Installation Sheet

June 2006

Introduction

Type HSR

This manual provides instructions for the installation,

startup, and adjustment of the Type HSR pressure

regulator. If maintenance is required, refer to the Type

HSR Instruction Manual, form 5753. To receive a copy of

the instruction manual, contact your Fisher Sales Ofce or

Sales Representative.

Specications

Maximum Emergency Inlet Pressures

150 psi (10,3 bar)

Maximum Emergency Outlet (Casing) Pressures

25 psig (1,72 bar)

Outlet Pressure Ranges

4 to 6-inches w.c. (10 to 15 mbar),

6 to 8-inches w.c. (15 to 20 mbar),

8 to 10-inches w.c. (20 to 25 mbar),

10 to 12.5-inches w.c. (25 to 31 mbar),

12.5 to 20-inches w.c. (31 to 50 mbar),

20 to 35-inches w.c. (50 to 87 mbar),

1.25 to 2.2 psig (0,09 to 0,15 bar)

Temperature Capabilities

-20° to 160°F (-29° to 71°C)

(2)

(1)

(1)

Installation

WARNING

!

Personal injury, equipment damage, or

leakage due to escaping gas or bursting

of pressure-containing parts might result

if these regulators are overpressured or

installed where service conditions could

exceed the limits for which the regulators

were designed, or where conditions exceed

any ratings of the adjacent piping or

piping connections. To avoid such injury

or damage, provide pressure-relieving

or pressure-limiting devices (as required

by the appropriate code, regulation or

standard) to prevent service conditions

from exceeding those limits.

Additionally, physical damage to a

regulator could cause personal injury and

property damage due to escaping gas. To

avoid such injury and damage, install the

regulator in a safe location.

A regulator may vent some gas to the

atmosphere in hazardous or ammable gas

service, vented gas might accumulate and

cause personal injury, death or property

damage due to re or explosion. Vent

a regulator in hazardous gas service to

a remote, safe location away from air

intakes or any hazardous location. The

vent line must be protected against

condensation or clogging.

Before installing the regulator, check for damage which

might have occurred in shipment. Also check for dirt

or foreign matter which may have accumulated in the

regulator body or in the pipeline. Apply pipe compound to

the male threads of the pipeline and install the regulator

so that the ow is in the direction of the arrow cast on

the side of the body. The diaphragm actuator assembly

can be rotated to any position relative to the body, in 90°

increments. Remove the two cap screws that hold the

body to the actuator in order to rotate the diaphragm

actuator assembly.

Do not install the regulator in a location where there can

be excessive water accumulation, such as directly beneath

a downspout or in an undrained pit.

To obtain the maximum ow capacities or other

performance characteristics, the length of pipe from the

regulator outlet to the meter should have no bends and

should be the same size as the regulator outlet. Replace

the regulator if water gets into the spring case or the lower

casing of the regulator.

CAUTION

You are advised to use new vent piping

because defective threads on the relief

vent piping may interfere with the venting

assembly if the piping obstructs the

movement of the vent apper.

On indoor installations, the vent should be piped outside

the building. Remove the screen from the regulator vent

connection and connect vent piping from that connection

to the outdoors. Install a weather and insect resistant

vent assembly on the outside end of the pipe. Inspect

the vent opening regularly. On some installations, it may

be necessary to install the regulator beneath a protective

hood. The vent should be pointing or sloping down

sufciently to allow any condensate to drain. Also check

the regulator periodically for external or internal corrosion.

Overpressure Protection

WARNING

!

Some type of overpressure protection is

needed if actual inlet pressure can exceed

the outlet pressure rating. Overpressuring

any portion of this equipment may cause

damage to regulator parts, leaks in

the regulator, or personal injury due to

bursting of pressure-containing parts or

explosion of accumulated gas.

www.emersonprocess.com/regulators

D103075X012

Type HSR

Type HSR regulators provide internal relief that limits the

total outlet pressure buildup over setpoint. This internal relief

may be adequate for the application, if not, provide additional

pressure relief or a pressure-limiting device downstream.

Regulators should be inspected for damage after any

overpressure condition.

WARNING

!

To avoid personal injury or property damage

due to explosion or damage to regulator or

downstream components during startup,

release downstream pressure to prevent an

overpressure condition on the diaphragm of

the regulator.

In order to avoid an overpressure condition

and possible equipment damage, pressure

gauges should always be used to monitor

pressures during startup.

Startup

With proper installation completed, slowly open the

shutoff valve. Check all connections for leaks. Check the

downstream equipment for proper operations.

Adjustment

To increase the outlet pressure setting, turn the adjusting

screw clockwise. To reduce the outlet pressure setting, turn

the adjusting screw counterclockwise. A pressure gauge

should always be used to monitor downstream pressure

while adjustments are being made. Do not adjust the spring

to produce an outlet pressure setting above the limit identied

on the information label. If the required pressure setting is

not within the range of the spring being used, substitute with

the correct spring. When changing the spring, also change

the range identied on the information label to indicate the

actual pressure range of the spring in use. After the spring

adjustment has been completed, replace the closing cap.

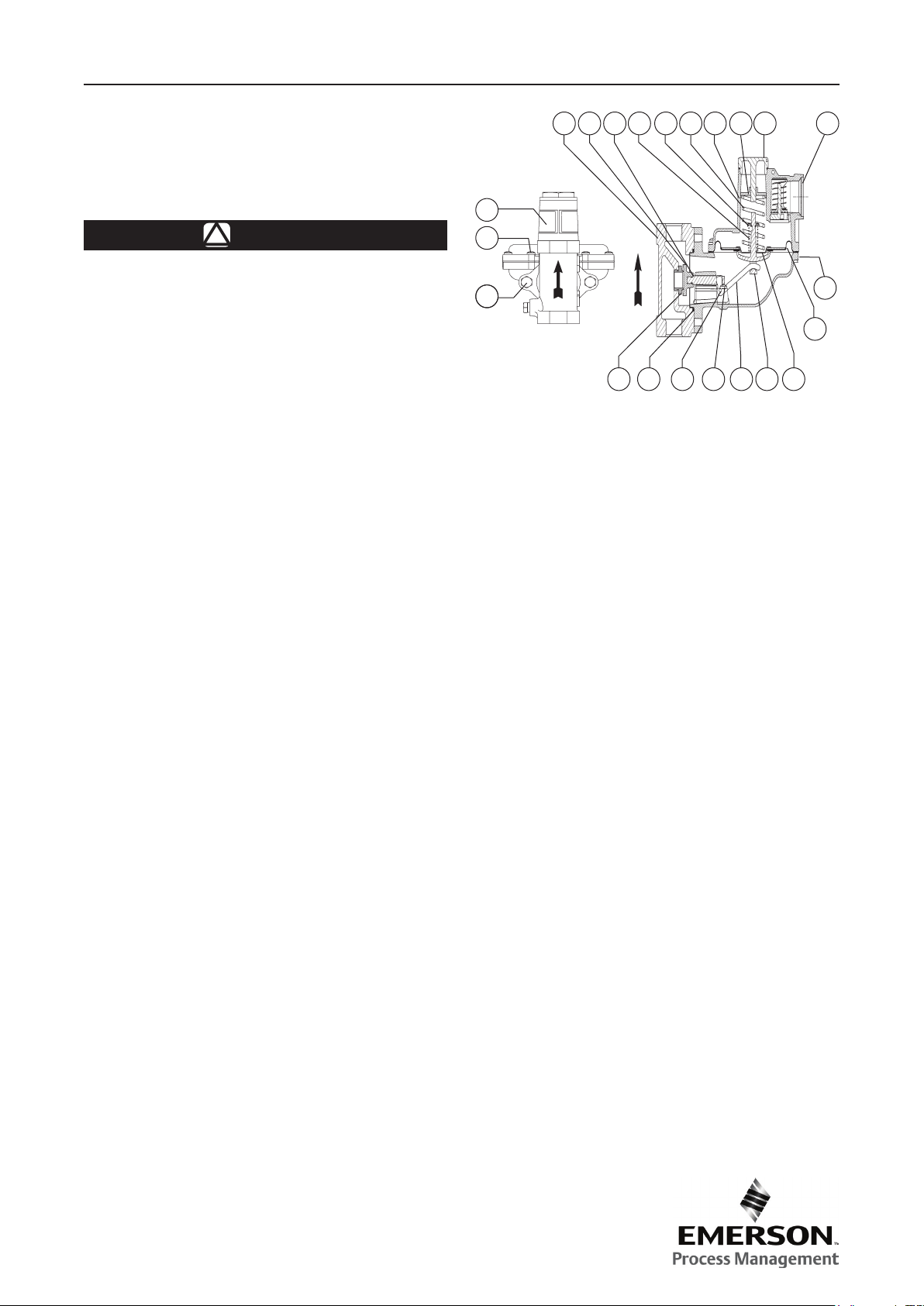

27

9

17

T80573-2A

15

23

5

22

10

16

Type HSR Regulator Assembly

Parts List

Key Description

1 Spring Case Assembly

2 Lower Casing

3 Screen

4 Lever

5 Stem

6 Straight Pin

7 Machine Screw (2 required)

8 Closing Cap

9 Machine Screw (8 required)

10 Relief Valve Spring

11 Diaphragm

12 Pusher Post

13 Lower Spring Seat

14 Relief Spring Retainer

15 Body

16 O-Ring

17 Cap Screw (2 required)

22 Orice

23 Disc

25 Spring

26 Adjusting Screw

27 Information Label

14

8

26

1

25

6

4

7

12

3

2

11

13

Industrial

USA - Headquarters

McKinney, Texas 75070 USA

Tel: 1-800-558-5856

Outside U.S. 1-469-293-4201

Asia-Pacic

Shanghai, China 201206

Tel: 86-21-5899 7887

Europe

Bologna, Italy 40013

Tel: 39 051 4190611

For further information visit www.emersonprocess.com/regulators

The Emerson logo is a trademark and service mark of Emerson Electric Co. All other marks are the property of their prospective owners. Fisher is a mark owned by Fisher Controls, Inc.,

a business of Emerson Process Management.

The contents of this publication are presented for informational purposes only, and while every effort has been made to ensure their accuracy, they are not to be construed as warranties

or guarantees, express or implied, regarding the products or services described herein or their use or applicability. We reserve the right to modify or improve the designs or specications

of such products at any time without notice.

Emerson Process Management does not assume responsibility for the selection, use or maintenance of any product. Responsibility for proper selection, use and maintenance of any

Emerson Process Management product remains solely with the purchaser.

©Fisher Controls International, Inc., 2003, 2006; All Rights Reserved

Natural Gas Technologies

USA - Headquarters

McKinney, Texas 75070

Tel: 1-800-558-5856

Outside U.S. 1-469-293-4201

Asia-Pacic

Singapore, Singapore 128461

Tel: +65 6777 8211

Europe

Bologna, Italy 40013

Tel: 39 051 4190611

Gallardon, France 28320

Tel: +33 (0)2 37 33 47 00

Industrial/High Purity

TESCOM

Elk River, Minnesota 55330 USA

Tel: 1-763-241-3238

Selmsdorf, Germany 23923

Tel: +49 (0) 38823 31 0

Loading...

Loading...