Emerson Fisher FIELDVUEDVC6200p Brochure

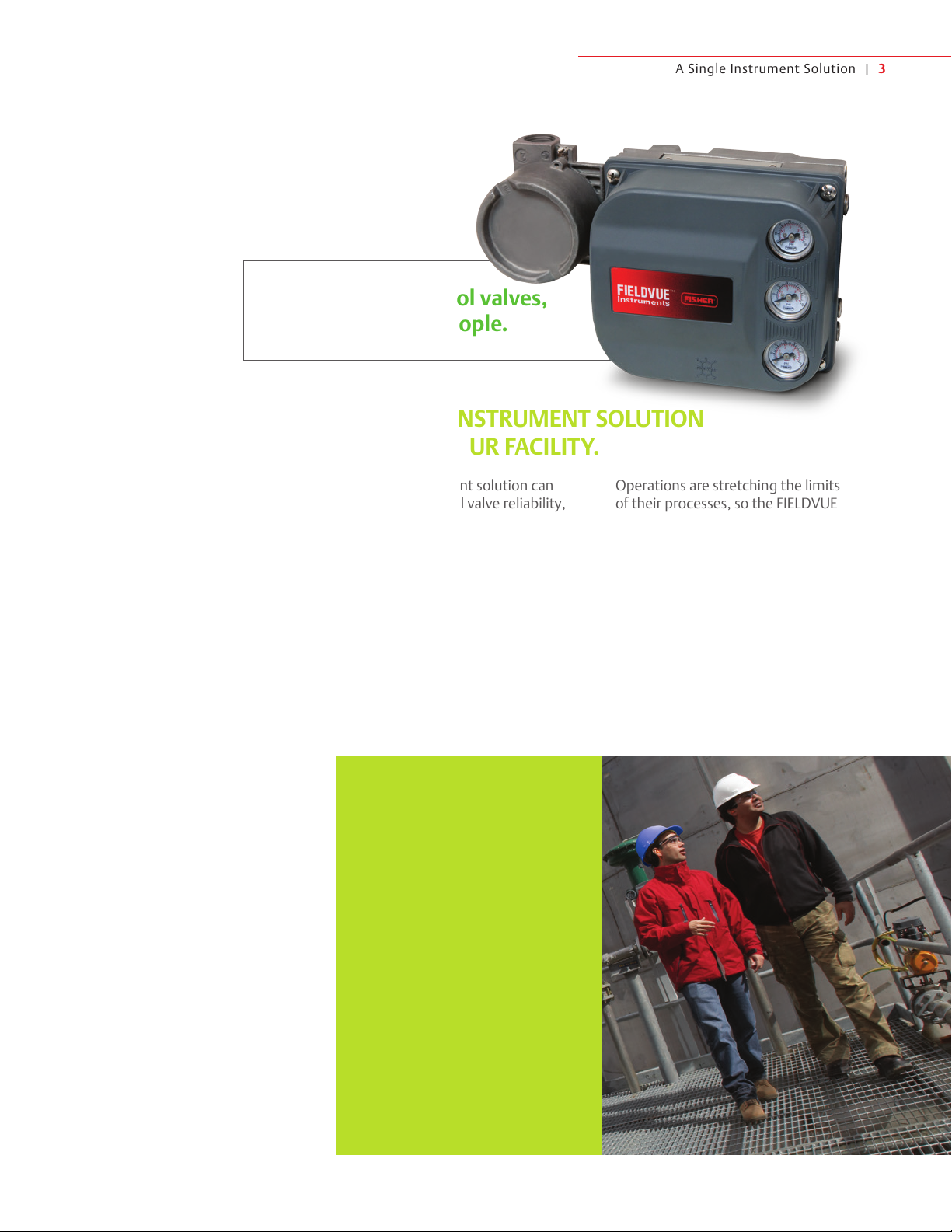

FIELDVUE™ DVC6200 Series Digital Valve Controller

A Single Instrument Solution Across Your Facility

2 | A Single Instrument Solution

What if you had a single instrument solution that could...

Meet your control valve RELIABILITY needs with solutions and experience? Pages 4–5

Handle the majority of your CONTROL AND SAFETY applications? Pages 6–7

Improve operational PERFORMANCE? Pages 8–9

Increase PRODUCTIVITY and reduce maintenance costs? Pages 10–11

Poor valve reliability or performance can undermine process operations. Are control valves

working the way they are supposed to in your facility?

With FIELDVUE digital valve controllers, we

have not only seen a step-change improvement in

valve reliability but also in process performance.

“

Tim Prestifilippo

Instrument & Control Technician

Southern Company, USA

”

Designed for control valves,

by control valve people.

A SINGLE INSTRUMENT SOLUTION

ACROSS YOUR FACILITY.

A Single Instrument Solution | 3

A single instrument solution can

meet your control valve reliability,

performance, and diagnostics needs

across your facility. The Fisher®

FIELDVUE™ DVC6200 Series digital

valve controller is a valve-mounted,

microprocessor-based instrument from

Emerson that brings intelligence to the

entire control valve assembly.

WHAT USERS ARE SAYING ABOUT

THE FIELDVUE INSTRUMENT

This technology makes it possible

to set a more aggressive loop strategy

that, at the same time, is more stable

and reliable.

Operations are stretching the limits

of their processes, so the FIELDVUE

instrument has evolved to meet these

needs. Keep your process in control

using vital, real-time information about

control valve assemblies. Information

can be accessed anywhere along the

loop. The FIELDVUE instrument is

available with either the HART® 5 or 7,

WirelessHART,® Foundation™ fieldbus, or

PROFIBUS® communication protocol.

The reliability of the FIELDVUE

DVC6200 instrument, plus its on-line

monitoring capabilities, enables our

operators to avoid manual checks

and valve repairs in areas filled with

ammonia vapors.

To optimize process control, I start by

improving control valve performance.

I’ve made sure that every critical valve

has a FIELDVUE controller.

4 | A Single Instrument Solution

MEET YOUR CONTROL VALVE RELIABILITY NEEDS

WITH SOLUTIONS AND EXPERIENCE.

The FIELDVUE instrument has logged

billions of operating hours and has

earned high praise from companies

that employ its technology to improve

plant availability. The FIELDVUE

instrument is very robust—units

installed over twenty years ago are still

performing today.

Count on proven technology.

A long-time favorite within industry,

the FIELDVUE instrument is proven

with over 1.5 million instruments

installed—the largest installed base

available today. It can fit on nearly any

control valve regardless of the make,

model, or size.

Linkage-less for more uptime.

A magnet array and Hall Effect sensor

are used in the FIELDVUE instrument

to detect valve position on slidingstem and rotary control valves. With

no linkage to wear, loosen, corrode,

or vibrate, it can handle harsh

environments and nonstop cycling.

Protected components.

The sealed terminal box isolates

field-wiring connections from other

areas and keeps water and harsh

atmosphere away from internal parts.

Electronic components on the printed

circuit board are fully encapsulated

and isolated from the environment.

Survival in harsh conditions.

Built for extreme conditions, the

FIELDVUE instrument has proven

itself by surviving the most difficult

process conditions. Product testing

includes highly accelerated vibration

and temperature testing to help assure

reliable performance in your process.

Optional stainless steel housing

provides extended service life in hostile

and corrosive environments.

Separate Wiring Compartment

The sealed terminal box isolates field-wiring

connections from other areas of the

instrument and keeps water and corrosive

process atmosphere away from

electronic components.

Scan or click the

QR code to

watch the video.

Discover more

Just how rugged are FIELDVUE

digital valve controllers? Watch some

examples of product durability testing.

Linkage-Less, Non-Contact

Feedback Technology

With no sliding parts to wear, loosen,

corrode, or vibrate, a magnet array and

Hall Effect sensor are used to detect valve

position. This technology provides a robust

solution for harsh environments and

nonstop cycling.

A Single Instrument Solution | 5

Modular Design

Makes Maintenance

Quick and Easy

The master module design

allows fast replacement of the

I/P converter, relay, gauges, and

encapsulated electronics

without disturbing the

mounting, pneumatic tubing,

or field wiring.

Position Transmitter

The optional integral valve position

transmitter eliminates the need for a

separate valve position transmitter.

Encapsulated

Electronics

Electronic circuitry on the

printed circuit board is fully

encapsulated and isolated

from the terminal box,

conduit, and plant

environment.

Integrally Mounted

Gauges

Supply and output gauges

are under the cover, fully

protected from the

environment and against

rough handling, helping assure

maintenance-free performance.

Loading...

Loading...