Page 1

1077 Handwheel Actuator

D101625X012

Fisherr 1077 Manual Handwheel

Rotary Actuator

Fisher 1077 manual-only handwheel actuator is for use

with rotary-shaft valves such as the 9500 butterfly

valve; 8532, 8560, and 8580 eccentric disc valves;

V150, V200 and V300 Vee-Ballt valves; V250 valves;

and CV500 and V500 valves. Figure 1 shows the

gearbox of the actuator. In this actuator, torque is

transmitted from the handwheel through the

handwheel input shaft to a worm and drive sleeve gear

(sector) with splined bore. The worm and drive sleeve

gear multiply the torque and transmit it to a splined

valve shaft or splined stub shaft. The size 10-KE:6

actuator additionally has a spur gear reduction drive

for increased torque capability.

W8176-1

Fisher 1077 Handwheel Actuator

Product Bulletin

61.8:1077

July 2012

Features

Easy to Install and Maintain–Splined valve shaft

mates directly with the drive gear sleeve, reducing

the number of parts required and simplifying

installation and maintenance.

Easy to Operate–Handwheel rotation direction

required to open the valve disc or ball is marked on

the handwheel; the rotation indicator is marked in

bold print at the open and closed positions and with

bold incremental lines to indicate the valve disc or

ball position.

Consistency of Operation–When installed

according to instructions, clockwise handwheel

rotation closes the valve in all applications.

Accurate Valve Disc or Ball P ositioning–Travel stops

can be adjusted and locked in place to provide

accurate disc or ball positioning at closed

(0-degree) and open (90-degree) positions. Travel

stops for 60-degree operation may be used to

establish a disc or ball closing stop at any angle

Figure 1. Gearbox Subassembly

DRIVESLEEVEGEARAND

HUB

WORM

W4580

between 0 and 30 degrees and/or to establish a disc or

ball opening stop at any angle between 60 and 90

degrees. This option is available on sizes 2-KE and 7-KE

as a set screw change. For sizes 0-KE, 6-KE, 9-KE, and

10-KE:6, a different actuator is required when

changing from 90-degree to 60-degree ball rotation.

TRAVEL

STOPS

www.Fisher.com

Page 2

Product Bulletin

61.8:1077

July 2012

Specifications

1077 Handwheel Actuator

D101625X012

Available Configuration

Manual-only handwheel actuator for use with splined

and keyed rotary-shaft valves

Actuator Sizes

See tables 1 and 2

Acceptable Valve Shaft Diameters

See tables 1 and 2

Output Torque

See tables 1 and 2

Wheel-Rim Force

See tables 1 and 2

Handwheel Turns Required for Full Rotation

See tables 1 and 2

Handwheel Rotation

Direct Acting Construction: Clockwise handwheel

rotation closes the valve (produces clockwise rotation

of the valve shaft) as shown in figure 2.

Reverse Acting Construction: Clockwise handwheel

rotation closes the valve (produces counterclockwise

rotation of the valve shaft) as shown in figure 2.

Maximum Output Rotation

Standard: 90 degrees

Optional: 60 degrees

J valve ball or disc closed

position may be set to any angle between 0 and 30

degrees, and/or

J valve ball or disc open position

may be set to any angle between 60 and 90 degrees.

(This option is available on actuator sizes 2-KE and

7-KE as a set screw change. For sizes 0-KE, 6-KE, 9-KE,

and 10-KE:6, a different actuator is required when

changing from 90-degree to 60-degree ball rotation.)

Construction Materials

Housing: Cast iron

Housing Cover: Cast iron

Worm: Steel

Drive Sleeve Gear:

For Sizes 0-KE through 7-KE: Phosphor bronze sector

with steel hub

For Sizes 9-KE and 10-KE:6: Manganese bronze sector

with ductile iron hub

Worm Gear Shaft and Handwheel Shaft: Steel

Handwheel:

Through 431 mm (16-Inch) Diameter:Castiron

Over 431 mm (16-Inch) Diameter: Fabricated steel

Mounting Yoke

For N PS 30 and 36 8510, NPS 16 V250, and any other

valve with 76.2 or 88.9 mm (3 or 3-1/2 Inch) Shaft

Diameter:Castiron

For All Valve Bodies Other Than Those Listed Above:

Painted steel

Mounting Positions

J Right-hand (actuator on the right side of the valve

when viewed from the valve inlet) or

J Left-hand

(actuator on the left side of the valve when viewed

from the valve inlet). Position 1 as shown in figure 3 is

standard; however, the actuator may be m ounted in

any of the positions shown in figure 3. Refer to figure 2

to determine the correct actuator construction.

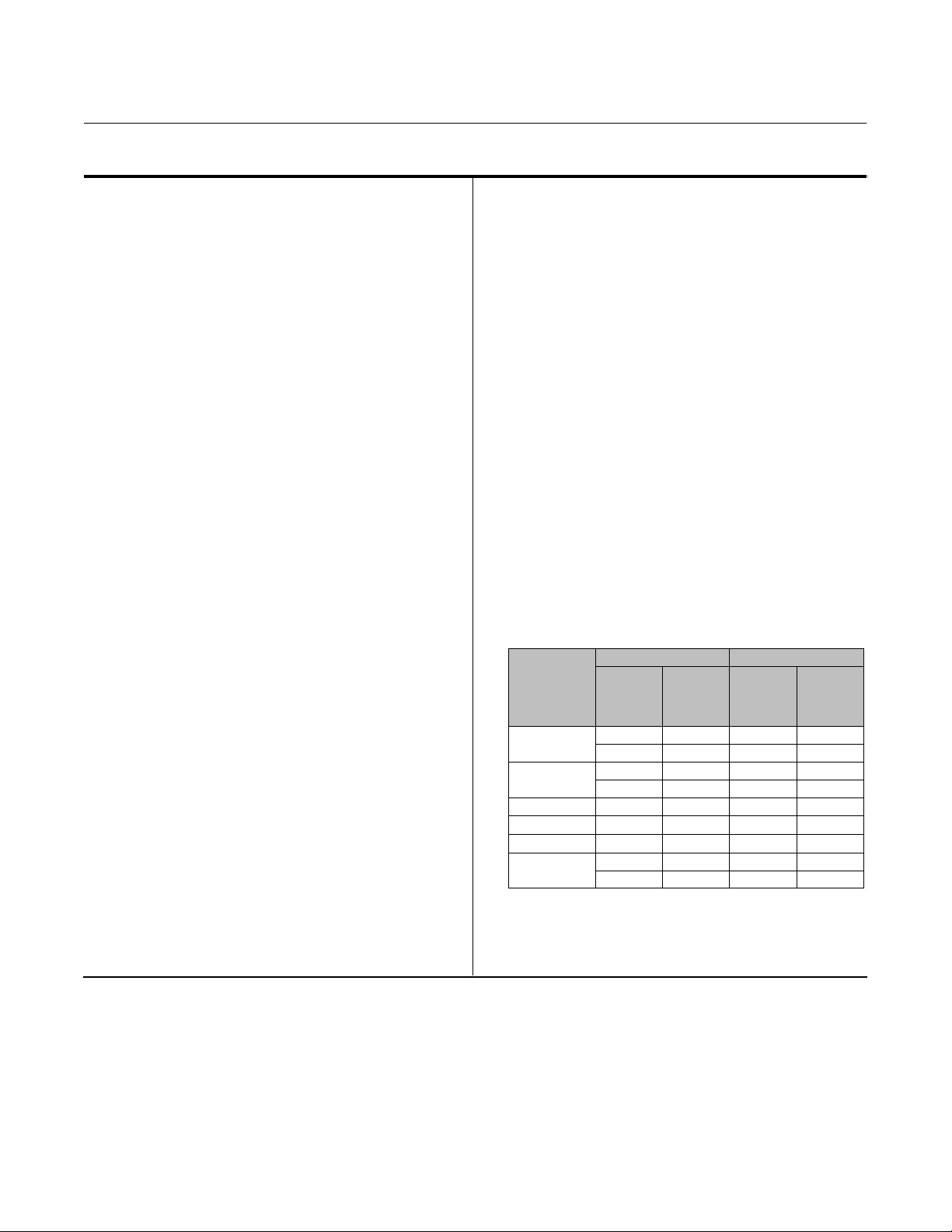

Approximate Weight

METRIC UNITS U.S. UNITS

ACTUATOR

0-KE

2-KE

6-KE 610 20.2 24 43

7-KE 762 28.2 30 60

9-KE 914 40.9 36 87

10-KE:6

Handwheel

Diameter,

mm

152 3.7 6 8

203 4.7 8 10

203 10.3 8 22

305 11.3 12 24

432 62.6 16 133

610 62.6 24 133

Weight of

Actuator

Assembly,

kg

Handwheel

Diameter,

Inches

Weight of

Actuator

Assembly,

Pounds

Accessories

Position and Limit Switches:

or

J One or two limit switches, can be mounted

J One position switch,

2

Page 3

Product Bulletin

1077 Handwheel Actuator

D101625X012

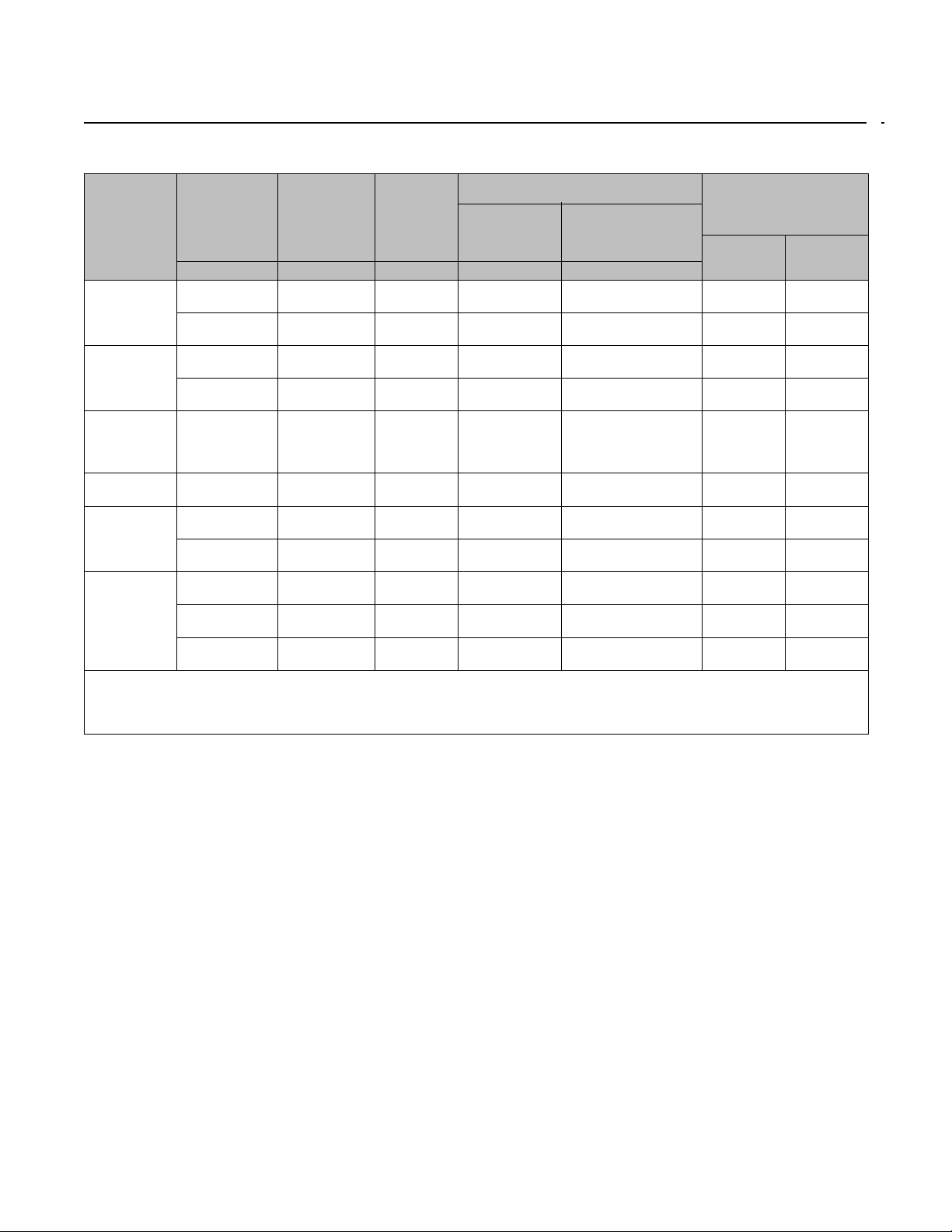

Table1.ActuatorSizeSelection (Metric Units)

WHEEL-RIM FORCE

ACTUATOR

SIZE

ACCEPTABLE

VALVE SHAFT

DIAMETER

MAXIMUM

ALLOWABLE

TORQUE

(1)

HANDWHEEL

DIAMETER

To Produce

Maximum

Allowable

Torque

To Produce Torque

Lower Than Maximum

Allowable Shaft Torque

mm NSm mm N N

12.7

0-KE

15.9

19.1

22.2 and 25.4

22.2 and 25.4 468 203 485

2-KE

31.8

38.1

31.8

6-KE

38.1

44.5

50.8

7-KE

44.5

50.8

44.5

9-KE

50.8

63.5 3390

63.5 6305 431 431

10-KE:6

76.2 6780

88.9 6780

1. Values shown are the maximum allowable torque of a splined valve shaft except where indicated. Without regard to the shaft, maximum allowable torque output is 271 NSmforthesize

0-KE actuator, 678 N

10-KE:6 actuator.

2. Limited to this value by the maximum allowable output torque of the actuator.

3. Wheel-rim force required to produce maximum actuator output torque.

4. Handwheel is 152 mm (6-inch) diameter for keyed-shaft constructions.

Smforthesize2-KEactuator,1360NSmforthesize6-KEactuator,2260NSmforthesize7-KEactuator,3390N•mforthesize9-KEactuator,and6780NSmforthesize

58

138

240

271

678

678

1110

1360

1360

1360

2260

2260

2260

2260

152

152

(4)

(2)

203

203

129

307

396

445

Torque Req'd

(NSm) ÷ 0.4572

(3)

Torque Req'd

(NSm) ÷ 0.6096

Torque Req'd

(NSm) ÷ 0.9652

(2)

(2)

305

305

610

(2)

(2)

(2)

(2)

610

610

610

762

762

762

762

(2)

914 463

467

467

365

445

445

445

440

440

436

436

(3)

(3)

(2)

(2)

(3)

(3)

Torque Req'd

(NSm) ÷ 1.4478

Torque Req'd

(NSm) ÷ 3.0480

Torque Req'd

(NSm) ÷ 5.1435

Torque Req'd

(NSm) ÷ 6.096

(3)

Torque Req'd

(NSm) ÷ 7.3152

Torque Req'd

(NSm) ÷ 15.476

(2)

(2)

610 310

610 310

(3)

(3)

Torque Req'd

(NSm) ÷ 21.848

Torque Req'd

(NSm) ÷ 21.848

HANDWHEEL TURNS

REQUIRED FOR FULL VALVE

DISC OR BALL ROTATION

60-Degree

Rotation

4 6

4 6

6-1/2 9-1/2

6-1/2 9-1/2

6-1/2 10

9 13-1/2

10-1/2 16

10-1/2 16

48 72

48 72

48 72

61.8:1077

July 2012

90-Degree

Rotation

3

Page 4

Product Bulletin

61.8:1077

July 2012

Table2.ActuatorSizeSelection(U.SUnits)

WHEEL-RIM FORCE

ACCEPTABLE

ACTUATOR

SIZE

VALVE SHAFT

DIAMETER

Inches Inch-Pounds Inches Pounds Pounds

1/2

0-KE

5/8

3/4

7/8 and 1

7/8 and 1 4140 8 109

2-KE

1-1/4

1-1/2

1-1/4

6-KE

1-1/2

1-3/4

2

7-KE

1-3/4

2

1-3/4

9-KE

2

2-1/2 30,000

2-1/2 55,762 16 97

10-KE:6

3 60,000

3-1/2 60,000

1. Values shown are the maximum allowable torque of a splined valve shaft except where indicated. Without regard to the shaft, maximum allowable torque output is 2400 inch-pounds for the

size 0-KE actuator, 6000 inch-pounds for the size 2-KE actuator, 12,000 inch-pounds for the size 6-KE actuator, 20,000 inch-pounds for the size 7-KE actuator, 30,000 inch-pounds for the size

9-KE actuator, and 60,000 inch-pounds for the size 10-KE:6 actuator.

2. Limited to this value by the maximum allowable output torque of the actuator.

3. Wheel-rim force required to produce maximum actuator output torque.

4. Handwheel is 152 mm (6-inch) diameter for keyed-shaft constructions.

MAXIMUM

ALLOWABLE

TORQUE

(1)

515

1225

2120

(2)

2400

(2)

6000

(2)

6000

9820

12,000

(2)

12,000

(2)

12,000

(2)

20,000

(2)

20,000

23,524

23,524

(2)

(2)

(2)

HANDWHEEL

DIAMETER

6

6

(4)

8

8

12

12

24

24

24

24

30

30

30

30

36 104

24 69

24 69

To Produce

Maximum

Allowable

Torque

29

69

89

(3)

100

(3)

105

(3)

105

82

100

(3)

100

(3)

100

(3)

99

(3)

99

98

98

(3)

(3)

(3)

To Produce Torque

Lower Than Maximum

Allowable Shaft Torque

(In.-Lb.) ÷ 18.00

(In.-Lb.) ÷ 24.00

(In.-Lb.) ÷ 38.00

(In.-Lb.) ÷ 57.00

(In.-Lb.) ÷ 120.00

(In.-Lb.) ÷ 202.50

(In.-Lb.) ÷ 240.00

(In.-Lb.) ÷ 288.00

(In.-Lb.) ÷ 612.00

(In.-Lb.) ÷ 864

(In.-Lb.) ÷ 864

1077 Handwheel Actuator

D101625X012

HANDWHEEL TURNS

REQUIRED FOR FULL VALVE

DISC OR BALL ROTATION

60-Degree

Rotation

Torque Req'd

Torque Req'd

Torque Req'd

Torque Req'd

Torque Req'd

Torque Req'd

Torque Req'd

Torque Req'd

Torque Req'd

Torque Req'd

Torque Req'd

4 6

4 6

6-1/2 9-1/2

6-1/2 9-1/2

6-1/2 10

9 13-1/2

10-1/2 16

10-1/2 16

48 72

48 72

48 72

90-Degree

Rotation

4

Page 5

1077 Handwheel Actuator

D101625X012

Table 3. Direct and Reverse Acting Actuator Constructions

VALVE SERIES OR DESIGN VALVE SERIES OR DESIGN

MOUNTING

Right-Hand

Left-Hand

Left-Hand

(Optional)

1. A left hand ball will be required for the NPS 3 through 12 Series B and the NPS 14 to 20, with or without attenuator.

(1)

Figure 2. Direct and Reverse Acting Actuator Constructions (also see table 3)

Ball/Plug

Rotation To

Close

CCW

CCW

CCW

CCW

CW

CW

V250 V150, V200 and V300

REVERSE REVERSE REVERSE

NA

NA

NA

NA

REVERSE REVERSE

DIRECT

CV500

V500

NA

NA

Disc/Ball

Rotation To

Close

CW

CW

CW

CW

NA

NA

Product Bulletin

61.8:1077

July 2012

V250

NA

NA

DIRECT DIRECT

NA

NA

8532, 8560

8580, and 9500

DIRECT

NA

NA

40B1561-A

DIRECT ACTING CONSTRUCTION

Installation

The valve body and actuator assembly may be installed

in any of the positions shown in figure 3. The actuator

will be factory mounted on the valve body in the

position specified.

REVERSE ACTING CONSTRUCTION

Dimensions are shown in figure 4. Make clearance

considerations before mounting the actuator to

determine the most suitable mounting position.

5

Page 6

Product Bulletin

61.8:1077

July 2012

Figure 3. Available Mounting Positions

POSITION 1

FLOW

DIRECTION FOR

RIGHT-HAND

MOUNTING

POSITION 4

DIRECT ACTING ACTUATOR CONSTRUCTION

POSITION 1

1077 Handwheel Actuator

D101625X012

VALVE BODY

FLOW DIRECTION

FOR

LEFT-HAND

MOUNTING

POSITION 3

FLOW

DIRECTION FOR

RIGHT-HAND

MOUNTING

30B0668-A

B2002-3

VALVE BODY

FLOW DIRECTION

FOR LEFT-HAND

MOUNTING

POSITION 4

POSITION 3

REVERSE ACTING ACTUATOR CONSTRUCTION

6

Page 7

Product Bulletin

1077 Handwheel Actuator

D101625X012

Table4.EnvelopeDimensions

ACTUATOR SIZE HANDWHEEL DIAMETER J VALVE SHAFT DIAMETER F H L M N V Z

mm

0-KE

2-KE

6-KE 610

7-KE 762 44.5, 50.8 152 381 105 103 191 324 384

9-KE

10-KE:6

0-KE0

2-KE

6-KE 24.00

7-KE 30.00 1-3/4, 2 6.00 15.00 4.12 4.06 7.50 12.75 15.12

9-KE

10-KE:6

1. Used with NPS 30, 36 8510 and NPS 16 V250.

2. The 19.1 mm (3/4-inch) keyed shaft construction uses a 152 mm (6-inch) handwheel.

152 12.7, 15.9

203 19.1

203 22.2, 25.4

305 31.8, 38.1 238 165 200 243

762 44.5, 50.8

914

406

610 76.2, 88.9

6.00 1/2, 5/8

8.00 3/4

8.00 7/8, 1

12.00 1-1/4, 1-1/2 9.38 6.50 7.88 9.56

30.00 1-3/4, 2

36.00

16.00

24.00 3, 3-1/2

(2)

, 22.2, 25.4 170

31.8, 38.1

44.5, 50.8 191 321 368

63.5 241

(1)

63.5

63.5

(1)

63.5

Inches

(2)

,7/8,1 6.69

1-1/4, 1-1/2

1-3/4, 2 7.50 12.62 14.50

2-1/2 9.50

(1)

2-1/2

2-1/2

(1)

2-1/2

164

70

124

145 356 83 84

178 406 119 117

178 419 127 117

2.75

4.88

5.69 14.00 3.25 3.31

7.00 16.00 4.69 4.62

7.00 16.50 5.00 4.62

45 52 111 186 222

221

79 79

6.44

1.75 2.06 4.38 7.31 8.75

8.69

3.12 3.12

61.8:1077

July 2012

111 187 230

165 213 260

191

346

305 448

241 346 432

305 448 533

4.38 7.38 9.06

6.50 8.38 10.25

7.50

12.00 17.62

9.50 13.62 17.00

12.00 17.62 21.00

13.62

17.00

21.00

432

533

Figure 4. Envelope Dimensions (also see table 4)

JØ

H

M

10B0529-H

E0870

L

F

V

N

SØ

Z

7

Page 8

Product Bulletin

61.8:1077

July 2012

Ordering Information

When ordering, specify:

Application

1077 Handwheel Actuator

D101625X012

tables and figures. Indicate a choice whenever there is

a selection to be made.

1. Valve body type or design, size, and shaft diameter.

2. Valve disc or ball rotation (e.g., 0 to 60 or 0 to 90

degrees). For adjustability between 0 and 30 degrees

for the closed stop position, or for adjustability

between 60 and 90 degrees for the open stop position,

the 60-degree travel stop is used. This option is

available on actuator sizes 2-KE, 7-KE, 9-KE, and

10-KE:6 as a set screw change. For sizes 0-KE and 6-KE

a different actuator is required when changing from

90-degree to 60-degree ball rotation.

3. Right- or left-hand mounting and desired mounting

position from figure 3. If the control valve assembly is

to be used for bidirectional flow, assume that the flow

direction arrows in figure 3 point to the seal retainer or

flow ring end of the valve body.

Handwheel Actuator

Refer to the Specifications section. Review the

description for each specification and in the referenced

Note

When specifying a mounting position, make certain that the

handwheel diameter specified will not interfere with the

valve body, pipe flanges, or line bolting connected to the

system.

Accessories

If ordering limit switches, specify the number of

switches desired (one or two). For one limit switch,

specify whether switching is to occur at the open or

closed valve position.

Valve Body and Accessories

Refer to the separate valve body and accessory

information bulletins for ordering information.

Neither Emerson, Emerson Process Management, nor any of their affiliated entities assumes responsibility for the selection, use or maintenance

of any product. Responsibility for proper selection, use, and maintenance of any product remains solely with the purchaser and end user.

Fisher and Vee-Ball are marks owned by one of the companies in the Emerson Process Management business unit of Emerson Electric Co. Emerson Process

Management, Emerson, and the Emerson logo are trademarks and service marks of Emerson Electric Co. All other marks are the property of their respective

owners.

The contents of this publication are presented for informational purposes only, and while every effort has been made to ensure their accuracy, they arenot

to be construed as warranties or guarantees, express or implied, regarding the products or services described herein or their use or applicability. All sales are

governed by our terms and conditions, which are available upon request. We reserve the right to modify or improve the designs or specifications of such

products at any time without notice.

Emerson Process Management

Marshalltown, Iowa 50158 USA

Sorocaba, 18087 Brazil

Chatham, Kent ME4 4QZ UK

Dubai, United Arab Emirates

Singapore 128461 Singapore

www.Fisher.com

E 1986, 2012 Fisher Controls International LLC. All rights reserved.

8

Loading...

Loading...