Page 1

Product Bulletin

1079 Manual Actuator

D500209X012

22.2:1079

January 2013

Fisherr 1079 Declutchable Manual Actuator

The 1079 manual actuator is a declutchable unit for

manual operation of keyed or square shaft control

valves and equipment that use a Hytork actuator. The

1079 manual actuator mounts directly on the Hytork

actuator and can be engaged to allow manual

operation of the valve when the power actuator is not

in use or disengaged to allow automatic operation of

the valve by the power actuator. The mechanism used

allows manual actuator engagement at any point of

poweractuatorrotation.

W6214

Fisher 1079 Manual Actuator Mounted on a

Hytork Actuator and A41 Valve

Features

Direct Attachment to the Power Actuator-- Direct

mounting to the actuator housing simplifies

installation and eliminates the need for yokes and

other brackets.

Engage Manual Actuator At Any Point of Rotation--

A lever-operated eccentricbearingsupportonthe

input shaft allows engagement of the worm gear

with the sector at any point of rotation.

Positive Operation-- The disengagement lever is

held in both the engaged and disengaged positions

by a spring-loaded pin, which must be released

before the lever can be moved. This reduces the

possibility of inadvertent or accidental operation. In

addition, stop-pins at the fully engaged and fully

disengaged positions provide positive limits for

lever travel.

www.Fisher.com

Page 2

Product Bulletin

22.2:1079

January 2013

Specifications

1079 Manual Actuator

D500209X012

Available Configurations

Direct acting; see Handwheel Rotation

Manual Actuator Sizes

See tables 1, 2, and 3

PowerActuatorCompatibility

Compatible with all sizes of Hytork actuator; see

tables 1, 2, and 3

Maximum Torque Output

See tables 1, 2, and 3

Wheel-Rim Force

See tables 1, 2, and 3

Handwheel Rotation

Clockwise handwheel rotation closes valve (produces

clockwise valve shaft rotation, as viewed from the

actuator end of the shaft)

Construction Materials

Housing and Cover: Cast iron

Drive Sleeve/Gear (Sector): Low-carbon steel/bronze

Worm Gear: Heat-treated steel

Input Shaft and Eccentric: Low-carbon steel

Pin Detent: 300 Series stainless steel

Shaft Bearings: Bronze

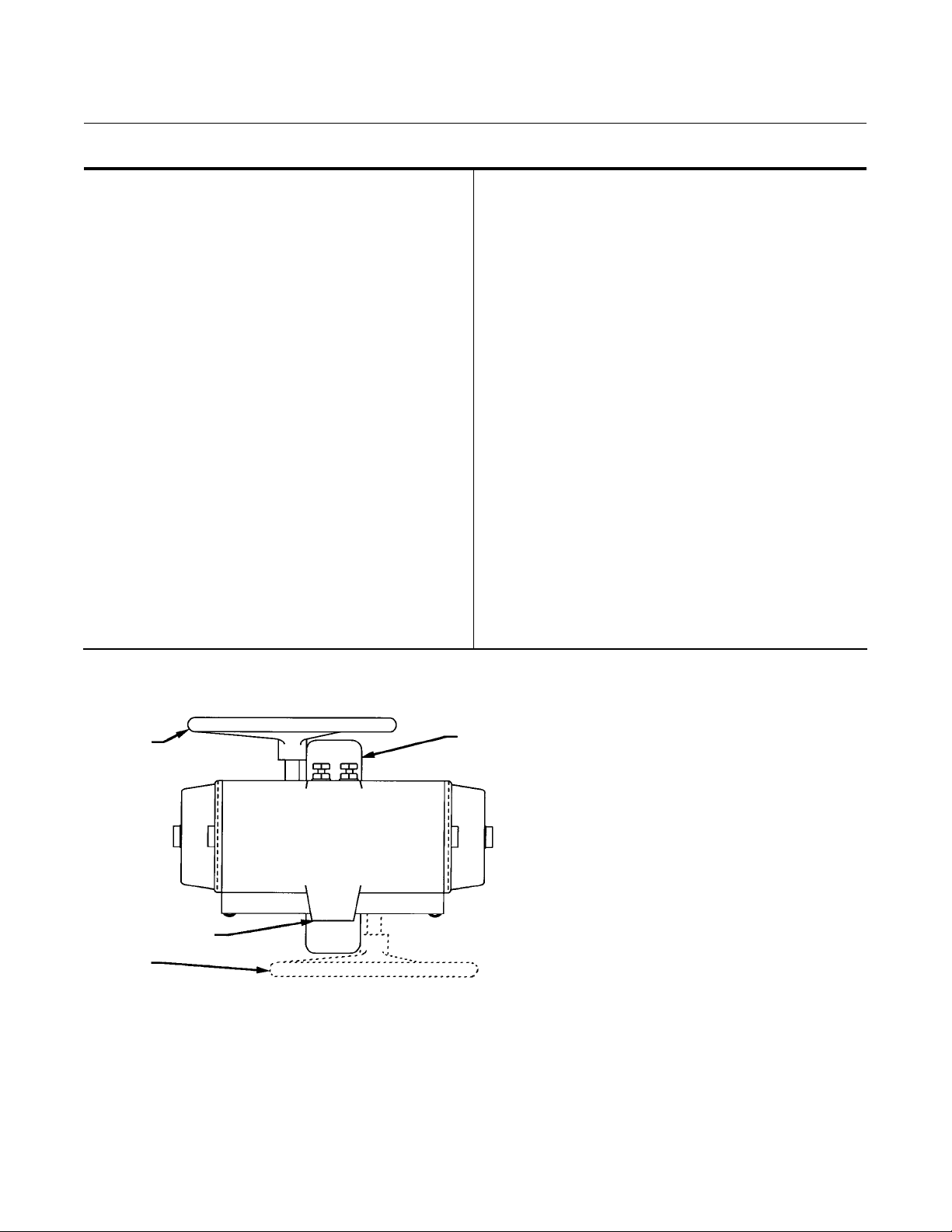

Standard Mounting Positions (see figure 1)

J Standard mounting is with the input shaft

perpendicular to the Hytork piston travel, with the

handwheel opposite the actuator supply c onnections;

J Optional mounting is with the handwheel on the

same side as the Hytork actuator supply connections

Approximate Weight without Handwheel

Size AAA: 7.3 kg (16 lb)

Size AA: 10 kg (22 lb)

Size A: 14 kg (31 lb)

Size B: 16 kg (35 lb)

Size C: 24 kg (52 lb)

Size D: 33 kg (72 lb)

Handwheel Weight

6-inch: 1.0 kg (2.25 lb)

8-inch: 2.0 kg (4.50 lb)

12-inch: 4.0 kg (8.75 lb)

24-inch: 5.4 kg (12.00 lb)

30-inch: 6.7 kg (14.75 lb)

36-inch: 7.8 kg (17.25 lb)

Figure 1. Fisher 1079 Actuator Mounting Positions

STANDARD

MOUNTING

POSITION

HYTORK ACTUATOR

SUPPLY CONNECTIONS

OPTIONAL MOUNTING

POSITION

A6186

SEAL RETAINER

SIDE OF VALVE

2

Page 3

Product Bulletin

1079 Manual Actuator

D500209X012

Table1.ActuatorSizeSelectionandSpecifications for Keyed Shaft Valves (Fisher A31A)

MAXIMUM

ALLOWABLE

TORQUE

245

271

129

245

542

542

542

542

542

129

245

671

834

926

926

926

671

834

927

1171

1233

1582

1582

1582

1582

671

834

927

1171

1233

2203

2530

2568

2712

927

1171

1233

2203

2530

2568

4067

4067

(2)

2165

2400

1145

2165

4800

4800

4800

4800

4800

1145

2165

5941

7383

8200

8200

8200

5941

7383

8205

10,360

10,911

14,000

14,000

14,000

14,000

5941

7383

8205

10,360

10,911

19,494

22,396

22,728

24,000

8205

10,360

10,911

19,494

22,396

22,728

36,000

36,000

WHEEL-RIM FORCE FOR

(3)

(3)

(3)

(3)

(3)

(3)

(3)

(3)

(3)

(3)

(3)

(3)

(3)

(3)

(3)

(3)

ACTUATOR

SIZE

HYTORK

ACTUATOR

SIZE

GEAR

RATIO

HANDWHEEL

DIAMETER

mm Inches mm Inches NSm lbfSin N lbf

VALVE SHAFT

DIAMETER

(1)

203 8 14.3 0.5625 129 1145 214 48

AAA 70 thru280 24:1

305 12

203 8

AA 70 thru280 24:1

305 12

A 680A 40:1 610 24

B 1125 40:1 610 24

610 24

C 1370 54:1

762 30

610 24

D 2585 & 4580 64:1

762 30

914 36

1. Shaft diameter at the keyway.

2. Unless otherwisenoted, torque is limited by S17400 stainless steel (17-4PH H1025) shaft material at 38_C (100_F). For other shaftmaterials, consult your Emerson Process Management

sales office.

3. Maximum manual actuator output.

4. NPS 12 CL150 A31A and NPS 8 CL300 A31A.

17.5

23.8

14.3

17.5

23.8

28.6

30.2

31.8

41.3

14.3

17.5

23.8

28.6

30.2

31.8

41.3

23.8

28.6

31.8

30.2

31.8

38.1

41.3

44.5

47.6

23.8

28.6

31.8

30.2

31.8

38.1

41.3

44.5

47.6

31.8

30.2

31.8

38.1

41.3

44.5

47.6

57.2

0.6875

0.9375

0.5625

0.6875

0.9375

1.125

1.1875

1.25

1.625

0.5625

0.6875

0.9375

1.125

1.1875

1.25

1.625

0.9375

1.125

1.25

1.1875

1.25

1.5

1.625

1.75

1.875

0.9375

1.125

1.25

1.1875

1.25

1.5

1.625

1.75

1.875

1.25

1.1875

1.25

1.5

1.625

1.75

1.875

2.25

(4)

(4)(5)

(4)

(5)

(4)

(5)

(4)

(5)

22.2:1079

January 2013

MAXIMUM TORQUE

267

298

151

298

418

418

418

418

418

44

80

222

276

302

302

302

182

227

254

320

338

431

431

431

431

138

169

187

236

249

445

409

418

440

160

200

209

378

347

351

463

463

60

67

34

64

94

94

94

94

94

10

18

50

62

68

68

68

41

51

57

72

76

97

97

97

97

31

38

42

53

56

100

92

94

99

36

45

47

85

78

79

104

104

3

Page 4

Product Bulletin

22.2:1079

January 2013

Table2.ActuatorSizeSelectionandSpecifications for Valves (Fisher A41)

ACTUATOR

SIZE

AAA 70 thru280 24:1

AA 70 thru 280 24:1

A 680A 40:1 610 24

B 1125 40:1 610 24

C 1370 54:1

D

1. Shaft diameter at packing box.

2. Unless otherwisen oted, torque is limited by S17400 (17-4 PH H1025) stainless steel shaft. For othershaft materials, contact yo ur Emerson Process Management sales office.

3. Maximum manual actuator output. For AAA, C, and D, themaximum output is 2400, 24000, and 36000 in-lb, respectively.

HYTORK

ACTUATOR

SIZE

2585 &

4580

GEAR

RATIO

64:1

HANDWHEEL DIAMETER

mm Inches mm Inches NSm lbfSin N lbf

152 6

203 8 15.9 0.625 138 1225 229 51

305 12 15.9 0.625 138 1225 152 34

152 6

203 8 19.1 0.750 240 2120 392 88

203 8

305 12

610 24

762 30 44.5 1.750 2658 23524 433 97

610 24

762 30 44.5 1.750 2658 23524 365 82

VALVE SHAFT

DIAMETER

12.7

15.9

12.7

15.9

19.1

25.4

31.8

31.8

38.1

19.1

25.4

31.8

38.1

31.8

38.1

44.5

31.8

38.1

31.8

38.1

(1)

0.500

0.625

0.500

0.625

0.750

1.000

1.250

1.250

1.500

0.750

1.000

1.250

1.500

1.250

1.500

1.750

1.250

1.500

1.250

1.500

MAXIMUM ALLOWABLE

58

138

58

138

240

468

542

542

542

240

468

926

926

1110

1356

1582

1110

1356

1110

1356

1079 Manual Actuator

TORQUE

(2)

515

1225

515

1225

2120

4140

4800

4800

4800

2120

4140

8200

8200

9820

12000

14,000

9820

12000

9820

12000

WHEEL-RIM FORCE FOR

MAXIMUM TORQUE

127

305

127

305

280

(3)

(3)

(3)

(3)

(3)

(3)

546

629

418

418

78

153

303

303

303

371

431

227

278

190

231

D500209X012

29

69

29

69

63

123

141

94

94

18

34

68

68

68

83

97

51

63

43

52

4

Page 5

Product Bulletin

1079 Manual Actuator

D500209X012

Table3.ActuatorSizeSelectionandSpecifications for Square Shaft Valves (Fisher A11)

ACTUATOR

SIZE

AAA 70 thru280 24:1

AA 70 thru 280 24:1

A 680A 40:1 610 24

B 1125 40:1 610 24

C 1370 54:1

D

1. Shaft diameter at square connection.

2. Unless otherwiseno ted, torque is limitedby S17400 stainless steel (17-4 PH H1025) shaft material at 38_C (100_F). Forother shaft materials, consult your Emerson Process Management

sales office.

3. Maximum manual actuator output.

HYTORK

ACTUATOR

SIZE

2585 &

4580

GEAR

RATIO

64:1

HANDWHEEL DIAMETER

mm Inches mm Inches NSm lbfSin N lbf

203 8 10.3 0.40625 89 790 147 33

305 12 15.9 0.625 271 2400

203 8 10.3 0.40625 89 790 102 23

305 12

610 24

762 30

610 24

914 36

VALVE SHAFT

DIAMETER

15.9

22.2

15.9

22.2

25.4

15.9

22.2

25.4

34.9

34.9

15.9

22.2

25.4

34.9

34.9

15.9

22.2

25.4

34.9

34.9

(1)

0.625

0.875

0.625

0.875

1

0.625

0.875

1

1.375

1.375

0.625

0.875

1

1.375

1.375

0.625

0.875

1

1.375

1.375

MAXIMUM ALLOWABLE

318

542

318

782

926

318

782

1351

1582

1582

318

782

1351

2712

2712

318

782

1351

3520

3520

TORQUE

(2)

2813

4800

2813

6922

8200

2813

6922

11,956

14,000

14,000

2813

6922

11,956

24,000

24,000

2813

6922

11,956

31,157

31,157

(3)

(3)

(3)

(3)

(3)

(3)

(3)

WHEEL-RIM FORCE FOR

MAXIMUM TORQUE

22.2:1079

January 2013

298 67

245

418

102

254

302

85

214

369

431

431

67

160

276

440

440

53

133

231

400

400

55

94

23

57

68

19

48

83

97

97

15

36

62

99

99

12

30

52

90

90

5

Page 6

Product Bulletin

22.2:1079

January 2013

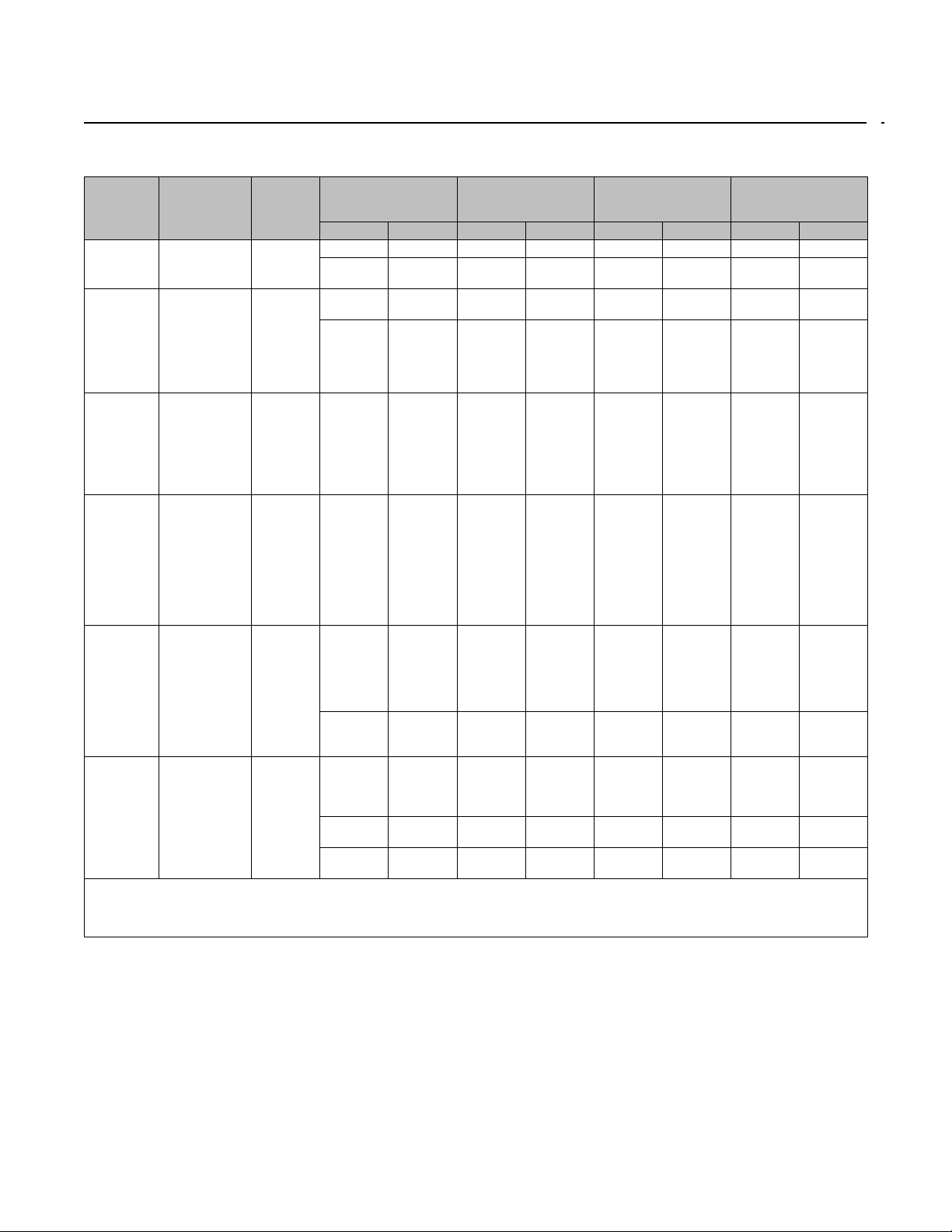

Figure 2. Dimensions (also see table 4)

HW M

NE

ENGAGED

GE

ENGAGED

1079 Manual Actuator

D500209X012

EW

CL OF

ACTUATOR

J

13B8871-B

A6259

KW

ND

DISENGAGED

FD

DISENGAGED

DW

6

Page 7

Product Bulletin

1079 Manual Actuator

D500209X012

Table 4. Dimensions (also see figure 2)

1079

Actuator

Size

AAA 45 152 184 67 73 106 128 30 46 52 35 SQ

AAA 45 203 184 67 73 132 153 55 46 52 35 SQ

AAA 45 305 184 67 73 183 204 106 46 52 35 SQ

AAA 70-280 152 184 67 73 106 128 30 46 52 50 SQ

AAA 70-280 203 184 67 73 132 153 55 46 52 50 SQ

AAA 70-280 305 184 67 73 183 204 106 46 52 50 SQ

AA 425A 203 203 90 78 130 165 43 59 64 72 SQ

AA 425A 305 203 90 78 181 216 94 59 64 72 SQ

A 680A 610 381 105 89 337 378 238 67 73 72 SQ

B 1125 610 381 108 105 346 394 222 83 89 88 SQ

C 1370 610 406 143 117 349 416 200 105 111 88 SQ

C 1370 762 406 143 117 425 492 276 105 111 88 SQ

D

D

D

AAA 45 6.00 7.25 2.62 2.88 4.19 5.03 1.17 1.83 2.03 1.39 SQ

AAA 45 8.00 7.25 2.62 2.88 5.19 6.03 2.17 1.83 2.03 1.39 SQ

AAA 45 12.00 7.25 2.62 2.88 7.19 8.03 4.17 1.83 2.03 1.39SQ

AAA 70-280 6.00 7.25 2.62 2.88 4.19 5.03 1.17 1.83 2.03 1.95SQ

AAA 70-280 8.00 7.25 2.62 2.88 5.19 6.03 2.17 1.83 2.03 1.95SQ

AAA 70-280 12.00 7.25 2.62 2.88 7.19 8.03 4.17 1.83 2.03 1.95 SQ

AA 425A 8.00 8.00 3.56 3.06 5.12 6.50 1.69 2.31 2.50 2.84 SQ

AA 425A 12.00 8.00 3.56 3.06 7.12 8.50 3.69 2.31 2.50 2.84 SQ

A 680A 24.00 15.00 4.12 3.50 13.25 14.88 9.38 2.62 2.88 2.84 SQ

B 1125 24.00 15.00 4.25 4.12 13.62 15.50 8.75 3.25 3.50 3.48 SQ

C 1370 24.00 16.00 5.62 4.62 13.75 16.38 7.88 4.12 4.38 3.48 SQ

C 1370 30.00 16.00 5.62 4.62 16.75 19.38 10.88 4.12 4.38 3.48 SQ

D

D

D

1032

Actuator

Size

2585 &

4580

2585 &

4580

2585 &

4580

2585 &

4580

2585 &

4580

2585 &

4580

J HW M DW EW FD GE NE ND

mm

610 406 152 162 371 430 186 119 125 117 SQ

762 406 152 162 448 506 262 119 125 117 SQ

914 406 152 162 524 583 338 119 125 117 SQ

Inches

24.00 16.00 5.97 6.38 14.62 16.94 7.31 4.69 4.94 4.60 SQ

30.00 16.00 5.97 6.38 17.62 19.94 10.31 4.69 4.94 4.60 SQ

36.00 16.00 5.97 6.38 20.62 22.94 13.31 4.69 4.94 4.60 SQ

22.2:1079

January 2013

KW Bolt

Pattern

7

Page 8

Product Bulletin

22.2:1079

January 2013

Ordering Information

When ordering, specify:

1. Manual actuator size

2. Handwheel size

3. Standard or optional mounting

1079 Manual Actuator

D500209X012

Neither Emerson, Emerson Process Management, nor any of their affiliated entities assumes responsibility for the selection, use or maintenance

of any product. Responsibility for proper selection, use,and maintenanceof any product remains solely with the purchaser andend user.

Fisher is a mark owned by one of the companies in the Emerson Process Management business unit of Emerson Electric Co. Emerson Process Management,

Emerson, and the Emerson logoare trademarks and service marks of Emerson Electric Co. All other marks are the property of their respective owners.

The contents of this publication are presented for informational purposes only, and while every effort has been made to ensure their accuracy, they arenot

to be construed as warranties or guarantees, express or implied, regarding the products or services described herein or their use or applicability. All sales are

governed by our terms and conditions, which are available upon request.We reservethe rightto modifyor improvethe designs or specifications ofsuch

products at any time without notice.

Emerson Process Management

Marshalltown, Iowa 50158 USA

Sorocaba, 18087 Brazil

Chatham, Kent ME4 4QZ UK

Dubai, United Arab Emirates

Singapore 128461 Singapore

www.Fisher.com

E 1993, 2013 Fisher ControlsInternational LLC. All rights reserved.

8

Loading...

Loading...