Page 1

User Guide

MCi210

Part Number: 0478-0033-02

Issue: 2

www.controltechniques.com

Page 2

General Information

The manufacturer accepts no liability for any consequences resulting from inappropriate, negligent or

incorrect installation or adjustment of the optional operating parameters of the equipment or from

mismatching the variable speed drive with the motor.

The contents of this guide are believed to be correct at the time of printing. In the interests of a commitment

to a policy of continuous development and improvement, the manufacturer reserves the right to change the

specification of the product or its performance, or the contents of the guide, without notice.

All rights reserved. No parts of this guide may be reproduced or transmitted in any form or by any means,

electrical or mechanical including photocopying, recording or by an information storage or retrieval system,

without permission in writing from the publisher.

Drive software version

This product is supplied with the latest software version. If this drive is to be connected to an existing system

or machine, all drive software versions should be verified to confirm the same functionality as drives of the

same model already present. This may also apply to drives returned from a Control Techniques Service

Centre or Repair Centre. If there is any doubt please contact the supplier of the product.

Environmental statement

Control Techniques is committed to minimising the environmental impacts of its manufacturing operations

and of its products throughout their life cycle. To this end, we operate an Environmental Management

System (EMS) which is certified to the International Standard ISO 14001. Further information on the EMS,

our Environmental Policy and other relevant information is available on request, or can be found at

www.greendrives.com.

The electronic variable-speed drives manufactured by Control Techniques have the potential to save

energy and (through increased machine/process efficiency) reduce raw material consumption and scrap

throughout their long working lifetime. In typical applications, these positive environmental effects far

outweigh the negative impacts of product manufacture and end-of-life disposal.

Nevertheless, when the products eventually reach the end of their useful life, they must not be discarded

but should instead be recycled by a specialist recycler of electronic equipment. Recyclers will find the

products easy to dismantle into their major component parts for efficient recycling. Many parts snap

together and can be separated without the use of tools, while other parts are secured with conventional

fasteners. Virtually all parts of the product are suitable for recycling.

Product packaging is of good quality and can be re-used. Large products are packed in wooden crates,

while smaller products come in strong cardboard cartons which themselves have a high recycled fibre

content. If not re-used, these containers can be recycled. Polythene, used on the protective film and bags

for wrapping product, can be recycled in the same way. Control Techniques' packaging strategy prefers

easily-recyclable materials of low environmental impact, and regular reviews identify opportunities for

improvement.

When preparing to recycle or dispose of any product or packaging, please observe local legislation and

best practice.

REACH legislation

EC Regulation 1907/2006 on the Registration, Evaluation, Authorisation and restriction of Chemicals

(REACH) requires the supplier of an article to inform the recipient if it contains more than a specified

proportion of any substance which is considered by the European Chemicals Agency (ECHA) to be a

Substance of Very High Concern (SVHC) and is therefore listed by them as a candidate for compulsory

authorisation.

For current information on how this requirement applies in relation to specific Control Techniques products,

please approach your usual contact in the first instance. Control Techniques position statement can be

viewed at:

http://www.controltechniques.com/REACH

Copyright © November 2012 Control Techniques Ltd.

Issue Number: 2

Firmware: 01.00.00.XX onwards

Page 3

Contents

1 Safety information ................................................................. 5

1.1 Warnings, Cautions and Notes ................................................................5

1.2 Electrical safety - general warning ..........................................................5

1.3 System design and safety of personnel ..................................................5

1.4 Environmental limits ................................................................................6

1.5 Access .....................................................................................................6

1.6 Compliance with regulations ...................................................................6

1.7 Adjusting parameters ..............................................................................6

1.8 Stored charge ..........................................................................................6

2 Introduction ............................................................................7

2.1 MCi210 module .......................................................................................7

2.2 User programming ...................................................................................7

2.3 Option module identification .................................................................... 8

2.4 Conventions used in this guide ...............................................................8

3 Mechanical installation .........................................................9

3.1 General Installation .................................................................................9

4 Electrical installation ...........................................................10

4.1 MCi210 module information ..................................................................10

4.2 Ethernet .................................................................................................11

4.3 Digital I/O ...............................................................................................12

5 Parameters ........................................................................... 13

5.1 Overview ...............................................................................................13

5.2 Menus ....................................................................................................13

5.3 Parameter save and restore ..................................................................14

5.4 Remanent variables ..............................................................................14

5.5 Menu 0 - MCi210 Module information ...................................................15

5.6 Menu 1 - User Application ..................................................................... 19

5.7 Menu 2 - Ethernet configuration ............................................................ 25

5.8 Menu 3 - Timer ...................................................................................... 32

5.9 Menu 4 - Digital I/O ...............................................................................35

5.10 Menu 9 - Resources .............................................................................. 38

5.11 Menu 10 - Easy mode cyclic data .........................................................40

5.12 Menu 11 - Synchronization ....................................................................54

5.13 Menu 15 - Modbus ................................................................................61

6 Variable allocation menus ..................................................68

7 Digital I/O ..............................................................................69

8 Timer .....................................................................................70

9 User programming ...............................................................72

9.1 Machine Control Studio ......................................................................... 72

MCi210 User Guide 3

Issue Number: 2

Page 4

10 Diagnostics ........................................................................73

10.1 Run-time errors .....................................................................................73

10.2 Drive trip display codes .........................................................................73

10.3 Run-time error codes .............................................................................74

10.4 Ethernet error codes ..............................................................................75

10.5 Module error codes ...............................................................................76

4 MCi210 User Guide

Issue Number: 2

Page 5

1 Safety information

WARNING

CAUT ION

NOTE

information

Safety

1.1 Warnings, Cautions and Notes

A Warning contains information, which is essential for avoiding a safety hazard.

A Caution contains information, which is necessary for avoiding a risk of damage to the

product or other equipment.

A Note contains information, which helps to ensure correct operation of the product.

1.2 Electrical safety - general warning

The voltages used in the drive can cause severe electrical shock and/or burns, and could be lethal.

Extreme care is necessary at all times when working with or adjacent to the drive.

Specific warnings are given at the relevant places in this User Guide.

1.3 System design and safety of personnel

The drive is intended as a component for professional incorporation into complete equipment or a

system. If installed incorrectly, the drive may present a safety hazard.

The drive uses high voltages and currents, carries a high level of stored electrical energy, and is

used to control equipment which can cause injury.

Close attention is required to the electrical installation and the system design to avoid hazards

either in normal operation or in the event of equipment malfunction. System design, installation,

commissioning/start-up and maintenance must be carried out by personnel who have the

necessary training and experience. They must read this safety information and this User Guide

carefully.

The STOP and SAFE TORQUE OFF functions of the drive do not isolate dangerous voltages from

the output of the drive or from any external option unit. The supply must be disconnected by an

approved electrical isolation device before gaining access to the electrical connections.

With the sole exception of the SAFE TORQUE OFF function, none of the drive functions

must be used to ensure safety of personnel, i.e. they must not be used for safety-related

functions.

Careful consideration must be given to the functions of the drive which might result in a hazard,

either through their intended behavior or through incorrect operation due to a fault. In any

application where a malfunction of the drive or its control system could lead to or allow damage,

loss or injury, a risk analysis must be carried out, and where necessary, further measures taken to

reduce the risk - for example, an over-speed protection device in case of failure of the speed

control, or a fail-safe mechanical brake in case of loss of motor braking.

The system designer is responsible for ensuring that the complete system is safe and

designed correctly according to the relevant safety standards.

Introduction

Mechanical

installation

installation

Electrical

Parameters

Variable allocation

menus

Digital I/O

Timer

programming

User

Diagnostics Index

MCi210 User Guide 5

Issue Number: 2

Page 6

1.4 Environmental limits

Instructions regarding transport, storage, installation and use of the drive must be complied with,

including the specified environmental limits. These instructions can be found in the relevant drive

documentation. Drives must not be subjected to excessive physical force.

1.5 Access

Drive access must be restricted to authorized personnel only. Safety regulations which apply at the

place of use must be complied with.

1.6 Compliance with regulations

The installer is responsible for complying with all relevant regulations, such as national wiring

regulations, accident prevention regulations and electromagnetic compatibility (EMC) regulations.

Particular attention must be given to the cross-sectional areas of conductors, the selection of fuses

or other protection, and protective ground (earth) connections.

Instructions for achieving compliance with specific EMC standards may be found in the relevant

drive documentation.

Within the European Union, all machinery in which this product is used must comply with the

following directives:

2006/42/EC: Safety of machinery.

2004/108/EC: Electromagnetic Compatibility.

1.7 Adjusting parameters

Some parameters have a profound effect on the operation of the drive. They must not be altered

without careful consideration of the impact on the controlled system. Measures must be taken to

prevent unwanted changes due to error or tampering.

1.8 Stored charge

The drive contains capacitors which remain charged to a potentially lethal voltage after the AC

supply has been disconnected. If the drive has been energized, the AC supply must be isolated for

at least ten minutes before work may continue.

6 MCi210 User Guide

Issue Number: 2

Page 7

2 Introduction

information

Safety

2.1 MCi210 module

The MCi210 is a CoDeSys-based user-programmable option module for Unidrive M. It is an

intelligent module that expands on the functionality of the Unidrive M by offering the following

features:

• CoDeSys based user programming

• Digital I/O

• Timer Unit

• Onboard Ethernet (2 ports)

• File system

2.2 User programming

The MCi210 module is capable of running a CoDeSys program created by a user with the Machine

Control Studio (MC Studio) software. It is an integrated development environment that supports all

five of the programming languages of the IEC 61131-3 standard, including Structured Text (ST),

Ladder Diagram (LD), Function Block Diagram (FBD), Sequential Function Chart (SFC) and

Instruction List (IL). Continuous Function Chart (CFC) is also supported.

The user has a number of tasks available to them. These are documented below.

• Initial

• Freewheeling

• Clock0

• Clock1

• Clock2

• Clock3

•Position

• Event0

• Event1

• Event2

• Event3

•ErrorTask

The Freewheeling, Clockn and Position tasks are cyclic tasks. The Clockn and Position tasks will

run at an interval set by the user in MC Studio. The Freewheeling task is the lowest priority task and

will run when processor resource allows.

Introduction

Mechanical

installation

installation

Electrical

Parameters

Variable allocation

menus

Digital I/O

Timer

MCi210 User Guide 7

Issue Number: 2

programming

User

Diagnostics Index

Page 8

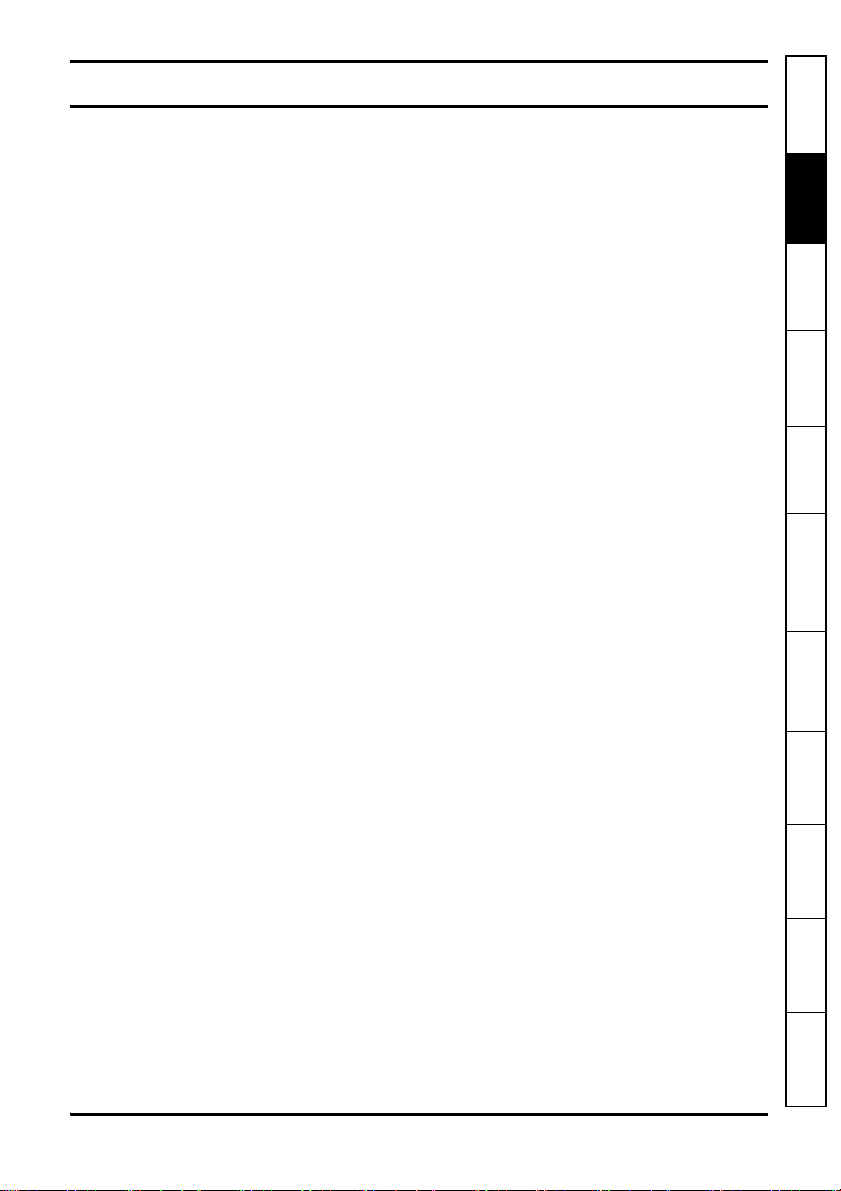

2.3 Option module identification

1

2

MCi210

3000005001

STDN39

AB

3000005001

Option module

name

Ethernet link /

activity indicators

Serial number

Date code

Approval

Figure 2-1 MCi210 module

The MCi210 module can be identified by:

1. The label located on the topside of the option module.

2. The color coding across the front of the option module and the connector types.

MCi210: Moss green with two 8P8C (RJ45) connectors and a 6-way pluggable connector.

Figure 2-2 MCi210 label

1: Topside module label

2: Underside module label

2.4 Conventions used in this guide

The configuration of the host drive and System Integration option module is performed using

menus and parameters. A menu is a logical collection of parameters that have similar functionality.

The MCi210 module contains a number of menus that are grouped by the slot number that the

module is installed into.

The method used to determine the menu or parameter is as follows:

•Pr S.mm.ppp - signifies a module parameter, where S is the slot number that the module is

installed in, mm is the module menu number and ppp is the parameter within that menu.

•Pr mm.000 - signifies any drive menu and parameter number 00.

8 MCi210 User Guide

Issue Number: 2

Page 9

3 Mechanical installation

WARNING

Before installing or removing an option module from any drive, ensure the AC supply

has been disconnected for at least 10 minutes and refer to Chapter 1 Safety

information on page 5. If using a DC bus supply ensure this is fully discharged before

working on any drive or option module.

3.1 General Installation

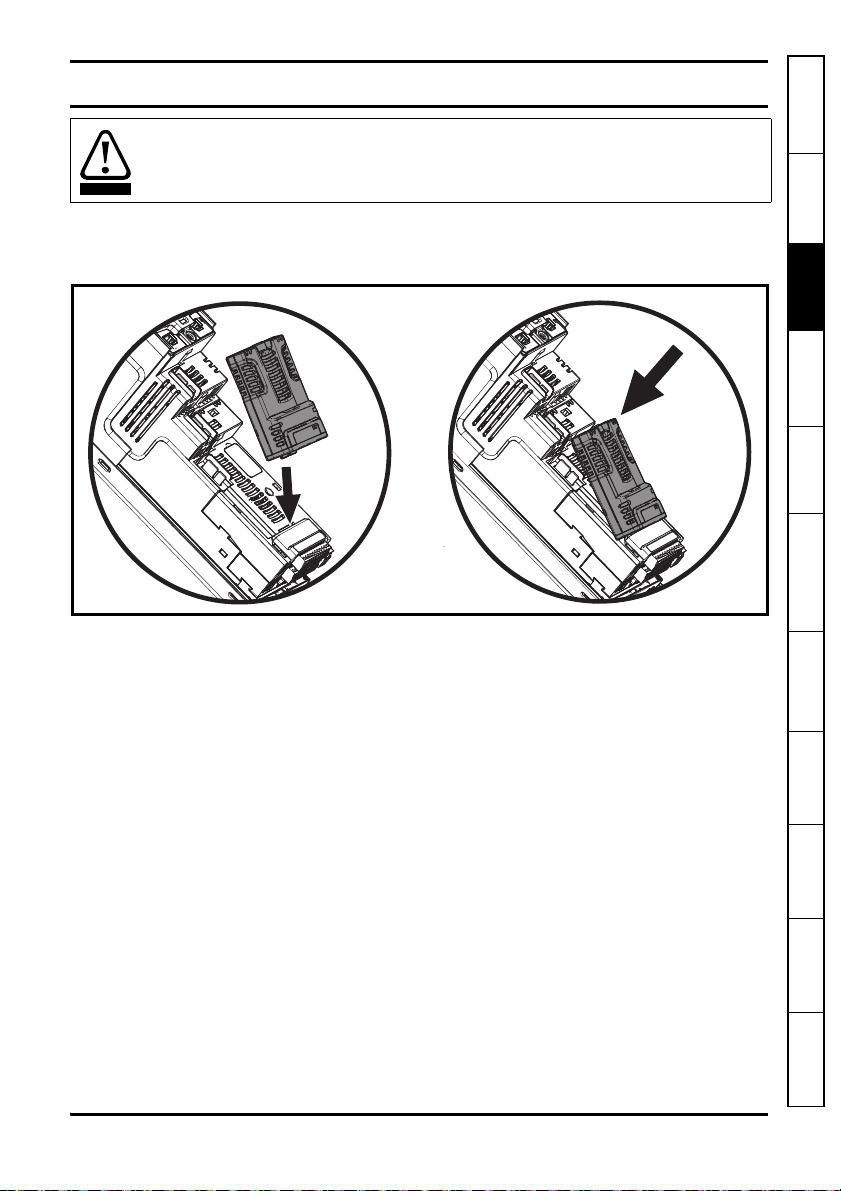

The installation of an option module is illustrated in Figure 3-1.

Figure 3-1 Option module installation

information

Safety

Introduction

Mechanical

installation

installation

Electrical

Parameters

Variable allocation

menus

3.1.1 Installing the first option module

Option module slots must be used in the following order: slot 3, slot 2 and slot 1.

• Align the option module above the drive as shown

• Insert the option module tab into the slot on the drive

• Press down on the option module until it clicks into place

MCi210 User Guide 9

Issue Number: 2

Digital I/O

Timer

programming

User

Diagnostics Index

Page 10

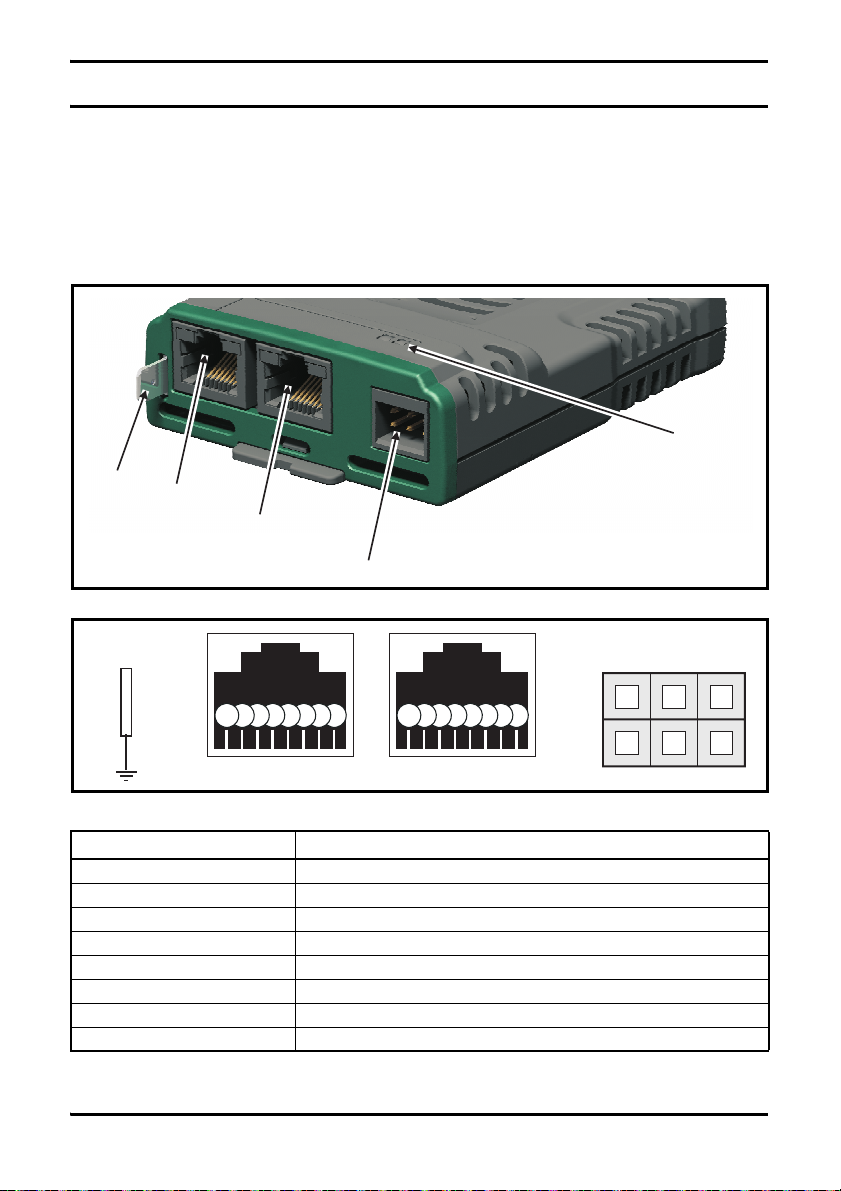

4 Electrical installation

Ethernet

port A

Ethernet

port B

Link LEDs

Digital I/O

Ground

tab

123

Digital I/O

Spade

connector

1234567812345678

456

4.1 MCi210 module information

The MCi210 module provides two standard 8P8C (RJ45) UTP/STP (Un-shielded / Shielded

Twisted Pair) connections to a 100 Mbps Ethernet network using an inbuilt switch. A grounding tab

is provided for supplementary bonding of the 8P8C connectors. A link/activity indicator is provided

for each of the Ethernet ports. The indicators are located on the top surface of the module.

The MCi210 module also provides a 6-way pluggable connector for digital inputs and outputs.

Figure 4-1 MCi210

Figure 4-2 MCi210 Connections

Table 4-3 8P8C (RJ45) Ethernet port connector pin out

Terminal Description

1 Transmit +

2 Transmit -

3 Receive +

4N/A

5N/A

6 Receive -

7N/A

8N/A

10 MCi210 User Guide

Issue Number: 2

Page 11

Table 4-4 6-way digital I/O pluggable connector pin out

Terminal Description

1 Digital input 1

2 Digital input 2

3 Digital input 3

4 Digital I/O 4

5 Digital output 5

6 0 V common

4.2 Ethernet

4.2.1 Isolation

The shells of the 8P8C (RJ45) Ethernet ports are isolated from 0V of the module and the drive.

The ground tab on the MCi210 module is not required for electrical safety and is available only to

increase immunity from electrical noise.

4.2.2 Cabling

Standard UTP (unshielded twisted pair) or STP (shielded twisted pair) cables are supported. It is

recommended that a minimum specification CAT5e is used in new installations.

The Ethernet interface on the module supports the 'Auto cross-over detection', therefore a crossover cable is not required when connecting the Ethernet port on the module directly to the Ethernet

port of a PC.

4.2.3 Link / activity indicators

Each Ethernet port has a corresponding link / activity indicator on the topside of the module as

shown in Figure 4-1. Table 4-5 below details the different statuses of the indicators.

Table 4-5 Ethernet link / activity indicator status

Indicator status Description

Off Ethernet connection not detected

Solid green Ethernet connection detected but no data

Flashing green Ethernet connection detected and data flow

information

Safety

Introduction

Mechanical

installation

installation

Electrical

Parameters

Variable allocation

menus

Digital I/O Timer

MCi210 User Guide 11

Issue Number: 2

programming

User

Diagnostics Index

Page 12

4.3 Digital I/O

WARNING

WARNING

The digital I/O circuits are isolated from the power circuits in the drive by basic insulation

(single insulation) only. The installer must ensure that the external control circuits are

insulated from human contact by at least one layer of insulation (supplementary

insulation) rated for use at the AC supply voltage.

If the digital inputs or outputs are to be connected to other circuits classified as Safety

Extra Low Voltage (SELV) (e.g. to a personal computer), an additional isolating barrier

must be included in order to maintain the SELV classification.

The MCi210 is equipped with 3 digital inputs, 1 selectable digital input or output and 1 digital output.

These inputs and outputs can be read to or controlled by the user program in the module.

The digital outputs are a positive logic arrangement with high side drivers only, such that they are at

+24 V when active and can supply a total maximum 20 mA of current shared between the two

outputs. When inactive they are effectively floating. The digital outputs are protected against shortcircuit or overload. The trip threshold is 20 mA, and if tripped both outputs will be deactivated and

the drive will show a "Slotx Error - Output overload" trip (where x indicates the slot number that

module is installed in).

The digital I/O are controlled using menu 4 in the module. Refer to section 5.9 Menu 4 - Digital I/

O on page 35 for more information.

4.3.1 Digital I/O specifications

1 Digital Input 1

2 Digital Input 2

3 Digital Input 3

4 Digital I/O 4 (when configured as an input)

Type Positive logic IEC 61131-2

Maximum input voltage ±30 V

Switching threshold 9.5 V ±0.3 V

Load >2 mA at 15 V

4 Digital I/O 4 (when configured as an output)

5 Digital output 5

Type Positive logic

Output voltage 0 V to 24 V

Maximum output current

6 0 V common

Common to the 0 V of the host drive

20 mA (from one output only or shared between

both outputs)

12 MCi210 User Guide

Issue Number: 2

Page 13

5 Parameters

information

Safety

5.1 Overview

The MCi210 module holds two parameter databases; the MCi210 database and the database for

the drive to which the module is installed.

The MCi210 database parameters can be accessed from the drive’s keypad, a user program in the

MCi210, PC Tools or a module in another slot of the drive. The notation S.mm.ppp is used to

access these parameters where S is the slot number, mm is the menu number and ppp is the

parameter number. For example, to access Pr 03.010 of an MCi210 installed in slot 2 of a drive

from a module in slot 3 it will be accessed using Pr 2.3.010.

The MCi210 module will also hold a copy of the host drive’s database. At power up, if the database

held in the MCi210 is different to that of the drive, the MCi210 will upload the drive's database and

overwrite the stored database. If the two databases match the drive's database will not be

uploaded.

A module that is powered up for the first time will not contain a drive database and therefore will

always perform a drive database upload.

5.2 Menus

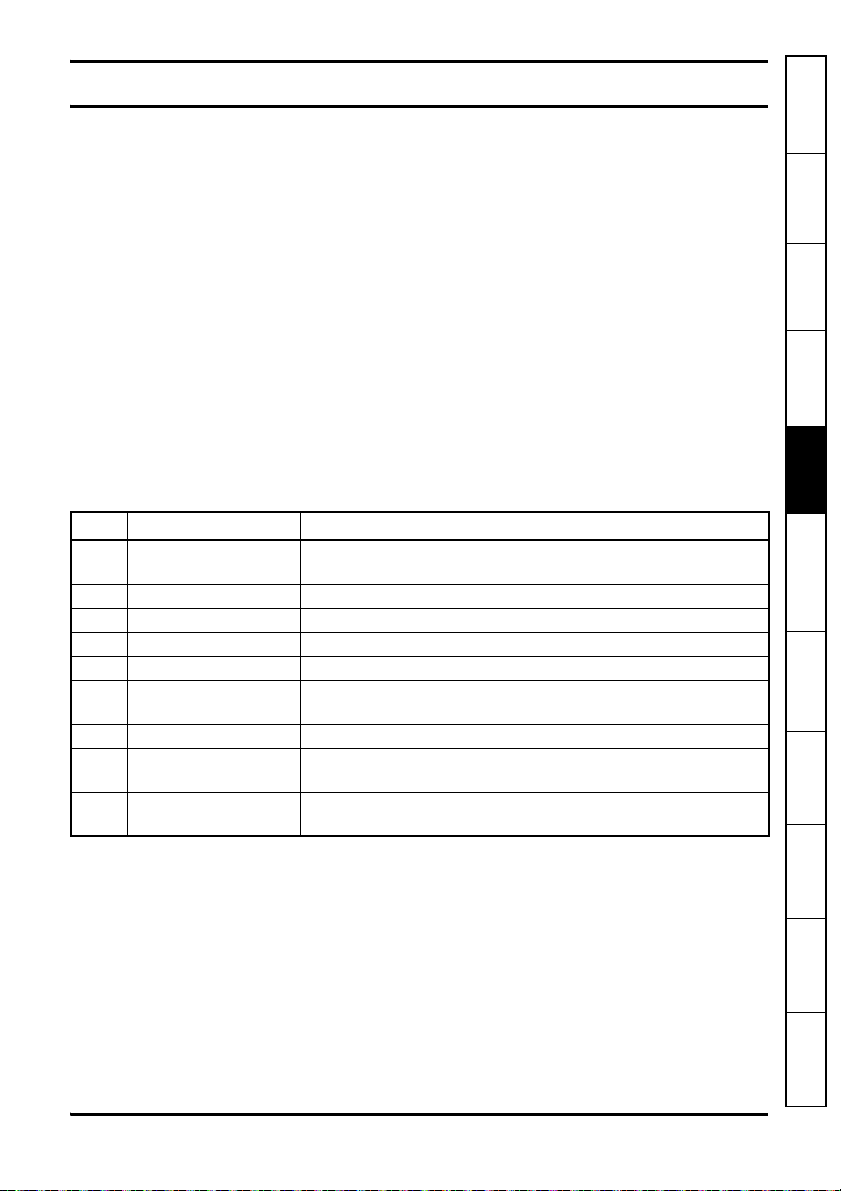

Table 5-1 below details each of the module's internal menus.

Table 5-1 MCi210 Internal Menu descriptions

Menu Name Description

MCi210 module

S.0

information

S.1 User application Allows the user program to be controlled and monitored

S.2 Ethernet configuration Allows the Ethernet interface to be configured

S.3 Timer Allows the timer unit to be controlled

S.4 Digital I/O Allow the digital I/O to be controlled or monitored

S.9 Resources

S.10 Easy mode cyclic data Allows Ethernet cyclic data links to be configured

S.11 Synchronization

S.15 Modbus

Where S is the slot number that the module is installed in.

The module's menu 0 is also displayed in menu 15, 16 or 17 on the drive depending on which slot

the module is installed in. MC Studio can be used to set up a custom or application menu for the

module and if set up, the custom menu will be displayed in menu 25, 26 or 27 depending on which

slot the module is installed in. Table 5-2 below shows the location of module's menu 0 and custom

menu on the drive.

Provides module information such as firmware version and serial

number

Provides information regarding the resources of the Ethernet

interface and module temperature

Allows the Ethernet based synchronization to be set-up and

monitored

Allow the Modbus protocol supported by the Ethernet interface to

be set-up

Introduction

Mechanical

installation

installation

Electrical

Parameters

Variable allocation

menus

Digital I/O

Timer

programming

User

Diagnostics Index

MCi210 User Guide 13

Issue Number: 2

Page 14

Table 5-2 Module's menu 0 and custom menu locations on the drive

Slot number Module’s Menu 0 location

115 25

216 26

317 27

Custom / Application

menu location

5.3 Parameter save and restore

Any user-save parameters in the option module's internal menus are stored in non-volatile memory

on the module and not in the drive. Therefore, if the module is moved to a different slot or to a

different drive then any saved parameter values will follow the module. If a module is to be

replaced, ensure that the parameter values for the module have been backed up before replacing

it.

5.4 Remanent variables

The module supports both Retain and Persistent variables. Both of these types of variable allow

values to be retained after a power-cycle or module reset, however there is a difference between

Retain and Persistent variables.

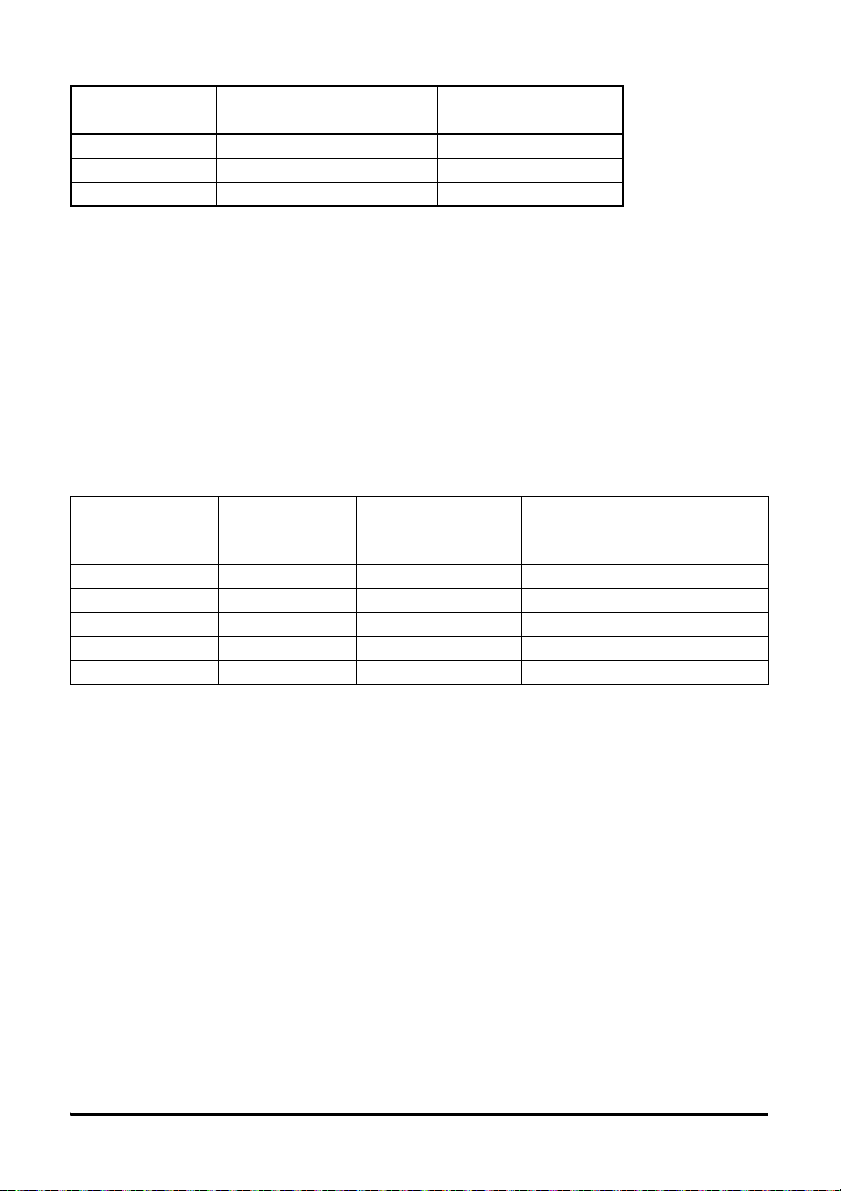

The following table indicates the behaviour of all variable types:

VAR PERSISTENT

Command VAR VAR RETAIN

Reset warm - X X

Reset cold - - X

Reset origin - - -

Online change X X X

Reboot module - X X

Key:

X = Value is maintained

- = Value is initialized

VAR RETAIN PERSISTENT

VAR PERSISTENT RETAIN

RETAIN variables are declared in MC Studio as shown below:

VAR RETAIN

iRem1 : INT; (* 1. Retain variable*)

END_VAR

PERSISTENT variables are declared in MC Studio as shown below:

VAR_GLOBAL PERSISTENT RETAIN

iVarPers1 : DINT; (* 1. Persistent+Retain Variable App1 *)

bVarPers : BOOL; (* 2. Persistent+Retain Variable App1 *)

END_VAR

14 MCi210 User Guide

Issue Number: 2

Page 15

5.4.1 Reset warm

A reset warm is performed from the MC Studio software and will reset only standard variables to

their initialisation values.

5.4.2 Reset cold

A reset cold can be performed from the drive's keypad or MC Studio and will reset RETAIN and

standard variables to their initialisation values.

5.4.3 Reset origin

This reset will reset all (including RETAIN and PERSISTENT) variables to their initialisation values

and will erase the application on the module. This can only be performed from MC Studio.

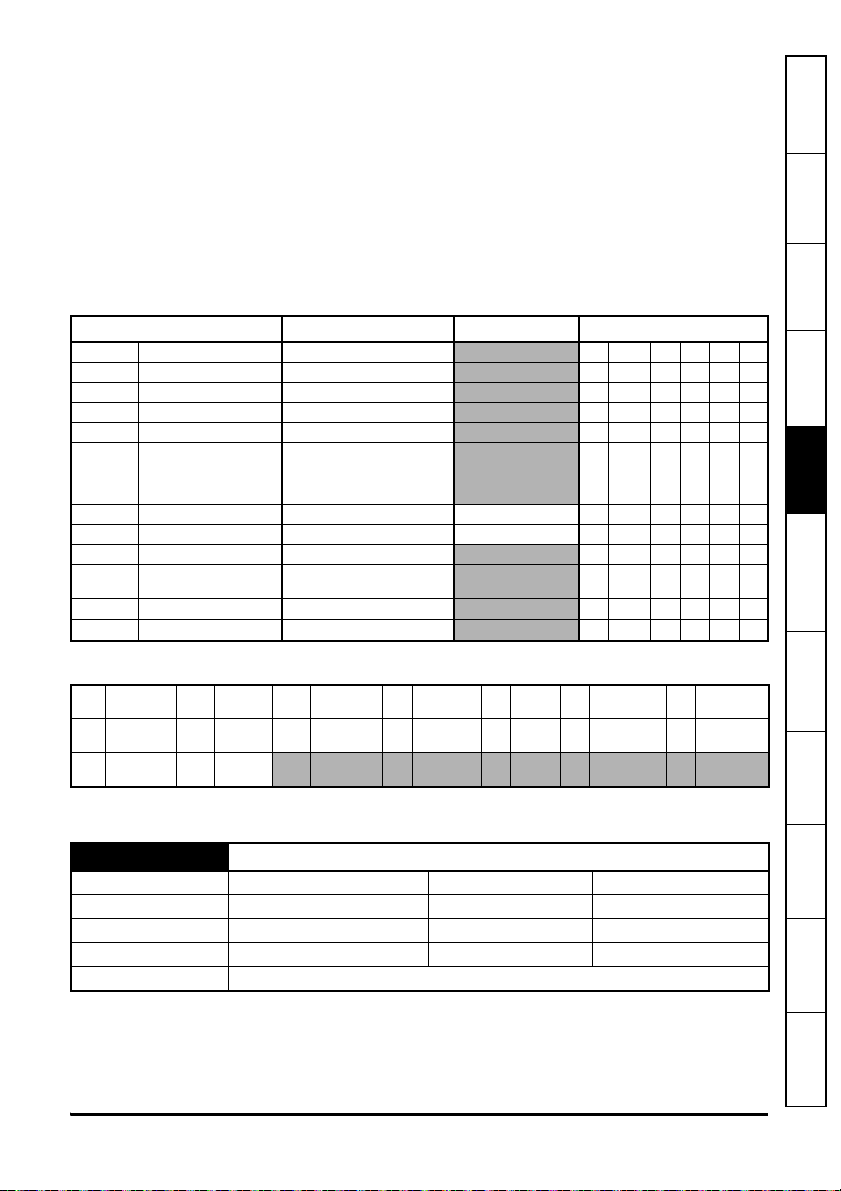

5.5 Menu 0 - MCi210 Module information

Parameter Range Default Type

S.00.001 Module ID 0 to 65535 RO Num ND NC PT

S.00.002 Software Version 00.00.00.00 to 99.99.99.99 RO Num ND NC PT

S.00.003 Hardware Version 0.00 to 99.99 RO Num ND NC PT

S.00.004 Serial Number LS 0 to 99999999 RO Num ND NC PT

S.00.005 Serial Number MS 0 to 99999999 RO Num ND NC PT

Bootldr-Update (-2),

S.00.006 Module Status

S.00.007 Reset Module Off (0) or On (1) Off (0) RW Bit NC

S.00.008 Default Module Off (0) or On (1) Off (0) RW Bit NC

S.00.009 Ac ti ve A la r m B it s 0 to 1111111111111111 RO Bin NC

S.00.010 Active IP Address

S.00.030 Slot Number Indicator 0 to 8 RO Num ND NC PT

S.00.031 Slot Menu Number 0 to 255 RO Num ND NC PT

Bootldr-Idle (-1),

Initializing (0), OK (1),

Config (2), Error (3)

128.000.000.000 to

127.255.255.255

RO Txt ND NC PT

RO IP NC

information

Safety

Introduction

Mechanical

installation

installation

Electrical

Parameters

Variable allocation

menus

Digital I/O

Read /

RW

Write

No default

ND

value

IP IP address Mac

RO

NC

Read

only

Not

copied

Mac

address

Num

PT

Number

parameter

Protected

parameter

Bit

RA

Bit

parameter

Rating

dependent

Txt

US

Text

string

User

save

Bin

PS

Binary

parameter

Powerdown save

FI Filtered

DE Destination

S.00.001 Module ID

Minimum 0 Maximum 65535

Default 310 Units

Type 16 Bit Volatile Update Rate Power-up write

Display Format None Decimal Places 0

Coding RO, ND, NC, PT, BU

This parameter shows the Module ID. This is 310 for the MCi210 module.

MCi210 User Guide 15

Issue Number: 2

Timer

programming

User

Diagnostics Index

Page 16

S.00.002 Software Version

Minimum 0 (Display: 00.00.00.00) Maximum

Default Units

Type 32 Bit Volatile Update Rate Power-up write

Display Format Version Number Decimal Places 0

Coding RO, ND, NC, PT

This parameter shows the Module firmware version in ww.xx.yy.zz format

S.00.003 Hardware Version

Minimum 0.00 Maximum 99.99

Default Units

Type 16 Bit Volatile Update Rate Power-up write

Display Format None Decimal Places 2

Coding RO, ND, NC, PT

This parameter shows the hardware version of the module.

S.00.004 Serial Number LS

Minimum 0 Maximum 99999999

Default Units

Type 32 Bit Volatile Update Rate Power-up write

Display Format None Decimal Places 0

Coding RO, ND, NC, PT

999999

(Display: 99.99.99.99)

S.00.005 Serial Number MS

Minimum 0 Maximum 99999999

Default Units

Type 32 Bit Volatile Update Rate Power-up write

Display Format None Decimal Places 0

Coding RO, ND, NC, PT

The module serial number is available as a pair of 32 bit values where Serial Number LS (S.00.004)

provides the least significant 8 decimal digits and Serial Number MS (S.00.005) provides the most

significant 8 decimal digits. The reconstructed serial number is ((S.00.005 x100000000) +

S.00.004). For example serial number "0001234567898765" would be stored as S.00.005 = 12345,

S.00.004 = 67898765.

16 MCi210 User Guide

Issue Number: 2

Page 17

S.00.006 Module Status

NOTE

NOTE

Minimum -2 Maximum 3

Default Units

Type 8 Bit Volatile Update Rate Background

Display Format None Decimal Places 0

Coding RO, Txt, ND, NC, PT

Value Text Description

-2 Bootldr - Update The bootloader is performing a flash update.

-1 Bootldr - Idle The bootloader is idle.

0 Initializing The module is initializing

1 OK Module is initialized with no errors present

2 Config A configuration error has been detected

3Error

An error has occured preventing the module from running

correctly

This parameter shows the status of the module.

S.00.007 Reset Module

Minimum 0 Maximum 1

Default 0 Units

Type 1 Bit Volatile Update Rate Read every 200 ms

Display Format None Decimal Places 0

Coding RW, NC

When set the module performs a warm reset. When the reset has been performed and the module

is performing its initialization routines the parameter will be cleared to zero.

information

Safety

Introduction

Mechanical

installation

installation

Electrical

Parameters

Variable allocation

menus

Digital I/O

The drive, and any other modules installed to the drive will not be affected by the reset.

S.00.008 Default Module

Minimum 0 Maximum 1

Default 0 Units

Type 1 Bit Volatile Update Rate Read on reset

Display Format None Decimal Places 0

Coding RW, NC

To default the module set this parameter to On (1) and perform a module reset. Once complete, this

parameter will return to Off (0). Defaulting the module will cause it to return to its "Out of Box

configuration" and any settings stored on the module will be returned to their default values. This

will include any web page customizations, e-mail settings, etc.

Take care using this parameter as any configuration information will be irretrievably lost.

The password for the 'root' account is not reset back to default.

MCi210 User Guide 17

Issue Number: 2

Timer

programming

User

Diagnostics Index

Page 18

S.00.009 Active Alarm Bits

Minimum 0 (Display: 0) Maximum

Default Units

Type 16 Bit Volatile Update Rate Background

Display Format Binary Decimal Places 0

Coding RO, NC, BU

Bit Alarm

0 User Program

1eCMP

2 Modbus

3 Ethernet/IP

4 Reserved

5File System

6 Module Too Hot

This parameter displays the currently active alarms. Each bit represents an alarm as detailed in the

table above.

S.00.010 Active IP Address

Minimum

Default Units

Type 32 Bit Volatile Update Rate Background

Display Format IP Address Decimal Places 0

Coding RO, NC, PT

This parameter shows the active IP Address of the module.

-2147483648

(Display: 128.0.0.0)

Maximum

65535

(D ispla y:1111111111111111)

2147483647

(Display:

127.255.255.255)

S.00.030 Slot Number Indicator

Minimum 0 Maximum 8

Default Units

Type 8 Bit Volatile Update Rate Written on power-up

Display Format None Decimal Places 0

Coding RO, ND, NC, PT, BU

This parameter shows the slot number that the module is installed in.

18 MCi210 User Guide

Issue Number: 2

Page 19

S.00.031 Slot Menu Number

Minimum 0 Maximum 255

Default Units

Type 8 Bit Volatile Update Rate Written on power-up

Display Format None Decimal Places 0

Coding RO, ND, NC, PT, BU

This parameter shows the drive menu number associated with the slot that the module is installed

in.

For example:

• If the module is installed in slot 1, this parameter will show 15.

• If the module is installed in slot 2, this parameter will show 16.

• If the module is installed in slot 3, this parameter will show 17.

5.6 Menu 1 - User Application

information

Safety

Introduction

Mechanical

installation

installation

Electrical

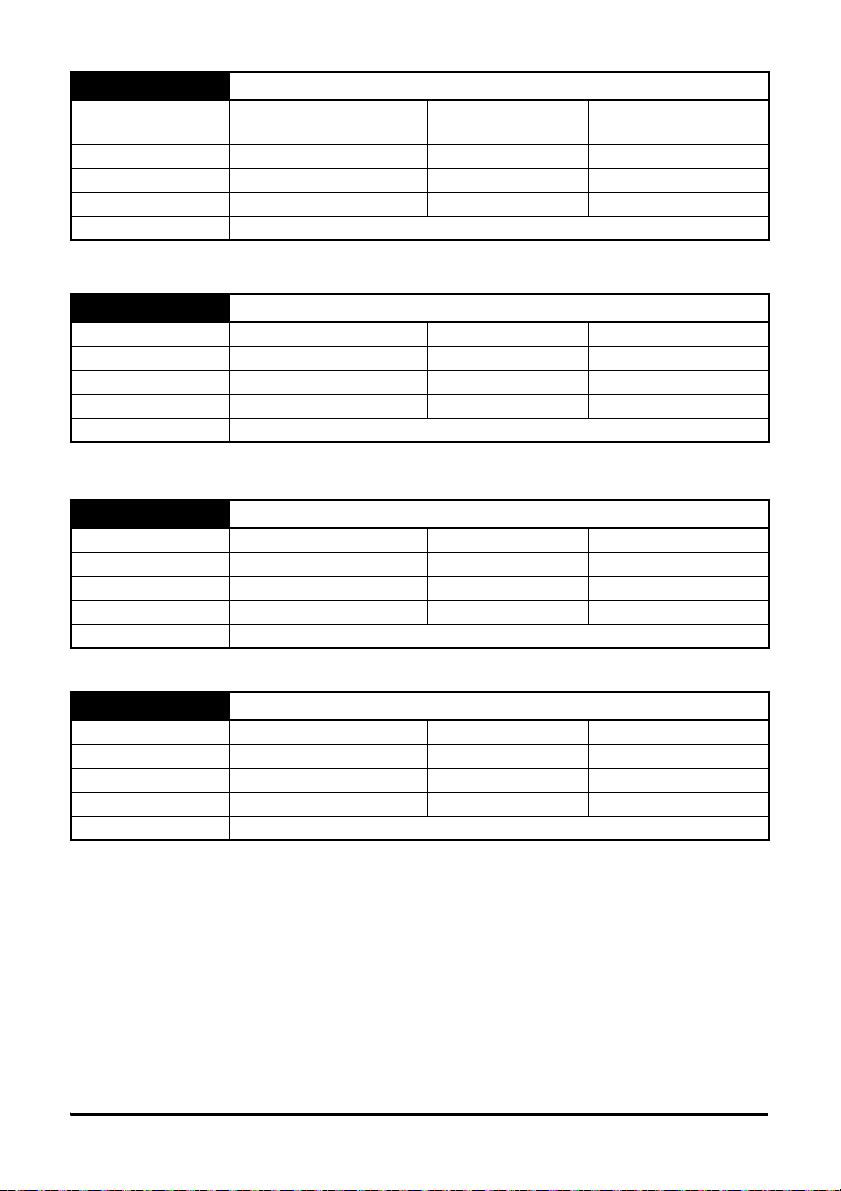

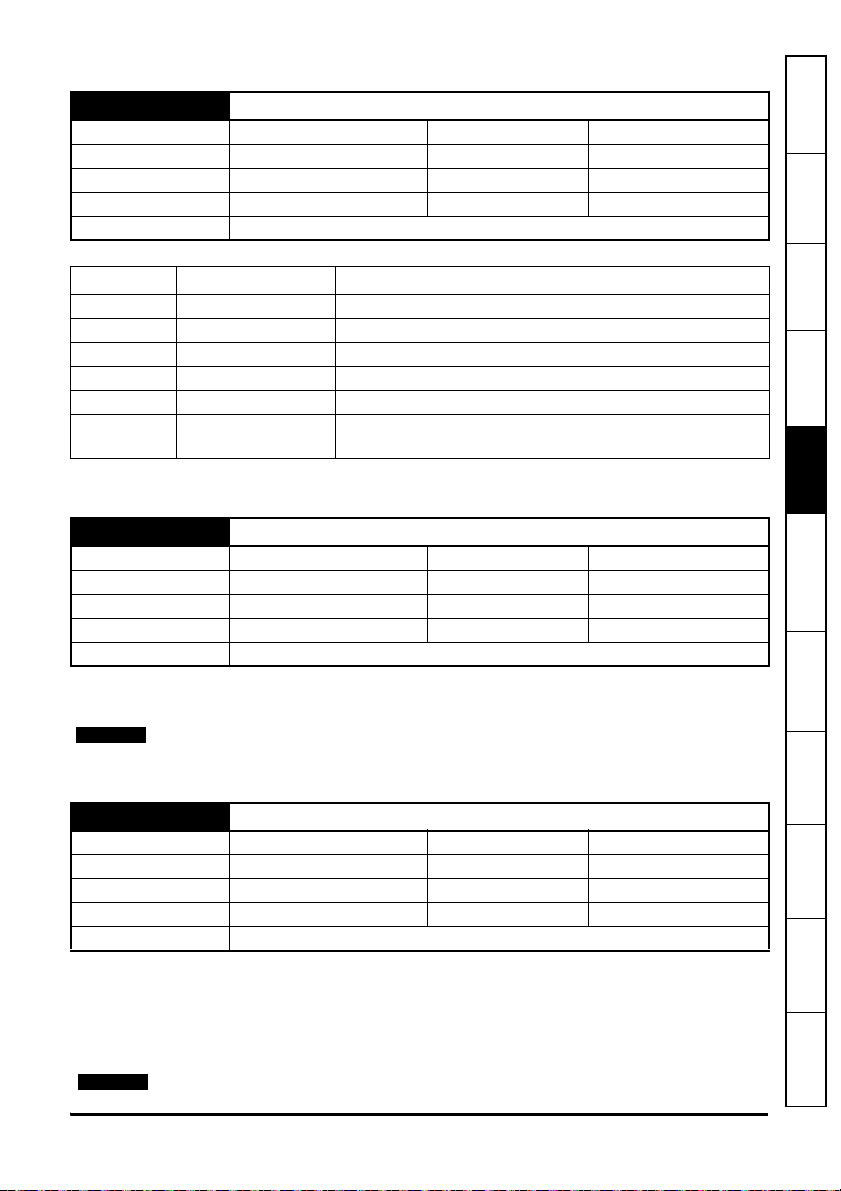

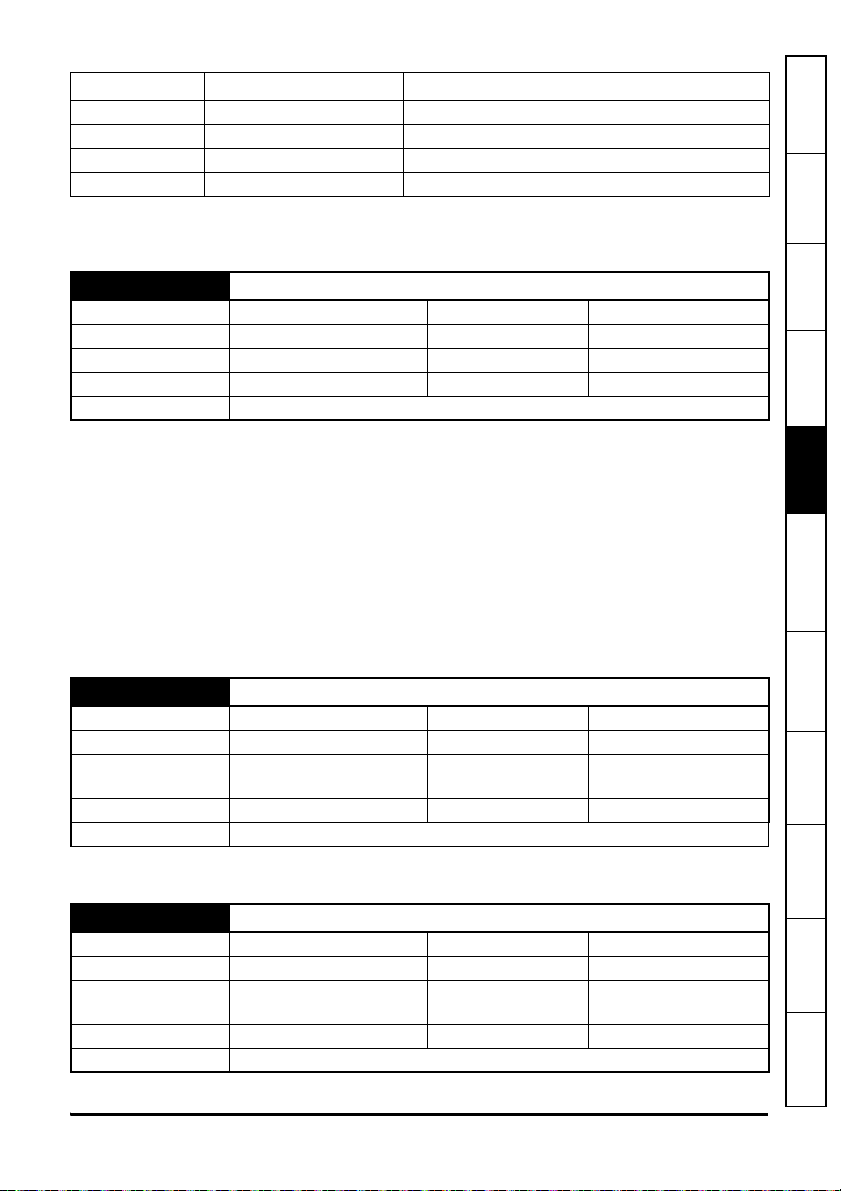

Parameter Range Default Type

S.01.001 Selected UCI Number 0 to 9 0 RW Num ND NC PT

S.01.002 Active UCI Number 0 to 9 RO Num ND NC PT

S.01.003 User Program Status

S.01.004 Available CPU Resources 0 to 100 % RO Num ND PT

S.01.013 Auto-run Enable Off (0), or On (1) On (1) RW Bit US

Global Run-time Trip

S.01.014

Enable

S.01.015 Disable Reset on trip Clear Off (0), or On (1) Off (0) RW Bit US

S.01.017 Enable Out of Range Error Off (0), or On (1) Off (0) RW Bit US

S.01.019 Save Retain Data Request Off (0), or On (1) Off (0) RW Bit NC

Power Down Retain Data

S.01.020

Save

Under Voltage State User

S.01.021

Program Behaviour

S.01.025 Reserved 0 to 2147483647 0 RW

S.01.049 Run time error code 0 to 8448 RO Num ND PT

S.01.050 Run time error task ID

Read /

RW

Write

No default

ND

value

IP IP address Mac

RO

NC

Read

only

Not

copied

Mac

address

None (0), Stopped (1),

Run (2), Error (3)

Off (0), or On (1) Off (0) RW Bit US

Disabled (0), UV (1),

UV (no 24V) (2)

P-S-R (0), S-S-CR-RU (1),

S-S (2)

USER_TASK_INIT (0),

USER_TASK_EVENT0 (1),

USER_TASK_EVENT1 (2),

USER_TASK_EVENT2 (3),

USER_TASK_EVENT3 (4),

USER_TASK_POS (5),

USER_TASK_CLOCK0 (6),

USER_TASK_CLOCK1 (7),

USER_TASK_CLOCK2 (8),

USER_TASK_CLOCK3 (9),

USER_TASK_FWHEEL (10),

TASK_UNKNOWN (11)

Number

Num

PT

SMP

parameter

Protected

parameter

Slot menu

parameter

Bit

RA

Bit

parameter

Rating

dependent

Disabled (0) RW Txt US

S-S-CR-RU (1) RW Txt US

Text

Txt

string

User

US

save

RO Txt PT

RO Txt ND PT

Binary

Bin

parameter

Power-

PS

down save

FI Filtered

DE Destination

Parameters

Variable allocation

menus

Digital I/O

Timer

programming

User

Diagnostics Index

MCi210 User Guide 19

Issue Number: 2

Page 20

S.01.001 Selected UCI number

Minimum 0 Maximum 9

Default 0 Units

Type 8 Bit Volatile Update Rate

Display Format None Decimal Places 0

Coding RW, ND, NC, PT, BU

This parameter specifies which User Customizable Image folder is currently selected and therefore

which user program is launched when the module is initialized. The currently selected folder is used

for any PC Tool downloads and may not be the same as the Active UCI Number.

This allows for multiple user programs / customizations to be stored in the option module. If the

selected UCI has been changed the module must be reset for the new application to become

active.

Please note the difference between the Selected UCI and the Active UCI (Active UCI number

(S.01.002)). The Selected UCI is the image that the user wishes to be active after a module reset,

the Active UCI displays the UCI image currently active.

S.01.002 Active UCI number

Minimum 0 Maximum 9

Default Units

Type 8 Bit Volatile Update Rate Background write

Display Format None Decimal Places 0

Coding RO, ND, NC, PT, BU

This parameter indicates the currently active UCI. All user program control and state parameters

and command relate to the Active UCI except for user program download via eCMP. This allows for

downloading to one UCI folder while running from another.

Note the difference between the Selected UCI (Selected UCI number (S.01.001)) and the Active

UCI. The Selected UCI is the image that the user wishes to be active after a module reset, the

Active UCI displays the UCI image currently active.

Read during

initialization

S.01.003 User Program Status

Minimum 0 Maximum 3

Default Units

Type 8 Bit Volatile Update Rate Background write

Display Format None Decimal Places 0

Coding RO, Txt, ND, PT, BU

This parameter indicates the status of a user program, if it is present. If no user program is present

in the module then it will also indicate this.

If the status indicates a run-time error (3, Error) the user's Error task may be running otherwise the

user program will have stopped.

20 MCi210 User Guide

Issue Number: 2

Page 21

Value Text Description

0 None No user program is present

1 Stopped The user program is not running

2 Run The user program is running

3 Error Run-time error

If the module contains a user program this parameter displays its status otherwise it displays 0 (no

program present).

S.01.004 Available CPU Resources

Minimum 0 Maximum 100

Default Units %

Type 8 Bit Volatile Update Rate Written every 1 s

Display Format None Decimal Places 0

Coding RO, ND, PT, BU

This parameter is updated once per second and shows the average resource free (amount of CPU

resources available for the user non-cyclic tasks) during that period. This parameter is not

calculated synchronously with the cyclic task(s).

Cyclic tasks, with the exception of the freewheeling task, have a higher priority and will normally

have a duration of less than one second so this parameter will give an indication of the average

system free resource, but if cyclic tasks execute for more than one second without being

rescheduled this parameter may show 0 % resource free, as during the most recent sample period

the cyclic tasks took all of the system resource. This is normal.

This parameter is calculated only when the user program is running. When the user program is not

running the parameter is set to 100 %.

information

Safety

Introduction

Mechanical

installation

installation

Electrical

Parameters

Variable allocation

menus

Digital I/O

S.01.013 Auto-run enable

Minimum 0 Maximum 1

Default 1 Units

Type 1 Bit User Save Update Rate

Read during

initialization

Display Format None Decimal Places 0

Coding RW, NR, BU

When set to 1 (On) the user program will start automatically on a module reset or at power up.

S.01.014 Global run-time trip enable

Minimum 0 Maximum 1

Default 0 Units

Type 1 Bit User Save Update Rate

Read during

initialization

Display Format None Decimal Places 0

Coding RW

When set to 1 (On) the module may cause the drive to trip when a run-time error occurs.

MCi210 User Guide 21

Issue Number: 2

Timer

programming

User

Diagnostics Index

Page 22

S.01.015 Disable reset on trip clear

Minimum 0 Maximum 1

Default 0 Units

Type 1 Bit User Save Update Rate Background read

Display Format None Decimal Places 0

Coding RW

When this parameter is 0 the module will reset when a drive trip is cleared. When the parameter is

set to On, the module will continue running (i.e. not reset) when a drive trip is cleared.

S.01.017 Enable out of range error

Minimum 0 Maximum 1

Default 0 Units

Type 16 Bit Volatile Update Rate Background read

Display Format None Decimal Places 0

Coding RW

When this parameter is 0, and an out of range value is written to a parameter, then the value will be

automatically limited to that parameter's maximum or minimum value.

When this parameter is 1, and an out of range value is written to a parameter, then a run-time error

(code 44) will occur.

S.01.019 Save retain data request

Minimum 0 Maximum 1

Default 0 Units

Type 1 Bit Volatile Update Rate Read every 200 ms

Display Format None Decimal Places 0

Coding RW, NC

When set the module will save any retain data that the user has defined, up to a maximum of 2 kB.

When the save is complete, the parameter will be cleared to zero. The save will be processed as a

background task and will not affect any scheduled user tasks.

S.01.020 Power down retain data save

Minimum 0 Maximum 2

Default 1 Units

Type 8 Bit User Save Update Rate

Display Format None Decimal Places 0

Coding RW, Txt, NC

The parameter allows the user to define the action on the retain data when the drive enters under

voltage state.

When set to 0 no action will be taken and the retain data will not be saved.

When set to 1 the retain data will be automatically saved when the drive enters the under voltage

state.

When Under Voltage is

detected

22 MCi210 User Guide

Issue Number: 2

Page 23

When set to 2 the retain data will be automatically saved when the drive enters the under voltage

state, but only if no 24 V backup supply is detected.

Value Text Description

0 Disabled Retain data not automatically saved

1 UV Retain data automatically saved on under voltage

2 UV (no 24V)

Retain data saved on under voltage AND no 24 V backup supply

detected

S.01.021 Under voltage state user program behaviour

Minimum 0 Maximum 2

Default 1 Units

Read when an Under

Type 8 Bit User Save Update Rate

Voltage is detected and

S.01.020 is set to a nonzero value

Display Format None Decimal Places 0

Coding RW, Txt, BU

Value Text Description

0P-S-R

Pause-Save Data- Resume (User Program may trip due task

overrun)

1 S-S-CR-RU Stop-Save-ColdReset-RUn

2 S-S Stop-Save

This parameter defines the user program behaviour when the module detects an Under Voltage

(UV) state.

The action of save resistant / persistent data depends on parameter S.01.020.

information

Safety

Introduction

Mechanical

installation

installation

Electrical

Parameters

Variable allocation

menus

Digital I/O

S.01.049 Run time error code

Minimum 0 Maximum 8448

Default 0 Units

Type 16 Bit Volatile Update Rate Written every second

Display Format None Decimal Places 0

Coding RO, ND, PT, BU

This parameter displays the code for the currently active run-time error.

MCi210 User Guide 23

Issue Number: 2

Timer

programming

User

Diagnostics Index

Page 24

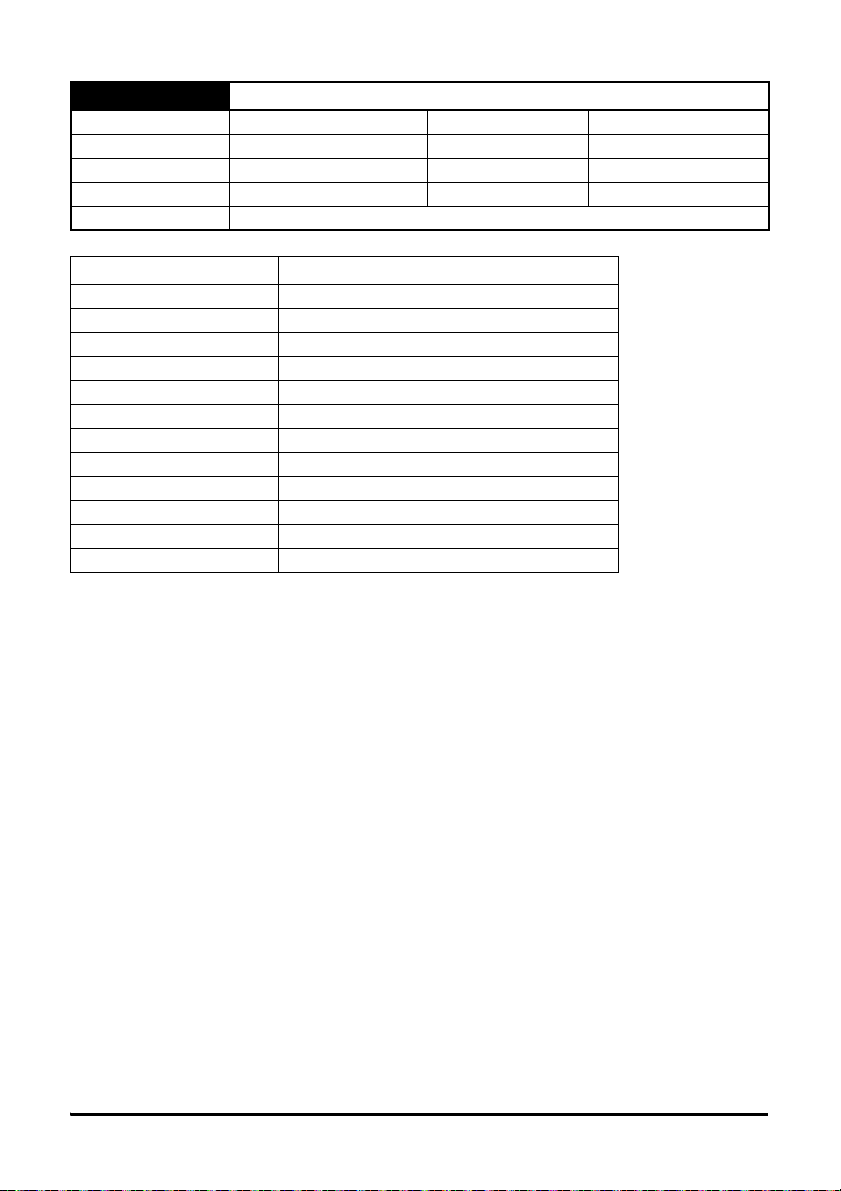

S.01.050 Run time error task ID

Minimum 0 Maximum 11

Default 0 Units

Type 8 Bit Volatile Update Rate Written every second

Display Format None Decimal Places 0

Coding RO, Txt, ND, PT, BU

Value Text

0 USER_TASK_INIT

1 USER_TASK_EVENT0

2 USER_TASK_EVENT1

3 USER_TASK_EVENT2

4 USER_TASK_EVENT3

5 USER_TASK_POS

6 USER_TASK_CLOCK0

7 USER_TASK_CLOCK1

8 USER_TASK_CLOCK2

9 USER_TASK_CLOCK3

10 USER_TASK_FWHEEL

11 TASK_UNKNOWN

This parameter displays the task in error for the currently active run-time error.

24 MCi210 User Guide

Issue Number: 2

Page 25

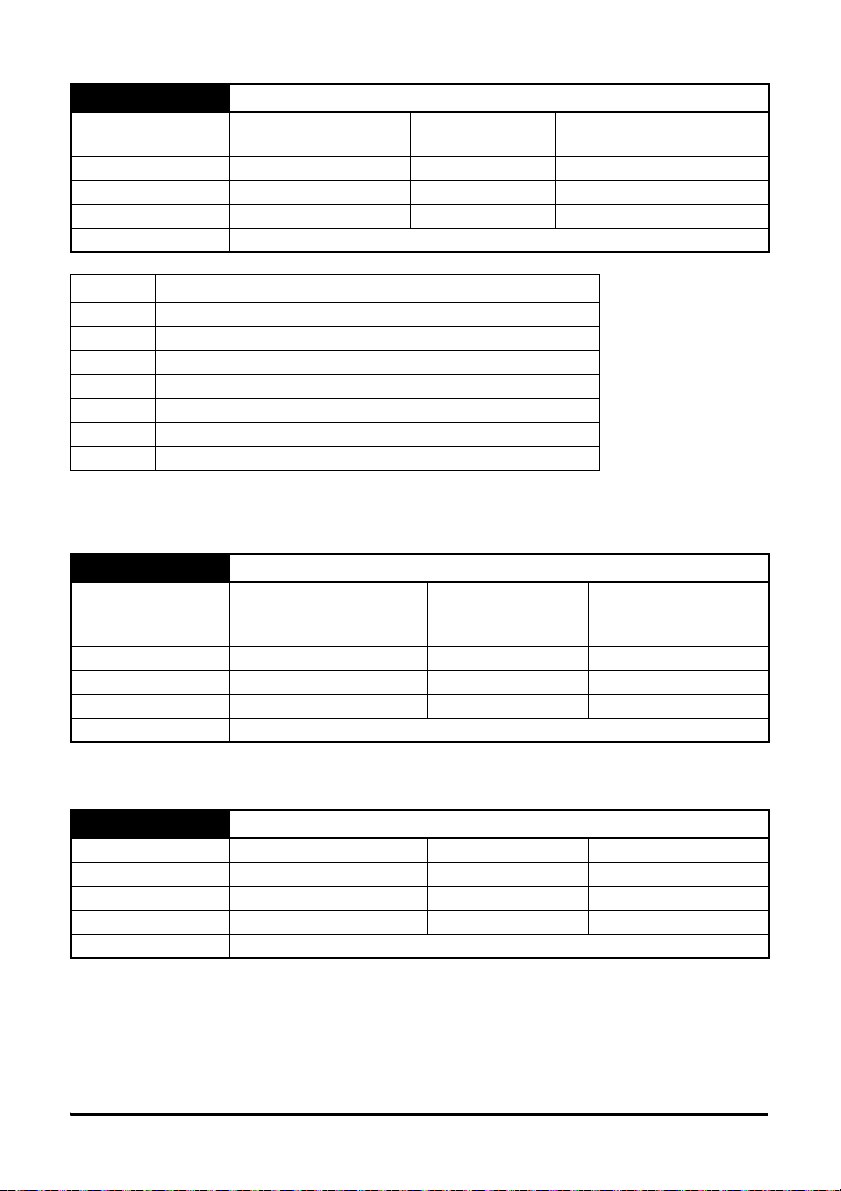

5.7 Menu 2 - Ethernet configuration

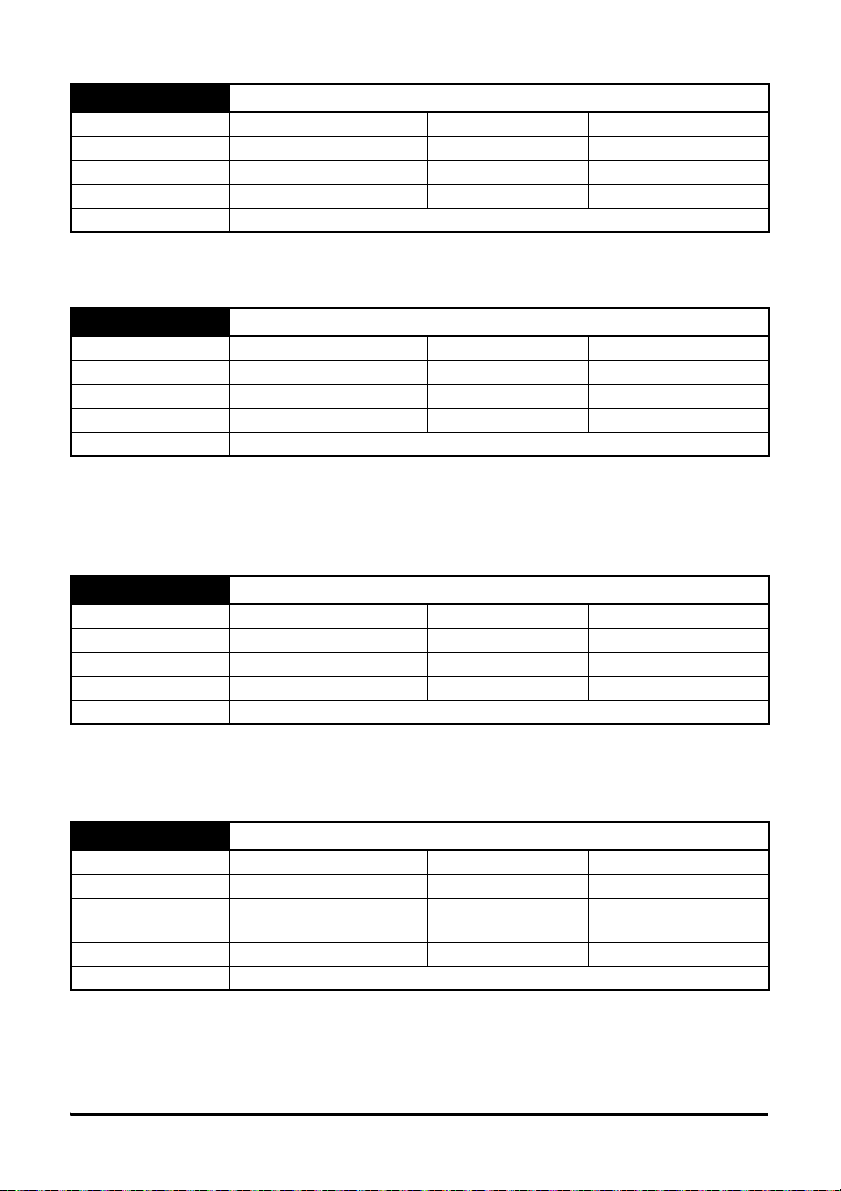

Parameter Range Default Type

Initializing (0),

S.02.003 Network Status

S.02.004

S.02.005 DHCP Enable Off (0) or On (1) On (1) RW Bit US

S.02.006 IP Address

S.02.007 Subnet Mask

S.02.008 Default Gateway

S.02.009 Primary DNS

S.02.010 Secondary DNS

S.02.011 MAC Address

S.02.020 Priority Protocol

S.02.021 Web Server Enable Off (0) or On (1) On (1) RW Bit US

S.02.022 Web Server Port 0 to 65535 80 RW Num US

S.02.023 Email Enable Off (0) or On (1) On (1) RW Bit US

S.02.024 Ethernet MTU 158 to 1500 1500 RW Num US

S.02.025 Gateway Mode

S.02.030 VLAN Enable Off (0) or On (1) Off (0) RW Bit US

S.02.031 VLAN ID 0 to 255 0 RW Num US

Network Message

Count

Links Down (1),

DHCP In Progress (2),

No Address (3),

Ready (4), Active (5)

0 to 65535 RO Num ND NC PT

000.000.000.000 to

255.255.255.255

000.000.000.000 to

255.255.255.255

000.000.000.000 to

255.255.255.255

000.000.000.000 to

255.255.255.255

000.000.000.000 to

255.255.255.255

00:00:00:00:00:00 to

FF:FF:FF:FF:FF:FF

None (0), Modbus TCP (1),

Ethernet/IP (2)

Switch (0), Gateway (1),

Strict Gateway (2)

192.168.001.100 RW IP US

255.255.255.000 RW IP US

192.168.1.254 RW IP US

000.000.000.000 RW IP US

000.000.000.000 RW IP US

0RWTxt US

Switch (0) RW Txt US

RO Txt ND NC PT

RO Mac ND NC PT

information

Safety

Introduction

Mechanical

installation

installation

Electrical

Parameters

Variable allocation

menus

Digital I/O

Read /

RW

Write

No default

ND

value

IP IP address Mac

RO

NC

Read

only

Not

copied

Mac

address

Num

PT

SMP

Number

parameter

Protected

parameter

Slot menu

parameter

Bit

RA

Bit

parameter

Rating

dependent

Txt

US

Text

string

User

save

Bin

PS

Binary

parameter

Powerdown save

FI Filtered

DE Destination

MCi210 User Guide 25

Issue Number: 2

Timer

programming

User

Diagnostics Index

Page 26

S.02.003 Network Status

Minimum 0 Maximum 5

Default Units

Type 8 Bit Volatile Update Rate Written every second

Display Format None Decimal Places 0

Coding RO, Txt, ND, NC, PT, BU

Value Text Description

0 Initializing The network interface is being initialized

1 Links Down

2 DHCP In Progress

3 No Address

4 Ready

5 Active The network interface is receiving or transmitting data

This parameter indicates the status of the network that the module is connected to.

S.02.004 Network Message Count

Minimum 0 Maximum 65535

Default Units Messages/s

Type 16 Bit Volatile Update Rate Written every second

Display Format None Decimal Places 0

Coding RO, ND, NC, PT, BU

The number of frames that the module is transmitting / receiving every second.

No link connection has been detected on either of the Ethernet

ports

The module is attempting to obtain an IP Address, subnet mask,

default gateway and DNS server addresses from a DHCP server

The module does not have an IP Address - either the user has

not provided one manually or one could not be allocated via

DHCP

The network interface has been successfully configured but no

data is being received or transmitted

S.02.005 DHCP Enable

Minimum 0 Maximum 1

Default 1 Units

Type 1 Bit User Save Update Rate Background read

Display Format None Decimal Places 0

Coding RW, BU

This parameter controls whether or not the module will attempt to use a Dynamic Host

Configuration Protocol (DHCP) server to obtain an IP Address, subnet mask, default gateway and

DNS servers.

26 MCi210 User Guide

Issue Number: 2

Page 27

When DHCP is enabled, the following parameters will become read-only immediately (no reset

required):

IP Address (S.02.006)

Subnet Mask (S.02.007)

Default Gateway (S.02.008)

Primary DNS (S.02.009)

Secondary DNS (S.02.010)

information

Introduction

Safety

S.02.006 IP Address

Minimum 0 (Display: 0.0.0.0) Maximum

Default

3232235876

(Display: 192.168.1.100)

Units

4294967295

(Display: 255.255.255.255)

DHCP enabled : write on

Type 32 Bit User Save Update Rate

event; DHCP disabled :

read on reset

Display Format IP Address Decimal Places 0

Coding RW, BU

This parameter controls and displays the IP Address of the module.

If DHCP is enabled (DHCP Enable (S.02.005)) this parameter becomes read-only and, until an IP

Address is allocated to the module, will display 0.0.0.0.

If DHCP is disabled the module will initialize, on reset or power cycle, with the IP Address stored for

the parameter.

S.02.007 Subnet Mask

Minimum 0 (Display: 0.0.0.0) Maximum

Default

4294967040

(Display: 255.255.255.0)

Units

4294967295

(Display:255.255.255.255)

DHCP enabled : write on

Type 32 Bit User Save Update Rate

event; DHCP disabled :

read on reset

Display Format IP Address Decimal Places 0

Coding RW, BU

This parameter controls and displays the subnet mask of the module.

If DHCP is enabled (DHCP Enable (S.02.005)) this parameter becomes read-only and, until an IP

Address is allocated to the module, will display 0.0.0.0.

If DHCP is disabled the module will initialize, on reset or power cycle, with the subnet mask stored

for the parameter.

Mechanical

installation

installation

Electrical

Parameters

Variable allocation

menus

Digital I/O

Timer

programming

User

Diagnostics Index

MCi210 User Guide 27

Issue Number: 2

Page 28

S.02.008 Default Gateway

Minimum 0 (Display: 0.0.0.0) Maximum

Default

Type 32 Bit User Save Update Rate

Display Format IP Address Decimal Places 0

Coding RW, BU

This parameter controls and displays the default gateway of the module.

If DHCP is enabled (DHCP Enable (S.02.005)) this parameter becomes read-only and, until an IP

Address is allocated to the module, will display 0.0.0.0.

If DHCP is disabled the module will initialize, on reset or power cycle, with the default gateway

stored for the parameter.

S.02.009 Primary DNS

Minimum 0 (Display: 0.0.0.0) Maximum

Default 0 (Display: 0.0.0.0) Units

Type 32 Bit User Save Update Rate

Display Format IP Address Decimal Places 0

Coding RW, BU

The module can use this IP Address when it wishes to resolve the IP Address for a domain name.

This parameter performs the same function as the Secondary DNS parameter (Secondary DNS

(S.02.010)), however the address specified in this parameter will be tried first. Only when this

address is unsuccessful will the Secondary DNS address be tried.

If DHCP is enabled (DHCP Enable (S.02.005)) this parameter becomes read-only and, until an IP

Address is allocated to the module, will display 0.0.0.0.

If DHCP is disabled the module will initialize, on reset or power cycle, with the primary DNS

address stored for the parameter.

3232236030

(Display: 192.168.1.254)

Units

4294967295

(Display: 255.255.255.255)

DHCP enabled: write on

event;

DHCP disabled: read on

reset

4294967295

(Display:255.255.255.255)

DHCP enabled: write on

event;

DHCP disabled: read on

reset

28 MCi210 User Guide

Issue Number: 2

Page 29

S.02.010 Secondary DNS

Minimum 0 (Display: 0.0.0.0) Maximum

4294967295

(Display: 255.255.255.255)

Default 0 (Display: 0.0.0.0) Units

DHCP enabled: write on

Type 32 Bit User Save Update Rate

event;

DHCP disabled: read on

reset

Display Format IP Address Decimal Places 0

Coding RW, BU

The module can use this IP Address when it wishes to resolve the IP Address for a domain name.

This parameter performs the same function as the Primary DNS parameter (Primary DNS

(S.02.009)), however the address specified in this parameter will be tried only when the Primary

DNS address is unsuccessful.

If DHCP is enabled (DHCP Enable (S.02.005)) this parameter becomes read-only and, until a

secondary DNS address is allocated to the module, will display 0.0.0.0.

If DHCP is disabled the module will initialize, on reset or power cycle, with the secondary DNS

address stored for the parameter.

S.02.011 MAC Address

Minimum

0 (Display:

00:00:00:00:00:00)

Maximum

281474976710655

(Display: FF:FF:FF:FF:FF:FF)

Default Units

Type 64 Bit Volatile Update Rate Power-up write

Display Format Mac Address Decimal Places 0

Coding RO, ND, NC, PT, BU

This parameter shows the 48-bit MAC address of the module.

information

Safety

Introduction

Mechanical

installation

installation

Electrical

Parameters

Variable allocation

menus

Digital I/O

S.02.020 Priority Protocol

Minimum 0 Maximum 2

Default 0 Units

Type 8 Bit User Save Update Rate Background read

Display Format None Decimal Places 0

Coding RW, Txt, BU

This parameter enables the selection of the fieldbus protocol to have priority over all other

protocols. A tick period of 1 ms will be given to the highest priority fieldbus protocol, 5 ms to all

other fieldbus protocols (equal priority).

If no fieldbus protocol has been selected to have priority over others, all protocols will have equal

priority and a tick rate of 5 ms.

MCi210 User Guide 29

Issue Number: 2

Timer

programming

User

Diagnostics Index

Page 30

Value Text Description

0 None All protocols have equal priority

1 Modbus TCP Modbus TCP has highest priority

2 Ethernet/IP Ethernet/IP has highest priority

S.02.021 Web Server Enable

Minimum 0 Maximum 1

Default 1 Units

Type 1 Bit User Save Update Rate Background read

Display Format None Decimal Places 0

Coding RW, BU

This parameter controls the running of the webserver on the module.

S.02.022 Web Server Port

Minimum 0 Maximum 65535

Default 80 Units

Type 16 Bit User Save Update Rate

Display Format None Decimal Places 0

Coding RW, BU

This parameter shows the web server port. This may be changed for added security.

Read on module reset

and HTTP_ENABLE

S.02.024 Ethernet MTU

Minimum 158 Maximum 1500

Default 1500 Units Bytes

Type 16 Bit User Save Update Rate Read on module reset

Display Format None Decimal Places 0

Coding RW, BU

This parameter specifies the MTU (Maximum Transmittable Unit) in bytes allowed by the Ethernet

interface.

30 MCi210 User Guide

Issue Number: 2

Page 31

S.02.025 Gateway Mode

Minimum 0 Maximum 2

Default 0 Units

Type 8 Bit User Save Update Rate Read on module reset

Display Format None Decimal Places 0

Coding RW, Txt, BU

Value Text

0Switch

1 Gateway

2 Strict Gateway

This parameter specifies the operation mode of the gateway. By default the gateway is disabled

and the switch operates in normal switch mode, by enabling the gateway mode all packets are

filtered by the module and prioritized before being forwarded on. In strict mode the gateway will

drop packets from unsupported protocols.

S.02.030 VLAN Enable

Minimum 0 Maximum 1

Default 0 Units

Type 1 Bit User Save Update Rate Background read

Display Format None Decimal Places 0

Coding RW

This parameter controls whether the module will use VLAN tagging.

When used in conjunction with Drive VLAN ID (S.02.031) network traffic from the interface will be

tagged with the chosen VLAn identifier.

When default values for Drive VLAN ID (S.02.031) is set, enabling this parameter will add VLAN

prioritization to all packets helping to ensure real-time packets are not delayed by those of lower

priority. If disabled, prioritization will use the Diffserv field in IP traffic only, meaning non-IP traffic

can still affect real-time IP traffic.

information

Safety

Introduction

Mechanical

installation

installation

Electrical

Parameters

Variable allocation

menus

Digital I/O

Timer

S.02.031 Drive VLAN ID

Minimum 0 Maximum 255

Default 0 Units

Type 8 Bit User Save Update Rate

Read on module reset

and VLAN_ENABLE

Display Format None Decimal Places 0

Coding RW, BU

This parameter specifies the VLAN ID that the interface will be a member of. Any packets entering

the switch without this VLAN ID will not be handled.

MCi210 User Guide 31

Issue Number: 2

programming

User

Diagnostics Index

Page 32

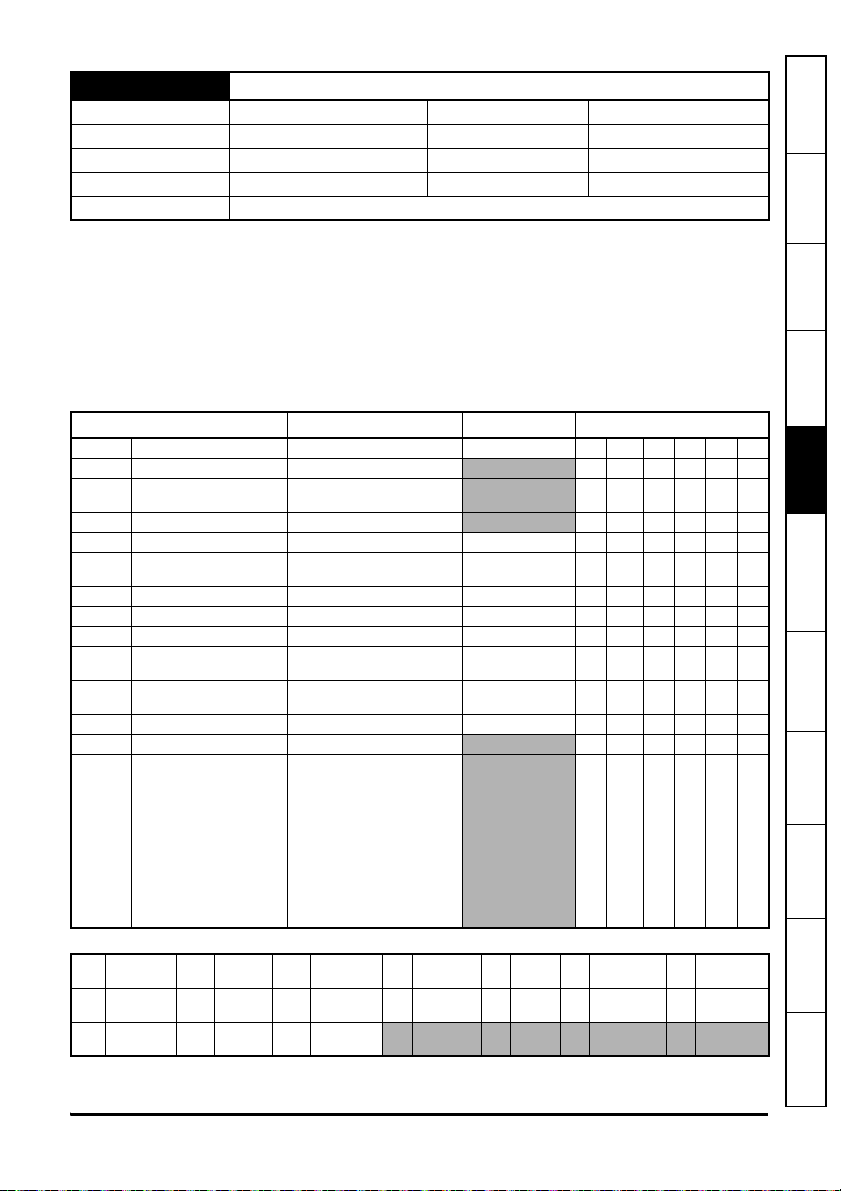

5.8 Menu 3 - Timer

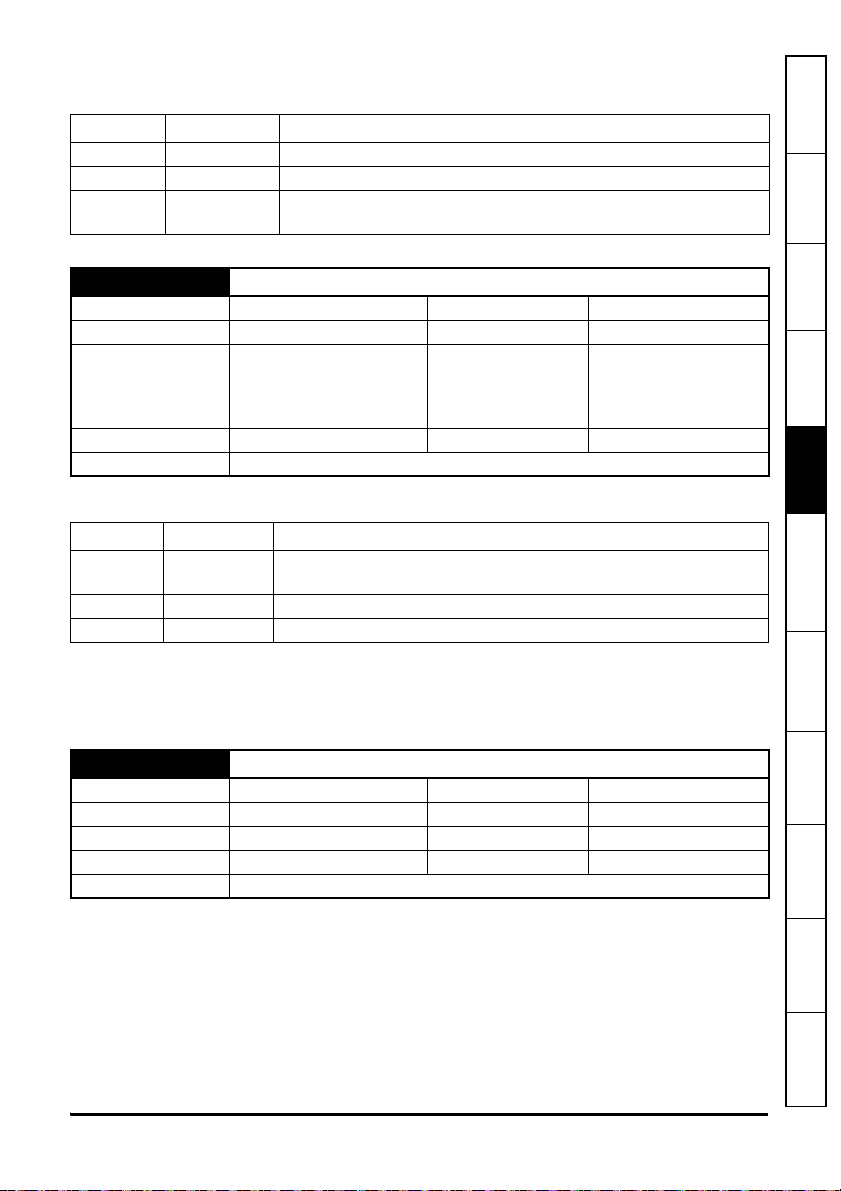

Parameter Range Default Type

S.03.001 Timer Unit Control Word

S.03.002 Timer Unit Status Word 000 to 111 RO Bin ND NC

S.03.003 Timer Unit Timer Counter 0 to 65535 0 RW Num

S.03.004 Timer Unit Wrap Around Limit 0 to 65535 0 RW Num US

S.03.005 Timer Unit Capture Cache 0 to 65535 RO Num

0000000000 to

110 1111100

0000000000 RW Bin US

Read /

RW

Write

No default

ND

value

IP IP address Mac

RO

NC

Read

only

Not

copied

Mac

address

Num

PT

SMP

Number

parameter

Protected

parameter

Slot menu

parameter

Bit

RA

Bit

parameter

Rating

dependent

Txt

US

Text

string

User

save

Bin

PS

Binary

parameter

Powerdown save

FI Filtered

DE Destination

S.03.001 Timer Unit Control Word

Minimum 0 (Display: 0000000000) Maximum 892 (Display: 1101111100)

Default 0 (Display: 0000000000) Units

Type 16 Bit User Save Update Rate Immediate

Display Format Binary Decimal Places 0

Coding RW, BU

This parameter is used to configure and control the Timer Unit.

The Timer Unit control word is a bit-mapped parameter, as shown in the table below:

Bit Description

Event Task Schedule:

Selects the event task that will be scheduled when the Timer Event Flag

(Timer Unit Status Word (S.03.002) b0) is set:

• 0 = No Event task scheduled

0to2

• 1 = Schedule Event0 task

• 2 = Schedule Event1 task

• 3 = Schedule Event2 task

• 4 = Schedule Event3 task

Enable Timer:

3

• 0 = Timer is disabled

• 1 = Timer is enabled

Clock Source:

4

• 0 = Internal clock

• 1 = External clock provided on digital input (DigIn1 or DigIn2, b9 depending)

Internal Clock Rate:

•0 = 50 MHz

• 1 = 12.5 MHz

5to6

• 2 = 3.125 MHz

• 3 = 0.78125 MHz

32 MCi210 User Guide

Issue Number: 2

Page 33

Bit Description

Timer Mode:

• 0 = Free Running Mode

The selected clock drives the counter. The Timer Event Flag (Timer Unit Status Word

(S.03.002) b0) is set on wraparound.

• 1 = Capture Mode 1

The selected clock drives the counter. A rising edge transition on Digital Input 3 causes

the current counter value to be latched into the Timer Capture Cache

(Timer Unit Capture Cache (S.03.005)) parameter and the Timer Event Flag

(Timer Unit Status Word (S.03.002) b0) is set. The counter then continues incrementing

(the Timer Event Flag (Timer Unit Status Word (S.03.002) b0) is not set on wrap-around).

7to8

• 2 = Capture Mode 2

The selected clock drives the counter. A falling edge transition on Digital Input 3 causes

the current counter value to be latched into the Timer Capture Cache

(Timer Unit Capture Cache (S.03.005)) parameter and the Timer Event Flag

(Timer Unit Status Word (S.03.002) b0) is set. The counter then continues incrementing

(the Timer Event Flag (Timer Unit Status Word (S.03.002) b0) is not set on wrap-around).

Note: Every time the Timer Event Flag is set an event task will be scheduled if is

configured (Bit 0-2).

In Free Running Mode (Mode 0) this will only occurs when timer counter wraps around.

In capture modes (Mode 1 and 2) this will only occurs when a rising or falling edge,

respectively, is detected.

External Source Clock selection:

9

• 0 = External clock provided on digital input 1 (Digital Input 1 State (S.04.001))

• 1 = External clock provided on digital input 2 (Digital Input 2 State (S.04.002))

information

Safety

Introduction

Mechanical

installation

installation

Electrical

Parameters

Variable allocation

menus

S.03.002 Timer Unit Status Word

Minimum 0 (Display: 000) Maximum 7 (Display: 111)

Default Units

Type 8 Bit Volatile Update Rate Immediate

Display Format Binary Decimal Places 0

Coding RO,ND,NC, BU

This parameter displays the status of the module's Timer Unit. The following table details the status

word bits.

MCi210 User Guide 33

Issue Number: 2

Digital I/O

Timer

programming

User

Diagnostics Index

Page 34

Bit Description

Timer Event Flag:

• 0 = No event has occurred

• 1 = An event has occurred (see description for Timer Mode ((Timer Unit Control Word

0

1

2

Minimum 0 Maximum 65535

Default 0 Units

Type 16 Bit Volatile Update Rate Immediate

Display Format None Decimal Places 0

Coding RW, BU

This parameter sets or displays the current Timer Unit value.

(S.03.001) bit 7 - bit 8). This flag will not be set if Event Task Schedule

(Timer Unit Control Word (S.03.001) bit 0 - bit 2) is set to zero

Note: This bit is automatically cleared when the parameter is read.

Wrap-around flag:

• 0= Wrap-around has not occurred

• 1= Counter wrap-around has occurred

Note: This bit is automatically cleared when the parameter is read.

Timer Enabled:

• 0 = Timer is disabled

• 1 = Timer is enabled

Note: In case Register is configured the timer cannot be enabled.

S.03.003 Timer Unit Timer Counter

S.03.004 Timer Unit Wrap Around Limit

Minimum 0 Maximum 65535

Default 0 Units

Type 16 Bit User Save Update Rate Immediate

Display Format None Decimal Places 0

Coding RW, BU

This parameter sets the wrap-around limit for the Timer Unit. When the Timer Counter (Timer Unit

Timer Counter (S.03.003)) reaches this value bit 0 of Timer Unit Status Word (S.03.002) will be set

if the Timer Unit is configured to be in free running mode (see Timer Unit Control Word (S.03.001)).

34 MCi210 User Guide

Issue Number: 2

Page 35

S.03.005 Timer Unit Capture Cache

Minimum 0 Maximum 65535

Default 0 Units

Type 16 Bit Volatile Update Rate Immediate

Display Format None Decimal Places 0

Coding RO, BU

This parameter stores the Timer Unit value (Timer Unit Timer Counter (S.03.003)) on a rising or

falling edge transition on the module's digital input 3 if the Timer Mode (as set in Timer Unit Control

Word (S.03.001)) is configured in either capture mode 1 or capture mode 2.

5.9 Menu 4 - Digital I/O

Parameter Range Default Type

S.04.001 Digital Input 1 State Off (0) or On (1) RO Bit ND NC PT

S.04.002 Digital Input 2 State Off (0) or On (1) RO Bit ND NC PT

S.04.003 Digital Input 3 State Off (0) or On (1) RO Bit ND NC PT

S.04.004 Digital Input / Output 4 State Off (0) or On (1) RO Bit ND NC PT

S.04.010 Digital Output 5 Off (0) or On (1) Off (0) RW Bit

Digital Input/Output 4

S.04.011

Demand

S.04.020 Digital Outputs State 00 to 11 00 RW Bin

Digital Input/Output 4

S.04.021

Direction

S.04.022 Event Task Trigger 0 to 4 RO Num ND NC PT

Off (0) or On (1) Off (0) RW Bit

Off (0) or On (1) Off (0) RW Bit

information

Safety

Introduction

Mechanical

installation

installation

Electrical

Parameters

Variable allocation

menus

Read /

RW

Write

No default

ND

value

IP IP address Mac

RO

NC

Read

only

Not

copied

Mac

address

Num

PT

SMP

Number

parameter

Protected

parameter

Slot menu

parameter

Bit

RA

Bit

parameter

Rating

dependent

Txt

US

Text

string

User

save

Bin

PS

Binary

parameter

Powerdown save

FI Filtered

DE Destination

S.04.001 Digital Input 1 State

Minimum 0 Maximum 1

Default Units

Type 1 Bit Volatile Update Rate Immediate

Display Format None Decimal Places 0

Coding RO, ND, NC, PT

When read, this parameter will indicate the state of Digital Input 1. An inactive input (low) will give

the value 0 and active input (high) will give 1.

MCi210 User Guide 35

Issue Number: 2

Digital I/O

Timer

programming

User

Diagnostics Index

Page 36

S.04.002 Digital Input 2 State

Minimum 0 Maximum 1

Default Units

Type 1 Bit Volatile Update Rate Immediate

Display Format None Decimal Places 0

Coding RO, ND, NC, PT

When read, this parameter will indicate the state of Digital Input 2. An inactive input (low) will give

the value 0 and active input (high) will give 1.

S.04.003 Digital Input 3 State

Minimum 0 Maximum 1

Default Units

Type 1 Bit Volatile Update Rate Immediate

Display Format None Decimal Places 0

Coding RO, ND, NC, PT

When read, this parameter will indicate the state of Digital Input 3. An inactive input (low) will give

the value 0 and active input (high) will give 1.

S.04.004 Digital Input/Output 4 State

Minimum 0 Maximum 1

Default Units

Type 1 Bit Volatile Update Rate Immediate

Display Format None Decimal Places 0

Coding RO, ND, NC, PT

When read, this parameter will indicate the state of Digital I/O 4. An inactive input (low) will give the

value 0 and active input (high) will give 1.

When this terminal is configured as an output (using Digital Input/Output 4 Direction (S.04.021)),

this parameter is still accessible and will indicate the state of the terminal not the requested output

value e.g. if the user tries to set the output high, but, due to a wiring error, the output is being held

low, this parameter will give the value 0.

S.04.010 Digital Output 5 State

Minimum 0 Maximum 1

Default 0 Units

Type 1 Bit Volatile Update Rate Immediate

Display Format None Decimal Places 0

Coding RW

When written, this parameter will set the state of Digital Output 5. Setting to 0 will place the output

low and setting to 1 will place the output high.

36 MCi210 User Guide

Issue Number: 2

Page 37

S.04.011 Digital Input/Output 4 Demand

Minimum 0 Maximum 1

Default 0 Units

Type 1 Bit Volatile Update Rate Immediate

Display Format None Decimal Places 0

Coding RW

If Digital I/O 4 is configured as an output (Digital Input/Output 4 Direction (S.04.021)), writing to this

parameter will set the state of Digital I/O 4. Setting to 0 will place the output low and setting to 1 will

place the output high.

#

S.04.020 Digital Outputs State

Minimum 0 (Display: 00) Maximum 3 (Display: 11)

Default 0 (Display: 00) Units

Type 8 Bit Volatile Update Rate Immediate

Display Format Binary Decimal Places 0

Coding RW, ND, NC, BU

Bitmapped parameter that can be used to set Digital I/O 4 Digital Output 5. This parameter is

effectively a combination of Digital Output 5 (S.04.010) and Digital Input/Output 4 Demand

(S.04.011).

Bit Description

Used to control the state of Digital Output 5:

0

• 0 = Output set low

• 1 = Output set high

Used to control the state of Digital IO 4:

• 0 = Output set low

• 1 = Output set high

1

This bit will only have an effect if digital input/output 4 is configured as an output

(Digital Input/Output 4 Direction (S.04.021)).

information

Safety

Introduction

Mechanical

installation

installation

Electrical

Parameters

Variable allocation

menus

Digital I/O

Timer

S.04.021 Digital Input/Output 4 Direction

Minimum 0 Maximum 1

Default 0 Units

Type 1 Bit Volatile Update Rate Immediate

Display Format None Decimal Places 0

Coding RW

Setting this parameter to 0 will configure Digital I/O 4 as an input. Setting it to 1 will configure it as

an output.

MCi210 User Guide 37

Issue Number: 2

programming

User

Diagnostics Index

Page 38

S.04.022 Event Task Trigger

Minimum 0 Maximum 4

Default Units

Type 16 Bit Volatile Update Rate Immediate

Display Format None Decimal Places 0

Coding RO, ND, PT, BU

Used to trigger an event task. When the event task has completed the parameter will be cleared to

zero. The following table details the usage:

Value Description

0 None

1 Trigger Event0

2 Trigger Event1

3 Trigger Event2

4 Trigger Event3

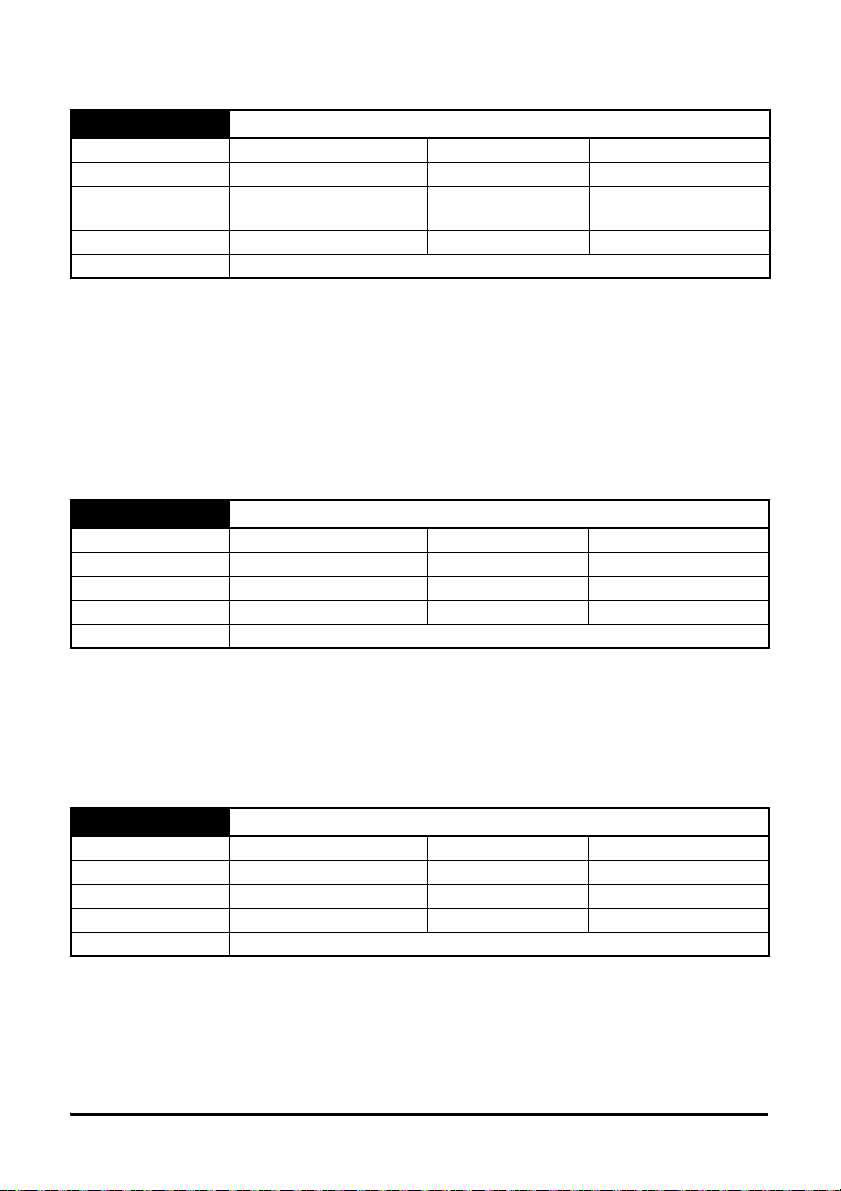

5.10 Menu 9 - Resources

Parameter Range Default Type

S.09.001 Cyclic Tx Links Free 0 to 255 RO Num ND NC

S.09.002 Cyclic Rx Links Free 0 to 255 RO Num ND NC

S.09.003 Fieldbus Links Free 0 to 255 RO Num ND NC

S.09.004 Cyclic Mappings Free 0 to 255 RO Num ND NC

S.09.009 Idle Task % Free 0 to 255 % RO Num ND NC

S.09.010

S.09.020

S.09.030 PCB Temperature -128 to 127 °C RO Num ND NC

Synchronous Task %

Free

Synchronous Task %

Worst Free

0 to 255 % RO Num ND NC

0 to 255 % RO Num ND NC

Read /

RW

Write

No default

ND

value

IP IP address Mac

RO

NC

Read

only

Not

copied

Mac

address

Num

PT

SMP

Number

parameter

Protected

parameter

Slot menu

parameter

Bit

RA

Bit

parameter

Rating

dependent

Txt

US

Text

string

User

save

Bin

PS

Binary

parameter

Powerdown save

FI Filtered

DE Destination

S.09.001 Cyclic Tx Links Free

Minimum 0 Maximum 255

Defaultf Units

Type 8 Bit Volatile Update Rate Background write

Display Format None Decimal Places 0

Coding RO, ND, NC, BU

This parameter shows the number of available transmit cyclic links.

38 MCi210 User Guide

Issue Number: 2

Page 39

S.09.002 Cyclic Rx Links Free

Minimum 0 Maximum 255

Default Units

Type 8 Bit Volatile Update Rate Background write

Display Format None Decimal Places 0

Coding RO, ND, NC, BU

This parameter shows the number of available receive cyclic links.

S.09.003 Fieldbus Links Free

Minimum 0 Maximum 255

Default Units

Type 8 Bit Volatile Update Rate Background write

Display Format None Decimal Places 0

Coding RO, ND, NC, BU

This parameter shows the number of available transmit / receive process images for fieldbus

protocols such as Ethernet/IP.

information

Safety

Introduction

Mechanical

installation

installation

Electrical

Parameters

S.09.004 Cyclic Mappings Free

Minimum 0 Maximum 255

Default Units

Type 8 Bit Volatile Update Rate Background write

Display Format None Decimal Places 0

Coding RO, ND, NC, BU

This parameter shows the number of available mappings in the system for use in cyclic links.

S.09.009 Idle Task % Free

Minimum 0 Maximum 255

Default Units %

Type 8 Bit Volatile Update Rate Background write

Display Format None Decimal Places 0

Coding RO, ND, NC, BU

This parameter shows the current resource available for the idle task.

S.09.010 Synchronous Task % Free

Minimum 0 Maximum 255

Default Units %

Type 8 Bit Volatile Update Rate Background write

Display Format None Decimal Places 0

Coding RO, ND, NC, BU

This parameter shows the current resource available for the synchronous task.

Variable allocation

menus

Digital I/O

Timer

programming

User

Diagnostics Index

MCi210 User Guide 39

Issue Number: 2

Page 40

S.09.020 Synchronous Task Worst % Free

Minimum 0 Maximum 255

Default Units %

Type 8 Bit Volatile Update Rate Background write

Display Format None Decimal Places 0

Coding RO, ND, NC, BU

This parameter shows the worst case free resource of the synchronous task.

S.09.030 PCB Temperature

Minimum -128 Maximum 127

Default Units °C

Type 8 Bit Volatile Update Rate Background write

Display Format None Decimal Places 0

Coding RO, ND, NC