Page 1

Product Bulletin

1080 Manual Actuator

D500238X012

22.2:1080

January 2013

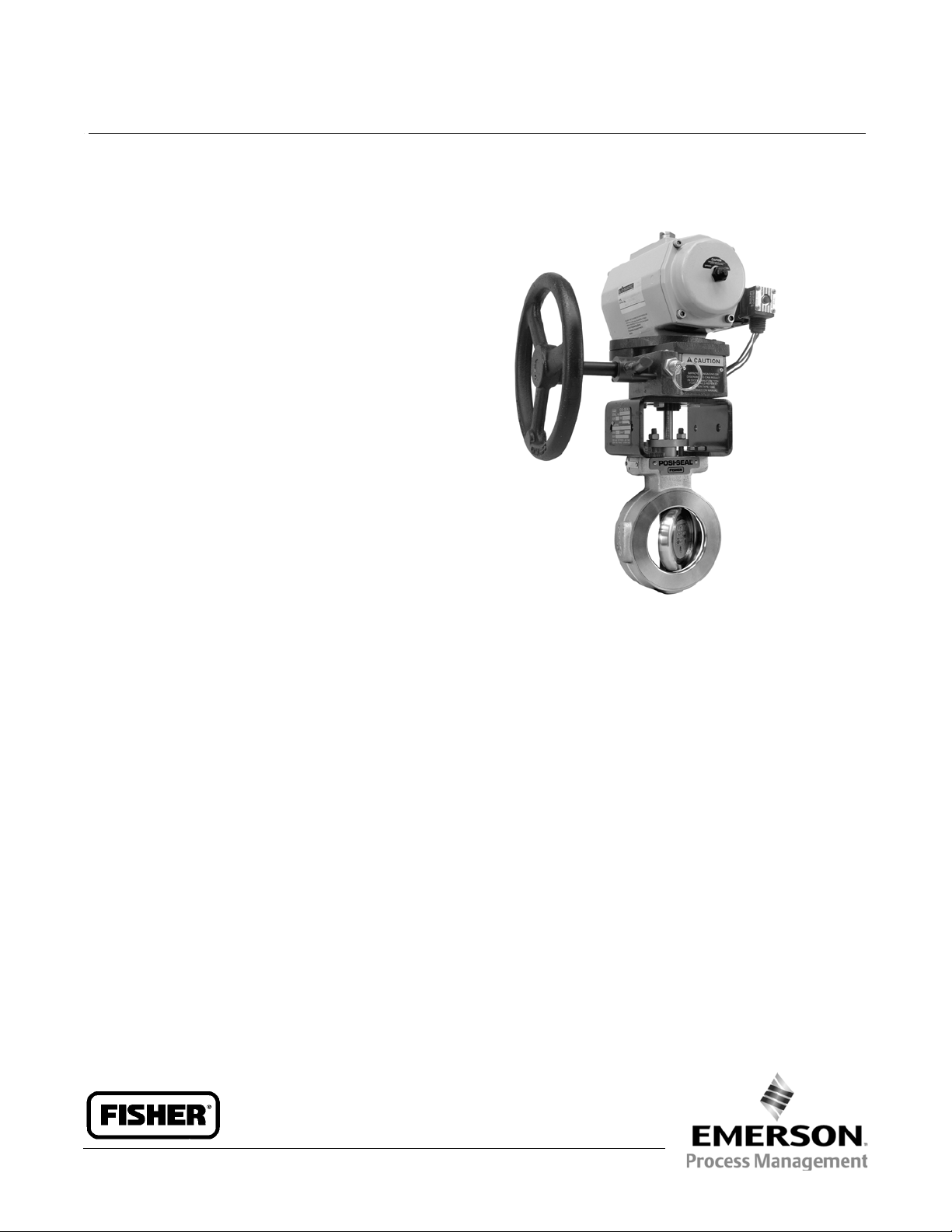

Fisherr 1080 Declutchable Manual Actuator

The Fisher 1080 manual actuator is a Declutchable

Actuator for manual operation of A41 double D shaft

control valves that use a 1035/El-O-Matic power

actuator. As shown in the following figure, the 1080

manual actuator mounts directly on the 1035

actuator. It can be engaged to allow manual operation

of the valve when the power actuator is not in use or

disengaged to allow automatic operation of the valve

by the power actuator.

Features

Direct Attachment to the Power Actuator– Direct

mounting to the actuator housing simplifies

installation and eliminates the need for additional

mounting parts.

Engage Manual Actuator At Any Point of Rotation–

A lever-operated eccentricbearingsupportonthe

input shaft allows engagement of the worm gear

with the sector at any point of rotation.

Simplified Selection– Each size of the 1080

corresponds to the capabilities of a size of the 1035.

So you need only calculate the size of the 1035,

when ordering both a 1035 and 1080 (see table 1).

W9256

Fisher 1080 Manual Actuator Mounted on a

1035/El-O-Matic Actuator

Positive Operation– The disengagement lever is

held in both the engaged and disengaged positions

by a spring-loaded pin, which must be released

before the lever can be moved. This reduces the

possibility of inadvertent or accidental operation. In

addition, stop-pins at the fully engaged and fully

disengaged positions provide positive limits for

lever travel.

www.Fisher.com

Page 2

Product Bulletin

22.2:1080

January 2013

Specifications

1080 Manual Actuator

D500238X012

Available Configurations

Direct acting; see Handwheel Rotation

Manual Actuator Sizes

See table 1

PowerActuatorCompatibility

Compatible with all sizes of 1035 actuator; see table 1

Maximum Torque Output

See table 1, Wheel-Rim Force

Handwheel Rotation

Clockwise handwheel rotation closes valve (produces

clockwise valve shaft rotation)

Construction Materials

Housing and Cover: Cast iron

Drive Sleeve/Gear (Sector): Low-carbon steel/bronze

Worm Gear: Heat-treated steel

Input Shaft and Eccentric: Low-carbon steel/bronze

Pin Detent: 300 Series stainless steel

Shaft Bearings: Bronze

Mounting Positions (see figure 1)

J Standard mounting is with the input shaft

perpendicular to the 1035 actuator piston travel, with

the handwheel opposite the actuator supply

connections;

handwheel on the same side as the 1035 actuator

supply connections

Dimensions

Seefigure2

Approximate Weight without Handwheel

Size AAA: 5.4 kg (12 lb)

Size AA: 10 kg (22 lb)

Size A: 14 kg (31 lb)

Size B: 22 kg (49 lb)

Size C: 34 kg (76 lb)

Size D: 52 kg (115 lb)

Size F: 68 kg (150 lb)

Handwheel Weight

8-inch: 2.0 kg (4.50 lb)

12-inch: 4.0 kg (6.75 lb)

16-inch: 6.8 kg (15.00 lb)

24-inch: 5.4 kg (12.00 lb)

30-inch: 6.8 kg (15.00 lb)

36-inch: 7.8 kg (17.25 lb)

J optional mounting is with the

Ordering Information

Each size of the 1080 corresponds to a specific size of

1035 as shown in table 1. The torque output of the

1080 actuator is matched to the capabilities of the

1035 power actuator.

The1080actuatorcanhandletheSpringReturn1035

actuatortorquesaswellastheDoubleActing1035

actuator,becausetheDoubleActingtorqueat100

psig is approximately equal to the sum of both the

Spring Return spring start torque and the Spring

Return air end torque at 100 psig.

An optional bypass valve should be ordered for use on

a 1035 actuator if you plan to engage the manual

actuator while the power actuator has air pressure

applied to it. For activation of the 1080, air pressure

mustnotbetrappedinthe1035ormustbeequalized

between the pistons by a bypass valve.

2

Page 3

1080 Manual Actuator

D500238X012

Product Bulletin

22.2:1080

January 2013

Table1.ActuatorSizeSelection and Specifications

ACTUATOR

SIZE

AAA/S1 E25

AAA/S2

AAA/S3 E100 132 1,168 218 49

AA/S4

A/S4 E600 32:1 8

B/S5 E950 40:1 10 1,356 12,000 1,290 11,300 271 61

C/S6 E1600 54:1 13.5 762 30 2,034 18,000 2,140 18,600 298 67

D/SQ3 P2500 64:1 16 914 36 3,390 30,000 3,377 29,891 383 86

F/SQ4 P4000 282:1 70.5 406 16 6,779 60,000 5,701 50,458 334 75

1. Only the 1080/1035 combinations shown are available.

2. Maximum torque output of the 1080 actuatoronly.

3. Torque output of the 1035 actuator at100 psig and required 1080 torque output for use with the 1035.

4. Amount of force necessary at rim ofthe handwheel to matchtorque output of the 1035 at 100psig.

1035

ACTUATOR

SIZE

E40

E65

E200

E350

GEAR

RATIO

24:1 6 203 8 271 2,400

34:1 8.5 305 12 542 4,800

NUMBER OF

TURNS TO

CLOSE

(1)

HANDWHEEL

DIAMETER

mm Inches NSm lbSin NSm lbSin N lbf

610 24

1080 MAXIMUM

926 8,200 866 7,550 276 62

TORQUE

(2)

1035 TORQUE

31 274 49 11

58

89

289

502

513

788

2,558

4,443

WHEEL RIM FORCE

(3)

FOR MAXIMUM

TORQUE

93

147

222

387

Figure 1. Fisher 1080 Actuator Mounting Positions

1080

HANDWHEEL

FLOW

DIRECTION

FOR LEFT-HAND

MOUNTING

FLOW DIRECTION

FORRIGHT-HAND

MOUNTING

1080 HANDWHEEL

FLOW DIRECTION

FOR LEFT-HAND

MOUNTING

1035 PRESSURE

PORTS

FLOW DIRECTION

FORRIGHT-HAND

MOUNTING

(4)

21

33

50

87

1035 PRESSURE PORTS

FOR USE WITH 1035 ACTUATOR ALL SIZES

FLOW DIRECTION

FORRIGHT-HAND

MOUNTING

MOUNTING POSITION 1

(STANDARD)

1035 PRESSURE PORTS

FLOW DIRECTION

FOR LEFT-HAND

MOUNTING

FOR USE WITH 1035 ACTUATOR SIZES E25 THRU E350 AND P4000

NOT AVAILABLE FOR 1035 ACTUATOR SIZES E600 THRU E1600 AND P2500

MOUNTING POSITION 2

FLOW DIRECTION

FORRIGHT-HAND

MOUNTING

1080

HANDWHEEL

1080 HANDWHEEL

FOR USE WITH 1035 ACTUATOR ALL SIZES

MOUNTING POSITION 3

75B0768

B2702

Note:

Right-andleft-handmountingisbasedontheA41valvedriveshaftbeingmountedintherecommendedhorizontalposition.

FOR USE WITH 1035 ACTUATORSIZES E25 THRU E350 AND P4000

NOT AVAILABLE FOR 1035 ACTUATOR SIZES E600 THRU E1600 ANDP2500

MOUNTING POSITION 4

FLOW DIRECTION

FOR LEFT-HAND

MOUNTING

1035

PRESSURE PORTS

3

Page 4

Product Bulletin

22.2:1080

January 2013

Table 2. Dimensions

1080

Actuator

Size

AAA/S1 E25 203 191 68 30 73 132 153 55 46 51 50

AAA/S2 E40, E65 203 191 68 30 73 132 153 55 46 51 70

AAA/S3 E100 203 191 68 30 73 132 153 55 46 51 70

AA/S4 E200, E350 305 210 89 29 83 181 216 94 59 64 102

A/S4 E600 610 381 105 32 89 337 378 238 67 73 125

B/S5 E950 610 381 114 41 105 346 394 222 83 89 140

C/S6 E1600 762 406 143 44 117 425 492 276 105 111 165

D/SQ3 P2500 914 427 171 67 168 524 583 338 119 125 165

F/SQ4 P4000 406 451 171 162 168 365 441 178 127 137 165

AAA/S1 E25 8 7.50 2.69 1.188 2.88 5.19 6.03 2.18 1.83 2.03 1.969

AAA/S2 E40, E65 8 7.50 2.69 1.188 2.88 5.19 6.03 2.18 1.83 2.03 2.756

AAA/S3 E100 8 7.50 2.69 1.188 2.88 5.19 6.03 2.18 1.83 2.03 2.756

AA/S4 E200, E350 12 8.25 3.50 1.126 3.25 7.13 8.50 3.69 2.31 2.50 4.016

A/S4 E600 24 15.00 4.13 1.253 3.50 13.25 14.88 9.38 2.63 2.88 4.921

B/S5 E950 24 15.00 4.50 1.625 4.12 13.62 15.50 8.75 3.25 3.50 5.512

C/S6 E1600 30 16.00 5.62 1.750 4.62 16.75 19.38 10.88 4.12 4.38 6.496

D/SQ3 P2500 36 16.81 6.75 2.630 6.63 20.63 22.94 13.31 4.69 4.94 6.496

F/SQ4 P4000 16 17.75 6.75 6.380 6.63 14.38 17.38 7.00 5.00 5.38 6.496

1035

Actuator

Size

J HW M D DW EW FD GE NE ND

mm

Inches

1080 Manual Actuator

D500238X012

KW Bolt

Circle

Diameter

Figure 2. Dimensions (also see table 2)

HW

DISENGAGED

18B6626-D

E0720

J

ENGAGED

KW

Neither Emerson, Emerson Process Management,nor any of their affiliated entitiesassumes responsibility for the selection, use or maintenance

of anyproduct. Responsibility for proper selection, use, and maintenance ofany productremains solely with the purchaser and end user.

Fisher isa mark owned by one of thecompanies in the Emerson Process Management business unit of Emerson Electric Co. Emerson Process Management,

Emerson, and the Emerson logoare trademarks and service marks of Emerson Electric Co. All other marks are the property of their respective owners.

The contents of this publication are presented for informational purposes only, and while every effort has been made to ensure their accuracy, they arenot

to be construed as warranties or guarantees, express or implied, regarding the products or services described herein or their use or applicability. All sales are

governed by our terms and conditions, which are available upon request.We reservethe rightto modifyor improvethe designs or specifications ofsuch

products at any time without notice.

Emerson Process Management

Marshalltown, Iowa 50158 USA

Sorocaba, 18087 Brazil

Chatham, Kent ME4 4QZ UK

Dubai, United Arab Emirates

Singapore 128461 Singapore

www.Fisher.com

M

GE

ENGAGED

NE

ENGAGED

FD

DISENGAGED

ND

DISENGAGED

EW

DW

CENTER LINE

OF ACTUATOR

D

E 1998, 2013 Fisher ControlsInternational LLC. All rights reserved.

4

Loading...

Loading...