Instruction Manual

Form 5007

August 2008

133 Series Self-Operated Regulators

133 Series

W1327

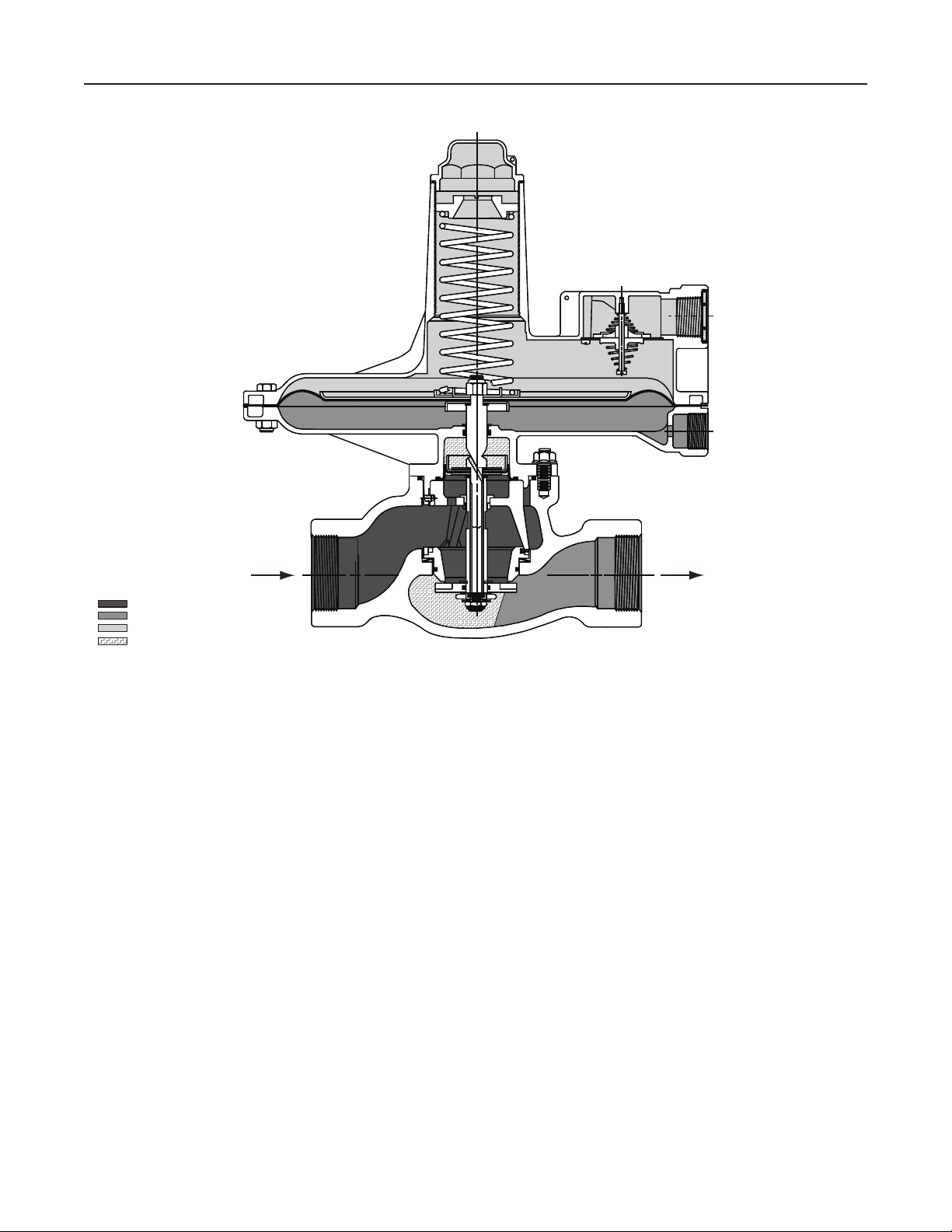

TYPES 133H, 133L, AND 133Z REGULATORS

Figure 1. 133 Series Gas Regulators

Introduction

WARNING

!

Installation, operation and maintenance

procedures performed by unqualied

personnel may result in improper

adjustment and unsafe operation. Either

condition may result in equipment

damage or personnel injury. Use qualied

personnel when installing, operating and

maintaining the 133 Series regulators.

If a leak develops in the system, the

escaping gas may accumulate and

become a re or explosion hazard.

Immediately call qualied service

personnel in case of trouble.

Scope of Manual

This manual provides specications, instructions

for installation, adjustment, maintenance, and parts

information for the 133 Series.

W6803

TYPE 133HP REGULATOR

Only personnel qualied through training or experience

should install, operate and maintain this regulator. If

there are any questions concerning these instructions,

contact your local Sales Ofce before proceeding.

Description

The 133 Series self-operated gas regulators, shown

in Figure 1 are primarily designed for industrial and

commercial applications supplying gas to furnaces,

burners and other appliances. The 133 Series

balancing system enables the regulator to provide

accurate control gas pressure for maximum combustion

efciency despite varying inlet pressure conditions. The

single port construction provides bubble tight shutoff.

An external downstream control line is required for

the operation of the regulator. A restriction collar is

available to reduce the ow capacity of the regulator.

www.emersonprocess.com/regulators

D100270X012

133 Series

Specications

End Connections

2-inch Cast iron NPT (internal), cast iron

CL125 FF anged, steel NPT (internal). or steel

CL150 RF anged

Outlet Pressure Ranges

See Table 1

Maximum Inlet Pressures

(1)

See Table 2

Maximum Outlet Pressures

See Table 2

Pressure Registration

External; downstream control line is required.

Construction Materials

Body: Cast iron or Steel

Orice and Cage: Aluminum

Valve Disk: Aluminum/Neoprene (CR)

O-Rings: Nitrile (NBR)

Diaphragms: Nitrile (NBR)/Nylon (PA)

(neoprene (CR) in actuator)

Guide Bushing: Nylon

Stem and Stem Sleeve: Stainless steel

Diaphragm Plate: Steel

Balancing Diaphragm Plate: Plated Steel

Spring Case:

Type 133 HP: Cast Iron

Types 133H, 133L, and 133Z: Aluminum

Lower Casing: Aluminum

Closing Cap: Cast iron

Adjusting Screw: Steel

Optional Restriction Collar: Aluminum

Temperature Capabilities

(1)

-20° to 150°F (-29° to 66°C)

Control Line Connection

Types 133H, 133L, and 133Z: 3/4-inch NPT

(internal); connection will be positioned directly

over body outlet (standard position) or 90 degrees

right or left of standard position if specied

Type 133HP: 1/4-inch NPT (internal) connection

positioned directly over body outlet

Vent Connection

Types 133H, 133L, and 133Z: 1-inch NPT (internal)

with screen; standard position is in line with control

line connection directly over body outlet. Vent will

always be positioned over the control line connection

Type 133HP: 1/2-inch NPT (internal) connection

positioned directly over body inlet with a Fisher®

Type Y602-7

Approximate Weight

Types 133H, 133L, and 133Z NPT End

Connections: 35 pounds (15,9 kg)

Types 133H, 133L, and 133Z Flanged End

Connections: 40 pounds (18,1 kg)

Type 133HP NPT End Connections:

56.5 pounds (25,6 kg)

Type 133HP Flanged End Connections:

62.5 pounds (28,3 kg)

1. None of the pressure/temperature limits in this Instruction Manual, nor any applicable standard limitation, should not be exceeded.

Type Number Description

Type 133H—High pressure construction for outlet

pressure range of 1.5 to 10 psig (0,10 to 0,69 bar).

The Type 133H can also use the 2-inches w.c. to

2 psig (5,00 mbar to 0,14 bar) springs of the

Type 133L. The maximum operating inlet pressure

is 60 psig (4,14 bar) with a maximum emergency inlet

pressure of 125 psig (8,62 bar).

Type 133HP—Extra high pressure construction for outlet

pressure range of 2 to 60 psig (0,14 to 4,14 bar). The

maximum operating inlet pressure rating of 150 psig

(10,3 bar) with a maximum emergency inlet pressure of

150 psig (10,3 bar).

2

Type 133L—Low pressure construction for outlet

pressure range of 2-inches w.c. to 2 psig (5,00 mbar

to 0,14 bar). The maximum operating inlet pressure

is 60 psig (4,14 bar) with a maximum emergency inlet

pressure of 125 psig (8,62 bar).

Type 133Z—Zero governor construction for outlet

pressure range of -1 to 4-inches w.c. (-2,00 to

10,00 mbar). The maximum operating inlet pressure is

20 psig (1,38 bar) with a maximum emergency inlet

pressure of 125 psig (8,62 bar).

133 Series

INLET PRESSURE

OUTLET PRESSURE

ATMOSPHERIC PRESSURE

BOOST PRESSURE

INLET PRESSURE

OUTLET PRESSURE

ATMOSPHERIC PRESSURE

BOOST PRESSURE

A6555

Figure 2. Operational Schematic of Type 133L Regulator (Also Typical of Type 133H)

Principle Operation

Refer to the operational schematics in Figures 2 and 3.

In the 133 Series, downstream pressure is registered

under the diaphragm via the external control line and

is used as the operating medium. Increased demand

lowers the downstream pressure and allows the spring

to move the diaphragm and stem assembly down,

opening the valve disk and supplying more gas to the

downstream system. Decreased demand increases

the downstream pressure and moves the diaphragm

and stem assembly up, closing the valve disk and

decreasing the gas supply to the downstream system.

Boosting System

The 133 Series incorporates a balancing diaphragm

and a boosting system. When the regulator is locked

up, inlet pressure is registered on the top of the valve

disk and on the bottom of the balancing diaphragm

through registration holes in the top of the cage. Also,

downstream pressure is registered on the bottom

of the valve disk and on the top of the balancing

diaphragm through a passage formed by grooves in

the registration disk and an annular space between the

stem and stem sleeve.

When the valve disk is open, gas ows from the inlet

over the edge of the valve disk to the outlet. Under

the valve disk near the registration disk, there is little

gas ow. The gas pressure near the registration disk

is higher than it is in the ow path where gas velocity

tends to lower the pressure. The higher pressure

near the disk is registered on the top of the balancing

diaphragm through the registration disk and the

annular space between the stem and stem sleeve.

This pressure registered on the top of the balancing

diaphragm aids downward disk travel and

compensates for spring and diaphragm effect. This

improves regulator range ability and performance.

3

133 Series

Type 133HP

Type 133HP

INLET PRESSURE

OUTLET PRESSURE

ATMOSPHERIC PRESSURE

overpressure protection is needed if the actual inlet

pressure exceeds the outlet pressure rating.

Maximum operating inlet pressure for the 133 Series

regulators is given in Table 2. All models must

be protected against inlet pressure above their

listed maximum.

Regulator operation below these emergency pressure

limitations does not preclude the possibility of damage

from external sources or from debris in the gas line.

The regulator should be inspected for damage after

any overpressure condition.

Downstream Control Line

An external downstream control line must be installed

before putting the 133 Series regulators in operation.

Without the control line, the regulator will remain wideopen. The downstream control line should be a pipe of

at least 1/2-inch (12,7 mm) diameter; connect it to the

downstream pipe line at least 5 to 10 pipe diameters

from the regulator and in a straight section of pipe.

INLET PRESSURE

OUTLET PRESSURE

ATMOSPHERIC PRESSURE

A6883

Figure 3. Operational Schematic of Type 133HP

Installation

Before installing the 133 Series regulators, inspect it

for shipping damage and be certain that the body and

orice are clean. Blow out the pipeline to remove pipe

scale and other foreign material.

The regulator may be installed in any position as long

as the ow through the body is the same as indicated

by the ow direction arrow on the body and the vent

opening is unobstructed and protected from the

entrance of rain, ice and other foreign material.

If the regulator has threaded end connections, coat

male threads with pipe compound. For anged

end connections, tighten the ange bolts evenly.

Install a three valve bypass around the 133 Series if

continuous operation is necessary.

The regulator must be protected from damage by

vehicles and other outside sources.

Overpressure Protection

The 133 Series regulators, as is the case with most

regulators, has an outlet pressure rating that is

lower than the inlet pressure rating. Some type of

The external downstream control line connection on

the Type 133HP is 1/4-inch threaded NPT.

Vent

The 133 Series vent is screened to prevent insects

or foreign material from entering. On indoor

installations, if a vent to atmosphere is required,

remove the snap ring and screen (keys 8J and 8H;

Figure 10, 11, or 12) from the Types 133H, 133L, and

133Z. Remove the Type Y602-7 screened vent and

pipe nipple (keys 50 and 49; Figure 14) from

the spring case (key 8) and pipe the vent to the

outside. The Types 133H, 133L, and 133Z have

a 1-inch NPT (internal) connection and the Type 133HP

has a 1/2-inch NPT (internal) construction.

The vent pipe should be as short as possible with

a minimum of bends and elbows. The pipe should

also have as large a diameter as possible. Install

a weather and bug resistant vent assembly on the

outside end of the vent pipe.

For indoor installation that have been piped to the

outside and for outdoor installations, the vent opening

must be positioned so that water, ice and other foreign

material cannot enter the spring case. Use care not to

place the vent opening below downspouts and eaves.

The vent opening should be checked periodically to

see that the opening has not been plugged by foreign

material. On some installations it may be necessary to

provide additional protection from the elements.

4

133 Series

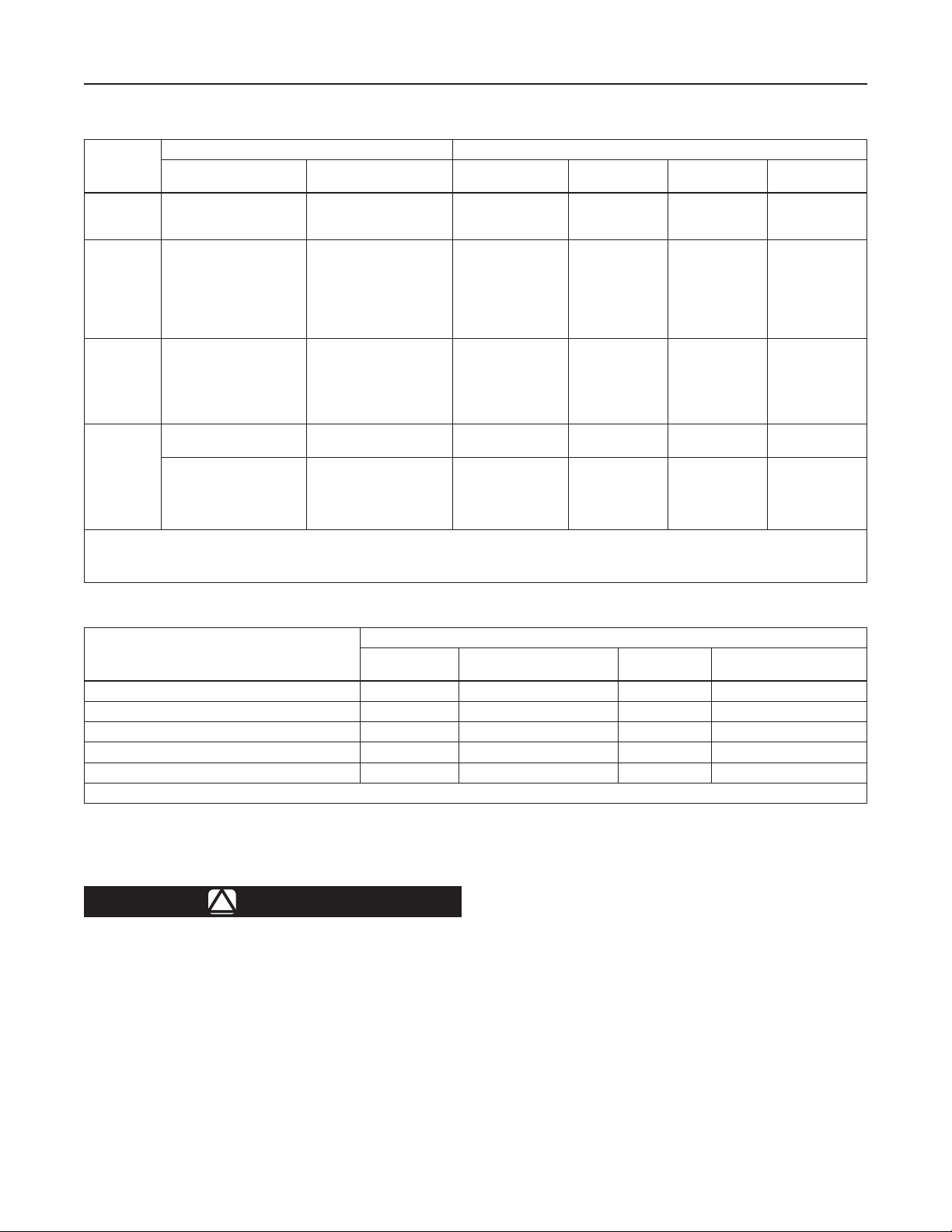

Table 1. 133 Series Outlet Pressure Ranges, Control Springs

OUTLET PRESSURE RANGE CONTROL SPRINGS

TYPE

(1)

133H

(1)

133HP

(1)

133L

and

(2)

133H

(1)

133Z

1. Pressure ranges shown are correct if the regulator is installed with the actuator portion above the body portion. If the regulator is installed with the actuator portion below the body,

the pressure ranges will be lowered by approximately 2-inches w.c. (5,00 mbar) for the Type 133L and by approximately 3-inches w.c. (7,00 mbar) for the Types 133H and 133Z.

2. If the 2-inches w.c. to 2 psig (5,00 mbar to 0,14 bar) springs (all 6 ranges) are used in the Type 133H, the pressure ranges will increase by approximately 1-inch w.c. (2,00 mbar) due

to the weight of the Type 133H parts (assuming that the actuator is installed above the body).

Inches w.c./Psig bar/mbar Part Number

1.5 to 3 psig

2 to 5 psig

5 to 10 psig

2 to 5 psig

4.5 to 10 psig

6 to 20 psig

16 to 30 psig

26 to 40 psig

36 to 50 psig

45 to 60 psig

2 to 4-inches w.c.

3.5 to 6-inches w.c.

5 to 9-inches w.c.

8.5 to 18-inches w.c.

14 to 28-inches w.c.

0.75 to 2 psig

-1 to 1-inch w.c. -2,00 to 2,00 mbar

0 to 4-inches w.c. 0 to 10,00 mbar

0,10 to 0,21 bar

0,14 to 0,34 bar

0,34 to 0,69 bar

0,14 to 0,34 bar

0,31 to 0,69 bar

0,41 to 1,38 bar

1,10 to 2,07 bar

1,79 to 2,76 bar

2,48 to 3,45 bar

3,10 to 4,14 bar

5,00 to 10,00 mbar

9,00 to 15,00 mbar

12,00 to 22,00 mbar

21,00 to 45,00 mbar

35,00 to 70,00 mbar

0,05 to 0,14 bar

1H975927032

10A9440X012

1J146927142

17B8632X012

17B8633X012

10C1238X012

10C1240X012

10C1241X012

10C1242X012

10C1243X012

1D892527022

1D892627022

1D892727012

1D893227032

1D893327032

1H975827032

1K633427012

(Extension Spring)

1K633427012

(Extension Spring)

1D892527022

(Composition Spring)

and

Color Code

Stripe

Orange

Yellow

Blue

Yellow

Orange

Silver

Red

Blue

Green

White

Brown

Red

Black

White

Green

Blue

Black 2 (50,80) 0.075 (1,91)

Black

Brown

Free Length,

Inch (mm)

7-3/8 (187)

6-15/32 (164)

6-3/16 (157)

8-1/2 (216)

8-1/2 (216)

8-1/4 (210)

8-1/4 (210)

8-1/4 (210)

8-1/4 (210)

8-1/4 (210)

6-1/8 (156)

7-1/2 (190)

7-7/8 (200)

7-1/2 (190)

7-1/4 (184)

7-3/8 (187)

2 (50,80)

6-1/8 (156)

Wire Diameter,

Inch (mm)

0.250 (6,35)

0.283 (7,19)

0.375 (9,53)

0.281 (7,14)

0.343 (8,71)

0.406 (10,31)

0.500 (12,70)

0.500 (12,70)

0.531 (13,49)

0.225 (5,72)

0.109 (2,77)

0.120 (3,05)

0.130 (3,30)

0.156 (3,96)

0.182 (4,62)

0.225 (5,72)

0.075 (1,91)

0.109 (2,77)

Table 2. Maximum Inlet and Outlet Pressures

TYPE NUMBER

PRESSURES

Maximum Operating Inlet Pressure 60 (4,14) 150 (10,34) 60 (4,14) 20 (1,38)

Maximum Emergency Inlet Pressure 125 (8,62) 150 (10,34) 125 (8,62) 125 (8,62)

Maximum Operating Outlet Pressure

Maximum Outlet Pressure Over Outlet Pressure Setting 3 (0,21) - - - - 3 (0,21) 3 (0,21)

Maximum Emergency Outlet (Casing) Pressure 15 (1,03) 150 (10,34) 15 (1,03) 15 (1,03)

1. With highest spring range available only.

(1)

Startup

133H

Psig (bar)

10 (0,69) Setpoint Plus 40 psi (2,76) 2 (0,14) 4-inches w.c. (10,00 mbar)

133HP

Psig (bar)

133L

Psig (bar)

133Z

Psig (bar)

setting by more than 3 psig (0,21 bar), or

the valve seat or diaphragm plates can be

damaged. The procedure used in putting

WARNING

!

the regulator in service must be planned

accordingly. Pressure gauges should

If the downstream system is already

pressured by another regulator or by a

manual bypass, then extra precautions

must be taken when placing the 133 Series

in service. The outlet of the regulator

must never be subjected to pressures

higher than the inlet pressure, or the

balancing diaphragm may be damaged.

Also, the control line pressure must never

exceed the set point dictated by the spring

always be used to monitor downstream

and control line pressures during startup.

If the downstream system is not pressured by

another regulator or by manual bypass, use the

following procedure.

1. Slowly open the upstream shutoff valve.

2. Slowly open the downstream shutoff valve.

3. Check all connections for leaks.

5

Loading...

Loading...