Page 1

Instruction Manual

Form 5733

July 2004

FL Series Pressure Reducing Regulators

E0821

E0820

FL Series

Type FL

Figure 1. T ype FL and T ype MFL with T ype SRS Silencer

Introduction

Scope of Manual

This manual provides instructions for installation,

adjustment, maintenance, and parts ordering for the FL

Series regulators.

Description

The FL Series regulators are accurate pilot-operated,

pressure balanced, soft seated regulators designed for

high pressure transmission/city gate, large capacity

distribution systems and power plant feeds. The FL

Series provides smooth, quiet operation, tight shutoff and

long life. The regulator utilizes a main valve actuator , a

Type PRX pressure reducing pilot, and a Type SA/2 pilot

Type MFL with Type SRS Silencer

supply pressure regulator. The T ype PRX pilot uses inlet

pressure reduced by a Type SA/2 supply pressure

regulator, as loading pressure to operate the main valve

actuator. The outlet pressure is sensed through a

control line on the main valve actuator and also on the

Type PRX pilot diaphragm.

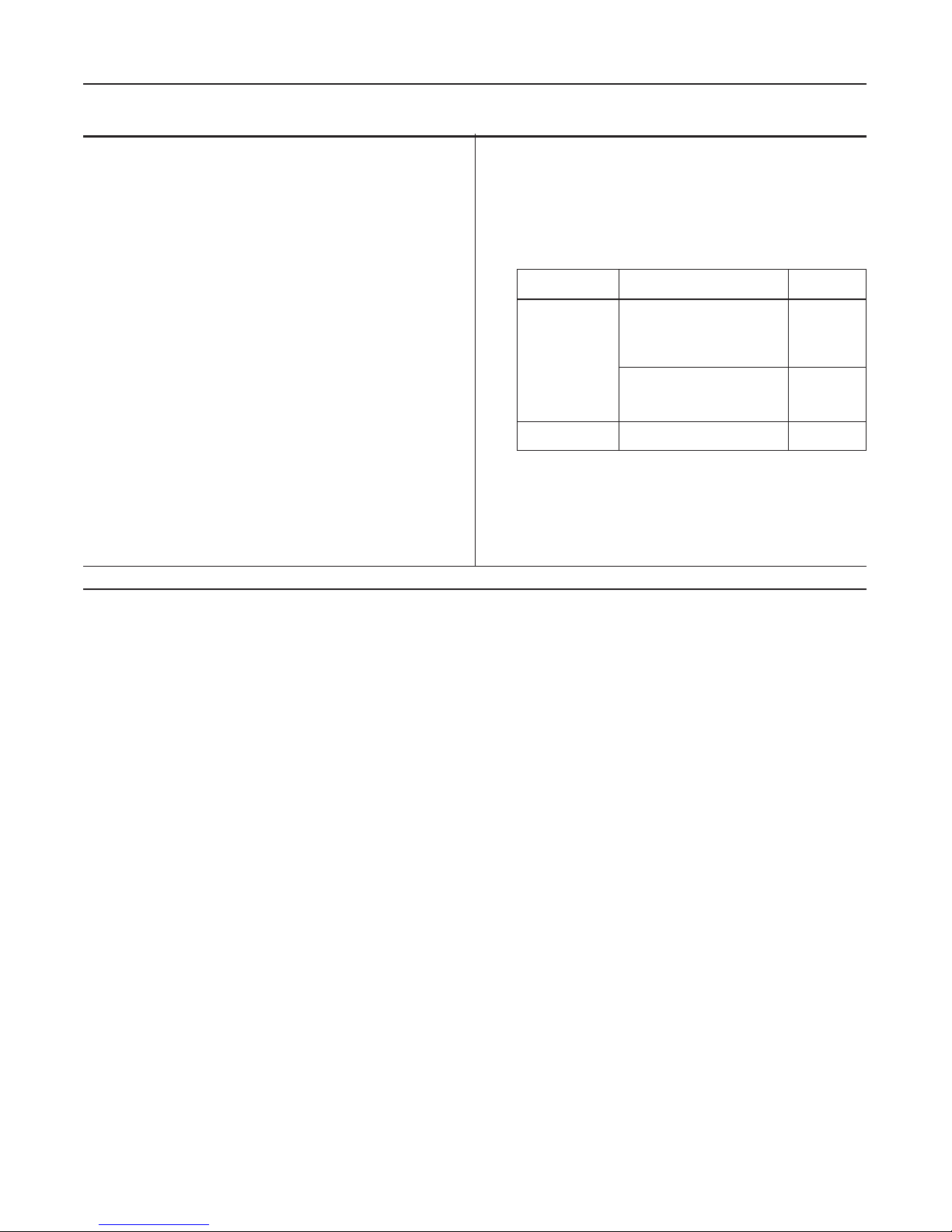

Specifications

The Specifications section gives some general specifications for the FL Series regulators. The nameplates

give detailed information for a particular regulator as it

comes from the factory .

D103068X012

www.FISHERregulators.com

Page 2

FL Series

EPYT

ERUSSERPTELTUO

(GISP,EGNARrab)

GNIRPS

ROLOC

021/XRP

521/XRP

61ot3.7

62ot5.41

44ot32

08ot14

321ot37

)1,1ot5,0(

)

8,1ot1(

)3ot6,1(

)5,5ot8,2(

)5,8ot5(

etihW

wolleY

neerG

eulB

kcalB

012ot611

433ot302

534ot913

906ot124

)5,41ot8(

)3

2ot41(

)03ot22(

)24ot92(

revliS

dloG

munimulA

deR

PA-021/XRP

PA-521/XRP

0611ot534)08ot03(raelC

Specifications

Available Configurations

FL: Pilot-operated pressure reducing regulator

for medium to high outlet pressures

MFL: Monitor and regulator combined into a single

unit for overpressure protection

Maximum Emergency (Design Pressure)

1450 psig (100 bar)

Miminum Operating Differential Pressure

7.3 psid (0,5 bar d)

Outlet Pressure Ranges

Body Sizes

FL and MFL:

1, 1-1/2, 2, 2-1/2, 3, 4, and 6-inch (DN 25, 40, 50, 65,

80, 100, and 150) (6-inch for FL only)

FL and MFL with SRS Silencer (inlet x outlet):

1 x 4, 1-1/2 x 6, 2 x 6, 2-1/2 x 8, 3 x 10, 4 x 10, and

6 x 12-inch (DN 25 x 100, 40 x 150, 50 x 150,

65 x 200, 80 x 250, 100 x 250, and 150 x 300)

(6 x 12-inch for FL only)

Main Valve End Connection Style and Pressure

Ratings

Maximum Inlet and Outlet (Casing) Pressure

(1)

ANSI Class 300 RF: 740 psig (51,0) bar

ANSI Class 600 RF: 1450 psig (100) bar

(1)

1450 psig (100 bar)

1. The pressure/temperature limits in this instruction manual or any applicable standard limitation should not be exceeded.

Pressure Registration

External

Maximum Temperature Capabilities

–20° to 150°F (–29° to 66°C)

(1)

Principle of Operation

The pilot-operated T ype FL (figure 2) uses inlet pressure as the operating medium, which is reduced

through pilot operation to load the actuator diaphragm.

Outlet or downstream pressure opposes loading

pressure in the actuator and also opposes the pilot

control spring.

When outlet pressure drops below the setting of the

pilot control spring, pilot control spring force on the pilot

diaphragm thus opens the pilot valve plug, providing

additional loading pressure to the actuator diaphragm.

This diaphragm loading pressure opens the main valve

plug, supplying the required flow to the downstream

system. Any excess loading pressure on the actuator

diaphragm escapes downstream through the bleed

restriction in the pilot.

When the gas demand in the downstream system has

been satisfied, the outlet pressure increases. The

increased pressure is transmitted through the downstream control line and acts on the pilot diaphragm. This

pressure exceeds the pilot spring setting and moves the

diaphragm, closing the orifice. The loading pressure

acting on the main diaphragm bleeds to the downstream

system through a bleed restriction in the pilot.

2

Adjustment

The adjustment of the regulator is performed by means

of the pilot adjusting screw, which varies the compression of the control spring. Adjustment is performed while

the regulator is in operation with the aid of a test pressure gauge of suitable range or of a water column. The

shutoff valve downstream of the regulator must not be

completely closed; it is necessary that a small quantity

of gas flows downstream to allow the outlet side to vent

down, when it is necessary to lower the pressure.

Loosen the locknut and turn the adjusting screw slowly to

adjust outlet pressure. Use a pressure gauge to check

the outlet pressure until the desired pressure is reached.

Monitoring Systems

Monitoring regulation is overpressure protection by

containment, therefore, there is no relief valve to vent to

the atmosphere. When the working regulator fails to

control the pressure, a monitor regulator installed in

series, which has been sensing the downstream and

control pressure, goes into operation to maintain the

downstream pressure at a slightly higher than normal

pressure. During an overpressure situation, monitoring

Page 3

E0827

INLET PRESSURE

OUTLET PRESSURE

LOADING PRESSURE

PILOT SUPPLY PRESSURE

A TMOSPHERIC PRESSURE

FL Series

Figure 2. T ype FL Operational Schematic

keeps the customer on line. Also, testing is relatively

easy and safe. To perform a periodic test on a monitoring regulator, increase the outlet set pressure of the

working regulator and watch the outlet pressure to

determine if the monitoring regulator takes over at the

appropriate outlet pressure.

Wide-Open Monitoring Systems (figure 3)

There are two types of wide-open monitoring systems:

upstream and downstream. The difference between

upstream and downstream monitoring is that the

functions of the regulators are reversed. Systems can

be changed from upstream to downstream monitoring,

and vice-versa, by simply reversing the setpoints of the

two regulators. The decision to use either an upstream

or downstream monitoring system is largely a matter of

personal preference or company policy .

In normal operation of a wide-open configuration, the

working regulator controls the system’s outlet pressure. With a higher outlet pressure setting, the monitor

regulator senses a pressure lower than its setpoint and

tries to increase outlet pressure by going wide-open. If

the working regulator fails, the monitoring regulator

assumes control and holds the outlet pressure at its

outlet pressure setting.

Working Monitoring Regulators (figure 3)

In a working monitoring system, the upstream regulator

requires two pilots and it is always the monitoring

regulator. The additional pilot permits the monitoring

regulator to act as a series regulator to control an

intermediate pressure during normal operation. In this

way , both units are always operating and can be easily

checked for proper operation.

In normal operation, the working regulator controls the

outlet pressure of the system. The monitoring

regulator’s working pilot controls the intermediate

pressure and the monitoring pilot senses the system’s

outlet pressure. If the working regulator fails, the

monitoring pilot will sense the increase in outlet

pressure and take control.

Note

The working regulator must be rated for

the maximum allowable operating

pressure of the system because this will

be its inlet pressure if the monitoring

regulator fails. Also, the outlet pressure

rating of the monitoring pilot, and any

other components that are exposed to

3

Page 4

FL Series

the intermediate pressure must be rated

for full inlet pressure.

Working monitor installations require a T ype FL main

valve with a Type PRX/120 or PRX/120-AP working pilot

and a T ype PRX/125 or PRX/125-AP monitoring pilot for

the upstream regulator and a Type FL with the appropriate T ype PRX/120 or PRX/120-AP pilot for the downstream regulator. The Type MFL incorporates the

monitor and regulator into one compact unit.

Installation and Startup

Personal injury or equipment damage,

due to bursting of pressure-containing

parts may result if this regulator is overpressured or is installed where service

conditions could exceed the limits given

in the Specification section and on the

appropriate nameplate, or where conditions exceed any rating of the adjacent

piping or piping connections.

To avoid such injury or damage, provide

pressure-relieving or pressure-limiting

devices to prevent service conditions from

exceeding those limits. Also, check that

the installation is in compliance with all

applicable codes and regulations.

Additionally, physical damage to the

regulator could break the pilot off the

main valve, causing personal injury and

property damage due to bursting of

pressure-containing parts. T o avoid such

injury and damage, install the regulator in

a safe location.

Single Pilot Regulator

Installation

A T ype FL regulator bleeds no gas to atmosphere

during normal operation, thus making the regulator

suitable for installation in pits and other enclosed

locations without elaborate venting systems. This

regulator also can be installed in pits subject to

flooding by venting the pilot spring case above the

expected flood level so that the pilot setting can be

referenced to atmospheric pressure.

1. Use qualified personnel when installing, maintaining, or operating this regulator. Inspect the regulator

and the pipeline to be certain both are free of foreign

materials.

2. Install the regulator so that the flow arrow cast on

the main valve matches the flow direction of process

fluid through the regulator.

3. Apply pipe compound to the male pipeline threads

before installing a regulator with screwed end connections. Use gaskets between pipeline and regulator

flanges when installing a regulator with flanged end

connections.

A regulator may vent some gas to the

atmosphere. In hazardous or flammable

gas service, vented gas may accumulate, causing personal injury, death, or

property damage due to bursting of

pressure-retaining parts. Vent a regulator in hazardous gas service to a remote, safe location away from air

intakes or any hazardous location. The

vent line or stack opening must be

protected against condensation or

clogging.

4. A T ype PRX pilot has a 1/4-inch NPT vent connection in the spring case. To remotely vent gas from the

spring case, remove the screened vent, and connect

1/4-inch piping or tubing to the spring case connection.

The piping or tubing should vent to a safe location, have

as few elbows as possible, and have a screened vent

on its exhaust. Install the regulator and any remote

vent piping or tubing so that the vent is protected from

condensation, freezing, or any substance that could

clog it.

5. Connect a pilot supply line from the upstream

piping to the 1/4-inch NPT pilot inlet.

6. Connect a downstream control line to a straight

run of pipe 6 to 10 pipe diameters from the regulator

outlet as shown in figure 3. If such a distance is not

practical, connect the control line away from elbows,

swages, nipples, or any area where abnormal flow

velocities occur.

7. Install a hand valve in the control line.

8. Install the other end of the downstream control

line to the 1/2-inch NPT connection in either side of the

case body.

4

Page 5

TYPE PRX/120 OR

PRX/120-AP

FL Series

TYPE SA/2

TYPE SA/2

B

L

S

A

Single Pilot System Installation

TYPE PRX/120 OR

PRX/120-AP

B

L

S

A

4 x A

B

A

6 x A

TYPE PRX/120 OR

PRX/120-AP

L

S

A

TYPE SA/2

TYPE SA/2

E0825

TYPE PRX/125 OR

PRX/125-AP

B

4 x A

Upsteam or Downstream Wide-Open Monitoring System Installation

TYPE PRX/120 OR

PRX/120-AP

L

A

B

L

S

S

A

TYPE PRX/120 OR

B

L

S

A

PRX/120-AP

4 x A

6 x A

Working Monitoring System Installation

A

6 x A

A

Figure 3. Installation Drawings

5

Page 6

FL Series

9. Consult the appropriate instruction manual for

installation of an optional pneumatic or electric remote

control-drive unit. For optional remote pneumatic loading

of a Type PRX pilot, make the spring case piping

connections just as they would be made for remote

venting.

Prestartup Considerations

Each regulator is factory-set for the outlet pressure

specified on the order. If no setting was specified,

outlet pressure was factory-set at the mid-range of the

pilot control spring. Before beginning the startup

procedure in this section, make sure the following

conditions are in effect:

• Block valves isolate the regulator

• Vent valves are closed

• A bypass, if any, is in operation

In all cases, check the control spring setting to make

sure it is correct for the application.

ing screw counterclockwise decreases the spring

compression and pressure setting.

Pilot Adjustment

T o adjust a st andard Type PRX pilot, loosen the

locknut, and turn the adjusting screw. Then tighten the

locknut to maintain the adjustment position.

Startup

1. Open the upstream block (isolating) valve. Open

hand valve A in the external pilot supply line before

opening the downstream isolating valve (see figure 3).

2. Open the downstream block (isolating) valve for

minimum flow .

3. Slowly open hand valve B in the downstream

control line, while at the same time adjusting the pilot

setting, if necessary.

4. Completely open the downstream block valve.

5. Slowly close the bypass valve, if any .

Pilot supply pressure must be introduced into the regulator before introduction of any downstream pressure, or

internal damage may occur due to

reverse pressurization of the pilot and

main valve components.

Pressure gauges should always be used

to monitor downstream pressure during

startup. Procedures used in putting this

regulator into operation must be

planned accordingly if the downstream

system is pressurized by another regulator or by a manual bypass.

Note

Pilot supply pressure must be at least 15

psig (1,0 bar) greater than control pressure to operate the regulator at rated

travel.

Although remote loading or control constructions may

require separate adjustments on associated equipment,

the only adjustment normally necessary on a

Type FL-PRX regulator is the pressure setting of the

pilot control spring. Turning the adjusting screw

clockwise into the spring case increases the spring

compression and pressure setting. Turning the adjust-

Wide-Open Monitor Regulator

Installation

1. For both the wide-open monitoring regulator and

the working regulator, perform the Single Pilot Regulator Installation procedures through step 9.

2. Connect the control line of a wide-open monitoring

regulator (figure 3) to downstream piping near the

working regulator control line connection. During

normal operation the wide-open monitoring regulator

stands wide open with the pressure reduction being

taken across the working regulator . Only in case of

working regulator failure does the wide-open monitoring

regulator take control at its slightly higher setting.

Prestartup Considerations

Each regulator is factory-set for the outlet pressure

specified on the order. If no setting was specified,

outlet pressure was factory-set at the mid-range of the

pilot control spring. Before beginning the startup

procedures in this section, make sure the following

conditions are in effect:

• Block valves isolate the regulator

• Vent valves are closed

6

Page 7

FL Series

• Hand valves are closed

• A bypass, if any, is in operation

In all cases, check the control spring setting to make

sure it is correct for the application.

Introduce pilot supply pressure into the

regulator before introducing any downstream pressure, or internal damage

may occur due to reverse pressurization

of the pilot and main valve components.

Always use pressure gauges to monitor

downstream pressure during startup. If

the downstream is pressurized by

another regulator, plan startup procedures accordingly .

Note

Pilot supply pressure must exceed

control pressure by at least 15 psig

(1,0 bar) in order to operate the regulator at rated travel.

Although remote loading or control constructions may

require separate adjustments on associated equipment,

the only adjustment normally necessary on a

Type FL-PRX regulator is the pressure setting of the

pilot control spring. Turning the adjusting screw

clockwise into the spring case increases the spring

compression and pressure setting. Turning the adjusting screw counterclockwise decreases the spring

compression and pressure setting.

Pilot Adjustment

T o adjust a st andard Type PRX pilot, loosen the

locknut, and turn the adjusting screw. Then tighten the

locknut to maintain the adjustment position.

Startup

3. Slowly open the hand valve in the control line

while, at the same time, adjusting the pilot setting if

necessary.

4. Completely open the downstream block valve.

5. Slowly close the bypass valve, if any .

Working Monitor Regulator

Installation

All T ype FL working monitor regulators are bench set at

the factory according to the service conditions specified

on the customer’s order. Examine the unit on arrival to

make sure no damage has occurred in shipment. Clean

and blow out pipelines to be sure no welding slag or

other foreign material is present.

Install the T ype FL into the pipeline using adequate

gaskets for flanged regulator units and good piping

technique. Be sure to provide suitable pressure gauges

where appropriate, block valves, bypass valves and

piping, and bleed valves to permit safe and easy

maintenance of both the working monitor regulator and

the second-stage working regulator. Be sure flow will be

in the direction indicated by the arrow cast on the body

Refer to the figure 3 schematic and figure 4, and

proceed in the following steps.

1. Attach the intermediate pressure control line

(1/2-inch NPT pipe) between the 1/2-inch NPT pipe tee

and the intermediate pressure portion of the downstream piping. Install hand valve B in this line.

2. Connect 1/2-inch NPT distribution pressure

control line piping between the 1/2-inch NPT connection in the mounting bracket and the pipeline downstream of the second-stage working regulator . Include

hand valve A in this control line.

Note

Each pilot has a nameplate identifying it

as the working or monitor pilot.

This procedure is to be repeated in turn for each

regulator in the installation.

1. Slowly open the hand valve in the pilot supply line.

2. Slowly open the upstream block (isolating) valve

and partially open the downstream block valve for

minimum flow .

3. Pipe the pilot supply line to 1/4-inch NPT connection in the back of the working pilot body . Supply

pressure should be filtered if excess dirt or condensate

is present in the supply gas.

4. Install downstream working regulator per guidelines.

7

Page 8

FL Series

Startup

1. Before introducing any pressure to the unit, close

hand valve A in the distribution pressure control line and

hand valve B in the intermediate pressure control line.

Pilot supply pressure must be introduced into the regulator prior to introduction of any downstream pressure or

internal damage may occur due to

reverse pressurization of the pilot and

main valve components. Pilot supply

pressure must be at least 15 psi (1,0 bar)

greater than control pressure for proper

operation.

2. Slowly open the hand valve in the pilot supply line.

3. Slowly open the upstream block valve and partially

open the downstream block valve for minimum flow.

4. Slowly open hand valve B and allow the intermediate pressure to increase to the working pilot setting.

5. Put the second-stage working regulator into

operation according to recommended procedures and

instructions furnished with the second-stage working

regulator.

3. Adjust the second-stage working regulator to the

desired distribution pressure by following instructions

for that particular regulator .

4. Adjust the setting of the monitoring pilot to

establish the desired emergency distribution pressure,

which is to be maintained in the event of failure of the

second-stage working regulator . The steps followed

may vary with each piping situation. The basic method

remains the same.

The following procedure serves as an example which

can be used or modified to make monitoring pilot

adjustments in any installation.

Increase the outlet pressure setting of the secondstage working regulator until the monitoring pilot takes

control of the distribution pressure. Adjust the monitoring pilot setting until the desired emergency distribution

pressure is achieved. Refer to table 2 for the recommended minimum differential between the monitoring

pilot setting and the desired distribution pressure.

With settings as desired on both the monitoring and

the working pilots, tighten the locknuts to maintain

proper adjustment screw positions. Then re-adjust the

second-stage working regulator to the desired distribution pressure.

Shutdown

6. After the distribution pressure has been estab-

lished slowly open hand valve A.

Pilot Adjustment

The second-stage working regulator must be set to

operate at a lower pressure than the monitoring pilot or

the monitoring pilot will try to take control of the

distribution pressure. Follow the steps listed to obtain

the desired results.

1. Increase the setting of the monitoring pilot by

loosening the locknut and turning the adjusting screw

clockwise (into the spring case cap) until the working

pilot is in control of the intermediate pressure and the

second-stage working regulator is in control of the

distribution pressure.

2. Adjust the setting of the working pilot by loosening the jam nut and turning the adjusting screw clockwise (into the spring case cap) to increase the intermediate pressure, or counterclockwise (out of the spring

case cap) to reduce the intermediate pressure. Adjust

until desired intermediate pressure is reached.

In any installation it is important to slowly open and

close the valves and to vent the outlet pressure before

venting the inlet pressure to prevent damage caused by

reverse pressurization of the pilot or main valve.

Single Pilot Regulators and Wide-Open

Monitor Regulators

As well as applying to a single-pilot regulator, the steps

in this procedure also are valid for a wide-open monitoring installation and should be repeated for each regulator in such an installation.

1. Close the upstream isolating valve.

2. Close block valve A in the supply line.

3. Close the downstream isolating valve.

4. If the downstream control line taps into the

pipeline above the downstream isolating valve,

open vent valve C between the regulator and the

downstream isolating valve. Permit all pressure to

bleed out of the regulator.

8

Page 9

FL Series

If the downstream control line taps into the pipeline below the downstream isolating valve, close

hand valve B. Then open vent valve C and vent valve D,

permitting all pressure to bleed out of the regulator.

5. Open vent valve E to release any inlet pressure

that may be trapped in the regulator.

Working Monitor Regulators

1. Close the upstream isolating valve.

2. Close hand valve in pilot supply line.

3. Close the downstream isolating valve.

4. Open a bleed valve between the second-stage

working regulator and the downstream isolating valve.

Permit all pressure to bleed out of the working monitor

regulator and the second-stage working regulator.

5. Open vent valve to vent any intermediate pressure

trapped in the system.

6. Open vent valve to release any inlet pressure

trapped in the regulator.

Maintenance

The regulator parts are subject to normal wear and must

be inspected periodically and replaced as necessary.

The frequency of inspection and replacement depends

on the severity of service conditions and on applicable

federal, state and local codes and regulations.

4. Reinstall the pad.

Main Valve Diaphragm Maintenance

1. Place main valve with inlet side up.

2. Remove the travel indicator assembly by removing

the indicator cover (key 40) and indicator bushing

(key 38). Check O-ring (key 37), replace if necessary .

Remove the indicator support (key 36). Check O-ring

(key 35), replace if necessary . Lif t out indicator stem

assembly (keys 33 and 34).

3. Remove inlet flange (key 1) by removing socket

head cap screws (key 5). Due to force created by the

spring (key 6), take care when removing inlet flange.

Check O-rings (keys 3 and 4) and anti-friction rings

(key 2), replace if necessary.

4. Lift out spring (key 6). Remove hex head cap

screws, washers, and nuts (keys 9, 14, and 15). Lift

off the inlet cover (key 1 1). Check O-ring (key 3) and

anti-friction rings (key 2), replace if necessary .

5. Remove diaphargm assembly by removing screws

(key 27) to separate the outlet and the inlet plates

(keys 12 and 8). Check diaphragm (key 10) and O-rings

(keys 26 and 28) for damage and replace if necessary .

Check sleeve (key 16) seating surface for damage.

6. Reassemble in reverse order.

PRX Pilot Maintenance

To avoid personal injury or property

damage from sudden release of pressure, isolate the regulator from the

pressure system, and release all pressure

from the pilot and main valve before

performing maintenance operations.

Main Valve

Main Valve Pad Replacement

1. Remove outlet flange (key 22) by removing socket

head cap screws (key 5).

2. Remove pad holder assembly and O-ring (key 18).

3. Remove pad (key 20) from pad holder (key 19) by

removing cap screw (key 25) and pad retainer (key 21),

replace pad if necessary .

Always remove spring (key 7) tension

before performing maintenance on this

unit. T o remove spring tension, loosen

locknut (key 2) and back out adjusting

screw (key 1) until compression is

removed from the spring.

Lower Case Maintenance

1. Disconnect pilot and remove it from the line.

2. Remove screws (key 10) from lower cover (key 21)

and the separate lower cover from the body (key 16).

3. Use a wrench to hold the stem (key 23) and break

loose the stem nut (key 20). Remove the stem nut and

washer (key 1 1).

4. Remove the diaphragm plate (key 13), diaphragm

(key 14), pad holder (key 22), and O-ring (key 18).

9

Page 10

FL Series

Inspect the parts for damage or wear , and replace if

necessary.

5. Remove orifice (key 19) and O-ring (key 17).

Inspect the parts for damage or wear , and replace if

necessary . Lightly lubricate the O-ring and place in the

body (key 16). Install the orifice.

6. Set the pad holder (key 22) in the body (key 16).

7. Lightly lubricate the rims of the diaphragm (key 14)

and place it on top of the pad holder (key 22). Set the

diaphragm plate (key 13) on the diaphragm (key 14).

8. Lightly lubricate the O-ring (key 18) and place it in

the lower case (key 21).

9. Place the washer (key 1 1) and stem nut (key 20)

on the stem (key 23) and tighten.

If also performing

Upper Case Maintenance, skip to step 2 of the Upper

Case Maintenance section.

10. Insert machine screws (key 10) in the lower cover

(key 21) and tighten uniformly to ensure proper seal.

Upper Case Maintenance

1. Disconnect pilot and remove it from the line.

2. Loosen locknut (key 2) and back out adjusting

screw (key 1) until compression is removed from the

spring. Remove cap (key 3).

3. Lift the spring carrier (key 6), spring (key 7), and

O-ring (key 4) out of the upper cover (key 8). Inspect

O-ring and replace if necessary .

4. Remove machine screws (key 10) from lower cover

(key 21) and the separate lower cover from the body

(key 16), unless removed during lower diaphragm

maintenance. Use a wrench to hold stem (key 19)

securely while removing the stem nut (key 26).

5. Remove remaining loose components: washer ,

upper diaphragm plate, diaphragm, lower diaphragm

plate, and O-rings (keys 11, 13, 14, 15, 18, and 25).

Inspect diaphragm and O-rings for damage or wear, and

replace if necessary .

6. Lightly lubricate the O-ring (key 25). Place O-ring

over the stem (key 19) and press it down into the body

(key 16).

7. Set the lower diaphragm plate (key 15) into the

body (key 16).

9. Set the upper diaphragm plate (key 13) on top of

the diaphragm (key 14).

10. Place washer (key 1 1) and stem nut (key 26) on

the stem (key 19) and tighten using a wrench to hold

the stem.

1 1. Set the spring carrier (key 6).

Damper and Restrictor Maintenance

1. Remove screw (key 31) and plate (key 29).

2. Remove ring nuts (key 30).

3. Remove damper adjusting screw (key 27). Remove

and inspect O-ring (key 28) for damage or wear, and

replace if necessary . Lightly lubricate O-ring before

placing on the adjusting screw. Insert damper adjusting screw into the body (key 16) and tighten. Insert

ring nut (key 30) and tighten. Back out damper

adjusting screw until it stops.

4. Remove restrictor adjusting screw with hole

(key 32). Remove and inspect O-ring (key 28) for

damage or wear, and replace if necessary . Lightly

lubricate O-ring before placing on the adjusting screw.

Insert restrictor adjusting screw into the body (key 16)

and completely tighten. Insert ring nut (key 30) and

completely tighten. Back out restrictor adjusting screw

1/2 turn.

Note

When using a Type PRX/120 pilot with a

Type PRX/125 pilot as a monitor, use the

following settings:

• restrictor - completely tighten and

then back out three full turns.

• damper - back out until it stops.

5. Install plate (key 29) and screw (key 31).

T ype SA/2

1. Disconnect pilot supply filter regulator and remove

it from the line.

2. Remove bolts, washers, and nuts (keys 2, 9, and 10)

from body (key 16) and the separate upper and lower

covers (keys 1 1 and 19) from the body (key 16). When

separating the covers from the body , be aware of loose

components: (keys 1, 3, 4, 8, 12, 18, 20, and 21).

8. Lightly lubricate the rims of the diaphragm (key 14)

and place it in the body (key 16) on top of the lower

diaphragm plate (key 15).

10

3. Remove and inspect O-ring (key 13) for damage or

wear, and replace if necessary. Lightly lubricate the

O-ring before placing it back in the (key 1 1).

Page 11

FL Series

4. Clean screens (key 8). Replace filter pad (key 12).

5. Inspect diaphragm (key 18) for damage or wear,

and replace if necessary . Check the seating surface of

the (key 17) for erosion, scratches, spurs, or other

damage, and replace if necessary .

6. Unscrew and remove (key 5). Inspect O-ring

(key 6) for damage or wear, and replace if necessary .

Lightly lubricate the O-ring and place it on (key 5).

7. Pull (key 15) out of the body (key 16). Inspect the

seat for damage, and replace if necessary .

8. Set the (key 15) on the spring (key 14) and insert

the (key 5). Tighten the (key 5) until it stops.

9. Lightly lubricate the outer and inner rims of the

diaphragm (key 18). Place the diaphragm assembly on

top of the (key 5). The (key 17) will slide into (key 5).

Use care to avoid damage to parts when reassembling.

10. Set the spring (key 1) on top of the (key 21).

1 1. Align the (key 19) over the body (key 16) with the

sense port (V) opposite the pilot supply port (R).

12. Place the filter pad (key 12) and screens (key 8),

one on each side of the filter pad, on the (key 1 1).

13. Pick up the body (key 16) and place it on the

(key 1 1) with the inlet port (M) aligned vertically with the

sense port (V).

14. Insert bolts (key 2). Place washers (key 9) and

nuts (key 10) on the end of the bolts. Tighten the nuts.

Parts Ordering

Refer to the T ype number when contacting your Fisher

Sales Office or Sales Representative for technical

information. When ordering parts, also be sure to

include the complete 1 1-character part kit number .

Parts List

FL Main V alve (figure 4)

Key Description

Part Kit (includes key number: 2, 3, 4, 10, 18,

20, 26, 28, 35, 38, 46, and 47) See Table

1 Inlet Flange

2* Anti-Friction Ring

3* O-Ring

4* Body O-Ring

5 Screw

6 Spring

7 Fitting

8 Inlet Plate

9 Screw

10* Diaphragm

11 Inlet Cover

12 Outlet Plate

13 Outlet Cover

14 Washer

15 Nut

16 Sleeve

17 Fitting

18* O-Ring

19 Pad Holder

20* Pad

21 Pad Retainer

22 Outlet Flange

23 Gasket

24 Disassembly Spacer

25 Screw

26* O-Ring

27 Screw

28* O-Ring

29 Metal Plate

30 Nameplate Sticker

31 Drive Screw

32 Flow Arrow

33 Spring Collet

34 Indicator

35* O-Ring

36 Support

37 Indicator Bushing

38* O-Ring

39 Indicator Label

40 Indicator Cover

43 SR Silencer

46* O-Ring

47* O-Ring

48 Washer

M ATERIAL

NITRILE GD89984X012 GD89977X012 GD89985X012 GD89975X012 GD89986X012 GD89987X012 GD89988X012 ~

VITON GD89984X022 GD89977X022 GD89985X022 GD89975X022 GD89986X022 GD89987X022 GD89988X022 ~

NITRILE SR-SRS GD89973X012 GD89976X012 GD89972X012 GD89974X012 GD89971X012 GD89970X012 GD89969X012 ~

VITON SR-SRS GD89973X022 GD89976X022 GD89972X022 GD89974X022 GD89971X022 GD89970X022 GD89969X022 ~

~ CALL FOR KIT NUMBER

1 (DN 25) 1-1/2 (DN 40) 2 (DN 25) 2-1/2 (DN 65) 3 (DN 80) 4 (DN 100) 6 (DN 150) 8 (DN 200)

* Indicates Recommended Spare.

FL Series Parts Kit Part Numbers

SIZE, IN C H ES (D N )

11

Page 12

FL Series

12

Figure 4. FL Assembly

Page 13

FL Series

SRS Main V alve (figure 5)

Key Description

23 Gasket

24 Flange Spacer

200 Body

201 Retainer

202 Stud

203 Atenuator Plate

204 Spring Pin

205 Flange

206 Nut

207 Atenuator Plate

208 Atenuator Plate

209 Spacer

210 Spring Cage

211 Spring

Figure 5. SRS Assembly

13

Page 14

FL Series

TYPE PRX/120 OR PRX/125

TYPE PRX/120-AP OR PRX/125-AP

TYPE PRX/120 OR PRX/125 TYPE PRX/120-AP OR PRX/125-AP

14

Figure 6. PRX Series Pilot Assembly

Page 15

PRX Series Pilots (figure 6)

Description Part Number

Elastomer Parts Kits (includes keys: 4, 5, 14, 17,

18, 25, and 28)

Types PRX/120 and PRX/125

Nitrile GD89982X012

Fluoroelastomer GD89982X022

Types PRX/120-AP and PRX/125-AP

Nitrile GD89982X012

Fluoroelastomer GD89982X022

Key Description

1 Adjusting Screw

2 Lockut

3 Cap

(1)

4

Upper Cover O-Ring

(1)

5

O-Ring

6 Spring Carrier Plate

7 Spring (See table 2)

8 Upper Cover

9 Spring Carrier Plate

10 Machine Screw

11 Washer

12 Filter

13 Diaphragm Plate

(1)

14

Diaphragm

15 Diaphragm Plate

16 Body

(1)

17

Orifice O-Ring

(1)

18

Lower Cover O-Ring

19 Orifice

20 Nut

21 Lower Cover

22 Pad Holder

23 Stem

24 Nameplate

26 Upper Diaphragm Nut

27 Damper Adjusting Screw

(1)

28

Restrictor/Damper O-Ring

29 Plate

30 Ring Nut

31 Damper/Restrictor Screw

32 Restrictor Adjusting Screw with Hole

33 Plug

34 Plug

FL Series

T ype SA/2 Pilot Supply Filter Regulator

(figure 7)

Description Part Number

Elastomer Parts Kits (includes keys: )

Nitrile GD89995X012

Fluoroelastomer GD89995X022

Key Description

1 Spring

2 Socket Head Cap Screw

3 Washer

4 Plate

5 Regulator Seat

6 O-ring

7 Body

8 Filter Net

9 Washer

10 Nut

1. Recommended Spare Part

Figure 7. Type SA/2 Assembly

Key Description

11 Filter Cover

12 Felt

13 O-Ring

14 Spring

15 Pad Holder Unit

16 Nameplate

17 Screw Unit

18 Diaphragm

19 Regulator Cover

20 Spring Washer

21 Nut

15

Page 16

FL Series

Fisher is a mark owned by Fisher Controls International, Inc., a business of Emerson Process Management. The Emerson logo is a trade mark and service mark of Emerson Electric Co. All other marks are the

property of their respective owners.

The contents of this publication are presented for informational purposes only, and while every effort has been made to ensure their accuracy, they are not to be construed as warranties or guarantees, express

or implied, regarding the products or services described herein or their use or applicability. We reserve the right to modify or improve the designs or specifications of such product s at any time without notice.

Fisher does not assume responsibility for the selection, use or maintenance of any product. Responsibility for proper selection, use and maintenance of any Fisher product remains solely with the purchaser.

For information, contact Fisher:

Marshalltown, Iowa 50158 USA

McKinney, Texas 75070 USA

28320 Gallardon, France

40013 Castel Maggiore (BO), Italy

Sao Paulo 05424 Brazil

Singapore 128461

©Fisher Controls International, Inc., 2002, 2004; All Rights Reserved

www.FISHERregulators.com

Loading...

Loading...