Page 1

Instruction Manual

D102778X012

April 2018

Type OS2 Slam-Shut Device

WARNING

!

Failure to follow these instructions or to

properly install and maintain this equipment

could result in an explosion and/or fire

causing property damage and personal injury

or death.

Fisher™ slam-shut devices must be installed,

operated and maintained in accordance

with federal, state and local codes, rules

and regulations and Emerson Process

Management Regulator Technologies,

Inc. instructions.

If the slam-shut device vents gas or a leak

develops in the system, service to the unit

may be required. Failure to correct trouble

could result in a hazardous condition.

Call a gas service person to service the

unit. Only a qualified person must install or

service the slam-shut devices.

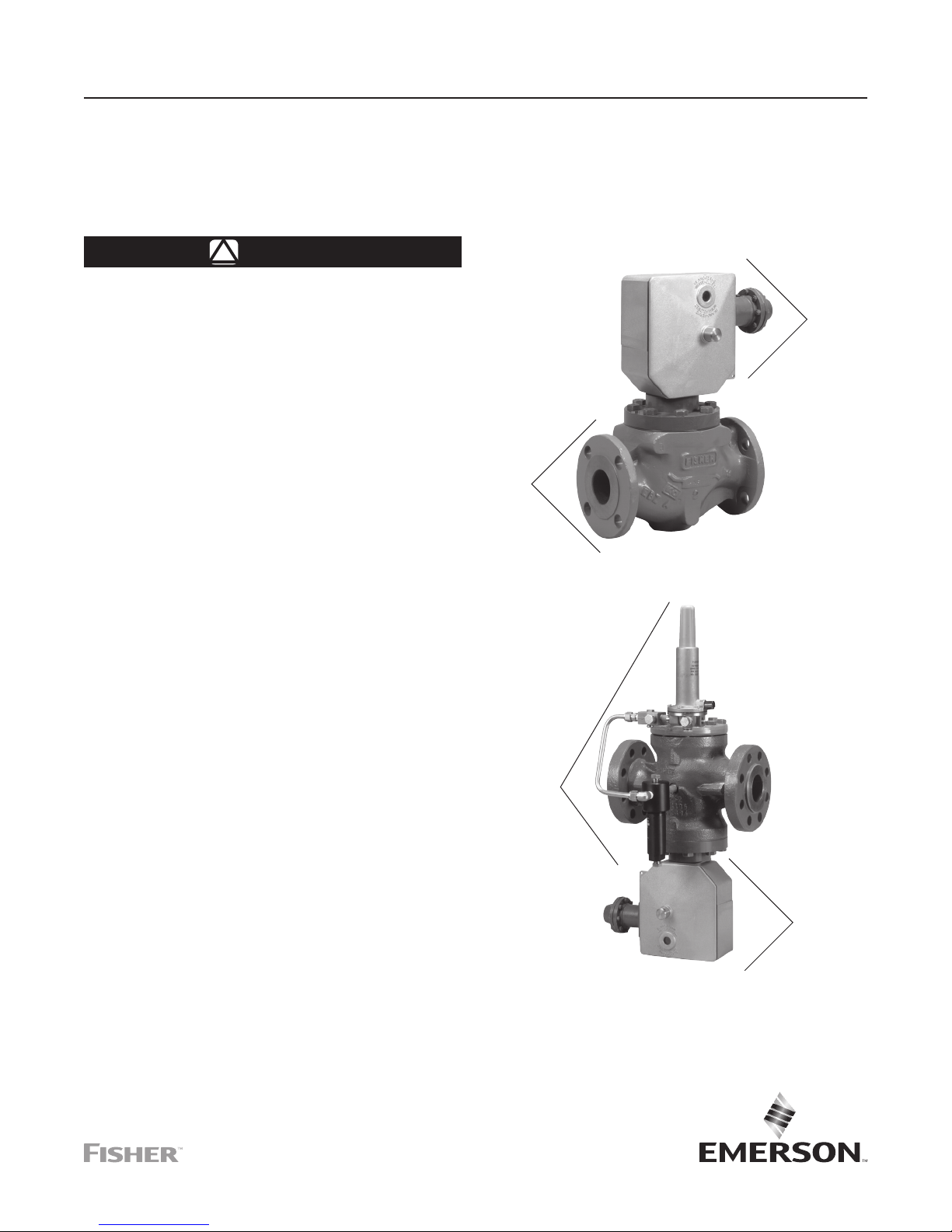

TYPE E

VALVE

BODY

W8133

TYPE OSE

Type OS2

TYPE OS2

SLAM-SHUT

DEVICE

Introduction

Scope of the Manual

This instruction manual provides installation, maintenance

and parts ordering information for the Types OS2 and OSD2

slam-shut devices. The Type OS2 slam-shut device is used

on Type OSE with NPS 1 through 6 / DN 25 through 150

body sizes, while Type OSD2 is used on NPS 8 and 10 /

DN 200 and 250 body sizes.

For more information on Type OS2 installed on other

regulators such as Types EZHOSX, EZHSO-OSX,

EZLOSX and EZROSX, refer to the instruction manuals of

these products.

Description

Slam-shut devices are used to totally and rapidly cut off

gas flow when the inlet and/or outlet pressure in the system

either exceeds or drops below the setpoints. The Type OSE

consists of a valve, mechanism box (BM1 or BM2) and either

one or two modular sensing elements called manometric

devices (Type BMS1 or BMS2) (see Figure 2). All information

for the Type OSE (which includes a Type OS2 slam-shut

device and a Type E valve body) is contained in this

Instruction Manual.

TYPE EZR

REGULATOR

W8136

TYPE EZROSX

Figure 1. Type OS2 Slam-Shut Device on

Types OSE and EZROSX Constructions

TYPE OS2

SLAM-SHUT

DEVICE

North America Only

Page 2

Type OS2

Specifications

This section lists the specifications for the Type OS2 slam-shut valve. Factory specifications are stamped on the nameplate

fastened on the valve at the factory.

Body Sizes and End Connection Styles

Type OSE

WCC Steel

1 and 2 NPT; NPS 1, 2, 3, 4 and 6 /

DN 25, 50, 80, 100 and 150

CL150 RF, CL300 RF or CL600 RF

LCC Steel

NPS 8 and 10 / DN 200 and 250

CL150 RF, CL300 RF or CL600 RF

Cast Iron

1 and 2 NPT; NPS 1, 2, 3, 4 and 6 /

DN 25, 50, 80, 100 and 150

CL125 FF or CL250 RF

Types EZHOSX and EZHSO-OSX

LCC Steel

NPS 1, 2, 3 and 4 / DN 25, 50, 80 and 100

CL150 RF, CL300 RF or CL600 RF

Type EZLOSX

LCC Steel

NPS 2, 3 and 4 / DN 50, 80 and 100

CL150 RF, CL300 RF or CL600 RF

Type EZROSX

LCC Steel

NPS 1, 2, 3, 4 and 6 / DN 25, 50, 80, 100

and 150 CL150 RF, CL300 RF or CL600 RF

Maximum Inlet Pressure

(1)(2)

1470 psig / 101 bar or maximum body rating,

whichever is lower

Maximum Set Pressure

1470 psig / 101 bar or maximum body rating,

whichever is lower

Minimum Set Pressure

4.02 in. w.c. / 10 mbar

Outlet Pressure Ranges

See Table 2

Maximum Flowing Pressure Differential

BODY SIZE

NPS DN psig bar

1 25 360 24.8

2 50 360 24.8

3 80 360 24.8

4 100 150 10.3

6 150 85 5.9

8 200 119 8.2

10 250 67 4.6

MAXIMUM FLOWING

PRESSURE DIFFERENCE

(3)

Process Temperature Capabilities

(2)

-22 to 180°F / -30 to 82°C

Accuracy

+/-2.5% for set pressures at or below 1.45 psig / 0.1 bar

or +/-1% for set pressures above 1.45 psig / 0.1 bar,

+/-5% for the piston Types 27 and 17

Maximum Shutoff Pressure Differential

1470 psig / 101 bar or maximum body rating,

whichever is lower

Pressure Sensing Connections

1/4 NPT

Response Time

<1 second

Pressure Registration

External

Valve Plug Travel and Stem Diameter

BODY SIZE VALVE PLUG TRAVEL

NPS DN In. mm In. mm

1 25 1/2 13

2 50 1/2 13

3 80 1-1/8 29

4 100 2 51

6 150 2 51

8 200 2-3/4 70

10 250 3-1/4 82

VALVE PLUG STEM

DIAMETER

0.138 3.5

0.276 7.0

Approximate Weights

BODY SIZE APPROXIMATE WEIGHT

NPS DN lbs kg

1 25 36 16

2 50 70 32

3 80 121 55

(2)

4 100 216 98

6 150 445 202

8 200 785 356

10 250 1272 577

North America Only

Options

• Explosion-proof limit switch

• Additional manometric device for extra

pressure sensing

• Manual Push Button Trigger Switch

(4)

1. Relief pressure plus maximum allowable buildup over setting.

2. The pressure/temperature limits in this Instruction Manual or any applicable standard limitation should not be exceeded.

3.EndconnectionsforotherthanASMEstandardcanusuallybeprovided.ContactyourlocalSalesOfceforassistance.

4. The push button connects at the same Type BM2 port as a Type BMS2.

2

Page 3

Type OS2

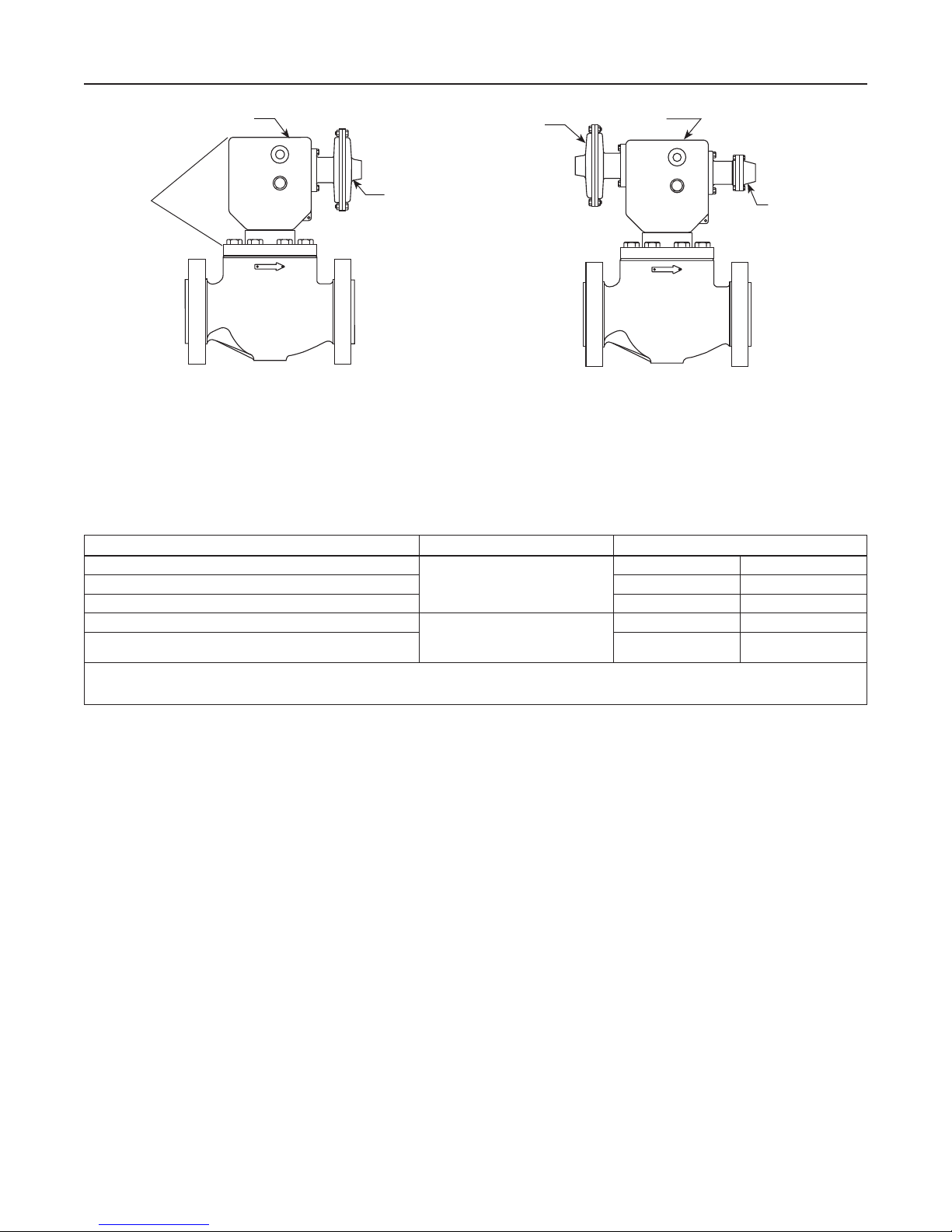

BM2

(TYPES BMS1 AND BMS2)

TYPE BMS1

(RIGHT SIDE)

TYPE OS2

BM1

E0564

MECHANISM BOX (BM1) WITH 1 MANOMETRIC

SENSING DEVICE (TYPE BMS1)

TYPE BMS1

TYPE BMS2

(LEFT SIDE)

E0565

MECHANISM BOX (BM2) WITH 2 MANOMETRIC SENSING DEVICES

TOP-MOUNTED (STAND-ALONE TYPE OSE VALVE)

Figure 2. Types of Installation (Mounting on Horizontal Pipeline Only)

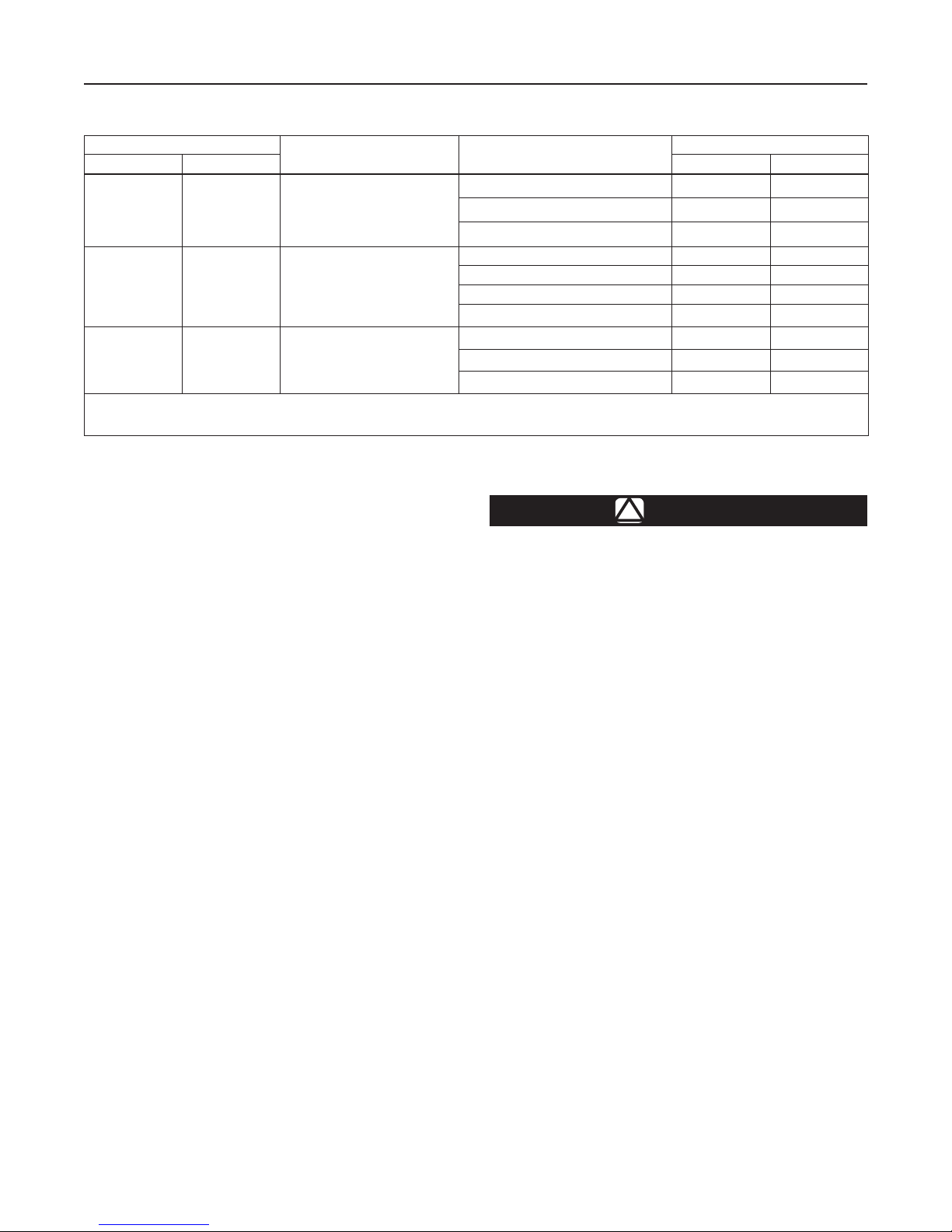

Table 1. Applications and Construction Guide (See Figure 2)

APPLICATION MECHANISM BOX REQUIRED MANOMETRIC SENSING DEVICE REQUIRED

Overpressure Shutoff (OPSO)

Underpressure Shutoff (UPSO) BMS1 - - - -

Overpressure Shutoff (OPSO) and Underpressure Shutoff (UPSO) BMS1

Overpressure Shutoff (OPSO) and Underpressure Shutoff (UPSO)

Overpressure Shutoff (OPSO), Overpressure Shutoff (OPSO) and

1. When using one manometric sensing device for both overpressure and underpressure shutoff, make sure that the difference between set pressures falls within the maximum range

shown in Table 2.

2. When using two manometric sensing devices (Types BMS1 and BMS2), the Type BMS1 can only be used for high trip.

Underpressure Shutoff (UPSO)

BM1

BM2

BMS1 - - - -

BMS1

BMS1

(1)

(2)

(2)

- - - -

BMS2

BMS2

(1)

North America Only

Type EZROSX (see Figure 1) is a combination of the

Type EZR regulator and the Type OS2 slam-shut device.

For installation, maintenance and parts information on

the Type EZR portion, refer to Type EZR Instruction

Manual D102600X012.

Type EZHOSX is a combination of the Type EZH regulator

and the Type OS2 slam-shut device. Details related to

installation, maintenance and parts information are listed in

the Type EZH Instruction Manual D103077X012.

Type EZLOSX is a combination of the Type EZL regulator

and the Type OS2 slam-shut device. Details related to

installation, maintenance and parts information are listed in

the Type EZL Instruction Manual D103091X012.

Incorporated in the Type OS2 (up to NPS 6 / DN 150 body

size) valve plug is an automatic internal bypass valve

mechanism, which balances pressures on both sides of the

plug when resetting. Type OSD2 will be used for NPS 8 and

10 / DN 200 and 250 Type OSE slam-shut valves; in this

case the bypass is not internal but external.

The Types OS2 and OSD2 slam-shut devices can be used

for all pressure ranges from 4.02 in. w.c. to 1470 psig /

10 mbar to 101 bar by simply replacing the manometric

sensing device. The Type OS2 can be configured for

OverPressure ShutOff (OPSO), UnderPressure ShutOff

(UPSO), OverPressure Shutoff and UnderPressure ShutOff

(OPSO/UPSO), manual shutoff or remote shutoff.

Mechanism Box (BM1 or BM2)

The mechanism box (BM1 or BM2, see Figure 2) is designed

to close the slam-shut valve. The detection of pressure

variances is sensed by a double-stage trip mechanism (see

Figure 7). The first stage is the detection stage and will only

trip when the system pressure reaches the set pressure of

the manometric sensing device. The second stage is the

power stage and once tripped by the first stage, the closing

spring causes the valve plug to slam-shut and remain

closed until the valve is manually reset. If there are any inlet

pressure variances or vibrations subjected to the second

stage components, they are not transmitted to the first stage

trip mechanism. This unique double-stage trip mechanism

virtually eliminates nuisance tripping commonly found in

other shutoff devices.

3

Page 4

Type OS2

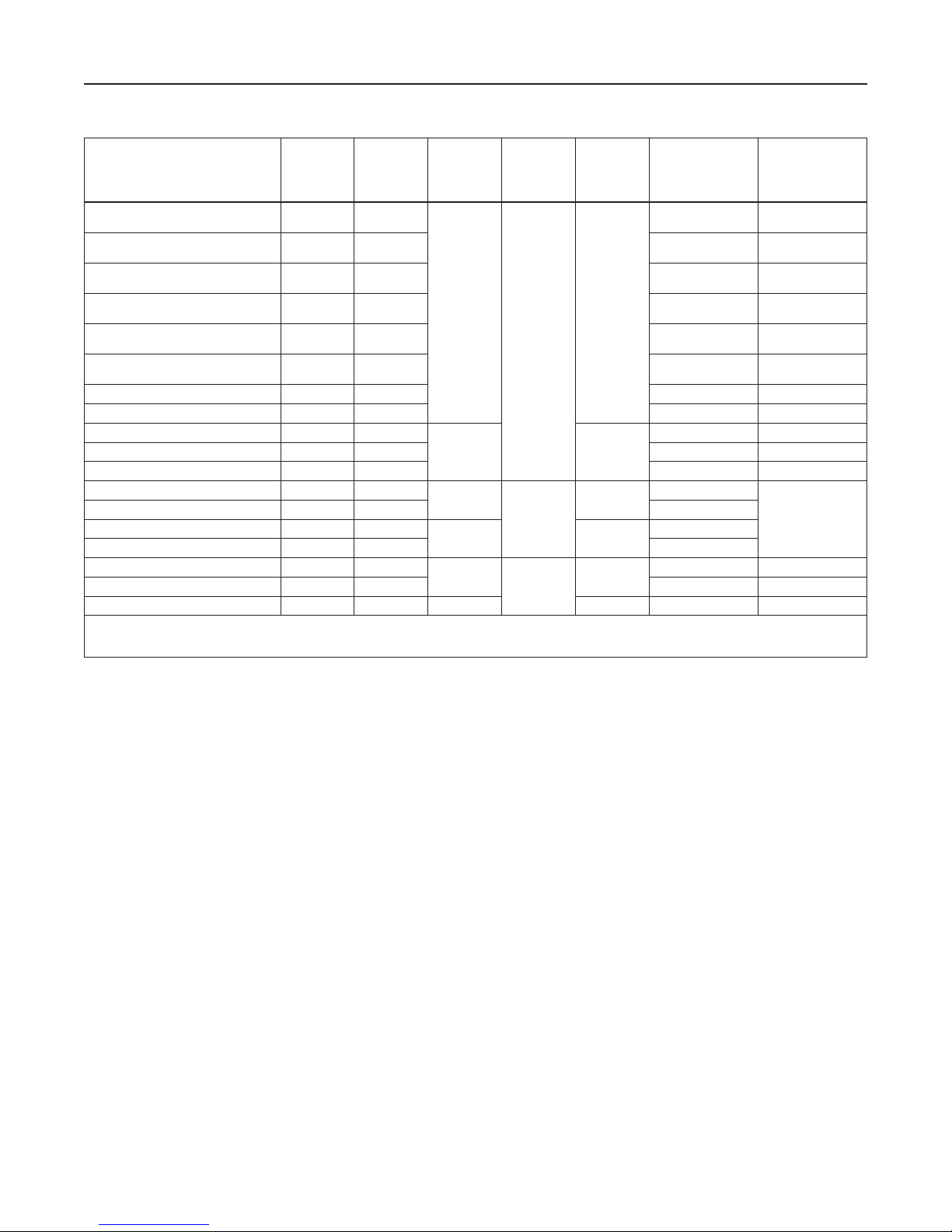

Table 2. Spring Ranges, Part Numbers and Maximum and Minimum Pressures for the Manometric Sensing Devices (Types BMS1 and BMS2)

SPRING RANGE

4.02 to 14.1 in. w.c. /

10 to 35 mbar

9.97 to 33.2 in. w.c. /

25 to 83 mbar

18 in. w.c. to 2.0 psig /

45 mbar to 0.14 bar

1.0 to 3.5 psig /

70 mbar to 0.24 bar

1.7 to 5.6 psig /

0.12 to 0.39 bar

2 to 11 psig /

0.14 to 0.76 bar

4 to 19 psig / 0.28 to 1.3 bar Brown FA113202X12 1.16 / 80 mbar 8.70 / 0.60

7 to 33 psig / 0.48 to 2.3 bar Black FA114139X12 2.47 / 0.17 16.0 / 1.1

15 to 75 psig / 1.0 to 5.2 bar Blue FA113200X12

31 to 161 psig / 2.1 to 11.1 bar Brown FA113202X12 10.2 / 0.70 79.8 / 5.5

59 to 235 psig / 4.1 to 16.2 bar Black FA114139X12 23.2 / 1.6 145 / 10.0

235 to 323 psig / 16.2 to 22.3 bar Brown FA113202X12

323 to 588 psig / 22.3 to 40.5 bar Black FA114139X12 94.3 / 6.5

588 to 808 psig / 40.5 to 55.7 bar Brown FA113202X12

808 to 1470 psig / 55.7 to 101 bar Black FA114139X12 174 / 12.0

81 to 323 psig / 5.60 to 22.3 bar Brown FA113202X12

122 to 514 psig / 8.41 to 35.4 bar Black FA114139X12 36.3 / 2.5 290 / 20.0

257 to 1058 psig / 17.7 to 73.0 bar Gray FA113201X12 315 1058 / 73.0 72.5 / 5.0 479 / 33.0

1. Minimum suggested difference between slam-shut set pressure and normal operating pressure of the system.

2. Maximum difference between overpressure and underpressure when using one manometric device (Type BMS1) with tripping hook (see Figure 5). For underpressure and overpressure

points greater than this maximum number, use a second manometric device (Type BMS2) for underpressure protection.

SPRING

COLOR

Purple FA113195X12

Orange FA113196X12

Red FA113197X12

Yellow FA113198X12

Green FA113199X12

Gray FA113201X12

SPRING PART

NUMBER

MANOMETRIC

SENSING

DEVICE TYPE

162

71 235 / 16.2

27

17 1470 / 101

236

MANOMETRIC

SENSING

DEVICE STYLE

Diaphragm

Piston

Bellows

MAXIMUM

SENSING INLET

PRESSURE,

psig / bar

74 / 5.1

1470 / 101

514 / 35.4

SETPOINT

TOLERANCE,

psig / bar

1.61 in. w.c. /

4 mbar

2.02 in. w.c. /

5 mbar

4.02 in. w.c. /

10 mbar

5.62 in. w.c. /

14 mbar

7.23 in. w.c. /

18 mbar

20.1 in. w.c. /

50 mbar

5.08 / 0.35 36.3 / 2.5

43.5 / 3.0

102 / 7.0

14.5 / 1.00 145 / 10.0

MAXIMUM DIFFERENCE

OVERPRESSURE AND

(1)

UNDERPRESSURE,

BETWEEN

(2)

psig / bar

4.02 in. w.c. /

10 mbar

10 in. w.c. /

25 mbar

20.1 in. w.c. /

50 mbar

24.1 in. w.c. /

60 mbar

2.18 / 0.15

5.08 / 0.35

Requires use

of Type BMS1

or BMS2

Manometric Sensing Device (Type BMS1

or BMS2) (See Figure 2)

Pressure from the system is sensed through control lines

into the manometric sensing device (Type BMS1, BMS2 or

Types BMS1 and BMS2). Depending on the configuration,

the Type BMS1 or BMS2 will transmit these pressure

fluctuations to the mechanism box. If these fluctuations

reach the setpoint of the manometric sensing device

(Type BMS1 or BMS2), the device will activate the tripping

mechanism in the mechanism box (Type BM1 or BM2) and

cause the valve to slam-shut.

Remote Shutoff

Remote Tripping is accomplished using a 3-way solenoid

valve installed in the control line of a Type BMS1 or

BMS2 manometric device configured for underpressure

protection (UPSO) or overpressure and underpressure

protection (OPSO/UPSO). When de-energized, the solenoid

valve allows the Type BMS manometric device to monitor

the controlled pressure as if the solenoid valve was not

present. When energized, the solenoid valve will be

repositioned to connect the Type BMS manometric device to

atmospheric pressure tripping the underpressure protection

slam-shut setting.

*For further instructions on Types EZR, EZH and EZL, refer to the corresponding instruction manual of these products.

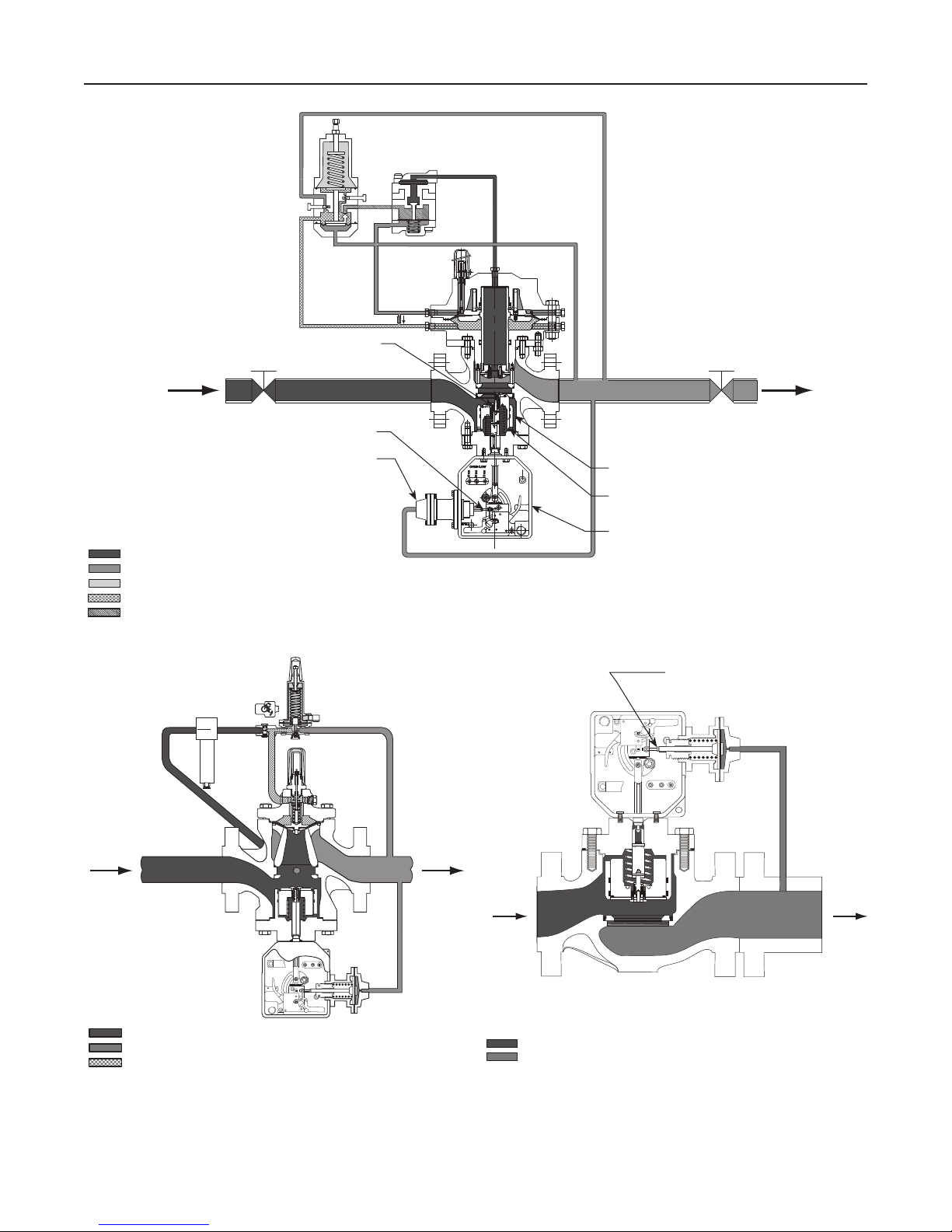

Principle of Operation* (See Figure 3)

The Type OSE slam-shut valve and the Type OS2 slam-shut

device used on Type EZHOSX, EZROSX or EZLOSX

provides overpressure and/or underpressure protection

by shutting off the flow to the downstream system. The

slam-shut valve is typically installed upstream of a pressure

reducing regulator as shown in Figure 4.

Pressure is registered on one side of the diaphragm, piston

or bellows and is opposed by the setpoint control spring of

the manometric sensing device. The Type OS2 slam-shut

device tripping pressure is determined by the setting of the

control spring.

Overpressure: when the sensed pressure increases

above the setpoint, the pressure on top of the diaphragm

overcomes the spring setting and moves the manometric

device stem.

Underpressure: when the sensed pressure decreases

below the setpoint, the control spring pressure below the

diaphragm overcomes the downstream pressure and pushes

the diaphragm which moves the manometric device stem.

When the sensed pressure rises above the set pressure (or

drops below the set pressure) the manometric device senses

the pressure change and triggers the detection stage which

North America Only

4

Page 5

TYPE

EVENT

50 mm

35 mm

15 mm

COURSE CLAPET

2

R

U

N

S

T

A

R

T

4

6

8

E0559

PRX

S

L

A

EQUALIZER BYPASS

MANOMETRIC DEVICE STEM

Type OS2

TYPE

SA/2

R

B

V

M

E0939

INLET PRESSURE

OUTLET PRESSURE

ATMOSPHERIC PRESSURE

LOADING PRESSURE

PILOT SUPPLY PRESSURE

MANOMETRIC DEVICE

R

U

N

2

4

6

S

T

8

A

R

T

TYPE EZHOSX

COURSE CLAPET

50 mm

35 mm

15 mm

VALVE PLUG

VALVE PLUG DISK

EVENT

MECHANISM BOX

MANOMETRIC DEVICE STEM

North America Only

E0559

INLET PRESSURE

OUTLET PRESSURE

LOADING PRESSURE

TYPE EZROSX TYPE OSE

E0558

INLET PRESSURE

OUTLET PRESSURE

Figure 3. Operational Schematics

5

Page 6

Type OS2

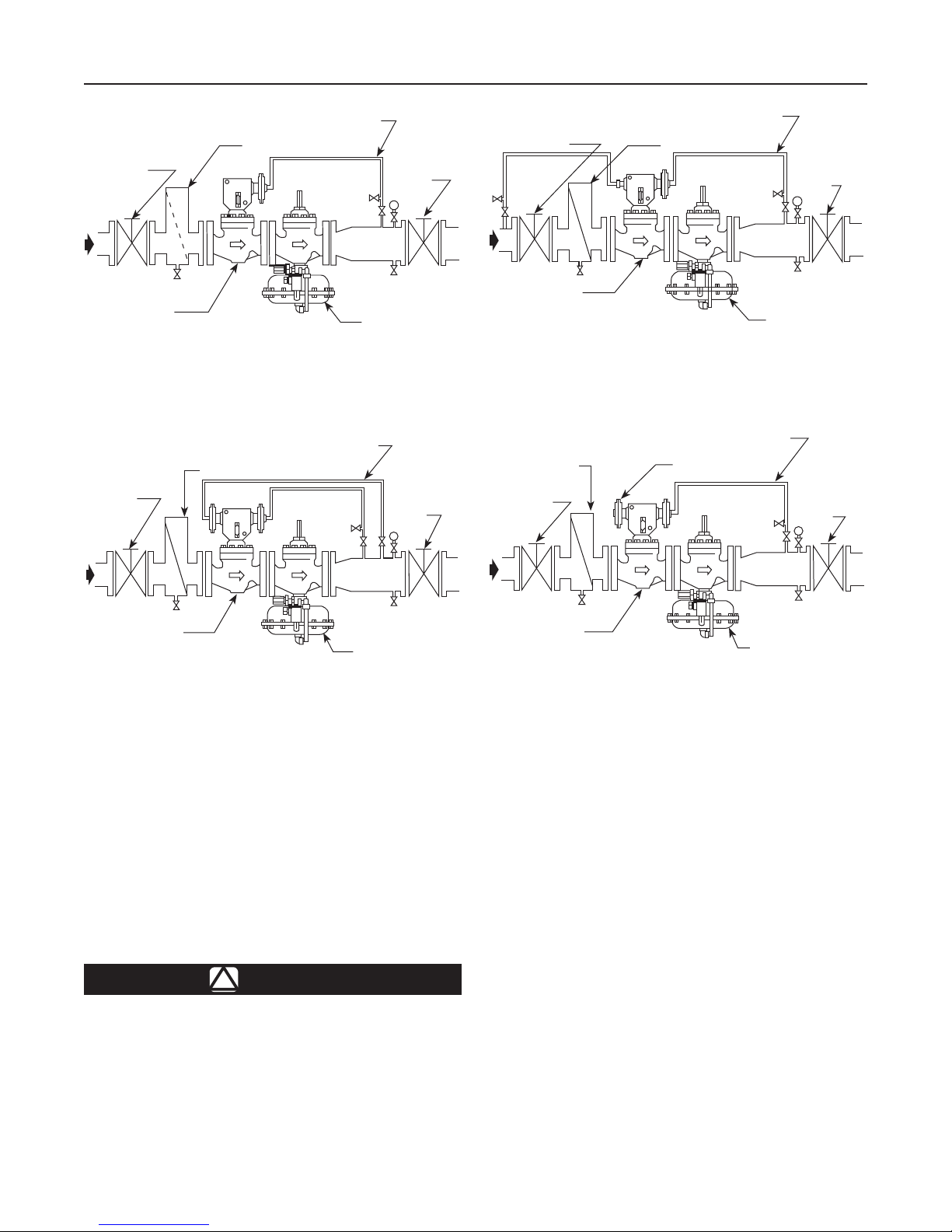

UPSTREAM

BLOCK VALVE

TYPE OSE

SLAM-SHUT VALVE

E0560

OVERPRESSURE AND UNDERPRESSURE SHUTOFF

UPSTREAM

BLOCK

VALV E

DOWNSTREAM SENSING LINE

OPTIONAL STRAINER

USING ONE MANOMETRIC DEVICE

DOWNSTREAM SENSING LINE

OPTIONAL STRAINER

BLOCK

VALV E

PRESSURE

REGULATOR

BLOCK

VALV E

UPSTREAM

BLOCK VALVE

TYPE OSE

SLAM-SHUT VALVE

E0561

OPTIONAL

STRAINER

UPSTREAM

BLOCK

VALV E

DOWNSTREAM SENSING LINE

OPTIONAL STRAINER

MINIMUM/MAXIMUM UPSTREAM AND

DOWNSTREAM PRESSURE

DOWNSTREAM SENSING LINE

EXTERNAL TRIP

PRESSURE

BLOCK

VALV E

PRESSURE

REGULATOR

BLOCK

VALV E

TYPE OSE

SLAM-SHUT VALVE

E0562

OVERPRESSURE AND UNDERPRESSURE SHUTOFF

USING TWO MANOMETRIC DEVICES

PRESSURE

REGULATOR

Figure 4. Typical Installations

activates the second stage, releasing the slam-shut valve

plug. A tight and total shutoff is ensured by the plug seal

O-ring closing on the orifice and is helped by the “dash pot”

effect between the bonnet skirt and the valve plug. A “dash

pot” effect occurs when the valve plug closes by having both

the closing spring and the inlet pressure pushing on top of

the valve plug. This is accomplished by ports around the skirt

of the bonnet allowing inlet pressure above the valve plug.

Installation*

WARNING

!

Personal injury, equipment damage or

leakage due to escaping gas or bursting

of pressure-containing parts may result

if the slam-shut valve is installed where

its capabilities can be exceeded or where

TYPE OSE

SLAM-SHUT VALVE

E0563

EXTERNAL SIGNAL

PRESSURE

REGULATOR

conditions exceed any ratings of the adjacent

piping or piping connections. To avoid this,

install the slam-shut valve where service

conditions are within unit capabilities and

applicable codes, regulations or standards.

Additionally, physical damage to the

slam-shut valve could break the mechanism

box off the main valve, causing personal

injury and property damage due to escaping

gas. To avoid such injury or damage, install

the unit in a safe location.

Installation, operation and maintenance

procedures performed by unqualified

personnel may result in improper adjustment

and unsafe operation. Either condition may

result in equipment damage or personal

injury. Use qualified personnel when

installing, operating and maintaining the unit.

North America Only

*For further instructions on Types EZR, EZH and EZL, refer to the corresponding instruction manual of these products.

6

Page 7

Type OS2

Table 3. Main Valve Body Sizes, End Connection Styles and Body Pressure Ratings

MAIN VALVE BODY SIZE

NPS DN psig bar

1

2

3

4

6

1

2

3

4

6

8

10

1.RatingsandendconnectionsforotherthanASMEstandardcanusuallybeprovided.ContactyourlocalSalesOfceforassistance.

2.SeeSpecicationsandTable2foradditionalpressureratings.

3. Available with NPS 1 and 2 / DN 25 and 50 only.

25

50

80

100

150

25

50

80

100

150

200

250

MAIN VALVE BODY MATERIAL END CONNECTION STYLE

(3)

NPT

Cast iron

WCC Steel

LCC Steel

CL125 FF 200 13.8

CL250 RF 500 34.5

(3)

NPT

CL150 RF 290 20.0

CL300 RF 750 51.7

CL600 RF 1500 103

CL150 RF 290 20.0

CL300 RF 750 51.7

CL600 RF 1500 103

(1)

STRUCTURAL DESIGN RATING

400 27.6

1500 103

(2)

Clean out all pipelines before installation and check to be

sure the valve has not been damaged or collected foreign

material during shipment. Use suitable line gaskets and

good bolting practices with a flanged body. The Type OSE

must be installed in a horizontal position with the mechanism

box above the body (see Figure 2). The Types EZHOSX,

EZROSX and EZLOSX are installed with the mechanism

box typically below the pipe. Type OS2 slam-shut device can

also be installed in a pit that is subject to flooding by venting

the mechanism box above the maximum possible flood

level. When used below ground, the vent must be relocated

(piped) to keep the mechanism box from collecting moisture

and/or other foreign material. Install obstruction-free tubing

or piping into the 1/4 NPT vent tapping. Provide protection

on the relocated vent by installing a screened vent cap into

the end of the vent pipe.

Type OS2 can be used along with a token relief valve to

minimize unnecessary shutoff. The relief valve is set to

open before the Type OS2 slam-shut device activates.

This arrangement allows the relief valve to handle minor

overpressure problems such as gas thermal expansion or

seat leakage due to dirt moving through the system which

may move out of the regulator during the next operating

cycle. The slam-shut device does activate if the regulator

has a major malfunction with excessive gas flow that

exceeds the token relief capacity.

The manometric device requires an external sensing line

which should be tapped into a straight run of pipe 8 to

10 pipe diameters downstream or upstream of the slam-shut

device. If impossible to comply with this recommendation

due to the pipe arrangement, it may be better to position

the sensing line tap nearer the regulator or slam-shut outlet

rather than downstream of a block valve. Do not position

the tap near any elbow, swage or nipple which might cause

turbulence. It is recommended to install an isolation valve

and a vent valve on the sensing line, which can be useful for

tripping and verifications.

Startup*

WARNING

!

To avoid personal injury or property

damage due to explosion or damage to

regulator or downstream components during

startup, release downstream pressure to

prevent an overpressure condition on the

diaphragm of the regulator. In order to avoid

an overpressure condition and possible

equipment damage, pressure gauges

should always be used to monitor pressures

during startup.

These startup procedures are for the Type OSE/OS2 only.

1. Make sure the upstream and downstream shutoff valves

are closed.

2. Slowly open the upstream shutoff valve.

3. For NPS 8 and 10 / DN 200 and 250 body sizes, slowly

open the bypass valve.

4. The slam-shut valve is shipped with the slam-shut

device in the tripped position. To reset the slam-shut,

follow the procedure under Resetting the Trip

Mechanism in the Adjustment section.

5. For NPS 8 and 10 / DN 200 and 250 body sizes, close

the slam-shut valve bypass.

6. Slowly open the downstream shutoff valve.

7. Check all connections for leaks.

8. Adjust the slam-shut pressure setting by following the

appropriate procedures in the Adjustment section.

North America Only

*For further instructions on Types EZR, EZH and EZL, refer to the corresponding instruction manual of these products.

7

Page 8

Type OS2

Adjustment

Typically, adjustments are carried out with the slam-shut

valve closed. Only the detection stage is reset (see Figure 7

and the section on Resetting the Tripping Mechanism).

Follow the procedures below for setpoint adjustment and use

the resetting tool (see Figure 8) to move the adjusting screw.

CAUTION

Before any adjustment, check that the

spring range installed corresponds to the

required setpoint.

CAUTION

Before beginning adjustment procedures, be

sure there is no pressure in the manometric

sensing device (Type BMS1 or BMS2).

Type BMS1 (Figure 5)

Overpressure Shutoff Only

Adjusting the Threaded Stem:

1. Remove the tripping hook or rotate so it cannot contact

Pin D2.

2. Turn in the adjusting screw until the distance between

the threaded stem and Pin D1 stops increasing.

3. Reset the detection stage only. (See Figure 7 and the

section on Resetting the Trip Mechanism.)

4. Adjust the threaded stem to a distance of 1/16 in. /

1.6 mm from Pin D1 (detection stage set).

5. Tighten threaded stem locknut.

Adjusting the Overpressure Trip Point:

1. Pressurize the Type BMS1 to the desired trip pressure.

2. Turn in the adjusting screw until the detection stage can

be reset.

3. Turn out the adjusting screw until the detection

stage trips.

4. Verify that the trip pressure is equal to the desired

pressure setting by reducing pressure to the

Type BMS1, resetting the detection stage and then

increasing pressure to the Type BMS1 until the detection

stage trips. Adjust trip pressure setting if necessary.

5. Tighten adjusting screw locknut.

Underpressure Shutoff Only

Adjusting the Threaded Stem and Tripping Hook:

1. Rotate the tripping hook so that it cannot contact Pin D2.

2. Turn out the adjusting screw.

3. Pressurize the Type BMS1 to the desired trip pressure.

ADJUSTING SCREW

LOCKNUT

ADJUSTING

SCREW

TRIPPING HOOK

LOCKNUTS

E0606

TRIPPING HOOK

PIN D2

TRIPPING

PLATE

PIN D1

Figure 5. Type BMS1 Construction

THREADED

STEM

THREADED STEM

LOCKNUT

OVERPRESSURE SHUTOFF

4. Reset the detection stage only. (See Figure 7 and the

section on Resetting the Trip Mechanism)

5. Adjust the threaded stem to a distance of

1/16 in. / 1.6 mm from Pin D1 (detection stage set).

6. Tighten threaded stem locknut.

7. Rotate the tripping hook into position and adjust the

tripping hook locknuts until the hook is at a distance of

1/16 in. / 1.6 mm from Pin D2.

8. Tighten tripping hook locknuts.

Adjusting the Underpressure Trip Point:

1. Maintain the desired trip pressure in Type BMS1.

2. Turn in the adjusting screw until the detection stage

is tripped.

3. Verify that the trip pressure is equal to the desired

pressure setting by increasing pressure to the

Type BMS1, resetting the detection stage and then

reducing pressure to the Type BMS1 until the detection

stage trips. Adjust trip pressure setting if necessary.

4. Tighten adjusting screw locknut.

Overpressure and Underpressure Shutoff

Adjusting the Threaded Stem:

1. Rotate the tripping hook so that it cannot contact Pin D2.

2. Turn out the adjusting screw.

3. Pressurize the Type BMS1 to the desired overpressure

trip pressure.

4. Reset the detection stage only. (See Figure 7 and the

section on Resetting the Trip Mechanism.)

5. Adjust the threaded stem until it just touches Pin D1.

6. Manually trip the detection stage by moving Pin D1.

7. Unscrew the threaded stem two turns which is a

distance of approximately 1/16 in. / 1.6 mm.

8. Tighten threaded stem locknut.

North America Only

8

Page 9

Type OS2

Adjusting the Overpressure Trip Point:

Same procedure as overpressure shutoff only.

Adjusting the Underpressure Trip Point:

1. Pressurize the Type BMS1 to a pressure between the

desired overpressure and underpressure trip points.

2. Reset the detection stage only. (See Figure 7 and the

section on Resetting the Trip Mechanism.)

3. Pressurize the Type BMS1 to the desired underpressure

trip pressure.

4. Adjust the hook by progressively moving the tripping

hook locknuts until the detection stage trips.

5. Tighten tripping hook locknuts.

6. Verify that the trip pressure is equal to the desired

pressure setting by increasing pressure to the

Type BMS1, resetting the detection stage and then

reducing pressure to the Type BMS1 until the detection

stage trips. Adjust trip pressure setting if necessary.

Type BMS2 (Figure 6)

Overpressure Shutoff Only

Adjusting the Overpressure Push Button:

1. Remove the tripping hook.

CAUTION

Be sure there is no pressure in the

manometric sensing device before doing the

following steps.

2. Turn in the adjusting screw until the distance between

the threaded stem and Pin D2 stops increasing.

3. Reset the detection stage only. (See Figure 7 and the

section on Resetting the Trip Mechanism.)

4. Adjust the push button to a distance of 1/16 in. / 1.6 mm

from Pin D2.

5. Tighten push button locknut.

Adjusting the Overpressure Trip Point:

Same procedure as adjusting the Type BMS1 for overpressure

shutoff only.

ADJUSTING

SCREW

ADJUSTING SCREW

LOCKNUT

E0607

OVERPRESSURE AND UNDERPRESSURE SHUTOFF

TRIPPING

HOOK

LOCKNUT

Figure 6. Type BMS2 Construction

PUSH BUTTON LOCKNUT

PUSH BUTTON

PIN D2

TRIPPING

PLATE

PIN D1

TRIPPING

HOOK

THREADED

STEM

THREADED

STEM

LOCKNUT

5. Adjust the tripping hook to a distance of 1/16 in. /

1.6 mm from Pin D1.

6. Tighten tripping hook locknut.

Adjusting the Underpressure Trip Point:

Same procedure as adjusting the Type BMS1 for

underpressure shutoff only.

Overpressure and Underpressure Shutoff

Adjusting the Push Button:

1. Remove the tripping hook.

2. Turn out the adjusting screw.

3. Pressurize the Type BMS2 to the overpressure shutoff

trip pressure.

4. Reset the detection stage only. (See Figure 7 and the

section on Resetting the Trip Mechanism.)

5. Adjust the push button until it just touches Pin D2.

6. Manually trip the detection stage by moving Pin D2

(see Figure 5).

7. Unscrew the push button two turns which is a distance

of approximately of 1/16 in. / 1.6 mm.

8. Tighten push button locknut.

Adjusting the Overpressure Trip Point:

Same procedure as overpressure shutoff only.

North America Only

Underpressure Shutoff Only

Adjusting the Underpressure Tripping Hook:

1. Remove the overpressure push button or move it so that

it cannot contact Pin D2.

2. Turn out the adjusting screw.

3. Pressurize the Type BMS2 to the desired underpressure

trip pressure.

4. Reset the detection stage only. (See Figure 7 and the

section on Resetting the Trip Mechanism.)

Adjusting the Underpressure Trip Point:

1. Pressurize the Type BMS2 to a pressure between the

desired overpressure and underpressure trip points.

2. Reset the detection stage only. (See Figure 7 and the

section on Resetting the Trip Mechanism.)

3. Pressurize the Type BMS2 to the desired underpressure

trip pressure.

4. Turn in the tripping hook until the detection stage trips.

5. Tighten tripping hook locknut.

9

Page 10

Type OS2

D2

SLIDING

CLEVIS

D1

SECOND

STAGE

RELEASING

SHAFT

TRAVEL STOP

RESET PIN WITH WHITE DOT

TRAVEL STOP

E0611

VALVE OPEN

SLAM-SHUT VALVE OPEN

STEP A

TRAVEL STOP

VALVE CLOSED

E0612

STEP B

VALVE CLOSED

SLAM-SHUT VALVE CLOSED

RESETTING

TOOL

TRAVEL STOP

VALVE OPEN

North America Only

E0613

RESET DETECTION STAGE (FIRST STAGE)

NOTE: ORIENTATION SHOWN IS FOR TYPE OSE. ORIENTATION FOR TYPES EZHOSX, EZROSX AND EZLOSX IS ROTATED 180°.

10

E0614

RESET POWER STAGE (SECOND STAGE)

Figure 7. Mechanism Trip Stages

Page 11

Type OS2

6. Verify that the trip pressure is equal to the desired

pressure setting by increasing pressure to the

Type BMS2, resetting the detection stage and then

reducing pressure to the Type BMS2 until the detection

stage trips. Adjust trip pressure setting if necessary.

Resetting the Trip Mechanism

Resetting of the Type OS2 slam-shut device is done

manually and, for NPS 8 and 10 / DN 200 and 250 body

sizes, with the bypass valve open. After the Type OS2 has

closed, it must be manually reset before it can be placed

back in service. Before resetting the Type OS2, check for

and correct the reason for the overpressure/underpressure

condition. For the following procedures, see Figures 7 and 8.

Note

To reset the detection stage, the pressure

in the manometric sensing device must

be below the overpressure trip point and/

or above the underpressure trip point.

Otherwise the detection stage cannot

be reset.

Note

Because the Type OS2 mounted on the

Type EZHOSX, EZROSX or EZLOSX is turned

180°, the following directions apply to the

Type OSE only, however, the reset procedure

for the Type EZHOSX, EZROSX or EZLOSX is

the same. When a specific direction is given

(i.e. top left), the Type EZHOSX, EZROSX

or EZLOSX direction will be reversed

(i.e. bottom right).

To reset the Type OS2, close the upstream block valve.

Open the front cover of the mechanism box.

Detection Stage (First Stage)

The reset pin with white dot is at the top center location of

the mechanism box, see Figure 8. Push this pin up and to

the right (Type OSE only, see note above). This action will

lock in the detection stage (see step A in Figure 7).

When movement is started on the stem, the internal bypass

in sizes from NPS 1 through 6 / DN 25 through 150 will open

and equalize the pressure on each side of the valve plug

before the valve plug can be moved off the seat. For NPS 8

and 10 / DN 200 and 250, external bypass valve should be

opened. Continue turning the reset tool.

CAUTION

Wait for the pressure on each side of the

valve plug to equalize before proceeding to

the following steps. Never use an extension

with the reset tool when resetting the

second stage. Failure to do so may result in

equipment damage.

This action will raise the valve plug, compress the closing

spring and latch the second stage (power stage) mechanism.

Replace the reset tool on its holder and replace the cover.

Slowly open the upstream block valve.

Shutdown*

WARNING

!

To avoid personal injury or property damage

due to explosion or damage to shutoff

device, regulator or downstream components

during shutdown, release downstream

pressure to prevent an overpressure

condition on the regulator diaphragm.

Installation arrangements may vary, but in any installation it

is important that the valves be opened or closed slowly. The

steps below apply to the typical installation.

1. Slowly close the downstream shutoff valve.

2. Slowly close the upstream shutoff valve.

3. Slowly open the vent valves downstream of the

slam-shut valve.

4. Slowly open the vent valves upstream of the

slam-shut valve.

North America Only

Power Stage (Second Stage)

Note

The reset tool is keyed and will only fit on

the second stage releasing shaft in one

orientation. Be sure the tool securely fits

onto the shaft before turning.

To reset the power stage, use the square reset tool located

on the lower left corner of the mechanism box. Place the

square end of the tool on the second stage releasing shaft at

the center of the box and slowly rotate clockwise (see step B

in Figure 7).

*For further instructions on Types EZR, EZH and EZL, refer to the corresponding instruction manual of these products.

Maintenance

Instructions are given for complete disassembly and

assembly. Key numbers are referenced in Figure 14 for

NPS 1 through 6 / DN 25 through 150 body sizes and

Figure 15 for NPS 8 and 10 / DN 200 and 250 body sizes

unless otherwise noted.

11

Page 12

Type OS2

Mechanism Box (BM1 or BM2)

Disassembly for NPS 1 through 6 / DN 25 through

150 Body Sizes (Refer to Figure 14)

WARNING

!

Avoid personal injury or damage to

property from sudden release of pressure

or uncontrolled gas or other process fluid.

Before disassembling, carefully relieve

all pressures. Use gauges to monitor

inlet and outlet pressures while releasing

these pressures.

Note

The only parts that are replaceable on

the Type OS2 are the equalizer bypass

component, manometric sensing device

(Types BMS1 and BMS2) and the sealing

components. The seat ring on the Type OSE

is pressed into the body and is not

field removable.

Note

The position of the travel stop (Figure 13)

depends on the Type of assembly and

body size. The travel stop must be in the B

position (Figure 13) for NPS 1 and 2 / DN 25

and 50 body sizes. For all other body sizes,

the travel stop must be in the C position

(Figure 13).

The cover is held on by one screw which can be unscrewed

manually or by using a socket (maximum recommended

torqueis1.8ft-lbs/2.4N•m).

1. Open the mechanism cover and replace the cover screw

O-ring by removing the circlip.

CAUTION

Trip the mechanism if it is not already

released by moving Pin D1 (see Figure 7) to

remove as much spring tension on the stem

as possible.

2. Trip the mechanism by carefully turning the tripping

plate (Pins D1 and D2) clockwise (refer to Figures 5

and 6).

3. Remove the clip (refer to Figure 8). Turn and detach

the clevis from the stem by pulling the pin from the

sliding clevis.

4. Remove the two cap screws (key 39) holding the

mechanism box (key 16) to the bonnet (key 15) and

remove the mechanism box.

5. Remove the nuts (key 23, for NPS 4 and 6 / DN 100

and 150 only) or cap screws (key 21) holding the bonnet

(key 15) to the body (key 1).

6. The bonnet (key 15), valve plug (key 5H) (with equalizer

bypass, key 5A in NPS 1 through 6 / DN 25 through

150 body sizes), main spring (key 12) and small stem

bushing (key 24) will lift out of the body as a unit. Set the

unit on a hard flat surface with the valve plug (key 5H)

at the bottom and press down on the bonnet (key 15) to

compress the main spring (key 12), allowing the stem to

be unhooked from the coupling head.

7. Use a spanner wrench (a wrench is supplied with one

of the replacement parts kits) to unscrew the equalizer

bypass (key 5A) from the valve plug (key 5H) (refer

to Figures 10 and 11). The NPS 1 / DN 25 body size

equalizer bypass (key 5A) holds the plug O-ring (key 32)

to the valve plug (key 5H). On the NPS 2 and 3 / DN 50

and 80 body sizes, the equalizer bypass (key 5A) holds

the plug disk and the plug O-ring (key 32) to the valve

plug (key 5H). The NPS 4 and 6 / DN 100 and 150 body

sizes valve plug disk and valve plug are held together

by six cap screws. On these body sizes, remove the cap

screws and valve plug disk to replace the plug O-ring

(refer to Figure 11).

Note

The equalizer bypass (key 5A) is a common

part between valve plug sizes from NPS 1

through 6 / DN 25 through 150 body sizes.

The equalizer bypass (key 5A) is not

serviceable and must be replaced as a unit.

8. To remove the equalizer bypass (key 5A) from

the coupling and coupling head, drive out the roll

Pin (key 5C) on the coupling (refer to Figure 10).

Disassembly for NPS 8 and 10 / DN 200 and 250

Body Sizes (Refer to Figures 13 and 15)

1. Remove the mechanism box (BM) cover (key 96).

2. Remove the travel stop (see Figure 13).

3. Unscrew the nuts (keys 97 and 98).

4. Remove the resetting latch (key 100).

5. Remove the bolt (key 113) and the spacer (key 114).

6. Remove the cam (key 121) and yoke (key 108).

7. Unscrew the two screws (key 117).

8. Retain the square nut (key 53) situated at the extremity

of the stem valve (key 20).

North America Only

12

Page 13

MECHANISM BOX

(BM, KEY 16)

CLIP

SLIDING CLEVIS

STEM

SCREW (KEY 39) AND

FLAT WASHER (KEY 40)

W8128A

LOCATION FOR

SWITCH (KEY 27)

RESET PIN WITH WHITE DOT

Figure 8. Type OS2 Internal Parts

Type OS2

TRIPPING PLATE

MANOMETRIC SENSING

DEVICE (TYPE BMS1, KEY 17)

MANOMETRIC DEVICE

THREADED STEM

SECOND STAGE RELEASING SHAFT

TRAVEL STOP

RESETTING TOOL

(KEY 3)

CAP SCREW

(KEY 21)

BONNET (KEY 15)

9. Unscrew the cap screws (key 21).

10. Remove the O-ring (key 11).

11. For NPS 8 / DN 200, insert a spacer (key 114) between

the cam (key 121) and square nut (key 53) or a stack

washer (key 99) between the bolt (key 113) and square

nut (key 53).

12. Remove the bonnet (key 15) / valve plug assembly

(key 13).

Disassembly of the Valve Plug (if required) (Refer

to Figure 15)

1. Remove the square nut (key 53).

2. Remove the small stem bushing (key 24).

3. Extract the bonnet (key 15) / valve cylinder (key 14).

Note

Normally, the bonnet (key 15) / valve cylinder

(key 14) part cannot be dismantled.

4. Remove the main spring (key 12).

5. Remove the screws (key 36) and fixing O-ring (key 34)

while the pin (key 35) remains mounted on the valve

plug body (key 13A).

Disassembly of the Valve Plug O-ring

(if required) (Refer to Figure 15)

1. The valve plug body (key 13A) is threaded to the

valve plug cylinder (key 13B), the O-ring (key 34) can

be reached by unscrewing the valve plug assembly

(keys 13A and 13B) using a bar of 800 and 4 screws

[2 M8 on valve plug cylinder (key 13B) and 2 M10 on

valve plug body (key 13A)].

Assembly for NPS 1 through 6 / DN 25 through

150 Body Sizes (Refer to Figure 14)

1. Attach a new equalizer bypass (key 5A) to the coupling

using a roll pin (key 5C, refer to Figure 10).

2. Screw the equalizer bypass (key 5A) into the valve

plug (key 5H) with the plug disk and a new plug O-ring

(key 32, Figure 11). Be careful not to nick or pinch the

O-ring (key 32) when tightening the equalizer bypass

(key 5A). On the NPS 4 and 6 / DN 100 and 150 body

sizes, attach the plug disk and a new plug O-ring

(key 32) to the valve plug (key 5H) using six cap screws

(refer to Figures 11 and 15).

3. Replace the valve piston ring (key 7) on the inside of the

bonnet skirt.

4. Refer to Figures 14 and 16. Place a new O-ring

(included in key 24) on the small stem bushing (key 24).

Set the valve plug assembly (key 5) on a hard flat

surface. Set the main spring (key 12) in place on the

valve plug (key 5H). Place the bonnet (key 15) on the

spring (key 12) and compress the spring by pressing

down on the bonnet. Attach the stem (key 24) to the

coupling head of the valve plug (key 5H) through the

bonnet (key 15). Slowly release the bonnet (key 15) to

allow the spring tension to seat the small stem bushing

(key 24) onto the bonnet and carefully place the O-ring

(key 1C).

5. Place the bonnet assembly (key 15) onto the body

(key 1) using a new O-ring (key 10) and a new

external O-ring (key 11). Secure the bonnet (key 15)

by tightening down the nuts (key 23, for NPS 4 and 6 /

DN 100 and 150 only) or cap screws (key 21).

North America Only

13

Page 14

Type OS2

COUPLING

COUPLING

HEAD

EQUALIZER BYPASS

(KEY 5A)

ROLL PINS

W6853_1

Figure 9. Equalizer Bypass and Coupling Assembly for

NPS 1 through 6 / DN 25 through 150 Body Sizes

6. Place the mechanism box (key 16) onto the bonnet

(key 15) and attach using two cap screws (key 39) and

two flat washers (key 40).

7. Hook the sliding clevis to the stem and insert the pin

(refer to Figures 7 and 8). Secure the Pinusing the clip.

8. To reset, see Resetting the Trip Mechanism in the

Adjustment section.

Assembly for NPS 8 and 10 / DN 200 and 250

Body Sizes (Refer to Figure 15)

1. Perform the operations described in Disassembly in

reverse order.

2. Replace O-rings at each disassembly.

3. Be careful when removing or replacing the valve

plug assembly (key 13) to avoid damaging the piston

ring (key 7).

4. Lubricate screws before tightening (molybdenum

graphite grease).

5. Lightly lubricate O-rings (silicone grease).

6. Replace the cover by tightening the screw manually or

by using a socket (maximum recommended torque is

1.8ft-lbs/2.4N•m).

If the valve plug assembly (key 13) has been disassembled:

7. Lightly lubricate the valve plug O-ring (key 34)

(silicone grease).

8. Lubricate the thread of the valve plug cylinder (key 13B)

(molybdenum graphite grease).

9. Positioning the valve plug O-ring (key 34):

• For NPS 8 / DN 200 Body Size: Screw the valve plug

body (key 13A) partly to the valve plug cylinder (key 13B)

and insert the O-ring (key 34) into the groove before

tightening to reach metal/metal contact.

COUPLING

HEAD

HOLES FOR

SPANNER

WRENCH

VALVE PLUG

(KEY 5H)

EQUALIZER

BYPASS (KEY 5A)

VALVE PLUG DISK

W6855

PLUG O-RING

(KEY 32)

Figure 10. Valve Plug and Equalizer Bypass Assembly for

NPS 1 through 6 / DN 25 through 150 Body Sizes

• For NPS 10 / DN 250 Body Size: Place the O-ring

(key 34) into the groove of the valve plug cylinder

(key 13B), assemble and screw the valve plug body

(key 13A) to reach metal/metal contact.

10. Wipe the valve plug O-ring (key 34) after assembly.

11. Lightly lubricate the stem valve (key 20) (silicone

grease) on the small stem bushing (key 24).

12. Check that the main spring (key 12) is

correctly positioned.

13. Positioning the O-ring (key 10):

• For NPS 8 / DN 200 Body Size: Mount on

connector part.

• For NPS 10 / DN 250 Body Size: Place in the bore of

the body.

For the following procedures, key numbers are not shown in

the assembly drawings for NPS 8 and 10 / DN 200 and 250

body sizes.

14. Lubricate the mechanism of the release relay

(mechanism box face contact plus cam, spacer, bolt

and resetting latch (keys 121, 114, 113 and 100)

(molybdenum graphite grease).

15. Leave minimum operational space [rotation of the cam

(key 121) / bolt (key 113)] between the locknut (key 98)

and the resetting latch (key 100).

16. Lubricate the BMS spring (key 33) (molybdenum

graphite grease).

North America Only

14

Page 15

SAFETY

MANOMETRIC

BOX (BMS)

BASE

SAFETY

MANOMETRIC

BOX 1 (TYPE BMS 1)

“HOOK” KIT

SAFETY

MANOMETRIC

BOX 2 (YPE BMS 2)

“HOOK” KIT

DIAPHRAGM,

TYPES 162 AND 71

Figure 11. Manometric Sensing Device Types

PISTON,

TYPES 27 AND 17

Type OS2

BELLOWS,

TYPES 236 AND 315

Manometric Sensing Device

(Type BMS1 or BMS2)

The Type BMS1 is the first manometric sensing device. The

Type BMS2 is the second manometric sensing device.

Disassembly

1. Disconnect the pressure sensing line from the

manometric sensing device (BMS, key 17).

2. If applicable, remove the BMS tripping hook from the

adjusTable stem of the BMS (see Figures 5 and 6).

3. Loosen and remove the hex head cap screws

(key 38A) and O-ring (key 38B) at the mechanism box

(BM, key 16)/manometric device (BMS, key 17) joint.

(See Figure 13).

4. Carefully pull the BMS (key 17) away from the BM

(key 16) followed by a rubber joint gasket (key 38C,

Figure 13).

5. Inspect the rubber joint gasket (key 38C) for

deterioration or damage and replace if necessary.

6. Loosen the adjustment locknut on the adjusting screw.

Then unscrew and remove the adjusting screw.

7. Remove the BMS spring (key 33) from the spring case.

For BMS Type 162 and 71 (Diaphragm, key 17)

(See Figure 12):

8. Loosen the cap screws and nuts on the casing and

remove the pressure sensing casing to reach the

diaphragm assembly (key 17).

9. If diaphragm replacement is desired, loosen the hex nut

that holds the diaphragm assembly to the valve stem.

For BMS Type 236 and 315 (Bellows, key 17)

(See Figure 12):

8. Loosen the socket screws at the pressure

sensing casing.

9. Remove the spring case from the pressure sensing

casing and then remove the bellows (key 17).

For BMS Type 27 and 17 (Piston, key 17)

(See Figure 12):

8. Loosen the socket screws on the pressure sensing

casing and remove the pressure sensing casing.

9. Loosen the socket screws on the spring case

and remove the spring case away from the pressure

sensing casing.

10. Slide the piston (key 17) out of the pressure

sensing casing.

Assembly

Proceed in the reverse order of Disassembly.

Parts Ordering*

When corresponding with your local Sales Office about

this equipment, always reference the equipment serial

number. When ordering replacement parts, also be sure

to include the complete 11-character part number from the

following parts list.

North America Only

*For further instructions on Types EZR, EZH and EZL, refer to the corresponding instruction manual of these products.

15

Page 16

Type OS2

Parts List

Key Description Part Number

Parts kit (includes keys 7, 10, 11, 32 and 34)

NPS 1 / DN 25 FA197123X12

NPS 2 / DN 50 FA197130X12

NPS 3 / DN 80 FA197132X12

NPS 4 / DN 100 FA197134X12

NPS 6 / DN 150 FA197136X12

NPS 8 / DN 200 FA197535X12

NPS 10 / DN 250 FA197536X12

Parts kit (includes keys 7, 10, 11, 32, a bypass assembly

and a spanner wrench)

NPS 1 / DN 25 FA197124X12

NPS 2 / DN 50 FA197131X12

NPS 3 / DN 80 FA197133X12

NPS 4 / DN 100 FA197135X12

NPS 6 / DN 150 FA197137X12

Replacement Bracket Kit for BMS

Type BMS1 FA181111T12

Type BMS2 FA181112T12

1 Valve Body Assembly

(For NPS 1 through 6 / DN 25 through 150 only)

Type OSE (E-Body)

WCC Steel body

NPS 1 / DN 25

NPT T80543T0072

CL150 RF T80543T0012

CL300 RF T80543T0022

CL600 RF T80543T0032

NPS 2 / DN 50

NPT T80544T0072

CL150 RF T80544T0012

CL300 RF T80544T0022

CL600 RF T80544T0032

NPS 3 / DN 80

CL150 RF T80545T0012

CL300 RF T80545T0022

CL600 RF T80545T0032

(For NPS 1 through 6 / DN 25 through 150 only)

(Body, Seat ring and Seat O-ring)

Type OSE (E-Body)

WCC Steel body

NPS 4 / DN 100

CL150 RF T80546T0012

CL300 RF T80546T0022

CL600 RF T80546T0032

NPS 6 / DN 150

CL150 RF T80547T0012

CL300 RF T80547T0022

CL600 RF T80547T0032

Cast iron body

NPS 1 / DN 25

NPT T80543T0042

CL125 FF T80543T0052

CL250 RF T80543T0062

NPS 2 / DN 50

NPT T80544T0042

CL125 FF T80544T0052

CL250 RF T80544T0062

NPS 3 / DN 80

CL125 FF T80545T0052

CL250 RF T80545T0062

Key Description Part Number

1 Valve Body Assembly (continued)

(For NPS 1 through 6 / DN 25 through 150 only)

(Body, Seat ring and Seat O-ring) (continued)

Type OSE (E-Body) (continued)

Cast iron body (continued)

NPS 4 / DN 100

CL125 FF T80546T0052

CL250 RF T80546T0062

NPS 6 / DN 150

CL125 FF T80547T0052

CL250 RF T80547T0062

Types EZHOSX, EZROSX and EZLOSX (X-Body)

LCC Steel body

NPS 1 / DN 25 (for Types EZHOSX and EZROSX only)

CL150 RF T80548T0012

CL300 RF T80548T0022

CL600 RF T80548T0032

NPS 2 / DN 50

CL150 RF T80549T0012

CL300 RF T80549T0022

CL600 RF T80549T0032

NPS 3 / DN 80

CL150 RF T80550T0012

CL300 RF T80550T0022

CL600 RF T80550T0032

NPS 4 / DN 100

CL150 RF T80551T0012

CL300 RF T80551T0022

CL600 RF T80551T0032

NPS 6 / DN 150 (for Type EZROSX only)

CL150 RF T80552T0012

CL300 RF T80552T0022

CL600 RF T80552T0032

1 Valve Body (For NPS 8 and 10 / DN 200 and 250 only)

Type OSE (E-Body)

LCC Steel body

NPS 8 / DN 200

CL150 RF FA144718X12

CL300 RF FA144717X12

CL600 RF FA144716X12

NPS 10 / DN 250

CL150 RF FA144721X12

CL300 RF FA144720X12

CL600 RF FA144719X12

2 Seat ring (not shown)

NPS 8 / DN 200 FA144794X12

NPS 10 / DN 250 FA144801X12

2 Seat O-ring (not shown)

NPS 8 / DN 200 FA400046X12

NPS 10 / DN 250 FA400092X12

3 Resetting Tool

NPS 1 through 6 / DN 25 through 150 FA242915T12

NPS 8 and 10 / DN 200 and 250 FA181258X12

4 Plug and Bypass Assembly (External) (not shown)

NPS 8 and 10 / DN 200 and 250 only FA406079X12

North America Only

16

Page 17

Type OS2

Key Description Part Number Key Description Part Number

5 Plug and Bypass Assembly

NPS 1 / DN 25 FA181114T12

NPS 2 / DN 50 FA181115T12

NPS 3 / DN 80 FA181116T12

NPS 4 / DN 100 FA181117T12

NPS 6 / DN150 FA181118T12

Bypass Assembly

NPS 1 through 6 / DN 25 through 150 FA180977T12

5A Bypass body

5B O-ring support

5C O-ring

5D O-ring

5E Rod plug

5F Spring

5G Guide, spring

5H Body plug

5J O-ring

Roll pin (2 required)

NPS 1 through 6 / DN 25 through 150 FA405635T12

7 Piston Ring (2 required)

NPS 1 / DN 25 FA401950T12

NPS 2 / DN 50 FA401951T12

NPS 3 / DN 80 FA401952T12

NPS 4 / DN 100 FA401953T12

NPS 6 / DN 150 FA401954T12

NPS 8 / DN 200 FA144908X12

NPS 10 / DN 250 FA144925X12

10 O-ring

NPS 1 / DN 25 19B2838X012

NPS 2 / DN 50 18B2124X012

NPS 3 / DN 80 18B8514X012

NPS 4 / DN 100 18B2140X012

NPS 6 / DN 150 19B0359X012

NPS 8 / DN 200 1P5585X0022

NPS 10 / DN 250 FA400093X12

11 O-ring, External, Bonnet

NPS 1 / DN 25 FA400009T12

NPS 2 / DN 50 FA400024T12

NPS 3 / DN 80 FA400259T12

NPS 4 / DN 100 FA400045T12

NPS 6 / DN 150 FA400262T12

NPS 8 / DN 200 FA400093X12

NPS 10 / DN 250 FA400017X12

12 Main Spring

Type OSE (E-Body)

NPS 1 / DN 25 FA144205X12

NPS 2 / DN 50 FA144206X12

NPS 3 / DN 80 FA144208X12

NPS 4 / DN 100 FA144208X12

NPS 6 / DN 150 FA144208X12

NPS 8 / DN 200 FA139554X12

NPS 10 / DN 250 FA139554X12

Type EZHOSX, EZROSX, EZLOSX (X-Body)

NPS 1 / DN 25 FA144205X12

NPS 2 / DN 50 FA144206X12

NPS 3 / DN 80 FA144208X12

NPS 4 / DN 100 FA144209X12

NPS 6 / DN 150 FA144210X12

13 Valve Assembly

NPS 8 / DN 200 FA181259X12

NPS 10 / DN 250 FA181260X12

14 Cylinder, Guide

NPS 8 / DN 200 FA144791X12

NPS 10 / DN 250 FA144798X12

15 Bonnet

NPS 1 / DN 25 FA144510T12

NPS 2 / DN 50 FA144511T12

NPS 3 / DN 80 FA144512T12

NPS 4 / DN 100 FA144513T12

NPS 6 / DN 150 FA144514T12

NPS 8 / DN 200 FA144790X12

NPS 10 / DN 250 FA144797X12

16 Mechanism Box (BM)

BM1

For NPS 1 through 6 / DN 25 through 150 FA181067T12

For NPS 8 and 10 / DN 200 and 250 FA181166X12

BM2

For NPS 1 through 6 / DN 25 through 150 FA181068T12

For NPS 8 and 10 / DN 200 and 250 FA181167X12

17 Manometric Device (BMS)

Diaphragm

Type 162 FA181105T12

Type 71 FA181106T12

Piston

Type 27 FA181107T12

Type 17 FA181108T12

Bellows

Type 236 FA181109T12

Type 315 FA181110T12

18 Flow Arrow (not shown) - - - - - - - - - - -

19 Drive Screw (2 required) (not shown) 1A368228982

20 Valve Stem

NPS 8 / DN 200 FA144793X12

NPS 10 / DN 250 FA144800X12

21 Cap Screw

NPS 1 / DN 25 (4 required) 1R281124052

NPS 2 / DN 50 (8 required) 1A453324052

NPS 3 / DN 80 (8 required) 1A454124052

NPS 4 / DN 100 (8 required) 1A440224052

NPS 6 / DN 150 (12 required) 1U513124052

NPS 8 / DN 200 (8 required) FA402493X12

NPS 10 / DN 250 (16 required) FA402493X12

22 Eyebolt (2 required)

NPS 4 and 6 / DN 100 and 150 FA403250T12

NPS 8 and 10 / DN 200 and 250 FA403252X12

23 Nut (2 required)

NPS 4 and 6 / DN 100 and 150 FA404154T12

NPS 8 and 10 / DN 200 and 250 FA404158X12

24 Small Stem Bushing Assembly

NPS 1 through 6 / DN 25 through 150 FA181040X12

NPS 8 and 10 / DN 200 and 250 FA198426X12

25 Type BMS1 Bracket Kit FA181111T12

26 Type BMS2 Bracket Kit FA181112T12

27 Trigger Switch, optional

For NPS 1 to 6 / DN 25 to 150 only FA196378X12

North America Only

17

Page 18

Type OS2

C1 CONTACT VERSION—EXPLOSION PROOF CONNECTION WITH CABLE AND TIGHT-SHUT PACKING GLAND

Maximum Current 7.0A 0.8A

Maximum Voltage 400V 250V

Protection EEx-d IIC T6

Tightness IP 66

Temperature -20 to 160°F / -29 to 71°C

Fastening 2 M3 screws

Cable 3 wires (Black, Blue, Brown) H05VVF (0.118 x 0.3 in.

AC DC

2

/ 3.0 x 7.6 mm2) D (0.256 in. / 6.5 mm)

OPTIONS

CONTACT

VERSIONS

C1 Explosion proof IP 68 Explosion proof 9.84 ft / 3.0 m wire Black Blue Brown Wires

INSTALLMENT TIGHTNESS CONNECTION

MECHANICAL

CONNECTIONS

Common NF NO Connection

ELECTRICAL CONNECTIONS

Figure 18. Optional Contact Limit Switch (continued)

Key Description Part Number Key Description Part Number

28 Nameplate, Body - - - - - - - - - - -

29 Drive Screw (2 required) (not shown) 1A368228982

30 Pipe Plug, Mechanism Box (NPS 1 through 6 /

DN 25 through 150 only) (not shown) 1A369224492

32 Plug O-ring

NPS 1 / DN 25 FA400257T12

NPS 2 / DN 50 FA400263T12

NPS 3 / DN 80 FA400258T12

NPS 4 / DN 100 FA400260T12

NPS 6 / DN 150 FA400261T12

33 BMS Control Spring See Table 2

34 O-ring

NPS 8 / DN 200 FA400090X12

NPS 10 / DN 250 FA400091X12

35 Pin

NPS 8 and 10 / DN 200 and 250 FA405634X12

36 Screw

NPS 8 / DN 200 (9 required) FA402638X12

NPS 10 / DN 250 (11 required) FA402638X12

37 Bonnet/BM Gasket FA142930T12

38A Hex Head Cap Screw (2 required)

For NPS 1 through 6 / DN 25 through 150 FA402018T12

38B Washer (2 required)

For NPS 1 through 6 / DN 25 through 150 FA461150T12

38C Joint Gasket

For NPS 1 through 6 / DN 25 through 150 FA145431X12

39 Screw FA402019X12

40 Flat Washer FA461150T12

53 Nut

For NPS 8 and 10 / DN 200 and 250 FA144804X12

96 Cover, BM Assembly

For NPS 8 and 10 / DN 200 and 250 FA181168X12

98 Nut, Lock

For NPS 8 and 10 / DN 200 and 250 FA404511X12

99 Washer (4 required)

For NPS 8 and 10 / DN 200 and 250 FA405006X12

100 Resetting Latch

For NPS 8 and 10 / DN 200 and 250 FA144849X12

108 Yoke

For NPS 8 and 10 / DN 200 and 250 FA144667X12

114 Mounting Assembly

For NPS 8 and 10 / DN 200 and 250 FA181041X12

118 Washer, Sealing (2 required)

For NPS 8 and 10 / DN 200 and 250 FA461150T12

120 Joint Gasket

For NPS 8 and 10 / DN 200 and 250 FA145431X12

121 Cam

For NPS 8 and 10 / DN 200 and 250 FA144845X12

North America Only

18

Page 19

25

Type OS2

16

17

17

E0604

A B C

NPS 1 THROUGH 6 / DN 25 THROUGH 150

38A

38B

38C

TRAVEL STOP

9616

North America Only

Figure 12. Mechanism Box (BM1) with 1 Manometric Sensing Device (Type BMS1)

B

A

NPS 8 AND 10 / DN 200 AND 250

19

Page 20

Type OS2

E0605

26

NPS 1 THROUGH 6 /

DN 25 THROUGH 150

16

17

3

16

17

B

A

3

NPS 8 AND 10 /

DN 200 AND 250

Figure 13. Mechanism Box (BM2) with 2 Manometric Sensing Devices (Type BMS2)

North America Only

20

Page 21

Type OS2

DETAIL OF NPS 1 /

DN 25 BODY

E0602 E0603

39

40

37

DETAIL OF

NPS 2 AND 3 /

DN 50 AND 80

BODIES

38

17

16

24

21

22

23

7

DETAIL AREA

VALVE PLUG

SHOWN

OPEN

VALVE PLUG

SHOWN

CLOSED

15

12

11

10

1

North America Only

7

5

E0601

Figure 14. Type OSE Slam-Shut Valve Assembly for NPS 1 through 6 / DN 25 through 150 Body Sizes

NPS 4 AND 6 / DN 100 AND 150 BODIES

21

Page 22

Type OS2

DETAIL OF NPS 10 / DN 250 BODY

22

23

17

16

24

53

20

21

15

11

10

34

36

35

Figure 15. Type OSE Slam-Shut Valve Assembly for NPS 8 and 10 / DN 200 and 250 Body Sizes

13A

36

20

12

14

7

13B

1

North America Only

22

Page 23

E0600

Type OS2

39

40

24

E0615

Figure 16. Small Stem Bushing Detail

WIRING

BU

BK

BN

NF—BK/BU

NO—BK/BN

KEY 27

NF—NORMALLY CLOSED

NO—NORMALLY OPEN

Figure 17. Optional Contact Limit Switch

LOCATION

OF CONTACT

SWITCH

North America Only

23

Page 24

Type OS2

Webadmin.Regulators@emerson.com

Fisher.com

Emerson Automation Solutions

Americas

McKinney, Texas 75070 USA

T +1 800 558 5853

+1 972 548 3574

Europe

Bologna 40013, Italy

T +39 051 419 0611

Facebook.com/EmersonAutomationSolutions

LinkedIn.com/company/emerson-automation-solutions

Twitter.com/emr_automation

Asia Pacic

Singapore 128461, Singapore

T +65 6777 8211

Middle East and Africa

Dubai, United Arab Emirates

T +971 4 811 8100

D102778X012 © 2001, 2018 Emerson Process Management Regulator

Technologies, Inc. All rights reserved. 04/18.

The Emerson logo is a trademark and service mark of Emerson

Electric Co. All other marks are the property of their prospective owners.

Fisher™ is a mark owned by Fisher Controls International LLC, a

business of Emerson Automation Solutions.

The contents of this publication are presented for information purposes

only, and while effort has been made to ensure their accuracy, they are

not to be construed as warranties or guarantees, express or implied,

regarding the products or services described herein or their use or

applicability. All sales are governed by our terms and conditions, which

are available on request. We reserve the right to modify or improve the

designs or specications of our products at any time without notice.

Emerson Process Management Regulator Technologies, Inc. does not

assume responsibility for the selection, use or maintenance of any

product. Responsibility for proper selection, use and maintenance of any

Emerson Process Management Regulator Technologies, Inc. product

remains solely with the purchaser.

North America Only

Loading...

Loading...