Page 1

Type H120 Relief Valve

Introduction

The Type H120 direct-operated relief valve registers directly

on a spring-opposed poppet assembly which includes a

Nitrile (NBR) disk. When the inlet pressure increases above

the spring setting, the poppet and disk assembly is pushed

away from the metal seat. Springs are available that provide

various xed relief pressures from 35 to 350 psig / 2.4 to

24.1 bar.

With this simple operation and wide spring setting selection,

the Type H120 relief valve may be used where venting

to atmosphere is acceptable, where the process gas is

compatible with the Nitrile (NBR) disk, where its relief capacity

is adequate, and where some pressure relieving tolerance is

acceptable. Common applications include use on pneumatic

control lines of air drills, jackhammers and other similar

equipment, and on high-pressure installations such as the

side outlet of a Type 1301F regulator.

Features

Bulletin 71.4:H120

April 2012

W4107

Figure 1. Type H120 Relief Valve

• Space-Saving Construction - Small relief valve size

allows installation where space is limited.

• Economical - Low initial cost, easy installation, and high

capacity per dollar invested reduces total cost of having

relief valve capabilities in your system.

• Durable - Brass or stainless steel body construction and

stainless steel spring reduce susceptibility to corrosion

damage and the preset, pinned spring retainer prevents

relief valve setpoint tampering.

• Optional Protective Cap - A Type P206 raincap can be

Installation

This relief valve may be installed in any position, but it must

be oriented so that gas discharged from the valve does not

create a re, toxic, or explosion hazard. The relief valve

should be protected from material and conditions that could

clog the outlet side of the valve and affect the venting of gas.

A Type P206 raincap should be installed over the outlet to

help protect the relief valve.

The relief valve and installation should be checked for

compliance with all applicable codes.

provided over the outlet to help protect the relief valve from

trash and debris.

Table 1. Relief Pressures and Capacities

FIXED RELIEF

PRESSURE

psig bar psig bar SCFH Nm3/h

35

60

120 8.3 25 1.7 12,825 344 T12687T0012 Orange 0.051 1.30 0.94 23.9

150

175

200

225

275

350

1. This is the initial leak point, the point at which the relief valve begins to discharge.

2. To convert to equivalent capacities of other gases, multiply the table value by 0.775 for air or 0.789 for nitrogen.

SETTING

(1)

2.4

4.1

10.3

12.1

13.8

15.5

19.0

24.1

BUILD-UP OVER

RELIEF PRESSURE

SETTING

25

25

30

35

40

45

55

70

1.7

1.7

2.1

2.4

2.8

3.1

3.8

4.8

CAPACITY IN SCFH / Nm3/h OF 0.6

SPECIFIC GRAVITY NATURAL GAS

6000

8175

14,890

17,400

20,350

21,750

23,525

34,560

161

219

399

466

545

583

630

926

(2)

SPRING PART

NUMBER

T1217837022 Yellow 0.047 1.19 0.91 23.1

T12688T0012 Brown 0.056 1.42 1.17 29.7

1F790837022 Black 0.062 1.58 1.13 28.7

SPRING

COLOR

CODE

SPRING WIRE

DIAMETER

inches mm inches mm

SPRING FREE

LENGTH

www.sherregulators.com

D100164X012

Page 2

Bulletin 71.4:H120

Specications

Inlet Connection Size

1/4 NPT

Maximum Allowable Relief (Inlet) Pressure

420 psig / 29.0 bar

Fixed Relief Capacities

(1)

See Table 1

Flow Capacities

See Table 1

Wide-Open Sizing Coefcient

Cg: 80

(1)

Temperature Capabilities

-20 to 160°F / -29 to 71°C

Approximate Weight

1/4 pound / 0.1 kg

Available Option

Type P206 raincap

Construction Materials

Body, Poppet, and Spring Retainer:

Brass and Stainless steel

Disk: Nitrile (NBR)

Spring: Stainless steel

Retainer Pin: Steel and Stainless steel

1. The pressure/temperature limits in this Bulletin or any applicable standard limitation should not be exceeded.

Ordering Information

When ordering a Type H120 relief valve, specify the type

number and the xed relief pressure required.

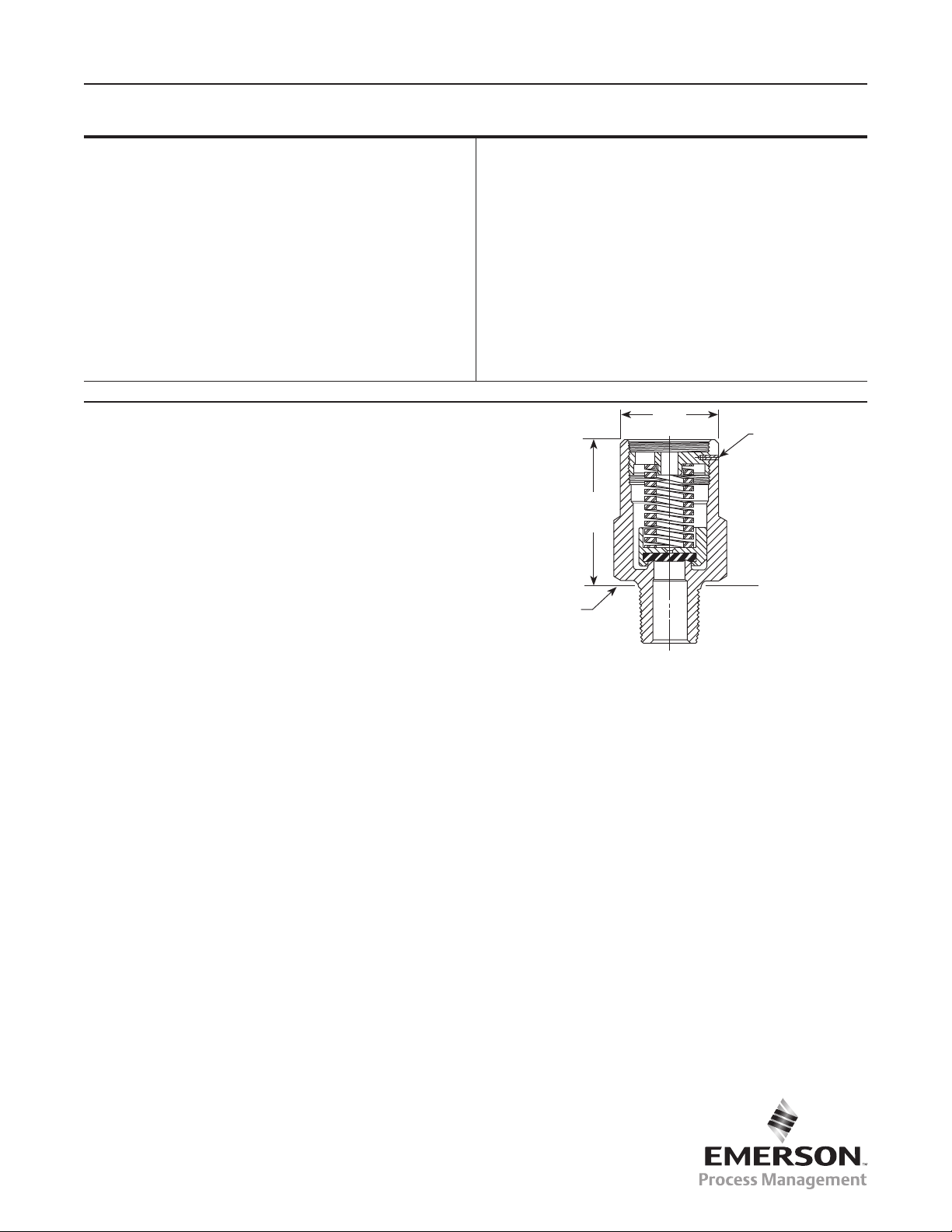

1.35 /

35

(1)

0.84 /

21

RETAINER PIN

APPROXIMATE

TOP OF BOSS

AF6126-H

A3283

INCHES /

mm

Figure 2. Construction Details and Outline Dimensions

Industrial Regulators

Emerson Process Management

Regulator Technologies, Inc.

USA - Headquarters

McKinney, Texas 75069-1872, USA

Tel: +1 800 558 5853

Outside U.S. +1 972 548 3574

Asia-Pacic

Shanghai 201206, China

Tel: +86 21 2892 9000

Europe

Bologna 40013, Italy

Tel: +39 051 419 0611

Middle East and Africa

Dubai, United Arab Emirates

Tel: +971 4811 8100

For further information visit www.fisherregulators.com

The Emerson logo is a trademark and service mark of Emerson Electric Co. All other marks are the property of their prospective owners. Fisher is a mark owned by Fisher Controls International LLC,

a business of Emerson Process Management.

The contents of this publication are presented for informational purposes only, and while every effort has been made to ensure their accuracy, they are not to be construed as warranties or

guarantees, express or implied, regarding the products or services described herein or their use or applicability. We reserve the right to modify or improve the designs or specications of such

products at any time without notice.

Emerson Process Management does not assume responsibility for the selection, use or maintenance of any product. Responsibility for proper selection, use and maintenance of any Emerson

Process Management product remains solely with the purchaser.

Natural Gas Technologies

Emerson Process Management

Regulator Technologies, Inc.

USA - Headquarters

McKinney, Texas 75069-1872, USA

Tel: +1 800 558 5853

Outside U.S. +1 972 548 3574

Asia-Pacic

Singapore 128461, Singapore

Tel: +65 6770 8337

Europe

Bologna 40013, Italy

Tel: +39 051 419 0611

Gallardon 28320, France

Tel: +33 2 37 33 47 00

TESCOM

Emerson Process Management

Tescom Corporation

USA - Headquarters

Elk River, Minnesota 55330-2445, USA

Tels: +1 763 241 3238

+1 800 447 1250

Europe

Selmsdorf 23923, Germany

Tel: +49 38823 31 287

Asia-Pacic

Shanghai 201206, China

Tel: +86 21 2892 9499

©Emerson Process Management Regulator Technologies, Inc., 1984, 2012; All Rights Reserved

Loading...

Loading...