Product Data Sheet

PS-001885, Rev O

April 2021

Micro Motion™ 5700 Transmitters with MVD

Technology

™

Repeatable, reliable, accurate measurements

■

Faster processing speed delivers the best response even in the most challenging applications such as

meter proving, filling & dosing, and batching

■

Smart Meter Verification™ provides you with the confidence you need in your meter performance

■

Zero verification confirms the calibration and indicates when it’s time to re-zero the meter

■

Approved for custody transfer and certified for SIL2 and SIL3, which provides measurement confidence

and reliability

A window into your process

■

Easy access to detailed measurement history gives you valuable insight into your process for better

troubleshooting and optimization

■

Real-time indication of multi-phase flow events allow for greater process control

■

High-accuracy density measurement reduces or eliminates waste in your process while the embedded

historian records upsets and process deviations

Productivity through simplified solutions

■

Designed to minimize the time and expertise needed to install and operate the flowmeter

■

Configurable I/O version, provides up to five fully configurable input/output channels that can be easily

upgraded with changing needs

■

Ethernet version includes multiple protocols on dual channels, plus a configurable I/O channel

■

PROFIBUS®-PA version includes PROFIBUS-PA output, a fixed mA output channel, and a configurable

frequency/discrete output channel

■

FOUNDATION™ Fieldbus version includes IEC-61158-2 FOUNDATION Fieldbus output, a fixed mA output

channel, and a configurable frequency / discrete output channel

■

Intrinsically safe output version, includes up to four configurable intrinsically safe output channels that

can easily be upgraded with changing needs

■

Offline configuration and auditing through new file shuttling capability

■

Wi-Fi display option enables point-to-point wireless communication in order to configure and

characterize the meter, download historical files, and run Smart Meter Verification for troubleshooting

purposes.

Available for a 5700 with configurable inputs and outputs only.

April 2021 5700 Transmitters

Micro Motion 5700 transmitters

The 5700 transmitters deliver the best measurement technology and offer unparalleled support – ensuring total measurement

confidence, valuable process insight and greater operational efficiency. These transmitters provide the scalability, compatibility

and performance that your application demands.

Simplified installation and commissioning

An intuitive interface, spacious side-access wiring compartment and convenient mounting brackets.

Smart Meter Verification: advanced diagnostics for your entire system

Our online tool verifies that your meter performs as well as the day it was installed, giving you assurance in less than 90 seconds.

Measurement history for easier troubleshooting and optimization

Detailed history files deliver key time-stamped information about your process from configuration changes and alerts to process

events and statistics.

Unmatched system connectivity and services interfaces

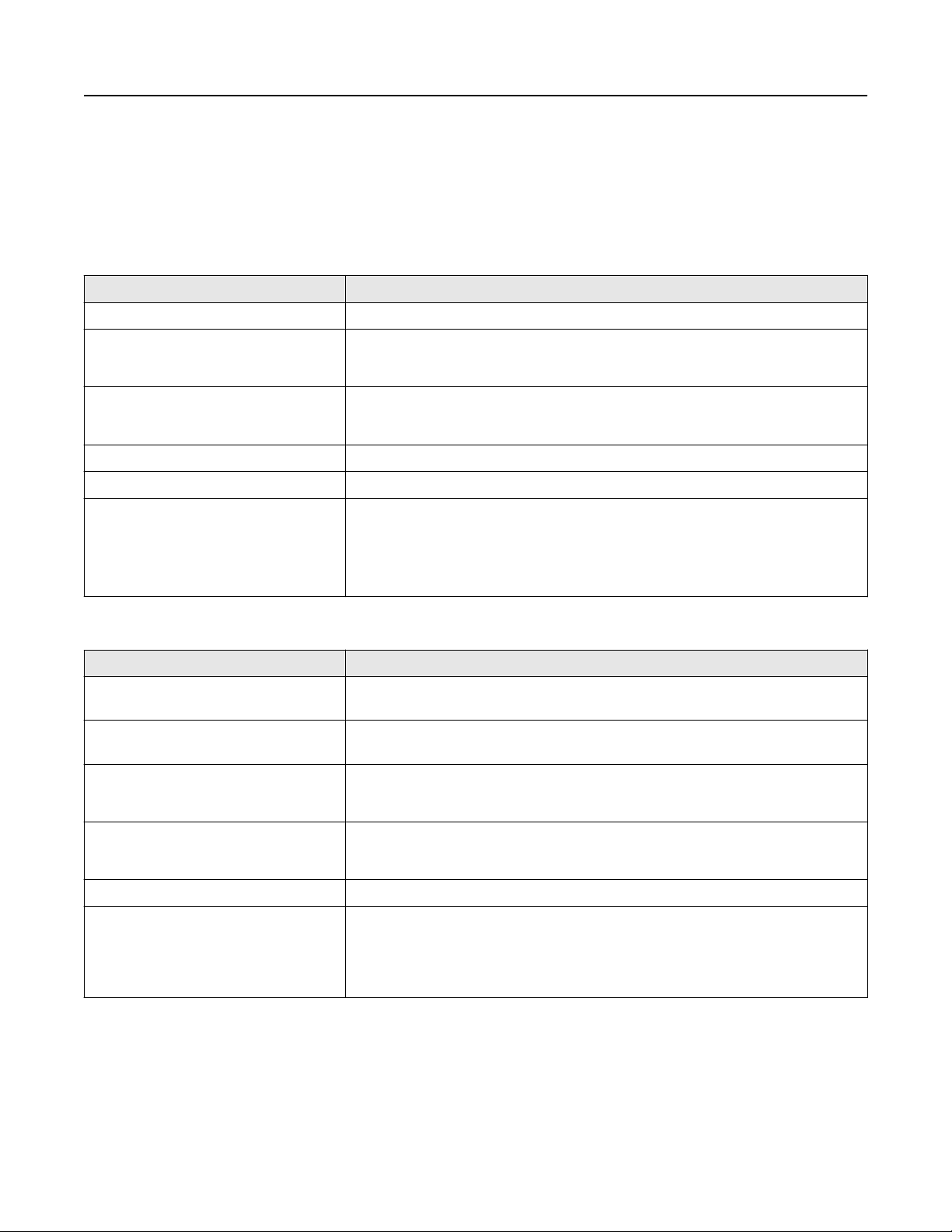

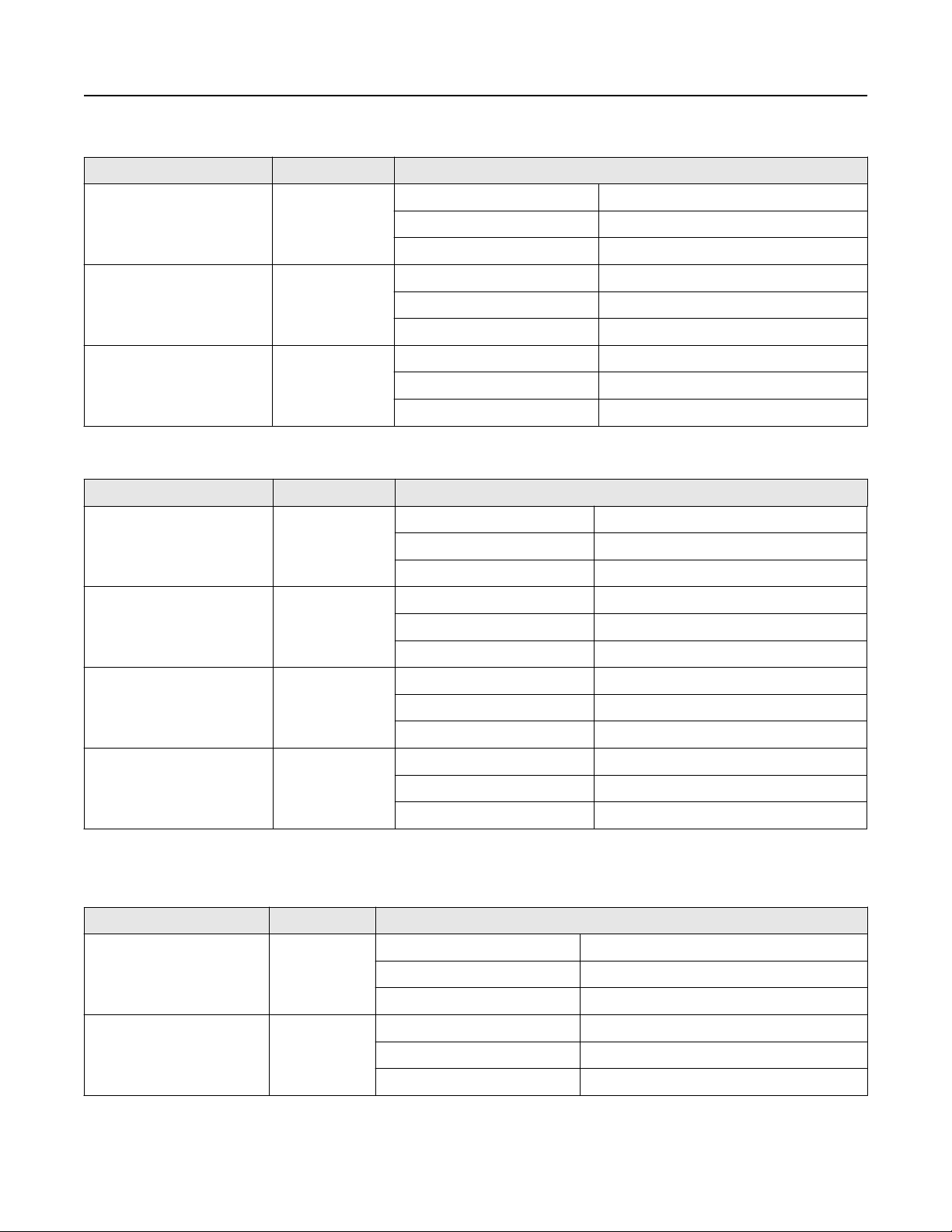

Configurable I/O version

Up to five fully configurable I/O channels with multiple mA, Discrete and Frequency

Outputs, and several powerful service interfaces.

www.emerson.com 3

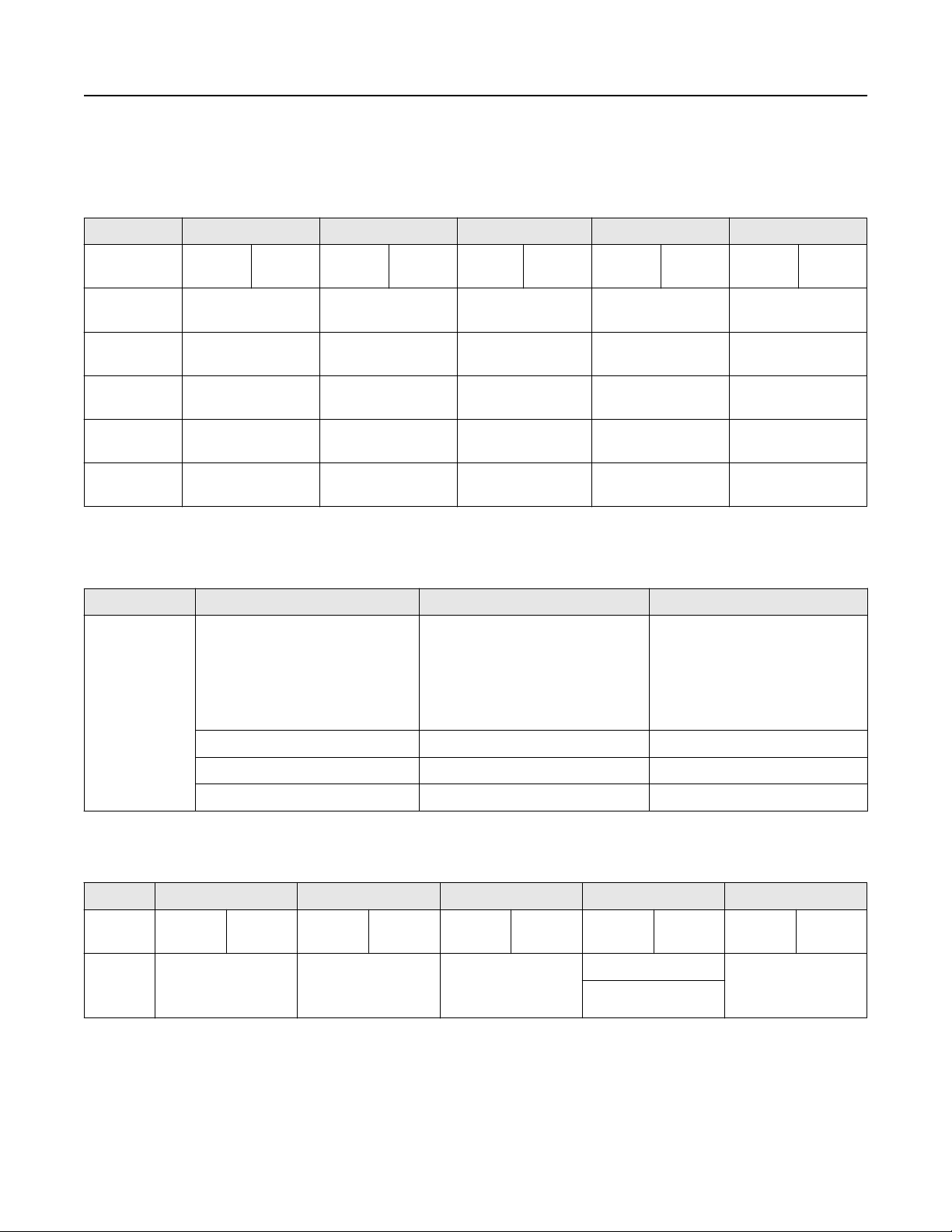

Discrete input

2 Ethernet ports

1 configurable

I/O channel for

mA, frequency,

or discrete output

Fieldbus output

mA output

Configurable channel

for frequency or

discrete output

PROFIBUS-PA output

mA output

Configurable channel

for frequency or

discrete output

Up to 3 mA outputs

Up to 2 frequency or

USP (service port)

HART connection

terminals

discrete outputs

5700 Transmitters April 2021

Ethernet version Two Ethernet outputs with EtherNet/IP®, Modbus® TCP, or PROFINET® — plus one

configurable output.

FOUNDATION Fieldbus version FOUNDATION Fieldbus output, mA Output, and a configurable channel for Frequency or

Discrete Output.

PROFIBUS-PA version PROFIBUS-PA output, mA Output, and a configurable channel for Frequency or

Discrete Output.

Intrinsically safe outputs version Up to four fully configurable output channels with up to three mA, and two Discrete

and Frequency Outputs.

4 www.emerson.com

April 2021

5700 Transmitters

Access information when you need it with asset tags

Newly shipped devices include a unique QR code asset tag that enables you to access serialized information directly from the

device. With this capability, you can:

■

Access device drawings, diagrams, technical documentation, and troubleshooting information in your MyEmerson account

■

Improve mean time to repair and maintain efficiency

■

Ensure confidence that you have located the correct device

■

Eliminate the time-consuming process of locating and transcribing nameplates to view asset information

5700 enhancements

Internal memory

The 5700 transmitter provides a backup of:

■

Manually-saved transmitter configurations

■

Meter verification baseline and history

■

Data log

■

Licensing key

If you need to replace your transmitter, move your old memory to the new transmitter without losing any data or licensing

information.

Software licensing

Software licensing makes it possible to:

■

Purchase permanent features and add them later

■

Trial features, such as concentration measurement, for 60 days before buying

■

Order up to 5 input/output channels through the license

Large graphical display

■

Supports multiple languages

■

Supports full configuration capabilities directly from the display

■

Provides understandable alert codes

Two-phase flow detection

Two-phase flow detection provides clear, concise information about fluid conditions, including notification about the following

fluid regimes:

■

Single phase

■

Moderate two-phase flow

■

Severe two-phase flow

Physical design

■

Conduit and terminal compartments are accessible from the sides

■

Modular board stack design

■

Spacious wiring compartments

■

Remote mounting bracket

■

A Universal Service Port (USP) connects and transfers data using standard, easily available equipment

www.emerson.com 5

5700 Transmitters

April 2021

Troubleshooting tools

The 5700 transmitter stores data in non volatile memory with Real Time Clock, including:

■

Audit trail

■

Alert log

■

Long term data historian: 5-minute Min, Max, Avg, Std Dev (10 years)

■

Short term data historian: 1-second data (30 days)

The 5700 transmitter contains descriptive alerts describing the issue and recommended steps for resolution.

■

Follows NE 107 Standard

Wi-Fi display option (5700 with configurable inputs and outputs only)

Wi-Fi display option enables point-to-point wireless communication in order to configure and characterize the meter, download

historical files, and run Smart Meter Verification for troubleshooting purposes.

Wi-Fi is not compatible with Weights & Measures options NT, OG, and OL.

The maximum Wi-Fi connection distance is 115 ft (35 m) from the front display and 50 ft (15 m) from the sides and back of the

transmitter housing.

Spectrum approvals for Wi-Fi

US and Canada (FCC and ISED)

Europe (ETSI)

Applications

Applications are custom designed programs and software that offer additional functionality and performance to transmitters.

These applications are available through options in the transmitter model code. For details, see the ordering information section.

Smart Meter Verification

Provides a quick, complete assessment of a Micro Motion Coriolis meter, determining whether the meter has been affected by

erosion, corrosion, or other influences affecting meter calibration. No secondary references are required to perform this operation,

and the meter can continue normal process measurement while the test is in progress.

Smart Meter Verification Professional on the 5700 transmitter also offers non-uniform coating detection, installation verification,

detection of optimal flow range, and two-phase flow detection. A 90-day trial version is included with all transmitters with

enhanced core processors. After the 90-day trial, a basic version of Smart Meter Verification will provide simple pass/fail results, and

simple diagnostics that run without interrupting your processes.

Discrete batch control

■

Simple batch control based on totalizer values

■

Frequency Output configured as Discrete Output for transmitters with analog or intrinsically safe outputs

■

Automatic overshoot compensation

■

Single and dual stage batching available on the configurable I/O and intrinsically safe versions when ordered with the Batching

Software (BS) package option

■

Optional constant batch mode provides a simplified batch screen flow, and stays in this mode until a password is entered to exit

mode, in addition to standard batch

■

Batch ticket printing available if Channel E is enabled (supports Terminal Window, Generic, Epson TM88v, Epson TMU-295 and

Digitec 6610A printers)

■

Batch ticket printing available with Ethernet (supports Epson TM88VI)

Note

Discrete batch control is not available with 5700 FOUNDATION Fieldbus or PROFIBUS-PA.

6 www.emerson.com

April 2021

5700 Transmitters

Petroleum measurement and API correction option

■

Accepts inputs from temperature and pressure devices

■

Calculates values as per May, 2004 API Chapter 11.1

— Relative density (specific gravity and API gravity) at reference temperature from observed density and temperature

— Volume corrected to reference temperature and pressure

■

Calculates flow-weighted average temperature and flow-weighted average observed density (specific gravity and API gravity)

Concentration measurement

Provides concentration measurement based on either industry-specific or liquid-specific units and relationships. Standard

measurement options include:

■

Industry-specific:

— °Brix

— °Plato

— °Balling

— °Baumé at SG60/60

— Specific gravity

■

Liquid-specific:

— %HFCS

— Concentration derived from reference density

— Concentration derived from specific gravity

Additionally, the application can be customized for site-specific concentration measurement (such as %HNO3, %NaOH).

Advanced Phase Measurement

■

Accurately measures liquid or gas flow in limited multiple-phase conditions

— Immediate and continuous access to production or process data

— Real time reporting of Gas Void Fraction (GVF)

■

Facilitates reliable measurement at a fraction of the cost of true multi-phase meters

— Historian automatically captures all production data

— Little to no maintenance or calibration

■

Combines with Net Oil Computer (NOC) or concentration measurement to measure two liquids in the presence of gas

— Provides single-well and multi-well real-time Net Oil and Net Water measurements

— Improves concentration measurement in processes with intermittent entrained gas

Piecewise Linearization (PWL) for enhanced gas applications

■

Provides gas calibration enhancement capability for industry-leading gas measurement performance

■

Designed specifically for midstream natural gas fiscal metering applications

Note

Piecewise Linearization is not available with 5700 FOUNDATION Fieldbus.

Third-party gas calibration services are not included.

www.emerson.com 7

5700 Transmitters April 2021

Electrical connections

Electrical isolation

For all 5700 versions, each I/O channel is isolated +/-50VDC from all other outputs and earth ground.

Configurable I/O version

Connection Description

Input/Output Up to 5 pairs of wiring terminals for transmitter I/O and communications

Power

■

One pair of wiring terminals accepts AC or DC power

■

One internal ground lug for power-supply ground wiring

Sensor

Service port (HART®) Two clips for temporary connection to the service port

Universal Service Port (USP) A USP connected to commercially-available USB equipment and cables

Wi-Fi display option Wi-Fi display option enables point-to-point wireless communication in order to

■

4-wire remote mount – 4 terminals for connection to 4-wire sensor

■

9-wire remote mount – 9 terminals for connection to 9-wire sensor

configure and characterize the meter, download historical files, and run Smart Meter

Verification for troubleshooting purposes.

The maximum Wi-Fi connection distance is 115 ft (35 m) from the front display and

50 ft (15 m) from the sides and back of the transmitter housing.

Ethernet version

Connection

Ethernet ports Two Ethernet ports for EtherNet/IP, Modbus TCP, PROFINET, and web server

Input/Output One configurable channel for mA Output, Frequency Output, Discrete Output, or

Power

Sensor

Description

connections

Discrete Input

■

One pair of wiring terminals accepts AC or DC power

■

One internal ground lug for power-supply ground wiring

■

4-wire remote mount – 4 terminals for connection to 4-wire sensor

■

9-wire remote mount – 9 terminals for connection to 9-wire sensor

Universal Service Port (USP) A USP connected to commercially-available USB equipment and cables

Embedded web server

■

Connects to embedded web server via Ethernet connection for on-board

configuration or data transfer

■

Supports secure web server connection with default Self-Signed Certificate and

optional support for Certificate Authority

8 www.emerson.com

April 2021

FOUNDATION Fieldbus version or PROFIBUS-PA version

Connection Description

5700 Transmitters

Input/Output

Power

Sensor

Universal Service Port (USP) A USP connected to commercially-available USB equipment and cables

FOUNDATION Fieldbus Two clips for a temporary connection to the service port

PROFIBUS-PA Two terminals for connection

■

One channel for mA Output

■

One configurable channel for Frequency Output or Discrete Output

These outputs are available as intrinsically safe, or non-intrinsically safe, based on

the output option selected. For PROFIBUS-PA, the outputs are intrinsically safe if

powered with an intrinsically safe power supply.

■

One pair of wiring terminals accepts AC or DC power

■

One internal ground lug for power-supply ground wiring

■

4-wire remote mount – 4 terminals for connection to 4-wire sensor

■

9-wire remote mount – 9 terminals for connection to 9-wire sensor

Intrinsically safe outputs version

Connection Description

Output Up to 4 pairs of wiring terminals for transmitter outputs and communications

Power

■

One pair of wiring terminals accepts AC or DC power

■

One internal ground lug for power-supply ground wiring

Sensor

Service port (HART) Two clips for temporary connection to the service port

Universal Service Port (USP) A USP connected to commercially-available USB equipment and cables

Note

■

Each screw terminal connection accepts one or two solid conductors, 24 AWG (0.205 mm²) to 12 AWG (3.31 mm²) or one or

two stranded conductors, 22 AWG (0.326 mm²) to 14 AWG (2.08 mm²). Each plug type connector accepts one stranded or

solid conductor, 24 AWG (0.205 mm²) to 12 AWG (3.31 mm²).

■

For integral mount transmitters (mounting code I), the connection between the transmitter and the sensor is not normally

accessed.

■

4-wire remote mount – 4 terminals for connection to 4-wire sensor

■

9-wire remote mount – 9 terminals for connection to 9-wire sensor

www.emerson.com 9

5700 Transmitters April 2021

Input/output signal detail

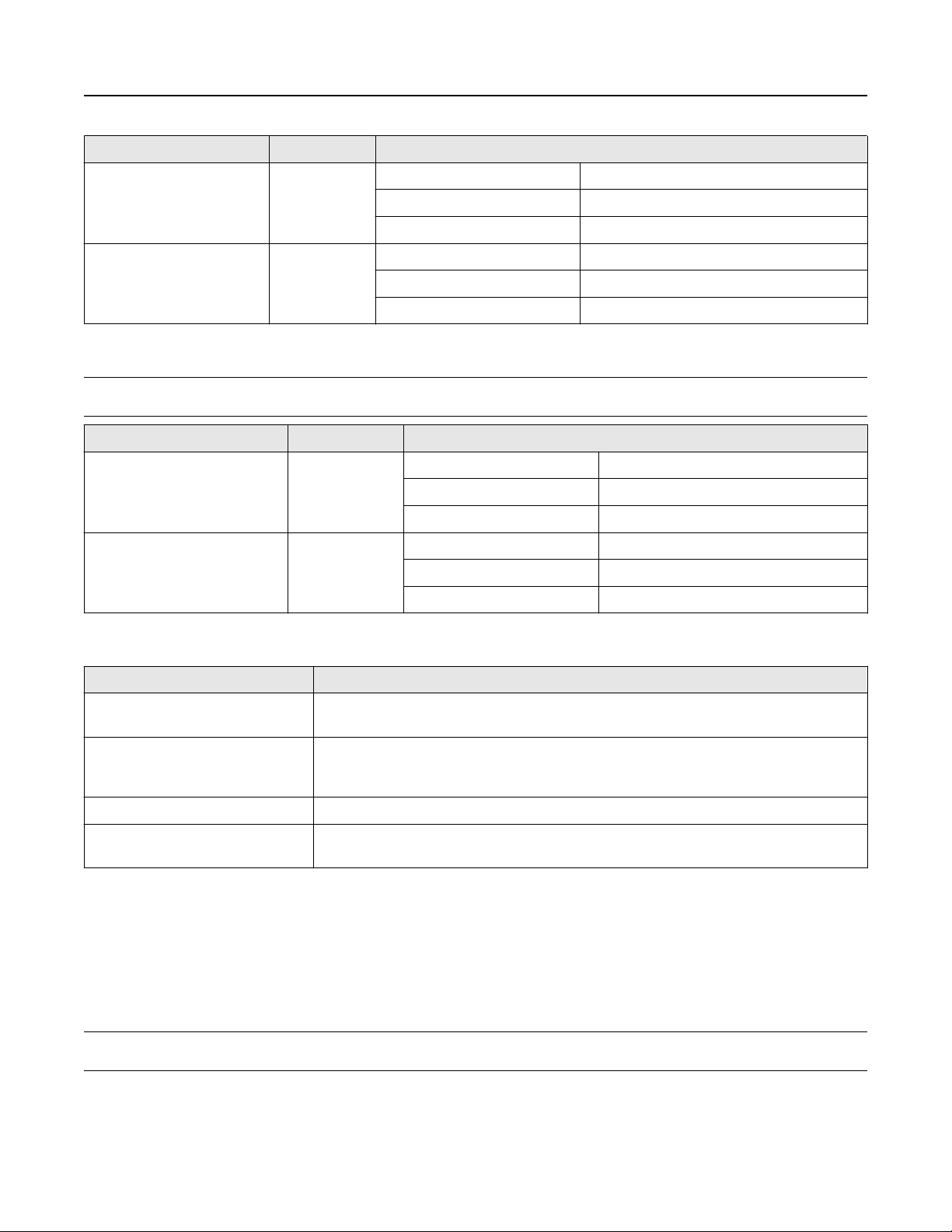

Configurable I/O channels (output board code A)

Signal Channel A Channel B Channel C Channel D Channel E

Wiring

terminals

mA Inputs and

Outputs

Frequency

Outputs

Discrete

Outputs

Discrete

Inputs

Frequency

Inputs

(1)

Frequency Output 2 can be mapped to Channel B or D. For multiple Frequency Outputs, use Frequency 1 on Channel C and Frequency 2 on either

Channel B or D.

1 2 3 4 5 6 7 8 9 10

mA Output 1 (HART) mA Output 2 mA Output 3 mA Input RS-485

Frequency Output

(1)

2

Discrete Output 1 Discrete Output 2 Discrete Output 3

Frequency Output 1 Frequency Output

Discrete Input 1 Discrete Input 2

(1)

2

Frequency Input

Ethernet channels (output board code C)

Signal

Channel

options

Channel A Channel B Channel C

EtherNet/IP

The same protocol must be

ordered on both Channel A and B.

ProLink™ III and the Integrated Web

server can always be connected to

either Channel A or B.

EtherNet/IP mA Output

Modbus TCP Modbus TCP Frequency Output

PROFINET PROFINET Discrete Output

Discrete Input

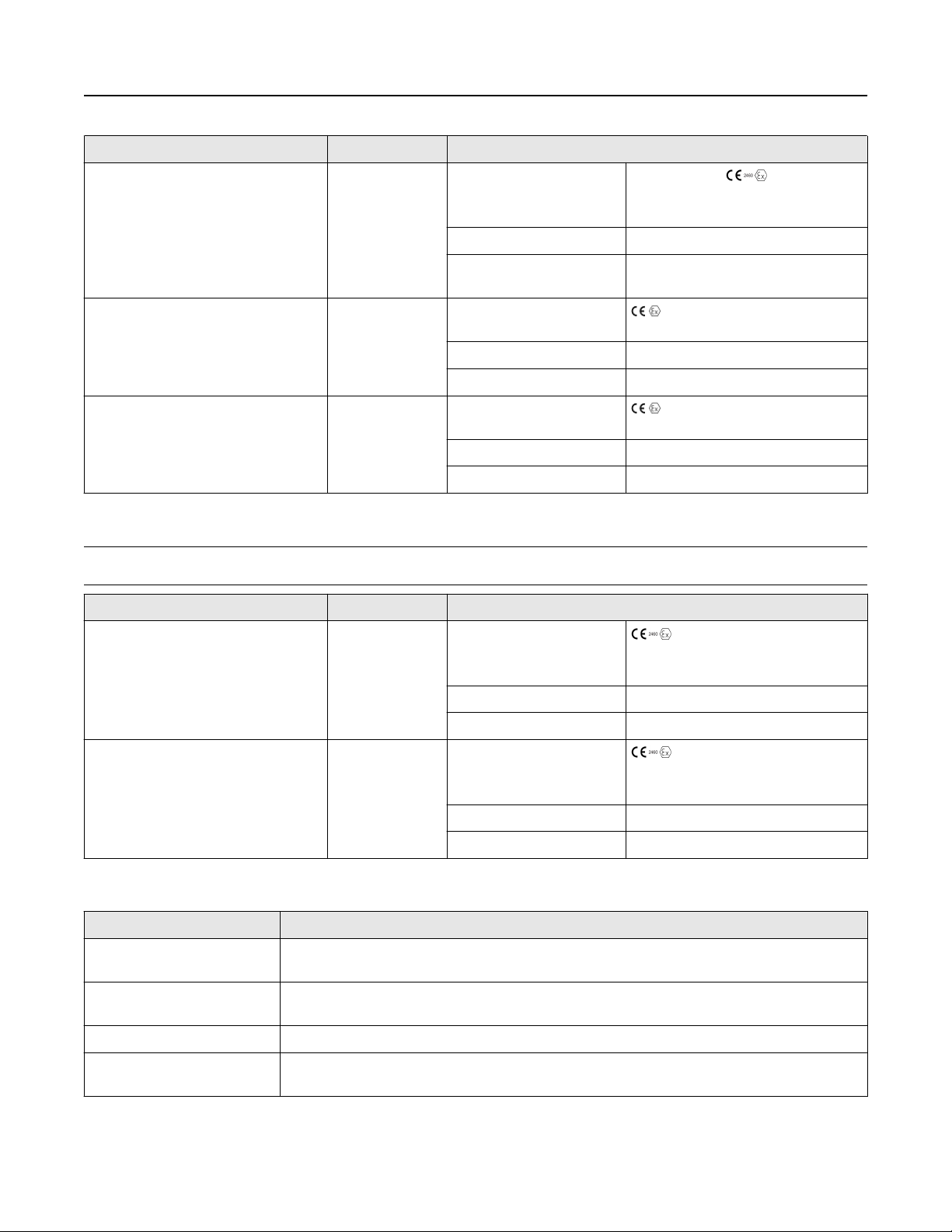

FOUNDATION Fieldbus channels (output board code E with Channel A assignment F for intrinsically safe H1

outputs)

Signal

Wiring

terminal

Channel

options

Channel A x Channel B Channel C x

1 2 3 4 5 6 7 8 9 10

FOUNDATION Fieldbus

(FISCO “ia” or FISCO

“ic”

x IS mA Output IS Frequency Output x

IS Discrete Output

10 www.emerson.com

April 2021

FOUNDATION Fieldbus channels (output board code N with H1 outputs)

Signal Channel A x Channel B Channel C x

5700 Transmitters

Wiring

terminal

Channel

options

1 2 3 4 5 6 7 8 9 10

FOUNDATION Fieldbus

(FISCO “ia” or FISCO

“ic”

x IS mA Output IS Frequency Output x

IS Discrete Output

PROFIBUS-PA (output board E with Channel A assignment G)

Signal Channel A x Channel B Channel C x

Wiring

terminal

Channel

(1)

options

(1)

The outputs for Channels B and C are intrinsically safe if powered with an intrinsically safe power supply.

1 2 3 4 5 6 7 8 9 10

PROFIBUS-PA x IS mA Output IS Frequency Output x

IS Discrete Output

Intrinsically safe output channels

Signal Channel A Channel B Channel C Channel D

Wiring terminals 1 2 3 4 5 6 7 8

mA Outputs mA Output (1) (HART) mA Output (2) mA Output (3)

Frequency

Outputs

Frequency Output (1) Frequency Output (2)

Discrete Outputs Discrete Output (1) Discrete Output (2)

Channel A specifications

Configurable I/O (output board code A)

Specification

Downscale fault Configurable from 1.0 – 3.6 mA, default value = 2.0 mA

External voltage (passive power) Maximum: 30VDC

Internal voltage (active power) Nominal: 24VDC

Linearity 0.015 % Span, Span = 16mA

Scalable range 4-20 mA

Upscale fault Configurable from 21.0 – 23.0 mA, default value = 22.0 mA

Note

mA Output is linear with process from 3.8 to 20.5 mA, per NAMUR NE 43 (February 2003).

mA Output

Maximum loop resistance: 1080 ohm @ 30VDC

www.emerson.com 11

5700 Transmitters April 2021

Ethernet (output board code C)

Specifications:

■

10BASE-T

■

100BASE-TX

FOUNDATION Fieldbus (output board code E with Channel A assignment F)

Specifications:

■

FOUNDATION Fieldbus H1 output

■

Wiring is intrinsically safe with intrinsically safe power supply

■

Transmitter fieldbus circuit is passive, and draws power from the fieldbus segment — current draw is 13 mA

■

Manchester encoded digital signal conforms to IEC 61158-2

FOUNDATION Fieldbus (output board code N)

Specifications:

■

FOUNDATION Fieldbus H1 output

■

FOUNDATION Fieldbus wiring is non-incendive

■

Transmitter fieldbus circuit is passive, and draws power from the fieldbus segment — current draw is 13 mA

■

Manchester encoded digital signal conforms to IEC 61158-2

PROFIBUS-PA (output board code E with Channel A assignment G)

■

PROFIBUS-PA output

■

Wiring is intrinsically safe with intrinsically safe power supply

■

Transmitter fieldbus circuit is passive, and draws power from the fieldbus segment — current draw is 13 mA

■

Manchester encoded digital signal conforms to IEC 61158-2

Intrinsically safe (output board code D)

Specification

Downscale fault Configurable from 3.2 – 3.6 mA, default value = 3.2 mA

Entity parameters Ui = 30V

External voltage (passive power) Minimum: 8VDC

Linearity 0.020 % Span, Span = 16 mA

Scalable range 4-20mA

Upscale fault Configurable from 21.0 – 23.0 mA, default value = 22.0mA

mA Output

Ii = 484mA

Pi = 2.05W

Ci = 150pF

Li = OuH

Maximum: 30VDC

Maximum loop resistance: 917 ohm @ 30VDC

12 www.emerson.com

April 2021 5700 Transmitters

Channel B specifications

Configurable I/O (output board code A)

Specification mA Output Frequency Output (2) Discrete Output (1)

Internal voltage

(active power)

External voltage

(passive power)

Scalable range 4-20mA 0.01 Hz – 10 kHz

Downscale fault Configurable from 1.0 – 3.6 mA,

Upscale fault Configurable from 21.0 – 23.0 mA,

Linearity 0.015 % Span, Span = 16mA Output is linear with flow rate

Resolution ± 1 pulse

Nominal: 24VDC

Maximum loop resistance: 820 ohm

Maximum: 30VDC

Maximum loop resistance: 1080 ohm @

30VDC

default value = 2.0 mA

default value = 22.0 mA

Nominal: 24VDC

Sourcing: 22 mA

Maximum: 30VDC

Maximum sinking: 500 mA

0Hz

Configurable from 10 Hz to

14.5 kHz, default value = 14.5

kHz

to 12.5 kHz

Nominal: 24VDC

Sourcing: 7 mA sourcing

Maximum: 30VDC

Maximum sinking: 500 mA

Ethernet (output board code C)

Specifications:

■

10BASE-T

■

100BASE-TX

FOUNDATION Fieldbus (output board code E with Channel A assignment F) or PROFIBUS-PA (output board code E

with Channel A assignment G)

Specification

External voltage (passive power) Minimum: 10VDC

Scalable range 4-20 mA

Downscale fault Configurable from 1.0 – 3.6 mA, default value = 2.0 mA

Upscale fault Configurable from 21.0 – 23.0 mA, default value = 22.0 mA

Linearity 0.015 % Span, Span = 16 mA

Entity parameters Ui = 30V

mA Output

Maximum: 30VDC

Maximum loop resistance: 869 ohms @ 30V

Ii = 484mA

Pi = 2.05W

Ci = 0.27nF

Li = 5uH

www.emerson.com 13

5700 Transmitters April 2021

FOUNDATION Fieldbus output board code N

Specification mA Output

External voltage (passive power) Minimum: 10VDC

Maximum: 30VDC

Maximum loop resistance: 869 ohms @ 30V

Scalable range 4-20 mA

Downscale fault Configurable from 1.0 – 3.6 mA, default value = 2.0 mA

Upscale fault Configurable from 21.0 – 23.0 mA, default value = 22.0 mA

Linearity 0.015 % Span, Span = 16 mA

Note

mA Output is linear with process from 3.8 to 20.5 mA, per NAMUR NE-43 (February 2003).

Intrinsically safe (output board code D)

Specification mA Output

External voltage (passive power) Minimum: 8VDC

Maximum: 30VDC

Maximum loop resistance: 917 ohm @ 30VDC

Scalable range 4-20mA

Downscale fault Configurable from 3.2 – 3.6 mA, default value = 3.2 mA

Upscale fault Configurable from 21.0 – 23.0 mA, default value = 22.0 mA

Linearity 0.020 % Span, Span = 16mA

Channel C specifications

Configurable I/O (output board code A) and Ethernet (output board code C)

Specification

Internal voltage (active

power)

External voltage

(passive power)

Scalable range 4-20 mA 0.01 Hz – 10 kHz

Downscale fault Configurable from 1.0 –

mA Output Frequency Output

Nominal: 24VDC

Maximum loop

resistance: 820 ohm

Maximum: 30VDC

Maximum loop

resistance: 1080 ohm @

30VDC

3.6 mA, default value =

2.0 mA

Nominal: 24VDC

Sourcing: 22 mA

Maximum: 30VDC

Maximum sinking: 500

mA

0Hz

(1)

Discrete Output

Nominal: 24VDC

Sourcing: 7 mA

Maximum: 30VDC

Maximum sinking: 500

mA

(2)

Discrete Input

Nominal: 24VDC

Sourcing: 7 mA

Maximum: 30VDC

Upscale fault Configurable from 21.0

– 23.0 mA, default value

= 22.0 mA

Resolution ± 1 pulse

Configurable from 10

Hz to 14.5 kHz, default

value = 14.5 kHz

14 www.emerson.com

April 2021 5700 Transmitters

Specification mA Output Frequency Output

(1)

Discrete Output

(2)

Discrete Input

Linearity 0.015 % Span, Span = 16mAOutput is linear with

flow rate to 12.5 kHz

Maximum positive

3VDC

threshold

Minimum negative

0.6VDC

threshold

(1)

Load resistor (500 Ω resistance recommended for 24V supply.) Use the following equations for other load resistance values: Rmax = [(Vsupply 6V) / 0.003] - Rbarrier (maximum value of load resistor allowed) Rmin = 0 ohms

(2)

Current = (Vsupply - 0.8V) / (1690 ohms + barrier internal resistance in ohms + load resistor in ohms)

Note

mA Output is linear with process from 3.8 to 20.5 mA, per NAMUR NE-43 (February 2003).

FOUNDATION Fieldbus (output board code E with Channel A assignment F) or PROFIBUS-PA (output board code E

with Channel A assignment G)

Specification Frequency Output

External voltage (passive power) Maximum: 30VDC

Minimum: 8VDC

Scalable range 0.01 Hz - 10 kHz

Downscale fault 0Hz

(1)

Discrete Output

Maximum: 30VDC

Minimum: 8VDC

(2)

Upscale fault Configurable from 10 Hz to 14.5 kHz,

default value = 14.5 kHz

Resolution ± 1 pulse

Entity parameters Ui = 30V

Ii = 484mA

Pi = 2.05W

Ci = 11.27nF

Li = 5uH

(1)

Load resistor (500 Ω resistance recommended for 24V supply.) Use the following equations for other load resistance values: Rmax = [(Vsupply 6V) / 0.003] - Rbarrier (maximum value of load resistor allowed) Rmin = 0 ohms

(2)

Current = (Vsupply - 0.8V) / (1690 ohms + barrier internal resistance in ohms + load resistor in ohms)

FOUNDATION Fieldbus (output code N)

Specification

Frequency Output

External voltage (passive power) Maximum: 30VDC

Minimum: 8VDC

(1)

(3)

Scalable range 0.01 Hz - 10 kHz

Downscale fault 0Hz

Upscale fault Configurable from 10 Hz to 14.5 kHz,

default value = 14.5 kHz

Resolution ± 1 pulse

Discrete Output

Maximum: 30VDC

Minimum: 8VDC

(2)

(4)

(1)

Load resistor (500 Ω resistance recommended for 24V supply.) Use the following equations for other load resistance values: Rmax = [(Vsupply 6V) / 0.003] - Rbarrier (maximum value of load resistor allowed) Rmin = 0 ohms

(2)

Current = (Vsupply - 0.8V) / (1690 ohms + barrier internal resistance in ohms + load resistor in ohms)

(3)

Load resistor (500 Ω resistance recommended for 24V supply.) Use the following equations for other load resistance values: Rmax = [(Vsupply 6V) / 0.003] (maximum value of load resistor allowed) Rmin = 250 ohms (minimum value of load resistance required)

www.emerson.com 15

5700 Transmitters April 2021

(4)

Current = (Vsupply - 0.8V) / (1690 ohms + load resistor in ohms)

Intrinsically safe (output board code D)

Specification mA Output Frequency Output

(1)

Discrete Output

External voltage (passive

power)

Scalable range 4-20 mA 0.01 Hz – 10 kHz

Downscale fault Configurable from 3.2 – 3.6

Upscale fault Configurable from 21.0 – 23.0

Accuracy ± 1 pulse

Linearity 0.015 % Span Span = 16mA Output is linear with flow rate

(1)

Load resistor (500 Ω resistance recommended for 24V supply.)

Note

mA Output is linear with process from 3.8 to 20.5 mA, per NAMUR NE-43 (February 2003).

Maximum: 30VDC

Maximum: 30VDC

Maximum loop resistance: 917

ohm @ 30VDC

mA, default value = 3.2 mA

mA, default value = 22.0 mA

Maximum: 30VDC Maximum: 30VDC

0Hz

Configurable from 10 Hz to

14.5 kHz, default value = 14.5

kHz

to 12.5 kHz

Channel D specifications

Channel D specifications do not apply to Ethernet, FOUNDATION Fieldbus, or PROFIBUS-PA configurations.

Configurable I/O (output board code A)

Specification

Internal voltage

(active power)

External voltage

(passive power)

Scalable range 0.01 Hz – 10 kHz 4 - 20 mA

Downscale fault 0Hz

Upscale fault Configurable from

Accuracy +/- 1 pulse

Frequency Output

(2)

Nominal: 24VDC

2.21 kilo ohm pullup resistor

Maximum: 30VDC

Maximum sinking:

500mA

10 Hz to 14.5 kHz,

default value = 14.5

kHz

mA Input Discrete Output

Nominal: 24VDC Nominal: 24VDC

Maximum: 30VDC Maximum: 30VDC

Fault indication if

mA Input drops

below 3.8 mA or

goes above 20.5

mA

(3)

2.21kilo ohm pullup resistor

Maximum sinking:

500 mA

Discrete Input (2) Frequency Input

Nominal: 24VDC

2.21 kilo ohm pullup resistor

Maximum: 30VDC Maximum: 30VDC

Nominal: 24VDC

2.21 kilo ohm pullup resistor

16 www.emerson.com

April 2021 5700 Transmitters

Specification Frequency Output

(2)

Input resistance 100 ohm

Max frequency 100 Hz 3500 Hz

Maximum positive

threshold

Minimum negative

threshold

mA Input Discrete Output

(3)

Discrete Input (2) Frequency Input

3VDC 3VDC

0.6VDC 0.6VDC

Intrinsically safe (output board code D)

Specification Frequency Output (2) Discrete Output (2)

External voltage (passive power) Maximum: 30VDC Maximum: 30VDC

Scalable range 0.01 Hz – 10 kHz

Downscale fault 0Hz

Upscale fault Configurable from 10 Hz to 14.5 kHz,

default value = 14.5 kHz

Accuracy ± 1 pulse

Channel E specifications

Channel E is not available for Ethernet, FOUNDATION Fieldbus, Intrinsically safe, or PROFIBUS-PA configurations.

Output option

Configurable I/O (output board code A) RS-485 Modbus

Specification

Sensor input mounting codes

Mounting codes

I (integral mount) Integrally mounted to sensor, no external input connection

C (9-wire remote mount) One 9-wire sensor signal input connection, intrinsically safe

R (4-wire remote mount) One 4-wire sensor signal input connection, intrinsically safe

Description

www.emerson.com 17

5700 Transmitters April 2021

Digital communications

Protocols Outputs and descriptions

Modbus/USP

■

One service port that can be used for a temporary connection only

■

Connects to a PC via USB as if the transmitter had a built-in USB/RS-485 converter

■

Supports all Modbus data rates

■

Requires a USB A/male-to-A/male cable

— A 4 ft (1.22 m) cable is supplied with each meter

Modbus/RS-485,HART/RS-485

HART/Bell 202

FOUNDATION Fieldbus

■

Available on Channel E, if purchased

■

One RS-485 output can be used for direct connection to HART or Modbus host

systems

■

Accepts data rates between 1200 baud and 38.4 kilobaud

■

115.2 kilobaud is also available as a special order item

■

Uses the latest HART 7 standard

■

Available on Channel A, if purchased

■

HART Bell 202 signal is superimposed on the primary milliamp output, and is

available for host system interface

■

Requires 250 to 600 ohms load resistance

■

Uses the latest HART 7 standard

■

Available on Channel A

■

Models/output codes:

— 5700 with output code E is FISCO “ia” certified in Zone 1 / Div 1and is FISCO

“ic” certified in Zone 2 / Div 2 (formerly known as FNICO)

— 5700 with output code N

■

Transmitters are registered with the Fieldbus Foundation, and conform to the

FOUNDATION Fieldbus H1 protocol specification.

■

FISCO:

— Field device in compliance with EN 60079-11:2012 and IEC 60076-11:2011

— Ui = 33 V, Ii = 380 mA, Pi = 5.32 W, Ci = 0.27 nF, Li = 5 µH

18 www.emerson.com

April 2021 5700 Transmitters

Protocols Outputs and descriptions

EtherNet/IP/Ethernet

Modbus TCP/Ethernet

■

Available on Channel A and Channel B

■

Supports Auto Negotiate with date rates of 10 MB and 100 MB and half and full

duplex

■

Supports Auto Detect of Ethernet Crossover cables

■

Supports Dynamic Host Configuration Protocol (DHCP)

■

Supports Device Level Ring (DLR)

■

Supports Address Conflict Detection (ACD)

■

Supports Quality of Service (QoS)

■

Supports file object for EDS download

■

Conforms to ODVA EtherNet/IP Specification CT 12

■

Conforms to the 10BASE-T and 100BASE-TX Ethernet standards

■

Supports secure web server connection with default Self-Signed Certificate and

optional support for Certificate Authority

■

Available on Channel A and Channel B

■

Supports Auto Negotiate with data rates of 10 MB and 100 MB and half and full

duplex

■

Supports Auto Detect of Ethernet Crossover cables

■

Supports Dynamic Host Configuration Protocol (DHCP)

■

Uses v1.1b of the Modbus TCP standard

■

Conforms to the 10BASE-T and 100BASE-TX Ethernet standards

■

Supports secure web server connection with default Self-Signed Certificate and

optional support for Certificate Authority

PROFINET/Ethernet

PROFIBUS-PA

■

Available on Channel A and Channel B

■

Supports Auto Negotiate with data rates of 10 MB and 100 MB and half and full

duplex

■

Supports Auto Detect of Ethernet Crossover cables

■

Conforms to Conformance Class A v2.31 standard

■

Conforms to the 10BASE-T and 100BASE-TX Ethernet standards

■

Supports secure web server connection with default Self-Signed Certificate and

optional support for Certificate Authority

■

Available on Channel A

■

Transmitters are registered with the Profibus Organization, and fulfill the

requirements of the PROFIBUS-PA Profile 3.02 for Process Control Devices.

■

Compatible with all PROFIBUS-PA host systems

■

FISCO:

— Field device in compliance with EN 60079-11:2012 and IEC 60076-11:2011

— Ui = 33 V, Ii = 380 mA, Pi = 5.32 W, Ci = 0.27 nF, Li = 5 µH

www.emerson.com 19

5700 Transmitters

April 2021

The 5700 with FOUNDATION Fieldbus support

Fieldbus software functionality

The 5700 FOUNDATION Fieldbus software is designed to permit remote testing and configuration of the transmitter using the

DeltaV™ Fieldbus Configuration Tool, or other FOUNDATION Fieldbus compliant hosts. The Coriolis sensor signal is channeled through

the flowmeter to the control room and the FOUNDATION Fieldbus configuration device.

Function block overview

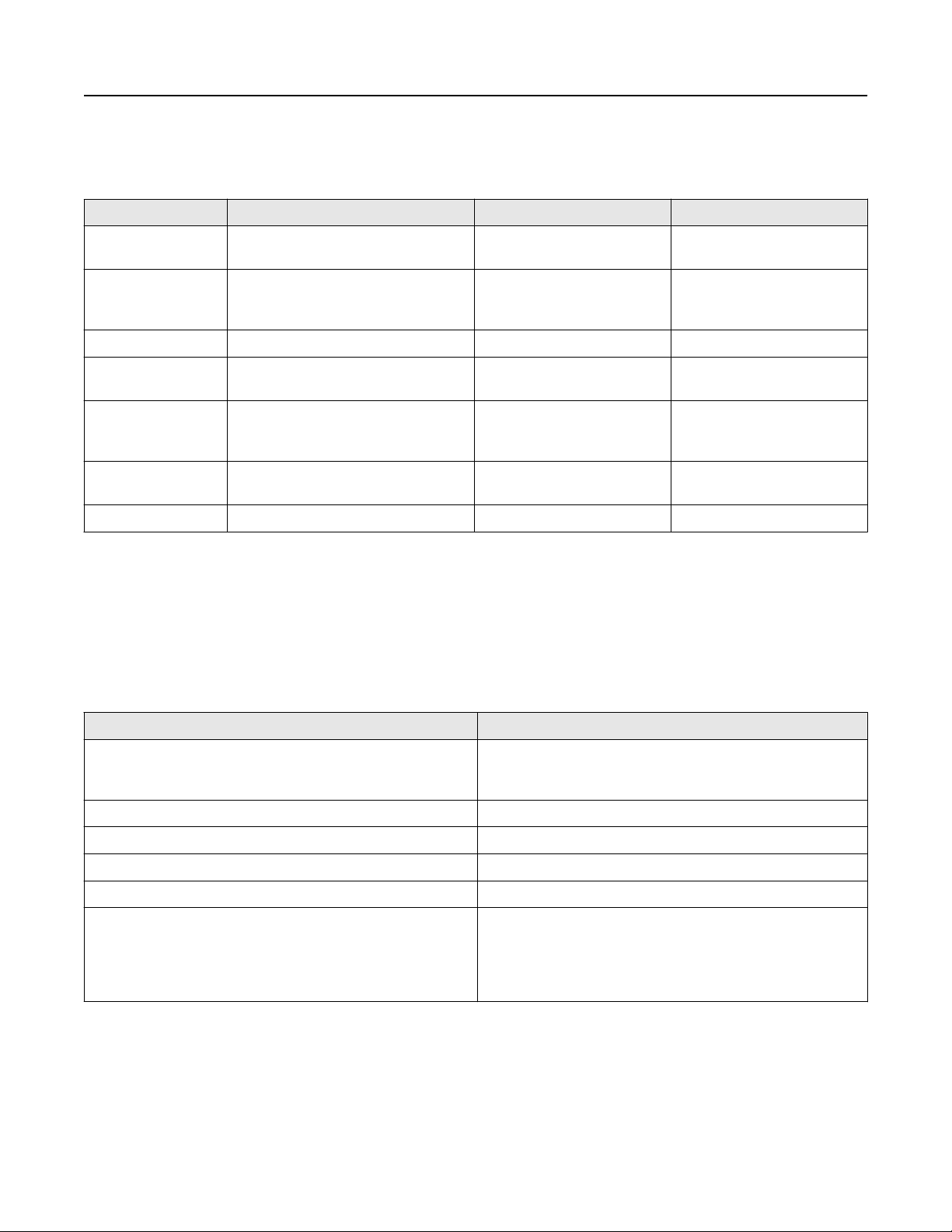

Function block type Quantity Execution time

(milliseconds)

Analog Input (AI) 4 14

Analog Output (AO) 2 14

Discrete Input (DI) 1 13

Discrete Output (DO) 1 12

Integration (INT) 2 12

Proportional, Integral, Derivative (PID) 1 13

Transducer blocks

Transducer blocks hold data from the Coriolis sensor, including process variables, configuration, calibration, and diagnostics.

The 5700 transmitter with FOUNDATION Fieldbus provides up to 7 transducer blocks:

■

Measurement - For process and diagnostic variables and configuration of process parameters.

■

Device - For device, display, channels configuration and device alert information

■

Device Totals and Inventories - For configuration of device totals and inventories

■

Meter Verification - For Smart Meter Verification

■

API referral - For petroleum measurement calculations using API MPMS Chapter 11.1

■

Concentration Measurement

— For complex density and concentration calculations (e.g.,%HFCS, SG60/60)

■

APM - For Advance Phase Measurement and NOC calculations

Resource block

The resource block contains physical device information, including available memory, manufacturer identification, type of device,

and features.

Analog Input function blocks

The Analog Input (AI) function block processes the measurement from the Coriolis sensor and makes it available to other function

blocks. It also allows filtering, alarm handling, and engineering unit changes. Each of the 4 5700 AI blocks can be assigned to one of

27 available variables. There are 4 permanent Analog Input function blocks.

Analog Output function blocks

The AO function block assigns an output value to a field device through a specified channel. The block supports mode control,

signal status calculation, and simulation. The AO block can report pressure from an external pressure source, temperature from an

external temperature source, or watercut from an external device. There are 2 permanent analog output function blocks.

20 www.emerson.com

April 2021

5700 Transmitters

Discrete Input function block

One permanent Discrete Input (DI) function block can be assigned to any of the Discrete Input variable channels in the transducer

block. The DI block channels are: forward/reverse indication, zero in progress, fault condition indication, and meter verification

failure.

Discrete Output function block

One permanent Discrete Output (DO) function block can be assigned to any of the Discrete Output variable channels in the

transducer block. The DO block channels are: Start Sensor Zero, Increment CM Curve, Start Meter Verification in Continuous

Measurement Mode, Reset All Process Totals, Start/Stop All Totals, Reset Config Totals 1-7.

Proportional integral derivative function block

One permanent Proportional Integral Derivative (PID) function block combines all the necessary logic to perform proportional/

integral/derivative control. The block supports mode control, signal scaling and limiting, feed forward control, override tracking,

alarm limit detection, and signal status propagation.

Integrator function block

Two permanent Integrator (INT) function blocks provides functionality for the transmitter totalizers. Any of 7 internal totals or any

of 7 internal inventories can be selected and reset.

Diagnostics and service

5700 transmitters automatically perform continuous self diagnostics. Using the Device transducer block, the user can perform online testing of the transmitter and sensor. Diagnostics are event driven and do not require polling for access.

PlantWeb™ Field Diagnostic is supported. The diagnostic information is based on NAMUR NE 107 standard.

The 5700 with PROFIBUS-PA support

The 5700 PROFIBUS-PA software is in compliance with the PROFIBUS PA Profile for Process Control Devices version 3.02. The

transmitter software supports Coriolis Flow profile with 3-AI + 1-TOT profile (PA Profile 139742) in a profile-specific configuration,

while in the manufacturer-specific profile (0E8B), the transmitter supports 4-AI + 4-TOT + 2-AO + 1-DI + 1-DO function blocks.

■

The transmitter supports condensed status for function block implementation

■

The device has adaptation mode for ident selection to simplify device configuration with host

■

The transmitter has hardware as well as software addressing capability

■

All Totalizer Function Blocks could output and control device internal totals or inventories for more accurate measurement

■

Device diagnostics information is based on NAMUR NE 107

Power supply

■

Self switching AC/DC input, automatically recognizes supply voltage

■

Complies with Low Voltage Directive 2014/35/EU per IEC 61010-1 Ed. 3.0 2010-06; Over voltage Category II, Pollution Degree 2

■

For European installations, install a switch or circuit breaker that is suitably located and easily reached. Mark the switch or circuit

breaker as the disconnecting device for the transmitter, in compliance with the Low Voltage Directive 2014/35/EU.

www.emerson.com 21

5700 Transmitters April 2021

Type Value

AC power

■

85 to 240 VAC, 50/60 Hz

■

6 watts typical, 11 watts maximum

DC power

Fuse 1.5A Slow Blow (UL 248-14)

■

18 to 100 VDC

■

6 watts typical, 11 watts maximum

■

Size the length and diameter of power conductors to provide 18VDC minimum at

the power terminals at a load current of 0.7A

Environmental limits

Ambient temperature limits

Type Temperature

Operating -40 °F (-40.0 °C) to 149 °F (65.0 °C)

Storage -40 °F (-40.0 °C) to 185 °F (85.0 °C)

Note

The display can lose visibility below -22 °F (-30.0 °C).

Vibration limits

Meets IEC 60068-2-6,endurance sweep, 5 to 2000 Hz up to 1.0 g.

Humidity limits

The humidity limits are 5 to 95% relative humidity, non-condensing at 140 °F (60.0 °C).

Environmental effects

EMI effects

Complies with:

■

EMC directive 2014/30/EU

■

NAMUR NE-21 (09.05.2012)

Ambient temperature effect

Ambient temperature effect on mA Outputs shall not exceed:

Configurable I/O version

Ethernet version ±0.0025% of span per degree C

FOUNDATION Fieldbus or PROFIBUS-PA version ±0.005% of span per degree C

Intrinsically safe outputs version ±0.005% of span per degree C

±0.0025% of span per degree C

22 www.emerson.com

April 2021 5700 Transmitters

Hazardous area classifications

CSA and CSA-US

■

Ambient temperature is limited to -40 °F (-40.0 °C) to 149 °F (65.0 °C) for CSA compliance.

Temperature code T4 is for Division 2 installations and T6 is for Division 1 installations.

■

Class I, Div. 1, Groups C and D. Class II, Div. 1, Groups E, F, and G explosion proof (when installed with approved conduit seals).

Otherwise, Class I, Div. 2, Groups A, B, C, and D.

■

Provides nonincendive sensor outputs for use in Class I, Div. 2, Groups A, B, C, and D; or intrinsically safe sensor outputs for use

in Class I, Div. 1, Groups C and D or Class II, Div. 1, Groups E, F, and G.

Code Description

AA Class I, Div. 1, Groups C and D. Class I, Div. 2, groups A,B,C,D Class II, Div. 1, Groups E, F, and G explosion proof

(when installed with approved conduit seals).

2A Class I, Div. 2, Groups A, B, C, and D.

IECEx

Ambient temperature range is -40 °F (-40.0 °C) to 149 °F (65.0 °C) for IECEx compliance.

Configurable I/O — ordering code A

Note

For EA and 3A approval codes, the marking will change when installed with Smart Wireless 775 THUM.

Classification

Flameproof IA Standard or Wi-Fi IIB display Ex db [ib] IIB+H2 T6 Gb

Flameproof/Increased safety EA Standard or Wi-Fi IIB display Ex db eb [ib] IIB+ H2 T6 Gb

Non sparking with an integral

transmitter on the sensor

Non sparking with a remote

transmitter on the sensor

Approval code Approval

No display, standard IIC, or

Wi-Fi IIC display

Dust marking Ex tb [ib] IIIC T75 °C Db IP66/IP67

No display, standard IIC, or

Wi-Fi IIC display

Dust marking Ex tb [ib] IIIC T75 °C Db IP66/IP67

3A Standard or Wi-Fi IIB display Ex nA nC IIB+H2 T4 Gc

No display, standard IIC, or

Wi-Fi IIC

Dust marking Ex tc IIIC T75 °C Dc IP66/IP67

3A Standard or Wi-Fi IIB display Ex nA nC [ib Gb] IIB+H2 T4 Gc

No display, standard IIC, or

Wi-Fi IIC

Ex db [ib] IIC T6 Gb

Ex db eb [ib] IICT6 Gb

Ex nA nC IIC T4 Gc

Ex nA nC [ib Gb] IIC T4 Gc

Dust marking Ex tc [ib Db] IIIC T75 °C Dc IP66/IP67

www.emerson.com 23

5700 Transmitters April 2021

Ethernet — ordering code C

Classification Approval code Approval

Flameproof IA Standard display Ex db [ib] IIB+H2 T6 Gb

No display or IIC display Ex db [ib] IIC T6 Gb

Dust marking Ex tb [ib] IIIC T75 °C Db IP66/IP67

Non sparking with an integral

transmitter on the sensor

Non sparking with a remote

transmitter on the sensor

3A Standard display Ex nA nC IIB+H2 T4 Gc

No display or IIC display Ex nA nC IIC T4 Gc

Dust marking Ex tc IIIC T75 °C Dc IP66/IP67

3A Standard display Ex nA nC [ib Gb] IIB+H2 T4 Gc

No display or IIC display Ex nA nC [ibGb] IIC T4 Gc

Dust marking Ex tc [ib Db] IIIC T75 °C Dc IP66/IP67

FOUNDATION Fieldbus — ordering code N

Classification Approval code Approval

Flameproof IA Standard display Ex db [ib] IIB+H2 T6 Gb

No display or IIC display Ex db [ib] IIC T6 Gb

Dust marking Ex tb [ib] IIIC T75 °C Db IP66/IP67

Flameproof/Increased safety EA Standard display Ex db eb [ib] IIB+ H2 T6 Gb

No display or IIC display Ex db eb [ib] IICT6 Gb

Dust marking Ex tb [ib] IIIC T75 °C Db IP66/IP67

Non sparking with an integral

transmitter on the sensor

3A Standard display Ex nA IIB+H2 T4 Gc

No display or IIC display Ex nA IIC T4 Gc

Dust marking Ex tc IIIC T75 °C Dc IP66/IP67

Non sparking with a remote

transmitter on the sensor

3A Standard display Ex nA [ib Gb] IIB + H2 T4 Gc

No display or IIC display Ex nA [ib Gb] IIC T4 Gc

Dust marking Ex tc [ib Db] IIIC T75 °C Dc IP66/IP67

FOUNDATION Fieldbus FISCO or PROFIBUS-PA — ordering code E

FISCO covers Ex ia, ib, and ic.

Classification

Flameproof IA Standard display Ex db [ia Ga] [ib] IIB+H2 T6 Gb

Flameproof/Increased safety EA Standard display Ex db eb [ia Ga][ib] IIB+H2 T6 Gb

Approval code Approval

No display or IIC display Ex db [ia Ga][ib] IIC T6 Gb

Dust marking Ex tb [ia Da] [ib] IIIC T75 °C Db IP66/IP67

No display or IIC display Ex db eb [ia Ga] [ib] IICT6 Gb

Dust marking Ex tb [ia Da] [ib] IIIC T75 °C Db IP66/IP67

24 www.emerson.com

April 2021

Classification Approval code Approval

5700 Transmitters

Non sparking with an

integral transmitter on the

sensor

Non sparking with a remote

transmitter on the sensor

3A Standard display Ex nA [ic] IIB+H2 T4 Gc

No display or IIC display Ex nA [ic] IIC T4 Gc

Dust marking Ex tc IIIC T75 °C Dc IP66/IP67

3A Standard display Ex nA [ic] [ib Gb] IIB+H2 T4 Gc

No display or IIC display Ex nA [ic] [ib Gb] IIC T4 Gc

Dust marking Ex tc [ib Db] IIIC T75 °C Dc IP66/IP67

Intrinsically safe outputs — ordering code D

Note

For EA and 3A approval codes, the marking will change when installed with Smart Wireless 775 THUM.

Classification Approval code Approval

Flameproof IA Standard display Ex db [ib] [ia] IIB+H2 T6 Gb

No display or IIC display Ex db [ib] [ia] IIC T6 Gb

Dust marking Ex tb [ib] [ia] IIIC T75 °C Db IP66/IP67

Flameproof/Increased safety EA Standard display Ex db eb [ib] [ia] IIB+ H2 T6 Gb

No display or IIC display Ex db eb [ib] [ia] IICT6 Gb

Dust marking Ex tb [ib] [ia] IIIC T75 °C Db IP66/IP67

IECEx mounting options for all models

Code

IA (all mounting options) Used in IECEx EPL Gb/Db Zone 1/21 with flameproof (Ex db) terminal compartment with

EA (all mounting options except

stainless steel option)

3A (mounting option I)

3A (mounting option R and C)

(1)

Not available for a 5700 configuration with intrinsically safe outputs

(1)

(1)

Description

[ib] output for sensors installed in Zone 1/21

Used in IECEx EPL Gb/Db Zone 1/21 with increased safety (Ex eb) terminal compartment

and flame proof (Ex db) electronic compartment with [ib] output for sensors installed in

Zone 1/21

Used in IECEx EPL Gc/Dc Zone 2/22, non sparking

Used in IECEx EPL Gc/Dc Zone 2/22, non sparking with [ib Gb/Db] output for sensors

installed in Zone 1/21

ATEX

Ambient temperature range is -40 °F (-40.0 °C) to 149 °F (65.0 °C) for ATEX compliance.

Configurable I/O — ordering code A

Note

For ZA and VA approval codes, the marking will change when installed with Smart Wireless 775 THUM.

www.emerson.com 25

5700 Transmitters April 2021

Classification Approval code Approval

Flameproof FA Standard or Wi-Fi IIB display

II 2 G/D

Ex db [ib] IIB+H2 T6 Gb

No display, standard IIC, or

Wi-Fi IIC display

Dust marking Ex tb [ib] IIIC T75 °C Db IP66/IP67

Flameproof/Increased safety ZA Standard or Wi-Fi IIB display

No display, standard IIC, or

Wi-Fi IIC display

Dust marking Ex tb [ib] IIIC T75 °C Db IP66/IP67

Non sparking with an integral

transmitter on the sensor

Non sparking with a remote

transmitter on the sensor

VA Standard or Wi-Fi IIB display

No display, standard IIC, or

Wi-Fi IIC display

Dust marking Ex tc IIIC T75 °C Dc IP66/IP67

VA Standard or Wi-Fi IIB display

No display, standard IIC, or

Wi-Fi IIC display

Dust marking Ex tc [ib Db] IIIC T75 °C Dc IP66/IP67

Ex db [ib] IIC T6 Gb

II 2 G/D

Ex db eb [ib] IIB+H2 T6 Gb

Ex db eb [ib] IIC T6 Gb

II 3 G/D

Ex nA nC IIB+H2 T4 Gc

Ex nA nC IIC T4 Gc

II 3(2) G/D

Ex nA nC [ib Gb] IIB+H2 T4 Gc

Ex nA nC [ib Gb] IIC T4 Gc

Ethernet — ordering code C

Classification

Flameproof FA Standard display

Non sparking with an integral

transmitter on the sensor

Approval code Approval

No display or IIC

display

Dust marking Ex tb [ib] IIIC T75 °C Db IP66/IP67

VA Standard display

No display or IIC

display

Dust marking Ex tc IIIC T75 °C Dc IP66/IP67

II 2 G/D

Ex db [ib] IIB+H2 T6 Gb

Ex db [ib] IIC T6 Gb

Ex nA nC IIB+H2 T4 Gc

Ex nA nC IIC T4 Gc

26 www.emerson.com

April 2021 5700 Transmitters

Classification Approval code Approval

Non sparking with a remote

transmitter on the sensor

VA Standard display

No display or IIC

display

Dust marking Ex tc [ib Db] IIIC T75 °C Dc IP66/IP67

FOUNDATION Fieldbus — ordering code N

Classification Approval code Approval

Flameproof FA Standard display

No display or IIC display Ex db [ib] IIC T6 Gb

Dust marking Ex tb [ib] IIIC T75 °C Db IP66/IP67

Flameproof/Increased safety ZA Standard display

No display or IIC display Ex db eb [ib] IIC T6 Gb

Dust marking Ex tb [ib] IIIC T75 °C Db IP66/IP67

Non sparking with an integral

transmitter on the sensor

VA Standard display

Ex nA nC [ib Gb] IIB+H2 T4 Gc

Ex nA nC [ib Gb] IIC T4 Gc

II 2G/D

Ex db [ib] IIB+H2 T6 Gb

II 2 G/D

Ex db eb [ib] IIB+H2 T6 Gb

Ex nA IIB+H2 T4 Gc

No display or IIC display Ex nA IIC T4 Gc

Dust marking Ex tc IIIC T75 °C Dc IP66/IP67

Non sparking with a remote

transmitter on the sensor

VA Standard display

No display or IIC display Ex nA [ib Gb] IIC T4 Gc

Dust marking Ex tc [ib Db] IIIC T75 °C Dc IP66/IP67

FOUNDATION Fieldbus FISCO or PROFIBUS-PA — ordering code E

FISCO covers Ex ia, ib, and ic.

Classification

Flameproof FA Standard display

Approval code Approval

No display or IIC display Ex db [ia Ga] [ib] IIC T6 Gb

Dust marking Ex tb [ia Da] [ib] IIIC T75 °C Db IP66/

Ex nA [ib Gb] IIB+H2 T4 Gc

II (1) 2 G/D

Ex db [ia Ga] [ib] IIB+H2 T6 Gb

IP67

www.emerson.com 27

5700 Transmitters April 2021

Classification Approval code Approval

Flameproof/Increased safety ZA Standard display

II (1) 2 G/D

Ex db eb [ia Ga] [ib] IIB+H2 T6 Gb

No display or IIC display Ex db eb [ia Ga] [ib] IIC T6 Gb

Dust marking Ex tb [ia Da] [ib] IIIC T75 °C Db IP66/

IP67

Non sparking with an integral

transmitter on the sensor

VA Standard display

Ex nA [ic] IIB+H2 T4 Gc

No display or IIC display Ex nA [ic] IIC T4 Gc

Dust marking Ex tc IIIC T75 °C Dc IP66/IP67

Non sparking with a remote

transmitter on the sensor

VA Standard display

Ex nA [ic] [ib Gb] IIB+H2 T4 Gc

No display or IIC display Ex nA [ic] [ib Gb] IIC T4 Gc

Dust marking Ex tc [ib Db] IIIC T75 °C Dc IP66/IP67

Intrinsically safe outputs — ordering code D

Note

For ZA approval codes, the marking will change when installed with Smart Wireless 775 THUM.

Classification

Flameproof FA Standard display

Flameproof/Increased safety ZA Standard display

Approval code Approval

II 2 G/D

Ex db [ib] [ia] IIB+H2 T6 Gb

No display or IIC display Ex db [ib] [ia] IIC T6 Gb

Dust marking Ex tb [ib] [ia] IIIC T75 °C Db IP66/IP67

II 2 G/D

Ex db eb [ib] [ia] IIB+H2 T6 Gb

No display or IIC display Ex db eb [ib] [ia] IIC T6 Gb

Dust marking Ex tb [ib] [ia] IIIC T75 °C Db IP66/IP67

ATEX mounting codes for all models

Code

FA (all mounting options) Used in ATEX II 2 G/D Zone 1/21 with flameproof (Ex db) terminal compartment with [ib] output

ZA (all mounting options

except stainless steel option)

VA (mounting option I)

VA (mounting option R and

(1)

C)

(1)

Not available for a 5700 configuration with intrinsically safe outputs.

(1)

Description

for sensors installed in Zone 1/21.

Used in ATEX II 2 G/D Zone 1/21 with increased safety (Ex eb) terminal compartment and flame

proof (Ex db) electronic compartment with [ib] output for sensors installed in Zone 1/21

Used in ATEX II 3 G/D Zone 2/22 with non-sparking.

Used in ATEX II (2) 3 G/D Zone 2/22, non-sparking with [ib Gb/Db]output for sensors installed in

Zone 1/21.

28 www.emerson.com

April 2021 5700 Transmitters

Environmental compliance

The battery in the 5700 transmitter cannot be serviced or replaced by users. In

compliance with RoHS (Restriction of Hazardous Substances) and WEEE (Waste

Electrical and Electronic Equipment), Micro Motion provides a service for battery

replacement and disposal.

The 5700 transmitter complies with RoHS Directive 2011/65/EU.

Ingress protection 5700 transmitters contain the following ingress protection for specific transmitters:

■

All 5700 transmitters have NEMA 4X protection.

■

5700I transmitters have IP66/IP67 protection.

■

5700C and 5700R transmitters have IP66/IP67/IP69(K)

(1)

The protection is IP69K when using standard NEN-ISO 20653:2013 and IP69 when using standard IEC/EN 60529.

(1)

protection.

Physical specifications

For transmitters integrally mounted to a sensor, you may need to add the weight of the transmitter to the sensor. Refer to the

sensor product data sheet.

Materials of construction

Where 4-wire cable is required, use Micro Motion 4-wire cable, depending on the specific model number ordered, 10 ft (3 m) of

shielded PVC cable (4-wire or 9-wire) will be included (see ordering information for details). For longer cable lengths, contact

customer support.

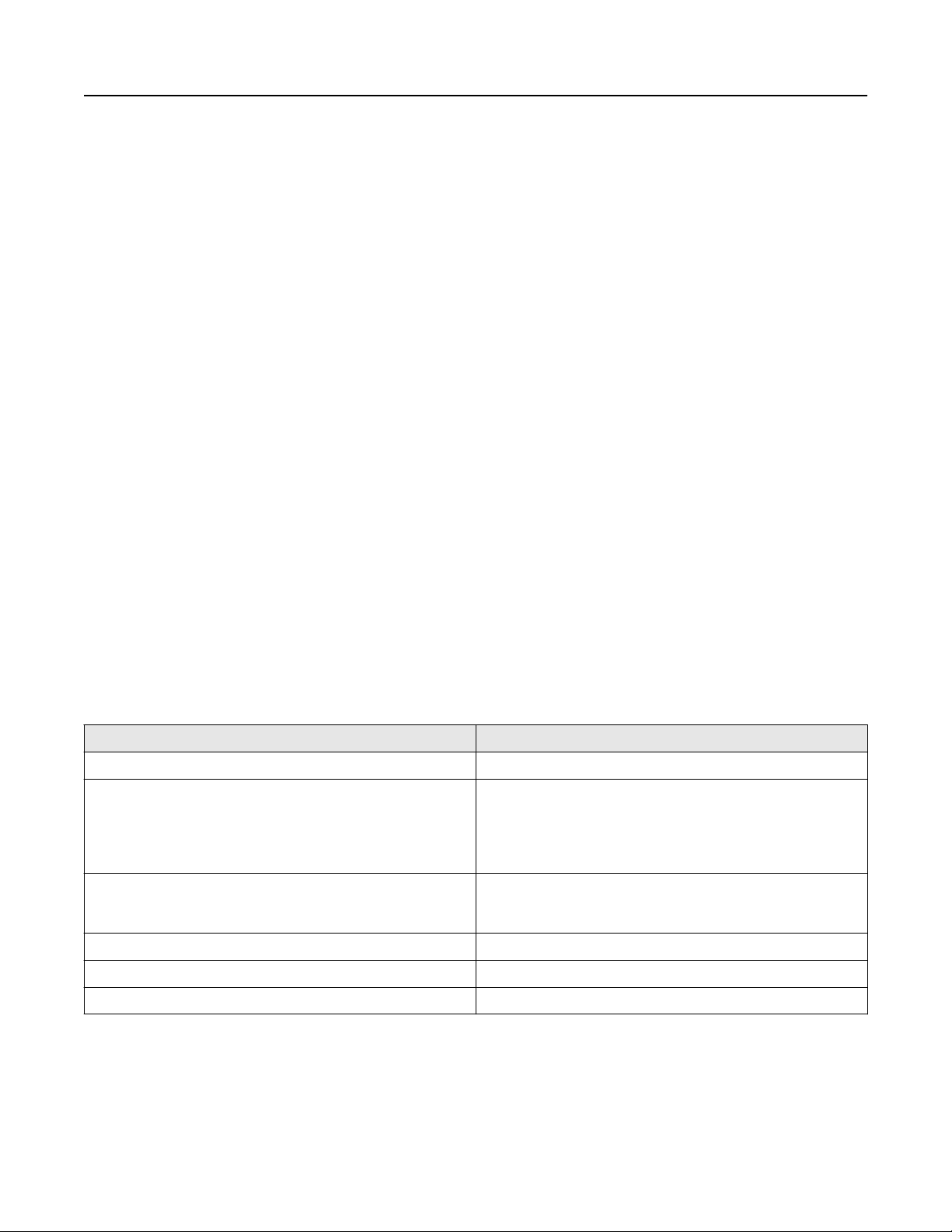

Specification

Housing

Weight

Terminal compartments

Cable gland entrances

Optional M12 connections

(Ethernet version only)

Value

■

Polyurethane-painted cast aluminum

■

316 stainless steel

■

Painted aluminum, 4-wire and 9-wire remote: 16 lb (7.3 kg)

■

Painted aluminum integral: 11 lb (5 kg)

■

Stainless steel remote version without bracket: 34 lb (15.4 kg)

■

Stainless steel remote version with bracket: 41 lb (18.6 kg)

■

Output terminals are physically separated from the power and service-port terminals

■

4-wire remote: M20 x 1.5 female or 1/2 in - 14 NPT conduit entries are available

■

9-wire remote: 3/4 in - 14 NPT female conduit port for sensor cable. For power and I/O, M20 x

1.5 female, or 1/2 in - 14 NPT conduit entries are available.

■

Pre-installed M12 quick connections available as an option

■

Option of (2) pre-installed for Ethernet connections and an option for additional (2)

connections for power and configurable output

■

Suitable for Class 1, Division 2 approval only

www.emerson.com 29

5700 Transmitters April 2021

Specification Value

Mounting

■

Integral or remote mounting options (stainless steel is available only for remote installations)

■

May be remotely connected to any 4-wire or 9-wire Micro Motion sensor

■

Remote mount aluminum housing version includes a 304L stainless steel mounting bracket

and hardware for installing the transmitter on the mounting bracket

■

Remote mount stainless steel housing version includes a 316L stainless steel mounting

bracket and hardware for installing the transmitter on the mounting bracket

■

For remote 4-wire or 9-wire mounts, the transmitter can be rotated 360 degrees with respect

to customer wall or pipe in 90-degree increments

■

For integral mount, the transmitter can be rotated with respect to the sensor in 45-degree

increments

Maximum cable lengths

between sensor and

transmitter

(1)

Standard interface/display

Display functions

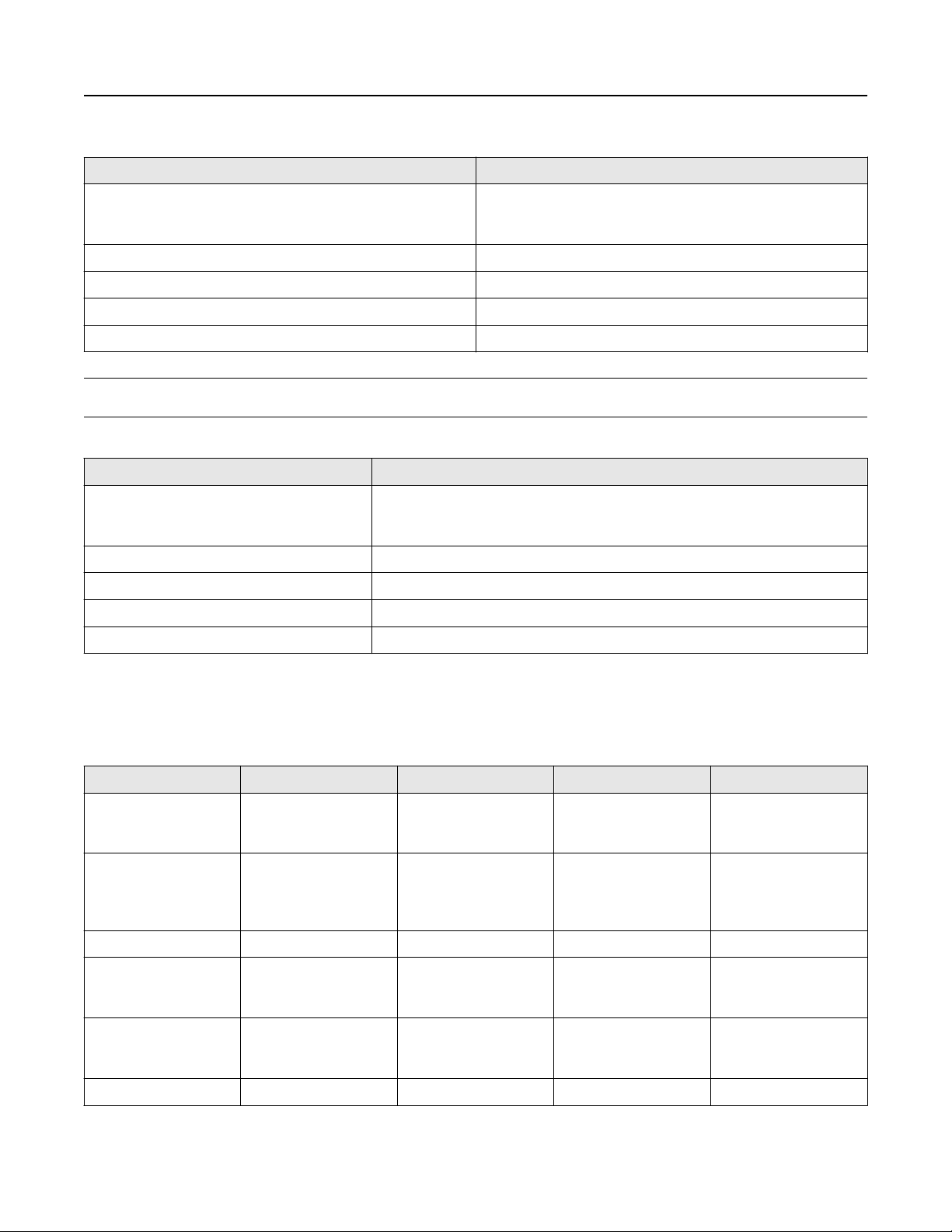

Cable type Wire gauge Maximum length

Micro Motion 9-wire Not applicable 1,000 ft (305 m)

(2)

Micro Motion 4-wire Not applicable 1,000 ft (305 m)

User-supplied 4-wire VDC 22 AWG (0.326 mm²) 300 ft (91 m)

VDC 20 AWG (0.518 mm²) 500 ft (152 m)

VDC 18 AWG (0.823 mm²) 1,000 ft (305 m)

RS-485 22 AWG (0.326 mm²)

1,000 ft (305 m)

or larger

■

Graphical backlit display with 4-button optical controls and flow meter-status LED

■

Depending on purchase option, transmitter housing cover has either a non-glass lens or

tempered glass lens option

■

To facilitate various mounting orientations, the display can be rotated on transmitter, 360

degrees, in 90-degree increments

■

Display supports English, German, French, Spanish, Portuguese, Russian, Chinese, and

Japanese

■

Complete operation and configuration through the display, no service tool required

■

View process variables

■

Start, stop, and reset totalizers

■

View and acknowledge alarms

■

View the Smart Meter Verification initiation and results from the display without interrupting

process measurement

■

Set the flow meter to zero, simulate outputs, change measurement units, configure outputs,

and set RS-485 communications options

■

View a three-color LED status light on display panel that indicates flow meter conditions at a

glance

30 www.emerson.com

April 2021 5700 Transmitters

Specification Value

Wi-Fi display option (5700

with configurable inputs and

outputs only)

(1)

For the cable sizing formula, see the appropriate Micro Motion 5700 installation manual.

(2)

For Smart Meter Verification, the limit is 66 ft (20 m)

■

Wi-Fi display option enables point-to-point wireless communication in order to configure

and characterize the meter, download historical files, and run Smart Meter Verification for

troubleshooting purposes.

■

Wireless communication is available for PCs with ProLink III version 4.6 or greater. ProLink III

is available for iOS/Android tablets for use with the Wi-Fi display option.

■

The maximum Wi-Fi connection distance is 115 ft (35 m) from the front display and 50 ft

(15 m) from the sides and back of the transmitter housing.

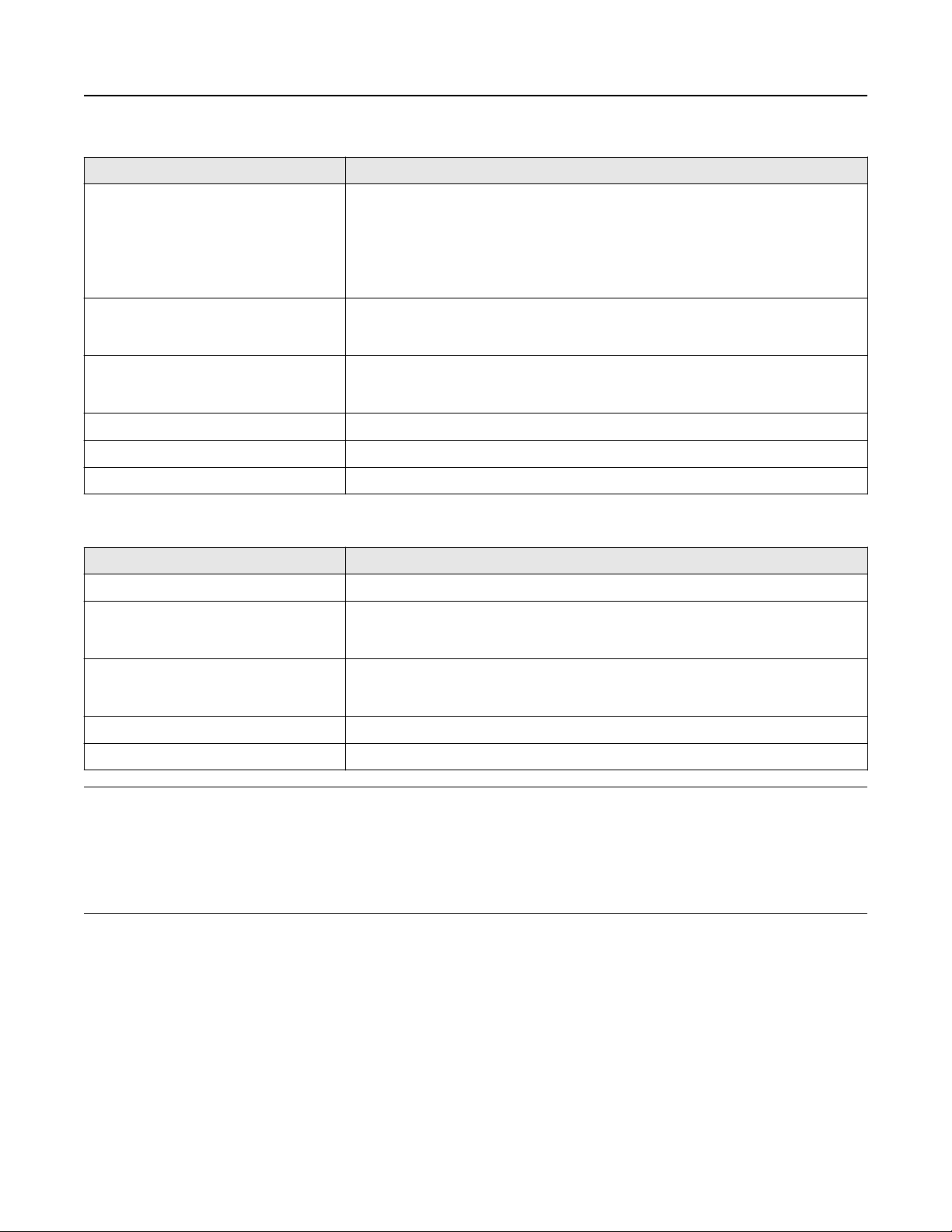

Dimensions

Remote mount aluminum transmitter

www.emerson.com 31

A

B

C

D

6.65

[

169

]

3.08

[78]

3.98

[

101

]

2.75

[70]

3.85

[98]

ø5.40

[

137

]

ø6.16

[

156

]

5.16

[

131

]

3.98

[

101

]

4.72

[

120

]

5700 Transmitters

Remote mount stainless steel transmitter

A. 4 x ½ in - 14 NPT or M20 x 1.5 female

B. ¾ in - 14 NPT female

C. Wall mount

D. Pole mount

April 2021

Integral mount aluminum transmitter

32 www.emerson.com

April 2021 5700 Transmitters

Ordering information

Model

Model Product description

5700 Micro Motion Coriolis field mount transmitter

Mounting options

Code Description

I Integral mount transmitter (polyurethane-painted aluminum housing)

R 4-wire remote mount transmitter (polyurethane-painted aluminum housing), bracket for wall or pipe

mounting, and hardware for 2 in (51 mm) pipe mount, includes 10 ft (3 m) 4-wire shielded PVC cable

C 9-wire remote transmitter with integrated core processor (polyurethane-painted aluminum housing),

bracket for wall or pipe mounting, and hardware for 2 in (51 mm) pipe mount, includes 10 ft (3 m) 9-wire

CFEPS cable

(1)

M

(1)

P

4-wire remote mount transmitter (stainless steel housing), bracket for wall or pipe mounting and hardware

for 2 in (51 mm) pipe mount

9-wire remote mount transmitter with integrated core processor (stainless steel housing), bracket for wall

or pipe mounting, and hardware for 2 in (51 mm) pipe includes 10 ft (3 m) CFEPS cable

(1)

Not available with approval codes ZA, EA, KA, or R1

Power options

Code

1 18 to 100 VDC or 85 to 240 VAC; self switching

Description

Display options

Available with all approval codes

Code

2 Backlit graphic display for CSA, UL, and IIB + H2 ATEX, and IECEx ratings

3 No display

(1)

U

(1)

Available with configurable I/O version only and not compatible with Weights & Measure options NT, OG, and OL.

Description

Backlit graphic display for CSA, UL, and IIB + H2 ATEX and IECEx ratings with Wi-Fi

www.emerson.com 33

5700 Transmitters April 2021

Available with FA, ZA, IA, EA, R1 and R2 approval codes

Code Description

5 Backlit graphic display for IIC ATEX, IECEx, and NEPSI rating

(1)

V

(1)

Available with configurable I/O version only and not compatible with Weights & Measure options NT, OG, and OL.

Backlit graphic display for IIC ATEX, IECEx, and NEPSI rating with Wi-Fi

Available with MA approval code

Code Description

7 Non-glass backlit graphic display

(1)

W

(1)

Available with configurable I/O version only and not compatible with Weights & Measure options NT, OG, and OL.

Non-glass backlit graphic display with Wi-Fi

Output board options

Code Description

A Configurable outputs

(1)(2)

C

(1)

E

(1)

N

(3)

D

Ethernet outputs, select EtherNet/IP, Modbus TCP, or PROFINET in channel assignment section

Intrinsically safe FOUNDATION Fieldbus H1 or PROFIBUS-PA outputs – select FOUNDATION Fieldbus or

PROFIBUS-PA in Output channel assignments.

Non-intrinsically safe FOUNDATION Fieldbus H1 outputs

Intrinsically safe outputs

(1)

Not available with Certificate Option SI.

(2)

Not available with approval options ZA, EA, or R1.

(3)

Not available with approval options VA, 3A, or R3.

Conduit connection options

Code

B 1/2 in NPT — no gland

(1)

C

(1)

D

E M20 — no gland

(1)

F

(1)

G

(1)

Not approved in Class 1 Division 1 installations.

Description

1/2 in NPT with brass/nickel cable gland

1/2 in NPT with stainless steel cable gland

M20 with brass/nickel cable gland

M20 with stainless steel cable gland

34 www.emerson.com

April 2021 5700 Transmitters

Approval options

Code Description

MA Micro Motion Standard (no approval)

AA CSA (US and Canada): Class I, Division 1, Groups C and D

ZA ATEX: II 2G, Ex db eb, Zone 1 and II 2D Ex tb, Zone 21

FA ATEX: II 2G, Ex d, Zone 1 and II 2D Ex tb, Zone 21

IA IECEx: EPL Gb, Ex d, Zone 1 and EPL Db Ex tb, Zone 21

EA IECEx: EPL Gb, Ex db eb, Zone 1 and EPL Db Ex tb, Zone 21

2A CSA (US and Canada): Class I, Division 2, Groups A, B, C, D; sensor connections will be intrinsically safe

without additional barrier

(1)(2)

VA

(1)

3A

R1 EAC: Ex de, Zone 1

R2 EAC: Ex d, Zone 1

R3 EAC: nA nC, Zone 2

ATEX: II 3G, Ex nA nC, Zone 2 and II 3D Ex tc Zone 22

IECEx: EPL Gc, Ex nA nC, Zone 2 and EPL Dc, Ex tc, Zone 22

(1)

Sensor connections will be intrinsically safe without additional barrier.

(2)

The 5700 stainless steel transmitter is flameproof (Exd) only. Applicable for approval codes ZA, EA, and R1.

Transmitter option 1

Code

Z Standard product

Description

Transmitter option 2

Code

Z Standard product

Description

Factory options

Code

Z Standard product

X ETO product

Description

www.emerson.com 35

5700 Transmitters April 2021

Output channel assignments

Channel A

Channel A: Available with output board code A

Code Description

Z Channel Off

A Channel On; mA Output with HART

Channel A: Available with output board code C

Code Description

C EtherNet/IP output 1

D Modbus TCP output 1

H PROFINET output 1

Channel A: Available with output board code E

Code Description

(1)

F

(2)(3)

G

(1)

Not available with additional feature codes NT, OG, OL, MW, BS, SI, MA, PWL.

(2)

Only available with approval codes MA, AA, ZA, FA, IA, EA, 2A, VA, 3A.

(3)

Not available with additional feature codes NT, OG, OL, MW, BS, SI.

Intrinsically safe FOUNDATION Fieldbus H1 outputs (fixed)

PROFIBUS-PA output (fixed)

Channel A: Available with output board code N

Code

(1)

F

(1)

Not available with additional feature codes NT, OG, OL, MW, BS, SI, MA, PWL.

Description

Non-intrinsically safe FOUNDATION Fieldbus H1 outputs

Channel A: Available with output board code D

Code

Z Channel Off

B Channel On; Intrinsically safe mA Output with HART

Description

Channel B

Channel B: Available with output board code A

Code

Z Channel Off

A Channel On; Configurable to mA Output, Frequency Output, and Discrete Output

Description

36 www.emerson.com

April 2021 5700 Transmitters

Channel B: Available with output board code C

Your selection must match Channel A.

Code Description

C EtherNet/IP output 1

D Modbus TCP output 1

H PROFINET output 1

Channel B: Available with output board codes E and N

Code Description

E Channel On; mA Output

Channel B: Available with output board code D

Code Description

Z Channel Off

B Channel On; Intrinsically safe mA Output

Channel C

Channel C: Available with output board code A

Code

Z Channel Off

A Channel On; Configurable to mA Output, Frequency Output, Discrete Output, and Discrete Input

Channel C: Available with output board code C

Code

C Configurable to mA Output, Frequency Output, Discrete Output, and Discrete Input

Channel C: Available with output board codes E and N

Code

E Channel On; Configurable to Frequency Output, and Discrete Output

Channel C: Available with output board code D

Code

Z Channel Off

Description

Description

Description

Description

B Channel On; Intrinsically safe mA Output

www.emerson.com 37

5700 Transmitters April 2021

Channel D

Channel D: Available with output board code A

Code Description

Z Channel Off

A Channel On; Configurable to mA Input, Frequency Input, Frequency Output, Discrete Output, and Discrete

Input

Channel D: Available with output board code C

Code Description

Z Channel Off

Channel D: Available with output board codes E and N

Code Description

Z Channel Off

Channel D: Available with output hardware board code D

Code Description

Z Channel Off

B Channel On; Intrinsically safe, configurable to mA Output, Frequency Output, Discrete Output

Channel E

Channel E: Available with output board code A

Code

Z Channel Off

A On; RS-485 Modbus, RS-485 HART, and printing support

Description

Channel E: Available with output board codes C, E, N, and D

Code

Z Channel Off

Description

Additional features

All of the following additional features are optional.

Instrument Tagging

Code

TG Instrument Tagging — customer information required (maximum 24 characters)

Description

38 www.emerson.com

April 2021 5700 Transmitters

Smart Meter Verification

Code Description

(1)

MV

(1)

Available with all mounting options, but mounting C is limited to 60 ft (18.29 m) of 9-wire cable and only available when purchased with new 9wire sensor.

Smart Meter Verification

Weights & Measures approval

Requires output board code A (or C for option NT only) and display code 2, 5, or 7. Select only one of the following codes.

Code Description

(1)

NT

(1)

OG

(1)

OL

(1)

Not available with PL, PG, PO, MA, MW, or SI.

Weights & Measures custody transfer approval — NTEP

Weights & Measures custody transfer approval — MID & OIML for gas

Weights & Measures custody transfer approval — MID & OIML for liquid

Enhanced measurement

Select only one of the following codes.

Code Description

(1)

PS

CM

PW

(1)

(1)(2)(3)

API referral software

Concentration measurement software

Piecewise Linearization for Gas software

(1)

Not available with PL, PG, PO, MA, MW, or SI.

(2)

Not available with hardware board E with Channel A, output option F,or hardware boards N or D.

(3)

Not available with add on option PL.

Additional software options

Code

(1)

BS

(1)

Not available with output hardware board E with Channel A output option, or hardware board N. Not available with certification option SI.

Description

Batching software package

Advanced Phase Measurement

Select any of the following feature codes.

Code

(1)(2)(3)

PG

(1)(2)

PL

(1)

Not available with add on options NT, OL, OG, or SI.

(2)

Not available with add on option PS.

(3)

Not available with add on option CM.

Description

Advanced Phase Measurement gas with liquid

Advanced Phase Measurement liquid with gas

Net Oil Computer software

Select only one of the following codes.

Code

MA

(1)(2)

Description

Manual Advanced Phase Measurement configuration

www.emerson.com 39

5700 Transmitters April 2021

Code Description

(2)(3)

MW

(4)

PO

Additional certification requires either:

■

Hardware output board option A with output Channel A and Channel D assignment of “A”

■

Hardware output board option D with output Channel A assignment of “B”

SI Safety certification of 4-20 mA Outputs per IEC 61508

(1)

Not available with hardware board E with Channel A output option F, or hardware boards N or D.

(2)

Not available with add on options NT, OG, OL, PL, PS, or SI.

(3)

Available only with output hardware board option A.

(4)

Not available with add on options CM, NT, OG, OL, PS, or SI.

Smart Wireless 775 THUM

Smart Wireless 775 THUM requires output code A or B option for Channel A.

Code Description

NI Smart Wireless 775 THUM Ready — 775 ordered separately and not assembled to the 5700

Net Oil Computer software — multiple wells

Net Oil Computer software — single well

Micro Motion highly recommends the PL option in conjunction with PO.

Ethernet connectors

Requires output hardware board code C. Select only one of the following codes.

Code

(1)

CA

(1)

CB

(1)

Available only with approval codes MA and 2A.

Description

(2) M12 connectors for Ethernet ports

(2) M12 connectors for Ethernet ports and (1) for Channel C and (1) for power

40 www.emerson.com

April 2021 5700 Transmitters

www.emerson.com 41

5700 Transmitters April 2021

42 www.emerson.com

April 2021 5700 Transmitters

www.emerson.com 43

PS-001885

Rev. O

April 2021

For more information:

©

2021 Micro Motion, Inc. All rights reserved.

www.emerson.com

The Emerson logo is a trademark and service mark of Emerson

Electric Co. Micro Motion, ELITE, ProLink, MVD and MVD Direct

Connect marks are marks of one of the Emerson Automation

Solutions family of companies. All other marks are property of

their respective owners.

Loading...

Loading...