Product Bulletin

21.1:Cryogenic-Rotary

D500230X012

October 2010

A31A Cryogenic Valve

Fisherr POSI-SEALt A31A Cryogenic High

Performance Butterfly Valve

Description

The Fisher A31A Cryogenic High Performance

Butterfly Valve (HPBV) is designed for extreme

temperature cryogenic services and features a valve

body extension which positions the packing system

and the actuator away from the extreme

temperatures. The NPS 3 through 12 valves feature

a unique one-piece investment cast extension

housing (see figures 1 and 2). The NPS 14 through

24 valves employ a two-piece fabricated extension

housing. The valve also features a metal NOVEX

seal as standard providing tight shutoff, low

operating torques and the rugged durability needed

for cryogenic service.

The A31A Cryogenic HPBV has been developed as

a valve/actuator package with a Double D drive shaft

(standard for NPS 3 through 12) to allow easy, direct

mounting to the Fisher 1035 Rack and Pinion

actuator, eliminating the need for external coupling

systems. Also available are keyed shaft (standard

for NPS 14 through 24) and splined drive shafts to

allow easy mounting to other Fisher actuators.

The A31A Cryogenic HPBV is available in either

flangeless (wafer) or single flange styles, and

S31600 (316 SST) is the standard valve body and

disc material. This valve is offered in full rated

CL150 and CL300 pressure classes.

Contents

Features 3..................................

Specifications 2.............................

Installation 3................................

Coefficients 16..............................

Tables

Approximate Weights 3..................

Material Temperature Ratings 6..........

Dimensions 7..........................

www.Fisher.com

W7451

Figure 1. Fisher POSI-SEAL A31A Cryogenic Valve with 1035 Actuator

A31A Cryogenic Valve

Specifications

Product Bulletin

21.1:Cryogenic-Rotary

October 2010

Valve Body Sizes and Ratings

NPS J 3, J 4, J 6, J 8, J 10, and J 12

CL150 and 300

J NPS 14 through 24 valves are also available in

CL150 and 300.

End Connection Style

J Flangeless, wafer-style or J single flange valve

body designed to fit between raised-face mating

flanges per ASME B16.5 CL150 or 300

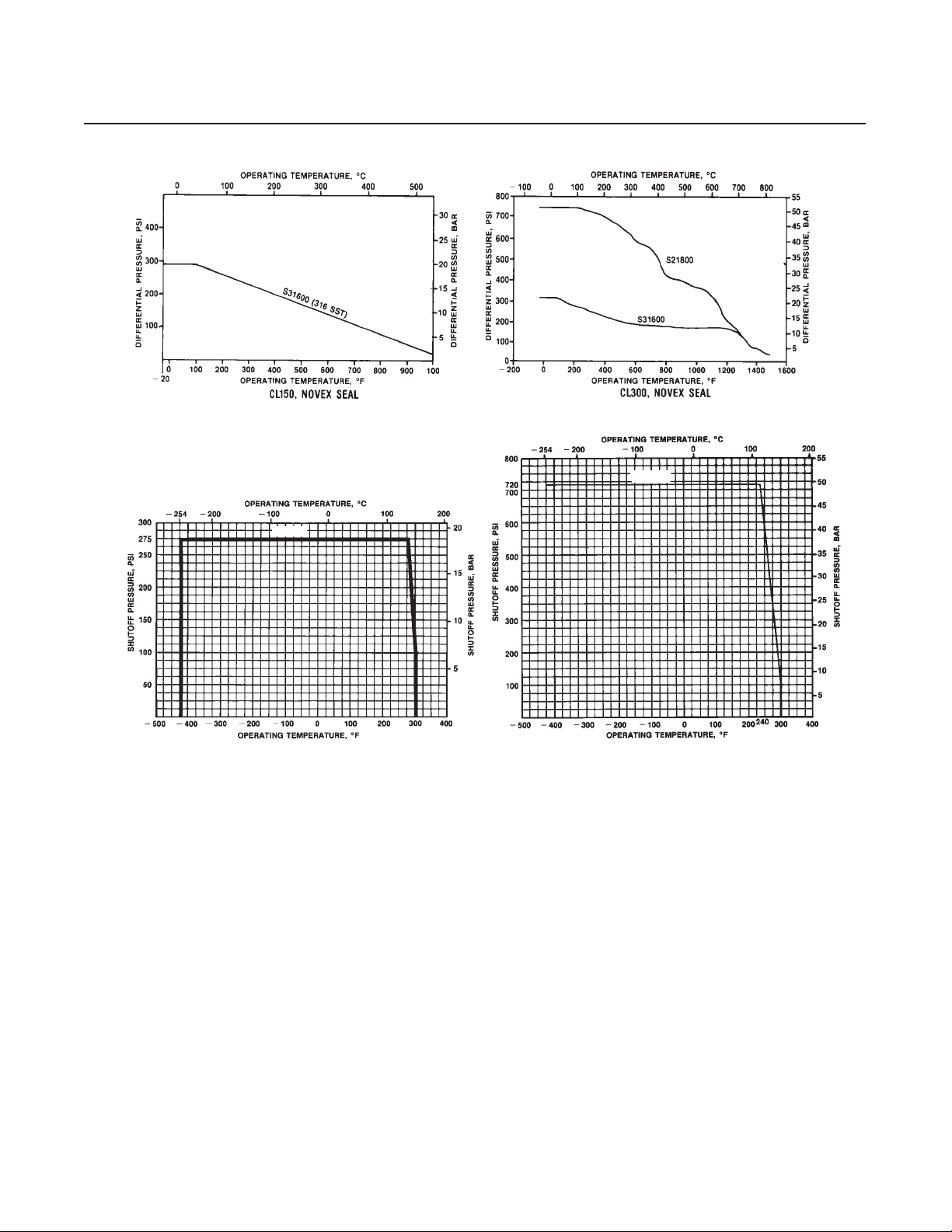

Maximum Inlet Pressure/Temperature

(1)

Consistent with CL150 and CL300

pressure/temperature ratings per ASME B16.34,

except that 38_C (100_F) rating is applicable to

254_C (425_F). NOVEX seal maximum

pressure/temperature rating is the same as the

valve body. See figure 4 for rating of CTFE seal.

Temperature Range

(1)

234 to 260_C (425 to 500_F)

Available Seal Configurations

See figure 3 and table 2

Standard Construction Materials

Valve Body and Disc: ASTM grades of S31600

stainless steel

Disc Coating:Hardcoating Standard (Chrome or

Nickel)

Shaft: J ASTM grade of S17400 H1150M SST

,

J N05500 (Optional), J N07718 (Optional)

Seal Ring: J S31600 (316 SST) NOVEX Std for

CL 150, J S21800 NOVEX Std for CL300,

J CTFE

(2)

optional, or J CTFE

(2)

with Aluminum

Back-up ring optional

Packing: J PTFE V-ring, or J graphite (optional)

Bearings: J PTFE Composition, or J bronze

(optional)

1. The pressure/temperature limits in this bulletin, and any application code or standard limitation, should not be exceeded.

2. CTFE not recommended for fast cycling, less than 2 seconds.

Valve Body Classification

Face-to-face dimensions are in compliance with

MSS SP68 and API 609 standards; valve bodies

are designed for installation between ASME

B16.5 CL150 or 300 raised-face flanges

Shutoff Classification

Unidirectional Reverse flow. Per ANSI/FCI 70-2 and

IEC 60534-4 at ambient temperature

NOVEX Seal: Class VI

CTFE Seal: 1/10 of Class IV

CTFE Seal with Aluminum back-up ring:

Class VI

Flow Characteristic

Modified equal percentage

Flow Coefficients

See the section titled Coefficients in this bulletin

Noise Levels

See Catalog 12 for sound pressure level

prediction

Available Actuators

J Rack and Pinion 1035 for NPS 3 through 12,

J Bettis G Series for keyed shaft

NPS 14 through 24 or

J Rotary Diaphragm 1051 and 1052 for splined

shafts

Disc Rotation

Clockwise to close

Valve Dimensions and Approximate Weights

See figures 6, 7, 8, 9, 10, 11, 12, and 13 and

tables 1, 3, 4, 5, 6, 7, 8, 9 and 10.

W7449

Figure 2. Fisher A31A Cryogenic Valve, Single Flange Style

2

Product Bulletin

21.1:Cryogenic-Rotary

October 2010

A31A Cryogenic Valve

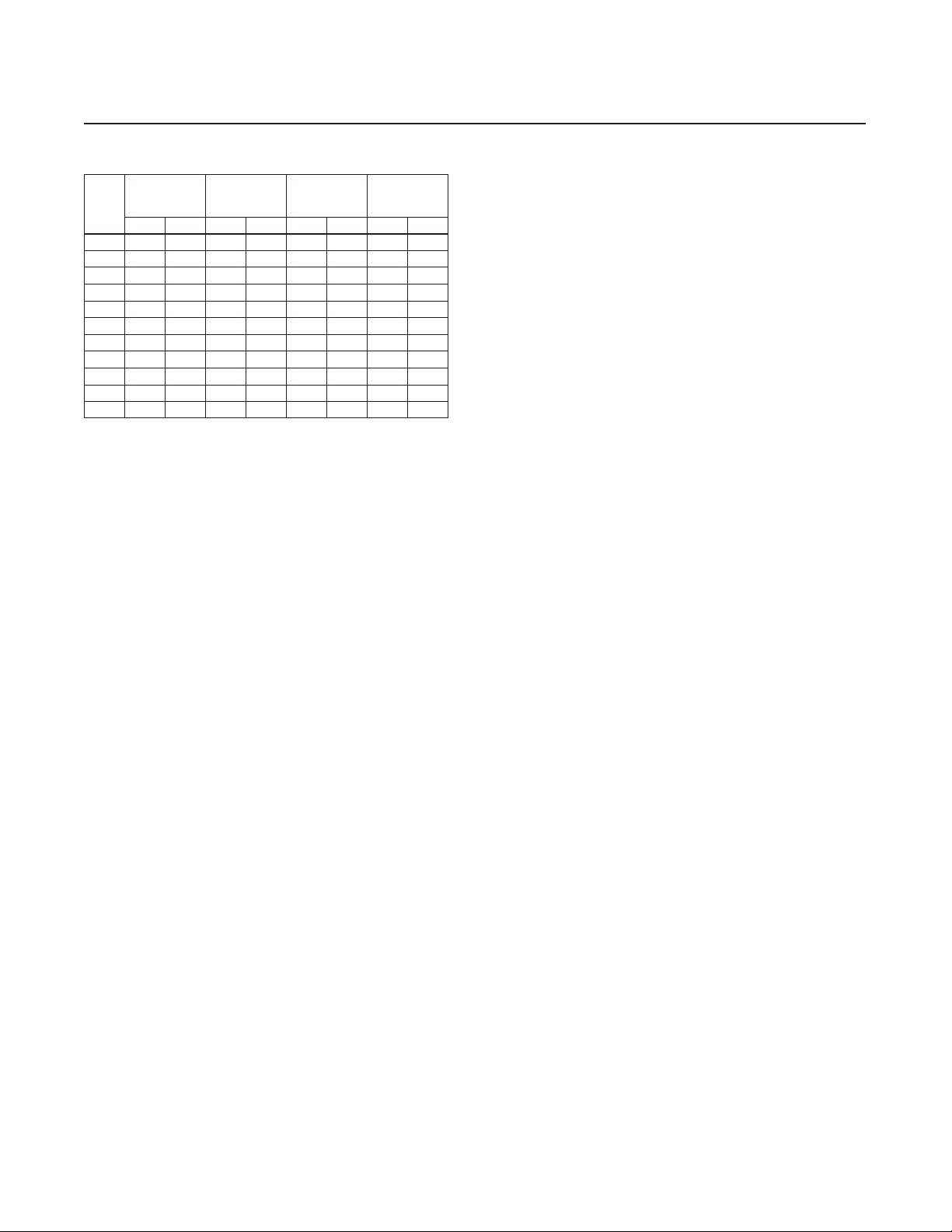

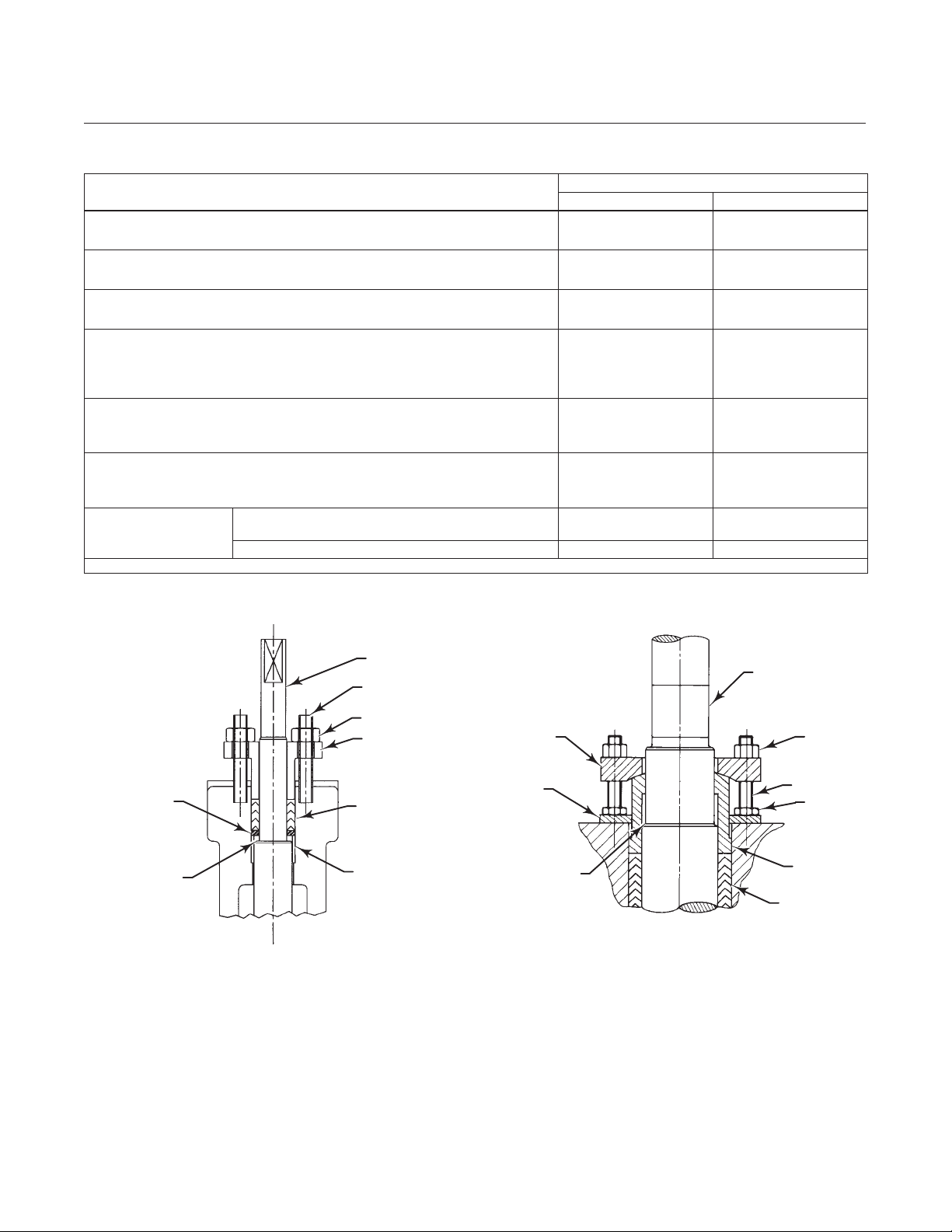

Table 1. Approximate Weights

VALVE

SIZE,

NPS

10 57 125 67 148 80 176 100 220

12 74 164 93 206 103 227 135 298

14 87 191 120 265 142 314 249 548

16 133 294 182 401 213 470 325 716

18 170 374 231 510 259 570 434 956

20 210 463 302 665 401 884 582 1282

24 326 719 455 1004 512 1128 863 1903

WAFER

CL150

kg lbs kg lbs kg lbs kg lbs

3 12 27 16 36 12 27 16 35

4 21 46 22 48 21 46 24 52

6 24 53 28 61 24 53 28 61

8 34 75 40 89 47 104 52 115

SINGLE

FLANGE

CL150

WAFER

CL300

SINGLE

FLANGE

CL300

Features

D Cryogenic Seal Improvement— The NOVEX

pressure-assisted metal seal design provides tight

shutoff (ANSI Class VI, ambient) and permits the

use of smaller, less expensive actuators in

applications requiring full ASME B16.34 shutoff

capabilities. The NOVEX seal is standard on all

A31A Cryogenic valves.

D Direct Actuation—The A31A Cryogenic NPS 3

through 8 Double D shaft allows direct mounting with

the 1035 actuator, eliminating the need for a coupler.

D Safety—Redundant shaft retention provides

added protection. The packing follower and shaft

step interact to hold the shaft securely in the valve

body. The NPS 3 through 12 valves use a one-piece

packing follower, and the NPS 14 through 24 valves

use a two-piece follower (see figure 5).

D Strength— The cast S31600 one-piece

extensions are welded directly onto the NPS 3

through 8 valves for greater strength under service

conditions.

D Easy Installation—The valve body self-centers

on the line flange bolts as a fast, accurate means of

centering the valve in the pipeline.

D Reliable Flange Gasketing Surface—Seal

retainer screws are located so there is no

interference with the sealing function of either flat

sheet or spiral wound line flange gaskets.

Installation

Recommended installation for the A31A Cryogenic

valve is with the shaft upstream of the seal (reverse

flow).

Dimensions for wafer-style and single-flange valves

are shown in figures 6, 7, 8, 9, 10, 11, 12, and 13

and tables 3, 4, 5, 6, 7, 8, 9 and 10.

D Excellent Shutoff Integrity—Concentric

rotation enables the valve disc to remain in the

closed position in spite of line pressure surges or

actuator failure.

For assistance in selecting the appropriate

combination of actuator action and open valve

position, consult your Emerson Process

Management sales office.

3

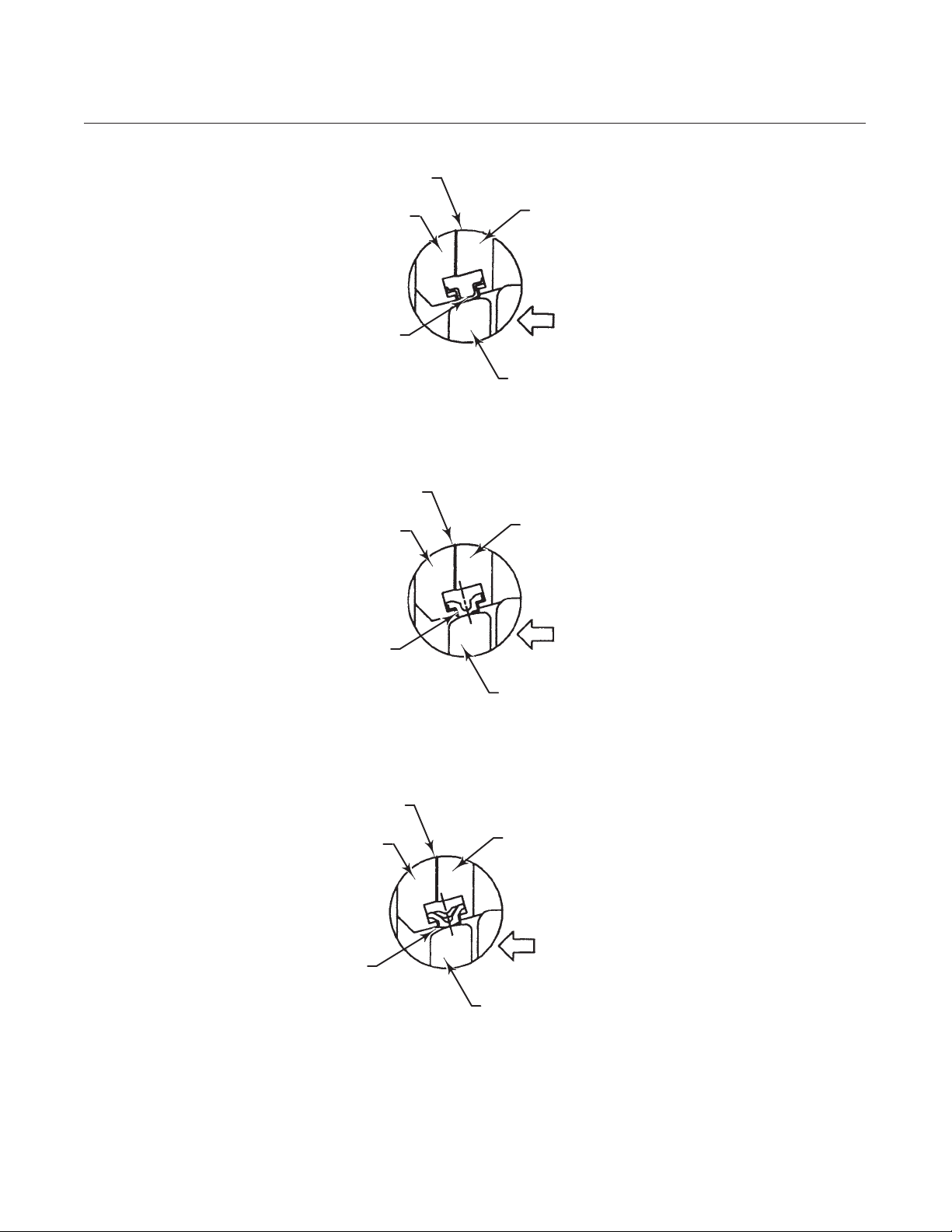

A31A Cryogenic Valve

GRAPHITE

GASKET

RETAINING

RING

Product Bulletin

21.1:Cryogenic-Rotary

October 2010

BODY

SEAL

RING

GRAPHITE

GASKET

RETAINING

RING

SEAL

RING

NOVEX SEAL

VALVE DISC

CTFE SEAL

VALVE DISC

BODY

HIGH PRESSURE

AT SHUTOFF

HIGH PRESSURE

AT SHUTOFF

GRAPHITE

GASKET

RETAINING

RING

SEAL

RING

16B5083

CTFE / ALUM SEAL

BODY

VALVE DISC

HIGH PRESSURE

AT SHUTOFF

Figure 3. Available Seal Configurations

4

Product Bulletin

21.1:Cryogenic-Rotary

October 2010

C0759-1

A31A Cryogenic Valve

CTFE

CTFE

A4132-1 A3715-2

CL150, CTFE SEAL CL300, CTFE SEAL

Figure 4. Maximum Pressure/Temperature Ratings

5

A31A Cryogenic Valve

Table 2. Material Temperature Ratings

COMPONENT AND MATERIAL OF CONSTRUCTION TEMPERATURE RANGE

Valve Body

CF8M (316 SST) CL150 and 300 254 to 260 –425 to 500

Disc

CF8M (316 SST) 254 to 260 –425 to 500

Disc Coating

Hard Coating

S17400 H1150M (standard)

N05500

N07718

Bearings

PTFE Composition Rexnord (standard)

Bronze

Packing

PTFE Packing (standard)

Graphite

NOVEX S31600 Seal Ring (CL150) (standard)

Seal Ring

1. The material for hard coating on the disc is either hard chrome plating or Electroless Nickel Coating (ENC) depending upon availability.

NOVEX S21800 Seal Ring (CL300) (standard)

(1)

254 to 260 –425 to 500

Shaft

196 to 260

198 to 260

254 to 260

254 to 163

254 to 260

254 to 232

254 to 260

254 to 260

254 to 260

CTFE Cryogenic Seal Ring 254 to 149 425 to 300

Product Bulletin

21.1:Cryogenic-Rotary

October 2010

_C _F

–320 to 500

325 to 500

425 to 500

–425 to 325

–425 to 500

–425 to 450

425 to 500

425 to 500

425 to 500

PACKING RING

ANTI-BLOWOUT

SHAFT SHOULDER

16B5082

SHAFT

STUD

HEX NUT

PACKING

FOLLOWER

V-RING PACKING

OUTBOARD

BEARING

PACKING

FLANGE

ANTI-BLOWOUT

FLANGE

SHAFT SHOULDER

A7090

NPS 3 THROUGH 12 NPS 14 THROUGH 24

Figure 5. Anti-Blowout Protection

SHAFT

TYPICAL PTFE

V-RING

PACKING

HEX NUT

STUD

HEX NUT

PACKING

FOLLOWER

6

Loading...

Loading...