Page 1

Installation Manual

20001700, Rev CG

December 2019

Micro Motion™ 1700 and 2700 Transmitters

Installation Manual

Page 2

Safety messages

Safety messages are provided throughout this manual to protect personnel and equipment. Read each safety message carefully

before proceeding to the next step.

Safety and approval information

This Micro Motion product complies with all applicable European directives when properly installed in accordance with the

instructions in this manual. Refer to the EU declaration of conformity for directives that apply to this product. The EU declaration

of conformity, with all applicable European directives, and the complete ATEX Installation Drawings and Instructions are available

on the internet at www.emerson.com or through your local Micro Motion support center.

Information affixed to equipment that complies with the Pressure Equipment Directive, can be found on the internet at

www.emerson.com.

For hazardous installations in Europe, refer to standard EN 60079-14 if national standards do not apply.

Other information

Full product specifications can be found in the product data sheet. Troubleshooting information can be found in the configuration

manual. Product data sheets and manuals are available from the Micro Motion web site at www.emerson.com.

Return policy

Follow Micro Motion procedures when returning equipment. These procedures ensure legal compliance with government

transportation agencies and help provide a safe working environment for Micro Motion employees. Micro Motion will not accept

your returned equipment if you fail to follow Micro Motion procedures.

Return procedures and forms are available on our web support site at www.emerson.com, or by phoning the Micro Motion

Customer Service department.

Emerson Flow customer service

Email:

• Worldwide: flow.support@emerson.com

• Asia-Pacific: APflow.support@emerson.com

Telephone:

North and South America

United States 800-522-6277 U.K. 0870 240 1978 Australia 800 158 727

Canada +1 303-527-5200 The Netherlands +31 (0) 704 136

Mexico +41 (0) 41 7686

111

Argentina +54 11 4837 7000 Germany 0800 182 5347 Pakistan 888 550 2682

Brazil +55 15 3413 8000 Italy 8008 77334 China +86 21 2892 9000

Europe and Middle East Asia Pacific

666

France 0800 917 901 India 800 440 1468

Central & Eastern +41 (0) 41 7686

111

Russia/CIS +7 495 995 9559 South Korea +82 2 3438 4600

Egypt 0800 000 0015 Singapore +65 6 777 8211

Oman 800 70101 Thailand 001 800 441 6426

Qatar 431 0044 Malaysia 800 814 008

Kuwait 663 299 01

South Africa 800 991 390

Saudi Arabia 800 844 9564

UAE 800 0444 0684

New Zealand 099 128 804

Japan +81 3 5769 6803

2

Page 3

Installation Manual Contents

20001700 December 2019

Contents

Chapter 1 Before you begin............................................................................................................5

1.1 About this document........................................................................................................................5

1.2 Hazard messages..............................................................................................................................5

1.3 Related documentation....................................................................................................................5

Chapter 2 Planning........................................................................................................................ 7

2.1 Meter components...........................................................................................................................7

2.2 Installation types.............................................................................................................................. 7

2.3 Maximum cable lengths between sensor and transmitter...............................................................11

2.4 Output options...............................................................................................................................12

2.5 Electrical connections.....................................................................................................................13

2.6 Environmental limits...................................................................................................................... 13

2.7 Hazardous area classifications........................................................................................................ 14

2.8 Power requirements....................................................................................................................... 14

Chapter 3 Mounting.....................................................................................................................17

3.1 Mounting for integral installations..................................................................................................17

3.2 Orientation.....................................................................................................................................17

3.3 Accessibility for maintenance......................................................................................................... 17

3.4 Mounting options...........................................................................................................................17

3.5 Rotate the transmitter on the sensor (optional)..............................................................................23

3.6 Rotate the user interface on the transmitter (optional)...................................................................24

Chapter 4 Preparing the wires......................................................................................................27

4.1 Prepare the 4-wire cable.................................................................................................................27

4.2 Prepare the 9-wire cable.................................................................................................................30

Chapter 5 Wiring the transmitter to the sensor............................................................................37

5.1 Wire the transmitter to the sensor (4-wire).....................................................................................37

5.2 Wire the transmitter to the remote core processor (4-wire)............................................................38

5.3 Wire the remote core processor to the sensor using jacketed cable (9-wire)...................................40

5.4 Wire the remote core processor to the sensor using shielded or armored cable (9-wire).................42

5.5 Sensor and remote core processor/transmitter terminals...............................................................45

Chapter 6 Grounding....................................................................................................................49

6.1 Ground the meter components...................................................................................................... 49

Chapter 7 Wiring the power supply..............................................................................................51

7.1 Wire the power supply....................................................................................................................51

Chapter 8 I/O wiring for transmitters with analog outputs........................................................... 53

8.1 Basic analog wiring......................................................................................................................... 53

Installation Manual iii

Page 4

Contents Installation Manual

December 2019 20001700

8.2 HART®/analog single loop wiring.................................................................................................... 53

8.3 RS-485 point-to-point wiring..........................................................................................................54

8.4 HART multidrop wiring................................................................................................................... 55

Chapter 9 I/O wiring for transmitters with intrinsically safe outputs.............................................57

9.1 Safe area mA Output wiring (2700)................................................................................................ 57

9.2 Safe area HART/analog single-loop wiring...................................................................................... 58

9.3 Safe area HART multidrop wiring.................................................................................................... 59

9.4 Safe area Frequency Output/Discrete Output wiring...................................................................... 60

9.5 Hazardous area wiring.................................................................................................................... 61

Chapter 10 I/O wiring for 2700 with configurable input/outputs.................................................... 69

10.1 Channel configuration..................................................................................................................69

10.2 Basic mA Output wiring................................................................................................................ 70

10.3 HART/analog single loop wiring....................................................................................................70

10.4 HART multidrop wiring.................................................................................................................71

10.5 Internally powered Frequency Output wiring on Channel B.......................................................... 72

10.6 Externally powered Frequency Output wiring on Channel B..........................................................73

10.7 Internally powered FO wiring on Channel C.................................................................................. 74

10.8 Externally powered Frequency Output wiring on Channel C..........................................................75

10.9 Internally powered Discrete Output wiring on Channel B..............................................................76

10.10 Externally powered Discrete Output wiring on Channel B........................................................... 77

10.11 Internally powered Discrete Output wiring on Channel C............................................................78

10.12 Externally powered Discrete Output wiring on Channel C........................................................... 79

10.13 Internally powered Discrete Input wiring.................................................................................... 80

10.14 Externally powered Discrete Input wiring................................................................................... 80

Chapter 11 I/O wiring for 2700 with FOUNDATION fieldbus or PROFIBUS-PA...................................81

11.1 FOUNDATION fieldbus wiring........................................................................................................... 81

11.2 PROFIBUS-PA wiring..................................................................................................................... 81

iv Micro Motion 1700 and 2700 Transmitters

Page 5

Installation Manual Before you begin

20001700 December 2019

1 Before you begin

1.1 About this document

This manual provides information on planning, mounting, wiring, and initial setup of the

1700-2700 transmitter. For information on full configuration, maintenance,

troubleshooting, or service of the transmitter, see the configuration and use manual.

The information in this document assumes that users understand basic transmitter and

sensor installation, configuration, and maintenance concepts and procedures.

1.2 Hazard messages

This document uses the following criteria for hazard messages based on ANSI standards

Z535.6-2011 (R2017).

DANGER

Serious injury or death will occur if a hazardous situation is not avoided.

WARNING

Serious injury or death could occur if a hazardous situation is not avoided.

CAUTION

Minor or moderate injury will or could occur if a hazardous situation is not avoided.

NOTICE

Data loss, property damage, hardware damage, or software damage can occur if a

situation is not avoided. There is no credible risk of physical injury.

Physical access

NOTICE

Unauthorized personnel can potentially cause significant damage and/or misconfiguration

of end users' equipment. Protect against all intentional or unintentional unauthorized use.

Physical security is an important part of any security program and fundamental to

protecting your system. Restrict physical access to protect users' assets. This is true for all

systems used within the facility.

1.3 Related documentation

You can find all product documentation on the product documentation DVD shipped with

the product or at www.emerson.com.

See any of the following documents for more information:

• Micro Motion Series 1000 and Series 2000 Transmitters with MVD Technology Product Data

Sheet

Installation Manual 5

Page 6

Before you begin Installation Manual

December 2019 20001700

• 1700 documents

— Micro Motion Model 1700 Transmitters with Analog Outputs Configuration and Use

Manual

— Micro Motion Model 1700 Transmitters with Intrinsically Safe Outputs Configuration

and Use Manual

• 2700 documents

— Micro Motion Model 2700 Transmitters with Analog Outputs Configuration and Use

Manual

— Micro Motion Model 2700 Transmitters with Configurable Input/Outputs Configuration

and Use Manual

— Micro Motion Model 2700 Transmitters with Intrinsically Safe Outputs Configuration

and Use Manual

— Micro Motion Model 2700 Transmitters with FOUNDATION™ Fieldbus Configuration and

Use Manual

— Micro Motion Model 2700 Transmitters with PROFIBUS-PA Configuration and Use

Manual

• Micro Motion Fuel Consumption Application for Transmitters Installation and Operation

Guide

• Micro Motion 9-Wire Flowmeter Cable Preparation and Installation Guide

• Micro Motion Enhanced Density Application Manual

• Sensor installation manual

6 Micro Motion 1700 and 2700 Transmitters

Page 7

Installation Manual

20001700 December 2019

Planning

2 Planning

2.1 Meter components

A meter consists of the following components:

• A transmitter

• A sensor

• A core processor that provides additional memory and processing functions

2.2 Installation types

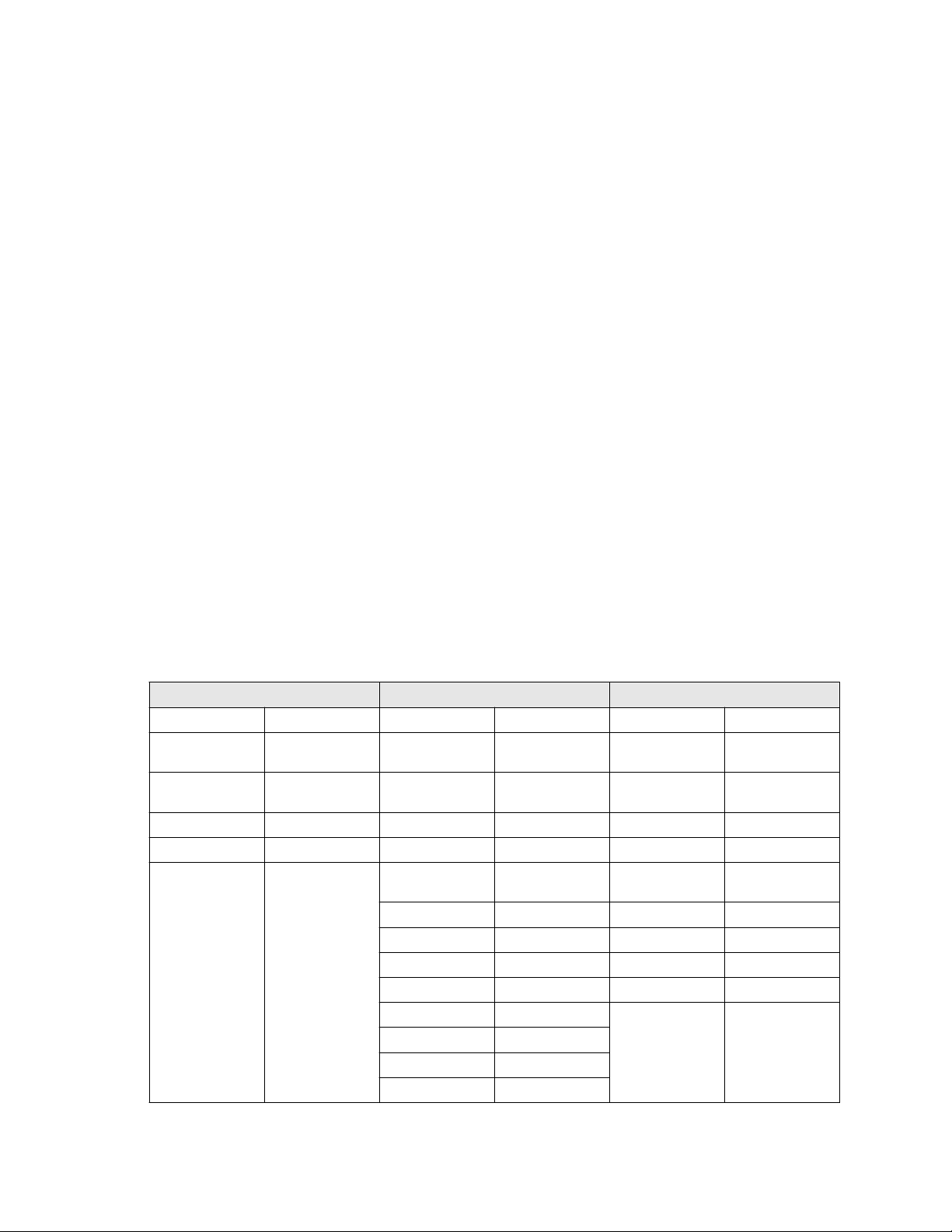

The transmitter was ordered and shipped for one of up to eight installation types. The fifth

character of the transmitter model number indicates the installation type.

Figure 2-1: Installation type indication for 1700 and 2700 transmitters

The model number is located on the device tag on the side of the transmitter.

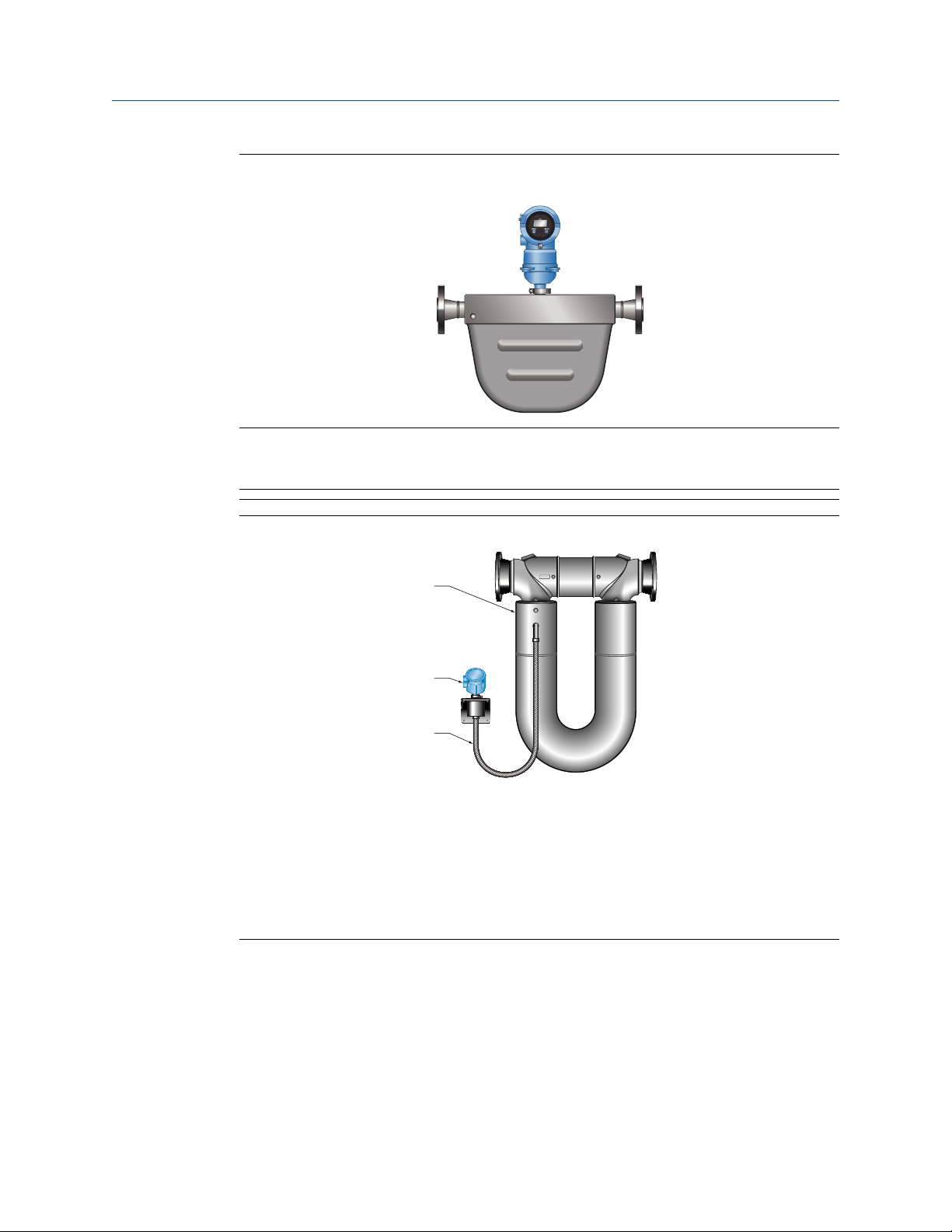

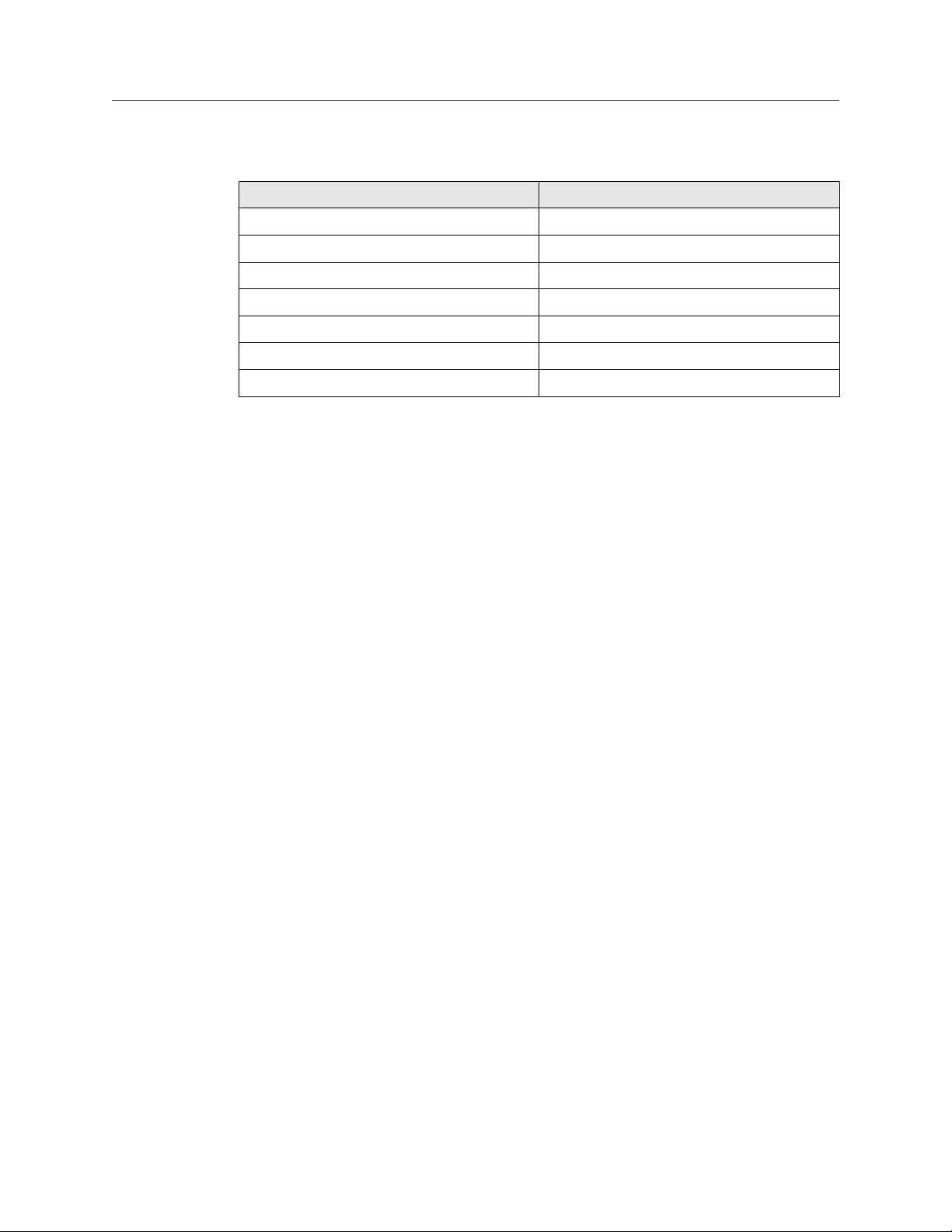

Table 2-1: Installation types for 1700 and 2700 transmitters

Model code Description

R Remote mount 4-wire

I Integral

E Remote enhanced core processor (painted aluminum housing) with remote

transmitter

C Remote mount 9-wire (painted aluminum housing with integral core)

B Remote core processor with remote transmitter

M Remote mount 4-wire (stainless steel housing)

P Remote mount 9-wire (stainless steel housing)

(1)

H

(1) This option is available only with the 2700 FOUNDATION™ fieldbus transmitter

The transmitter is mounted directly to the sensor. Integral installations do not require

separate transmitter installation. Power supply and I/O must be field wired to the

transmitter.

Remote mount 4-wire (painted aluminum housing) for connecting to

Compact Density Meter (CDM), Fork Density Meter (FDM), Fork Viscosity

Meter (FVM)

Installation Manual 7

Page 8

STATUS

SCROLL SELECT

Planning Installation Manual

December 2019 20001700

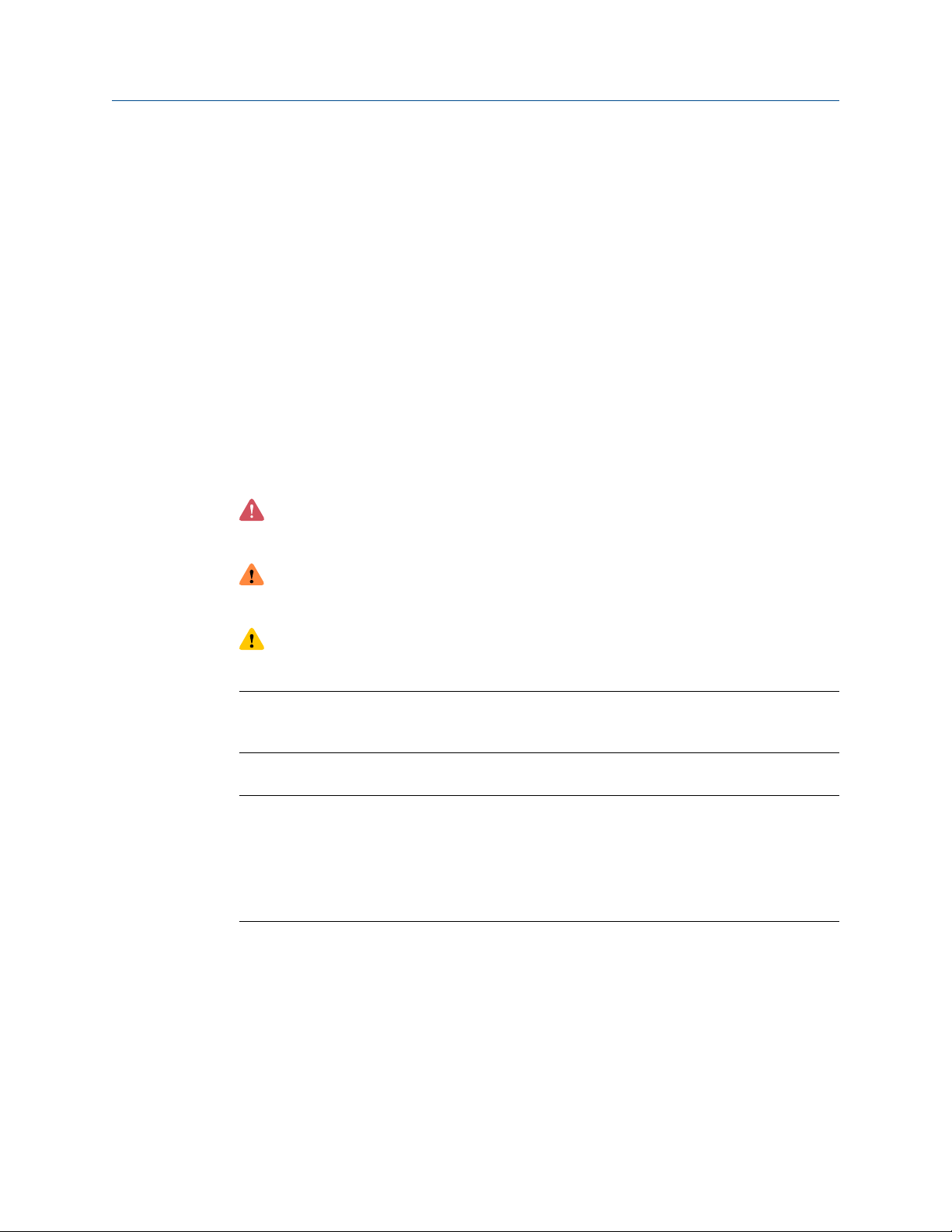

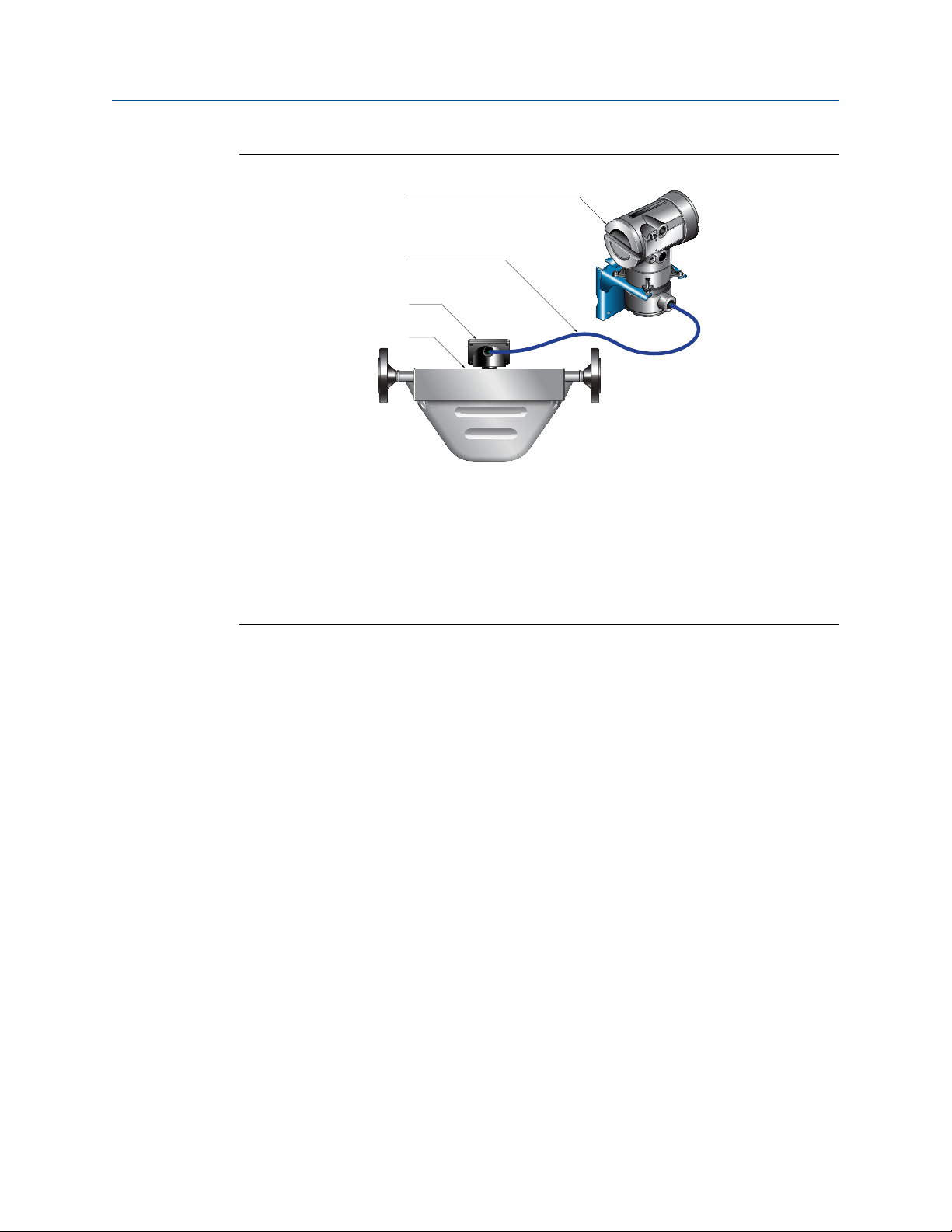

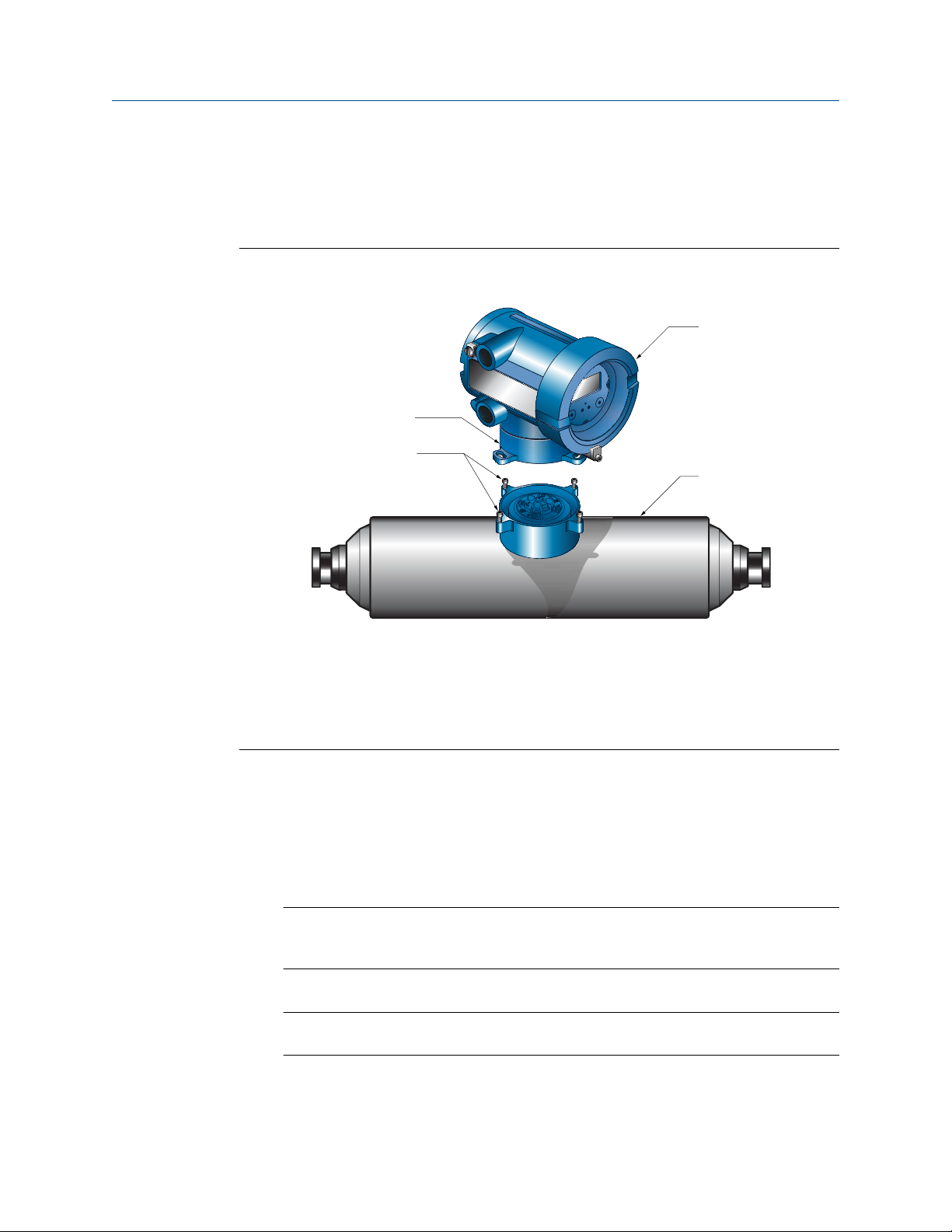

Figure 2-2: Integral installation (model code I)

Note

If replacing an integral 1700/2700 transmitter with a spare transmitter, retain the

transition ring. The replacement does not include a new transition ring.

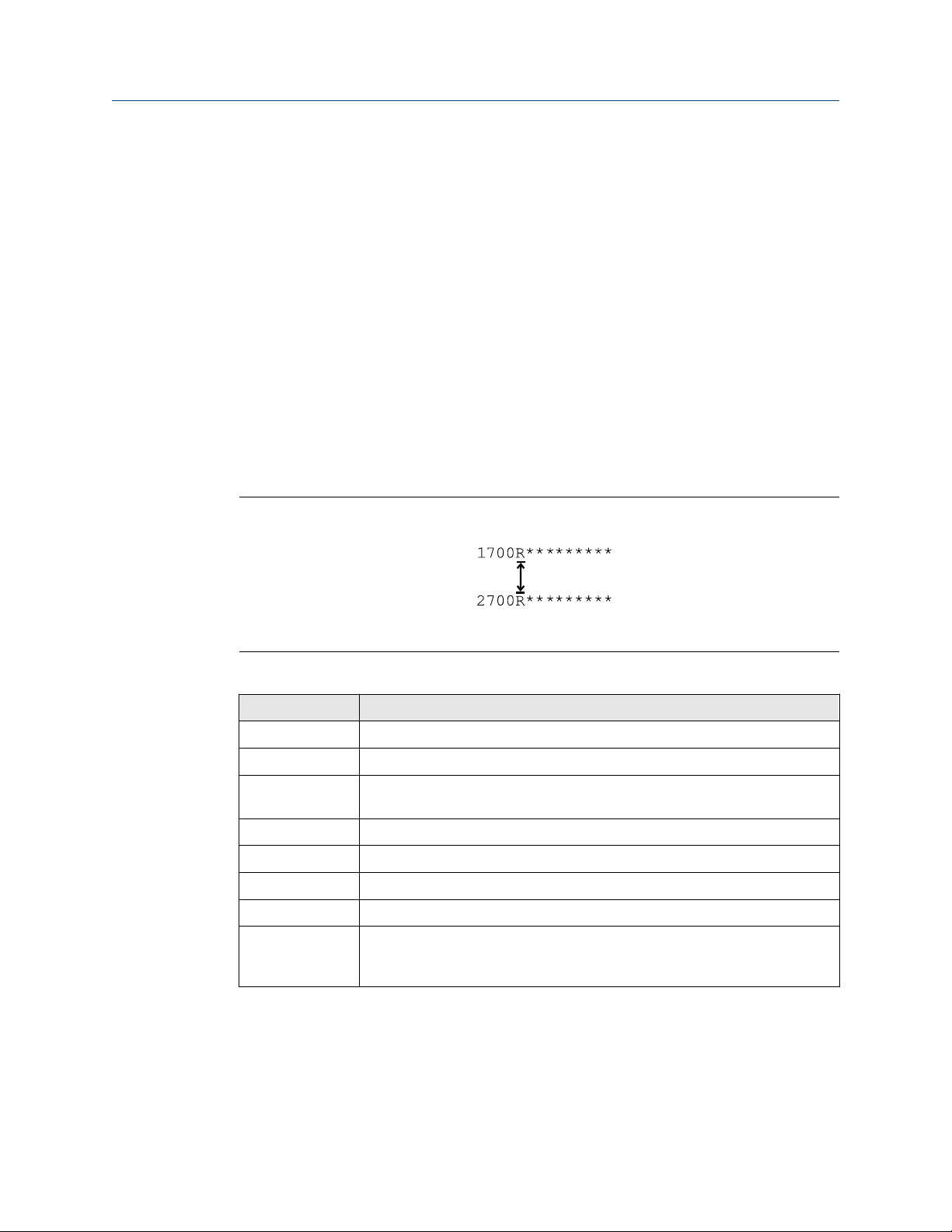

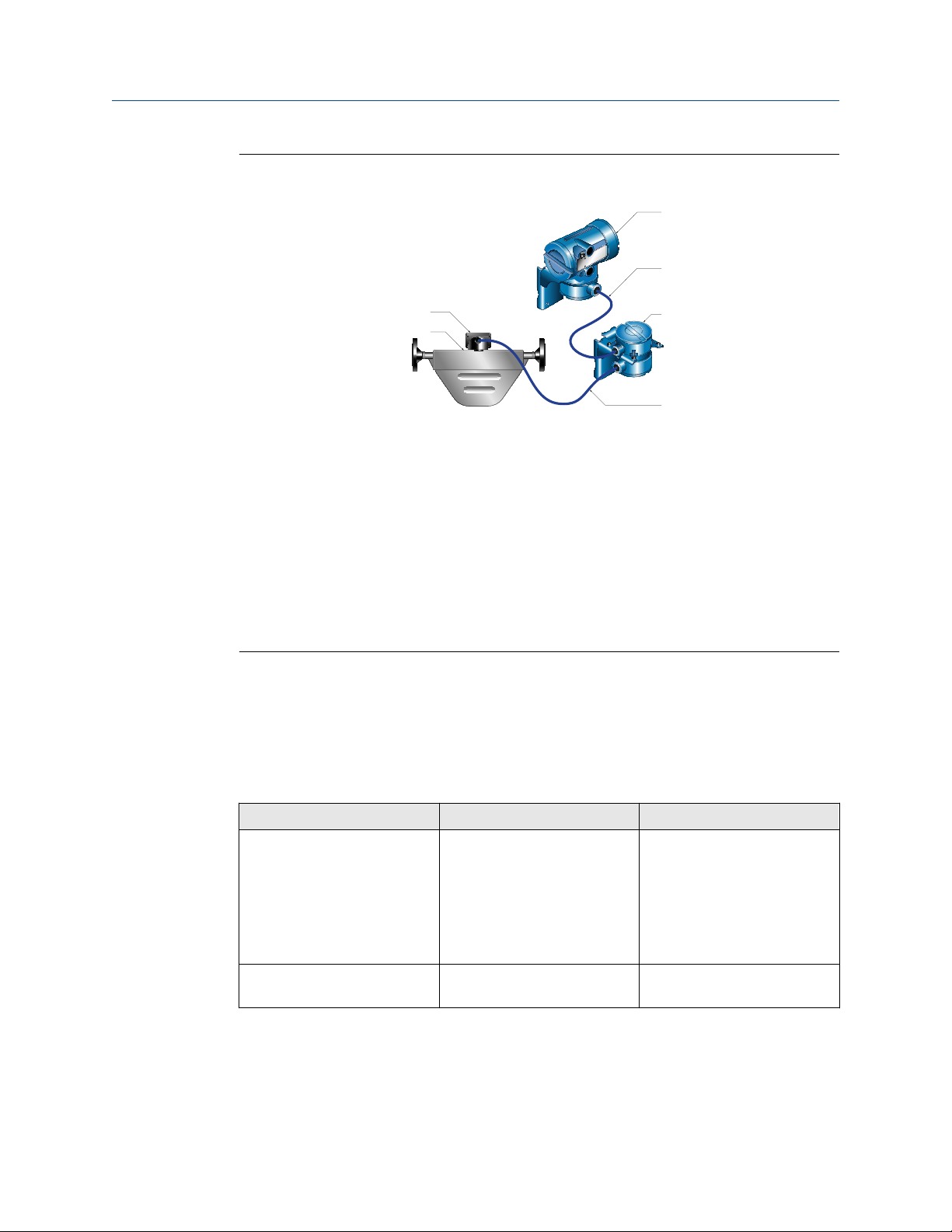

Figure 2-3: High-temperature meters with factory connection (model code I)

A

B

C

The transmitter is shipped with a flexible connection factory installed between the sensor

and the transmitter. The transmitter must be dismounted from its shipping location (spotwelded to the sensor case) and then mounted separately. Power supply and I/O must be

field wired to the transmitter.

A. Sensor

B. Transmitter or core processor

C. Factory-installed flexible connection

8 Micro Motion 1700 and 2700 Transmitters

Page 9

Installation Manual

Planning

20001700 December 2019

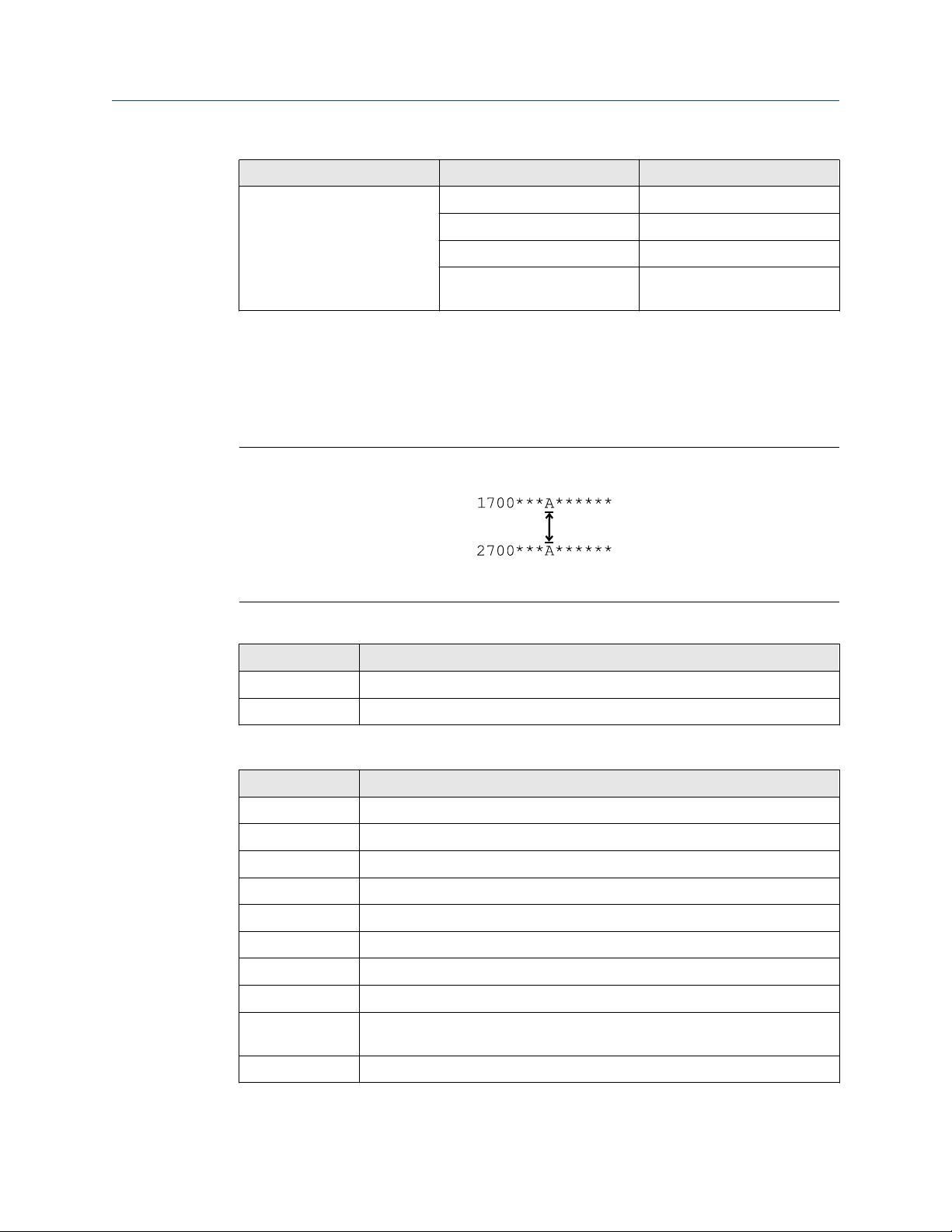

Figure 2-4: 4-wire remote installation for Coriolis meters (model code R or M)

A

B

C

D

A

The transmitter is installed remotely from the sensor. The 4-wire connection between the

sensor and transmitter must be field wired. Power supply and I/O must be field wired to

the transmitter.

A. Transmitter

B. Field-wired 4-wire connection

C. Core processor

D. Sensor

Figure 2-5: 4-wire remote installation for density and viscosity meters (CDM, FDM, or

FVM with fieldbus only model code H)

The transmitter is installed remotely from the Compact Density Meter (CDM), Fork Density

Meter (FDM), or Fork Viscosity Meter (FVM). The 4-wire connection between the sensor

and transmitter must be field wired. Power supply and I/O must be field wired to the

transmitter.

A. Transmitter

B. Field-wired 4-wire connection

C. Meter electronics

Installation Manual 9

Page 10

Planning Installation Manual

December 2019 20001700

Figure 2-6: 9-wire remote installation (model code P)

A

B

C

D

A

The transmitter and core processor are combined in a single unit that is installed remotely

from the sensor. The 9-wire connection between the transmitter/core processor and the

sensor must be field wired. Power supply and I/O must be field wired to the transmitter.

A. Transmitter

B. Field-wired 9-wire connection

C. Junction box

D. Sensor

10 Micro Motion 1700 and 2700 Transmitters

Page 11

Installation Manual Planning

20001700 December 2019

Figure 2-7: Remote core processor with remote sensor installation (model code B or

E)

C

D

A

B

E

F

The transmitter, core processor, and sensor are all mounted separately. The 4-wire

connection between the transmitter and core processor must be field wired. The 9-wire

connection between the core processor and the sensor must be field wired. Power supply

and I/O must be field wired to the transmitter. This configuration is sometimes called

double-hop.

A. Junction box

B. Sensor

C. Transmitter

D. Field-wired 4-wire connection

E. Core processor

F. Field-wired 9-wire connection

2.3 Maximum cable lengths between sensor and transmitter

The maximum cable length between the sensor and transmitter that are separately

installed is determined by cable type.

Cable type

Micro Motion 4-wire remote

mount

Micro Motion 9-wire remote

mount

Installation Manual 11

Wire gauge Maximum length

Not applicable • 1,000 ft (305 m) without

Ex-approval

• 500 ft (152 m) with IIC

rated sensors

• 1,000 ft (305 m) with IIB

rated sensors

Not applicable 60 ft (18 m)

Page 12

Planning Installation Manual

December 2019 20001700

Cable type Wire gauge Maximum length

User-supplied 4-wire VDC 22 AWG (0.326 mm²) 300 ft (91 m)

VDC 20 AWG (0.518 mm²) 500 ft (152 m)

VDC 18 AWG (0.823 mm²) 1,000 ft (305 m)

2.4 Output options

The transmitter was ordered and shipped for one of up to 10 output options. You must

know your transmitter output option to correctly install the transmitter. The eighth

character of the transmitter model number indicates the output option.

Figure 2-8: Output option indication for 1700 and 2700 transmitters

The model number is located on the device tag on the side of the transmitter.

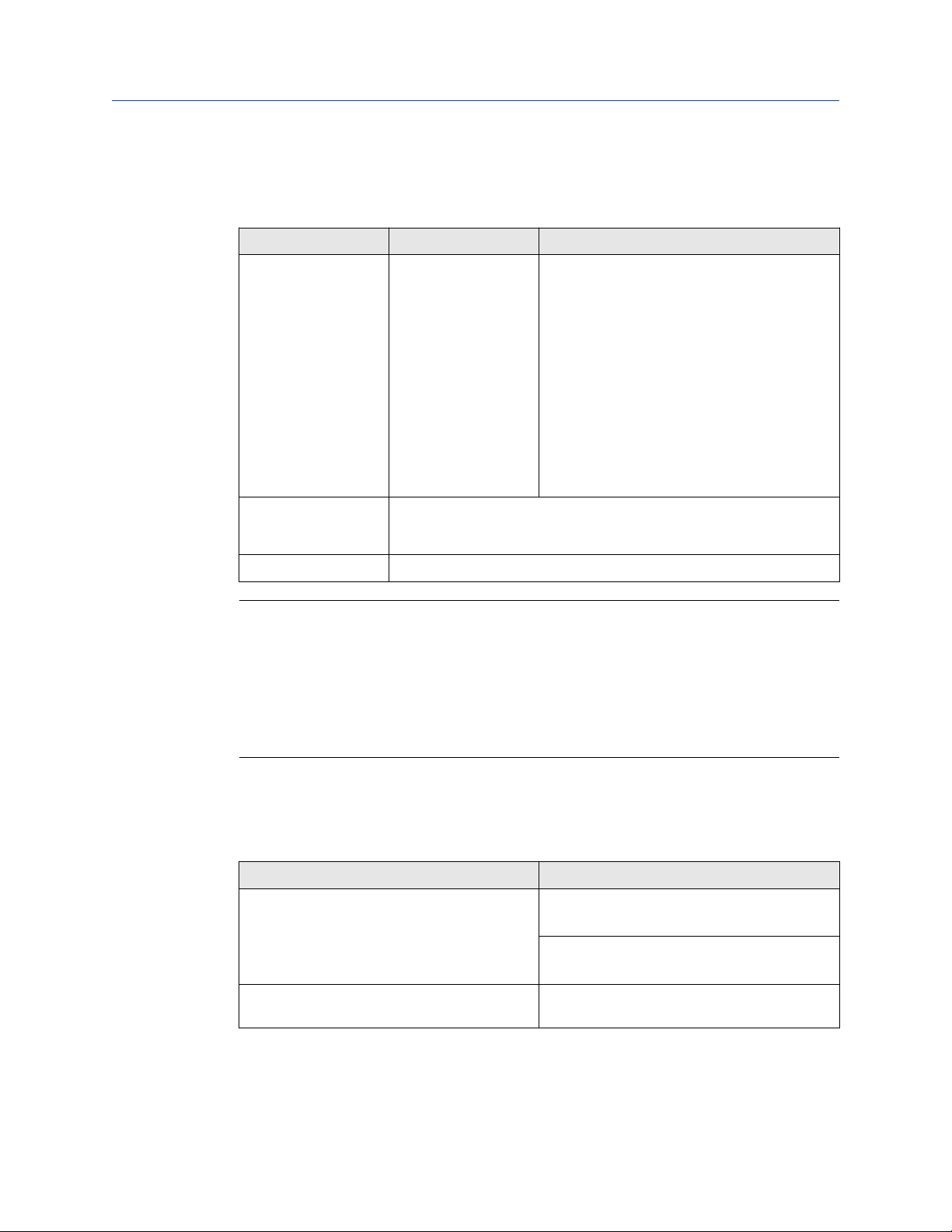

Table 2-2: Output options for 1700 transmitters

Letter Description

A Analog outputs – one mA, one frequency, one RS-485

D Intrinsically safe analog outputs – one mA, one frequency

RS-485 22 AWG (0.326 mm²)

or larger

1,000 ft (305 m)

Table 2-3: Output options for 2700 transmitters

Letter Description

A Analog outputs – one mA, one frequency, one RS-485

B Configurable I/O channels (default configuration of two mA, one frequency)

C Configurable I/O channels (custom configuration )

D Intrinsically safe analog outputs – two mA, one frequency

E Intrinsically safe FOUNDATION fieldbus H1 with standard function blocks

G PROFIBUS-PA

N Non-incendive FOUNDATION fieldbus H1 with standard function blocks

2 WirelessHART® – one mA, one frequency, one RS-485

3 WirelessHART – one mA, two configurable I/O channels (custom

configuration)

4 Intrinsically safe WirelessHART – two mA, one frequency

12 Micro Motion 1700 and 2700 Transmitters

Page 13

Installation Manual Planning

20001700 December 2019

2.5 Electrical connections

Table 2-4: 1700 and 2700 transmitters

Connection type 1700 2700

Input/Output • Intrinsically safe

version: Two pairs

of wiring terminals

for transmitter

outputs

• Non-intrinsically

safe analog

outputs (output

option A): Three

pairs of wiring

terminals for

transmitter

outputs

Power • One pair of wiring terminals accepts AC or DC power

• One internal ground lug for power-supply ground wiring

Service port Two clips for temporary connection to the service port

Three pairs of wiring terminals for transmitter

I/O and communications

Notes

• Each screw terminal connection accepts one or two solid conductors, 14 AWG

(2.08 mm²) to 12 AWG (3.31 mm²) or one or two stranded conductors, 22 AWG

(0.326 mm²) to 14 AWG (2.08 mm²). Each plug type connector accepts one stranded

or solid conductor, 24 AWG (0.205 mm²) to 12 AWG (3.31 mm²).

• For 1700/2700 transmitters with an integral core processor (mounting code C), the 4-

wire connection between the transmitter and core processor is not normally accessed.

2.6 Environmental limits

1700 and 2700

Type

Ambient temperature limits

Humidity limits 5 to 95% relative humidity, non-condensing at

Installation Manual 13

(1)

Value

Operating:

-40 °F (-40.0 °C) to 140 °F (60.0 °C)

Storage:

-40 °F (-40.0 °C) to 140 °F (60.0 °C)

140 °F (60.0 °C)

Page 14

Planning Installation Manual

December 2019 20001700

Type Value

Vibration limits Meets IEC 60068-2-6,endurance sweep, 5 to

2000 Hz up to 1.0 g

Housing rating NEMA 4X [IP66/67/69(K)]

(1) Display responsiveness decreases, and display may become difficult to read below -4 °F

(-20.0 °C). Above 131 °F (55.0 °C), some darkening of display might occur.

(2) The protection is IP69K-based NEN-ISO 20653:2013 and IP69 when using standard IEC/EN

60529.

(2)

2.7 Hazardous area classifications

If you plan to mount the transmitter in a hazardous area:

• Verify that the transmitter has the appropriate hazardous area approval. Each

transmitter has a hazardous area approval tag attached to the housing.

• Ensure that any cable used between the transmitter and the sensor meets the

hazardous area requirements.

2.8 Power requirements

Self-switching AC/DC input, automatically recognizes supply voltage

• 85 to 265 VAC, 50/60 Hz, 6 watts typical, 11 watts maximum

• 18 to 100 VDC, 6 watts typical, 11 watts maximum

• Complies with low voltage directive 2006/95/EC per EN 61010-1 (IEC 61010-1) with

amendment 2, and Installation (Overvoltage) Category II, Pollution Degree 2

Notes

For DC power:

• Power requirements assume a single transmitter per cable.

• At startup, the power source must provide a minimum of 1.5 amps of short-term

current per transmitter.

• Length and conductor diameter of the power cable must be sized to provide 18 VDC

minimum at the power terminals, at a load current of 0.5 amps.

M = 18V + R × L × 0.5A

M: Minimum supply voltage

R: Cable resistance

L: Cable length

Table 2-5: Typical power cable resistance at 68 °F (20.0 °C)

Wire gauge Resistance

14 AWG 0.0050 Ω/ft

16 AWG 0.0080 Ω/ft

14 Micro Motion 1700 and 2700 Transmitters

Page 15

Installation Manual Planning

20001700 December 2019

Table 2-5: Typical power cable resistance at 68 °F (20.0 °C) (continued)

Wire gauge Resistance

18 AWG 0.0128 Ω/ft

20 AWG 0.0204 Ω/ft

2.5 mm

1.5 mm

1.0 mm

0.75 mm

0.50 mm

2

2

2

2

2

0.0136 Ω/m

0.0228 Ω/m

0.0340 Ω/m

0.0460 Ω/m

0.0680 Ω/m

Installation Manual 15

Page 16

Planning Installation Manual

December 2019 20001700

16 Micro Motion 1700 and 2700 Transmitters

Page 17

Installation Manual

20001700 December 2019

Mounting

3 Mounting

3.1 Mounting for integral installations

There are no separate mounting requirements for integral transmitters.

3.2 Orientation

You can mount the transmitter in any orientation as long as the conduit openings do not

point upward.

NOTICE

Upward-facing conduit openings risk condensation moisture entering the transmitter

housing that could damage the transmitter.

3.3 Accessibility for maintenance

Mount the transmitter in a location and orientation that satisfies the following conditions:

• Allows sufficient clearance to open the transmitter housing cover. Micro Motion

recommends 8 in (203 mm) – 10 in (254 mm) clearance at the rear of the transmitter.

• Provides clear access for installing cabling to the transmitter.

3.4 Mounting options

There are two options available for mounting the transmitter:

• Mount the transmitter to a wall or flat surface.

• Mount the transmitter to an instrument pole.

3.4.1

Mount the transmitter to a wall

Prerequisites

• Use two 0.31 in (7.9 mm) U-bolts for a 2 in (51 mm) pipe, and four matching nuts that

can withstand the process environment. Appropriate bolts and nuts are shipped with

remote mount transmitters in the ship kit. The pipe mount kit can be ordered as part of

the 1700/2700 part number.

• Ensure that the surface is flat and rigid, does not vibrate, or move excessively.

• Confirm that you have the necessary tools, and the mounting kit shipped with the

transmitter.

Procedure

1. If desired, re-orient the transmitter on the mounting bracket.

Installation Manual 17

Page 18

B

D

C

A

Mounting Installation Manual

December 2019 20001700

a) Remove the junction end-cap from the junction housing.

b) Loosen each of the four 0.16 in (4.1 mm) cap screws.

c) Rotate the bracket so that the transmitter is oriented as desired.

d) Tighten the cap screws, torquing to 30 in lbf (3.39 N m) to 38 in lbf (4.29 N

m).

e) Replace the junction end-cap.

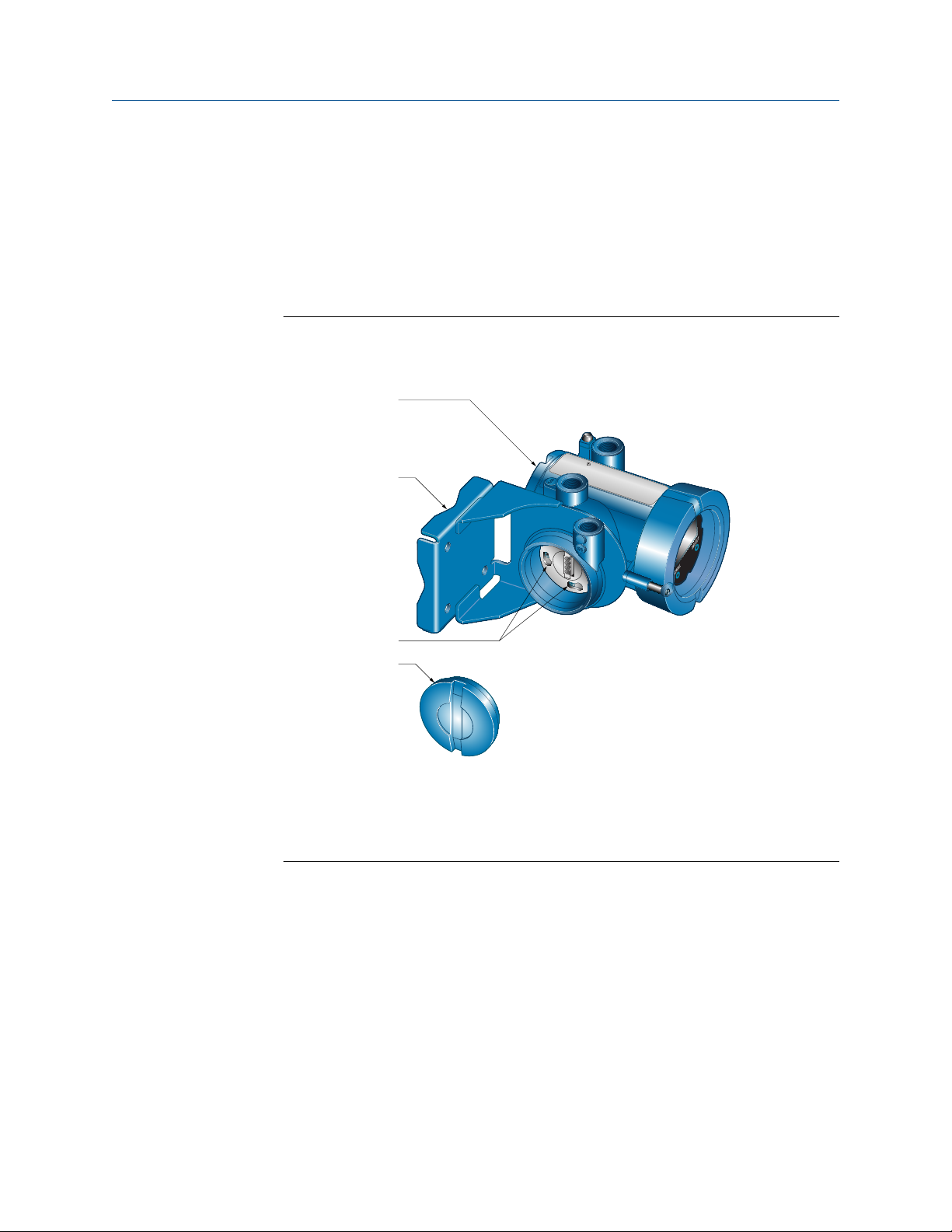

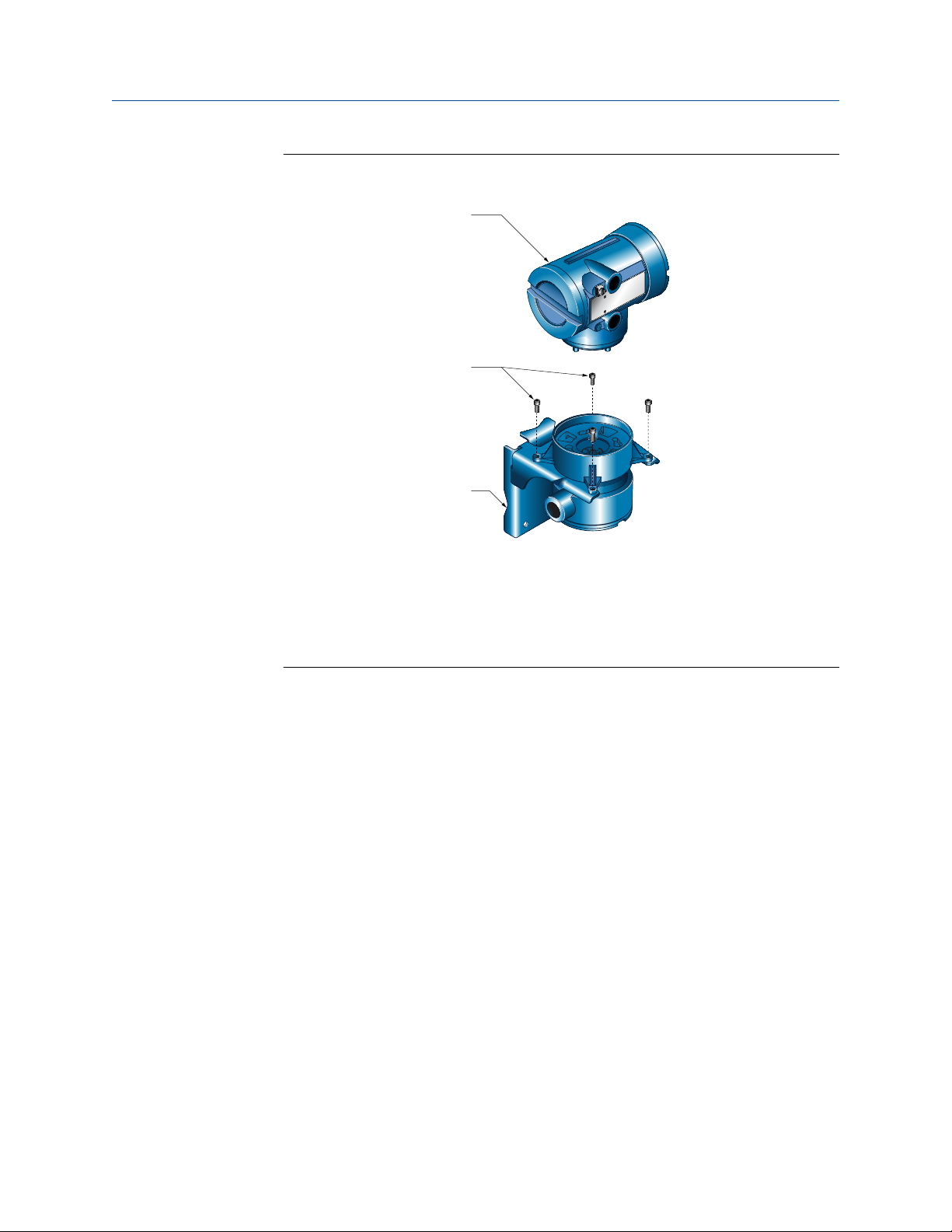

Figure 3-1: Components of 4-wire remote mount transmitter (aluminum

housing)

A. Transmitter

B. Mounting bracket

C. Cap screws

D. End-cap

18 Micro Motion 1700 and 2700 Transmitters

Page 19

Installation Manual Mounting

20001700 December 2019

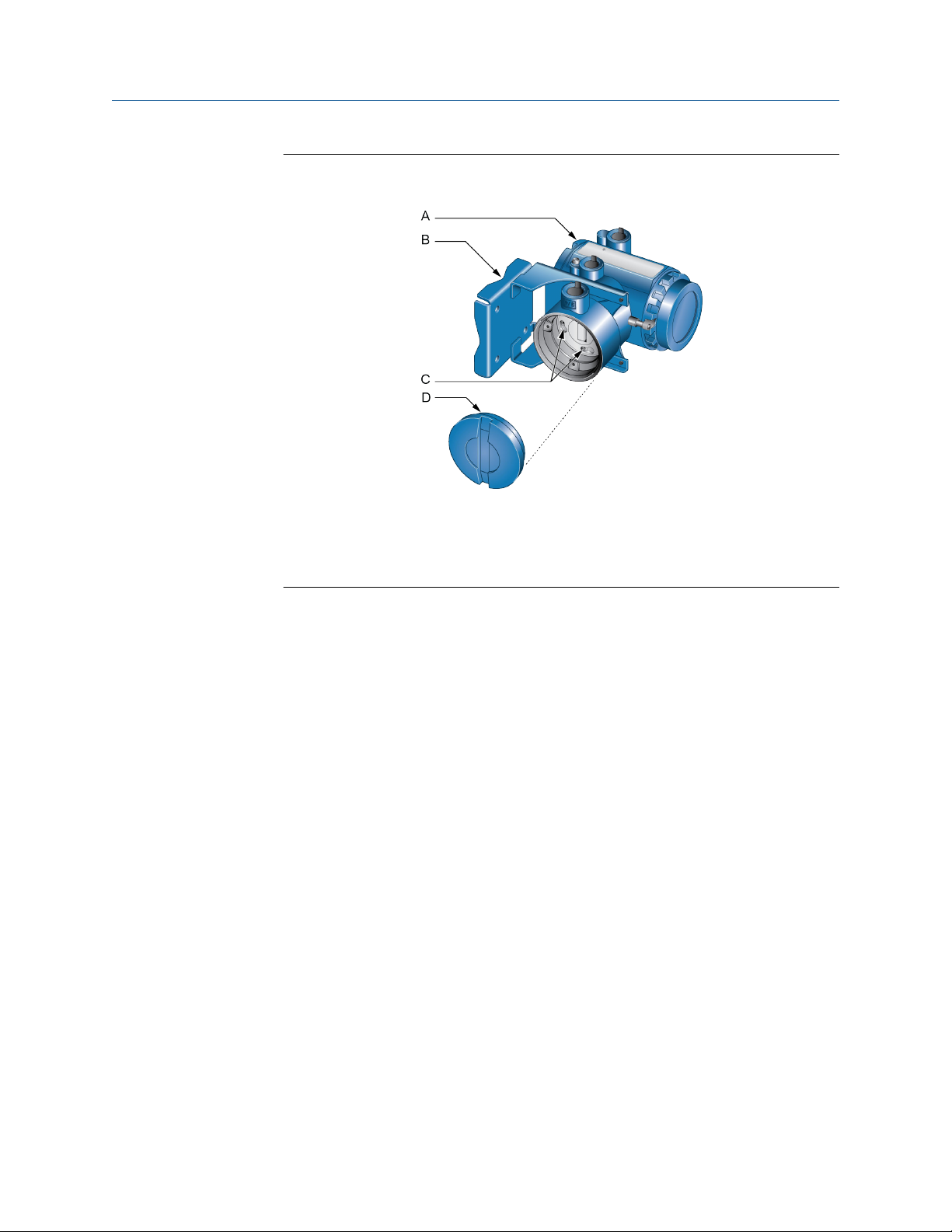

Figure 3-2: Components of a 4-wire remote mount transmitter (stainless steel

housing)

A. Transmitter

B. Mounting bracket

C. Cap screws

D. End-cap

Installation Manual 19

Page 20

A

B

C

Mounting

December 2019 20001700

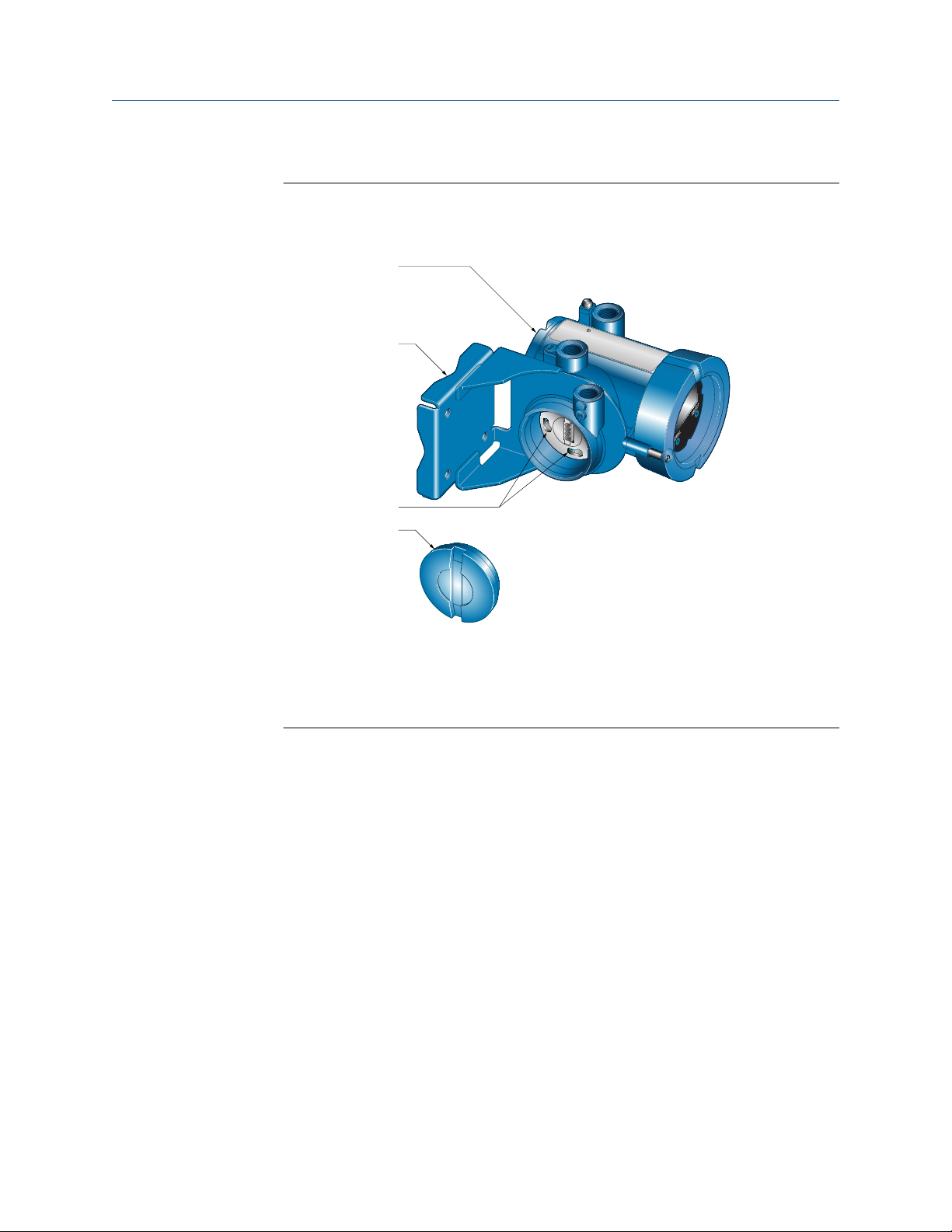

Figure 3-3: Components of 9-wire remote mount transmitter

Installation Manual

A. Transmitter

B. Cap screws

C. Mounting bracket

2. Attach the mounting bracket to the wall.

3.4.2

Mount the transmitter to an instrument pole

Prerequisites

• Use two 0.3125 in (8 mm) U-bolts for 2 in (51 mm) pipe, and four matching nuts, that

can withstand the process environment. Micro Motion does not supply U-bolts or nuts

(appropriate bolts and nuts are available as an option).

• Ensure the instrument pole extends at least 12 in (305 mm) from a rigid base, and is no

more than 2 in (51 mm) in diameter.

Procedure

1. If desired, re-orient the transmitter on the mounting bracket.

a) For 4-wire remote mount transmitters, remove the junction end-cap from

the junction housing.

b) Loosen each of the four 0.16 in (4.1 mm) cap screws.

c) Rotate the bracket so that the transmitter is oriented as desired.

d) Tighten the cap screws, torquing to 30 in lbf (3.39 N m) to 38 in lbf (4.29 N

m).

20 Micro Motion 1700 and 2700 Transmitters

Page 21

B

D

C

A

Installation Manual Mounting

20001700 December 2019

e) If applicable, replace the junction end-cap.

Figure 3-4: Components of 4-wire remote mount transmitter (aluminum

housing)

A. Transmitter

B. Mounting bracket

C. Cap screws

D. End-cap

Installation Manual 21

Page 22

A

B

C

Mounting Installation Manual

December 2019 20001700

Figure 3-5: Components of 9-wire remote mount transmitter

A. Transmitter and integral core

B. Cap screws

C. Mounting bracket

2. Attach the mounting bracket to an instrument pole.

22 Micro Motion 1700 and 2700 Transmitters

Page 23

A

B

C

D

Installation Manual

Mounting

20001700 December 2019

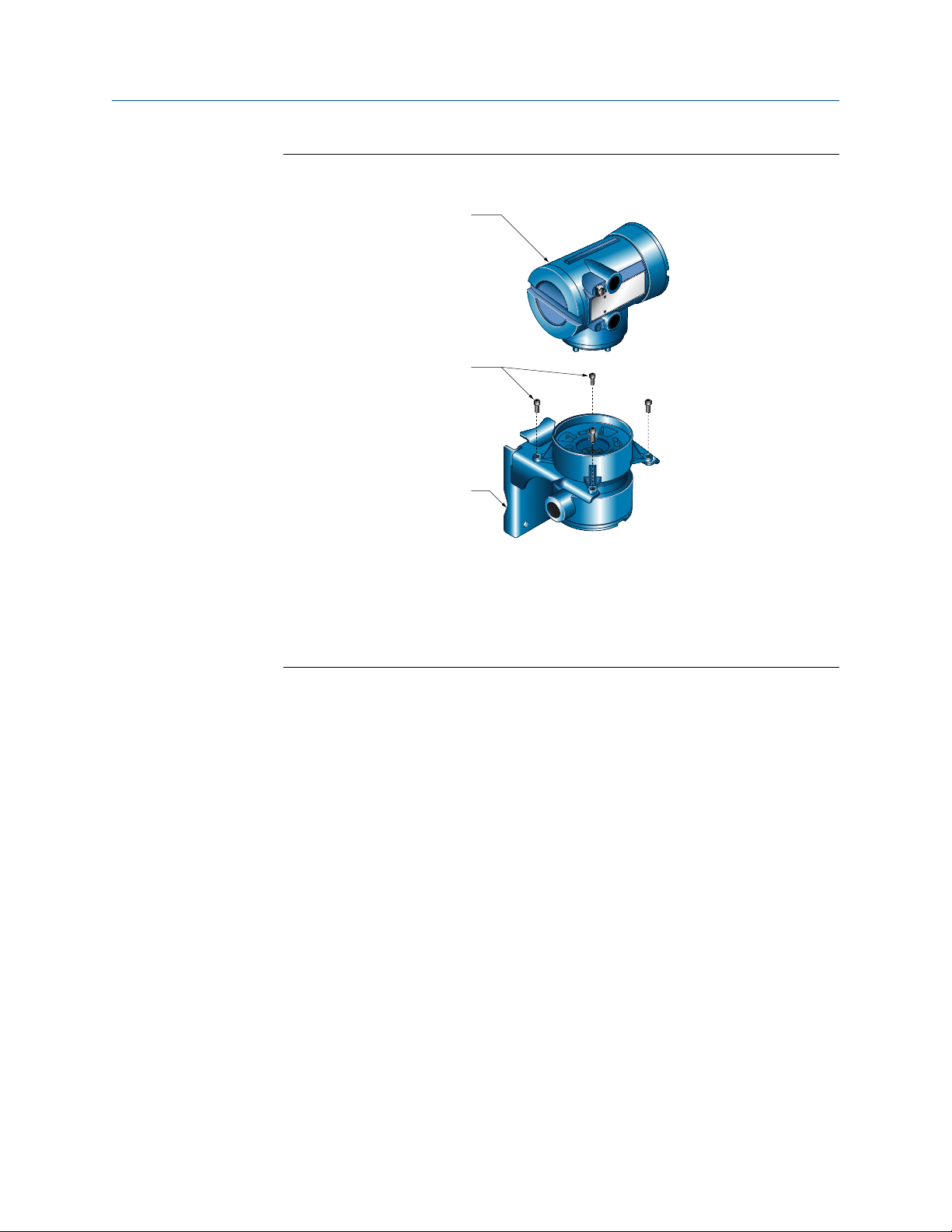

3.5 Rotate the transmitter on the sensor (optional)

In integral installations, you can rotate the transmitter on the sensor up to 360º in 90º

increments.

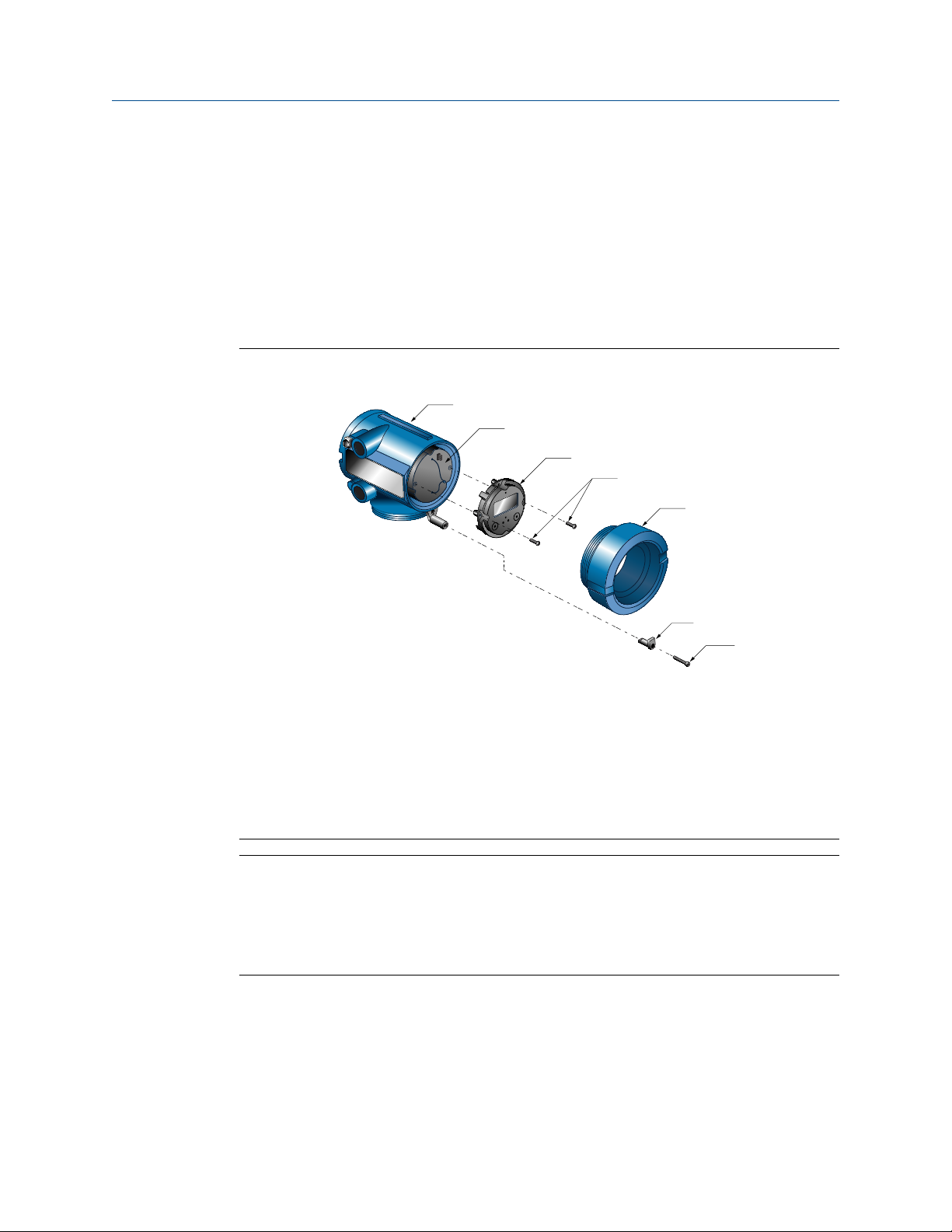

Figure 3-6: Components of an integral transmitter

A. Transmitter

B. Transition ring

C. Cap screws

D. Sensor

Procedure

1. Loosen each of the four cap screws 0.16 in (4.1 mm) that fasten the transmitter to

the base.

2. Rotate the transmitter counter-clockwise so that the cap screws are in the unlocked

position.

3. Gently lift the transmitter straight up, disengaging it from the cap screws.

NOTICE

Do not disconnect or damage the wires that connect the transmitter to the core

processor.

4. Rotate the transmitter to the desired orientation.

NOTICE

Do not pinch or stress the wires.

The slots on the transition ring should be aligned with the cap screws.

5. Gently lower the transmitter onto the base, inserting the cap screws into the slots.

Installation Manual 23

Page 24

A

B

C

G

E

F

D

Mounting

Installation Manual

December 2019 20001700

6. Rotate the transmitter clockwise so that the cap screws are in the locked position.

7. Tighten the cap screws, torquing to 1.70 ft lbf (2 N m) to 2.51 ft lbf (3 N m).

3.6 Rotate the user interface on the transmitter (optional)

The user interface on the transmitter electronics module can be rotated 90º or 180° from

the original position. .

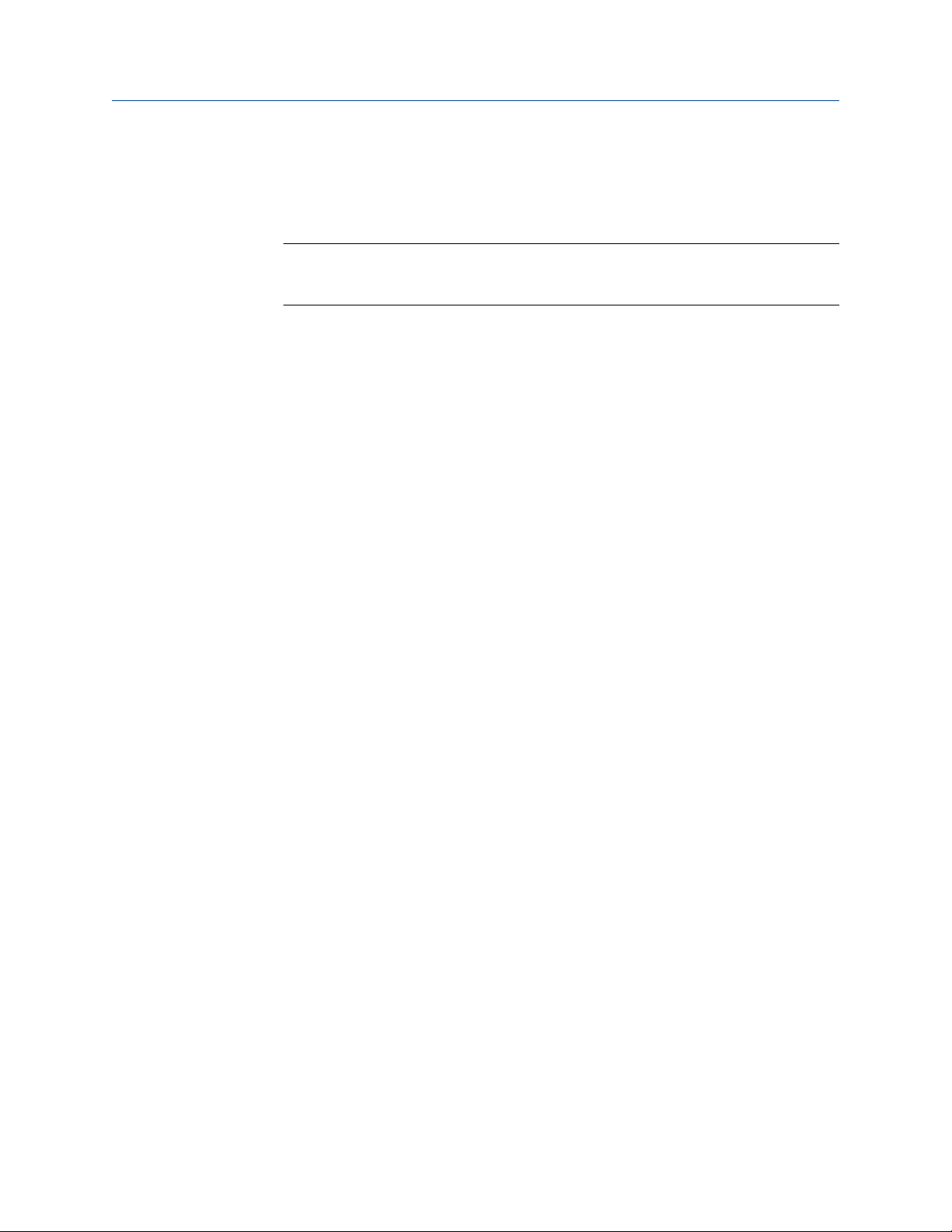

Figure 3-7: Display components

A. Transmitter housing

B. Sub-bezel

C. Display module

D. Display screws

E. End-cap clamp

F. Cap screw

G. Display cover

Notes

• When using the touch buttons, you must cover at least a 0.31 in (7.9 mm) diameter

circle over the surface above the touch button: using your thumb may be more

effective because it has a greater surface area.

• When the housing cover is removed, the touch buttons do not function.

Procedure

1. Shut off power to the unit.

2. Remove the end-cap clamp by removing the cap screw.

3. Turn the display cover counterclockwise to remove it from the main enclosure.

24 Micro Motion 1700 and 2700 Transmitters

Page 25

Installation Manual Mounting

20001700 December 2019

4. Carefully loosen (and remove if necessary) the semicaptive display screws while

holding the display module in place.

5. Carefully pull the display module out of the main enclosure until the sub-bezel pin

terminals are disengaged from the display module.

Note

If the display pins come out of the board stack with the display module, remove the

pins and reinstall them.

6. Rotate the display module to the desired position.

7. Insert the sub-bezel pin terminals into the display module pin holes to secure the

display in its new position.

8. If you have removed the display screws, line them up with the matching holes on

the sub-bezel, then reinsert and tighten them.

9. Place the display cover onto the main enclosure.

10. Turn the display cover clockwise until it is snug.

11. Replace the end-cap clamp by reinserting and tightening the cap screw.

12. Restore power to the transmitter.

Installation Manual 25

Page 26

Mounting Installation Manual

December 2019 20001700

26 Micro Motion 1700 and 2700 Transmitters

Page 27

Installation Manual Preparing the wires

20001700 December 2019

4 Preparing the wires

4.1 Prepare the 4-wire cable

4.1.1 4-wire cable types and usage

Micro Motion offers two types of 4-wire cable: shielded and armored. Both types contain

shield drain wires.

The cable supplied by Micro Motion consists of one pair of red and black 18 AWG

(0.823 mm²) wires for the VDC connection, and one pair of white and green 22 AWG

(0.326 mm²) wires for the RS-485 connection.

User-supplied cable must meet the following requirements:

• Twisted pair construction.

• Applicable hazardous area requirements, if the core processor is installed in a

hazardous area.

• Wire gauge appropriate for the cable length between the core processor and the

transmitter, or the host.

Wire gauge

VDC 22 AWG (0.326 mm²) 300 ft (91 m)

VDC 20 AWG (0.518 mm²) 500 ft (152 m)

VDC 18 AWG (0.823 mm²) 1,000 ft (305 m)

RS-485 22 AWG (0.326 mm²) or larger 1,000 ft (305 m)

Maximum cable length

Prepare a cable with a metal conduit

Procedure

1. Remove the core processor cover using a flat-blade screw driver.

2. Run the conduit to the sensor.

3. Pull the cable through the conduit.

4. Cut the drain wires and let them float at both ends of the conduit.

Prepare a cable with user-supplied cable glands

Procedure

1. Remove the core processor cover using a flat-blade screw driver.

2. Pass the wires through the gland.

3. Terminate the shield and drain wires inside the gland.

4. Assemble the gland according to vendor instructions.

Installation Manual 27

Page 28

Preparing the wires Installation Manual

December 2019 20001700

Prepare a cable with Micro Motion-supplied cable glands

Procedure

1. Remove the core processor cover using a flat-blade screw driver.

2. Pass the wires through the gland nut and clamping insert.

A. Gland nut

B. Clamping insert

3. Strip the cable jacket.

Option Description

NPT gland type Strip 4.5 in (114 mm)

M20 gland type Strip 4.25 in (107.9 mm)

4. Remove the clear wrap and filler material.

5. Strip most of the shielding.

Option

NPT gland type Strip all but 0.75 in (19.0 mm)

M20 gland type Strip all but 0.5 in (13 mm)

6. Wrap the drain wires twice around the shield and cut off the excess drain wires.

A. Drain wires wrapped around shield

7. For foil (shielded cable) only:

Note

For braided (armored cable) skip this step and contine to the next step.

Option

Description

Description

NPT

gland

type

28 Micro Motion 1700 and 2700 Transmitters

a. Slide the shielded heat shrink over the drain wires. Ensure that the

wires are completely covered.

b. Apply heat 250 °F (121.1 °C) to shrink the tubing. Do not burn the

cable.

Page 29

Installation Manual Preparing the wires

20001700 December 2019

Option Description

c. Position the clamping insert so the interior end is flush with the

braid of the heat shrink.

A. Shielded heat shrink

B. After heat is applied

M20

Trim 0.3 in (8 mm).

gland

type

A. Trim

8. Assemble the gland by folding the shield or braid back over the clamping insert and

0.125 in (3.18 mm) past the O-ring.

A. Shield folded back

9. Install the gland body into the conduit opening on the core processor housing.

10. Insert the wires through the gland body and tighten the gland nut onto the gland

body.

A. Shield folded back

B. Gland body

Installation Manual 29

Page 30

Preparing the wires Installation Manual

December 2019 20001700

4.2 Prepare the 9-wire cable

Micro Motion supplies three types of 9-wire cable: jacketed, shielded, and armored. The

type of cable you are using determines how you will prepare the cable.

4.2.1 9-wire cable types and usage

Cable types

Micro Motion supplies three types of 9-wire cable: jacketed, shielded, and armored. Note

the following differences between the cable types:

• Armored cable provides mechanical protection for the cable wires.

• Jacketed cable has a smaller bend radius than shielded or armored cable.

• If ATEX compliance is required, the different cable types have different installation

requirements.

Cable jacket types

All cable types can be ordered with a PVC jacket or Teflon® FEP jacket. Teflon FEP is

required for the following installation types:

• All installations that include a T-series sensor.

• All installations with a cable length of 250 ft (76.20 m) or greater, a nominal flow less

than 20 percent, and ambient temperature changes greater than 68 °F (20.0 °C).

Table 4-1: Cable jacket material and temperature ranges

Cable jacket

material

PVC -4 °F (-20.0 °C) 194 °F (90.0 °C) -40 °F (-40.0 °C) 221 °F (105.0 °C)

Teflon FEP -40 °F (-40.0 °C) 194 °F (90.0 °C) -76 °F (-60.0 °C) 302 °F (150.0 °C)

Cable bend radii

Table 4-2: Bend radii of jacketed cable

Jacket material Outside diameter

PVC 0.415 in (10.54 mm) 3.15 in (80.0 mm) 6.25 in (158.8 mm)

Teflon FEP 0.340 in (8.64 mm) 2.6 in (66 mm) 5.15 in (130.8 mm)

Handling temperature Operating temperature

Low limit High limit Low limit High limit

Minimum bend radii

Static (no load)

condition

Under dynamic load

30 Micro Motion 1700 and 2700 Transmitters

Page 31

A

C (4)

B (4)

D (5)

Installation Manual Preparing the wires

20001700 December 2019

Table 4-3: Bend radii of shielded cable

Minimum bend radii

Jacket material Outside diameter

PVC 0.525 in (13.33 mm) 4.25 in (107.9 mm) 8.5 in (216 mm)

Teflon FEP 0.425 in (10.80 mm) 3.25 in (82.6 mm) 6.38 in (162.1 mm)

Static (no load)

condition

Under dynamic load

Table 4-4: Bend radii of armored cable

Minimum bend radii

Jacket material Outside diameter

PVC 0.525 in (13.33 mm) 4.25 in (107.9 mm) 8.5 in (216 mm)

Teflon FEP 0.340 in (8.64 mm) 3.25 in (82.6 mm) 6.38 in (162.1 mm)

Static (no load)

condition

Under dynamic load

Cable illustrations

Figure 4-1: Cross-section view of jacketed cable

A. Outer jacket

B. Drain wire (4 total)

C. Foil shield (4 total)

D. Filler (5 total)

Installation Manual 31

Page 32

A

C (1)

B

D

E (4)

F (4)

G (5)

A

C (1)

B

D

E (4)

F (4)

G (5)

Preparing the wires Installation Manual

December 2019 20001700

Figure 4-2: Cross-section view of shielded cable

A. Outer jacket

B. Tin-plated copper braided shield

C. Foil shield (1 total)

D. Inner jacket

E. Drain wire (4 total)

F. Foil shield (4 total)

G. Filler (5 total)

Figure 4-3: Cross-section view of armored cable

A. Outer jacket

B. Stainless steel braided shield

C. Foil shield (1 total)

D. Inner jacket

E. Drain wire (4 total)

F. Foil shield (4 total)

G. Filler (5 total)

32 Micro Motion 1700 and 2700 Transmitters

Page 33

Installation Manual Preparing the wires

20001700 December 2019

4.2.2 Prepare jacketed cable

Prepare jacketed cable at sensor end

Procedure

1. Trim 4.5 in (114 mm) of cable jacket.

2. Remove the clear wrap and filler material.

3. Remove the foil that is around the insulated wires and separate them.

A. Trim cable jacket

4. Identify the drain wires in the cable. Clip off each drain wire as close as possible to

the cable jacket.

A. Drain wires clipped

5. Slide the 1.5 in (38 mm) heat-shrink tubing over the wires and cable jacket. The

tubing should completely cover the clipped ends of the drain wires.

A. Heat-shrink tubing

6. Without burning the cable, apply heat to shrink all tubing. Recommended

temperature is 250 °F (121.1 °C).

7. Allow the cable to cool, then strip 0.25 in (6.4 mm) of insulation from each wire.

Prepare jacketed cable at transmitter end

Procedure

1. Trim 4 in (102 mm) of cable jacket.

2. Remove the clear wrap and filler material.

3. Remove the foil that is around the insulated wires and separate them.

A. Trim cable jacket

Installation Manual 33

Page 34

Preparing the wires Installation Manual

December 2019 20001700

4. Identify the drain wires in the cable and bring them together.

5. Fan the other wires to the outside of the cable.

6. Twist the drain wires together.

7. Slide the 3 in (76 mm) heat-shrink tubing over the drain wires. Push the tubing as

close as possible to the cable jacket.

8. Slide the 1.5 in (38 mm) long heat-shrink tubing over the cable jacket. The tubing

should completely cover all portions of the drain wires that remain exposed next to

the cable jacket.

A. Heat-shrink tubing over cable jacket

B. Heat-shrink tubing over drain wires

4.2.3

9. Without burning the cable, apply heat to shrink all tubing. Recommended

temperature is 250 °F (121.1 °C).

10. Allow the cable to cool, then strip 0.25 in (6.4 mm) of insulation from each wire.

Prepare shielded or armored cable

Prepare shielded or armored cable at sensor end

Procedure

1. Without cutting the shield, strip 7 in (178 mm) of outer jacket.

2. Strip 6.5 in (165 mm) of braided shield, so 0.5 in (13 mm) of shield remains

exposed.

3. Remove the foil shield that is between the braided shield and inner jacket.

4. Strip 4.5 in (114 mm) of inner jacket.

A. Trim outer jacket

B. Trim braided shield

C. Trim inner jacket

5. Remove the clear wrap and filler material.

6. Remove the foil that is around the insulated wires and separate them.

34 Micro Motion 1700 and 2700 Transmitters

Page 35

Installation Manual Preparing the wires

20001700 December 2019

7. Identify the drain wires in the cable. Clip each drain wire as close as possible to the

cable jacket.

A. Drain wires clipped

8. Slide the 1.5 in (38 mm) heat-shrink tubing over the cable jacket. The tubing should

completely cover the clipped ends of the drain wires.

A. Heat-shrink tubing

9. Without burning the cable, apply heat to shrink all tubing. Recommended

temperature is 250 °F (121.1 °C).

10. Allow the cable to cool, then strip 0.25 in (6.4 mm) of insulation from each wire.

Prepare shielded or armored cable at transmitter end

Procedure

1. Without cutting the shield, strip 9 in (229 mm) of cable jacket.

2. Strip 8.5 in (216 mm) of braided shield, so 0.5 in (13 mm) of shield remains

exposed.

3. Remove the foil shield that is between the braided shield and inner jacket.

4. Strip 4 in (102 mm) of inner jacket.

A. Trim outer jacket

B. Trim braided shield

C. Trim inner jacket

5. Remove the clear wrap and filler material.

6. Remove the foil that is around the insulated wires and separate them.

7. Identify the drain wires in the cable and bring them together.

8. Fan the other wires to the outside of the cable.

Installation Manual 35

Page 36

Preparing the wires Installation Manual

December 2019 20001700

9. Twist the drain wires together.

10. Slide the 3 in (76 mm) heat-shrink tubing over the drain wires. Push the tubing as

close as possible to the cable jacket.

11. Slide the 1.5 in (38 mm) long heat-shrink tubing over the cable jacket. The tubing

should completely cover all portions of the drain wires that remain exposed next to

the cable jacket.

A. Heat-shrink tubing over cable jacket

B. Heat-shrink tubing over drain wires

12. Without burning the cable, apply heat to shrink all tubing. Recommended

temperature is 250 °F (121.1 °C).

13. Allow the cable to cool, then strip 0.25 in (6.4 mm) of insulation from each wire.

36 Micro Motion 1700 and 2700 Transmitters

Page 37

Installation Manual Wiring the transmitter to the sensor

20001700 December 2019

5 Wiring the transmitter to the sensor

Note

For integral installations, there is no need to connect wiring between the transmitter and

the sensor.

5.1 Wire the transmitter to the sensor (4-wire)

Use this procedure to wire the transmitter to the sensor in a 4-wire remote installation.

Procedure

1. Connect the cable to the sensor-mounted core processor as described in the sensor

documentation.

2. Feed the wires from the sensor through the conduit opening on the transmitter.

3. Connect wires to the appropriate terminals on the mating connector.

Tip

You may find it easier to unplug the mating connector to connect the wires. If you

do so, remember to firmly reseat the mating connector and tighten the mating

connector screws so that the mating connector cannot accidentally come loose.

Figure 5-1: Wiring path for transmitters with aluminum housing

A. 4-wire cable

B. Transmitter conduit opening

C. Mating connector

Installation Manual 37

Page 38

A

B

C

Wiring the transmitter to the sensor Installation Manual

December 2019 20001700

5.2 Wire the transmitter to the remote core processor (4-wire)

Use this procedure to wire the transmitter to the remote core processor in a 4-wire remote

sensor installation. This procedure applies to both 700 and 800 core processors.

Procedure

1. If you are installing a Micro Motion-supplied cable gland at the core processor

housing, identify the cable gland to use for the 4-wire cable conduit opening.

Figure 5-2: Cable gland identification

A. Cable gland used with 4-wire conduit opening

B. ¾ in–14 NPT cable gland used with 9-wire conduit opening

C. ½ in–14 NPT or M20x1.5 cable glands used with transmitter

2. Connect the cable to the core processor as described in the sensor documentation.

3. Feed the wires from the remote core processor through the conduit opening.

4. Connect wires to the appropriate terminals on the mating connector.

Tip

You may find it easier to unplug the mating connector to connect the wires. If you

do so, remember to firmly reseat the mating connector and tighten the mating

connector screws so that the mating connector cannot accidentally come loose.

38 Micro Motion 1700 and 2700 Transmitters

Page 39

Installation Manual Wiring the transmitter to the sensor

20001700 December 2019

Figure 5-3: Wiring path for transmitters with aluminum housing

A. 4-wire cable

B. Transmitter conduit opening

C. Mating connector

Installation Manual 39

Page 40

Wiring the transmitter to the sensor Installation Manual

December 2019 20001700

Figure 5-4: Wiring path for transmitters with stainless steel housing

A. 4-wire cable

B. Transmitter conduit opening

C. Mating connector

5.3 Wire the remote core processor to the sensor using jacketed cable (9-wire)

Use this procedure to wire the remote core processor to the sensor using jacketed cable in

a 9-wire remote sensor installation.

Prerequisites

For ATEX installations, the jacketed cable must be installed inside a user-supplied sealed

metallic conduit that provides 360° termination shielding for the enclosed cable.

WARNING

Sensor wiring is intrinsically safe. To keep sensor wiring intrinsically safe, keep the

sensor wiring separated from power supply wiring and output wiring.

40 Micro Motion 1700 and 2700 Transmitters

Page 41

Installation Manual Wiring the transmitter to the sensor

20001700 December 2019

NOTICE

• Keep cable away from devices such as transformers, motors, and power lines, which

produce large magnetic fields. Improper installation of cable, cable gland, or conduit

could cause inaccurate measurements or flow meter failure.

• Improperly sealed housings can expose electronics to moisture, which can cause

measurement error or flowmeter failure. Install drip legs in conduit and cable, if

necessary. Inspect and grease all gaskets and O-rings. Fully close and tighten all

housing covers and conduit openings.

Procedure

1. Run the cable through the conduit. Do not install 9-wire cable and power cable in

the same conduit.

2. To prevent conduit connectors from seizing in the threads of the conduit openings,

apply a conductive anti-galling compound to the threads, or wrap threads with PTFE

tape two to three layers deep.

Wrap the tape in the opposite direction that the male threads will turn when

inserted into the female conduit opening.

3. Remove the junction box cover and core processor end-cap.

4. At both the sensor and transmitter, do the following:

a) Connect a male conduit connector and waterproof seal to the conduit

opening for 9-wire.

b) Pass the cable through the conduit opening for the 9-wire cable.

c) Insert the stripped end of each wire into the corresponding terminal at the

sensor and transmitter ends, matching by color. No bare wires should remain

exposed.

Also see Sensor and remote core processor/transmitter terminals.

Table 5-1: Sensor and remote core processor terminal designations

Remote core

Wire color Sensor terminal

Black No connection Ground screw (see

Brown 1 1 Drive +

Red 2 2 Drive –

Orange 3 3 Lead length

processor

terminal

note)

Function

Drain wires

compensator/

composite RTD/ID

resistor

Yellow 4 4 Temperature

return

Green 5 5 Left pickoff +

Blue 6 6 Right pickoff +

Installation Manual 41

Page 42

Wiring the transmitter to the sensor Installation Manual

December 2019 20001700

Table 5-1: Sensor and remote core processor terminal designations

(continued)

Remote core

Wire color Sensor terminal

Violet 7 7 Temperature +

Gray 8 8 Right pickoff –

White 9 9 Left pickoff –

d) Tighten the screws to hold the wire in place.

e) Ensure integrity of gaskets, grease all O-rings, then replace the junction-box

and transmitter housing covers and tighten all screws, as required.

processor

terminal

Function

5.4 Wire the remote core processor to the sensor using shielded or armored cable (9-wire)

Use this procedure to wire the remote core processor to the sensor using shielded or

armored cable in a 9-wire remote sensor installation.

Prerequisites

For ATEX installations, shielded or armored cable must be installed with cable glands, at

both the sensor and remote core processor ends. Cable glands that meet ATEX

requirements can be purchased from Micro Motion. Cable glands from other vendors can

be used.

NOTICE

• Keep cable away from devices such as transformers, motors, and power lines, which

produce large magnetic fields. Improper installation of cable, cable gland, or conduit

could cause inaccurate measurements or flow meter failure.

• Install cable glands in the 9-wire conduit opening in the transmitter housing and the

sensor junction box. Ensure that the cable drain wires and shields do not make contact

with the junction box or the transmitter housing. Improper installation of cable or cable

glands could cause inaccurate measurements or flow meter failure.

• Improperly sealed housings can expose electronics to moisture, which can cause

measurement error or flowmeter failure. Install drip legs in conduit and cable, if

necessary. Inspect and grease all gaskets and O-rings. Fully close and tighten all

housing covers and conduit openings.

42 Micro Motion 1700 and 2700 Transmitters

Page 43

A B C D E F

G H I

Installation Manual Wiring the transmitter to the sensor

20001700 December 2019

Procedure

1. Identify the components of the cable gland and cable.

Figure 5-5: Cable gland and cable (exploded view)

A. Cable

B. Sealing nut

C. Compression nut

D. Brass compression ring

E. Braided shield

F. Cable

G. Tape or heat-shrink tubing

H. Clamp seat (shown as integral to nipple)

I. Nipple

2. Unscrew the nipple from the compression nut.

3. Screw the nipple into the conduit opening for the 9-wire cable. Tighten it to one

turn past hand-tight.

4. Slide the compression ring, compression nut, and sealing nut onto the cable. Make

sure the compression ring is oriented so the taper will mate properly with the

tapered end of the nipple.

5. Pass the cable end through the nipple so the braided shield slides over the tapered

end of the nipple.

6. Slide the compression ring over the braided shield.

7. Screw the compression nut onto the nipple. Tighten the sealing nut and

compression nut by hand to ensure that the compression ring traps the braided

shield.

8. Use a 1 in (25 mm) wrench to tighten the sealing nut and compression nut 20 ft lbf

(27.1 N m) to 25 ft lbf (33.9 N m) of torque.

Installation Manual 43

Page 44

A

B

C

E

D

F

G A

Wiring the transmitter to the sensor Installation Manual

December 2019 20001700

Figure 5-6: Cross-section of assembled cable gland with cable

A. Cable

B. Sealing nut

C. Seal

D. Compression nut

E. Braided shield

F. Brass compression ring

G. Nipple

9. Remove the junction box cover and remote core processor end-cap.

10. At both the sensor and remote core processor, connect the cable according to the

following procedure:

a) Insert the stripped end of each wire into the corresponding terminal at the

sensor and remote core processor ends, matching by color. No bare wires

should remain exposed.

Also see Sensor and remote core processor/transmitter terminals.

Table 5-2: Sensor and remote core processor terminal designations

Remote core

Wire color Sensor terminal

Black No connection Ground screw (see

Brown 1 1 Drive +

Red 2 2 Drive –

Orange 3 3 Lead length

Yellow 4 4 Temperature

processor

terminal

notes)

Function

Drain wires

compensator/

composite RTD/ID

resistor

return

Green 5 5 Left pickoff +

Blue 6 6 Right pickoff +

44 Micro Motion 1700 and 2700 Transmitters

Page 45

D

I

H

F

E

A

B

C

G

Installation Manual Wiring the transmitter to the sensor

20001700 December 2019

Table 5-2: Sensor and remote core processor terminal designations

(continued)

Remote core

Wire color Sensor terminal

Violet 7 7 Temperature +

Gray 8 8 Right pickoff –

White 9 9 Left pickoff –

b) Tighten the screws to hold the wires in place.

c) Ensure integrity of gaskets, grease all O-rings, then replace the junction box

cover and remote core processor end-cap and tighten all screws, as required.

processor

terminal

Function

5.5 Sensor and remote core processor/transmitter terminals

This section describes the sensor to remote control processor terminals or the sensor to

transmitter terminals.

Figure 5-7: All ELITE, H-Series, and T-Series sensor, and 2005 or newer F-Series sensor

terminals

A. Violet

B. Yellow

C. Orange

D. Brown

E. White

F. Green

G. Red

H. Gray

I. Blue

Installation Manual 45

Page 46

1

9

8

7

6

5

4

3

2

A

Wiring the transmitter to the sensor Installation Manual

December 2019 20001700

Figure 5-8: All D and DL, and pre-2005 F-Series sensor terminals

Figure 5-9: DT sensor terminals (user-supplied metal junction box with terminal

block)

A. Earth ground

46 Micro Motion 1700 and 2700 Transmitters

Page 47

A

B

I

H

G

F

E

D

C

J

Installation Manual Wiring the transmitter to the sensor

20001700 December 2019

Figure 5-10: Remote core processor/transmitter terminals

A. Brown

B. Violet

C. Yellow

D. Orange

E. Gray

F. Blue

G. White

H. Green

I. Red

J. Ground screw (black)

Installation Manual 47

Page 48

Wiring the transmitter to the sensor Installation Manual

December 2019 20001700

48 Micro Motion 1700 and 2700 Transmitters

Page 49

Installation Manual Grounding

20001700 December 2019

6 Grounding

6.1 Ground the meter components

• In integral installations, all components are grounded together.

• In 4-wire remote installations, the transmitter and sensor are grounded separately.

• In 9-wire remote installations, the transmitter/core processor assembly and sensor are

grounded separately.

• In a remote core processor with remote sensor installation, the transmitter, remote

core processor, and sensor are all grounded separately.

Prerequisites

If national standards are not in effect, adhere to the following guidelines for grounding:

• Use copper wire, 14 AWG (2.08 mm²) or larger wire size.

• Keep all ground leads as short as possible, less than 1 Ω impedance.

• Connect ground leads directly to earth, or follow plant standards.

Procedure

Depending on your installation type:

Option

For an integral

installation

For all other

installations

Description

Ground via the piping if possible (see the sensor documentation). If

grounding via the piping is not possible, ground according to

applicable local standards using the transmitter’s internal or

external ground screw.

a. Ground the sensor according to the instructions in the sensor

documentation.

b. Ground the transmitter according to applicable local

standards, using the transmitter’s internal or external ground

screw.

Installation Manual 49

Page 50

Grounding Installation Manual

December 2019 20001700

Figure 6-1: Transmitter internal grounding screw

Figure 6-2: Transmitter external grounding screw

50 Micro Motion 1700 and 2700 Transmitters

Page 51

A B

C

Installation Manual Wiring the power supply

20001700 December 2019

7 Wiring the power supply

7.1 Wire the power supply

A user-supplied switch may be installed in the power supply line. For compliance with lowvoltage directive 2006/95/EC (European installations), a switch in close proximity to the

transmitter is required.

Procedure

1. Remove the transmitter housing cover.

2. Open the warning flap.

3. Connect the power supply wires to terminals 9 and 10.

Terminate the positive (line) wire on terminal 10 and the return (neutral) wire on

terminal 9.

Figure 7-1: Power supply wiring terminals

A. Warning flap

B. Equipment ground

C. Power supply wiring terminals (9 and 10)

4. Ground the power supply using the equipment ground, also under the warning flap.

Installation Manual 51

Page 52

Wiring the power supply Installation Manual

December 2019 20001700

52 Micro Motion 1700 and 2700 Transmitters

Page 53

A

B

00042

Installation Manual I/O wiring for transmitters with analog outputs

20001700 December 2019

8 I/O wiring for transmitters with

analog outputs

8.1 Basic analog wiring

A. mA Output loop (820 Ω maximum loop resistance)

B. Frequency receiving device (output voltage level is +24 VDC ± 3%, with a 2.2 kΩ pull-up

resistor)

8.2 HART®/analog single loop wiring

Note

For HART communications:

• 600 Ω maximum loop resistance

• 250 Ω minimum loop resistance

Installation Manual 53

Page 54

B

A

B

C

A

RS-485A

RS-485B

I/O wiring for transmitters with analog outputs Installation Manual

December 2019 20001700

A. 820 Ω maximum loop resistance

B. HART-compatible host or controller

8.3 RS-485 point-to-point wiring

A. Other devices

B. Primary controller

C. Multiplexer

54 Micro Motion 1700 and 2700 Transmitters

Page 55

B

A

C

E

D

F

I give up

Installation Manual I/O wiring for transmitters with analog outputs

20001700 December 2019

8.4 HART multidrop wiring

Tip

For optimum HART communication, single-point ground the output loop to an

instrument-grade ground.

A. 250–600 Ω resistance

B. HART-compatible host or controller

C. HART-compatible transmitters

D. 1700 or 2700 transmitter

E. SMART FAMILY™ transmitters

F. 24 VDC loop power supply required for passive transmitters

Installation Manual 55

Page 56

I/O wiring for transmitters with analog outputs Installation Manual

December 2019 20001700

56 Micro Motion 1700 and 2700 Transmitters

Page 57

A

B

A

mA1

mA2

B

Installation Manual I/O wiring for transmitters with intrinsically safe outputs

20001700 December 2019

9 I/O wiring for transmitters with

intrinsically safe outputs

9.1 Safe area mA Output wiring (2700)

A. External DC power supply (VDC)

B. R

load

Installation Manual 57

Page 58

A

mA1

C

B

I/O wiring for transmitters with intrinsically safe outputs Installation Manual

December 2019 20001700

Safe area mA Output load resistance values

R

= (V

max

supply

− 12)/0.023

Minimum 250Ω and 17.5V required for HART communications

A. External resistor R

load

(ohms)

B. Supply voltage VDC (volts)

C. Operating region

9.2 Safe area HART/analog single-loop wiring

A. External DC power supply (VDC)

B. R

(250–600 Ω resistance)

load

C. HART-compatible host or controller

58 Micro Motion 1700 and 2700 Transmitters

Page 59

Installation Manual I/O wiring for transmitters with intrinsically safe outputs

20001700 December 2019

Safe area mA Output load resistance values

R

= (V

max

Minimum 250Ω and 17.5V required for HART communications

A. External resistor R

B. Supply voltage VDC (volts)

C. Operating region

load

(ohms)

supply

− 12)/0.023

9.3 Safe area HART multidrop wiring

Tip

For optimum HART communication, single-point ground the output loop to an

instrument-grade ground.

Installation Manual 59

Page 60

B

A

C

E

D

F

A

B

C

00042

I/O wiring for transmitters with intrinsically safe outputs Installation Manual

December 2019 20001700

A. 250–600 Ω resistance

B. HART-compatible host or controller

C. HART-compatible transmitters

D. 1700 or 2700 transmitter with intrinsically safe outputs

E. SMART FAMILY transmitter

F. 24 VDC loop power supply required for HART 4–20 mA passive transmitters

9.4 Safe area Frequency Output/Discrete Output wiring

A. External DC power supply (VDC)

B. Counter

C. R

load

60 Micro Motion 1700 and 2700 Transmitters

Page 61

Installation Manual I/O wiring for transmitters with intrinsically safe outputs

20001700 December 2019

Safe area Frequency Output/Discrete Output load resistance values

R

= (V

max

R

min

supply

= (V

supply

Minimum 100Ω for supply voltage less than 25.6 volts

A. External pull-up resistor R

range (ohms)

load

B. Supply voltage VDC (volts)

C. Operating region

9.5 Hazardous area wiring

Information provided about I.S. barriers is intended as an overview. Application-specific or

product-specific questions should be addressed to the barrier manufacturer or

Micro Motion.

WARNING

• Hazardous voltage can cause severe injury or death. Shut off the power before wiring

transmitter outputs.

• Improper wiring in a hazardous environment can cause an explosion. Install the

transmitter only in an area that complies with the hazardous classification tag on the

transmitter.

Table 9-1: Safety parameters

− 4)/0.003

− 25)/0.006

Parameter 4–20 mA Frequency/discrete

Voltage (Ui) 30 V 30 V

Current (Ii) 300 mA 100 mA

Power (Pi) 1.0 W 0.75 W

Installation Manual 61

Page 62

I/O wiring for transmitters with intrinsically safe outputs Installation Manual

December 2019 20001700

Table 9-1: Safety parameters (continued)

Parameter 4–20 mA Frequency/discrete

Capacitance (Ci) 0.0005 μF 0.0005 μF

Inductance (Li) 0.0 mH 0.0 mH

Voltage

Current

Capacitance

Inductance

The transmitter’s safety parameters require the selected barrier’s opencircuit voltage to be limited to less than 30 VDC (V

= 30 VDC). This

max

voltage is the combination of the maximum safety barrier voltage

(typically 28 VDC) plus an additional 2 VDC for HART communications

when communicating in the hazardous area.

The transmitter’s safety parameters require the selected barrier’s shortcircuit currents to sum to less than 300 mA (I

milliamp outputs and 100 mA (I

= 100 mA) for the frequency/discrete

max

= 300 mA) for the

max

output.

The capacitance (Ci) of the transmitter is 0.0005 μF. This value added to

the wire capacitance (C

) must be lower than the maximum allowable

cable

capacitance (Co) specified by the I.S. barrier. Use the following equation to

calculate the maximum length of the cable between the transmitter and

the barrier: C

+ C

i

cable

≤ C

o

The inductance (Li) of the transmitter is 0.0 mH. This value plus the field

wiring inductance (L

), must be lower than the maximum allowable

cable

inductance (Lo) specified by the I.S. barrier. The following equation can

then be used to calculate the maximum cable length between the

transmitter and the barrier: L

+ L

i

cable

≤ L

o

62 Micro Motion 1700 and 2700 Transmitters

Page 63

Installation Manual I/O wiring for transmitters with intrinsically safe outputs

20001700 December 2019

9.5.1 Hazardous area mA Output wiring

A. Hazardous area

B. Safe area

C. V

in

D. V

out

E. Ground

F. R

load

G. R

barrier

Note

Add R

load

and R

to determine Vin.

barrier

Installation Manual 63

Page 64

I/O wiring for transmitters with intrinsically safe outputs Installation Manual

December 2019 20001700

Safe area mA Output load resistance values

R

= (V

max

supply

− 12)/0.023

Minimum 250Ω and 17.5V required for HART communications

A. External resistor R

load

(ohms)

B. Supply voltage VDC (volts)

C. Operating region

64 Micro Motion 1700 and 2700 Transmitters

Page 65

Installation Manual I/O wiring for transmitters with intrinsically safe outputs

20001700 December 2019

9.5.2 Hazardous area Frequency Output/Discrete Output wiring using a galvanic isolator

A. Hazardous area

B. Safe area

C. External power supply

D. V

out

E. R

load

F. Galvanic isolator (see note)

G. Counter

Note

The galvanic isolator shown here has an internal 1000 Ω resistor used for sensing current:

• ON > 2.1 mA

• OFF < 1.2 mA

These current switching levels comply with DIN19234 (NAMUR)/DIN EN 60947-5-6/IEC

60947-5-6.

Installation Manual 65

Page 66

I/O wiring for transmitters with intrinsically safe outputs Installation Manual

December 2019 20001700

9.5.3 Hazardous area Frequency Output/Discrete Output wiring using barrier with external load resistance

A. Hazardous area

B. Safe area

C. R

barrier

D. V

in

E. V

out

F. Counter

G. R

load

H. Ground

Note

Add R

barrier

and R

to determine Vin.

load

66 Micro Motion 1700 and 2700 Transmitters

Page 67

Installation Manual I/O wiring for transmitters with intrinsically safe outputs

20001700 December 2019

Safe area Frequency Output/Discrete Output load resistance values

R

= (V

max

R

min

= (V

supply

supply

− 4)/0.003

− 25)/0.006

Minimum 100Ω for supply voltage less than 25.6 volts

A. External pull-up resistor R

range (ohms)

load

B. Supply voltage VDC (volts)

C. Operating region

Installation Manual 67

Page 68

I/O wiring for transmitters with intrinsically safe outputs Installation Manual

December 2019 20001700

68 Micro Motion 1700 and 2700 Transmitters

Page 69

Installation Manual I/O wiring for 2700 with configurable input/outputs

20001700 December 2019

10 I/O wiring for 2700 with configurable

input/outputs

10.1 Channel configuration

The six wiring terminals are divided into three pairs, and called Channels A, B, and C.

• Channel A = terminals 1 and 2

• Channel B = terminals 3 and 4

• Channel C = terminals 5 and 6

Variable assignments are governed by channel configuration.

Table 10-1: Channel configuration

Channel Terminals Configuration options Power

A 1, 2 mA Output with HART/Bell202 Internal

B 3, 4 mA Output (default) Internal

Frequency Output Internal or external

Discrete Output Internal or external

C 5, 6 Frequency Output (default) Internal or external

Discrete Output Internal or external

Discrete Input Internal or external

Notes

• For Channel A, the Bell 202 signal is superimposed on the mA Output.

• You must provide power to the outputs when a channel is set to external power.

• When both Channel B and Channel C are configured for Frequency Output (dual pulse),

Frequency Output 2 is generated from the same signal that is sent to the first

Frequency Output. Frequency Output 2 is electrically isolated but not independent.

• You cannot configure the combination of Channel B as Discrete Output and Channel C

as Frequency Output.

Installation Manual 69

Page 70

A

mA1

mA2

B

I/O wiring for 2700 with configurable input/outputs Installation Manual

December 2019 20001700

10.2 Basic mA Output wiring

A. 820 Ω maximum loop resistance

B. 420 Ω maximum loop resistance

10.3 HART/analog single loop wiring

Note

For HART communications:

• 600 Ω maximum loop resistance

• 250 Ω minimum loop resistance

70 Micro Motion 1700 and 2700 Transmitters

Page 71

B

A

B

A

C

E

D

F

I give up

Installation Manual I/O wiring for 2700 with configurable input/outputs

20001700 December 2019

A. 820 Ω maximum loop resistance

B. HART-compatible host or controller

10.4 HART multidrop wiring

Tip

For optimum HART communication, single-point ground the output loop to an

instrument-grade ground.

A. 250–600 Ω resistance

B. HART-compatible host or controller

C. HART-compatible transmitters

D. 2700 configurable I/O transmitter (internally powered outputs)

E. SMART FAMILY transmitters

F. 24 VDC loop power supply required for HART 4–20 mA passive transmitters

Installation Manual 71

Page 72

A

00042

I/O wiring for 2700 with configurable input/outputs Installation Manual

December 2019 20001700

10.5 Internally powered Frequency Output wiring on Channel B

A. Counter

Output voltage versus load resistance

Maximum output voltage = 15 VDC ± 3%

A. High level output voltage (volts)

B. Load resistance (ohms)

72 Micro Motion 1700 and 2700 Transmitters

Page 73

A

B

C

000042

Installation Manual I/O wiring for 2700 with configurable input/outputs

20001700 December 2019

10.6 Externally powered Frequency Output wiring on Channel B

A. Pull-up resistor

B. External DC power supply (3–30 VDC)

C. Counter

NOTICE

Exceeding 30 VDC can damage the transmitter. Terminal current must be less than 500

mA.

Recommended pull-up resistor versus supply voltage

A. External pull-up resistor range (ohms)

Installation Manual 73

B. Supply voltage (volts)

Page 74

A

00042

I/O wiring for 2700 with configurable input/outputs Installation Manual

December 2019 20001700

10.7 Internally powered FO wiring on Channel C

Figure 10-1: Internally powered FO wiring on Channel C

A. Counter

Maximum output voltage = 15 VDC ± 3%

A. High level output voltage (volts)

B. Load resistance (ohms)

74 Micro Motion 1700 and 2700 Transmitters

Page 75

A

B

C

000042

Installation Manual I/O wiring for 2700 with configurable input/outputs

20001700 December 2019

10.8 Externally powered Frequency Output wiring on Channel C

A. Pull-up resistor

B. External DC power supply (3–30 VDC)

C. Counter

NOTICE

Exceeding 30 VDC can damage the transmitter. Terminal current must be less than 500

mA.

Recommended pull-up resistor versus supply voltage

A. External pull-up resistor range (ohms)

Installation Manual 75

B. Supply voltage (volts)

Page 76

A

I/O wiring for 2700 with configurable input/outputs Installation Manual

December 2019 20001700

10.9 Internally powered Discrete Output wiring on Channel B

A. Total load

Output voltage versus load resistance

Maximum output voltage = 15 VDC ± 3%

A. High level output voltage (volts)

B. Load resistance (ohms)

76 Micro Motion 1700 and 2700 Transmitters

Page 77

B

A

Installation Manual I/O wiring for 2700 with configurable input/outputs

20001700 December 2019

10.10 Externally powered Discrete Output wiring on Channel B

A. External DC power supply (3–30 VDC)