Page 1

1008 Handwheel Actuator

D100106X012

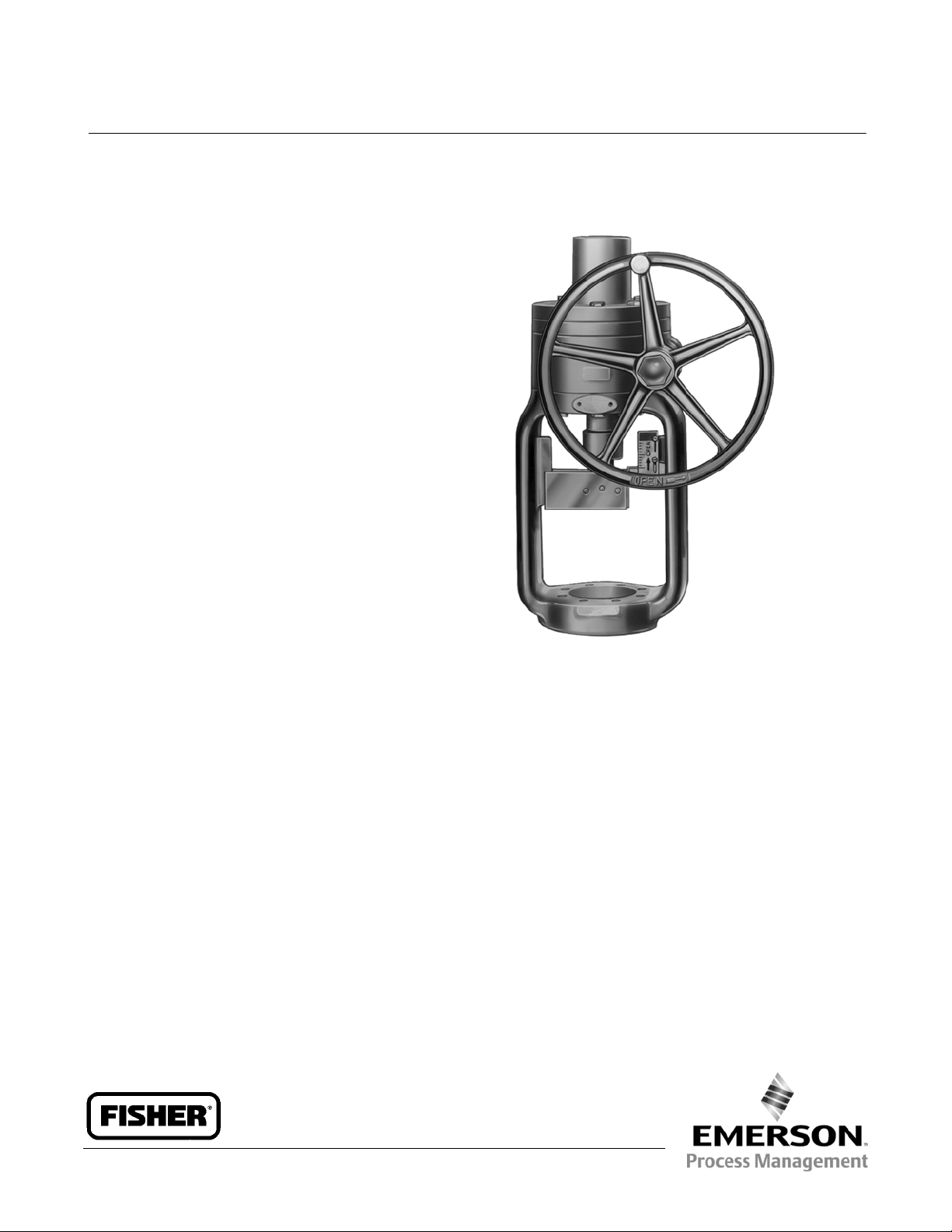

Fisherr 1008 Handwheel Actuator

The Fisher 1008 manual handwheel actuator is used in

applications that require a throttling type of control

valve that can be manually operated and set. This

actuator can be used on nearly all standard globe-style

or angle-style control valve body assemblies. No

special valve body adaptor is required for use with the

1008 actuator, so that future conversion from manual

to automatic control can be accomplished at

minimum cost.

The 1008 actuator is capable of giving precise manual

throttling control. A travel indicator mounted on the

actuator yoke provides a visual indication of valve plug

position at all times. A dial type valve plug position

indicator is also available as optional equipment.

Product Bulletin

61.8:1008

July 2012

Features

Easy to Install and Maintain–For sizes 30, 40, and

50, the yoke is attached to the valve body with a

forged steel hammer locknut (figure 1 shows a

typical locknut attachment). For the size 80

(figureNOTAG),theyokeisboltedtothevalve

body. The handwheel mechanism on all sizes is

totally enclosed.

Easy to Operate–Regardless of the valve plug

action, counterclockwise rotation of the handwheel

always opens the valve. In size 40 and larger, two

ball bearings are used in the handwheel assembly to

facilitate rotation. A spring loaded ball detent in the

handwheel prevents it from rotating due to

vibration.

W0590-1

Fisher 1008, Size 80 Actuator

Accurate Valve Plug Positioning–The valve stem

does not revolve, assuring the same seating surface

witheachfullstroke.Also,theyokeconstruction

ensures that the force required to turn the

handwheel cannot be transmitted to the valve

body. Sizes 30, 40, and 50 actuators can be

furnished with a Tejax Model A35 valve position

indicator (figure 2). This indicator enables you to

turn the handwheel to the desired position without

guesswork. The dial on the indicator is divided into

turns and fractions of turns so that you can return to

a predetermined valve setting quickly and easily.

www.Fisher.com

Page 2

Product Bulletin

61.8:1008

July 2012

Specifications

1008 Handwheel Actuator

D100106X012

Available Configuration

Manual-only handwheel actuator for use with

sliding-stem valves

Actuator Size

See table 1

Stem and Yoke Boss Diameters

See table 1

Maximum Stem Travel

See table 1

Maximum Usable Thrust

See table 1

Handwheel Rotation

Clockwise handwheel rotation closes the valve

For sizes 30, 40, and 50:

for push-down-to-close;

J Left hand screw assembly

J Right hand screw

assembly for push-down-to-open valve

For size 80: Handwheel assembly is reversible so that

it can be arranged for clockwise-to-close rotation.

Maximum Handwheel Force

See table 1

Handwheel Revolutions per Inch of Stem Travel

See table 1

1. When a Tejax indicator is used, the actuator must beinstalled ina horizontal position.

Construction Materials

Sizes 30, 40, and 50:

Handwheel:

Size 30: Ductile Iron

Sizes 40 and 50: Cast Iron

Yoke: Ductile Iron

Acme Power Nut: Stainless Steel (Not used on Size 30)

Acme Power Screw:

Size 30: Stainless steel

Size 40 and 50: Aluminum Bronze

Size 80:

Handwheel: Cast Iron

Yoke: Cast Iron

Worm Gear: Phosphor Bronze

Worm Shaft: Steel

Stem Screw: Steel

Approximate Weight

Size 30: 6.4 kg (15 lb)

Size 40: 15.9 kg (35 lb)

Size 50: 20.4 kg (45 lb)

Size 80: 45.4 kg (100 lb)

Options

J Sizes 40 and 50: Set screw to permit locking

handwheel in place

J Sizes 30, 40, and 50: Tejax Model A35 valve stem

position indicator

(1)

.

Indicator dial calibrated in turns and fractions of turns

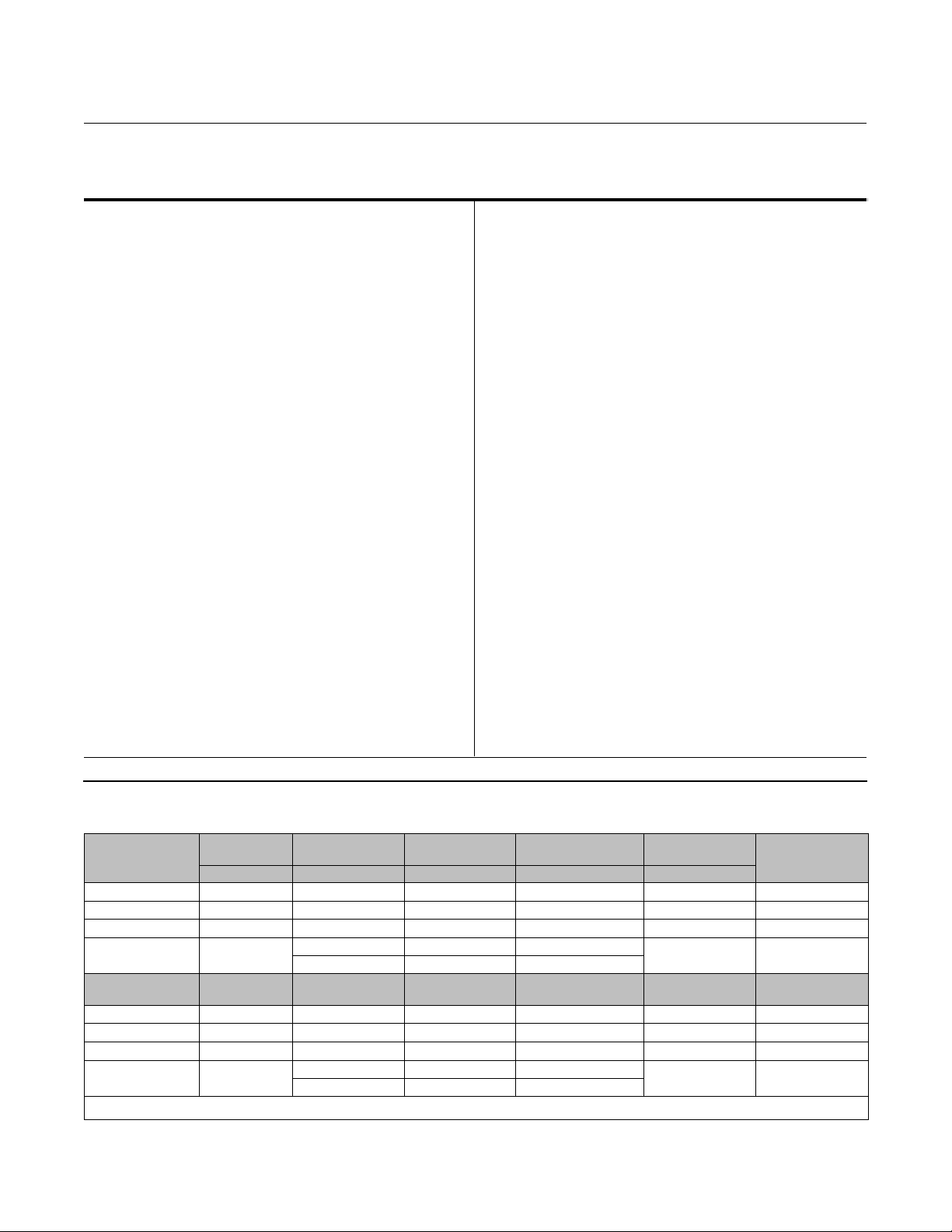

Table 1. Actuator Size Selection and Specifications

ACTUATOR

SIZE

30 54 10 7340 173.5 19 0.3

40 71 13 13122 160 51 0.3

50 90 19 29581 276 51 0.3

80 127

30 2-1/8 3/8 1650 39 0.75 8

40 2-13/16 1/2 2950 36 2 8

50 3-9/16 3/4 6650 62 2 8

80 5

1. For S31600stem at 38_C (100_F).

2. Alternate 102mm (4 inch) travel construction is available.

2

BOSS SIZE STEM DIAMETER

mm mm N N mm

25 50042 423

32 75620 623

Inch Inch Lbf Lbf Inch

1 11250 95

1-1/4 17000 140

MAXIMUM

USABLE THRUST

MAXIMUM FORCE ON

(1)

HANDWHEEL

MAXIMUM

TRAVEL

(2)

76

(2)

3

REVOLUTIONS

PER mm OF

TRAVEL

0.4

REVOLUTIONS PER

INCH OF TRAVEL

10

Page 3

1008 Handwheel Actuator

D100106X012

Product Bulletin

61.8:1008

July 2012

Figure 1. Fisher 1008, Size 30 Actuator

Mounted on ES Valve

W0595-3

Figure 2. Tejax Model A35 Valve Position Indicator

W6811-1

Ordering Information

Application

When ordering, specify:

1. Valve body type or design, size, and stem diameter.

2. Valve plug action, push-down-to-open or

push-down-to-close.

3. For sizes 30, 40, and 50: Tejax model A35 dial

indicator, if required.

4. For size 40 and 50: Set screw handwheel lock.

3

Page 4

Product Bulletin

61.8:1008

July 2012

Table 2. Overall Dimensions

ACTUATOR SIZE

40 386 15.19

50 448 17.63

Figure 3. Overall Dimensions (also see table 2)

222

(8.75)

219

(8.625)

1008 Handwheel Actuator

E

mm Inches

305

(12)

741

E

(29.1875)

D100106X012

324

(12.75)

432

(17)

mm

(INCH)

AN6753

18A1681-D

18A1668-C

B2403-1

SIZE 30

SIZE 40 and 50 SIZE 80

Neither Emerson, Emerson Process Management, nor any of their affiliated entitiesassumes responsibility for the selection, use or maintenance

of any product. Responsibility for proper selection, use, and maintenance of any product remains solely with the purchaser and end user.

Fisher isa mark owned by one of thecompanies inthe Emerson Process Managementbusiness unitof Emerson Electric Co. Emerson Process Management,

Emerson, and the Emerson logoare trademarks and service marks ofEmerson Electric Co. All other marks are the property of their respective owners.

The contents of this publication are presented for informational purposes only, and while every effort has been made to ensure their accuracy, they arenot

to be construed as warranties or guarantees, express or implied, regarding the products or services described herein or their use or applicability. All sales are

governed by our terms and conditions, which are available uponrequest. We reserve the right tomodify or improve thedesigns or specifications ofsuch

products at any time without notice.

Emerson Process Management

Marshalltown, Iowa 50158 USA

Sorocaba, 18087 Brazil

Chatham, Kent ME4 4QZ UK

Dubai, United Arab Emirates

Singapore 128461 Singapore

www.Fisher.com

E 1970, 2012 Fisher ControlsInternational LLC. All rights reserved.

4

Loading...

Loading...