Emerson HANCOCK Installation, Operation And Maintenance Instructions

HANCOCK CAST STEEL - GATE, GLOBE AND CHECK VALVES

INSTALLATION, OPERATION AND MAINTENANCE INSTRUCTIONS

Before installation these instructions must be fully read and understood

1.2 Inspection

Before carrying out a valve installation, it is

important to determine whether the valve is in

asatisfactory condition.

The following generally applicable procedure

may be helpful in avoiding subsequent valve

problems and should be observed.

a) Carefully unpack the valve and check tags,

identification plates, direction of rotation

of handwheels etc, against bill of material,

specifications, schematics etc.

b) Make a point of noting any special warning

Instructions for DN 50 - 600 (NPS 2 - 24)

ASMEclass 150, 300 and 600 bolted bonnet

caststeel valves.

SAFETY NOTICE

It is essential that a safe system of work

should be adopted before any maintenance

work is done on a valve. The following safety

considerations should be taken in to account

when preparing maintenance instructions.

Before removing valves from a pipework

system or dismantling a valve to carry out

maintenance, it will be necessary to open,

or partially open, the valves and to flush the

system to remove all traces of dangerous

fluidsand pressures.

It is important to recognize the danger

associated with the removal of the stem

packing gland with pressure in the pipework

system and the use of the backseat should not

be regarded as a device permitting repacking

of the stem packing gland whilst the valve

is under pressure as this is recognized as

dangerous practise.

tags or plates attached to or accompanying

the valve, and take any appropriate action.

c) Check the valve for any marking indicating

flow direction. If the flow direction is

indicated, appropriate care should be

exercised to install the valve for proper

flowdirection.

d) As far as is practicable, inspect the valve

interior through the end ports to determine

whether it is reasonably clean, free from

foreign matter and harmful corrosion.

Remove any special packing materials,

such as blocks used to prevent disk

movement during transport and handling,

and anti-corrosion packs. Wipe clean from

preservation coatings, particularly seatings.

e) If practicable, cycle the valve through open

and close. Check guides or seat faces, etc.

f) Immediately prior to valve installation,

check the pipework to which the valve is

tobe fastened for cleanliness and freedom

from foreign materials.

1 GENERAL INSTALLATION INSTRUCTIONS

1.1 General

The installation procedure is a critical stage in

the life of a valve and care should be taken to

avoid damaging the valve.

© 2017 Emerson. All Rights Reserved.Emerson.com/FinalControl VCIOM-02504-EN 19/04

HANCOCK CAST STEEL - GATE, GLOBE AND CHECK VALVES

INSTALLATION, OPERATION AND MAINTENANCE INSTRUCTIONS

1.3 Flanged joint assembly

Pipe flanged joints depend on compressive

deformation of gasket material between the

facing flange surfaces for tight sealing.

In order to obtain satisfactory flange joints,

thefollowing points should be observed.

a) Check the mating flange facings (both valve

and pipework flanges) for correct gasket

contact face, surface finish and condition.

b) Check the bolting for proper size, length

and material. A carbon steel bolt on a high

temperature flange joint can result in early

joint failure.

c) Check the gasket material. For flange joints

using low strength bolting, such as may be

provided for iron flanges, metal gaskets

(flat, grooved, jacketed, corrugated or spiral

wound) should not be used.

d) Check the gaskets for freedom from defects

or damage.

e) Take care to provide good alignment of

the flanges being assembled. Use suitable

lubricants on bolt threads. In assembly,

sequence bolt tightening to make the initial

contact of flanges and gaskets as flat and

parallel as possible. Tighten gradually and

uniformly to avoid the tendency to twist one

flange relative to other.

f) Parallel alignment of flanges is especially

important in the case of the assembly of a

valve in to an existing system. It should be

recognized in such instances that, if the

flanges are not parallel, it will be necessary

to introduce bending to make the flange

joint tight. Simply, forcing the flanges

together with the bolting may bend the pipe,

or it may bend the valve.

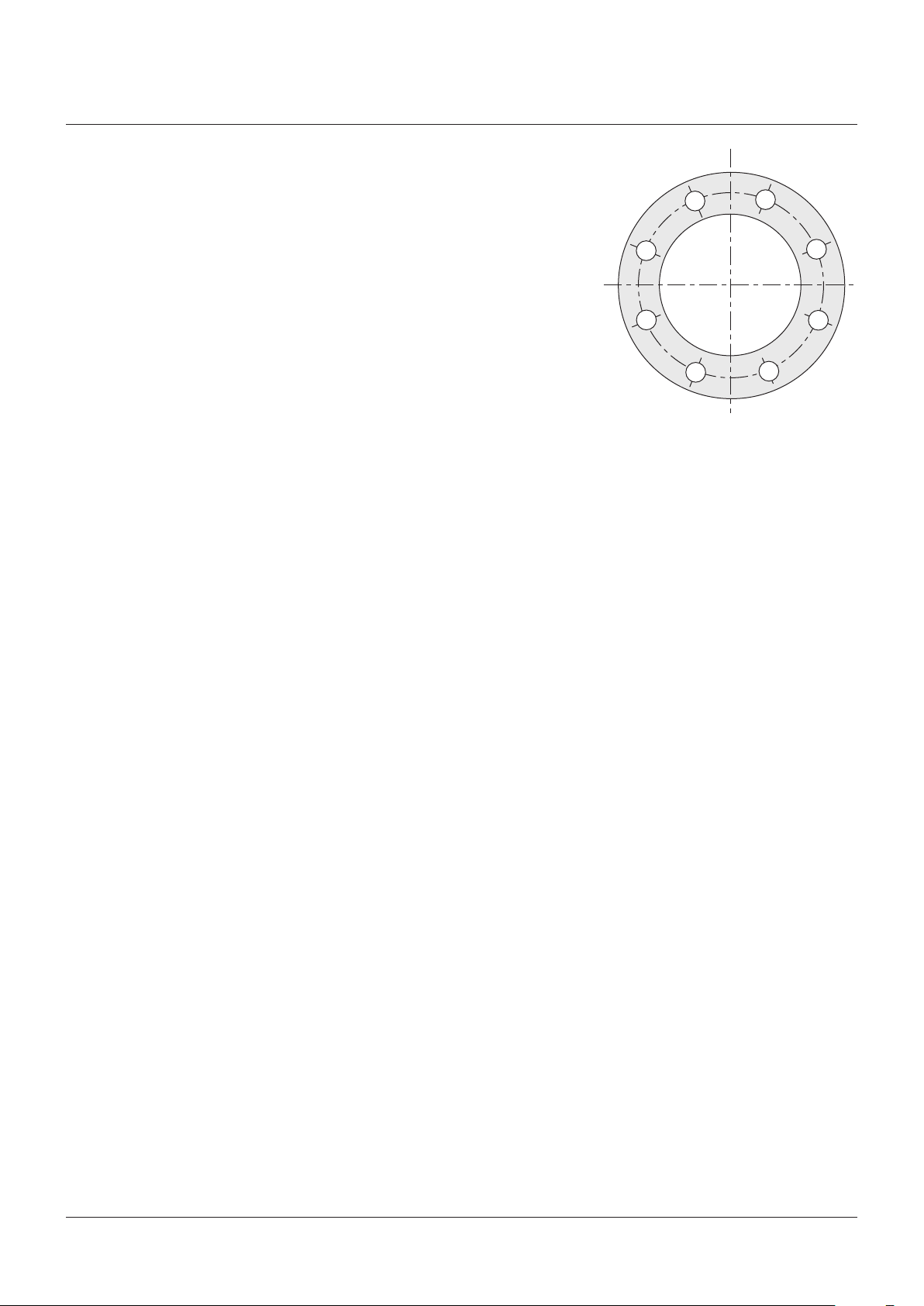

g) All bolts shall be tightened in a star

pattern as shown below to ensure uniform

gasketloading.

1.4 Butt weld joint assembly

All welding should comply with the appropriate

pipe system or application code. Welded

joints, properly made, provide a structural

andmetallurgical continuity between the

pipeand the valve body.

Butt welds require full penetration and

thickness at least equal to that of the pipes.

If a pipe of high strength alloy is welded to a

valve with body material of lower mechanical

strength, the weld should taper to a

compensating greater thickness at the valve

end, or the valve should have a matching high

strength welded-on extension.

Particular care is necessary when welding

valves into the line. Considerable distortion,

resulting in line strains, may occur if valves

are not welded into the line with care, where

required, the weld properly stress relieved,

but it is necessary to ensure that such stress

relieving does not result in valve components,

particularly the seatings being subjected to

unacceptable temperatures.

It is recommended that the valves are not

installed in the pipework at points of high

bending moments, as this can adversely

affectthe seating performances.

1.5 Testing and adjustment

Following installation, all valves should

be operated to check that they still

functioncorrectly.

On new pipework systems, system pressure

testing and commissioning follow after

installation when various checks are made.

Valves are usually supplied in the lubricated

condition, but it is recommended that checks

are made to ensure that this is still intact,

particularly after the application of heat

(e.g.welding operation).

A first observation can be made by actuating

the valve through an open-close or

close-opencycle.

It is common practice, after installation of

pipework systems, to clean the system by

blowing with a gas or steam or flushing with

a liquid to remove debris and / or internal

protective films and coatings. It should be

recognized that valve cavities may form a

natural trap in a pipework system and material

not dissolved in or carried out by the flushing

fluid may settle in such cavities and adversely

affect valve operation. Also, abrasive material

carried by a high velocity fluid stream may

cause serious damage to seating surfaces.

Do not subject the valve to pressures/

temperature testing in excess of its

statedlimits.

1

8

4

6

BOLT TORQUING SEQUENCE

1-2-3-4-5-6-7-8

5

3

7

2

2

Loading...

Loading...