2 Milliamp/Bell 202

3 & 4 Frequency • Frequency (default)

5 & 6 RS-485 RS-485 • HART (default)

(1) The Bell 202 signal is superimposed on the mA output.

4.3 Output wiring

Output wiring requirements depend on how you will use the analog functionality and the HART or

Modbus protocol. This chapter describes several possible configurations:

• Figure 4-1 shows the wiring requirements for the mA output (terminals 1 and 2) and the

frequency output (terminals 3 and 4).

• Figure 4-2 shows the wiring requirements for the mA output (terminals 1 and 2) if it will be

used for HART communications in addition to the mA signal.

• Figure 4-3 shows the wiring requirements for RS-485 communications using the RS-485

output (terminals 5 and 6).

• Figure 4-4 shows the wiring requirements for connecting the transmitter to a HART multidrop

network.

(1)

Milliamp/Bell 202

• Discrete

(1)

HART

None

• Modbus

Installation Manual 29

Page 34

Output Wiring – Model 1700/2700 Analog Transmitters

+

–

mA output loop

820 Ω maximum loop resistance

Frequency receiving device

+

–

00042

Output voltage level is +24 VDC ± 3%

Note: If you will configure the transmitter to poll an external temperature or pressure device, you

must wire the mA output to support HART communications. You may use either HART/analog

single-loop wiring or HART multidrop wiring.

It is the user’s responsibility to verify that the specific installation meets the local and national safety

requirements and electrical codes.

Figure 4-1 Basic analog wiring

30 Micro Motion® Model 1700 and 2700 Transmitters

Page 35

Output Wiring – Model 1700/2700 Analog Transmitters

820 Ω maximum loop resistance

For HART communications:

• 600 Ω maximum loop resistance

• 250 Ω minimum loop resistance

+

–

HART-

compatible host

or controller

Note: The RS-485 communication wires must be shielded.

Other devices

RS-485A

RS-485B

Primary

controller

Multiplexer

Figure 4-2 HART/analog single-loop wiring

Installing the Transmitter Output Wiring – AnalogSensor WiringBefore You Begin Installing the Transmitter Output Wiring – AnalogSensor WiringBefore You Begin Installing the Transmitter Output Wiring – AnalogSensor WiringBefore You Begin Installing the Transmitter Output Wiring – AnalogSensor WiringBefore You Begin

Figure 4-3 RS-485 point-to-point wiring

Installation Manual 31

Page 36

Output Wiring – Model 1700/2700 Analog Transmitters

HART-compatible

host or controller

HART-compatible

transmitters

SMART FAMILY

™

transmitters

Note: For optimum HART communication, make sure the output

loop is single-point-grounded to an instrument-grade ground.

24 VDC loop power

supply required for

passive transmitters

600 Ω maximum resistance

250 Ω minimum resistance

Model 1700 or 2700

analog transmitter

Figure 4-4 HART multidrop wiring with SMART FAMILY™ transmitters and a configuration tool

32 Micro Motion® Model 1700 and 2700 Transmitters

Page 37

Chapter 5

Output Wiring – Model 1700/2700 Intrinsically

Safe Transmitters

5.1 Overview

This chapter explains how to wire outputs for Model 1700 or 2700 transmitters with the intrinsically

safe outputs option board (output option code D).

Note: If you do not know what outputs option board is in your transmitter, see Section 1.4.

Intrinsically safe outputs require external power. “External power” means that the terminals must be

connected to an independent power supply. The output wiring instructions include power setup and

power wiring.

Note: The term “passive” is sometimes used to describe externally powered outputs.

Output wiring requirements depend on whether the transmitter will be installed in a safe area or a

hazardous area. This chapter describes several possible configurations:

• Section 5.3 describes wiring requirements for the outputs if the transmitter will be installed in

a safe area.

• Section 5.4 describes wiring requirements for the outputs if the transmitter will be installed in

a hazardous area.

It is the user’s responsibility to verify that the specific installation meets the local and national safety

requirements and electrical codes.

5.2 Output terminals and output types

Table 5-1 describes the outputs and communication protocols available for the Model 1700 or 2700

intrinsically safe transmitter.

Output Wiring – Configurable I/O SpecificationsOutput Wiring – Fieldbus/PROFIBUSOutput Wiring – Intrinsically Safe

Table 5-1 Terminals and output types

Terminals Model 1700 output type Model 2700 output type Communication

1 & 2 Milliamp/Bell 202

3 & 4 Frequency • Frequency (default)

5 & 6 Not used Milliamp None

(1) The Bell 202 signal is superimposed on the mA output.

Note: If you will configure the transmitter to poll an external temperature or pressure device, you

must wire the mA output to support HART communications. You may use either HART/analog

single-loop wiring or HART multidrop wiring.

Installation Manual 33

(1)

Milliamp/Bell 202

• Discrete

(1)

HART

None

Page 38

Output Wiring – Model 1700/2700 Intrinsically Safe Transmitters

Note: See Figure 5-2 for voltage and resistance values.

VDC

VDC

R

load

R

load

+

–

+

–

+

–

+

–

mA1

mA2

5.3 Safe area output wiring

The following notes and diagrams are designed to be used as a guide for wiring the Model 1700 or

Model 2700 outputs for safe area applications.

5.3.1 Safe area mA output wiring

The following 4–20 mA wiring diagrams are examples of proper basic wiring for the Model 1700 mA

output or Model 2700 primary and secondary mA outputs.

Note: This diagram shows the Model 2700, which has a secondary mA output. If you are using the

Model 1700, the secondary mA output does not exist.

Figure 5-1 Safe area basic mA output wiring

34 Micro Motion® Model 1700 and 2700 Transmitters

Page 39

Output Wiring – Model 1700/2700 Intrinsically Safe Transmitters

0

100

200

300

400

500

600

700

800

900

1000

12 14 16 18 20 22 24 26 28 30

R

max

= (V

supply

– 12)/0.023

If communicating with HART, a minimum of 250 Ω and 17.5 V is required

Supply voltage VDC (Volts)

External resistor R

load

(Ohms)

OPERATING REGION

Note: See Figure 5-2 for voltage and resistance values.

VDC

R

load

(250–600 Ω

resistance)

+

–

+

–

HART-

compatible host

or controller

mA1

Figure 5-2 Safe area mA output load resistance values

Output Wiring – Configurable I/O SpecificationsOutput Wiring – Fieldbus/PROFIBUSOutput Wiring – Intrinsically Safe

Figure 5-3 Safe area HART/analog single-loop wiring

Installation Manual 35

Page 40

Output Wiring – Model 1700/2700 Intrinsically Safe Transmitters

HART-compatible

host or controller

HART-compatible

transmitters

SMART FAMILY™

transmitter

Note: For optimum HART communication, make sure the output loop

is single-point-grounded to an instrument-grade ground.

24 VDC loop power

supply required for

HART 4–20 mA

passive transmitters

600 Ω maximum resistance

250 Ω minimum resistance

Model 1700 or 2700

I.S. transmitter

+

–

Note: See Figure 5-6 for voltage and resistance values.

Counter

VDC

R

load

+

–

+

–

00042

Figure 5-4 Safe area HART multidrop wiring with SMART FAMILY™ transmitters and a configuration tool

5.3.2 Safe area frequency/discrete output wiring

The following frequency/discrete output wiring diagram is an example of proper basic wiring for the

Model 1700 transmitter’s frequency output or the Model 2700 transmitter’s frequency/discrete output.

Figure 5-5 Safe area frequency/discrete output wiring

36 Micro Motion® Model 1700 and 2700 Transmitters

Page 41

Output Wiring – Model 1700/2700 Intrinsically Safe Transmitters

WARNING

0

1000

2000

3000

4000

5000

6000

7000

8000

9000

10000

5 7 9 11 13 15 17 19 21 23 25 27 29

R

max

= (V

supply

– 4)/0.003

R

min

= (V

supply

– 25)/0.006

Absolute minimum = 100 ohms for supply voltage less than 25.6 Volts

Supply voltage VDC (Volts)

External pull-up resistor R

load

range (Ohms)

OPERATING REGION

Figure 5-6 Safe area frequency/discrete output load resistance values

Output Wiring – Configurable I/O SpecificationsOutput Wiring – Fieldbus/PROFIBUSOutput Wiring – Intrinsically Safe

5.4 Hazardous area output wiring

The following notes and diagrams are designed to be used as a guide for wiring the Model 1700 or

Model 2700 outputs for hazardous area applications.

5.4.1 Hazardous area safety parameters

The proper barrier selection will depend on what output is desired, which approval is applicable, and

many installation-specific parameters. The information that is provided about I.S. barrier selection is

intended as an overview. Refer to barrier manufacturers for more detailed information regarding the

use of their products. Application-specific questions should be addressed to the barrier manufacturer

or to Micro Motion.

Hazardous voltage can cause severe injury or death.

To reduce the risk of hazardous voltage, shut off the power before wiring the

transmitter outputs.

Installation Manual 37

Page 42

Output Wiring – Model 1700/2700 Intrinsically Safe Transmitters

WARNING

A transmitter that has been improperly wired or installed in a hazardous area

could cause an explosion.

To reduce the risk of an explosion:

• Make sure the transmitter is wired to meet or exceed local code requirements.

• Install the transmitter in an environment that complies with the classification tag

on the transmitter. See Appendix A.

Table 5-2 Safety parameters

Parameter 4–20 mA output Frequency/discrete output

Voltage (Ui) 30 V 30 V

Current (I

Power (Pi) 1.0 W 0.75 W

Capacitance (Ci) 0.0005 μF 0.0005 μF

Inductance (L

) 300 mA 100 mA

i

) 0.0 mH 0.0 mH

i

Val ue

Hazardous area voltage

The Model 1700 or 2700 transmitter’s safety parameters require the selected barrier’s open-circuit

voltage to be limited to less than 30 VDC (Vmax = 30 VDC). This voltage is the combination of the

maximum safety barrier voltage (typically 28 VDC) plus an additional 2 VDC for HART

communications when communicating in the hazardous area.

Hazardous area current

The Model 1700 or 2700 transmitter’s safety parameters require the selected barrier’s short-circuit

currents to sum to less than 300 mA (Imax = 300 mA) for the milliamp outputs and 100 mA

(Imax = 100 mA) for the frequency/discrete output.

Hazardous area capacitance

The capacitance (Ci) of the Model 1700 or 2700 transmitter is 0.0005 μF. This value added to the

wire capacitance (Ccable) must be lower than the maximum allowable capacitance (Ca) specified by

the I.S. barrier. Use the following equation to calculate the maximum length of the cable between the

transmitter and the barrier:

Ci + Ccable ≤ Ca

Hazardous area inductance

The inductance (Li) of the Model 1700 or 2700 transmitter is 0.0 mH. This value plus the field wiring

inductance (Lcable), must be lower than the maximum allowable inductance (La) specified by the I.S.

barrier. The following equation can then be used to calculate the maximum cable length between the

transmitter and the barrier:

Li + Lcable ≤ La

38 Micro Motion® Model 1700 and 2700 Transmitters

Page 43

Output Wiring – Model 1700/2700 Intrinsically Safe Transmitters

Note: R

barrier

and R

load

should be added together to

determine the proper V

in

. Refer to Figure 5-2.

V

out

Hazardous area Safe area

V

in

Ground

R

load

4-20 mA

R

barrier

5.4.2 Hazardous area mA output wiring

Figure 5-7 provides an example of basic hazardous area wiring for the Model 1700 transmitter’s mA

output or the Model 2700 transmitter’s primary mA output.

Figure 5-7 Hazardous area mA output wiring

Output Wiring – Configurable I/O SpecificationsOutput Wiring – Fieldbus/PROFIBUSOutput Wiring – Intrinsically Safe

5.4.3 Hazardous area frequency/discrete output wiring

The following frequency/discrete output wiring diagrams are examples of proper hazardous area

wiring for the Model 1700 transmitter’s frequency output or the Model 2700 transmitter’s

frequency/discrete output:

• The diagram in Figure 5-8 utilizes a galvanic isolator that has an internal 1000 Ω resistor used

for sensing current:

- ON > 2.1 mA

- OFF < 1.2 mA

• The diagram in Figure 5-9 utilizes a barrier with external load resistance.

Installation Manual 39

Page 44

Output Wiring – Model 1700/2700 Intrinsically Safe Transmitters

External power supply

R

load

V

out

Galvanic isolator

Hazardous area Safe area

COUNTER

Note: R

barrier

and R

load

should be added together to

determine the proper V

in

. Refer to Figure 5-6.

Hazardous area Safe area

Ground

V

out

V

in

R

barrier

R

load

COUNTER

Figure 5-8 Hazardous area frequency/discrete output wiring using galvanic isolator

Figure 5-9 Hazardous area frequency/discrete output wiring using barrier with external load resistance

40 Micro Motion® Model 1700 and 2700 Transmitters

Page 45

Chapter 6

Output Wiring – Model 2700 Configurable I/O

Transmitters

6.1 Overview

This chapter explains how to wire outputs for Model 2700 transmitters with the configurable

input/outputs board (output option code B or C).

Note: If you don’t know what outputs option board is in your transmitter, see Section 1.4.

Output wiring requirements depend on how you will configure the transmitter terminals. The

configuration options are shown in Table 6-1 and Figure 6-1.

If Channel B is configured as a frequency output or discrete output, it can also be configured to use

either internal or external power. Channel C can be configured to use either internal or external power,

independent of its output configuration.

• “Internal power” means that the terminals are powered automatically by the transmitter. The

output wiring instructions do not include power setup and power wiring.

• “External power” means that the terminals must be connected to an independent power supply.

The output wiring instructions include power setup and power wiring.

Note: The terms “active” and “passive” are sometimes used to describe internally and externally

powered outputs.

It is the user’s responsibility to verify that the specific installation meets the local and national safety

requirements and electrical codes.

6.2 Channel configuration

The six terminals are divided into three pairs, and called Channels A, B, and C. Channel A is

terminals 1 and 2; Channel B is terminals 3 and 4; and Channel C is terminals 5 and 6. Variable

assignments are governed by channel configuration. Table 6-1 and Figure 6-1 show how each channel

may be configured, and the power options for each channel.

Output Wiring – Configurable I/O SpecificationsOutput Wiring – Fieldbus/PROFIBUSOutput Wiring – Intrinsically Safe

You can use a HART Communicator or ProLink II software to configure channels. To configure

channels, see the manual entitled Series 1000 and 2000 Transmitters Configuration and Use Manual.

Note: You cannot configure the following combination: Channel B = discrete output, Channel

C = frequency output. If you need both a frequency output and a discrete output, use the following:

Channel B = frequency output, Channel C = discrete output. For more information, see the manual

entitled Series 1000 and 2000 Transmitters Configuration and Use Manual.

Installation Manual 41

Page 46

Output Wiring – Model 2700 Configurable I/O Transmitters

Terminals 1 and 2 (Channel A)

mA1 output

Internal power only

HART (Bell 202) communications

Terminals 3 and 4 (Channel B)

mA2 output or FO or DO1

Power:

• mA – internal only

• FO or DO – internal or external

No communications

Terminals 5 and 6 (Channel C)

FO or DO2 or DI

Power: internal or external

No communications

mA = milliamp

FO = frequency output

DO = discrete output

DI = discrete input

+

–

+

–

+

–

Table 6-1 Channel configuration

Channel Terminals Configuration options Power

A 1 & 2 mA output with HART/Bell 202

B 3 & 4 • mA output (default) Internal

• Frequency output Internal or external

• Discrete output Internal or external

C 5 & 6 • Frequency output (default)

• Discrete output Internal or external

• Discrete input Internal or external

(1) The Bell 202 signal is superimposed on the mA output.

(2) You must provide power to the outputs when a channel is set to external power.

(3) When configured for two frequency outputs (dual pulse), frequency output 2 is generated from the same signal that is sent

to the first frequency output. Frequency output 2 is electrically isolated but not independent.

Figure 6-1 Configuration of configurable I/O terminals

(1)

(3)

Internal

(2)

Internal or external

6.3 mA output wiring

The following 4–20 mA wiring diagrams are examples of proper basic wiring for the Model 2700

primary and secondary mA outputs. The following options are shown:

• Basic mA wiring (Figure 6-2)

• HART/analog single-loop wiring (Figure 6-3)

• HART multidrop wiring (Figure 6-4)

Note: If you will configure the transmitter to poll an external temperature or pressure device, you

must wire the mA output to support HART communications. You may use either HART/analog

42 Micro Motion® Model 1700 and 2700 Transmitters

single-loop wiring or HART multidrop wiring.

Page 47

Output Wiring – Model 2700 Configurable I/O Transmitters

+

–

mA1

mA2

+

–

820 Ω maximum loop resistance

420 Ω maximum loop resistance

820 Ω maximum loop resistance

For HART communications:

•600 Ω maximum loop resistance

•250 Ω minimum loop resistance

+

–

HART-

compatible host

or controller

Figure 6-2 Basic mA wiring

Output Wiring – Configurable I/O SpecificationsOutput Wiring – Fieldbus/PROFIBUSOutput Wiring – Intrinsically Safe

Figure 6-3 HART/analog single-loop wiring

Installation Manual 43

Page 48

Output Wiring – Model 2700 Configurable I/O Transmitters

HART-compatible

host or controller

HART-compatible

transmitters

SMART FAMILY™

transmitters

Note: For optimum HART communication,

make sure the output loop is

single-point-grounded to an

instrument-grade ground.

24 VDC loop power

supply required for

HART 4–20 mA

passive transmitters

Model 2700

configurable I/O

transmitter

(internally powered

outputs)

600 Ω maximum resistance

250 Ω minimum resistance

Figure 6-4 HART multidrop wiring with SMART FAMILY™ transmitters and a configuration tool

6.4 Frequency output wiring

Frequency output wiring depends on whether you are wiring terminals 3 and 4 (Channel B) or

terminals 5 and 6 (Channel C), and also on whether you have configured the terminals for internal or

external power. The following diagrams are examples of proper wiring for these configurations:

• Channel B, internal power – Figure 6-5

• Channel B, external power – Figure 6-6

• Channel C, internal power – Figure 6-7

• Channel C, external power – Figure 6-8

Note: If both Channel B and Channel C are configured for frequency output, the Channel C signal is

generated from the Channel B signal, with a user-specified phase shift. The signals are electrically

isolated but not independent. This configuration is used to support dual-pulse and quadrature modes.

For more information, see the manual entitled Series 1000 and 2000 Transmitters Configuration and

Use Manual.

44 Micro Motion® Model 1700 and 2700 Transmitters

Page 49

Output Wiring – Model 2700 Configurable I/O Transmitters

Note: See Figure 6-13 for output voltage versus load resistance.

Counter

+

–

Output voltage level is +15 VDC ± 3%

00042

Note: See Figure 6-15 for recommended resistor versus supply voltage.

CAUTION

Excessive current will damage the transmitter.

Do not exceed 30 VDC input. Terminal current must be less than 500 mA.

Counter

Pull-up

resistor

3–30 VDC

+

–

+

–

000042

Figure 6-5 Frequency output – Terminals 3 & 4 (Channel B) – Internal power

Output Wiring – Configurable I/O SpecificationsOutput Wiring – Fieldbus/PROFIBUSOutput Wiring – Intrinsically Safe

Figure 6-6 Frequency output – Terminals 3 & 4 (Channel B) – External power

Installation Manual 45

Page 50

Output Wiring – Model 2700 Configurable I/O Transmitters

Output voltage level is +15 VDC ± 3%

Note: See Figure 6-14 for output voltage versus load resistance.

Counter

+

–

00042

Counter

Pull-up

resistor

3–30 VDC

+

–

Note: Refer to Figure 6-15 for