Page 1

Instruction Manual

IM-106-5500, Orignal Issue

August 2005

CCO 5500

Carbon Monoxide (CO) Analyzer

http://www.raihome.com

Page 2

Page 3

Instruction Manual

IM-106-5500, Original Issue

August 2005

CCO 5500 Carbon Monoxide (CO) Analyzer

CCO 5500

ESSENTIAL INSTRUCTIONS

READ THIS PAGE BEFORE PROCEEDING!

Rosemount Analytical designs, manufactures and tests its products to meet

many national and international standards. Because these instruments are

sophisticated technical products, you MUST properly install, use, and

maintain them to ensure they continue to operate within their normal

specifications. The following instructions MUST be adhered to

into your safety program when installing, using, and maintaining Rosemount

Analytical products. Failure to follow the proper instructions may cause any

one of the following situations to occur: Loss of life; personal injury; property

damage; damage to this instrument; and warranty invalidation.

• Read all instructions

product.

• If you do not understand any of the instructions, contact your

Rosemount Analytical representative for clarification.

• Follow all warnings, cautions, and instructions

supplied with the product.

• Inform and educate your personnel in the proper installation,

operation, and maintenance of the product.

• Install your equipment as specified in the Installation Instructions

of the appropriate Instruction Manual and per applicable local and

national codes. Connect all products to the proper electrical and

pressure sources.

• To ensure proper performance, use qualified personnel

operate, update, program, and maintain the product.

• When replacement parts are required, ensure that qualified people use

replacement parts specified by Rosemount. Unauthorized parts and

procedures can affect the product's performance, place the safe

operation of your process at risk, and VOID YOUR WARRANTY

Look-alike substitutions may result in fire, electrical hazards, or

improper operation.

• Ensure that all equipment doors are closed and protective covers

are in place, except when maintenance is being performed by

qualified persons, to prevent electrical shock and personal injury.

prior to installing, operating, and servicing the

and integrated

marked on and

to install,

.

http://www.raihome.com

The information contained in this document is subject to change without

notice.

Page 4

Instruction Manual

N

IM-106-5500, Original Issue

CCO 5500

August 2005

PREFACE The purpose of this manual is to provide information concerning the

components, functions, installation and maintenance of the CCO 5500.

Some sections may describe equipment not used in your configuration. The

user should become thoroughly familiar with the operation of this module

before operating it. Read this instruction manual completely.

DEFINITIONS The following definitions apply to WARNINGS, CAUTIONS, and NOTES

found throughout this publication.

Highlights an operation or maintenance procedure, practice, condition, statement, etc. If not

strictly observed, could result in injury, death, or long-term health hazards of personnel.

Highlights an operation or maintenance procedure, practice, condition, statement, etc. If not

strictly observed, could result in damage to or destruction of equipment, or loss of

effectiveness.

SYMBOLS

NOTE

Highlights an essential operating procedure, condition, or statement.

: EARTH (GROUND) TERMINAL

: PROTECTIVE CONDUCTOR TERMINAL

: RISK OF ELECTRICAL SHOCK

: WARNING: REFER TO INSTRUCTION BULLETI

NOTE TO USERS

The number in the lower right corner of each illustration in this publication is a

manual illustration number. It is not a part number, and is not related to the

illustration in any technical manner.

ii

Page 5

Instruction Manual

IM-106-5500, Original Issue

August 2005

CCO 5500

Table of Contents

Essential Instructions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . i

Preface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ii

Definitions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ii

Symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ii

SECTION 1

Description and

Specifications

SECTION 2

Installation

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

System Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Infrared Transmitter Unit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Infrared Receiver Unit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Signal Processor Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Power Supply Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Air Purge. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Isolating Valves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Principles and Modes of Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Calculation of Gas Concentration. . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Error Compensation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

Calculation Sequence. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

Normalization Equations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-11

Safety Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Electrical Supply Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

AC Supplies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Normalizing Inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Plant Status Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Cable Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Unpacking the Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Selecting Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Points to Consider . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

Duct Work . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

Isolating Valves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

Air Purge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

Transmitter and Receiver . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

Air Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

Signal Processor Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

Power Supply Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

Electrical Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

Installation of Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

Cable Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

http://www.raihome.com

Page 6

CCO 5500

Instruction Manual

IM-106-5500, Original Issue

August 2005

SECTION 3

Configuration and

Startup

SECTION 4

Normal Operation

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Safety Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Power Supply Voltage Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Turning the Power On . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Alignment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Detector Levels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Receiver Gain Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Signal Processor Gain Adjustment. . . . . . . . . . . . . . . . . . . . . . . . . 3-6

Transmitter Adjustments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

Source Intensity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

Chopper Frequency . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

Operating Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

Current Output Calibration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-19

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Normal Startup Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Modes of Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Key Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

Program Tree. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

Operating Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

Parameter Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

Identification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

Averages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

Output. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

Alarm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

Plant Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

Normalization. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

Display Format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

Diagnostic Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

Detector Levels. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-7

Chopper Motor Frequency . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-8

YVals and Gas ppm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-8

Calibration Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-8

Fault Condition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-9

Setup Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-10

Security Code Entry . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-10

Set Averages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-11

Configure O/P. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-12

Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-14

Normalization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-17

Setting the Normalizing Parameters. . . . . . . . . . . . . . . . . . . . . . . 4-18

Temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-18

Oxygen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-19

Pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-19

Water Vapor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-19

Reset Averages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-19

Calibrate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-20

Check Cell Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-20

Normal Shutdown Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-21

TOC-2

Page 7

Instruction Manual

IM-106-5500, Original Issue

August 2005

CCO 5500

Routine Checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-21

Notes for Using a Rosemount Analytical Check Cell . . . . . . . . . . 4-21

Alarms and Emergency Conditions . . . . . . . . . . . . . . . . . . . . . . . 4-23

Emergency Shutdown Procedure. . . . . . . . . . . . . . . . . . . . . . . . . 4-23

Isolation Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-23

Interface with Integrated Emissions Monitoring System . . . . . . . . 4-23

SECTION 5

Maintenance

SECTION 6

Troubleshooting

SECTION 7

Returning Material

SECTION 8

Replacement Parts

Routine (Preventive) Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Cleaning Windows . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Replacement of the Heater Element . . . . . . . . . . . . . . . . . . . . . . . 5-1

Replacement of Chopper Motor Assembly. . . . . . . . . . . . . . . . . . . 5-2

Replacement of Gas Cells . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

Electronics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

Span Factor Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

Fault Finding with the Keypad . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

Data Valid LED Out . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

Troubleshooting Tables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

Component Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-8

Heater Cartridge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-8

Chopper Motor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-8

LED Indications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-8

Test Points. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-9

Recommended Spare Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

APPENDIX A

Safety Data

Safety Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-2

TOC-3

Page 8

CCO 5500

Instruction Manual

IM-106-5500, Original Issue

August 2005

TOC-4

Page 9

Instruction Manual

IM-106-5500, Original Issue

August 2005

CCO 5500

Section 1 Description and Specifications

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 1-1

System Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 1-1

Principles and Modes of Operation . . . . . . . . . . . . . . . . . page 1-4

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 1-11

OVERVIEW Rapid advances in the design of 'across the duct' infrared gas analyzers have

led to the general acceptance of this technique for the monitoring of gas levels

in flue gases of power generation boilers and large industrial process steam

boilers.

The CCO 5500 is designed to operate on duct widths of less than 26 ft (8 m)

at flue gas temperatures up to 572

makes installation extremely simple, and through the use of microprocessor

technology they have many advanced features:

• Local normalizing inputs for compliance with legislation requirements

• Serial data facility to allow communication between analyzers and a

central data logging station

• User-definable output in either mg/m

• Four rolling averages are held - selectable from 10 seconds to 30 days

• Integral, back lit 32 character LCD provides diagnostic and

measurement information

• Plant status input to prevent emissions dilution during plant off periods

o

F (300oC). Their rugged construction

3

, mg/Nm3 or ppm

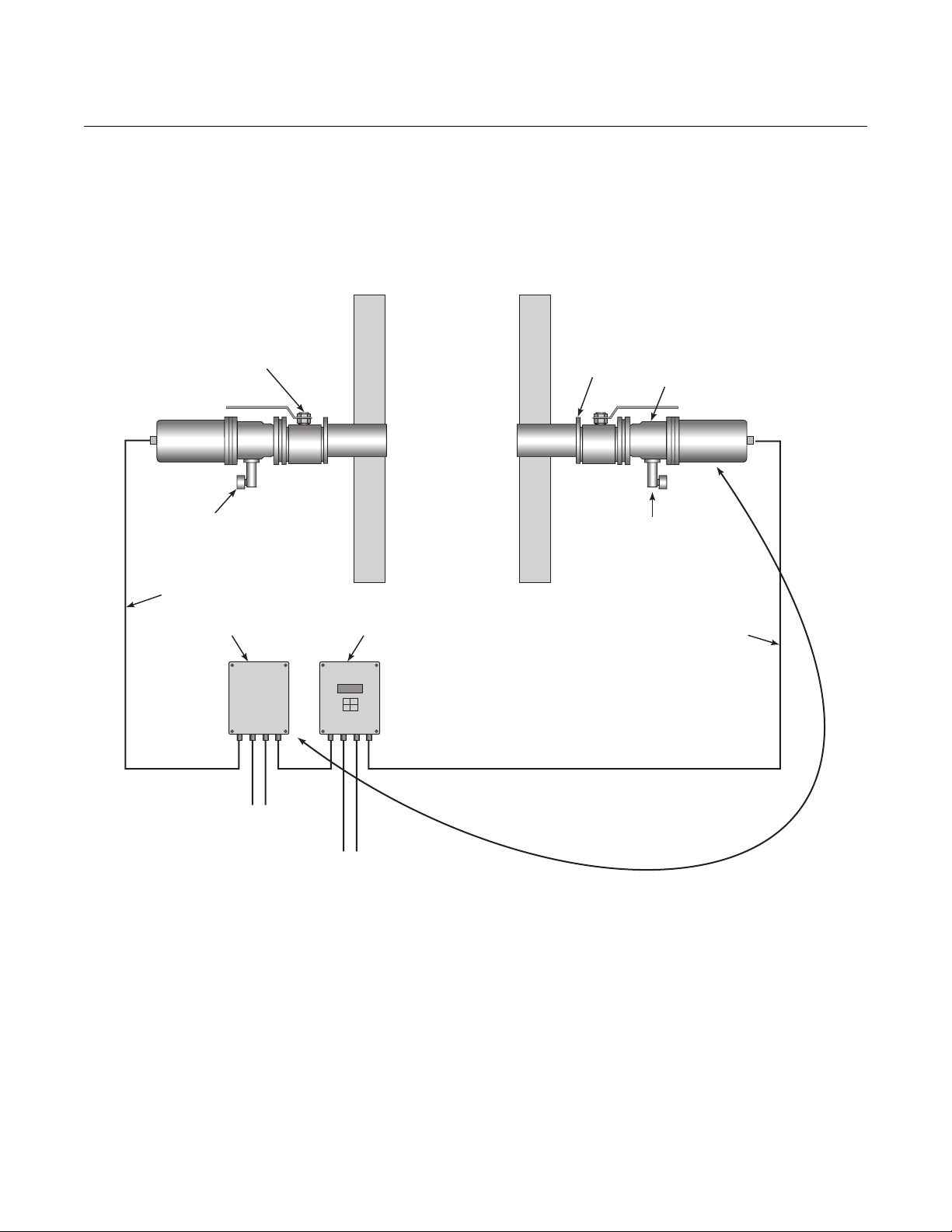

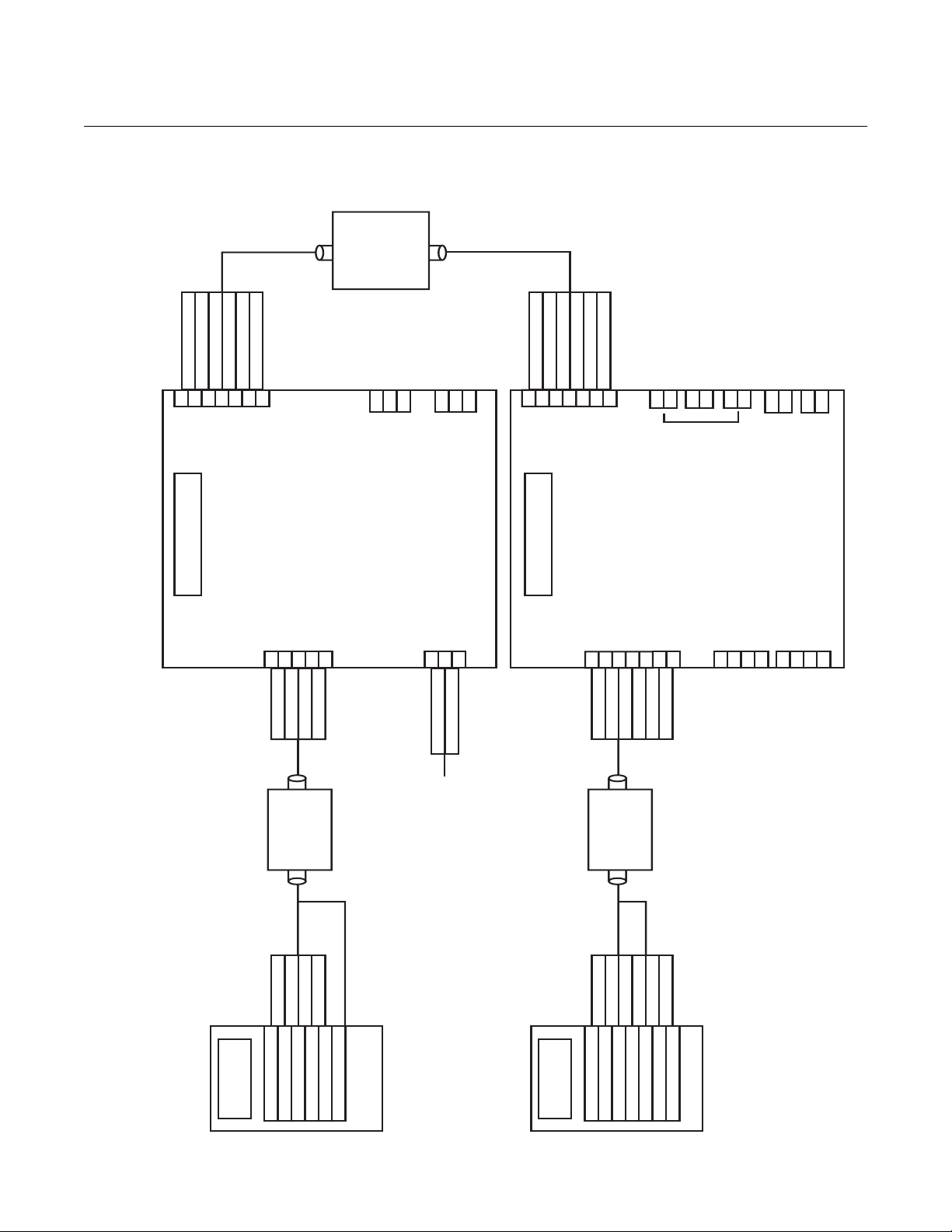

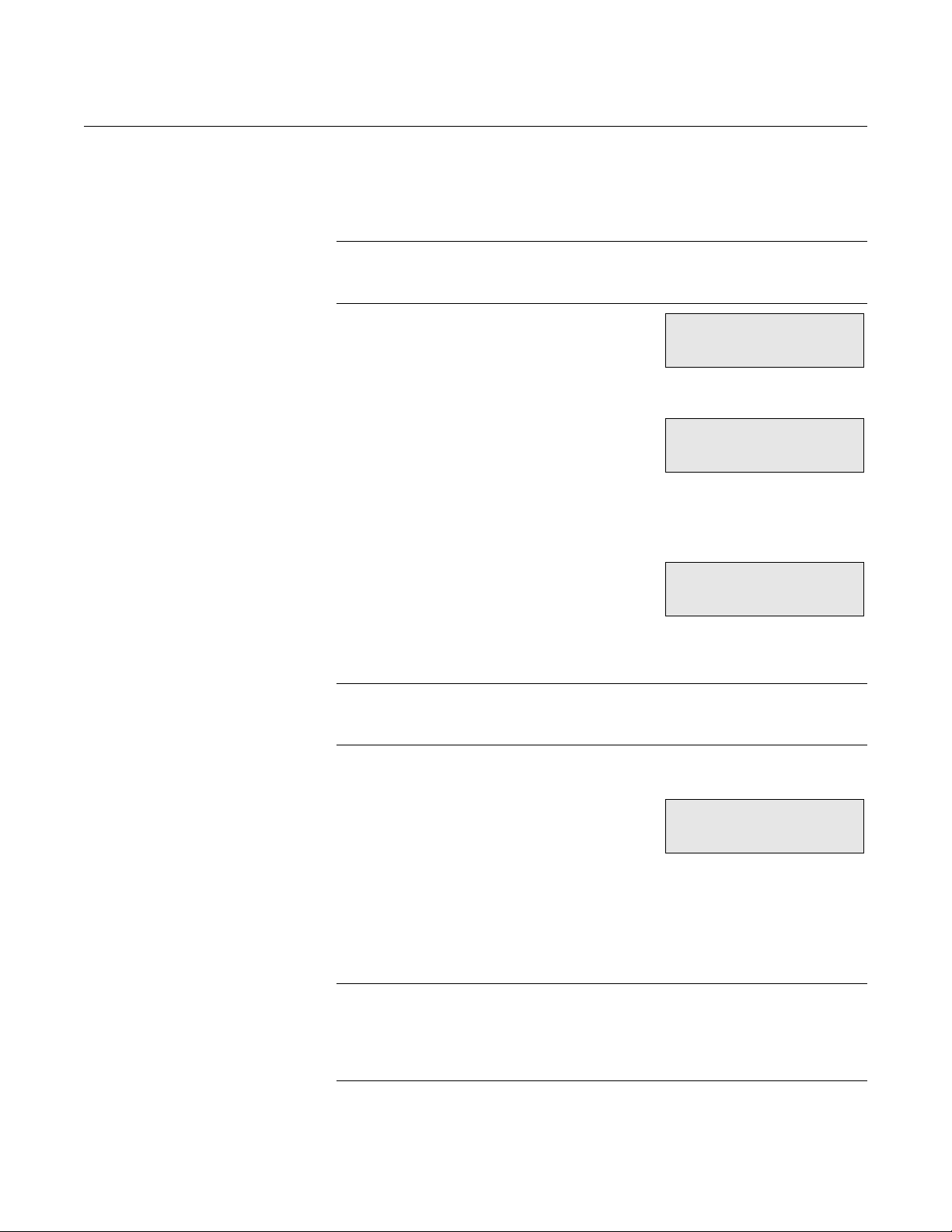

SYSTEM DESCRIPTION The CCO 5500 Carbon Monoxide (CO) Analyzer Monitor consists of four

items (Figure 1-1):

• An infrared transmitter unit to project a beam of infrared radiation

across the duct

•A receiver to measure that radiation

•A power supply unit to provide the necessary power rails, and

•A signal processor to compute the gas concentration from the signals

provided by the receiver unit.

http://www.raihome.com

Page 10

CCO 5500

SerialDataPo

Figure 1-1. Typical System Layout

Instruction Manual

IM-106-5500, Original Issue

August 2005

Each of these units is designed to be rugged and durable. They are all fully

sealed to IP65 standards and are suitable for outside mounting, without the

need for further weatherproof enclosures.

Transmitter

Isolation Valve

(If Used)

Pressure

Regulator

33 ft(10 m) Max.

Power Supply

Signal Processor

Site Mounting

Flange

Receiver

Air Purge

Purge Air

33 ft(10 m) Standard

Mains Supply &

Contact Outputs

Analogue Outputs,

Normalizing Inputs &

rt

82 ft(25 m) Maximum Total Cable Length

Between Receiver & Power Supply

Infrared Transmitter Unit At the heart of this unit is a small heater assembly designed to give a high

intensity uniform source of infrared energy over a long lifetime, in excess of

two years continuous operation, with a power consumption of only 26 watts.

The heater has a stainless steel cylindrical core, plasma coated with

refractory, and around which is a 'Kanthal' heating element. This is then

enclosed within refractory fibers and encapsulated in an aluminium cartridge.

In the infrequent event of failure, the complete heater assembly can be

replaced on site within ten minutes.

1-2

Page 11

Instruction Manual

IM-106-5500, Original Issue

August 2005

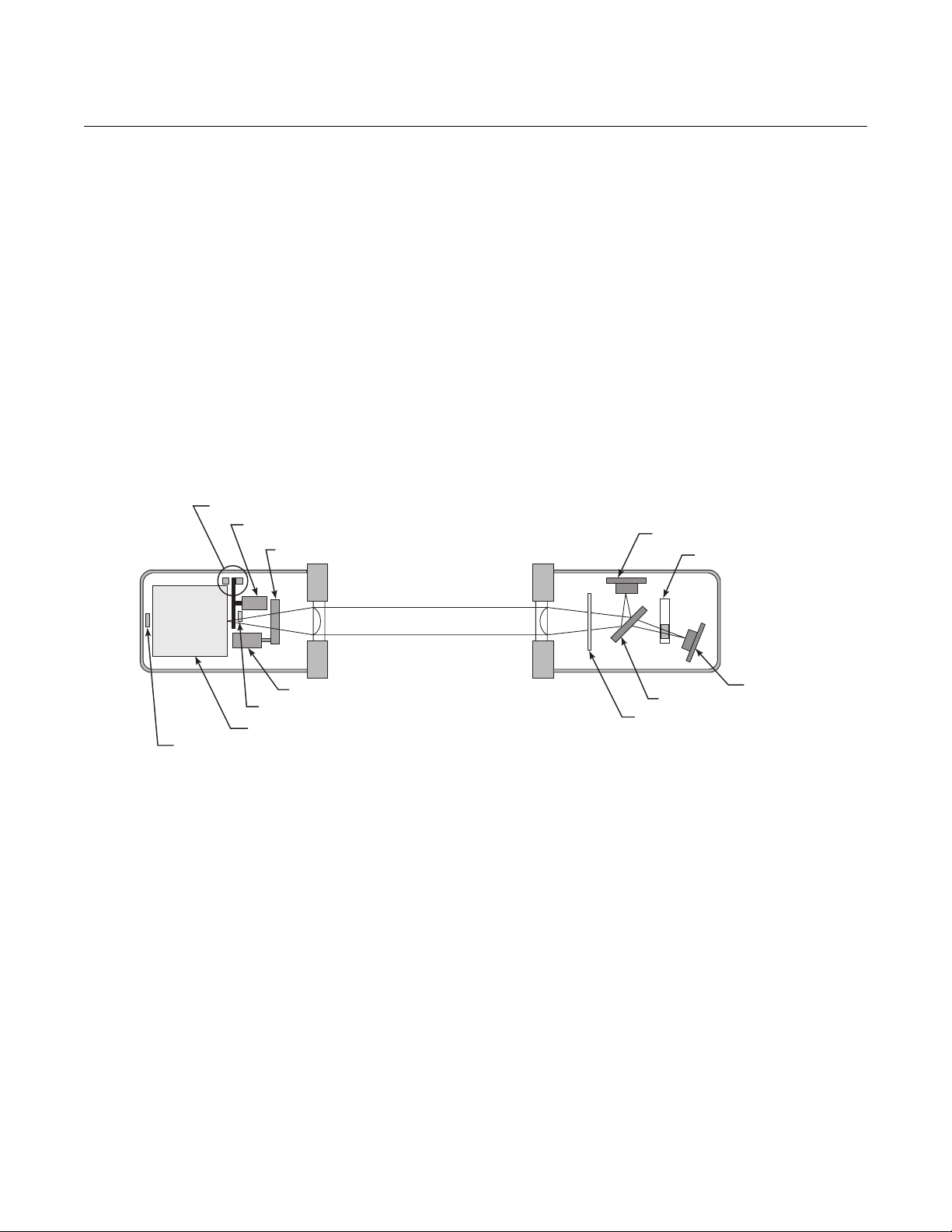

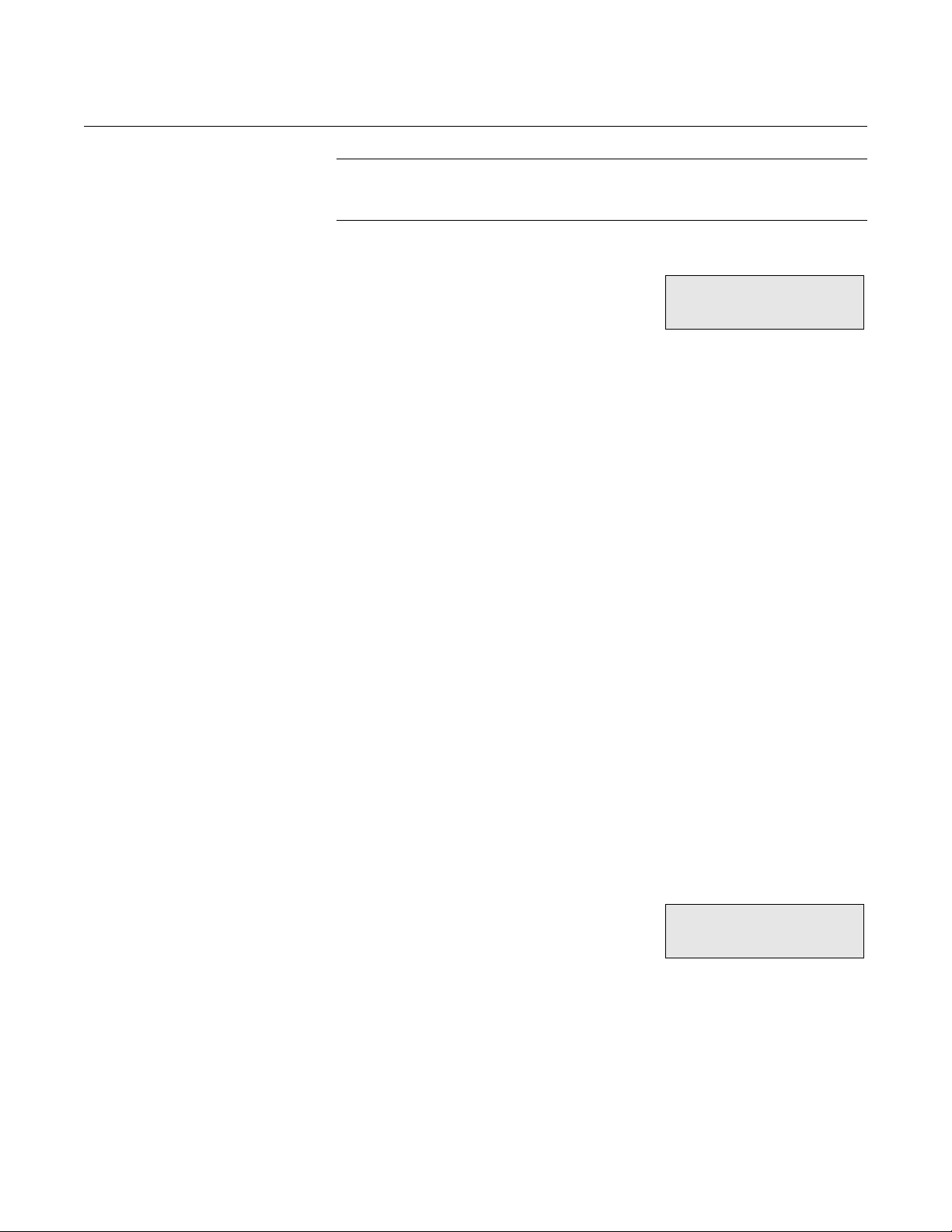

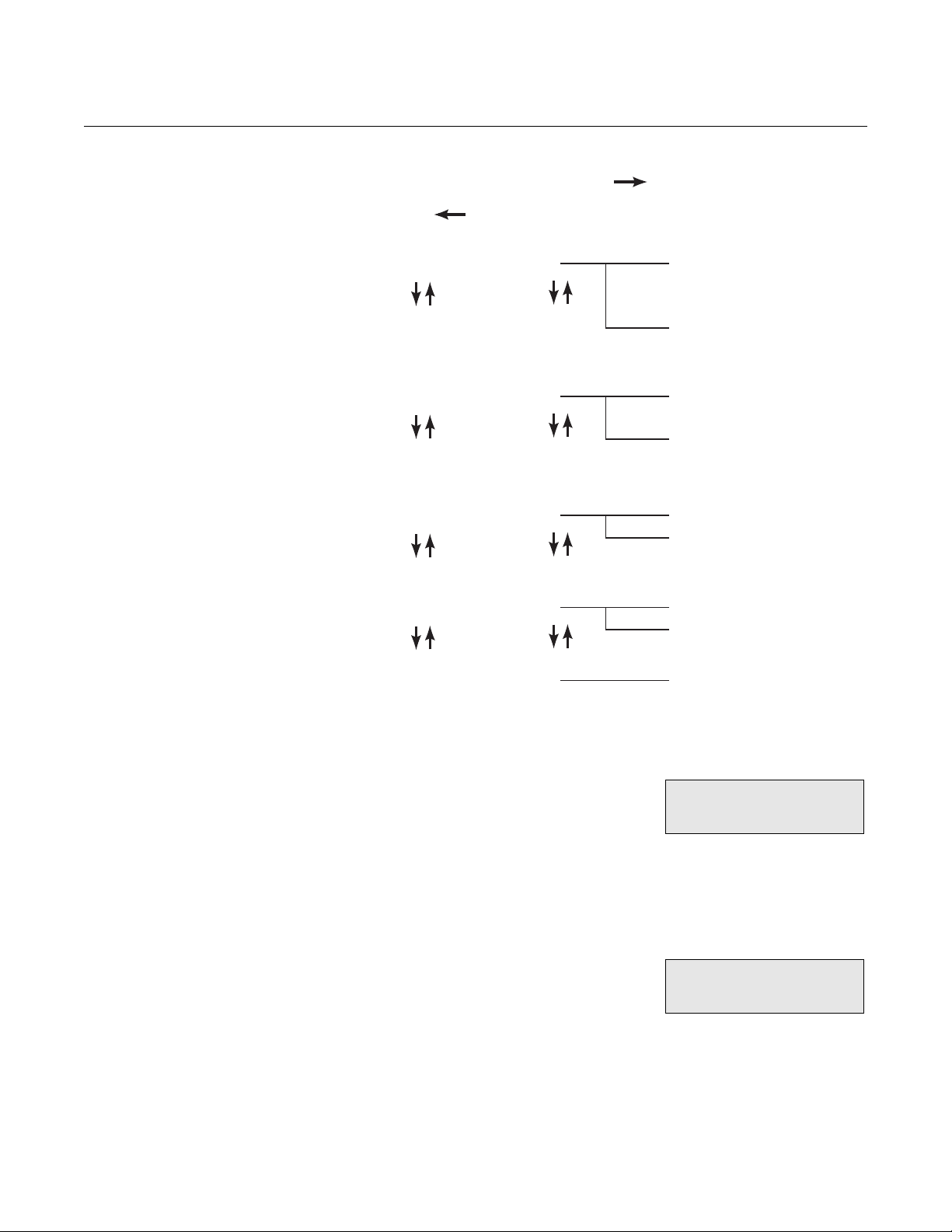

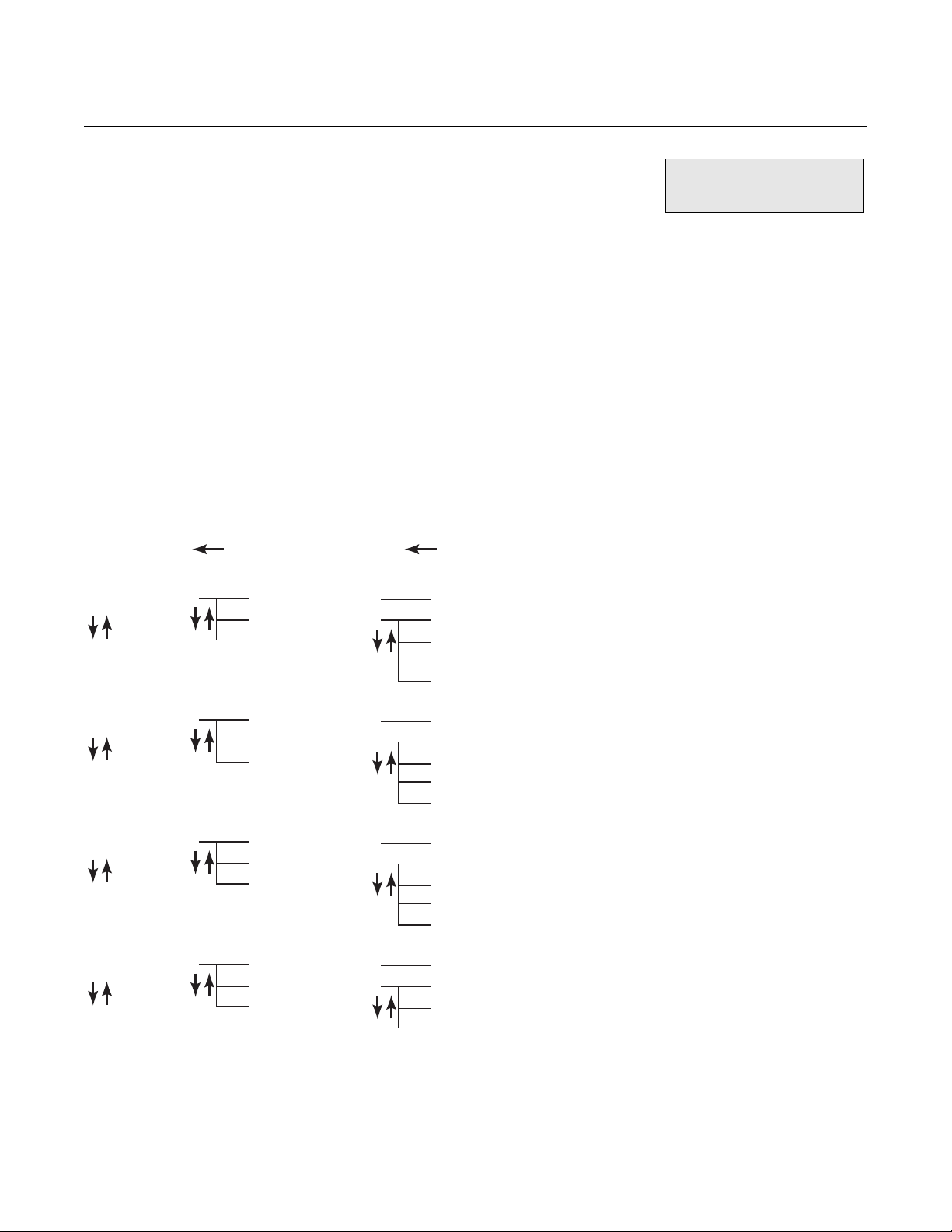

Figure 1-2. Transmitter and Receiver Schematic

Chopper Blade Detector

Chopper Blade & Motor

The radiation emitted by the heater is then 'chopped' by a motor-driven disc,

and focused across the duct by a lens. The chopper disc is driven by a small

DC motor. The phase and frequency of the chopper disc are monitored by a

radiation detector to provide a reference signal that is utilized by the signal

processor unit.

System calibration is achieved by a small calibration cell containing pure

reference gas (CO) that can be swung into the sight path by means of a

'stepper' motor and gearbox assembly to enable continuous calibration

updates to be maintained. The chopper motor and stepper motor represent

the only moving components in the entire system.

A printed circuit board mounted at the front of the unit provides control

circuitry for the heater, the motors, and the reference wave detector.

Figure 1-2 illustrates the transmitter and receiver units.

Calibrating Cell

CCO 5500

Detector D2

Gas Filter

Detector D1

Heated Infrared Source

Control Detector

Stepper Motor & Gearbox

Reference Detector

Beam Splitter

Interference Filter

Infrared Receiver Unit The precision and reliability which CO concentration levels can be measured

governs the performance of the complete instrument. For this reason design

efforts have been concentrated in producing an extremely simple and robust

receiver unit. It contains no moving parts, is fully sealed and designed to give

many years of trouble-free and maintenance-free operation.

The unit comprises a lens to focus radiation received from across the duct,

followed by a precision interference filter to limit the wave band of energy

used. This filter tolerance is strictly controlled since it alone determines the

instrument scale shape and calibration. The radiation then passes to an

optical beam-splitter where approximately half the radiation is reflected at

right angles directly onto a radiation detector. The other half of the radiation is

transmitted, by the beam-splitter, through a gas cell containing pure reference

gas (CO) and onto a second radiation detector.

The detectors used are lithium tantalate pyro-electric detectors, renowned for

their sensitivity, stability and ability to operate at normal ambient

temperatures, without the need for cooling. They respond only to changing

levels of radiation and thus to the chopped radiation from the infrared source

unit and not to background radiation from the flue or flue gas. The detector

signals are amplified and fed to the signal processor unit.

1-3

Page 12

Instruction Manual

IM-106-5500, Original Issue

CCO 5500

August 2005

Signal Processor Unit The signal processor unit is housed in a fully-sealed cast-aluminum

enclosure. It houses the microprocessor to monitor the data from the receiver

and produces a 4-20 mA output signal for gas levels within the flue.

A non-volatile RAM section - requiring no battery back-up - enables all of its

operation data to be retained during a power down condition. The instrument

can resume operation immediately when power is restored without having to

be recalibrated.

All operation data is entered via a surface-mounted keypad. A 32-character

LCD provides the operator with measurement details and diagnostic

information.

Inputs are available to receive the 4-20 mA outputs of normalizing

measurement transducers - O

data can also be entered via the keypad or via the serial data port.

A serial communication facility within the processor allows the instrument to

communicate with other Rosemount analyzers and a central data logging unit.

, temperature and pressure, if required. This

2

Power Supply Unit The power supply unit is housed in a fully-sealed cast-aluminium enclosure

and contains the power supplies for the instrument. A switched mode power

supply is utilized to provide an extremely stable power source, able to cope

with large fluctuations in the supply voltage. The contact outputs are also

taken from this unit - data valid and high gas alarm.

Air Purge The air purge unit has its own integral adjustable mount and provides the

interface between the site mounting flange and the transmitter and receiver

units. The purge is designed to provide a steady laminar flow of air away from

the instrument lens, preventing optical contamination.

A supply of air to the purge is essential.

Isolating Valves Isolating valves, if required, may be attached between the air purges and the

duct. These will allow protection for personnel servicing instruments on high

pressure ducts.

PRINCIPLES AND MODES OF OPERATION

Calculation of Gas Concentration

Gas levels are determined by measuring the absorption of infrared radiation,

transmitted through the flue gas, in a wave band sensitive to absorption by the

measurement gas. CCO 5500 monitors have two detectors; one measures

the radiation directly to provide a live output, sensitive to the measurement

gas, while a second detector measures the radiation after passing through a

gas cell filled with pure reference gas (CO), to provide a reference

measurement, completely unaffected by the measurement gas.

1-4

Page 13

Instruction Manual

IM-106-5500, Original Issue

August 2005

The basic expression from which the gas concentration in the gas is

determined is:

Y = G - K. D2/D1

Where D1 = the reference output from the detector

D2 = the live output from the detector

G = a scaling factor (1600)

K = a constant, known as the zero correction

factor, set so that when there is zero

measurement gas in the duct, Y = 0

thus, K = G. D1(0)

D2 (0)

This parameter Y is then smoothed, linearized and compensated for effects of

path length and flue gas temperature, to produce a measurement of gas

concentration in the flue gas.

CCO 5500

Error Compensation The accurate determination of gas concentration depends on the

measurement of the radiation levels received by the detectors. Any error in

that measurement caused by detector drift will produce errors in the

determination of the gas level. In order to maintain accuracy, it is necessary to

be able to compensate for such drifts. In the CCO 5500 analyzer a technique

of continuous calibration adjustment is used.

The operating cycle of the instrument is in two parts. First, measurements are

obtained from the two detector outputs D1 and D2. The calibration cell,

containing pure CO, is then positioned in the sight path and the two detector

outputs are measured again to give readings E1 and E2.

From the basic scale shape equation:

Y = G - K. D2/D1

and from the calibration equation

Yo = G - K. E2/E1

or K = (G - Yo). E1/E2

thus substituting in the scale shape equation

Y = G - (G - Yo). E1/E2. D2/D1

The two ratios E1/D1 and E2/D2, being derived each from one detector, are

independent of any detector drift, thus making the instrument output

independent of any drift or change in detector gain characteristic.

This operating routine, giving measurements first of D1 and D2 and then, with

the calibration cell in position, of E1 and E2, is repeated continuously and

provides an effective continuous calibration update to enable accuracy to be

maintained at all times.

1-5

Page 14

Instruction Manual

IM-106-5500, Original Issue

CCO 5500

August 2005

Calculation Sequence The calculations for one complete operating cycle of the instrument are given

below:

•measure D1 & D2

• measure E1 & E2

• compute Y

• smooth Y

• linearize and correct for path length

• normalize measurement

• smooth to produce final gas outputs

Normalization Equations Normalization of data collected by the analyses is essential to compare

emission levels of pollutants into the atmosphere. Software in Rosemount

Analyzers perform all calculations and provides results in various units, vpm,

3

mg/m

and mg/Nm3; derivation of these results is described in this section.

CCO 5500 CO analyzers are cross-duct type and thus measure the quantity

(or number of molecules) of gas within their sight path. This measurement is

converted into a concentration which is fully compensated for the expansion

effects of temperature, while assuming constant atmospheric pressure. This

basic measurement is referred to as 'ppm' (parts per million). However, to

obtain a true concentration 'vpm' (ppm by volume) the 'ppm' value must be

normalized for pressure using the following expression.

Correction to standard pressure -

vpm = ppm x standard pressure (abs)

measured pressure (abs)

where standard pressure is taken as 101 kPascals.

The next stage in the process is to determine the mass concentration. The

conversion at STP uses conversion factors determined as follows:

Conversion to mass concentration -

N=RMM

V

where N = conversion factor

RMM = relative molecular mass of the gas

V = 22.4 (standard volume of an ideal gas)

The conversion factor given below:

Conversion factors (N) -

Molecular mass (RMM) = 12 + 16 = 28

1 vpm = 28/22.4 = 1.25 mg/m

The mass concentration present is calculated as below:

3

mg/m

(STP) = N. vpm

3

1-6

This value is the mass concentration of the gas at STP.

Correction for oxygen and water vapor.

Finally the effects of water vapor and oxygen need to be considered.

Page 15

Instruction Manual

IM-106-5500, Original Issue

August 2005

CCO 5500

Since the vpm measurement is already normalized for temperature and

pressure, the only further normalization required is for the dilution effects of

water vapor and oxygen. These are straightforward calculations as shown

below:

mg/Nm

3

= mg/m3 (STP) x 20.9 - 0%2 standard x100

20.9 - (0%2 measured) DRY = 100 - H2O%

20.9% is taken as the level of free oxygen in dry air.

NOTE

If the measured O

% is a wet measurement the measured O2 concentration

2

must be corrected to a dry measurement. This is performed automatically by

the software if the measured O

concentration is defined as a wet

2

measurement; where:

(O

% measured) DRY = (O2% measured) WET x 100

2

100 - H2O%

If no correction is required for oxygen then standard O

If no correction is required for water vapor then H

= O2 measured.

2

O% = 0

2

After all these calculations have been performed the resulting measurement

is the effective mass concentration of the pollutant normalized to standard

conditions (in mg/Nm

3

).

Measured conditions -

Where measured values are required (e.g. to calculate rates of emissions)

they need to be recalculated for measured temperature and pressure as

shown below:

3

mg/m

= N.vpm x 273 x measured pressure

T standard pressure

substituting,

vpm = ppm x standard pressure

measured pressure

the measured mass concentration of the gas is:

3

= N.ppm x 273

mg/m

T

Principles of Cross-Duct Gas Analyzers

Cross-duct analyzers work on the basic principle that infrared (IR) energy is

absorbed by particular gases in a manner very specific to the gas.

Although cross-duct analysis will differ from gas to gas, the basic principles

are similar for all measured gases. This section examines the analysis of

carbon monoxide in detail.

1-7

Page 16

CCO 5500

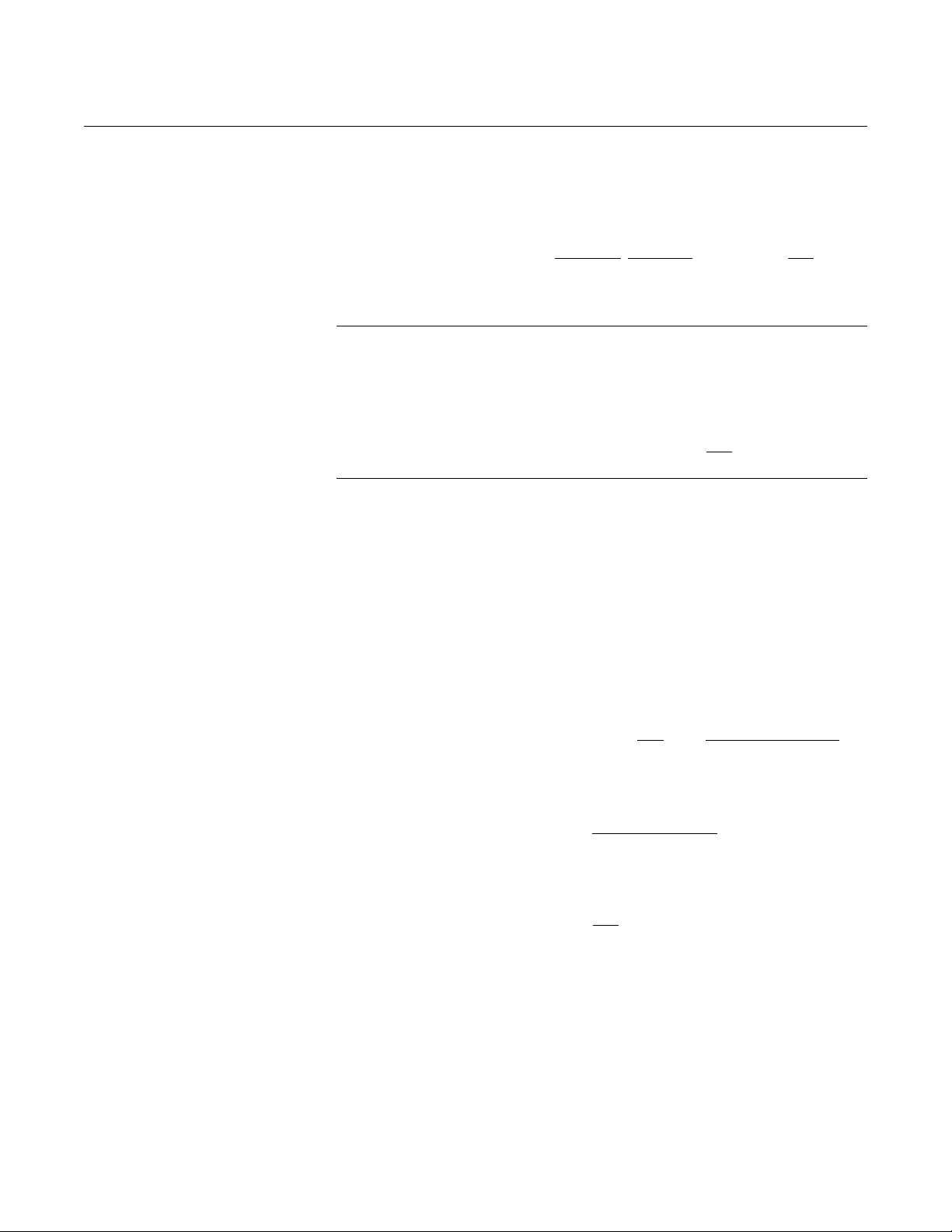

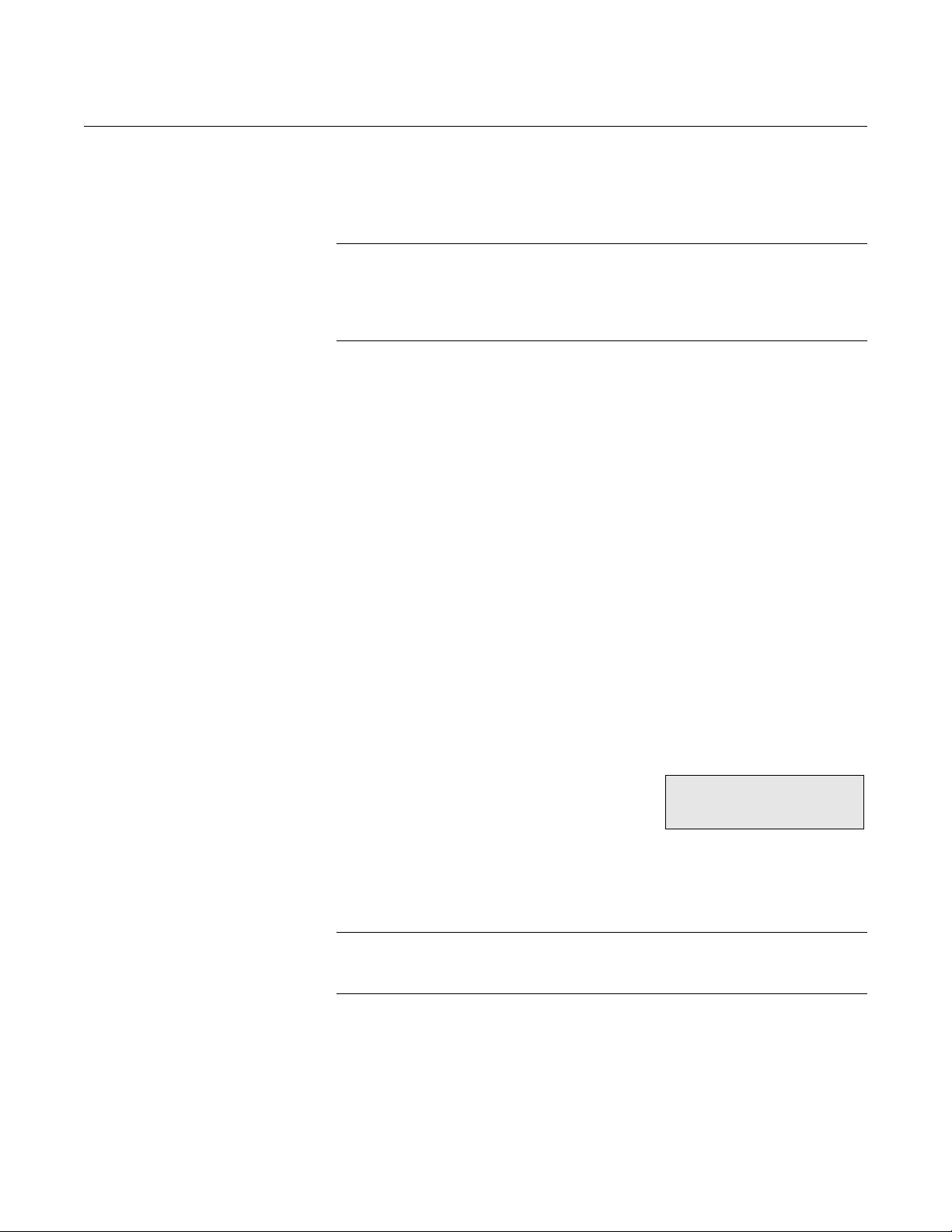

Figure 1-3. CO IR Absorption Spectrum

Instruction Manual

IM-106-5500, Original Issue

August 2005

Carbon Monoxide IR Absorption Spectrum

Carbon monoxide absorbs IR energy in a band between wavelengths of

approximately 4.5 and 4.9 µm. The absorption spectrum is complex and is

illustrated in Figure 1-3 below.

Absorption (%)

0

4.5 4.6 4.7 4.8 4.9

Wavelength (microns)

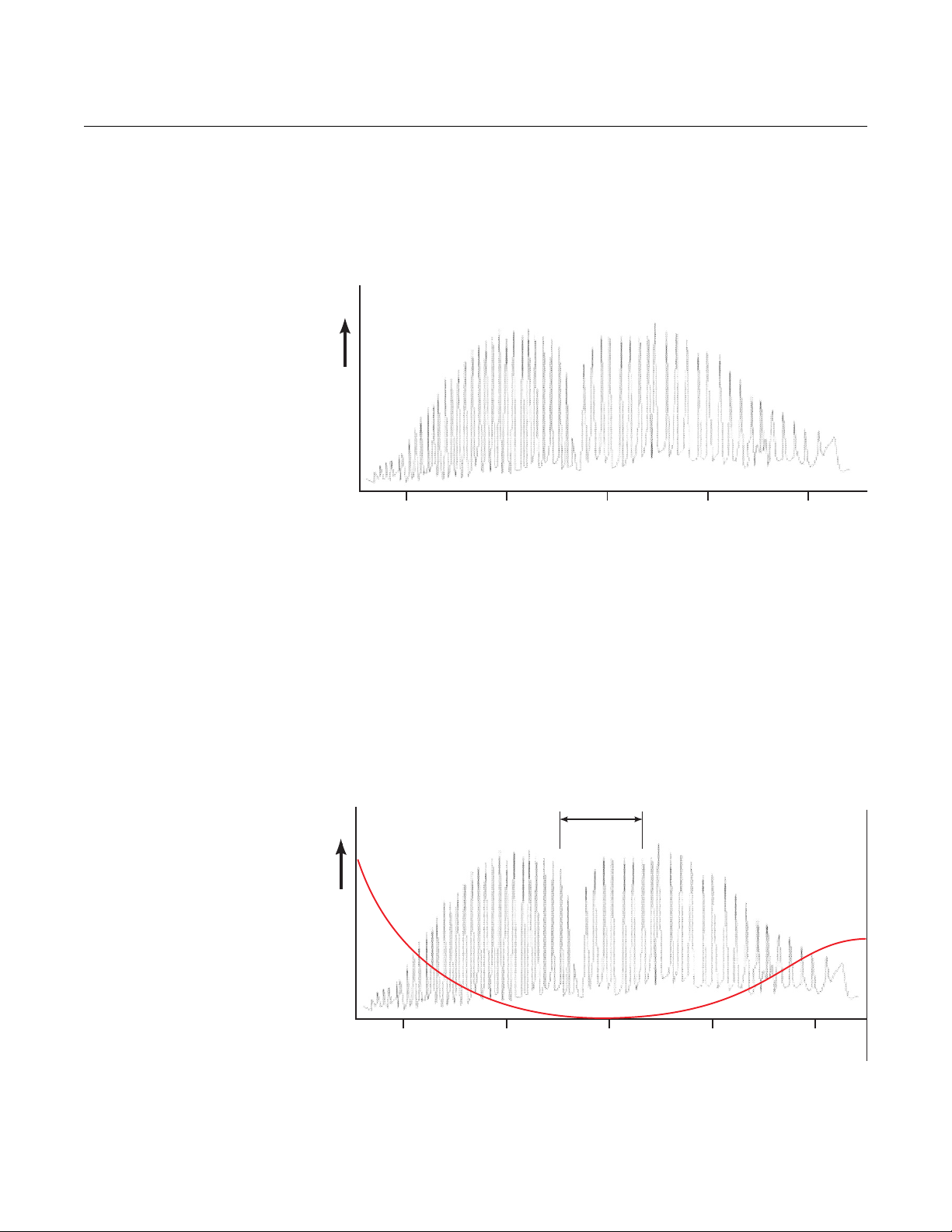

Figure 1-4. Comparison of Spectra

However, two other common flue gas constituents - carbon dioxide and water

vapor - also absorb energy within this wave band. Fortunately, at 4.7µm, IR

absorption by each of these gases is at a minimum. Figure 1-4 demonstrates

how the absorption spectra of CO, CO

and water vapor affect wavelengths of

2

between 4.5 and 4.9 µm.

Absorption Spectra of CO, CO

and Water Vapor

2

By using a narrow band pass filter which only passes IR energy at

wavelengths of around 4.7µm, correctly designed CO analyzers are able to

ignore the effects of water vapor and CO

. (The filter characteristics are

2

shown in Figure 1-4). No other flue gases absorb IR energy in this band.

Filter

Limits

CO

2

HO

2

Absorption (%)

1-8

0

4.5 4.6 4.7 4.8 4.9

Wavelength (microns)

Page 17

Instruction Manual

IM-106-5500, Original Issue

August 2005

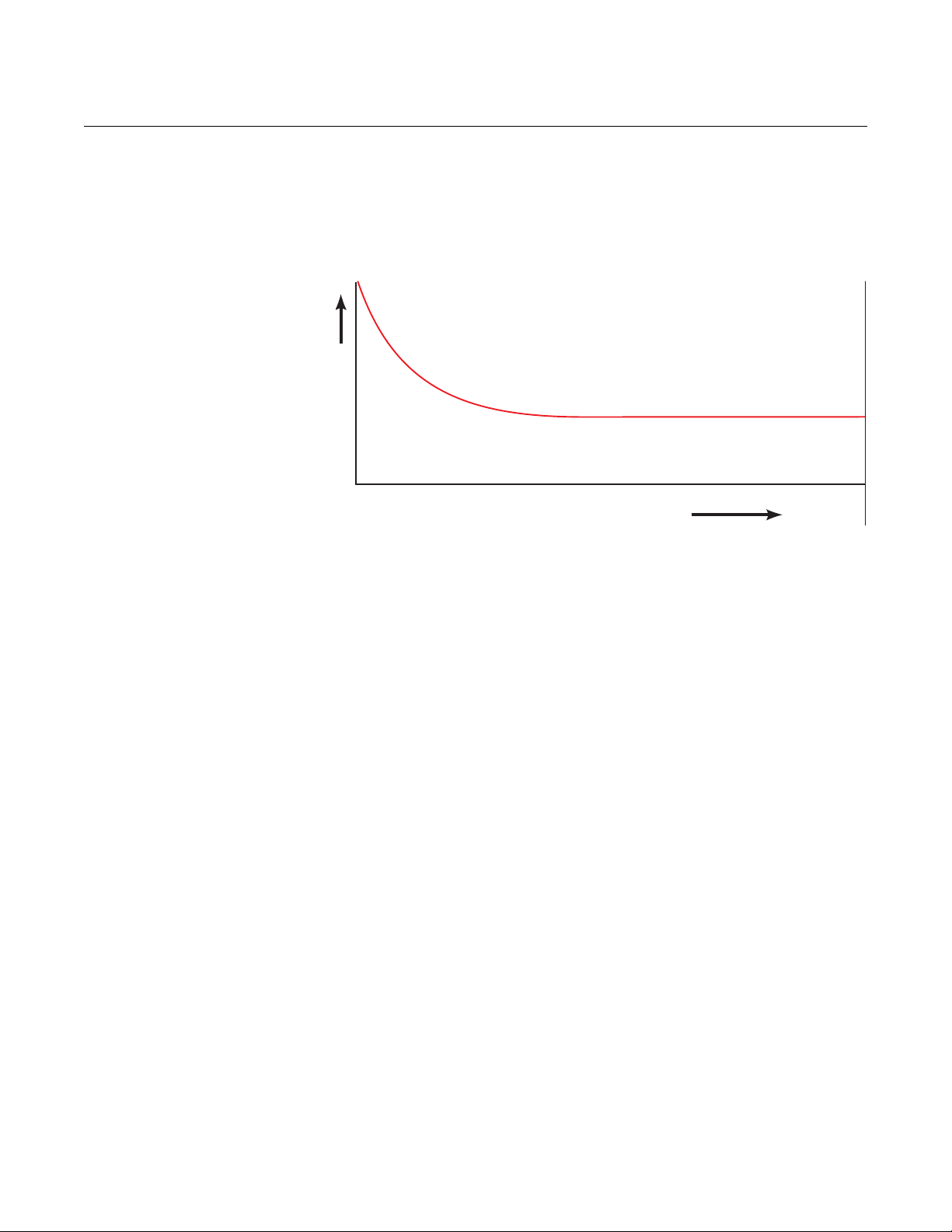

Figure 1-5. Transmissivity of CO

CCO 5500

Transmissivity of CO Within the 4.7µm Band

The transmission through the gas of the IR energy at about 4.7µm is affected

by the concentration of CO. Figure 1-5 illustrates how the energy within the

selected band varies with CO concentration.

Transmission (%)

0

CO Concentration (ppm.m)

The shape of this curve is fixed by the characteristics of the 4.7µm filter - it

cannot change, and the curve is practically flat at CO concentrations of above

10,000 ppm.meters. A cross-duct monitor effectively measures CO molecules

in its optical path, so the same concentration of CO will have a greater effect

across a large measurement path than a small measurement path. The term

ppm.meters is the concentration of CO within the duct multiplied by the gas

path length over which it has been measured.

Carbon Monoxide Calculation

CCO 5500 Analyzers make two measurements of IR energy in the narrow

band around 4.7µm. Both measurements are made after the beam has

passed through the gas to be measured. One, however, also passes through

a cell containing pure CO (the gas cell shown in Figure 1-2). This absorbs all

the energy capable of being absorbed by CO and provides a reference that is

unaffected by any CO in the duct, but will be affected by any other material

(e.g. dust) which reduces the energy received from the transmitter, in exactly

the same way as the other beam.

The second beam does not have such a cell in front of it and, as such, is very

sensitive to changes in CO within the duct.

The measurement of CO is calculated from a parameter Y, where:

Y=G-K.D2/D1

and D2 = the live detector output

D1 = the reference detector output

K = a composite gain factor which takes

account of all optical and electronic gains

G = scaling factor

1-9

Page 18

CCO 5500

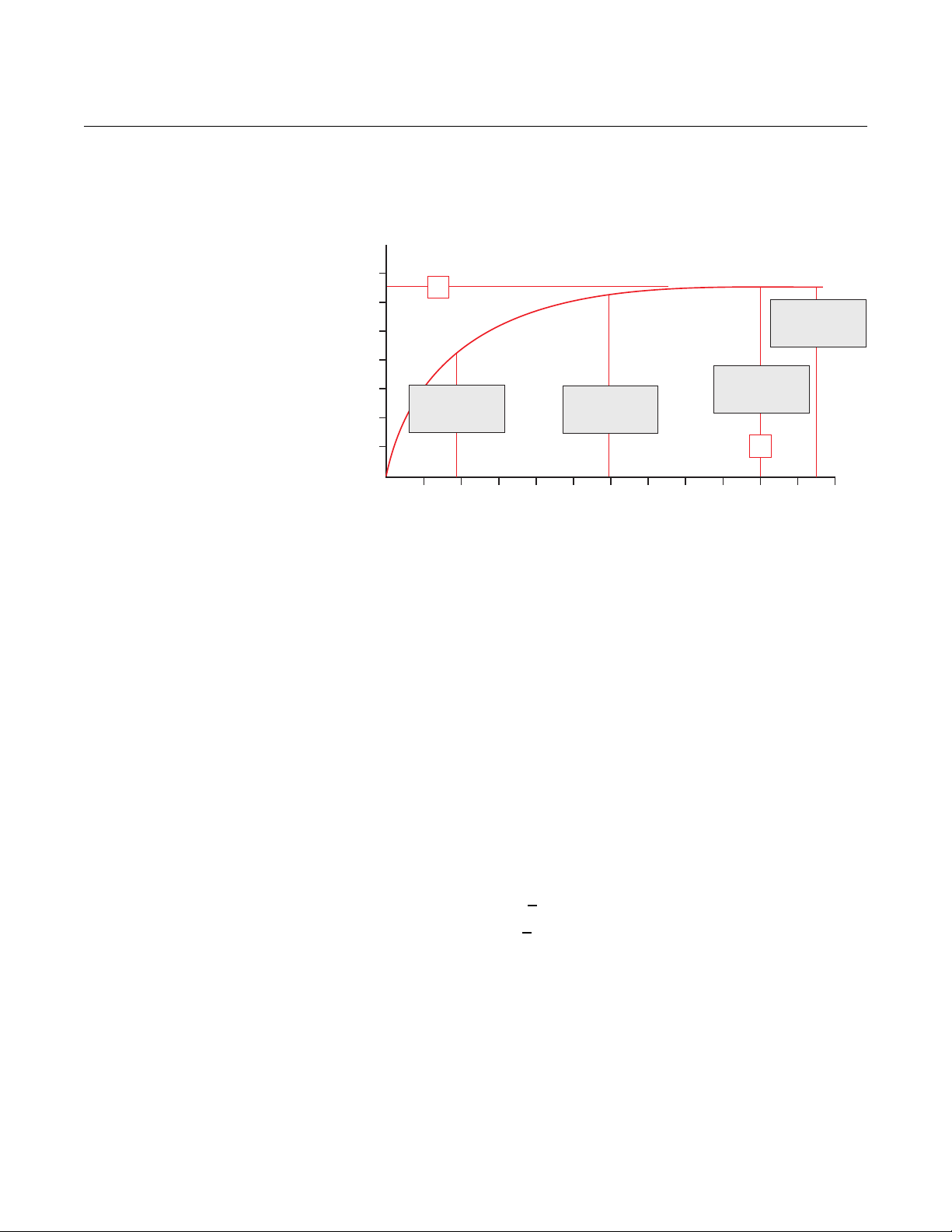

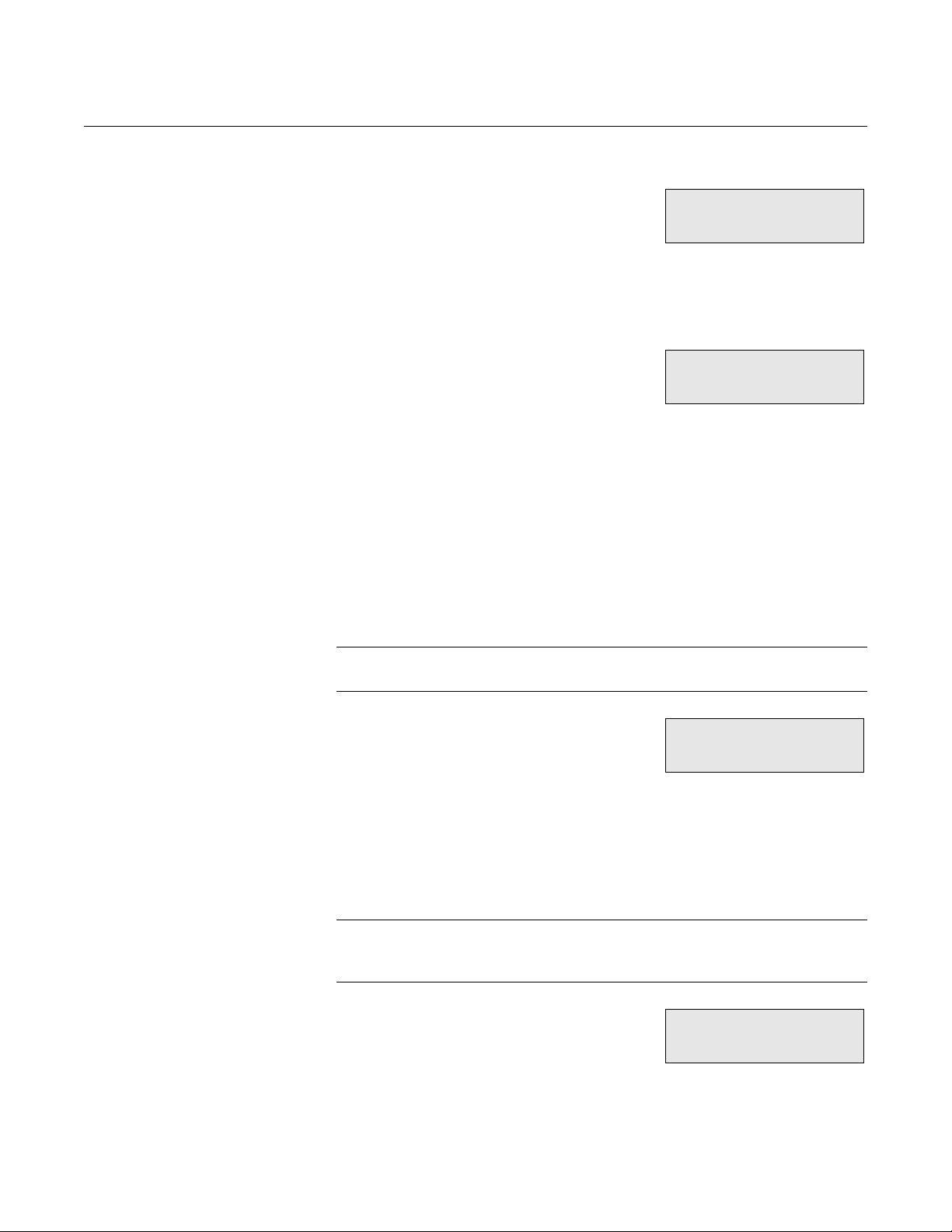

Figure 1-6. Calibration Curve

Instruction Manual

IM-106-5500, Original Issue

August 2005

Calibration

Figure 1-6 shows the parameter Y against the CO concentration.

0.14

0.12

0.10

0.08

Parameter Y

0.06

0.04

0.02

0

A

CO

In Duct

12

4

567891011123

CO ppm.m (x1000)

Practical

Limit

Calibration

Point

B

Calibration Point

Including

CO in Duct

This is the calibration curve for the instrument and is opposite in shape to the

transmissivity curve shown in Figure 1-5. Each is fixed by the characteristics

of the 4.7µm filter and cannot change. Rosemount Analytical analyzers make

full use of this scale shape to provide an easily attainable calibration point.

It is not necessary to calculate K because we know that when the constant K

is correct:

Y is 0 when the CO level is 0

If there is any drift in the measurement, it can only be due to a change in

some optical or electronic gain and can always be corrected by setting Y to

zero when the CO level is zero.

1-10

In practice, however, it is not always possible to produce a zero CO level, but

if we consider the calibration curve, we can see that:

if Y = 0 when CO = 0

then Y = a when CO = b

We can also see from Figure 1-6 that at high CO levels, the parameter Y

becomes completely insensitive to variable CO levels in the duct, such that:

Y = a when the CO >

By making Y = a when CO >

b

b, Y = 0 when CO = 0 and all these errors are

eliminated.

A gas cell containing pure carbon monoxide can be introduced into the IR

beam at the source. This cell represents a value of 10,000 ppm.meters and

provides a reference point for the calibration of the instrument. Any further CO

in the duct will have negligible effect on the reference point because the

calibration curve is flat at these high concentrations of CO. Well-designed

cross-duct analyzers introduce this gas cell regularly - every few seconds - to

continuously check and (if necessary) modify their zero position.

Page 19

Instruction Manual

IM-106-5500, Original Issue

August 2005

SPECIFICATIONS

CCO 5500

CCO 5500 Specifications

Span* Selectable from 0-100 ppm to 0-10,000 ppm,

within the range 200 to 6,000 ppm.meters at

STP

Display Units ppm

Averaging Four averages selectable from

Accuracy ±2% of measurements or

Outputs

Analog

High Alarm

Data Valid

Inputs

Oxygen

Temperature

Pressure

Plant Status Contact

Serial Port For remote instrument operation,

Path Length 1.6 to 26 ft (0.5 to 8 m)

Flue Gas Temperature 1202oF (0 to 650oC)

Construction Cast aluminium, fully sealed to IP65

Transmitter Electrically heated silicon nitride cylinder

Detector Lithium tantalate pyro-electric detector

Ambient Temperature Limits -4oF to 158oF (-20oC to 70oC)

Power Requirements 85-132/170-264V AC, 50/60 Hz, 50VA

Air Purge Consumption 2.2 cfm @ 14.9 psi (1 liter/sec @ 1 bar)

3

mg/m

(measured)

3

mg/Nm

(normalized)

10 seconds to 30 days

±5 ppm whichever is greater

4-20 mA isolated, 500S max.

Volt-free contact, 10A @ 250V

Volt-free contact, 10A @ 250V

4-20 mA

4-20 mA

4-20 mA

Volt-free Contact

normalizing inputs and outputs

(compressed air)

11 cfm (5 liter/sec) (blower air)

NOTE:

*The range of the output span is quoted in ppm.meters. To obtain the

minimum and maximum span for your application, divide these figures by the

path length in meters.

1-11

Page 20

CCO 5500

Instruction Manual

IM-106-5500, Original Issue

August 2005

1-12

Page 21

Instruction Manual

IM-106-5500, Original Issue

August 2005

Section 2 Installation

Safety Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 2-2

Electrical Supply Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 2-2

Unpacking the Equipment . . . . . . . . . . . . . . . . . . . . . . . . . page 2-3

Selecting Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 2-3

Duct Work . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 2-4

Isolating Valves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 2-6

Air Purge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 2-6

Transmitter and Receiver . . . . . . . . . . . . . . . . . . . . . . . . . . page 2-6

Air Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 2-7

Signal Processor Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 2-8

Power Supply Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 2-9

Electrical Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 2-9

CCO 5500

Before installing this equipment, read the “Safety instructions for the wiring and installation

of this apparatus” in Appendix A. Failure to follow safety instructions could result in serious

injury or death.

Install all protective equipment covers and safety ground leads after installation. Failure to

install covers and ground leads could result in serious injury or death.

Before making any electrical connections, make sure the AC power supply is first switched

off. Failure to do so could cause personal injury or even death. Make sure that the voltage

and frequency of the AC supply match the designations on the analyzer component tags.

http://www.raihome.com

Page 22

CCO 5500

Instruction Manual

IM-106-5500, Original Issue

August 2005

SAFETY CONSIDERATIONS

The mains power is supplied to the whole system via the power supply.

During installation, DO NOT connect the system to the mains until all units are

in place and fully wired up. Keep the isolating valves, if used, CLOSED. The

compressed air (to be supplied to the air purges) must be turned OFF until the

full installation is complete. If any servicing or rewiring is to be performed

ensure that the power supply is isolated. For configuration the system needs

to have power, compressed air and the isolating valves open.

ELECTRICAL SUPPLY DATA

AC Supplies

The CCO 5500 may be powered from either 85-132V AC/170-264V AC at

47-440 Hz. A switch within the power supply unit selects the input voltage and

an internal 2A/20 mm fuse protects the instrument.

Voltage fluctuations within the above ranges are tolerated without loss of

performance and the total power requirement is less than 50VA.

Outputs Three forms of output are provided:

1. A selectable, fully isolated, current output (either 4-20 mA or 0-20 mA),

maximum load 500S - taken from the signal processor.

2. Single pole change-over relays (rating 250V at 10A), for:

• Alarm triggering at a selectable gas threshold

• Data valid indication, operating under power failure and any

equipment fault condition - see the basic fault finding section for

further details - contact outputs are taken from the power supply unit

3. 4-wire serial data link for 2-way communication with a central processor

- taken from the signal processor unit.

Normalizing Inputs Pressure, temperature, and oxygen values can be held to normalize the

calculated gas value to standard conditions. These values may be read by the

instrument using the following methods:

1. Fixed value from the key pad.

2. 4-20 mA outputs from measurement transducers - the ranges represented by these inputs are set from within the processor - inputs are taken to the signal processor.

3. If the analyzer is part of an integrated system, the serial data line can carry the normalizing values.

Plant Status Input The plant status input facility is available to prevent the rolling average stacks

being diluted by measurements made during periods where the plant is shut

down. It is governed by one of three choices; a serial input (from an integrated

system), the logic input (terminals PS1 and PS2 in the signal processor) and

multiple. Multiple has five options; temperature, oxygen, water vapor

thresholds, and logic input. It is set in Mode 5. All these are described in more

detail later in this manual.

In normal operation (plant operating), the plant status will register as ON.

However, if the plant status condition is broken, the status will change to OFF

and the averaging stacks (minutes, hours, days) will not be updated.

2-2

Page 23

Instruction Manual

IM-106-5500, Original Issue

August 2005

CCO 5500

NOTE

For normal operation terminals PS1 and PS2 must not be linked together.

CABLE REQUIREMENTS 1. Power supply to signal processor - 7-core, shielded, multi-stranded,

2

.

UNPACKING THE EQUIPMENT

6/0.2 mm. 0.5 mm

NOTE

Although screened cable is specified for the interconnecting cable, it is not

necessary for the cable to be grounded.

2. Current loop output - any suitable 2-conductor cable - maximum length depends on keeping output load within the 500S maximum load requirement.

3. Contact outputs - any 2-conductor cable capable of supplying the power to the warning device/relay etc. 250V, 10A maximum.

4. A.C. power - any suitable 3-conductor power cable capable of transmitting 50VA.

5. Serial data link (if required) - twin twisted pair shielded cable - see IEM Communications Manual for further details (Doc. ID 0006/6).

6. Analog inputs - any suitable 2-conductor cable - Rosemount instruments have an internal impedance of 240S for these inputs.

A typical Rosemount Analytical CCO 5500 Carbon Monoxide (CO) Analyzer

should contain the following items. Record the part number, serial number,

and order number for each component of your system.

1. Transmitter with 33 ft (10 m) of cable and air purge.

2. Receiver with 33 ft (10 m) of cable and air purge.

3. Signal processor.

4. Power supply.

5. Site mounting flange (2).

6. Gaskets (4), selected screws and washers.

SELECTING LOCATION The equipment is designed for mounting on boiler ducting or stacks in

positions open to the weather. It is fully sealed and requires no further

enclosures or protection. The specific location of the instrument will depend

on the application and user requirements, but the following considerations

should be made when choosing a site.

2-3

Page 24

CCO 5500

1. The site must be accessible at both sides of the duct for servicing the

transmitter and receiver.

2. The site should be as free from extremes of temperature and vibration

as possible - permissible ambient temperature range -4

o

(-20

C to +70oC).

3. Flue gas temperatures should not exceed 572

measurement - at higher temperatures instrument accuracy will

deteriorate.

4. There must be an uninterrupted sight path available between the transmitter and the receiver.

5. The maximum cable length allowed between the power supply and the transmitter is 33 ft (10 m).

6. The maximum total cable length between the power supply and the receiver is 82 ft (25 m).

See Figure 1-1 for an illustration of a typical system arrangement.

Points to Consider Path Length

• Too long [>26 ft (8 m)] - low energy available.

• Too short [<1.6 ft (0.5 m)] - optical problems.

Instruction Manual

IM-106-5500, Original Issue

August 2005

o

F to 158oF

o

F (300oC) at the point of

Flue Gas Temperature

• Too low (<dewpoint) - potential water droplets.

• Too high [>662

o

F (>300oC)] - reduced sensitivity.

Ambient Temperature

• Too low [< -4

• Too high [>158

o

F (< -20oC)] - condensation on lenses.

o

F (+70oC)] - potential instrument problems.

Measurement Range

• Minimum range depends on acceptable measurement uncertainty,

which is 10 ppm.meters, e.g. for the level of uncertainty to be below 2%

of range, the minimum range would be 500 ppm. meters.

Note: 10 ppm CO = 12.5 mg/m

3

• For increased sensitivity (reduced uncertainty of measurement) the

path length must be maximized.

• Maximum ranges - 6000 ppm.meters.

Note: To correct ppm.meters to effective ppm, divide by the pathlength.

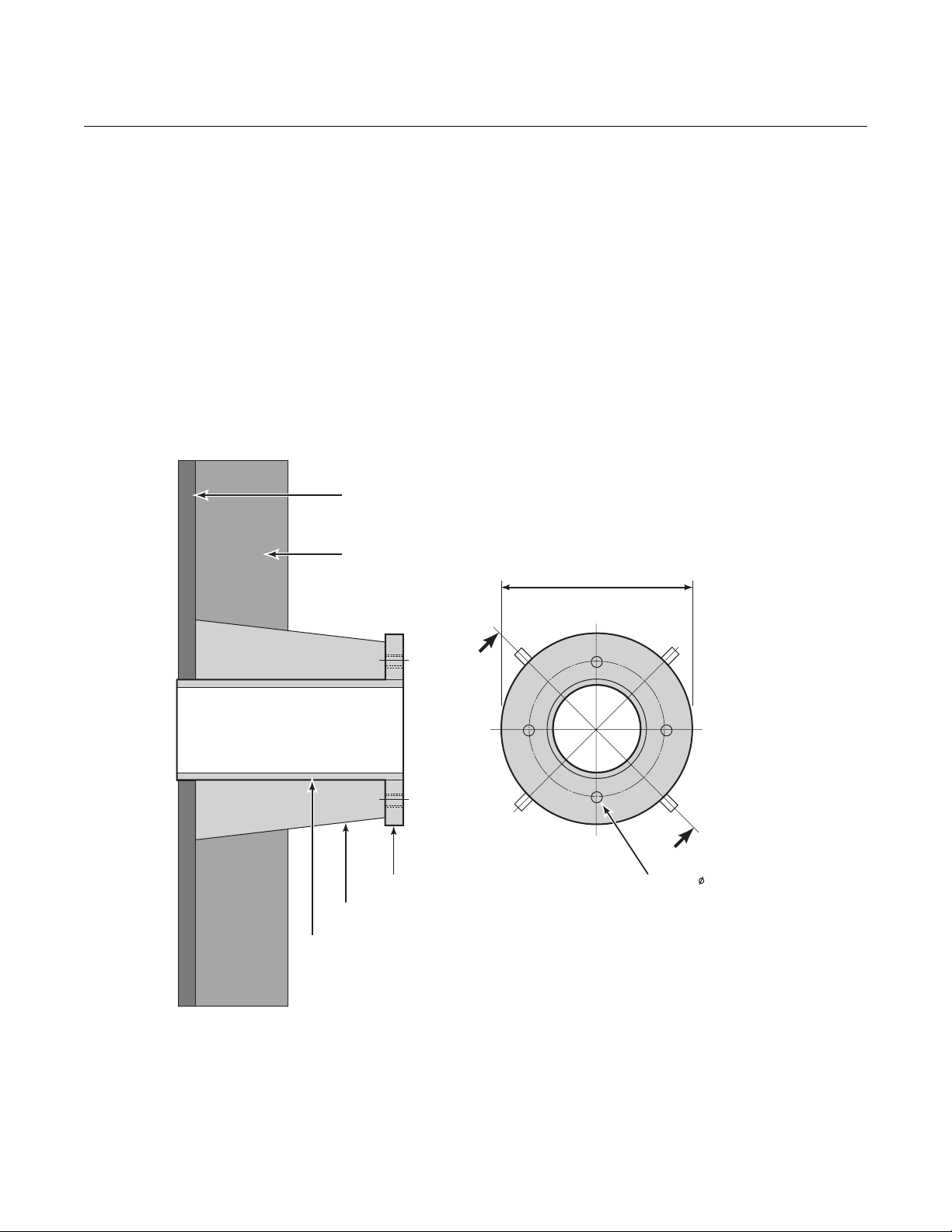

DUCT WORK The transmitter and receiver units are mounted on a site mounting flange,

Figure 2-1, on opposite sides of the duct. To protect operators, it is

recommended that an isolating valve is used for ducts that operate at a higher

than atmospheric pressure.

2-4

A stand-off pipe [nominal bore 3 in. (75 mm) - not supplied] should be used

between the duct and the site mounting flange. The pipe should be long

enough to clear the equipment from any duct lagging; it also helps to insulate

the equipment from any high duct temperatures.

Page 25

Instruction Manual

IM-106-5500, Original Issue

August 2005

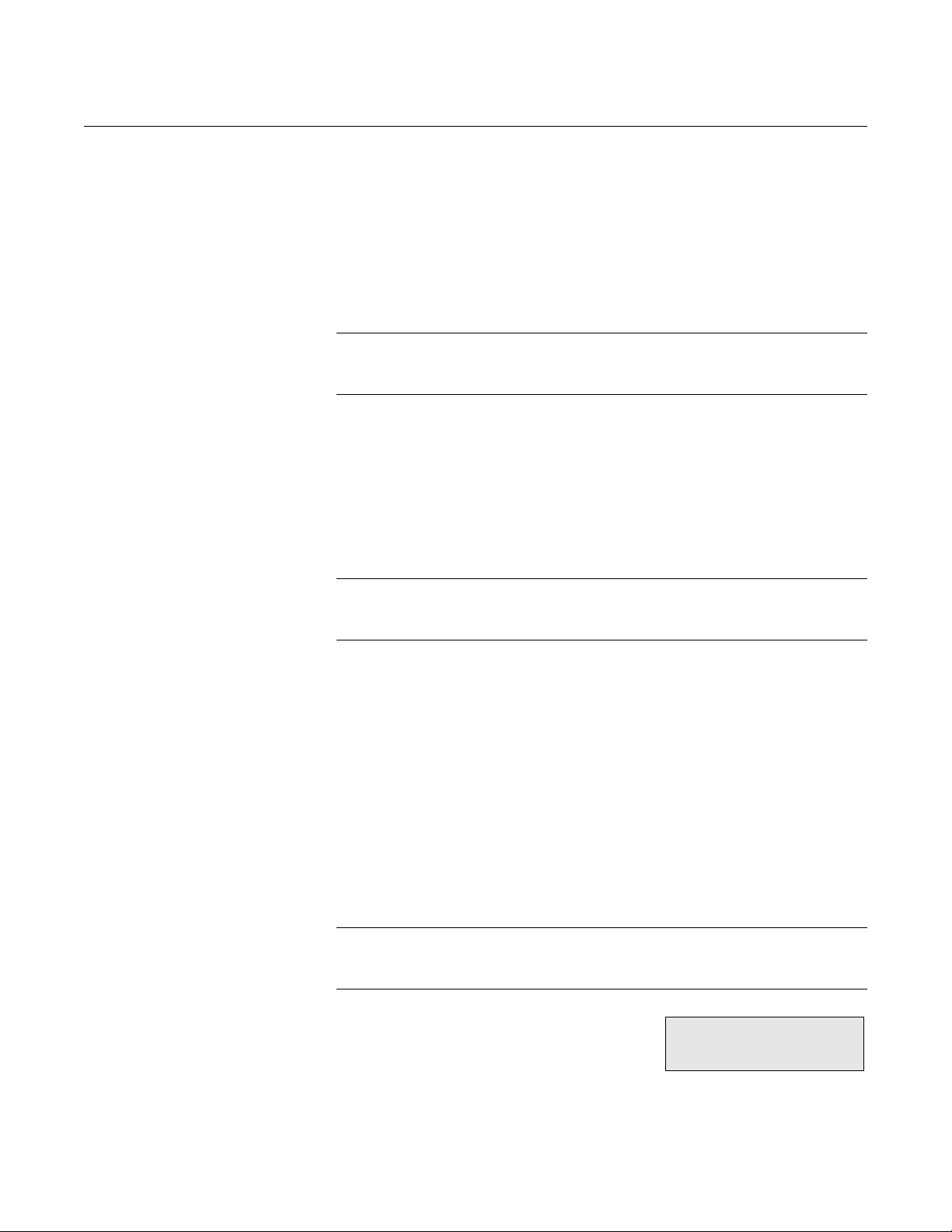

Figure 2-1. Site Mounting Flange

CCO 5500

A hole should be cut on either side of the duct to be measured; these holes

should accept a 'slip fit' with the stand-off pipe. The stand-off pipe should now

be welded into each hole and a mounting flange welded to each pipe with the

tapped holes positioned as shown in Figure 2-1 (it may be easier to weld the

pipe and the flange together before they are fixed to the duct). To avoid

vibration and movement, it may be necessary to fit spreader plates or bracing

fillets.

Alignment is satisfactory if one orifice can be clearly seen when viewed

through the stand-off pipe on the other side of the duct. It is suggested that

the stand-off pipe is 'tacked' on to the duct and the alignment checked visually

before a complete weld is made. The alignment of these holes is not critical,

as the integral adjustable mount compensates for up to 4

Duct Wall

o

of misalignment.

Lagging

Site Mounting Flange

Bracing Fillets

Stand-Off Pipe (if used)

3 in.(75 mm) dia. nominal

6.5 in.

(165 mm)

4 Holes M8

on 4.92 in. (125 mm)

Bolt Circle

2-5

Page 26

Instruction Manual

IM-106-5500, Original Issue

CCO 5500

August 2005

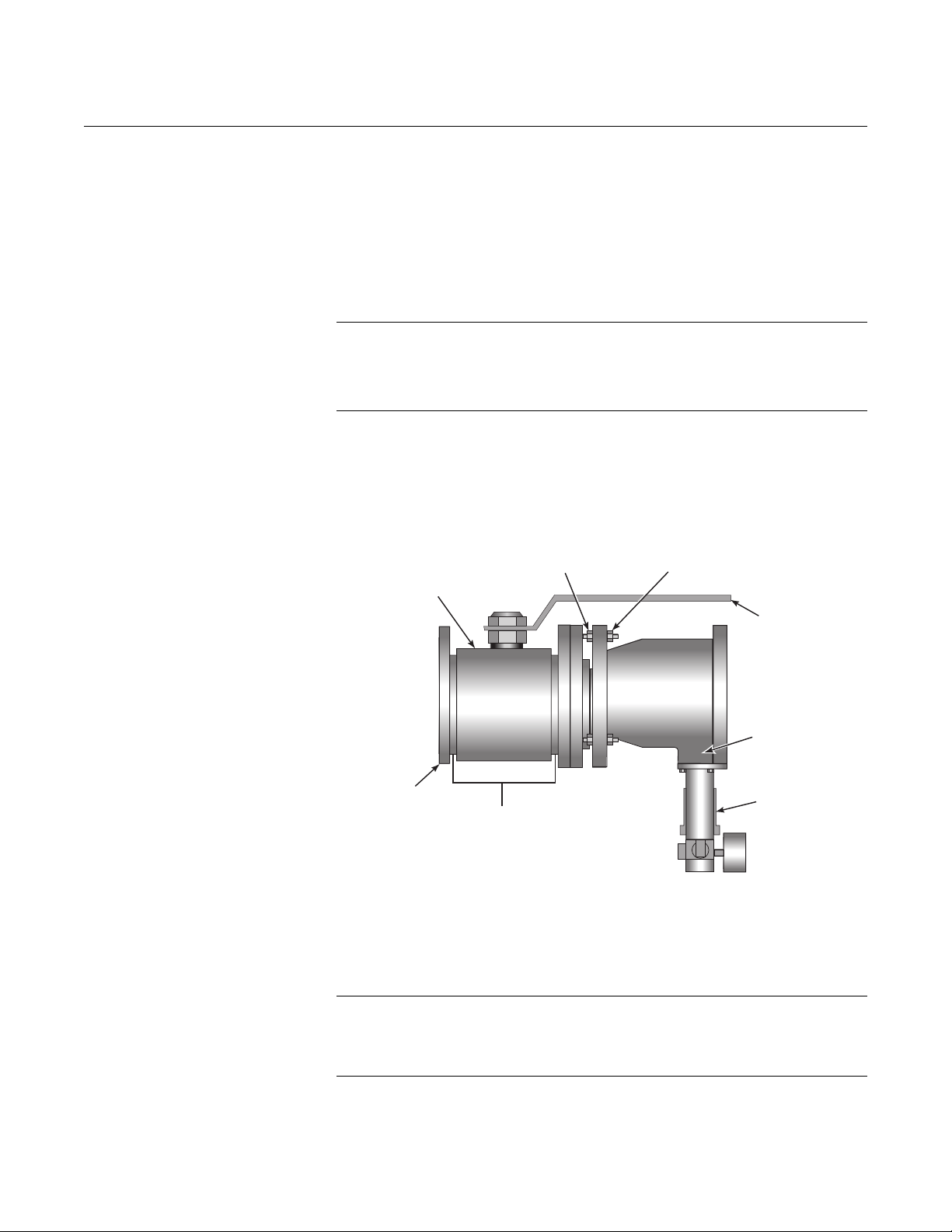

ISOLATING VALVES If isolating valves are used they mount directly onto the site mounting flanges.

AIR PURGE The air purge mounts on the isolating valve. They are mounted by separating

the front flange from the air purge by unscrewing the four locking nuts. A

'snout' and o-ring arrangement locate into the front flange; work the two apart

carefully. The front flange should now be bolted to the isolating valve if used

or site flanges with a rigid gasket fitted between them, using the four

countersunk screws provided.

NOTE

Before mounting the air purges, ensure that air is supplied to the air purge

unit. If this precaution is not observed then the air purge and the

optical surfaces may be severely contaminated.

The adjustable flange is then positioned on the front flange, taking care that

the o-ring seal and 'snout' locate smoothly into the central aperture. This is

then secured by the four locking nuts that screw down onto the adjustable

flange. The arrangement should now appear as shown in Figure 2-2.

Figure 2-2. Valve and Purge Arrangement

TRANSMITTER AND RECEIVER

Locking Nuts

Valve Handle

Air Purge

Pressure Regulator

Assembly

Isolation Valve

(if used)

Site Mounting

Flange

Adjusting Nuts

Rigid

Gasket

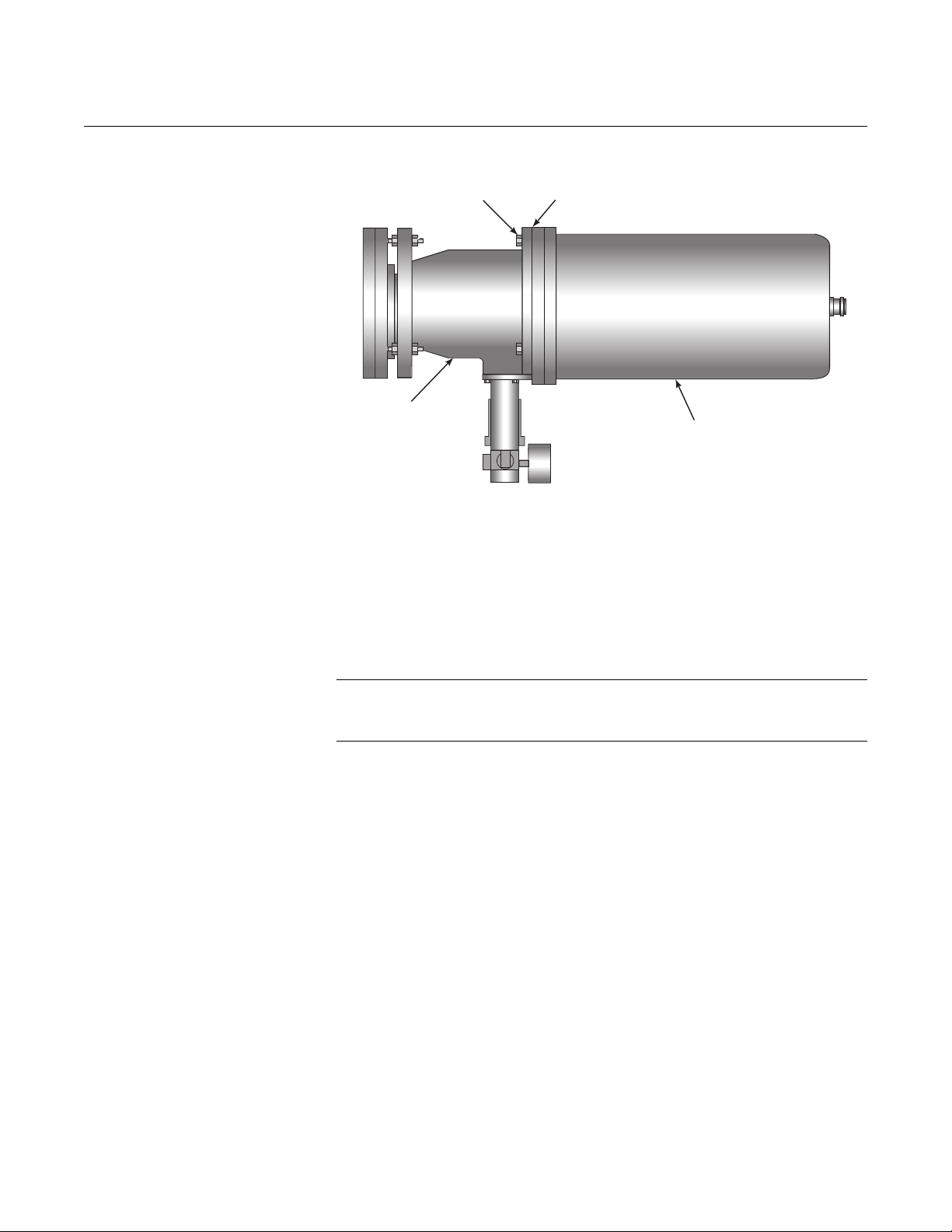

The transmitter and receiver attach to the rear face of the air purge with a

flexible gasket fitted between them, using the M6 x 20 hexagon head screws

provided (see Figure 2-3). A locating dowel ensures that the units can only be

attached to the air purge in one position - make sure this locates correctly.

2-6

NOTE

Before mounting the transmitter and receiver, ensure that air is supplied to the

air purge unit. If this precaution is not observed then the air purge and the

optical surfaces may be severely contaminated.

Page 27

Instruction Manual

IM-106-5500, Original Issue

August 2005

Figure 2-3. Analyzer Head Arrangement

Air Purge

Hexagon

Head Screws

CCO 5500

Flexible Gasket

Transmitter or

Receiver

AIR SUPPLY The purpose of the air purge is to keep the windows of the transmitter and the

receiver clean. Air may be supplied by one of three methods:

1. Negative pressure duct.

If the duct across which the instrument is measuring operates at a

negative pressure under all firing conditions, the air purge inlets may be

simply left open and the negative draft in the duct allowed to draw in

ambient air.

NOTE

For positive pressure ducts, they must be supplied with either compressed air,

or air from a blower.

2. Compressed air.

Using a fine flow regulator and filter, compressed air may be used to

provide the low flow required - an air supply of 14.7 psi (1 bar) is

required and the consumption is 2.2 cfm (1 liter/second) per purge.

3. Blower air.

A blower may be used to provide the air to the air purge - customers

may specify their own blower - it should be able to deliver 11 cfm (5

liters/second) per purge against the working pressure of the duct Rosemount Analytical can specify a blower if required.

2-7

Page 28

CCO 5500

Instruction Manual

IM-106-5500, Original Issue

August 2005

SIGNAL PROCESSOR UNIT

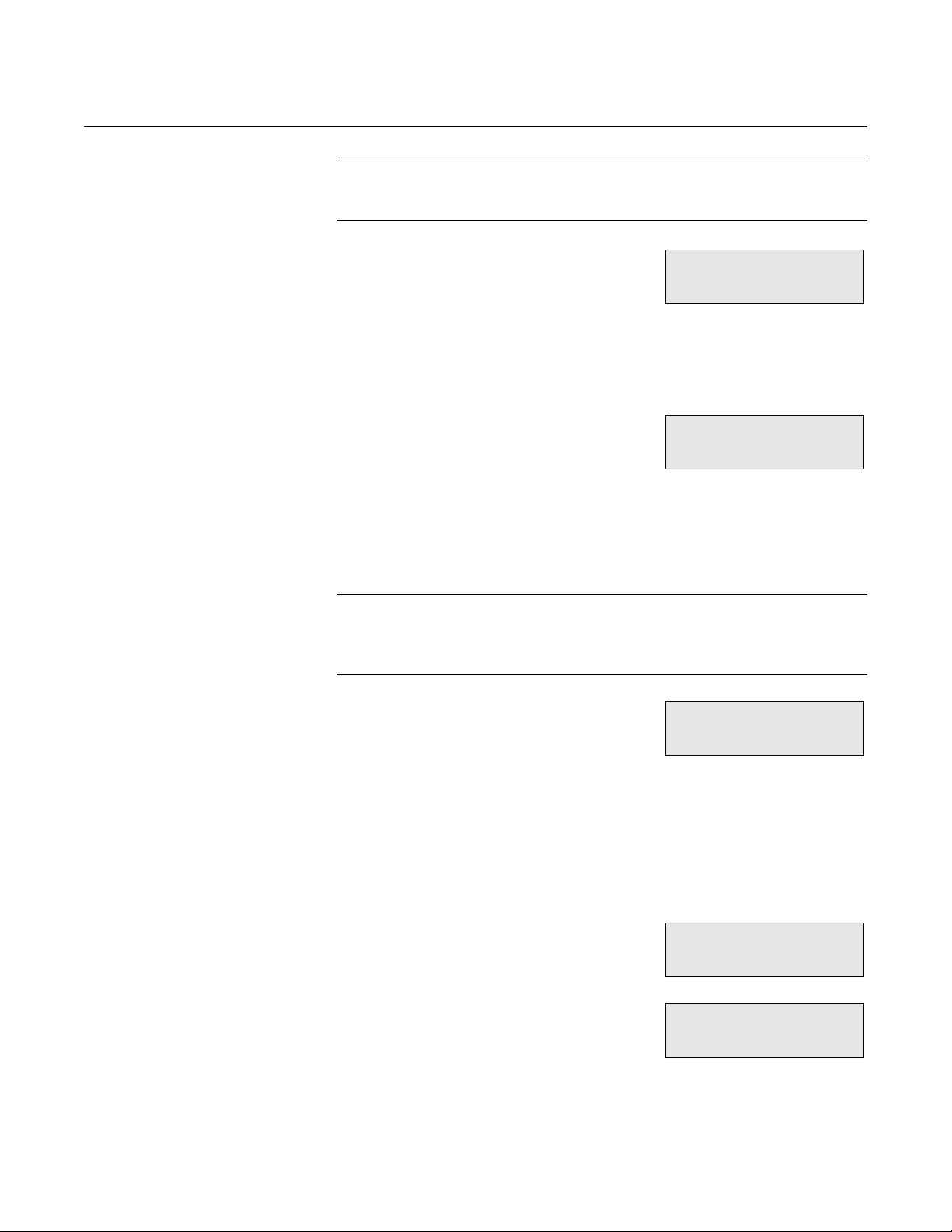

Figure 2-4. Signal Processor Unit/Power Supply Unit Mounting Detail

Cover Seal - Note that the

mounting holes are beyond

the extent of the seal

Assembled Box

110 mm Deep

9.1 in.

(230 mm)

Enough cable is supplied to mount the signal processor up to 33 ft (10 m)

from the receiver. To mount the signal processor (Figure 2-4), first remove the

cover by loosening the four captive screws, unplug the ribbon cable at the

connector on the lid PCB. Note that the processor case has a hinged lid. The

case is then secured to a firm support by use of the four mounting holes found

in the four corners of the case, outside the sealing rim. Since the mounting

holes are located outside the seal of the case, it is not necessary to seal the

mounting holes after installation, nor is it necessary to remove the circuitry

from the case for installation.

7.1 in.

(180 mm)

Cover

Base

4 Holes for M6

Mounting Screws

7.1 in.

(180 mm)

7.9 in.

(200 mm)

Approx. 6 in. (150 mm)

free space required

below box for cables

Cable Gland Entry

Blanking Plugs

2-8

Page 29

Instruction Manual

IM-106-5500, Original Issue

August 2005

CCO 5500

POWER SUPPLY UNIT Enough cable is supplied to mount the power supply up to a maximum of 33 ft

(10 m) from the transmitter. A maximum total cable length of 82 ft (25 m) may

be used to link the power supply to the receiver. These are the maximum

permitted lengths of cable and must not be exceeded.

Dimensions and mounting hole locations are identical to the signal processor

and are illustrated in Figure 2-4.

ELECTRICAL CONNECTIONS

Wiring should only be undertaken by a qualified technician.

Ensure that the power supply is isolated.

DO NOT switch power on until all installation work is complete and the system is ready for

configuring.

Installation of Cables Decide routing for all non-power cables (both those supplied by Rosemount

Analytical and those sourced locally). Use common routing wherever possible

and install leaving sufficient free-end length to make final connections.

Power cables should be installed separately, using different routes if possible

to reduce the risk of cross interference. Leave sufficient free-end length to

make final connections.

Rosemount supplied cables are provided with ferrite beads fitted to all cores

to protect against interference and should not be modified without consulting

Rosemount.

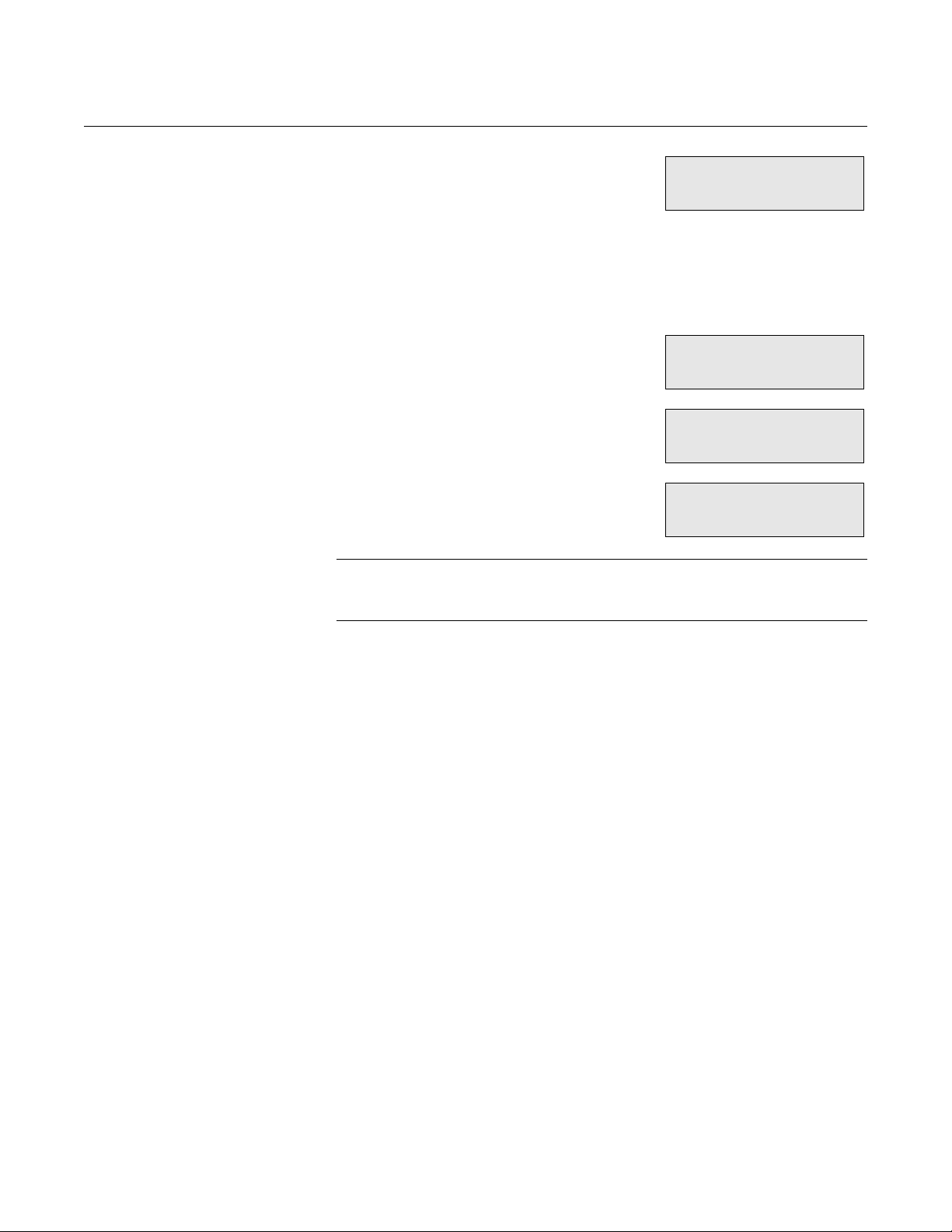

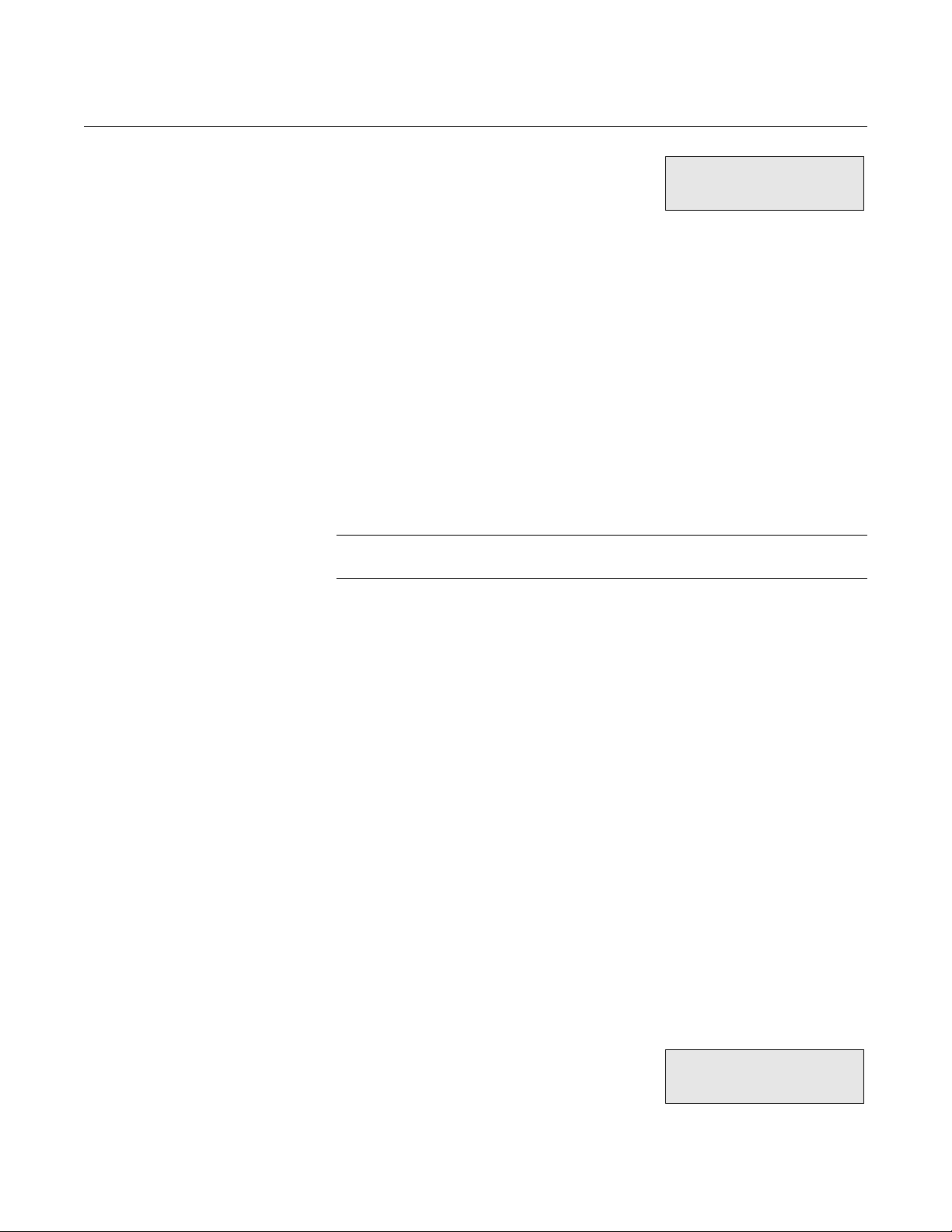

Cable Connections Overall system connections are illustrated in Figure 2-5.

2-9

Page 30

CCO 5500

Figure 2-5. System Cable Connections

TO SIGNAL

PROCESSOR

MOTOR DRIVE

REFERENCE WAVE

0V

+12V

ALARM CONTACT

DATA VALID

12345

MOTOR DIRECTION

6

7

2

0.5 mm

PVC COPPER

BRAID SCREEN

COMMON

W1

CABLE

8 CORE

INTERCONNECT

N/C

C1

COMMON

W2

N/O

O1

DATA VALID CONTACT

N/O

O2

ALARM CONTACT

N/C

C2

0V

DATA VALID

+12V SUPPLY

ALARM SIGNAL

12345

TO POWER

SUPPLY

MOTOR DRIVE

REFERENCE WAVE

6

MOTOR DIRECTION

OXYGEN

7

Instruction Manual

IM-106-5500, Original Issue

August 2005

4-20 mA (IN)0VTEMPERATURE

4-20 mA (IN)0VPRESSURE

4-20 mA (IN)

INPUTS

0V

13

PS1

PLANT STATUS

PS2

INPUT

+mA

ANALOG

8

9

101112

NORMALIZING

0mA

OUTPUT

POWER SUPPLY

8

BLUE

YELLOW

PVC COPPER

BLUE

YELLOW

9

101112

PURPLE

BLACK/WHITE

RED/BROWN

2

0.5 mm

8 CORE

BRAID SCREEN

PURPLE

BLACK/WHITE

RED/BROWN

SCREEN NOT TO BE GROUNDED

AT POWER SUPPLY

L

E

N

BLUE

GREEN/YELLOW

BROWN

50-60Hz

110V/220V

SIGNAL PROCESSOR

16

RED

RED

171819

BLACK

WHITE

BLUE

2

0.5 mm

PVC COPPER

BRAID SCREEN

BLACK

WHITE

BLUE

20

21

GREEN

YELLOW

PURPLE

8 CORE

SCREEN NOT TO BE GROUNDED

SCREEN

GREEN

YELLOW

PURPLE

TX+

22

AT SIGNAL PROCESSOR

23242526272829

SERIAL DATA

TX-

RX+

RX-

RX-

SERIAL DATA

RX+

TX-

TX+

30

2-10

TRANSMITTER

MOTOR DIRECTION

MOTOR DRIVE

REFERENCE WAVE

0V TO SOURCE

12V TO SOURCE

SCREEN

RECEIVER

+12V SUPPLY

0V

D1 SIGNAL

SIGNAL 0V

D2 SIGNAL

TEMP INPUT

SOLENOID DRIVE

Page 31

Instruction Manual

IM-106-5500, Original Issue

August 2005

CCO 5500

Section 3 Configuration and Startup

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 3-1

Safety Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 3-1

Power Supply Voltage Selection . . . . . . . . . . . . . . . . . . . . page 3-2

Turning the Power On . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 3-2

Alignment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 3-2

Detector Levels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 3-4

Transmitter Adjustments . . . . . . . . . . . . . . . . . . . . . . . . . . page 3-7

Operating Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 3-7

Current Output Calibration . . . . . . . . . . . . . . . . . . . . . . . . page 3-19

INTRODUCTION Configuring the instrument can take up to a couple of hours and consists of

the following operations:

1. Power supply voltage selection - select from either 110 or 220V supply.

2. Apply power - switch the power ON and observe the power supply rail indications.

3. Alignment - optically align the transmitter and receiver units using the integral adjustable mounts*.

4. Gain adjustment - adjust the gain within the receiver head and the signal processor*.

5. Operating parameters - set the operating parameters within the micro-processor for correct instrument operation.

6. Calibration - calibrate to a zero or an estimated gas concentration*.

7. Current output calibration - calibrate the analog current loop output.

8. Record the set-up and calibration data - it is strongly recommended that the operating parameters are recorded in Table 3-1, and the calibration data in Table 3-2.

SAFETY CONSIDERATIONS

NOTE

*These operations are preferably conducted when a clean stack condition

exists.

The mains power is supplied to the whole system via the power supply unit. If

any servicing or rewiring is to be performed ensure that the power supply is

isolated. For configuring the CCO 5500, the system needs power,

compressed air to the air purges and the isolating valves (if used) to be open.

3-1

Page 32

CCO 5500

POWER SUPPLY VOLTAGE SELECTION

Instruction Manual

IM-106-5500, Original Issue

August 2005

Disconnect and lock out power before removing the power supply cover.

With the mains supply switched OFF, unscrew the four captive screws on the

cover of the power supply and remove the cover. Select the correct supply

voltage using the sliding switch.

TURNING THE POWER ON

Once the supply voltage switch has been correctly set, switch the power ON.

Check that the power supply rail indication LED illuminates and that the LCD

display is functioning at the signal processor. Replace the lid of the power

supply.

After the initial power on and while the heated source is reaching

temperature, the display will show WAITING FOR REFERENCE. When the

source has reached an adequate temperature for the reference to be

detected, the message STABILIZING REF will be displayed, along with the

frequency and mark/space ratio - see diagnostic mode for details.

The reference frequency will take some time to stabilize (about 5 minutes

from cold startup). When it has been within tolerance for 10 consecutive

measurement cycles, the instrument will automatically change to the

operating mode - this is Mode 1 and is indicated by a number 1 appearing in

the top left hand corner of the LCD. The display will show a reading in ppm this is not accurate until configuration has been completed.

Allow 30 minutes before conducting the alignment procedure; this ensures

that the source temperature has stabilized.

ALIGNMENT In order for the instrument to operate satisfactorily, the transmitter and

receiver units need to be aligned. A degree of optical redundancy is built-in

and normal duct movements do not affect the operation of the instrument.

The transmitter and receiver need to be aligned. Remove the receiver from its

air purge and align the transmitter so the red light it emits can be seen at the

other side of the duct (through the receiver purge). Then replace the receiver

and align, using as a guide, the detector levels displayed by the signal

processor in Mode 5. Finally, the transmitter adjustment is 'fine tuned' once

again using the detector levels in Mode 5. All these processes are described

in the following steps.

3-2

1. Remove the receiver from its mounting flange. Adjust the alignment of

the transmitter flange until the bright red disc of the transmitter is

located centrally in the field of view, when viewed from the receiver air

purge. Use the adjusting nuts to alter alignment. First adjust in one

plane (using opposite nuts) then adjust in the other plane. Lock the

transmitter flange with the locking nuts.

2. Adjustments to the alignment are made using the four adjusting nuts, and the flange is locked in position using the locking nuts - these are illustrated in Figure 3-1.

Page 33

Instruction Manual

IM-106-5500, Original Issue

August 2005

Figure 3-1. Adjusting Nuts for Alignment

CCO 5500

ADJUSTING NUTS

FRONT FLANGE

REAR FLANGE

3. Replace the receiver on its air purge. The next adjustment is done using the detector levels as viewed from the signal processor.

4. To change mode on the signal processor the MODE key needs to be pressed once to access each mode. Enter SET UP MODE (Mode 5) by pressing the MODE key 4 times. 5 SET UP will then be displayed on the LCD. Press ENTER to access the mode.

5. Because Mode 5 is used to configure the instrument, a security code is

used to prevent any unauthorized alteration of settings. The default

code set at the factory is 0000. The cursor will flash over the first digit

that should be altered using the arrow keys until the desired number is

displayed, press ENTER and the cursor will move onto the second digit.

Similarly alter and press ENTER when the desired number is displayed.

When the fourth digit has been correctly entered the processor will

enter Mode 5.

6. Within Mode 5 select the CALIBRATE menu using the arrow keys. Press ENTER when calibrate is displayed.

7. Once again, use the arrow keys to select DISPLAY DETECTOR

LEVELS option and press ENTER to access. The D1 and D2 detector

levels will be displayed. Important - if not in this mode, the gas cell at

the source will periodically interrupt the IR beam and make alignment

difficult.

8. Adjust the alignment of the receiver by using the adjusting nuts. As for

the transmitter, the alignment is best conducted by adjusting in one

plane first, then in the other. As a 'rule of thumb', it will be observed that

the D2 detector level will be affected to a greater extent by adjustment

in one particular plane. Similarly, the D1 detector level will be affected

more by adjustment in the other plane.

9. Use this guide to ensure that the MAXIMUM possible values of both D1 and D2 are reached. After alignment has been achieved, lock the flange into position using the locking nuts.

10. If the displayed detector level is below 5000, increase the gain from the signal processor to about 10,000; if above 15,000, reduce to 10,000. Refer to Detector Levels for details of this operation.

LOCKING NUTS

3-3

Page 34

IM-106-5500, Original Issue

CCO 5500

NOTE

The alignment of the receiver unit is important. Take time to ensure that

maximum values of D1 and D2 are obtained.

11. To 'fine tune' the alignment, return once more and adjust the transmitter flange, again observing the values of D1 and D2 as appropriate; lock the flange in place when a MAXIMUM has been obtained.

12. After this procedure has been followed, the alignment is completed and there is rarely any need for further adjustments.

NOTE

The alignment of the receiver may be conducted by monitoring the output of

the detector directly. This can be done using a voltmeter set to AC volts (10V

max.) measuring across test points S0V and S2 for D3 and S0V and S1 for

D1 on the RECEIVER CONTROL BOARD within the receiver (Figure 3-3).

This is useful should the receiver be some distance from the signal processor.

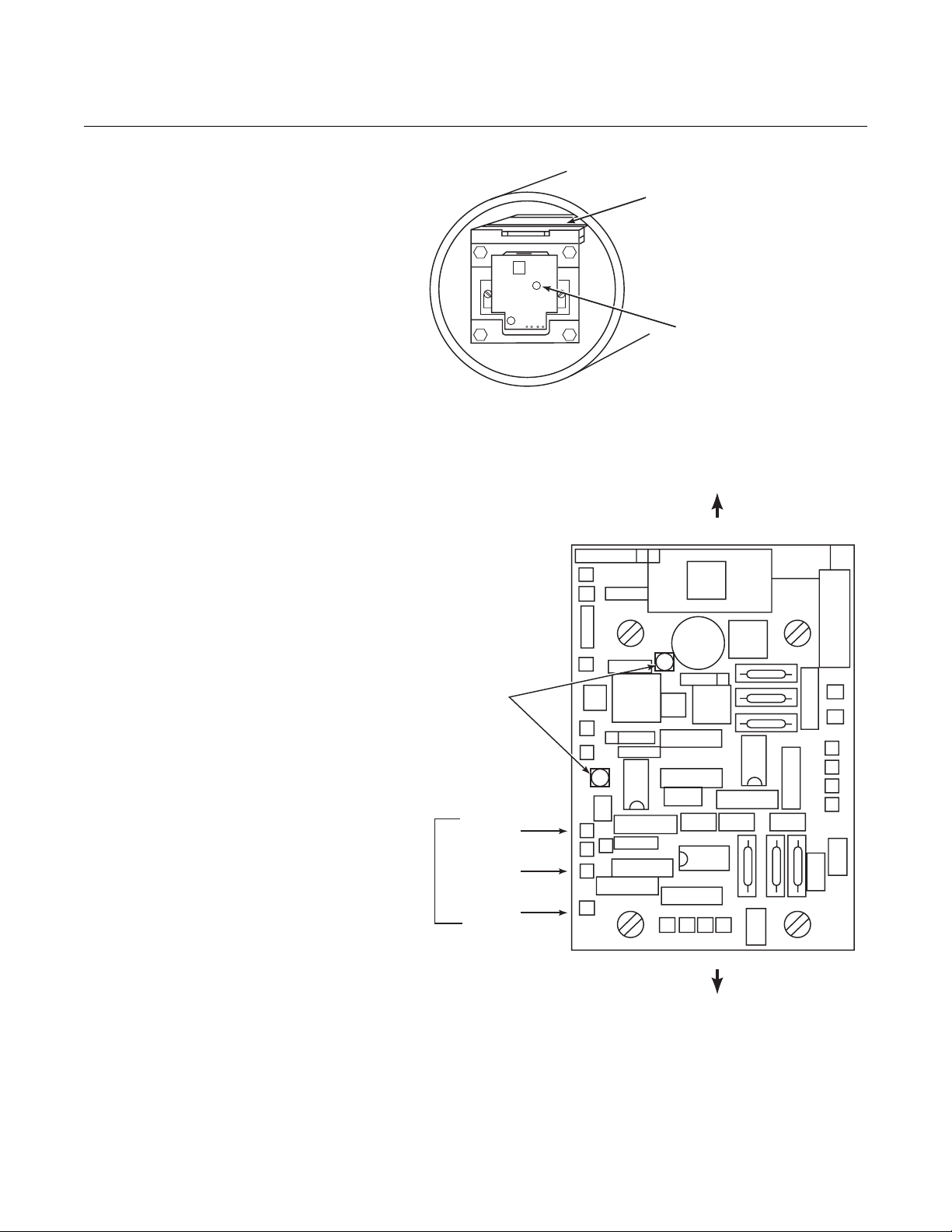

DETECTOR LEVELS The gain of the detector signals is set in two locations:

Instruction Manual

August 2005

Receiver Gain Adjustment

1. In the receiver: two potentiometers set the gain. Refer to Receiver Gain Adjustment.

2. In the signal processor: trim potentiometers adjust the level of the D1 and D2 signals before they enter the microprocessor. Refer to Receiver Gain Adjustment.

It is essential that the alignment procedure has been conducted and a

maximum detector signal obtained before attempting to optimize the detector

levels.

To give an optimum signal-to-noise ratio, the detector levels must be

maximized.

For the best signal-to-noise ratio, the gain of the detector signals within the

receiver must be set to a maximum, without saturating. The gains will have

been set by Rosemount Analytical at a pathlength of 6.5 ft (2 m). If the

pathlength is above 13 ft (4 m) or below 5 ft (1.5 m), this adjustment may be

necessary to optimize the detector levels. If the pathlength is within this

range, this section may be ignored unless there is insufficient or too much

gain.

1. Enter the Setup mode, CALIBRATE OPTION-SET DETECTORS, and display the value of D2/D1.

2. Loosen the cable gland and remove the end cap from the receiver body, letting the cable slip through the gland.

3. The receiver can now be accessed as shown in Figure 3-2.

3-4

Page 35

Instruction Manual

IM-106-5500, Original Issue

August 2005

Figure 3-2. Receiver Trim Pots

Figure 3-3. Receiver Test Points

CCO 5500

Control Board for

Side Detector D1

Control Board for

End Detector D2

4. Trim potentiometer(s) set the gain with the receiver. Levels should be measured with a voltmeter set to AC Volts.

TEST POINTS

Front of Receiver

Voltage

Indication

LEDs

S0V GREEN

S2 BLUE

S1 WHITE

End Detector

5. Connect the voltmeter to the S0V and S1 test points, as in Figure 3-3. Increase the gain using the trim pot at the END DETECTOR, until the voltage is a maximum of 4V rms.

6. Repeat the above procedure for the SIDE DETECTOR, measuring across S0V and S2 test point.

7. When the detector levels are satisfactory, replace the cover.

3-5

Page 36

CCO 5500

Instruction Manual

IM-106-5500, Original Issue

August 2005

NOTE

If the duct is operating and a high opacity may be present, reduce the set

voltages to 2V rms maximum. This is to prevent saturation should the opacity

level drop.

Signal Processor Gain Adjustment

Figure 3-4. Gain Adjustment Potentiometers

TRIM POT.

TEST POINT

LED

TRIM POT

TEST POINT

LED

After the detector level(s) at the receiver have been optimized if necessary,

the levels within the micro-processor should be adjusted. This adjustment is

conducted by means of two trim potentiometers within the signal processor,

Figure 3-4.

CON3

D2 TRIM

POT

D1 TRIM

POT

VIN

+V1

-V1

COUNT 1P

COUNT 3

T4

SOL MDRV

M-DIR

F

COM4

T7

T10

T6

T5

T8

T9

T3

T2

T1

-15

+12VB

0VB

REG

+15

+5

0V

5V

12V

+15V

-15V

0VA

0V1

-15V1

+15V1

3-6

+12V

PS

PS1

PS2

PLANT

STATUS

INPUT

+mA 0mA

ANALOG

OUTPUT

2A

POWER SUPPLY NOT USED

SB

FUSE

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15

16 17 18 19 20 21 22 23 24 25 26 27 28 29 30

RECEIVER SERIAL DATA

NORMALIZING IPs

1. *Set the gain to a minimum by turning the D2 - detector trim potentiometer within the signal processor fully CLOCKWISE - it is a 20-turn pot.

2. *Enter the DIAGNOSTIC MODE - DETECTOR LEVELS option, and display the values of D2 and D1. Turn the trim pot COUNTERCLOCKWISE until the D2 level is between 12,000 and 15,000. Allow time between adjustments for the readings to settle.

Page 37

Instruction Manual

IM-106-5500, Original Issue

August 2005

CCO 5500

NOTE

If the duct is operating and the opacity levels are high, reduce the D2 level to

about 8,500. This is to avoid saturation should the opacity level within the duct

reduce.

3. *To ensure that the detector signal is not saturating, observe the

saturation count signal displayed next to the detector levels. If a SAT #

of more than 0 is displayed, turn the trim pot slightly to reduce the gain

until a SAT # of 0 is displayed.

4. *Should saturation be indicated, with trim pot turned fully CLOCKWISE, reduce the gain in the receiver and repeat the procedure.

5. Repeat the steps above marked (*) for the D1 level, using the D1 trim potentiometer.

NOTE

The circuits are designed so that wherever saturation occurs (receiver or

processor), it will always be detected by the micro-processor. If the displayed

detector levels cannot be set to within this band or saturation cannot be

avoided, the detector levels should be optimized at the receiver. Refer to

Receiver Gain Adjustment.

TRANSMITTER ADJUSTMENTS

NOTE

It is recommended that Rosemount Analytical is consulted before making any

adjustments within the transmitter.

Two trim potentiometers within the transmitter unit allow adjustments to be

made to the intensity of the source and the frequency of the chopper motor.

These are set up at the factory and rarely need adjustment.

NOTE

Increasing source intensity may severely reduce the source life.

Source Intensity A trim pot, in the rear of the unit (furthest from the lens) is accessible after the

end cover has been removed. This allows adjustments to be made to the

intensity of the source.

Chopper Frequency Remove the head from the duct to conduct this process. A trim pot. in the front

of the unit (nearest to the lens) is accessible after the front flange has been

removed (achieved by loosening and removing the four screws holding the

flange in place). Once removed, the trim pot. is revealed. This allows

adjustments to be made to the frequency of the chopper motor.

OPERATING PARAMETERS

Operating parameters must be set in the instrument for it to function correctly.

All operating parameters are set within the signal processor during the setup

mode, where they are held in non-volatile memory and so retained in the

event of a power loss.

Even if the measured data is not going to be normalized the normalizing

parameters must be set for the instrument to function properly.

3-7

Page 38

CCO 5500

Instruction Manual

IM-106-5500, Original Issue

August 2005

NOTE

All operating parameters are entered in the setup mode.

Section 5, Normal Operation, lists all parameters in full. Basic details are

given here for configuration purposes.

To aid configuration and to record any subsequent changes to the operating

parameters, it is recommended that Table 3-1. Instrument Settings, at the end

of this procedure be completed to provide a record of the instrument setup.

1. Press the MODE key until the number 5 is displayed in the top left-hand corner.

2. Enter 0000 for the security code - this is the default code set at the factory.

3. After the correct code has been entered the six sub-modes are accessed by using the ARROW keys and pressing ENTER when the required option is displayed.

4. First the instrument averages need setting. a. Press the ENTER key when this

display is shown, the display will now

show one of the averages. Use the

ARROW keys to select the average time

that requires setting, and press the ENTER key to access the value.

Change the value by using the ARROW keys and input by pressing the

ENTER key.

b. Set the seconds averaging stack to the required value. This is limited

to within 10 to 60 seconds in 10-second intervals.

c. Set the minutes averaging stack to the required value. This is limited

to within 1 to 60 minutes in 1-minute intervals.

d. Set the hours averaging stack to the required value. This is limited to

within 1 to 24 hours in 1-hour intervals.

e. Set the days averaging stack to the required value. This is limited to

within 1 to 30 days in 1-day intervals.

5. The analogue current loop output is set

up in the next menu. Press the ENTER

key while this display is shown to select

it, then press the ARROW keys to step

through the available options. Press the ENTER key to enter each

option and change the displayed parameter.

a. Base of Output

5 SET AVERAGES

5 CONFIGURE O/P

3-8

An origin of 0 or 4mA can be set for

the current loop output. The ARROW

keys will 'toggle' between these two

options. Press the ENTER key to enter

the new value.

b. Averaging Time of the Output

5 CONFIGURE O/P

OUTPUT = 4 to 20 mA

Page 39

Instruction Manual

IM-106-5500, Original Issue

August 2005

CCO 5500

Any of the four averaging stacks

(seconds, minutes, hours or days)

may be used for the analog output.

They are selected by the ARROW

keys and entered using the ENTER key.

c. Output Units

The analog output can represent the

gas concentration in units of either

3

mg/m

, mg/Nm3 or ppm. The ARROW

keys will 'toggle' between these three

options. Press the ENTER key to enter the new value.

d. Output Span

Select the required span using the

ARROW keys for each digit. The

ENTER key is pressed to enter the

value of each digit. The units will be

displayed as either ppm, mg/m

been selected beforehand. The current value will be displayed for 1