Page 1

NetSure™ ACU+ (Advanced Control Unit Plus)

User Instructions, UM1M820BNA (Issue AH, March 4, 2013)

Specification Number: 1M820BNA, 1M820DNA

Model Number: M820B, M820D

Page 2

This page is intentionally blank.

Page 3

User Instructions UM1M820BNA

Spec No. 1M820BNA (Model M820B) Issue AH, March 4, 2013

Spec No. 1M820DNA (Model M820D)

TABLE OF CONTENTS

Chapter 1. Introduction .......................................................................................................... 1

1.1 Preface ......................................................................................................................................................... 1

1.2 Overview....................................................................................................................................................... 1

1.3 Function Descriptions ................................................................................................................................... 2

1.3.1 Rectifier Control ................................................................................................................................ 2

1.3.2 Converter Control ............................................................................................................................. 2

1.3.3 System Components Monitoring and System Alarms Generation ................................................... 3

1.3.4 Operating Data Acquisition and Data Logs ...................................................................................... 3

1.3.5 Battery Management ........................................................................................................................ 4

1.3.6 Intelligent Power Matching (Energy Optimization Mode) ................................................................. 8

1.3.7 Power Split Feature .......................................................................................................................... 9

1.3.8 Diesel Management Feature ............................................................................................................ 9

1.3.9 PLC (Programmable Logic Controller) Function ............................................................................ 10

1.3.10 Supervisory Module (SM Modules) Monitoring .............................................................................. 10

1.3.11 Hybrid Control Function .................................................................................................................. 10

1.3.12 Maximum Current Limit Function.................................................................................................... 15

Chapter 2. Operation ............................................................................................................ 16

2.1 Local Indicators .......................................................................................................................................... 16

2.2 Passwords and Access Levels ................................................................................................................... 17

2.3 Local Keypad and Display Access ............................................................................................................. 18

2.3.1 Local Menu Navigation Keys and LCD Display .............................................................................. 18

2.3.2 Local Display Menus ...................................................................................................................... 18

2.4 WEB Interface Access ................................................................................................................................ 19

2.4.1 Overview ......................................................................................................................................... 19

2.4.3 WEB Interface Menus ..................................................................................................................... 19

2.4.4 Connecting the Controller Locally (via the Ethernet Port) .............................................................. 19

2.4.5 Disabling Proxy Server Settings to Enable a Connection to the Controller over an Intranet

Network (if required) ....................................................................................................................... 20

2.4.6 Logging into the Controller ............................................................................................................. 21

2.5 Common Tasks Performed via the Local Keypad and/or Web Interface ................................................... 22

2.5.1 Backing Up the Configuration ......................................................................................................... 22

2.5.2 Reloading a Backed-Up Configuration ........................................................................................... 22

2.5.3 Reloading the Configuration File Stored in the ACU+ Controller ................................................... 22

2.5.4 Downloading a Configuration or an Application ("All") Package into the ACU+ Controller ............ 23

2.5.5 Rebooting the Controller ................................................................................................................. 24

2.5.6 Changing the Local LCD Display Contrast ..................................................................................... 24

2.5.7 Disabling the Local Keypad Sound ................................................................................................ 24

2.5.8 Changing the Date .......................................................................................................................... 24

2.5.9 Changing the Time ......................................................................................................................... 24

2.5.10 Adding, Deleting, and Modifying Users .......................................................................................... 24

2.5.11 Assigning Severity Level to Alarms ................................................................................................ 24

Table of Contents i

This document is property of Emerson Network Power, Energy Systems, North America, Inc. and contains confidential and proprietary information owned by Emerson Network Power, Energy

Systems, North America, Inc. Any copying, use, or disclosure of it without the written permission of Emerson Network Power, Energy Systems, North America, Inc. is strictly prohibited.

Page 4

UM1M820BNA User Instructions

Issue AH, March 4, 2013 Spec No. 1M820BNA (Model M820B)

Spec No. 1M820DNA (Model M820D)

2.5.12 Assigning Relays to Alarms ............................................................................................................ 25

2.5.13 Changing the Names of Items Displayed in the LCD and Web-Interface Menus .......................... 25

2.5.14 Viewing Alarms ............................................................................................................................... 25

2.5.15 Clearing Rectifier Lost, Rectifier Communication Fail, Converter Lost, Converter

Communication Fail, and All Converter Comm Fail Alarms ........................................................... 25

2.5.16 Clearing SMTemp Lost and SMTemp Probe Alarms ..................................................................... 25

2.5.17 Clearing Battery Alarms .................................................................................................................. 25

2.5.18 Clearing Logs.................................................................................................................................. 25

2.5.19 Clearing the Maintenance Alarm .................................................................................................... 26

2.5.20 Viewing the ACU+ Controller’s Device Inventory ........................................................................... 26

2.5.21 Updating the ACU+ Controller’s Device Inventory ......................................................................... 26

2.5.22 Programming the Audible Alarm Feature ....................................................................................... 26

2.5.23 Blocking Alarms .............................................................................................................................. 26

2.5.24 Configuring the ACU+ Identification of Rectifiers and Assigning which Input Phase is

Connected to the Rectifiers ............................................................................................................ 27

2.5.25 Configuring the ACU+ Identification of Converters ........................................................................ 28

2.5.26 Viewing/Changing the Float Voltage Setting .................................................................................. 29

2.5.27 Viewing/Changing the Equalize Voltage Setting ............................................................................ 29

2.5.28 Setting Digital Inputs ....................................................................................................................... 29

2.5.29 Setting Temperature Sensors ......................................................................................................... 29

2.5.30 Setting Battery Charge Temperature Compensation ..................................................................... 30

2.5.31 Setting Auto Equalize ..................................................................................................................... 30

2.5.32 Setting Battery Parameters ............................................................................................................ 31

2.5.34 Setting Battery Block and Battery Midpoint Monitoring (if equipped with an EIB Assembly) ......... 31

2.5.35 Setting IP Communications Parameters ........................................................................................ 31

2.5.36 Setting External Shunts (connected to the EIB Assembly) ............................................................ 31

2.5.37 Setting External Shunts (connected to the SM-DU+ Assembly) .................................................... 31

2.5.38 Setting the Load Current Alarm ...................................................................................................... 32

2.5.39 Placing the System in Float or Equalize Charge Mode .................................................................. 32

2.5.40 Manually Forcing Relays ................................................................................................................ 32

2.5.41 Manually Forcing LVDs .................................................................................................................. 32

2.5.42 Using the Relay Test Feature ......................................................................................................... 33

2.5.43 Spec. No. 588820300 Battery Rack System (Lithium Ion Battery Configuration) .......................... 34

2.6 Available Alarms ......................................................................................................................................... 35

2.7 Power Split Feature .................................................................................................................................... 73

2.7.1 Overview ......................................................................................................................................... 73

2.7.2 How Power Split Works .................................................................................................................. 73

2.7.3 Operating Modes ............................................................................................................................ 74

2.7.4 Requirements and Conditions ........................................................................................................ 74

2.7.5 Paralleling the Existing and ACU+ Power Systems ....................................................................... 75

2.7.6 Programming the ACU+ Power Split Feature ................................................................................ 77

2.7.7 Verifying the Operation of the Power Split Feature ........................................................................ 79

Chapter 3. Local Display Menus .......................................................................................... 80

3.1 Overview..................................................................................................................................................... 80

ii Table of Contents

This document is property of Emerson Network Power, Energy Systems, North America, Inc. and contains confidential and proprietary information owned by Emerson Network Power, Energy

Systems, North America, Inc. Any copying, use, or disclosure of it without the written permission of Emerson Network Power, Energy Systems, North America, Inc. is strictly prohibited.

Page 5

User Instructions UM1M820BNA

Spec No. 1M820BNA (Model M820B) Issue AH, March 4, 2013

Spec No. 1M820DNA (Model M820D)

3.2 Menus ......................................................................................................................................................... 80

3.2.1 Adjustment Range Restrictions ...................................................................................................... 81

3.3 Description of Local Display (and Web Interface) Menus Line Items ........................................................ 92

3.3.1 Settings Menu ................................................................................................................................. 92

3.3.2 ECO Mode (Energy Optimization) Menu ...................................................................................... 106

3.3.3 Manual Menu ................................................................................................................................ 106

3.3.4 Quick Setting Menu ...................................................................................................................... 109

Chapter 4. WEB Interface Menus ....................................................................................... 113

4.1 Overview................................................................................................................................................... 113

4.2 Homepage ................................................................................................................................................ 113

4.3 Menu Navigation Window......................................................................................................................... 115

4.3.1 Alarms ........................................................................................................................................... 116

4.4 Device Information Menu ......................................................................................................................... 118

4.4.1 Rectifier Group.............................................................................................................................. 118

4.4.2 Battery Group (except Li-Ion Battery Configuration) .................................................................... 123

4.4.3 Battery Group (Li-Ion Battery Configuration) ................................................................................ 128

4.5 Quick Settings Menu ................................................................................................................................ 130

4.6 Query Menu .............................................................................................................................................. 131

4.6.1 Alarm History Log Sub-Menu ....................................................................................................... 131

4.6.2 Data History Log Sub-Menu ......................................................................................................... 132

4.6.3 Control/System/Diesel Log Sub-Menu ......................................................................................... 133

4.6.4 Battery Test Log Sub-Menu .......................................................................................................... 134

4.7 Maintenance Menu ................................................................................................................................... 135

4.7.1 Network Configuration Sub-Menu ................................................................................................ 135

4.7.2 NMS (Network Management System) Configuration Sub-Menu .................................................. 136

4.7.3 HLMS (High Level Management System) Configuration Sub-Menu ............................................ 137

4.7.4 Edit PowerSplit Sub-Menu ............................................................................................................ 138

4.7.5 User Information Settings Sub-Menu ........................................................................................... 139

4.7.6 Clear Data Sub-Menu ................................................................................................................... 141

4.7.7 Restore Factory Defaults Sub-Menu ............................................................................................ 142

4.7.8 Download Sub-Menu .................................................................................................................... 143

4.7.9 Retrieve ‘SettingParam.run’ File Sub-Menu ................................................................................. 145

4.7.10 Time Sync Sub-Menu ................................................................................................................... 146

4.7.11 System Inventory Sub-Menu ........................................................................................................ 147

4.8 Configuration Menu .................................................................................................................................. 148

4.8.1 Auto Configuration Sub-Menu ...................................................................................................... 148

4.8.2 Site Information Modification Sub-Menu ...................................................................................... 149

4.8.3 Equipment Information Modification Sub-Menu ........................................................................... 150

4.8.4 Signal Information Modification Sub-Menu ................................................................................... 151

4.8.5 Alarm Suppressing Sub-Menu...................................................................................................... 153

4.8.6 PLC Sub-Menu ............................................................................................................................. 155

4.8.7 Alarm Relay Sub-Menu ................................................................................................................ 158

Table of Contents iii

This document is property of Emerson Network Power, Energy Systems, North America, Inc. and contains confidential and proprietary information owned by Emerson Network Power, Energy

Systems, North America, Inc. Any copying, use, or disclosure of it without the written permission of Emerson Network Power, Energy Systems, North America, Inc. is strictly prohibited.

Page 6

UM1M820BNA User Instructions

Issue AH, March 4, 2013 Spec No. 1M820BNA (Model M820B)

Spec No. 1M820DNA (Model M820D)

Chapter 5. Accessing the Controller via a Network Management System (NMS) ......... 159

5.1 General ..................................................................................................................................................... 159

5.2 NMS Supported by SNMP Agent ............................................................................................................. 159

5.3 MIB Installation ......................................................................................................................................... 159

5.3.1 Installation ..................................................................................................................................... 159

5.3.2 Contents of the Controller’s MIB................................................................................................... 159

5.4 Accessing the Controller through an NMS ............................................................................................... 163

5.4.1 Apply Administrative Authority ...................................................................................................... 163

Chapter 6. Replacement Procedures ................................................................................ 164

6.1 ACU+ Controller Replacement ................................................................................................................. 164

Chapter 7. Specifications ................................................................................................... 166

Revision Record ................................................................................................................... 168

iv Table of Contents

This document is property of Emerson Network Power, Energy Systems, North America, Inc. and contains confidential and proprietary information owned by Emerson Network Power, Energy

Systems, North America, Inc. Any copying, use, or disclosure of it without the written permission of Emerson Network Power, Energy Systems, North America, Inc. is strictly prohibited.

Page 7

User Instructions UM1M820BNA

Spec No. 1M820BNA (Model M820B) Issue AH, March 4, 2013

Spec No. 1M820DNA (Model M820D)

CHAPTER 1. INTRODUCTION

1.1 Preface

These instructions describe the complete functionality of the ACU+ Controller. Some functionality is

dependent on hardware connected to the ACU+ Controller. Your system may not utilize all the

functionality described.

Refer also to the ACU+ Configuration Drawing (C-drawing) furnished with your system for a list of factory

default settings.

1.2 Overview

The ACU+ Controller performs the following functions.

Rectifier Control, including an Energy Optimization Mode

Converter Control

System Components Monitoring and System Alarms Generation

(including recording alarms in logs)

Operating Data Acquisition and Data Logs

Battery Management

Intelligent Power Matching (Energy Optimization Mode)

Power Split Feature

Diesel Management Feature

PLC (Programmable Logic Controller) Function

Supervisory Module (SM Modules) Monitoring

Hybrid Control Function

Maximum Current Limit Function

The ACU+ controls the system automatically via configured parameters.

A User interfaces with the ACU+ Controller locally using the local keypad and LCD display or

locally/remotely using the WEB Interface.

The ACU+ Controller can also be accessed via SNMP (v1 and v2).

Chapter 1. Introduction 1

This document is property of Emerson Network Power, Energy Systems, North America, Inc. and contains confidential and proprietary information owned by Emerson Network Power, Energy

Systems, North America, Inc. Any copying, use, or disclosure of it without the written permission of Emerson Network Power, Energy Systems, North America, Inc. is strictly prohibited.

Page 8

UM1M820BNA User Instructions

Issue AH, March 4, 2013 Spec No. 1M820BNA (Model M820B)

Spec No. 1M820DNA (Model M820D)

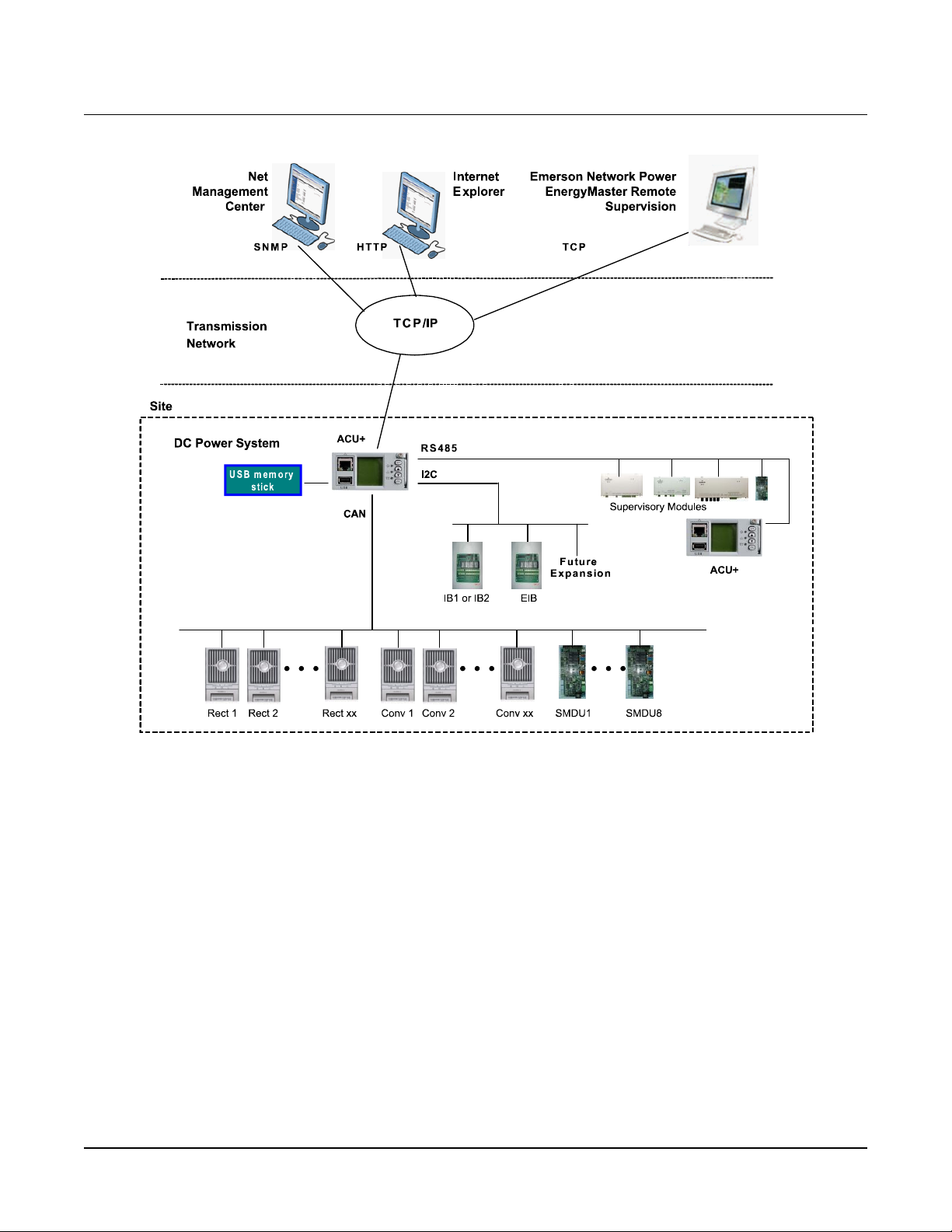

Figure 1 illustrates the various methods to interface with the ACU+ Controller remotely.

Figure 1

ACU+ Remote Communications

1.3 Function Descriptions

1.3.1 Rectifier Control

Rectifiers are automatically controlled by the ACU+ Controller. The ACU+ Controller provides an Energy

Optimization Mode function. Energy Optimization permits an installation to only operate rectifiers as

needed to maintain the load and keep batteries in a fully charged condition. As load increases, Energy

Optimization turns on additional rectifiers as needed to maintain the load. As load decreases, Energy

Optimization places rectifiers in standby to conserve energy usage. Rectifiers which are always operating

to maintain any load requirements are cycled through the group of rectifiers controlled by this feature to

provide uniform operating times for each rectifier.

1.3.2 Converter Control

Converters are automatically controlled by the ACU+ Controller.

2 Chapter 1. Introduction

This document is property of Emerson Network Power, Energy Systems, North America, Inc. and contains confidential and proprietary information owned by Emerson Network Power, Energy

Systems, North America, Inc. Any copying, use, or disclosure of it without the written permission of Emerson Network Power, Energy Systems, North America, Inc. is strictly prohibited.

Page 9

User Instructions UM1M820BNA

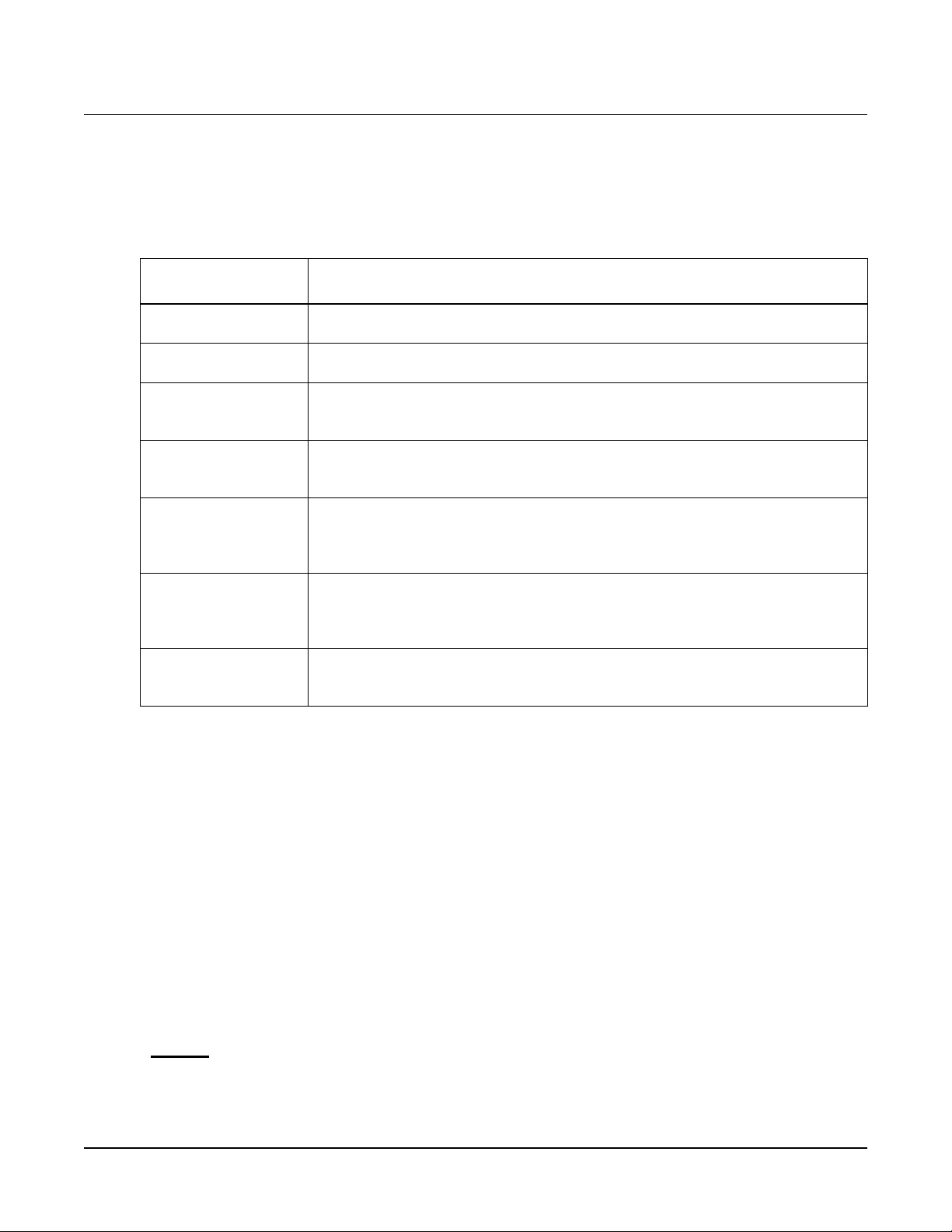

Alarm

Severity Level

ACU+ Red

Alarm Indicator

ACU+ Yellow

Alarm Indicator

ACU+

Audible Alarm

Critical Alarm (CA)

ON

OFF

ON

Major Alarm (MJ)

ON

OFF

ON

Minor Alarm (MN)

OFF

ON

OFF

No Alarm

OFF

OFF

OFF

Spec No. 1M820BNA (Model M820B) Issue AH, March 4, 2013

Spec No. 1M820DNA (Model M820D)

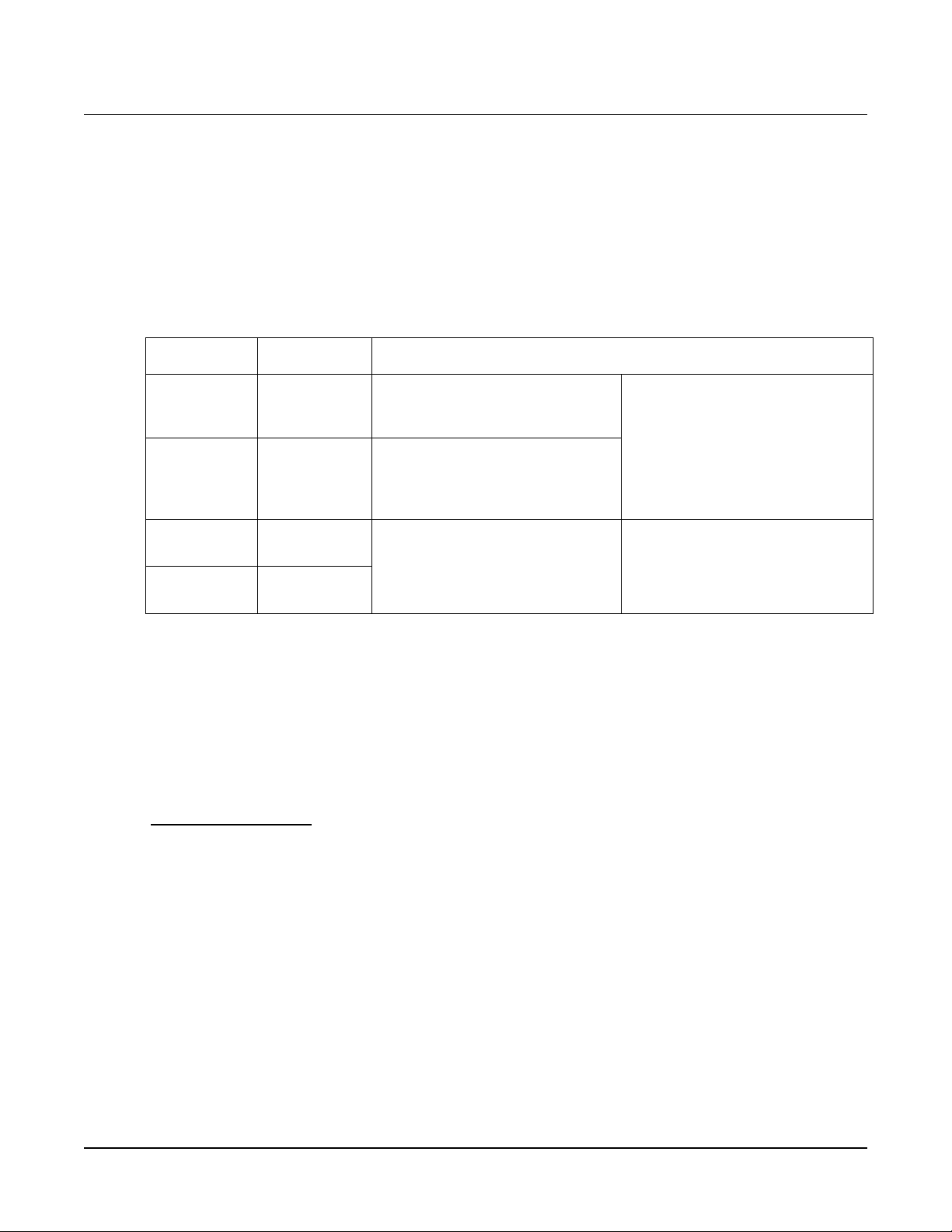

1.3.3 System Components Monitoring and System Alarms Generation

The ACU+ Controller monitors the components comprising the system (such as the rectifiers, converters,

and supervisory modules) and generates alarms if a fault condition occurs. The ACU+ Controller also

maintains an alarm history log.

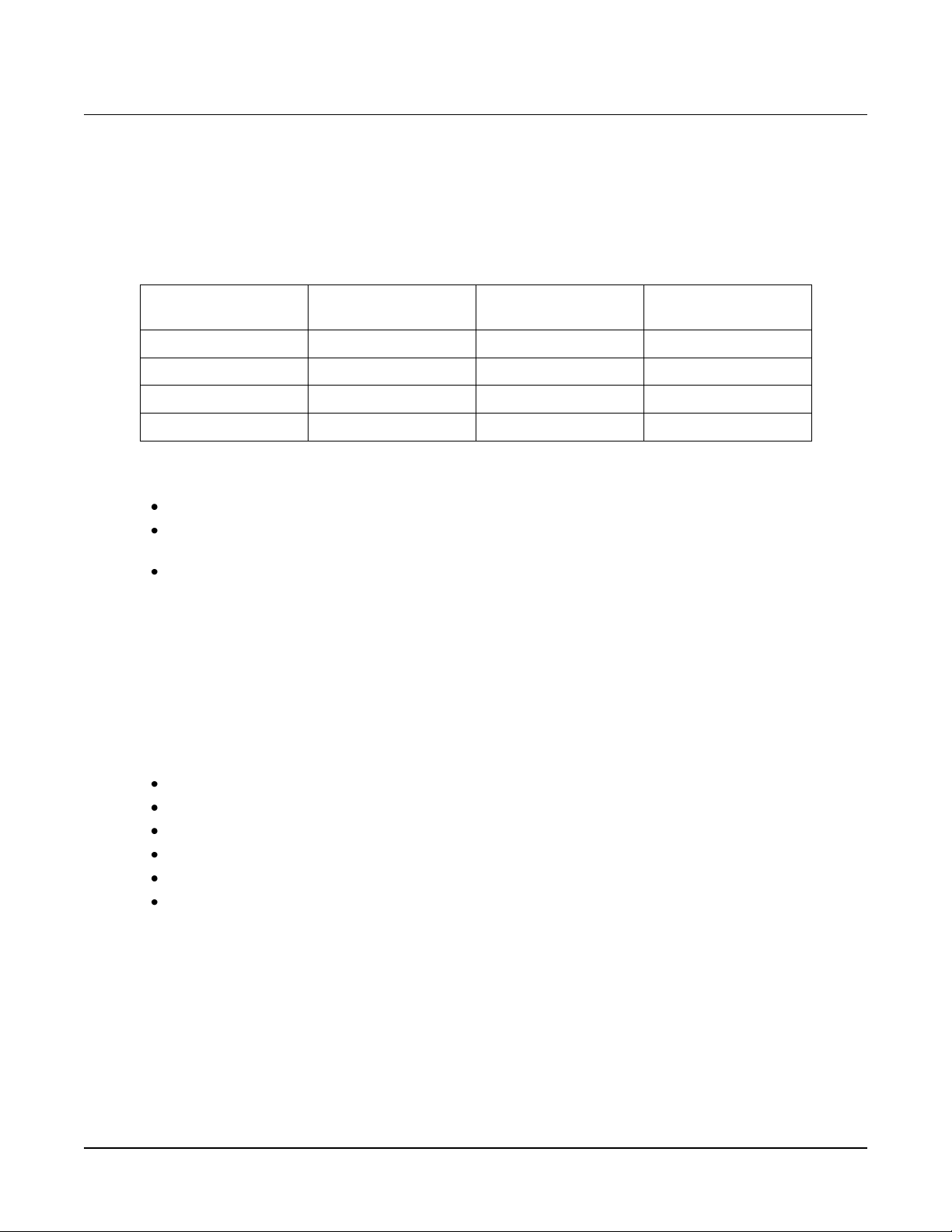

The available system alarms are programmed with an Alarm Severity Level. Each Alarm Severity Level

has different visual/audible alarm attributes. Available Alarm Severity Levels and their attributes are listed

in Table 1.

Table 1

Alarm Severity Levels

The alarm indicator turns OFF if the fault(s) that triggered the alarm clears.

The audible alarm can be silenced by pressing any key on the ACU+ Controller local interface pad.

The audible alarm is also silenced if the fault(s) that triggered the alarm clears.

An audible alarm cutoff feature can be programmed that silences the audible alarm after a pre-set

programmable time period. The audible alarm can also be disabled.

The available system alarms can also be mapped to alarm relays (located on ACU+ interface boards) that

can be wired to external alarm circuits.

1.3.4 Operating Data Acquisition and Data Logs

The ACU+ Controller acquires and analyses real time data from the system’s components such as the

rectifiers, converters, and supervisory modules.

The ACU+ Controller uses this data to process alarms and also records data in logs. The logs are viewed

using the WEB Interface and consists of...

Alarm History Log: records 600 latest alarms.

Data History Log: records 60000 latest history data.

Control Log: records 500 latest control events.

System Log: records 3000 latest system events.

Diesel Test Log: records 500 latest diesel test results.

Battery Test Log: up to twelve (12) battery discharge tests can be performed and recorded per year.

Note: Once maximum number of log entries is reached, new entries overwrite oldest entries.

Logs can be saved in the text (.txt) format.

Chapter 1. Introduction 3

This document is property of Emerson Network Power, Energy Systems, North America, Inc. and contains confidential and proprietary information owned by Emerson Network Power, Energy

Systems, North America, Inc. Any copying, use, or disclosure of it without the written permission of Emerson Network Power, Energy Systems, North America, Inc. is strictly prohibited.

Page 10

UM1M820BNA User Instructions

Issue AH, March 4, 2013 Spec No. 1M820BNA (Model M820B)

Spec No. 1M820DNA (Model M820D)

1.3.5 Battery Management

General Battery Management

The ACU+ Controller provides the following battery management functions

(except Lithium Ion Battery Configuration).

Battery Charge Temperature Compensation

Battery Equalize Charge

Battery Charge Current Limit

High and Low Battery Temperature Alarms

Battery Thermal Runaway Management (BTRM) Feature

(Reduces Voltage during a High Battery Temperature Condition)

Battery Discharge Tests

Battery Test Logs (maximum twelve [12] logs, maximum eighteen [18] battery strings per log)

Battery LVD (Low Voltage Disconnect)

Battery Capacity Prediction

Battery Block and Battery Midpoint Monitoring

Enhanced Battery Monitoring with SM-BRC

Thermal Runaway Detection/Management

Spec. No. 588820300 Battery Rack System (Lithium Ion Battery Configuration)

When the ACU+ is equipped with the Lithium Ion Battery Configuration for use with Spec. No. 588820300

NetSure™ Battery Rack System, the battery management functions are as follows.

The configuration only provides the battery float charge voltage (equalize charging is not applicable).

The only adjustable battery setting (besides the float voltage level) is the ABCL (Active Battery

Charge Current Limit) Point.

Active Battery Charge Current Limit (ABCL): This feature controls the amount of charge current

supplied to the lithium-ion batteries installed in the power plant to prevent failure of the batteries.

Battery status and alarms sent by the batteries to the ACU+ are displayed in the ACU+ interfaces.

Refer also to the instructions provided by the battery manufacturer for battery management functions

built into the battery itself.

NOTE THAT THE FOLLOWING DESCRIPTIONS ARE FOR THE GENERAL BATTERY

MANAGEMENT FUNCTIONS AND DO NOT APPLY TO THE LITHIUM ION BATTERY

CONFIGURATION.

4 Chapter 1. Introduction

This document is property of Emerson Network Power, Energy Systems, North America, Inc. and contains confidential and proprietary information owned by Emerson Network Power, Energy

Systems, North America, Inc. Any copying, use, or disclosure of it without the written permission of Emerson Network Power, Energy Systems, North America, Inc. is strictly prohibited.

Page 11

User Instructions UM1M820BNA

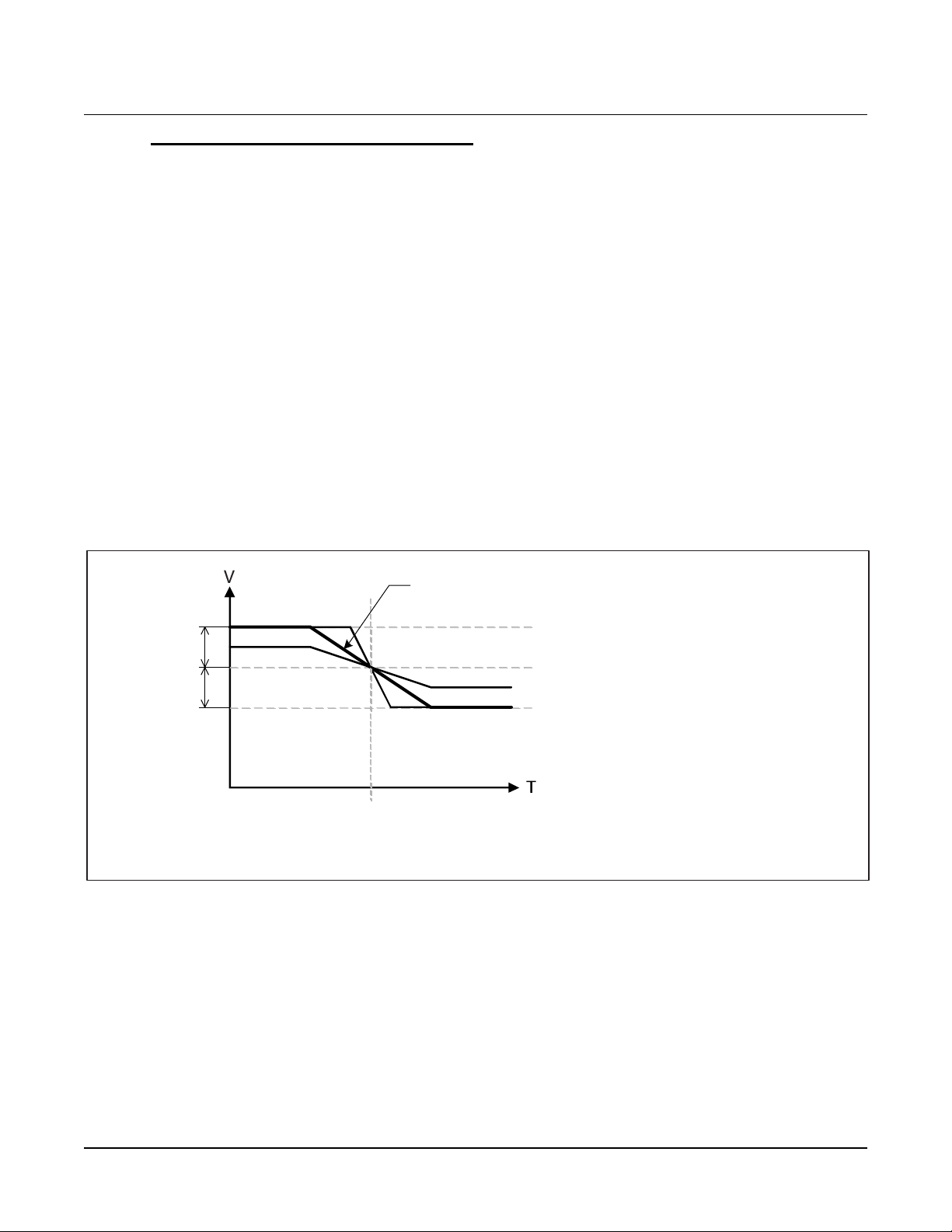

TempCompCoeff

setting (mV/°C).

nom

T

nom

T

V

nom

V

high

V

low

Upper voltage level where temperature compensation

clamps the voltage. Limitedto the TEMP COMP MAX V

setting.

Nominal voltage (voltage at nominal temperature).

Lower voltage level where temperature compensation

clamps the voltage. Limitedto the TEMP COMP MIN V

setting.

Nominal temperature (no temperature compensation is done at this temperature).

This is the Temp Comp setting.

1V Max (24V System)

2V Max (48V System)

1V Max (24V System)

2V Max (48V System)

Spec No. 1M820BNA (Model M820B) Issue AH, March 4, 2013

Spec No. 1M820DNA (Model M820D)

Battery Charge Temperature Compensation

The ACU+ Controller can be programmed to automatically increase or decrease system output voltage to

maintain battery float current as battery temperature decreases or increases, respectively. Battery life can

be extended when an optimum charge voltage to the battery with respect to temperature is maintained.

Temperature is monitored by a sensor mounted on the battery. See your power system documentation for

temperature sensor information. You can also set High2, High1, and Low compensation temperature

alarms.

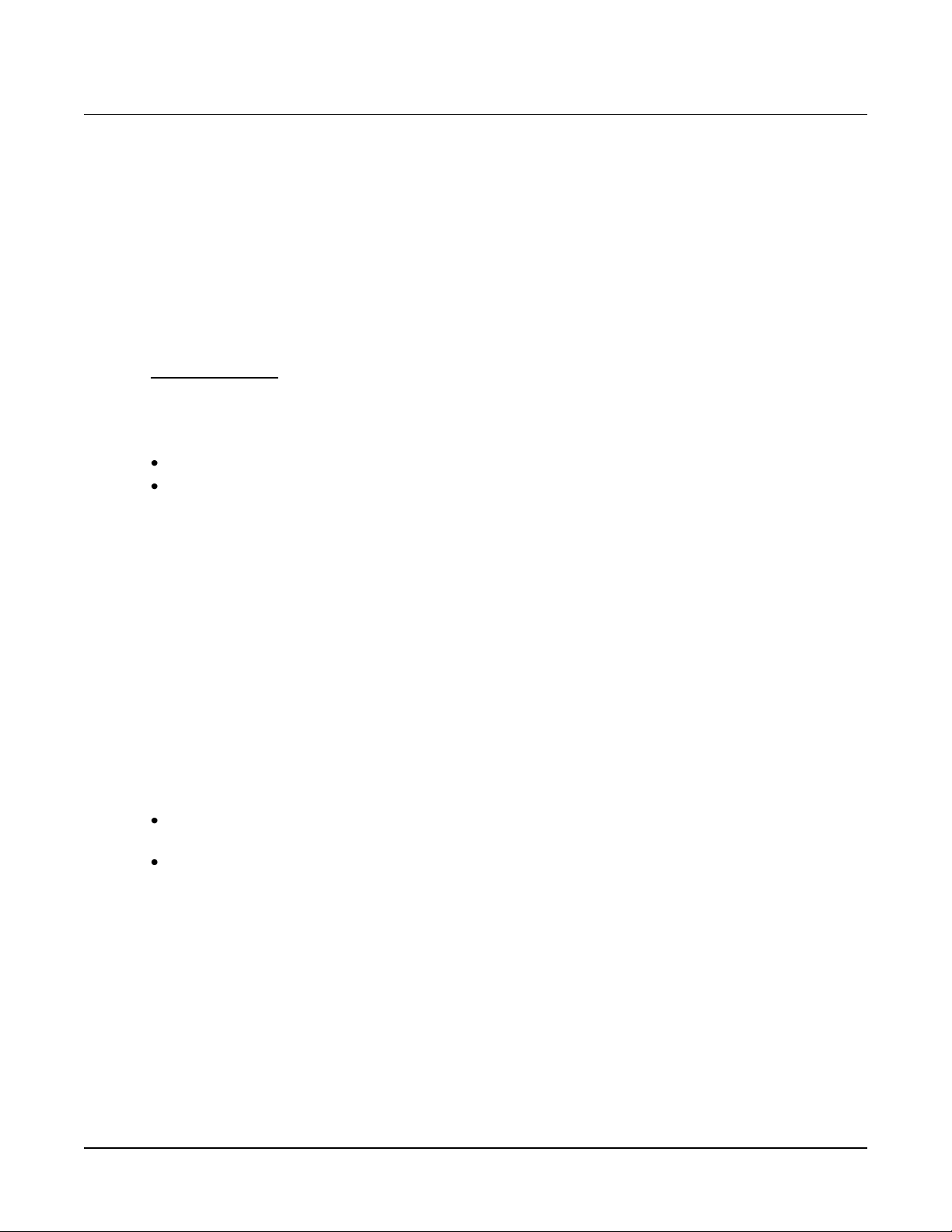

Functional Description (See Figure 2): Battery charge temperature compensation adds a correction

term, related to the temperature of the batteries, to the nominal value of the system voltage. The degree of

regulation (TempComp Coeff), expressed in mV/°C/battery string, can be set per battery manufacturer

recommendations.

To protect batteries and voltage-sensitive loads, compensation is automatically limited to a maximum of

two volts (48V systems) or one volt (24 volt systems) above or below the nominal output level (float

setting).

Temperature compensation will also clamp if the voltage reaches either the TEMP COMP MAX V setting

or the TEMP COMP MIN V setting. This feature can also be disabled.

Temperature compensation is automatically disabled if communication between the Controller and all

rectifiers is lost, a DC over or under voltage alarm activates, a low voltage disconnection occurs, manual

mode is entered, or the system enters the boost or test modes.

Figure 2

Temperature Compensated Voltage Control

Chapter 1. Introduction 5

This document is property of Emerson Network Power, Energy Systems, North America, Inc. and contains confidential and proprietary information owned by Emerson Network Power, Energy

Systems, North America, Inc. Any copying, use, or disclosure of it without the written permission of Emerson Network Power, Energy Systems, North America, Inc. is strictly prohibited.

Page 12

UM1M820BNA User Instructions

Issue AH, March 4, 2013 Spec No. 1M820BNA (Model M820B)

Spec No. 1M820DNA (Model M820D)

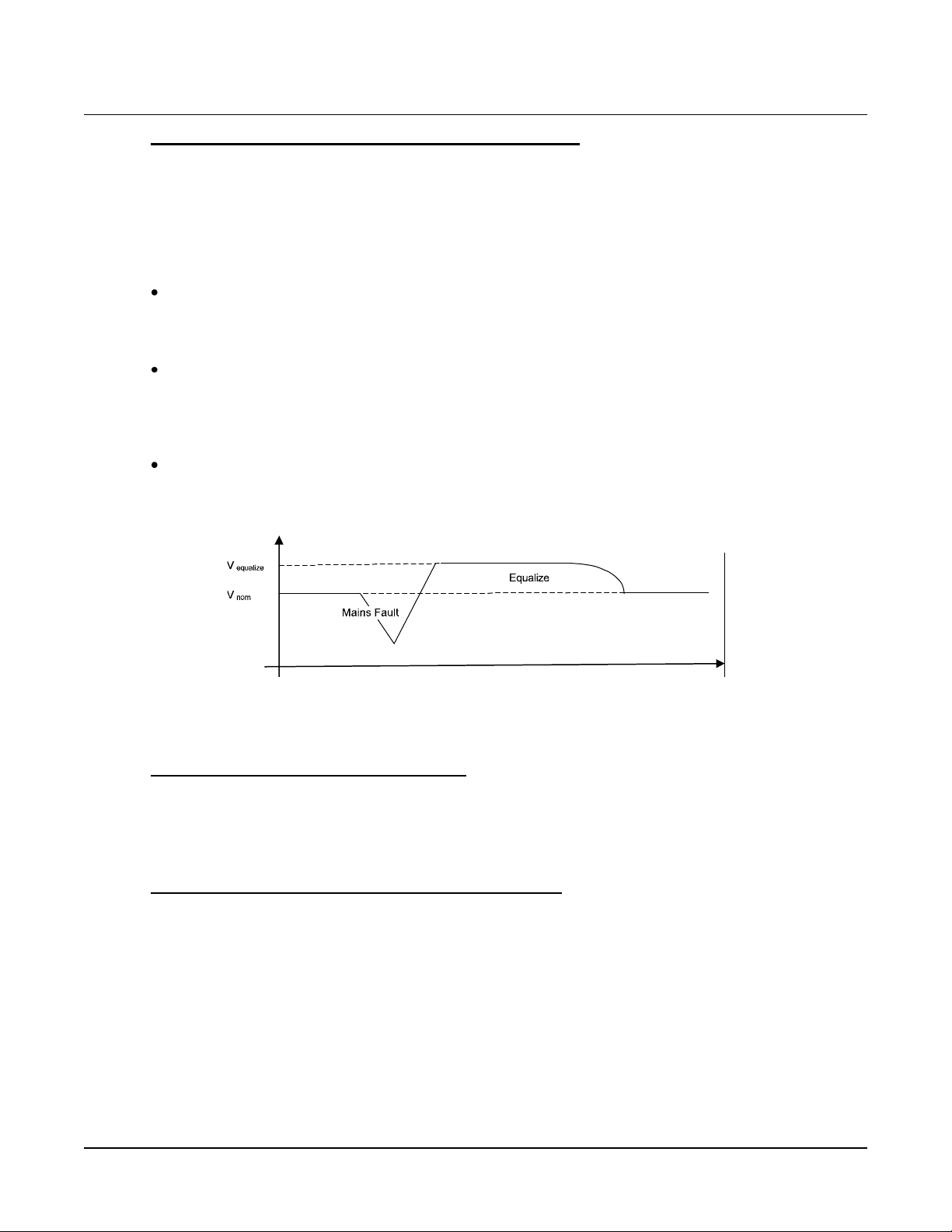

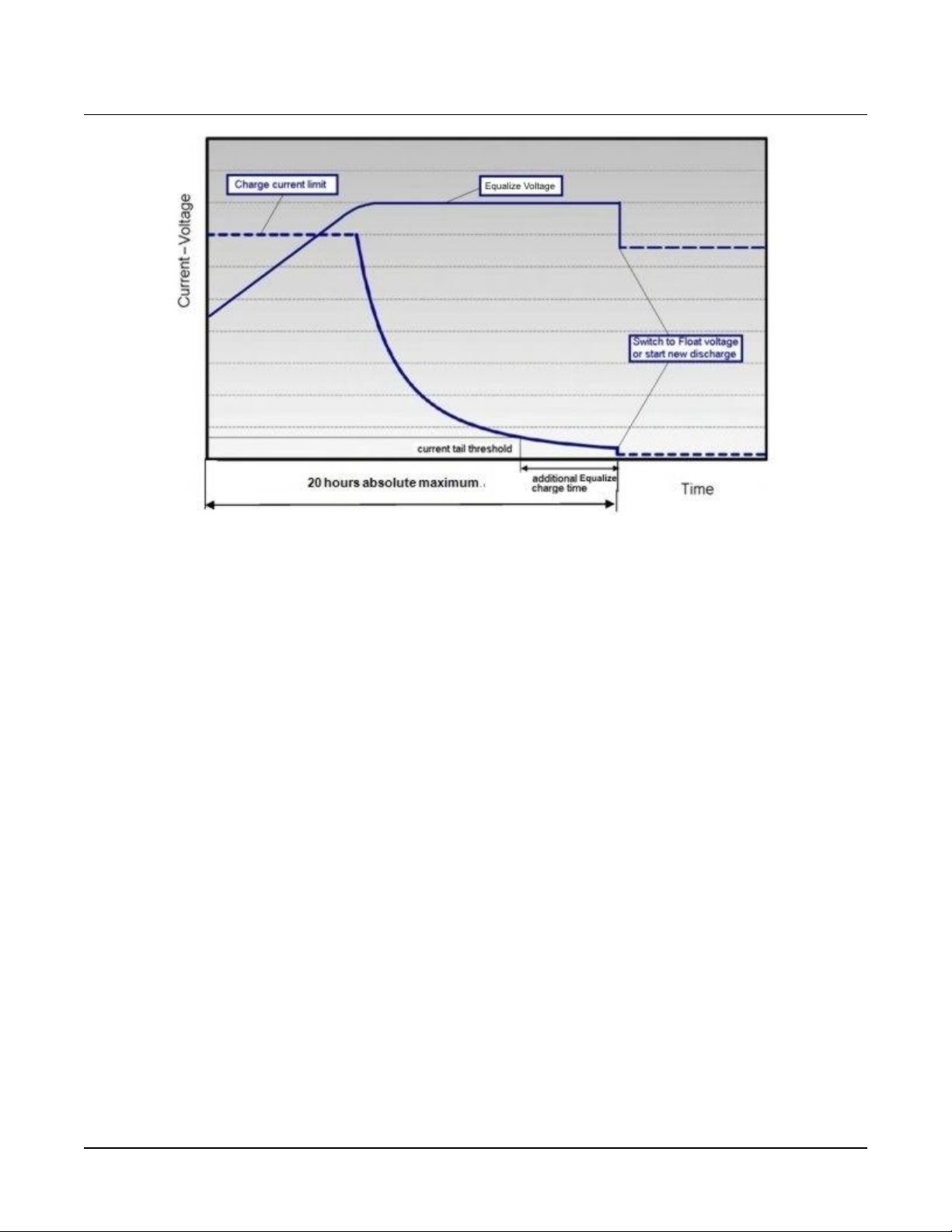

Battery Equalize Charge and Battery Charge Current Limit

The ACU+ Controller can increase system output voltage for equalizing the charge on all battery cells of a

conventional flooded cell battery, or for recharging the battery following a commercial power failure.

The charging function can be initiated cyclically (scheduled), automatically, or manually.

Refer to the battery manufacturer's instructions for equalize charging instructions.

Functional Description (See Figure 3):

Start of Charging: When the battery charge current exceeds a preset value for 3 minutes or if the

calculated battery capacity has decreased to a preset value (after a commercial AC failure, for

example), the charging function of the ACU+ is activated. A charging signal is sent from the ACU+ to

the rectifiers to increase the voltage up to the battery charging level V

equalize

Battery Current Limitation: After a commercial AC failure or when some battery cells are

permanently damaged, the current to the batteries can be quite extensive. To avoid overheating or

further damages to the battery, the ACU+ limits the battery current to a preset level by limiting the

charging voltage of the rectifiers. Should the battery current still exceed a higher preset value, an

alarm is issued.

End of Charging: When the charging current drops below a preset value, a defined prolonged

charging time is started before the charging is stopped and the voltage of the rectifiers return to the

float charging level (V

). For safety, there is a equalize charging limit time that stops the charging

nom

after a preset time.

Figure 3

Voltage Characteristics on Commercial AC Failure and Automatic Equalize Charging

High and Low Battery Temperature Alarms

The ACU+ Controller can monitor battery temperature via a temperature sensor mounted on a battery cell.

Values for high battery temperature and low battery temperature alarms can then be programmed into the

ACU+ Controller.

Battery Thermal Runaway Management (BTRM) Feature

You can designate a temperature sensor as the BTRM sensor. The BTRM sensor has High2 and High1

BTRM temperature alarm limits. If battery temperature exceeds the “BTRM Temp High2” setting, system

voltage is lowered to the BTRM voltage setting. This feature can also be disabled.

6 Chapter 1. Introduction

This document is property of Emerson Network Power, Energy Systems, North America, Inc. and contains confidential and proprietary information owned by Emerson Network Power, Energy

Systems, North America, Inc. Any copying, use, or disclosure of it without the written permission of Emerson Network Power, Energy Systems, North America, Inc. is strictly prohibited.

Page 13

User Instructions UM1M820BNA

Spec No. 1M820BNA (Model M820B) Issue AH, March 4, 2013

Spec No. 1M820DNA (Model M820D)

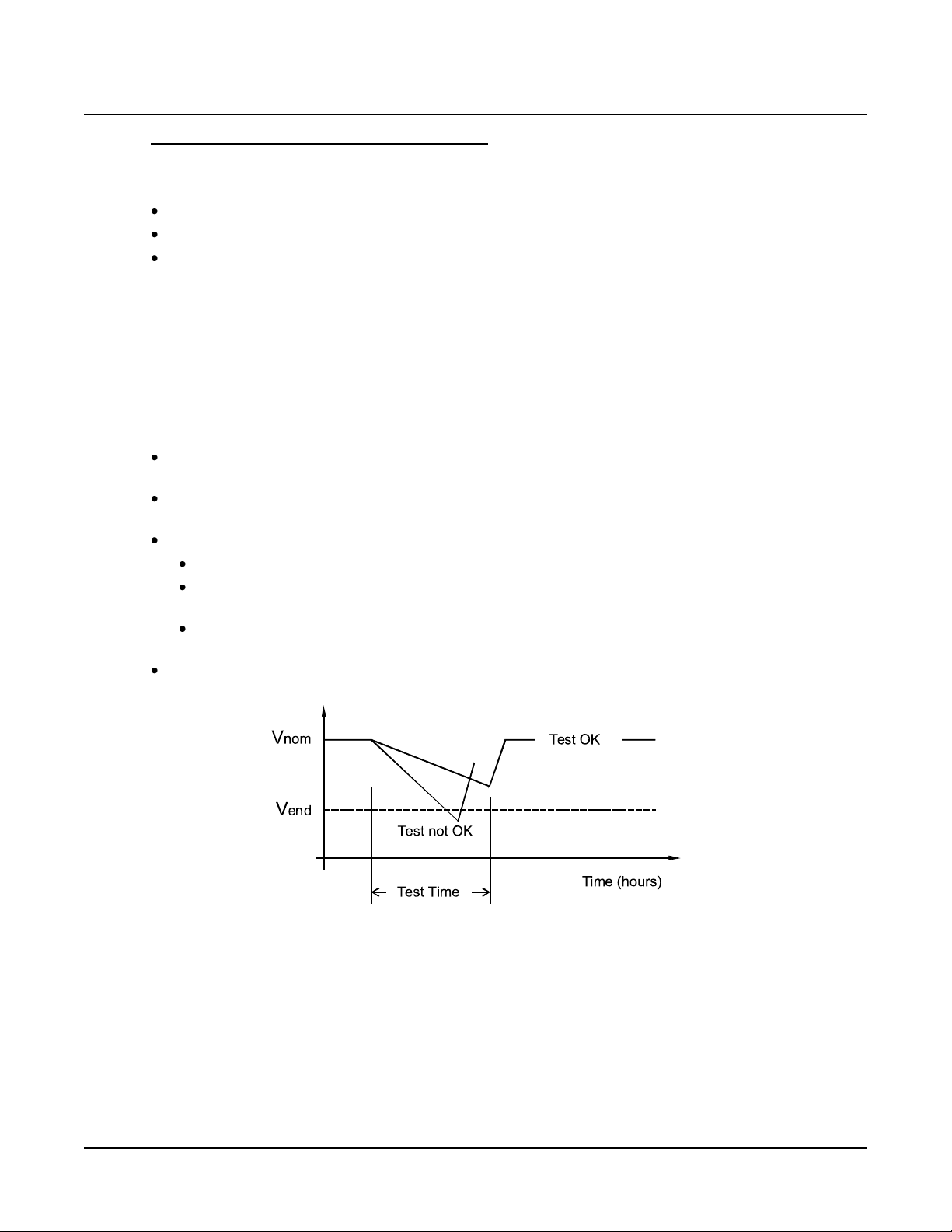

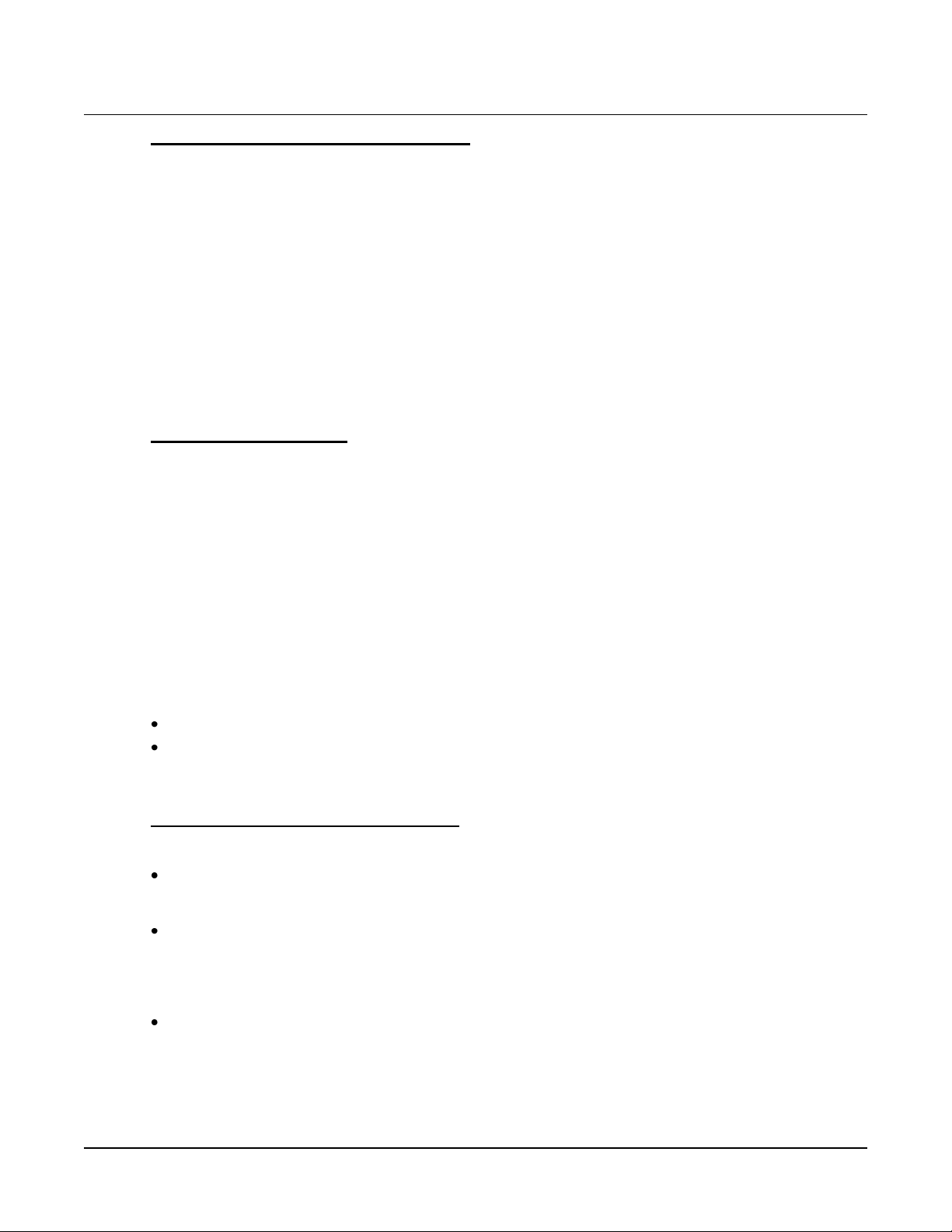

Battery Discharge Test and Battery Test Logs

The ACU+ Controller can perform battery discharge tests to check the condition of the battery.

There are (3) types of battery discharge tests.

Short Time Test

Time Test

Stable Current Test

A User can manually start a battery discharge test or program the ACU+ Controller to automatically start

battery discharge tests at scheduled intervals (cyclic battery tests). During a battery discharge test, the

ACU+ Controller controls the rectifiers output to place the entire load or partial load on the batteries. The

ACU+ Controller monitors the discharge of the battery and saves the results in a battery test log.

Functional Description: For manual battery discharge tests as well as for cyclic battery discharge tests,

the following parameters must be set: End Voltage, Test Time, and Battery Capacity Discharge Limit. See

Figure 4.

Battery Discharge Test Sequence:

In time test modes, the output voltage of the rectifiers is reduced so that only the batteries power the

load. If the batteries fail, the rectifiers power the load.

In stable current test mode, the output voltage of the rectifiers is reduced so that the batteries supply

the preset test current to the load.

The battery test continues until one of the following occurs:

The preset test time, see Figure 4, expires. The battery has passed the test.

The battery voltage drops below the preset end voltage level (V

) (Figure 4). The battery has not

end

passed the test and the test is interrupted. A battery test alarm is activated.

The battery capacity drops below the preset test end battery capacity. The battery has not passed

the test and the test is interrupted. A battery test alarm is activated.

After the battery discharge test, the output voltage of the rectifiers increase so that the rectifiers supply

the system and charge the batteries.

Figure 4

Battery Test Diagram

Chapter 1. Introduction 7

This document is property of Emerson Network Power, Energy Systems, North America, Inc. and contains confidential and proprietary information owned by Emerson Network Power, Energy

Systems, North America, Inc. Any copying, use, or disclosure of it without the written permission of Emerson Network Power, Energy Systems, North America, Inc. is strictly prohibited.

Page 14

UM1M820BNA User Instructions

Issue AH, March 4, 2013 Spec No. 1M820BNA (Model M820B)

Spec No. 1M820DNA (Model M820D)

Battery LVD (Low Voltage Disconnect)

To prevent serious damage to the batteries during a commercial AC power failure, the batteries can be

disconnected by voltage or time control.

The batteries are reconnected automatically when commercial AC power is restored and a predetermined

DC voltage level is reached.

Voltage Controlled Disconnection: When the set voltage level is reached, the batteries are

disconnected.

Time Controlled Disconnection: When the set time has elapsed, the batteries are disconnected.

Battery Capacity Prediction

The ACU+ can predict battery capacity.

Battery Block and Battery Midpoint Monitoring

The ACU+ can monitor battery blocks (12V blocks) or midpoint battery voltage of battery strings

connected to the EIB assembly. An alarm is issued when either battery block voltage or battery midpoint

voltage is abnormal.

Enhanced Battery Monitoring with SM-BRC

When connected to an SM-BRC, the ACU+ provides enhanced battery monitoring.

Thermal Runaway Detection and Management

Functional Description: The system uses several control mechanisms to avoid thermal runaway.

First: During a short high rate discharge, the batteries will normally get hot. The ACU+ takes this into

consideration. After completion of the discharge duty, the batteries are recharged with a limited current to

avoid heating the batteries any further.

Second: The temperature of the batteries can be monitored, and the ACU+ sets the charge voltage

appropriately, as previously described under Battery Charge Temperature Compensation.

Third: In addition to battery temperature compensation, if battery temperature rises above a set

temperature limit, the system stops battery charging completely by lowering the output voltage to the

“BTRM Voltage” setting. This allows the batteries to cool down. The system also provides alarm

notification of this occurrence. Power supplied to customer equipment is not interrupted.

Fourth: The battery LVD circuits can be programmed to open (disconnect) if a high temperature event

occurs (HTD – High Temperature Disconnect). The contactor(s) open when battery temperature rises

above a programmable value and close again when battery temperature falls below another

programmable value.

1.3.6 Intelligent Power Matching (Energy Optimization Mode)

With Energy Optimization Mode (ECO):

The Controller monitors load current versus system capacity.

The Controller commands some rectifiers to standby in rotation.

Refer to “1.3.1 Rectifier Control” for further description.

8 Chapter 1. Introduction

This document is property of Emerson Network Power, Energy Systems, North America, Inc. and contains confidential and proprietary information owned by Emerson Network Power, Energy

Systems, North America, Inc. Any copying, use, or disclosure of it without the written permission of Emerson Network Power, Energy Systems, North America, Inc. is strictly prohibited.

Page 15

User Instructions UM1M820BNA

Spec No. 1M820BNA (Model M820B) Issue AH, March 4, 2013

Spec No. 1M820DNA (Model M820D)

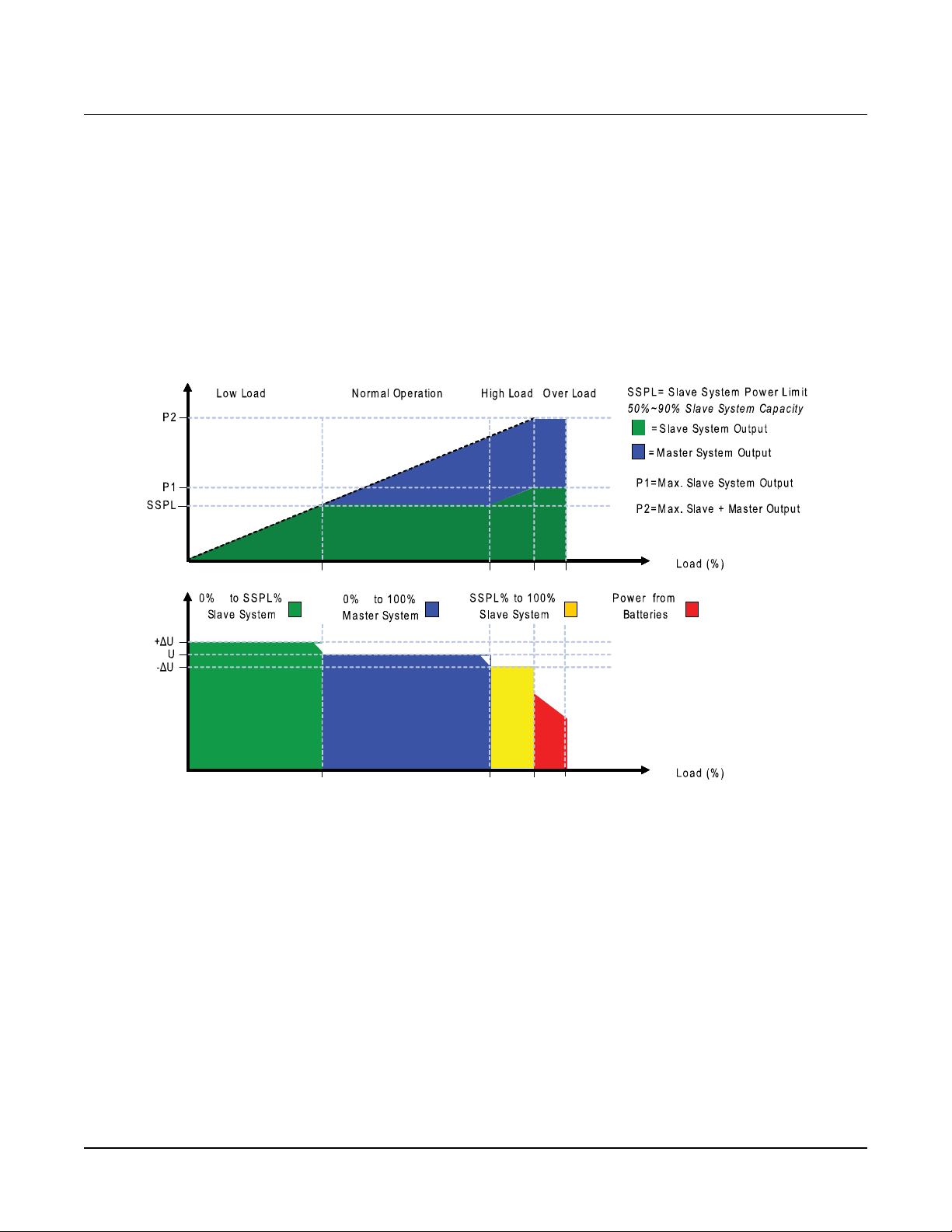

1.3.7 Power Split Feature

The Power Split feature allows you to connect the power system controlled via the ACU+ to an existing DC

power system instead of extending or completely replacing the existing DC power system.

The power system controlled via the ACU+ functions as a slave system to share load (split output) with the

existing system (master system) that requires expansion. The ACU+ does not require communication with

the master system’s Controller.

The Power Split feature provides for the sharing of total load in a controlled manner between the

paralleled power systems.

When Power Split is programmed, the ACU+ adjusts rectifier output voltage per load demands to ensure

proper sharing between the slave and master power systems. See Figure 5.

Figure 5

Power Split Feature

1.3.8 Diesel Management Feature

The Diesel Management feature is available when an SM-AC supervisory module is connected to the

ACU+ Controller. The Diesel Management feature consists of a Diesel Test. The Diesel Test can be

performed at specific intervals or a User can manually start the Diesel Test. The ACU+ records the test

results.

Chapter 1. Introduction 9

This document is property of Emerson Network Power, Energy Systems, North America, Inc. and contains confidential and proprietary information owned by Emerson Network Power, Energy

Systems, North America, Inc. Any copying, use, or disclosure of it without the written permission of Emerson Network Power, Energy Systems, North America, Inc. is strictly prohibited.

Page 16

UM1M820BNA User Instructions

Logical Component

Description

Logic NOT

NOT; Returns the inverted value of the input signal/parameter.

Logic OR

OR; Returns active (true) if any of the two signals/parameters are active (true).

Logic AND

AND; Returns active (true) if both of the two signals/parameters are active

(true).

AndOr

XOR; Returns active (true) if one and only one of the two signals/parameters

are active (true).

Greater Than (>)

GREATER THAN; Returns active (true) if the analog input signal goes above

the set threshold. Returns inactive (false) if the input signal goes below the set

threshold minus hysteresis value.

Less Than (<)

LESS THAN; Returns active (true) if the analog input signal goes below the set

threshold. Returns inactive (false) if the input signal goes above the set

threshold plus hysteresis value.

Delay

DELAY in seconds; Delays the applied signal/parameter with the defined time in

seconds before applying it to the output.

Issue AH, March 4, 2013 Spec No. 1M820BNA (Model M820B)

Spec No. 1M820DNA (Model M820D)

1.3.9 PLC (Programmable Logic Controller) Function

The PLC function allows a User to create "control program lines" by combining equipment analog signals,

parameters, and alarms in a sequence that controls equipment and/or operates relays.

Control program lines are created using the WEB Interface. See “4.8.6. PLC Sub-Menu”.

Available logical components are:

1.3.10 Supervisory Module (SM Modules) Monitoring

Various devices (supervisory modules) can be connected to the ACU+ Controller to extend its monitoring

capabilities.

1.3.11 Hybrid Control Function

Hybrid Control is designed for use in new installations or as an upgrade of existing sites powered by a

diesel generator(s) when grid power is not available. The Hybrid Control is also applicable to sites with

highly unreliable or frequently unavailable grid power connection. The primary power source is still

considered to be the diesel generator(s).

Note: The Hybrid Control function requires a specific configuration. Hybrid Control menus will not

normally be displayed unless your ACU+ has been configured by Emerson for this function.

Contact Emerson for a Hybrid Control configuration.

General

Hybrid Control allows the option of selecting one of the following: Fixed Daily Time based operation or

Capacity Discharge based operation.

10 Chapter 1. Introduction

This document is property of Emerson Network Power, Energy Systems, North America, Inc. and contains confidential and proprietary information owned by Emerson Network Power, Energy

Systems, North America, Inc. Any copying, use, or disclosure of it without the written permission of Emerson Network Power, Energy Systems, North America, Inc. is strictly prohibited.

Page 17

User Instructions UM1M820BNA

Spec No. 1M820BNA (Model M820B) Issue AH, March 4, 2013

Spec No. 1M820DNA (Model M820D)

Fixed Daily Time based operation is intended to be used with a combination of AC powered active

cooling (air conditioners) and DC powered cooling (heat exchangers, etc). The cycle period is

synchronized to the 24hr day-night cycle. It makes optimum use of the different temperature conditions

during the day and the night in order to facilitate Hybrid fuel saving operation.

Capacity Discharge based operation is intended for sites utilizing only DC powered cooling (heat

exchangers, etc). The cycle period is determined by User selectable depth of discharge (DOD) of the

batteries per cycle and associated recharge time. It provides optimum Hybrid fuel saving operation.

Operation from Grid Power is performed with both Fixed Daily Time and Capacity Discharge modes of

operation. Grid power is always given priority when available.

As the two types of control are specific to the hardware configuration of the site, the Fixed Daily Time or

Capacity Discharge is a User selectable option on installation.

Hybrid Operation

Generator Control: Potential free relay contact output from the ACU+ interface board controls the start

and stop of the diesel generator. The signal is generated by the ACU+ Controller and operates according

to the Hybrid software mode of operation. The control logic is as follows:

Energized output relay – Generator OFF.

De-energized output relay – Generator ON.

This is a fail-safe logic to ensure generator operation in all cases where power or control to the relay is

lost.

Further to that, the type of signal to the generator can be selected as N/O (Normally Open) or N/C

(Normally Closed) by selecting the relevant output pins of the control relay.

Number of Generator Control Outputs: The ACU+ Hybrid software can control one or two generators.

Each generator control is designated as DG1 or DG2 output. A User selectable menu will allow selecting

DG1, DG2, or DG1 and DG2. When both are selected they will be alternatively used (two generator

operation).

Diesel Fail Alarm: A diesel fail alarm will be generated if the Diesel Generator ON signal fails to bring the

generator to operation and provide the system with AC power. Alarm will be triggered after 60 seconds

(default value, settable) from ON signal. If two generator operations are selected simultaneously with the

alarm, the second Diesel Generator ON signal will be activated.

Battery Fuse Trip Alarm: In the event of a Battery Fuse trip condition an alarm will be generated.

Under Voltage Alarms:

Under Voltage Alarm 1: An Under Voltage Alarm 1 is set. If voltage decreases below this setting, an

alarm is raised.

Under Voltage Alarm 2: An Under Voltage Alarm 2 is set. If voltage decreases below this setting, the

Diesel Generator is started and an alarm is raised.

LVD 1: Normal loads are disconnected. LVD 2: Priority loads are disconnected. Charge Voltage:

Refer to Figure 6.

Chapter 1. Introduction 11

This document is property of Emerson Network Power, Energy Systems, North America, Inc. and contains confidential and proprietary information owned by Emerson Network Power, Energy

Systems, North America, Inc. Any copying, use, or disclosure of it without the written permission of Emerson Network Power, Energy Systems, North America, Inc. is strictly prohibited.

Page 18

UM1M820BNA User Instructions

Issue AH, March 4, 2013 Spec No. 1M820BNA (Model M820B)

Spec No. 1M820DNA (Model M820D)

Figure 6

Charge Voltage

Equalize Charge: The battery will be recharged at equalize voltage. This is the voltage set in the initial

phase of battery recharge. See Figure 6.

As the voltage limit is reached, the charge current is gradually reduced – effect known as current tail.

When the current tail falls below a set of threshold levels, additional equalize charge time is added.

The equalize charge current tail threshold is settable from 0.01 to 0.05. Default setting is 0.02 (2A per

100Ah). The additional equalize charge time is settable from 0 hours to 7 hours (settable in minutes from

0 to 720), default setting is 4 hours. The duration of the equalize charge is determined as the time from the

start of the recharge to the end of the additional time. (Maximum charge time, determined from the time

charge starts, is settable in the range of 5-24h.)

The end of recharge is determined by a three (3) step approach:

Step1 - calculated battery capacity exceeds 90%. Calculation is performed by measurement of battery

current and time, in Ah.

Step 2 - charge current tail threshold is reached.

Step 3 - additional charge time is added.

Float Charge: Default float voltage is 54.0V at 20°C with a temperature compensation of -72mV per °C.

If battery temperature exceeds 38°C, the charge voltage is reduced to 51V to reduce gassing and prevent

thermal runaway. The same is applicable as well for equalizing charge.

Equalizing Charge: As the cyclic use does not ensure complete battery recharge after every cycle, an

equalizing charge cycle is added. The equalizing cycle will occur up to four times a month, settable for

every 7 to 60 days intervals. Start date and time is settable. Equalizing charge time is 20 hours

independent of discharge time setting. Equalizing charge is performed at equalize voltage until end of

additional equalize time and thereafter at float voltage for the remaining time. Also see Figure 6.

Equalize charge independently settable 0-720 min (already set in equalize charge).

12 Chapter 1. Introduction

This document is property of Emerson Network Power, Energy Systems, North America, Inc. and contains confidential and proprietary information owned by Emerson Network Power, Energy

Systems, North America, Inc. Any copying, use, or disclosure of it without the written permission of Emerson Network Power, Energy Systems, North America, Inc. is strictly prohibited.

Page 19

User Instructions UM1M820BNA

Spec No. 1M820BNA (Model M820B) Issue AH, March 4, 2013

Spec No. 1M820DNA (Model M820D)

Early Termination of the Discharge Periods

During discharge, over temperature and under voltage conditions will interrupt the discharge and

change the operation to charge – Diesel Generator ON.

Over Temperature: The diesel generator will start and run for a period before it is stopped again. The run

time is User selectable in the range 30 to 120 minutes, default setting is 60 minutes. Temperature is

referenced to cabinet/shelter ambient temperature sensor connected to the Controller, not battery

temperature. Over temperature start can be disabled completely from User settings menu.

Under Voltage: The under voltage start is triggered by under voltage alarm 2 voltage settings.

The diesel generator will start and run until the normal recharge cycle is due to finish depending on

selected mode of operation.

Example for Fixed Daily Time: If the normal recharge cycle is from 7am until 7pm and under voltage has

started the diesel generator at 5:30am, the effective recharge will be from 5:30am until 7pm.

Example for Capacity Discharge: If this mode is selected, the recharge will terminate. Operation with Grid Power

Grid power is always prioritized when available. If grid power becomes available during battery discharge,

the discharge cycle is terminated and recharge cycle is initiated. If grid power becomes available during

diesel generator operation, the diesel generator is switched OFF and operations continue on grid power.

Battery Recharge with Grid Power: Battery recharge with grid power can start from the beginning (case

of grid power becoming available during battery discharge) or can continue over from diesel generator

recharge depending on the timing. In both cases, the recharge process will follow the recharge profile

shown in Figure 6. If battery becomes fully recharged and grid power is still present, the operations will

continue to be powered from grid and no battery discharge will be initiated for the duration of grid

availability. In this case battery voltage will revert back to Float voltage.

Battery Discharge after Grid Failure: At the point of grid power failure, the battery capacity is unknown

as these events occur in random manner. For the purpose of maximizing the use of grid power and in

anticipation of grid power becoming available again, the Hybrid operation will continue with battery

discharge cycle. Discharge will continue until:

The preset discharge time elapses (Fixed Daily Time).

The preset DOD is reached (Capacity Discharge).

In both cases, the discharge can be terminated earlier as described in “Early Termination of the Discharge Periods”.

Relay Assignment – when in Hybrid Mode

Relay 1: Generator Alarm

No Generator Voltage Alarm. No AC supply, 60 sec delay.

Relay 2: Battery Alarms

Logic alarm generated from: under voltage 1, under voltage 2, LVD1, LVD2, battery high temp,

battery very high temp, overvoltage 1, overvoltage 2, battery temp sensor fail, battery fuse alarms,

and high load alarm.

Relay 3: Rectifier Alarms

Logic alarm generated from: multiple rectifier fail, rectifier fail, rectifier fan failure, rectifier HVSD,

rectifier AC failure, and rectifier not responding.

Chapter 1. Introduction 13

This document is property of Emerson Network Power, Energy Systems, North America, Inc. and contains confidential and proprietary information owned by Emerson Network Power, Energy

Systems, North America, Inc. Any copying, use, or disclosure of it without the written permission of Emerson Network Power, Energy Systems, North America, Inc. is strictly prohibited.

Page 20

UM1M820BNA User Instructions

Issue AH, March 4, 2013 Spec No. 1M820BNA (Model M820B)

Spec No. 1M820DNA (Model M820D)

Relay 4: System Alarms

Logic alarm generated from: load fuse alarms, high ambient temperature, ambient temp sensor fail,

smoke detected, and water detection.

Relay 5: Generator Run At High Temp

Output to intelligent cooling devices linked to AC supply (DG run).

Relay 6: Intruder Alarm

Alarm triggered by dry contact door/motion sensor.

Relay 7: Diesel 1 in Operation

Output to DG1 on site. DG is set on for the duration of the signal.

Relay 8: Diesel 2 in Operation

Output to DG2 on site. DG is set on for the duration of the signal.

Fixed Daily

In this mode of operation the total duration of a complete cycle is 24hr. Such duration is necessary as the

operation is synchronized with day-night temperature pattern. When an extended recharge cycle is

required, the termination of it will still follow the 24hr schedule.

Cycle Duration: A complete cycle consists of discharge and charge periods to the combined total of

24hrs. The discharge period starts at 7pm. It is then followed by recharge period (Diesel Generator ON)

for the remaining of the 24hrs. The discharge time is User selectable in the range 1hrs to 22hrs, default

setting is 12hrs.

Discharge: The discharge start time and duration are settable. Discharge period starts at 7pm. The

discharge time is User selectable in the range 1hrs to 22hrs, default setting is 12hrs.

Recharge: Recharge period (Diesel Generator ON) follows after discharge for the remaining of the 24hrs.

Recharge is performed at equalize voltage until added equalize time elapses and at float voltage for the

remaining charge time.

High Load Alarm: In order to identify conditions where the load requirements are exceeding the

dimensioning of the Hybrid site, an alarm must be generated. The alarm will be triggered upon exceeding

the maximum capacity per discharge cycle. The threshold value will be set as default to 40% of battery

capacity. It will require capacity measurement per cycle. The alarm will be set once the high load threshold

value is reached and is reset at the beginning of the next discharge period. This alarm will also allow

distinguishing the root cause of under voltage conditions: is it high load demand or is it a battery ageing

and associated loss of capacity issue or insufficient charge capacity.

Capacity Discharge

The cycle period is determined by User selectable capacity discharge of the batteries and associated

recharge times. After that the cycle repeats itself. It does not follow a 24hr pattern.

Capacity Discharge and Recharge: The battery discharge period is determined by the percentage of

the nominal battery capacity [Ah] that will be discharged per cycle.

The depth of discharge [DOD] per cycle is User selectable in the range 20% to 80%. Default setting is

60%. The value is set as battery capacity at the end of each discharge period. Therefore, if a 60%

discharge is chosen, the discharge value is set to 40%.

The time to recharge to full battery capacity depends on battery capacity at the start of the charge cycle

and available recharge current.

When the additional charge time has been reached; the generator will be stopped, the recharge cycle will

end, and discharge cycle will be initiated.

14 Chapter 1. Introduction

This document is property of Emerson Network Power, Energy Systems, North America, Inc. and contains confidential and proprietary information owned by Emerson Network Power, Energy

Systems, North America, Inc. Any copying, use, or disclosure of it without the written permission of Emerson Network Power, Energy Systems, North America, Inc. is strictly prohibited.

Page 21

User Instructions UM1M820BNA

Spec No. 1M820BNA (Model M820B) Issue AH, March 4, 2013

Spec No. 1M820DNA (Model M820D)

For practical purposes, the battery capacity at the end of every recharge period is set to 100% as long as

Step1, Step 2, and Step 3 have elapsed.

If end of charge is not reached within the set maximum hrs, the recharge will be terminated anyway and

discharge cycle will be initiated.

1.3.12 Maximum Current Limit Function

The current available from the rectifiers can be programmed (in AMPS) from 10% to 121% of combined

rectifier capacity. The factory setting is 121% unless otherwise specified. The current available from the

converters can be programmed (in AMPS) from 50% to 116% of combined converter capacity. The factory

setting is 116% unless otherwise specified. Refer to the ACU+ Configuration Drawing (C-drawing)

supplied with your system documentation for your system’s settings.

If a rectifier or converter is added, the respective current limit point will automatically increase by the

percentage each existing rectifier or converter was set to provide prior to the addition.

If a rectifier or converter is removed from the system (and the Rect Comm Fail or Conv Comm Fail alarm

is reset), the respective current limit point will remain unchanged unless the capacity of the remaining

rectifiers or converters is not sufficient to maintain the present current limit point. If that happens, the

current limit point will automatically increase to the maximum (121% of the remaining rectifiers or 116% of

the remaining converters).

Chapter 1. Introduction 15

This document is property of Emerson Network Power, Energy Systems, North America, Inc. and contains confidential and proprietary information owned by Emerson Network Power, Energy

Systems, North America, Inc. Any copying, use, or disclosure of it without the written permission of Emerson Network Power, Energy Systems, North America, Inc. is strictly prohibited.

Page 22

UM1M820BNA User Instructions

Indicator

Normal State

Fault State

Fault Cause

Status

(Green)

On

Off

No input power to the ACU+

Controller.

Minor

Alarm

(Yellow)

Off

On

The system has one or more active

Minor alarms. Alarm conditions are

programmable.

Critical/Major

Alarm (Red)

Off

On

The system has one or more active

Critical or Major alarms. Alarm

conditions are programmable.

ESC

ENT

USB

Port

10/100M Ethernet

Port (RJ-45)

M820B

Critical or Major

Alarm Indicator

(Red)

MinorAlarm

Indicator (Yellow)

Status

Indicator

(Green)

Menu

Navigation

Keys

Status

Indicator

(Green)

MinorAlarm

Indicator (Yellow)

Critical or Major

Alarm Indicator

(Red)

ESC ENT

Menu Navigation Keys

USB

Port

10/100M Ethernet

Port (RJ-45)

M820D

Issue AH, March 4, 2013 Spec No. 1M820BNA (Model M820B)

Spec No. 1M820DNA (Model M820D)

CHAPTER 2. OPERATION

2.1 Local Indicators

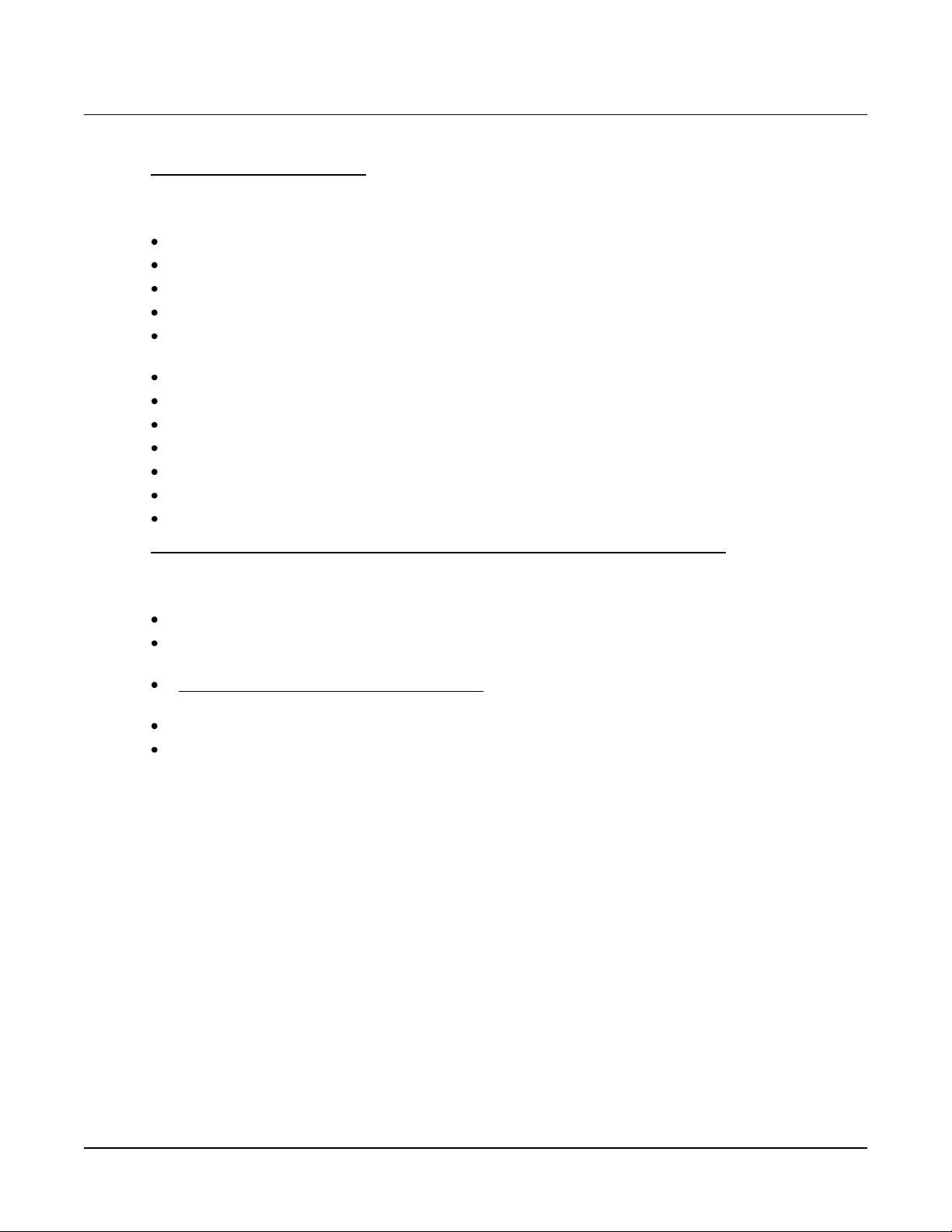

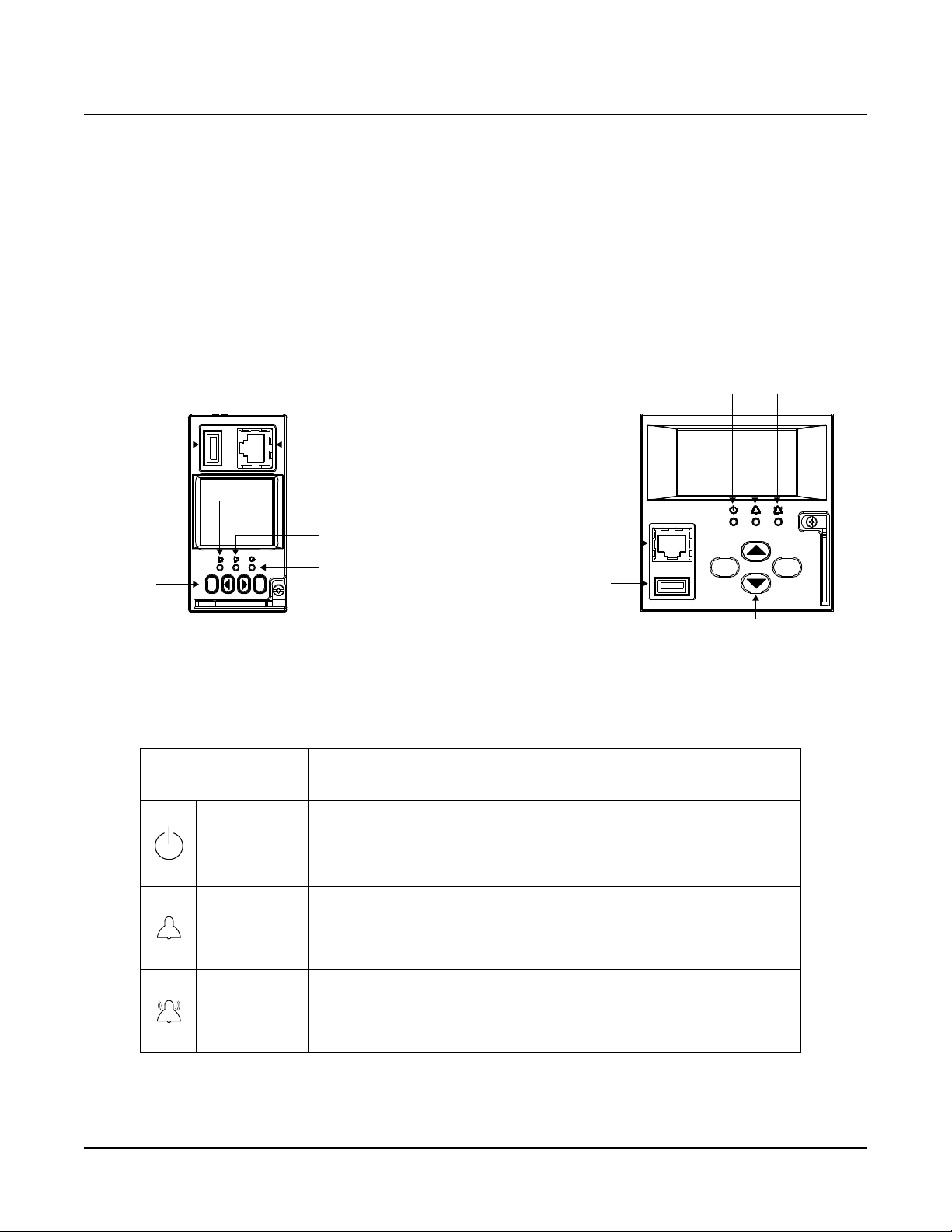

Location and Identification: Refer to Figure 7.

Description: There are three (3) indicators located on the ACU+ Controller’s front panel. Refer to Table 2

for the function of the indicators.

16 Chapter 2. Operation

This document is property of Emerson Network Power, Energy Systems, North America, Inc. and contains confidential and proprietary information owned by Emerson Network Power, Energy

Systems, North America, Inc. Any copying, use, or disclosure of it without the written permission of Emerson Network Power, Energy Systems, North America, Inc. is strictly prohibited.

Local Indicators and Menu Navigation Keys Locations

Figure 7

Table 2

Local Indicators

Page 23

User Instructions UM1M820BNA

Access Level

(Authority Level)

Default User Name

and Password

Authority

Level A (Browser)

none set

The User can only read (browse) information in the

menus.

Level B (Operator)

none set

The User has access to the system "Control" menus.

Level C (Engineer)

none set

The User has access to the system "Setting" menus

and can download the configuration file.

Level D (Administrator)

Admin, 1

The User has full access to all menus; including update

the OS application and modifying, adding, and deleting

Users.

Spec No. 1M820BNA (Model M820B) Issue AH, March 4, 2013

Spec No. 1M820DNA (Model M820D)

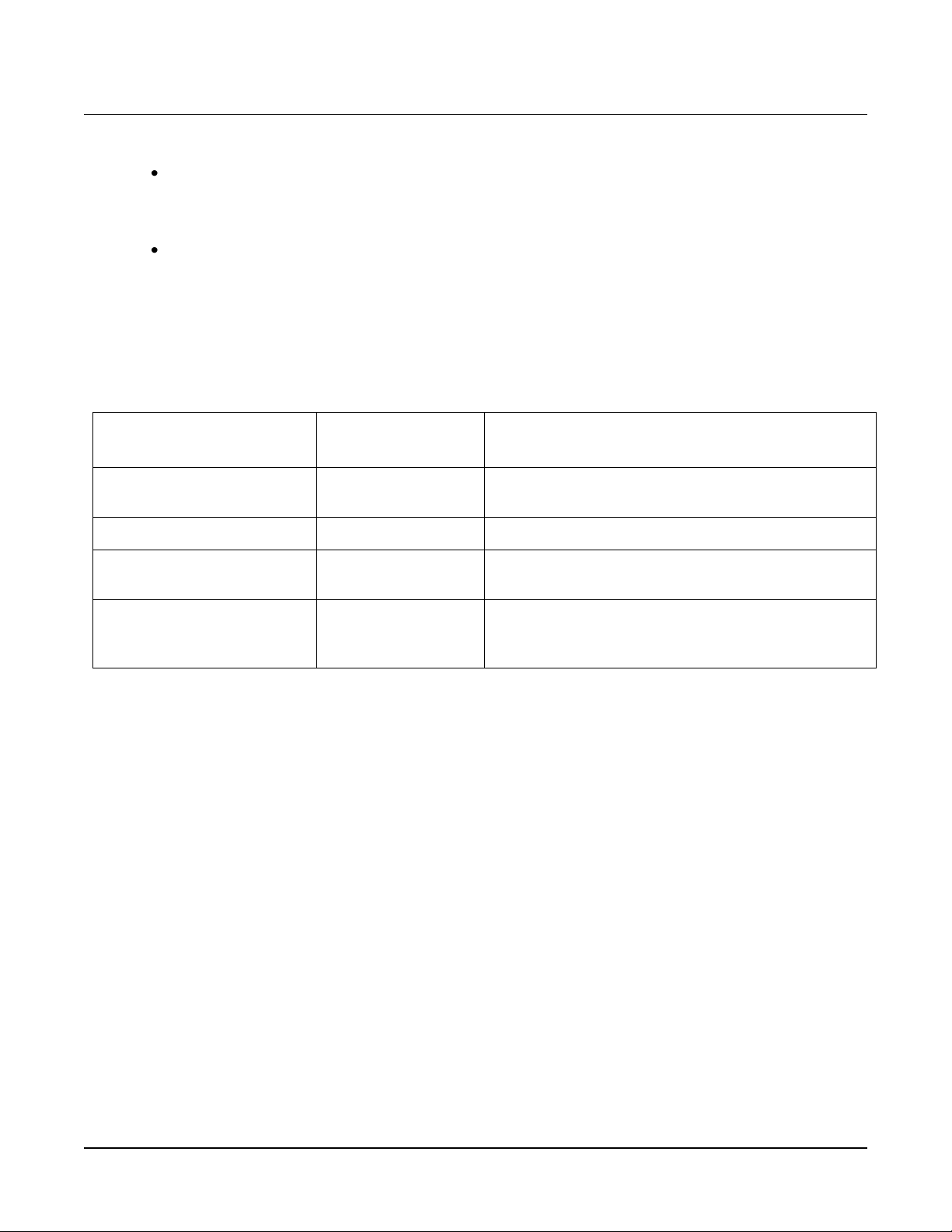

2.2 Passwords and Access Levels

Users (for local and Web access to the ACU+ Controller) are set via the Web Interface.

Note that anyone can browse the ACU+ via the local keypad and display. A password is required to

change settings. Web access always requires a User Name and password to be entered to gain

access.

Users are configured with a User Name, password, and access level.

User Name: Maximum 13 Characters (0-9, a-z, A-Z, _ ).

Password: Maximum 13 Characters (0-9, a-z, A-Z, _ ).

Once a password is entered, it remains in effect for a preset time period to allow navigating between

menus without re-entering the password.

Access Level: Refer to the following table.

A User has access to his/her level menus, plus all menus of the lesser access levels.

Chapter 2. Operation 17

This document is property of Emerson Network Power, Energy Systems, North America, Inc. and contains confidential and proprietary information owned by Emerson Network Power, Energy

Systems, North America, Inc. Any copying, use, or disclosure of it without the written permission of Emerson Network Power, Energy Systems, North America, Inc. is strictly prohibited.

Page 24

UM1M820BNA User Instructions

Key Symbol

Key Name

Function

ESC

Escape

Press this key to go back to a

previous menu or to cancel setting

a parameter.

Press ESC and ENT together to

reset the ACU+ Controller, then

press ENT to accept or ESC to

cancel.

ENT

Enter

Press this key to go forward to the

next menu, to select a parameter

to edit, or to validate a parameter

setting change.

Up

Press or to scroll through

the menus or to change the value

of a parameter.

--

Down

Issue AH, March 4, 2013 Spec No. 1M820BNA (Model M820B)

Spec No. 1M820DNA (Model M820D)

2.3 Local Keypad and Display Access

2.3.1 Local Menu Navigation Keys and LCD Display

Location and Identification: Refer to Figure 7.

Description: There are four (4) menu navigation keys and an LCD display located on the ACU+

Controller’s front panel. Refer to Table 3 for the function of the menu navigation keys.

Note: When the LCD is lit, if no button is pushed for 8 minutes, the backlight of the LCD display

extinguishes and the ACU+ Controller returns to the Main Screen. Press any key to re-activate the

LCD display.

Press any key to silence an audible alarm.

2.3.2 Local Display Menus

Refer to “Chapter 3. Local Display Menus”.

Note: A valid password is required to access menus that allow changing any power system parameter.

Navigating the Menus

To Select a Sub-Menu:

Press the up or down arrow keys to move the cursor up and down the list of sub-menus in the menu

screen (selects the sub-menu), then press ENT to enter the selected sub-menu.

To Enter a Password:

If a password screen opens, a password must be entered to allow the User to make adjustments. To enter

a password, with the cursor at the User Name field (default is “Admin”), press the down arrow key to move

cursor down to the password line. Press ENT. “0” is highlighted. Press the up arrow key once to change

the “0” to”1” (default password is “1”), then press ENT twice. (Note: If you have been assigned a unique

User Name and password, follow this procedure to enter these.)

To Change a Parameter:

Press the up or down arrow keys to move the cursor up and down the list of parameters in the menu

screen (selects the parameter to change), then press ENT to change the selected parameter. The

parameter field highlights. Press the up or down arrow keys to change the parameter value. Press ENT to

confirm the change.

Table 3

Local Menu Navigation Keys

18 Chapter 2. Operation

This document is property of Emerson Network Power, Energy Systems, North America, Inc. and contains confidential and proprietary information owned by Emerson Network Power, Energy

Systems, North America, Inc. Any copying, use, or disclosure of it without the written permission of Emerson Network Power, Energy Systems, North America, Inc. is strictly prohibited.

Page 25

User Instructions UM1M820BNA

Spec No. 1M820BNA (Model M820B) Issue AH, March 4, 2013

Spec No. 1M820DNA (Model M820D)

2.4 WEB Interface Access

Note: The ACU+ supports a 10/100M Ethernet connection.

2.4.1 Overview

Via the WEB Interface, a User (with proper access level) can:

View real-time operating information (rectifiers, converters, AC, DC, Batteries, etc.).

View and download information recorded in logs.

Send control commands.

Set programmable parameters.

Download and upload configuration files.

Download firmware to the Controller.

2.4.2 Setting IP Communications Parameters

The Controller’s IP parameters (IP, subnet mask, and gateway addresses) must be set to match your

company’s network settings. The default settings for these parameters are shown below.

IP Address: 192.168.1.2

Subnet Mask Address: 255.255.255.0

Gateway Address: 192.168.1.1

Local Menu Navigation: Main Menu / Settings / Communication / enter parameters.

WEB Menu Navigation: Maintenance / Network Configuration / enter parameters.

2.4.3 WEB Interface Menus

Refer to “Chapter 4. WEB Interface Menus”.

2.4.4 Connecting the Controller Locally (via the Ethernet Port)

Before connecting your computer directly to the Controller’s Ethernet Port, record your current network

settings as outlined below, then change these settings to match the communications settings

programmed into the Controller.

Procedure

1) Record your computer’s network settings by launching Control Panel in your computer. Navigate

through Network Connections Local Area Connection Properties Internet Protocol

(TCP/IP) Properties.

2) Record whether the "Obtain an IP address automatically" or "Use the following IP address" button

is selected. If "Use the following IP address" button is selected, also record the following:

IP Address:

Subnet Mask:

Default Gateway:

3) Record your Controller’s network settings by navigating the Controller’s local display panel to Main

Menu Settings Communication.

4) Record the following information:

IP Address:

Subnet Mask:

Default Gateway:

Example:

IP Address: 192.168.1.2

Chapter 2. Operation 19

This document is property of Emerson Network Power, Energy Systems, North America, Inc. and contains confidential and proprietary information owned by Emerson Network Power, Energy

Systems, North America, Inc. Any copying, use, or disclosure of it without the written permission of Emerson Network Power, Energy Systems, North America, Inc. is strictly prohibited.

Page 26

UM1M820BNA User Instructions

Issue AH, March 4, 2013 Spec No. 1M820BNA (Model M820B)

Spec No. 1M820DNA (Model M820D)

Subnet Mask: 255.255.255.0

Default Gateway: 192.168.1.1

5) Change your local computer’s network settings using the information you acquired in Step 4),

except that the last part of the IP address needs to be replaced with any different number.

IP Address:

Subnet Mask:

Default Gateway:

Example:

IP Address: 192.168.1.3

Subnet Mask: 255.255.255.0

Default Gateway: 192.168.1.1

6) Select OK. Note that you may have to reboot your local computer for the settings to take effect.

Follow any instruction you see on the screen.

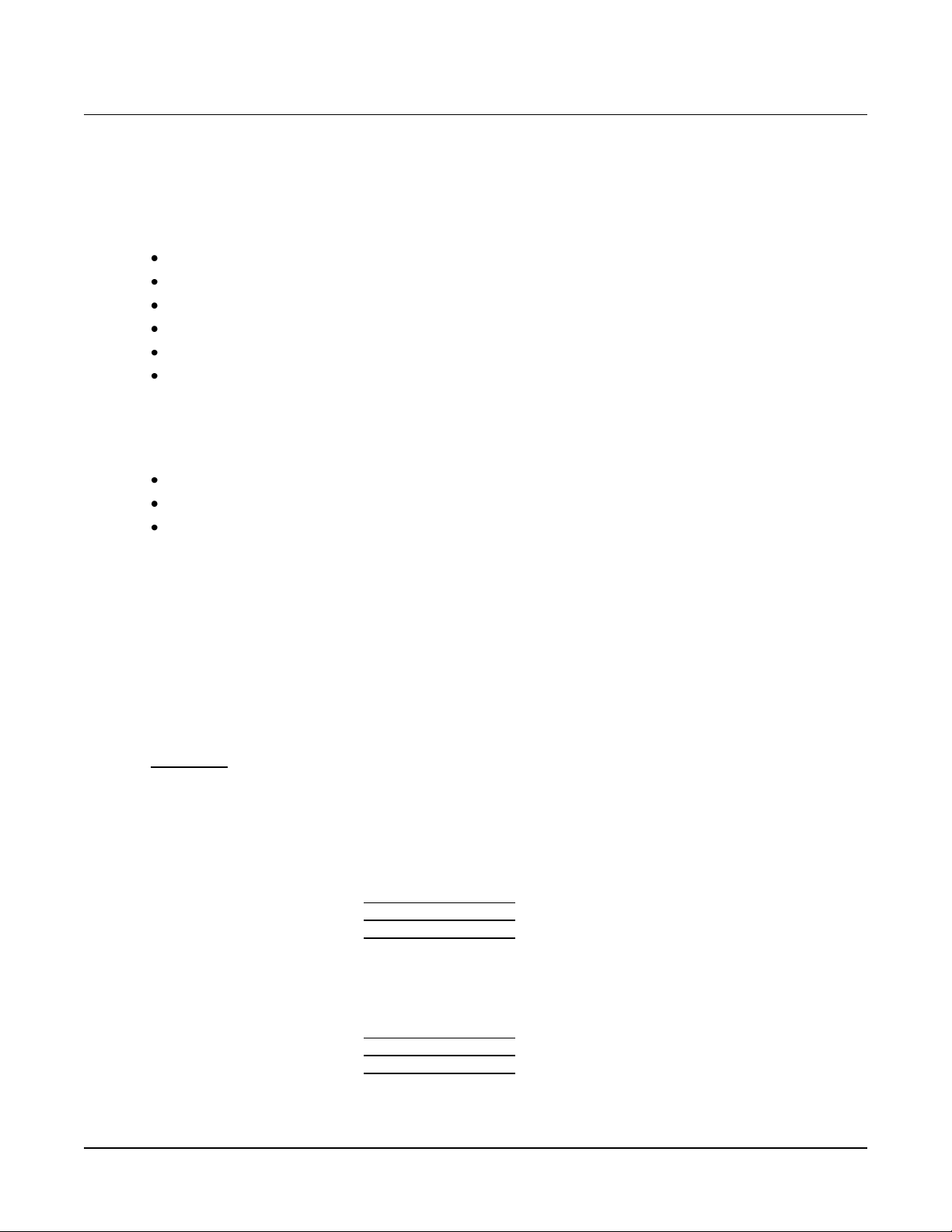

2.4.5 Disabling Proxy Server Settings to Enable a Connection to the Controller over an Intranet Network (if required)

Note: This procedure needs to be performed only when the Controller is connected to an Intranet and the

User’s computer is set to access the Intranet through a proxy server. Note that if the Controller is

connected to the Internet and the User’s computer is connected to an Intranet, the User may not

be able to disable the proxy server and access the Controller.

If the Controller’s Ethernet Port is connected to your company’s Intranet Network and your computer is

also connected to the Intranet Network but requires access via a proxy server, you must disable the proxy

server settings to access the Controller. Follow the procedure below to disable the proxy server settings.

Procedure

1) Launch “Internet Explorer”.

2) Select Internet Options from the Tools menu. The “Internet Options” window opens. In the

“Internet Options” window, select the Connections Tab.

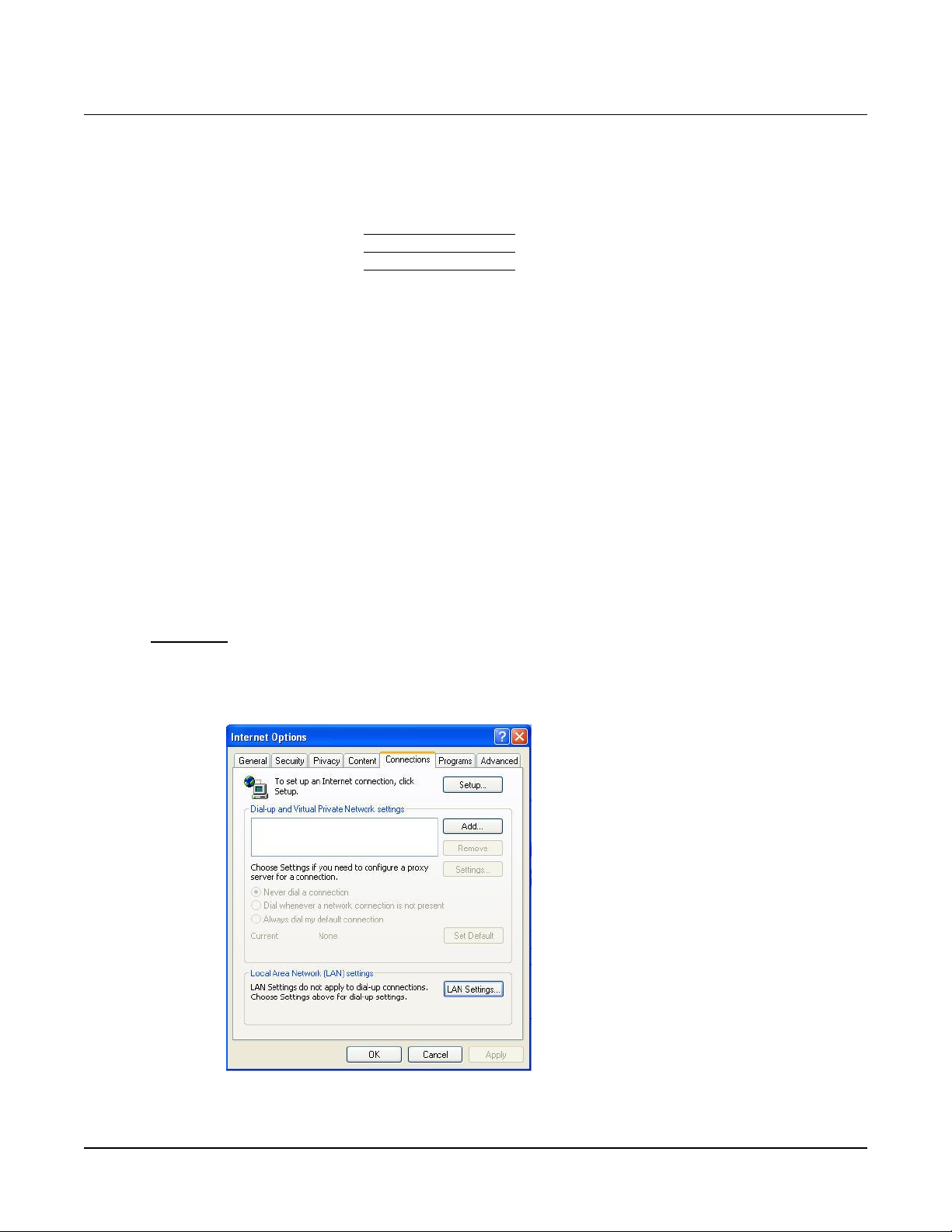

3) Click on the LAN Settings... button. The following window opens. In the LAN Settings window,

uncheck the Proxy Server box and click OK.

20 Chapter 2. Operation

This document is property of Emerson Network Power, Energy Systems, North America, Inc. and contains confidential and proprietary information owned by Emerson Network Power, Energy

Systems, North America, Inc. Any copying, use, or disclosure of it without the written permission of Emerson Network Power, Energy Systems, North America, Inc. is strictly prohibited.

Page 27

User Instructions UM1M820BNA

Spec No. 1M820BNA (Model M820B) Issue AH, March 4, 2013

Spec No. 1M820DNA (Model M820D)

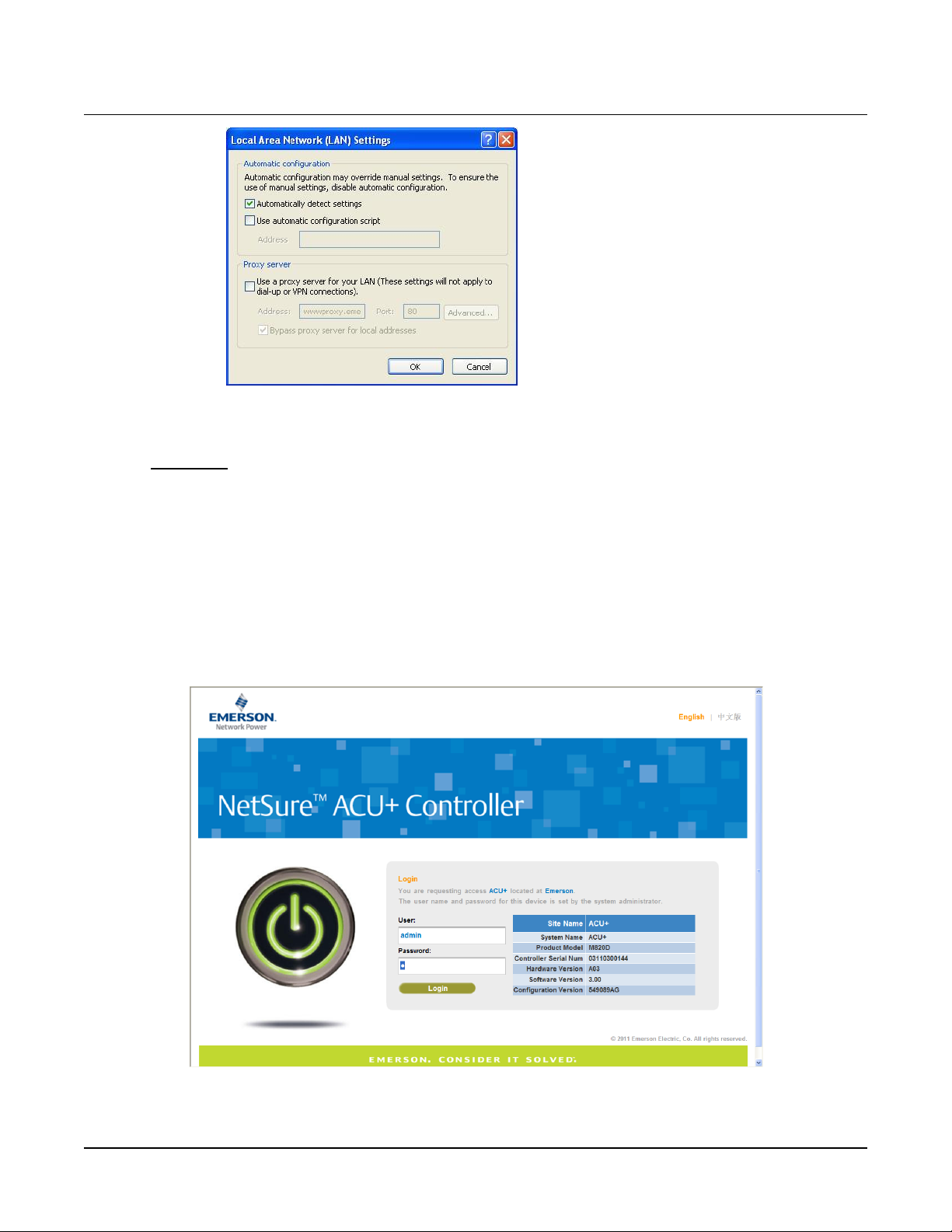

2.4.6 Logging into the Controller

Procedure

1) Internet Explorer, version 5.5 or newer, is required. It is best to view the WEB Interface at

1280 x 1024 resolution. In newer versions of Internet Explorer, you may need to turn Compatibility

View On (Tools Menu / Compatibility View).

2) In Internet Explorer, enter the IP address programmed into the Controller and press ENTER. The

following WEB Interface window opens. Enter a valid User Name and Password then click LOGIN.

Note: By default, the “User Name” is "admin" and the “Password” is “1”.

3) After entering a valid User Name and Password and clicking LOGIN, the "HOMEPAGE" window

opens. Refer to “Chapter 4. WEB Interface Menus”.

Chapter 2. Operation 21

This document is property of Emerson Network Power, Energy Systems, North America, Inc. and contains confidential and proprietary information owned by Emerson Network Power, Energy

Systems, North America, Inc. Any copying, use, or disclosure of it without the written permission of Emerson Network Power, Energy Systems, North America, Inc. is strictly prohibited.

Page 28

UM1M820BNA User Instructions

Issue AH, March 4, 2013 Spec No. 1M820BNA (Model M820B)

Spec No. 1M820DNA (Model M820D)

2.5 Common Tasks Performed via the Local Keypad and/or Web Interface

Refer also to “Chapter 3. Local Display Menus” and “Chapter 4. WEB Interface Menus”.

2.5.1 Backing Up the Configuration

A file named “SettingParam.run” is automatically created/appended by the Controller whenever a User

makes changes to any parameter settings via the LCD or WEB interface. This file can be saved to your

computer so you can restore any custom settings you may have made.

Prior to changing settings, ensure the current “SettingParam.run” file is backed up. After making changes,

create a new backup file. Note that you may change the name of a “SettingParam.run” file to differentiate

it from other files saved. The new name can use alpha and numeric characters preceding the original

“SettingParam.run” name (the end of the new file name must always be “SettingParam.run”; for example,

an acceptable filename would be “seville4SettingParam.run”).

Local Menu Navigation: none.

WEB Menu Navigation: See also “4.7.9. Retrieve ‘SettingParam.run’ File Sub-Menu”.

1) Log onto the Controller using the WEB Interface.

2) Click on “Retrieve SettingParam.run” in the MAINTENANCE MENU.

3) Click on the “Retrieve File” button to save the file named "SettingParam.run" to you hard drive.