Emerson Fisher POSI-SEAL A31A, Fisher easy-e ED, Fisher easy-e ES, Fisher easy-e ET, Fisher easy-e EZ Brochure

...

For Nonstop Operation of High-Cycle Applications

Use Fisher Control Valve Assemblies

®

2 | Nonstop High-Cycle Applications

For Nonstop Operation of High-Cycle Operations,

Use Fisher Control Valve Assemblies

Nonstop High-Cycle Applications | 3

igh-cycle applications such as pressure swing adsorption

H

and molecular sieve adsorption are very abusive on control

valve assemblies. Stroking frequency exceeds 60,000 cycles

per year and tight shutoff to Class V or Class VI is required to

maintain industrial gas purity and efficiency.

Proper selection of control valve assemblies is imperative.

®

control valve assemblies typically consist of the control

Fisher

valve, an actuator, and a digital valve controller.

Incorporating Fisher control valve assemblies from Emerson into

your high-cycle applications can have significant benefits.

Improve Reliability – End users have increased turnaround

schedules to five years using Fisher control valve assemblies.

Their long-term reliability is demonstrated by rigorous testing to

more than 1,000,000 cycles and they are licensor accepted.

Improve Uptime – When you use Fisher control valve

assemblies you can expect to see improvements in uptime,

as they are engineered to meet high-cycle application

requirements. The durability of their mechanical moving parts

and soft parts is the key to long periods of operation.

Read how Emerson’s Fisher

control valve assemblies have

helped customers with their

high-cycle applications.

These proven results flyers

provide solid, quantifiable

results from real customers.

Improve Purity – Higher quantities of on-specification industrial

gas can be produced using Fisher control valve assemblies that

maintain tight shutoff throughout their lifetime.

In addition to providing top quality, expertly engineered

control valve assemblies, Emerson offers application assistance,

responsive replacement parts service, and training.

Revamping Control Valves and

Adding FIELDVUE Instruments

Saved a Refinery and its PSA

Unit $2,000,000 Per Year

Control Valve Maintenance

Requirements Reduced in PSA

Units by Using Fisher Valves

4 | Nonstop High-Cycle Applications

Applications Discussion

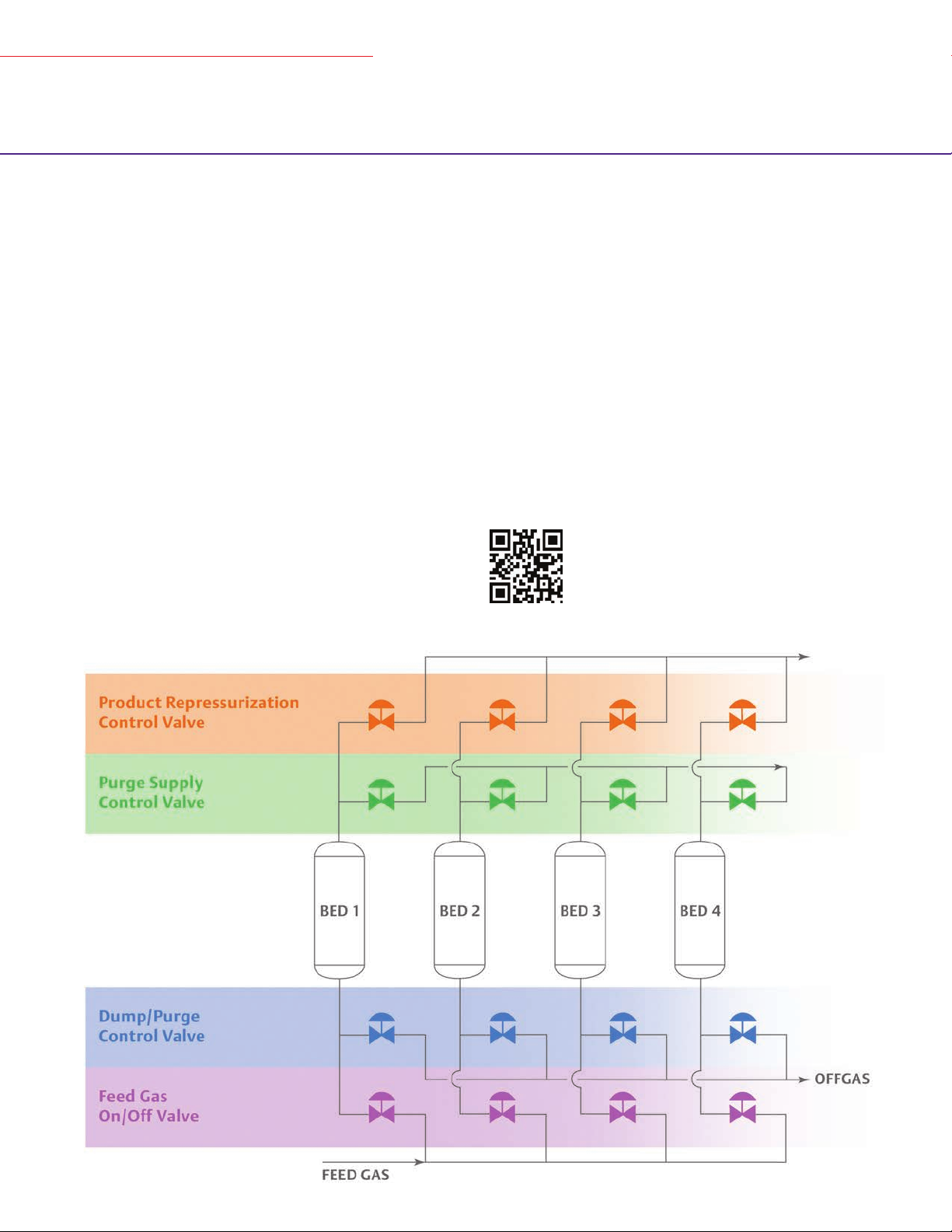

Pressure Swing Adsorption (PSA)

PSA is a process that involves separating impurities from

a feedgas mixture to produce a single product gas such as

hydrogen, oxygen, or nitrogen.

Feedgas cycles through fixed-bed adsorbers, which are

surrounded by control valves that use forward and reverse

flow to rapidly switch gases between parallel vessels. Within

the fixed-bed adsorber, impurities are removed from the

product gas at high pressure and then rejected as the

system pressure “swings” to a lower pressure. The ability to

completely adsorb impurities allows the production of high

purity (99.99%) end product.

PSA Unit

The PSA unit is a severe service application for control

valve assemblies. High cycling action and tight shutoff

is required. Annual cycle service exceeds 60,000 cycles

for four-bed units like the one shown below.

The challenge of PSA is that control valve assemblies are

expected to cycle as often as every thirty seconds and provide

tight, bi-directional shutoff. Common failures of control valve

assemblies in PSA units include:

•

Stem or shaft breakage due to deficient pinning design

•

Poor valve-actuator-positioner linkages leading to multiple

mechanical failures in a high-cycle environment

•

Loss of shutoff

Your PSA units can achieve longer lifecycles with Fisher control

valve assemblies. Fisher control valve assemblies for PSA

applications are tested to one million cycles to meet Emerson’s

high-cycle quality standard.

The high-performance, linkage-less feedback system in

FIELDVUE

™

digital valve controllers has no wearing parts

so cycle life is maximized. The feedback system eliminates

physical contact between the valve stem and the digital valve

controller. It is completely non-contact and

does not rely on linkages, eliminating the most

common control valve failure mode. Scan the

QR code to learn more about the linkage-less

feedback system in the DVC6200 instrument.

Nonstop High-Cycle Applications | 5

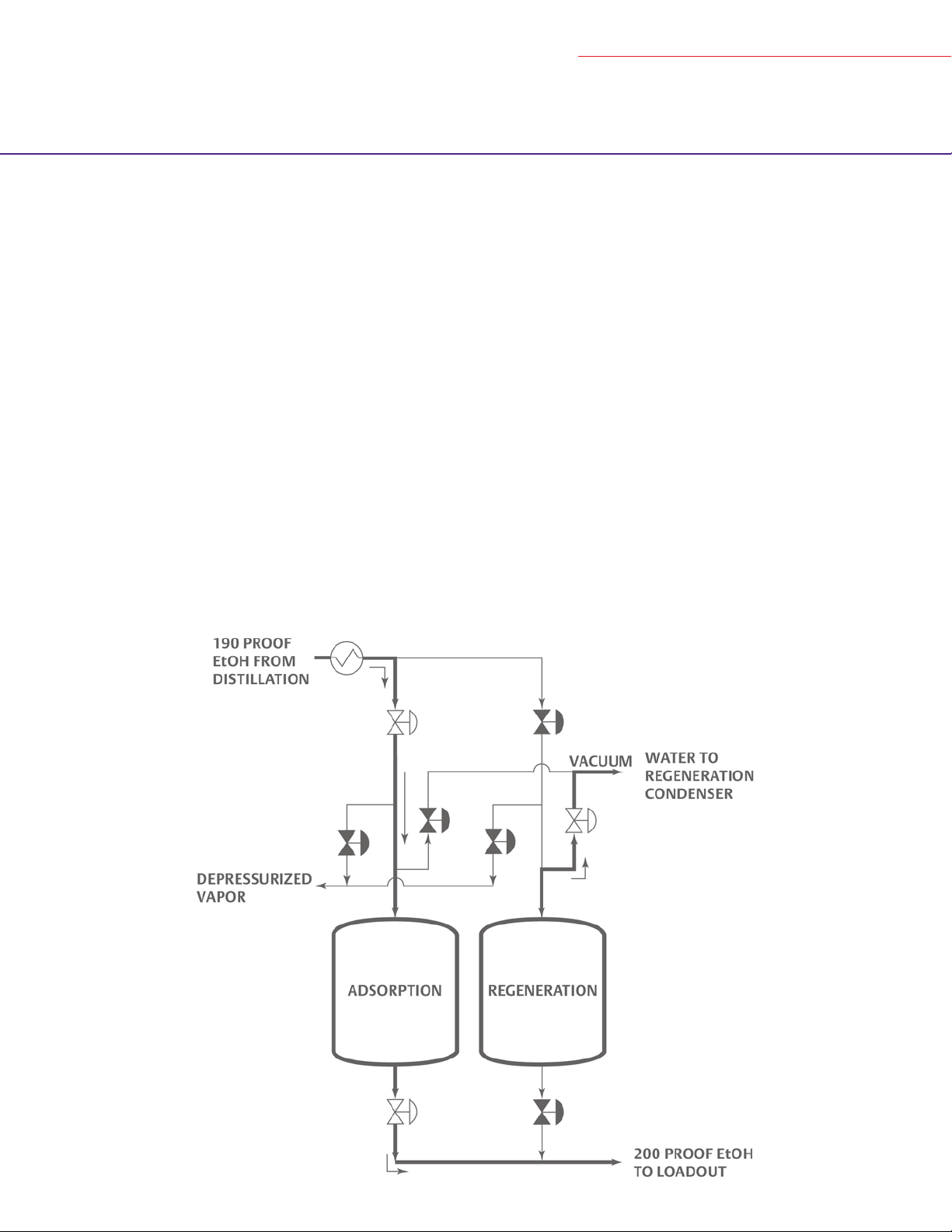

Molecular Sieve Adsorption

With the competitive environment in the ethanol industry

constantly increasing, now is the time to focus on improving

overall plant efficiency and reliability. Regardless of plant

scale, the molecular sieve adsorption application presents a

significant opportunity for such improvements.

In surveying ethanol producers from around the world, some

of the most commonly reported maintenance problems

related to the molecular sieve adsorption unit include:

•

Selection of oversized butterfly valves leading to poor

control and reduced cycle life

•

Accelerated bearing wear, often seen after only a few months

•

Poor valve-actuator-positioner linkages leading to multiple

mechanical failures in a high-cycle environment

•

Poor performance from low-quality valve positioners in both

the adsorption and regeneration cycles

Continued enhancement of this essential component of

the ethanol process is critical to achieving plant output and

revenue targets. Fisher control valve assemblies for molecular

sieve adsorption applications are tested to one million cycles

to meet Emerson’s high-cycle quality standard.

Molecular Sieve Adsorption

Improper selection of control valve

assemblies can lead to unscheduled

downtime. During this downtime,

a typical 50 million gallon-per-year

ethanol facility can suffer over

$10,000 USD per hour in lost revenue.

Loading...

Loading...