Page 1

Instructions Leaflet

IP221, Rev. AA

November 2004

Mobrey

Level

Electropulse systems

Safety Information 2

1. Introduction

1.1 Sensors 3

1.2 Interface detection 4

1.3 Sludge density detection 5

1.4 Head amplifier units 5

1.5 Control Units 6

2. Installation

2.1 Calibration 7

2.2 Sensor and head amplifier installation 10

2.3 Control Unit Installation 12

2.4 Wiring 12

2.5 Intrinsically safe application 15

3. Fault Finding 16

4. Specification and description

4.1 Sensors 17

4.2 Head amplifiers 17

4.3 Control Units 18

5. Recommended Spare Parts

For instructions specific to units

used in hazardous area

installations

refer to leaflet IP221/SI

Appendices

Appendix I Part Numbers 20

Appendix II List of illustrations 22

Appendix III List of tables 22

Maintenance / Inspection 23

Contents

Gap Sensors

Hi-Sens

Attenuation method

Reflection method

Normallay acting

Inverse acting

Summary

Cables

Head amplifier

Control Unit

www.mobrey.com

1

Page 2

Warning :

If this equipment is used in a manner not specified by the manufacturer, the protection

provided may be impaired. All installation and commissioning of this equipment must be

carried out by electrically competent persons.

Protection of permanently installed equipment :

This equipment is regarded as permanently installed equipment. Ensure wiring is suitable for the load

current and the insulation is suitable for the voltage, temperature and environment of the installation.

A supply disconnection device must be included in the installation, fitted as close as practical to and

not be obstructed by the equipment. It must be double pole and marked as the disconnection device.

Each relay circuit must be protected by a fuse not exceeding the maximum rated current for the relay

as specified in the manual.

On wall mount unit disconnect supply before removing control unit from base. Control units must be

correctly assembled to achive stated IP ratings.

Explanation of symbols :

The IEC symbols used on the equipment are as follows :

Refer to Manual.

!

The Protective earth terminal must be connrected to an external Protective earthing system.

Functional earth terminal. |f this terminal is used it must be connected to an external

earthing system at the same potential as the protecive earthing system.

2

Page 3

1. Introduction

The Mobrey Electropulse system is used for the detection of liquids or liquids with suspended / settled

solids. It consists of three units, a sensor, a head amplifier unit, and a control room unit.

1.1 Sensors

There are many different Mobrey sensors available, but they fall into two categories:

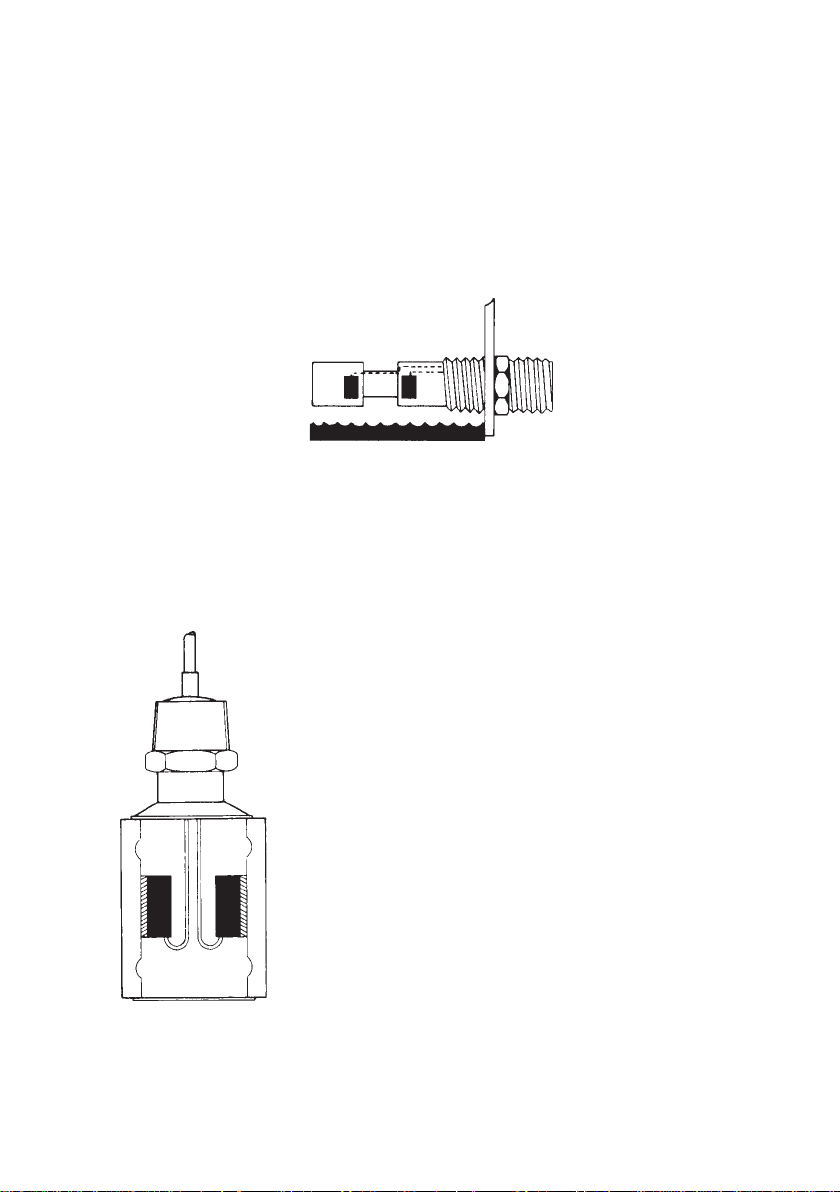

a) Gap sensors

Figure 1.1 - Gap sensor, cut away to show construction

Gap sensors feature two ultrasonic transducers mounted one either side of the gap. When immersed in a

liquid the signal transmitted is carried by the liquid across the gap, to the receiver, when the liquid level

drops below the sensor, the signal cannot be carried across the gap, and is not received by the second

transducer.

b) Hi-Sens cylindrical sensors

The Hi-Sens sensor consists of two ultrasonic transducers mounted

on the inside of a cylinder. When the sensor is not submersed in

the liquid the signal from one transducer resonates round the

cylinder like a bell ringing. If the liquid rises up around the

sensor, this ringing is damped and the signal received by the

second transducer is significantly reduced. This reduction is

monitored by the head amplifier unit. Switching occurs when the

liquid is about half way up the cylinder.

Figure 1.2 - Hi-Sens, cutaway to show

construction

Use of Hi-Sens transducers in high alarm applications, and gap

sensors in low level alarm applications achieves a Failsafe system

in which any sensor or cable failure will be indicated as a fault or

an alarm by the control unit.

3

Page 4

1.2 Interface detection

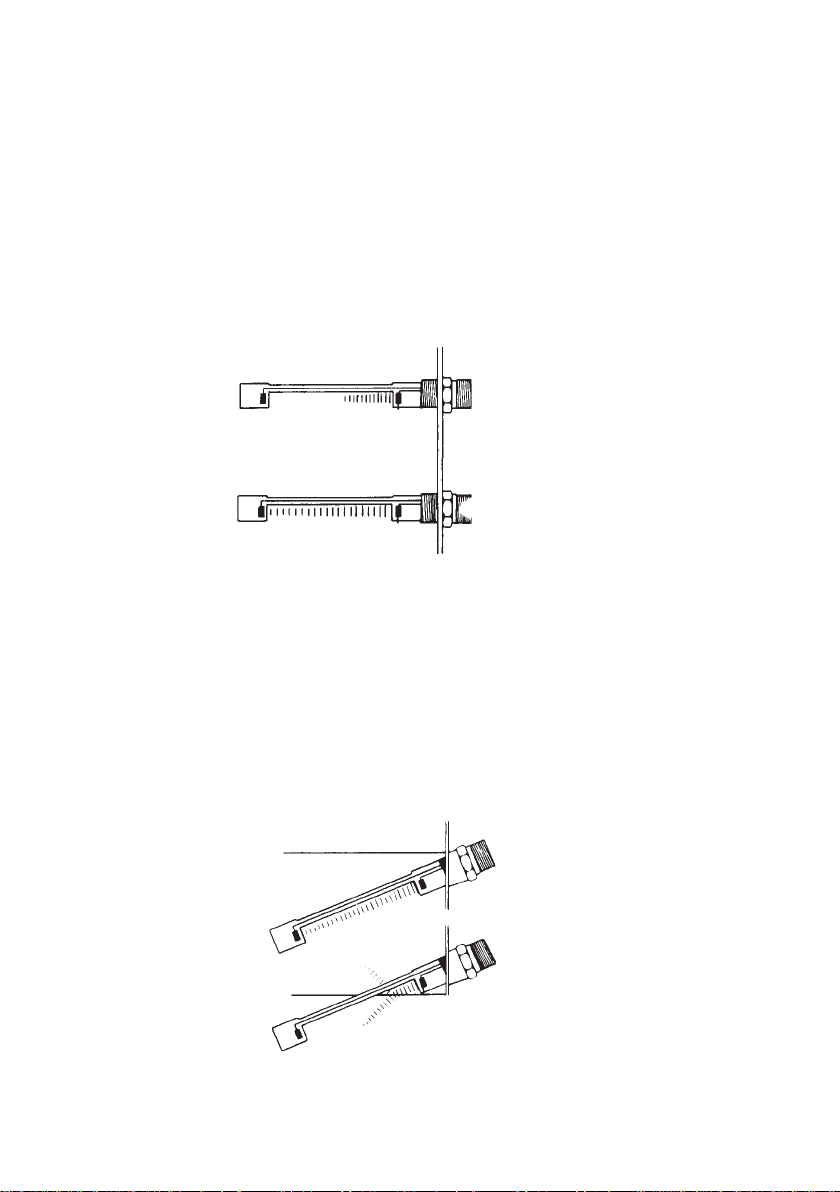

Attenuation method – Figure 1.3

Attenuation is the reduction in strength of the ultrasonic signal caused by its transmission through a

liquid. Viscous liquids, emulsions and liquids containing solid particles have a greater attenuation

than clear thin liquids. Usually the difference in attenuation between the two liquids is sufficient and

the attenuation method can be used to determine which liquid is in the sensor gap. In this case the

gain of the control unit is set so that the relay is energised only when the liquid with the lower

attenuation is in the gap. For this application Sensor Type 402S is used horizontally. The heavy-duty

sensor type 433S may also be used, perhaps from above on an extension tube. For use in pipes, the

sensor pair 442S should be mounted in line, facing one another, generally horizontally across the

diameter, to detect the interface or presence of liquid. As an example, the interface between oil and

water can be detected using this method.

OIL

Receiver Crystal

Sensor in Oil. The ultrasonic beam is

attenuated and will not reach the

receiver crystal.

WATER

Receiver Crystal

Sensor in Water. The ultrasonic beam

reaches the receiver crystal.

Transmitter Crystal

Figure 1.3 - Attenuation Method

Transmitter Crystal

Reflection Method – Figure 1.4

If the attenuation’s are similar and the attenuation method does not work, then the reflection method

must be used.

If an ultrasonic beam is transmitted from one liquid to another at a suitable angle, it does not go

straight through the interface, but is bent, so that it does not reach the receiver crystal. If there is no

interface in the gap, but only one liquid, then the beam travels in a straight line, is received and the

relay energised.

For this application the sensor must be mounted at about 10º from the horizontal, as shown in Figure

1.4. Note that this method gives an alarm only when the reflective surface of the interface itself is at

the sensor.

Oil

Water

Sensor in lower liquid. The ultrasonic

beam reaches the receiver crystal.

Figure 1.4

Oil

Receiver

Crystal

Water

Transmitter

Crystal

Sensor at interface level. The ultrasonic

beam is reflected/refracted and will not

reach the receiver crystal.

In order to differentiate between two liquids, interface sensors have a large gap (usually 150mm) and

oscillate at 3.75MHz.

4

Page 5

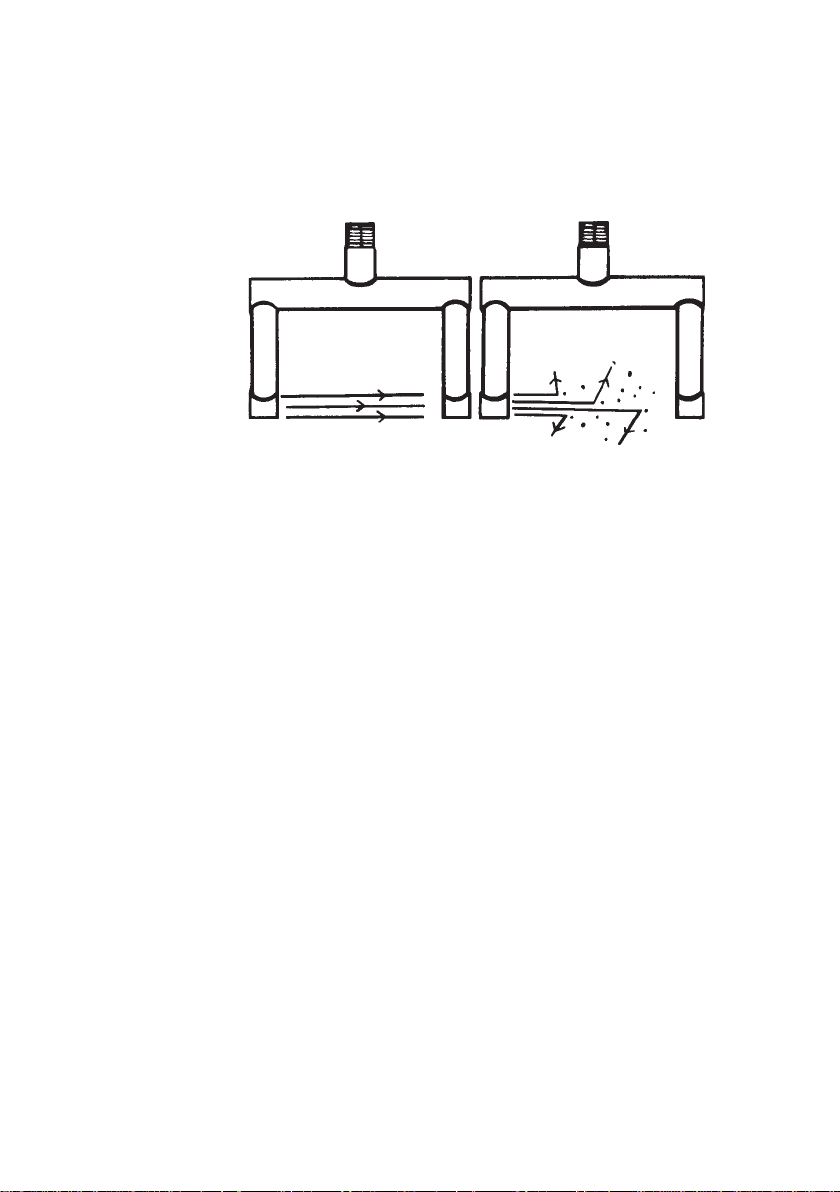

1.3 Solids Density Detection

The Electropulse system can be used in conjunction with a 433S type sensor to provide blanket level

detection in settling tanks, facilitating the control of automatic de-sludging. In addition the

Electropulse system can be used to detect the solids density of a slurry in a pipe line. In this case the

Mobrey pipe section is used instead of the sensor.

Figure 1.5 - Sludge

density sensor,

operation

(a) Clear liquid, signal transmitted (b) Solids attenuate the signal

Figure 1.5 shows the operation of the sensor. In a clear liquid the ultrasonic signal is carried across

the gap so the sensor oscillates and the control unit gives a ‘Normal’ indication. When a sludge is

present this scatters the signal as shown in Figure 1.5(b) The signal is attenuated, and the control

unit gives an alarm indication.

1.4 Head Amplifier Units

The head amplifier is mounted on the end of, or near to the sensor. It converts the low level high

frequency signal of the sensor into a series of low frequency current pulses that are sent to the control

unit. These pulses are virtually immune to electrical interference.

This means that the length of the cable between the head amplifier and the control room can be 1km

or more. There are five versions available, which fall into two categories:

i) Normal acting head amplifiers

When the sensor is in its normal state (i.e. Dry for Hi-Sens and Wet for Gap Sensors) the signal from the

transmitting transducer is received by the second transducer, and fed back to the head amplifier

causing it to transmit current pulses to the control unit. If an alarm state occurs the sensor no longer

oscillates, and the head amplifier stops transmitting the pulses. The control unit indicates the alarm

condition.

Thus in the normal state, the whole system is active. If a fault occurs in the electronics then the

pulses cease and an alarm state is indicated immediately. In this way the whole circuit is continually

monitored. This is in addition to the fault checking facilities of the control unit.

There are four versions of the normally acting head amplifier. Usually it is possible to mount the head

amplifier on the sensor, but it may be necessary for reasons of temperature or space, to use a head

amplifier which is mounted adjacent to the sensor, and is connected to it by a short length of coaxial

cable. Both of these types are available either in an industrial case, or a heavy-duty case that is

suitable for open deck mounting in marine applications.

The sensor mounted marine head amplifier may contain a double circuit board for use with dual HiSens or gap sensors.

5

Page 6

ii) Inverse acting head amplifiers

When it is required to use a Hi-Sens sensor for low level detection, or a Gap Sensor for high level

detection, an inverse acting amplifier must be used. Examples of this are given below:

• Hi-Sens can be used to detect low levels in very light liquids or foams.

• A miniature Gap Sensor 366S, may be used to detect high level when there is insufficient room for

a Hi-Sens.

• High temperature, corrosive, or aerated liquids, where Gap Sensor can be used at high level if

required.

The head amplifier transmits pulses when the sensor is not oscillating (its normal state), and stops

transmitting in the alarm condition when the sensor is oscillating. Thus the normal light on the control

unit indicates a wet Hi-Sens, or dry gap sensors. When the inverting amplifier is used the sensor is in

its quiescent state for most of the time. For this reason sensor cables can be monitored to check for

cable breaks with some sensors.

Note that when an inverse acting head amplifier is used the sensor is not oscillating under normal

conditions and therefore the integrity is not as high as that of a normally acting head amplifier, which

should be used wherever possible.

Inverse acting amplifiers are only available in adjacent mounting industrial housings.

Summary of sensor head amplifiers

1.1

1.2

Type

Sensor mounting

Adjacent mounting

Inverse acting

Sensor State

Hi-Sens Dry

Lo-Sens Wet

Hi-Sens Wet

Lo-Sens Dry

Industrial Case

***S*PI***

MEP*AI

MEP*XI

Normally acting head

amplifier *PI*, *PM*, AI

Normal State

Pulses transmitted

Green light on c.u.

Alarm State

No Pulses transmitted

Red light on c.u.

Marine

***S*PM***

-

Output

Inverse acting head

amplifier XI

Alarm State

No Pulse transmitted

Red light on c.u.

Normal state

Pulses transmitted

Green light on c.u.

Sensor cable check circuitry is built into the industrial adjacent mounted head amplifiers, where the

coaxial cable linking head amplifier and sensor may be exposed on site. This is only operable where

the sensor in use has Earth continuity between the two coaxial cables, see section 2.2 Lack of screen

continuity along these cables causes the head amplifier to signal a fault condition to the control room

readout unit. To use the facility a wire link in the head amplifier must be cut during installation.

(See section 2.2)

1.5 Control Units

The control unit is available in two forms, a free standing plastic case (MEP*L), or a rack mounting

unit (MEP*R). Operation is the same in either case.

Front panel indicators show normal condition (green), alarm (red), and fault (amber). A front panel

switch to test fault and alarm circuits is provided, together with a variable time delay for the alarm

circuit.

Relay contacts are provided to indicate an alarm condition. A second relay is supplied on rack

mounting control units to indicate a fault. On both units, a fault also causes an alarm to be

indicated.

6

Page 7

2. Installation

2.1 Calibration

When installing the sensor, it should be remembered that it is measuring instrument, and should be

treated with care. Before installation the sensor and control unit should be inspected for transit

damage, the gap faces of gap sensors must be parallel. Before installation, the equipment should be

calibrated, if possible, using a representative sample of the liquid in which it is to be used. The head

amplifier unit should be wired to the control unit, which should be connected to its power supply.

Wiring instructions are given in section 2.4.

When the mains supply to the control unit is switched on, either the green ‘normal’ light or the red

‘alarm’ light should be on, the amber ‘fault’ light should be off. The lid of the head amplifier unit is

removed by undoing the four screws or Allen bolts. Care should be taken not to damage the sealing

gasket, which should be replaced with the lid. When using integral head amplifiers, the sensor must

not be unscrewed from the head amplifier unit as this is likely to damage the internal wiring (and may

violate ATEX approval).

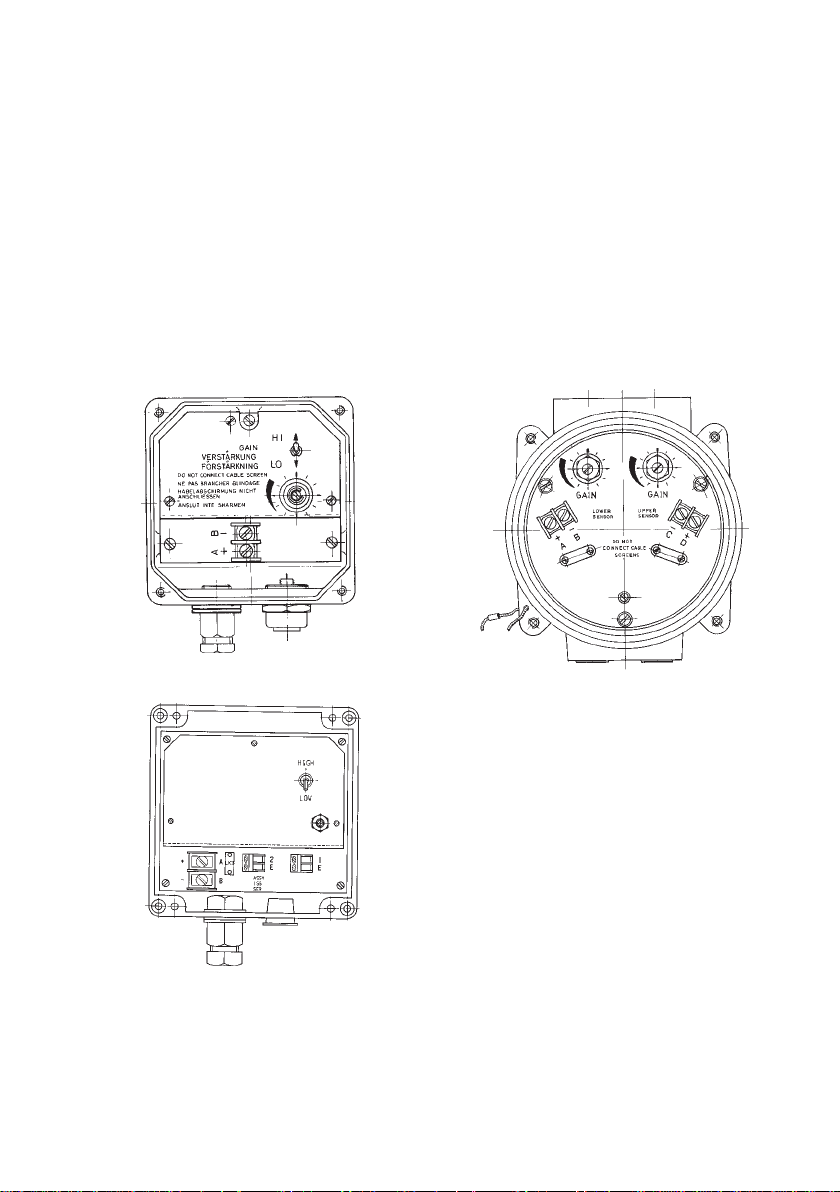

i) ***S*PI

ii) ***S*PM

Figure 2.1 - Head

amplifier internals

iii) MEP*AI and MEP*XI

The marine head amplifier ***S*PM has one gain potentiometer for each sensor attached. It is factory

calibrated for the side range of liquids carried on tankers. It is advisable to check the function of the

system before final installation, using a sample of the liquid. The gain potentiometers are covered by

a screw cap, which should be replaced after re-calibration.

The industrial head amplifiers ***S*PI, MEP*AI and MEP*XI have a gain switch, which is illustrated in

Figure 2.2 (i) and 2.2 (iii).

7

Page 8

Calibration procedure by sensor type

i) Hi-Sens Sensors

1) Ensure that the sensor is clean and dry, that nothing is touching the sensor body, and that the

delay adjustment on the control unit is fully anti-clockwise.

2) Set the gain potentiometer in the head amplifier fully anti-clockwise, and the gain switch (if

fitted) in the low gain position.

3) The control unit should now indicate ‘alarm’ (or ‘normal’ for inverse acting head amplifiers).

4) Gradually increase the gain until the control unit indicates ‘normal’ (or ‘alarm’ for inverse acting

control units). This is beginning of the operating band.

5) The optimum gain setting can be found by rotating the potentiometer a further 30º (one division on

the clock face),

6) Check that the control unit switches satisfactorily when the sensor is immersed in the liquid.

ii) Gap Sensors

1) Ensure that the sensor is clean, and immerse it in a sample of the liquid, making sure that the gap

is full of the liquid, and unobstructed. Adjust the time delay on the control unit fully anticlockwise.

2) Set the head amplifier gain control fully anti-clockwise, with the gain switch (if fitted) in the high

gain position.

3) The control unit should now indicate alarm (or normal for inverse acting head amplifiers) if it does

not switch to low gain (if a gain switch is fitted).

4) Gradually increase the gain until the control unit indicates normal (or alarm for inverse acting

head amplifiers). Note the position of the potentiometer and gain switch. This is the lower end of

the working range.

5) Remove the sensor from the liquid, and allow the liquid to drain away. Ensure that nothing is

touching the sensor body. The control unit should now indicate alarm (or normal for inverse

acting head amplifiers).

6) Gradually increase the gain until the control unit indicates normal (or alarm for inverse acting

head amplifiers). Note the position of the potentiometer and gain switch. This is the upper limit

of the working range.

7) The optimum gain setting is midway between the points recorded in steps 4 and 6. It may be

necessary to estimate this point if the gain switch has been used.

8) Check that the control unit switches correctly when the sensor is immersed in the liquid.

iii) Interface Sensors – Attenuation Method

1) Ensure that the sensor is clean, and that the delay on the control unit is fully anti-clockwise.

2) With the sensor in the lower liquid adjust the gain potentiometer anti-clockwise, using the gain

switch if necessary, until the control unit changes from ‘Normal’ to ‘Alarm’.

3) Note the position of the potentiometer. If the control unit does not switch to ‘Alarm’ use the

bottom end of the scale as a reference.

4) Immerse the sensor in the upper liquid. The control unit should now indicate ‘Alarm’. If it does

not then the reflection method should be used.

8

Page 9

5) With the sensor in the upper liquid, increase the gain, using the switch if necessary, until the

control unit changes to ‘Normal’. Note the position of the potentiometer. If the control unit does

not change to normal then the end of the scale should be used as a reference.

6) The gain should be set half way between the settings found in steps 3 and 5.

7) Check that the unit switches correctly giving a normal indication in the lower liquid and an alarm

indication in the upper liquid.

8) If an inverse acting head amplifier is used, ‘Normal’ and ‘Alarm’ conditions quoted above are

reversed.

iv) Interface Sensors – Reflection Method

1) Check that the sensor is clean and that the control unit delay is fully anti-clockwise.

2) Immerse the sensor in each liquid in turn, adjusting the gain potentiometer until the control unit

changes from ‘Alarm’ to ‘Normal’. Note the position at which this occurs for both liquids. If the

two positions differ by more than two divisions, the attenuation method can be used.

3) For the reflection method, the gain should be set one division greater than the higher of the two

settings found in step 2.

4) This gives a rough calibration. The gain should be increased if spurious alarms cannot be

overcome by increasing the delay. The gain should be decreased if the unit fails to detect

interfaces.

5) For the reflection method the sensor should be mounted at an angle of 10º to the horizontal.

6) Where the interface consists of an emulsion layer, the sensor functions as the reflection method,

giving an ‘Alarm’ condition only at the interface, but in this case, it is not necessary to angle the

sensor at 10º.

7) If an inverse acting head amplifier is used, ‘Normal’ and ‘Alarm’ conditions quoted above are

reversed.

v) Sludge Sensor

1) Ensure that the control unit delay is set fully anti-clockwise.

2) When used with a 433S type sensor, the sensor should be positioned at the top of the sludge

blanket during calibration.

3) The gain can now be adjusted until the control unit changes state with the sensor in this position.

4) Check that raising and lowering the sensor into and out of the sludge blanket causes the control

unit to switch.

5) If the pipe section is used, the tank should be de-sludged until the pipe contains solids at roughly

the required switching point. The gain is then adjusted until the unit just switches. This should

only be done when the slurry in the pipe is flowing.

6) The pipe section should be installed with the sensors in a horizontal plane, and with 10 diameters

of straight unrestricted pipe upstream and six diameters downstream.

9

Page 10

2.2 Sensor and head amplifier installation

Make sure that there is room inside the tank for the sensor without anything touching it, and that the

gap is not obstructed. At least an inch of clearance must be left around Hi-Sens senors. The head

amplifier should have its cable glands downwards if possible to reduce the possible to reduce the

possibility of ingress of rainwater.

For threaded sensors a hole is drilled in the tank at the appropriate level, and this is tapped to take

the sensor. On thin walled tanks it may be necessary to fit a boss to the tank. Use PTFE tape or

similar to seal the thread so that the sensor does not have to be over-tight for a good seal, as this may

damage the sensor. The sensor should be screwed in using a spanner on the hexagonal fitting, not by

turning the sensor head unit. It is assumed that the sensor will be earthed through the tank.

For flanged sensors, arrange a suitable counter flange, and fit using a gasket, tightening the bolts

evenly. If possible the bridge of sensors 302S and 402S should be to the side of the gap, and not above

or below it, and all gap sensors should have their gaps vertical. This is so that any sludge in the tank

cannot settle on the faces of the sensor.

Interface probes 402S and 433S may be mounted at an angle of 10º to the horizontal so that they can

be used in either attenuation or reflection mode. Mounting details for the adjacent head amplifier are

shown in Figure 2.3. Both model types MEP*AI and MEP*XI adjacent mounted amplifiers have a sensor

cable continuity check system built in. This cable check is only operative when one of the following

sensors is in use.

30HS, 302S, 312S, 312SP, 323S, 352S, 362S, 373S, 393S, 402S, 433S

The cable check circuit is activated by breaking Link 3, positioned next to the A & B terminals. (See

Figure 2.1)

56.0

24.0

4 FIXING HOLES

Ø 4.5mm

15.0

120.0

90.0

OF FIXING HOLES

122.0

25.0

Figure 2.2 - Adjacent head

amplifier mounting details

110.0

OF FIXING HOLES

44.0 32.0

10

Page 11

* DIN RAIL Mounting Clip available on request

Figure 2.3 - Control unit mounting details

11

Page 12

2.3 Control unit installation

The control units should be installed in an area suitable to their specifications. They are designed to

be used indoors, but could be installed outside using a suitable weatherproof enclosure. The front

panel should be accessible to the operator.

The standard control unit MEP*L is installed by undoing the two screws on the top and bottom of the

unit, and removing the base. This can now be mounted as required, making sure that the connection

terminals are on the left-hand side of the base.

The 19” rack unit should be mounted in a suitable cabinet in the usual fashion. It accepts up to

fourteen rack modules to type MEP*R. It should be noted that I.S. control units MEP3R will only fit

into an I.S. rack MEP3B and that the rack is included in the approval. Mounting details are shown on

the previous page.

Allow at least a 50mm gap between each rack on multiple rack installations to allow air circulation.

On installations of multi-rack systems, the fitting of a cabinet air circulating fan is recommended.

Wires to the MEP*B rack units are connected to the terminal blocks mounted on the rear panel of the

rack. In the factory the modules are fitted starting from the left hand side when viewed from the front

of the rack. If desirable, the connectors and modules can be repositioned in the rack. To assist with

cable wiring, the connector block wire access faces the rear of the rack and the screw terminals are

therefore angled. To fit cable to the 5 modules closest to the right hand end of the rack (numbers 10-

14) it is necessary to release the connector and rotate it slightly to allow screwdriver access.

2.4 Wiring

i) Cable

The connection from amplifier to the control unit should be made with two-core twisted pair instrument

cable with overall screen. The cores should be at least 0.5mm

2

and the cable length not more than 1

km, the screen may be omitted on cable runs of 10m or less, provided that the installation will not be

subject to excessive electrical noise.

A summary of wiring arrangements is shown in figure 2.4.

Please consult the factory if this specification does not cover your needs, and for recommended

cables.

Sensor

35m *Max

(cable supplied with sensor)

MEP*A* and MEP*X*

only

* 15 max on i.s. systems

SECTION THROUGH CABLE

Head amplifier

Outer Sheath

Refer to section 2.5 for I.S. requirements

Figure 2.4 - Wiring summary for illustration only

N.B. Relays are

shown in their

‘normal’

operating states

Do not connect

screen

Alarm relay

Fault relay

(MEP*R only)

1km max.

Connect screen at

this end only

Screen

12

Control unit

Cores

Min. area 0.5mm

Max loop Impedance 35Ω

Inner Sheaths

Supply

Protective

earth

N.B. Control unit contacts

may not be in the order

illustrated

2

Page 13

ii) Head Amplifier Unit

The head amplifier terminals A+ and B- should be connected to the cores of the control unit cable. In

the case of the dual marine unit, lower sensor connections A+ and B- are connected to the two cores

of one cable, and upper sensor connections, C- and D+ to the other. The screen should not be

connected in any head amplifier unit, as this could cause an earth loop. The marine head amplifier

has cable grips which should be used. Care should be taken not to overtighten these, as this could

result in damage to the circuit board. The cable is then taken out through the cable entry in the head

amplifier.

When an adjacent head amplifier (AI or XI) is used, the sensor cable pins 1 and 2 are connected to

terminals 1 and 2 respectively in the sensor head amplifier. The green earth wires are connected to

the ‘E’ terminals, as shown below.

.

Red wire with

No. 2 tag to 2

green wire to E

Red wire with

No 1 tag to 1

green wire to E

To sensor

Figure 2.5

iii) Control unit

The system is designed to be noise immune; however, it is good practice to separate the

instrumentation cables from power cables. Figure 2.6 shows the terminal arrangements. The head

amplifier cable cores are connected to the + and – terminals on the control unit, ensuring that +A and

+D is connected to the + terminal, and –B or –C respectively is connected to the – terminal. The

screen is connected to the “SCN” terminal marked sensor on the rack-mounted unit.

The main connections are made to the L and N terminals of the control unit. The control unit must be

earthed, this is mandatory on intrinsically safe units.

The free standing control unit has one relay, which is a double pole changeover (DPCO) relay. This

relay is normally energised and will release if an alarm or fault condition occurs. The rack-mounting

unit has a single pole changeover (SPCO) fault relay, and an SPCO or DPCO alarm relay. The alarm

relay is normally energised and releases if an alarm or fault condition occurs. The fault relay

energises if a fault occurs. Thus in ‘normal’ mode with the green light on, the alarm relay is

energised, and the fault relay is not, as shown in Figure 2.4.

An HBC fuse should be included in the relay circuit as specified in Table 2.1.

All fuses are 20mm x 5mm

Control

Unit

MEP3R/*D

MEP3R/*S

MEP3L/*D

Relay

DPCO

SPCO

DPCO

Relay contact

rating (each)

45VA

500VA

500VA

Maximum fuse rating

at 120V

400mA

4A

4A

at 240V

200mA

2A

2A

Table 2.1 - Relay Ratings

13

Page 14

MEP 3B

I.S.

MEP 3L

I.S.

Screen to be

connected

Relays

To head

amplifier

Protective

Earth

Neutral

Live

Supply

Figure 2.6 - Control Unit Connections

14

Page 15

2.5 Intrinsically safe installation

Control units type MEP3* and head amplifier units to type MEP3** and ***S*P*H** are approved by

ATEX as intrinsically safe equipment to II 1 G Ex ia IIC. Refer to safety instruction IP221/SI and local

code of practice.

The following points must be noted when installing these units:i) The cable from the head amplifier to the control unit must be screened, and the screen must be

connected at the control unit end only.

ii) On I.S systems the cable from sensor to head amplifier must be less than 15 meters long. If more

than 3 meter is required, special cable must be used.

iii) The control unit must be earthed using at least 4mm2 wire. All screen earth and main earth

connections must be commoned. In the case of the rack unit, MEP3B, the chassis must be

earthed and each unit connected independently to the chassis earth.

iv) I.S. cables must exit the control separately from the mains and relay cables.

v) It is the responsibility of the installer to ensure that local codes of practice are followed.

Intrinsically Safe Electropulse is approved by ATEX & standards EN50014 and EN50020.

The certificates are listed below:

Description

Certificates of Conformity

MEP3 L

MEP3 R/MEP3 B

Sensor & Head Amplifier

Adjacent Amplifier

Sensors (separate)

Approval

Code

II (1) G [EExia] IIC

II 1 G EExia IIC T4

II 1 G EExia IIC T4

II 1 G EExia IIC T4

Table 2.2 - Approvals

To Standard

EN 50014 & EN 50020

EN 50014 & EN 50020

EN 50014 & EN 50020

EN 50014 & EN 50020

15

Page 16

3. Fault Finding

If the unit does not work as described in the text, this section suggests some simple checks which will

rectify most faults. If the system still ceases to work or there is any doubt as to its working, the factory

should be consulted. IT SHOULD BE NOTED THAT SOME OF THE TESTS BELOW VIOLATE I.S.

REQUIREMENTS AND SHOULD NOT BE ATTEMPTED ON I.S INSTALLATIONS. If in doubt please contact

the factory.

The first test is always to check the mains supply voltage. The correct supply voltage is written on the

circuit board, and is easily checked. Connecting a unit to the wrong voltage will at best prevent it from

working, and at worst cause irreparable damage. It is also useful if possible, to exchange the control

unit for another which is known to be working, being careful to check that they both run at the same

voltage. This is a simple matter as both types of control unit unplug from their connections.

The following is a list of common faults and suggested remedies. Make sure when fault finding that

the control units are connected to the correct head amplifier.

Possible faults and suggested remedies:

No front panel lights lit

i) Check that mains is connected and switched on.

ii) Check the fuse, and replace if necessary. The part numbers for fuses are:

• All rack modules - H1525 (F 500mA HBC)

• Free standing unit 240V - K1793 (T 63mA, 35A Breaking capacity)

• Free standing unit 120V - K1796 (T 125mA, 35A Breaking capacity)

All fuses are 5mm x 20mm IEC 127.

Fault indicated

i) Check for short circuits between the head amplifier cable cores, or open circuits. Disconnect the

cable from the control unit, and measure the resistance between the two wires to the head

amplifier. The resistance should be a little over 100K ohm in one direction, and about 3.5K ohms

to 50k ohms in the other with the head amplifier connected depending on the meter used. Check

that the resistance between either core and the screen is at least 2M ohm when the screen is

disconnected at both ends.

ii) Excessive current causes a fault alarm. The head amplifier usually consumes 12-16mA. This is

measured by disconnecting one of the head amplifier terminals, and connecting a millammeter

between the head amplifier terminal and the end of the wire. Reconnect the wire when this

measurement has been taken.

iii) Cable cores must be connected at both ends, and the screen must be connected at the control

unit end only.

iv) Make sure that the cable is within the specification of section 2.4 (i).

v) Ensure that the link in the head amplifier has not been removed unless the unit is used with one

of the sensors listed in Section 2.2

Unit not switching

Recalibrate as described in Section 2.1.

Relay contacts not changing

i) If the lamps are indicating the correct status of the appropriate sensor, but the relay contacts at

the rear of the unit are apparently not changing state, check the external fuses in the relay

circuits.

ii) Check that the relay inside the unit is switching freely.

16

Page 17

4. Specification and Description

4.1 Sensors

Sensor

Type

Minimum

Temperature

ºC

302S

30HS

312S

312SP

323S

352S

362S

366S

373S

393S

39HS

402S

420S

433S

442S

HL*S

-70

0

-70

-70

-70

-70

-210

-210

-70

-70

0

-70

-70

-70

-70

-70

* Note that 1 kg/cm2 = 100kPa

4.2 Head Amplifiers

Power supply:

Operating frequency:

Gain:

Output:

Temperature Range:

Test Switches:

Normal 11.5V, 12-16mA from the control unit

1 or 3.7 MHz

Potentiometer adjustable, switchable ranges on MEP**I

Current pulses transmitted to control unit in ‘Normal’ mode (270 Hz)

-25 to 85ºC

Optional: MEP* AI, ***S*PI**, ***S*PM** simulates a break in the sensor cables

(fault test)

MEP*XI simulates active sensor, stopping pulses (alarm test)

Housing:

i) ***S*PI**: IP54 Aluminium housing, mounted on sensor, Pg 16 cable entries

ii) ***S*PM**: IP68 Gunmetal or Stainless steel, mounted on sensor, M20 cable

entries, holds up to two head amplifier circuits.

iii) MEP*AI: IP65 Polycarbonate, mounted adjacent to sensor

MEP*XI

Cable:

i) Head amplifier Not supplied, see Section 2.4 (i) for specification.

ii) Sensor to head MEP* (AI, XI) only, supplied with sensors.

Earthing:

Head amplifier must not be connected to the screen of the control unit cable.

On adjacent amplifier, the screens of the sensor cables must be connected to the

head amplifier.

Intrinsic Safety:

Units type MEP3 are intrinsically safe, see table 2.3 for certificate details

Maximum

Temperature

ºC

150

250

130

130

130

150

65

65

150

150

250

150

150

150

150

130

Maximum

Pressure

Kg/cm

56

50

21

20

21

56

70

3.5

56

56

50

103

280

105

105

100

2

Table 4.1 - Sensor specification

to control sensor

amplifier

17

Fitting

R¾”

R1½”

R1”

R1”

R¾”

R¾”

R¾”

M6

R¾”

R¾”

R¾”

R¾”

¾” NPT

R¾”

R¾”

Flange

or screw

Frequency

1

1

1

1

1

1

3.75

3.75

1

1

1

3.75

3.75

1.20

3.75

1

Page 18

4.3 Control Units

Supply:

Power consumption:

Output:

Connections:

Earthing:

Intrinsic safety:

Output to Head Amplifier:

Temperature Range:

Housing:

Environment:

Installation Category:

Indicators:

Fault Indication:

Test Switch:

Alarm Delay:

Reset:

E.M.C.

L.V.D.

Free Standing Unit MEP*L

Less than 7VA

Alarm relay

DPCO relay, energised in normal

mode, releases on fault or alarm

Screw terminal in the base of the

case.

Mains input and sensor connections are fully floating with respect to earth.

The earth terminal on the freestanding unit and the rack must be earthed.

The units must be left to warm up for 15 minutes before being exposed

IP20 enclosure. Optional DIN rail

mounting or wall mounting.

A fault is indicated if too much, or too little current is taken by the head

amplifier, indicating a short circuit or an open circuit.

Alarm relay de-energises

a) Test Alarm Simulates the alarm condition by stopping the pulses.

Alarm relay de-energises

b) Test Fault simulates a short circuit in the cable between control

room and the head amplifier, fault and alarm is indicated.

Alarm relay de-energises

1-10 seconds. Preset on front panel (20 turns span)

Returns to normal approx. 200ms after alarm is cleared.

BS EN61326: 1998 (Emissions) for Class B Equipment

BSEN61326: 1998 (Immunity) for continuous unmonitored operation in

industrial locations

EN61010-1

1: 220/240V ±10%, 50/60Hz

2: 110/120V ±10%, 50/60Hz

See Table 2.1 for relay ratings

To take wires up to 1.5mm2

See Figure 2.7 for wiring details

Units MEP*L and MEP*R are intrinsically safe.

See table 2.2 for certificate details.

Approximately 11.5V 20mA maximum

-10ºC to 65ºC

to sub-zero temperatures.

Maximum altitude : 2000m

Maximum humidity : 95%

CAT II (264V a.c. MAX) Pollution 2

CAT III (132V a.c. MAX) Pollution 2

Green = Normal

Red = Alarm

Amber = Fault

At least one LED should be on at any time.

18

Rack Mounted Unit MEP*R

Less than 6VA

Fault relay:

fault mode

Alarm relay:

Low current DPCO, Energised in

normal mode releases on fault or

alarm

Terminal block on the rear of the

rack unit.

19” rack unit to hold up to 14

controls.

3 LEDs

Alarm relay de-energises

Fault relay energises

Alarm relay de-energises

Alarm relay de-energises

Fault relay energises

SPCO, Energises in

High current SPCO,

Page 19

5. Recommended Spare Parts

5.1 Sensor and head amplifier

Sensors and head amplifiers are supplied as integral items, and therefore no spare parts are available.

In the case of sensor mounted head amplifiers, the sensor is attached to the head amplifier, and the

two are not usually available separately.

5.2 Control Units

i) Fuses

Standard Control Unit:

MEP*L/1* (220/240V) K179 T 63mA, 35A Breaking capacity (IEC 127)

MEP*L/2* (110/120V) K1796 T 125mA, 35A Breaking capacity (IEC 127)

Rack Mounted Unit:

MEP*R/** All voltages H1525 F 500mA, 1500A Breaking capacity (IEC127)

All fuses are 5mm×20mm

ii) Edge Connectors (Rack units only)

I.S. units: K1806 4 way edge connector

MEP3R K1805 1 2 way edge connector

Screws for mounting connectors 9722-827 M3 × 8mm cheese head (2 required per

connector)

Washer 9726-807 M3 (2 required per connector)

19

Page 20

Appendix I - Part Numbers

Please note that the existence of a part number does not imply the availability of a unit.

1. Sensors and Sensors with Head Amplifiers

Fitting

0 Outside Fitting

2 Double Fitting

3 Inside Fitting

6 Inside Fitting M6

8 Sludge Pipe

9 Flange

Head Amplifier Type

P Sensor Mounted

U Adjacent Mounted

Approval

O None

H ATEX

L Lloyds Register of Shipping

P PTB

S SEV

F LCIE

Options

T Test Switch

3 0 2 S D P 8 0 T

Sensor Connection

Sensor Type

See Catalogue

Note: Pre 1984 sensors have an M or an I in the third place to indicate Marine or Industrial head

amplifier.

2. Head Amplifiers (Adjacent mounted)

Intrinsic Safety

3 Intrinsically Safe

Material

D Stainless steel

Y Epoxy resin

P Polyether sulphone

J Cryogenic Epoxy Resin

M Monel

C Hastelloy C

Mounting

A Standard acting

X Reverse acting

Sensor Type

C Single

0 PVC Cable & Phono Plugs

1 PTFE Cable & Phono Plugs

4 PVC Cable & BNC Plugs

5 PTFE Cable & BNC Plugs

7 PVC Cable & Pins

8 PTFE Cable & Pins

9 Special Cable

M Marine Head Amplifier

I Industrial Head Amplifier

J Junction Box

Test Switch

T Included

N Omitted

Type

I Industrial

M E P 3 A I / 3 C A N

Electronics

3 1 MHz Switched Gain

4 3.7 MHz Switched

20

Industrial Only

}

Material

A Aluminium Alloy

G Gunmetal

S Stainless Steel

P Plastic

Page 21

3. Control Units

M E P 3 L / 1 D

Intrinsic Safety

3 Intrinsically Safe

4. Racks

Mounting

R Rack Mounted

L Wall Mounted

M E P 3 B / 0 7

Intrinsic Safety

3 Intrinsically Safe

Mains Voltage

1 220/240

Volts

2 110/120

Volts

Number of spaces for control units

01 to 14

Remaining spaces are blanked off

Output Relay

S Single Pole Changeover

D Double Pole Changeover

21

Page 22

Appendix II – List of illustrations

Section Figure Title Page

1. Introduction 1.1 Gap Sensor 3

1.2 Hi-Sens Sensor 3

1.3 Attenuation Method 4

1.4 Interface Method 4

1.5 Sludge Density Sensor 5

2. Installation 2.1 Head Amplifier 7

2.2 Adjacent head amplifier 8

2.3 Control unit mounting details 11

2.4 Wiring Summary 12

2.5 Sensor connections to adjacent head amplifier 13

2.6 Control unit connections 14

Appendix III - List of tables

Section Table Title Page

1. Introduction 1.1 Head amplifier – types 6

1.2 Head amplifier – operation 6

2. Installation 2.1 Relay ratings and fuses 13

2.2 Approvals 15

4. Specification 4.1 Sensor specification 17

22

Page 23

Maintenance / Inspection

This is limited to periodic inspection by a qualified person to ensure that the installation including

wiring and equipment housing is safe.

Clean only with a damp cloth, ensuring that no moisture enters control unit.

Check unit for damage and if damaged do not use.

23

Page 24

Instructions Leaflet

IP221, Rev. AA

November 2004

Level

abcdef

The Emerson logo is a trade mark and service mark of Emerson Electric Co.

Rosemount is a registered trademark of Rosemount Inc.

Mobrey is a registered trademark of Mobrey Ltd.

All other marks are the property of their respective owners.

We reserve the right to modify or improve the designs or specifications of product and services at any time without notice.

International:

Emerson Process Management

Mobrey Measurement

158 Edinburgh Avenue,

Slough, Berks, SL1 4UE, UK

T +44 1753 756600

F +44 1753 823589

www.mobrey.com

Americas:

Emerson Process Management

Rosemount Inc.

8200 Market Boulevard

Chanhassen, MN USA 55317

T (US) (800) 999-9307

T (International) (952) 906-8888

F (International) (952) 949-7001

24

Loading...

Loading...