Emerson Hy-Line, Large-Part Vibration Welding Systems, M624HL, Mini II, VW4O-2 Technical Information

Page 1

Material Compatibility

Vibration Welding

Vibration Welding

Vibration Welding

Virtually all thermoplastic polymers can be welded to themselves

utilizing the vibration welding technique. Vibration welding also

offers the largest range of welding of dissimilar materials, as well

as the ability to weld different molding grades (injection molded,

extruded, etc.) to each other. Since it uses mechanical friction to

weld, the process puts as much energy as required at the interface

to melt the plastic. As long as the parts are able to be vibrated

relative to each other in the plane of the joint, the process may

be used.

This method of assembly, when compared with ultrasonic

assembly, is particularly advantageous for semi-crystalline resins

such as acetal, nylon, thermoplastic polyester, polyethylene, and

polypropylene, as well as PVC, cellulosics, thermoplastic rubber,

and elastomers, filled and reinforced resins, and those exhibiting

hygroscopic properties. Fillers such as glass, minerals, talc, and

mica do not present a problem for the process, as long as the

percentage is kept under 40%. Different grades of a material can be

welded to each other.

Vibration welding replaces ultrasonic welding in many troublesome

applications, since the ultrasonic process relies on transmitting

energy through the part to the joint interface. For example, the

ability to transmit weld energy is dependent upon the grade of

material, as well as part shape and size, the percentage of regrind,

the heat history of the plastic, as well as the color additives, melt

flow index and filler content. Vibration welding is not subject to the

same constraints, since energy is not transmitted through the part,

but rather it is generated directly at the interface.

Equipment Configurations

Branson vibration welders are available for part sizes up to 70” x

36” and larger. The smallest vibration welder has a footprint of

36” by 38”. The modular component design allows components

to be integrated into automated production lines. Multiple

control levels are available, and many units are capable of

remote monitoring and diagnostics.

Branson Ultrasonics Corporation

41 Eagle Road, Danbury, CT 06813-1961

(203) 796-0400 • Fax: (203) 796-9838

www.bransonultrasonics.com

e-mail: info@bransonultrasonics.com

475 Quaker Meeting House Rd.,

Honeoye Falls, NY 14472

(585) 624-8000 • Fax: (585) 624-1262

Vibration Welding © Branson Ultrasonics Corporation 1999

The Emerson logo is a trademark and service mark of Emerson

Electric Co. Revised and printed in the U.S.A. 4/11

WELDING l STAKING l INSERTION l SWAGING l FORMING l SPOT WELDING l DEGATING l CUTTING AND SEALING

Vibration Welding

Traditional Vibration Welding and “Clean”

Vibration Welding

Page 2

How It

Works

Vibration welding uses the frictional heat generated at the joint interface

of two parts to be welded to melt the plastic. Branson offers both linear

and orbital vibration welders. Linear welding moves one section in a recip-

rocating motion against the mating piece. In orbital welding, the upper

section is vibrated using constant velocity orbital motion – circular motion

in all directions.

Vibration Welding

Vibration welding is a velocity process; in

order to melt plastic, the parts must be made

to move relative to one another. Motion is

produced and controlled by alternating ener-

gy to opposed electromechanical coils for lin-

ear motion or the sequencing of energy

through three coils for orbital motion. The

high frequency vibrational motion required

for welding is applied through a spring mass

system. The vibrating mass (springs, lamina-

tions, and tool) is tuned to run at its resonant

Linear & Orbital Vibration Welding

Branson offers two types of vibration

welding: linear vibration and orbital vibra-

tion. Linear vibration welding—in produc-

tion for over 20 years—uses transverse, recip-

rocating motion; the vibration occurs in only

one axis. Two frequencies are available with

linear welding: 120 Hz and 240 Hz. The fre-

quency used is based on the application: high

frequency has more flexibility in part design,

especially parts with internal components; the

lower frequency is better with dissimilar

materials. The newest process, orbital vibra-

tion welding uses constant velocity motion, a

non-rotating circular motion in all directions

at 240 Hz. The vibration motion occurs

equally in both the x and y axes and all axes

in between.

Process Advantages

The vibration welding process eliminates

the need for solvents, adhesives, mechanical

+

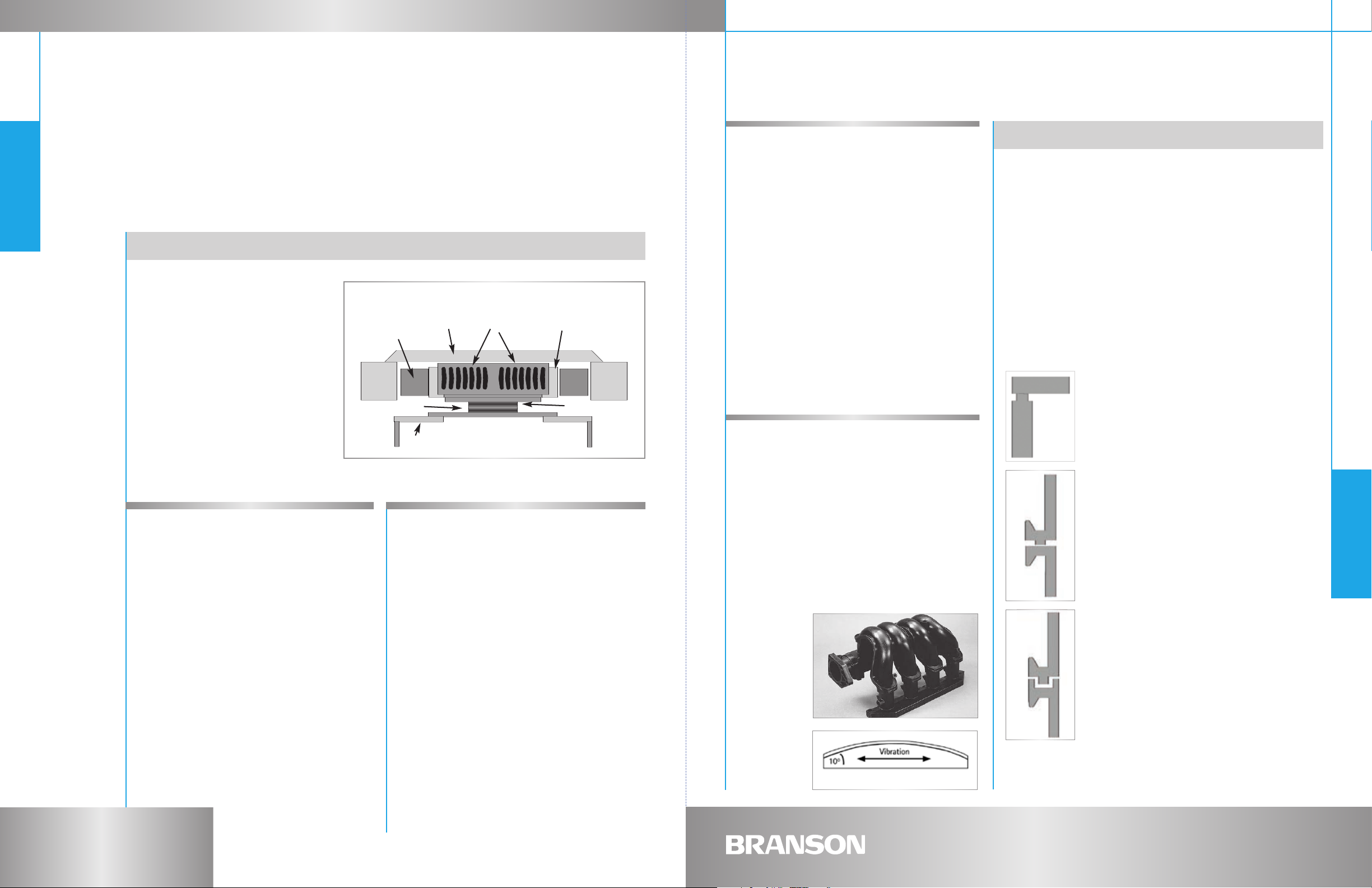

Lower Upper Tooling

SpringsElectromagnetic

Coil

I-Section

Frame

Lifting Table

Principle of Operation

Lower Tooling

Upper Tooling

Vibration Welding

Vibration welding uses the frictional heat generated at the joint interface of two parts to be welded to

melt the plastic. Branson offers both linear and orbital vibration welders. Linear welding moves one

section in a back-and-forth, single axis motion against the mating piece. In orbital welding, the upper

section is vibrated using constant velocity orbital motion – circular motion in all directions. Clean

Vibration Technology is an option for linear vibration welding that applies IR preheat to the plastic parts

and attains virtually particulate free “clean” joints.

Vibration Welding: How It Works

Vibration welding is a velocity process; in

order to melt plastic, the parts must be

made to move relative to one another.

Motion is produced and controlled by

alternating energy to opposed

electromechanical coils for linear motion or

the sequencing of energy through three

coils for orbital motion. The high frequency

vibrational motion required for welding is

applied through a spring mass system. The

vibrating mass (springs, laminations, and

tool) is tuned to run at its resonant

frequency. A digital power supply is used to set and maintain the resonant frequency using a controlled feedback loop.

Linear & Orbital Vibration

Welding

Branson offers two types of vibration welding: linear

vibration and orbital vibration. Linear vibration welding -

in production for over 25 years - uses transverse,

reciprocating motion; the vibration occurs in only one

axis. Two frequencies are available with linear welding:

100 Hz and 240 Hz. The frequency used is based on the

application: high frequency has more flexibility in part

design, especially parts with internal components; the

lower frequency is better with dissimilar materials.

Orbital vibration welding uses constant velocity motion,

a non-rotating circular motion in all directions at 240 Hz.

The vibration motion occurs equally in both the x and y

axes and all axes in between.

Vibration Welding Process

Advantages

The vibration welding process eliminates the need for

solvents, adhesives, mechanical fasteners, and other

consumables.

Additional advantages and benefits of the vibration welding

process include:

• Fast, clean, energy efficient

• Suitable for large parts (up to 70” x 36” and larger!) and

irregularly-shaped parts

• No need for elaborate ventilation systems to remove

fumes or heat

• High productivity with lower cost than many alternate

assembly methods

• Ease of interface with automated assembly line production

• Can weld multiple smaller parts at one time.

Clean Vibration Welding

with IR Preheat Option

One of Branson’s Clean Joining Technologies is Clean

Vibration (CVT). This is a vibration weld process with

non-contact heating and plasticization of the joint planes

by means of broad-band metal-foil emitters (see picture).

A subsequent vibration welding process of the molten layers

of plastic follows (no solid friction, no local melt zones,

uniform material flow).

The result is a “clean” vibration joint (compact weld bead,

no ‘angel hair’ by-product) with excellent mechanical

properties. (Contact Branson for information on this and

other Clean Joining Technologies such as Laser Welding

and IR Welding).

Part Configuration

It is a common misconception that vibration welding joints

must be in a flat plane. Many parts are welded with all types

of joint shapes. As long as there remains one axis of motion,

the parts are candidates for linear vibration welding. As an

example, refer to the automotive air intake manifold (shown

in Figure 4), where the vibration motion is left to right.

Small angles in the direction of vibration (shown in Figure 5)

can also be welded.

Figure 4

Figure 5

Designing for Vibration Welding

Three basic requirements must be met when designing parts for

assembly using vibration welding:

• There must be enough relative motion (0.080”/2.032 mm)between

the mating parts to ensure that the proper amplitude can be utilized.

• The parts must be capable of being held rigidly in their respective

fixtures. Walls must be designed to minimize or eliminate flexing.

• A uniform clamp force must be able to be applied to the joint.

The amount of relative motion and the design features required to

prevent wall flexure during the process vary depending upon the polymer

being welded and the type of weld required. Several typical joint and

part design details are listed below:

BUTT JOINT

The simplest joint design, the butt joint can be

used on short walls or walls that are parallel to the

vibration motion. No flash containment is included

in this design.

BUTT JOINT WITH GRIP TAB DETAIL

This design also uses a flange with a grip tab or

reverse flange detail to eliminate wall flexure and

part warpage. It allows the clamp force to be

applied directly over the weld area on parts that

have tall walls.

TONGUE AND GROOVE WITH GRIP TABS

This joint provides pre-welding part alignment and

also incorporates a design which will contain and

hide the weld flash. This joint design will produces

the “cleanest” finished appearance.

There are infinite variations to these three basic joint designs. Refer to

Branson’s joint design specification sheet for typical dimensions and

other joint and part design information.

Vibration Welding

Loading...

Loading...