Page 1

Mobrey MCU900 Series

4–20 mA + HART® Compatible Controller

Reference Manual

IP2030/RM, Rev AA

June 2014

Page 2

Page 3

Reference Manual

IP2030/RM, Rev AA

Title Page

June 2014

Mobrey MCU900 Series

Universal Control Unit

Read this manual before working with the product.

For personal and system safety, and for optimum product performance,

make sure you thoroughly understand the contents before installing, using,

or maintaining this product.

For the latest customer support information, visit the Mobrey brand

pages at www.emersonprocess.com, and then click on the Mobrey

Service or Product Support quick links.

The products described in this document are NOT designed for

nuclear-qualified applications.

Using non-nuclear qualified products in applications that require

nuclear-qualified hardware or products may cause inaccurate readings.

For information on Rosemount nuclear-qualified products, contact an

Emerson Process Management Sales Representative.

Replacement equipment or spare parts not approved by Emerson for use as

spare parts could reduce the capabilities of the Mobrey MCU900 Series

control unit, and may render the instrument dangerous.

Use spare parts supplied or sold by Emerson

1

Page 4

Page 5

Reference Manual

IP2030/RM, Rev AA

Table of Contents

1Section 1: Introduction

1.1 Safety messages. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

1.2 Manual overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

1.3 Control unit versions and software releases . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

1.4 Customer support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

1.5 Product recycling/disposal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

2Section 2: Control Unit Overview

2.1 Safety messages. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

2.2 About the Mobrey MCU900 Series Control Unit. . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

2.2.1 Wall and panel mounting options. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Table of Contents

June 2014

2.2.2 4–20mA HART transmitter input options . . . . . . . . . . . . . . . . . . . . . . . . . . .4

2.2.3 Control functionality . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

2.3 Control unit functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

2.3.1 Standard functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.3.2 Difference, sum, and product functions (on MCU902 only) . . . . . . . . . . .5

2.3.3 Data logging functions (on MCU90F only) . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.4 Control unit front panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

2.4.1 Keypad . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.4.2 Status LED . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

2.4.3 Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

3Section 3: Installation

3.1 Safety messages. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

3.2 Considerations before installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

3.2.1 Safety considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

3.3 Mounting the control unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3.3.1 Mounting the wall-mount version . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

3.3.2 Mounting the panel version. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

3.4 Electrical installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

3.4.1 Making electrical connections on wall-mount units . . . . . . . . . . . . . . . . .13

Tab le of C ontents

3.4.2 Making electrical connections on panel-mount units . . . . . . . . . . . . . . . .15

3.4.3 Power connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

3.4.4 Earthing connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

TOC-i

Page 6

Table of Contents

June 2014

Reference Manual

IP2030/RM, Rev AA

3.4.5 Transmitter connections and cabling. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

3.4.6 Connecting HART transmitters to the Mobrey MCU902 . . . . . . . . . . . . .18

3.4.7 Relay connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

3.4.8 Current output connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

3.4.9 Digital control voltage-free contact inputs. . . . . . . . . . . . . . . . . . . . . . . . .21

3.4.10 RS232 connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

4Section 4: Getting started

4.1 Safety messages. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

4.2 Switching on the MCU901 and MCU90F for the first time . . . . . . . . . . . . . . . . . . 26

4.2.1 Switching on with one new HART transmitter connected . . . . . . . . . . . .27

4.2.2 Switching on with one 4–20 mA transmitter connected . . . . . . . . . . . . .29

4.3 Switching on the MCU902 for the first time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

4.4 A quick tour of the menu system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

4.5 Programming the control unit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

4.5.1 The basics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32

4.5.2 Step-by-step programming of the control unit . . . . . . . . . . . . . . . . . . . . .37

4.5.3 Run App and Program operating modes . . . . . . . . . . . . . . . . . . . . . . . . . . .38

4.5.4 Application Wizard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .39

4.5.5 Optional change: system settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .42

4.5.6 Optional change:

transmitter input channel settings (advanced users) . . . . . . . . . . . . . . . .43

4.5.7 Programming Input Channel 1 for a 4–20 mA input

(advanced users) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .44

4.5.8 Programming Channel 1 for a HART input (advanced users). . . . . . . . . .48

4.5.9 Programming Channel 2 for a HART input (MCU902 only)

(advanced users) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .50

4.5.10 Volumetric contents and flow measurement applications

(advanced users) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .52

4.5.11 Set-up the volumetric contents calculations for a

popular linear / uniform vessel (advanced users). . . . . . . . . . . . . . . . . . . .52

4.5.12 Set-up the volumetric contents calculations for a popular

non-linear / non-uniform shaped vessel (advanced users). . . . . . . . . . . .53

TOC-ii

4.5.13 Set-up flow calculations for non-linear / non-uniform

open channel profiles (advanced users) . . . . . . . . . . . . . . . . . . . . . . . . . . .56

4.5.14 Set-up open channel flow calculations for pre-programmed flat,

parabolic, and Parshall flumes (advanced users) . . . . . . . . . . . . . . . . . . . .58

4.5.15 Set-up Kindsvater Shen (V-notch ISO1438) flow calculations. . . . . . . . .59

4.5.16 Set-up exponential flow law calculations . . . . . . . . . . . . . . . . . . . . . . . . . .59

Table of Contents

Page 7

Reference Manual

IP2030/RM, Rev AA

Table of Contents

June 2014

4.5.17 Using a plotted profile for calculating volume or flow . . . . . . . . . . . . . . .61

4.5.18 Digital inputs IN1 and IN2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .63

4.5.19 Data logging on the Mobrey MCU90F . . . . . . . . . . . . . . . . . . . . . . . . . . . . .64

4.5.20 Set-up the current output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .68

4.5.21 Set-up the relays . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .69

4.5.22 Set-up alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .91

4.5.23 Set-up totalizing on the Mobrey MCU901 control unit. . . . . . . . . . . . . . .95

4.5.24 Set-up totalizing on the Mobrey MCU902 control unit. . . . . . . . . . . . . . .97

4.5.25 Set-up totalizing on the Mobrey MCU90F control unit . . . . . . . . . . . . . . .99

4.5.26 Display configuration options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

4.5.27 Serial communications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

4.5.28 PIN Security. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

5Section 5: Servicing and Health Checking

5.1 Safety messages. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

5.2 Servicing the MCU900 Series control unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

5.2.1 Replacing the fuse on mains ac-powered control units . . . . . . . . . . . . 108

5.3 Health checking the MCU900 Series control unit . . . . . . . . . . . . . . . . . . . . . . . . 110

5.3.1 Simulation (self-test). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

5.3.2 Display test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

5.3.3 Calibration of the Current Input (I

5.3.4 Fixing the Current Output (I

out

5.3.5 Calibration of the Current Output (I

). . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

in

). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

). . . . . . . . . . . . . . . . . . . . . . . . . . 112

out

5.3.6 Monitoring the control unit readings. . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

5.3.7 Diagnostic data for the MCU900 Series control unit . . . . . . . . . . . . . . . 115

5.3.8 Model code, serial number, and software and hardware revisions. . . 116

AAppendix A: Reference Data

A.1 Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

A.1.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

Tab le of C ontents

A.1.2 Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

A.1.3 Electrical . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

A.1.4 Mechanical . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

A.1.5 Environment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

A.2 Dimensional drawings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

TOC-iii

Page 8

Table of Contents

June 2014

Reference Manual

IP2030/RM, Rev AA

BAppendix B: Product Certifications

B.1 Safety messages. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

B.2 European directive information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 124

B.3 Hazardous locations certifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 124

B.3.1 ATEX intrinsically safe approvals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 124

B.3.2 IECEx intrinsically safe approvals. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 124

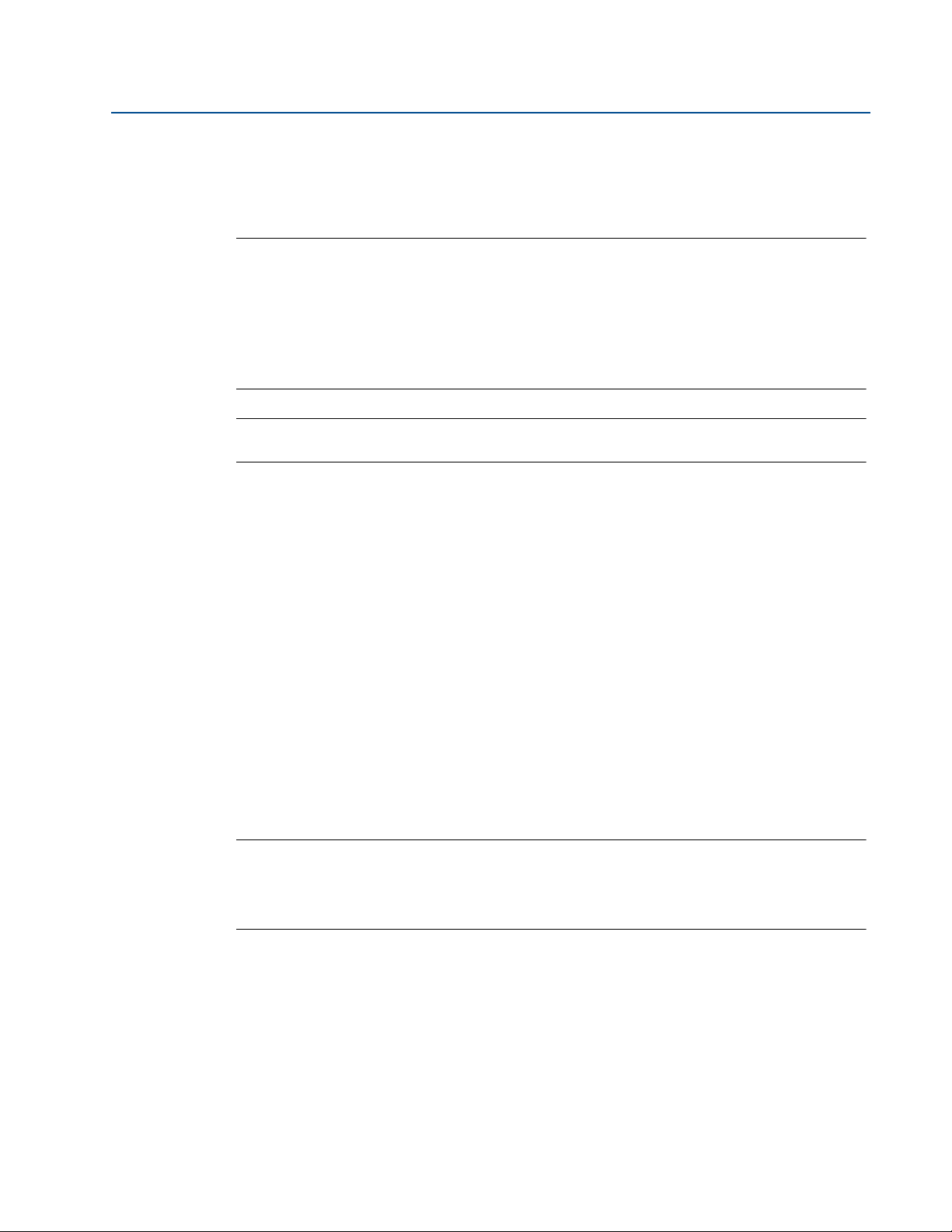

CAppendix C: Menus and Parameters

C.1 Menus and parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 125

DAppendix D: Additional Features

D.1 Restoring the factory defaults . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 135

D.1.1 How to restore the factory default settings . . . . . . . . . . . . . . . . . . . . . . 135

D.2 ADVANCED parameter access . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 136

EAppendix E: Support for HART® Transmitters

E.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 139

E.2 Fully supported HART transmitters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 139

E.3 Generic support for HART transmitters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 139

E.3.1 Compatibility between transmitter and control unit . . . . . . . . . . . . . . 139

E.3.2 Universal and common practice commands . . . . . . . . . . . . . . . . . . . . . 140

6Index

TOC-iv

Table of Contents

Page 9

Reference Manual

IP2030/RM, Rev AA

Section 1 Introduction

Safety messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 1

Manual overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 2

Control unit versions and software releases . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 2

Customer support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 2

Product recycling/disposal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 2

1.1 Safety messages

Procedures and instructions in this manual may require special precautions to ensure the safety

of the personnel performing the operations. Information that raises potential safety issues is

indicated by a caution symbol ( ). The external hot surface symbol ( ) is used when a surface

is hot and care must be taken to avoid possible burns. If there is a risk of an electrical shock the

( ) symbol is used. Refer to the safety messages listed at the beginning of each section before

performing an operation preceded by this symbol.

Section 1: Introduction

June 2014

Failure to follow these installation guidelines could result in death or serious injury:

The Mobrey MCU900 Series Control Unit must be installed, connected,

commissioned, operated, and maintained by suitably qualified personnel only,

observing any national and local requirements that may apply

Use the equipment only as specified in this manual. Failure to do so may impair the

protection provided by the equipment

Explosions could result in death or serious injury:

Please review the approvals section of this reference manual for any restrictions

associated with an installation

Electrical shock could cause death or serious injury:

If the control unit is installed in a high voltage environment and a fault condition or

installation error occurs, high voltage may be present on leads and terminals

Use extreme caution when making contact with the leads and terminals

Make sure that power to the control unit is off while making connections

Section 1: Introduction

1

Page 10

Section 1: Introduction

June 2014

1.2 Manual overview

This manual provides installation, configuration and maintenance information for the

Mobrey MCU900 Series control unit.

Section 2: Control Unit Overview

Section 3: Installation

Section 4: Getting started

Section 5: Servicing and Health Checking

Appendix A: Reference Data

Appendix B: Product Certifications

Appendix C: Menus and Parameters

Appendix D: Additional Features

Reference Manual

IP2030/RM, Rev AA

Appendix E: Support for HART® Transmitters

1.3 Control unit versions and software releases

The following control unit versions are covered in this product manual:

Mobrey MCU901 Standard Control Unit

Mobrey MCU902 Differential Control Unit

Mobrey MCU90F Logging Control Unit

The software release covered in this product manual is issue 4.00.00 (and above).

1.4 Customer support

For the latest customer support information, visit the Mobrey brand pages at

www.emersonprocess.com, and then click on the Mobrey Service or Product Support

quick links.

1.5 Product recycling/disposal

Recycling of equipment and packaging should be taken into consideration. The product and

packaging should be disposed of in accordance with local and national legislation.

Section 1: Introduction2

Page 11

Reference Manual

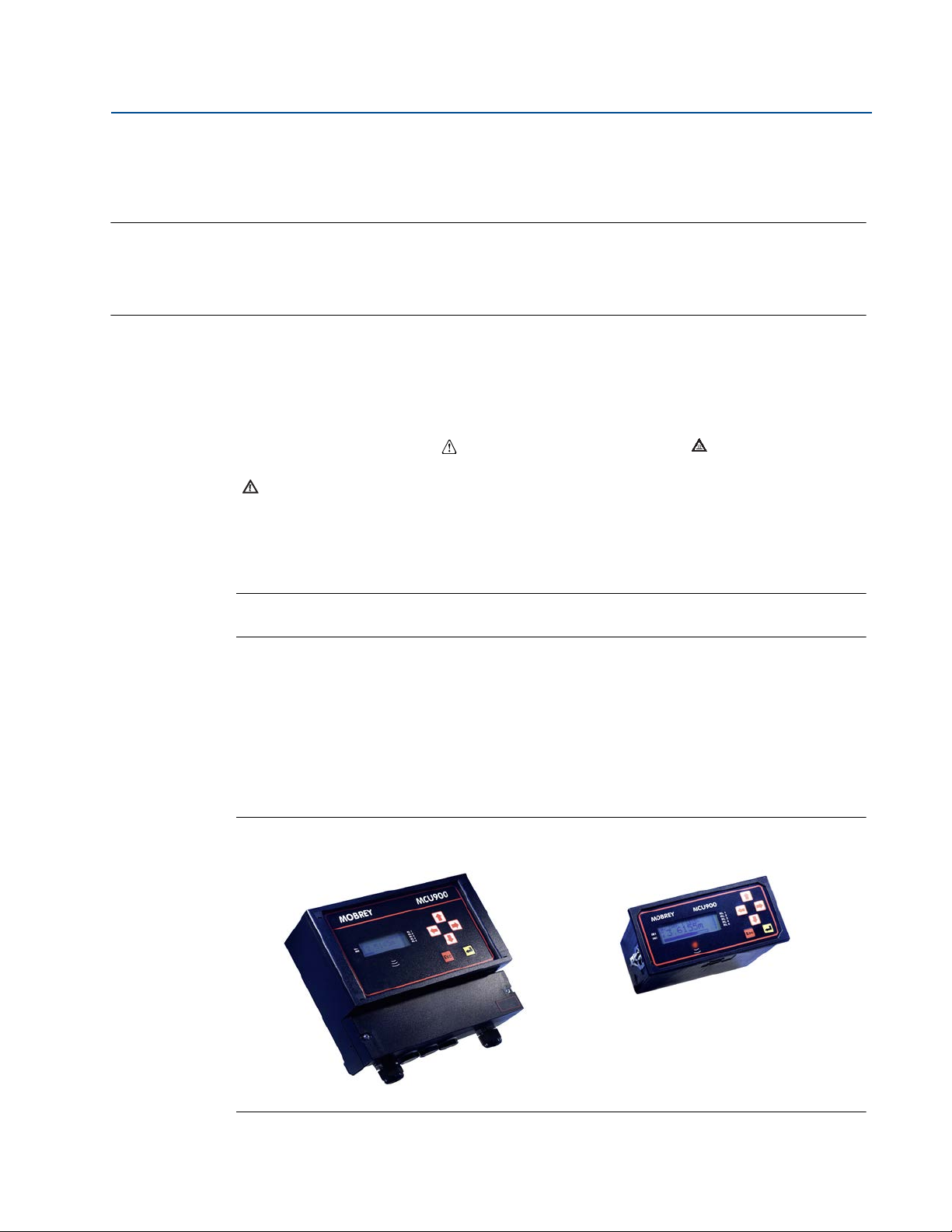

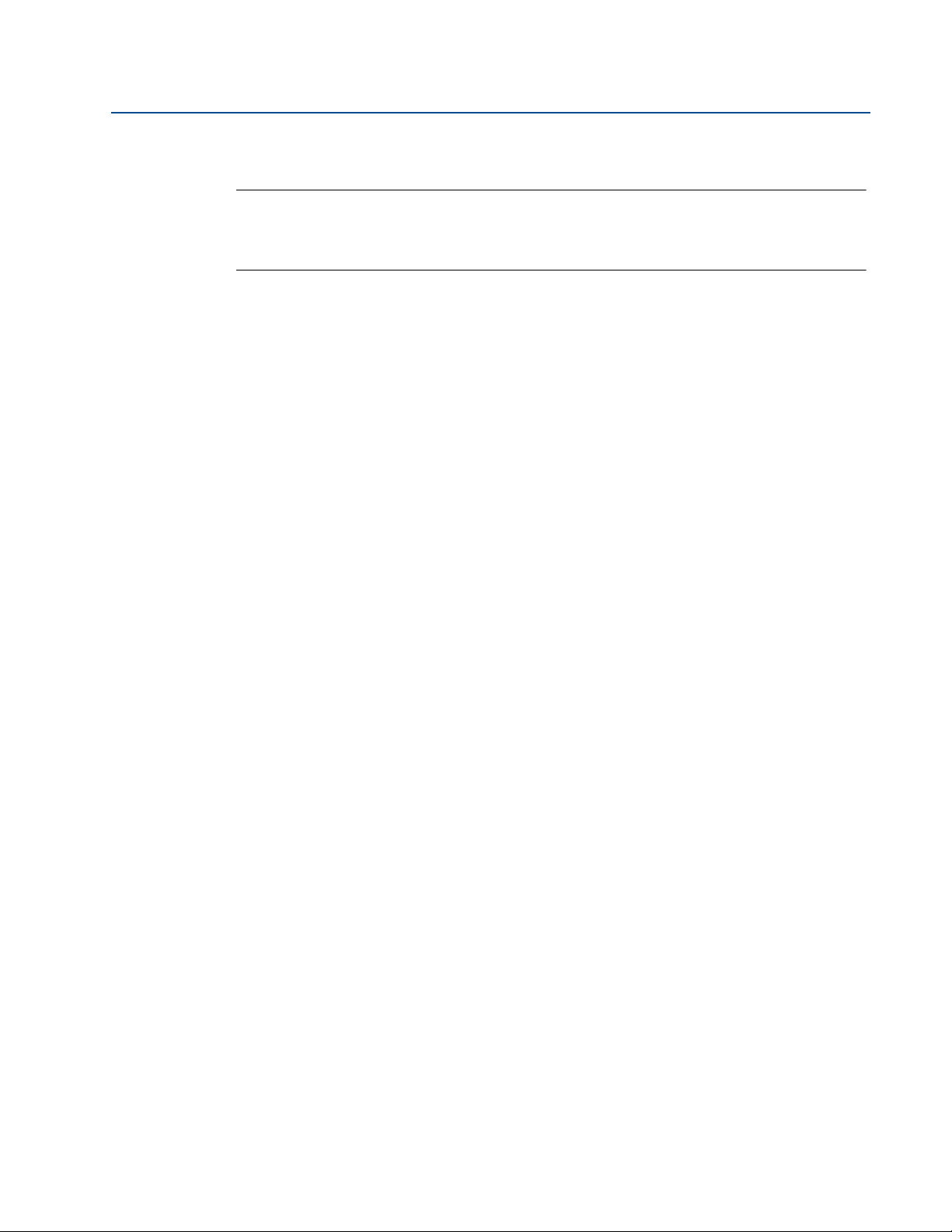

Wall Mount

Panel Mount

IP2030/RM, Rev AA

Section 2: Control Unit Overview

Section 2 Control Unit Overview

Safety messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 3

About the Mobrey MCU900 Series Control Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 3

Control unit functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 5

Control unit front panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 6

2.1 Safety messages

Procedures and instructions in this manual may require special precautions to ensure the safety

of the personnel performing the operations. Information that raises potential safety issues is

indicated by a caution symbol ( ). The external hot surface symbol ( ) is used when a surface

is hot and care must be taken to avoid possible burns. If there is a risk of an electrical shock the

( ) symbol is used. Refer to the safety messages listed at the beginning of each section before

performing an operation preceded by this symbol.

June 2014

2.2 About the Mobrey MCU900 Series Control Unit

Note

A full specification for the control unit is in Appendix A: Reference Data.

2.2.1 Wall and panel mounting options

The wall mounting option has a tough, weatherproof enclosure for internal or external

installation.

The panel mounting option has a black enclosure, and is designed for control room panel or

cabinet installation.

Figure 2-1. Mounting options

Section 2: Control Unit Overview

3

Page 12

Section 2: Control Unit Overview

B

E

E

20mA

4mA

F

D

D

C

A

G

June 2014

2.2.2 4–20mA HART transmitter input options

4–20mA HART transmitter input options:

The Mobrey MCU901 Standard control unit and the Mobrey MCU90F Logging control

unit accepts one 4–20mA or HART transmitter input

The Mobrey MCU902 Differential control unit accepts two HART transmitter inputs

Note

The Mobrey MCU900 Series is designed for non-hazardous (safe) area installation, but

can be connected to a transmitter installed in a hazardous area.

See Appendix B: Product Certifications for the control unit certifications.

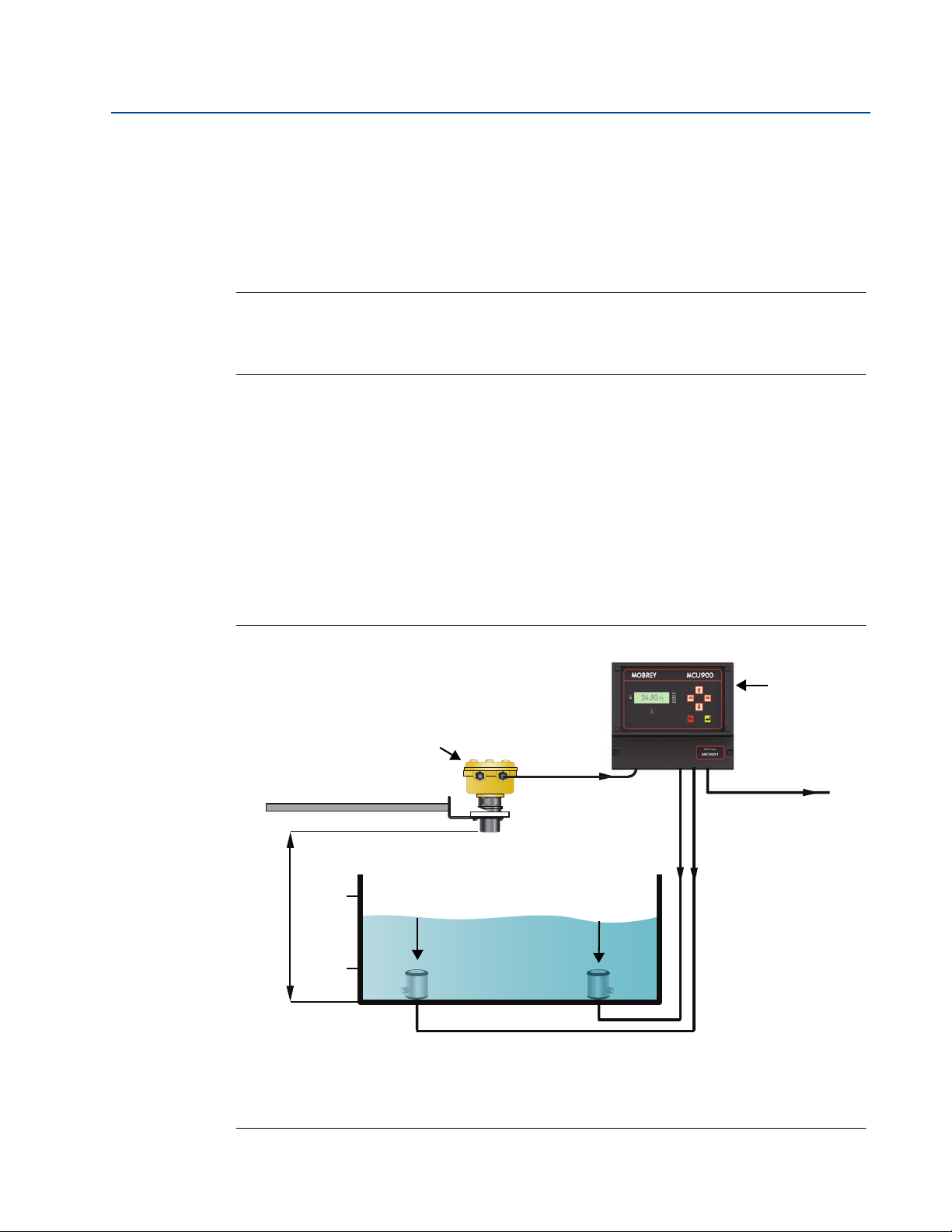

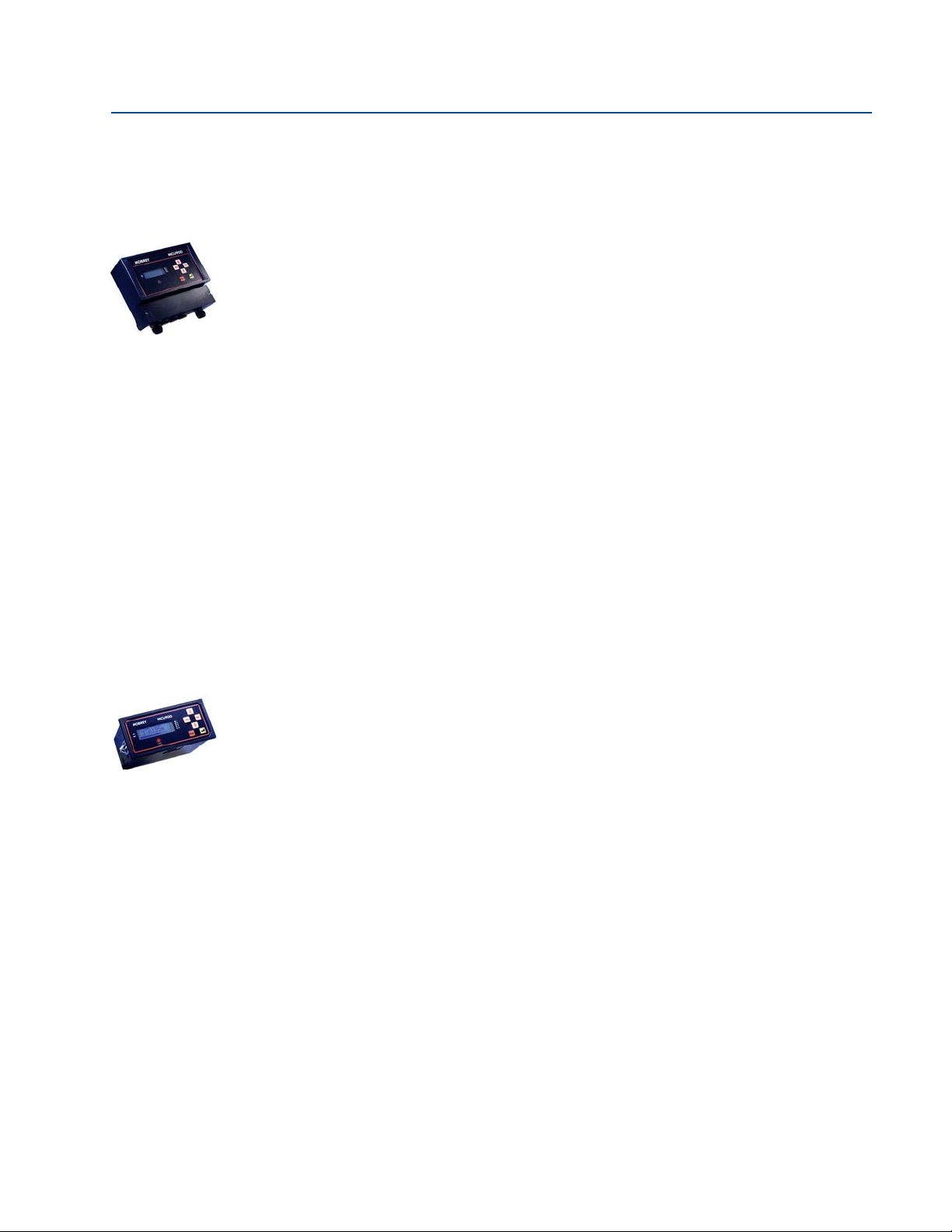

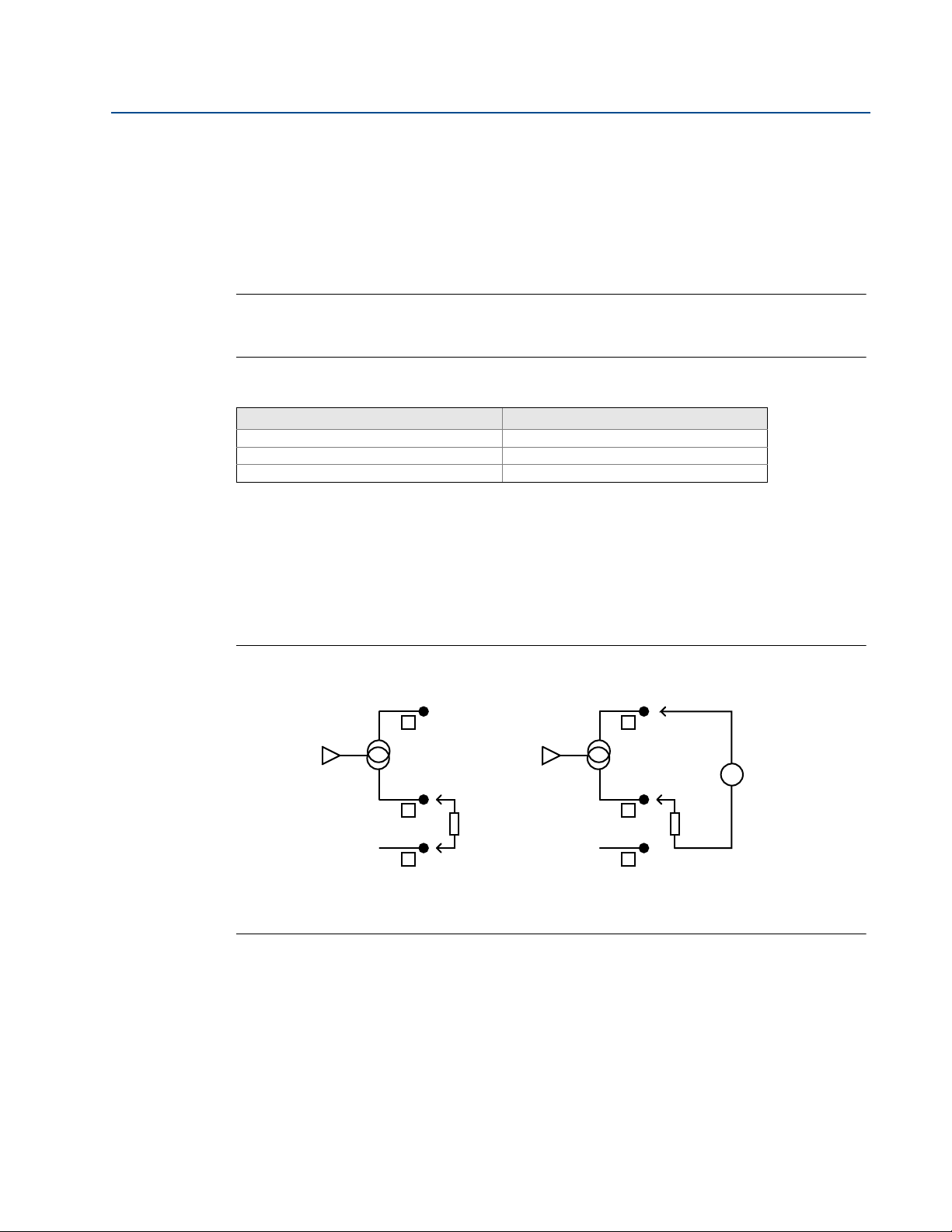

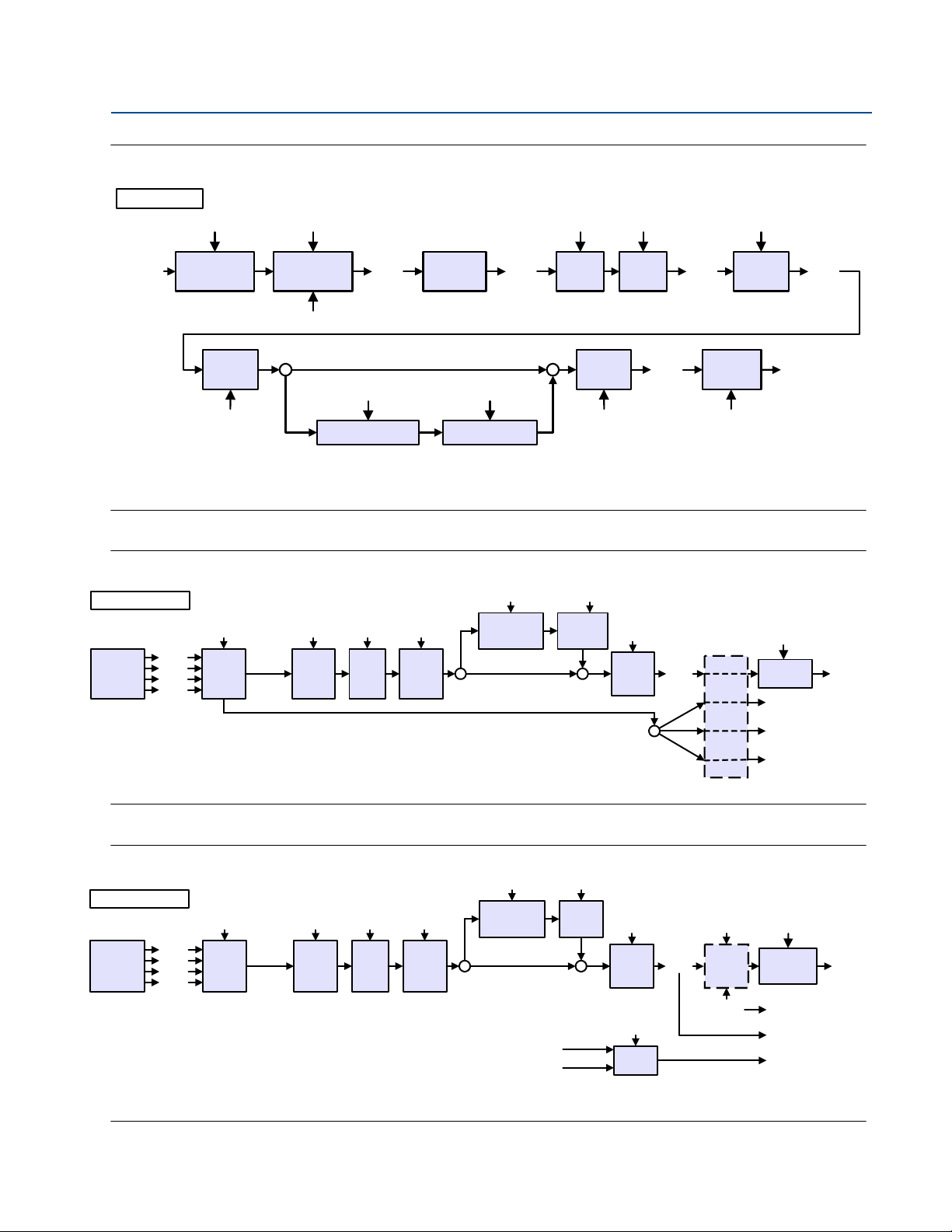

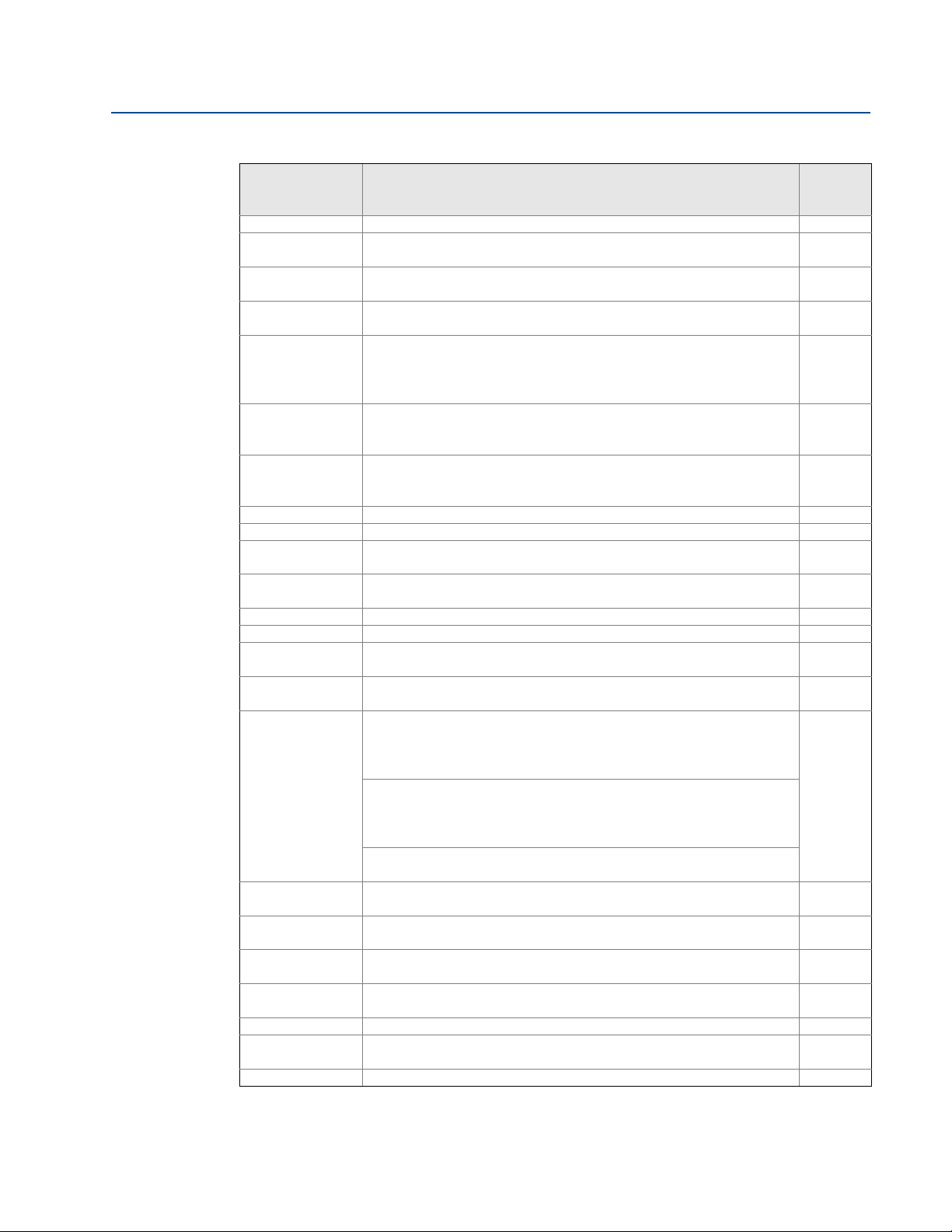

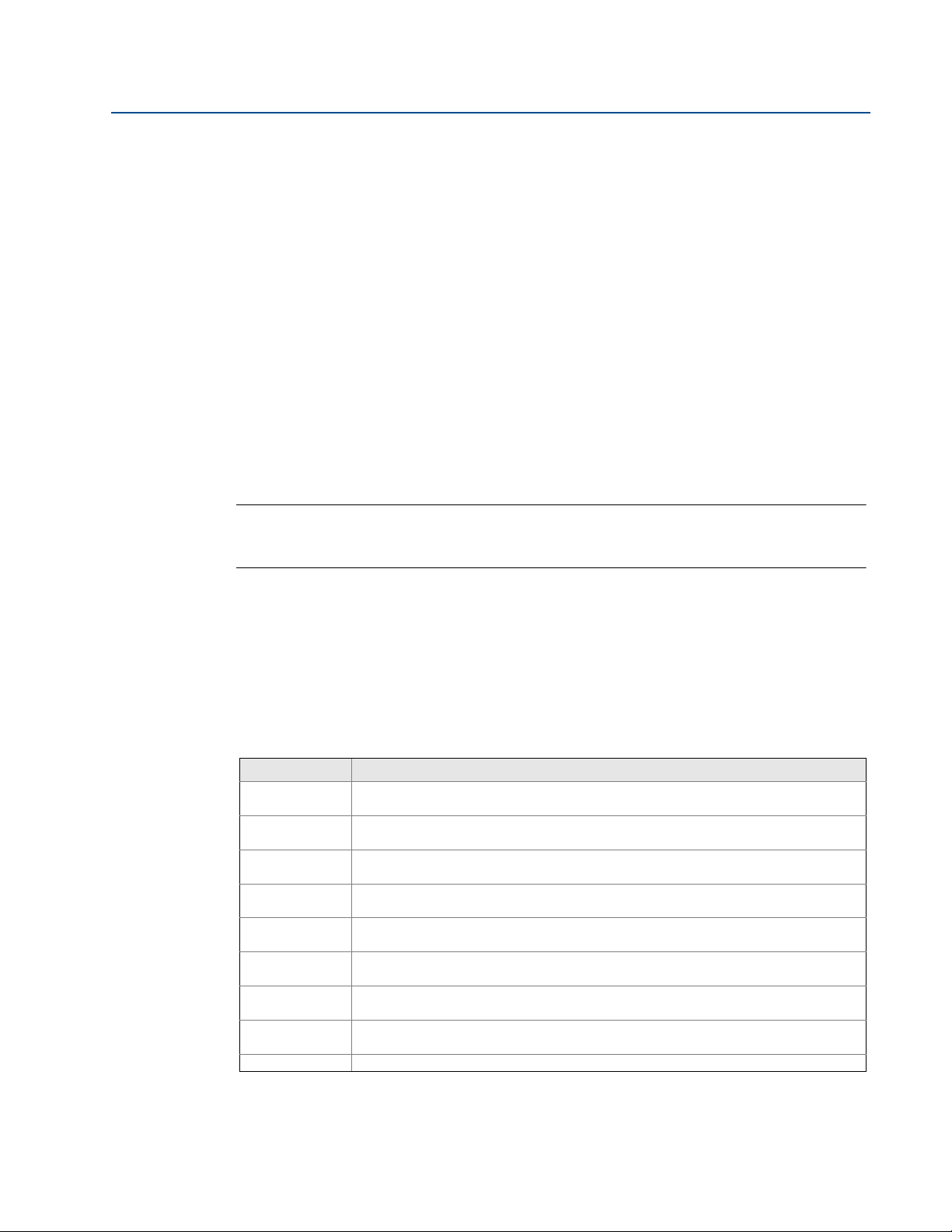

2.2.3 Control functionality

Control functionality is provided by five SPDT voltage-free contact relays in the control unit

(see Figure 2-2 on page 4). The five relay outputs are fully field adjustable to perform a wide

variety of control, fault indication, or alarm duties.

Reference Manual

IP2030/RM, Rev AA

For applications where the control unit functionality is linked to other external events, there are

two digital input ports for accepting contact closure signals.

The isolated 4–20 mA signal output from the Current Output of the control unit is driven by a

Primary / Process Value (PV) e.g. level.

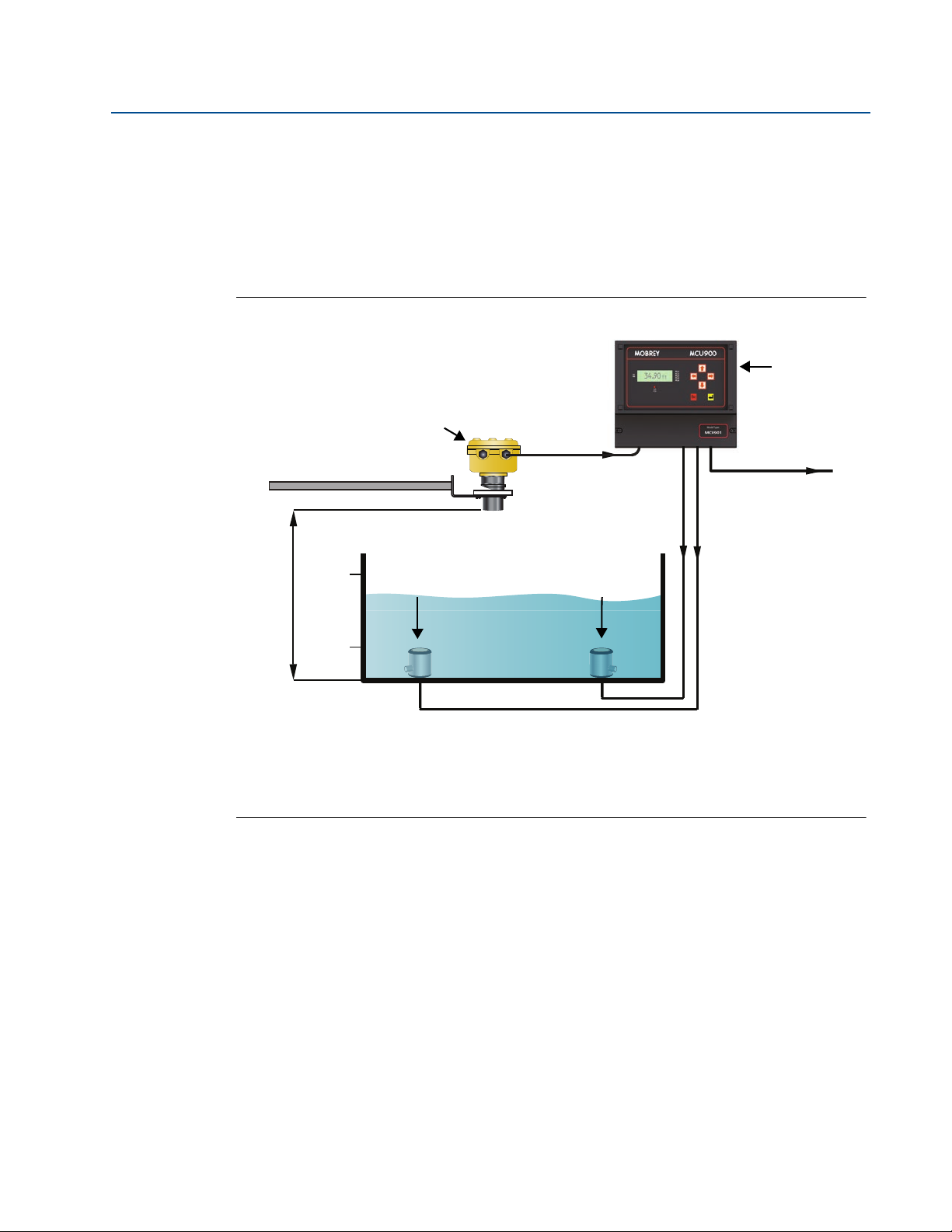

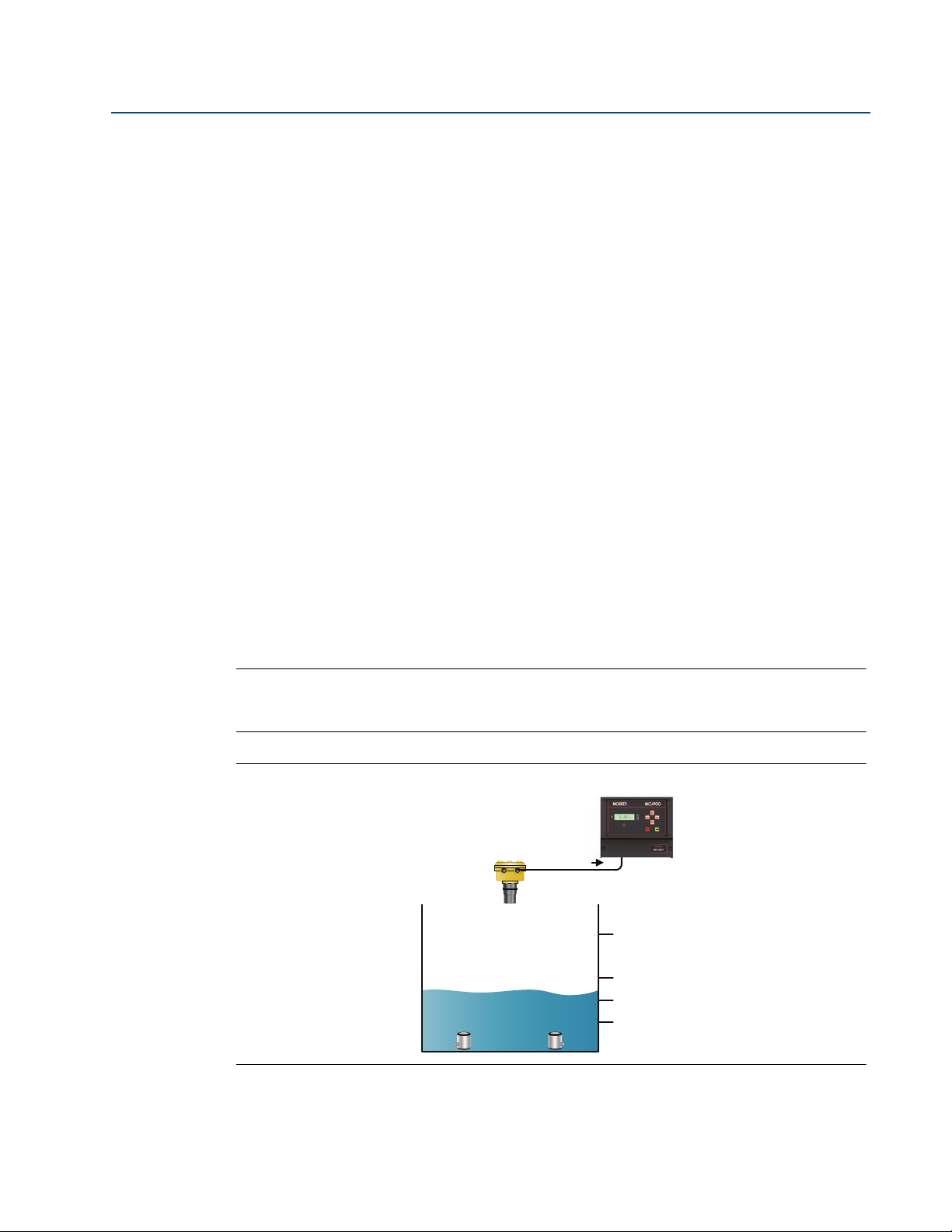

Figure 2-2. Typical application using a Mobrey MCU900 Series control unit

A. Mobrey MSP Series Level Transmitter E. Pump

B. Mobrey MCU900 Series Control Unit F. Transmitter Bottom Reference

C. 4–20 mA signal output G. 4–20 mA and HART signal input

D. Relay

Section 2: Control Unit Overview4

Page 13

Reference Manual

IP2030/RM, Rev AA

2.3 Control unit functions

2.3.1 Standard functions

The Mobrey MCU900 Series control unit provides these standard functions:

Calculation and display of the control unit Primary / Process Value (PV)

The control unit PV is typically a live transmitter reading, which can be any measured

value e.g. level, temperature, or pressure.

Alternatively, the control unit PV is a volume or flow value calculated using the live

transmitter level reading. The control unit is pre-programmed with standard tank

shapes and flow algorithms to simplify the configuration for calculating volume or flow

from the live transmitter level reading. A 20-point programmable look-up table is

provided for non-standard applications.

Output of measured variable as an isolated 4–20mA signal

The output signal is driven by the control unit Primary / Process Value (PV).

Relay control functions

There are five freely assignable relay outputs. By default, Relay 5 is a fault relay but can

be assigned to a control duty. The other relays are available to operate at user-entered

PV values.

Section 2: Control Unit Overview

June 2014

The control unit is pre-programmed with popular pump control routines for wet well

and sump control, along with energy saving overrides.

Voltage-free (digital) contact closure inputs

There are two digital input ports for accepting contact closure signals to override

control unit functions.

HART transmitter interrogation and programming

Any HART transmitter can be connected. The control unit recognizes the transmitter as

an “unknown instrument” but supports the Universal and Common Practice HART

commands (see Appendix E: Support for HART® Transmitters).

When a Mobrey MSP Series HART transmitter is connected, the control unit recognizes

the transmitter and allows full access to the transmitter’s configuration parameters.

Refer to the reference manual of the transmitter for full information about

programming the transmitter parameters (e.g. Transmitter Bottom Reference) using

the MCU900 Series control unit or other HART-based devices.

2.3.2 Difference, sum, and product functions (on MCU902 only)

The Mobrey MCU902 Differential control unit has all the functions of the standard control unit,

plus extra functions for calculating the difference, sum, or product of two separate inputs from

HART transmitters.

2.3.3 Data logging functions (on MCU90F only)

The Mobrey MCU90F Logging control unit has all the functions of the standard control unit, plus

a 7000 event logging function.

Section 2: Control Unit Overview

5

Page 14

Section 2: Control Unit Overview

1.572 m

Esc

12:47

RL1

RL2

RL3

RL4

IN1

IN2

RL5

MCU

A

B

C

June 2014

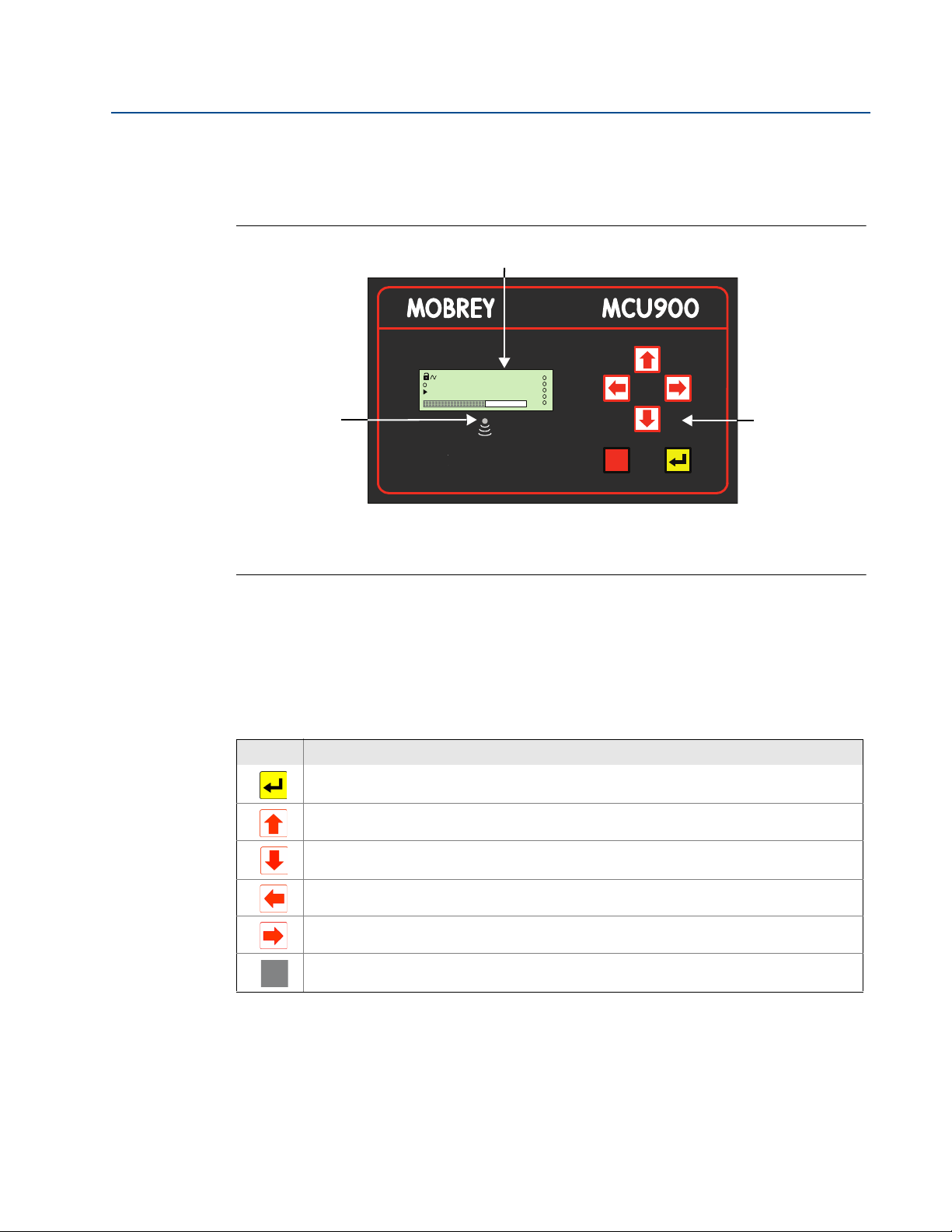

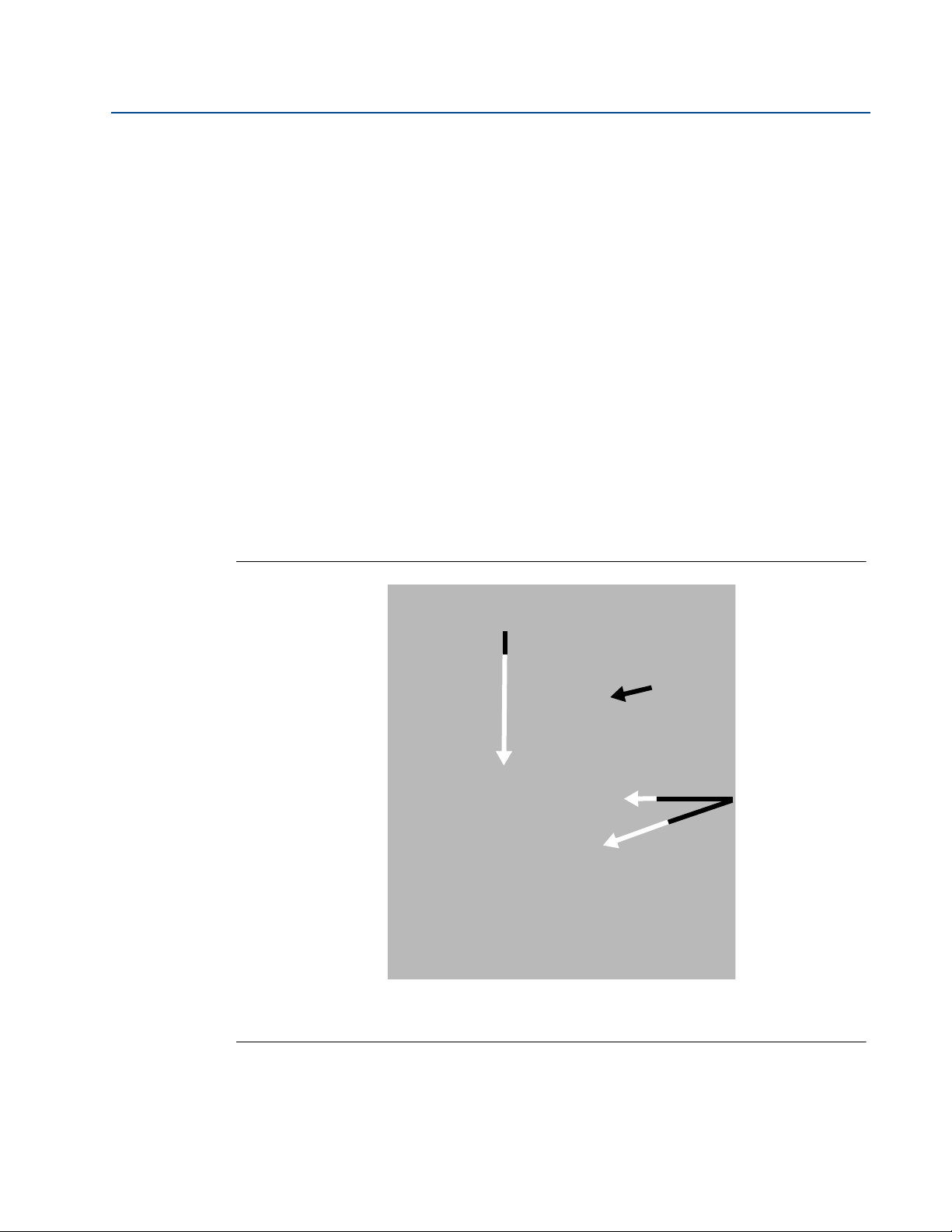

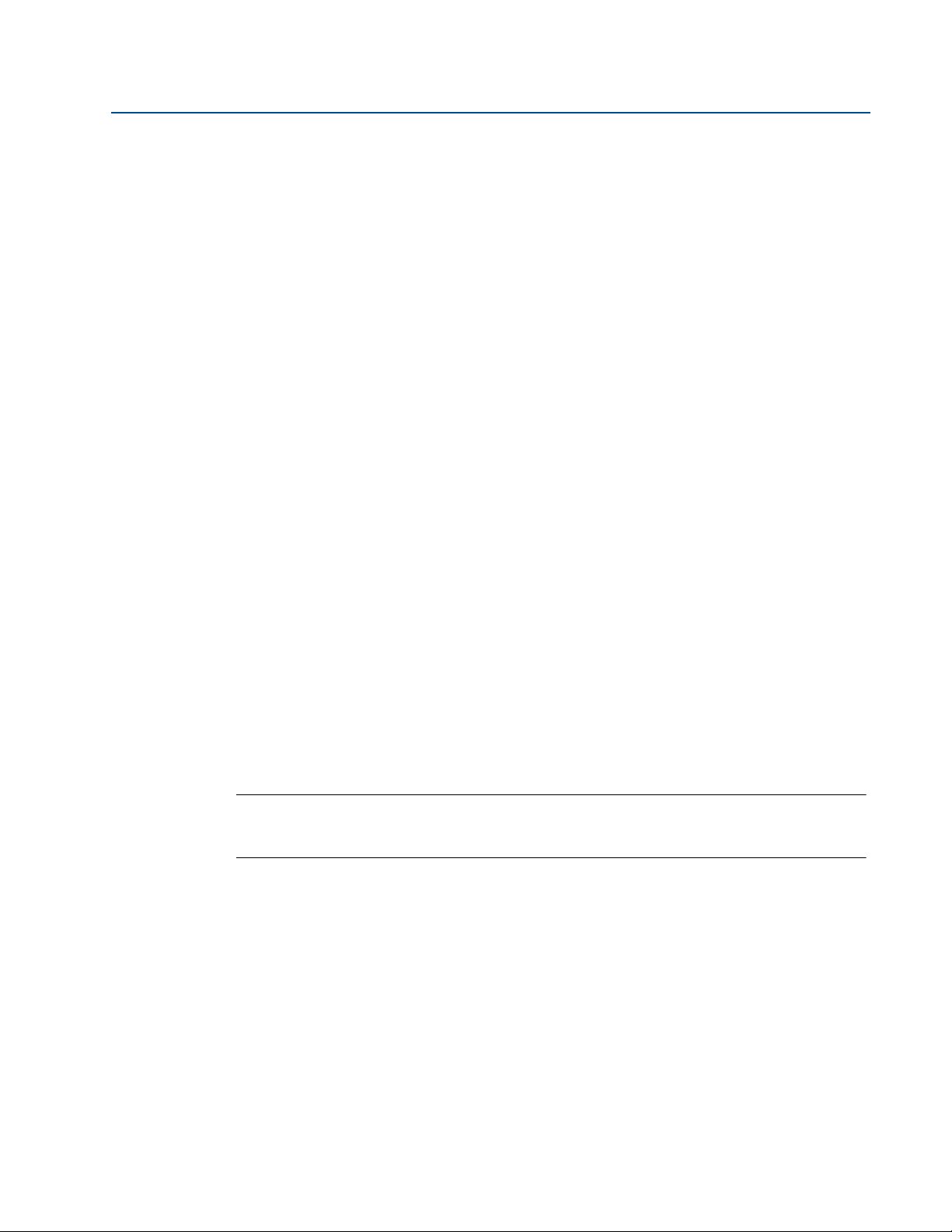

2.4 Control unit front panel

This front panel fascia has an integral keypad, display, and health status LED.

Figure 2-3. Front panel fascia

Reference Manual

IP2030/RM, Rev AA

A. 4-line Back-lit LCD Display

B. Status LED

C. Keypad

2.4.1 Keypad

The membrane keypad has six function buttons (Ta bl e 2 - 1 ). The buttons are used for navigating

a menu system and for viewing or changing application parameters.

Table 2-1. Keypad Function Buttons

Button What the button will do

When the Primary / Process Value (PV) is shown, use the red (ENTER) button to access the menu system.

At other times, this button is for selecting a menu option and for confirming something.

When navigating the menu system, the UP-ARROW button is for moving upwards one line.

At other times, this button is for scrolling through a list of alphanumeric characters or a list of options.

When navigating the menu system, the DOWN-ARROW button is for moving downwards one line.

At other times, this button is for scrolling through a list of alphanumeric characters or a list of options.

The LEFT-ARROW button is for moving left e.g. to another character when editing a parameter value.

The RIGHT-ARROW button is for moving right e.g. to another character when editing a parameter value.

When navigating the menu system, use the ESCAPE button to return to a previous menu level and the

Full PV Display. At other times, e.g. while editing, the button is for restoring a setting that is being edited.

2.4.2 Status LED

The LED is positioned just below the LCD (Figure 2-3 on page 6). It flashes once per second to

indicate that the control unit and transmitters are operating correctly. The LED is constantly lit if

there are operating difficulties e.g. a transmitter fault.

Section 2: Control Unit Overview6

Page 15

Reference Manual

Mobrey MCU901

Mobrey MCU902

B

D

E

A

C

F

G

H

K

I

J

Mobrey MCU90F

IP2030/RM, Rev AA

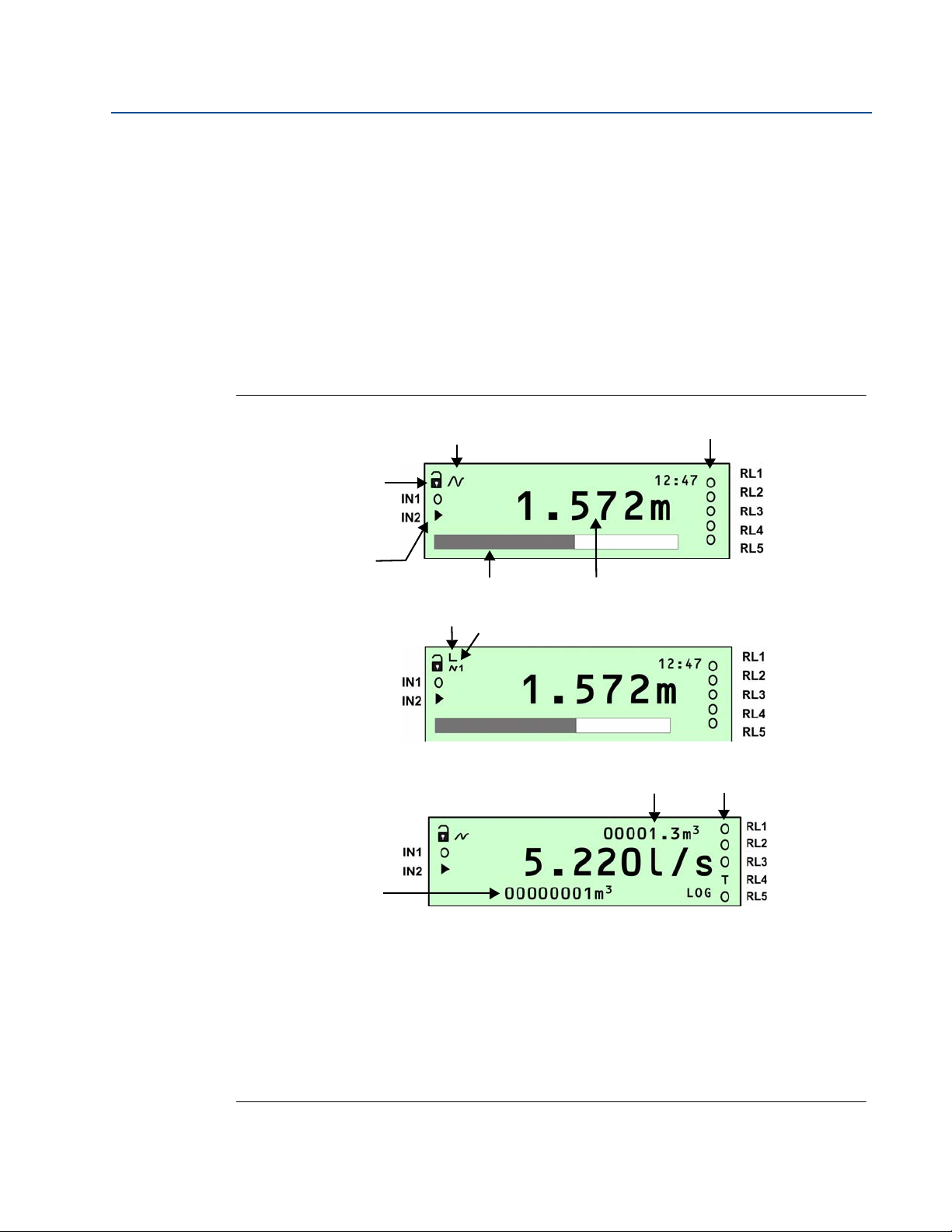

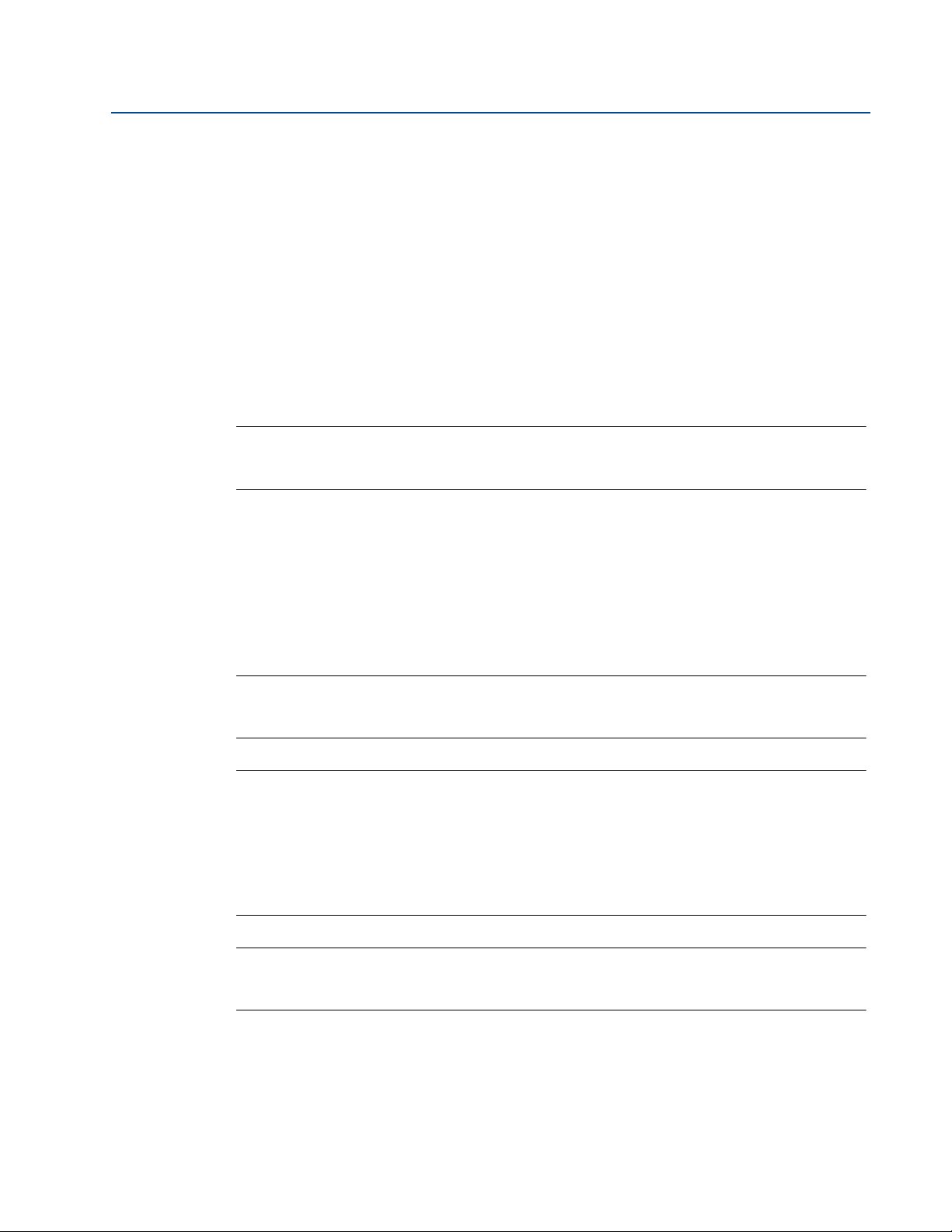

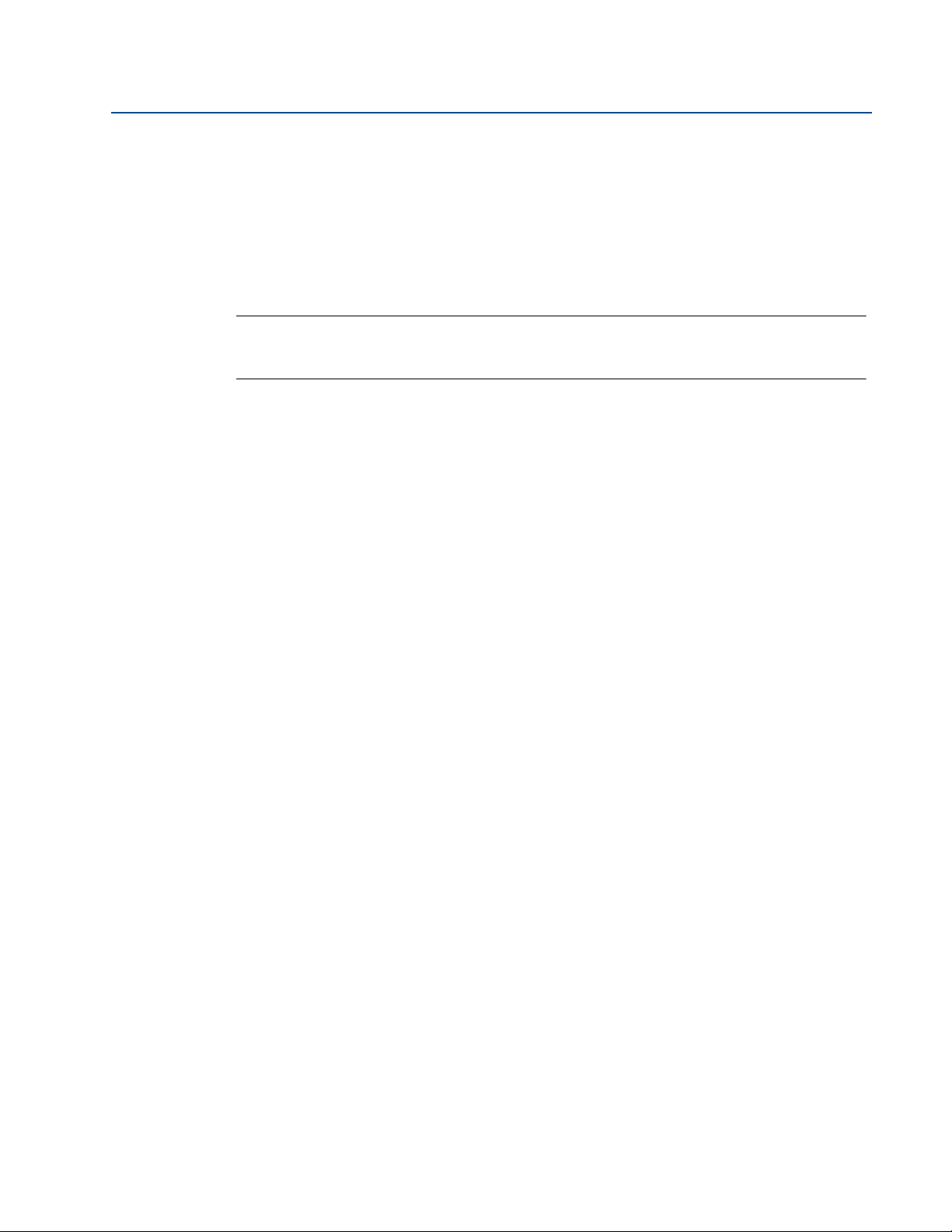

2.4.3 Display

After the power-up and self-checks are completed, the Full PV Display is presented.

The default Full PV Display typically features a digital clock, a measured variable with display

units, and status icons. There are some display differences between control units:

On the MCU901 and MCU902, a bar graph indicates the 4–20mA output signal.

(The MCU90F display can be changed to show the bar graph).

On the MCU902, an extra icon on the first line and indicates if one or two HART

transmitters connected to the control unit.

On the MCU90F, there are two totalizers displayed; one above and one below the

control unit Primary / Process Value (PV).

Figure 2-4. Typical displays of the MCU901, MCU902, and MCU90F

Section 2: Control Unit Overview

June 2014

A. Program/Run App mode (locked padlock = Run App mode) H. HART Transmitter Communicating

B. HART Transmitter Communicating (absent if Idle) (1=Tx1, 2=Tx2)

C. Relay (RL) Status: O = De-energized,

A = Alarm, S = Sampler, T = Totalizer A = Alarm, S = Sampler, T = Totalizer

D. Primary / Process Value (PV) of Control Unit J. Totalizer 1

E. Bar graph of 4–20mA Output K. Totalizer 2 (Daily Total)

F. Digital Input Status: O = Open,

G. HART Transmitter Allocated:

Left Vertical Bar = Tx1; Right Vertical Bar = Tx2

Section 2: Control Unit Overview

= Energized, I. Relay (RL) Status: O = De-energized,= Energized,

= Closed

7

Page 16

Section 2: Control Unit Overview

1.572 m

1.572 m

12:47

1

Full PV Display

Large PV Display

June 2014

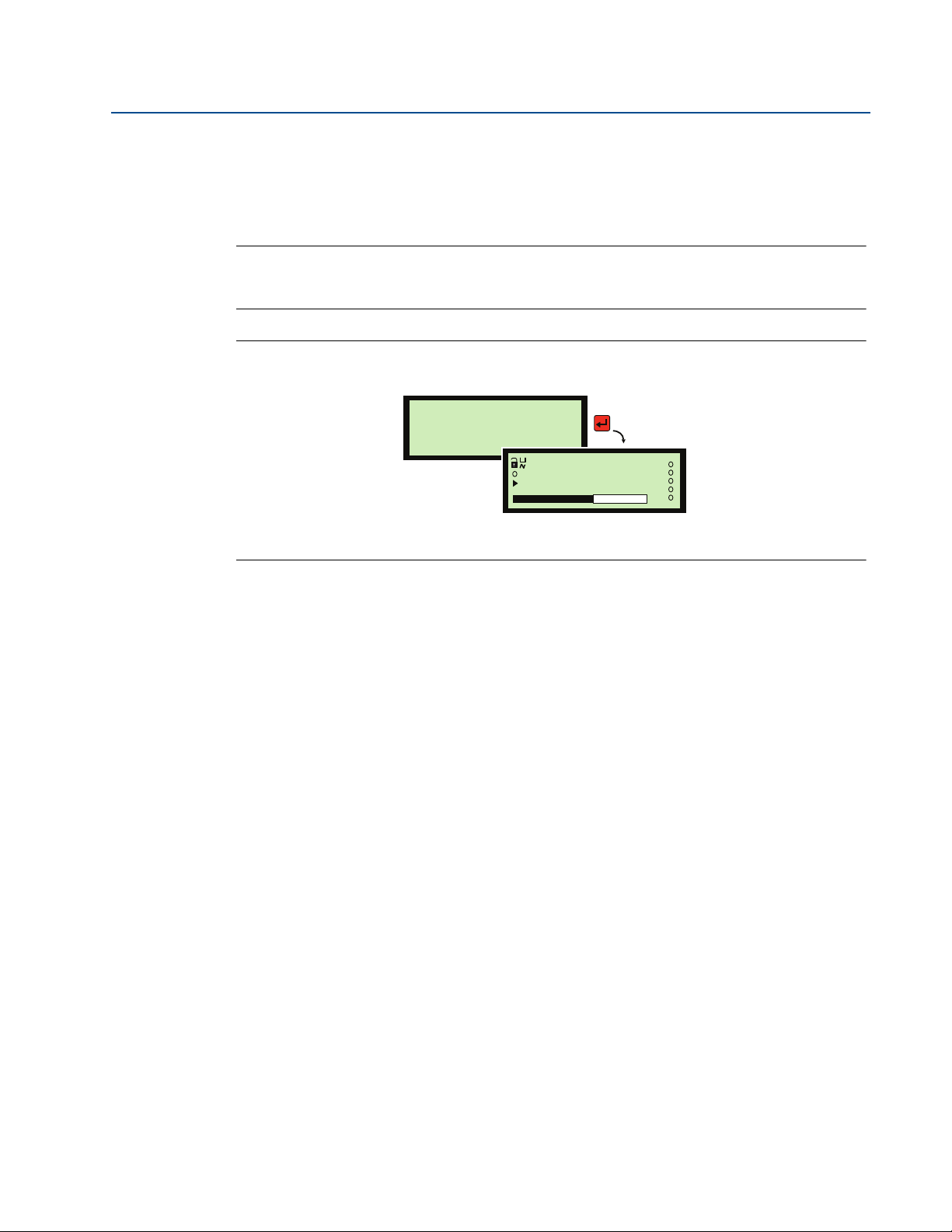

After a period of keypad inactivity, the display automatically changes to the Large PV Display.

This shows only the control unit Primary / Process Value (PV) and Display units, but in a larger

character size to facilitate easier viewing.

To restore the Full PV Display, press the red (ENTER) button.

Note

The Large PV Display feature can be switched off using parameter P574.

See “Display configuration options” on page 102.

Figure 2-5. Large PV Display

Reference Manual

IP2030/RM, Rev AA

Section 2: Control Unit Overview8

Page 17

Reference Manual

IP2030/RM, Rev AA

Section 3 Installation

Safety messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 9

Considerations before installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 10

Mounting the control unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 11

Electrical installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 13

3.1 Safety messages

Procedures and instructions in this manual may require special precautions to ensure the safety

of the personnel performing the operations. Information that raises potential safety issues is

indicated by a caution symbol ( ). The external hot surface symbol ( ) is used when a surface

is hot and care must be taken to avoid possible burns. If there is a risk of an electrical shock the

( ) symbol is used. Refer to the safety messages listed at the beginning of each section before

performing an operation preceded by this symbol.

Section 3: Installation

June 2014

Failure to follow these installation guidelines could result in death or serious injury:

The Mobrey MCU900 Series control unit must be installed, connected,

commissioned, operated, and maintained by suitably qualified personnel only,

observing any national and local requirements that may apply

Use the equipment only as specified in this manual. Failure to do so may impair the

protection provided by the equipment

Explosions could result in death or serious injury:

Please review the approvals section of this reference manual for any restrictions

associated with an installation

Electrical shock could cause death or serious injury:

If the control unit is installed in a high voltage environment and a fault condition or

installation error occurs, high voltage may be present on leads and terminals

Use extreme caution when making contact with the leads and terminals

Make sure that power to the control unit is off while making connections

Section 3: Installation

9

Page 18

Section 3: Installation

June 2014

3.2 Considerations before installation

Note

The Mobrey MCU900 Series is designed for non-hazardous (safe) area installation, but can

power and take input from an intrinsically safe transmitter installed in a hazardous area.

See Appendix B: Product Certifications for the control unit certifications.

3.2.1 Safety considerations

Guidelines

1. This product is classified type A in accordance with European EMC directive

2004/108/EC. To ensure electro-magnetic compatibility, in any member country, this

product should not be installed in a residential area.

2. Do not mount the control unit on a structure that is subject to vibration, or in a position

where damage may be caused by impact, thermal stress or liquid ingress.

3. The fuse must only be replaced with the type specified (see page 108 for procedure).

Reference Manual

IP2030/RM, Rev AA

4. If the equipment is likely to come into contact with aggressive substances, it is the

responsibility of the user to take suitable precautions that prevent it from being

adversely affected, thus ensuring that the type of protection is not compromised.

Aggressive Substances - e.g. acidic liquids or gases that may attack metals or solvents

that may affect polymeric materials.

Suitable Precautions - e.g. regular checks as part of routine inspections or establishing

from the material's data sheet that it is resistant to specific chemicals.

5. The user should not repair this equipment.

6. Terminal 30 (intrinsically safe earth/ground) of the control unit must be connected to a

high integrity earth/ground point.

7. A mains powered Control Unit must not be connected to a supply exceeding 250 V

r.m.s. or dc, or to apparatus containing a source of voltage exceeding 250 V r.m.s. or dc.

8. A direct current (dc) powered control unit must not be connected to a supply

exceeding 30 Vdc or apparatus containing a source of voltage exceeding 30 Vdc.

9. The intrinsically safe outputs of the control unit may be connected to certified

equipment used in a hazardous area. Refer to Appendix B: Product Certifications for

details of relevant certifications.

10. Cable between the MCU900 Series control unit and a transmitter should be shielded,

twisted-pair with the shield connected to terminal 3 (marked with earth symbol) on the

MCU900 Series control unit. The shield should be left unconnected at the transmitter

unless there is a terminal specifically provided for this purpose.

11. Cable runs should be separate from any high voltage or mains cables to avoid crosstalk

or interference.

12. Refer to the technical data in Appendix A: Reference Data.

Section 3: Installation10

Page 19

Reference Manual

IP2030/RM, Rev AA

3.3 Mounting the control unit

3.3.1 Mounting the wall-mount version

Guidelines

This housing is rated IP65. It is suitable for mounting outside, but this should be above

any flood level, away from any overflow path, and away from direct sunlight

Do not mount the control unit on a structure that is subject to vibration, or in a position

where damage may be caused by impact, thermal stress, or liquid ingress

The mass of the mains powered unit is 1.4 kg, and the DC powered unit is 1.0 kg.

To conform with safety requirements, the wall on which the unit is mounted should be

capable of supporting four times this weight

It is not necessary, or advisable, to remove the upper part of the unit housing that

contains the LCD and keypad. There are no user serviceable parts inside. The unit must

not be modified in any way

Procedure

Section 3: Installation

June 2014

1. Mount the unit on a suitable wall or structure using the fixing points shown on

Figure A-1 on page 121.

2. Make the electrical connections

(see “Making electrical connections on wall-mount units” on page 13).

3.3.2 Mounting the panel version

Guidelines

This housing is rated IP40 and is designed for panel mounting in a weatherproof

environment. An optional fascia overlay hood is available which improves the IP rating

to IP65 – see Product Data Sheet IP2031 on the Mobrey brand pages at

www.emersonprocess.com for ordering information

Do not mount the control unit on a structure that is subject to vibration, or in a position

where damage may be caused by impact, thermal stress, or liquid ingress

Where three of more units are fitted in the same cabinet or panel, ensure that there is

adequate air circulation to aid cooling. It is recommended that an air circulation fan be

fitted

The unit requires at least 6.5 in. (165 mm) clearance behind the mounting panel to

avoid cable fouling

After mounting the control unit, all wiring is made at the rear of the unit using the two

part terminal blocks provided. (A pre-wired data download socket suitable for front

panel mounting is provided on the MCU90F)

Section 3: Installation

Mount the control unit on a panel with thickness 1.5 to 10 mm, ensuring the panel is

strong enough to support the 2.6 lb. (1.2 kg) weight of the unit

Ensuring there is enough clearance behind the chosen position in the panel (6.5 in [165

mm] minimum), cut a horizontal slot 5.43 in. (138 mm) long by 2.68 in. (68 mm) high

in the panel and remove any rough edges

11

Page 20

Section 3: Installation

C

B

A

June 2014

Procedure

1. Unpack the two screw clips provided.

2. Identify the moulded lugs (protrusions) in the recesses on each side of the control unit.

3. Holding the screwdriver-slot-end of the threaded spindle of one of the screw clamps

4. Remove the screw clamps from both of the screw clamp frames.

5. Slide the control unit into the panel, ensuring that the panel seal provided is in place

6. Re-fit the screw clamps, one on each side, and tighten with a screwdriver to clamp the

Reference Manual

IP2030/RM, Rev AA

(Ignore the recesses on the top and bottom of the unit).

and looking at the control unit rear, engage a screw clamp frame onto the control unit

side (see Figure 3-1 on page 12) and see how the four steel lugs (protrusions) of the

screw clamp frame engage with the moulded lugs of the unit. Gently pull the screw

clamp for the lugs to engage with each other.

behind the front panel bezel.

control unit against the panel.

7. For electrical connections,

see “Making electrical connections on panel-mount units” on page 15.

Figure 3-1. The fitted screw clamp

A. Screw Clamp Frame

B. Front Panel Bezel

C. Screw Clamp With Threaded Spindle

Section 3: Installation12

Page 21

Reference Manual

IP2030/RM, Rev AA

3.4 Electrical installation

It is the responsibility of the installer to:

Refer to safety data and electrical specifications in Appendix A: Reference Data

Refer to the certifications and control drawings in Appendix B: Product Certifications

Check and obtain any work permits required before applying power to the unit

Observe all local regulations and approval requirements

Ensure the wiring is suitable for the load current

Ensure the wiring insulation is suitable for the voltage, temperature, and environment

of the installation

Ensure suitable cable glands or conduit connections are used when wiring to the

control unit to maintain enclosure integrity

Never remove or modify the mechanical barriers separating the terminal area from the

main enclosure and separating the transmitter input terminals from other terminals.

Section 3: Installation

June 2014

3.4.1 Making electrical connections on wall-mount units

All field wiring connections are accessible by removing the lower terminal cover, which is

secured by two screws on the wall-mount control unit.

The cabling between the Mobrey MCU900 Series control unit and a transmitter should be a

screened (shielded), twisted-pair type with the cable screen (shield) connected to terminal 3

(marked with earth/ground symbol) on the Mobrey MCU900 Series control unit. The cable

screen (shield) should be left unconnected at the transmitter end unless there is a terminal

specifically provided for this purpose.

Cable runs should be separate from any high voltage or mains cables to avoid crosstalk or

interference.

Figure 3.4.2 on page 15 shows the layout of the control unit terminals. All terminal blocks are

suitable for wires 14 to 26 AWG (0,5 to 1,5 mm

for wires 10 AWG (2,5 mm

). Insulation should be stripped back 1/4 in. (7 mm).

Transmitter connections are made on the left side of the terminals enclosure. The intrinsically

safe earth/ground (terminal 30) must be connected to a high integrity earth/ground point if the

transmitter connected to terminals 1 and 2 is sited in a hazardous area.

Note

Use only 167 F (75 C) copper conductors for field wiring.

), except the mains terminals which are suitable

Section 3: Installation

Note

In intrinsically safe systems, apparatus connected to the MCU900 Series control unit

must not be supplied from a voltage greater than 250V r.m.s. or 250 Vdc.

13

Page 22

Section 3: Installation

10 11 12

0VIN2IN1

789

24V

I

out

0V

456

RX TX

0V

1316141715

18

NO COM NC

NCCOMNO

25 26 27

NO

COM

NC

1922202321

24

NO COM NC

NCCOMNO

1

24V

I

in

2 3

FUSE

200mA (T)

28

L

N

29 30

IS EARTH

June 2014

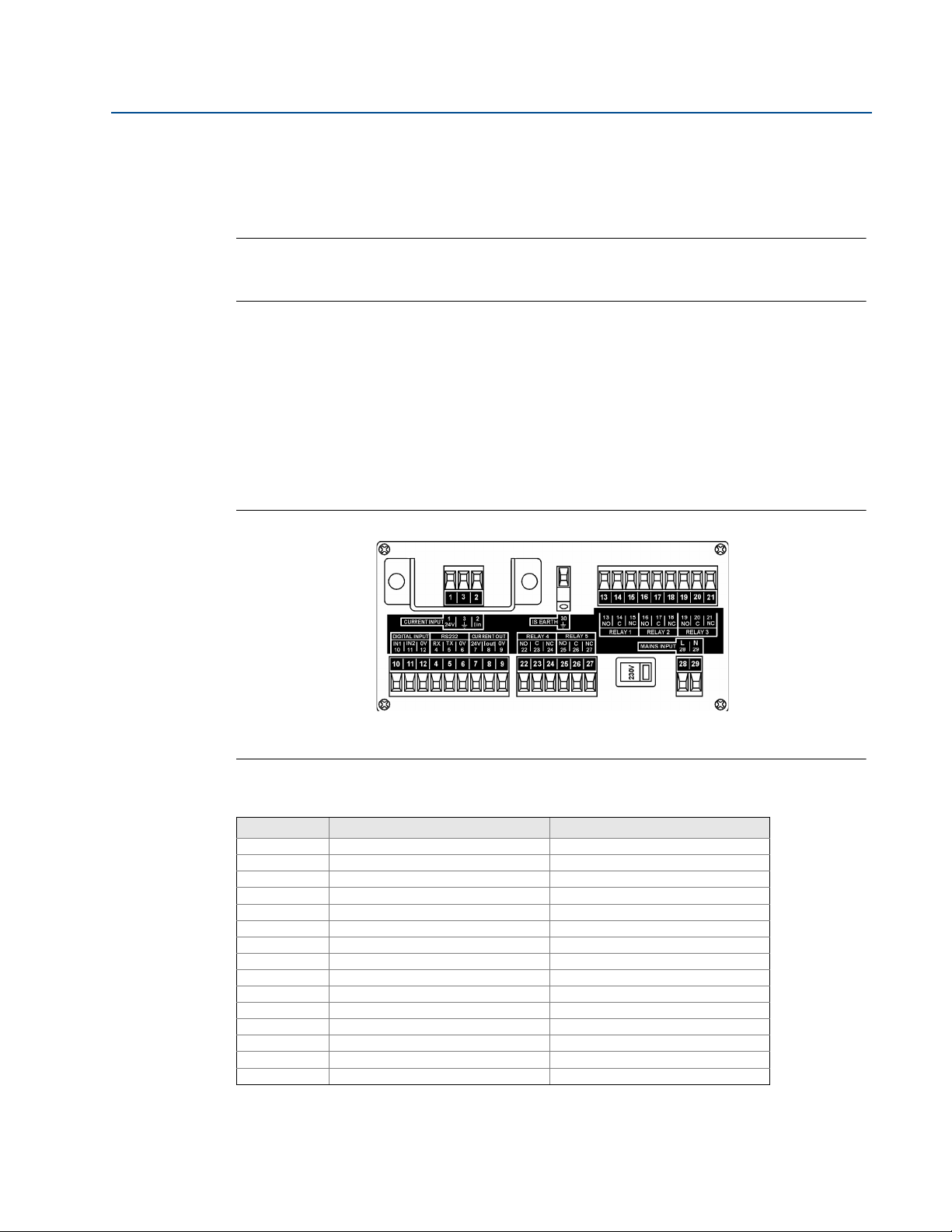

Figure 3-2. Connection terminals layout (for mains-powered wall-mount unit)

(The direct current (dc) powered unit has a slightly different layout – terminals 31 and 32 replace terminals 28 and 29).

Table 3-1. Connection terminal descriptions (for wall-mount unit)

Ter mi na l Function Terminal marking

1 Loop supply 24V

2 Current input Iin

3 Cable screen Earth (Earth symbol)

4-6 RS232 RX-TX-0V

7-9 Current output 24V-Iout-0V

10-12 Digital input 1 and 2 IN1-IN2-0V

13-15 Relay 1 NO-COM-NC

16-18 Relay 2 NO-COM-NC

19-21 Relay 3 NO-COM-NC

22-24 Relay 4 NO-COM-NC

25-27 Relay 5 NO-COM-NC

28-29

30 I.S. Earth/Ground (Earth/Ground symbol)

31

32

(1) Mains-powered control unit only.

(2) Direct current (dc) powered control unit only.

Reference Manual

IP2030/RM, Rev AA

(1)

(2)

(2)

Mains input L-N

Negative Positive +

Cable glands for the wall-mount unit

The five cable-entry positions are pre-drilled to accept M20 cable glands. The Mobrey MCU90F

control unit has a data download socket factory pre-fitted in one of these cable-entry positions.

Two cable glands, rated IP65 and suitable for cable with outside diameter 4 to 7 mm, are

supplied for use with the mains supply and transmitter cable. M20 blanking plugs are supplied

for the other three cable entry positions.

All glands and blanking plugs are supplied in a plastic bag. The installer must fit these, or

suitable equivalents, in place of the transit red-caps, to ensure weatherproofing of the control

unit. The white sealing washers supplied with the cable glands and blanking plugs must be fitted

on the outside of the enclosure under gland/blanking plug.

Section 3: Installation14

Page 23

Reference Manual

IP2030/RM, Rev AA

Section 3: Installation

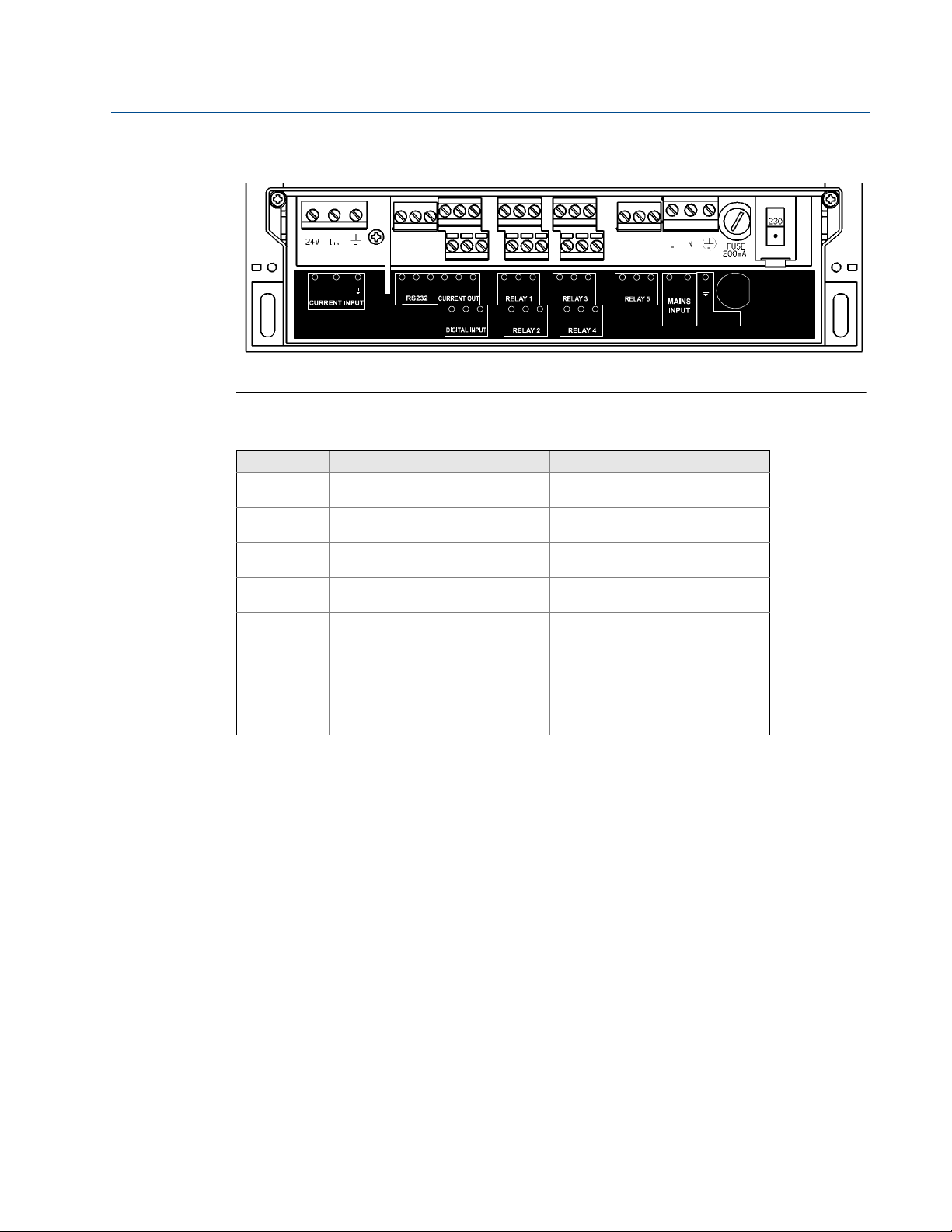

3.4.2 Making electrical connections on panel-mount units

Field wiring connections are made to the back of the panel-mount control unit using the

two-part (plug/socket) terminal connectors provided. Figure 3-3 shows the rear panel layout.

Note

The plug/socket terminal connectors on the panel mount unit are polarized (keyed)

to prevent inter-changeability and incorrect connection.

Cabling between the Mobrey MCU900 Series control unit and a transmitter should be a

screened (shielded), twisted-pair type with the cable screen (shield) connected to terminal 3

(marked with earth/ground symbol) on the control unit. The cable screen (shield) should be left

unconnected at the transmitter end unless there is a terminal specifically provided for this

purpose. Cable runs should be separate from any high voltage or mains cables to avoid crosstalk

or interference.

Connect terminal 30 (intrinsically safe earth/ground) to a high integrity earth/ground point if

the transmitter connected to terminals 1 and 2 is sited in a hazardous area.

June 2014

Figure 3-3. Connection terminals layout (for mains-powered panel-mount unit)

(The direct current (dc) powered unit has a slightly different layout – terminals 31 and 32 replace terminals 28 and 29).

Table 3-2. Connection descriptions for panel mount unit

Ter mi na l Function Terminal marking

1 Loop supply 24V

2 Current input Iin

3 Cable screen Earth (Earth symbol)

4-6 RS232 RX-TX-0V

7-9 Current output 24V-Iout-0V

10-12 Digital input 1 and 2 IN1-IN2-0V

13-15 Relay 1 NO-COM-NC

16-18 Relay 2 NO-COM-NC

19-21 Relay 3 NO-COM-NC

22-24 Relay 4 NO-COM-NC

25-27 Relay 5 NO-COM-NC

(1)

28-29

30 I.S. Earth (Earth symbol)

(2)

31

(2)

32

(1) Mains-powered control unit only.

(2) Direct current (dc) powered control unit only.

Mains input L-N

Negative Positive +

Section 3: Installation

15

Page 24

Section 3: Installation

June 2014

3.4.3 Power connections

When the control unit is powered by mains alternating current (ac) power, select the voltage as

115V or 230V using the voltage-selector slide switch.

When the control unit is direct current (dc) powered, ensure the supply is adequate (15 to 30

Vdc). Do not exceed 30 Vdc.

A switch or circuit breaker should be installed in close proximity to the instrument, and labelled

as such. Although the Mobrey MCU900 Series control unit meets all European standards for

surge immunity on power and signal lines, it is recommended that lightning suppressors are

also fitted if local conditions make this advisable.

3.4.4 Earthing connections

The IP-rated Mobrey MCU900 Series control unit is double insulated and does not require a

mains earth.

Do not connect terminal 30 to a mains earth. Terminal 30 is provided for use as an intrinsically

safe (or functional) earth connection, which must be used when a transmitter is mounted in a

hazardous area and is connected to terminals 1 and 2.

Reference Manual

IP2030/RM, Rev AA

Terminal 3 is to be used for connection of a twisted-pair cable screen (shield) when the control

unit is powering the transmitter (see Figure 3-4 on page 17). This screen (shield) should be left

unconnected at the transmitter end unless there is a terminal provided for this purpose.

When connected to equipment located in a hazardous area, not meeting the requirements of

clause 6.3.12 (Isolation of circuits from earth or frame) in IEC 60079-11:2006

(EN 60079-11:2007), equipotential earthing must be ensured between the equipment and the

intrinsically safe earth. An example of equipotential earthing is a cable with a cross-sectional

2

area greater than 4 mm

and a resistance of less than 1 ohm.

3.4.5 Transmitter connections and cabling

Connection of a transmitter to the control unit does not confer intrinsic safety on the

transmitter. It is the responsibility of the user to ensure any transmitter installed in a hazardous

area is suitable for use and certified accordingly. The installation should be in accordance with a

recognized code of practice.

Check that the electrical parameters of the installed system of control unit, transmitter, any

loop-powered devices, and interconnecting cable to ensure compliance with the product

certificates and technical data. Particular attention must be given to the cable and the

transmitter to ensure that the total capacitance and inductance limits stated in the technical

data in Appendix B: Product Certifications are not exceeded.

Cable joins are allowable in cabling the transmitter, provided that the joint is made within an

IP20/NEMA 3 (minimum) enclosure suitable for the environment, and that wiring withstands a

test voltage of 500 V r.m.s. to earth.

The maximum length of cable permissible between the transmitter and control unit is

determined by limits imposed by the intrinsic safety certificates of the instruments and control

drawings.

Section 3: Installation16

Page 25

Reference Manual

A

B

24 V

I

IN

1

2

3

1

2

3

A

B

24 V

I

IN

IP2030/RM, Rev AA

Section 3: Installation

June 2014

No other outputs from the control unit must be routed through a hazardous area unless

protected by an additional I.S. Barrier (not supplied).

It is the responsibility of the user to ensure that any transmitter is installed in accordance with

the manufacturer’s instructions supplied with the transmitter.

Cable between the MCU900 Series control unit and a transmitter should be shielded

twisted-pair with the shield connected to terminal 3 (marked with earth symbol) on the

MCU900 Series control unit. The shield should be left unconnected at the transmitter unless

there is a terminal specifically provided for this purpose.

Cable runs should be separate from any high voltage or mains cables to avoid crosstalk or

interference. Multi-core cable may be used if the other cores carry only low voltage (24 Vdc

nominal) signals and each pair of cores is individually screened (shielded).

Loop-powered transmitters must be connected to terminals 1, 2, and 3 on the control unit

(see Figure 3-4).

The MCU900 Series control unit supplies 23 Vdc from a 400 Ohm source to power transmitters.

Separately powered transmitters must be connected to terminals 2 and 3 (see Figure 3-5).

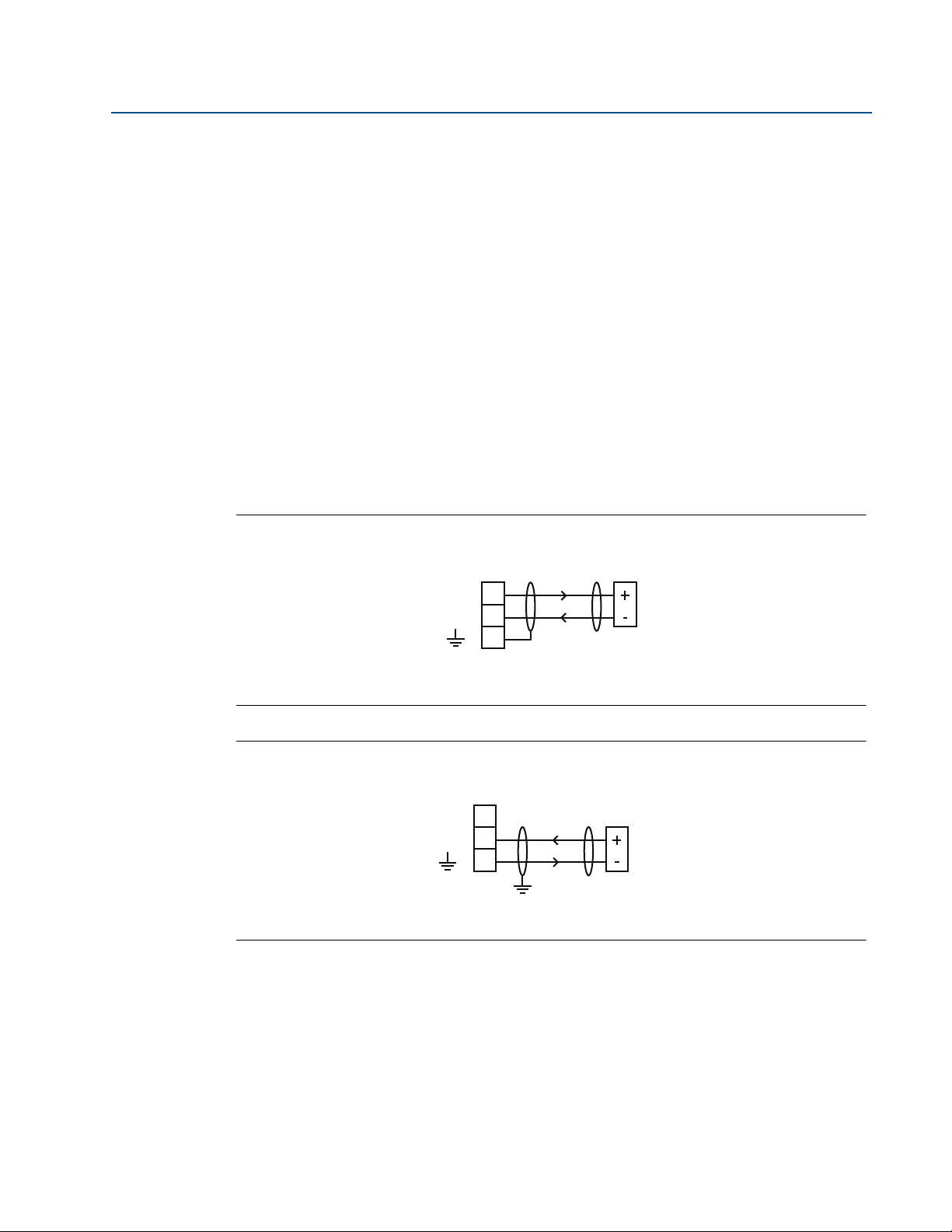

Figure 3-4. Loop-powered transmitter connections to MCU900 Series control unit

1

2

3

A. Control unit

B. Transmitter

Figure 3-5. Self-powered transmitter connections to MCU900 Series control unit

A. Control unit

B. Transmitter

Section 3: Installation

17

Page 26

Section 3: Installation

1

2

3

1

2

3

A

A

BB

C

June 2014

Reference Manual

IP2030/RM, Rev AA

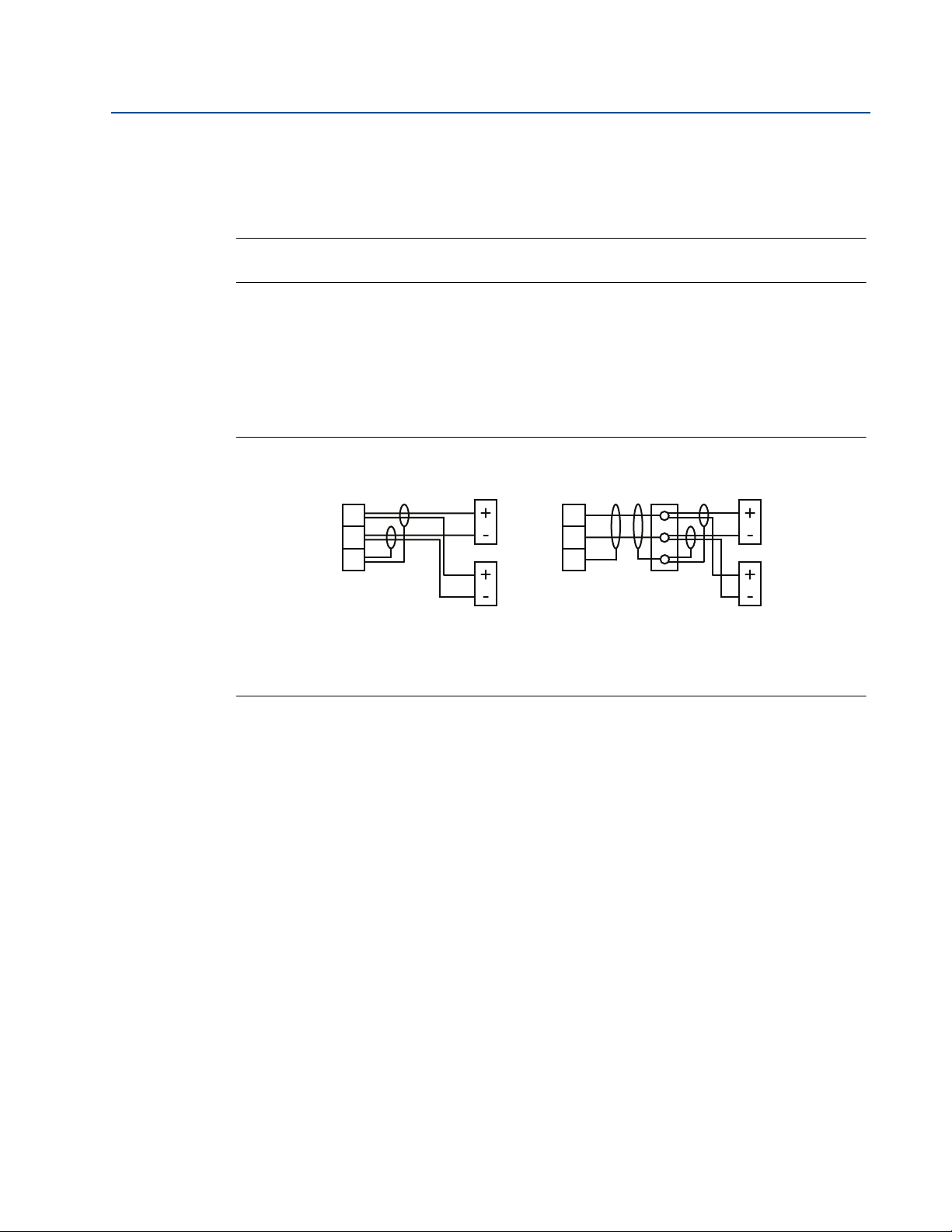

3.4.6 Connecting HART transmitters to the Mobrey MCU902

The Mobrey MCU902 control unit takes the input from two HART transmitters and calculates

the sum, difference, or product of the two inputs.

Note

The transmitters must be HART compatible for the MCU902 to operate correctly.

Connection of the two transmitters to the MCU902 can be done by:

cabling both transmitter cables wired directly into Current Input terminals on the

MCU902 (Figure 3-6), or

using a single cable wired directly into Current Input terminals with the two

transmitters connected to this single cable via a suitable junction box (Figure 3-6).

Figure 3-6. Connecting two HART transmitters to the Mobrey MCU902

A. HART Transmitter Tx1

B. HART Transmitter Tx2

C. Junction box

For correct operation, each HART transmitter must be changed to “multi-drop” mode to allow

them to communicate with the Mobrey MCU902 control unit through a common connection.

Each HART transmitter must therefore have their poll address changed from the factory default

address of “0” to a unique address.

The MCU902 control unit is used to achieve this address change, but requires the transmitters

to be connected in a specific sequence as detailed here:

1. With the power supply turned off, connect the first HART transmitter to the Current

Input terminals on the MCU902 control unit (see Figure 3-6).

2. Check the voltage-selector-switch is set for the correct voltage on the

mains-powered control unit (115 or 230 Vac), and then turn the power on.

3. After applying power, the control unit searches for a HART transmitter.

A HART transmitter with the factory default polling address of 0 is found after 15

seconds. The control unit automatically changes the Transmitter Poll Address from “0”

to “1” and it is designated “Tx1” (Transmitter 1) and assigned to Channel 1.

The control unit reads parameters from the HART transmitter and makes them

available for local interrogation and programming within the menu system.

Section 3: Installation18

Page 27

Reference Manual

IP2030/RM, Rev AA

Section 3: Installation

June 2014

4. When an un-configured Mobrey MSP Series Level Transmitter is being used for the first

time, a prompt appears asking for the Trans mitter [1] B ottom Refe r ence.

If commissioning the system now, edit and save a new Transmitter Bottom Reference or

keep the existing Transmitter Bottom Reference. After the start-up process is complete,

the display appears showing a measurement e.g. liquid level or the menu system.

If the system is not to be commissioned at this time, simply switch off the power and

the same prompt re-appears when switching on the power next time. The Transmitter

Bottom Reference can be changed later, but it is better to get it correct now.

Note

If the Re-connecting to Digital Transmitter message does not appear, check that the

operating mode of the control unit is set to Run App mode (see page 38) and that the

Input Channel Source is set for a digital HART input (see page 48 or page 50)

5. Turn the power supply off and connect the second HART transmitter (see Figure 3-6),

such that both HART transmitters are connected at the same time.

6. Turn the power supply on.

7. The MCU902 control unit searches for, and detects, the two connected HART

transmitters.

After the second HART transmitter is found, the control unit automatically changes the

Transmitter Poll Address from “0” to “2” and it is designated “Tx2” (Transmitter 2) and

assigned to Channel 2.

The control unit reads parameters from the HART transmitter and makes them

available for local interrogation and programming within the menu system.

8. When an un-configured Mobrey MSP Series Level Transmitter is being used for the first

time, a prompt appears asking for the Trans mitter [2] B ottom Refe r ence.

If commissioning the system now, edit and save a new Transmitter Bottom Reference or

keep the existing Transmitter Bottom Reference. After the start-up process is complete,

the display appears showing a measurement e.g. liquid level or the menu system.

If the system is not to be commissioned at this time, simply switch off the power and

the same prompt re-appears when switching on the power next time. The Transmitter

Bottom Reference can be changed later, but it is better to get it correct now.

9. The two HART transmitters are now known to the control unit, and will be remembered

each time the power is switched off and on.

Section 3: Installation

19

Page 28

Section 3: Installation

Internally Powered Loop Powered

June 2014

3.4.7 Relay connections

The five voltage-free contact relays are grouped as shown in Tab l e 3 -3 . Whilst each relay is

individually double-insulated, their arrangement is such that the insulation between relays in

the same group is standard or ‘basic’ insulation. Care must be taken in order to avoid the risk

of electric shock. It is allowed to use relays in the same group to control circuits with both mains

and dc, or low voltage circuits.

Note

The relay labels (NO-C-NC) in Ta b l e 3- 1 and Ta bl e 3 - 2 represent the relay terminals in

the de-energized state.

Table 3-3. Relay configuration groups

Wall Mount MCU900 Series control unit Panel Mount MCU900 Series control unit

Relay 1 and 2: Group 1 Relay 1, 2 and 3 : Group 1

Relay 3 and 4 : Group 2 Relay 4 and 5 : Group 2

Relay 5: Group 3

Reference Manual

IP2030/RM, Rev AA

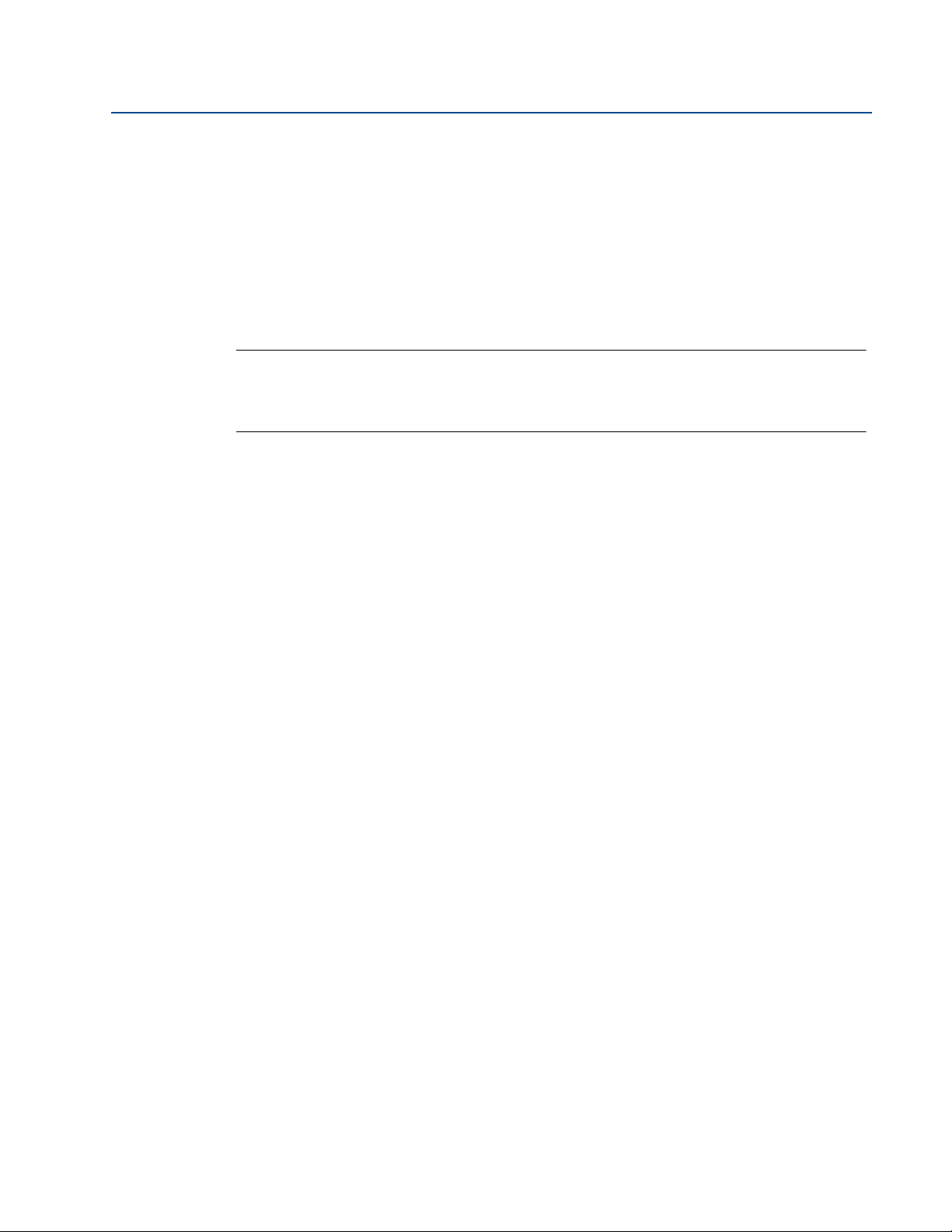

3.4.8 Current output connections

The Current Output may be connected in internally-powered or loop-powered mode, as shown in

Figure 3-7. In loop-powered mode, an external power source is required. A minimum of 2.5 V dc

is required across terminals 7 and 8 for correct operation. The voltage must not exceed 30 Vdc.

Figure 3-7. Alternative output current configurations

24V

7

Io

8

0V

9

+

Load

-

24V

0V

7

+

External

Supply

Io

8

+

Load

-

-

9

Section 3: Installation20

Page 29

Reference Manual

IP2030/RM, Rev AA

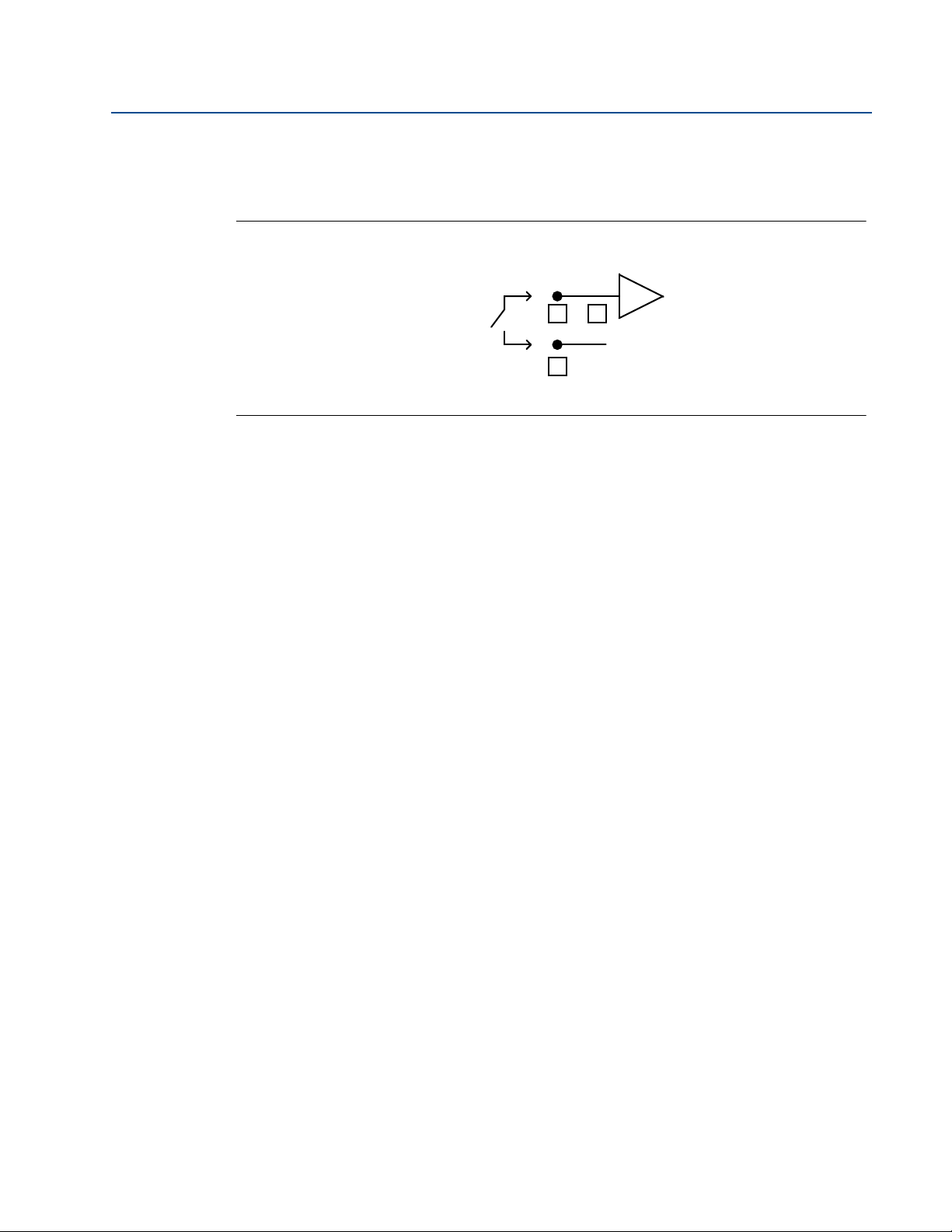

3.4.9 Digital control voltage-free contact inputs

There are two trigger inputs, IN1 and IN2. Each input is connected as shown in Figure 3-8.

Figure 3-8. Connections for external trigger input

Section 3: Installation

June 2014

External

Contact

Closure

IN

or10 11

0V

12

Section 3: Installation

21

Page 30

Section 3: Installation

Note B

Use the supplied mini-B nut to secure the socket to the panel.

Note A

Cut-out the hole in the panel to the dimensions

shown in Figure A-2 on page 122.

June 2014

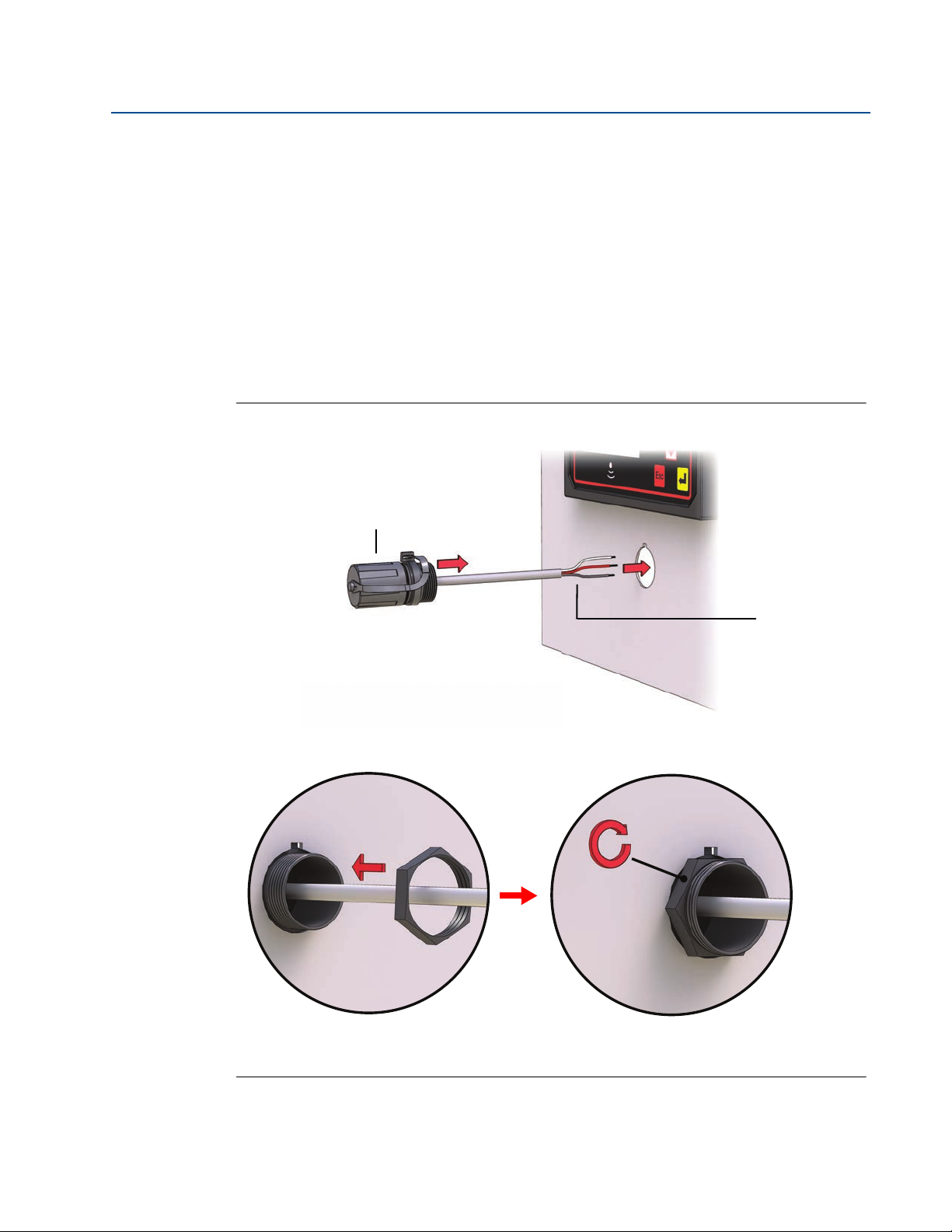

3.4.10 RS232 connections

The RS232 connections, terminals 4, 5 and 6, are for downloading logged data to a PC or a

handheld device.

Wall-mountable Mobrey MCU90F control units are supplied with a factory pre-fitted

RS232 data-download socket, which is also pre-wired to terminals 4, 5, and 6.

The panel-mountable Mobrey MCU90F control unit is supplied with a data-download

socket ready to be fitted to a panel (see Figure 3-9 on page 22) and then wired to

terminals 4, 5, and 6 on the rear of the control unit (see Figure 3-10 on page 23).

When there is data to be downloaded using Mobrey LOG-VIEW or other software, connect the

RS232 data-download cable supplied with the socket (see Figure 3-11 on page 23).

Figure 3-9. Fitting the RS232 data-download socket to a panel

Reference Manual

IP2030/RM, Rev AA

A. RS232 socket with cap fitted.

B. RS232 socket flying lead.

Section 3: Installation22

Page 31

Reference Manual

4: Rx (White)

5: Tx (Red)

6: 0V (Black)

Note B

Note A

Note C

IP2030/RM, Rev AA

Section 3: Installation

June 2014

Figure 3-10. Wiring the socket flying lead to terminals 4, 5, and 6 (panel mount unit)

Figure 3-11. Connecting the RS232 data-download cable supplied with the socket

A. RS232 data-download cable.

B. Unscrewed socket cap.

C. See Mobrey LOG-VIEW manual IP130 for further information on downloading logged data.

Section 3: Installation

23

Page 32

Section 3: Installation

June 2014

Reference Manual

IP2030/RM, Rev AA

Section 3: Installation24

Page 33

Reference Manual

IP2030/RM, Rev AA

Section 4 Getting started

Safety messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .page 25

Switching on the MCU901 and MCU90F for the first time . . . . . . . . . . . . . . . . . . . . page 26

Switching on the MCU902 for the first time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 29

A quick tour of the menu system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 30

Programming the control unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 32

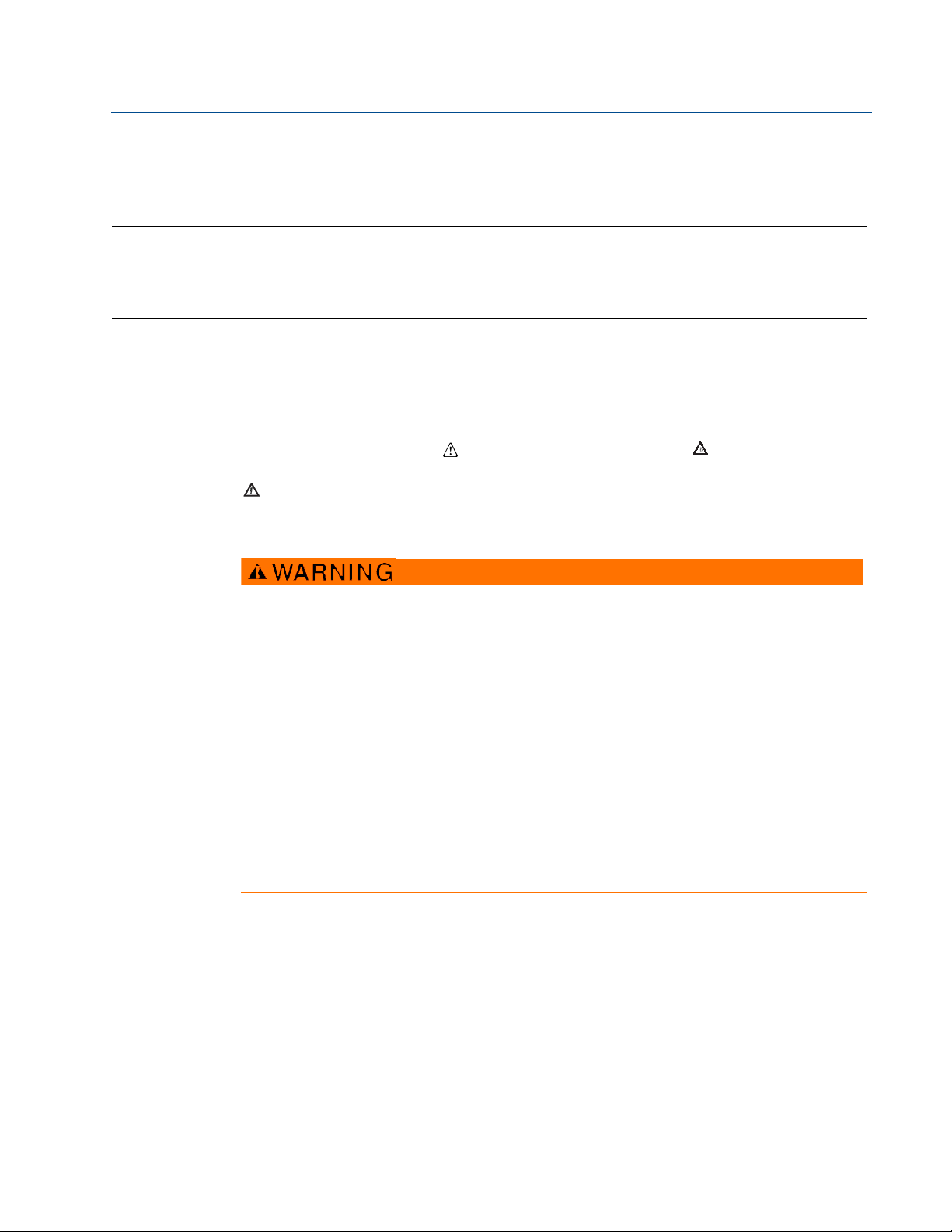

4.1 Safety messages

Procedures and instructions in this section may require special precautions to ensure the safety

of the personnel performing the operations. Information that raises potential safety issues is

indicated by a warning symbol ( ). Refer to the safety messages listed at the beginning of each

section before performing an operation preceded by this symbol.

Section 4: Getting started

June 2014

Failure to follow these installation guidelines could result in death or serious injury:

The Mobrey MCU900 Series control unit must be installed, connected,

commissioned, operated, and maintained by suitably qualified personnel only,

observing any national and local requirements that may apply

Use the equipment only as specified in this manual. Failure to do so may impair the

protection provided by the equipment

Explosions could result in death or serious injury:

Please review the approvals section of this reference manual for any restrictions

associated with an installation

Electrical shock could cause death or serious injury:

If the control unit is installed in a high voltage environment and a fault condition or

installation error occurs, high voltage may be present on leads and terminals

Use extreme caution when making contact with the leads and terminals

Make sure that power to the control unit is off while making connections

Section 4: Getting started

25

Page 34

Section 4: Getting started

B

E

E

20mA

4mA

F

D

D

C

A

G

June 2014

Reference Manual

IP2030/RM, Rev AA

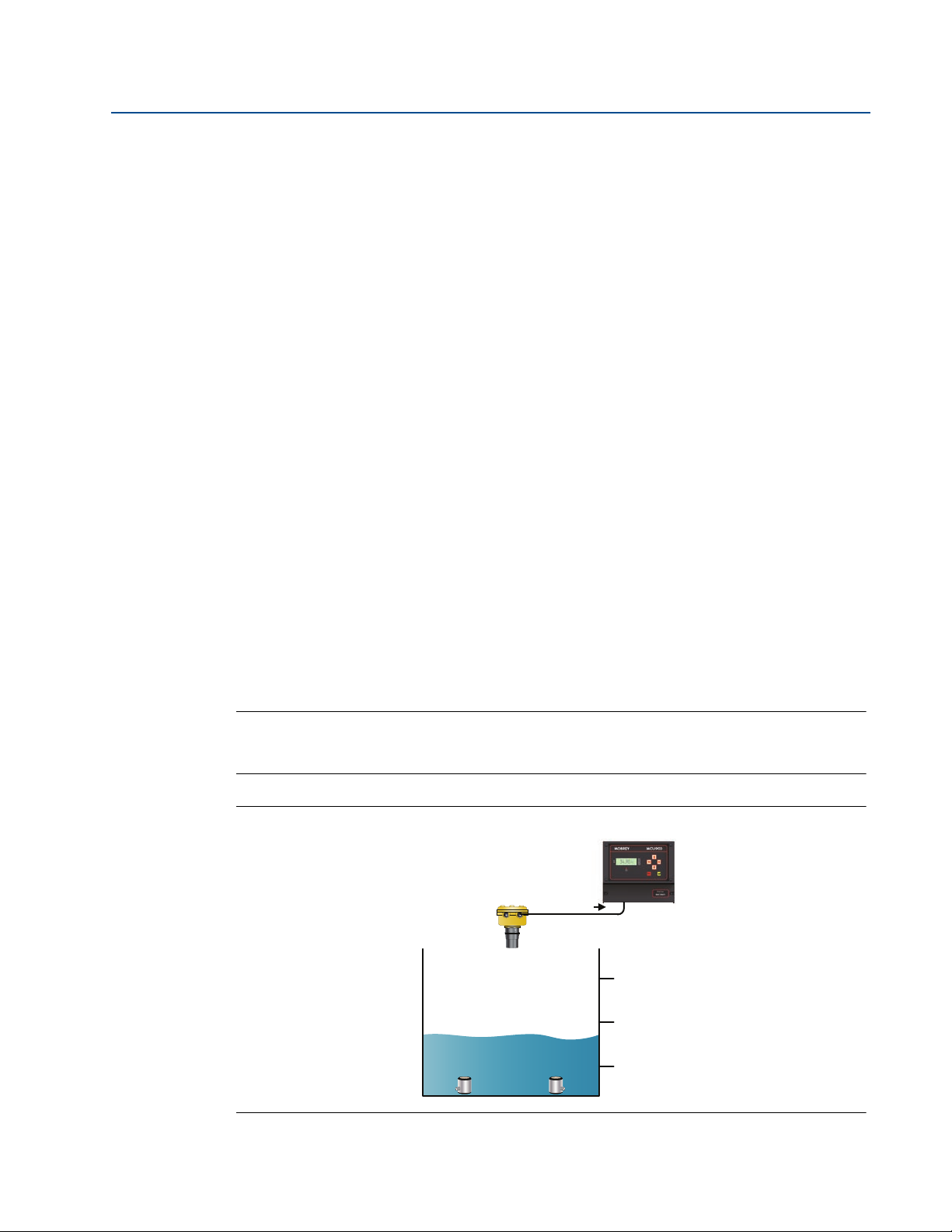

4.2 Switching on the MCU901 and MCU90F for the

first time

The Mobrey MCU901 and MCU90F control units accept the input from a single HART or

4–20 mA transmitter. Connect the transmitter to the Current Input terminals on the control

unit as explained in the section “Electrical installation” on page 13.

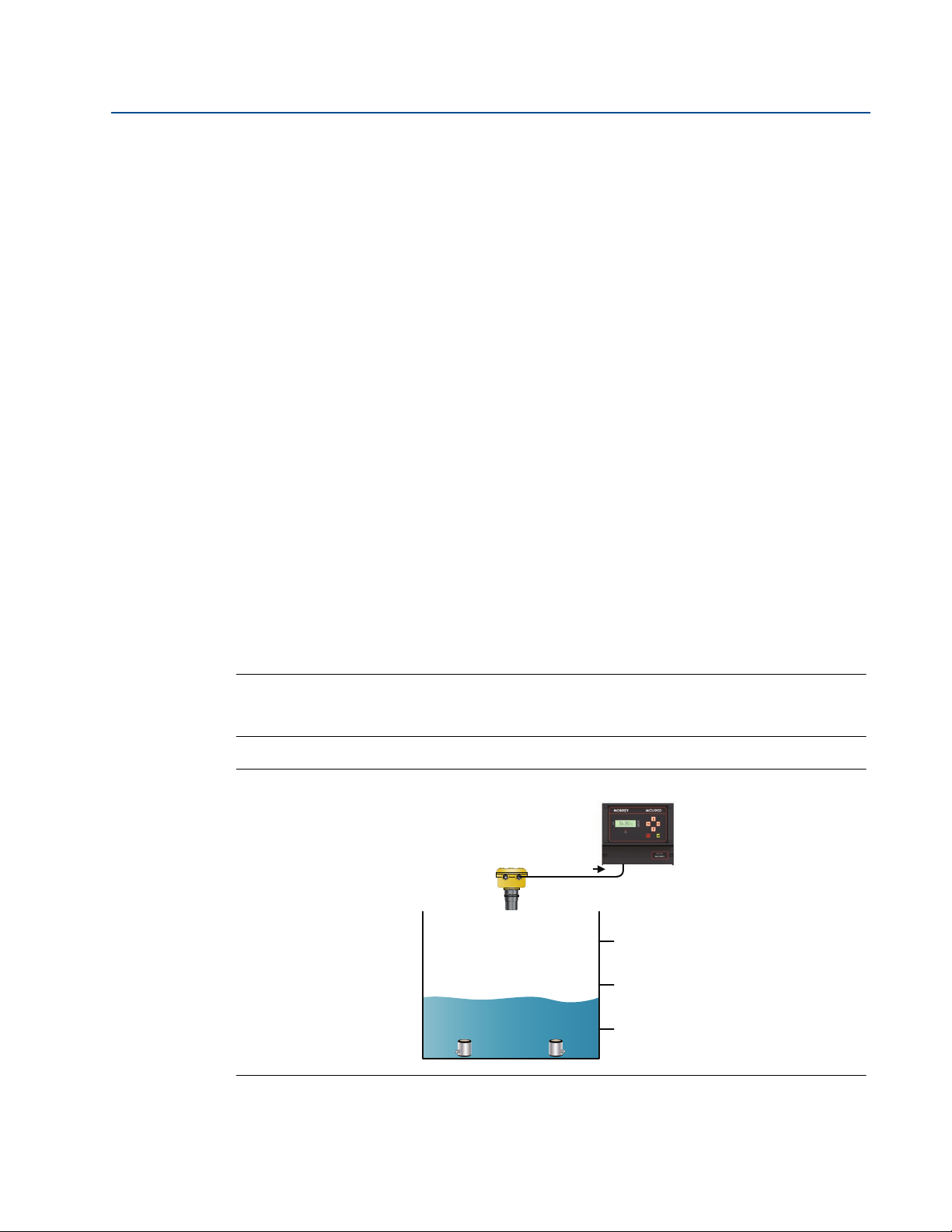

Figure 4-1. The Mobrey MCU901 or MCU90F control unit with one transmitter

A. Mobrey MSP Series Transmitter E. Pump

B. Mobrey MCU900 Series Control Unit F. Transmitter Bottom Reference

C. 4–20 mA signal output G. 4–20 mA and HART signal input

D. Relay

Section 4: Getting started26

Page 35

Reference Manual

Re-connecting to

Digital Transmitter

Please Wait

Re-connecting to

Digital Transmitter

Please Wait

Re-connecting to

Digital Transmitter

Please Wait

(start of search)

(after 3 seconds)

(after 15 seconds)

IP2030/RM, Rev AA

Section 4: Getting started

June 2014

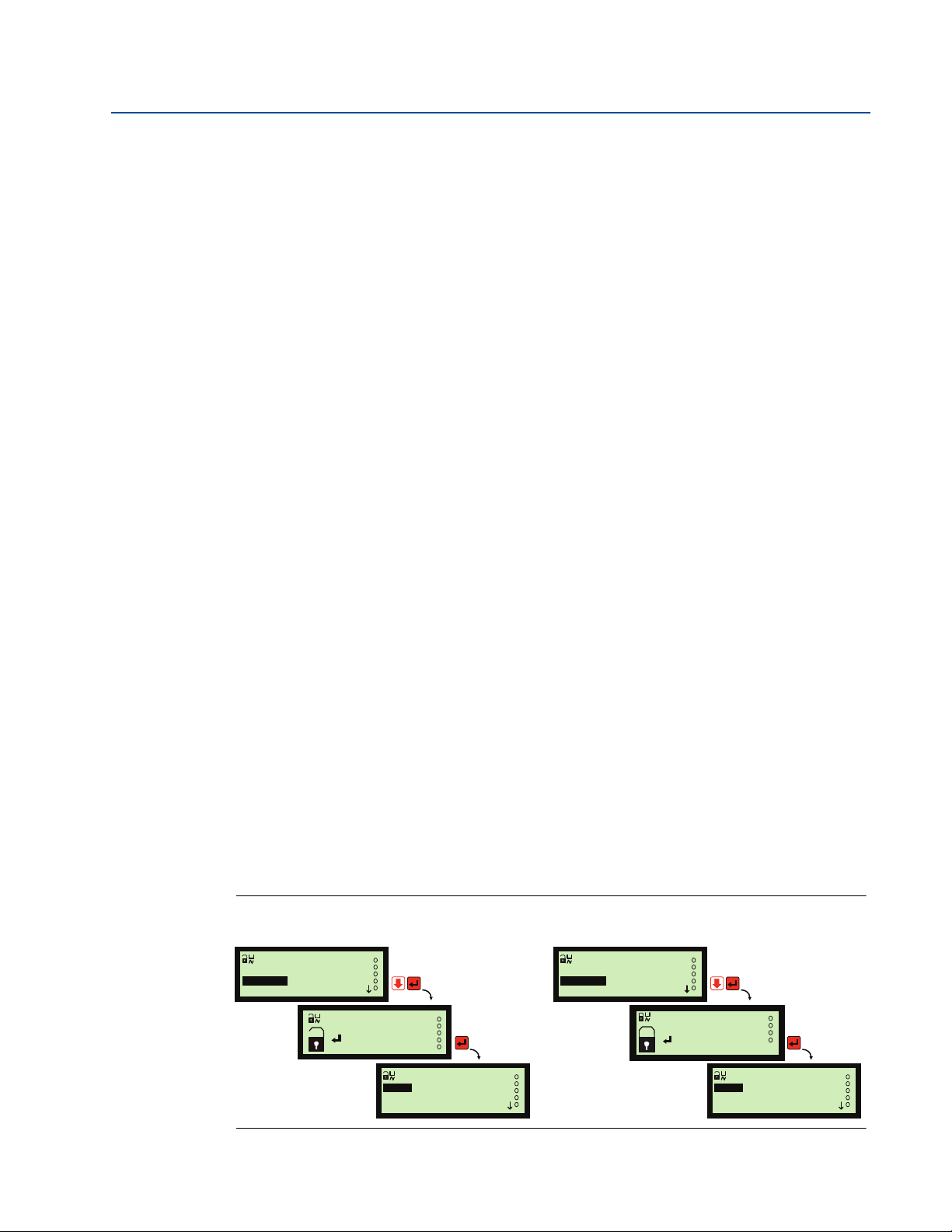

4.2.1 Switching on with one new HART transmitter connected

After applying power, the control unit first displays the control unit version e.g. MCU901 and the

software version. It then automatically searches for a HART transmitter.

Figure 4-2. Searching for a HART transmitter after applying power

A HART transmitter with the factory default polling address of 0 is found after 15 seconds.

When found by the controller, it is designated “Tx1” (Transmitter 1) and assigned to Channel 1.

However, if the polling address is in the range 1 to 15, a prompt appears allowing the polling

address and the tag name to be changed. This is optional, and pressing the red (ENTER) button

continues the start-up process.

At this time, the control unit reads parameters from the HART transmitter and makes them

available for local interrogation and programming within the menu system of the control unit.

When an un-configured Mobrey MSP Series Level Transmitter is being used for the first time, a

prompt appears asking for the Transmitter Bottom Referen ce (Figure 4-3). This value is used

to automatically set-up the 4–20 mA output span of the transmitter over this range.

If the system is not to be commissioned at this time, simply switch off the power and the same

prompt re-appears when switching on the power next time. The Transmitter Bottom Reference

can be changed later, but it is better to get it correct now.

If commissioning the system now, edit and save a new Transmitter Bottom Reference or

keep (save) the existing Transmitter Bottom Reference (Figure 4-3).

Note

If the Re-connecting to Digital Transmitter message does not appear, check that the

operating mode of the control unit is set to Run App mode (see page 38) and that the

Input Channel Source is set for a digital HART input (see page 48 or page 50)

After the start-up process is complete, the display appears showing a measurement e.g. liquid

level or the menu system. The value on the display is the Primary / Process Variable (PV) of the

control unit, but this can be changed (see “Display configuration options” on page 102).

Section 4: Getting started

Whenever power is lost and restored, the control unit re-establishes digital communications

with the HART transmitter and the PV display re-appears.

27

Page 36

Section 4: Getting started

Re-connecting to

Digital Transmitter

Please Wait

Bottom Reference =

distance to sensor

from tank bottom

=Continue

Edit Transmitter

Bottom Reference ?

12.000 m

ESC=No =Yes

to edit

Bottom Reference

06.500 m

ESC=Back =Save

5

Save new

Bottom Reference ?

06.500 m

ESC=No =Yes

Bottom Reference

saved.

Setup controller ?

ESC=No =Yes

Esc

Esc

Esc

Esc

Save

Bottom Reference ?

12.000 m

ESC=No =Yes

Esc

x4

Controller SETUP

menu appears –

Use App Wizard

(see page 39)

Controller MAIN

menu appears

(Yes)

(Yes)

(Yes)

(No)

(No)

(Back)

(No)

(Continue)

(06.500 m)

(No)

(Yes)

Note A

Note B

x5

x2

June 2014

Figure 4-3. Prompts for Transmitter Bottom Reference

Reference Manual

IP2030/RM, Rev AA

A. Default Bottom Reference as read from a Mobrey MSP900FH Transmitter configured with metric base units. Example is for illustration only.

B. The 6.500 m has been used here as an example new bottom reference. Enter the value that is required for your level measurement.

Section 4: Getting started28

Page 37

Reference Manual

C

A

D

B

E

C

IP2030/RM, Rev AA

Section 4: Getting started

4.2.2 Switching on with one 4–20 mA transmitter connected

After applying power with a 4–20 mA transmitter connected, the Full PV Display appears and

indicates a control unit Primary / Process Value (PV) of zero. It is then necessary to configure the

control unit for a 4–20 mA input instead of a digital HART input.

See “Optional change: transmitter input channel settings (advanced users)” on page 43 for this

procedure.

4.3 Switching on the MCU902 for the first time

The Mobrey MCU902 takes the input from two HART transmitters and calculates a single sum,

difference, or product of the two inputs.

It is important to connect the two HART transmitters in the correct sequence, as detailed in

“Connecting HART transmitters to the Mobrey MCU902” on page 18.

After both HART transmitters are connected, the top-left corner shows communications with

both transmitters by alternating “1” and “2” next to the digital communications icon.

June 2014

The factory default configuration shows the reading from the first connected transmitter (Tx1).

This configuration can be changed to show the sum, difference or product of the readings from

both transmitters.

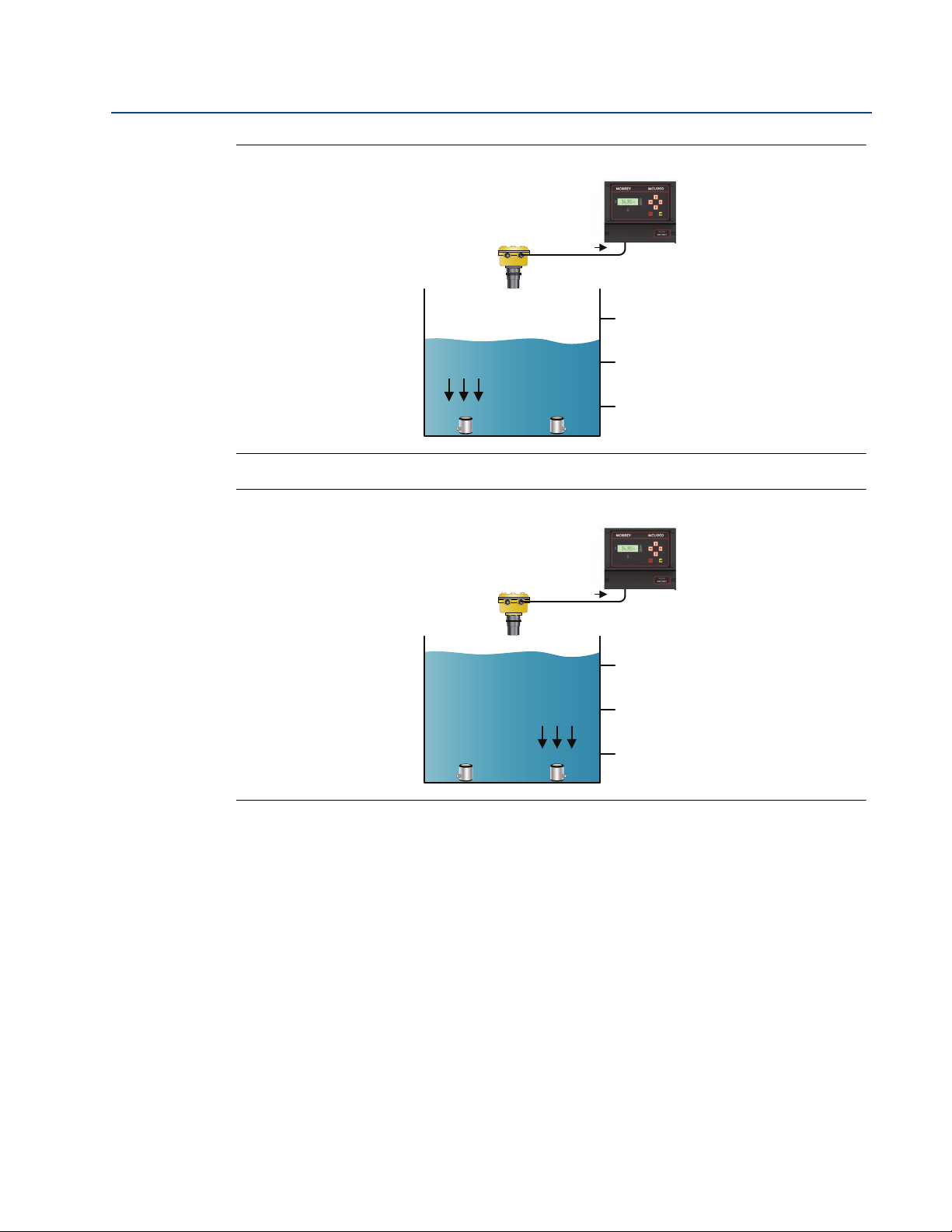

Figure 4-4. The MCU902 and two HART transmitters

A. Mobrey MCU900 Series Control Unit D. Transmitter [1] Bottom Reference

B. Mobrey MSP Series Transmitter E. Transmitter [2] Bottom Reference

C. HART Communications

Section 4: Getting started

29

Page 38

Section 4: Getting started

June 2014

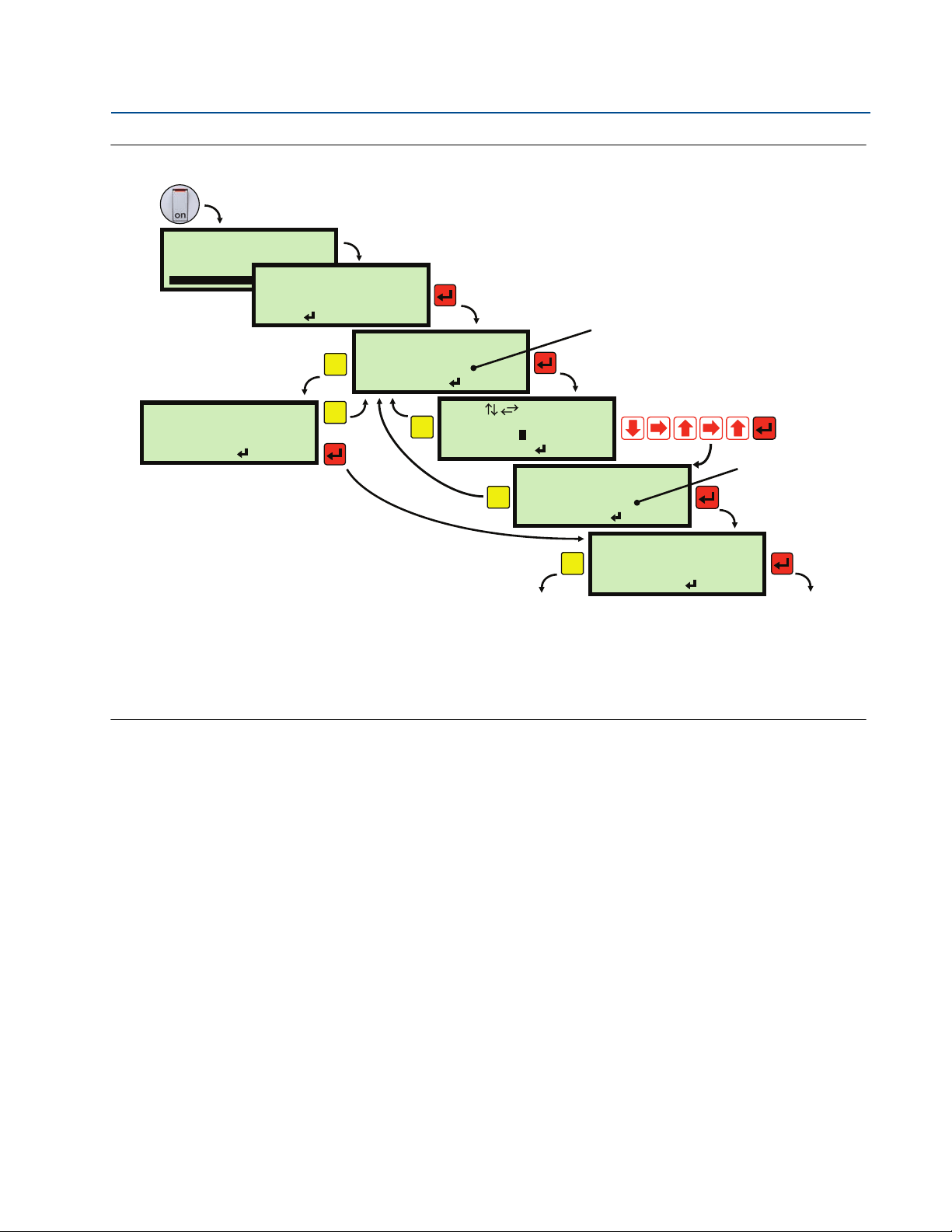

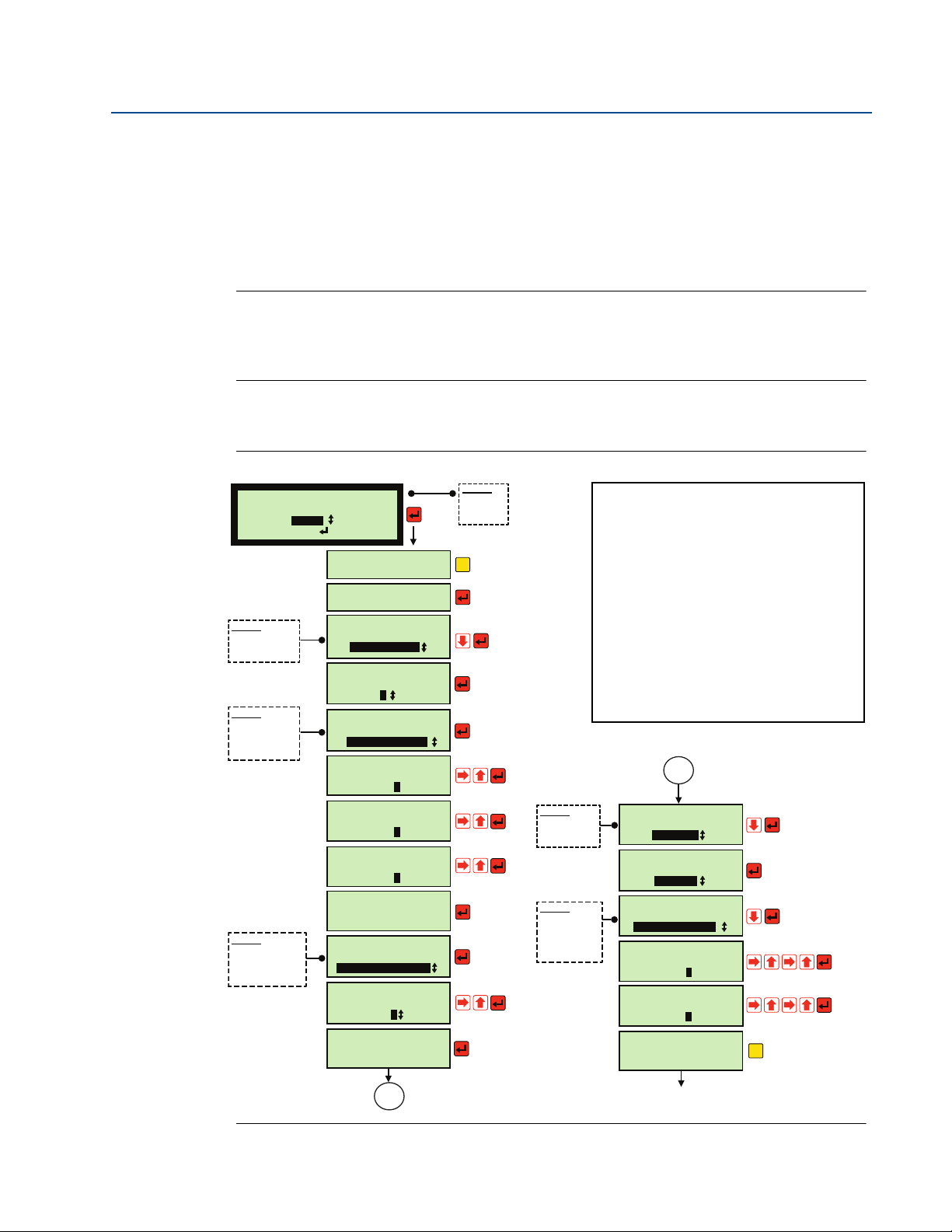

4.4 A quick tour of the menu system

Follow these instructions for a quick tour of the menu system:

1. This quick tour begins at the Full Display or Large PV Display (Figure 4-5 on page 31).

If already within the menu system, use the Esc button repeatedly until the Full Display

re-appears.

2. Press the red (ENTER) button to display the MAIN MENU (see Figure 4-5 on page 31).

The MAIN MENU is the top level of the menu system.

3. Navigation of the menu system is achieved by using the ARROW buttons,

the red (ENTER) button, and the Esc button.

The Esc button returns you to the previous menu level, unless you are at the top level.

4. The highlighted and blinking text indicates what menu option will be selected if the

red (ENTER) button was pressed now. Do not press it yet.

Reference Manual

IP2030/RM, Rev AA

5. The

6. The MAIN MENU sits above a series of sub-menus, which lead to further levels of

7. Press the red (ENTER) button to select the highlighted menu option SETUP.

8. The SELECT INSTRUMENT menu now appears. This screen is for selecting whether to

9. Press the red (ENTER) button to select the highlighted menu option Controller: ****.

10. The control unit SETUP menu now appears with menu options APPLICATION, DISPLAY,

11. Use the DOWN-ARROW button to highlight OUTPUT and then press the red (ENTER)

12. The OUTPUT menu now appears with menu options CURRENT OUTPUT, RELAY,

symbol on the display indicates there are further menu options available,

accessible by using the DOWN-ARROW button.

An

symbol indicates there are further menu options available, accessible by using the

UP-ARROW button.

sub-menus that lead to parameter screens (see Figure 4-6 on page 31).

enter the setup menu for the control unit (controller) or a found HART transmitter.

If there are no HART transmitters connected, Step 7 results in the SETUP menu for the control

unit appearing straight away. Skip to Step 10.

and OUTPUT visible.

button to select and enter the OUTPUT menu.

TOTALIZER, PV DAMPING, ALARM, and FAU LT.

13. Explore these menu options to see screens for setting-up for an application and for

displaying read-only information.

14. After exploring, hold down the Esc button once to return to the MAIN MENU.

Section 4: Getting started30

Page 39

Reference Manual

A

B

MAIN MENU

Run App?

MONITOR

SETUP

SELECT INSTRUMENT

Tx1: ****

Tx2: ****

Controller : ****

MAIN MENU

Run App?

MONITOR

Advanced

SELECT INSTRUMENT

Tx1: ****

Tx2: ****

Controller : ****

ADVANCED

Dxxx

Pxxx

1

1

1

1

1

=

Run App?

= Yes

1

Esc=No

Program?

=Yes

Esc=No

1

Note A

Note B

Note C

Note D

Note E

Note F

or

IP2030/RM, Rev AA

Figure 4-5. How to enter the menu system

1.572m

1

1.572m

SETUP

Run App?

MONITOR

A. Large PV display.

B. Full display showing PV in normal size characters and other information.

Figure 4-6. MAIN MENU overview

12:47

1

Section 4: Getting started

June 2014

MAIN MENU

Section 4: Getting started

A. Toggles the operating mode of the control unit. An open padlock indicates that Program mode is selected and

parameter values can be changed.

B. Selecting Controller: ****leads to the SETUP menu for setting up the control unit for an application.

C. Selecting Tx1: **** leads to the SETUP menu for adjusting the HART transmitter Tx1 operation (and similarly for Tx2

on the Mobrey MCU902). The Transmitter Bottom Reference for Tx1 (and similarly for Tx2) can be changed here.

D. Selecting Controller: **** leads to menus for viewing live readings and diagnostic information for the control unit.

E. Selecting Tx1: **** leads to menus for viewing live readings and diagnostic information from the HART transmitter

Tx1 (and similarly for Tx2 on the Mobrey MCU902).

F. Advanced access menu for advanced users to directly select parameter screens when the parameter number is

known. For a guide to this, see Appendix D Additional Features.

31

Page 40

Section 4: Getting started

June 2014

4.5 Programming the control unit

4.5.1 The basics

This chapter covers programming using the front panel of the MCU900 Series control unit to

make changes to the factory default set-up of the control unit.

Use the Application Wizard (App Wizard) to easily set-up the control unit for a level, flow, or

contents volume application, and then optionally adjust the set-up by editing parameters in the

menu system. See Appendix C: Menus and Parameters for a full list of menus and parameters.

Note

If a Mobrey MSP Series transmitter is connected, refer to the reference manual of the

transmitter for full information about programming the transmitter parameters

(e.g. Transmitter Bottom Reference) using the MCU900 Series control unit or other

HART-based devices.

For information about how the control unit supports other HART transmitters, see

Appendix C: Menus and Parameters and Appendix E: Support for HART® Transmitters.

Reference Manual

IP2030/RM, Rev AA

The basics about parameters

The MCU900 Series control unit has menu-based parameters for programming – setting up for

an application, adjusting default settings, etc. – and for viewing information.

Parameters are populated throughout the menu system. They are grouped in sub-menus, which

are organized for intuitive programming. Each parameter has a unique 3-digit identification

number, prefixed by a 'P' (if programmable) or a 'D' (if for display purposes only).

Note

A full list of menus and parameters is in Appendix C: Menus and Parameters

With some experience, it becomes easy to locate parameters. Alternatively, parameters can be

accessed directly by entering their unique 3-digit identification number. Details of this

Advanced access feature are in Appendix D: Additional Features.

To understand the basics about editing a parameter setting, follow the worked examples for

editing a numerical parameter and the calendar date parameter.

Section 4: Getting started32

Page 41

Reference Manual

x3

x2

Note A

IP2030/RM, Rev AA

Section 4: Getting started

June 2014

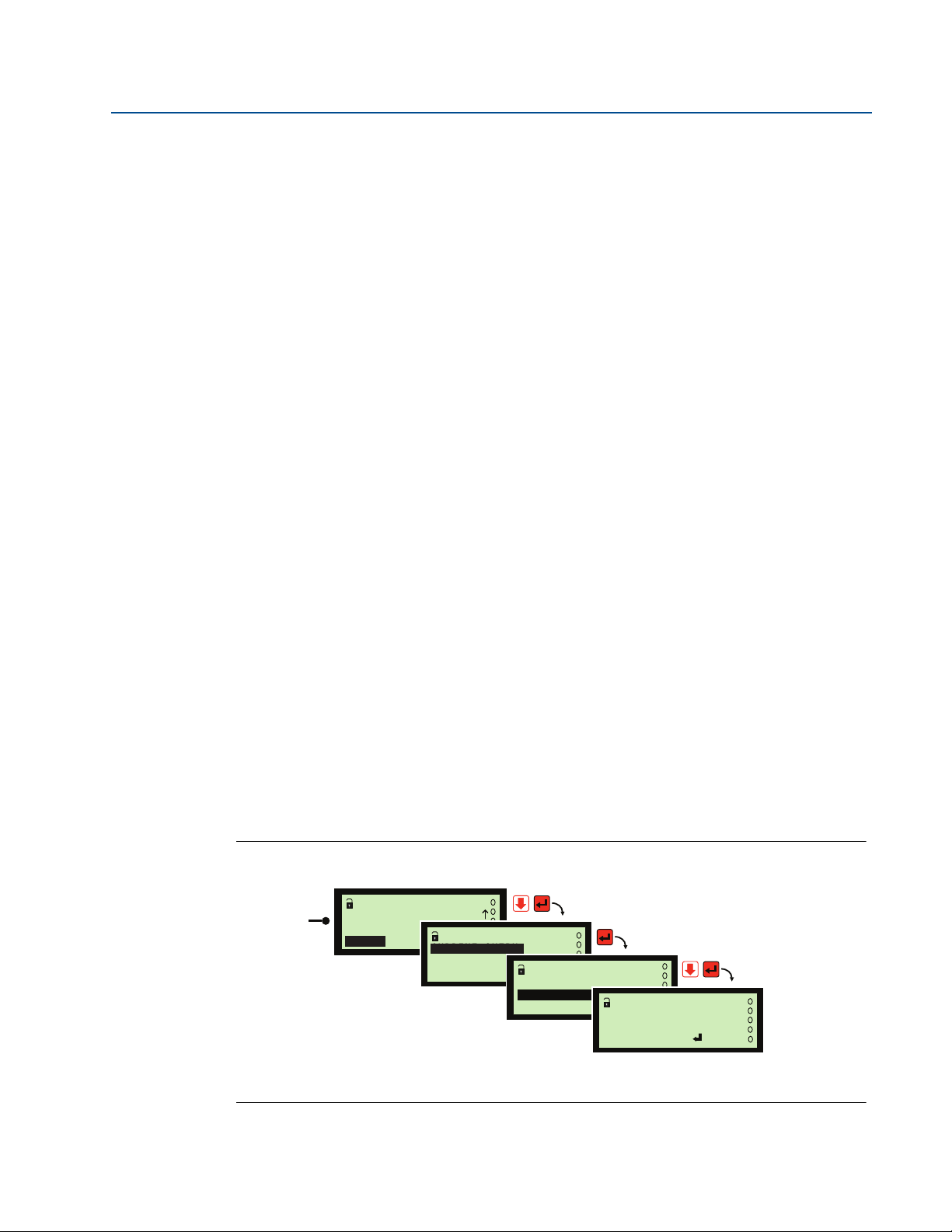

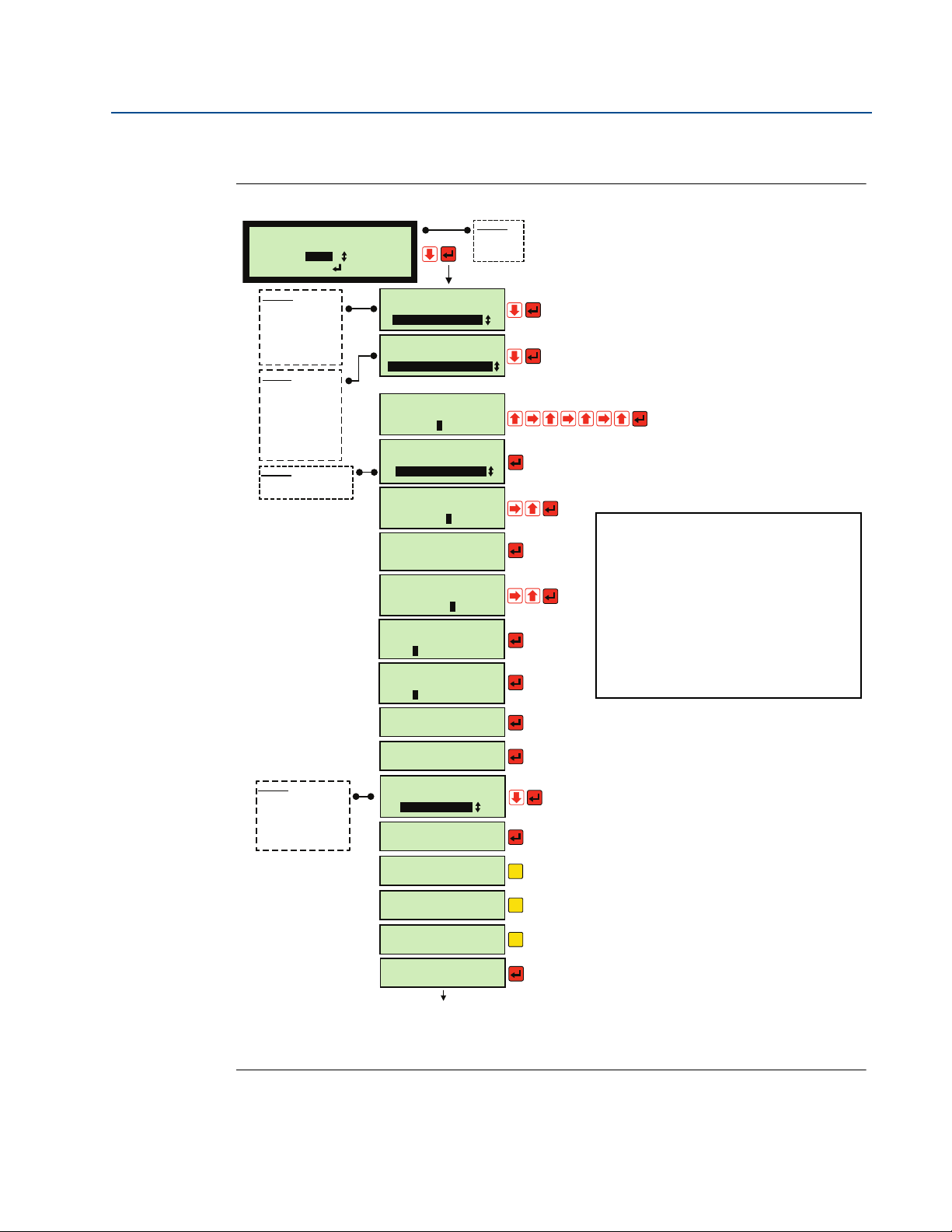

How to edit a numerical parameter

1. Navigate to the Up Range Value parameter screen (see Figure 4-7).

2. When entering any parameter screen, it is in View Mode (Figure 4-8 on page 34).

Help with what can be done next is on display line 4.

(In View Mode, the Esc button is used to leave (quit) the parameter screen.

The SETTINGS menu then re-appears, as seen before selecting the parameter screen).

3. To enter Edit Mode, press the red (ENTER).

4. A highlighted “+” appears (Figure 4-8) to show this positive sign can be changed to be a

negative sign. The UP-ARROW or DOWN-ARROW cycles between “+” and “–”.

(Also, note that on display line 4, “Edit” has changed to be “Save”).

5. Change the number from “+12.000” to “+6.500” (Figure 4-8):

a. Press the RIGHT-ARROW button once to move right one space and highlight the “1”.

(The LEFT-ARROW can be used to move the highlight back one space).

b. Press the UP-ARROW button five times to change the “1” to a “6”.

(The DOWN-ARROW can be used to scroll down through the numbers and decimal point).

c. Press the RIGHT-ARROW button once to highlight the “2”.

d. Press the DOWN-ARROW button three times to change the “2” to a decimal point.

e. Press the RIGHT-ARROW button once to highlight the old decimal point.

f. Press the DOWN-ARROW button six times to change the old decimal point to a “5”.

(Note that other button press sequences could have been used to edit 6.500).

6. Press the red (ENTER) button to save the +6.500 and return to View Mode

that on display line 4, “Save” has changed back to “Edit”).

e

(Not

7. Press the Esc button to return to the SETTINGS menu.

Figure 4-7. Navigation to a numerical parameter screen

SETUP

CURRENT OUTPUT

CURRENT OUTPUT

RELAY

TOTALIZER

OUTPUT

Low Range Val

Up Range Val

Alarm Action

CURRENT OUTPUT

Up Range Val P401

12.000 m

Esc=Quit =Edit

APPLICATION

DISPLAY

OUTPUT

.

Section 4: Getting started

A. This is the SETUP menu for the control unit – see Figure 4-6 on page 31 for how to get here.

33

Page 42

Section 4: Getting started

Note A

Note B

Note D

Note C

June 2014

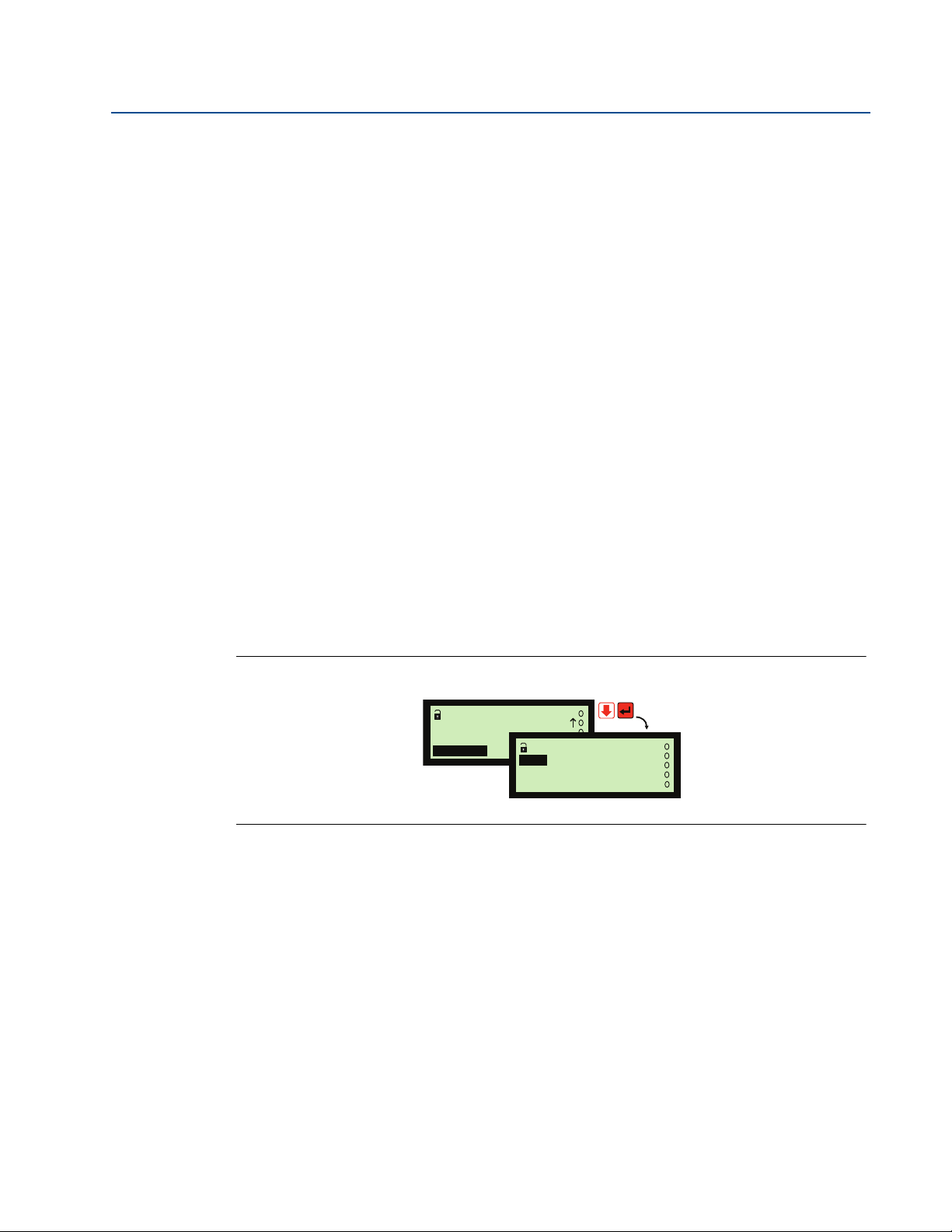

Figure 4-8. Example of editing a numerical value

Up Range Val P401

12.000 m

Esc=Quit =Edit

Up Range Val P401

12.000 m

+

Esc=Quit =Save

Up Range Val P401

+12.000 m

Esc=Quit =Save

1

Up Range Val P401

+62.000 m

Esc=Quit =Save

6

Up Range Val P401

+6..000 m

Esc=Quit =Save

Reference Manual

IP2030/RM, Rev AA

.

Up Range Val P401

+6.5000 m

Esc=Quit =Save

A. When entering any parameter screen, it is in View Mode. Help with what can be done next is on display line 4.