Page 1

Instruction Manual

Form 5777

September 2004

i2P-100 Transducer

Type i2P-100 Electro-Pneumatic Transducers

Contents

Introduction 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Scope of Manual 1. . . . . . . . . . . . . . . . . . . . . . . . . . .

Description 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Specifications 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Educational Services 4. . . . . . . . . . . . . . . . . . . . . . .

Installation 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Mounting 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Pneumatic Connections 6. . . . . . . . . . . . . . . . . . . .

Supply Pressure Requirements 6. . . . . . . . . . . .

Diagnostic Connections 7. . . . . . . . . . . . . . . . . . .

Vent 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Electrical Connections 8. . . . . . . . . . . . . . . . . . . . .

Operating Information 8. . . . . . . . . . . . . . . . . . . . . . .

Calibration 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Equipment Required 9. . . . . . . . . . . . . . . . . . . . .

Calibration Procedure 9. . . . . . . . . . . . . . . . . . . .

Principle of Operation 10. . . . . . . . . . . . . . . . . . . . . .

Maintenance 10. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Troubleshooting 11. . . . . . . . . . . . . . . . . . . . . . . . .

Converter Module Replacement 11. . . . . . . . . . . .

Electronics Module Replacement 11. . . . . . . . . . .

Relay Maintenance 12. . . . . . . . . . . . . . . . . . . . . . .

Parts Ordering 13. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Parts List 13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Introduction

Scope of Manual

This instruction manual provides installation,

operation, maintenance, and parts ordering

information for the Type i2P-100 transducer (see

figure 1). Refer to separate manuals for instructions

covering equipment used with the transducer.

No person may install, operate or maintain a Type

i2P-100 electro-pneumatic transducer without

first D being fully trained and qualified in valve,

actuator and accessory installation, operation and

maintenance, and D carefully reading and

understanding the contents of this manual. If you

have any questions about these instructions, contact

your Fisher sales office.

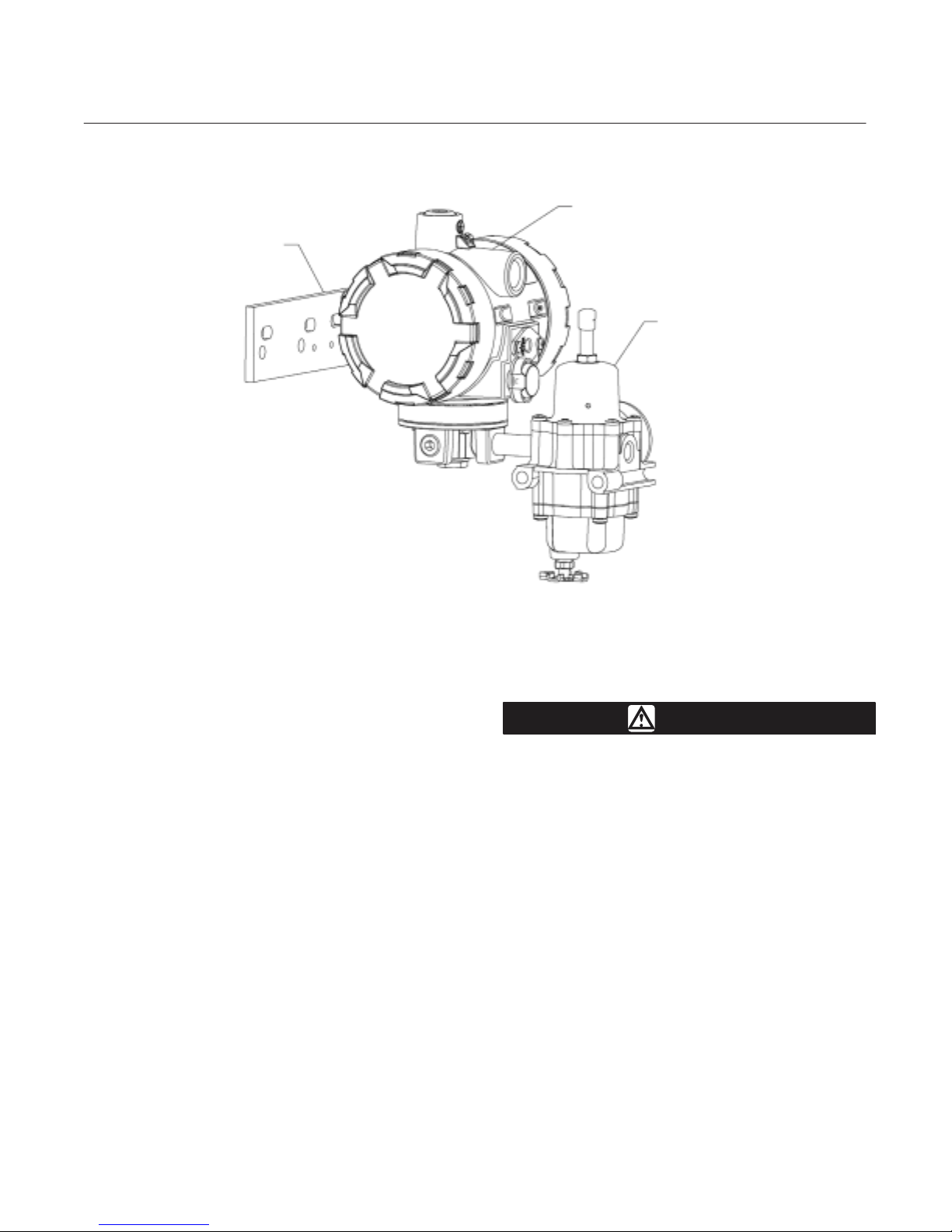

INTEGRAL

PNEUMATIC

RELAY

W8710

Figure 1. Type i2P-100 Electro-Pneumatic Transducer

Description

The transducer, shown in figure 3, receives a 4 to 20

milliampere dc input signal and transmits a

proportional user field-configurable pneumatic output

pressure to a final control element. The pneumatic

output ranges are typically 0.2 to 1.0 bar (3 to 15

psig) and 0.4 to 2.0 bar (6 to 30 psig). A typical

application is in electronic control loops where the

final control element is a control valve assembly that

is pneumatically operated. The input signal and

output pressure range of the transducer is indicated

on the nameplate, attached to the housing.

CAUTION

Dropping or rough handling of the

transducer can cause damage to the

converter module resulting in a shifted

output or a minimum output.

REPLACEABLE

FILTER WITH

REMOVABLE

ORIFICE

VENT

www.Fisher.com

D103198X012

Page 2

i2P-100 Transducer

Instruction Manual

Form 5777

September 2004

Table 1. Specifications

Input Signal

(1)

Available as standard with 4- 20 mA.

User configurable by dip switch for split ranging,

see table below.

Output Signal

(1)

Available as standard 0.2 to 1.0 bar (3 to 15 psig)

or 0.4 to 2.0 bar (6 to 30 psig). User configurable

by dip switch selection and zero and span

potentiometer adjustment, see table below.

INPUT SIGNAL

4 to 20 mA dc

4 to 12 mA dc 0.2 to 1.0 3 to 15

12 to 20 mA dc 0.2 to 1.0 3 to 15

OUTPUT PRESSURE

BAR

0.2 to 1.0 3 to 15

0.4 to 2.0 6 to 30

PSIG

Equivalent Circuit

The Type i2P- 100 equivalent circuit is a series

circuit consisting of a constant voltage drop

(battery) of approximately 4 V dc and a total

resistance of 40 ohms. Input is shunted by two

6.8 V zener diodes (see figure 9).

Supply Pressure

(1,5)

Recommended: 0.3 bar (5 psi) higher than upper

range limit of output signal

Maximum: 3.4 bar (50 psig)

Maximum Output Air Capacity

(2)

8.0 m3/hr (5.0 scfm) at 1.4 bar (20 psig) supply

pressure

Performance

(3)

Reference Accuracy: ±1.0% of full scale output

span; includes combined effects of hysteresis,

linearity, and deadband

Independent Linearity

output span

Hysteresis

(1)

: 0.4% of full scale output span

Frequency Response

(1)

: ±0.75% of full scale

(1)

: Gain is attenuated 3 dB

at 6 Hz with transducer output signal piped to a

typical instrument input

Temperature Effect: ±0.14% per degrees

Celsius (±0.75% per degrees Fahrenheit) of span

Supply Pressure Effect: 0.2% of full scale output

span per bar supply pressure change (0.2% of

full scale output span per psi supply pressure

change)

Vibration Effect: Less than 1% of full scale

output span when tested to SAMA PMC 31.1,

Condition 3

Electromagnetic Interference (EMI)

(1)

: Tested

per IEC 61326-1 (Edition 1.1).Conforms to the

European EMC Directive. Meets emission levels

for Class A equipment (industrial locations) and

Class B equipment (domestic locations). Meets

immunity requirements for industrial locations

(Table A.1 in the IEC specification document).

Immunity performance shown in table 2.

Operating Ambient Temperature Limits

(5)

-40 to 85_C ( -40 to +180_F)

Medium: Air or Natural Gas

Average Steady State Flow Rate

OUTPUT RANGE

0.2 to 1.0 bar (3-15 psig) 0.4 to 2.0 bar (6-30 psig)

SUPPLY PRESSURE

1.5 bar (20 psig) 2.4 bar (35 psig)

OUTPUT FLOW RATE OUTPUT FLOW RATE

Bar Psig

0.2 3 0.08 3.0 0.4 6 0.09 3.6

0.6 9 0.12 4.5 1.2 18 0.19 7.0

1.0 15 0.17 6.3 2.1 30 0.27 10.2

2

Normal

3

m

/h

Scfh Bar Psig

(4)

(1)(2)

Normal

3

m

/h

Scfh

(continued)

Electrical Classification

Hazardous Area

(6)

:

Explosion proof, Dust-Ignition proof, DIV 2,

Intrinsically Safe

Explosion proof, Non-incendive,

Dust-Ignition proof, Intrinsically Safe

APPROVED

ATEX

Intrinsically Safe, Type n and Flameproof

(LCIE)

IECEx

Intrinsically Safe, Type n and Flameproof

(CSA)

Approved for use with natural gas

(4)

Page 3

Instruction Manual

Enclosure

I/O signal/control

Form 5777

September 2004

i2P-100 Transducer

Table 1. Specifications (continued)

Electrical Housing: NEMA 3R, CSA enclosure

Type 3R, IP66 per IEC60529

housing cap (see figure 10).

Switch: Allows input signal split range and

user-configurable 0.2 to 2 bar (3 to 30 psig)

Connections

Supply and Output Pressure: 0.25 inch NPT

female connection

Vent: 0.25 inch NPT female

output.

Mounting Position

J Actuator J pipestand or J surface

Electrical: J Standard 0.5 inch NPT

Wire Size: 18 to 22 AWG

Adjustments

(7)

Zero and Span: Trim potentiometers (20 turn) for

zero and span adjustments are located under the

1. These terms are defined in ISA Standard S51.1.

2. Normal m3/hr—Normal cubic meters per hour (0_C and 1.01325 bar, absolute). Scfh—Standard cubic feet per hour (60_F and 14.7 psia).

3. Performance values are obtained using a transducer with a 4 to 20 mA dc input signal and a 0.2 to 1.0 bar (3 to 15 psig) output signal at an ambient temperature of 24_ C (75_F).

4. This product is approved for use with Natural Gas. Natural gas to contain no more than 20 ppm of hydrogen sulphide.

5. The pressure and temperature limits in this manual and any applicable standard or code limitation should not be exceeded.

6. Approvals are pending

7. For other ranges, zero and span adjustments are needed.

Table 2. Immunity Performance

Port Phenomenon Basic Standard Performance Criteria

Electrostatic discharge (ESD) IEC 61000-4-2 A

Enclosure

I/O signal/control

Specification limit = ±1% of span

Radiated EM field IEC 61000-4-3 A

Rated power frequency magnetic field IEC 61000-4-8 A

Burst (fast transients) IEC 61000-4-4 A

Surge IEC 61000-4-5 A

Conducted RF IEC 61000-4-6 A

Approximate Weight (Transducer Only)

2.5 kg (5.5 lbs)

Actuator Stroking Time

See figure 2

100

90

80

OUTPUT

(% OF TYPE i2P-100 OUTPUT SPAN)

70

60

50

40

30

20

10

0

0 102030405060708090100

A6815 / IL

LOADING

EXHAUSTING

TIME (%)

Figure 2. Output-Time Relationships for Type i2P-100

Transducer

Specifications

Specifications for the Type i2P-100 transducer are

listed in table 1.

WARNING

This product is intended for a specific

current range, temperature range and

other application specifications.

Applying different current, temperature

and other service conditions could

result in malfunction of the product,

property damage or personal injury.

3

Page 4

i2P-100 Transducer

CONDUIT

CONNECTION

FIELD

TERMINATION AND

ELECTRONICS

MODULE CAP

CONVERTER

MODULE CAP

FIELD

TERMINATION AND

ELECTRONICS

MODULE CAP

W8693

Instruction Manual

Form 5777

September 2004

CONDUIT

CONNECTION

CONVERTER

MODULE CAP

W8723

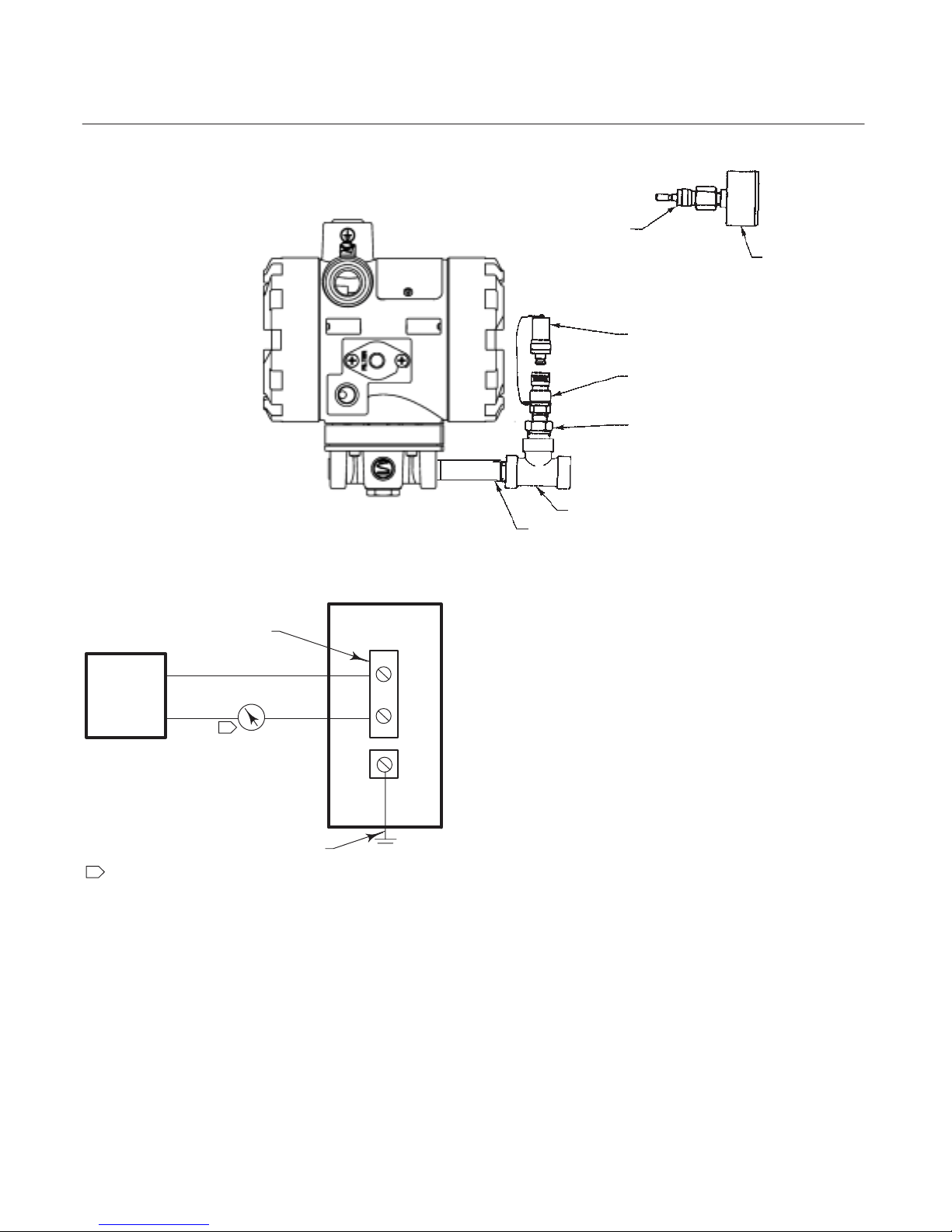

Figure 3. Type i2P-100 Electro-Pneumatic Transducer

Mounted on a Size 30 667 Sliding-Stem Actuator

Educational Services

For information on available courses for the Type

i2P-100 Electro-Pneumatic Transducer, as well as a

variety of other products, contact:

Emerson Process Management

Educational Services, Registration

P.O. Box 190; 301 S. 1st Ave.

Marshalltown, IA 50158- 2823

Phone: 800- 338- 8158 or

Phone: 641- 754- 3771

FAX: 641- 754- 3431

e-mail: education@emersonprocess.com

Note

Fisher does not assume responsibility

for the selection, use and maintenance

of any product. Responsibility for the

selection, use and maintenance of any

Fisher product remains with the

purchaser and end-user.

Figure 4. Type i2P-100 Electro-Pneumatic Transducer

Mounted on a Size 33 1052 Rotary Actuator, 3610J Positioner

and V300B Rotary Valve.

Installation

The i2P-100 transducer has been designed and

approved for use with either air or natural gas as the

supply medium. In normal operation the unit will vent

the supply medium into the surrounding atmosphere

unless it is remotely vented. When using natural gas

as the supply medium in a non-hazardous location,

remote venting of the unit is required. Failure to do

so could result in personal injury, property damage,

and area re-classification. For hazardous locations

remote venting of the unit may be required,

depending upon the area classification, and as

specified by the requirements of local, regional, and

federal codes, rules and regulations. Failure to do so

when necessary could result in personal injury,

property damage, and area re-classification.

WARNING

To avoid personal injury or property

damage from the sudden release of

pressure:

D Always wear protective clothing

and eyewear when performing any

installation operations.

D If installing into an existing

application, also refer to the WARNING

at the beginning of the Maintenance

section of this instruction manual.

D Check with your process or safety

engineer for any additional measures

that must be taken to protect against

process media.

4

Page 5

Instruction Manual

Form 5777

September 2004

i2P-100 Transducer

74.2

81.6

(2.92)

(3.21)

67.8

(2.67)

GE0643

(sheet 1 of 4)

33.3

(1.31)

58.7

(2.31)

55.7

(2.19)

36.3

(1.43)

34.7

(1.37)

98.7

0.25 18 NPT

SUPPLY

CONNECTION

CONNECTION

(3.89)

0.25 18 NPT VENT

OR PIPE-A-WAY

CONNECTION

67 (2.62) CAP

REMOVAL

CLEARANCE

0.5 14 NPT

CONDUIT

103.9

(4.09)

0.25 18 NPT

OUTPUT

CONNECTION

75.2

(2.96)

22.3

(0.88)

22.9

(0.90)

33.3

(1.31)

33.3

(1.31)

0.25 18 NPT

OUTPUT

CONNECTION

75.7

(2.98)

103.9

(4.09)

67 (2.62) CAP

REMOVAL

CLEARANCE

mm

(INCH)

Figure 5. Dimensions and Connections

WARNING

This unit vents the supply medium into

the surrounding atmosphere. When

installing this unit in a non-hazardous

location with natural gas as the supply

medium, you must remotely vent this

unit to a safe location. Failure to do so

could result in personal injury or

property damage from fire or

explosion, and area re-classification.

When installing this unit in a

hazardous location remote venting of

the unit may be required, depending

upon the area classification, and as

specified by the requirements of local,

regional, and federal codes, rules and

regulations. Failure to do so when

necessary could result in personal

injury or property damage from fire or

explosion, and area re-classification.

Vent line piping should comply with

local and regional codes and should

be as short as possible with adequate

inside diameter and few bends to

reduce case pressure buildup.

Mounting

When a transducer is ordered as part of a control

valve assembly, the factory mounts the transducer

on the actuator and connects the necessary tubing,

then adjusts the transducer as specified on the

order. See figure 3 and 4 for typical mounting

configurations.

Transducers also can be ordered separately for

mounting on a control valve assembly already in

service, or for mounting on a 2-inch diameter

pipestand, or a flat surface. The transducer may be

ordered either with or without mounting parts.

Mounting parts include a mounting plate and bolts

and, if ordered for pipestand mounting, a pipe clamp.

Tubing is not included if the transducer is not factory

mounted. Use 0.375 inch diameter tubing for all

input and output connections. The length of tubing

5

Page 6

i2P-100 Transducer

MOUNTING

BRACKET

Instruction Manual

Form 5777

September 2004

i2P-100 TRANSDUCER

REGULATOR

Figure 6. Typical Type i2P-100 Mounting With Type 67CFR Filter Regulator

between the transducer output and the final control

element should be as short as possible. Transducer

overall dimensions are shown in figure 5. If

weatherproofing is required, mount the transducer

so that the vent can drain. Do not allow moisture or

condensate to collect in the vent.

Note

The vent will not drain properly when

mounted in the downward position.

Pneumatic Connections

As shown in figure 5, all pressure connections on the

transducer are 0.25 inch NPT female connections.

Use 0.375 inch tubing for all pressure connections.

Refer to the vent subsection below for remote vent

connections.

Supply Pressure Requirements

WARNING

Severe personal injury or property

damage could result from an unstable

process if the instrument supply

medium is not clean, dry, oil-free and

non-corrosive. While use and regular

maintenance of a filter that removes

particles larger than 40 microns in

diameter will suffice in most

applications, check with a Fisher Field

office and Industry Instrument air

quality standards for use with

corrosive air or if you are unsure about

the proper amount or method of air

filtration or filter maintenance.

Supply pressure must be clean, dry air or

noncorrosive gas. Use a Fisher Type 67CFR Filter

Regulator, or equivalent, to filter and regulate supply

air. The filter regulator can be mounted on a bracket

with the transducer as shown in figure 6 or mounted

on the actuator mounting boss. An output pressure

gauge may be installed on the regulator to indicate

6

Page 7

Instruction Manual

Form 5777

September 2004

GE06439-A

(sheet 1 of 4)

B2395-1/IL

STEM

PROVIDED WHEN

GAUGE IS SPECIFIED

PIPE TEE

PIPE NIPPLE

i2P-100 Transducer

GAUGE

BODY PROTECTOR

BODY

PIPE BUSHING

Figure 7. Diagnostics Hookup for Type i2P-100 Transducer

TERMINAL

BLOCK

CONTROL

DEVICE

+

-

NOTE:

1

FOR TROUBLESHOOTING OR MONITORING OPERATION,

AN INDICATING DEVICE CAN BE A VOLTMETER ACROSS

A 250 OHM RESISTOR OR A CURRENT METER.

A3875/IL

Figure 8. Typical Field Wiring Diagram

FIELD WIRING

-+

1

EARTH

GROUND

TRANSDUCER

HOUSING

+

-

the supply pressure to the transducer. Also, as an

aid for calibration, a second gauge may be installed

on the transducer to indicate transducer output

pressure.

Connect the nearest suitable supply source to the

0.25 inch NPT IN connection on the filter regulator (if

furnished) or to the 0.25 inch NPT SUPPLY

connection on the transducer case (if the filter

regulator is not attached).

Diagnostic Connections

To support diagnostic testing of

valve/actuator/positioner packages, special

connectors and hardware are available. Typical

connector installations are shown in figure 7. The

hardware used includes a 0.25 inch NPT pipe nipple

and pipe tee with a 0.125 inch NPT pipe bushing for

the connector. The connector consists of a 0.125

inch NPT body and body protector.

Note

If the Type i2P-100 transducer is used

in a valve assembly with a positioner,

no hook-up for diagnostic testing is

required for the Type i2P-100. The

hook-up for diagnostic testing should

be installed at the positioner.

Install the connectors and hardware between the

Type i2P-100 transducer and the actuator.

1. Before assembling the pipe nipple, pipe tee, pipe

bushings, actuator piping, and connector body, apply

sealant to all threads.

2. Turn the pipe tee to position the connector body

and body protector for easy access when doing

diagnostic testing.

7

Page 8

i2P-100 Transducer

Instruction Manual

Form 5777

September 2004

Vent

WARNING

This unit vents the supply medium into

the surrounding atmosphere. When

installing this unit in a non-hazardous

location with natural gas as the supply

medium, you must remotely vent this

unit to a safe location. Failure to do so

could result in personal injury or

property damage from fire or

explosion, and area re-classification.

When installing this unit in a

hazardous location remote venting of

the unit may be required, depending

upon the area classification, and as

specified by the requirements of local,

regional, and federal codes, rules and

regulations. Failure to do so when

necessary could result in personal

injury or property damage from fire or

explosion, and area re-classification.

Vent line piping should comply with

local and regional codes and should

be as short as possible with adequate

inside diameter and few bends to

reduce case pressure buildup.

If a remote vent is required, the vent line must be as

short as possible with a minimum number of bends

and elbows. To connect a remote vent, remove the

plastic vent (key 71, figure 13). The vent connection

is 0.25 inch NPT female. Use 0.375 inch tubing to

provide a remote vent.

4 - 20 mA

6.8V 6.8V 4V

40 Ohm

Figure 9. Equivalent Circuit

Use the 0.5 inch NPT conduit connection, shown in

figure 5, for installation of field wiring.

Refer to figures 8, 9, and 10 when connecting field

wiring from the control device to the transducer.

Connect the positive wire from the control device to

the transducer ‘‘+’’ terminal and, the negative wire

from the control device to the transducer ‘‘- ’’

terminal. Do not overtighten the terminal screws.

Maximum torque is 0.45 NSm (4 lbfSin.). Connect the

transducer grounding terminal to earth ground.

Grounding terminals are provided both inside and

outside the transducer housing.

Operating Information

The normal mode of operation for Type i2P-100

transducer requires that the pneumatic output

pressure be piped to the final control element. If this

is not done the resulting pneumatic output will vent

to the atmosphere.

Electrical Connections

WARNING

For explosion-proof applications, or

when using natural gas as the supply

medium, disconnect power before

removing the housing cap. Personal

injury or property damage from fire or

explosion may result if power is not

disconnected before removing the cap.

For intrinsically safe installations, refer

to the nameplate or to instructions

provided by the barrier manufacturer,

for proper wiring and installation.

8

Calibration

WARNING

On explosion-proof instruments, or

when using natural gas as the supply

medium, remove electrical power

before removing either of the the

housing caps in a hazardous area.

Personal injury or property damage

may result from fire or explosion if

power is applied to the transducer with

the cap removed in a hazardous area.

For intrinsically safe areas, current

monitoring during operation must be

with a meter approved for use in

hazardous areas.

Page 9

Instruction Manual

Form 5777

September 2004

i2P-100 Transducer

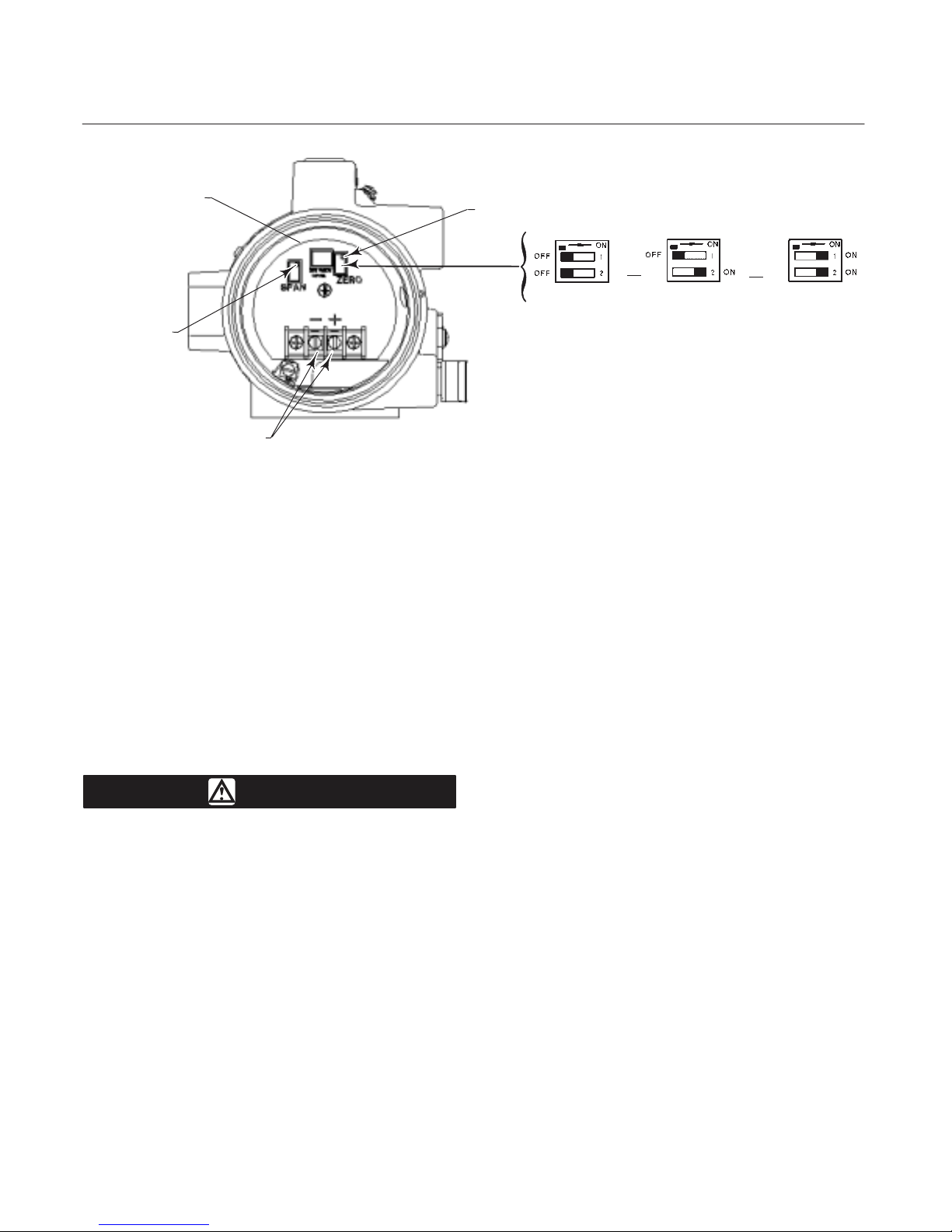

PCB/CUP

ASSEMBLY

SPAN

ADJUSTMENT

FIELD

WIRING

NOTES:

1. INPUT SIGNAL SPLIT RANGE IS SELECTABLE VIA DIP-SWITCH CONFIGURATION.

2. OUTPUT RANGE DIP-SWITCH SELECTION FOR 0.2 TO 2.0 BAR (3 TO 30 PSIG).

FOR OTHER RANGES, ZERO AND SPAN ADJUSTMENTS NEEDED.

CONNECTION

- +

{

Figure 10. Zero and Span Adjustments and Switch Settings

Equipment Required

Choose a current or voltage source that is capable,

without switching ranges, of driving the transducer

through its entire input range. Switching ranges on a

current or voltage source will produce spikes or

mid-scale reverses in the input signal presented to

the transducer, causing errors. The current source

should be capable of delivering 30 mA with 30 V dc

maximum compliance voltage.

Calibration Procedure

WARNING

To avoid personal injury or property

damage due to an uncontrolled

process provide some temporary

means of process control before

beginning the calibration procedure.

Refer to figure 10 for adjustment locations.

Note

The following steps are for a 4- 20 mA,

0.2 to 1.0 bar (3 to 15 psig) configured

unit. The same procedure is used for

other configurations.

1. Remove electronics module cover (cover

adjacent to conduit entry, see figure 3 and 4).

ZERO

ADJUSTMENT

SWITCH

SETTINGS

4- 20 , 3-15

(1,2)

GE03345

OR

4- 12 , 3-15

4- 20 , 6-30

OR

12- 20 , 3-15

2. Input and output ranges are selectable by dip

switch selection. Refer to figure 10 for dip switch

settings. Adjust dip switch settings and zero and

span as necessary to achieve the desired

input/output range.

3. If a current source other than the control device is

used as the input source, disconnect the control

device and connect the current source positive

terminal to the transducer ‘‘+’’ terminal and the

current source negative terminal to the transducer

‘‘- ’’ terminal.

If an external meter is used, connect the current

source positive terminal to the transducer ‘‘+’’

terminal. Connect the meter positive terminal to the

transducer ‘‘- ’’ terminal and the meter negative

terminal to the current source negative terminal as

shown in figure 8.

4. Check the supply pressure to ensure it is at the

recommended pressure. Refer to table 1, the

Specifications table, for supply pressure

recommendations.

5. Adjust the input current to the low milliamperes

dc.

6. The output pressure should be 0.2 bar (3 psig). If

not, adjust the ZERO potentiometer until the output

pressure is 0.2 bar (3 psig).

7. Adjust the input current to the high milliamperes

dc.

8. The output pressure should be 1.0 bar (15 psig).

If not, adjust the SPAN potentiometer until the output

pressure is 0.8 bar (15 psig).

9

Page 10

i2P-100 Transducer

Instruction Manual

Form 5777

September 2004

FIELD TERMINATOR AND

ELECTRONICS CIRCUIT

COIL

ZERO

AND

SPAN

CIRCUIT

{

DC

CURRENT

INPUT

SIGNAL

DIAPHRAGM

EXHAUST

DIAPHRAGM

OUTPUT

PRESSURE

A3877-2/IL

Figure 11. Type i2P-100 Transducer Schematic

F

-

+

F

CURRENT-TO-PRESSURE

CONVERTER ASSEMBLY

MAGNET

BEAM

FLAPPER

NOZZLE

PNEUMATIC

RELAY

RESTRICTION

VALVE

PLUG

SUPPLY

PRESSURE

9. Repeat steps 5 through 8 until the output

pressure is within the referenced accuracy

requirements without further adjustment.

10. If a current source other than the control device

was used, disconnect the current source and

reconnect the control device.

Principle of Operation

The converter module receives a standard dc

current input signal from a control device to operate

coils in a force balanced beam system which in turn,

controls bleed air through an integral nozzle/flapper

arrangement. The nozzle pressure provides the

input signal to operate the relay as shown in figure

11. Relay output pressure is applied, through tubing,

directly to the final control element or valve/actuator

assembly.

Maintenance

The normal mode of operation for Type i2P-100

transducer requires that the pneumatic output

pressure be piped to the final control element. If this

is not done the resulting pneumatic output will vent

to the atmosphere.

Due to normal wear or damage from external

sources such as debris in the supply medium,

periodic maintenance or repair of the transducer

may be necessary. Maintenance of the transducer

consists of troubleshooting, removal for inspection,

and replacement of component parts, as well as

removal and inspection of the external removable

filter/restriction and cleaning or replacing as

necessary (see figure 1).

WARNING

To avoid personal injury or property

damage from the sudden release of

pressure:

D Always wear protective clothing

and eyewear when performing any

maintenance operations.

D Disconnect any operating lines

providing air pressure, electric power,

or a control signal to the actuator. Be

sure the actuator cannot suddenly

open or close the valve.

D Use bypass valves or completely

shut off the process to isolate the

valve from process pressure. Relieve

process pressure on both sides of the

valve.

D Use lock-out procedures to be

sure that the above measures stay in

effect while you work on the

equipment.

D Check with your process or safety

engineer for any additional measures

that must be taken to protect against

process media.

WARNING

For explosion-proof applications, or

when using natural gas as the supply

medium, disconnect power before

removing the housing cap. Personal

injury or property damage from fire or

explosion may result if power is not

disconnected before removing the cap.

CAUTION

When you replace components, use

only components specified by the

factory. Always use proper component

replacement techniques, as presented

10

Page 11

Instruction Manual

Form 5777

September 2004

i2P-100 Transducer

in this manual. Improper techniques

can cause poor quality repairs and

impair the safety features of the

device.

The converter module and the

electronics module are non-repairable.

If troubleshooting or alignment

attempts indicate a faulty converter or

electronics module, replace the

module or return the transducer to

your Fisher sales office for repair.

Troubleshooting

Electrical

The following procedures require taking the control

valve/actuator assembly out of service. Provide

some temporary means of process control before

taking the control valve out of service.

1. Ensure terminal lug connections from the control

device to the transducer are of the correct polarity

(refer to the electrical connection procedures in the

Installation section of this manual).

2. At the transducer, ensure that the milliampere dc

signal is applied, and ensure that it is within the 4 to

20 milliampere range.

4. Force the converter module to maximum output

pressure with a 30 milliampere dc signal. Output

pressure should build up to the approximate value of

the supply pressure [maximum of 3.4 bar (50 psi)].

5. When the input current is removed, the

transducer output pressure should drop to less than

0.14 bar (2 psig). If it does not, check to ensure the

vent and exhaust air passageway is free from

foreign material.

6. To inspect the relay assembly, refer to the Relay

Maintenance procedures in this manual.

7. If the problem has not been resolved, see

Converter Module Replacement in this manual.

Converter Module Replacement

Removal

Refer to figure 13 for key number locations.

1. Remove the housing cap (key 2) (the cap farthest

away from the conduit). Note that the two set screws

(key 8) need to be loosened to remove the cap.

2. Unscrew the two captive screws (key 52) and

remove the converter module from the housing.

3. Inspect the O-ring (key 55) and replace if

necessary.

3. Check switches and ensure that they are properly

set. Refer to figure 10.

4. If the problem has not been resolved, see

Electronics Module Replacement in this manual.

Pneumatic

Provide a 4 to 30 milliampere dc current source,

supply pressure, and a gauge to monitor the output

pressure when checking transducer operation. Refer

to figure 13 for key number locations.

1. Ensure that supply pressure to the transducer

meets your requirements [0.3 bar (5 psi) higher than

upper range limit of output signal, with a maximum of

3.4 bar (50 psi)].

2. Ensure that the filter (key 11) and restrictor

(key 10) are open and clean. Remove the two

screws (key 14), the filter cap (key 13) and the

O-ring (key 12) to access the filter and restrictor.

3. If a filter/regulator is used, ensure that it is

working correctly. If not, ensure the dripwell is not

plugged because of excessive moisture

accumulation. If necessary, drain off any moisture,

and clean or replace the filter element.

Replacement

1. Lubricate the O-ring (key 55) with a lubricating

compound such as Dow Corning III before replacing

the converter module in the housing.

2. Insert the converter module into position in the

housing (key 1). Replace the two screws (key 52)

and tighten them.

3. Replace the housing cap (key 2), making sure to

re-tighten the two set screws (key 8).

4. Electrically calibrate the unit using the procedure

in the Calibration section of this manual.

Electronics Module Replacement

Removal

Refer to figure 13 for key number locations.

1. Remove the housing cap (key 2) (the cap closest

to the conduit). Note that the two set screws (key 8)

need to be loosened to remove the cap.

2. Note the location of the wires, then remove the

electrical wiring from the terminal block.

11

Page 12

i2P-100 Transducer

Instruction Manual

Form 5777

September 2004

VALVE PLUG

(KEY 39)

ONE OF THREE

TABS ON VALVE PLUG

END OF SPRING COIL

BODY PLUG

(KEY 32)

A6057-1/IL

Figure 12. Valve Plug, Inner Valve Spring and

Body Plug Assembly

INNER VALVE

SPRING

(KEY 35)

O-RING

(KEY 42)

3. Remove the three screws (key 26) and remove

the electronics module from the housing.

Replacement

1. Insert the electronics module into position in the

housing (key 1). Replace the three screws (key 26)

and tighten them.

2. Replace the electrical wiring removed in step 1 of

the removal procedures. Do not overtighten the

terminal screws. Maximum torque is 0.45 NSm (4

lbfSin).

3. Electrically calibrate the unit using the procedure

in the Calibration section of this manual.

4. Replace the housing cap (key 2), making sure to

re-tighten the set screw (key 8).

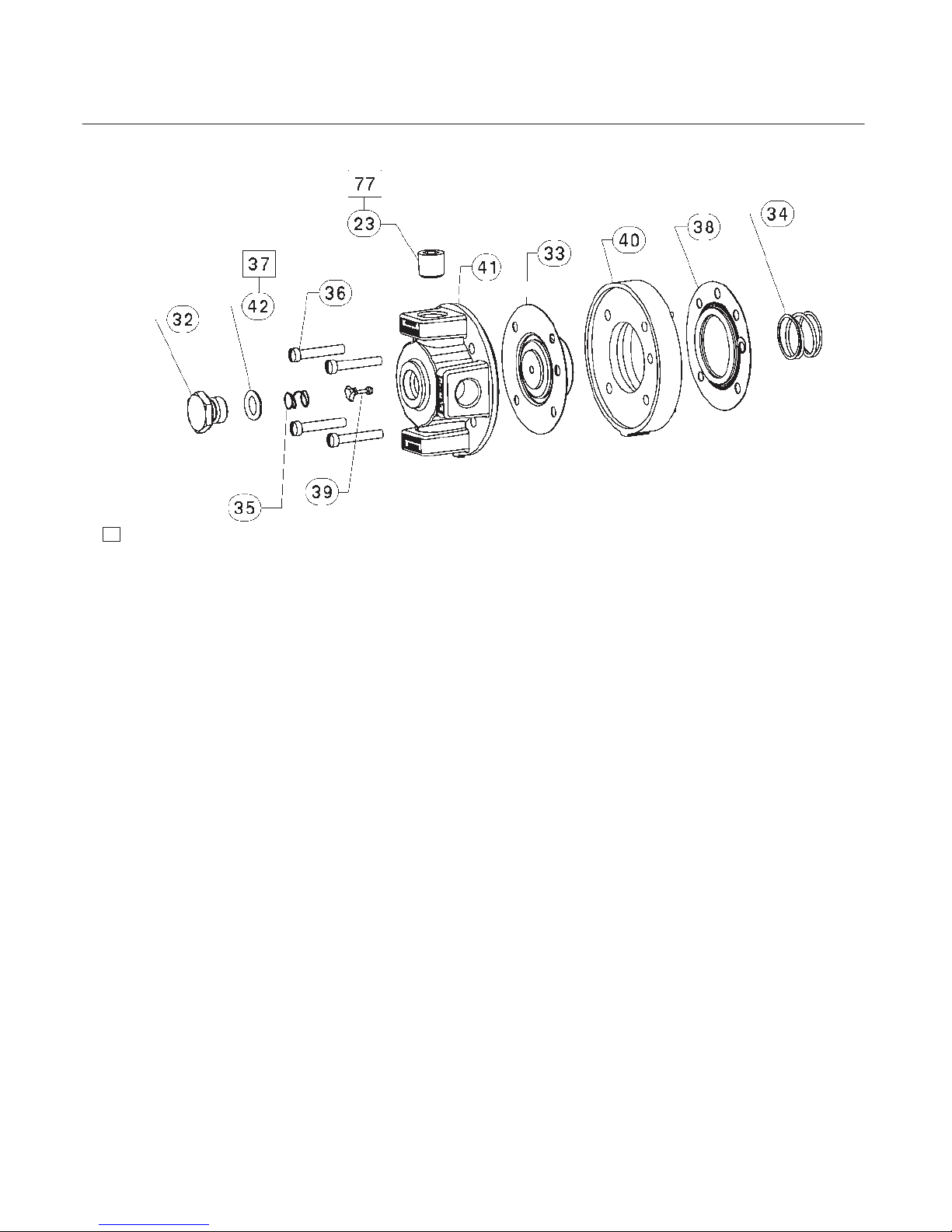

Relay Maintenance

Refer to figures 12 and 14 for key number locations.

Removal

1. Remove the four mounting screws (key 36,

shown in figure 14) and remove the relay from the

transducer. Be careful not to lose the bias spring

(key 34) and input diaphragm (key 38).

2. Remove the body plug (key 32) that holds the

inner valve spring (key 35) and valve plug (key 39) in

place from the relay body assembly.

3. Remove the exhaust port assembly (key 33) from

the relay assembly.

4. Inspect the springs, exhaust seat, valve plug, and

other parts for wear or damage; replace as

necessary. Note: the valve plug supply seat is an

insert in the relay body (key 41). If this insert is bad,

replace the relay body.

5. Make sure all parts of the relay are clean and that

all passages are clear of foreign matter.

Assembly

1. Assemble the inner valve spring (key 35) onto the

body plug (key 32) and fit the valve plug (key 39)

onto the inner valve spring as shown in figure 12. To

assure best alignment between the valve plug, inner

valve spring, and body plug; fit the valve plug onto

the inner valve spring so that one of the three tabs at

the base of the valve plug sets at the end of the last

coil of the inner valve spring.

2. Lubricate the O-ring (key 42) with Dow Corning III

(key 37). Insert the assembled valve plug, inner

valve spring, and body plug into the relay body (key

41). Compress the spring and thread the body plug

(key 5) into place. Then, tighten the body plug.

3. Insert two of the mounting screws (key 36) into

two opposite holes of the relay body (key 41). Hold

the screws in place while assembling the following

parts on the relay body. The screws serve as studs

to align the parts as they are being assembled.

4. When replacing the exhaust port assembly

(key 33), make sure all passages and screw holes

are aligned and that the hole in the center of the

exhaust port assembly fits over the valve plug

(key 39). Place the exhaust port assembly on the

relay body (key 41). Hold assembled parts in place.

5. Make sure the tabs on the body block (key 40)

align with the tabs on the relay body (key 41) and

that the side with 5 holes faces the relay body. Place

the body block on the assembled parts. Hold

assembled parts in place.

12

Page 13

Instruction Manual

Form 5777

September 2004

i2P-100 Transducer

6. When replacing the input diaphragm (key 38),

make sure all passages and screw holes are

aligned. Place the input diaphragm on the body

block (key 40). Hold assembled parts in place.

7. Install the bias spring (key 34) into the transducer

housing assembly (key 1). Make sure the tabs on

the body block and relay body align with the tab on

the transducer housing assembly. Place the

assembled parts onto the transducer housing

assembly. Thread the two mounting screws (key 36)

into the transducer housing assembly. Install the

remaining two mounting screws. Tighten all

mounting screws to 2 NSm (20 lbfSin).

8. Perform the procedure in the Calibration section

of this manual.

Parts Ordering

A serial number is assigned to each transducer and

stamped on the nameplate. Always refer to this

serial number when corresponding with your Fisher

sales office regarding spare parts or technical

information. When ordering replacement part, also

specify the complete 11-character part number from

the Parts list.

Note

Use only genuine Fisher replacement

parts. Components that are not

supplied by Fisher should not, under

any circumstances, be used in any

Fisher instrument. Use of components

not supplied by Fisher will void your

warranty, might adversely affect the

performance of the instrument, and

might jeopardize worker and

workplace safety.

Note

Fisher does not assume responsibility

for the selection, use and maintenance

of any product. Responsibility for the

selection, use and maintenance of any

Fisher product remains solely with the

purchaser and end-user.

Parts List (see figure 13)

Housing

Key Description Part Number

1 Housing, Aluminum

2 Cover (2 req’d) 48B6515X022

3 Configuration Label GE03345X012

4* O-Ring (2 req’d) 1K1810X0102

6 Feed Thru (2 req’d) GE03087X012

7 Wire Retainer (2 req’d) 16A2821X012

8 Set Screw (2 req’d) 1B4556X0012

9* O-Ring GC070193X13

10 Restrictor, Primary 10C2233X012

11* Filter 10C2246X012

12* O-Ring 14A1968X032

13 Filter Cap GB0122X0012

14 Machine Screw (2 req’d) 19B0821X012

15 Flame Arrestor GE06959X012

16 Flame Arrestor GE02963X012

17 Sealant, Silicone (not furnished with transducer)

18 Loctite 271 Sealant or equivalent (not furnished

with transducer)

19 Adhesive

55 O-Ring 1C8538X0162

69 Nameplate, CSA approvals, aluminum - - 70 Screw (2 req’d) 1P426928982

71 Vent Assembly GE06162X012

76 Pipe Plug 1H5137X0012

*Recommended spare parts

13

Page 14

i2P-100 Transducer

Instruction Manual

Form 5777

September 2004

NOTE:

APPLY LUBRICANT/SEALANT/ADHESIVE

30C2230-A / IL

Figure 13. Type i2P-100 Transducer Assembly

PWB/Cup Assembly

24* PWB/Cup Assembly GE10168X012

97 Machine Screw (2 req’d) GE11776X012

98 Machine Screw GE11777X012

Relay Assembly (see figure 14)

41 Relay / Body Assembly GE03512X012

42 O-Ring 1E5477X0062

36 Machine Screw, fill hd (4 req’d) 1H1581X0012

32 Body Plug 11B2363X012

33 Exhaust Port Assembly 11B2364X012

34 Spring 11B2369X012

35 Spring 11B6843X012

38 Upper Diaphragm 21B2362X012

39 Valve Plug 21B2370X012

40 Body Block 31B2356X012

I/P Converter Assembly

43* I/P Converter Assembly 30C2218X012

Gauge/Pipe Plug

23 Pipe plug, use when gauge is not specified (not shown)

Alloy steel pl 1C333528992

Stainless steel 1C3335X0032

23 Gauge, (not shown)

0- 30 psig/0 - 0.2 MPa/0- 2 bar 11B8579X022

0- 60 psig/0 - 0.4 MPa/0- 4 bar 11B8579X032

14

*Recommended spare parts

Page 15

Instruction Manual

Form 5777

September 2004

NOTE:

APPLY LUBRICANT/SEALANT/ADHESIVE

30C2258-B/ IL

i2P-100 Transducer

Figure 14. Type i2P-100 Relay Assembly

Key Description Part Number

Diagnostic Connections

FlowScanner diagnostic system hook-up

Includes pipe tee, pipe nipple, pipe

bushings, connector body, and body

protector. See figure 7 for part

identification. Also, part number provides

correct quantities of each item.

Note

If the Type i2P-100 Transducer is used in a

valve assembly with a positioner, no hook-up

for diagnostic testing is required for the Type

i2P-100. The hook-up for diagnostic testing

should be installed at the positioner.

Side Output

For units with gauges

SST fittings 12B8040X052

Brass fittings 12B8040X062

For units without gauges

SST fittings 12B8040X072

Brass fittings 12B8040X082

Key Description Part Number

Mounting Parts

Yoke Mounting

Type 470 size 23 through 64

80 Mounting Bracket, steel 3P426825022

81 Washer, steel pl (4 req’d) 1B865928982

82 Cap Screw, steel pl (4 req’d) 1A381624052

480 Series actuator boss

80 Mounting Bracket, steel 3P426825022

81 Washer, steel pl (4 req’d) 1B865928982

82 Cap Screw, steel pl (4 req’d) 1A381624052

83 Screw, steel pl (2 req’d) 1C5958X0022

85 Mounting Bracket, Steel 3L276725092

86 Hex Nut, steel pl (2 req’d) 1A352724122

Type 585C size 25 and 50

80 Mounting Bracket, steel 3P426825022

81 Washer, steel pl (4 req’d) 1B865928982

82 Cap Screw, steel pl (4 req’d) 1A381624052

83 Screw, steel pl (2 req’d) 1A352624052

15

Page 16

i2P-100 Transducer

Instruction Manual

Form 5777

September 2004

Key Description Part Number

Type 585C (470) size 60, 68, 100, and 130 ; Type 657

and 667 size 30, 34, 40, 45, 50, 60, 70, 80 & 87; Type

1051 and 1052 size 40, 60 and 70; Type 1061all sizes

80 Mounting Bracket, steel 3P426825022

81 Washer, steel pl (4 req’d) 1B865928982

82 Cap Screw, steel pl (4 req’d) 1A381624052

83 Screw, steel pl (2 req’d) 1C870224052

84 Spacer 1K766824092

Casing Mounting

Type 657 and 667 size 30, 34, 40, 45, 50 and 60

80 Mounting Bracket, steel 1F401225072

81 Washer, steel pl (2 req’d) 1B865928982

82 Cap Screw, steel pl (2 req’d) 1A381624052

83 Screw (req’d) 1A582824052

Type 657 and 667 size 70

80 Mounting Bracket, steel 1F401225072

81 Washer, steel pl (2 req’d) 1B865928982

82 Cap Screw, steel pl (2 req’d) 1A381624052

83 Screw (req’d) 1A368324052

Key Description Part Number

Type 1051 and 1052 size 20, 33, 40, 60 and 70

80 Mounting Bracket, steel 1F401225072

81 Washer, steel pl (2 req’d) 1B865928982

82 Cap Screw, steel pl (2 req’d) 1A381624052

83 Screw (req’d) 1A582824052

Type 1250 and 1250R all sizes

80 Mounting Bracket, steel 30B1265X022

81 Washer, steel pl (2 req’d) 1B865928982

82 Cap Screw, steel pl (2 req’d) 1A381624052

87 Washer 10B6610X012

91 U-Bolt (2 req’d) 19A7930X012

92 Hex Nut (req’d) 19A4838X012

Pipestand Mounting

80 Mounting Bracket, steel 3P426825022

81 Washer, steel pl (4 req’d) 1B865928982

82 Cap Screw, steel pl (2 req’d) 1A381624052

88 Pipe Clamp, steel pl 1P427028982

Surface Mounting

80 Mounting Bracket, Steel GE07077X012

82 Cap Screw 1B6098X0012

N97

FlowScanner and Fisher are marks owned by Fisher Controls International LLC, a member of the Emerson Process Management business division

of Emerson Electric Co. The Emerson logo is a trademark and service mark of Emerson Electric Co. All other marks are the property of their

respective owners.

The contents of this publication are presented for informational purposes only, and while every effort has been made to ensure their accuracy, they are

not to be construed as warranties or guarantees, express or implied, regarding the products or services described herein or their use or applicability.

We reserve the right to modify or improve the designs or specifications of such products at any time without notice.

Fisher does not assume responsibility for the selection, use or maintenance of any product. Responsibility for proper selection, use and

maintenance of any Fisher product remains solely with the purchaser and end-user.

Emerson Process Management

Fisher

Marshalltown, Iowa 50158 USA

Cernay 68700 France

Sao Paulo 05424 Brazil

Singapore 128461

www.Fisher.com

16

EFisher Controls International LLC 2004; All Rights Reserved Printed in USA

Loading...

Loading...