Page 1

Instruction Manual

HAS60E-IM-HW

06/2007

Instruction Manual

Chemiluminescence Detector

CLD Analyzer Module (combined with NGA 2000 Platform,

ML T, CA T 200 or TFID Analyzer)

st

Edition 06/2007

1

www.EmersonProcess.com

Page 2

CLD Chemiluminescence Detector Instruction Manual

HAS60E-IM-HW

06/2007

ESSENTIAL INSTRUCTIONS

READ THIS P AGE BEFORE PROCEEDING!

Emerson Process Management (Rosemount Analytical) designs, manufactures and test s

its products to meet many national and international standards. Because these instruments

are sophisticated technical products, you MUST properly install, use, and maintain

them to ensure they continue to operate within their normal specifications. The following

instructions MUST be adhered to and integrated into your safety program when installing,

using and maintaining Emerson Process Management (Rosemount Analytical) products.

Failure to follow the proper instructions may cause any one of the following situations to

occur: Loss of life; personal injury; property damage; damage to this instrument; and warranty

invalidation.

• Read all instructions prior to installing, operating, and servicing the product.

• If you do not understand any of the instructions, contact your Emerson Process

Management (Rosemount Analytical) representative for clarification.

• Follow all warnings, cautions, and instructions marked on and supplied with the product.

• Inform and educate your personnel in the proper installation, operation, and

maintenance of the product.

• Install your equipment as specified in the Installation Instructions of the appropriate

Instruction Manual and per applicable local and national codes. Connect all products

to the proper electrical and pressure sources.

• T o ensure proper performance, use qualified personnel to install, operate, update, program,

and maintain the product.

• When replacement parts are required, ensure that qualified people use replacement parts

specified by Emerson Process Management (Rosemount Analytical). Unauthorized parts

and procedures can affect the product’s performance, place the safe operation of your

process at risk, and VOID YOUR W ARRANTY. Look-alike substitutions may result in fire,

electrical hazards, or improper operation.

• Ensure that all equipment doors are closed and protective covers are in place, except

when maintenance is being performed by qualified persons, to prevent electrical

shock and personal injury.

The information contained in this document is subject to change without notice. Misprints

reserved.

1st Edition 06/2007

© 2007 by Emerson Process Management

Emerson Process Management

GmbH & Co. OHG

Industriestrasse 1

D-63594 Hasselroth

Germany

T +49 (0) 6055 884-0

F +49 (0) 6055 884-209

Internet: www.EmersonProcess.com

Page 3

Instruction Manual

HAS60E-IM-HW

June 2007

NGA 2000 CLD

Table of Contents

PREFACE ...........................................................................................................................P - 1

DEFINITIONS .....................................................................................................................P - 1

SAFETY INSTRUCTIONS WIRING AND INSTALLATION OF THIS APPARATUS.......P - 2

OPERATING AND MAINTAINING THIS APPARATUS .......................................................P - 3

SAFETY SUMMARY ........................................................................................................... P - 4

AUTHORIZED PERSONNEL ..............................................................................................P - 4

GASES AND GAS CONDITIONING (SAMPLE HANDLING) .............................................. P - 7

POWER SUPPLY................................................................................................................ P - 7

ELECTROSTATIC DISCHARGE ......................................................................................... P - 8

GENERAL PRECAUTIONS FOR HANDLING AND STORING HIGH PRESSURE GAS

CYLINDERS ...................................................................................................................P - 9

DOCUMENTATION ...........................................................................................................P - 10

COMPLIANCES ................................................................................................................P - 10

SUITABILITY TESTS ........................................................................................................P - 10

GLOSSARY OF TERMS ................................................................................................... P - 11

ANALYZER SYSTEM ARCHITECTURE ........................................................................... A - 1

SECTION 1 DESCRIPTION AND SPECIFICATIONS ........................................................ 1 - 1

1-1 OVERVIEW ................................................................................................................ 1 - 1

1-2 TYPICAL APPLICATIONS .......................................................................................... 1 - 1

1-3 THEORY OF TECHNOLOGY ..................................................................................... 1 - 1

1-4 FEATURES ................................................................................................................. 1 - 1

1-5 SPECIFICATIONS ...................................................................................................... 1 - 5

a. General ................................................................................................................... 1 - 5

b. Physical .................................................................................................................. 1 - 5

c. Sample ................................................................................................................... 1 - 5

d. Gas Connections .................................................................................................... 1 - 5

ITable of ContentsEmerson Process Management GmbH & Co.OHG

Page 4

Instruction Manual

HAS60E-IM-HW

NGA 2000 CLD

June 2007

SECTION 2 INSTALLATION .............................................................................................. 2 - 1

2-1 UNPACKING ............................................................................................................... 2 - 1

2-2 ASSEMBLY................................................................................................................. 2 - 1

2-3 LOCATION .................................................................................................................. 2 - 2

2-4 GASES ....................................................................................................................... 2 - 2

a. Gas Conditioning (Sample Handling) ..................................................................... 2 - 2

b. Connections............................................................................................................ 2 - 3

c. Specifications ......................................................................................................... 2 - 3

Zero Gas ..............................................................................................................................2 - 3

Span Gas .............................................................................................................................2 - 3

Ozonator Source Gas .......................................................................................................... 2 - 3

Sample Gas Pressure ..........................................................................................................2 - 3

Bypass Sample Gas Flow ....................................................................................................2 - 3

Leak Test ..............................................................................................................................2 - 4

Contaminants .......................................................................................................................2 - 4

2-5 ELECTRICAL CONNECTIONS .................................................................................. 2 - 4

SECTION 3 OPERATION .................................................................................................. 3 - 1

3-1 OVERVIEW ................................................................................................................ 3 - 1

3-2 STARTUP & INITIALIZATION ..................................................................................... 3 - 1

3-3 PREPARATIONS ........................................................................................................ 3 - 2

3-4 CALIBRATION PROCEDURE .................................................................................... 3 - 4

a. Calibration Setup .................................................................................................... 3 - 4

Calibration Gas List ..............................................................................................................3 - 4

Calibration Parameters ........................................................................................................ 3 - 5

b. Flow Balance Adjustment: ...................................................................................... 3 - 6

Zero Adjustment ...................................................................................................................3 - 6

Span Adjustment .................................................................................................................. 3 - 6

3-5 SYSTEM & NETWORK I/O MODULE CONTROLS (SETUP) - SYSTEM SIO .......... 3 - 8

a. Analog Output Setup .............................................................................................. 3 - 8

Output number: .................................................................................................................... 3 - 8

Choose signal source module... ........................................................................................... 3 - 8

Choose Signal... ...................................................................................................................3 - 8

Signal value for 0% (100%) output: ..................................................................................... 3 - 9

Output current: ..................................................................................................................... 3 - 9

Hold output during calibration: ............................................................................................. 3 - 9

b. Serial interface Setup ........................................................................................... 3 - 11

II Table of Contents Emerson Process Management GmbH & Co.OHG

Page 5

Instruction Manual

HAS60E-IM-HW

June 2007

NGA 2000 CLD

c. Relay Outputs Setup ............................................................................................ 3 - 12

Output number: .................................................................................................................. 3 - 12

Invert signal: .......................................................................................................................3 - 12

Choose source module... ...................................................................................................3 - 12

Choose signal... .................................................................................................................3 - 12

3-6 CONVERTER TEMPERATURE ADJUSTMENT ...................................................... 3 - 13

3-7 MEASUREMENT OF CONVERTER EFFICIENCY .................................................. 3 - 14

a. Test Setup for Measurement of Conversion Efficiency ......................................... 3 - 14

b. Test Procedure ..................................................................................................... 3 - 14

c. Subnormal Conversion Efficiency ......................................................................... 3 - 15

d. Replacement of Converter .................................................................................... 3 - 16

e. Capillaries ............................................................................................................. 3 - 16

f. TEA Scrubber ....................................................................................................... 3 - 16

SECTION 4 MAINTENANCE AND SERVICE .................................................................... 4 - 1

4-1 OVERVIEW ................................................................................................................ 4 - 1

4-2 FUSES ........................................................................................................................4 - 2

4-3 FANS .......................................................................................................................... 4 - 2

4-4 OZONATOR ................................................................................................................ 4 - 2

4-5 PRINTED CIRCUIT BOARDS .................................................................................... 4 - 2

4-6 CONVERTER ............................................................................................................. 4 - 4

4-7 DETECTOR DISASSEMBLY ...................................................................................... 4 - 5

a. Reaction Chamber Removal .................................................................................. 4 - 5

b. Reaction Chamber Installation ............................................................................... 4 - 5

c. Photodiode Removal .............................................................................................. 4 - 5

d. Photodiode Installation ........................................................................................... 4 - 5

4-8 LEAKAGE TEST ......................................................................................................... 4 - 7

a) Required Tools........................................................................................................ 4 - 7

b) Procedure ............................................................................................................... 4 - 7

SECTION 5 TROUBLESHOOTING ................................................................................... 5 - 1

5-1 OVERVIEW ................................................................................................................ 5 - 1

IIITable of ContentsEmerson Process Management GmbH & Co.OHG

Page 6

Instruction Manual

HAS60E-IM-HW

NGA 2000 CLD

June 2007

SECTION 6 REPLACEMENT PARTS ............................................................................... 6 - 1

6-1 MATRIX ...................................................................................................................... 6 - 1

6-2 REPLACEMENT PARTS ............................................................................................ 6 - 2

SECTION 7 RETURN OF MATERIAL ............................................................................... 7 - 1

7-1 RETURN OF MATERIAL ............................................................................................ 7 - 1

7-2 CUSTOMER SERVICE............................................................................................... 7 - 1

7-3 TRAINING................................................................................................................... 7 - 1

LIST OF FIGURES AND TABLES ...................................................................................... L - 1

1 LIST OF FIGURES ..................................................................................................... L - 1

2 LIST OF TABLES ....................................................................................................... L - 2

IV Table of Contents Emerson Process Management GmbH & Co.OHG

Page 7

Instruction Manual

HAS60E-IM-HW

June 2007

NGA 2000 CLD

PREFACE

The purpose of this manual is to provide information concerning the components, functions, installation and

maintenance of the NGA 2000 CLD and the System Accessories of the NGA 2000 System.

Some sections may describe equipment not used in your configuration. The user should become thoroughly

familiar with the operation of this module before operating it. Read this instruction manual completely.

DEFINITIONS

The following definitions apply to WARNINGS, CAUTIONS and NOTES found throughout this publication.

WARNING

Highlights on operation or maintenance procedure, practice, condition, statement, etc.

If not strictly observed, could result in injury, death, or long-term health hazards of personnel.

CAUTION

Highlights on operation or maintenance procedure, practice, condition, statement, etc.

If not strictly observed, could result in damage to or destruction of equipment, or loss of effectiveness.

NOTE

Highlights an essential operating procedure, condition or statement.

P - 1PrefaceEmerson Process Management GmbH & Co.OHG

Page 8

Instruction Manual

HAS60E-IM-HW

NGA 2000 CLD

June 2007

IMPORTANT

SAFETY INSTRUCTIONS

WIRING AND INSTALLATION OF THIS APPARATUS

The following safety instructions apply specifically to all EU member states. They should be strictly adhered to

in order to assure compliance with the Low Voltage Directive. Non-EU states should also comply with the

following unless superseded by local or National Standards.

1. Adequate earth connections should be made to all earthing points, internal and external, where provided.

2. After installation or troubleshooting, all safety covers and safety grounds must be replaced. The integrity

of all earth terminals must be maintained at all times.

3. To ensure safe operation of this equipment, connection to the mains supply should only be made through

a circuit breaker which will disconnect

breaker may also include a mechanically operated isolating switch. Circuit breakers or switches must

comply with a recognized standard such as IEC947. All wiring must conform with any local standards.

all circuits carrying conductors during a fault situation. The circuit

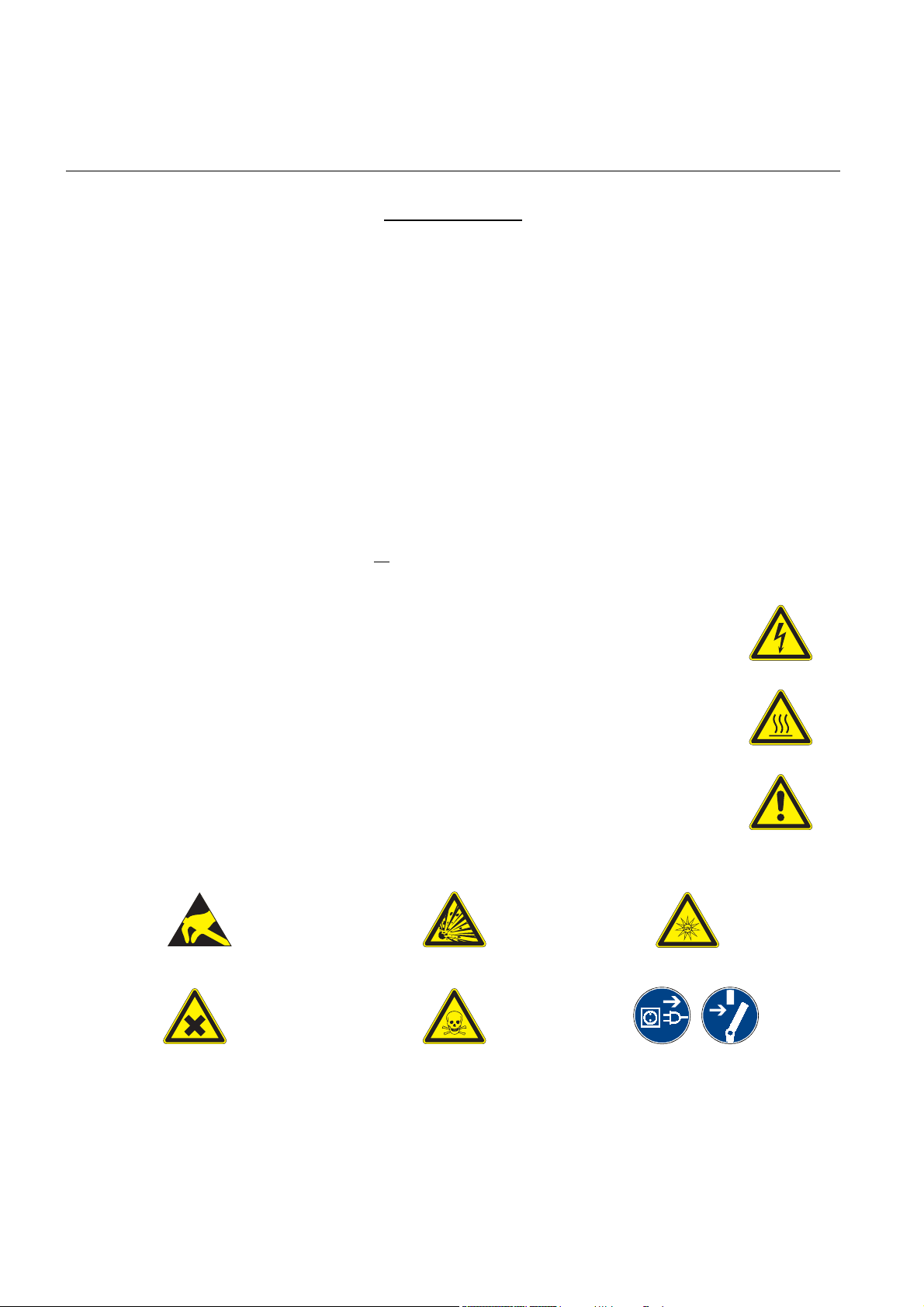

4. Where equipment or covers are marked with the symbol to the right, hazardous voltages

are likely to be present beneath. These covers should only be removed when power is

removed from the equipment — and then by trained service personnel only.

5. Where equipment or covers are marked with the symbol to the right, there is a danger

from hot surfaces beneath. These covers should only be removed by trained service

personnel when power is removed from the equipment. Certain surfaces may remain

hot to the touch.

6. Where equipment or covers are marked with the symbol to the right, refer to the Instruction Manual for instructions.

7. Further graphical symbols used in this product:

Elektrostatic discharge (ESD)

Harmful (to Health)!

Explosion Hazard!

Toxic!

UV Source!

Disconnect from Mains!

All graphical symbols used in this product are from one or more of the following standards:

EN61010-1, IEC417, and ISO3864.

P - 2 Preface Emerson Process Management GmbH & Co.OHG

Page 9

Instruction Manual

HAS60E-IM-HW

June 2007

NGA 2000 CLD

OPERATING AND MAINTAINING THIS APPARATUS

This instrument has left the factory in compliance with all applicable safety regulations.

To maintain this operating condition, the user must strictly follow the instructions and consider the warnings in

this manual or provided on the instrument.

Before switching on the instrument, verify that the electrical supply voltage matches the instrument´s operating voltage as set in the factory.

Any interruption in the instrument´s ground line, whether inside or outside the instrument, or removal or

interruption of its ground line connection, could result in hazardous operating conditions. Intentionally interrupting the instrument´s protective ground is strictly prohibited.

Opening cover panels could expose voltage-carrying components. Connectors may also be under voltage.

The instrument must be disconnected from all electrical supplies before attempting any calibrations, maintenance operations, repairs or component replacements requiring opening of the instrument. Any calibrations,

maintenance operations, or repairs that need the instrument to be opened while connected to electrical

supplies should be subject to qualified technicians familiar with the hazards involved only!

Use only fuses of the correct type and current ratings as replacements. Using repaired fuses and short

circuiting of fuse holders is prohibited.

Observe all applicable regulations when operating the instrument from an auto-transformer or variac.

Substances hazardous to health may emerge from the instrument‘s exhaust.

Please pay attention to the safety of your operation personnel. Protective measures must be taken, if required.

NOTE

Software compatibility is necessary for all NGA 2000 components in your system to work together.

The version of your Platform’s software must be equal to or greater than the version of any other

module(s) for successful compatibility.

You can locate the version of each NGA 2000 component as follows:

Platform Controller Board

Turn power ON. The display should show „Control Module V3. ...“. This is the software version.

Analyzer Module

See note on the name plate label located on the right side of the Analyzer Module case.

P - 3PrefaceEmerson Process Management GmbH & Co.OHG

Page 10

Instruction Manual

HAS60E-IM-HW

NGA 2000 CLD

June 2007

SAFETY SUMMARY

If this equipment is used in a manner not specified in these instructions, protective systems may be

impaired.

AUTHORIZED PERSONNEL

To avoid loss of life, personal injury and damage to this equipment and on-site property, do not

operate or service this instrument before reading and understanding this instruction manual and

receiving appropriate training. Save these instructions.

WARNING

ELECTRICAL SHOCK HAZARD !

Do not operate without covers secure. Do not open while energized. Installation and/or servicing

requires access to live parts which can cause death or serious injury.

Refer servicing to qualified personnel.

For safety and proper performace this instrument must be connected to a properly grounded threewire source of power.

WARNING

TOXIC AND OXIDIZING GAS

This module generates ozone which is toxic by inhalation and is a strong irritant to throat and

lungs. Ozone is also a strong oxidizing agent. Its presence is detected by a characteristic pungent

odor.

The module’s exhaust contains both ozone and nitrogen dioxide, both toxic by inhalation, and may

contain other constituents of the sample gas which may be toxic. Such gases include various

oxides of nitrogen, unburned hydrocarbons, carbon monoxide and other products of combustion

reactions. Carbon monoxide is highly toxic and can cause headache, nausea, loss of consciousness, and death.

Avoid inhalation of the ozone produced within the module, and avoid inhalation of the sample and

exhaust products transported within the module. Avoid inhalation of the combined exhaust products at the exhaust fitting.

Keep all tube fittings tight to avoid leaks. The user is responsible for leakage testing only at the inlet

and outlet fittings on the rear panel.

Connect rear exhaust outlet to outside vent with stainless steel or Teflon line. Check vent line and

connections for leakage.

P - 4 Preface Emerson Process Management GmbH & Co.OHG

Page 11

Instruction Manual

HAS60E-IM-HW

June 2007

NGA 2000 CLD

WARNING

OVERBALANCE HAZARD

This analyzer module may tip instrument over if it is pulled out too far and the Platform is not

properly supported.

CAUTION

Tampering with or unauthorized substitution of components may adversely affect the safety of this

instrument. Use only factory documented/approved components for repair.

Because of the danger of introducing additional hazards, do not perform any unauthorized modification to this instrument!

WARNING

POSSIBLE EXPLOSION HAZARD

This equipment is not designed and should not be used in the analysis of flammable samples.

Use of this equipment in this way could result in explosion or death.

WARNING

POSSIBLE EXPLOSION HAZARD

Ensure that all gas connections are made as labeled and described within this manual and leak

free. Improper gas connections may cause explosion, serious injury or death.

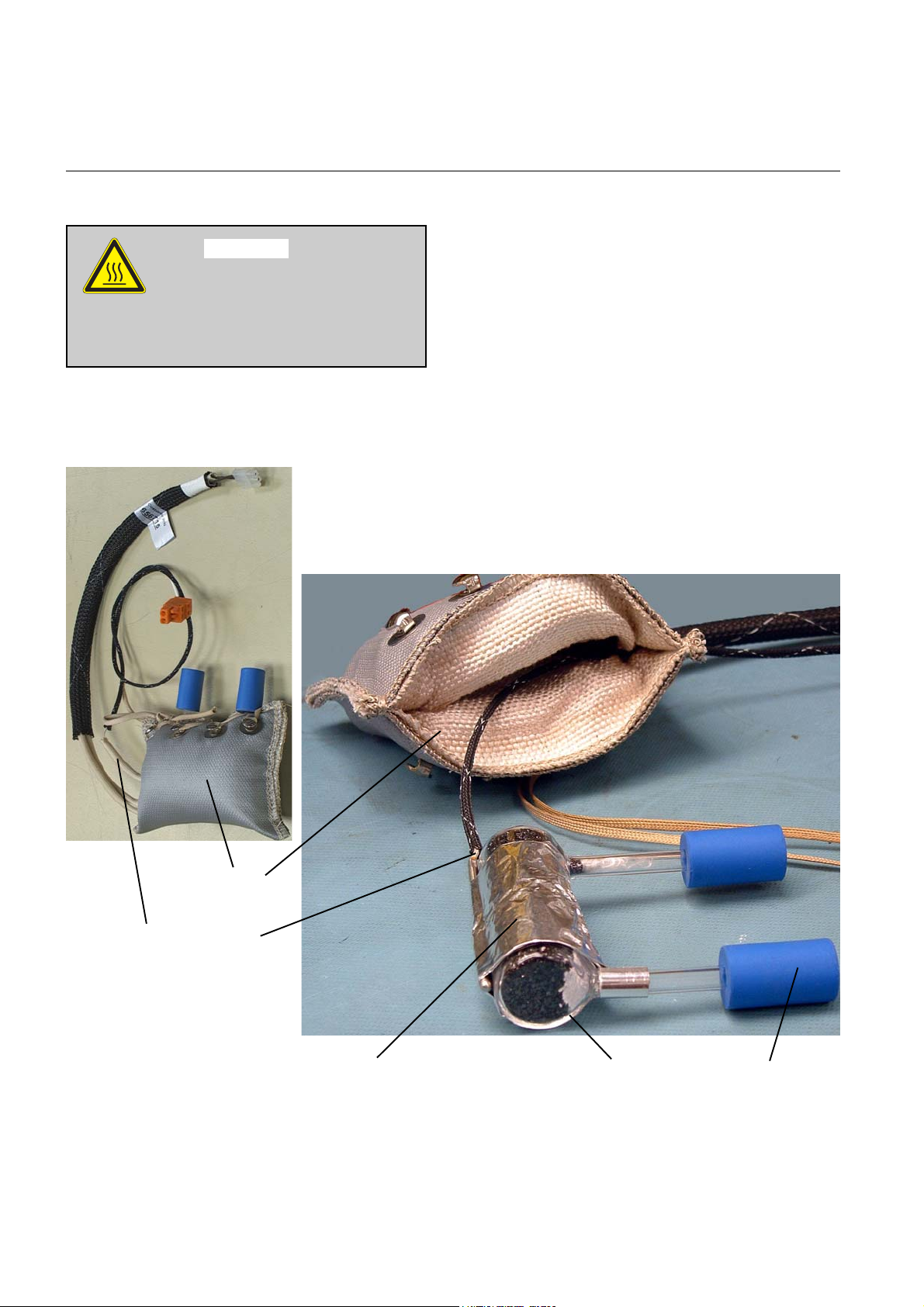

CAUTION

HIGH TEMPERATURES !

While working at thermostated components inside the analyzer modules hot components may be

accessible!

CAUTION

Do not interchange gas inlets and outlet! All gases must be conditioned before supplying!

When supplying corrosive gases ensure that gas path components are not affected!

Exhaust lines must be installed in a descending way, need to be pressureless, frost-protected

and in compliance with applicable legislative requirements!

P - 5PrefaceEmerson Process Management GmbH & Co.OHG

Page 12

NGA 2000 CLD

WARNING

Before opening gas paths they must be purged with ambient air or

neutral gas (N

or harmful to health sample gas components!

Ultraviolet light from the ozone generator can cause permanent eye damage !

Do not look directly at the ultraviolet source !

Use of ultraviolet filtering glases is recommended.

) to avoid hazards caused by toxic, flammable, explosive

2

WARNING

INTERNAL UV SOURCE !

Instruction Manual

HAS60E-IM-HW

June 2007

WARNING

TOXIC CHEMICAL HAZARD!

The optional UV lamp contains mercury. Lamp breakage could result in mercury exposure !

Mercury is highly toxic if absorbed through the skin or ingested, or if vapors are inhaled.

Handle lamp assembly with extreme care. If the lamp is broken, avoid skin contact and inhalation in

the area of the lamp or the mercury spill.

Immediately clean up and dispose of the mercury spill and lamp residue as follows:

• Wearing rubber gloves and goggles, collect all droplets of mercury by means of a suction

pump and aspirator bottle with a long capillary tube. (Alternately, a commercially available

mercury spill clean-up kit is recommended.)

• Carefully sweep any remaining mercury and lamp debris into a dust pan. Carefully transfer all

mercury, lamp residue and debris into a platic bottle which cab be tightly capped.

• Label and return to hazardous material reclamation center. Do not place in the trash, incinerate

or flush down the sewer.

• Cover any fine droplets of mercury in non-accessible crevices with calcium polysulfide and

sulfur dust.

P - 6 Preface Emerson Process Management GmbH & Co.OHG

Page 13

Instruction Manual

HAS60E-IM-HW

June 2007

NGA 2000 CLD

GASES AND GAS CONDITIONING (SAMPLE HANDLING)

WARNING

Take care of the safety instructions applicable for the gases

(sample gases, test gases and ozonator air)!

CAUTION

PRESSURIZED GAS

This module requires periodic use of pressurized gas. See General Precautions for Handling and

Storing High Pressure Gas Cylindes, page P-6.

CAUTION

EXTERNALLY RESTRICT SAMPLE FLOW TO LESS THAN 2,200 cc/min.

No restrictor is provided in the inlet of this module. For those users who cannot externally limit

sample flow, contact your local service or sales office.

POWER SUPPLY

CAUTION

Verify the power voltage at site of installation corresponds to the analyzer

module´s rated voltage as given on the nameplate label!

Verify the safety instruction given by power supply unit manufacturer !

CAUTION

The mains socket has to be nearby the power supply unit and easily accessible!

Disconnecting from power requires unplugging the power connector!

To comply with the CE mark requirements use only power supply units of type

SL10 or equivalent units. Equivalent units must provide SELV output voltages!

Verify proper polarity when connecting DC 24 V operated analyzer modules !

P - 7PrefaceEmerson Process Management GmbH & Co.OHG

Page 14

Instruction Manual

HAS60E-IM-HW

NGA 2000 CLD

June 2007

ELECTROSTATIC DISCHARGE

CAUTION

The electronic parts of the Analyzer Module can be irreparably damaged if

exposed to electrostatic discharge (ESD).

The instrument is ESD protected when the covers have been secured and safety

precautions observed. When the housing is open, the internal components are

not ESD protected anymore.

Although the electronic parts are reasonable safe to handle, you should be aware of the following considerations:

Best ESD example is when you walked across a carpet and then touched an electrical grounded metal

doorknob. The tiny spark which has jumped is the result of electrostatic discharge (ESD).

You prevent ESD by doing the following:

Remove the charge from your body before opening the housing and maintain during work with opened

housing, that no electrostatic charge can be built up.

Ideally you are opening the housing and working at an ESD - protecting workstation. Here you can wear a

wrist trap.

However, if you do not have such a workstation, be sure to do the following procedure exactly:

Discharge the electric charge from your body. Do this by touching a device that is grounded electrically

(any device that has a three - prong plug is grounded electrically when it is plugged into a power receptacle).

This should be done several times during the operation with opened housing (especially after leaving the

service site because the movement on a low conducting floors or in the air might cause additional ESDs).

P - 8 Preface Emerson Process Management GmbH & Co.OHG

Page 15

Instruction Manual

HAS60E-IM-HW

June 2007

NGA 2000 CLD

GENERAL PRECAUTIONS FOR HANDLING AND STORING

HIGH PRESSURE GAS CYLINDERS

Edited from selected paragraphs of the Compressed Gas Association´s „Handbook of Compressed

Gases“ published in 1981.

Compressed Gas Association

1235 Jefferson Davis Highway

Arlington, Virginia 22202

Used by Permission

1. Never drop cylinders or permit them to strike each other violently.

2. Cylinders may be stored in the open, but in such cases, should be protected against extremes of weather

and, to prevent rusting, from the dampness of the ground. Cylinders should be stored in the shade when

located in areas where extreme temperatures are prevalent.

3. The valve protection cap should be left on each cylinder until it has been secured against a wall or bench,

or placed in a cylinder stand, and is ready to be used.

4. Avoid dragging, rolling, or sliding cylinders, even for a short distance; they should be moved by using a

suitable hand-truck.

5. Never tamper with safety devices in valves or cylinders.

6. Do not store full and empty cylinders together. Serious suckback can occur when an empty cylinder is

attached to a pressurized system.

7. No part of cylinder should be subjected to a temperature higher than 52 °C (125 °F). A flame should never

be permitted to come in contact with any part of a compressed gas cylinder.

8. Do not place cylinders where they may become part of an electric circuit. When electric arc welding,

precautions must be taken to prevent striking an arc against the cylinder.

P - 9PrefaceEmerson Process Management GmbH & Co.OHG

Page 16

Instruction Manual

9

6

HAS60E-IM-HW

NGA 2000 CLD

June 2007

DOCUMENTATION

The following CLD instruction materials are available. Contact Customer Service Center or the local representative to order.

HAS60E-IM-HW Instruction Manual NGA 2000 CLD (this document)

HAS60E-IM-SW39 Software Manual NGA 2000 CLD

90002496 Instruction Manual NGA 2000 Platform

COMPLIANCES

This product may carry approvals from several certifying agencies, including the Canadian Standards Association (which

is also an OSHA accredited, Nationally Recognized Testing Laboratory), for use in non-hazardous, indoor locations.

Emerson Process Management has satisfied all obligations from the European Legislation to harmonize the product

requirements in Europe.

This product complies with the standard level of NAMUR EMC. Recommendation (May 1993).

NAMUR

This product satisfies all obligations of all relevant standards of the EMC framework in Australia and New Zealand.

N

SUITABILITY TESTS

P - 10 Preface Emerson Process Management GmbH & Co.OHG

Page 17

Instruction Manual

HAS60E-IM-HW

June 2007

NGA 2000 CLD

GLOSSARY OF TERMS

Analyzer Module

The module that contains all sensor/detector components for development of a Primary Variable signal;

includes all signal conditioning and temperature control circuitry.

Backplane

The interconnect circuit board which the Controller Board, Power Supply, Analyzer Module power and network

cables, I/O Modules and Expansion Modules plug into.

Control Module

The Operator Interface plus the Controller Board.

Controller Board

The computer board that serves as the Network Manager and operate the Display and Keypad.

Distribution Assembly

The Backplane and the card cages that hold I/O and Expansion Modules.

I/O Module

A circuit board that plugs into the Backplane from the rear of the Platform. Has a connector terminal for

communication with external data acquisition devices and provides an input/output function.

Power Supply

Any of a variety of components that provides conditioned power to other NGA 2000 components, from the

Power Supply Board that plugs into the front of the Backplane in a stand-alone instrument to several larger

ones that can power larger collections of modules and components.

P - 11PrefaceEmerson Process Management GmbH & Co.OHG

Page 18

Instruction Manual

HAS60E-IM-HW

NGA 2000 CLD

June 2007

Primary Variable

The measured species concentration value from an Analyzer Module.

Secondary Variable

Data placed on the network by a module regarding current status, e.g., sample flow, temperature and pressure.

Softkeys

The five function softkeys located below the front panel display; they assume the function displayed directly

above each on the display, a function dictated by software.

System

Any collection of Analyzer Module(s), Platform(s) and I/O Module(s).

P - 12 Preface Emerson Process Management GmbH & Co.OHG

Page 19

Instruction Manual

HAS60E-IM-HW

June 2007

NGA 2000 CLD

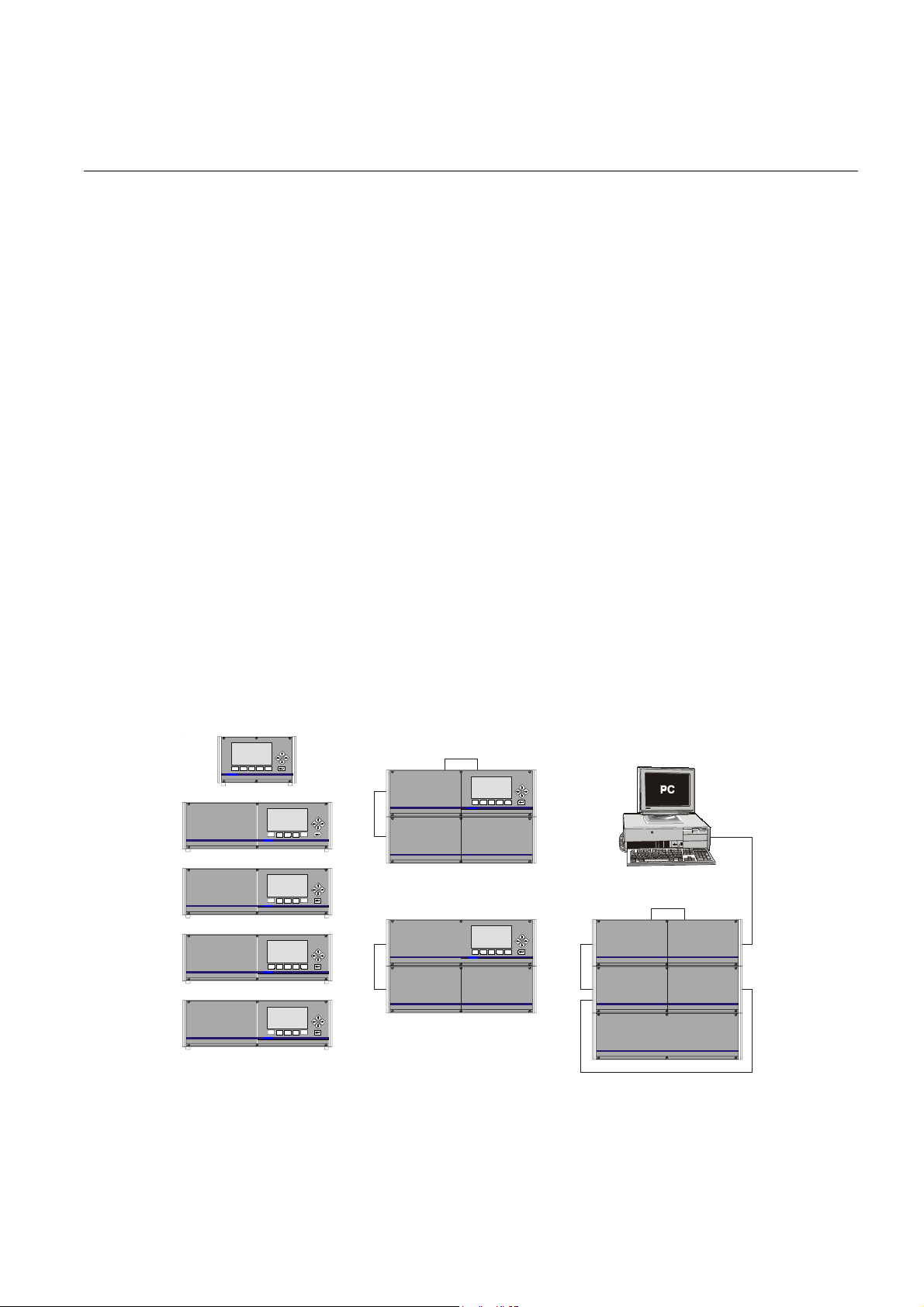

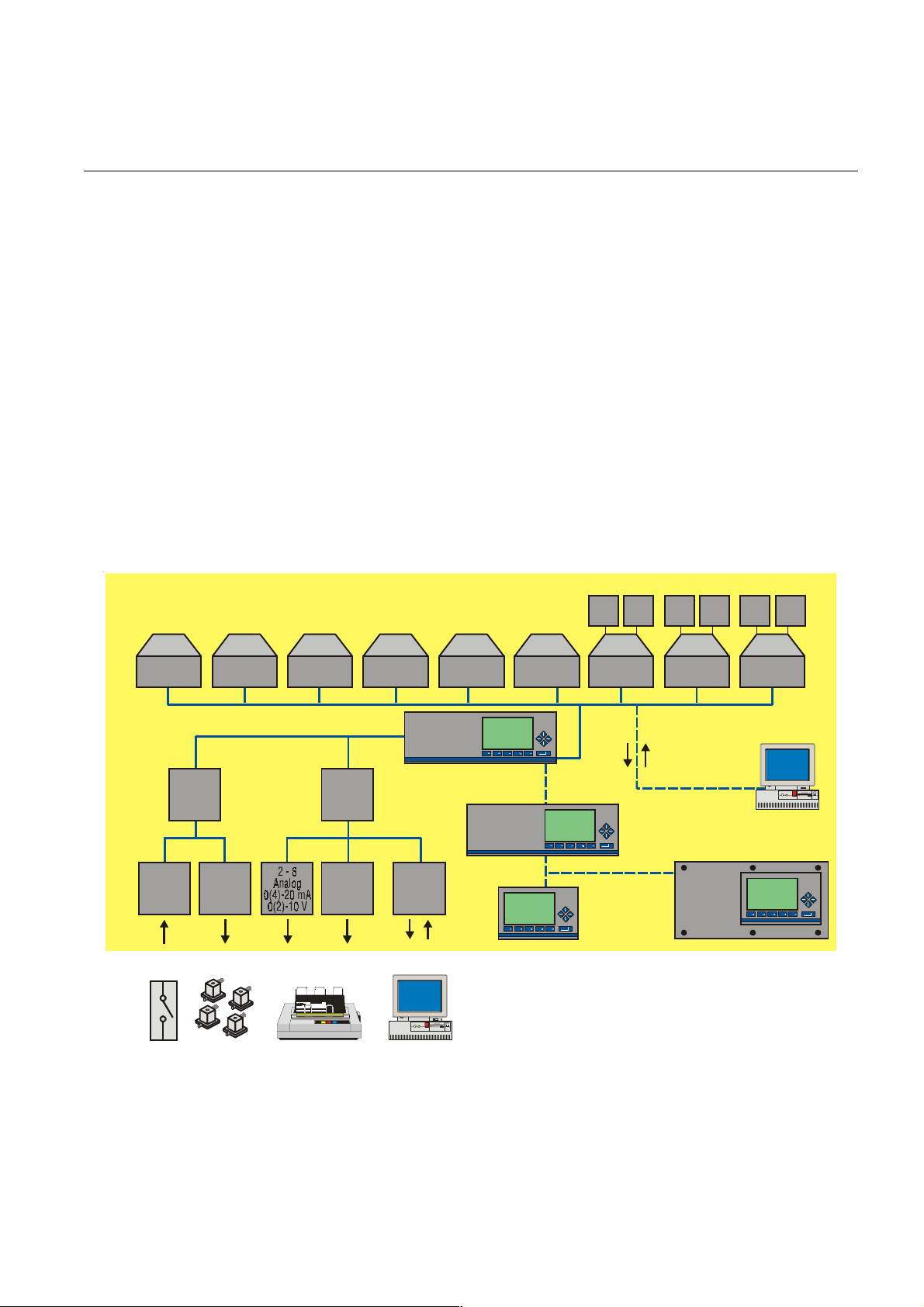

ANALYZER SYSTEM ARCHITECTURE

The NGA 2000 CLD is available as a "stand-alone analyzer" or as a "blind" Analyzer Module (AM). The CLD

analyzer module can be part of the stand-alone analyzer

or a component of an analyzers system (Fig. A-1).

The NGA 2000 system made it possible, to configure

the CLD as a flexible "stand-alone analyzer" consisting

of a CLD "Analyzer Module", a Platform (complete with

front panel display/operator interface), and input/output

(I/O) modules.

The “analyzer module” is a “blind” analysis unit but retains all the advanced design features. The AM variant

is designed for integration as part of a NGA 2000 analysis system or special customer developed networks.

The platform/MLT´s front panel can act as operator interface for a stand-alone analyzer or as the a central

interface for multiple Analyzer Modules. In multi analyzer systems, this feature eliminates duplication of the

display/operator interface. In addition to the obvious operational benefits there are significant cost and system

packaging advantages not possible with conventional

analyser configurations.

This flexible network communication architecture is

shown in the schematic of Fig. A-2.

½ 19" MLT

Analyzer

ROSEMOUNT NGA 2000NGA 2000

Platform with MLT AM

or

19" MLT Analyzer

CLD

FID

PMD

NGA Network

½ 19" MLT

Analyzer

ROSEMOUNT NGA 2000NGA 2000

MLT MLT

ROSEMOUNT NGA 2000NGA 2000

CLD FID

NGA Network

ROSEMOUNT NGA 2000NGA 2000

ROSEMOUNT NGA 2000NGA 2000

ROSEMOUNT NGA 2000NGA 2000

ROSEMOUNT NGA 2000NGA 2000

NGA NetworkNGA Network

Platform with MLT AM

19" MLT Analyzer

CLD

FID PS

or

CLD PS

Figure A-1: From separate analyzers to analyzer system

NGA Network

NGA Network

PS

A - 1Analyzer System ArchitectureEmerson Process Management GmbH & Co.OHG

Page 20

NGA 2000 CLD

Instruction Manual

HAS60E-IM-HW

June 2007

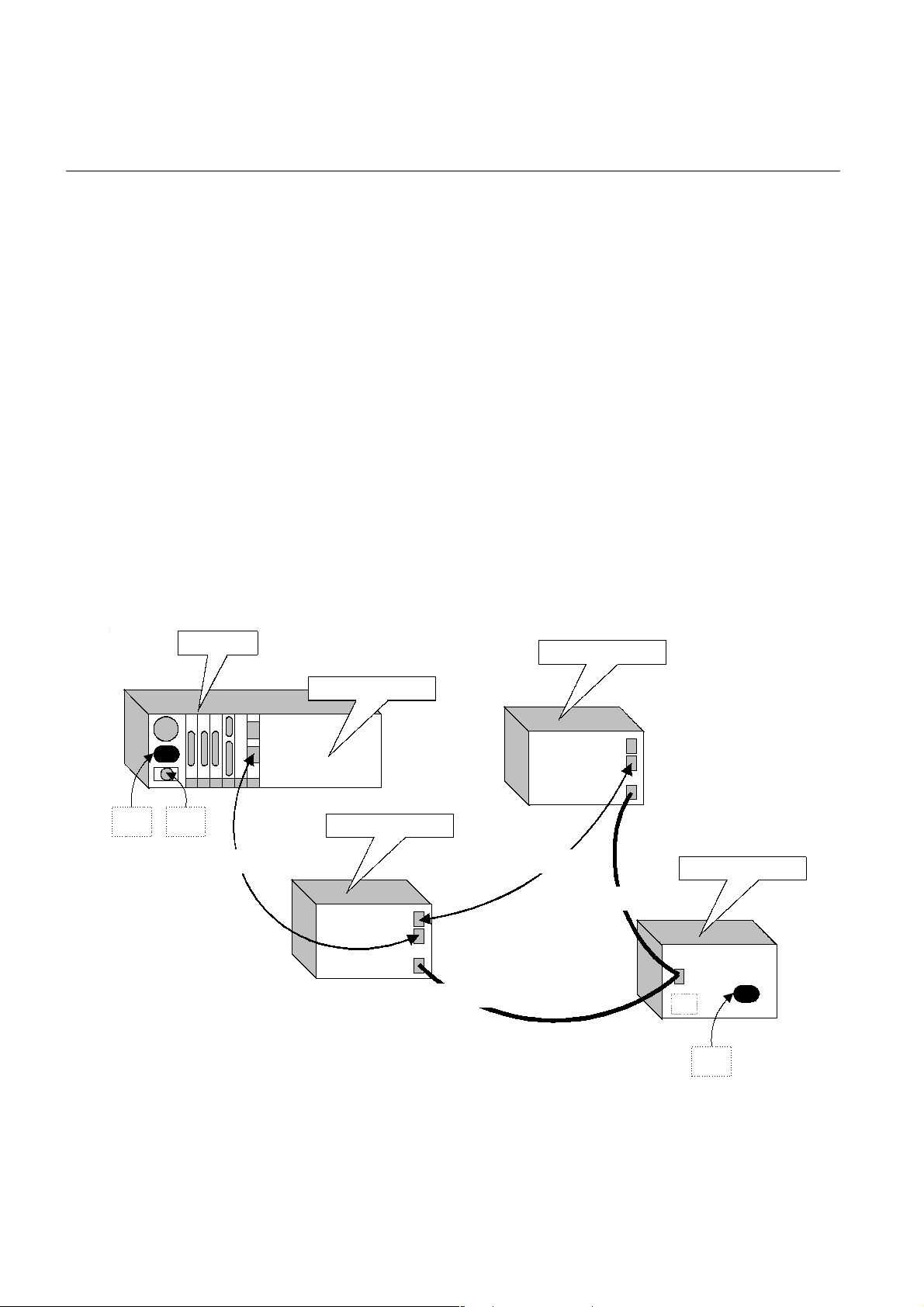

The modular configurable bi-directional network offers

the following options:

❏ Stand-alone analyzers (Single devices)

• analyzer modules in a platform including

optional inputs and outputs (SIO/DIO).

Platform

❏ Simple interconnection of analyzer modules to an

analyzer system based on one of the three structures - see below.

These structures can be distinguished by acting

of the host

• with platform as host including system inputs

and outputs (SIO/DIO)

• with MLT/TFID/CAT 200 analyzer as controller

including system inputs and outputs (SIO/DIO)

• with customer owned specific control units

(not described in this manual, consult factory)

For combination possibilities of NGA 2000 I/O´s see table

A-1.

Analyzer Module

AC DC

Network Cable

Analyzer Module

Analyzer Module

Network Cable

24VDC Cable

Figure A-2: Example of NGA cabling

Power supply

24VDC Cable

DC

AC

A - 2 Analyzer System Architecture Emerson Process Management GmbH & Co.OHG

Page 21

Instruction Manual

HAS60E-IM-HW

June 2007

NGA 2000 CLD

Based on a platform, MLT or TFID analyzer the schematic on Figure A-3 illustrates the simplicity of a networked system which incorporates AM’s, such as Chemiluminesence Detectors, MLT's (NDIR/UV/VIS plus Oxygen or TCD) and Flame Ionisation Detectors.

The system I/O modules (SIO, DIO) of the platform (or

MLT/TFID analyzer) support all integrated analyzer modules with analog, digital and serial interfaces as well as

relay outputs.

Analyzer Modules (AMs)

Other system functionality includes links to associated

sample handling (PLC) and Data Acquisition Systems

such as WinControl.

Local I/O are existing to MLT, TFID and CAT 200 analyzers only and support the corresponding analyzer module only.

Local I/Os via Internal System Bus

DIO SIO

DIO SIO

DIO SIO

O

2

PMD

DIO SIO

8

Digital

Inputs

HC

HFID

System I/Os via Internal System Bus

24

Digital

Outputs

Solenoid

Valves

NO

WCLD

Printer

or PLC

x

3

Relay

Outputs

NO/NO

CLD

RS 232 /

x

19" MLT 3/4

Analyzer

RS 485

Personal

Computer

ppm O

2

TO2

Alternatively

19" Platform/

TFID Analyzer

Alternatively

HC

FID

½ 19" MLT

Analyzer

HC

TFID

NGA

Network

NGA 2000ROSEMOUNT

NGA 2000ROSEMOUNT

NGA 2000ROSEMOUNT

CO/NO/SO /

EO - MLT

2

Alternatively to Platform

or MLT/TFID Analyzer

MLT 2

Analyzer

PO

2

2

MLT

Field PC

Workstation

NGA 2000ROSEMOUNT

Figure A-3: Example/Possibilities of NGA Analyzer Systems

A - 3Analyzer System ArchitectureEmerson Process Management GmbH & Co.OHG

Page 22

NGA 2000 CLD

System unit SIO/DIO-Configuration

Instruction Manual

HAS60E-IM-HW

June 2007

CLD/FID/HFID analyzer module (AM):

• without front panel,

i.e. without control unit (host)

• can be combined with

a platform,

a MLT analyzer,

a TFID analyzer;

a CAT 200 analyzer or

a customer developed control unit

Platform (Control Module Software):

• Control unit with front panel

• Without measurement channels

CLD analyzer

• CLD analyzer module into a platform with

front panel

• CLD analyzer module combined with

MLT/TFID/CAT 200 analyzer

• No local CLD/FID/HFID I/O’s

• 1 SIO and up to 4 DIO's (or 5 DIO's)

can be installed in the platform

(CM I/O’s)

• SIO and DIO’s can be configured

for all AM channels connected to the

platform

• 1 SIO and 4 DIO’s (or 5 DIO’s) can be

installed in the platform

• 1 SIO and 1 DIO (or 2 DIO’s) can be

installed in the MLT/TFID/CAT 200

analyzer (CM I/O)

• SIO and DIO can be configured

for all AM’s connected to the

MLT/TFID/CAT 200 analyzer

Table A-1: Possibilities of NGA 2000 I/O combinations

A - 4 Analyzer System Architecture Emerson Process Management GmbH & Co.OHG

Page 23

Instruction Manual

HAS60E-IM-HW

June 2007

NGA 2000 CLD

SECTION 1

DESCRIPTION AND SPECIFICATIONS

1-1 OVERVIEW

This manual describes the Chemiluminescence (CLD)

Analyzer Module of Emerson Process Mangement´s

NGA 2000 Series of gas analysis components (See Figure 1-2, Figure 1-3 and Figure 1-4).

The CLD Analyzer Module is designed to continously

determine the concentration of Nitric Oxide and oxides

of Nitrogen (NO plus Nitrogen Dioxide [NO

]) in a flow-

2

ing gaseous mixture. The concentration is expressed in

parts-per-million.

The CLD Analyzer Module is designed as a slide-in

module (if configured in stand-alone instrument fashion),

removable from the front of the Platform, with gas connections made from the rear. All electronics relative to

sample detection and conditioning are included in this

module.

1-2 TYPICAL APPLICATIONS

The CLD Analyzer Module has specific applications in

the following areas:

• Oxides of Nitrogen emissions from the combustion of fossil fuels in

Vehicle engine exhaust

Incinerators

Boilers

Gas appliances

Turbine exhaust

• Nitric acid plant emissions

• De-NO

control system

x

• Nitric oxide emissions from decaying organic

material (e.g., landfills).

The reactions involved are:

NO + O

NO

As NO and O

→ NO

3

* → NO

2

mix in the reaction chamber, the intensity

3

* + O

2

+ red light

2

2

of the emitted red light is measured by a photodiode and

is proportional to the concentration of NO in the original

gas sample.

To measure NO

(NO + NO2), any NO2 in the sample is

x

reduced to NO (at < 95 % efficiency) by being continously

passed through a heated bed of vitreous carbon (this

occurs before the sample gas is presented to the ozone).

Any NO initially present in the sample passes through

this converter stage unchanged before being routed to

the reaction chamber.

The photodiode generates a DC current, which is then

amplified, conditioned and expressed on the network as

the Primary Variable.

Exhaust

NO Molecule

NO

Ozone

O3 Molecule

O2 Molecule

NO2 Molecule

(excitated)

NO2 Molecule

Figure 1-1: Function Principle of

CLD Measurement

1-3 THEORY OF TECHNOLOGY

The CLD Analyzer Module uses the chemiluminescence

method of detection. This technology is based on the

reaction of NO with ozone (O

) to produce NO2 and oxy-

3

gen (O2). Some of the NO2 molecules thus produced

are in an electronically excited state (NO2* - the "*“ refers

to the excitation). These revert immediately to the ground

state, with emission of photons (essentially, red light).

1-4 FEATURES

Among the features included in the CLD Analyzer Module are:

• 1) ozonator air loss shutoff and

• 2) NO/NO

mode capability.

x

1 - 1Description and SpecificationsEmerson Process Management GmbH & Co.OHG

Page 24

NGA 2000 CLD

Instruction Manual

HAS60E-IM-HW

June 2007

Bulkhead Reducer

1/4T-1/8T SS

Ozone Air

Sample

Bulkhead Reducer

1/4T - 1/8T SS

Exhaust

Bulkhead

1/4T SS

Connector

Cross

1/8T BRS

Male Connector

1/8T - 3/8NPT BRS

Flow Balance

Valve

903207

Tee Assembly

1/8T - 1/4MPT

Tee

1/4T-1/8FPT SS

1/4T SS

1/8T - 1/8NPT BRS

Male Connector

1/8T - 3/8NPT BRS

Pressure Sensor

30 psig Air

655254

1/8T - 1/8MPT KYNAR

Elbow

Back

Pressure

Regulator

(see Table 1-1)

Reducer

1/4T - 1/8T SS

Elbow

1/8T - 1/4MPT SS

Connector

0.116 ID Viton BLK

Pressure Switch

655215

Bypass

Flow Sensor

902931

Elbow

1/8T - 1/4MPT

SS

Air Restrictor

430 cc/min. @ 12 psig

658157

Connector Glass

BLUE

Elbow

1/8T - 1/8MPT

KYNAR

Tee 1/8T

KYNAR

NOx to NO

Converter

655250

Top

Tee 1/8T

KYNAR

Cross

1/8T SS

1/8T - 3/8NPT SS

Pump Capillary

1/8 OD TEFLON

(see Table 1-1)

Male Connector

Ozone Generator

657719

Connector Glass

BLUE

Vent Capillary

70 cc/min. 5 psig

634398

Te e

1/8T

KYNAR

Sample Pressure Sensor

15 psig

655253

Elbow

1/8T SS

1/8 OD SS

Elbow

1/8T SS

1/8 OD SS

Reduction Union

1/8T - 1/16T SS

Reaction Chamber

Ozone

Exhaust

Sample

Sample Capillary

(see Table 1-1)

Figure 1-2: Flow Diagram - CLD Analyzer Module with Bypass Flow Sensor

Brief Description

Part Number

Sample Capillaries

Sample Capillary 200 cc/min. @ 5 psig 659658

Sample Capillary 200 cc/min. @ 2 psig 660404

Sample Capillary 70 cc/min. @ 5 psig 659657

Sample Capillary 70 cc/min. @ 2 psig 660403

Pump Capillaries

Pump Capillary 200 cc/min. @ 5 psig 657473

Pump Capillary 200 cc/min. @ 2 psig 660405

Back Pressure Regulators

Back Pressure Regulator Brass 5 psig 655269

Back Pressure Regulator Stainless Steel 5 psig 659063

Back Pressure Regulator Brass 2 psig 660400

Back Pressure Regulator Stainless Steel 2 psig 660401

Table 1-1: Components depending on Module Configuration

1 - 2 Description and Specifications Emerson Process Management GmbH & Co.OHG

Page 25

Instruction Manual

HAS60E-IM-HW

June 2007

NGA 2000 CLD

Bulkhead Reducer

1/4T-1/8T SS

Ozone Air

Sample

Bulkhead Reducer

1/4T - 1/8T SS

Cross

1/8T BRS

Male Connector

1/8T - 3/8NPT BRS

Flow Balance

Valve

903207

Tee Assembly

1/8T - 1/4MPT

Connector

1/8T - 1/8NPT BRS

Male Connector

1/8T - 3/8NPT BRS

Pressure Switch

655215

Pressure Sensor

30 psig Air

655254

Back

Pressure

Regulator

(see Table 1-1)

Exhaust

Bulkhead

1/4T SS

0.116 ID Viton BLK

Connector Glass

Elbow

1/8T - 1/4MPT

SS

Air Restrictor

430 cc/min. @ 12 psig

658157

NOx to NO

Converter

655250

Top

BLUE

Tee 1/8T

Cross

1/8T SS

Tee 1/8T

KYNAR

1/8T - 3/8NPT SS

KYNAR

Male Connector

Ozone Generator

657719

Connector Glass

BLUE

Vent Capillary

70 cc/min. 5 psig

634398

Pump Capillary

1/8 OD TEFLON

(see Table 1-1)

Sample Pressure Sensor

15 psig

655253

Tee 1/8T

KYNAR

Te e

1/8T

KYNAR

Union 1/8T SS

1/8 OD SS

Union 1/8T SS

1/8 OD SS

Reduction Union

1/8T - 1/16T SS

Reaction Chamber

Ozone

Exhaust

Sample

Sample Capillary

(see Table 1-1)

Figure 1-3: Flow Diagram - CLD Analyzer Module without Bypass Flow Sensor

1 - 3Description and SpecificationsEmerson Process Management GmbH & Co.OHG

Page 26

NGA 2000 CLD

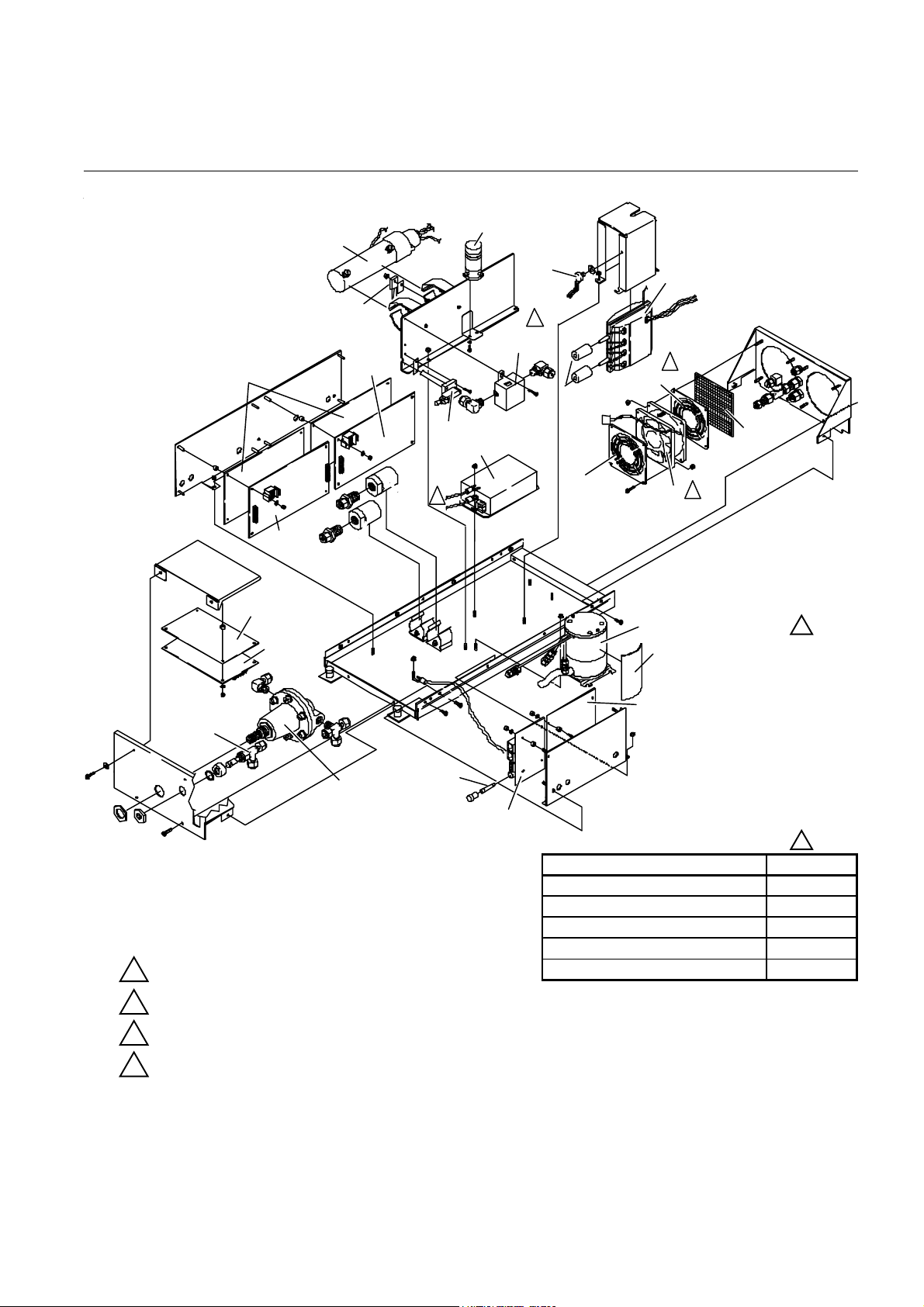

Driver Board

Instruction Manual

HAS60E-IM-HW

June 2007

Inlet/Outlet

Fittings

Fan

NO2 to NO Converter

3/2-way Solenoid Valve

Ozone Generator

Signal Board

Sample Backpressure

Regulator (under Cover)

Detector

Flow Sensor

Power Supply Board

Flow Balance Needle

Valve

Figure 1-4: CLD Analyzer Module - Top View

1 - 4 Description and Specifications Emerson Process Management GmbH & Co.OHG

Page 27

Instruction Manual

HAS60E-IM-HW

June 2007

1-5 SPECIFICATIONS

a. General

Measurement Species: ........................ NO, NOx

Ranges: .............................................. 0 to 5 ppm through 0 to 10,000 ppm NO, NOx

Repeatability: ...................................... ± 0.5 % of fullscale (at constant temperature)

Min. Detectable Level: ......................... 0.1 ppm

Noise: .................................................. < 1 % of fullscale, peak to peak

Linearity: ............................................. ± 1 % of fullscale

Response Time: .................................. < 1 sec. for 90 % of fullscale for ranges of 25 ppm or greater

t90 Response ...................................... 1-2 sec.

Zero Drift: (at constant temperature) .... <± 1 % of fullscale/24 hours, <± 2 % of fullscale/week

Span Drift: (at constant temperature) ... <± 1 % of fullscale/24 hours, <± 3 % of fullscale/week

Effect of Temperature: ......................... < 2 % of fullscale (over any 10 °C ambient temperature variation interval for

Ambient Temperature: ......................... 0 °C to 45 °C (32 °F to 113 °F)

Rated Power: ...................................... 24V DC 150W

NGA 2000 CLD

< 3 sec. for 90 % of fullscale for ranges of less than 25 ppm

a rate of change no greater than 10 °C/hour)

b. Physical

Case Classification: ............................. General purpose for installation in weather-protected area

Dimensions: ........................................ See Figure 2-5: Outline and Mounting Dimensions

Weight:................................................ 8.1 kg (18 lbs.)

Mounting: ............................................ Inside a Platform or custom-installed in a panel

Max. Length of LON Cable: ................. 1,600m (1 mile) between Analyzer Module and Platform

c. Sample

Temperature: ....................................... 0 °C to 45 °C (32 °F to 131 °F)

Total Flow Rate: ................................... (Externally measured) 900 to 2,200 cc/min. with backpressure regulator

Particles: ............................................. Filtered to < 2 microns

Dewpoint: ............................................ 5.5 °C below ambient temperature, no entrained liquid

Materials in contact with Sample: ........ Stainless steel, Teflon, glass, brass and neoprene

Optional: ............................ Stainless steel, Teflon, glass and Kynar

Ozonator Gas: ..................................... Clean, dry air or oxygen; flow rate: 1 l/min. maximum;

d. Gas Connections

Ozone Air: ........................................... 1/4" O.D. tube fitting, stainless steel

Exhaust: .............................................. 1/4" O.D. tube fitting, stainless steel

Sample In: ........................................... 1/4" O.D. tube fitting, stainless steel

pressure adjusted to 1,344 hPa (5 psig) or to 1,138 hPa (2 psig)

pressure: 689 hPa to 1,034 hPa-gauge (10 to 15 psig); maintain a constant

pressure ± 34 hPa (± 0.5 psig)

See the Preface section of the Platform manual for specifications regarding Platform-related components (e.g., case

dimensions) and the I/O Module manual for specifications regarding I/O (e.g., relay outputs).

1 - 5Description and SpecificationsEmerson Process Management GmbH & Co.OHG

Page 28

NGA 2000 CLD

Instruction Manual

HAS60E-IM-HW

June 2007

1 - 6 Description and Specifications Emerson Process Management GmbH & Co.OHG

Page 29

Instruction Manual

HAS60E-IM-HW

June 2007

SECTION 2

INSTALLATION

WARNING

Before starting to install this equipment, read the

"Essential instructions" on the inside cover and

the Safety Summary beginning on page P-2.

Failure to follow the safety instructions could result in serious injury or death.

2-1 UNPACKING

If the Chemiluminescence (CLD) Analyzer Module is

received as a separate unit, carefully examine the shipping carton and contents for signs of damage. Immediately notify the shipping carrier if the carton or contents

is damaged. Retain the carton and packing material until all components associated with the CLD Analyzer

Module are operational.

NGA 2000 CLD

2-2 ASSEMBLY

If the CLD Analyzer Module requires assembly with other

components (e.g., the Platform and associated I/O Modules), do so at this time.

To install the CLD Analyzer Module into a Platform:

1. Loosen the six fastening screws for the front panel

of the Platform, hold the handles, and swing the

front panel to the farest right.

2. Following the guides on the bottom left and bottom center of the Platform, carefully slide the CLD

Analyzer Module halfway into place

3. Lift the spring-loaded pins on the front of the CLD

Analyzer Module, and carefully slide in the rest of

the distance.

If the module and Platform are difficult to assemble,

remove the module, ensure the top cover of the

module is firmly seated on the hold-down screws,

and repeat the assembly procedure.

4. Secure the module in position by releasing the pins,

which seat in the available holes in the bottom of

the case (see Figure 2-1, below).

5. Connect network cable and power cable to the

Analyzer Module (refer to Section 2-5 for electrical

connections).

6. After startup and calibration have been performed,

secure the front panel of the Platform with the six

screws provided.

Pin Seats

Analyzer Module Guides

Figure 2-1: Analyzer Module Installation into Instrument Platform (view without front panel)

2 - 1InstallationEmerson Process Management GmbH & Co.OHG

Page 30

NGA 2000 CLD

Instruction Manual

HAS60E-IM-HW

June 2007

2-3 LOCATION

Install the CLD Analyzer Module in a clean, weather-protected, vibration-free location free from extreme temperature variations and moisture. For best results, install the

instrument near the sample stream to minimize sample

transport time.

The analyzer should be installed within ±15° of horizontal.

NOTE

Unrestricted air flow to the rear of the Analyzer Module is critical to its performance and reliablilty.

Operating ambient temperature is 0 °C to 45 °C (32 °F to

113 °F). Temperature change should not exceed 10 °C

(18 °F) per hour. The same temperature range restrictions apply to the location of the air and span gas cylinders.

2-4 GASES

a. Gas Conditioning (Sample Handling)

NOTE

All gases must be conditioned before supplying!

The gases must be

- dry

- free of dust (filtered for particulates down to two

microns)

- free of aggressive components affecting gas paths

materials (e.g. by corrosion)

- free of Ammonia etc. in order to prevent crystallin

formation

before entering the Analyzer Module.

The gases should have a dew point 5 °C (13 °F) below

coldest ambient temperature.

CAUTION

EXTERNALLY RESTRICT SAMPLE/CALIBRATION

GAS FLOW TO LESS THAN 2,200 cc/min.

MAXIMUM NO

LEVEL IN PARTS

PER MILLION

800 Air

2,500 Air

10,000 Oxygen

GAS SUPPLIED TO

x

REAR PANEL AIR

INLET

Table 2-1: Gas Specifications

Damage to internal components may occur if this

flow level is exceeded.

No restrictor is provided in the sample inlet of this

module. For those users who cannot externally

limit sample flow, contact your local service or

sales office.

SETTIN G ON OZONE

PRESSURE GAUGE

(pressure values: gauge)

690 hPa (10 psig); provides flow

of approximately 500 cc/min. to

ozone generator

690 hPa (10 psig); provides flow

of approximately 1,000 cc/min. to

ozone generator.

1035 hPa (15 psig); provides flow

of approximately 1,000 cc/min to

ozone generator.

SETTING ON SAMPLE

PRESSURE GAUGE

(pressure values: gauge)

344 hPa (5 psig); provides flow

of approximately 200 cc/min. to

reaction chamber

344 hPa (5 psig); provides flow

of approximately 70 cc/min. to

reaction chamber.

103 hPa (1.5 psig); procides

flow of approximately 20 cc/min.

to reaction chamber.

2 - 2 Installation Emerson Process Management GmbH & Co.OHG

Page 31

Instruction Manual

HAS60E-IM-HW

June 2007

NGA 2000 CLD

Exhaust Ozonator Air

Exhaust Fan Sample IN Intake Fan

Figure 2-2: CLD Rear Panel Connections

b. Connections

Connect inlet and outlet lines for sample, ozonator air,

and exhaust to appropriately labeled fittings on the rear

panel (see Figure 2-2) , each of which is a 1/4-inch ferrule-type compression fitting.

Stainless steel or Teflon tubing is recommended for the

sample line. Exhaust tubing should be 1/4 inch (6.3 mm)

or larger, and made of stainless steel or Teflon.

Zero/span gases should be introduced at the SAMPLE

IN fitting at normal sample inlet flow rate/pressure.

c. Specifications

Each gas should be supplied from a cylinder equipped

with a clean, non-corrosive, two-stage regulator. A shutoff valve is recommended.

Zero Gas

Nitrogen (N

) is recommended for use as zero gas.

2

Alternatively synthetic air or NOx free ambient air can be

used.

Calibration Gas

A mixture of NO in a background of nitrogen is recommended as span gas. For maximum accurancy, the concentration of NO in the span gas should be about 80 %

to 100 % of full scale range.

Ozonator Source Gas

For analyzers with ranges less than 0 to 2,500 ppm NO

free ambient air should be used for generation of the

ozone required for the chemiluminescence reaction. For

ranges higher than 0 to 2,500 ppm, NOx free oxygen is

required. See Table 2-1 for correct pressure settings.

When using ambient air an external air conditioning unit

(LAM) can optionally be used (contact your local service

or sales office).

CAUTION

At no time should ozonator gas pressure exceed

2,070 hPa-gauge (30 psig). Damage to internal components may occur if this pressure level is exceeded.

Sample Gas Pressure

See Table 2-1 for correct pressure settings.

Bypass Sample Gas Flow

Bypass sample gas flow rate should be between 700

and 2,000 cc/min. with backpressure regulator pressure

(see Capillary Pressure in „Current Measurement Parameters“ menu, which can be viewed by selecting the

PARMS softkey in "Main Menu") adjusted to 344 hPa (5

psig).

x

2 - 3InstallationEmerson Process Management GmbH & Co.OHG

Page 32

NGA 2000 CLD

Instruction Manual

HAS60E-IM-HW

June 2007

Leak Test

The CLD Analyzer Module is completely tested at the

factory for gas leakage (leakage rate - 7.5 hPa/min. with

He or - 2.5 hPa/min. with N

). The user is responsible for

2

leakage testing at the inlet and outlet fittings on the rear

panel minimum twice a year (see Section 4-8).

Contaminants

White crystal deposits on the windows of the reaction

chamber, and the clogging of capillaries and vent are

usually due to sample contaminates such as ammonia

reacting with the high ozone levels and NO components.

To eliminate the contaminates, the sampling system

should be reworked or a preventive maintenance program developed (if dropout is not excessive). Another

source of crystalline formation is contaminated air.

NOTE

Contamination is a result of a not properly working sample handling systrem and is not be covered by Emerson Process Management warranty.

2-5 ELECTRICAL CONNECTIONS

NOTE

Electrical installation must be in compliance with

the requirements of NAMUR and DIN VDE and/or

any applicable national or local codes (like local

electricity supply enterprises (ESE)).

Refer to figure 2-3. Two electrical connections are required on the Analyzer Module: POWER and NETWORK. On the Analyzer Module, two NETWORK connectors are available, either of which is appropriate for:

1. Interconnection with the Backplane of the Platform. (See Instruction Manual for the NGA 2000

Platform).

2. "Daisy-chaining" with other NGA 2000 components.

Connect Analyzer Module POWER to a 24 VDC, 10 A

power source, either the Platform or external power

source.

Regulator Adjust Slot

Metering Valve

SAMPLE

REGULATOR

FLOW

BALANCE

24 V

Polarity

1 +

2 3 GND

T 6A

~

250 V

Figure 2-3: Front Panel Controls and Electrical Connections

LON

LON

Network

1

2

Connection “1”

Network

Connection “2”

Power

Connection

Fuse

2 - 4 Installation Emerson Process Management GmbH & Co.OHG

Page 33

Instruction Manual

CABLE

DIGITAL

I/O

655246

3

HAS60E-IM-HW

June 2007

NGA 2000 CLD

Optional with Bypass Flow

1

Sensor Configuration

POWER SUPPLY BOARD-LON/POW ER

MODULE ASSEMBLY 657510

J2

J1

LON/PWR MODULE

656761

J5

3 2 1

RED

CABLE, CONTR OLLER PWR 90303 4-V1

NC

J6

2

1

1

POWER SUPPLY

2

BOARD 657520

J13

8 7

1

2

J1

10

9

3

12

J11

1

10

J3

6

1

7

12

RED

HEATERS

DETECTOR

CONVERTER HEATER JACKET 655228

J3

E3

E2

E1

ORN

GRN

BLK

GRN

BLK

1

GRN

J2

2

ORN

3

WHT

THERM OSTAT

2

WHT

CONVERTER TEMPERATURE

SENSOR 655282

CONVERTER

655250

NC

1

J1

J4

1

J2

COMPUTER ANALYSIS BOARD 658350

1

J3

CABLE, INTERNAL NETWORK 903035-V1

HARNESS, SIGNAL POWER 655252

CABLE, FLOW SENSOR 655384

FLOW

RED

SENSOR

902931

BLK

WHT

1

HARNESS, DRIVER POWER 655243

HEATER/THERMOSTAT ASSEMBLY 655235

PHOTODIODE

THERMISTOR 655216

SOCKET

NO/NOx

WHT

WHT

SHLD

OZONATOR

POWER

SUPPLY

657716

SHIELD

GRN

SOLENOID

655263

JUMPER

657162

ASSEMBLY

655218-V1

THERMO STAT

657298

HARNESS, EXPANSION I/O 655249

1 1 1

J5 J6

1

J7

2

OZONATOR

657719

TRANSISTOR

2SD1308

655264

SAMPLE

PRESSURE

SENSOR

655253

E

C

B

B = YEL

C = RED

E = BLU

PRESSURE

SWITCH (NO)

4-15 PSIG

655215

YEL (COM)

BRN (NO)

RED

SAMPLE

PRESSURE

SENSOR

655254

RED

WHT

J5

J3

J6

BLK

WHT

SIGNAL BOARD 655580

5

4

3

J8

2

1

J9

J1

J13

1 2 3 4 5 6 7 8 9

ORN

WIRE*

BRN

*COAX CABLE

1 2 3 6

1 4 5 6

GRN

WHT

RED

BLK

RED

SHLD*

GRN

YEL

WHT

BLU

BLK

WHT

RED

J11

8

J2

GRN

WHT

BLK

CABLE, ANALOG I/O 903033

BLK

BLK

7 6

1

,

WHT

RED

RED

4 3 1

J4

J3

J8

J10

DRIVER BOARD

655620

3

J11

1

J2 J6

10

1

2

2

4

BLK

3

J2

2

RED

1

4

BLK

3

J1

2

1

RED

WHT

2

1

WHT

BRN

2

1

BRN

4

ORN

3

J9

2

ORN

1

1

2

3

4

5

6

7

8

BLU

5

4

RED

3

J5

2

YEL

1

4

3

J12

BRN

2

1

YEL

12

10

CABLE, DIAGNOSTICS 903032-V1

24

2

Brief Description Part Number

Detector 200 cc/min. @ 5 psig 659754

Detector 200 cc/min. @ 2 psig 42716203

Detector 70 cc/min. @ 5 psig 42716204

Detector 70 cc/min. @ 2 psig 42716205

FAN 655245

FAN 655245

Figure 2-4: CLD Wiring Diagram

2 - 5InstallationEmerson Process Management GmbH & Co.OHG

Page 34

NGA 2000 CLD

[

]

[23].9[23].9[33]

4.3

[109]

2.5

[64]

1.5

[38]

4.1

[104]

8.4

[213]

6.1

[155]

8.2

[208]

[18]

Instruction Manual

HAS60E-IM-HW

June 2007

.4

[10]

.7

.8

[20]

2.8

[71]

.5

[13]

1.1

[28]

4.1

4.1

104

6.0

[152]

17.5

[445]

1.3

[33]

1.3

Dimensions:

INCHES

[MM]

Figure 2-5: Outline and Mounting Dimensions

2 - 6 Installation Emerson Process Management GmbH & Co.OHG

Page 35

Instruction Manual

HAS60E-IM-HW

June 2007

NGA 2000 CLD

SECTION 3

OPERATION

3-1 OVERVIEW

Once the CLD has been correctly assembled and installed, the analyzer is ready for operation.

Before operating the system, verify that the Leak Checks

have been performed in accordance with Section 2-4.

In this section, all operations for starting up the analyzer

are explained. For more detailed information about software screens see associated Software Manual.

For the remainder of this section, Analyzer Module interconnection with a Platform or some interfacing component is assumed. Display and Keypad information refers

to that which the user can expect to see and do with

regard to the Front Panel of the Platform.

Depending from the software version that is installed,

menu layout can change, whereas the principle of operation always stays the same.

This instruction manual is based on menus of software

version 3.7.1.

3-2 STARTUP & INITIALIZATION

the startup sequence will interrogate the network to locate and identify all components on the network. The

user will have to bind appropriate combinations of components after the startup sequence. See the Platform

manual for instructions on binding combinations of modules.

Pressing the F1 key during initializing will reset the CLD

brightness and contrast to factory settings. Pressing the

F3 softkey will abort the network initializing, aborting any

connection to other analyzers. In that case, only the

menus of the local analyzer will be available.

At the end of the initializing routine the "measure" screen

will display. This screen is the access to all other channels, menus and submenus. The actual display may differ from that shown depending on any custom configuration.

After the warm-up period (about one hour for the CLD

Analyzer Module), all modules are completely functional.

Establish that correct ozonator air pressure and sample

flow rate are within specifications (see Section 1-5). Calibrate and adjust converter efficiency, and begin operation as the following sections indicate.

Apply LON connection and power to the CLD Analyzer

Module. If it is associated with a Platform, do this by

plugging in the Platform to a power source. The Platform has no ON/OFF power button. Once power has

been supplied to the Platform, the CLD Analyzer Module

will be energized.

After switching on the CLD, the analyzer will begin its

booting procedure which is apparent on the CLD screen.

The first part of the initialization procedure is a self check

of the software and analyzer components. Various displays will show the status of the initialization including

revision notes, "Initializing network interface", "Searching for nodes", "Scanning Module 2: CLD, 12 % Complete", and "Calculating bindings".

If the user´s system contains only one Analyzer Module,

all system components, the Controller Board and the

network "self-install" (bind together) during initial startup.

If the system contains more than one Analyzer Module,

3 - 1OperationEmerson Process Management GmbH & Co.OHG

Page 36

NGA 2000 CLD

Instruction Manual

HAS60E-IM-HW

June 2007

3-3 PREPARATIONS

After performing start-up and initialization that is described

in Section 3-2, operating variables must be adjusted, i.e.

the Analyzer Module is to be calibrated.

In the following, analyzer function control and calibration

procedure is described step-by-step.

CLD

7.50

0.00 10.00Range 1

Sample Flow:

Sample press:

Ozonator: OFF-PRESS. SW.

Converter temp:

Display Status... Main... Channel BasicCal

1300 ml/min

4.0 hPa

30.9 C

200

50.0

150.0

ppm NO

1500

490.0

500.0

Figure 3-1: Measure Mode Display

After starting up the Analyzer Module, the Measure Mode

Display is displayed as shown in figure 3-1.

To now check back physical parameters of the CLD Analyzer Module with the values defined in your Test Data

Sheet, that you received with the analyzer, you have to

select the "Physical Measurements"-Menu.

Enter the diagnostics menu "Physical Measurements"

as follows, using the softkeys F1 through F5:

The menu "Physical Measurements" lets you monitor

physical measurement parameters of the CLD analyzer.

During warm-up time of the analyzer, you can observe

temperature values (sensor temperature, block temperature...) of internal components.

After warm up, check

• Block Temperature

• Detector Temperature

• Converter Temperature

with the operating values given by yout Test Data Sheet.

You will find an excerpt of a Test Data Sheet as an example on the next page in figure 3-3.

NOTE:

As long as operating temperatures are not yet

reached by the internal components of the analyzer, it is not ready for operation. Warm-up can

last up to one hour.

After warm-up or during warm-up procedure of the analyzer you can connect all gas supply lines to the back of

the analyzer.

Supply gases at the pressures given in the Test Data

Sheet and restrict flow by an external flow limiter to 1.3

through 1.5 l/min.

Internal sample gas and ozonator pressures:

Main (Menu)...

Expert Controls and Setup...

Analyzer Module Setup...

Physical Measurements...

Line#1

Sample Capillary Pressure:

Ozone Supply Pressure:

Ozonator Status:

Ozonator Power:

Bypass Flow:

Converter temperature:

Ozonator temperature:

Sensor temperature:

Block temperature:

Capillary Flow Rate:

Pressure limits...

Pressure limits...

HOME ESCAPE MORE HISTORY INFO

Physical Measurements

0.000 ppm

0.7 hPa

4.0 hPa

OFF - PRES. SW.

Enabled

2 ml/min

199.9 ml/min

320 C

51.5 C

1.1 C

51.5 C

You will find internal physical paramters in the Test

Data Sheet that you have received with the analyzer. Externally supply gases at the given pressures with an external adjustment.

Option Bypass Flow:

Depending on measuring capillary, bypass flow

should by 900 - 2,000 cc/min. If no bypass is installed, restrict flow externally to 1.3 - 1.5 l/min.

Figure 3-2: Physical Measurements Display

3 - 2 Operation Emerson Process Management GmbH & Co.OHG

Page 37

Instruction Manual

HAS60E-IM-HW

June 2007

NGA 2000 CLD

Figure 3-3: Excerpt of a Test Data Sheet with values that are to be compaired with physical measurements.

3 - 3OperationEmerson Process Management GmbH & Co.OHG

Page 38

NGA 2000 CLD

Instruction Manual

HAS60E-IM-HW

June 2007

3-4 CALIBRATION PROCEDURE

The CLD analyzer module may require periodic calibration with known zero and span gases in order to maintain a desire level of analytical accurancy. It is recommended, after initial startup, that the CLD Analyzer Module is calibrated at least once every eight hours.

This practice should continue until evidence indicates

that some other interval is more appropriate depending

on the analytical accurancy required.

Calibration is the process of flowing known zero or span

calibration gas into the analyzer for a specified period

(averaging time), after which the analyzer will automatically set its zero or span factors so that the concentration measurement equals the calibration gas value. A

limit can be set, beyond which any attempt by the analyzer to reset its concentration measurement will cause

a warning alarm. In this case, user intervention would be

required to reset the alarm and attempt another calibration.

a. Calibration Setup

Calibration Gas List

This menu is used to set the concentration values of the

calibration gases for each range.

Main (Menu)...

Analyzer and I/O expert controls & setup...

Analyzer module setup...

Calibration gas list...

Line#1

Calibration Gas List

Zero gas - range 1:

NO Span gas - range 1:

NOx Span gas - range 1:

Zero gas - range 2:

NO Span gas - range 2:

NOx Span gas - range 2:

0.000 ppm

0.00 ppm

10.00 ppm

10.00 ppm

0.00 ppm

19.90 ppm

19.90 ppm

MORE...

Line#1

Zero gas - range 3:

NO Span gas - range 3:

NOx Span gas - range 3:

Zero gas - range 4:

NO Span gas - range 4:

NOx Span gas - range 4:

Calibration...

HOME ESCAPE INFO

Calibration Gas List

MORE

0.000 ppm

0.00 ppm

101.0 ppm

101.0 ppm

0.00 ppm

250.0 ppm

250.0 ppm

Figure 3-5: Calibration Gas List

Channels 3 and 4

If not yet done, put in the ozonator and zero gas concentrations that you supply to the analyzer. See gas cylinder

certification for exact values.

In case that measuring ranges differ from ordering code,

put in the measuring ranges:

Main (Menu)...

Analyzer and I/O, expert controls & setup...

Analyzer module setup...

Gas measurement parameters...

Range settings...

Line#1