Page 1

Hydrastep 2468CB and 2468CD

Hydrastep 2468

Operating Manual

24685034, Rev. AE

June 2011

www.emersonprocess.com

Electronic Gauging System

(Dual Power Supply Version)

Page 2

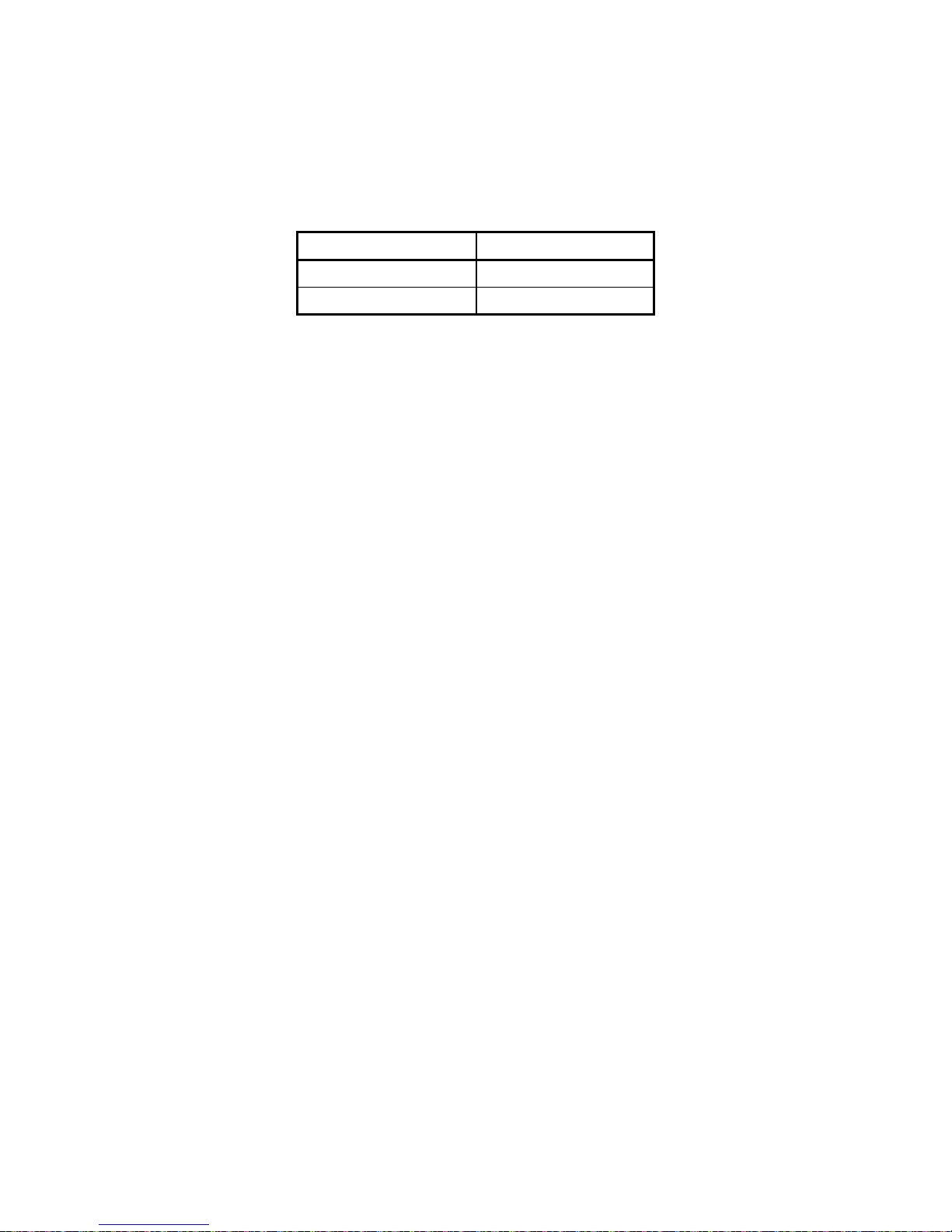

CATEGORY SYMPTOM POSSIBLE CAUSES (See Note 1) SOLUTION (See Note 2)

PSU (AC)

PSU (DC)

Hydrastep system does not power-up.

Hydrastep system does not power-up.

Wrong voltage setting.

Incorrect supply.

Blown fuse.

Incorrect cable termination. Incorrect supply.

Blown fuse.

Incorrect cable termination.

Refer to Part 1, Section 2.4.2.4.

Refer to Part 1, Section 2.4.2.4.

MAIN DISPLAY

Chequered / intermittent display.

No display.

Yellow LED illuminated.

Incorrect configuration. Refer to Part 1, Section 2.5.2.

Refer to Part 1, Section 2.5.2.1.

Refer to Part 1, Section 2.5.2.2.

REMOTE DISPLAY

Chequered / intermittent display.

No display.

Yellow LED illuminated.

Incorrect configuration.

Incorrect interface cable connection.

Check Main Display, as above.

See Part 1, Section 4.2 (Relevant display). Check cable connections. See Part 1, Section4.4.

ELECTRODE ALARM

ERROR

Flashing Red (steam) and Green (water)

LED’s with Yellow alarm LED illuminated.

Electrode contamination Incorrect column installation reducing

condensate flow.

Water conductivity is too high.

Refer to Part 2, Section 3.

Refer to Part 2, Section 2.3.

Refer to Part 1, Section 2.5.1.3.

Refer to Part 1, Section 2.5.1.4.

WATER/STEAM

SWITCHING

THRESHOLD

Water above steam (green above red) with

yellow LED illuminated

Threshold not matched to application.

Electrode contamination.

Refer to Part 1, Section 2.5.2.3. Refer to Part 2, Section 3.

Note 1: Further detailed information can be found in Fault finding Part 1, Sections 2.6 and 4.5.

Note 2: References are to Operating Manuals 24685033 (for 2468CA and 2468CC models) and 24685034 (for 2468CB and 2468CD models).

Page 3

HYDRASTEP START-UP

It is possible that some of these conditions will be seen on a new Hydrastep installation.

** This does not mean that the equipment you have purchased is faulty **

Due to the nature of the areas that Hydrastep is normally installed, various conditions can occur that make the instrument operate in an unusual manner.

It would be easy to think you have installed defective equipment, but it is very unlikely that this is the case.

Great care must be taken when installing a Hydrastep system so that these problems are less likely to be seen; firstly, please take the time to ensure that the various people involved

in the fitting of the components have been shown and have read the handbook, which is supplie d with all new Hydrastep systems.

This, along with the wiring diagrams (also supplied), should make for a trouble free installation.

1. Please read and understand Part 2 of the handbook, which explains the pressure side of the equipment.

2. Ensure wiring is of the correct type and that the wiring diagram supplied has been followed.

3. Hydrastep relies on a ‘path back to earth’. Please make sure that all earth points are made and are of a good standard.

4. Great care must be taken with the mounting of the water column; the columns must be vertical; angles stated in the manual should be as close as possible, as this ensures

condensate flow back into the column.

5. Lagging of the pipe work must be as stated; ** The last 0.5 m of the (top) steam leg MUST NOT be insulated as this will inhibit condensate flow into the column; this will cause a

flickering display.**

6. Please be aware of your water quality as some adjustments to the Hydrastep may be required if it has a high conductivity. Please let us know when placing your order if your

water conductivity is high. We can modify the units up to 1600Us/cm.

7. Units will not leave the factory configured for customer orders unless requested. If you wish it to be configured, please request it on your order and it will then be done. Options

include mains voltage to be used, trip points (if relay cards are to be fitted), number of electrodes to be used and remote display option (if ordered). These points are not pre-set

as standard as the factory do not know your requirement unless stated on your order.

8. Care should be taken to make sure that a new set of electrodes have been fitted after the first acid wash of the system. The electrodes may well have been damaged during this

process and a new set should go in before you run the system up for the first time.

9. The most common problem seen with Hydrastep systems is a flickering pattern on the display while the boiler is being brought up to operating pressure and temperature. This is

not a fault and is caused by a few conditions specific to power stations:

(a) If a boiler is new or has seen a large amount re-work, it may well get a coating of magnetite inside of it, when it is first started up. This creates a small DC voltage that is

picked up on the electrodes and shows its self as a flickering in the bottom few electrodes. When the system is brought up to its normal working condition’s this will settle but

can take a couple of days to do so.

(b) It is possible that the top electrodes may have a wet coating on them until these working conditions are met; again, if left to settle, this will work at normal working conditions.

(c) Should the plant generate a higher than normal amount of DC noise, we can supply a blocking cap that is built into a PCB that will stop this problem.

If you are in any doubt about what you are doing, contact Customer Support of Rosemount Measurement Limited on +44 (0) 1753 756600 for guidance.

Rosemount Measurement

Customer Support

(April 2005)

Page 4

About this manual

This manual describes the Hydrastep 2468CB and 2468CD Electronic Gauging Systems along with the

recommended options. Except where stated otherwise, the information contained in this manual can be assumed

to apply to either system.

This manual is divided into three parts; the first covers the electrical/electronic system; the second describes the

pressure parts; the third is for coverage of all other aspects.

Part 1 – Electrical/Electronic System

Chapter 1 introduces the Hydrastep 2468 Electronic Gauging System and its operating principles.

Chapter 2 covers the installation, configuration and fault analysis procedures.

Chapter 3 covers the installation, configuration and fault analysis procedures for the Relay Output Board (Chapter 3a),

the Delay Relay Output Board (Chapter 3b) and the Opto-isolated Output Board (Chapter 3c).

Chapter 4 covers the installation, configuration and fault analysis procedures for all versio ns of the Remote

Display Unit.

Part 2 – Pressure Parts

Chapter 1 is a general introduction to the Hydrastep system of water level determination.

Chapter 2 describes the water column and its components – the preparation, installation of the water column on to

the boiler, acid and steam purging of the boiler system and the fitting of the electrode sensors.

Chapter 3 details the fault repair procedures carried out on the system pressure parts and their commissioning.

Chapter 4 provides a general description of the pressure parts used in the Hydrastep systems.

Chapter 5 details the Pressure Parts specifications.

Caution:

For installation under the Pressure Equipment Directive (PED) 97/23/EC, refer to safety instruction

manual 24688006/SI.

Caution:

For installation under ATEX directive 94/09/EC, refer to safety instruction manual 24685033/SI.

Part 3 – Appendix

Appendix A contains a CSA certified connection drawing and associated notes.

Caution:

For installation in potentially explosive atmospheres in Canada and USA, refer to control drawing

24685037 in Part 3.

Page 5

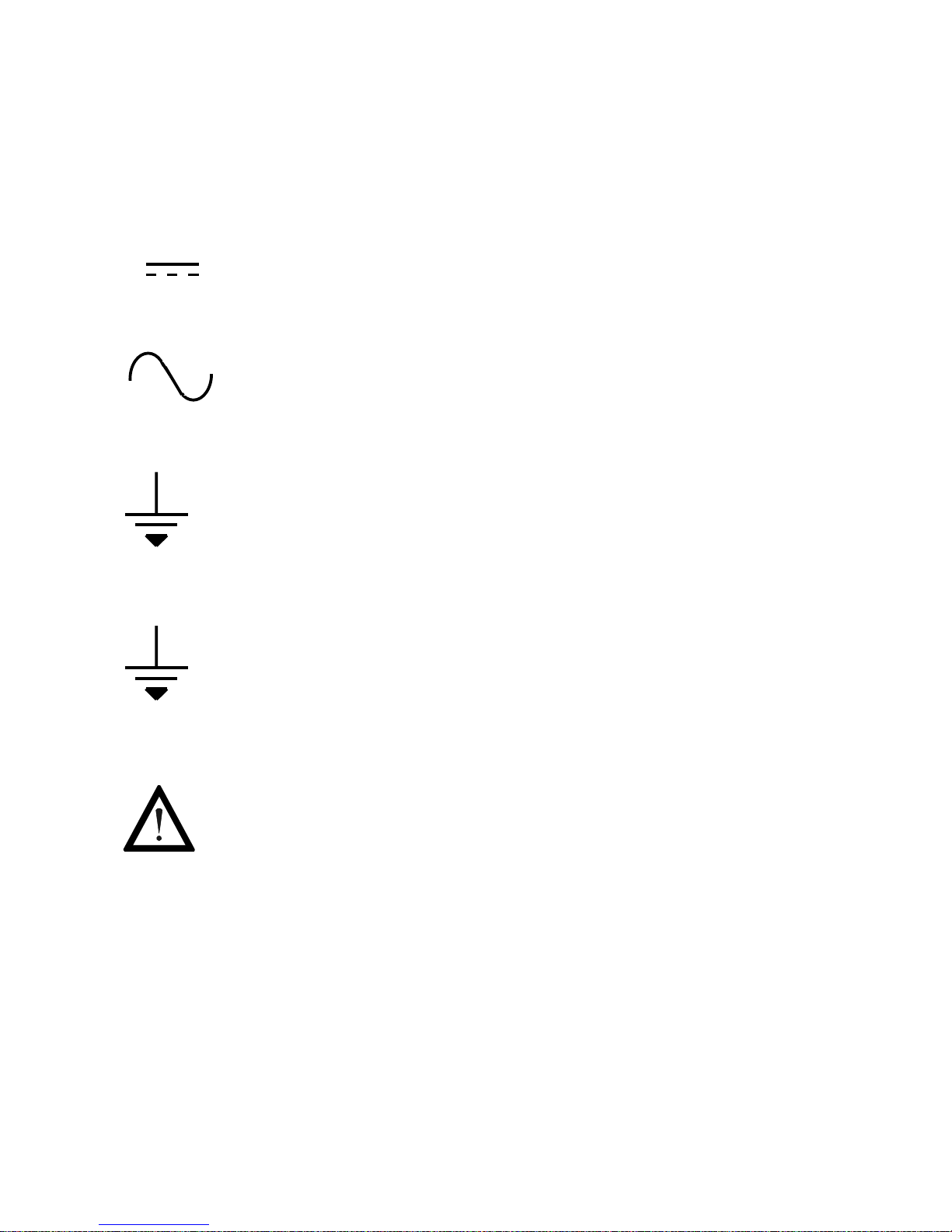

SYMBOLS USED IN THIS MANUAL AND ON THE UNIT

Symbol Meaning

Direct Current

Alternating Current

Earth (ground) terminal

Protective conductor terminal

Caution (refer to accompanying documents)

Page 6

Page 7

24685034 Pt.1-1

Part 1

Hydrastep 2468CB & 2468CD

Electronic Gauging System

Page 8

Pt.1-2 24685034

Page 9

24685034 Pt.1-3

DANGEROUS VOLTAGES ARE PRESENT IN

THIS EQUIPMENT. ANY WARNING NOTICES

OR PROCEDURES CONTAINED IN THIS

MANUAL OR ON THE EQUIPMENT SHOULD BE

STRICTLY OBSERVED TO MAINTAIN SAFETY.

THE USE OF THIS EQUIPMENT IN A MANNER

NOT SPECIFIED IN THIS MANUAL MAY IMPAIR

THE PROTECTION PROVIDED BY THIS

EQUIPMENT. GREAT CARE SHOULD BE

EXERCISED WHEN SERVICING THIS

EQUIPMENT.

TO ENSURE COMPLIANCE WITH THE EMC

DIRECTIVE (WHERE APPLICABLE) THE

INSTRUCTIONS ON CABLE SCREENING,

ROUTING AND TERMINATION GIVEN IN THIS

MANUAL MUST BE FOLLOWED.

Page 10

Pt.1-4 24685034

Page 11

24685034 Pt.1-5

Part 1

Contents

Chapter 1 Introduction to the Hydrastep 2468 Electronic

Gauging System

Chapter 2 2468CB & 2468CD Dual Power Supply Version

Chapter 3a 2468 - Relay Output Board Option

Chapter 3b Delay Relay Output Board Option

Chapter 3c 2468 Opto-isolated Output Board Option

Chapter 4 Remote Display Options 24683B C & D

Page 12

Pt.1-6 24685034

Page 13

Hydrastep 2468CB and 2468CD Manual Introduction to the Hydrastep 2468 Electronic Gauging System

24685034

1-1

1

Introduction to the Hydrastep 2468

Electronic Gauging System

Contents

Page No.

1.1 WATER LEVEL MEASUREMENT .......................................................... 3

1.2 HYDRASTEP 2468 ELECTRONIC GAUGING SYSTEM ....................... 5

1.2.1 INPUT BOARDS .................................................................................. 5

1.2.2 DISPLAY BOARDS .............................................................................. 5

1.2.3 SYSTEM FAULTS (2468CB OR 2468CD) ........................................... 6

1.3 SYSTEM OPTIONS ................................................................................. 6

1.3.1 OUTPUT BOARDS .............................................................................. 6

1.3.2 REMOTE DISPLAY UNITS .................................................................. 6

1.3.3 OPTION DETAILS ................................................................................ 6

1.4 HYDRASTEP 2468 UPGRADE PATHS AND AVAILABLE OPTIONS .. 7

Illustrations

Figure 1.1 - Front panel of the Hydrastep 2468 gauging system, with local display .......... 2

Figure 1.2 - Schematic of resistance measuring cell and electrodes ................................. 3

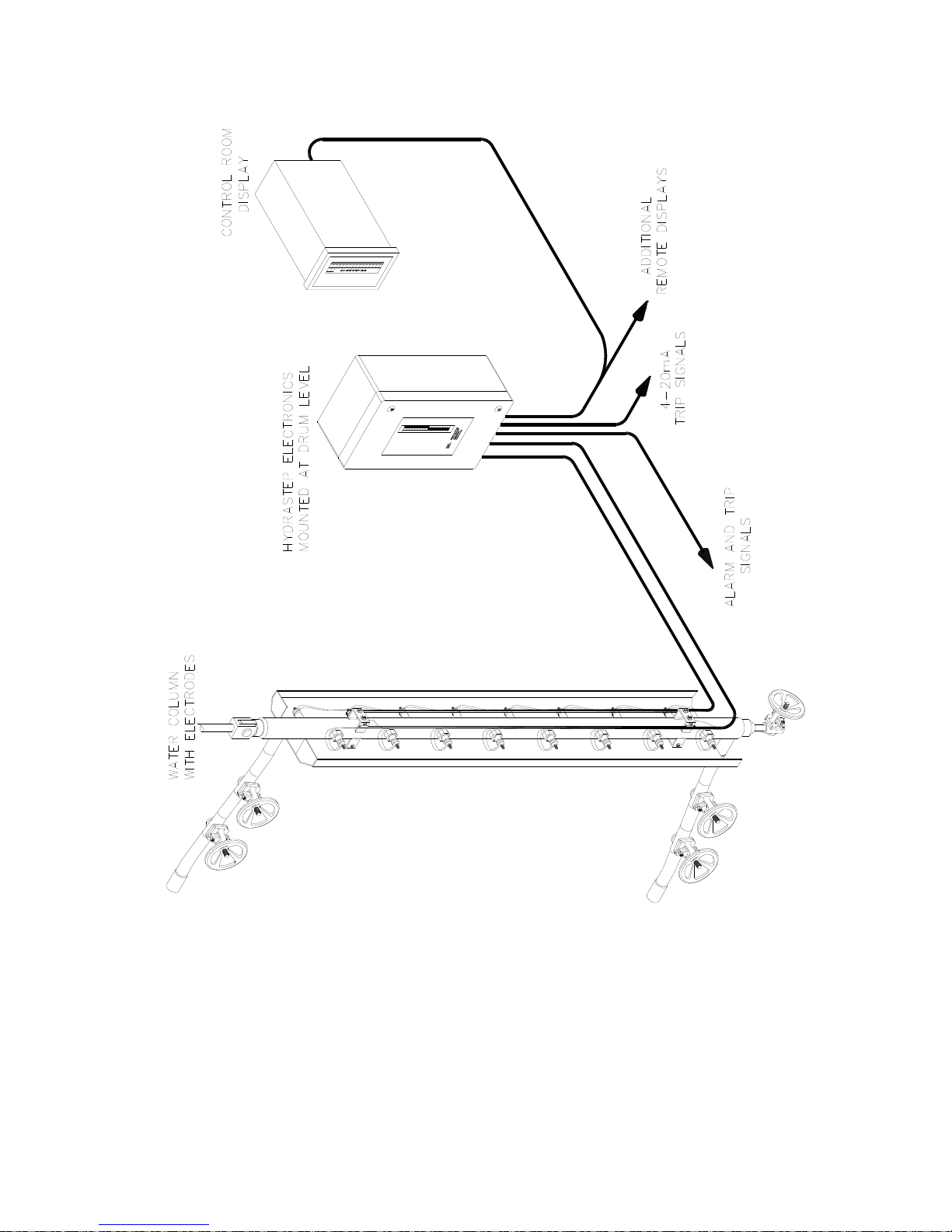

Figure 1.3 - Typical Hydrastep 2468 System Installation.................................................... 4

Tables

Table 1.1 - Upgrade paths and available options ............................................................... 7

Page 14

Introduction to the Hydrastep 2468 Electronic Gauging System Hydrastep 2468CB and 2468CD Manual

1-2 24685034

0040

Figure 1.1 - Front panel of the Hydrastep 2468 gauging system

Page 15

Hydrastep 2468CB and 2468CD Manual Introduction to the Hydrastep 2468 Electronic Gauging System

24685034

1-3

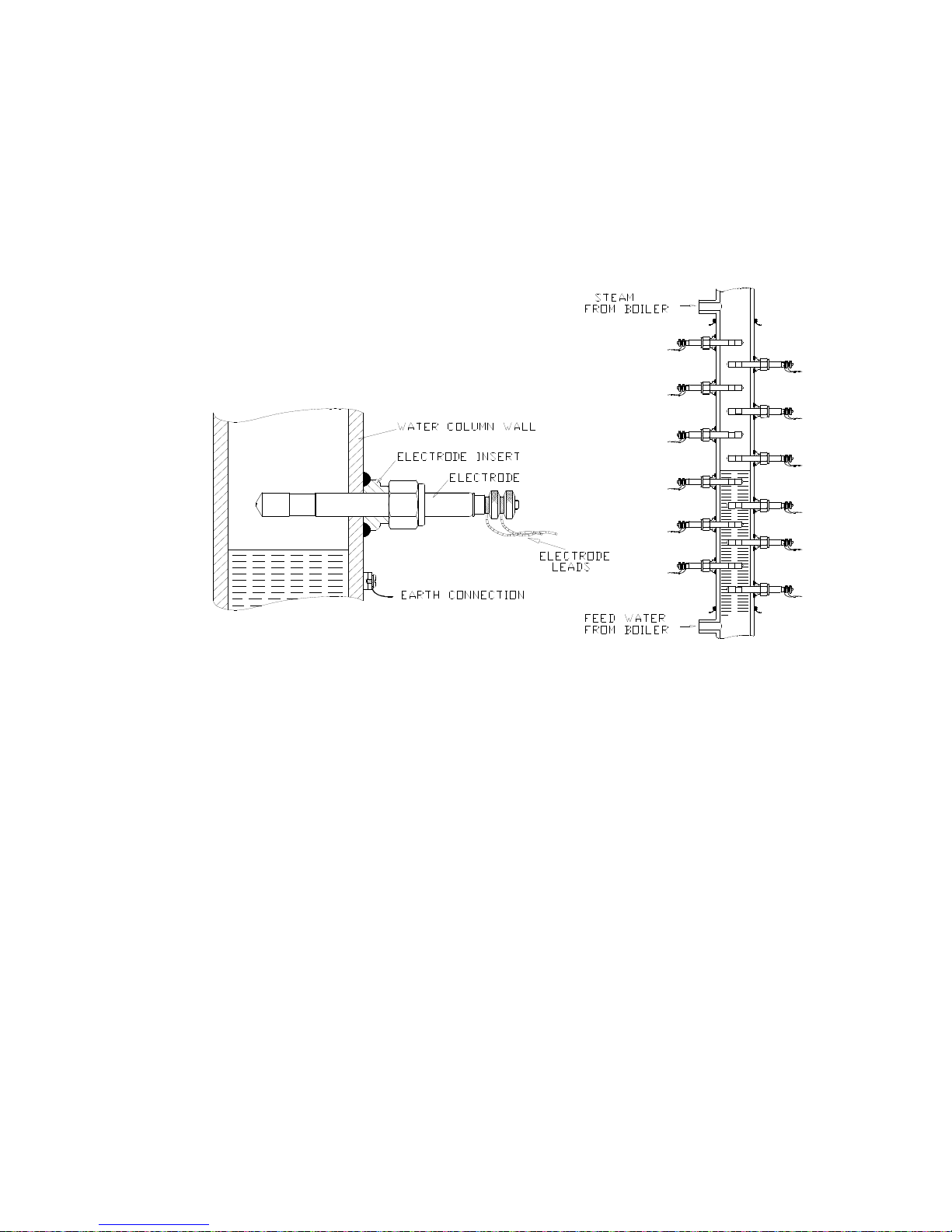

1.1 WATER LEVEL MEASUREMENT

The Hydrastep 2468 Electronic Gauging System is designed as an electronic alternative to

water level gauges on boilers, giving a more reliable and safer water level indication than

conventional visual gauges. It uses the significant difference in resistivities of water and

steam in temperatures up to 370C (698F) to determine the water level.

Figure 1.2 - Schematic of resistance measuring cell and electrodes

A vertical row of electrodes is installed in the water level column attached to boiler and

typically aligned so that half the electrodes are above and half below the normal water level

(see Figure 1.2). The resistance measurement is made between the insulated tip of each

electrode and the wall of the column.

The “cell constant” defining the actual resistance measured is determined by the length and

diameter of the electrode tip and the column bore. In practice, the cell constant is chosen so

that the resistance in water is less than 100k ohms and the steam resistance is greater than

10M ohms. Since the resistivities of water and steam are substantially different, the system

is simple and requires no setting up adjustments. It is not susceptible to power supply

variations, ambient temperature changes, etc., resulting in a highly reliable system.

A general overview showing how a typical Hydrastep 2468 System is installed is illustrated

in Figure 1.3.

Page 16

Introduction to the Hydrastep 2468 Electronic Gauging System Hydrastep 2468CB and 2468CD Manual

1-4 24685034

Figure 1.3 - Typical Hydrastep 2468 System Installation

Page 17

Hydrastep 2468CB and 2468CD Manual Introduction to the Hydrastep 2468 Electronic Gauging System

24685034

1-5

1.2 HYDRASTEP 2468 ELECTRONIC GAUGING SYSTEM

The Hydrastep 2468 is a sophisticated and flexible electronic gauging system. It is supplied

in two main versions:

A Single Power Supply System with Local Level Display

A Dual Power Supply System with Local Level Display

For both systems, the printed circuit boards are housed in the same enclosure, allowing

customers full capability to expand their system as and when conditions dictate.

Table 1.1 on page 1.7 is a summary of all upgrade paths and options for the Hydrastep 2468

system.

1.2.1 INPUT BOARDS

All versions of the Hydrastep 2468 unit contain one or two input boards. The input boards

mount on to the base plate in the enclosure. Each input board provides power supplies,

electrode drive, signal processing, fault analysis and an analogue output.

The input board can accept inputs from 8, 10, 12, 14 or 16 electrodes. When two input

boards are used (in a ‘dual power supply’ system) the electrodes are ‘interlaced’; that is, the

odd numbered electrodes are connected to one input board and the even numbered

electrodes are connected to the other. Full details of the wiring are covered in Chapter 2

under Installation.

Each input board also includes a current output circuit that provides an analogue

representation of the water level in the column. The analogue output can be configured to

give a current output in one of the following ranges:

0 to 20mA

4 to 20mA

20 to 0mA

20 to 4mA

1.2.2 DISPLAY BOARD

The display board is mounted on to the hinged lid of the unit and provides indication through

the viewing window on the enclosure. It also supplies configuration information to the input

board(s); that is, the number of electrodes connected to the unit and the required

water/steam switching threshold.

Figure 1.1 shows the local display with water level and system fault indication. Water level

is indicated by two columns of LEDs, one red to indicate steam and one green to indicate

water. The number of LEDs illuminated is dependent on the number of electrodes present

and a blanking panel is available to mask the LEDs not used. In addition to the system fault

indication is an opto-isolated system fault output. Switches are provided to allow the

number of electrodes to be selected (8, 10, 12, 14, 16, 18, 20, 22, 24, 26, 28, 30 or 32). Two

solder link pads are provided to select the water/steam switching threshold (0.6S/cm or

1.6S/cm).

Page 18

Introduction to the Hydrastep 2468 Electronic Gauging System Hydrastep 2468CB and 2468CD Manual

1-6 24685034

1.2.3 SYSTEM FAULTS (2468CB OR 2468CD)

System fault indication, a yellow LED and an opto-isolated output, is provided for a ‘water

above steam’ condition, an electrode fault or wiring failure and the detection of an internal

fault. A further fault is indicated when the electrode number switch is incorrectly set. This

fault is indicated by a chequered display of red and green LEDs on the level display.

Faults and their remedies are covered in Chapter 2 under ‘Fault Analysis & Corrective

Action’.

1.3 SYSTEM OPTIONS

1.3.1 OUTPUT BOARDS

Each input board can accept one or two output boards that can be used for water level

signalling, alarm or trip functions. Each output board provides four relay outputs or four optoisolated outputs. The first output board is fitted directly on top of the input board using three

nylon pillars. A second output board (when required) can be fitted on top of the first output

board using the same type of fixture. The various output boards are described in Chapter 3.

1.3.2 REMOTE DISPLAY UNITS

Provision is made to drive Remote Display Units. The display board is capable of driving up

to 6 remote display units. Only one of these can be powered by the Hydrastep unit, any

additional remote displays must be locally powered.

A remote display unit ‘mimics’ the display on the Hydrastep 2468 and is as described in

Chapter 4.

1.3.3 OPTION DETAILS

1. Relay Board 24680504 has 4 fully configurable relay outputs Chapter 3a

2. Relay with Time Delay board 24680509 has 4 fully configurable relay outputs Chapter 3b

3. Opto-isolator board 24680505 has 4 fully configurable opto-isolated outputs Chapter 3c

4. Remote Display 24683B. Panel mounted DIN size 8 to 32 electrode displ ay Chapter 4

5. Remote Display 24683C Panel mounted large LED 8 to 32 electrode display Chapter 4

6. Remote Display 24683D Wall mounted splash proof version of 24683C Chapter 4

Page 19

Hydrastep 2468CB and 2468CD Manual Introduction to the Hydrastep 2468 Electronic Gauging System

24685034

1-7

1.4 HYDRASTEP 2468 UPGRADE PATHS AND AVAILABLE

OPTIONS

Table 1.1 describes the available versions of the Hydrastep 2468 Electronic Gauging System

and their possible options.

Existing System

Available Options

Comments

Description Part No.

2468 CA or

2468 CC

16 point EGS with

local display

Single power

supply.

Relay output board

Time delay relay

output board

Opto-isolated

output board

Remote display

unit

Input board

upgrade (ac)

Input board

upgrade (dc)

24680504C

24680509B

24680505A

24683B, C, or D

24680501C

24680516B

}

}

} Up to two boards (of any one

} type) can be fitted.

}

}

Up to 6 can be used

Provides an additional power

supply (ac mains source) and

16 point input circuit. Upgrades

2468CA to 2468CB.

Provides an additional power

supply (24V dc source) and 16

point input circuit. Upgrades

2468CC to 2468CD.

2468 CB or

2468 CD

32 point EGS with

local display

Dual power supply.

Relay output board

Time delay relay

output board

Opto-isolated

output board

Remote display

unit

24680504C

24680509B

24680505A

24683B, C, or D

}

}

} Up to four boards (of any one

} type) can be fitted.

}

}

Up to 6 can be used

Note: If required, a 24680501C board can be fitted to a 2468CC (or a 24680516B board

can be fitted to a 2468CA) to upgrade to a 2468CE. The 2468CE is a 32 point

Electronic Gauging System (EGS) with one ac mains source power supply and one

24Vdc source power supply.

Table 1.1 - Upgrade paths and available options

Page 20

Introduction to the Hydrastep 2468 Electronic Gauging System Hydrastep 2468CB and 2468CD Manual

1-8 24685034

Page 21

Hydrastep 2468CB and 2468CD Manual 2468CB & 2468CD Dual Power Supply Version

24685034

2-1

2

2468CB & 2468CD

Dual Power Supply Version

Contents

Page No.

2.1 INTRODUCTION ....................................................................................... 2-3

2.2 ELECTRODE CABLING SYSTEM ........................................................... 2-3

2.3 ELECTRONIC ENCLOSURE .................................................................... 2-3

2.3.1 INPUT BOARD (PCB 24680501 AND PCB 24680516) ......................... 2-5

2.3.1.1 Analogue Output Drive Capability ........................................... 2-5

2.3.2 REMOTE DISPLAY DRIVE CAPABILITY .............................................. 2-5

2.3.3 DISPLAY BOARD (PCB 24680515)....................................................... 2-6

2.3.3.1 Link LK1 .................................................................................. 2-6

2.3.3.2 Links LK2, LK3, LK4 and LK5 ................................................. 2-7

2.3.4 PCB INTERCONNECTIONS .................................................................. 2-7

2.4 INSTALLATION ........................................................................................ 2-8

2.4.1 MECHANICAL INSTALLATION ............................................................. 2-8

2.4.2 ELECTRICAL INSTALLATION ............................................................. 2-10

2.4.2.1 Electrode Connections .......................................................... 2-10

2.4.2.2 Connecting Cables to Water Column Electrodes ................. 2-11

2.4.2.3 Connecting the Electrode Cable Assemblies to 2468

Enclosure………………………………………………………....2-12

2.4.2.4 Hydrastep Power Supply Cables .......................................... 2-13

2.4.2.5 Analogue Output Connection ................................................ 2-15

2.4.2.6 Opto-Isolated Fault Output Connection ................................ 2-16

2.5 SYSTEM CONFIGURATION .................................................................. 2-17

2.5.1 INPUT BOARD (PCB 24680501 OR 24680516) ................................. 2-17

2.5.1.1 Analogue Output Configuration ............................................. 2-17

2.5.1.2 Pulsed Output Setting ........................................................... 2-18

2.5.1.3 Electrode Error Configuration ............................................... 2-18

2.5.1.4 Configuring the Unit to Detect Electrode Error ..................... 2-19

Page 22

2468CB & 2468CD Dual Power Supply Version Hydrastep 2468CB and 2468CD Manual

2-2 24685034

2.5.2 DISPLAY BOARD 24680515 ............................................................... 2-20

2.5.2.1 Link LK1 Setting .................................................................... 2-20

2.5.2.2 Configuring the ‘Number of Electrodes’ Switch .................... 2-20

2.5.2.3 ‘Switching Threshold’ Setting ................................................ 2-22

2.5.2.4 ‘Compatibility’ Setting ............................................................ 2-22

2.6 FAULT ANALYSIS & CORRECTIVE ACTION ....................................... 2-23

2.6.1 COMPONENT REPLACEMENT .......................................................... 2-30

2.6.1.1 Removing the Input Board (24680501 or 24680516) ........... 2-30

2.6.1.2 Refitting the Input Board ....................................................... 2-30

2.6.1.3 Removing the Display Board 24680515 ............................... 2-30

2.6.1.4 Refitting the Display Board ................................................... 2-30

2.6.2 PARTS LIST - HYDRASTEP 2468 CB & CD VERSIONS ................... 2-31

2.7 SPECIFICATION ..................................................................................... 2-32

Illustrations

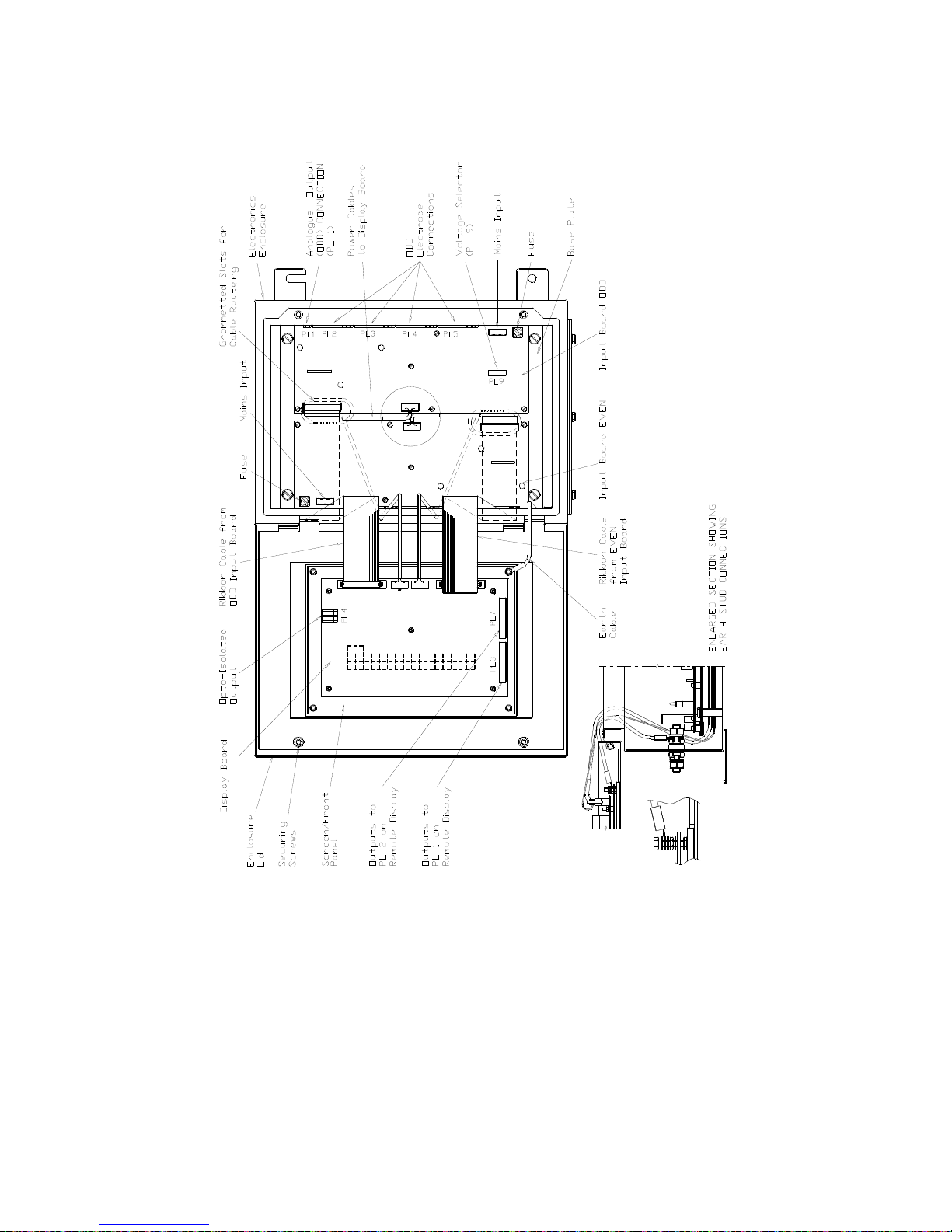

Figure 2.1: Outline drawing showing PCB layout and interconnections ............................... 2-4

Figure 2.2: Installation diagram for Hydrastep 2468 Electronic Gauging System unit ......... 2-9

Figure 2.3: Enclosure cable layout for 16 electrode system ............................................... 2-12

Figure 2.4: Voltage Selection (240V or 110V) .................................................................... 2-14

Figure 2.5- Location of display board links LK1 to LK5 & switch SW1 with configuration…..….

details………………………………………………………………………………….2-21

Figure 2.6- Split pads SP1, SP2, SP5 & SP6 locations and settings ................................. 2-22

Tables

Table 2.1 - Analogue output configurations ...................................................................... 2-17

Table 2.2 - Number of electrodes being displayed ........................................................... 2-20

Table 2.3 - Fault analysis/corrective action chart ............................................................. 2-23

Page 23

Hydrastep 2468CB and 2468CD Manual 2468CB & 2468CD Dual Power Supply Version

24685034 2-3

2.1 INTRODUCTION

This chapter introduces the dual power supply version of the Hydrastep 2468 Electroni c

Gauging System, its mechanical installation, system configuration, simple fault

analysis/corrective action capability and its specification.

2.2 ELECTRODE CABLING SYSTEM

This system can have 8, 10, 12, 14, 16, 18, 20, 22, 24, 26, 28, 30 or 32 electrodes and uses

18-core electrode cables. The cables consist of nine pairs of coloured cores with the black

cores in each cable used for the EARTH terminations. Each electrode requires one pair of

cores, one core for the signal drive and one for the signal return.

Number of

Electrodes

Number of Cables

Required

8

10-16

18-24

26-32

1

2

3 or 4

4

The electrode cable is pre-formed for simple installation. The connections to the electrodes

are terminated on the connection stud of the electrode. Either core can be connected to the

electronic enclosure as the signal drive or return.

2.3 ELECTRONIC ENCLOSURE

The basic arrangement of boards in the electronic enclosure is as follows:

Two input boards su pply power to the system and to the input signal processing

circuits. These boards are: PCB 24680501, ac (mains) input, or PCB 24680516, dc

input. One board is mounted on the right hand side of the base plate and receives the

odd numbered electrode inputs. The other board is mounted on the left hand side of

the base plate and receives the even numbered electrode inputs.

A display board (PCB 24680515) contains the LED drive circuits for the two columns

(32 red LEDs and 32 green LEDs) and the system fault LEDs. This board is mounted

on the rear of the front panel, with the LEDs protruding through the front panel.

Up to four output boards, Relay Board (PCB 2468 0504), Relay with time delay Board

(24680509) or Opto-isolator Board (PCB 24680505) may be fitted, two per input

board. Output board mounting pillars are fitted to each input board during

manufacture to support the first output board mounted.

Refer to Figure 2.1 on page 2-4 for an annotated view of the internal layout of the unit.

Page 24

2468CB & 2468CD Dual Power Supply Version Hydrastep 2468CB and 2468CD Manual

2-4 24685034

Figure 2.1: Outline drawing showing PCB layout and interconnections

Page 25

Hydrastep 2468CB and 2468CD Manual 2468CB & 2468CD Dual Power Supply Version

24685034 2-5

2.3.1 INPUT BOARD (PCB 24680501 AND PCB 24680516)

The input board processes the electrode inputs to provide water level data for display

purposes and a current output representing the water level. Fault detection is also carried

out where the condition of the electrode inputs are examined and a FAULT is indicated

when:

1. An open circuit in either of the electrode conductor cores is present.

2. A short circuit to EARTH on either the electrode or conductor cores.

3. A water above steam condition exists.

4. An internal circuit fault condition exists.

A current output circuit is also provided on each input board. This gives an analogue

representation of the water level. The sense (forward or reverse) and type (0-20mA or

4-20mA) is selectable and described in Section 2.5 of this chapter. Fault indication on the

analogue output is an oscillating waveform (of approximately 0.5 Hz) superimposed o n the

main analogue signal.

The electrode inputs to each input board are passed to the other input board so that each

analogue circuit can output the full range content of electrode input signals. However,

should either of the input boards fail, the remaining board recognises that data is missing

and doubles its own electrode input signal to remedy the data loss giving a maximum error of

± 1 electrode.

Provision is made on each input board to accept one or two output boards, either relay

outputs or opto-isolated outputs. Both types of output board are offered as options.

Each input board produces the power supplies for the whole instrument which are derived

either from the local mains voltage supply of 110V ac or 240V ac nominal for the 24680501

input board or 20V dc to 40V dc for the 24680516 input board.

Apart from the input voltage there are two other differences between the AC (24680501) and

DC (24680516) input boards. These are the analogue output drive capability and the

remote display drive capability.

2.3.1.1 Analogue Output Drive Capability

With the minimum DC supply voltage of 20V for the DC input board (24680516) the

maximum load that can be driven by the analogue output is 500.

At the minimum mains input voltage the AC input board (24680501) the maximum load that

can be driven by the analogue output is 600.

2.3.2 REMOTE DISPLAY DRIVE CAPABILITY

The remote display drive capability is only a consideration when the 2468C is providing

power for a remote display. With either input board the unit is capable of driving six remote

displays at up to 1000m (3280ft) from the unit but only powering one remote display (any

others must be locally powered). With the AC input board the maximum cable loop

resistance to the remote display is 27 whilst with the DC input the maximum cable loop

resistance to the remote display is 7. (See remote display section for more details).

Page 26

2468CB & 2468CD Dual Power Supply Version Hydrastep 2468CB and 2468CD Manual

2-6 24685034

2.3.3 DISPLAY BOARD (PCB 24680515)

The display board receives its power supplies and electrode data from the input boards.

This data is decoded and used to illuminate the required LEDs mounted on the display

board. The data is also converted to serial format for transmission to remote display units.

The water level in the column is indicated on the front panel by two columns of 32 LEDs, one

green column to indicate the electrodes which are in water and one red column to indicate

the electrodes which are in steam. The number of LEDs illuminated is dependent on the

number of electrodes being used in the system. When 8 to 16 electrodes are being used,

the unit illuminates two LEDs per electrode. When between 18 and 32 electrodes are being

used, the unit illuminates one LED per electrode. In both cases, the display is top biased

(unused LEDs are at the bottom of the display). A blanking label is provided to mask any

LEDs that are not used.

The system fault is indicated by the yellow LED. Provision is also made for external

indication of a system fault. This takes the form of an opto-isolated output which is normally

in its short-circuit state. When an alarm condition exists, the opto-isolated output is opencircuited.

Full illumination of the Fault LED indicates a water above steam condition has been

detected. Illumination of half the Fault LED indicates an electrode, wiring or input board

related fault. The top half of the Fault LED illuminates when faults are detected by the left

hand input board (the even electrodes) and the bottom half of the Fault LED illuminates

when faults are detected by the right hand input board (the odd electrodes). Faults are

covered under “Fault Analysis & Corrective Action” in section 2.4 of this chapter.

The switch that sets the number of electrodes to be scanned is also mounted on this board.

A ‘chequered pattern’ is displayed by the RED and GREEN columns if an invalid switch

setting is made on the number of electrodes switch.

The water/steam switching threshold (0.6S/cm or 1.6S/cm) may be changed by solder

split pads.

2.3.3.1 Link LK1

The display board caters for both single input board and dual input boards versions of the

Hydrastep 2468 system. With dual input boards, the odd electrode inputs are connected to

one half of the display board circuit with the even electrode inputs connected to the other half

of the circuit.

With the single input board, only one half of the board is connected to the odd and even

electrode inputs. In this case the link LK1 must be fitted to connect the odd and even

halves of the display board circuit.

Note: This link MUST be removed for the dual input board system.

Page 27

Hydrastep 2468CB and 2468CD Manual 2468CB & 2468CD Dual Power Supply Version

24685034 2-7

2.3.3.2 Links LK2, LK3, LK4 and LK5

These links are used to select either the 8 - 16 display mode (two LEDs per electrode) or the

18 - 32 display mode (one LED per electrode).

Two link headers are provided with the unit and must be fitted in either LK2 and LK4, to

enable the 8 - 16 electrode mode, or LK3 and LK5, to enable the 18 - 32 electrode mode.

No. of Electrodes used Link Headers fitted

8 - 16 electrodes LK 2 & LK 4

18 - 32 electrodes LK 3 & LK 5

See also Figure 2.5 on page 2-21.

2.3.4 PCB INTERCONNECTIONS

Signal interconnection between the input boards and the display board is via ribbon cables.

The power supplies to the display board come from each input board via a 6-core cable.

Slots are provided in the base plate to guide the cables towards the hinge-side of the

enclosure case, thus minimising any cable strain when the enclosure lid is opened. See

Figure 2.1 for layout details.

Page 28

2468CB & 2468CD Dual Power Supply Version Hydrastep 2468CB and 2468CD Manual

2-8 24685034

2.4 INSTALLATION

This section deals with the mechanical installation of the electronic enclosure and the

electrical connections required for the basic system. Any installation dealing wit h the options

available for use on this version of the system are covered in Chapters 3 & 4.

Notes:

1. The Electronic Enclosure cover should not be removed or opened until the equipment is

ready for physical installation to its fixing point. Under no circumstances should the

Electronic Enclosure be left open unless internal work is actually in progress.

2. When working on a bench with the enclo sure ope n, the lid should be supported in its

open position.

3. To clean the instrument, use a damp cloth with a mild, water-based cleaner. Clean the

exterior of the instrument only. Do not allow liquids to enter or spill into the instrument.

2.4.1 MECHANICAL INSTALLATION

The electronic enclosure must be sited within electrode cable length of the water column fixture.

The preferred site for the electronic enclosure is a wall or vertical bracket structure where easy

access is available for viewing and servicing, and of suitable composition/load bearing ability to

be capable of supporting 4 times the equipment weight (see page 2-32 for weight specification.)

It is assumed that the water column is fully installed.

The electronic enclosure is equipped with four welded feet, allowing it to be secured in a

vertical position. Using a template derived from the enclosure details, given in Figure 2.2,

drill the necessary holes in the prepared surface. Secure the electronic enclosure with M10

bolts or equivalent fixings.

The wiring enters the unit through a gland plate in the bottom of the enclosure. A blank

gland plate is provided to give users a choice in the type of glands and gland configuration

for the required system. Alternatively, cable entry can be made directly via trunking. Note

that the gland plate should be removed for fitting of the glands. EMC compatibility for

European installations is proven for an enclosure using a gland plate and RF glands making

a good annular (ring shape) connection to screened cables for all connections. An

installation using unscreened cables or trunked routing without a gland plate and RF gland

would not be covered by the manufacturer’s EMC declaration of conformity.

The cabling involved is:

Mains Supplies (2 cables) Remote Display (up to 6 cables)

Electrode Inputs (up to 4 cable s) Analogue Outputs (1 or 2 cables)

Relay or Opto-isolated Outputs Opto-isolated Fault Output (1 cable)

(Up to 16 relay or opto-isolated outputs)

Page 29

Hydrastep 2468CB and 2468CD Manual 2468CB & 2468CD Dual Power Supply Version

24685034 2-9

Figure 2.2: Installation diagram for Hydrastep 2468 Electronic Gauging System unit

Page 30

2468CB & 2468CD Dual Power Supply Version Hydrastep 2468CB and 2468CD Manual

2-10 24685034

2.4.2 ELECTRICAL INSTALLATION

This section deals with the interconnection between the electrodes and the electronic

enclosure, the connection of the ac mains power supply to the electronic enclosure and the

analogue output connections from the electronic enclosure.

2.4.2.1 Electrode Connections

Hydrastep Electrode Cables

Special electrode cable assemblies of length 3, 10, 18 or 30 metres are provided with the

system for connecting the Hydrastep 2468 Electronic Enclosure to the Water Column

Electrodes. The cable looms are 18-core multi-strand conductors.

The conductors are colour coded for ease of installation and have pure nickel ring clamps

fitted at one end for connection to the electrodes. A set of wire crimps is provided for use on

the Enclosure connections.

The black conductors in each cable are used for the EARTH terminations, leaving eight

pairs of coloured conductors for connection to the electrodes. At least one cable assembly is

required and certain conductor pairs in the cables will be redundant. The exceptions are the

8, 16 and 32 electrode systems where all the conductors in the cables are fully used.

Electrode connections

Pin

Number

Function PL2, PL3, PL4, PL5

1

Electrode Drive

2

Electrode Pickup

3

Functional Earth

4

Electrode Drive

5

Electrode Pickup

6

Electrode Drive

7

Electrode Pickup

8

Functional Earth

9

Electrode Drive

10

Electrode Pickup

The connection requirements for

the 16 electrode system is used as

the example case. A full set of

electrode connection diagrams is

included at the end of Chapter 2

covering the pin-by-pin pairings for

all electrode systems mentioned.

Page 31

Hydrastep 2468CB and 2468CD Manual 2468CB & 2468CD Dual Power Supply Version

24685034 2-11

2.4.2.2 Connecting Cables to Water Column Electrodes

(16 Electrode System - See Page 2-WD.7)

The following assumes that the electrodes have been fitted to the water column.

1. Gain access to the electrodes mounted on the water column.

2. Undo both knurled nuts on the stud of the bottom electrode (referenced EL.1 on the

drawings) and remove both the nuts and washers.

3. Take one of the brown (BN) conductors in Cable 1 and fit the ring clamp of the

conductor over the stud, followed by a washer and a knurled nut. Tighten the nut to form

a good secure contact, ensuring the conductor run to the cableform clamping bar is free

from snags and sharp bends.

4. Repeat the operation for the remaining brown (BN) conductor of Cable 1.

5. Take the next electrode up, referenced EL.2 on the drawings, and repeat the operations

detailed in paragraph 2 above.

6. Take the brown (BN) conductors of Cable 2 and repeat the fitting instructions detailed in

paragraph 3 above.

7. Repeat the operations of paragraphs 2 and 3 for the remaining tabulated

conductor/electrode pairings on the next page and connect as detailed on page 2-WD.7.

8. Check that all conductor runs affecting Cables 1 and 2 on the water column are

satisfactory then clamp the cable securely to its clamping bar.

9. Refit any Electrode Protection Covers to the water column.

Water column connections for 16 electrodes

Electrode

Number

Conductor

Number

Cable

Number

Enclosure

Connection

Electrode

Number

Conductor

Number

Cable

Number

Enclosure

Connection

1 Brown 1 PL2 pin 1 10 Green 2 PL3 pin 1

Brown PL2 pin 2 Green PL3 pin 2

2 Brown 2 PL2 pin 1 11 Blue 1 PL3 pin 4

Brown PL2 pin 2 Blue PL3 pin 5

3 Red 1 PL2 pin 4 12 Blue 2 PL3 pin 4

Red PL2 pin 5 Blue PL3 pin 5

4 Red 2 PL2 pin 4 13 Purple 1 PL3 pin 6

Red PL2 pin 5 Purple PL3 pin 7

5 Orange 1 PL2 pin 6 14 Purple 2 PL3 pin 6

Orange PL2 pin 7 Purple PL3 pin 7

6 Orange 2 PL2 pin 6 15 Grey 1 PL3 pin 9

Orange PL2 pin 7 Grey PL3 pin 10

7 Yellow 1 PL2 pin 9 16 Grey 2 PL3 pin 9

Yellow PL2 pin 10 Grey PL3 pin 10

8 Yellow 2 PL2 pin 9 Earth Black 1 PL2 pin 3

Yellow PL2 pin 10 Black PL2 pin 3

9 Green 1 PL2 pin 9 Earth Black 2 PL2 pin 3

Green PL2 pin 10 Black PL2 pin 3

Note: There are two conductors of each colour per cable.

Page 32

2468CB & 2468CD Dual Power Supply Version Hydrastep 2468CB and 2468CD Manual

2-12 24685034

Figure 2.3: Enclosure cable layout for 16 electrode system

2.4.2.3 Connecting the Electrode Cable Assemblies to 2468 Enclosur e

WARNING Mains voltages are present in this instrument when power

is connected. De-energise before opening front cover.

Four 10-way plugs are provided on each PCB1 to terminate all the necessary connections

from the electrode cables.

1. Ensure power is removed from electronic en closure and open the front cover.

2. Feed Cables 1 and 2 into the enclosure through its gland (if applicable). Prepare the

cable screens and terminate the screens at the gland plate.

Screened cables must be used, and each one grounded at the cable gland entering the

enclosure. Use a good quality RF cable gland and ensure a good annual (ring shape)

connection with the screen. The screens should not be grounded at the electrode end.

3. Prepare the individual conductor lengths to suit their orientation in the terminal blocks

PL2 and PL3 on their respective PCB 24680501 as shown in Figure 2.3.

It is considered good practice to twist wire-pairs together for each electrode circuit, and

twist the pairs that are in the same cable together into one bundle.

Page 33

Hydrastep 2468CB and 2468CD Manual 2468CB & 2468CD Dual Power Supply Version

24685034 2-13

Wiring to the ‘hinge-side’ 24680501 board (even-numbered electro des) should not be

pressed hard against the ribbon cables, but instead run forward of the connectors and

away from the side of the casing. Do not route them over the board.

Wiring to the ‘catch-side’ 24680501 board (single channel set-up / odd-numbered

electrodes) should be tucked into the back of the enclosure, next to the connectors, as

close to the casing as possible and below the base plate level.

4. Fit the free sockets into the terminal blocks PL2 and PL3.

5. Prepare the conductor core ends, fit the crimp terminal s and connect the conductors to

their respective free sockets.

6. Ensure that both cables have a stress-free run inside the encl osure.

2.4.2.4 Hydrastep Power Supply Cables

WARNING Mains voltages are present in this instrument when power

is connected. De-energise before opening front cover.

AC Powered Units (input board 24680501)

The Hydrastep 2468C must be installed with a fuse or circuit breaker with a maximum rating

of 5A mounted as close as practicable, in an easily reached location. The fuse or circuit

breaker must be uniquely identified as the disconnecting device.

The cable gland used must have an inlet or bushing with a smoothly rounded bell-mouthed

opening with a radius of curvature of at least one and a half times the overall diameter of the

mains cable fitted. Alternatively, a fixed guard made of insulating material protruding beyond

the inlet opening by at least five times the cable diameter may be used.

A shielded power cable, and shielded signal cables with the connection to the unit through

RF glands mounted on the gland plate should be used for all units that need to comply with

the requirements of the European EMC Directive.

Gain access to each input board and proceed as follows:

1. Ensure that the mains cable is safely isolated before starting work, and ensure that

enough length is prepared to install it according to the route described in Step 2 and

Step 3 below. The power inlet must be dedicated to that function only. No signal wiring

must share the power inlet cable. Two separate protected AC mains circuits (of the

same electrical phase) may be provided in a suitably rated multi-way cable.

2. Use a good quality RF cable gland, and ensure there is a good annular (ring shape)

connection with the screen. A ferrite (supplied) must be attached inside the unit to each

supply input, as close to the inlet gland as possible. Make a double-turn through each

ferrite – ensure that the cable is prepared with enough length to accommodate this –

and have the entire run stress-free.

3. Route the cables to both boards along the right-hand (catch) side of the enclosure.

The supply wiring to the even-numbered electrode boards should run up the right-hand

side and across the top of the enclosure. Do not run it close to the display board ribbon

cables. The run must be stress-free, and it is good practice to twist power pairs

together. The use of a self-adhesive cable tie (not supplied) is recommended to hold the

power cables close to the metalwork and away from the PCB.

4. Connect the live and neutral conductor to their respective terminals.

5. Check the voltage setting by checking which voltage selection plug is fitted (set to 240V

at the factory) and, if required, adjust as guided in

Figure 2.4.

Page 34

2468CB & 2468CD Dual Power Supply Version Hydrastep 2468CB and 2468CD Manual

2-14 24685034

6. With power disconnected release voltage selection plug PL9 by squeezing lugs. Insert

appropriate selector plug.

7. Remove fuse and fit 200mA ceramic anti-surge fuse for 240Vac nominal and 400mA

ceramic anti-surge fuse for 110Vac nominal.

The Hydrastep 2468C unit must be earthed via the protective earth terminal (stud) on

the enclosure. The cable or braid used to attach the unit to the protective earth must

be capable of carrying a current of at least 10A. No disconnecting device should be

fitted to the protective earth conductor.

TRANSFORM ER

Fuse

LN

Voltage Selection P lug

(Set to 110V)

TRANSFORMER

Fuse

LN

Volta ge S e le ction P lu g

(Set to 240V)

(A) 240 V (B) 11 0 V

Figure 2.4: Voltage Selection (240V or 110V)

DC Powered Units (input board 24680516)

A shielded power cable, and shielded signal cables with the connection to the unit through

RF glands mounted on the gland plate should be used for all units that need to comply with

the requirements of the European EMC Directive. The supply is connected to the unit in the

same way as for the AC version. A ferrite (supplied) must be attached inside the enclosure

for each DC inlet (with a double-turn). The DC inlet must not be shared by signal wiring for

any other purpose. Route the supply wires in twisted pairs as described in the AC section.

The DC supply must be either negative earth of fully isolated from plant ground

1. Positive (+Vs) is connected to the terminal marked L.

2. Negative (-Vs) is connected to the terminal marked N.

3. A separate ground wire is required which must be connected to the earth stud on the

enclosure.

4. For a non-isolated supply, the maximum difference between the plant earth at the water

column and the -Vs supply is 7V.

5. Use a good quality RF cable gland, and ensure there is a good annular (ring shape)

connection with the screen.

The Hydrastep 2468C unit must be earthed via the protective earth terminal (stud) on

the enclosure. The cable or braid used to attach the unit to the protective earth must

be capable of carrying a current of at least 10A. No disconnecting device should be

fitted to the protective earth conductor.

Page 35

Hydrastep 2468CB and 2468CD Manual 2468CB & 2468CD Dual Power Supply Version

24685034 2-15

2.4.2.5 Analogue Output Connection

WARNING Mains voltages are present in this instrument when power

is connected. De-energise before opening front cover.

Plug PL1 on each input board is used for the analogue output. A 2-core screened cable is

required and is connected into a 2-way socket such that:

The positive output conductor terminates in socket SK1 pin 1.

The negative output conductor terminates in socket SK1 pin 2.

Gain access to each PCB 24680501 and connect the analogue output cable as follows:

1. Pass the analogue cable through its gland

(if applicable) and into the enclosure.

2. Prepare the analogue cable to give a stress-

free run to PL1 on each PCB 24680501,

allowing for a double-turn to pass through a

ferrite.

Analogue wiring must not share cables with

power input, electrode input, or relay output.

It is considered good practice to twist the analogue pairs together.

3. Use a good quality RF cable gland, and ensure there is a good annular (ring shape)

connection with the screen. A ferrite (supplied) must be attached to each analogue pair

inside the enclosure, as close to the cable gland as possible. Make a double-turn through

each ferrite.

4. Prepare the conductor ends, fit the crimp connectors and connect the cores into their

respective socket SK1 terminals.

5. Fit the socket into plug PL1 and check the cable run.

Page 36

2468CB & 2468CD Dual Power Supply Version Hydrastep 2468CB and 2468CD Manual

2-16 24685034

2.4.2.6 Opto-Isolated Fault Output Connectio n

WARNING Mains voltages are present in this instrument when power

is connected. De-energise before opening front cover.

Plug PL4 is used for the FAULT output. A 2-core screened cable, capable of taking 1A and

30V is required and is connected into its 2-way terminal block such that:

Note: No fault present = Short circuit, < 1.1V at 1 Amp

Fault present = Open circuit, < 1 mA at 30V

The positive output conductor terminates in socket PL4 pin 2.

The negative output conductor terminates in socket PL4 pin 1.

Gain access to PCB 24680515 and connect the FAULT output cable as follows:

1. Prepare the FAULT output cable to give a stress-free run to PL4 on PCB 24680515.

Fault output wiring must not share cables with power inputs or electrode inputs, and is

considered good practice to twist the FAULT cable pairs together.

2. Use a good quality RF cable gland, and ensure there is a good annular (ring shape)

connection with the screen.

3. Prepare the conductor ends and connect the conductors into their respective terminal.

Check the cable run and tie it to the present loom. Tighten the gland nut (if applicable)

and close the instrument front cover.

Part of Display Board showing PL4

If the installation is adversely affected by the operation of nearby equipment, then re-routing

the cables to these instructions should improve the performance:

Avoid bundling the cables from both channels togethe r

Ensure that cables run against earthed metalwo rk where possible

Use screened cables for all connections, making sure that a good annular (ring shape)

connection is made with a good quality RF cable gland

Electrode, Relay, and Analogue Output wiring on the left-hand (enclosure hinge) side should

not be pressed hard against the ribbon cables, but instead run forward of the connectors and

away from the side of the casing. Do not run the wiring over the PCB.

Wiring on the right-hand (enclosure catch) side should be tucked into the back of the enclosure,

next to the connectors, and as close to the casing as possible and below the vase plate level.

Supply wiring should be run close to the metalwork, forward of the signal wiring, but never

along the left-hand (hinged) side of the enclosure near the ribbon cables.

The ribbon cables must be run under the back plate and up the left-hand (hinged) side of the

enclosure, and secured by using clips (supplied).

Page 37

Hydrastep 2468CB and 2468CD Manual 2468CB & 2468CD Dual Power Supply Version

24685034 2-17

This concludes the electrical installation requirements for the basic instrument configuration.

Connections within the enclosure for the options available will be covered in the Installation

sections of the appropriate Chapter 3a (Relay Outputs), 3b (Relay with time delay Outputs),

3c (Opto-isolated Outputs) or Chapter 4 (Remote Display).

2.5 SYSTEM CONFIGURATION

This section describes mains voltage selection, analogue output setting and electrode error

configuration on each input board. Also the ‘number of electrodes’ setting and configuration

of the water/steam switching threshold value display board is described.

The three main PCBs require configuration. These are:

Two Input Boards - PCB 24680501 or 24680516

Display Board - PCB 24680515

2.5.1 INPUT BOARD (PCB 24680501 OR 24680516)

Two settings may be configured on this board, the analogue output range and sense, and

the electrode error configuration.

2.5.1.1 Analogue Output Configuration

WARNING Mains voltages are present in this instrument when power

is connected. De-energise before opening front cover.

Two sets of split pads are provided to select the required range (0-20mA or 4-20mA) and the

sense of the mA current output (normal sense as shown or in reverse, i.e. 4-20mA or 20-4mA).

To configure the analogue output, refer to Table 2.1 then:

1. Ensure the power supply is disconnected.

2. Locate the position of split pads SP1 and SP2 on the input board (PCB).

3. Refer to Table 2.1, select which configuration is required and where ‘bridged’ is ticked,

bridge the gap on the pad with solder. Where ‘open circuit’ is ticked, ensure that any

solder bridge on the split pad is removed and the gap is clean.

4. Carry out a resistance test across any altered split pad for short circuit or open circuit

conditions as appropriate.

Table 2.1 - Analogue output configurations

Page 38

2468CB & 2468CD Dual Power Supply Version Hydrastep 2468CB and 2468CD Manual

2-18 24685034

2.5.1.2 Pulsed Output Setting

As configured at the factory, the analogue output pulses if a fault condition occurs.

1. To disable this feature the split pad SP10 must be broken by cutting the track that

passes between the pads.

2. To re-enable the pulse for fault conditions the split pad can be bridged with solder.

2.5.1.3 Electrode Error Configuration

An electrode error is triggered if the electrode resistance measured falls below the set

electrode error threshold. Possible causes are a short to ground (short in cabling or dirty

electrode) or a break in the electrode wire (may also be very conductive water). This unit

can either be configured to take electrode error into account when measuring electrode

resistance or the facility can be disabled. When enabled, if an electrode error occurs the

alarm (yellow) LED relating to the board on which the error occurred is illuminated and the

LED pair (red and green) corresponding to the electrode, alternate between red and green.

Input Board (Option Board Removed)

Note: If SP6 has been bridged, this may be left in

position even if SP7 is subsequently bridged.

Page 39

Hydrastep 2468CB and 2468CD Manual 2468CB & 2468CD Dual Power Supply Version

24685034 2-19

2.5.1.4 Configuring the Unit to Detect Electrode Error

WARNING Mains voltages are present in this instrument when power

is connected. De-energise before opening front cover.

1. Disconnect the power supply. Gain access to the input PCB by opening the cover and

removing the option board.

2. Check split pads SP6 & SP7 on the input PCB are open circuit and clean (this i s the

default setting).

3. To change the electrode error threshold value or to disabl e the feature, bridge the split

pads SP6 or SP7 with solder as shown in the table above.

Repeat the procedure used in configuring the first input board to set up the remaining input

board as required. This concludes the configuration on the input boards.

WARNING Bridging SP7 will disable the electrode fault alarm. In this

condition, a fouled electrode in water will not be detected.

This is of particular importance when electrodes are used

for low level alarm or cut off.

By bridging split pad 6 on the input board, the conductivity fault detection level will be increased

from 104S (normal) to 300S (high). This may be sufficient in some cases, but not all.

Factory modifications are available to further increase this level to 800S, 1600S or

2000S. At each of these stages, the measuring sensitivity of the Hydrastep system is

reduced, so the most appropriate level should be chosen, not the highest. Contact your local

representative for further details.

Note that input boards that have been modified are marked with the number 24680229A and

the conductivity level that is acceptable.

Offset voltages:

When an offset voltage is present on the return

signal and is relatively high compared to the ac

voltage, it may have the effect of lifting the

square wave to the water/steam switching point.

This will cause one, or more, electrodes to flash

rapidly on the display as the detection circuits

alternate between steam and water. When

combined with the problem described above, the

display becomes very confusing.

Input adapter boards (24680523A) are available

which fit into the electrode cable connectors on

the input board (see inset picture, right). These

have series capacitors in the return side of the

cables, blocking any dc offset voltages.

The electrode cable then plugs into the Input

Adapter Board instead of the electrode cable

connector.

1. Input Adapter Board.

2. Input Board (Partial Top View).

3. Adapter plugged into electrode cable connector

(Horizontal View).

Page 40

2468CB & 2468CD Dual Power Supply Version Hydrastep 2468CB and 2468CD Manual

2-20 24685034

2.5.2 DISPLAY BOARD 24680515

The Display Board needs to know how many electrodes are being used and if one or two input

boards are being used. A centrally mounted dual-in-line switch assembly, SW1 (titled “Number

of Electrodes”) uses four individual switch channels to select between an 8 and 32 electrode

operation as shown in Table 2.2 below. A socket LK1 (situated near switch SW1) is provided to

link the two halves of the display board together with a link header when only one input board is

used. In this case when two input boards are being used, the link header is not fitted.

Sockets are also provided at LK2, LK3, LK4 and LK5 locations (see Figure 2.5), to select an

8 - 16 (two LEDs per electrode) display mode or an 18 - 32 (one LED per electrode) display

mode. For hazardous area applications, links 2, 3, 4 and 5, when fitted, must be secured

into the sockets using a cable tie passed underneath the socket base.

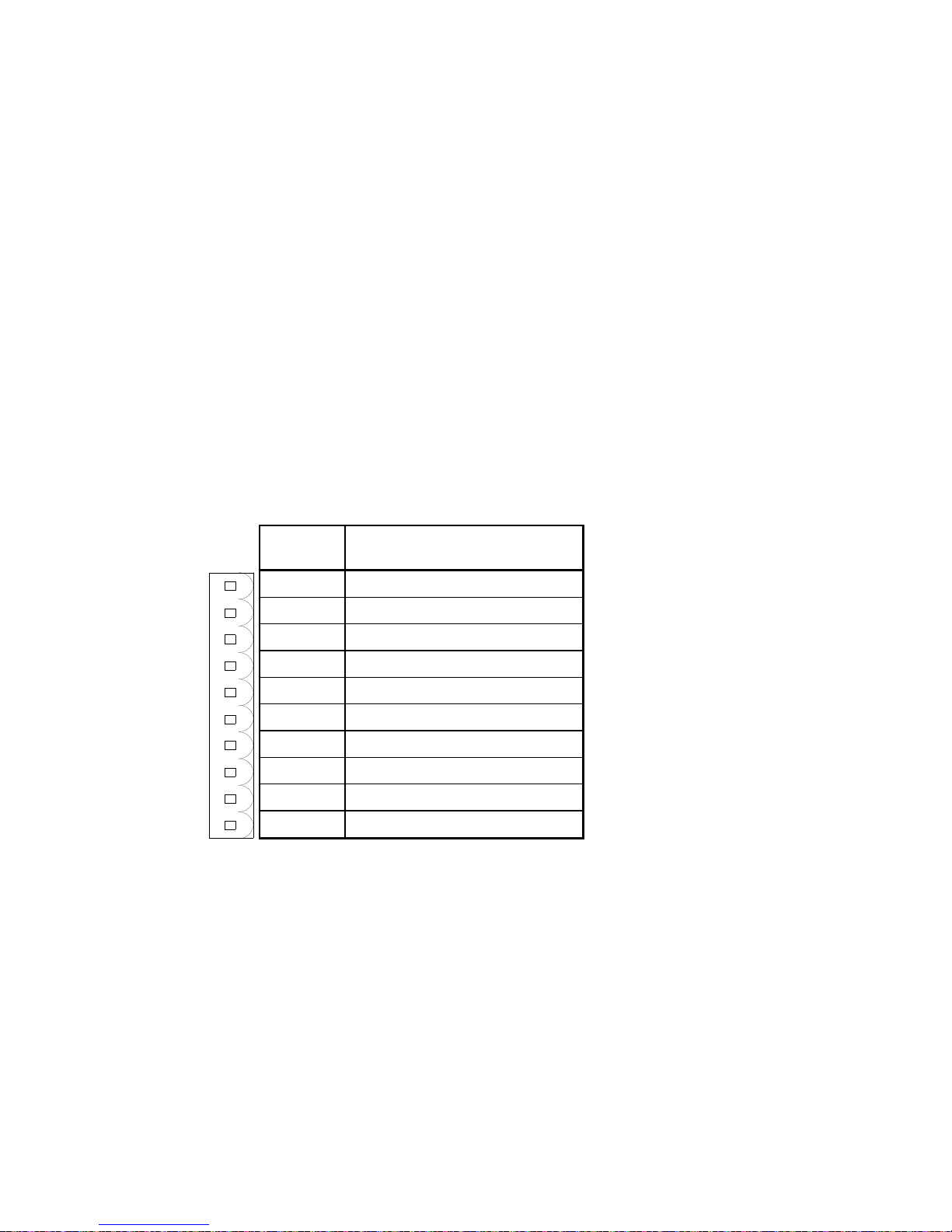

SWITCH SW1 NO. OF ELECTRODES LINKS 2-5

CHANNEL NO. IN WATER PER INPUT LINKS LINKS

1 2 3 4 COLUMN BOARD 2 & 4 3 & 5

Off Off On On 8 4

On On Off On 10 5 Fitted Not

Off On Off On 12 6 Fitted

On Off Off On 14 7

Off Off Off On 16 8

On On On Off 18 9

Off On On Off 20 10

On Off On Off 22 11

Off Off On Off 24 12 Not Fitted

On On Off Off 26 13 Fitted

Off On Off Off 28 14

On Off Off Off 30 15

Off Off Off Off 32 16

Table 2.2 - Number of electrodes being displayed

2.5.2.1 Link LK1 Setting

Ensure that link header LK1 is not fitted (see Figure 2.5).

2.5.2.2 Configuring the ‘Number of Electrodes’ Switch

WARNING Mains voltages are present in this instrument when power

is connected. De-energise before opening front cover.

1. Disconnect the power supply. Gain access to PCB 24680515 by opening the cover.

2. Locate position of ‘Number of Electrodes’ switch SW1 see Figure 2.5.

3. Depending upon the number of electrodes being used, set the switches as defined in

Table 2.2. The switch positions in the example shown are for a twelve electrode system.

Page 41

Hydrastep 2468CB and 2468CD Manual 2468CB & 2468CD Dual Power Supply Version

24685034 2-21

Figure 2.5- Location of display board links LK1 to LK5 & switch SW1

with configuration details

Note: When two input boards are fitted, odd

electrodes use one input board, even

electrodes use the other input board, and

switch SW1 is set to the number of electrodes

per input board.

For 18 – 32 electrodes, links LK3 and LK5

must be fitted.

For 8 – 16 electrodes, links LK2 and LK4

must be fitted.

An invalid switch setting causes the main

column LEDs to display a chequered pattern.

Page 42

2468CB & 2468CD Dual Power Supply Version Hydrastep 2468CB and 2468CD Manual

2-22 24685034

2.5.2.3 ‘Switching Threshold’ Setting

WARNING Mains voltages are present in this instrument when power

is connected. De-energise before opening front cover.

1. Disconnect the power supply. Gain access to PCB 24680515 by opening the cover.

2. Check split pads SF1 & SP2 on the PCB are open circuit and clean (this is the normal

setting 0.6S/cm). See Figure 2.6 for details.

3. If the preferred setting is 1.6S/cm (i.e. low temperature), bridge the split pads SP1 &

SP2 with solder.

Figure 2.6- Split pads SP1, SP2, SP5 & SP6 locations and settings

2.5.2.4 ‘Compatibility’ Setting

The split pads SP5 and SP6 should be open when used with a 24680501C or 24680516B

input board. When used with a 24680501A, 24680501B or 24680516A input boards these

split pads should be made. With these older input cards the LEDs corresponding to an

‘electrode error’ will not alternate but remain steady.

Page 43

Hydrastep 2468CB and 2468CD Manual 2468CB & 2468CD Dual Power Supply Version

24685034 2-23

2.6 FAULT ANALYSIS & CORRECTIVE ACTION

Faults in the system will generally be indicated by the YELLOW LED on the front panel and

by the fault output on the display board. The main faults, which are catered for, are:

Water above steam condition

Electrode or Wiring fault

Detection of an internal circuit fault

When any of the above mentioned conditions exist within the Hydrastep 2468CB system, the

yellow LED is illuminated to indicate the FAULT state. Since the electrode inputs are split

between the two input boards, the ALARM indicator is configured to differentiate between

ODD and EVEN electrode faults. An opto-coupler output, normally short-circuited, becomes

open-circuited on a FAULT state, providing an ALARM indication output for external use.

The current output indicates an alarm condition by a 0.5Hz waveform superimposed on the

main analogue signal.

A further FAULT is indicated when the number of electrodes switch on the display board is

set to an invalid number. This error brings up an alternate LED illumination display, that is a

chequered display of GREEN and RED LEDs on the two front panel columns.

WARNING Mains voltages are present in this instrument when power

is connected. De-energise before opening front cover.

Some parts of the water column and electrodes may be

very hot. Please ensure parts are adequately cooled or that

suitable precautions are taken before handling.

Indication Fault(s) Analysis and Corrective Action

State 1

Top and

bottom

halves of

fault LED

illuminated

One or more

LED pairs

alternating

between

water and

steam

Water conductivity.

All LED pairs in water

alternating between

water and steam.

Check ac voltage on all electrodes immersed in

water with a true r.m.s. voltmeter. If several of the

immersed electrodes show a voltage of less than

approximately 0.1V ac then very high water

conductivity is probable.

Check water column installation is correct; sloping

pipework and insulation details. Make sure that

there is sufficient condensate flow through the

column.

If the normal water conductivity is high, the

electrode error circuit can be de-sensitised or

disabled.

If the normal water conductivity is still too high

(40mV ac at electrode), the electrode error circuit

must be disabled – refer to the electrode error

configuration section.

Water above steam,

caused by electrode

wiring or internal fault

Electrode connection

open-circuit or shortcircuit to earth

The electrode channel(s) causing the problem will

be evident from the unit display by an alternating

indication in the steam area.

Check the suspect electrode(s) has the correct pair

of conductors connected, check the connections to

the input board. Rectify if incorrect.

Table 2.3 - Fault analysis/corrective action chart

Page 44

2468CB & 2468CD Dual Power Supply Version Hydrastep 2468CB and 2468CD Manual

2-24 24685034

Indication Fault(s) Analysis and Corrective Action

State 1 (contd.)

Incorrect wiring,

broken connection

or damaged cable

assembly

Affected

electrode(s)

alternate between

water and steam.

Check ac voltage on electrodes with a true r.m.s.

voltmeter. A voltage of less than 0.1V ac indicates a fault

condition.

If wiring to the electrode is correct and the electrode

gives a voltage reading of greater than 0.1V ac and a

fault is still indicated, carry out the following procedure:

1. Remove both conductors from the suspect electrode.

With the conductors isolated from each other, the

level display should show the electrode as

alternating between water and steam (green and

red).

2. With the conductors touching each other, the level

display should show electrode as being in steam.

The above procedure checks the electrode wiring. If the

display does not show the correct results, then check for

a break in either of the suspect electrode conductors.

Carry out repair to any faulty connection or substitute a

new conductor or cable assembly in place of the

defective item.

Dirt on electrode

Affected

electrode(s)

alternate between

water and steam.

If the wiring checks carried out as described above have

not located a fault, then dirt on an electrode insulator may

be the cause of the problem giving an effective short-

circuit to ground.

Check the electrodes for dirt over the external insulator

and clean with a cloth as required.

Checking for dirt on the internal insulator of the electrode

requires the draining of the water column (refer to Part 2

of this manual for the correct procedure).

Once the water column is drained, check the ac voltage

on each electrode using a true r.m.s. voltmeter. Any

electrode showing a voltage of less than 3V ac needs

cleaning or replacement. Electrodes must be removed

from the column for inspection and cleaning.

Note: The electrode insulator can be cleaned using a

clean cloth

Internal fault If the wiring checks carried out as described above ha ve

not located a fault, then it is possible an internal fault

exists.

1. Disconnect the electrode cable sockets from the

input board.

2. Make up four 10-way sockets (six or eight sockets

required for systems with more than 16 points) with

wire links connecting the following pins on each

socket; 1-2, 4-5, 6-7, 9-10.

Table 2.3 - Fault analysis/corrective action chart (continued)

Page 45

Hydrastep 2468CB and 2468CD Manual 2468CB & 2468CD Dual Power Supply Version

24685034 2-25

Indication Fault(s) Analysis and Corrective Action

State 1 (contd.)

3. Insert these sockets in place of the electrode cable

sockets in the input boards, the level display should

now show an all steam state and no fault

indication. If this does not occur an internal fault

exists.

The circuit fault may be on either input board or the

display board. If spares are available, change the input

board first and if the fault is not rectified change the

display board. If spares are not available, call the

service engineer.

State 2

Top and bottom

halves of fault

LED illuminated

No LED pairs

alternating

between water

and steam

Internal fault This state is indicating a fault which is not related to an

electrode error because no LED pairs are alternating

between water and steam. It is therefore likely that an

internal fault exists.

Follow same procedure as above.

State 3

Top half of fault

LED illuminated

One or more

LED pairs

alternating

between water

and steam

Electrode wiring or

internal fault

Even numbered

electrode connection

open-circuit or

short-circuit to earth

Affected electrode

alternates between

water and steam.

Incorrect wiring,

broken connection or

damaged cable

assembly

Check that all even numbered electrodes indicating

water have the correct pair of conductors connected.

Check the connections to the left hand input board.

Rectify wiring if incorrect.

Check ac voltage on all even electrodes immersed in

water with a true r.m.s. voltmeter. A voltage of less than

0.1V ac indicates a fault condition.

If wiring to all even electrodes is correct and the

electrodes still give a voltage reading of greater than

0.1V ac and a fault is still indicated, carry out the

following procedure:

1. Remove both conductors from electrode 2. With the

conductors isolated from each other, the level

display should show electrode 2 as alternating

between water and steam (green and red).

2. With the conductors touching each other, the level

display should show electrode 2 as being in steam.

3. Repeat operations 1 and 2 for all affected even

numbered electrodes until a faulty indication is

found.

The above procedure checks the electrode wiring. If

the display does not show the correct results, then

check for a break in either of the suspect electrode

conductors.

Carry out repair to any faulty connection or substitute a

new conductor or cable assembly in place of the

defective item.

Table 2.3 - Fault analysis/corrective action chart (continued)

Page 46

2468CB & 2468CD Dual Power Supply Version Hydrastep 2468CB and 2468CD Manual

2-26 24685034

Indication Fault(s) Analysis and Corrective Action

State 3 (contd.)

Dirt on electrode

Affected electrode

alternates

between water and

steam.

If the wiring checks carried out as described above have

not located a fault, then dirt on an electrode insulator may

be the cause of the problem giving an effective shortcircuit to ground.

Check all even numbered electrodes alternating between

water and steam for dirt over the external insulator and

clean with a cloth as required.

Checking for dirt on the internal insulator of the electrode

requires draining of the water column (refer to the

appropriate manual for the correct procedure).

Once the water column is drained, check the ac voltage

on each even numbered electrode using a true r.m.s.

voltmeter. Any electrode showing a voltage of less than

3V ac needs cleaning or replacement. Electrodes must

be removed from the column for inspection and cleaning

Note: The electrode insulator can be cleaned using a

clean cloth

Internal circuit fault

on left hand circuit

board or the

display board

If the wiring checks carried out as described above have

not located a fault, then it is possible that an internal fault

exists.

1. Disconnect the electrode cable sockets from the

input boards.

2. Make up four 10-way sockets (six or eight sockets

required for systems with more than 16 points) with

wire links connecting the following pins on each

socket: 1-2, 4-5, 6-7, 9-10.

3. Insert these sockets in place of the electrode cable

sockets in the input boards. The level display should

now show an all steam state and no fault indication.

If this does not occur an internal fault exists.

The circuit fault may be on either input board or the

display board. If spares are available, change the left

hand input board first, and if the fault is not rectified

change the display board followed by the right hand input

board. If spares are not available, call the service

engineer.

State 4

Top half of fault

LED illuminated

No LED pairs

alternating

between water

and steam

Internal circuit fault

on left hand circuit

board or the

display board

This state is indicating a fault which is not related to an

electrode error because no LED pairs are alternating

between water and steam. It is therefore likely that an

internal fault exists.

Follow same procedure as above.

Table 2.3 - Fault analysis/corrective action chart (continued)

Page 47

Hydrastep 2468CB and 2468CD Manual 2468CB & 2468CD Dual Power Supply Version

24685034 2-27

Indication Fault(s) Analysis and Corrective Action

State 5

Bottom half of

fault LED

illuminated

One or more

LED pairs

alternating

between water

and steam

Electrode wiring or

internal fault

Odd numbered

electrode

connection opencircuit or

short-circuit to

earth

Affected electrode

alternates

between water and

steam.

Incorrect wiring,

broken connection

or damaged cable

assembly

Check that all odd numbered electrodes indicating

water have the correct pair of conductors connected.

Check the connections to the right hand input board.

Rectify wiring if incorrect.

Check ac voltage on all odd electrodes immersed in

water with a true r.m.s. voltmeter. A voltage of less than

0.1V ac indicates a fault condition.

If wiring to all odd electrodes is correct and the

electrodes still give a voltage reading of greater than

0.1V ac and a fault is still indicated, carry out the

following procedure:

1. Remove both conductors from electrode 1. With the

conductors isolated from each other, the level

display should show electrode 1 as being

alternating between water and steam (green and

red).

2. With the conductors touching each other, the level

display should show electrode 1 as being in steam.

3. Repeat operations 1 and 2 for all affected odd

numbered electrodes until a faulty indication is

found.

The above procedure checks the electrode wiring. If the

display does not show the correct results, then check for