Page 1

Product Bulletin

61.8:1078

D101339X012

January 2009

1078 Manual Actuator

Fisherr 1078 Declutchable Manual Actuator

Fisherr 1078 manual actuators, figures 1 and 2, are

declutchable actuators for manual operation of

control valves and equipment that use power

actuators. The 1078 manual actuator mounts directly

to Fisher 1051 sizes 33, 40, and 60; 1052 sizes 33,

40, 60, and 70; 1061 sizes 30, 40, 60, 68, 80, and

100; and to all sizes of 1066 and 1066SR actuators.

For 1051 size 33, 1052 size 33, 1066, and 1066SR

actuators, coupling to the power actuator is via a

flatted shaft installed in the lever or hub. The

dimensions of these shafts are the same as those

used with H mounting adaptations. The stub shaft

fits into a square broach in the manual actuator

sector, and spacers secure the shaft in the

appropriate position.

W6244−1/IL

Figure 1. Fisherr 1078 Declutchable Manual Actuator

Mounted on a 1052 Size 33 Actuator

(Standard Construction)

www.Fisher.com

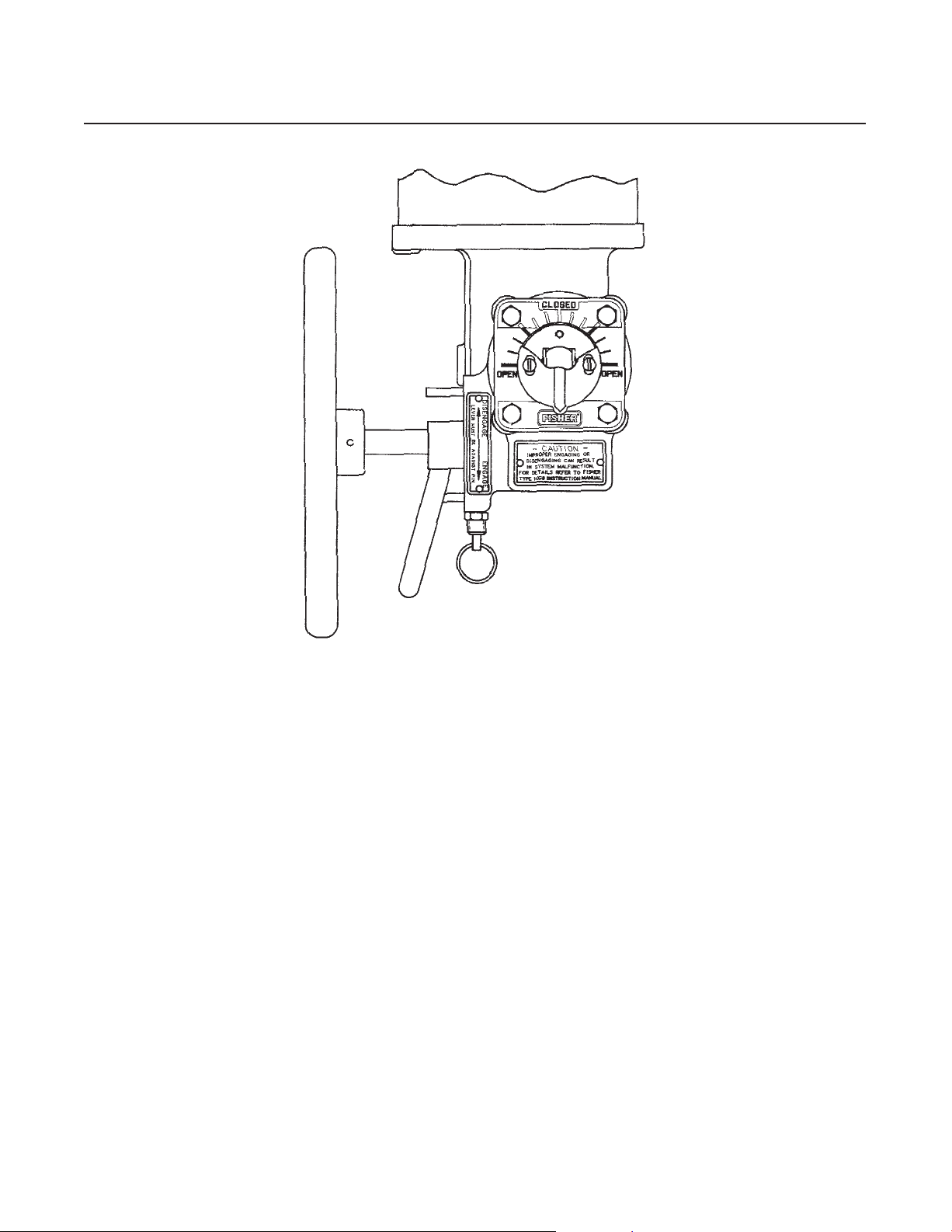

W6283/IL

Figure 2. Fisherr 1078 Declutchable Manual Actuator

Mounted on a 1052 Size 40 Actuator and V500 Valve

(Optional Construction)

D101339X012

Page 2

1078 Manual Actuator

Specifications

Product Bulletin

61.8:1078

January 2009

Available Configurations

Direct and reverse acting; see Handwheel

Rotation and the Ordering Information section,

(Standard construction is with the handwheel

shaft pointing down away from the power actuator

as shown in figure 1)

Manual Actuator Sizes

See tables 1, 2, 3 and 4

See figures 4 and 5 for dimensions

Coupling Shaft Diameters

See tables 1, 2, 3 and 4

Power Actuator Compatibility

See tables 1, 2, 3 and 4

Maximum Torque Output

See tables 1, 2, 3 and 4

Wheel-Rim Force

See tables 1, 2, 3 and 4

Handwheel Rotation

Clockwise handwheel rotation closes the valve.

Direct-acting units produce output rotation

matching input rotation; reverse-acting units

produce output rotation opposite input rotation.

Standard Mounting Positions

J1051 (size 33) or 1052 (size 33): Handwheel

down (see figure 1)

J1051 (size 40 and 60) (see figure 2) or 1052

(size 40, 60, and 70)

handwheel right-hand or left-hand mount

(optional)

J1061 (sizes 30, 40, 60, 68, 80, and 100)

Handwheel down (std) or handwheel right-hand or

left-hand mount (optional)

J1066 or 1066SR: Handwheel to left (see figure

3) or, with a 67AFR, handwheel down

Approximate Weight Without Handwheel

Size AAA: 2.7 kg (6 pounds)

Size AA: 6.8 kg (15 pounds)

Size A: 9.5 kg (21 pounds)

Size 2A: 13.6 kg (30 pounds)

Size 1A: 15.9 kg (35 pounds)

Size B: 23.1 kg (51 pounds)

Size C: 29.9 kg (66 pounds)

Size D: 63.5 kg (140 pounds)

Size

II-FA: 81.6 kg (180 pounds)

Handwheel Weight

(1)

: Handwheel down (std) or

(1)

:

Construction Materials

Housing and Cover: Cast iron

Drive Sleeve/Gear (Sector): Aluminum/bronze

Worm Gear: Heat-treated steel

Input Shaft and Eccentric: Low-carbon steel

Pin Detent: 300 Series stainless steel

Handwheel or Input Shaft Bearings: Bronze

1. If a positioner is used, the right-hand or left-hand mounting option will be limited to the side away from the positioner.

2

6-inch: 1.8 kg (4 pounds)

8-inch: 2.3 kg (5 pounds)

12-inch: 3.2 kg (7 pounds)

16-inch: 6.8 kg (15 pounds)

24-inch: 5.4 kg (12 pounds)

30-inch: 6.4 kg (14 pounds)

36-inch: 7.3 kg (16 pounds)

Page 3

Product Bulletin

61.8:1078

January 2009

1078 Manual Actuator

41B0314-A / DOC

Figure 3. Fisherr 1078 Declutchable Manual Actuator Mounted on a 1066 Actuator

Features

DDirect Attachment to the Power

ActuatorDirect mounting to the actuator housing

simplifies installation and eliminates the need for yokes

and other brackets.

DEngage Manual Actuator At Any Point of

RotationA lever-operated eccentric bearing

support on the input shaft allows engagement of the

worm gear with the sector at any point of rotation.

Because the travel indicator components are

mounted on a through shaft, accurate travel

indication is maintained during manual actuator

disengagement or engagement.

DPositive OperationThe disengagement

lever is locked in both the engaged and disengaged

positions by a detent mechanism, which must be

released before the lever can be moved. This

provision reduces the possibility of inadvertent or

accidental operation. In addition, stop-pins at the

fully engaged and fully disengaged positions provide

positive limits for lever travel. (Note that stop pins

are not available on 1078 size

II-FA actuators.)

3

Page 4

Product Bulletin

1078 Manual Actuator

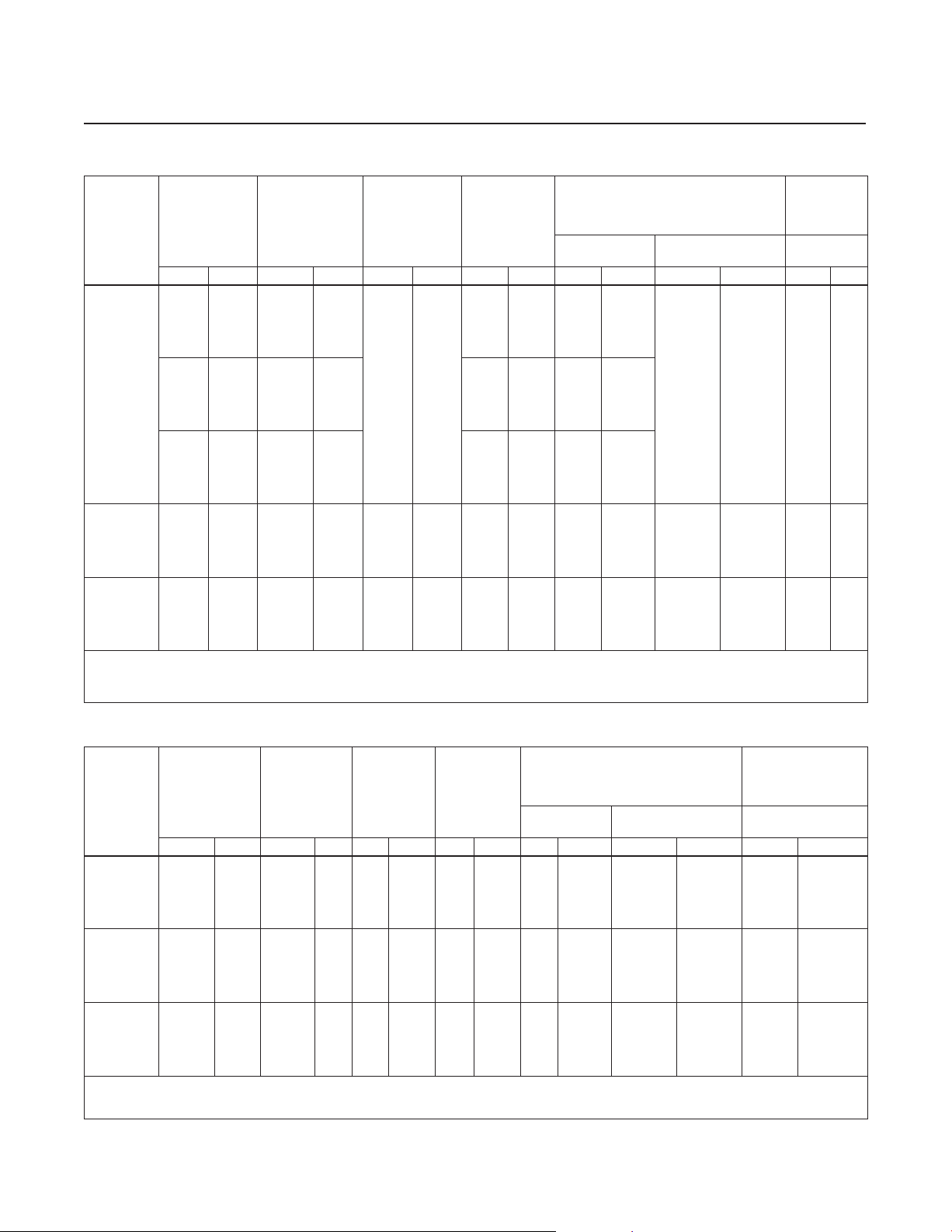

Table 1. Fisherr 1051, 1052, and 1066SR Actuator Size Selection and Specifications for Sizes AAA, AA, and A

MANUAL

ACTUATOR

SIZE

(max output

torque)

AAA

(2400 in.lbs)

AA

(4800 in.lbs)

A

(8200 in.lbs)

1. Requires flatted shaft as in the H mounting adaptation.

2. Field conversion of actuators for F and G mounting adaptations requires installation of new parts. The 1051 or 1052 Size 33 actuator requires installation of appropriate lever and stub

shaft. The 1066 actuator requires installation of appropriate hub assembly.

3. Compare table value with torque requirements of the valve plus the torque required to compress the power actuator spring (from Fisher Catalog 14). Note that dynamic torque of the

valve may have a positive or negative effect on total torque required.

SHAFT SIZE

mm Inch Type Size mm Inch

12.7

15.9

19.1

(22.2,

25.4)

12.7

15.9

19.1

(22.2,

25.4)

12.7

15.9

19.1

(22.2,

25.4)

12.7

15.9

19.1

(22.2,

25.4)

12.7

22.2,

25.4)

(31.8,

38.1)

(1)

1/2

5/8

3/4

(7/8,

1)

1/2

5/8

3/4

(7/8,

1)

1/2

5/8

3/4

(7/8,

1)

1/2

5/8

3/4

(7/8,

1)

3/4

(7/8,

1)

(1-1/4,

1-1/2)

POWER

ACTUATOR

1051 33

1052 33

1066SR 20

1066SR 27 305 12

1066SR 75 610 24

(2)

STANDARD

HANDWHEEL

DIAMETER

305 12

MAXIMUM

TORQUE

NSm LbfSin

143

223

271

271

190

270

271

271

169

249

271

271

283

363

464

541

717

926

926

(3)

1271

1981

2400

2400

1681

2391

2400

2400

1495

2205

2400

2400

2515

3225

4120

4800

6350

8200

8200

WHEEL-RIM-FORCE

For Maximum

Torque

N Pounds N Pounds 60 90

157

245

298

298

209

297

298

298

186

274

298

298

218

279

357

416

299

385

385

35

55

67

67

47

66

67

67

42

61

67

67

49

63

81

94

66

85

85

For Less Than

Maximum Torque

Divide

NSm req’d

by 0.91

Divide

NSm req’d

by 1.3

Divide

NSm req’d

by 2.4

req’d by

req’d by

req’d by

Divide

lbfSin

36

Divide

lbfSin

51

Divide

lbfSin

96

61.8:1078

January 2009

HAND-

WHEEL

TURNS FOR

ROTATION

Degrees

4 6

5.7 8.5

5.3 8

Table 2. Fisherr 1066 Actuator Size Selection and Specifications for Sizes AAA, AA, and A

STANDARD

MANUAL

ACTUATOR

SIZE

(max output

torque)

AAA

(2400 in.lbs)

AA

(4800 in.lbs)

A

(8200 in.lbs)

1. Requires flatted shaft as in the H mounting adaptation.

2. Field conversion of actuators for F and G mounting adaptations requires installation of new parts. The 1066 actuator requires installation of appropriate hub assembly.

3. Compare table value with torque requirements of the valve (from Fisher Catalog 14). Note that dynamic torque of the valve may have a positive or negative effect on total torque

required.

4

SHAFT SIZE

mm Inch Type Size mm Inch

12.7

15.9

19.1

(22.2,

25.4)

12.7

15.9

19.1

(22.2,

25.4)

12.7

(22.2,

25.4)

(31.8,

38.1)

(1)

1/2

5/8

3/4

(7/8,

1)

1/2

5/8

3/4

(7/8,

1)

3/4

(7/8,

1)

(1-1/4,

1-1/2)

POWER

ACTUATOR

1066 20 305 12

1066 27 305 12

1066 75 610 24

(2)

HAND-

WHEEL

DIAMETER

MAXIMUM

TORQUE

NSm LbfSin

58

138

239

271

58

138

239

467

239

467

926

(3)

515

1225

2120

2400

515

1225

2120

4140

2120

4140

8200

WHEEL-RIM-FORCE

For Maximum

Torque

N Pounds N Pounds 60 90

62

44

98

14

34

59

67

10

24

41

81

22

43

85

151

262

298

106

182

360

191

385

For Less Than

Maximum Torque

Divide

NSm req’d

by 0.91

Divide

NSm req’d

by 1.3

Divide

NSm req’d

by 2.4

req’d by

req’d by

req’d by

Divide

lbfSin

36

Divide

lbfSin

51

Divide

lbfSin

96

HANDWHEEL

TURNS FOR

ROTATION

Degrees

4 6

5.7 8.5

5.3 8

Page 5

Product Bulletin

61.8:1078

January 2009

Table 3. Fisherr 1051and 1052 Actuator Size Selection and Specifications for Sizes 2A, 1A, B, and C

STANDARD

MANUAL

ACTUATOR

SHAFT SIZE

POWER

ACTUATOR

SIZE

(max output

torque)

mm Inch Type Size mm Inch

12.7 1/2

2A

(4800 in.lbs)

15.9,

14.3x

9.5

19.1 3/4

(22.2,

25.4)

31.8 1-1/4 541 4800 416 94

5/8,

5/8

1051

1052

(4)

40

9/16x

(7/8,1) 467

12.7 1/2

1A

(8200 in.lbs)

15.9,

14.3x

9.5

19.1 3/4

(22.2,

25.4)

31.8 1-1/4

19.1 3/4

(22.2,

25.4)

31.8 1-1/4

31.8,

28.6x

31/8

38.1

31.8x

38.1

(44.4,

50.8),

39.7

x44.5

5/8,

9/16x

5/8

1051

1052

(3)

40 305 12

(7/8,1) 467

1051

1052

1051

(7/8,1)

10524060

1051

10524060

1-1/4,

1-1/8x

1-1/4

1-1/2,

1-1/4x

1-1/2

1051

10526070

(1-3/4,

2),

1-9/16

x1-3/4

3/4

B

31.8

(12,000

in.lbs)

38.1,

(44.4,

50.8)

C

31.8 1-1/4

(18,000

in.lbs)

(44.4,

50.8)

1. Field conversion of actuators for F and G mounting adaptations requires installation of new parts. The 1051 or 1052 Size 33 actuator requires installation of appropriate lever and stub

shaft.

2. Compare table value with torque requirements of the valve plus the torque required to compress the power actuator spring (from Fisher Catalog 14). Note that dynamic torque of the

valve may have a positive or negative effect on total torque required.

3. 2A 3/4 inch shaft will also mount on the 1051 and 1052 size 60.

4. Maximum torque of connection between power and manual actuator.

5. If mounted on the 1051 and 1052 Size 70, the Travel is for only 60 Degrees.

7/8-1

1-1/4

1-1/2,

(1-3/4,

2)

(1-3/4,

2)

1051

10526070

1051

10526070

HAND-

(1)

WHEEL

MAXIMUM

TORQUE

(2)

DIAMETER

NSm LbfSin

203 8 380 3365 441 99

460 4075 354 80

305 12

541 4800 416 94

(4)

4140

(4)

429 3795 330 74

509 4505 392 88

541 4800 416 94

(4)

4140

(4)

541 4800 416 94

610 24 929 8200 378 85

(5)

610 24 1356 12,000 369 83

1735 15,355 361 79

1839 16,275 383 84

610 24

2034 18,000 414 93

2034 18,000 414 93

For Maximum

N Pounds N Pounds 60 90

360 81

360 81

1078 Manual Actuator

WHEEL-RIM-FORCE

Torque

For Less Than

Maximum Torque

Divide

NSm req’d

by 0.86

req’d by

Divide

NSm req’d

by 1.3

req’d by

Divide

NSm req’d

by 1.3

req’d by

Divide

NSm req’d

by 2.4

req’d by

Divide

NSm req’d

by 3.6

req’d by

Divide

NSm req’d

by 4.8

req’d by

Divide

lbfSin

34

Divide

lbfSin

51

Divide

lbfSin

51

Divide

lbfSin

96

Divide

lbfSin

144

Divide

lbfSin

194

HANDWHEEL

TURNS FOR

5.7 8.5

5.3 8

6.7 10

9 13.5

ROTATION

Degrees

5

Page 6

Product Bulletin

1078 Manual Actuator

Table 4. Fisherr 1061 Actuator Size Selection and Specifications for Sizes 2A, 1A, B, C, D, and II-FA

STANDARD

MANUAL

ACTUATOR

SHAFT SIZE

POWER

ACTUATOR

SIZE

(max output

torque)

mm Inch Type Size mm Inch

12.7 1/2

15.9,

14.3x

9.5

2A

(4800 in.lbs)

1A

(8200 in.lbs)

B

(12,000

in.lbs)

C

(18,000

in.lbs)

D

(30,000

in.lbs)

(2)

II-FA

(60,000

in.lbs)

1. Compare table value with torque requirements of the valve (from Fisher Catalog 14). Note that dynamic torque of the valve may have a positive or negative effect on total torque

required.

2. Has spur gear.

3. 2A 3/4 inch shaft will also mount on the 1061 size 40, 60, and 68.

4. Maximum torque of connection between power and manual actuator.

19.1

(22.2,

25.4)

31.8 1-1/4 541 4800 416 94

19.1 3/4

(22.2,

25.4)

31.8,

28.6x

31/8

38.1

31.8x

38.1

(44.4,

50.8),

39.7

x44.5

19.1 3/4

22.2,

25.4

31.8 1-1/4

38.1,

(44.4,

50.8)

31.8 1-1/4

(44.4,

50.8)

(44.4,

50.8)

54,

63.5

57.2x

63.5

76x

63.5,

101.6x

63.5

76x

63.5,

101.6x

63.5

5/8,

9/16x

5/8

1061 30

(3)

3/4

(7/8,1)

1051,

1061

(7/8,1) 1061 467 4140 382 86

1-1/4,

1-1/8x

1-1/4

1-1/2,

1-1/4x

1-1/2

(1-3/4,

1-9/16

x1-3/4

7/8,1 468 4140 130 29

1-1/2,

(1-3/4,

(1-3/4,

(1-3/4,

2-1/8,

2-1/2,

2-1/4x

2-1/2

1/2,4x

2 1/2

1/2,4x

2 1/2

1061

2),

1061

1061

2)

1061

2)

2)

1061

3x2

1061

3x2

1061

40,

60,

68

40,

60,

68

40,

60,

68

40,

60,

68

80,

100

80,

100

HAND-

WHEEL

MAXIMUM

TORQUE

(1)

WHEEL-RIM-FORCE

DIAMETER

For Maximum

Torque

NSm LbfSin

58 515 89 20

152 6

203 8 239 2120 276 62

305 12

305 12

610 24 929 8200 378 85

610 24

610 24

762 30 2658 23,524 369 82

914 36 3390 30,000 394 87

406 16 6301 55,762 400 90

138 1225 214 48

(4)

467

4140

239 2120 276 62

239 2120 66 15

1109 9815 308 68

1356 12,000 377 83

1109 9815 231 51

2034 18,000 424 93

N Pounds N Pounds 60 90

(4)

360 81

For Less Than

Maximum Torque

Divide

NSm req’d

by 0.66

Divide

NSm req’d

by 0.86

Divide

NSm req’d

by 1.3

Divide

NSm req’d

by 1.2

Divide

NSm req’d

by 2.4

Divide

NSm req’d

by 3.6

Divide

NSm req’d

by 4.8

Divide

NSm req’d

by 7.2

Divide

NSm req’d

by 8.6

Divide

NSm req’d

by 15.7

Divide

lbfSin req’d

Divide

lbfSin req’d

Divide

lbfSin req’d

Divide

lbfSin req’d

Divide

lbfSin req’d

Divide

lbfSin req’d

by 144

Divide

lbfSin req’d

by 194

Divide

lbfSin req’d

by 287

Divide

lbfSin req’d

by 345

Divide

lbfSin req’d

by 619

by 26

by 34

by 51

by 48

by 96

61.8:1078

January 2009

HANDWHEEL

TURNS FOR

ROTATION

Degrees

5.7 8.5

5.3 8

5.3 8

6.7 10

9 13.5

10.7 16

48 72

6

Page 7

Product Bulletin

61.8:1078

January 2009

Table 5. Dimensions for Actuator Sizes AAA, AA, and A

1078

Size

AAA 20, 33 305 184 40 67 178 204 106 46 51 57.1 SQ − − −

AA 27 305 203 56 70 181 216 94 59 64 76.2 SQ − − −

A 75 610 381 68 83 337 378 238 67 73 88.9 SQ − − −

AAA 20, 33 12.00 7.25 1.56 2.62 7.00 8.02 4.18 1.82 2.02 2.25 SQ − − −

AA 27 12.00 8.00 2.19 2.75 7.12 8.50 3.69 2.31 2.50 3.00 SQ − − −

A 75 24.00 15.00 2.69 3.25 13.25 14.88 9.38 2.63 2.88 3.50 SQ − − −

ROTARY

ACTUATOR

SIZE

A B C D E F G H J

mm

Inches

1078 Manual Actuator

Square

Bolt

Pattern

Circular

Bolt

Pattern

11B2634-C

A5431-1 / IL

Figure 4. Dimensions for Actuator Sizes AAA, AA, and A (also see table 5)

7

Page 8

Product Bulletin

1078 Manual Actuator

Table 6. Dimensions for Actuator Sizes 2A, 1A, B, C, D, and II-FA

1078

Size

2A

1A

B

C 610 254 102 149 400 416 200 105 111

D

II-FA 406 356 11 7 203 337 328 84 119 125

2A

1A

B

C 24.00 10.00 4.00 5.88 15.75 16.38 7.88 4.12 4.38

D

II-FA 16.00 14.00 4.62 8.00 13.25 12.94 3.31 4.69 4.94

A B C D E F G H J

mm

152 230 55.4 116 155 140 17.5 58.7 63.5

203 181 165 42.9

305 232 216 93.7

305 229 68.3 124 235 229 82.6 69.9 76.2

610 387 381 235

203 229 84.1 140 194 191 19.1 82.6 88.9

305 244 241 69.9

610 397 394 222

762 254 11 7 203 505 506 262 11 9 125

914 581 583 338

Inches

6.00 8.00 2.18 4.56 6.12 5.5 0.69 2.31 2.50

8.00 7.12 6.5 1.69

12.00 9.12 8.5 3.69

12.00 9.00 2.69 4.88 9.25 9.00 3.25 2.75 3.00

24.00 15.25 15.00 9.25

8.00 9.00 3.31 5.50 7.62 7.50 0.75 3.25 3.50

12.00 9.62 9.50 2.75

24.00 15.62 15.50 8.75

30.00 10.00 4.62 8.00 20.25 19.94 10.31 4.69 4.94

36.00 23.25 22.94 13.31

January 2009

61.8:1078

8

Page 9

Product Bulletin

61.8:1078

January 2009

1078 Manual Actuator

ENGAGED

G

ENGAGED

E

D

G

DISENGAGED

ENGAGED

CB

H ENGAGED

J DISENGAGED

SIZES 2A, 1A, B, C, D

E

D

DISENGAGED

B

C

B2463 / IL

135_

H ENGAGED

J DISENGAGED

SIZE II-FA

ENGAGED

Figure 5. Dimensions for Actuator Sizes 2A, 1A, B, C, D, and II-FA (also see table 6)

9

Page 10

1078 Manual Actuator

Product Bulletin

61.8:1078

January 2009

Ordering Information

Whenever a power actuator is ordered with a 1078

manual actuator, all components are configured and

mounted according to specifications of the order.

Size AAA, AA, and A

Field installation of the 1078 onto existing actuators

with F or G mounting adaptations requires

installation of new power actuator parts. (The F and

G mounting adaptations are the mounting methods

normally used to mount 1051, 1052, 1066 and

1066SR actuators on Fisher valves.) For the 1051 or

1052 size 33, a lever with stub shaft must be

installed. For the 1066 or 1066SR actuator, a hub

assembly with stub shaft must be installed. Field

installation on power actuators with H mounting

adaptations requires dual stub shaft construction

(standard on the 1066 or 1066SR actuator). (The H

mounting adaptation is the mounting method

normally used to mount 1051, 1052, 1066 and

1066SR actuators on equipment and valves other

than Fisher valves.) Installation of a valve to bypass

cylinder or diaphragm pressure during manual

operation is also recommended.

Table 7. Handwheel/Valve Shaft Rotation

1078 ACTUATOR ACTION

VALV E

Right-Hand Left-Hand

8510, 8522,

8532, 8560,

and 9500

V150, V200,

and V300

V250

V500 and

CV500

1. Direct acting is when the clockwise handwheel rotation produces clockwise

valve shaft rotation to close the valve.

2. Reverse acting is when the clockwise handwheel rotation produces counter

clockwise valve shaft rotation to close the valve.

3. A left hand ball will be required for the NPS 3 through 12 series B and the NPS

14 through 20, with or without an attenuator.

Direct Acting

Reverse

Acting

Reverse

Acting

Reverse

Acting

Actuator Mounting

(1)

Direct Acting NA

(2)

Reverse

Direct Acting NA

Reverse

Acting

Acting

Left-Hand

(Optional)

Direct Acting

NA

(3)

When ordering, specify:

1. Power actuator type and size, and valve shaft

size.

2. Right or left hand mounting and desired mounting

position.

3. Direct or reverse acting manual actuator

construction. Refer to the mounting positions shown

in the appropriate actuator bulletin and order

according to the guidelines in table 7.

Size 2A, 1A, B, C, D, and

II-FA

Field installation of the 1078 onto the following

existing actuators with F or G mounting adaptations

[1051 (sizes 40 and 60), 1052 (sizes 40, 60, and 70),

and 1061 (sizes 30, 40, 60, 68, 80, and 100)]

requires additional parts in most cases. Remove the

cover and hub and then replace with the 1078

actuator. Most assemblies require a new lever and

splined adaptor.

Note

Neither Emerson, Emerson Process

Management, nor any of their affiliated

entities assumes responsibility for the

selection, use, or maintenance of any

product. Responsibility for the

selection, use, and maintenance of any

product remains with the purchaser

and end-user.

10

Page 11

Product Bulletin

61.8:1078

January 2009

1078 Manual Actuator

11

Page 12

1078 Manual Actuator

Product Bulletin

61.8:1078

January 2009

Fisher is a mark owned by one of the companies in the Emerson Process Management business division of Emerson Electric Co. Emerson

Process Management, Emerson, and the Emerson logo are trademarks and service marks of Emerson Electric Co. All other marks are the property

of their respective owners.

The contents of this publication are presented for informational purposes only, and while every effort has been made to ensure their accuracy, they

are not to be construed as warranties or guarantees, express or implied, regarding the products or services described herein or their use or

applicability. All sales are governed by our terms and conditions, which are available upon request. We reserve the right to modify or improve the

designs or specifications of such products at any time without notice. Neither Emerson, Emerson Process Management, nor any of their affiliated

entities assumes responsibility for the selection, use or maintenance of any product. Responsibility for proper selection, use, and maintenance of

any product remains solely with the purchaser and end-user.

Emerson Process Management

Marshalltown, Iowa 50158 USA

Sorocaba, 18087 Brazil

Chatham, Kent ME4 4QZ UK

Dubai, United Arab Emirates

Singapore 128461 Singapore

www.Fisher.com

12

EFisher Controls International LLC 1989, 2009; All Rights Reserved

Loading...

Loading...