Emerson Fisher 1080 Installation Instructions

Instruction Manual

D500236X012

1080 Manual Actuator

Fisherr 1080 Declutchable Manual Actuator

October 2012

Contents

Introduction 1.................................

Scope of Manual 1.............................

Description 2.................................

Specifications 2...............................

Educational Services 2.........................

Installation 4..................................

Installing the Manual Actuator 4.................

Operation 5...................................

Engaging the Manual Actuator 6.................

Disengaging the Manual Actuator 7..............

Maintenance 7.................................

Lubrication 8.................................

Parts Ordering 11...............................

Figure 1. Fisher 1080 Manual Actuator Mounted on a

1035/El-O-Matic Actuator

W9256

Introduction

Scope of Manual

This instruction manual includes installation, operation, and maintenance information for the Fisher 1080

Declutchable Manual Actuator. Refer to separate instruction manuals for instructions covering the 1035/El-O-Matic

actuator and the control valve.

Do not install, operate, or maintain a 1080 manual actuator without being fully trained and qualified in valve, actuator,

and accessory installation, operation, and maintenance. To avoid personal injury or property damage, it is important

to carefully read, understand, and follow all the contents of this manual, including all safety cautions and warnings. If

you have any questions about these instructions, contact your Emerson Process Management sales office before

proceeding.

www.Fisher.com

1080 Manual Actuator

October 2012

Table 1. Specifications

Instruction Manual

D500236X012

Available Configurations

Direct acting; see Handwheel Rotation

Manual Actuator Sizes

See table 2

PowerActuatorCompatibility

Compatible with Fisher 1035 actuator;

see table 2

Maximum Torque Output

See table 2

Wheel-Rim Force

See table 2

Handwheel Rotation

Clockwise handwheel rotation closes valve (produces

clockwise valve shaft rotation)

Mounting Positions

Standard mounting is with the input shaft

perpendicular to the 1035 piston travel and the

handwheel opposite the actuator supply connections

(see figure 2). Right hand or left hand mounting is

specified when ordered. Mounting position 1 is

standard.

Approximate Weight without Handwheel

Size AAA: 5.4 kg (12 lb)

Size AA: 10 kg (22 lb)

Size A: 14 kg (31 lb)

Size B: 22 kg (49 lb)

Size C: 34 kg (76 lb)

Size D: 52 kg(115 lb)

Size F: 68 kg (150 lb)

Handwheel Weight

8-inch: 2.0 kg (4.50 lb)

12-inch: 4.0 kg (8.75 lb)

16-inch: 6.8 kg (15.00 lb)

24-inch: 5.4 kg (12.00 lb)

30-inch: 6.8 kg (15.00 lb)

36-inch: 7.8 kg (17.25 lb)

Description

The 1080 manual actuator, shown in figure 1, is a declutchable unit for manual operation of Fisher A41 and A31A

Cryogenic control valves that use a 1035 power actuator. The 1080 manual actuator mounts directly on the 1035

actuator. It can be engaged to allow manual operation of the valve when the power actuator is not in use or

disengaged to allow automatic operation of the valve by the power actuator. The mechanism used allows manual

actuator engagement at any point of power actuator rotation.

Specifications

The 1080 manual actuator specifications are given in table 1.

Educational Services

For information on available courses for 1080 manual actuators,aswellasavarietyof other products, contact:

Emerson Process Management

Educational Services, Registration

P.O. Box 190; 301 S. 1

Marshalltown, IA 50158-2823

Phone: 800-338-8158 or

Phone: 641-754-3771

FAX: 641-754-3431

e-mail: education@emerson.com

st

Ave.

2

Instruction Manual

D500236X012

1080 Manual Actuator

October 2012

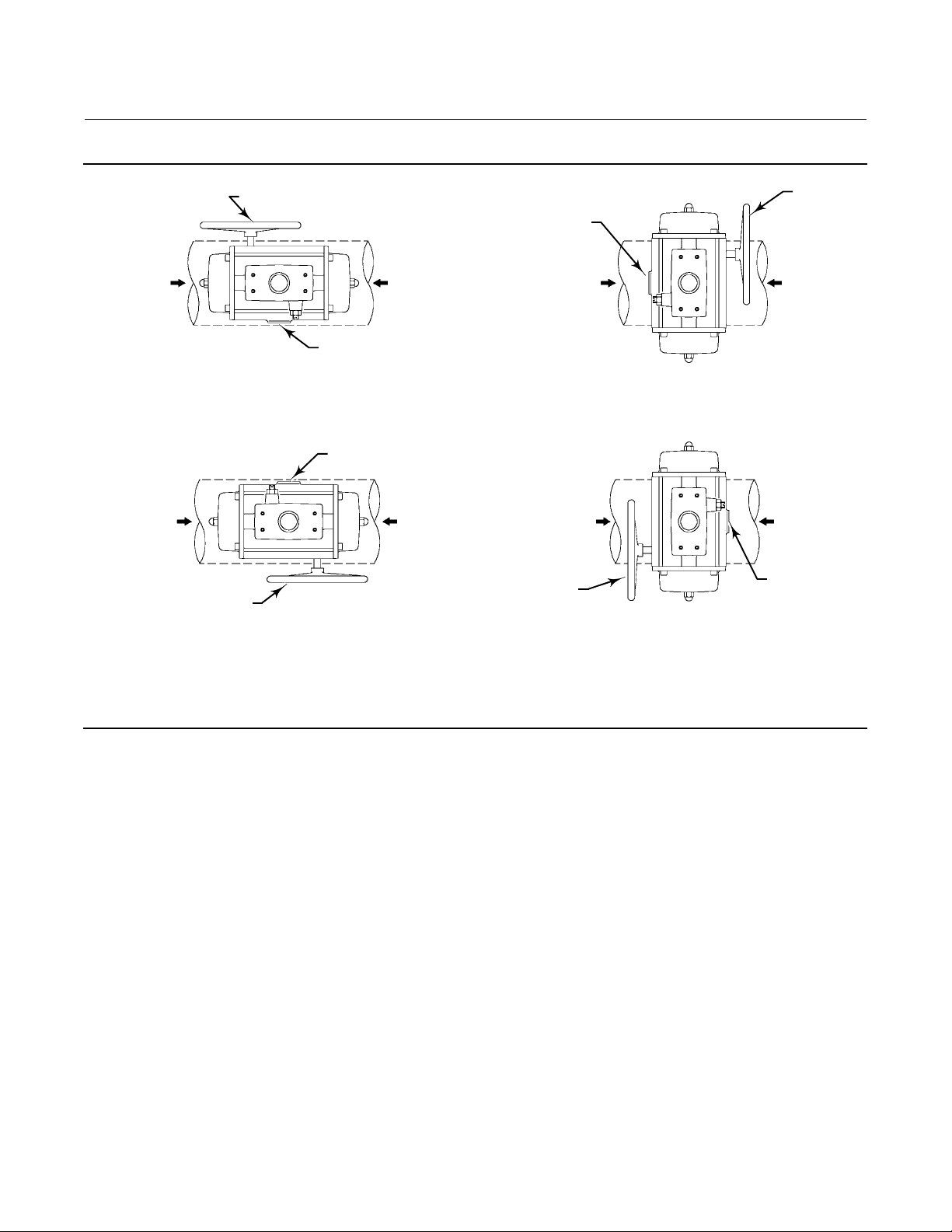

Figure 2. Fisher 1080 Actuator Mounting Positions

1080 HANDWHEEL

FLOW DIRECTION

FOR RIGHT HAND

MOUNTING

FLOW DIRECTION

FOR LEFT HAND

MOUNTING

1035 PRESSURE PORTS

FOR USE WITH 1035 ACTUATOR ALL SIZES

MOUNTING POSITION 1

(STANDARD)

1035 PRESSURE PORTS

FLOW DIRECTION

FOR RIGHT HAND

MOUNTING

FLOW DIRECTION

FOR LEFT HAND

MOUNTING

1080 HANDWHEEL

FOR USE WITH 1035 ACTUATOR ALL SIZES

MOUNTING POSITION 3

NOTE:

RIGHT AND LEFT HAND MOUNTING IS BASED ON THE A41 VALVEDRIVE SHAFT BEING MOUNTED IN THE RECOMMENDED HORIZONTALPOSITION.

75B0768

B2702

1035

PRESSURE PORTS

FLOW DIRECTION

FOR RIGHT HAND

MOUNTING

FOR USE WITH 1035 ACTUATOR SIZES E25 THRU E350 & P4000

NOT AVAILABLE FOR 1035 ACTUATOR SIZES E600 THRU E1600 & P2500

MOUNTING POSITION 2

FLOW DIRECTION

FOR RIGHT HAND

MOUNTING

1080

HANDWHEEL

FOR USE WITH 1035 ACTUATOR SIZES E25 THRU E350 & P4000

NOT AVAILABLE FOR 1035 ACTUATOR SIZES E600 THRU E1600 & P2500

MOUNTING POSITION 4

1080

HANDWHEEL

FLOW DIRECTION

FOR LEFT HAND

MOUNTING

FLOW DIRECTION

FOR LEFT HAND

MOUNTING

1035

PRESSURE PORTS

3

1080 Manual Actuator

October 2012

Instruction Manual

D500236X012

Installation

The 1080 manual actuator is normally shipped mounted between the A31A Cryogenic or A41 valve assembly and the

1035 actuator. If the manual actuator is shipped separately for installation on the 1035 actuator, or if the manual

actuator was removed for maintenance, mount the manual actuator by following the instructions in this section.

Field conversion of the 1035 actuator for use with the 1080 manual actuator requires fastening an adaptor plate,

included with the manual actuator, to the 1035 actuator. The 1080 actuator is installed between the valve and the

1035 actuator.

Figure 2 shows the manual actuator mounting positions. Positions 1 and 3 are possible with all sizes of the 1035.

Positions 2 and 4 are only possible for 1035 sizes E25 through E350 and P4000. Fasten the adaptor plate to the power

actuator with the mounting bolts provided with the manual actuator. Use the torque values given in table 3.

Installing the Manual Actuator

If you purchased the 1080 actuator as part of a valve and power actuator assembly, step 13 is the only step you will

need to perform in the following procedures. If you purchased the 1080 actuator separately, perform all the steps and

read all warnings and cautions below.

WARNING

Refer to the WARNING at the beginning of the Maintenance section in this instruction manual.

1. Isolatethecontrolvalvefromthelinepressure,releasepressure from both sides of the valve body, and drain the

process media from both sides of the valve. Also shut off all pressure lines to the power actuator and release all

pressure from the power actuator. Use lock-out procedures to be sure that the above measures stay in effect while

you work on the equipment.

2. For spring-return power actuators, allow the power actuator to remain in the position where the spring is relaxed.

For double-acting power actuators, apply supply pressure as appropriate to position the valve disc in either the

open or closed position.

3. Note whether the valve disc is in the open or closed position.

4. Engage the handwheel on the manual actuator. See the Engaging and Disengaging the Manual Actuator section in

this manual for instructio ns.

5. If using position 1 or 3 from figure 2, rotate the handwheel to line up t he index mark on the top of the manual

actuator shaft and the drive shaft on the top of the power actuator. If using position 2 or 4 from figure 2, the index

mark on top of the power actuator input drive on the 1080 must be perpendicular to the face of the valve disc and

the slot in the top of the power actuator shaft (see figure 3).

6. Determine the correct relative positions of the power and manual actuators (see figure 2).

7. Remove the adaptor plate on the top of the gear box (see figure 3).

8. Attach the adaptor plate to the bottom of the power actuator with bolts furnished with the adaptor plate.

9. Slide the power actuator input drive into the power actuator (see figure 3).

10. Rotate either the manual actuator or the power actuator slightly so that the mounting holes on the manual

actuator align with the mounting holes in the mounting plate on the power actuator.

11. Fasten the manual actuator to the mounting plate with the bolts, washers and nuts provided (see table 3).

4

Loading...

Loading...