Emerson Fisher FIELDVUEDVC6200, Fisher FIELDVUEDVC6200f, Fisher FIELDVUEDVC6200p Quick Start Guide

Page 1

Quick Start Guide

D103556X012

DVC6200 Digital Valve Controllers

January 2014

Fisherr FIELDVUE™ DVC6200 Series Digital Valve

Controllers

Contents

Before You Begin 2......................................

Step 1. Install the DVC6200 on the Valve 3...................

Step 2. Connect the Pneumatic Tubing 15...................

Step 3. Connect the Electrical Wires 19......................

Step 4. Configure the DVC6200 29.........................

Special Instructions for Safety Instrumented Systems 31.......

Hazardous Area Approvals and Special Instructions for

“Safe Use”and Installations in Hazardous Locations 39.......

W9713

This quick start guide provides installation and initial setup information for DVC6200 Series digital valve controllers

SIS

www.Fisher.com

Page 2

DVC6200 Digital Valve Controllers

January 2014

Quick Start Guide

D103556X012

SIS

Before You Begin

Do not install, operate, or maintain a DVC6200 digital valve controller without being fully trained and qualified in

valve, actuator, and accessory installation, operation, and maintenance. To avoid personal injury or property damage,

it is important to carefully read, understand, and follow all contents of this quick start guide, including all safety

cautions and warnings. Refer to Hazardous Area Approvals and Special Instructions for “Safe Use” and Installations in

Hazardous Locations, on page 39, for approval specific safe use information. If you have any

questions about these instructions, contact your Emerson Process Management sales office

before proceeding.

WARNING

Avoid personal injury or property damage from sudden release of process pressure or bursting of parts. Before proceeding

with any Installation procedures:

D Always wear protective clothing, gloves, and eyewear to prevent personal injury or property damage.

D Do not remove the actuator from the valve while the valve is still pressurized.

D Disconnect any operating lines providing air pressure, electric power, or a control signal to the actuator. Be sure the

actuator cannot suddenly open or close the valve.

D Use bypass valves or completely shut off the process to isolate the valve from process pressure. Relieve process pressure

from both sides of the valve.

D Use lock‐out procedures to be sure that the above measures stay in effect while you work on the equipment.

D Check with your process or safety engineer for any additional measures that must be taken to protect against process

media.

D Vent the pneumatic actuator loading pressure and relieve any actuator spring precompression so the actuator is not

applying force to the valve stem; this will allow for the safe removal of the stem connector.

WARNING

To avoid static discharge from the plastic cover when flammable gases or dust are present, do not rub or clean the cover

with solvents. To do so could result in a spark that may cause the flammable gases or dust to explode, resulting in personal

injury or property damage. Clean with a mild detergent and water only.

For information on installation and usage of DVC6200 Series digital valve controllers, visit the Fisher channel on YouTube and

search for FIELDVUE.

http://www.youtube.com/user/FisherControlValve

2

Page 3

Quick Start Guide

D103556X012

DVC6200 Digital Valve Controllers

January 2014

SIS

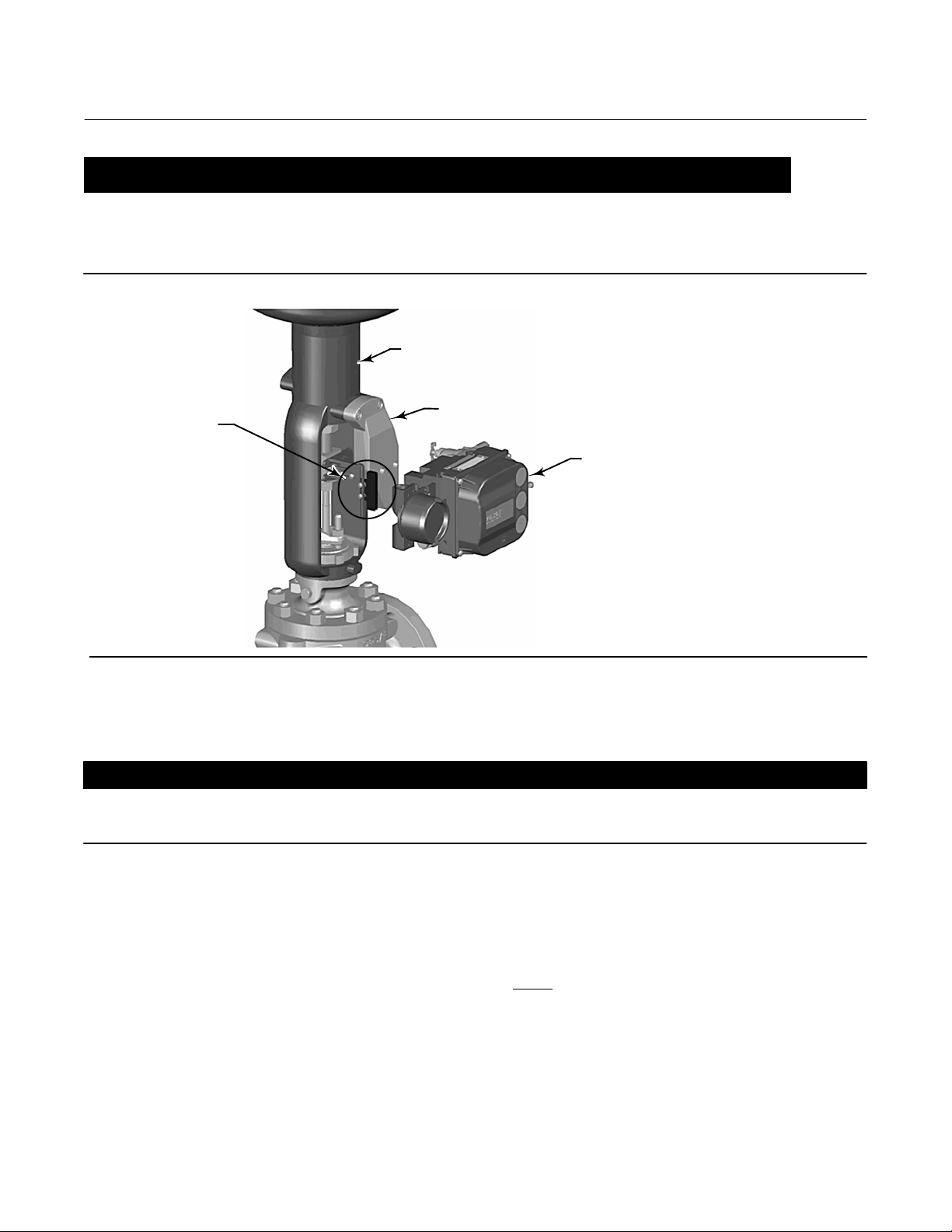

Step 1—Install the DVC6200 on the Valve

If ordered as part of a control valve assembly, the factory will mount the digital valve controller on the actuator and

calibrate the instrument. If you purchased the digital valve controller separately, you will need a mounting kit. The

following procedures are general guidelines. See the instructions that come with the mounting kit for detailed

information on mounting the digital valve controller to a specific actuator model.

CAUTION

The magnet assembly material has been specifically chosen to provide a long‐term stable magnetic field.

However, as with any magnet, care must be taken when handling the magnet assembly. Another high powered magnet

placed in close proximity (less than 25 mm) can cause permanent damage. Potential sources of damaging equipment

include, but are not limited to: transformers, DC motors, stacking magnet assemblies.

General Guidelines for use of High Power Magnets with Positioners

Use of high power magnets in close proximity to any positioner which is operating a process should be avoided. Regardless

of the positioner model, high power magnets can affect the positioner’s ability to control the valve. Technicians should

avoid the use of high power magnets in close proximity with any positioner.

Use of Magnetic Tools with the DVC6200

D Magnetic Tip Screw Drivers – Magnetic tip screw drivers can be used to work on the DVC6200. However, they should

not be brought in close proximity to the magnet assembly (located at the back of the instrument) during process

operations.

D Calibrator Strap Magnets

these calibrators would not be used while an instrument is controlling the process. High power magnets

should be kept at least 15 cm (6 inches) from the DVC6200.

– These are high power magnets used to hold 4-20 mA calibrators. Normally,

Note

The mounting instructions also apply to the DVC6215 remote mount feedback unit.

D

As a general rule, do not use less than 60% of the magnet assembly travel range for full travel measurement. Performance will

D

decrease as the assembly is increasingly subranged.

The linear magnet assemblies have a valid travel range indicated by arrows molded into the piece. This means that the hall

D

sensor (the center point of the channel on the back of the DVC6200 housing) has to remain within this range throughout the

entire valve travel. The linear magnet assemblies are symmetrical. Either end may be up.

The magnet assembly may be referred to as a magnetic array in user interface tools.

D

Mounting the instrument vertically, with the vent at the bottom of the assembly, or horizontally, with the vent pointing down, is

D

recommended to allow drainage of moisture that may be introduced via the instrument air supply.

For sliding‐stem linear actuators up to 210 mm (8.25 inches) travel proceed to page 4

For sliding‐stem linear actuators over 210 mm (8.25 inches) travel proceed to page 6

For GX actuators proceed to page 7

For Fisher rotary actuators proceed to page 11

For quarter‐turn rotary actuators proceed to page 12

3

Page 4

DVC6200 Digital Valve Controllers

January 2014

Quick Start Guide

D103556X012

Sliding‐Stem Linear Actuators Up to 210 mm (8.25 inches) Travel

1. Isolate the control valve from the process line pressure and release pressure from both sides of the valve body. Shut

off all pressure lines to the actuator, releasing all pressure from the actuator. Use lock‐out procedures to be sure

that the above measures stay in effect while you work on the equipment.

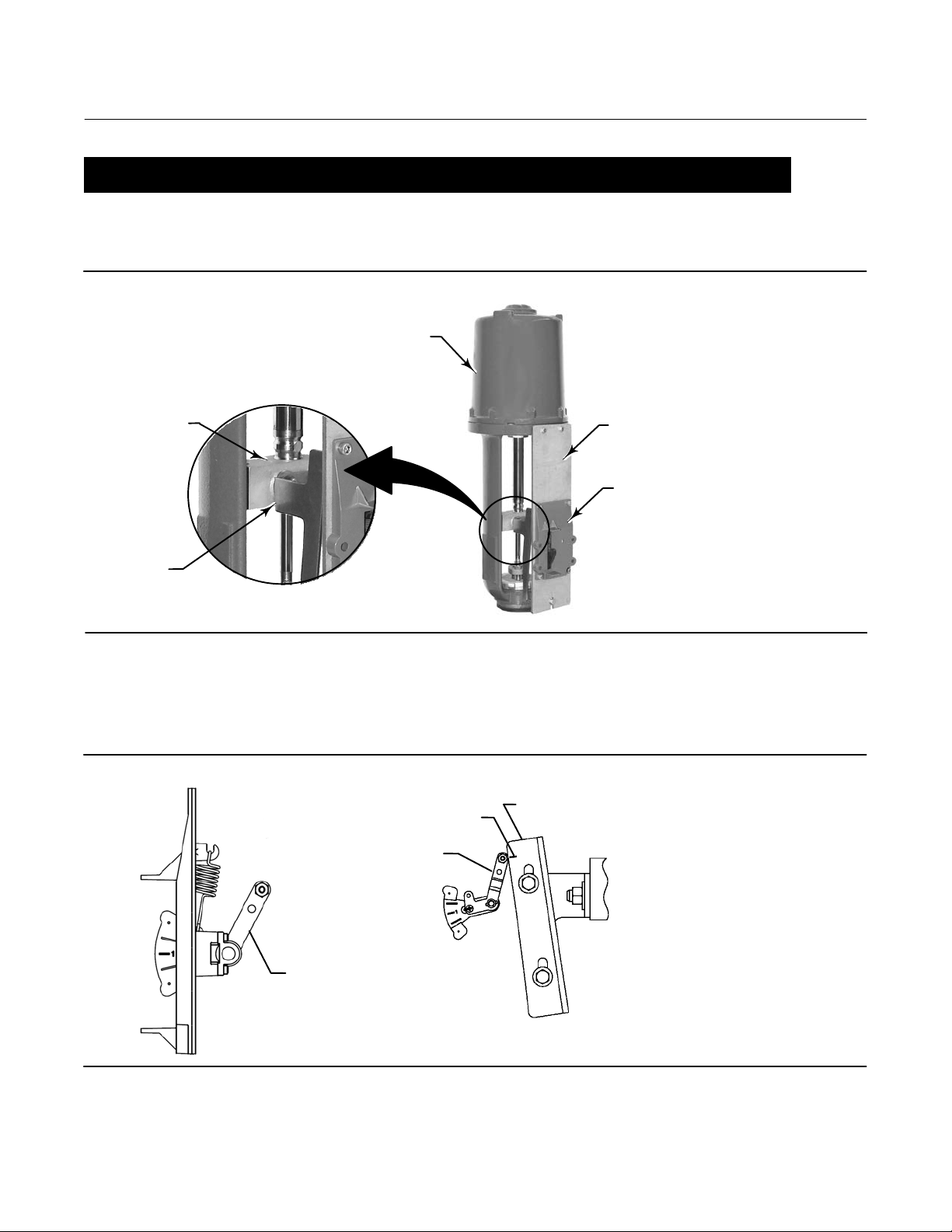

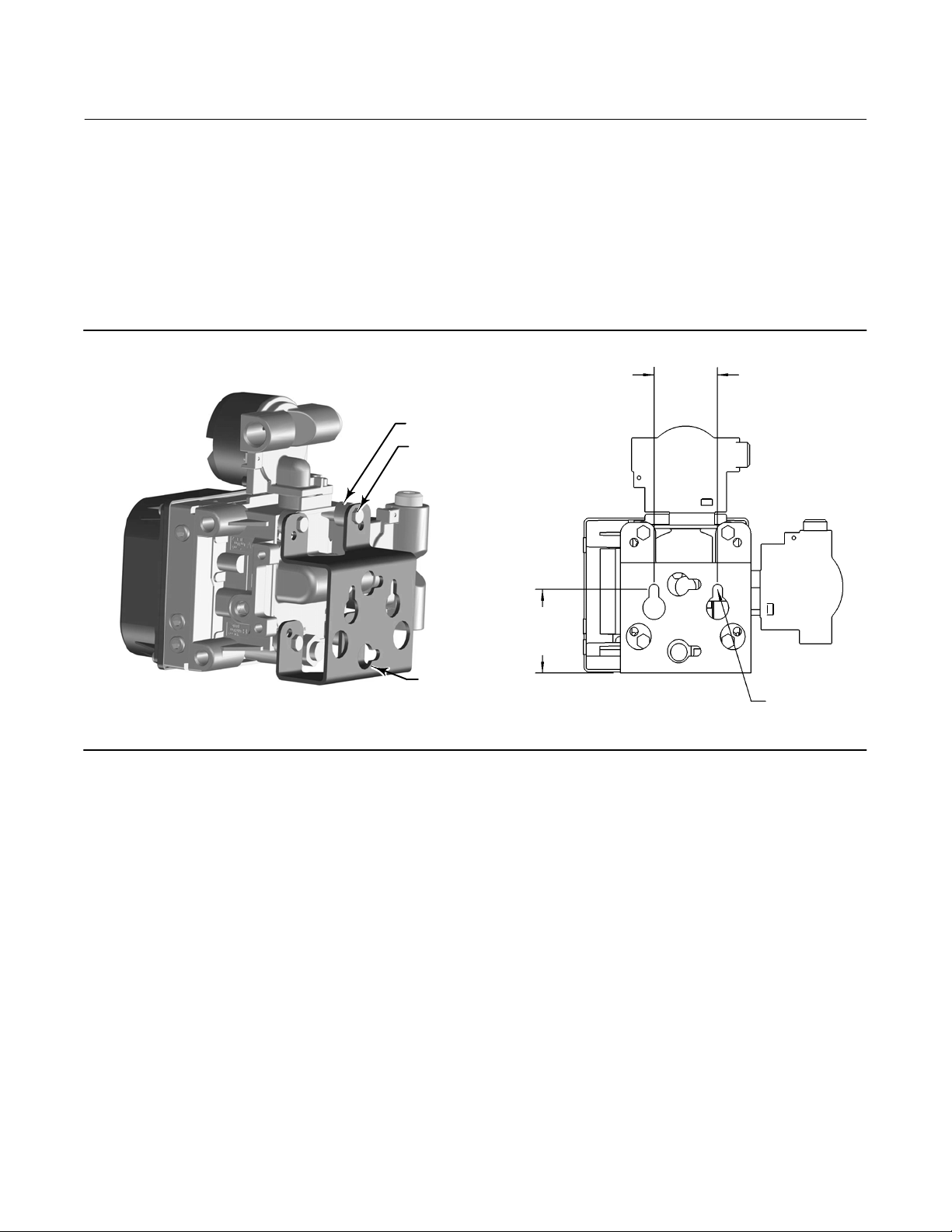

Figure 1. Mounting Parts for Sliding‐Stem Actuator with up to 210 mm (8.25 inches) Travel

ACTUATOR

MOUNTING

FEEDBACK BRACKET

AND MAGNET ASSEMBLY

BRACKET

DIGITAL VALVE

CONTROLLER

X0381-1

2. Attach the mounting bracket to the actuator.

3. Loosely attach the feedback pieces and magnet assembly to the valve stem connector. Do not tighten the fasteners

because fine adjustment is required.

CAUTION

Do not install a magnet assembly that is shorter than the physical travel of the actuator. Loss of control will result from the

magnet assembly moving outside the range of the index mark in the feedback slot of the DVC6200 housing.

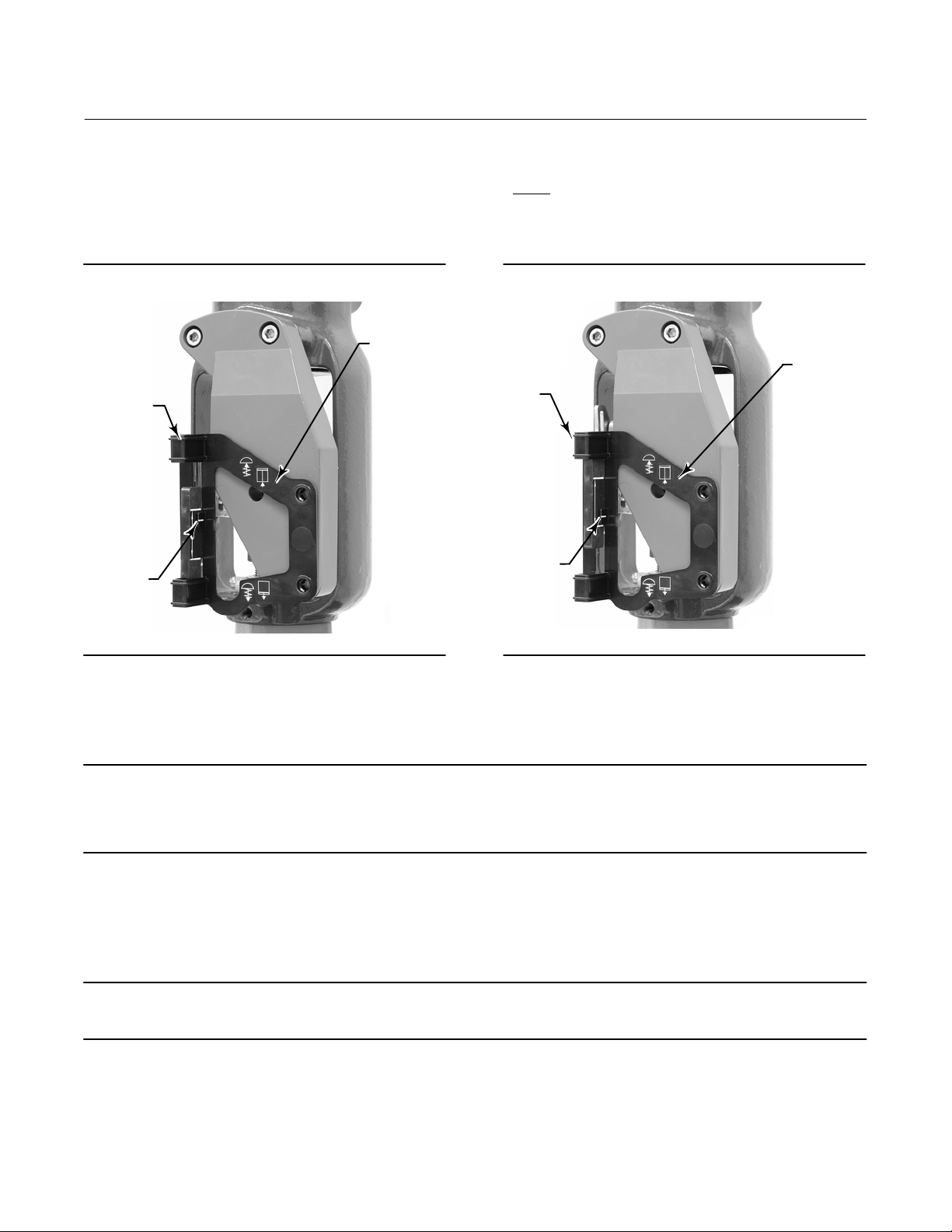

4. Using the alignment template (supplied with the mounting kit), position the magnet assembly inside the retaining

slot.

5. Align the magnet assembly as follows:

D For air‐to‐open actuators (e.g. Fisher 667) vertically align the magnet assembly so that the center line of the

alignment template is lined up as close as possible with the upper

magnet assembly. The magnet assembly should be positioned so that the index mark in the feedback slot of the

DVC6200 housing is within the valid range on the magnet assembly throughout the range of travel. See figure 2.

extreme of the valid travel range on the

4

Page 5

Quick Start Guide

D103556X012

DVC6200 Digital Valve Controllers

D For air‐to‐close actuators (e.g. Fisher 657) vertically align the magnet assembly so that the center line of the

alignment template is lined up as close as possible with the lower

extreme of the valid travel range on the

magnet assembly. The magnet assembly should be positioned so that the index mark in the feedback slot of the

DVC6200 housing is within the valid range on the magnet assembly throughout the range of travel. See figure 3.

January 2014

Figure 2. Air‐to‐Open Magnet Assembly Alignment

ALIGNMENT

TEMPLATE

RETAINING

SLOT

INDEX

MARK

W9718

6. Tighten the fasteners and remove the alignment template.

Figure 3. Air‐to‐Close Magnet Assembly Alignment

ALIGNMENT

RETAINING

SLOT

INDEX

MARK

W9719

TEMPLATE

Note

Use a flat end hex key to tighten the mounting assembly fasteners to a torque of 2.37 N•m (21 lbf•in) for 4 mm screws, and

5.08 N•m (45 lbf•in) for 5 mm screws. While tightening the fasteners using the hex key should be sufficient, blue (medium) thread

locker may be used for additional security.

7. Mount the digital valve controller to the mounting bracket, using the mounting bolts.

8. Check for clearance between the magnet assembly and the DVC6200 feedback slot.

Note

Ensure that there is clearance between the magnet assembly and the DVC6200 housing slot throughout the full range of travel.

9. For remote mount applications, proceed to page 13 for DVC6205 base unit mounting. Otherwise, proceed to

Step 2—Connect the Pneumatic Tubing on page 15.

5

Page 6

DVC6200 Digital Valve Controllers

January 2014

Quick Start Guide

D103556X012

Sliding‐Stem Linear Actuators Over 210 mm (8.25 inches) Travel

1. Isolate the control valve from the process line pressure and release pressure from both sides of the valve body. Shut

off all pressure lines to the pneumatic actuator, releasing all pressure from the actuator. Use lock‐out procedures to

be sure that the above measures stay in effect while working on the equipment.

Figure 4. Mounting on Sliding‐Stem (Linear) Actuators over 210 mm (8.25 Inches) Travel

ACTUATOR

VALVE STEM

CONNECTOR

CAM

W9709

MOUNTING ADAPTOR

LONG STROKE MOUNTING KIT

(DVC6200 NOT SHOWN)

2. Install the cam to the valve stem connector as described in the instructions included with the mounting kit.

3. Install the mounting adaptor to the actuator.

4. Attach the digital valve controller and mounting kit assembly to the mounting adaptor. The roller on the digital

valve controller feedback arm will contact the actuator cam as it is being attached.

Figure 5. Roller Arm Variation used for Sliding‐Stem (Linear) Actuators over 210 mm (8.25 Inches) Travel

CAM/ROLLER

POSITION MARK

ROLLER ARM

CAM

ROLLER

ARM

E1543

E1229

ACTUATOR IS FULLY EXTENDED

5. For remote mount applications, proceed to page 13 for DVC6205 base unit mounting. Otherwise, proceed to

Step 2—Connect the Pneumatic Tubing on page 15.

6

Page 7

Quick Start Guide

D103556X012

DVC6200 Digital Valve Controllers

January 2014

Fisher GX Actuators

1. Isolate the control valve from the process line pressure and release pressure from both sides of the valve body. Shut

off all pressure lines to the actuator, releasing all pressure from the actuator. Use lock‐out procedures to be sure

that the above measures stay in effect while you work on the equipment.

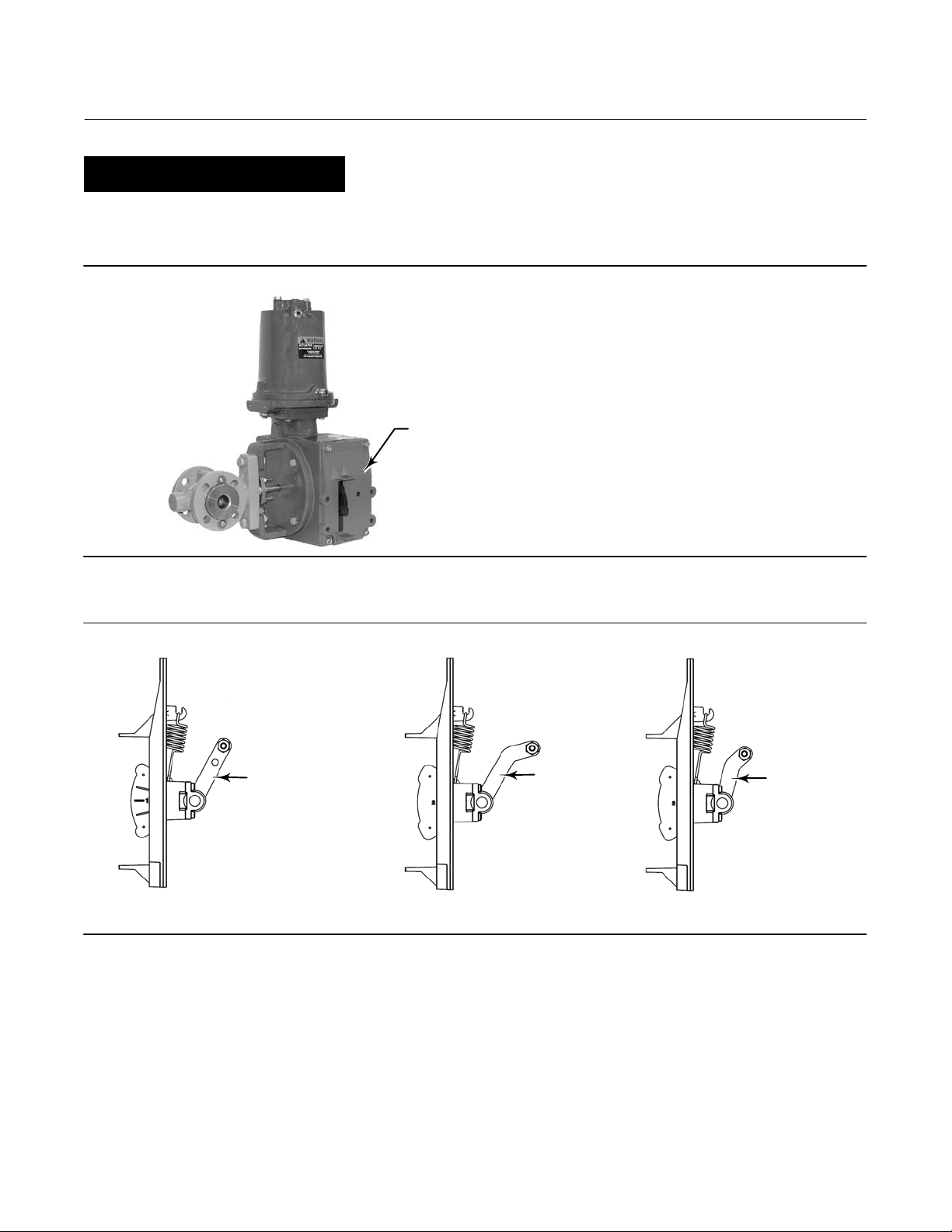

2. The DVC6200 digital valve controller mounts directly on the GX actuator without the need for a mounting bracket.

Make sure you have the correct DVC6200 housing, identified by mounting bolt slots (not holes) below the output

press sure port.

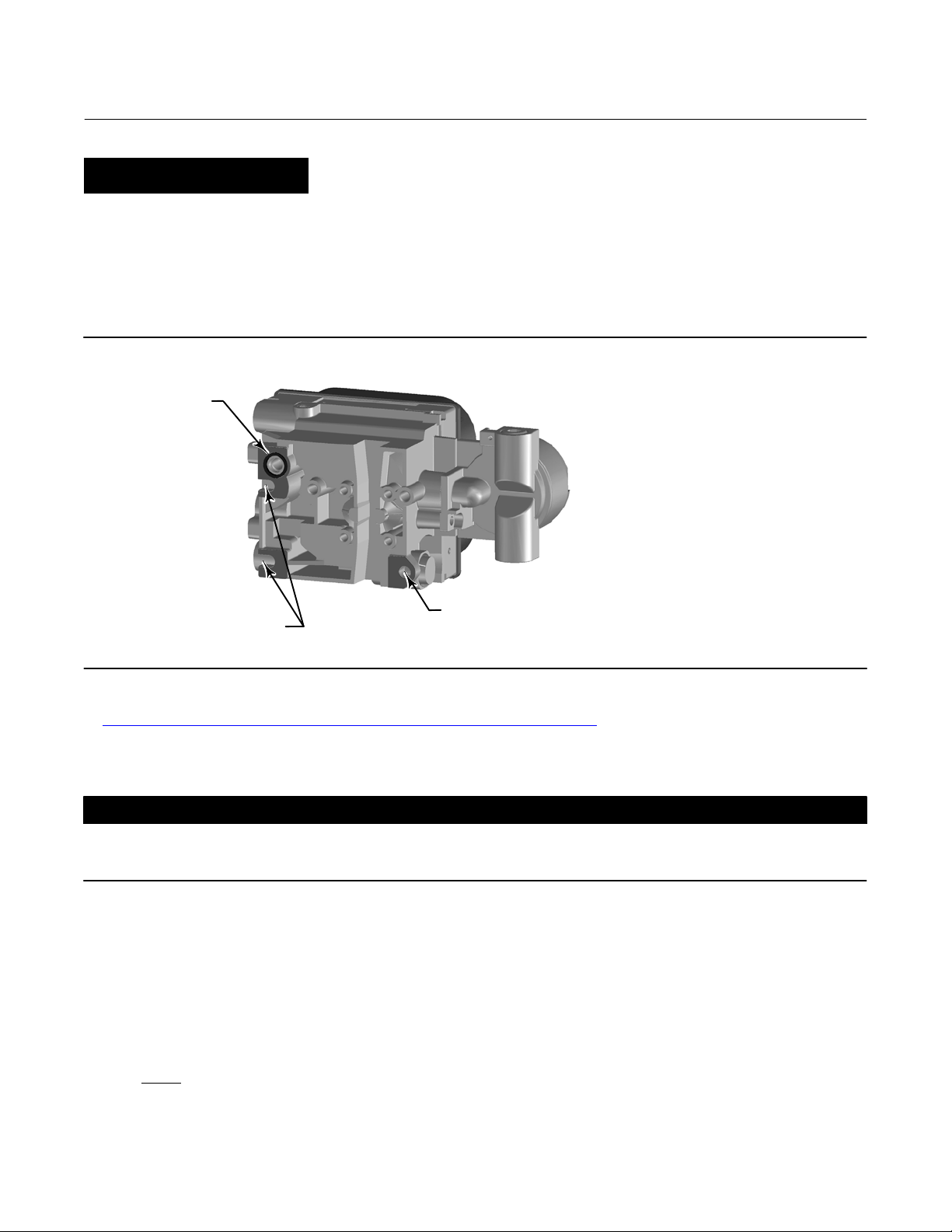

Figure 6. Housing Configuration for Fisher GX Actuators

INTEGRAL OUTPUT

PRESSURE PORT

HOLE FOR

SLOTS FOR

MOUNTING BOLTS

W9704

MOUNTING BOLT

3. Identify the yoke side to mount the DVC6200 digital valve controller based on the actuator fail mode. Refer to the

GX Control Valve and Actuator System instruction manual (D103175X012)

.

4. Loosely attach the feedback pieces and magnet assembly to the valve stem connector. Do not tighten the fasteners

because fine adjustment is required.

CAUTION

Do not install a magnet assembly that is shorter than the physical travel of the actuator. Loss of control will result from the

magnet assembly moving outside the range of the index mark in the feedback slot of the DVC6200 housing.

5. Using the alignment template (supplied with the mounting kit), position the feedback assembly inside the retaining

slot.

6. Align the magnet assembly as follows:

For air‐to‐open GX actuators

Vertically align the magnet assembly so that the center line of the alignment template is lined up as close as possible

with the upper

so that the index mark in the feedback slot of the DVC6200 housing is within the valid range on the magnet assembly

throughout the range of travel. See figure 7.

extreme of the valid travel range on the magnet assembly. The magnet assembly should be positioned

7

Page 8

DVC6200 Digital Valve Controllers

January 2014

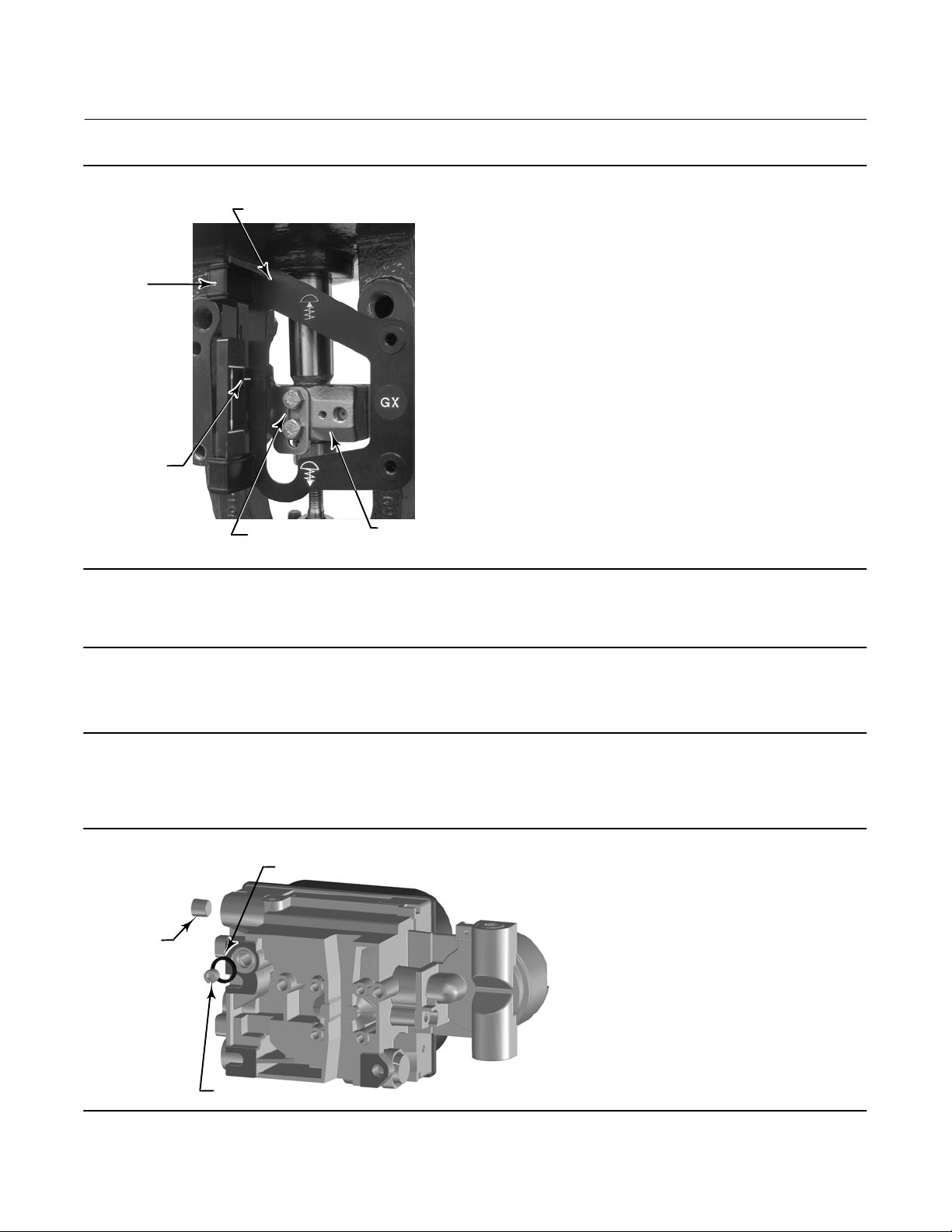

Figure 7. Air‐to‐Open Fisher GX Magnet Assembly Alignment

ALIGNMENT TEMPLATE

RETAINING

SLOT

INDEX

MARK

Quick Start Guide

D103556X012

W9218

FEEDBACK PIECES

VALVE STEM

CONNECTOR

7. Tighten the fasteners and remove the alignment template.

Note

Use a flat end hex key to tighten the mounting assembly fasteners to a torque of 2.37 N•m (21 lbf•in) for 4 mm screws, and

5.08 N•m (45 lbf•in) for 5 mm screws. While tightening the fasteners using the hex key should be sufficient, blue (medium) thread

locker may be used for additional security.

8. Remove the plug (R1/8) from the back of the DVC6200 housing. This pneumatic output port on the DVC6200 lines

up with the integral GX actuator pneumatic port. See figure 8.

Figure 8. Modifications for Fisher GX Actuator; Air‐to‐Open Construction Only

INSTALL O‐RING

INSTALL

1/4 NPT PLUG

W9707

8

REMOVE R1/8 PLUG

Page 9

Quick Start Guide

D103556X012

DVC6200 Digital Valve Controllers

January 2014

9. Install the plug (1/4 NPT, included in the mounting kit) to the external output pneumatic port A.

10. Using a 5 mm hex wrench, attach the digital valve controller to the GX actuator mounting pad on the side that has

the open pneumatic port. Be sure to place the O‐ring between the digital valve controller's pneumatic output and

the actuator mounting pad. Pneumatic tubing is not required because the air passages are internal to the actuator.

11. Check for clearance between the magnet assembly and the DVC6200 feedback slot.

12. If not already installed, install a vent in the port on the upper diaphragm casing's air supply connection on the

actuator yoke leg.

13. For remote mount applications, proceed to page 13 for DVC6205 base unit mounting. Otherwise, proceed to

Step 2—Connect the Pneumatic Tubing on page 15.

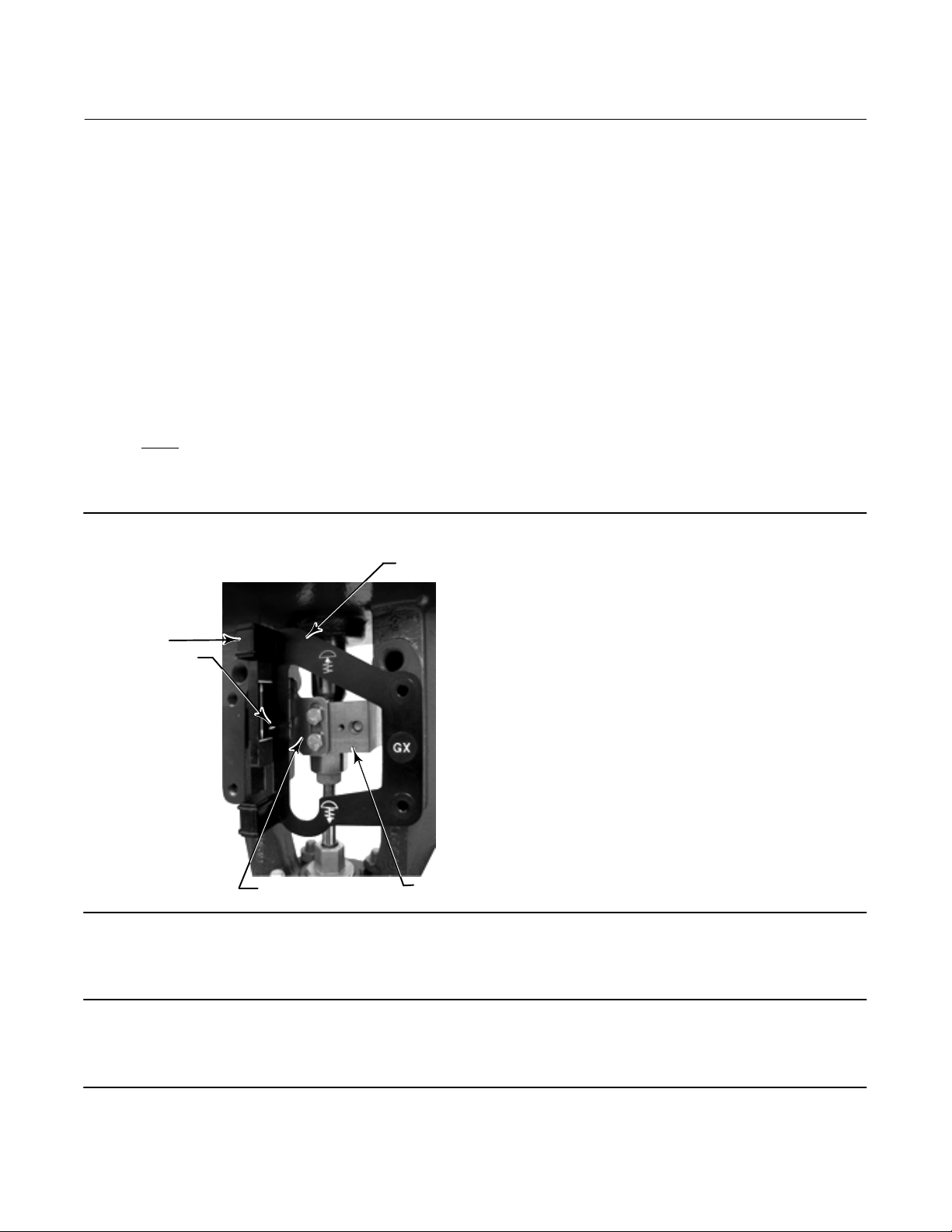

For air‐to‐close GX actuators

Vertically align the magnet assembly so that the center line of the alignment template is lined up as close as possible

with the lower

so that the index mark on the pole pieces (back of the DVC6200 housing) is within the valid range on the magnet

assembly throughout the range of travel. See figure 9.

Figure 9. Air‐to‐Close Fisher GX Magnet Assembly Alignment

extreme of the valid travel range on the magnet assembly. The magnet assembly should be positioned

ALIGNMENT

TEMPLATE

RETAINING

SLOT

INDEX MARK

W9219

FEEDBACK PIECES

VALVE STEM

CONNECTOR

7. Tighten the fasteners and remove the alignment template.

Note

Use a flat end hex key to tighten the mounting assembly fasteners to a torque of 2.37 N•m (21 lbf•in) for 4 mm screws, and

5.08 N•m (45 lbf•in) for 5 mm screws. While tightening the fasteners using the hex key should be sufficient, blue (medium) thread

locker may be used for additional security.

9

Page 10

DVC6200 Digital Valve Controllers

January 2014

Quick Start Guide

D103556X012

8. Using a 5 mm hex wrench, attach the digital valve controller to the GX actuator mounting pad.

9. Check for clearance between the magnet assembly and the DVC6200 feedback slot.

10. Install tubing between the actuator casing and the appropriate DVC6200 pneumatic output port.

11. If not already installed, install a vent in the port on the lower diaphragm casing.

12. For remote mount applications, proceed to page 13 for DVC6205 base unit mounting. Otherwise, proceed to

Step 2—Connect the Pneumatic Tubing on page 15.

Note

When field converting a GX actuator from air-to-close to air-to-open (or vice‐versa), you will need to change the plugs for the

pneumatic passages in the DVC6200 housing.

D

To convert to air-to-open, remove the R1/8 pneumatic plug on the back of the DVC6200 housing and install an O‐ring. Plug

the external pneumatic output with a 1/4 NPT plug. Refer to figure 8.

To convert to air-to-close, remove the external pneumatic plug. Install an R1/8 plug on the back of the DVC6200 housing.

D

Install tubing between the pneumatic output connection of the DVC6200 to the pneumatic port on top of the actuator

casing.

10

Page 11

Quick Start Guide

D103556X012

DVC6200 Digital Valve Controllers

January 2014

Fisher Rotary Actuators

1. Isolate the control valve from the process line pressure and release pressure from both sides of the valve body. Shut

off all pressure lines to the pneumatic actuator, releasing all pressure from the actuator. Use lock‐out procedures to

be sure that the above measures stay in effect while working on the equipment.

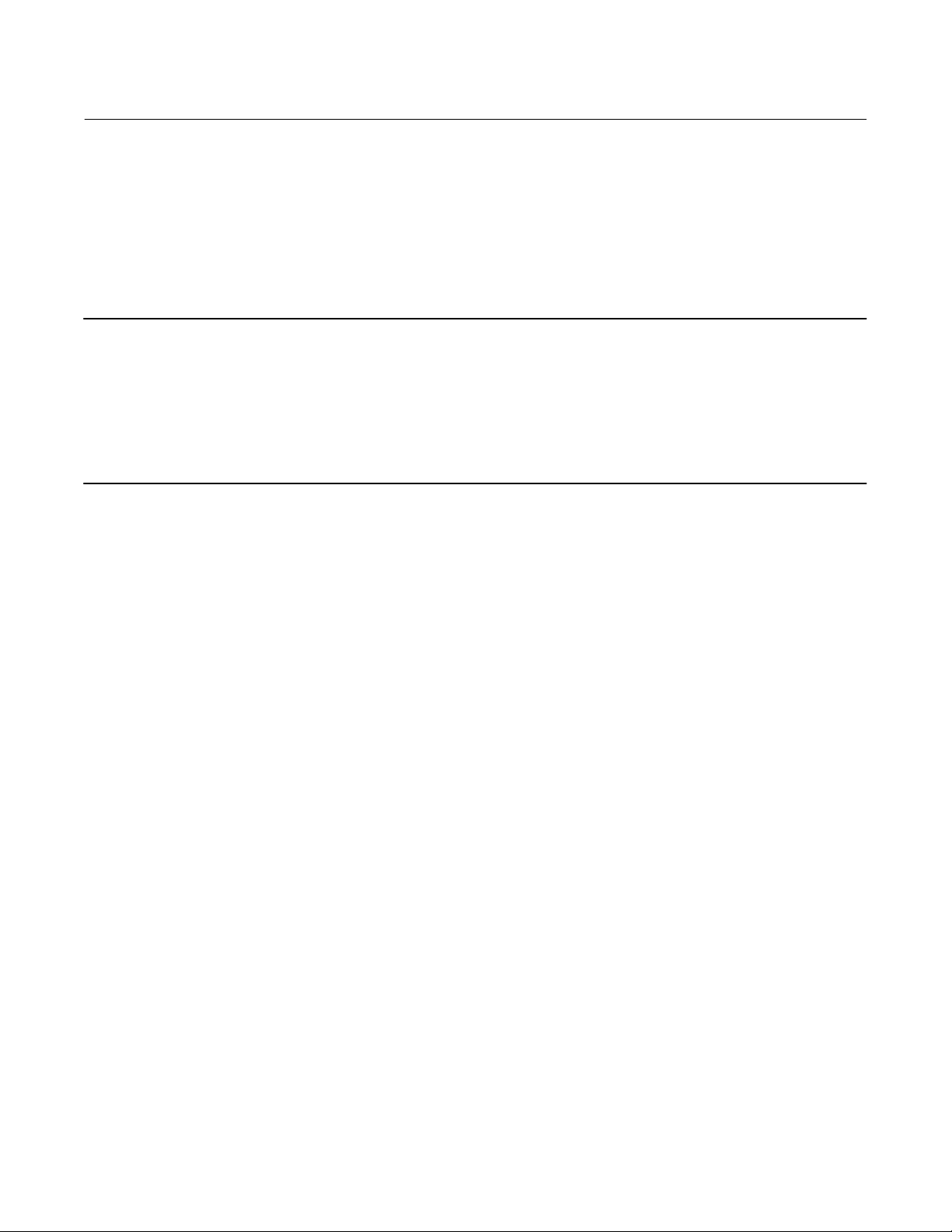

Figure 10. Mounting on Rotary Actuators

ROTARY MOUNTING KIT

(DVC6200 NOT SHOWN)

W9708

2. Verify that the appropriate cam is installed on the actuator as described in the instructions included with the

mounting kit.

Figure 11. Rotary Actuator Mounting Variations

ROLLER ARM

2052 SIZE 2 AND 3

1051/1052 SIZE 40-70

SIZE 1061 SIZE 30-100

NOTE THE DIFFERENCE IN THE SHAPE AND LENGTH OF THE ROLLER ARM

E1229

2052 SIZE 1

ROLLER ARM

1051 SIZE 33

1052 SIZE 20-33

ROLLER ARM

3. Mount the DVC6200 on the actuator as follows:

D If required, a mounting adaptor is included in the mounting kit. Attach the adaptor to the digital valve controller,

then attach the digital valve controller assembly to the actuator. The roller on the digital valve controller

feedback arm will contact the actuator cam as it is being attached.

D If no mounting adaptor is required, attach the digital valve controller and mounting kit assembly to the actuator.

The roller on the digital valve controller feedback arm will contact the actuator cam as it is being attached.

4. For remote mount applications, proceed to page 13 for DVC6205 base unit mounting. Otherwise, proceed to

Step 2—Connect the Pneumatic Tubing on page 15.

11

Page 12

DVC6200 Digital Valve Controllers

January 2014

Quick Start Guide

D103556X012

Quarter‐Turn Rotary Actuators

The DVC6200 digital valve controller can be mounted to any quarter‐turn rotary actuator, as well as those that comply

with the NAMUR guidelines. A mounting bracket and associated hardware are required. Refer to figure 12.

1. Isolate the control valve from the process line pressure and release pressure from both sides of the valve body. Shut

off all pressure lines to the actuator, releasing all pressure from the actuator. Use lock‐out procedures to be sure

that the above measures stay in effect while you work on the equipment.

Figure 12. Mounting on Quarter‐Turn Actuators

W9715

M6 MOUNTING BOLTS (4)

2. Attach the magnet assembly to the actuator shaft. At mid‐travel, the flats on the magnet assembly should be

approximately parallel to the channel on the back of the DVC6200 housing, as shown in figure 13.

Figure 13. Magnet Assembly Orientation on Quarter‐Turn Actuators

DVC6200

ORIENTATION

AT ONE TRAVEL

EXTREME

ORIENTATION

AT MID‐TRAVEL

(FLATS PARALLEL

TO DVC6200

CHANNEL)

ORIENTATION

AT THE OTHER

TRAVEL EXTREME

1 THIS EXAMPLE SHOWS AN ACTUATOR WITH 90_ TRAVEL. ON AN ACTUATOR THAT HAS LESS THAN 90_ TRAVEL THE MAGNET ASSEMBLY MAY NOT BE

PARALLEL AT THE MID-TRAVEL POINT. TO VERIFY THE MAGNET ASSEMBLY POSITION IS IN WORKING RANGE, CONFIRM TRAVEL COUNTS ARE WITHIN THE

EXPECTED RANGE OF 175-3800 USING VALVELINK SOFTWARE OR A FIELD COMMUNICATOR.

1

ACTUATOR

W9700

3. Install the mounting bracket on the actuator.

4. Attach the digital valve controller to the mounting bracket using the 4 mounting bolts, as shown in figure 12.

5. Check for clearance between the magnet assembly and the DVC6200 feedback slot.

6. For remote mount applications, proceed to page 13 for DVC6205 base unit mounting. Otherwise, proceed to

Step 2—Connect the Pneumatic Tubing on page 15.

12

Page 13

Quick Start Guide

D103556X012

DVC6200 Digital Valve Controllers

January 2014

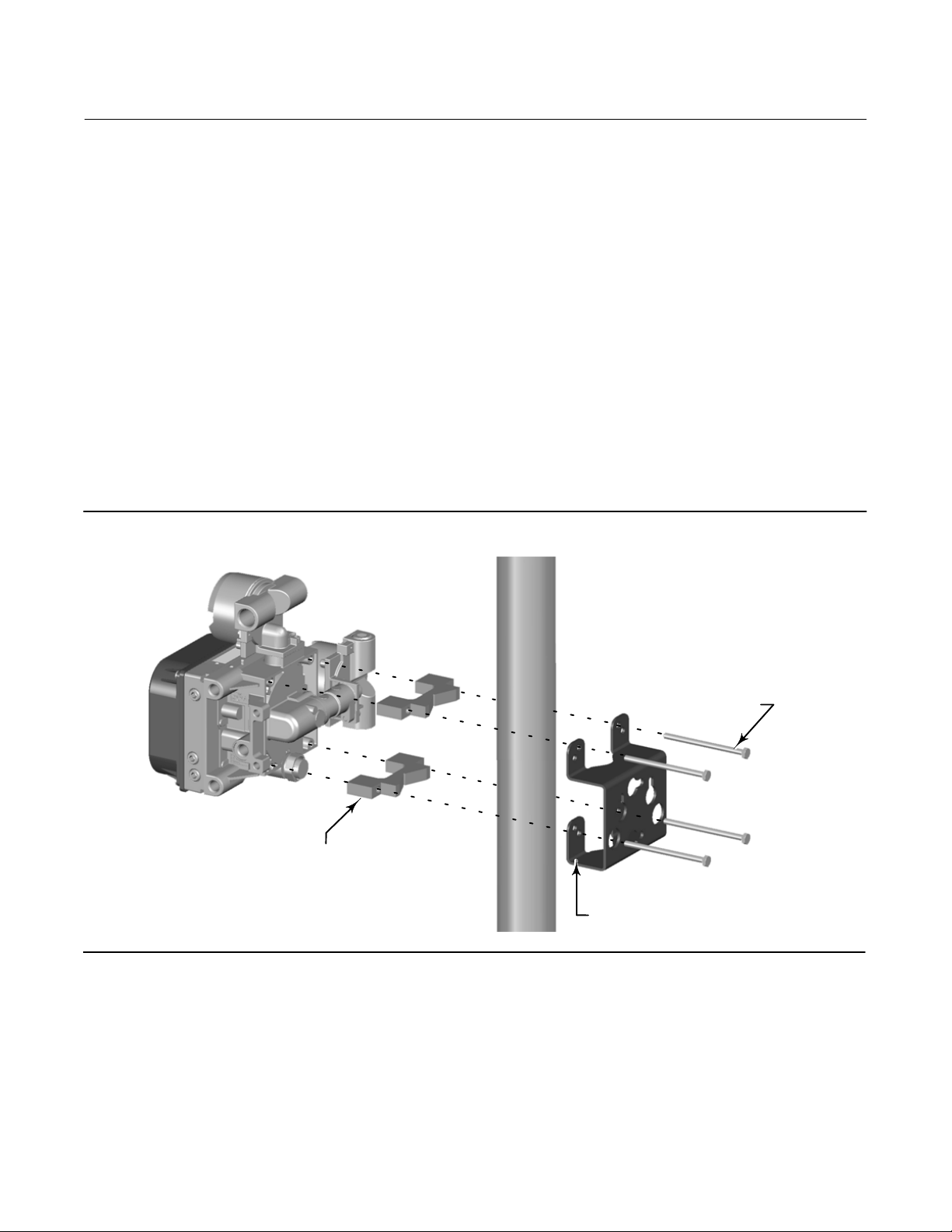

DVC6205 Remote Mount Base Unit Mounting

For remote‐mounted digital valve controllers, the DVC6205 base unit ships separately from the control valve and does

not include tubing, fittings or wiring.

Pipestand Mounting

1. Position a standoff on the back of the base unit.

2. Using two 101.6 mm (4‐inch) 1/4‐20 hex head screws loosely attach the base unit to the pipestand with the

mounting bracket.

3. Position the second standoff, then using the remaining 101.6 mm (4‐inch) hex head screws, securely fasten the

base unit to the pipe stand.

4. Tighten all screws.

5. Proceed to Step 2—Connect the Pneumatic Tubing on page 15.

Figure 14. FIELDVUE DVC6205 Pipestand Mounting

X0437

4‐INCH 1/4‐20

HEX HEAD SCREW

STANDOFF

MOUNTING BRACKET

13

Page 14

DVC6200 Digital Valve Controllers

January 2014

Quick Start Guide

D103556X012

Wall Mounting

1. Install the wall mounting screws by using the mounting bracket as a template.

2. Install the mounting bracket to the back of the base unit using the spacers and screws provided in the mounting kit.

3. Slide the assembly on the wall mounting screws and tighten.

4. Proceed to Step 2—Connect the Pneumatic Tubing on page 15.

Figure 15. FIELDVUE DVC6205 Wall Mounting

57

(2.25)

SPACER

1‐INCH 1/4‐20

HEX HEAD

SCREW

X0428

MOUNTING

BRACKET

72

(2.82)

10C1796‐A

2 MOUNTING

HOLES

8.6/0.34

14

Page 15

Quick Start Guide

D103556X012

DVC6200 Digital Valve Controllers

Step 2—Connect the Pneumatic Tubing

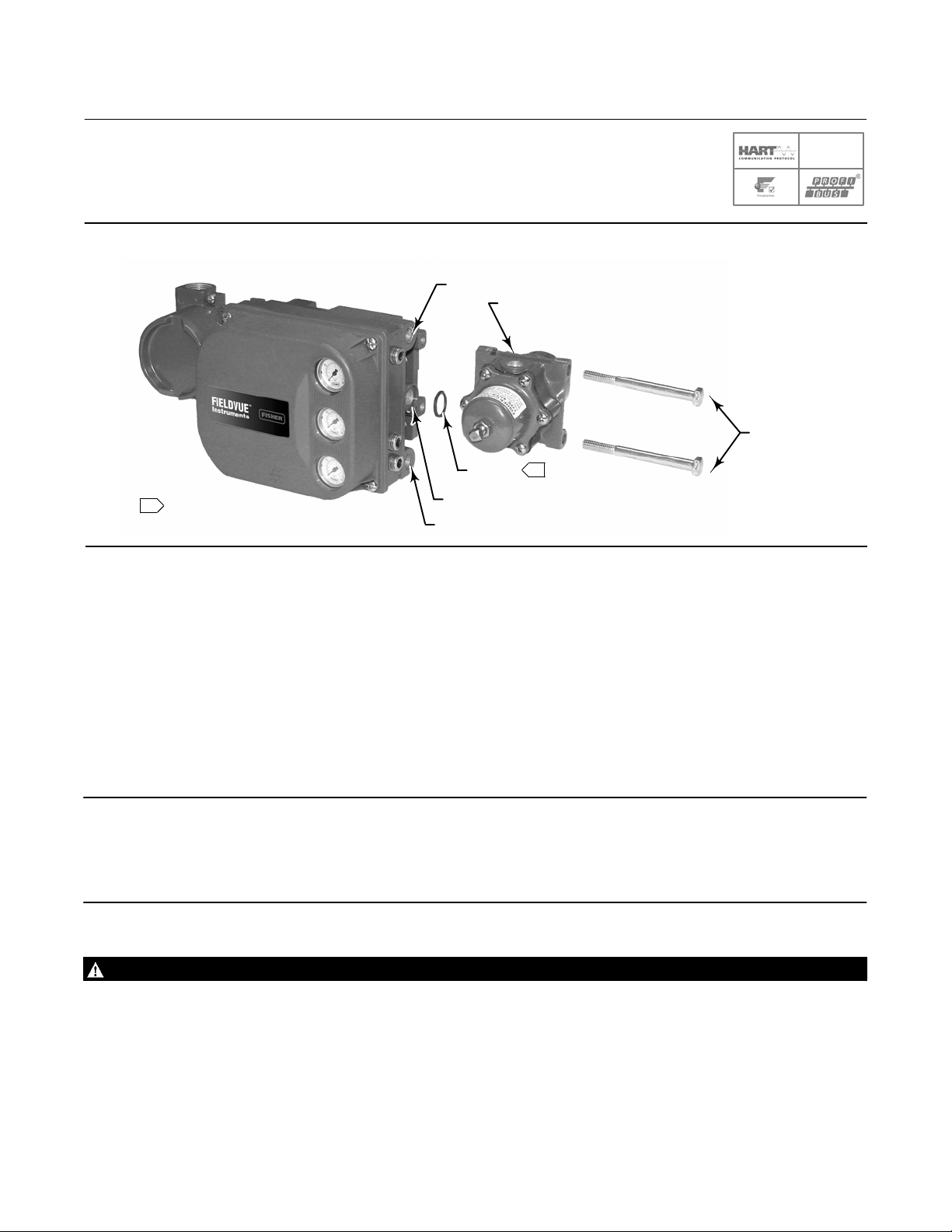

Figure 16. Integral Mounting of a Fisher 67CFR Regulator on a FIELDVUE DVC6200 Digital Valve Controller

OUTPUT A (1/4 NPT)

67CFR

CAP SCREWS

January 2014

SIS

1

NOTE:

1 APPLY LUBRICANT

W9702-1

O‐RING

SUPPLY CONNECTION (1/4 NPT)

OUTPUT B (1/4 NPT)

1. Connect the DVC6200 pneumatic output to the actuator input using at least 10 mm (3/8inch) diameter tubing.

D When using a singleacting direct digital valve controller (relay A or C) on a singleacting actuator, connect

OUTPUT A to the actuator pneumatic input.

D When using a singleacting reverse digital valve controller (relay B) on a singleacting actuator, connect OUTPUT

B to the actuator diaphragm casing.

D When using a doubleacting digital valve controller (relay A) on a doubleacting actuator, connect OUTPUT A and

OUTPUT B to the appropriate actuator pneumatic input. With no input current to the DVC6200, OUTPUT A is at

zero pressure and OUTPUT B is at full supply pressure when the relay is properly adjusted.

Note

To have the actuator stem extend from the cylinder with increasing input signal, connect OUTPUT A to the actuator cylinder

connection farthest from the actuator stem. Connect OUTPUT B to the cylinder connection closest to the actuator stem. To have

the actuator stem retract into the cylinder with increasing input signal, connect OUTPUT A to the actuator cylinder connection

closest to the actuator stem. Connect OUTPUT B to the cylinder connection farthest from the actuator stem.

WARNING

Supply pressure must be clean, dry air that meets the requirements of ISA Standard 7.0.01.

Alternatively, natural gas must be clean, dry, oil‐free, and noncorrosive. H

Severe personal injury or property damage may occur from an uncontrolled process if the instrument supply medium is not

clean, dry, oilfree, and noncorrosive. While use and regular maintenance of a filter that removes particles larger than 40

micrometers in diameter will suffice in most applications, further filtration down to 5 micrometer particle size is

recommended. Lubricant content is not to exceed 1 ppm weight (w/w) or volume (v/v) basis. Condensation in the air

supply should be minimized.

S content should not exceed 20 ppm.

2

15

Page 16

DVC6200 Digital Valve Controllers

January 2014

Check with an Emerson Process Management field office and industry instrument air quality standards for use with

corrosive air or if you are unsure about the amount of air filtration or filter maintenance.

When using natural gas as the supply medium, or for explosion proof applications, the following warnings also apply:

D Remove electrical power before removing the housing cap. Personal injury or property damage from fire or explosion

may result if power is not disconnected before removing the cap.

D Remove electrical power before disconnecting any of the pneumatic connections.

D When disconnecting any of the pneumatic connections or any pressure retaining part, natural gas will seep from the

unit and any connected equipment into the surrounding atmosphere. Personal injury or property damage may result

from fire or explosion if natural gas is used as the supply medium and appropriate preventive measures are not taken.

Preventive measures may include, but are not limited to, one or more of the following: ensuring adequate ventilation

and the removal of any ignition sources.

D Ensure that all caps and covers are correctly installed before putting this unit back into service. Failure to do so could

result in personal injury or property damage from fire or explosion.

Quick Start Guide

D103556X012

2. Connect a filter or filter regulator to the DVC6200 supply input using at least 10 mm (3/8inch) diameter tubing.

D When using an integral mounted 67CFR filter regulator, lubricate an Oring and insert it in the recess around the

SUPPLY connection on the digital valve controller. Attach the filter regulator to the side of the digital valve

controller. Thread a 1/4inch sockethead pipe plug into the unused outlet on the filter regulator. This is the

standard method of mounting the filter regulator. No tubing is required.

D When using a yoke mounted 67CFR filter regulator, mount the filter regulator with two cap screws to the

predrilled and tapped holes in the actuator yoke. Thread a 1/4inch sockethead pipe plug into the unused

outlet on the filter regulator. No Oring is required.

D When using a casing mounted filter regulator, use a separate casing mounting bracket (typically provided with

the filter regulator). Attach the mounting bracket to the filter regulator and then attach this assembly to the

actuator casing. Thread a 1/4inch sockethead pipe plug into the unused outlet on the filter regulator. No Oring

is required.

D If the supply pressure is less than the maximum actuator and instrument pressure rating, a regulator is not

required. However, a filter is always required. Attach the filter securely to the actuator or instrument.

WARNING

Personal injury or property damage can occur from cover failure due to overpressure. Ensure that the housing vent

opening is open and free of debris to prevent pressure buildup under the cover.

This unit vents the supply medium into the surrounding atmosphere. When installing this unit in a nonhazardous

(nonclassified) location in a confined area, with natural gas as the supply medium, you must remotely vent this unit to a

safe location. Failure to do so could result in personal injury or property damage from fire or explosion, and area

reclassification.

When installing this unit in a hazardous (classified) location remote venting of the unit may be required, depending upon

the area classification, and as specified by the requirements of local, regional, and national codes, rules and regulations.

Failure to do so when necessary could result in personal injury or property damage from fire or explosion, and area

reclassification.

In addition to remote venting of the unit, ensure that all caps and covers are correctly installed. Failure to do so could result

in personal injury or property damage from fire or explosion, and area reclassification.

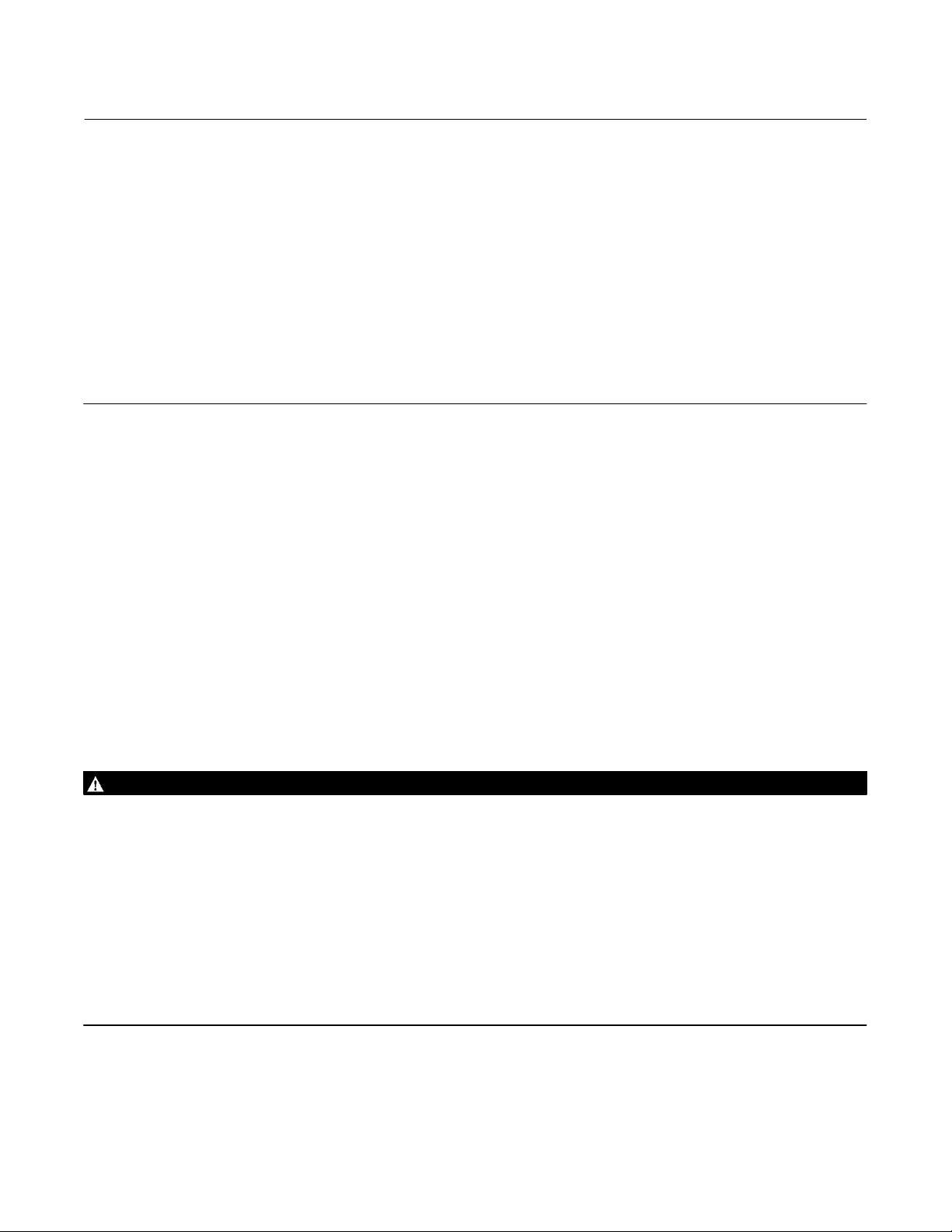

3. If necessary, remove the plastic vent on the DVC6200 and install a pipeaway vent line using at least 12.7 mm

(1/2inch) diameter tubing. The vent line must be as short as possible with a minimum number of bends and elbows

to prevent back pressure buildup.

16

Page 17

Quick Start Guide

D103556X012

Figure 17. Vent Connection

DVC6200 Digital Valve Controllers

January 2014

X0429

PLASTIC EXHAUST VENT (3/8 NPT)

WARNING

To avoid personal injury or property damage resulting from bursting or parts, do not exceed maximum supply pressure.

Personal injury or property damage may result from fire or explosion if natural gas is used as the supply medium and

appropriate preventive measures are not taken. Preventive measures may include, but are not limited to, one or more of

the following: Remote venting of the unit, reevaluating the hazardous area classification, ensuring adequate ventilation,

and the removal of any ignition sources.

Note

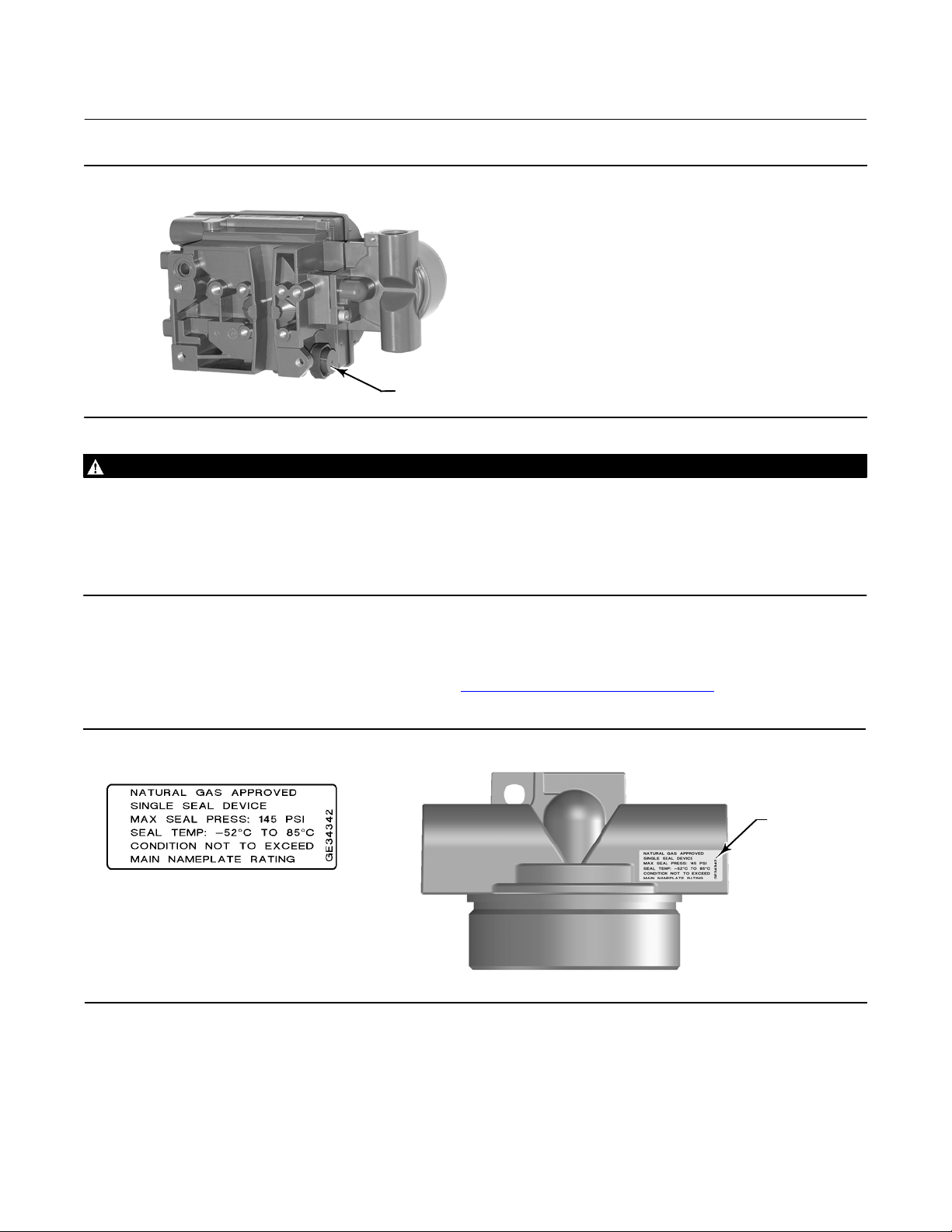

The Natural Gas Certified, Single Seal device option simplifies conduit sealing requirements. Natural Gas Certified, Single Seal

instruments can be identified by the natural gas approval label shown in figure 18. Read and follow all local, regional, and federal

wiring requirements for natural gas installations. Contact your Emerson Process Management sales office

obtaining a Natural Gas Certified, Single Seal DVC6200 digital valve controller.

Figure 18. Label for Natural Gas Certified Terminal Box

for information on

LABEL LOCATED

ON TOP OF

TERMINAL BOX

X0748

4. Connect the pneumatic supply line to the 1/4 NPT IN connection on the filter regulator.

5. Proceed to Step 3—Connect the Electrical Wires on page 19.

17

Page 18

DVC6200 Digital Valve Controllers

January 2014

Quick Start Guide

D103556X012

18

Page 19

Quick Start Guide

D103556X012

DVC6200 Digital Valve Controllers

January 2014

SIS

Step 3—Connect the Electrical Wires

WARNING

Select wiring and/or cable glands that are rated for the environment of use (such as hazardous area, ingress protection and

temperature). Failure to use properly rated wiring and/or cable glands can result in personal injury or property damage

from fire or explosion.

Wiring connections must be in accordance with local, regional, and national codes for any given hazardous area approval.

Failure to follow the local, regional, and national codes could result in personal injury or property damage from fire or

explosion.

To avoid personal injury resulting from electrical shock, do not exceed maximum input voltage specified on the product

nameplate. If the input voltage specified differs, do not exceed the lowest specified maximum input voltage.

Personal injury or property damage caused by fire or explosion may occur if this connection is attempted in a potentially

explosive atmosphere or in an area that has been classified as hazardous. Confirm that area classification and atmosphere

conditions permit the safe removal of the terminal box cover before proceeding.

The valve may move in an unexpected direction when power is applied to the digital valve controller. To avoid personal

injury and property damage caused by moving parts, keep hands, tools, and other objects away from the valve/actuator

assembly when applying power to the instrument.

For FOUNDATION fieldbus™ or PROFIBUS PA devices proceed to page 20

For HARTr devices proceed to page 22

19

Page 20

DVC6200 Digital Valve Controllers

January 2014

Quick Start Guide

D103556X012

FOUNDATION fieldbus or PROFIBUS PA Devices

Refer to the DVC6200f instruction manual (D103412X012) or the DVC6200p instruction manual (D103563X012),

available at www.FIELDVUE.com or from your local Emerson Process Management sales office

information.

for additional

The digital valve controller is normally powered over the bus from a power supply. Refer to the F

OUNDATION fieldbus or

PROFIBUS site planning guide, available from your Emerson Process Management sales office, for proper wire types,

termination, length, grounding practices, etc.

Note

To avoid the valve going to an unknown position when power is applied, the unit digital valve controller is shipped from the factory

with the transducer block mode Out of Service.

Wire the digital valve controller as follows, refer to figure 19.

1. Remove the wiring terminal box cap.

2. Bring the field wiring into the terminal box. When applicable, install conduit using local and national electrical codes

which apply to the application.

3. The instrument is not polarity sensitive. Connect one wire from the controller output to one of the LOOP screw

terminals in the terminal box shown in figure 19. Connect the other wire from the controller output to the other

LOOP screw terminal in the terminal box.

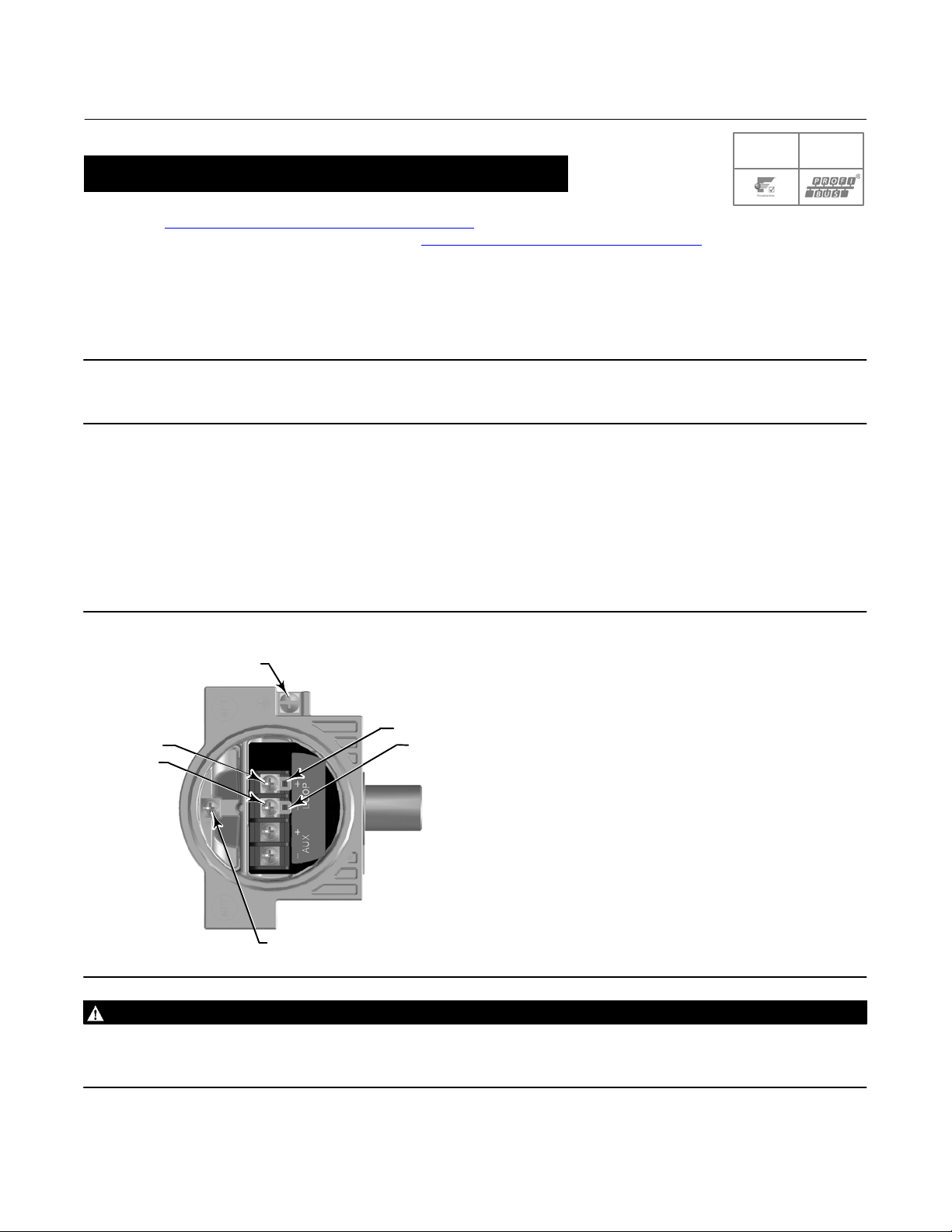

Figure 19. Loop Connections Terminal Box

EARTH

GROUND

TALK +

LOOP +

LOOP -

TALK -

X0438

SAFETY

GROUND

WARNING

Personal injury or property damage can result from the discharge of static electricity. Connect a 14 AWG (2.08 mm2)

ground strap between the digital valve controller and earth ground when flammable or hazardous gases are present. Refer

to national and local codes and standards for grounding requirements.

20

Page 21

Quick Start Guide

D103556X012

DVC6200 Digital Valve Controllers

January 2014

4. Make connections to the ground terminal(s) following national and local codes and plant standards. As shown in

figure 19, two ground terminals are available for connecting a safety ground, earth ground, or drain wire. The safety

ground terminal is electrically identical to the earth ground.

5. Replace and hand tighten the cover on the terminal box.

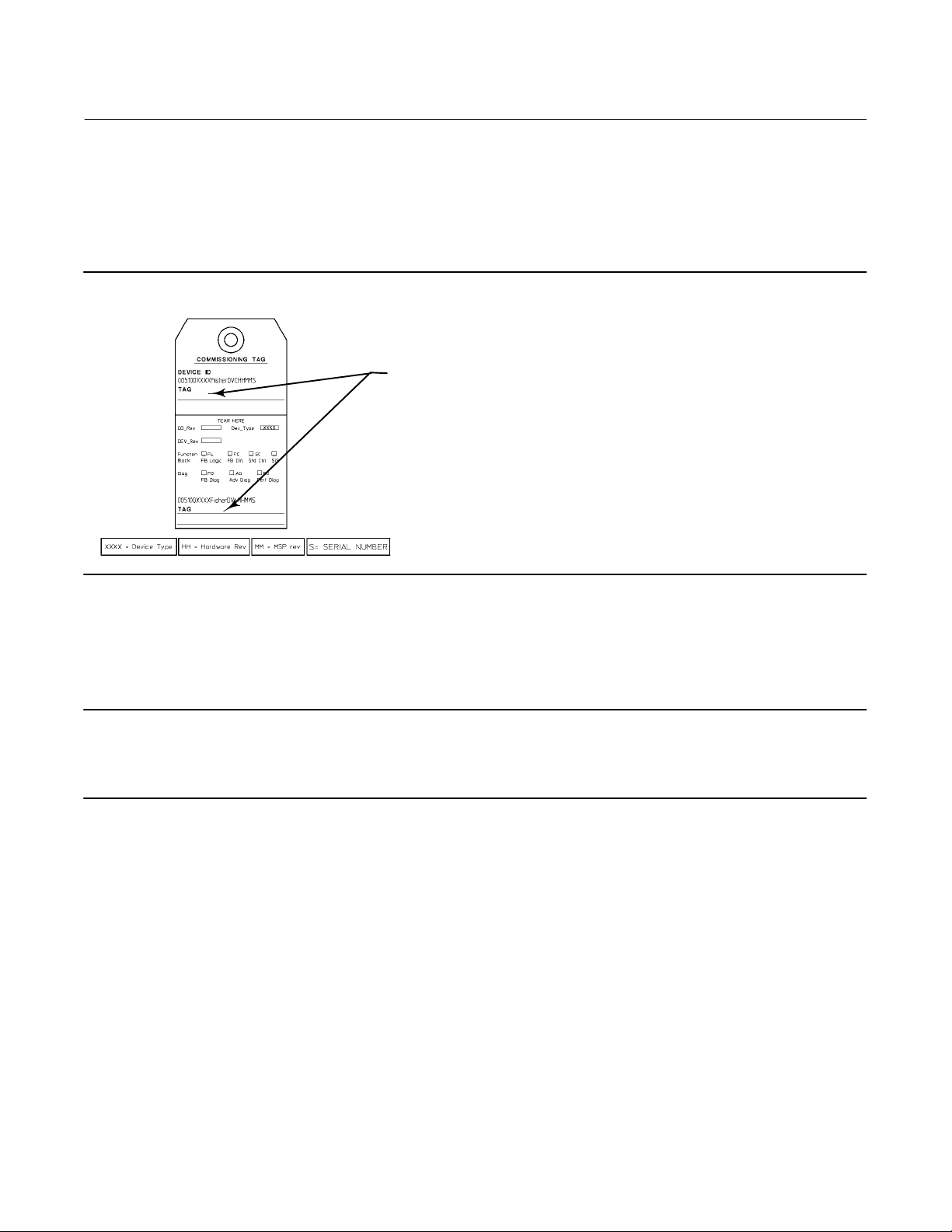

6. Write the valve tag number on the top and bottom of the paper commissioning tag, as shown in figure 20.

Figure 20. Paper Commissioning Tag

WRITE THE VALVE

TAG NUMBER HERE

18B9406‐G

7. Remove the lower half of the paper commissioning tag and deliver it to the control system configurator. With the

piece of paper, the control system configurator will be able to easily change the Device ID placeholder to the actual

valve tag number.

Note

Alternatively, the valve tag number can be entered at the factory when specified at the time of order entry. When the valve tag

number is electronically stored on the DVC6200, the control system will display the valve tag number instead of the Device ID. As a

result, step 6 and 7 will not be required.

8. For Remote Mount applications, proceed to page 26. Otherwise proceed to Step 4—Configure the Digital Valve

Controller on page 29.

21

Page 22

DVC6200 Digital Valve Controllers

January 2014

Quick Start Guide

D103556X012

SIS

HART Devices

Refer to the DVC6200 HW1 instruction manual (D103409X012), the DVC6200 HW2 instruction manual

(D103605X012), or the DVC6200 SIS instruction manual (D103557X012) available at www.FIELDVUE.com or from

your local Emerson Process Management sales office

The digital valve controller is normally powered by a control system output channel. Shielded cable will ensure proper

operation in electrically noisy environments.

Wire the digital valve controller as follows, refer to figure 21:

1. Remove the wiring terminal box cap.

2. Bring the field wiring into the terminal box. When applicable, install conduit using local and national electrical codes

which apply to the application.

3. Connect the control system output channel positive wire to the LOOP + screw terminal in the terminal box. Connect

the control system output channel negative (or return) wire to the LOOP - screw terminal in the terminal box.

for additional information.

WARNING

Personal injury or property damage, caused by fire or explosion, can result from the discharge of static electricity. Connect

a 14 AWG (2.08 mm

gases are present. Refer to national and local codes and standards for grounding requirements.

4. As shown in figure 21, two ground terminals are available for connecting a safety ground, earth ground, or drain

wire. The safety ground is electrically identical to the earth ground. Make connections to these terminals following

national and local codes and plant standards.

Figure 21. Loop and Talk Connections

EARTH

GROUND

2

) ground strap between the digital valve controller and earth ground when flammable or hazardous

TALK +

TALK -

EARTH

GROUND

TALK -

TALK +

EARTH

GROUND

TALK -

TALK +

LOOP LOOP +

22

X0439

SAFETY GROUND

LOOP -

LOOP +

X0431

LOOP -

SAFETY GROUND

LOOP +

X0430

SAFETY GROUND

Page 23

Quick Start Guide

D103556X012

Note

Depending on the control system you are using, an HF340 HART filter may be needed to allow HART communication. The HART

filter is a passive device that is inserted in field wiring from the HART loop. The filter is normally installed near the field wiring

terminals of the control system I/O. Its purpose is to effectively isolate the control system output from modulated HART

communication signals and raise the impedance of the control system to allow HART communication. For more information on

the description and use of the HART filter, refer to the HF340 HART filter instruction manual (D102796X012)

system requires a HART filter refer to the DVC6200 HW1 instruction manual (D103409X012)

manual (D103605X012), or the DVC6200 SIS instruction manual (D103557X012) or contact your Emerson Process Management

sales office.

DVC6200 Digital Valve Controllers

January 2014

. To determine if your

, the DVC6200 HW2 instruction

5. Replace and hand tighten the cover on the terminal box.

6. For applications that require a Position Transmitter or Discrete Switch (page 24), Remote Feedback

Mounting (page 26), and/or THUM

™

Adapter (page 28), proceed to the appropriate page. For DVC6200 SIS

applications proceed to Special Instructions for Safety Instrumented Systems on page 31. Otherwise, proceed

to Step 4—Configure the Digital Valve Controller on page 29.

23

Page 24

DVC6200 Digital Valve Controllers

January 2014

Quick Start Guide

D103556X012

SIS

Position Transmitter or Discrete Switch

The DVC6200 HART communicating device has an optional output circuit that can be configured as a 420 mA

position transmitter or a discrete switch. Configuration of the output circuit requires the proper DIP switch electrical

setting on the main electronics board (figure 22) and also must be enabled with a user interface tool. The DIP switch

electrical setting is preconfigured at the factory when ordered properly.

Figure 22. OUTPUT Connections and Transmitter / Switch Settings

DIP SWITCH FOR

TRANSMITTER/SWITCH

SELECTION

OUTPUT+

X0430

OUTPUT-

X0432

The position transmitter circuit derives its operating power from the control system input channel in the same manner

as a 2wire transmitter. The position transmitter circuit operates independently from the digital valve controller.

The discrete switch is a solid state circuit (1amp maximum) which opens and closes based on a user configurable trip

point. The trip point can be based on valve travel anywhere within the calibrated travel range, or based on a device

alert. In order for the switch output to function, the digital valve controller must be powered. If power is lost, the

switch will always go to the open state. The output circuit, whether operating as a transmitter or switch, is galvanically

isolated from the position control loop circuit such that different ground references between the 2 circuits are

allowed.

Wire the OUTPUT terminals as follows (refer to figure 23):

1. Route the field wiring into the terminal box through the conduit connection.

2. When applicable, install conduit using any local and national electrical codes that apply to the connection.

3. Connect the control system input channel positive wire to the OUT (+) terminal. Connect the control system input

channel negative wire to the OUT () terminal.

4. Replace and hand tighten the cover on the terminal box.

5. For applications that require Remote Feedback Mounting (page 26) and/or a THUM Adapter (page 28), proceed to

the appropriate page. For DVC6200 SIS applications proceed to Special Instructions for Safety Instrumented

Systems on page 31. Otherwise, proceed to Step 4—Configure the Digital Valve Controller on page 29.

24

Page 25

Quick Start Guide

D103556X012

Figure 23. FIELDVUE DVC6200 with Position Transmitter or Discrete Switch, Field Wiring Schematic

DVC6200 Digital Valve Controllers

AO

4 - 20 mA

January 2014

AI

8-30 VDC

POWERED

AO

4 - 20 mA

POSITION TRANSMITTER

GE61668

DI

MAX 30V

DISCRETE SWITCH

25

Page 26

DVC6200 Digital Valve Controllers

January 2014

Quick Start Guide

D103556X012

SIS

Remote Mount Feedback Unit

The DVC6205 base unit is designed to receive a valve travel signal via the DVC6215 feedback unit.

WARNING

Do not place feedback wiring in the same conduit as other power or signal wiring.

Personal injury or property damage, caused by wiring failure, can result if the feedback wiring connecting the base unit

with the remote feedback unit shares a conduit with any other power or signal wiring.

Note

4‐conductor shielded cable, 18 to 22 AWG minimum wire size, in rigid or flexible metal conduit, is required for connection

between base unit and feedback unit. Pneumatic tubing between base unit output connection and actuator has been tested to

91 meters (300 feet). At 15 meters (50 feet) there was no performance degradation. At 91 meters there was minimal pneumatic

lag.

1. Remove the termination caps from both the DVC6215 feedback unit and DVC6205 base unit.

2. Install conduit between the feedback unit and the base unit following applicable local and national electrical codes.

3. Route the 4conductor shielded cable through the conduit.

4. Connect each wire of the 4conductor shielded cable between the corresponding terminals on the feedback unit

and the base unit (refer to figure 24).

WARNING

The cable shield is typically not insulated. It is required that you insulate the cable shield prior to installation.

When connecting the cable shield in step 5 ensure that any exposed shielding does not contact the DVC6215 housing, as

shown in figure 25. Failure to do so can result in ground loop issues.

5. Connect the cable shield between terminal S on the feedback unit and terminal S on the base unit.

CAUTION

Failure to secure the cable wires in the support clips in step 6 can result in broken wires in applications with high levels of

vibration.

6. Secure the cable wires, using the support clips in the DVC6215 feedback unit (as shown in figure 25), to help

prevent shifting and movement of the wires.

7. Replace and hand‐tighten all covers.

8. For applications that require a THUM Adapter proceed to page 28. For DVC6200 SIS applications proceed to Special

Instructions for Safety Instrumented Systems on page 31. Otherwise proceed to Step 4—Configure the Digital Valve

Controller on page 29.

26

Page 27

Quick Start Guide

D103556X012

DVC6200 Digital Valve Controllers

January 2014

Figure 24. Terminal Details for Connecting the Base Unit and Feedback Unit for Remote‐Mounted Digital Valve

Controllers

FEEDBACK

CONNECTIONS

TERMINAL BOX

GROUND

SCREW

FEEDBACK CONNECTIONS

TERMINAL BOX

Figure 25. Wire Clips

X0131

BASE UNIT

TO FEEDBACK UNIT TERMINAL 1

TO FEEDBACK UNIT TERMINAL 2

TO FEEDBACK UNIT TERMINAL 3

TO FEEDBACK UNIT TERMINAL 4

TO FEEDBACK UNIT TERMINAL S

USING CABLE SHIELD

TERMINAL 1

TERMINAL 2

X0132

FEEDBACK UNIT

TERMINAL S

TERMINAL 4

TERMINAL 3

FEEDBACK UNIT

X0434

CLIP TO

SUPPORT THE

INSULATED SHIELD WIRE

CABLE SHIELD

INSULATED WITH

ELECTRICAL TAPE

CLIP TO SUPPORT THE

4-CONDUCTOR WIRES

EXPOSED CABLE SHIELDING

- REQUIRES INSULATION

(e.g. WITH SHRINK TUBING

OR ELECTRICAL TAPE)

X0435

4-CONDUCTOR WIRES WITH SHIELD

27

Page 28

DVC6200 Digital Valve Controllers

January 2014

Quick Start Guide

D103556X012

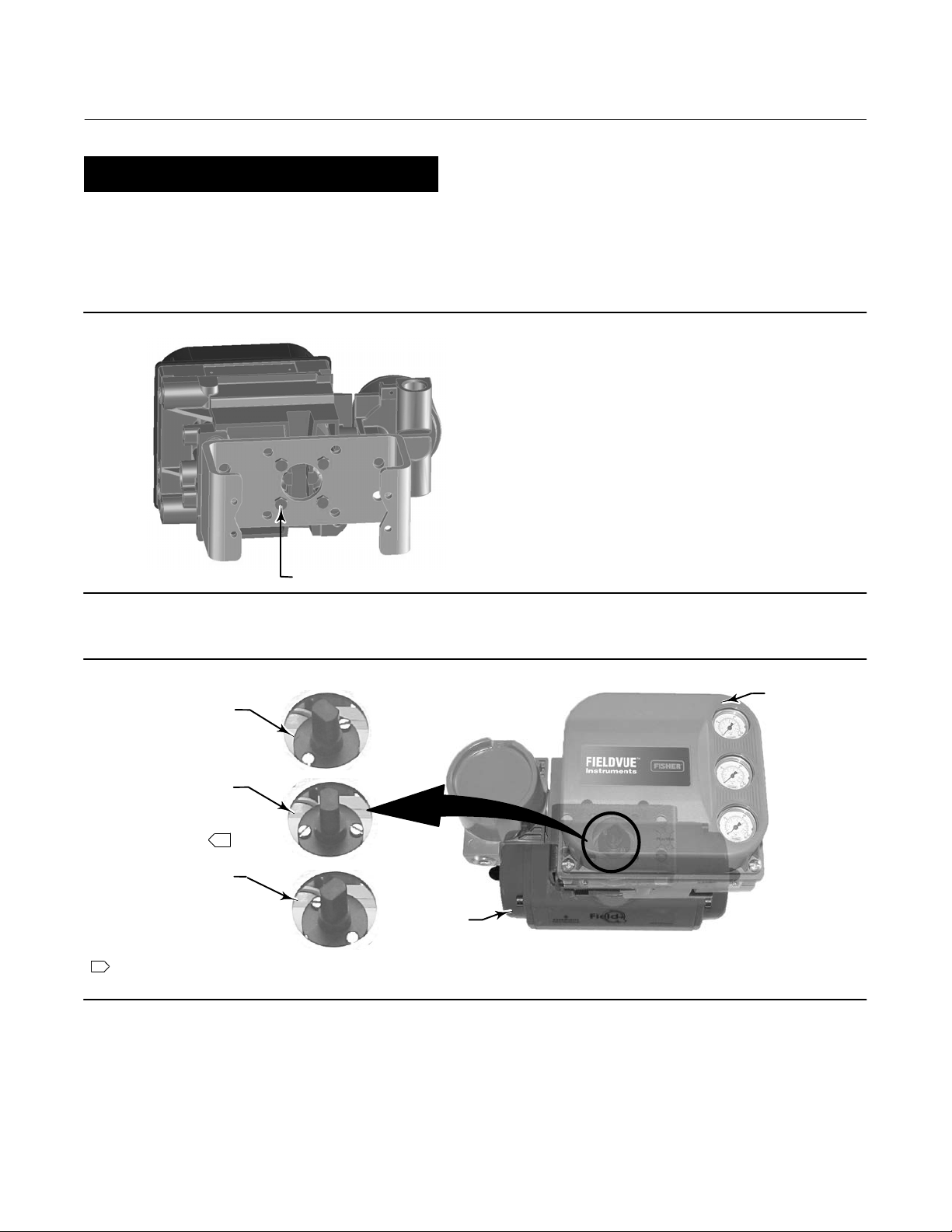

Smart Wireless THUM Adapter

Refer to the quick installation guide that comes with the Smart Wireless THUM Adapter (0082501004075) for

additional information.

Note

The recommended mounting orientation for the THUM Adapter is vertically up, as shown in figure 26 for optimal wireless

communication range.

Figure 26. THUM Adapter Installed On DVC6200 Digital Valve Controller

TOP CONDUIT

ENTRANCE

X0433

1. Remove the DVC6200 terminal box plug from the top conduit entrance.

2. Thread the THUM Adapter into the top conduit entrance.

3. Using the wire splice included with the THUM Adapter (or other suitable wire splice), connect the wires as shown in

figure 27 below.

Figure 27. Wiring the THUM Adapter

4-20 mA

LOOP +

4-20 mA

LOOP -

SPLICE

CONNECTOR

GG18677

WIRED DEVICE

GROUND

LOOP -

LOOP +

THUM ADAPTER

GREEN

RED

BLACK

WHITE

YELLOW

4. Carefully coil the wires inside the terminal box.

5. Replace and hand tighten the cover on the terminal box.

6. Proceed to Step 4—Configure the Digital Valve Controller on page 29.

28

Page 29

Quick Start Guide

D103556X012

DVC6200 Digital Valve Controllers

January 2014

SIS

Step 4—Configure the Digital Valve Controller

WARNING

D Select wiring and/or cable glands that are rated for the environment of use (such as hazardous area, ingress protection

and temperature). Failure to use properly rated wiring and/or cable glands can result in personal injury or property

damage from fire or explosion.

D Wiring connections must be in accordance with local, regional, and national codes for any given hazardous area

approval. Failure to follow the local, regional, and national codes could result in personal injury or property damage

from fire or explosion.

D To avoid personal injury resulting from electrical shock, do not exceed maximum input voltage specified on the product

nameplate. If the input voltage specified differs, do not exceed the lowest specified maximum input voltage.

D Personal injury or property damage caused by fire or explosion may occur if this connection is attempted in a

potentially explosive atmosphere or in an area that has been classified as hazardous. Confirm that area classification

and atmosphere conditions permit the safe removal of the terminal box cover before proceeding.

D The valve may move in an unexpected direction when power is applied to the digital valve controller. To avoid personal

injury and property damage caused by moving parts, keep hands, tools, and other objects away from the

valve/actuator assembly when applying power to the instrument.

D While configuring the digital valve controller the valve may move, causing process fluid or pressure to be released. To

avoid personal injury and property damage caused by the release of process fluid or pressure, isolate the valve from the

process and equalize pressure on both sides of the valve or bleed off the process fluid.

D Changes to the instrument setup may cause changes in the output pressure or valve travel. Depending on the

application, these changes may upset process control, which may result in personal injury or property damage.

CAUTION

Before proceeding, check that all pressure connections, fasteners, and plugs are installed and tightened.

For remote mount installations, ensure that the Base Unit is wired to the Feedback Unit before providing electrical power.

Failure to do so may cause the DVC6205 to go into "Pressure Control" mode if Pressure Fallback is configured. The unit can

be returned to "Travel Control” mode using Detailed Configuration.

1. Install the latest version of the communication software on the user interface tool. This may include Device

Descriptions (DD, EDD), ValveLink

Contact your local Emerson Process Management sales office

for information on locating the necessary files.

Table 1. User Interface Tools and Software Available for Instrument Configuration and Calibration

475 Field Communicator (DD)

AMS Device Manager (DD)

ValveLink Software

ValveLink Mobile Software

Field Device Type Frame (DTM)

Siemens SIMATIC™ PDM Software (DD, GSD) Ļ

™

software, Device Type Manager (DTM), or GSD. Refer to table 1 below.

to ensure that you have the latest software version or

DVC6200

HART

Ļ Ļ Ļ

Ļ Ļ Ļ

Ļ Ļ Ļ

Ļ Ļ

Ļ Ļ Ļ

DVC6200 SIS

HART

DVC6200f

F

OUNDATION fieldbus

DVC6200p

PROFIBUS PA

29

Page 30

DVC6200 Digital Valve Controllers

January 2014

Quick Start Guide

D103556X012

2. Apply pneumatic supply pressure to the digital valve controller and adjust the supply pressure regulator according

to the actuator requirements and limitations.

3. Apply electrical power to the digital valve controller.

4. Establish communication with the digital valve controller and commission the instrument as described in the host

system documentation.

Note

If the TALK terminals on the digital valve controller are to be used for communication, remove the terminal box cap to access the

terminals.

5. Launch the user interface tool.

6. Perform Device Setup to configure and calibrate the instrument on the control valve assembly.

7. Enter any additional custom configuration items (optional).

Note

On HART devices with the optional transmitter or switch option, you must enable and configure the output terminals. The

configuration is disabled by default from the factory.

8. To enable the digital valve controller to follow set point, place the instrument In Service (HART devices) or place the

transducer block in Auto (fieldbus and PROFIBUS devices).

30

Page 31

Quick Start Guide

D103556X012

DVC6200 Digital Valve Controllers

January 2014

SIS

Special Instructions for Safety Instrumented Systems

DVC6200 SIS instruments are identified by an SIS label on the terminal box cover. Please refer to the Safety Manual

(D103601X012) for further information regarding the design, installation, and operation of the DVC6200 SIS product.

The following section illustrates typical installation scenarios for a DVC6200 SIS. The digital valve controller can be

configured to trip on low current (deenergize to trip, DETT) or high current (energize to trip, ETT). See figure 28 for

the DIP switch configuration of this action on the printed wiring board. This setting is preconfigured at the factory

when ordered properly.

Figure 28. DIP Switch Location

PT-PT/

MULTI-DROP

SELECTION

X0436

Table 2. DIP Switch Configuration

Switch Label Operational Mode DIP Switch Position

PT-PT 420 mA PointtoPoint Loop LEFT

Multi 24 VDC MultiDrop Loop RIGHT

Hardware Shutdown Enabled LEFT

Hardware Shutdown Disabled RIGHT

Trip Current Low (DETT) De-energize to trip LEFT

Trip Current High (ETT) Energize to trip RIGHT

1. Refer to figure 28 for switch location.

BACK OF PWB

ASSEMBLY SUB‐MODULE

DE-ENERGIZE TO TRIP

ENERGIZE TO TRIP

SELECTION

(1)

Note

DVC6200 SIS instruments in PTPT mode require the Hardware Shutdown Switch be Enabled for FMEDA failure rates to be valid for

4-20 mA operation.

WARNING

When Hardware Shutdown is enabled, the instrument will respond to a signal change regardless of instrument mode. The

valve may move in an unexpected direction when power is applied to the digital valve controller. To avoid personal injury

and property damage caused by moving parts, keep hands, tools, and other objects away from the valve/actuator assembly

when applying power to the instrument.

31

Page 32

DVC6200 Digital Valve Controllers

January 2014

Quick Start Guide

D103556X012

An optional local control panel (LCP100), shown in figure 29, can be installed to provide manual operation of the

DVC6200 SIS instrument. Refer to the instruction manual

that comes with the LCP100 for further information

(D103272X012).

Note

If the LCP100 is connected to a DVC6200 SIS in a zone 1 explosion-proof “d” environment, there must be a conduit seal installed

between the DVC6200 SIS and the LCP100 in order to maintain the explosion-proof integrity of the DVC6200 SIS.

The LCP100 cannot be connected to a DVC6200 SIS that is part of a zone 0 or zone 1 intrinsically safe “i” installation.

Figure 29. LCP100 Connected to a DVC6200 SIS Instrument

X0248

For de-energize to trip DVC6200 SIS and de-energize to trip solenoid valve, proceed to page 33

For de-energize to trip DVC6200 SIS, no solenoid valve, proceed to page 35

For DVC6200 SIS for PST only and de-energize to trip solenoid valve, proceed to page 37

For solenoid valve health monitoring installations, proceed to page 38

32

Page 33

Quick Start Guide

D103556X012

DVC6200 Digital Valve Controllers

January 2014

De-Energize to Trip (DETT) DVC6200 SIS and DETT Solenoid Valve

In a typical deenergize to trip application with a solenoid valve, the logic solver (or DCS) trip signal deenergizes the

solenoid valve and also reduces the signal to the digital valve controller to 4 mA (or 0 VDC). This opens the solenoid

valve vent and drives the digital valve controller to the no output pressure condition. As a result, the safety valve

moves to its noair, fail safe position.

Figure 30. FIELDVUE DVC6200 SIS and Solenoid

Valve Powered Separately

LOGIC SOLVER

OR DCS

4-20 mA DETT

OR 0-24 VDC DETT

LOGIC SOLVER

0-24 VDC DETT

1

S

AS

Figure 31. FIELDVUE DVC6200 SIS and Solenoid

Valve Powered Together

LOGIC SOLVER

0-24 VDC DETT

LC340

LINE CONDITIONER

LOW POWER

SOLENOID VALVE

S

AS

1 AN LC340 LINE CONDITIONER IS REQUIRED FOR 0-24 VDC DETT

E1455

E1456

Note

When using an ASCO™

lowpower solenoid valve, model EF8316G303 or EF8316G304 (or an equivalent lowpower solenoid valve)

a separate external air supply for the pilot is required. Ensure that the solenoid valve's “selection gasket” is in the “external

position”. The pilot pressure must be at least 15 psig higher than the solenoid valve line pressure. For more information, refer to

the ASCO catalog or contact your Emerson Process Management sales office

.

1. Install the solenoid valve on the actuator casing or actuator yoke.

2. Install at least 10 mm (3/8inch) diameter tubing such that the solenoid valve is in the pneumatic path between the

DVC6200 SIS output and the actuator input.

33

Page 34

DVC6200 Digital Valve Controllers

January 2014

Quick Start Guide

D103556X012

3. If the DVC6200 SIS and solenoid valve are powered separately:

D Connect the logic solver output card +/ terminals to the corresponding solenoid valve +/ wires.

D Connect the logic solver (or DCS) output card +/ terminals to the corresponding DVC6200 SIS LOOP +/

D terminals.

Note

For the digital valve controller to operate with a 420 mA control signal the DIP switch must be in the pointtopoint loop position,

as shown in table 2. The control mode must be set to analog. This is set at the factory when ordered properly.

4. If the DVC6200 SIS and solenoid valve are powered together:

D Install an LC340 line conditioner to allow HART communication over the segment. Refer to the instruction

D manual that comes with the LC340 (D102797X012) for more information.

D Connect the logic solver output card +/ terminals to the corresponding LC340 SYS +/ terminals.

D Connect the digital valve controller LOOP +/ terminals to the corresponding LC340 FLD +/ terminals.

D Connect the solenoid valve +/ wires to the corresponding LC340 FLD +/ terminals.

Note

For the digital valve controller to operate with a 024 VDC voltage control signal the DIP switches must be in the “Multi” position

and the “Hardware Shutdown Disabled” position, as shown in figure 28 and table 2. The control mode must also be set to digital

with a user interface tool. These are set at the factory when ordered properly.

Ensure that the LC340 Line Conditioner voltage drop, the solenoid valve engagement voltage (at maximum temperature), and the

wiring voltage drop do not exceed the logic solver maximum output voltage. The line conditioner introduces an approximate 2.0

volt drop in the SIS system wiring with a 50 mA load. An ASCO EF8316 solenoid valve requires 18.4 V and 42 mA to trip. The digital

valve controller draws approximately 8 mA. Based on these conditions, table 3 lists the maximum loop wire resistance permitted

for various logic solver output voltages.

Table 3. Maximum Loop Wire Resistance per Logic Solver Output Voltage

Logic Solver Output

Voltage

(VDC)

24.00

23.75

23.50

23.25

23.00

22.75

22.50

1. Maximums in this table assume a line conditioner and a solenoid that requires a minimum of 20.4 V and 42 mA to engage.

2. Wire length includes both wires in a twisted pair.

Maximum Loop

Wire Resistance

(Ohms)

32.0

27.0

22.0

17.0

12.0

7.0

2.0

22 AWG 20 AWG 18 AWG 16 AWG

952

804

655

506

357

208

60

(1)

Maximum Wire Length (feet)

1429

1205

982

759

536

313

89

2381

2009

1637

1265

893

521

149

(2)

3175

2679

2183

1687

1190

694

198

5. Proceed to Step 4—Configure the Digital Valve Controller on page 29.

34

Page 35

Quick Start Guide

D103556X012

DVC6200 Digital Valve Controllers

January 2014

De-Energize to Trip (DETT) DVC6200 SIS, no Solenoid Valve

In a typical deenergize to trip application without a solenoid valve, the logic solver trip signal deenergizes the digital

valve controller to 4 mA (or 0 VDC). This drives the digital valve controller to the no output pressure condition. As a

result, the safety valve moves to its noair, fail safe position.

Figure 32. FIELDVUE DVC6200 SIS Powered

with 4-20 mA

LOGIC SOLVER

4-20 mA DETT

E1457

AS

Figure 33. FIELDVUE DVC6200 SIS Powered

with 0-24 VDC

LOGIC SOLVER

0-24 VDC DETT

LC340

LINE CONDITIONER

AS

E1458

1. If the DVC6200 SIS is powered with 420 mA, connect the logic solver output card +/ terminals to the

corresponding DVC6200 SIS LOOP +/terminals.

Note

For the digital valve controller to operate with a 420 mA control signal the DIP switch must be in the pointtopoint loop position,

as shown in table 2. The control mode must be set to analog. This is set at the factory when ordered properly.

35

Page 36

DVC6200 Digital Valve Controllers

January 2014

Quick Start Guide

D103556X012

2. If the DVC6200 SIS and solenoid valve are powered together:

D Install an LC340 line conditioner to allow HART communication over the segment. Refer to the instruction

D manual that comes with the LC340 (D102797X012) for more information.

D Connect the logic solver output card +/ terminals to the corresponding LC340 SYS +/ terminals.

D Connect the digital valve controller LOOP +/ terminals to the corresponding LC340 FLD +/ terminals.

Note

For the digital valve controller to operate with a 024 VDC voltage control signal the DIP switches must be in the “Multi” position

and the “Hardware Shutdown Disabled” position, as shown in figure 28 and table 2. The control mode must also be set to digital

with a user interface tool. These are set at the factory when ordered properly.

3. Proceed to Step 4—Configure the Digital Valve Controller on page 29.

36

Page 37

Quick Start Guide

D103556X012

DVC6200 Digital Valve Controllers

January 2014

DVC6200 SIS for PST only and De-Energize to Trip (DETT) Solenoid Valve

In this application, the logic solver trip signal deenergizes the solenoid valve, which opens the solenoid vent valve. The

DVC6200 SIS is configured as energize to trip (ETT) and uses a reverse acting relay (Relay B) to drive the digital valve

controller to the no output pressure condition. The energize to trip option provides maximum actuator pressure at

minimum control signal (4 mA). Therefore, loss of the control signal will not cause the safety valve to trip. The safety

valve moves to its noair, fail safe position when the logic solver (or DCS) sets the current to the digital valve controller

to 20 mA. Partial stroke testing occurs at minimum control signal (4 mA).

Figure 34. FIELDVUE DVC6200 SIS and Solenoid Valve Powered Separately

LOGIC SOLVER

OR DCS

4-20 mA ETT

E1459

LOGIC SOLVER

0-24 VDC DETT

S

AS

SINGLE-ACTING, REVERSE (RELAY B)

4 mA = FULL SUPPLY TO ACTUATOR

1. Install the solenoid valve on the actuator casing or actuator yoke.

2. Install at least 10 mm (3/8inch) diameter tubing such that the solenoid valve is in the pneumatic path between the

DVC6200 SIS output and the actuator input.

3. Connect the logic solver output card +/ terminals to the corresponding solenoid valve +/ wires.

4. Connect the logic solver (or DCS) output card +/ terminals to the corresponding DVC6200 SIS LOOP +/ terminals.

5. Proceed to Step 4—Configure the Digital Valve Controller on page 29.

37

Page 38

DVC6200 Digital Valve Controllers

January 2014

Quick Start Guide

D103556X012

Solenoid Valve Health Monitoring

If a solenoid valve is installed between the DVC6200 SIS pressure output and the actuator, the control valve assembly

can be configured to verify the operation of the solenoid valve. This applies to singleacting actuator applications only.

The “unused” output port of the DVC6200 SIS is tubed such that the pressure downstream of the solenoid valve is

measured. When the solenoid valve is pulsed, the DVC6200 SIS senses the momentary pressure drop across the

solenoid valve.

Figure 35. Tubing for Solenoid Valve Health

Monitoring, DeEnergize to Trip DVC6200 SIS

S

AS

E1460

Figure 36. Tubing for Solenoid Valve Health

Monitoring, Energize to Trip DVC6200 SIS

S

AS

SINGLE-ACTING, REVERSE (RELAY B)

4 mA = FULL SUPPLY TO ACTUATOR

E1461

1. For DETT applications (figure 35):

D Install at least 10 mm (3/8inch) diameter tubing between output B (bottom port) of the DVC6200 SIS output and

D the tubing segment between the solenoid valve and safety valve actuator.

2. For ETT DVC6200 SIS applications (figure 36):

D Install at least 10 mm (3/8inch) diameter tubing between output A (top port) of the DVC6200 SIS output and the

D tubing segment between the solenoid valve and safety valve actuator.

3. Proceed to Step 4—Configure the Digital Valve Controller on page 29.

38

Page 39

Quick Start Guide

D103556X012

DVC6200 Digital Valve Controllers

January 2014

SIS

Hazardous Area Approvals and Special Instructions

for “Safe Use” and Installations in Hazardous Locations

Certain nameplates may carry more than one approval, and each approval may have unique installation/wiring

requirements and/or conditions of “safe use”. These special instructions for “safe use” are in addition to, and may

override, the standard installation procedures. Special instructions are listed by approval type.

Note

This information supplements the nameplate markings affixed to the product.

Always refer to the nameplate itself to identify the appropriate certification. Contact your Emerson Process Management sales

office for approval/certification information not listed here.

Approval information is for both aluminum and stainless steel constructions.

WARNING

Failure to follow these conditions of “safe use” could result in personal injury or property damage from fire or explosion, or

area re‐classification.

For CSA Approvals proceed to page 40

For FM Approvals proceed to page 47

For ATEX Approvals proceed to page 54

For IECEx Approvals proceed to page 61

39

Page 40

DVC6200 Digital Valve Controllers

January 2014

CSA

Ordinary Locations Approval

Complies with general electrical safety CAN/CSAC22.2 No. 6101012004

SELV, conduit connected, Enclosure Type 4X, IP66, Installation Category I, Pollution Degree 4

Quick Start Guide

D103556X012

DVC6200 Series (HART HW1, F

OUNDATION fieldbus, PROFIBUS)

Rated Input 9-30 VDC, 4-20 mA

-52_C to + 80_C Ambient

DVC6205 (HART HW1, F

OUNDATION fieldbus, PROFIBUS) DVC6215 Remote Mount

Rated Input 9-30 VDC, 4-20 mA Rated Input 10 VDC max, 3.5 mA max

Outputs 0-9.6 VDC, 0-3.5 mA -52 to 125_C Ambient

-52_C to + 80_C Ambient

Explosion-proof and Dust Ignition-proof

DVC6200 and DVC6205 Series (HART HW1 & HW2, SIS, FOUNDATION FIELDBUS, PROFIBUS)

Class I, Division 1, Groups B,C,D ; Class I, Division 2, Groups A,B,C,D

Class II, Division 1, Groups E,F,G ; Class II, Division 2, Groups F,G

Class III, Division 1

Ex d IIC

Ex nC IIC

Type 4X, IP66

Single Seal Device (HART HW2 and SIS pending)

Rated input 30 Vmax, 20 mA

- 52_C < Ambient < + 80_C

Max inlet pressure 145 psig (air or natural gas)

Temperature Code: T6 (Tamb ≤ 75_C), T5 (Tamb ≤ 80_C)

DVC6215 Remote Mount

Class I, Division 1, Groups A,B,C,D ; Class I, Division 2, Groups A,B,C,D

Class II, Division 1, Groups E,F,G ; Class II, Division 2, Groups F,G

Class III

Ex d IIC

Ex nA IIC

Type 4X, IP66

Rated input 30 Vmax, 20 mA

- 52_C < Ambient < + 125_C

Temperature Code: T6 (Tamb ≤ 75_ C), T5 (Tamb ≤ 90_C), T4 (Tamb ≤ 125_C)

40

Page 41

Quick Start Guide

D103556X012

DVC6200 Digital Valve Controllers

Intrinsically Safe

Class I, Division 1, Groups A,B,C,D

Class II, Division 1, Groups E,F,G

Class III, Division 1

Ex ia IIC

Type 4X, IP66

Single Seal Device (HART HW2 and SIS pending)

Rated input 30 V DC max, 20 mA

- 52 _C < Ambient < + 80_C (-52_C to 125_C for DVC6215)

Max inlet pressure 145 psig (air or natural gas)

Intrinsically safe when connected per installation drawing GE42818, as shown in the following figures

DVC6200 HW1 figure 37 and 42...........................................

DVC6200 HW2 and DVC6200 SIS figure 38 and 42...........................

DVC6205, DVC6205 SIS, and DVC6215 Remote Mount figure 39 and 42........

DVC6200f and DVC6200p figure 40 and 42.................................

DVC6205f, DVC6205p, and DVC6215 Remote Mount figure 41 and 42.........

January 2014

Figure 37. CSA Loop Schematic—FIELDVUE DVC6200 HW1

HAZARDOUS LOCATION

CLASS I, ZONE 0, GROUP IIC

CLASS I, DIV 1, GROUPS ABCD

CLASS II, DIV 1, GROUPS EFG

CLASS III

DVC6200, DVC6200S

Vmax = 30 VDC

Imax = 226 mA

Ci = 5 nF

Li = 0.55 mH

Pi = 1.4 W

1 NOTE 7

T CODE T (amb)

T5 ≤ 80_C

T6 ≤ 75_C

1 SEE NOTES IN FIGURE 42

GE42818 sheet 2, Rev. F

NON‐HAZARDOUS LOCATION

CSA APPROVED BARRIER

1 NOTE 1, 3, 4, 5, 6

41

Page 42

DVC6200 Digital Valve Controllers

January 2014

Figure 38. CSA Loop Schematics—FIELDVUE DVC6200 HW2 and DVC6200 SIS

Quick Start Guide

D103556X012

CLASS I, ZONE 0, GROUP IIC

CLASS I, DIV 1, GROUPS ABCD

CLASS II, DIV 1, GROUPS EFG

CLASS III

HW2 - WITH OR WITHOUT I/O PACKAGE

DVC6200, DVC6200S

LOOP TERMINALS

Vmax = 30 VDC

Imax = 130 mA

Ci = 15 nF

Li = 0.55 mH

Pi = 1.0 W

OUTPUT TERMINALS

Vmax = 28 VDC

Imax = 100 mA

Ci = 15 nF

Li = 0.5 mH

Pi = 1.0 W

HAZARDOUS LOCATION

1 NOTE 7

NON‐HAZARDOUS LOCATION

CSA APPROVED BARRIER

NOTE 1, 3, 4, 5, 6 1

CSA APPROVED BARRIER

NOTE 1, 3, 4, 5, 6 1

POWER MAY BE APPLIED TO

EITHER THE LOOP TERMINALS OR

OUTPUT TERMINALS OR TO BOTH

SETS OF TERMINALS AT THE SAME

TIME

UNITS WITHOUT THE I/O PACKAGE

WILL NOT HAVE “OUTPUT

TERMINALS” AVAILABLE FOR

CONNECTION

T CODE T (amb) T (amb)

T5 ≤ 80_C ≤ 80_C

T6 ≤ 61_C ≤ 74_C

1 SEE NOTES IN FIGURE 42

GE42818 Sheet 11, Rev. C

42

WITH

I/O PACKAGE

WITHOUT

I/O PACKAGE

Page 43

Quick Start Guide

D103556X012

Figure 39. CSA Loop Schematics FIELDVUE DVC6205, DVC6205 SIS, and DVC6215

DVC6200 Digital Valve Controllers

January 2014

CLASS I, ZONE 0, GROUP IIC

CLASS I, DIV 1, GROUPS ABCD

CLASS II, DIV 1, GROUPS EFG

CLASS III

DVC6215

Vmax = 30 VDC

Imax = 226 mA

Ci = 50 nF

Li = 0.55 mH

Pi = 1.4 W

NOTE 1, 3 1

T CODE T (amb)

T4 ≤ 125_C

T5 ≤ 90_C

T6 ≤ 75_C

1 SEE NOTES IN FIGURE 42

GE42818 Sheet 12, Rev. C

HAZARDOUS LOCATION

CLASS I, ZONE 0, GROUP IIC

CLASS I, DIV 1, GROUPS ABCD

CLASS II, DIV 1, GROUPS EFG

CLASS III

HW2 - WITH OR WITHOUT I/O PACKAGE

REMOTE

FIELD WIRING

TERMINAL BOX

Voc = 30 VDC

Isc = 21.2 mA

Ca = 55 nF

La = 78 mH

Po = 160 mW

T CODE T (amb) T (amb)

T5 ≤ 80_C ≤ 80_C

T6 ≤ 61_C ≤ 74_C

DVC6205

WITH

I/O PACKAGE

FIELD WIRING

TERMINAL BOX

LOOP TERMINALS

Vmax = 30 VDC

Imax = 130 mA

Ci = 15 nF

Li = 0.55 mH

Pi = 1.0 W

OUTPUT TERMINALS

Vmax = 28 VDC

Imax = 100 mA

Ci = 15 nF

Li = 0.5 mH

Pi = 1.0 W

WITHOUT

I/O PACKAGE

NON‐HAZARDOUS LOCATION

CSA APPROVED BARRIER

NOTE 1, 3, 4, 5, 6 1

NOTE 7

1

CSA APPROVED BARRIER

NOTE 1, 3, 4, 5, 6 1

POWER MAY BE APPLIED TO EITHER

THE LOOP TERMINALS OR OUTPUT

TERMINALS OR TO BOTH SETS OF

TERMINALS AT THE SAME TIME

UNITS WITHOUT THE I/O PACKAGE

WILL NOT HAVE “OUTPUT TERMINALS”

AVAILABLE FOR CONNECTION

43

Page 44

DVC6200 Digital Valve Controllers

January 2014

Figure 40. CSA Loop Schematics—FIELDVUE DVC6200f and DVC6200p

Quick Start Guide

D103556X012

1 NOTE 7

GE42818 Sheet 3, Rev. F

T CODE T (amb)

T4 ≤ 80_C

T5 ≤ 77_C

T6 ≤ 62_C

CSA APPROVED

ENTITY DEVICE

T CODE T (amb)

T4 ≤ 80_C

T5 ≤ 77_C

T6 ≤ 62_C

NOTE 1, 3 1

HAZARDOUS LOCATION

CLASS I, ZONE 0, GROUP IIC

CLASS I, DIV 1, GROUPS ABCD

CLASS II, DIV 1, GROUPS EFG

CLASS III

DVC6200F, DVC6200FS

DVC6200P, DVC6200PS

Vmax = 24 VDC

Imax = 380 mA

Ci = 5 nF

Li = 0 mH

Pi = 1.4 W

ENTITY FIELDBUS LOOP

HAZARDOUS LOCATION

CLASS I, ZONE 0, GROUP IIC

CLASS I, DIV 1, GROUPS ABCD

CLASS II, DIV 1, GROUPS EFG

CLASS III

DVC6200F, DVC6200FS

DVC6200P, DVC6200PS

NON‐HAZARDOUS LOCATION

CSA APPROVED

BARRIER

1 NOTE 1, 3, 4, 5, 6

NON‐HAZARDOUS LOCATION

CSA APPROVED

FISCO TERMINATOR

GE42818 Sheet 4, Rev. F

1 SEE NOTES IN FIGURE 42

44

CSA APPROVED

FISCO DEVICE

Vmax = 17.5 VDC

Imax = 380 mA

Ci = 5 nF

Li = 0 mH

Pi = 5.32 W

NOTE 2, 3 1

CSA APPROVED

FISCO BARRIER

1 NOTE 2, 3, 4, 5, 6

FISCO LOOP

Page 45

Quick Start Guide

D103556X012

Figure 41. CSA Loop Schematics FIELDVUE DVC6205f, DVC6205p, and DVC6215

DVC6200 Digital Valve Controllers

January 2014

NOTE 7 1

GE42818 Sheet 9, Rev. D

CSA

APPROVED

ENTITY

DEVICE

NOTE 1, 3 1

CSA

APPROVED

FISCO DEVICE

NOTE 2, 3 1

CLASS I, ZONE 0, GROUP IIC

CLASS I, DIV 1, GROUPS ABCD

CLASS II, DIV 1, GROUPS EFG

CLASS III

DVC6215

Vmax = 30 VDC

Imax = 226 mA

Ci = 50 nF

Li = 0.55 mH

Pi = 1.4 W

NOTE 1 1

T CODE T (amb)

T4 ≤ 125_C

T5 ≤ 90C

T6 ≤ 75_C

CLASS I, ZONE 0, GROUP IIC

CLASS I, DIV 1, GROUPS ABCD

CLASS II, DIV 1, GROUPS EFG

CLASS III

DVC6215

Vmax = 30 VDC

Imax = 226 mA

Ci = 50 nF

Li = 0.55 mH

Pi = 1.4 W

NOTE 2 1

CLASS I, ZONE 0, GROUP IIC

CLASS I, DIV 1, GROUPS ABCD

CLASS II, DIV 1, GROUPS EFG

CLASS III

DVC6205f, DVC6205p

Voc = 24 VDC

Isc = 17.5 mA

Ca = 121 nF

La = 100 mH

Po = 105 mW

Vmax = 24 VDC

Imax = 380 mA

Ci = 5 nF

Li = 0 mH

Pi = 1.4 W

T CODE T (amb)

T4 ≤ 80_C

T5 ≤ 77_C

T6 ≤ 62_C

ENTITY FIELDBUS LOOP

CLASS I, ZONE 0, GROUP IIC

CLASS I, DIV 1, GROUPS ABCD

CLASS II, DIV 1, GROUPS EFG

CLASS III