Page 1

A11 Valve

D500203X012

Fisherr POSI-SEALt A11

High-Performance Butterfly Valve

The Fisher A11 High-Performance Butterfly Valve

maintains tight shutoff, and can be specified for a wide

range of pressure and temperature conditions,

including cryogenic applications.

TheA11valveisavailableineitherawaferora

single-flange design (single-flange only for CL600, 900,

and 1500). A square or keyed shaft can combine with a

variety of handlevers, handwheels, or pneumatic

piston diaphragm actuators. A splined shaft can

combine with a variety of spring-and- diaphragm or

pneumatic piston actuators. These combinations help

make the A11 valve a reliable, high-performance

butterfly valve for both throttling and on-off

applications in the process industries.

Product Bulletin

21.1:A11

May 2013

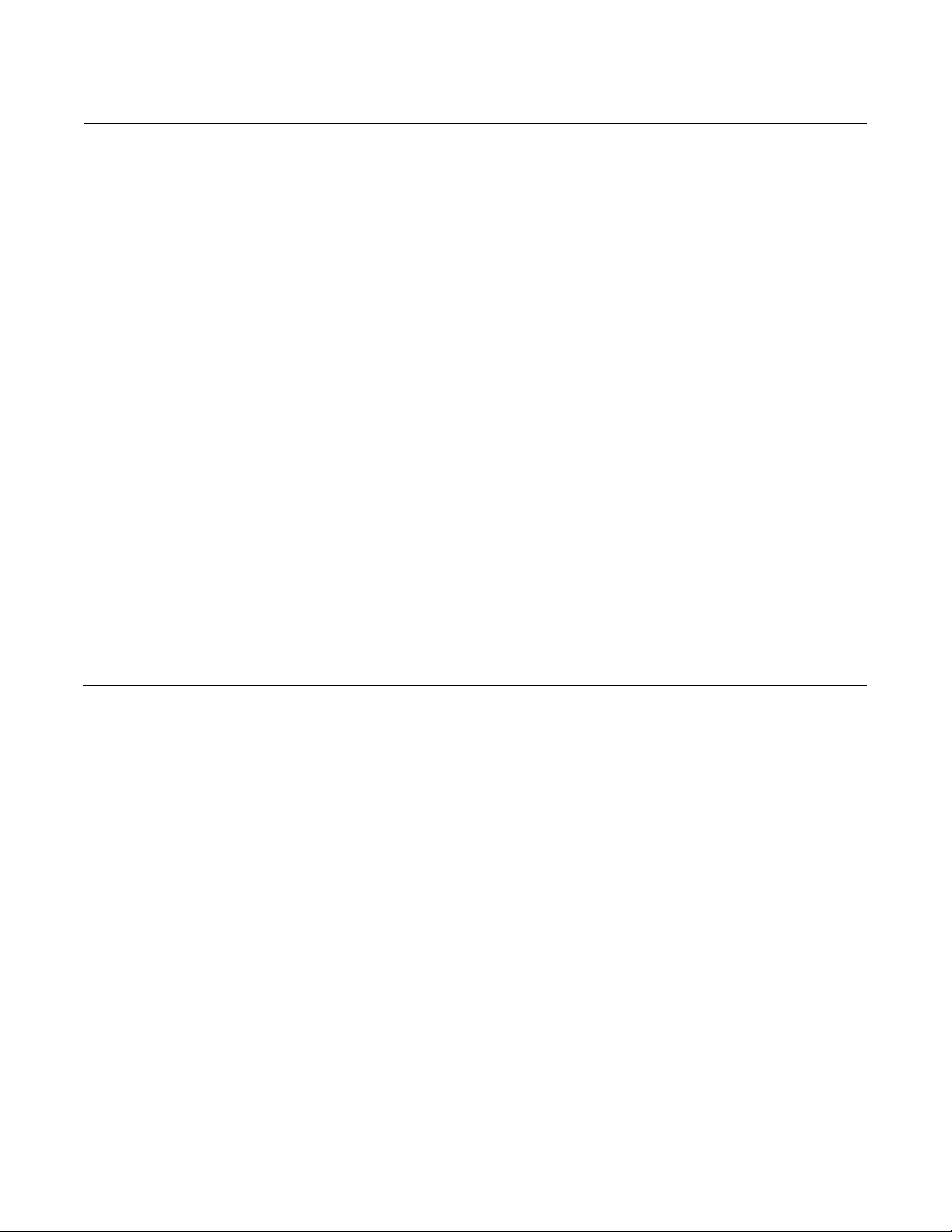

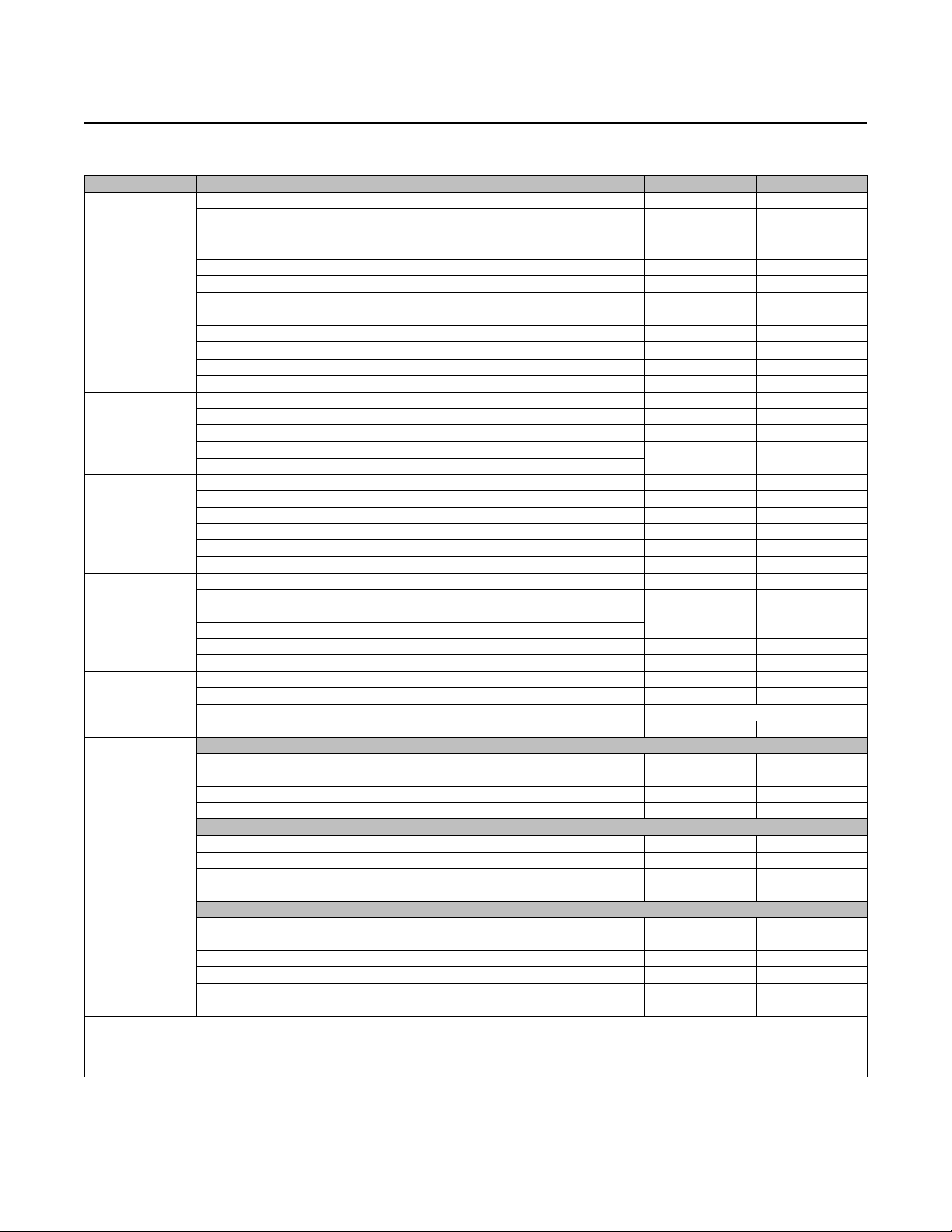

The A11 valve can be supplied with one of several

dynamic seals (figure 1) that can be used in a variety of

demanding applications. With the appropriate seal

selection and materials of c onstruction, the

pressure-assisted seal helps provide excellent shutoff

against the full ASME class pressure range for the A11

valve.

Features

Shaft Versatility– This valve will meet your actuator

needs with a choice of square, keyed, or splined

shaft connections.

Excellent Shutoff Integrity–The pressure-assisted

seal design provides tight shutoff and permits the

use of smaller, less expensive actuators in

applications requiring full ASME B16.34 shutoff

capabilities.

W9570-1

Excellent Emissions Capabilities– The optional

ENVIRO-SEALt packing systems are designed with

very smooth shaft surfaces and live-loading to

provide improved sealing, guiding, and loading

force transmission. The seal of the ENVIRO-SEAL

system can control emissions to below 100 ppm

(parts per million).

Sour Service Capability– Trim and bolting materials

are available for applications involving sour liquids

and gases. These constructions comply with NACE

MR0175-2002, MR0103, and MR0175 / ISO 15156.

High-Temperature/Cryogenic Capabilities–

Optional valve constructions allow this valve to

meet both high-temperature and cryogenic

applications (see table 7 for cryogenic and

high-temperature actuator configurations).

Easy Installation–The valve body self-centers on the

line flange bolts as a fast, accurate means of

centering the valve in the pipeline.

www.Fisher.com

Page 2

Product Bulletin

21.1:A11

May 2013

A11 Valve

D500203X012

Features (continued)

Reliable Flange Gasketing Surface–Seal retainer

screws are located so there is no interference with

the sealing function of either flat sheet or spiral

wound line flange gaskets.

True Bidirectional Shutoff Performance–Afeature

of the valve design is that the torque necessary to

openandclosethevalveisthesameregardlessof

the direction in which the differential pressure is

applied.

Ease of Maintenance–Interchangeability of all parts,

including shafts and discs, simplifies service and

reduces maintenance costs.

Standard Seal

Configurations

Standard Soft Seal (PTFE CL150 and 300, and ETFE

CL600, 900, and 1500)–A resilient dynamic seal

with an elastomeric back-up ring for low to

moderate temperature applications.

Metal Seal–This stainless steel seal is available for

severe service and high-temperature applications to

704_C (1300_F) for NACE applications and 816_C

(1500_F) for other applications.

NOVEX Seal–The NOVEX stainless steel seal is

available for severe service, Cryogenic, and

high-temperature applications to 816_C (1500_F).

Available for CL150/150, 150, and 300, up to

NPS 36 only.

Phoenix III Seal–This three-component,

metal-and-polymeric seal is available for severe

service with low to moderate temperature

applications.

High-Pressure Seal (CL600, 900, and 1500)–This

robust, stainless steel seal is available for severe

service, cryogenic, and high-temperature

applications to 704_C (1300_F), for NACE, and for

other applications to 816_C (1500_F).

Cryo-Tight Cryogenic Seal–This resilient dynamic

seal is available with or without an aluminum

back-up ring for low temperature applications.

Table of Contents

Features 1.....................................

Standard Seal Configurations 2...................

Specifications 3................................

Installation 4..................................

Dimensions and Weights 9.......................

Pressure Drops 16..............................

2

Page 3

A11 Valve

D500203X012

Specifications

Product Bulletin

21.1:A11

May 2013

Available Configurations and Sizes

J Flangeless (wafer) or J Single-flange (lugged)

Available Sizes and Shaft Styles

PRESSURE

RATING

CL150/150

(1)

CL150 30 to 72 --- --CL300 30 to 72 --- ---

CL600

CL900

CL1500

CL2500 Consult your Emerson Process Management Sales Office

1. Refers to a valve construction consisting of a CL150 body and trim suitable for a

shutoff pressure drop of 150 psid.

Keyed Square Splined

30 to 72 --- ---

14 to 48

(standard),

3to12

(optional)

12 to 24

(standard),

6to10

(optional)

10 to 20

(standard)

VALVE SIZE, NPS

3to12

(optional)

6to10

(standard)

---

3to12

(standard)

14 to24

(optional)

Consult your

Emerson Process

Management

sales office

Maximum Temperature Capabilities

See table 1

High-Temperature and Cryogenic Applications: See

table 7 for available valve and actuator combinations

Shutoff Classification per ANSI/FCI 70-2andIEC

60534-4

Standard Soft Seal: Bubble-tight shutoff (exceeds

Class VI)

Metal Seal: 20% of Class IV (reverse direction only)

NOVEX Seal: Standard Class V (Class VI optional,

reverse direction only)

Phoenix III Seal: Bubble-tight (reverse direction only),

Class VI (forward direction only)

High Pressure Seal: Standard Class V (Class VI

optional, reverse direction only)

Cryogenic Seal (Reverse direction only): NOVEX: Class

VI

CTFE: 10% of Class IV

CTFE with Aluminum Backup Ring: Class VI

End Connection Style

Flangeless or single flange style designed t o fit

between raised-face mating flanges of appropriate

class pressure rating

ASME B16.5

NPS 3 through 24: CL600

Flow Characteristic

Modified equal percentage

Flow Coefficients

See Fisher Catalog 12

NPS 6 through 24: CL900

NPS 10 through 20: CL1500

ASME B16.47 Class A and MSS-SP-44

NPS 30 through 48: CL150, 300, and 600

NPS 30 through 36: CL900

Consult your Emerson Process Management sales

office for valves compatible with API 605 and ASME

B16.47 Class B flanges

Maximum Inlet Pressure

(1)

Valve Body: Consistent with CL150, 300, 600, 900,

and 1500 pressure/temperature ratings per ASME

Noise Levels

See Fisher Catalog 12 for sound pressure level

prediction

Available Actuators

Handlever; handwheel; or pneumatic piston, spring

return, double-acting, spring and diaphragm

Disc Rotation

Clockwise (CW) to close

B16.34, see table 17

Seal: seefigure1

Materials of Construction

See table 1

Disc Hard Surfacing: All CL600, 900, and 1500 disc

edges must be coated, regardless of the seal type.

Metal, NOVEX, Phoenix III and cryogenic seals require

the disc to be coated, regardless of the valve class.

1. The pressure/temperature limits in this bulletin, and any applicable codeor standard limitation, should no t be exceeded.

Valve Dimensions and Approximate Weights

See figures 3, 4, 5, 6 and 7

For general packing guidelines, see Bulletin 59.3:042

Packing Selection Guidelines for Rotary Valves,

D102093X012

For information on ENVIRO-SEAL packing system see

Bulletin 59.3:041 ENVIRO-SEAL Packing Systems for

Rotary Valves, D101638X012

(1)

3

Page 4

Product Bulletin

21.1:A11

May 2013

A11 Valve

D500203X012

Figure 1. Available Seal Configurations

BACK-UP

RING

SEAL RING

RETAINING

RING

RETAINING

RING

GRAPHITE

GASKET

RETAINING

RING

E0578

BODY

VALVE DISC

SOFT SEAL WITH

BACK-UP O-RING

BODY BODY

VALVE DISC

NOVEX SEAL

BODY

VALVE DISC

METAL SEAL

LARGEST

OUTSIDE

DIAMETER

HIGH PRESSURE

AT SHUTOFF

LARGEST

OUTSIDE

DIAMETER

SEAL

RING

HIGH PRESSURE

AT SHUTOFF

SEAL

RING

HIGH PRESSURE

AT SHUTOFF

2

1

1

GRAPHITE

GASKET

GRAPHITE

GASKET

RETAINING

RING

GRAPHITE

GASKET

RETAINING

RING

BACK-UP

RING

BODY

VALVE DISC

PHOENIX III

FIRE-SAFE SEAL

VALVE DISC

CRYOGENIC SEAL

HPS

SEAL RING

BODY

VALVE DISC

HIGH-PRESSURE SEAL (HPS)

Notes:

1

This unidirectional seal must be installed so that the retaining ring is downstream from the high pressure side of the valve at shutoff, as shown.

2

For this bidirectional seal, the “preferred” valve orientation places the retaining ring downstream from the high pressureside ofthe valveat shutoff.

LARGEST

OUTSIDE

DIAMETER

SEAL

RING

RESILIENT

INSERT

HIGH PRESSURE

AT SHUTOFF

LARGEST

OUTSIDE

DIAMETER

CRYOGENIC

SEAL RING

HIGH PRESSURE

AT SHUTOFF

HIGH PRESSURE

AT SHUTOFF

1

1

1

Installation

Preferred valve orientation for the A11 valve is reverse

flow direction. Reverse flow direction is into the side of

the valve body opposite the retaining ring or into the

shaft side of the disc.

For erosive and many severe service applications,

valves with bidirectional seals can and should be

installed with the shaft horizontal and in the forward

flow direction to prevent direct impingement of the

process media on the seal, and to minimize the

exposure of the shaft bearings to the process media.

4

The standard soft seal and the Phoenix III seal both

offer bidirectional shutoff. Valves using either metal,

NOVEX, or cryogenic seals are unidirectional and must

be installed in the reverse flow orientation.

For assistance in selecting the appropriate

combination of actuator action and open valve

position, consult your Emerson Process Management

sales office.

Dimensions and weights for wafer-style and

single-flangevalvesareshowninfigures3,4,5,6,

and 7.

Page 5

Product Bulletin

A11 Valve

D500203X012

Table 1. Material Temperature Ranges

PART NAME MATERIAL TEMP _C TEMP _F

WCC Steel, SA-516-70 or SA-105 -29 to 427 -20 to 800

(2)

(2)

Valve Body

(5)

Disc

(1)

CF8M, CF8C, CF8

CF8M, CF8C, CF8

Disc Seating Surface

Coating

Shaft

(3)

Bearings

Seal Ring

Backup Ring

Packing

Square Ring Graphite for Non-oxidizing Service -254 to 816 -425 to 1500

1. Special gasket retainer bolts are required for over 538_C (1000_ F).

2. Special retainingring screws for single flange valves over 538_C (1000_F).

3. Special thrustbearings are required for high temperature applications over 343_C (650_F) (with 6 and 12 inch extensions). Constructions with carbon steel valvesand SST discs may require

special thrust bearingsat temperatures greater than 343_C(650_F).

4. Special option; contact your Emerson Process Managementsales office.

5.ForvalvesNPS30andlargerattemperaturesover254_C(450_F),thediscmaterialshouldbethesameasthevalvebodymaterial.

CF8M,CF8,CF3M,CF3 -254 to 538 -425 to 1000

FMS 20B16 a Fisher material standard (0.04% min carbon)

over 538 to 816 over 1000 to 1500

LCC -45 to 343 -50 to 650

C12A -29 to 649 -20 to 1200

WC9 -29 to 593 -20 to 1100

CG8M, CG3M, CF8C -198 to 538 -325 to 1000

WCC S teel -29 to 427 -20 to 800

CF8M,CF8,CF3M,CF3 -254 to 538 -425 to 1000

FMS 20B16 a Fisher material standard (0.04% min carbon)

over 538 to 816 over 1000 to 1500

CB7Cu-1 -29 to 427 -20 to 800

CG8M, CG3M, CF8C -198 to 538 -325 to 1000

Chrome Plating -254 to 316 -425 to 600

Chromium Coat per FFS 2E1 -254 to 593 -425 to 1100

Electroless Nickel Coating(ENC) -254 to 343 -425 to 650

Chromium Carbide Coating

CoCr-A(Alloy6)

(4)

-254 to 816 -425 to 1500

S17400 (H1025) -73 to 427 -100 to 800

S17400 (H1150M) -196 to 427 -320 to 800

(4)

N05500

-254 to 482 -425 to 900

N07718 -254 to 704 -425 to 1300

(4)

S20910

N07750

(4)

-254 to 593 -320 to 1100

over 593 to 816 over 1100 to 1500

PEEK -73 to 260 -100 to 500

PTFE Composition -254 to 163 -425 to 325

S31600 (316 SST Nitrided)

R30006 (Alloy 6)

Bronze

PTFE Lined N04400

(4)

(4)

(4)

-254 to 816 -425 to 1500

-254 to 302 -425 to 575

-254 to 232 -425 to 450

Soft - PTFE -62 to232 -80 to 450

Soft - ETFE -54 to 149 -65 to 300

Metal - All See table 2

HPS - S20910

(4)

-254 to 649 -425 to 1200

Used with Soft Seal

Fluorocarbon -29 to 204 -20 to 400

EPR -54 to 182 -65 to 360

(4)

Nitrile

Chloroprene

(4)

-29 to 93 -20 to 200

-43 to 149 -45 to 300

Used with Phoenix III Seal

Fluorocarbon -40 to 232 -40 to 450

EPR -62 to 204 -80 to 400

(4)

Nitrile

Chloroprene

(4)

-40 to 149 -40 to 300

-54 to 149 -65 to 300

Used with Cryogenic Seal

Aluminum

(4)

-254 to 149 -425 to 300

PTFE V-Ring -254 to 232 -425 to 450

PTFE ENVIRO-SEAL -254 to 232 -425 to 450

Square Ring Graphite for Oxidizing Service -254 to 538 -425 to 1000

Graphite ENVIRO-SEAL -140 to 315 -325 to 600

21.1:A11

May 2013

5

Page 6

Product Bulletin

21.1:A11

May 2013

Table 2. Temperature Limits for Metal Seal

MAXIMUM

SEAL TYPE PRESSURE RATING SEAL MATERIAL

S31600 w/CF8M disc

S31600 w/WCC disc

S31600 w/CF8M disc

S31600 w/WCC disc

(2)

(2)

S20910 NACE w/ CF8M disc

S20910 w/WCC disc

S17400 H1150Mw/ CF8M disc

Metal

CL150/150, and150

300

(1, 2)

600

(2)

S17400 H1150Mw/ WCCdisc

1. When used with CF8M discs, S20910 is the preferred seal material. When usedwith WCC discs, S17400H1150M is the preferred material.

2. For valves with WCC discs at temperatures over 254_C (450_F),contact your Emerson Process Management salesoffice for seal materialselection.

Table 3. Trim Descriptions - CL600

Trim Type

Trim

Number

500

502

Standard

504

506

High-

Temperature

514H

516H

Cryogenic 517C

1. Trim 500 is furnished as standard trim in all CL600 A11 valves.

2. If operating temperature is above 343_C(650_F), see table 7for available actuator configurations.

3. Trim includes6-inch shaft extension.

4. Trim includes12-inch shaft extension.

5. Trim includes Cryogenic shaft extension, see table6 for extension length.

(1)

(2)

(3)

(4)

(5)

Temperature

Range

-29 to149_C

-20 to 300_F

-46 to232_C

-50 to 450_F

-40 to149_C

-40 to 300_F

-46 to427_C

-50 to 800_F

-46 to427_C

-50 to 800_F

-46 to538_C

-50 to 1000_F

-196 to163_C

-320 to325_F

Disc

Material

Disc Edge Coating Seal Type Seal Material Shaft Bearings Packing

CF8M Chrome Plated Soft ETFE S17400 H1025 PEEK PTFE

CF8M Chrome Plated Metal S20910 S17400 H1025 PEEK PTFE

CF8M Chrome Plated Phoenix III S31600/ETFE S17400 H1025 PEEK PTFE

CF8M

CF8M

CF8M

CF8M Chrome Plated HPS

Chromium Coat per

FFS 2E1

Chromium Coat per

FFS 2E1

Chromium Coat per

FFS 2E1

Metal S20910 S17400 H1025

Metal S20910 S17400 H1025

Metal S21800 N07718

S20910

Nitrided

TEMPERATURE LIMITS

_C _F

538

232

816

232

649

232

232

427

S17400 H1150M

1000

450

1500

450

1200

450

450

800

Composition

A11 Valve

D500203X012

BACKUP RING

316 SST

Nitrided

316 SST

Nitrided

316 SST

Nitrided

PTFE

No

No

No

No

Graphite

Graphite

Graphite

PTFE

Table 4. Trim Descriptions - CL900 and CL1500

Trim Type

Trim

Number

500

502

Standard

504

506

High-

Temperature

1. Trim 500 is furnished as standard trim in all CL1500 A11 valves.

2. If operating temperature is above 343_C(650_F), see table 7for available actuator configurations.

3. Trim includes6-inch shaft extension.

4. Trim includes12-inch shaft extension.

5. Consult Fisher bulletin 59.3:042 (D102093X012) for packing selection guidelinesregarding pressure/temperaturelimits.

514H

516H

6

(1)

(2)

(3)

(4)

Temperature

Range

-29 to149_C

-20 to 300_F

-46 to232_C

-50 to 450_F

-40 to149_C

-40 to 300_F

-46 to427_C

-50 to 800_F

-46 to427_C

-50 to 800_F

-46 to538_C

-50 to 1000_F

Disc

Material

Disc Edge Coating Seal Type Seal Material Shaft Bearings Packing

CB7Cu-1 Chrome Plated Soft ETFE S17400 H1025 PEEK PTFE

CB7Cu-1 Chrome Plated HPS

CB7Cu-1 Chrome Plated Phoenix III S31600/ETFE S17400 H1025 PEEK PTFE

CB7Cu-1

CB7Cu-1

CF8M

Chromium Coat per

FFS 2E1

Chromium Coat per

FFS 2E1

Chromium Coat per

FFS 2E1

HPS

HPS

HPS

S20910

Nitrided

S20910

Nitrided

S20910

Nitrided

S21800

Nitrided

S17400 H1025 PEEK PTFE

S17400 H1025

S17400 H1025

N07718

316 SST

Nitrided

316 SST

Nitrided

316 SST

Nitrided

Graphite

Graphite

Graphite

(5)

Page 7

A11 Valve

D500203X012

Table 5. Trim Descriptions - CL150/150, CL150, and CL300

Trim Type

Standard

High-

Temperature

Cryogenic 567C

1. Trim 550 is furnished as standard trim in all CL150/150, 150, and 300 A11 valves.

2. If operating temperature is above 343_C(650_F), see table 7for available actuator configurations.

3. Trim includes6-inch shaft extension.

4. Trim includes12-inch shaft extension.

5. Trim includes Cryogenic shaft extension, see table6 for extension length.

6. NPS 42 and 48 will have an S31600 metal seal ring in place ofthe S31600 NOVEX seal ring.

Trim

Number

550

552

554

555

556

564H

566H

(1)

(2)

(3)

(4)

(5)

Temperature

Range

-29 to204_C

-20 to 400_F

-46 to232_C

-50 to 450_F

-40 to232_C

-40 to 450_F

-46 to316_C

-50 to 600_F

-46 to427_C

-50 to 800_F

-46 to427_C

-50 to 800_F

-46to538_C

- 50 to 1000_F

-196 to163_C

-320 to325_F

Disc

Material

CF8M or

WCC

CF8M or

WCC

CF8M or

WCC

CF8M or

WCC

CF8M or

WCC

CF8M or

WCC

CF8M

CF8M Chrome Plated NOVEX

Disc Edge Coating Seal Type Seal Material Shaft Bearings Packing

None Soft PTFE S17400H1025 PEEK PTFE

Chrome Plated NOVEX

Chrome Plated Phoenix III S31600/PTFE S17400 H1025 PEEK PTFE

Chrome Plated NOVEX

Chromium Coat per

FFS 2E1

Chromium Coat per

FFS 2E1

Chromium Coat per

FFS 2E1

NOVEX

NOVEX

NOVEX

Product Bulletin

(6)

S31600 S17400 H1025 PEEK PTFE

(6)

S31600 S17400 H1025

(6)

S31600 S17400 H1025

(6)

S31600 S17400 H1025

(6)

S31600 N07718

(6)

S31600 S17400 H1150M

316 SST

Nitrided

316 SST

Nitrided

316 SST

Nitrided

316 SST

Nitrided

PTFE

Composition

21.1:A11

May 2013

Graphite

Graphite

Graphite

Graphite

PTFE

Table 6. Cryogenic Shaft Extension Lengths

CRYOGENIC EXTENSION LENGTH, INCH FOR VALVE BODY SIZE, NPS

3 4 6 8 10 12 14 16 18 20 24 30 36 42 48

14-3/4 17-3/4 19-1/4 26-3/4 28-1/2 33-1/2 36 36 36 36 36 36 36 36 36

1. Extension lengthmeasured from center ofvalve body to bottom of packing flange.

(1)

Note

Trim will include the standard disc material included in the

FS number selected. If the trim number indicates only a

CF8M disc, the trim cannot be used with an FS number

including a WCC disc.

7

Page 8

Product Bulletin

21.1:A11

May 2013

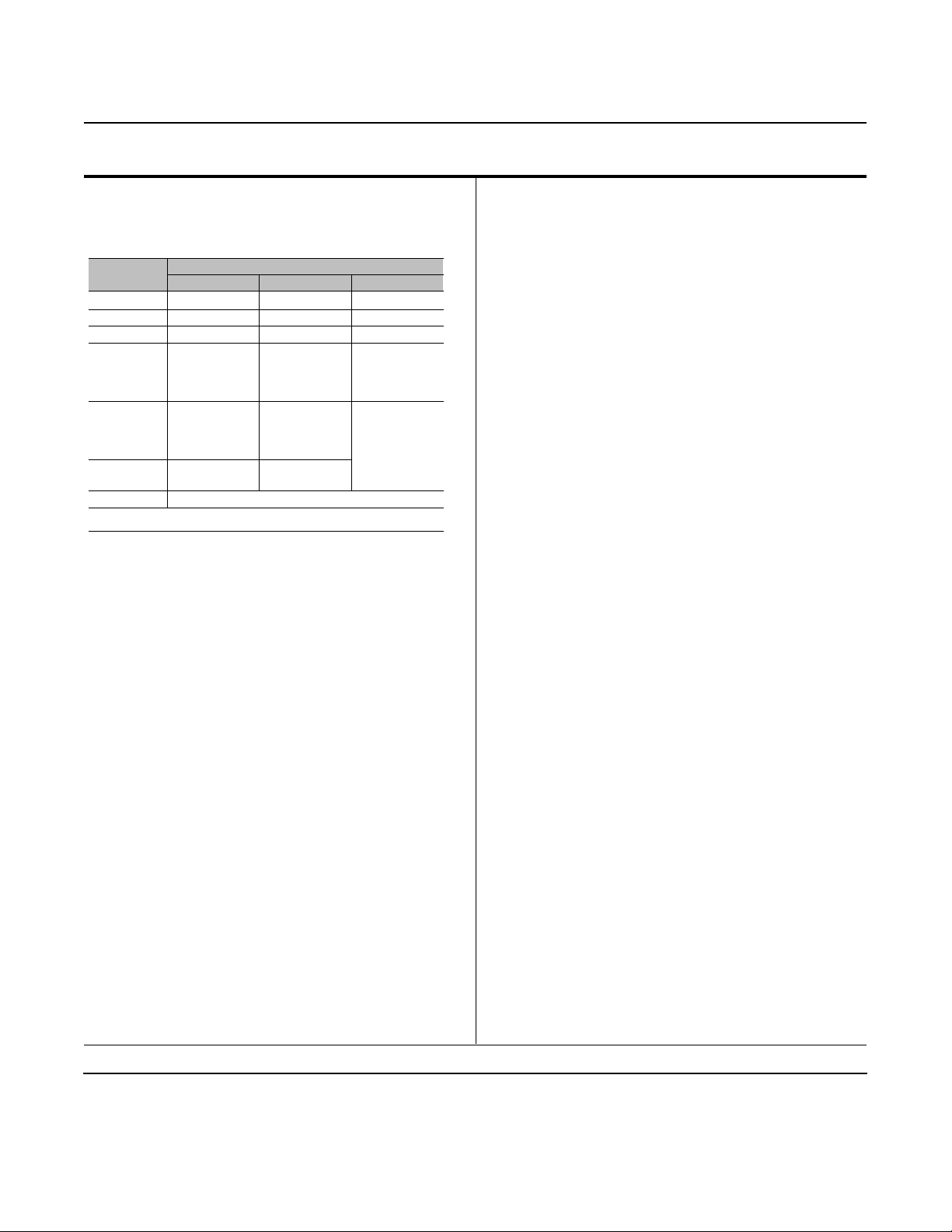

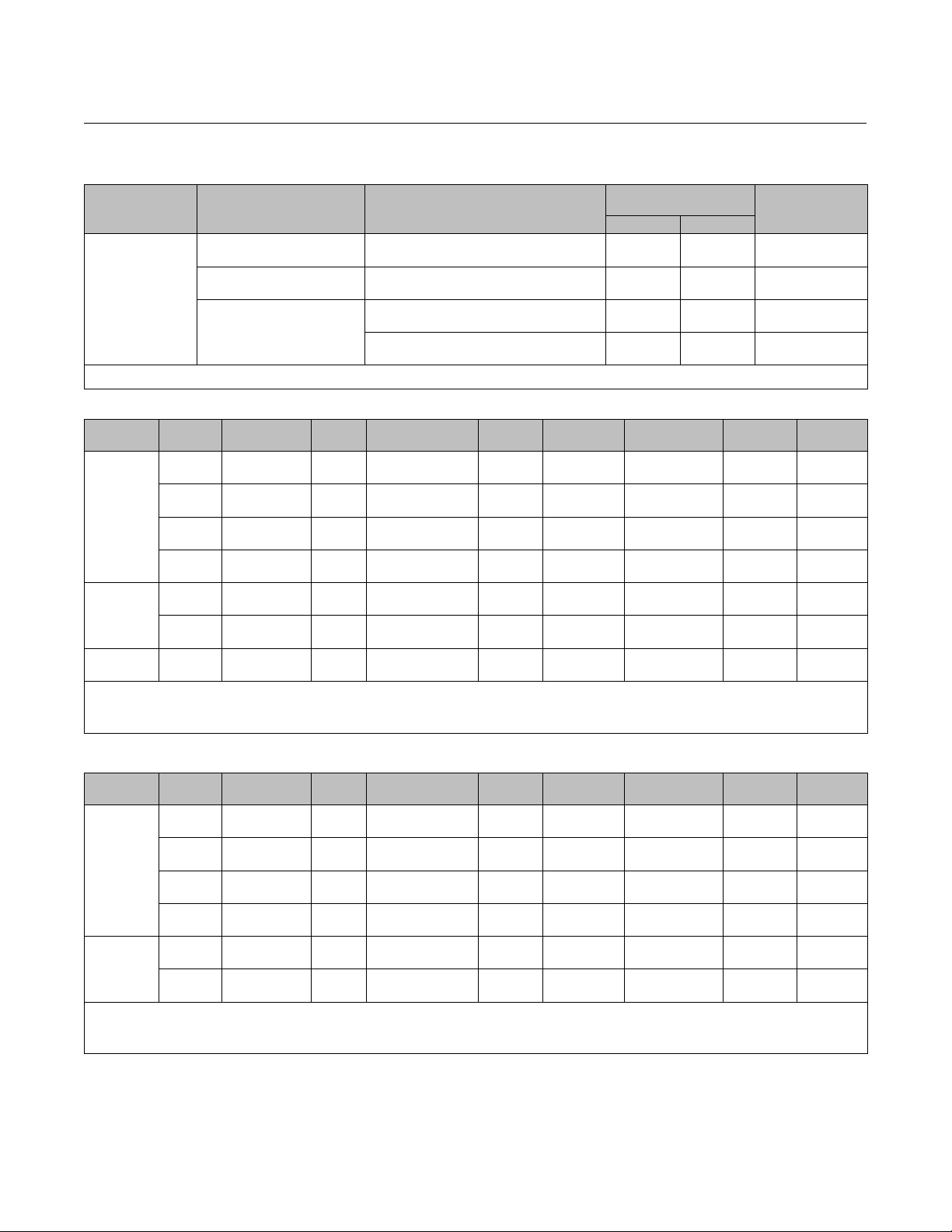

Table 7. Valve/Actuator Combinations

TEMPERATURE RANGE

-254 to-196_C

(-425 to-320_F)

-196 to-46_C

(-320 to-50_F)

-46 to343_C

(-50 to650_F)

343 to426_C

(650 to800_F)

426 to538_C

(800 to1000_F)

538 to816_C

(1000 to1500_F)

1. Select splined shaft option when necessary (standardfor NPS 3-12 CL600valves).

2. See figure 2 for actuator mounting positions.

3. Select keyed shaft option when usingBettis “G” Series Actuator, NPS 6-12.

4. Consult your Emerson ProcessManagement sales office.

5. Select square shaft option when using FieldQ or 1035 actuators.

Valve with cryogenic extension and special trim

materials

Valve with cryogenic extension and trim and

Valve (select appropriate trim) and standard

Mounting positions 1 and 3: Valve (select

appropriate trim) and standard actuator

Mounting positions 2 and 4: Valve with 6-inch

extension (select trim 514H or 564H) and

standard actuator - ambient temperature may

dictate the need for a high-temperature

Mounting positions 1 and 3: Valve (select

appropriate trim) and standard actuator

Mounting positions 2 and 4: Valve with 6-inch

extension (select trim 564H or 514H with N07718

shaft) and standard actuator - ambient

temperature may dictate the need for a

Valve with 12-inch extension and special trim

materials

1052, 1061, or 2052

(4)

and standard actuator

(1, 2)

standard actuator

actuator

diaphragm

high-temperature diaphragm

(4)

and standard actuator

SELECTION GUIDELINES

Bettis™

Valve withcryogenic extension and special trim

materials

Valve with cryogenic extension and trim and

Valve (select appropriate trim) and standard

Valve (select appropriate trim) and actuator with

Valve with 6-inch extension(select trim514H)

Valve (select appropriate trim) and actuator with

Valve with 6-inch extension (select trim 564H or

514H withN07718 shaft) and standard actuator

Valve with 12-inch extension and special trim

materials

A11 Valve

D500203X012

(3)

, FieldQt

high-temperature O-rings option

high-temperature O-rings option

(5)

(5)

, 1035

(4)

and standard actuator

standard actuator

actuator

or

and standard actuator

or

(4)

and standard actuator

,orHytorkXL

Figure 2. Mounting Styles and Positions

STYLE D

4

33

STYLE A

NORMAL

FLOW

GE37285

4

POSITION 1

STANDARD

2

3

POSITION 1

STANDARD

2

STYLE C

POSITION 1

STANDARD

4

2

NORMAL

FLOW

STYLE B

POSITION 1

STANDARD

4

2

3

8

Page 9

Product Bulletin

A11 Valve

D500203X012

Table 8. Dimensions and Weights Wafer and Single Flange Style CL150/150

Wafer

A

Single

Flange

B C D E F H J K L

mm kg

See

Thread

Info

Below

Inches lbs

76.2

Thread

Below

See

Info

(1)

M

744 57.2 12.7 528

R

VALVE

SIZE,

NPS

30 864 994 121 559 516 295 95.25 337

36 1029 1178 149 683 613 295 95.25 337 76.2 888 57.2 12.7 806

42 1207 1356 210 762 695 314 114.3 337 76.2 1032 69.9 15.9 1302

48 1364 1524 229 889 826 314 114.3 305 152 1180 69.9 15.9 1904

30 34.00 39.12 4.75 22.00 20.31 11.62 3.75 13.25 1-1/4-8 3.00 7/8-9 29.30 2.25 1/2 1164

36 40.50 46.38 5.88 26.88 24.12 11.62 3.75 13.25 1-1/2-8 3.00 7/8-9 34.96 2.25 1/2 1778

42 47.50 53.38 8.25 30.00 27.38 12.38 4.5 13.25 1-1/2-8 3.00 7/8-9 40.64 2.75 5/8 2871

48 53.69 60.00 9.00 35.00 32.50 12.38 4.5 12.00 1-1/2-8 6.00 1-1/4-7 46.47 2.75 5/8 4198

1. M dimensionis disc chordal swing diameter.

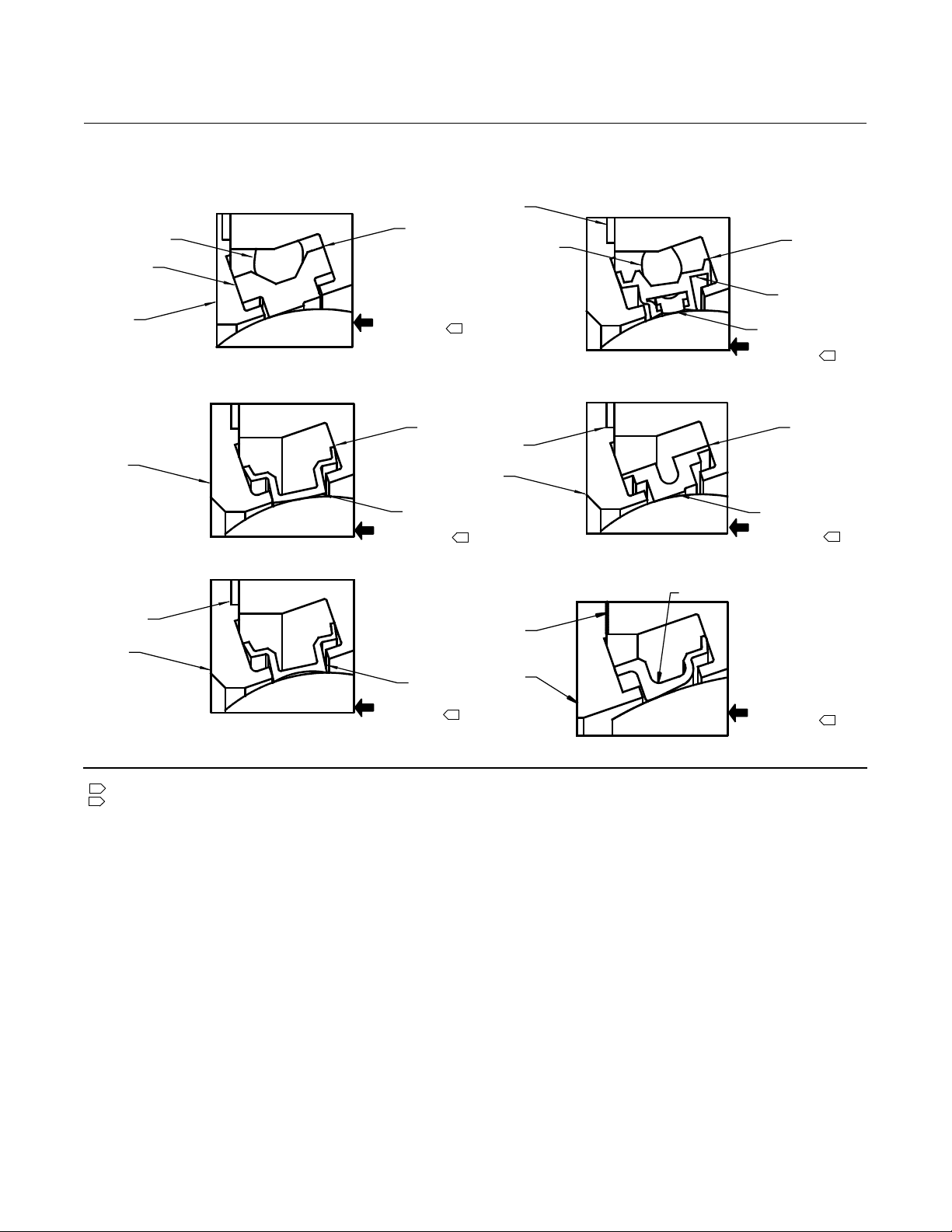

Figure 3. Dimensions Wafer and Single Flange Style CL150/150 (also see table 8)

21.1:A11

May 2013

KEY SQ

SIZE

APPROX

WEIGHT

D

C

E

B

NPS 48 ONLY

H

H

F

H

K

L

R

A

L

4HOLES,JDIA.

K

DC

E

F

13B4598-D

13B4556-D

B2633-1

JDIA.

R

A

9

Page 10

Product Bulletin

21.1:A11

May 2013

Table 9. Dimensions and Weights Wafer and Single Flange Style CL150

Wafer

A

Single

Flange

B C D E F H J K L

mm kg

76.2

See

Thread

Info

Below

Inches lbs

Thread

Below

(1)

M

735.8 69.9 15.9 528

See

Info

VALVE

SIZE,

NPS

30 866.6 991 158.8 590.6 520.7 314.5 114.3 336.6

36 1031.7 1175 177.8 657.4 619.3 314.5 114.3 304.8 152.4 887.7 69.9 15.9 806

42 1050 1360 228.6 838.2 730.3 314.5 114.3 304.8 152.4 1028.2 69.9 15.9 1302

48 1371.6 1524 260.4 901.7 797.1 314.5 114.3 508.0 203.2 1110.9 69.9 15.9 1904

30 34.12 39.00 6.25 23.25 20.50 12.38 4.5 13.25 1-1/4-8 3.00 7/8-9 28.97 2-3/4 5/8 1164

36 40.62 46.25 7.00 25.88 24.38 12.38 4.5 12.00 1-1/2-8 6.00 1-1/4-7 34.95 2-3/4 5/8 1778

42 47.50 53.56 9.00 33.00 28.75 12.38 4.5 12.00 1-1/2-8 6.00 1-1/4-7 40.48 2-3/4 5/8 2871

48 54.00 60.00 10.25 35.50 31.38 12.38 4.5 20.00 1-1/2-8 8.00 1-1/4-7 46.09 2-3/4 5/8 4198

1. M dimensionis disc chordal swing diameter.

Figure 4. Dimensions Wafer and Single Flange Style CL150 (also see table 9)

A11 Valve

D500203X012

KEY SQ

R

SIZE

APPROX

WEIGHT

D

JDIA.

DC

A

C

E

F

LDIA.

RDIA.

H

E

F

R

B

K

H

K

10

13B4160-A

13B4443-D

B2377-2

ADIA.

4HOLES,JDIA.

NPS 36, 42 and 48

Page 11

Product Bulletin

A11 Valve

D500203X012

Table 10. Dimensions and Weights Wafer and Single Flange Style CL300

Wafer

A

Flange

Single

B C D E F H J K L M

mm kg

203

See

Thread

Info

Below

Inches lbs

See

Thread

Info

Below

(1)

R

681 70 15.9 952

VALVE

SIZE

NPS

30 865 1105 241 648 576 314 114.3 508

36 1035 1286 27 3 740 675 353 152.4 432 203 838 95 22.2 1315

42 1162 1346 29 9 867 768 363 163.6 432 203 943 102 25.4 2263

48 1315 1484 42 2 934 888 497 114.3 660 330 1125 146 38.1 3056

30 34.06 43.50 9.50 25.50 22.69 12.38 4.5 20.00 1-3/4-8 8.00 1-1/4-7 26.80 2-3/4 5/8 2100

36 40.75 50.62 10.75 29.12 26.56 13.88 6 17.00 2-8 8.00 1-1/4-7 32.99 3-3/4 7/8 2900

42 45.75 53.00 11.75 34.12 30.25 14.31 6.44 17.00 1-5/8-8 8.00 1-1/4-7 37.13 4 1 4989

48 51.75 58.44 16.62 36.75 34.94 19.56 4.5 26.00 1- 7/8-8 13.00 1-1/4-7 44.29 5-3/4 1-1/2 6738

1. M dimensionis disc chordal swing diameter.

21.1:A11

May 2013

KEY SQ

SIZE

APPROX

WEIGHT

Figure 5. Dimensions Wafer and Single Flange Style CL300 (also see table 10)

ADIA.

13B4054-B

A6048-2/IL

ADIA.

13B4157-A

A6052-2

D

CE

F

RDIA.

JDIA.

D

C

E

F

RDIA.

4HOLES,JDIA.

LDIA.

K

H

LDIA.

B

K

H

B

LDIA

254

(10)

NPS 36 and 42

451.2

(18)

LDIA

LDIA

H

K

NPS 30

H

K

109.5

(4.31)

H

K

NPS 48

11

Page 12

Product Bulletin

21.1:A11

May 2013

Table 11. Dimensions and Weights Single Flange Style CL600

VALVE

SIZE,

NPS

A B C D

Keyed

Shaft

E F

Splined

Shaft

Sq

Shaft

Keyed

Shaft

Splined

Shaft

G

Square

H K

(1)

M

mm kg

3 213 46 146 83 210 187 57 66.68 67 10.3 89 --- 64 12.7

4 276 61 178 105 210 214 67 66.68 73 15.9 114 --- 86 15.9 19.1 4.8 10

6 346 73 235 156 210 214 90 66.68 86 22.2 114 --- 127 25.4 25.4 6.4 25

8 424 89 260 230 210 208 90 66.80 92 25.4 127 51 182 31.8 38.1 6.4 52

10 521 114 321 282 210 356 95 66.80 156 34.9 127 51 221 38.1 44.5 9.5 113

12 569 140 356 318 210 356 95 73.15 156 34.9 273 51 260 44.5 44.5 9.5 153

14 613 159 371 343 295 356 --- 95.25 156 --- 337 76.2 282 57.2 50.8 12.7 186

16 689 178 432 384 314 356 --- 114.3 156 --- 337 76.2 321 69.9 55.9 15.9 274

18 752 197 476 430 314

20 823 229 508 449 314

24 946 229 562 524 314

(2)

(2)

(2)

--- 114.3

--- 114.3

--- 114.3

(2)

(2)

(2)

--- 305 152.4 371 69.9

--- 305 152.4 399 69.9

--- 508 203.2 516 69.9

Inches lbs

3 8.38 1.81 5.75 3.25 8.25 7.38 2.25 2.625 2.62 13/32 3.50 --- 2.52 1/2

4 10.88 2.38 7.00 4.12 8.25 8.44 2.62 2.625 2.88 5/8 4.50 --- 3.40 5/8 3/4 3/16 23

6 13.62 2.88 9.25 6.12 8.25 8.44 3.56 2.625 3.38 7/8 4.50 --- 4.98 1 1 1/4 54

8 16.69 3.50 10.25 9.06 8.25 8.19 3.56 2.63 3.63 1 5.00 2.00 7.17 1-1/4 1-1/2 1/4 115

10 20.50 4.50 12.62 11.12 8.25 14.00 3.75 2.63 6.13 1-3/8 5.00 2.00 8.70 1-1/2 1-3/4 3/8 249

12 22.38 5.50 14.00 12.50 8.25 14.00 3.75 2.88 6.13 1-3/8 10.75 2.00 10.22 1-3/4 1-3/4 3/8 337

14 24.12 6.25 14.62 13.50 11.63 14.00 --- 3.75 6.13 --- 13.25 3.00 11.09 2-1/4 2 1/2 410

16 27.12 7.00 17.00 15.12 12.38 14.00 --- 4.5 6.13 --- 13.25 3.00 12.63 2-3/4 2-1/2 5/8 605

18 29.62 7.75 18.75 16.94 12.38

20 32.38 9.00 20.00 17.69 12.38

24 37.25 9.00 22.12 20.62 12.38

1. M dimension is the disc chordal swing diameter.

2. Consult your Emerson ProcessManagement sales office.

(2)

--- 4.5

(2)

--- 4.5

(2)

--- 4.5

(2)

(2)

(2)

--- 12.00 6.00 14.62 2-3/4

--- 12.00 6.00 15.71 2-3/4

--- 20.00 8.00 20.32 2-3/4

R

Keyed Splined

14.2 x

15.9

9/16 x

A11 Valve

D500203X012

KEY SQ

SIZE

3.2 9

(2)

15.9 361

(2)

15.9 526

(2)

15.9 669

1/8 20

5/8

(2)

5/8 796

(2)

5/8 1160

(2)

5/8 1475

APPROX

WEIGHT

Table 12. Dimensions Single Flange Style CL600

VALVE SIZE, NPS

3-24 See Thread Info Below See Thread Info Below

VALVE SIZE, NPS Inches

3 0.53 3/4-108holes

4 0.53 7/8-98holes

6 0.53 1-812holes

8 1/2-13 1-1/8-812holes

10 3/4-10 1-1/4-816holes

12 3/4-10 1-1/4-820holes

14 7/8-9 1-3/8-820holes

16 7/8-9 1-1/2-820holes

18 1-1/4-7 1-5/8-820holes

20 1-1/4-7 1-5/8-824holes

24 1-1/4-7 1-7/8-824holes

L P

mm

12

Page 13

A11 Valve

D500203X012

Figure 6. Dimensions Single Flange Style CL600 (also see table 11)

Product Bulletin

21.1:A11

May 2013

PDIA.

13B4151-A

B2379-2

D

C

NPS 3 THROUGH 6 SINGLE FLANGE

ADIA.

E

F

4HOLES,

13.5(0.53) DIA.,

THRU ON AN H

DIA. CIRCLE

Figure 7. Dimensions Single Flange Style CL600 (also see table 11)

CD

E

F

Gsq

B

M

mm

(INCH)

B

3/4 INCH

8-INCH ONLY

E

PDIA.

13B4156-A

A6053-2

RDIA.

ADIA.

H

NPS 8 THROUGH 24 SINGLE FLANGE

Gsq

DIMENSIONS FOR

SQUARE-END SHAFTS

4HOLES,

K

LDIA.

13

Page 14

Product Bulletin

21.1:A11

May 2013

Table 13. Dimensions and Weights Single Flange Style CL900

VALVE

SIZE,

NPS

6 381 76 233 233 210 90 67 22 235 46 126 25 6 59.0

8 470 109 305 305 210 90 67 35 273 51 164 38 10 120

10 546 146 353 353 210 95 67 35 273 51 182 44 10 210

12 610 229 445 445 295 --- 95 --- 337 76 165 57 13 450

14 635 216 451 451 295 --- 95 --- 337 76 208 57 13 444

16 705 241 438 438 314 --- 117 --- 337 76 217 70 16 513

18 781 273 524 524 314 --- 114 --- 337 76

20 857 292 695 695 314 --- 114 --- 305 165 284 70 16 991

24 1041 333 657 657 314 --- 117 --- 572 203 366 95 22 1628

6 15.00 3.00 9.19 9.19 8.25 3.56 2.62 0.87 9.25 1.812 4.98 1.00 1/4 130

8 18.50 4.31 12.00 12.00 8.25 3.75 2.62 1.37 10.75 2.00 6.46 1.50 3/8 264

10 21.50 5.75 13.88 13.88 8.25 3.75 2.62 1.37 10.75 2.00 7.17 1.75 3/8 463

12 24.00 9.00 17.50 17.50 11.62 --- 3.75 --- 13.25 3.00 6.48 2.25 1/2 993

14 25.00 8.50 17.75 17.75 11.62 --- 3.75 --- 13.25 3.00 8.17 2.25 1/2 978

16 27.75 9.50 17.25 17.25 12.38 --- 4.62 --- 13.25 3.00 8.55 2.75 5/8 1132

18 30.76 10.75 20.63 20.63 12.38 --- 4.50 --- 13.25 3.00

20 33.75 11.50 27.38 27.38 12.38 --- 4.50 --- 12.00 6.50 11.19 2.75 5/8 2185

24 41.00 13.12 25.88 25.88 12.38 --- 4.62 --- 22.50 8.00 14.40 3.75 7/8 3590

1. M dimension is the disc chordal swing diameter.

2. Contact your Emerson Process Management sales office.

A B C D

Keyed

Shaft

E

Sq Shaft

F

mm kg

Inches lbs

G

Square

H K M

(2)

(2)

R

(1)

Keyed

70 16 703

2.75 5/8 1550

A11 Valve

D500203X012

KEY SQ

SIZE

APPROX

WEIGHT

Table 14. Dimensions Single Flange Style CL900

VALVE SIZE, NPS

6

8

10

12

14

16

18

20

24

VALVE SIZE, NPS Inches

6 5/8-11 4 Holes 1-1/8-812Holes

8 3/4-10 4 Holes 1-3/8-812Holes

10 3/4-10 4 Holes 1-3/8-816Holes

12 7/8-94Holes 1-3/8-820Holes

14 7/8-94Holes 1-1/2-820Holes

16 7/8-94Holes 1-5/8-820Holes

18 1-1/4-76Holes 1-7/8-820Holes

20 1-1/4-76Holes 2-820Holes

24 1-1/4-76Holes 2-1/2-820Holes

L J

mm

See Thread Info Below See Thread Info Below

14

Page 15

Product Bulletin

A11 Valve

D500203X012

Table 15. Dimensions and Weights Single Flange Style CL1500

VALVE

SIZE,

NPS

10 584 178 399 399 295 95 337 76 118 57 13 311

12 673 267 445 445 305 105 337 76

14 754 283 483 483 210 114 337 76

16 826 321 559 559 314 152 305 152

18 914 349 629 629 379 164 508 203

20 991 410 682 682 404 171 508 203

10 23.00 7.00 15.69 15.69 11.62 3.75 13.25 3.00 4.63 2.25 1/2 685

12 26.50 10.50 17.50 17.50 12.00 4.13 13.25 3.00

14 29.69 11.13 19.00 19.00 8.25 4.50 13.25 3.00

16 32.52 12.63 22.00 22.00 12.38 6.00 12.00 6.00

18 36.00 13.75 24.75 24.75 14.94 6.44 20.00 8.00

20 39.00 16.13 26.84 26.84 15.89 6.75 20.00 8.00

1. M dimension is the disc chordal swing diameter.

2. The disc size is less than the face-to-face dimension ofthis valve. Therefore, the disc chordal swing is not applicable when sizing this valve.

A B C D

E

Keyed

Shaft

F H K

mm kg

Inches lbs

(1)

M

R Keyed

(2)

(2)

(2)

(2)

(2)

(2)

(2)

(2)

(2)

(2)

64 16 663

70 16 810

70 22 1152

102 25 1613

108 25 2250

2.50 5/8 1462

2.75 5/8 1785

2.75 7/8 2540

4.00 1 3555

4.25 1 4960

Table 16. Dimensions Single Flange Style CL1500

VALVE SIZE, NPS

10

12

14

16

18

20

VALVE SIZE, NPS Inches

10 7/8-94Holes 1-7/8-812Holes

12 7/8-94Holes 2-816Holes

14 7/8-94Holes 2-1/4-816Holes

16 1-1/4-76Holes 2-1/2-816Holes

18 1-1/4-76Holes 2-3/4-816Holes

20 1-1/4-76Holes 3-816Holes

See Thread Info Below See Thread Info Below

L J

mm

May 2013

KEY SQ

SIZE

21.1:A11

APPROX

WEIGHT

Figure 8. Dimensions Single Flange Style CL900 and CL1500 (also see tables 13 and 15)

A

D

C

J

E

F

R

L

K

H

B

15

Page 16

Product Bulletin

21.1:A11

May 2013

A11 Valve

D500203X012

Pressure Drops

table 17 for body limitations and tables 18, 19, 20, and

21 for trim limitations. Information on limits for

S31254, CW2M, M35-1 and other alloy constructions

Pressure drop limits of any given valve are based on

valve body, and trim material limits. To find the

appropriate pressure drop limitation, choose the

desired valve size and temperature range. Then search

can be obtained by contacting your Emerson Process

Management sales office. The lowest number from the

tables is the appropriate limit. The tables for both trim

and body limits must be consulted.

Table17.MaximumAllowableShutoffPressureDrops(Valve Ratings) Based on Carbon Steel and Stainless Steel

Valve Types

TEMPERATURE

RANGE

-254 to-29 --- 10.3 --- 19.0 --- 49.6 --- 99.3 --- 148.9 --- 248.2

-29 to 38 10.3 10.3 20 19.0 51.7 49.6 103.4 99.3 155.1 148.9 258.6 248.2

-450 to-20 --- 150 --- 275 --- 720 --- 1440 --- 2160 --- 3600

-20 to100 150 150 290 275 750 720 1500 1440 2250 2160 3750 3600

1000 --- 10 --- 20 --- 365 --- 725 --- 1090 --- 1820

1. For pressure/temperaturerating of other materials, contact your Emerson Process Management sales office.

(1)

(The tables for both trim and body limits must be consulted)

PRESSURE RANGE

CL150/150 CL150 CL300 CL600 CL900 CL1500

WCC CF8M WCC CF8M WCC CF8M WCC CF8M WCC CF8M WCC CF8M

_C Bar

93 9.3 9.0 17.9 16.2 51.7 42.7 103.4 85.5 155.1 128.2 258.6 213.4

149 8.3 7.9 15.9 14.8 50.3 38.6 100.3 77.2 150.7 115.8 251.0 192.7

204 7.2 7.2 13.8 13.4 48.6 35.5 96.9 70.7 145.5 106.2 242.7 177.2

260 6.2 6.2 11.7 11.7 45.9 33.1 91.7 65.8 137.6 98.9 229.3 164.8

316 5.2 5.2 9.7 9.7 41.7 31.0 83.4 62.1 125.1 93.4 208.6 155.5

343 4.5 4.5 8.6 8.6 40.7 30.3 81.0 61.0 121.7 91.4 202.7 152.4

371 4.1 4.1 7.6 7.6 38.3 30.0 76.5 60.0 114.8 90.0 191.3 149.6

399 3.4 3.4 6.6 6.6 34.8 29.3 70.0 59.0 104.8 88.3 174.8 147.2

427 2.8 2.8 5.5 5.5 28.3 29.0 56.9 58.3 85.2 87.2 141.7 145.5

454 --- 2.4 --- 4.5 --- 29.0 --- 57.6 --- 86.5 --- 144.1

482 --- 1.7 --- 3.4 --- 28.6 --- 57.2 --- 85.8 --- 143.1

510 --- 1.4 --- 2.4 --- 26.5 --- 53.4 --- 80.0 --- 133.1

538 --- 0.7 --- 1.4 --- 25.2 --- 50.0 --- 75.2 --- 125.5

_F Psi

200 135 130 260 235 750 620 1500 1240 2250 1860 3750 3095

300 120 115 230 215 730 560 1455 1120 2185 1680 3640 2795

400 105 105 200 195 705 515 1405 1025 2110 1540 3520 2570

500 90 90 170 170 665 480 1330 955 1995 1435 3325 2390

600 75 75 140 140 605 450 1210 900 1815 1355 3025 2255

650 65 65 125 125 590 440 1175 885 1765 1325 2940 2210

700 60 60 110 110 555 435 1110 870 1665 1305 2775 2170

750 50 50 95 95 505 425 1015 855 1520 1280 2535 2135

800 40 40 80 80 410 420 825 845 1235 1265 2055 2110

850 --- 35 --- 65 --- 420 --- 835 --- 1255 --- 2090

900 --- 25 --- 50 --- 415 --- 830 --- 1245 --- 2075

950 --- 20 --- 35 --- 385 --- 775 --- 1160 --- 1930

16

Page 17

A11 Valve

D500203X012

Product Bulletin

21.1:A11

May 2013

Table18.MaximumAllowableShutoffPressureDrops

CL150/150 CL150 CL300

Valve Body Size, NP S Valve BodySize, NPS Valve Body Size, NPS

(2)

,

(2)

,

TEMPERATURE

RANGE

30 36 42 48 30 36 42 48 30 36 42 48

_C Bar

-46 to 38 10.34 10.34 10.34 10.34 32.06 27.85 18.55 12.34 38.47 51.02 46.06 51.02

38 to 149 10.34 10.34 10.34 10.34 27.58 27.58 18.55 12.34 27.58 27.58 27.58 27.58

149 to 232 3.447 3.447 3. 447 3.447 3.447 3.447 3.447 3.447 3.447 3.447 3.447 3.447

-46 to 38 10.34 10.34 10.34 10.34 29.72 23.72 16.27 11.17 32.82 45.44 41.23 61.64

38 to 149 10.34 10.34 10.34 10.34 25.72 23.72 16.27 11.17 32.82 45.44 41.23 61.64

149 to 232 10.34 10.34 10.34 10.34 24.2 23.72 16.27 11.17 32.82 45.44 41.23 61.09

-46 to 38 10.34 8.136 10.34 4.964 21.24 16 9.584 5.792 26.48 35.78 31.37 48.06

38 to 149 10.34 8.136 10.34 4.964 17.93 16 9.584 5.792 26.48 35.78 31.37 39.64

149 to 232 10.34 8.136 10.34 4.964 16.75 16 9.584 5.792 20.68 20.68 20.68 20.68

-46 to 38 10.34 10.34 10.34 7.722 22.75 16.62 11.45 7.653 22.75 32.47 29.51 44.33

38 to 149 10.34 10.34 10.34 7.722 19.65 16.62 11.45 7.653 22.75 32.47 29.51 44.33

149 to 232 10.34 10.34 10.34 7.722 18.48 16.62 11.45 7.653 22.75 32.47 29.51 44.33

232 to 316 10.34 10.34 10.34 7.722 17.65 16.96 11.45 7.653 22.75 32.47 29.51 44.33

343 to 427 10.34 10.34 10.34 7.722 16.89 16.96 11.45 7.653 22.75 32.54 29.51 44.33

427 to 538 10.34 10.34 10.34 7.722 24.55 16.96 11.45 7.653 22.75 32.54 29.51 44.33

-196 to -46 10.34 10.34 10.34 10.34 26.34 28.89 20.82 14.34 41.78 55.23 46.61 56.95

-46 to 149 10.34 10.34 10.34 10.34 17.24 22.89 16.89 14.34 41.78 43.99 36.89 45.23

_F Psi

-50 to 100 150 150 150 150 465 404 269 179 558 740 668 740

100 to 300 150 150 150 150 400 400 269 179 400 400 400 400

300 to 450 50 50 50 50 50 50 50 50 50 50 50 50

-50 to 100 150 150 150 150 431 344 236 162 476 659 598 894

100 to 300 150 150 150 150 373 344 236 162 476 659 598 894

300 to 450 150 150 150 150 351 344 236 162 476 659 598 886

-50 to 100 150 118 150 72 308 232 139 84 384 519 455 697

100 to 300 150 118 150 72 260 232 139 84 38 4 519 455 575

300 to 450 150 118 150 72 243 232 139 84 30 0 300 300 300

-50 to 100 150 150 150 112 330 241 166 111 330 471 428 643

100 to 300 150 150 150 112 285 241 166 111 330 471 428 643

300 to 450 150 150 150 112 268 241 166 111 330 471 428 643

450 to 600 150 150 150 112 256 246 166 111 330 471 428 643

650 to 800 150 150 150 112 245 246 166 111 330 472 428 643

800 to 1000 150 150 150 112 356 246 166 111 330 472 428 643

-320 to -50 150 150 150 150 382 419 302 208 606 801 676 826

-50 to 300 150 150 150 150 250 332 245 208 606 638 535 656

TRIM

NUMBER

550

552

554

555,

556

556 316 to 427 10.34 10.34 10.34 7.446 16.89 16.62 11.17 7.446 22.75 32.47 29.51 44.33

564H,

566H

564H

566H

567C

TRIM

NUMBER

550

552

554

555,

556

556 600 to 800 150 150 150 108 245 241 162 108 330 471 428 643

564H,

566H

564H

566H

567C

1. Consult your Emerson ProcessManagement sales office if higher pressure drops arerequired.

2. Trim 564Hwith optional N07718 shaft for temperatures up to 482_C. (1000_F).

(1)

PRESSURE RANGE

17

Page 18

Product Bulletin

21.1:A11

May 2013

A11 Valve

D500203X012

Table 19. Maximum Allowable Shutoff Pressure Drops, CL600

TRIM

NUMBER

500

502

504

506

514H,

516H

514H

516H

517C -196 to 163 Consult your Emerson Process Managementsales office.

517C

TRIM

NUMBER

500

502

504

506

514H,

516H

514H

516H

517C -320 to 325 Consult your Emerson Process Managementsales office.

517C

1. Consult your Emerson ProcessManagement sales office if higher pressure drops arerequired.

2. Trim 514Hwith optional N07718 shaft for temperatures up to 482_C (1000_F).

3. Trim 517C with optional CTFE cryogenic seal withoutbackup ring.

TEMP RANGE NPS 3 NPS 4 NPS 6 NPS 8 NPS 10 NPS 12 NPS 14 NPS 16 NPS 18 NPS 20 NPS 24

_C Bar

-46 to 38 98.9 103.1 103.4 103.4 99.1 103.4 103.4 103.4 103.4 103.4 60.9

38 to 93 75.8 75.8 75.8 75.8 75.8 75.8 75.8 75.8 75.8 75.8 60.9

93 to 121 41.4 41.4 41.4 41.4 41.4 41.4 41.4 41.4 41.4 41.4 41.4

121 to 149 6.9 6.9 6.9 6.9 6.9 6.9 6.9 6.9 6.9 6.9 6.9

-46 to 38 95.0 100.4 103.4 103.4 98.0 92.2 103.4 103.4 103.4 94.8 55.2

38 to 232 82.3 87.6 82.1 95.1 86.9 74.1 103.4 103.4 103.4 94.8 55.2

-46 to 38 93.1 100.1 103.4 103.4 98.1 87.1 103.4 103.4 103.4 84.7 46.2

38 to 93 79.5 94.3 96.5 96.5 93.0 79.2 96.5 96.5 96.5 84.7 46.2

93 to 121 62.1 62.1 62.1 62.1 62.1 62.1 62.1 62.1 62.1 62.1 46.2

121 to 149 20.7 20.7 20.7 20.7 20.7 20.7 20.7 20.7 20.7 20.7 20.7

-46 to 38 91.8 98.4 75.4 103.4 95.6 65.7 103.4 103.4 93.3 67.2 38.1

38 to 343 62.1 78.9 51.4 76.5 82.2 48.4 101.8 83.2 93.3 67 .2 38.1

343 to 427 58.7 75.1 48.8 73.3 80.5 46.5 98.5 80.5 93.3 67.2 38.1

343 to 427 58.7 75.1 48.8 73.3 80.5 46.5 98.5 80.5 93.3 67.2 38.1

(2)

,

427 to 538 97.8 103.4 83.6 103.4 101.2 71.7 103.4 103.4 93.4 67.2 38.1

-196 to -129 88.4 92 .3 100.2 98.7 89.9 103.4 103.4 103.4 103.4 103.4 78.3

(3)

(2)

(3)

-129 to -46 79.6 83.2 90.3 89.1 81.6 94.8 102.3 103.4 103.4 103.4 78.3

-46 to 38 67.6 70.7 76.7 76.3 70.3 77.6 88.6 93.1 94.5 103.4 78.3

38 to 149 61.2 64.1 69.5 69.4 64.3 66.7 81.2 85.1 86.3 96.5 78.3

_F Psi

-50 to 100 1435 1495 1500 1500 1437 1500 1500 1 500 1500 1500 883

100 to 200 1100 1100 1100 1100 1100 1100 1100 1100 1100 1100 883

200 to 250 600 600 600 600 600 600 600 600 600 600 600

250 to 300 100 100 100 100 100 100 100 100 100 100 100

-50 to 100 1378 1456 1500 1500 1422 1337 1500 1 500 1500 1375 800

100 to 450 1194 1270 1191 1380 1260 1075 1500 1500 1500 1375 800

-50 to 100 1350 1453 1500 1500 1422 1264 1500 1 500 1500 1229 670

100 to 200 1153 1368 1400 1400 1349 1148 1400 1400 1400 1229 670

200 to 250 900 900 900 900 900 900 900 900 900 900 670

250 to 300 300 300 300 300 300 300 300 300 300 300 300

-50 to 100 1331 1427 1093 1500 1401 953 1500 1500 1353 974 553

100 to 650 900 1144 746 1110 1192 702 1477 1206 1353 974 553

650 to 800 852 1089 708 1064 1167 675 1429 1168 1353 974 553

650 to 800 852 1089 708 1064 1167 675 1429 1168 1353 974 553

,

800 to 1000 1418 1500 1213 1500 1468 1040 1500 1500 1354 974 553

-320 to -200 1282 1339 1454 1431 1304 1500 1500 1500 1500 150 0 1135

-200 to -50 1155 1206 1309 1293 1184 1375 1484 1500 1500 1500 1135

-50 to 100 980 1025 111 3 1106 1020 1126 1285 1350 1371 1500 1135

100 to 300 887 929 1008 1006 933 967 1178 1234 1251 1400 1135

(1)

18

Page 19

A11 Valve

D500203X012

Product Bulletin

21.1:A11

May 2013

Table 20. Maximum Allowable Shutoff Pressure Drops, CL900

TRIM

NUMBER

500

502

504

506

514H,

516H

514H

516H

TRIM

NUMBER

500

502

504

506

514H,

516H

514H

516H

1. Consult your Emerson ProcessManagement sales office if higher pressure drops arerequired.

2. Consult Fisher bulletin 59.3:042 (D102093X012) for packing selection guidelinesregarding pressure/temperaturelimits.

3. Trim 514Hwith optional N07718 shaft.

TEMP RANGE NPS 6 NPS 8 NPS 10 NPS 12 NPS 14 NPS 16 NPS 18 NPS 20 NPS 24

_C Bar

-46 to 38 103.4 103.4 103.4 103.4 103.4 103.4 103.4 103.4 103.4

38 to 93 75.8 75.8 75.8 75.8 75.8 75.8 75.8 75.8 75.8

93 to121 41.4 41.4 41.4 41.4 41.4 41.4 41.4 41.4 41.4

121 to149 6.9 6.9 6.9 6.9 6.9 6.9 6.9 6.9 6.9

-46 to 38 100.0 155.1 110.7 155.1 146.6 154.2 151.9 120.0 128.7

38 to149 84.6 146.2 110.7 150.7 146.5 139.3 139.1 120.0 128.6

149 to232 78.8 140.4 110.7 141.7 141.7 131.5 134.1 120.0 128.7

-46 to 38 103.4 103.4 103.4 103.4 103.4 103.4 103.4 91.0 92.8

38 to 93 96.5 96.5 96.5 96.5 96.5 96.5 96.5 91.0 92.8

93 to121 62.1 62.1 62.1 62.1 62.1 62.1 62.1 62.1 62.1

121 to149 20.7 20.7 20.7 20.7 20.7 20.7 20.7 20.7 20.7

-46 to 38 81.1 122.2 78.5 131.3 104.1 119.8 118.7 82.5 89.9

38 to149 67.6 122.2 78.5 131.3 104.1 103.4 118.7 82.5 89.9

149 to232 62.6 122.2 78.5 131.3 104.1 97.4 118.7 82.5 89.9

232 to343 58.1 121.3 78.5 121.3 104.1 91.8 118.7 82.5 89.9

343 to427 55.5 105.1 78.5 105.1 104.1 88.7 105.1 82.5 89.9

343 to427 55.5 105.1 78.5 105.1 104.1 88.7 105.1 82.5 89.9

(3)

,

427 to538 70.4 62.5 58.7 88.0 48.9 39.1 37.2 52.8 43.0

_F Psi

-50 to 100 1500 1500 1500 1500 1500 1500 1500 1500 1500

100 to200 1100 1100 1100 1100 1100 1100 1100 1100 1100

200 to250 600 600 600 600 600 600 600 600 600

250 to300 100 100 100 100 100 100 100 100 100

-50 to 100 1451 2250 1606 2250 2126 2237 2203 1741 1866

100 to300 1227 2120 1606 2185 2125 2020 2017 1741 1865

300 to450 1143 2036 1606 2055 2055 1907 1945 1741 1866

-50 to 100 1500 1500 1500 1500 1500 1500 1500 1320 1346

100 to200 1400 1400 1400 1400 1400 1400 1400 1320 1346

200 to250 900 900 900 900 900 900 900 900 900

250 to300 300 300 300 300 300 300 300 300 300

-50 to 100 1176 1773 1138 1905 1510 1737 1721 1197 1304

100 to300 980 1773 1138 1905 1510 1500 1721 1197 1304

300 to450 908 1773 1138 1905 1510 1412 1721 1197 1304

450 to650 842 1760 1138 1760 1510 1332 1721 1197 1304

650 to800 805 1525 1138 1525 1510 1286 1525 1197 1304

650 to800 805 1525 1138 1525 1510 1286 1525 1197 1304

(3)

,

800 to1000 1021 907 851 1276 709 567 539 766 624

(1, 2)

19

Page 20

Product Bulletin

21.1:A11

May 2013

A11 Valve

D500203X012

Table 21. Maximum Allowable Shutoff Pressure Drops, CL1500

TRIM NUMBER

500

502

504

506

514H, 516H 343 to 427 96.9 175.1 116.5 139.5 175.1 174.8

(3)

514H

, 516H 427 to 538 78.2 70.4 86.0 78.2 66.5 74.3

TRIM NUMBER _F Psi

500

502

504

506

514H, 516H 650 to 800 1406 2540 1689 2024 2540 2535

(3)

514H

, 516H 800 to 1000 1134 1021 1248 1134 964 1077

1. Consult your Emerson ProcessManagement sales office if higher pressure drops arerequired.

2. Consult Fisher bulletin 59.3:042 (D102093X012) for packing selection guidelinesregarding pressure/temperaturelimits.

3. Trim 514Hwith optional N07718 shaft.

TEMP RANGE NPS 10 NPS 12 NPS 14 NPS 16 NPS 18 NPS 20

_C Bar

-46 to 38 103.4 103.4 103.4 103.4 103.4 103.4

38 to93 75.8 75.8 75.8 75.8 75.8 75.8

93 to121 41.4 41.4 41.4 41.4 41.4 41.4

121 to149 6.9 6.9 6.9 6.9 6.9 6.9

-46 to 38 179.0 248.1 169.4 201.5 249.7 243.0

38 to149 155.0 226.5 169.5 201.5 228.1 222.1

149 to232 146.1 218.2 169.5 201.5 219.7 214.0

-46 to 38 103.4 103.4 103.4 103.4 103.4 103.4

38 to93 96.5 96.5 96.5 96.5 96.5 96.5

93 to121 62.1 62.1 62.1 62.1 62.1 62.1

121 to149 20.7 20.7 20.7 20.7 20.7 20.7

-46 to 38 133.5 186.2 116.5 139.5 235.4 174.7

38 to149 114.2 186.2 116.5 139.5 224.8 174.7

149 to232 107.1 186.2 116.5 139.5 216.3 174.7

232 to343 100.6 186.2 116.5 139.5 202.2 174.7

343 to427 96.9 175.1 116.5 139.5 175.1 174.7

-50 to 100 1500 1500 1500 1500 1500 1500

100 to200 1100 1100 1100 1100 1100 1100

200 to250 600 600 600 600 600 600

250 to300 100 100 100 100 100 100

-50 to 100 2596 3599 2457 2922 3622 3525

100 to300 2248 3285 2458 2922 3309 3221

300 to450 2119 3164 2458 2922 3187 3104

-50 to 100 1500 1500 1500 1500 1500 1500

100 to200 1400 1400 1400 1400 1400 1400

200 to250 900 900 900 900 900 900

250 to300 300 300 300 300 300 300

-50 to 100 1936 2700 1689 2024 3414 2534

100 to300 1657 2700 1689 2024 3260 2534

300 to450 1553 2700 1689 2024 3137 2534

450 to650 1459 2700 1689 2024 2933 2534

650 to800 1405 2540 1689 2024 2540 2534

(1, 2)

Neither Emerson, Emerson Process Management,nor any of their affiliated entitiesassumes responsibility for the selection, use or maintenance

of anyproduct. Responsibility for proper selection, use, and maintenance of any product remains solelywith the purchaser and end user.

Fisher, POSI-SEAL, ENVIRO-SEAL, Bettis, and FieldQ are marks owned by one ofthe companies inthe EmersonProcess Management business unit of

Emerson Electric Co. Emerson Process Management, Emerson, and the Emerson logo are trademarks andservice marksof Emerson Electric Co. All other

marks are the property of their respective owners.

The contents of this publication are presented for informational purposes only, and while every effort has been made to ensure their accuracy, they arenot

to be construed as warranties or guarantees, express or implied, regarding the products or services described herein or their use or applicability. All sales are

governed by our terms and conditions, which are availableupon request. Wereserve the right tomodify orimprove thedesigns orspecifications of such

products at any time without notice.

Emerson Process Management

Marshalltown, Iowa 50158 USA

Sorocaba, 18087 Brazil

Chatham, Kent ME4 4QZ UK

Dubai, United Arab Emirates

Singapore 128461 Singapore

www.Fisher.com

E 1992, 2013 Fisher ControlsInternational LLC. All rights reserved.

20

Loading...

Loading...