Installation, Operation and Maintenance Manual

VCIOM-15257-EN Rev. 1

May 2020

EIM HQ Series Quarter-Turn Electric Actuator

Models HQ-006 / Manual HQ-402-0606

Notes

May 2020

Installation, Operation and Maintenance Manual

VCIOM-15257-EN Rev. 1

This page intentionally left blank

Installation, Operation and Maintenance Manual

VCIOM-15257-EN Rev. 1

Table of Contents

Section 1: General

Generalities ............................................................................................................. 1

Section 2: Actuator Mounting

Actuator Mounting ................................................................................................. 2

Section 3: External Construction

External Construction ............................................................................................. 3

Section 4: Standard Wiring Diagram

Standard Wiring Diagram ........................................................................................ 4

Table of Contents

May 2020

Section 5: Manual Override

Manual Override ..................................................................................................... 5

Section 6: Electrical Connection

Electrical Connection .............................................................................................. 6

Section 7: Limit Switch Setting Instructions

Limit Switch Setting Instructions ............................................................................. 7

Section 8: Lubrication

Lubrication .............................................................................................................. 8

Section 9: MDPI Settings

MDPI Settings ......................................................................................................... 9

Section 10: Maintenance and Storage

Maintenance and Storage ..................................................................................... 10

Section 11: Troubleshooting

Troubleshooting ................................................................................................... 11

Table of Contents

Section 12: Product Features and Specications

Product Features and Specications ...................................................................... 12

i

Section 1: General

May 2020

Section 1: General

HQ series electric actuators are design to provide reliable and efcient operation of 90°

quarter-turn valves, dampers, etc.

WARNING

!

Use caution when working in, with, or around valves and actuators. High pressures, forces,

voltages and ammable media can be present. Failure to follow instructions for proper

electrical wiring, storage, set-up and maintenance may cause serious injury, damage

equipment, or void warranty.

Installation, Operation and Maintenance Manual

VCIOM-15257-EN Rev. 1

1

General

Installation, Operation and Maintenance Manual

VCIOM-15257-EN Rev. 1

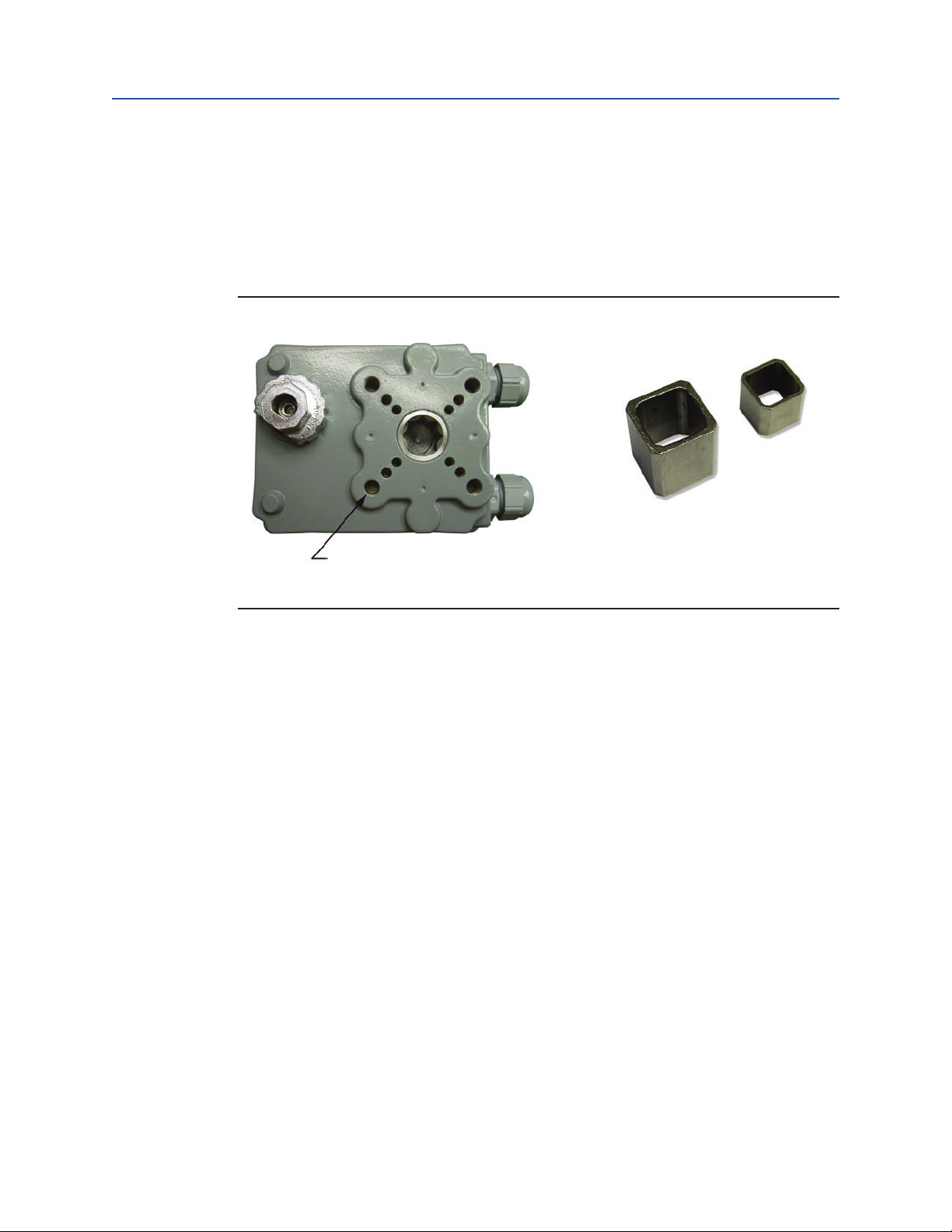

Section 2: Actuator Mounting

The actuator may be mounted in any position. The HQ-006 actuator is supplied with a

female output drive and adaptor bushings. ISO5211 FO3/FO5 and FO7 Bolt patterns are

provided for actuator mounting.

Figure 1 Actuator Mounting Flange and Adapter Bushings

Section 2: Actuator Mounting

May 2020

9 mm ID

11 mm ID

F03, F05 and F07 Bolt Circles

Actuator Mounting

2

Section 3: External Construction

May 2020

Installation, Operation and Maintenance Manual

Section 3: External Construction

Figure 2

CABLE ENTRY

2 Plcs PG 0.531" (13.5)

(1/4" - 1/2" Wire Cable)

VCIOM-15257-EN Rev. 1

3

External Construction

Installation, Operation and Maintenance Manual

Section 4: Standard Wiring Diagram

VCIOM-15257-EN Rev. 1

Section 4: Standard Wiring Diagram

Figure 3

INCOMING POWER

1 PH (110 OR 220 V A C)

LIVE

May 2020

AUX. CONTACT

2 EXTRA SWITCHES

MAX. 250 V AC 3 A

CLOSE

LAMP

OPEN

LAMP

OPENSTOPCLOSE

HEATER

2W

NEUTRAL

BASE

EARTH

Standard Wiring Diagram

4

Section 5: Manual Override

May 2020

Installation, Operation and Maintenance Manual

Section 5: Manual Override

The HQ-006 actuator comes standard with a manual override nut. This is located on the

bottom of the unit, and can be easily operated with a 5M wrench.

Figure 4

VCIOM-15257-EN Rev. 1

5

Manual Override

Installation, Operation and Maintenance Manual

VCIOM-15257-EN Rev. 1

Section 6: Electrical Connection

• Move valve to mid-position by override nut. This will allow sufcient time to stop

actuator in case of improper hook-up.

• Identify means of removing power during hook-up.

• Be sure no erroneous remote control signals can be received causing actuator

to energize.

• Electrically operate the valve in the open direction. If the valve closes, actuator

must be stopped and checked for improper eld wiring.

• Set all eld conduit entries in accordance with National Electric Code Requirements.

Section 6: Electrica l Connection

May 2020

Electrica l Connection

6

Section 7: Limit Switch Setting Instructions

May 2020

Installation, Operation and Maintenance Manual

VCIOM-15257-EN Rev. 1

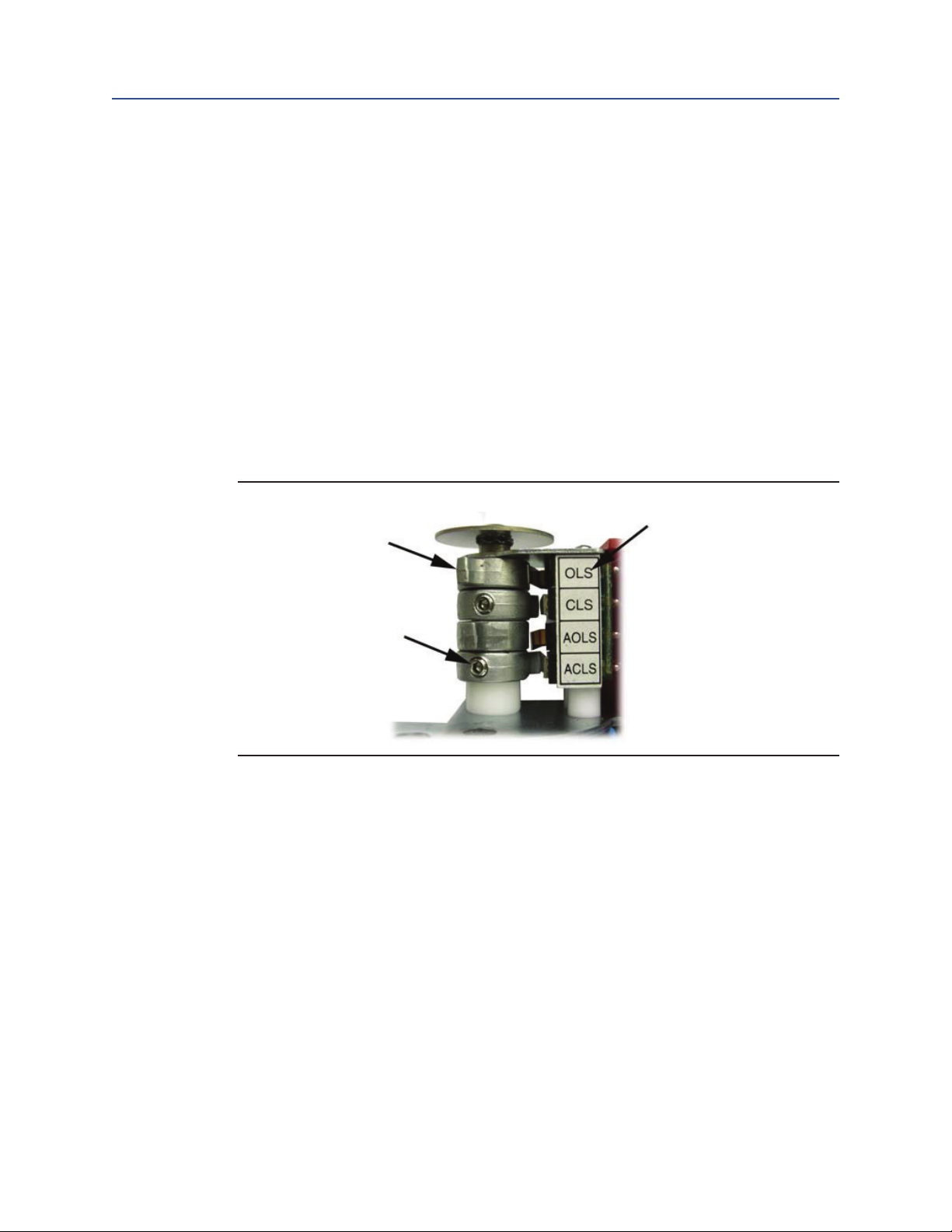

Section 7: Limit Switch Setting Instructions

• Operate the actuator manually to closed position

• Using a hex wrench, loosen the cam adjustment screw in the CLS limit switch cam

• Rotate the CLS cam towards limit switch lever until the switch ‘clicks’

• Tighten set screw with hex wrench

• Operated the actuator manually to open position

• Using a hex wrench, loosen the cam adjustment screw in the OLS limit switch cam

• Rotate the OLS can towards limit switch lever until the switch ‘clicks’

• Tighten set screw with hex wrench

• Repeat for AOLS and ACLS

Figure 5

Limit

Cam

Switch

Cam

adjustment

screw

7

Limit Switch Setting Instructions

Installation, Operation and Maintenance Manual

VCIOM-15257-EN Rev. 1

Section 8: Lubrication

The HQ series actuators are totally enclosed units with a permanently lubricated gear

trains (Moly EP Grease). Once installed lubrication should not be required. However,

periodic preventative maintenance will extend the operating life of the actuator.

Section 8: Lubrication

May 2020

Lubrication

8

Section 9: MDPI Settings

May 2020

Section 9: MDPI Settings

• Manually rotate actuator to fully closed position

• Remove actuator cover

• Loosen indicator screw

• Adjust indicator to correct orientation

• Tighten indicator screw

• Replace cover

• Check indicator alignment

Installation, Operation and Maintenance Manual

VCIOM-15257-EN Rev. 1

9

MDPI Settings

Installation, Operation and Maintenance Manual

VCIOM-15257-EN Rev. 1

Section 10: Maintenance and Storage

Section 10: Maintenance and Storage

At least once a year a check should be made of your EIM HQ Series Actuator.

• Disconnect all power to actuator.

• Open electrical enclosure. Inspect and tighten all electrical connections.

• Visually inspect for any electrical or mechanical damage. Replace worn or

damaged components.

• Check lubrication consistency and levels. Fill or replace if required.

Actuators must be stored in a clean, cool and dry area. The unit shall be stored with the

cover installed and the conduit openings sealed. Storage must be off the oor, covered

with a sealed dust protector.

May 2020

Maintenance and Storage

10

Section 11: Troubleshooting

May 2020

Installation, Operation and Maintenance Manual

Section 11: Troubleshooting

The following instructions are offered for the most common difculties encounter during

installation and start-up.

Table 1.

SYMPTOM PROBABLE CAUSE CORRECTIVE ACTION

Open in control circuit

Motor will not run

No power available

to actuator

Manual override

nut hard to turn

Valve only opens

or closes partially

with motor

Manual override

nut will not

operate valve

Motor runs but will

not operate valve

Insulation resistance breakdown

in motor

Tripped circuit breaker Reset circuit breaker

Valve stem improperly lubricated Lubricate with grease

Actuator lubrication has broken down

Valve packing gland too tight

Jammed valve Refer to valve maintenance

Limit switch improperly set Check setting and reset if necessary

Stripped gearing Replace as necessary

Broken handwheel shaft Replace as necessary

Broken valve stem Repair or replace as necessary

Stripped gearing Replace as necessary

VCIOM-15257-EN Rev. 1

Refer to appropriate wiring diagram

and check for continuity

Perform Megger Test

Clean out old grease and replace

with recommended lubricant

Loosen packing gland nuts as

necessary

11

Troubleshooting

Installation, Operation and Maintenance Manual

VCIOM-15257-EN Rev. 1

Section 12: Product Features and Specications

Section 12: Product Features

and Specications

Enclosure Rated Weatherproof IP67

Enclosure High grade aluminium alloy, corrosion coated

Power Supply 110/220 V AC, 1 PH, 50/60 Hz

Motor Reversible Motor

Limit Switches 4 x open/close SPDT, 250VAC 3 A rating

Stall Protection Built-in thermal protection

Indicator MDPI (Mechanical Dial Position Indicator)

Manual Override Manual Override Nut

Space Heater 2 W anti-condensation

May 2020

Conduit Entries (2) x PG13.5

Lubrication Grease moly EP

Ambient Temperatur -20 °C – +70 °C

External Coating Dry powder polyester

Product Features and Specications

12

World Area Conguration Centers (WACC) offer sales support, service, inventory and commissioning to our global customers.

Choose the WACC or sales ofce nearest you:

NORTH & SOUTH AMERICA

19200 Northwest Freeway

Houston TX 77065

USA

T +1 281 477 4100

Av. Hollingsworth

325 Iporanga Sorocaba

SP 18087-105

Brazil

MIDDLE EAST & AFRICA

P. O. Box 17033

Jebel Ali Free Zone

Dubai

T +971 4 811 8100

P. O. Box 10305

Jubail 31961

Saudi Arabia

T +966 3 340 8650

T +55 15 3413 8888

24 Angus Crescent

ASIA PACIFIC

Longmeadow Business Estate East

P.O. Box 6908 Greenstone

No. 9 Gul Road

#01-02 Singapore 629361

T +65 6777 8211

No. 1 Lai Yuan Road

1616 Modderfontein Extension 5

South Africa

T +27 11 451 3700

EUROPE

Wuqing Development Area

Tianjin 301700

P. R. China

T +86 22 8212 3300

Holland Fasor 6

Székesfehérvár 8000

Hungary

T +36 22 53 09 50

Strada Biffi 165

29017 Fiorenzuola d’Arda (PC)

Italy

T +39 0523 944 411

For complete list of sales and manufacturing sites, please visit

www.emerson.com/actuationtechnologieslocations or contact us at

info.actuationtechnologies@emerson.com

www.emerson.com/eim

VCIOM-15257-EN ©2020 Emerson. All rights reserved.

The Emerson logo is a trademark and service mark of Emerson Electric Co.

TM

EIM

is a mark of one of the Emerson family of companies.

All other marks are property of their respective owners.

The contents of this publication are presented for informational purposes

only, and while every effort has been made to ensure their accuracy,

they are not to be construed as warranties or guarantees, express or

implied, regarding the products or services described herein or their use

or applicability. All sales are governed by our terms and conditions, which

are available upon request. We reserve the right to modify or improve the

designs or specifications of such products at any time without notice.

Loading...

Loading...