Page 1

FIELDVUEt DVC2000 Digital Valve Controller

www.FIELDVUE.com

For the telephone number of the Emerson Process

Management sales office nearest you, contact:

In North America

Fisher Controls International LLC

1 (641) 754-3011

In Latin America

Fisher Controls International LLC

1 (314) 746-9900

In Asia Pacific

Emerson Process Management

Asia Pacific Private Ltd.

(65) 6777-8211

In Europe

Emerson Process Management Ltd.

+44 1634 895800

For equipment service or support needs, contact your

local Emerson Process Managment sales office.

www.Fisher.com

D103217X012 April 2010

Fisher and FIELDVUE are marks owned by one of the companies in the Emerson Process

Management business division of Emerson Electric Co. Emerson, Emerson Process

Management, and the Emerson logo are trademarks and service marks of Emerson Electric

Co. HART is a mark owned by the HART Communication Foundation. All other marks are

the property of their respective owners.

EFisher Controls International LLC 2010; All Rights Reserved

TM

475 Field

Communicator

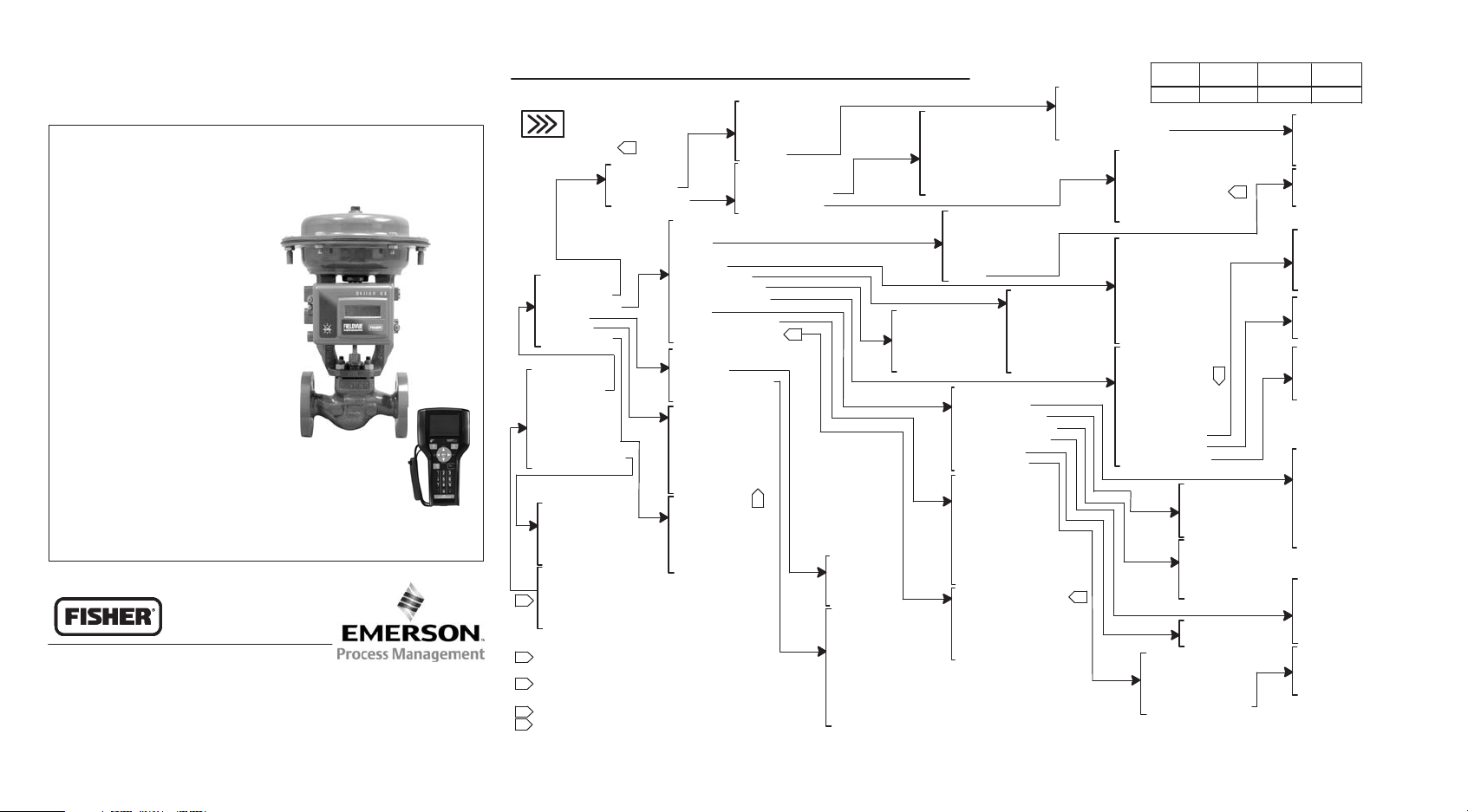

Field Communicator Menu Tree - DVC2000 Digital Valve Controller

Instrument Level HC, AD, and PD

Hot Key

1 Instrument Mode

2 Protection

3 Tuning

1‐1

Setup & Diag

1 Basic Setup

1

2 Detailed Setup

3 Display

4 Calibrate

5 Stroke Valve

Online

1 Setup & Diag

2 Analog In

3 Travel

4 Travel SP

5 Drive Sgl

6 Pressure

7 Instrument Status

Instrument Status

7

1 Valve Alerts

2 Failure Alerts

3 Operational Status

4 Display Record

Field Communicator

1 Offline

2 Online

1

3 Frequency Device

4 Utility

Notes:

1

This menu is available by pressing the left

arrow key from the previous menu.

2

Available only if the instrument has a transmitter

and limit switches installed.

3

See menu 1‐1‐1‐4

4

See menu 1‐1‐1‐4‐3

3

Basic Setup

1 Auto Setup

2 Manual Setup

Detailed Setup

1 Mode

2 Protection

3 General

1‐2

4 Measured Var

5 Actuator & Valve

6 Response Control

7 Alerts

8 Self Test Shutdown

9 Transmitter/Switches

Display

1‐3

1 Variables

2 Device Information

3 DD Revision

1‐4

Calibrate

1 Analog In Calib

2 Auto Calib Travel

3 Manual Calib Travel

4 Pressure Calib

5 Auto Tuner

6 Transmitter Calib

Stroke Valve

1‐5

1 Done

2 Ramp Open

3 Ramp Closed

4 Ramp to Target

5 Step to Target

1‐1‐1

1‐1‐2

Auto Setup

1 Setup Wizard

2 Auto Calib Travel

3 Auto Tuner

4 Tuning

Manual Setup

1 Instrument Mode

2 Press & Actuator

3 Tuning & Calib

2

2

1‐3‐1

1‐3‐2

1‐1‐2‐2

1‐2‐1

Actuator & Valve

1 Max Supply Press

1‐2‐5

2 Actuator Style

3 Valve Style

4 Zero Control Signal

1‐2‐7

Variables

1 Temp

2 Cycle Count

3 Tvl Accum

Device Information

1 HART Univ Rev

2 Device Rev

3 Firmware Rev

4 Firmware Date

5 Main Elec Rev

6 Sec Elec Rev

7 Sensor Serial Num

8 Inst Level

9 Device ID

1‐2‐9

1‐2‐8

1‐1‐1‐4

Press & Actuator

1 Pressure Units

2 LUI Pressure Units

3 Max Supply Press

4 Actuator Style

5 Valve Style

7 Zero Control Signal

Mode

1 Instrument Mode

2 Control Mode

3 Restart Cont Mode

4 Restart

5 Burst

1‐2‐4

Measured Var

1 Analog In Units

2 Input Range Hi

3 Input Range Lo

4 Pressure Units

5 LUI Pressure Units

6 Temp Units

Alerts

1 Travel Alerts

2 Travel Dev Alert

3 Travel Accum Alert

4 Cycle Count Alert

5 Other Alerts

6 Alert Record

Self Test Shutdown

1 Flash Rom Fail

2 Temp Comp Fail

3 Ref Voltage Fail

4 Drive Current Fail

5 NVM Fail

6 Temp Sensor Fail

7 Press Sensor Fail

8 Travel Sensor Fail

Transmitters/Switches

1 Switch 1 Trip Point

2 Switch 1 Closed

3 Switch 2 Trip Point

4 Switch 2 Closed

5 Transmitter Action

Menu Tree applies to:

Tuning

1 Tuning Set

2 Damping Factor

3 Expert Tuning Gains

Tuning & Calib

1 Tuning Set

1‐1‐2‐3

2 Damping Factor

3 Expert Tuning Gains

4 Tvl Cutoff Lo

5 Auto Calib Travel

General

1 HART Tag

2 Message

1‐2‐3

3 Descriptor

4 Date

5 Valve Serial Num

6 Inst Serial Num

7 Polling Address

8 LUI Language

Response Control

1 Tuning Set

1‐2‐6

2 Damping Factor

3 Expert Tuning Gains

4 Input Char

5 Custom Char Table

6 Setpt Filter Time

7 Limits & Cutoffs

8 Min Open/Close

9 Integral Settings

1‐2‐7‐2

1‐2‐7‐3

2

1‐2‐7‐5

Alert Record

1 Display Record

1‐2‐7‐6

2 Clear Record

3 Inst Date & Time

4 Record Group Enab

Device

Hardware

Revision

Revision

1 1, 2, & 3

1 1

1‐1‐1‐4‐3

1‐2‐1‐5

4

1‐2‐6‐7

1‐2‐6‐8

1‐2‐6‐9

4

1‐2‐7‐1

Travel Dev Alert

1 Tvl Dev Alert Enab

2 Tvl Dev Alert Pt

3 Tvl Dev Time

Travel Accum Alert

1 Tvl Accum Alrt Enab

2 Tvl Accum Alrt Pt

3 Tvl Accum DB

4 Tvl Accum

Other Alerts

1 Drive Alert Enab

1‐2‐7‐4

1‐2‐7‐6‐4

Firmware

Revision

Revision

Expert Tuning Gains

1 Prop Gain

2 Vel Gain

3 MLFB Gain

Burst

1 Burst Enable

2 Burst Command

Limits & Cutoffs

1 Travel Limit Hi

2 Travel Limit Lo

3 Travel Cutoff Hi

4 Travel Cutoff Lo

Min Open/Close

1 Min Opening Time

2 Min Closing Time

Integral Settings

1 Enab Int Control

2 Integral Gain

3 Integral Dead Zone

Travel Alerts

1 Tvl Hi/Lo Enab

2 Tvl HH/LL Enab

3 Tvl Alert Hi Pt

4 Tvl Alert Lo Pt

5 Tvl Alert Hi Hi Pt

6 Tvl Alert Lo Lo Pt

7 Tvl Alrt DB

Cycle Count Alert

1 Cycl Cnt Alrt Enab

2 Cycl Cnt Alrt Pt

3 Cycle Count DB

4 Cycle Count

Record Group Enable

1 Valve Group Enab

2 Failure Group Enab

3 Lim Switch Stat En

DD

Page 2

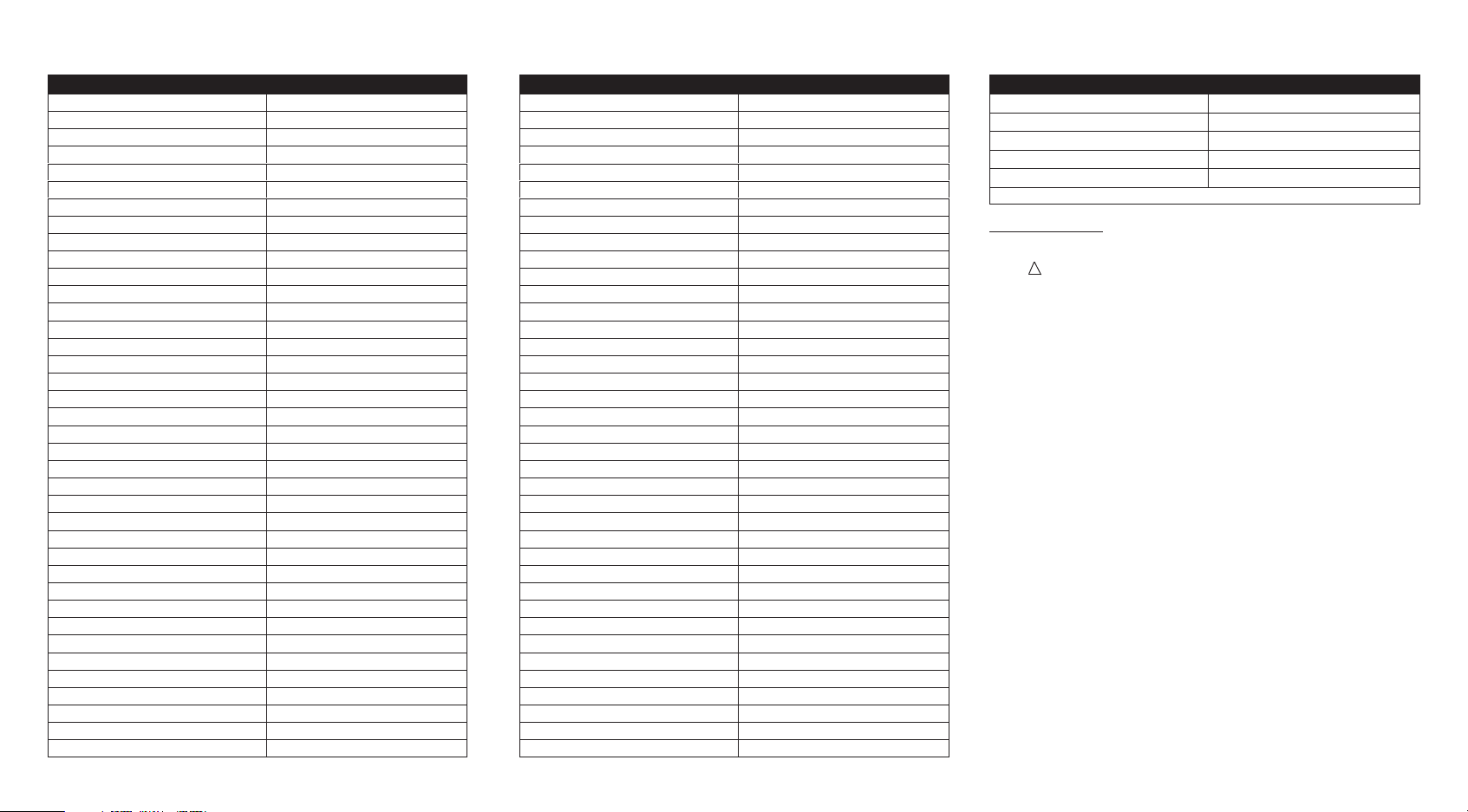

Function/Variable Fast‐Key Sequence

Actuator Style 1‐1‐2‐2‐4 or 1‐2‐5‐2

Alert Record 1‐2‐7‐6

Alert Record Group Enable 1‐2‐7‐6‐4

Analog Input 2

Analog Input Calibration 1‐4‐1

Analog Input Range High 1‐2‐4‐2

Analog Input Range Low 1‐2‐4‐3

Analog Input Units 1‐2‐4‐1

Auto Calibrate Travel 1‐4‐2 or 1‐1‐2‐3‐5

Auto Setup 1‐1‐1

Auto Tuner 1‐1‐1‐3

Basic Setup 1‐1

Burst 1‐2‐1‐5

Calibrate 1‐4

Control Mode 1‐2‐1‐2

Custom Characteristic Table 1‐2‐6‐5

Cycle Count and Alert 1‐2‐7‐4

Descriptor 1‐2‐3‐3

Device Description Revision 1‐3‐3

Device Identification 1‐3‐2‐9

Device Revision 1‐3‐2‐2

Drive Alert Enable 1‐2‐7‐5‐1

Drive Signal 5

Failure Alerts 7‐2

Firmware Date 1‐3‐2‐4

Firmware Revision 1‐3‐2‐3

HARTR Tag

1‐2‐3‐1

HART Universal Revision 1‐3‐2‐1

Input Characterization 1‐2‐6‐4

Instrument Level 1‐3‐2‐8

Instrument Mode Hot Key

Instrument Serial Number 1‐2‐3‐6

Instrument Status 7

Integral Control Enable 1‐2‐6‐9‐1

Integral Dead Zone 1‐2‐6‐9‐3

Integral Gain 1‐2‐6‐9‐2

LUI Language 1‐2‐3‐8

LUI Pressure Units 1‐2‐4‐5

Function/Variable Fast‐Key Sequence

Main Electronics Revision 1‐3‐2‐5

Manual Calibrate Travel 1‐4‐3

Manual Setup 1‐1‐2

Maximum Supply Pressure 1‐1‐2‐2‐3 or 1‐2‐5‐1

Message 1‐2‐3‐2

Minimum Closing Time 1‐2‐6‐8‐2

Minimum Opening Time 1‐2‐6‐8‐1

Operational Status 7‐3

Polling Address 1‐2‐3‐7

Pressure 6

Pressure Calibration 1‐4‐4

Pressure Units 1‐2‐4‐4

Protection Hot Key

Restart 1‐2‐1‐4

Restart Control Mode 1‐2‐1‐3

Secondary Electronics Revision 1‐3‐2‐6

Self Test Shutdown 1‐2‐8

Sensor Serial Number 1‐3‐2‐7

Set Point Filter Time 1‐2‐6‐6

Setup Wizard 1‐1‐1‐1

Stroke Valve 1‐5

Switch 1 Closed

Switch 1 Trip Point

Switch 2 Closed

Switch 2 Trip Point

(1)

(1)

(1)

(1)

1‐2‐9‐2

1‐2‐9‐1

1‐2‐9‐4

1‐2‐9‐3

Temperature 1‐3‐1‐1

Temperature Units 1‐2‐4‐6

Transmitter Action

Transmitter Calibration

(1)

(1)

1‐2‐9‐5

1‐4‐6

Travel 3

Travel Accumulator Alert 1‐2‐7‐3

Travel Alerts 1‐2‐7‐1

Travel Cutoff High 1‐2‐6‐7‐3

Travel Cutoff Low 1‐2‐6‐7‐4

Travel Deviation Alert 1‐2‐7‐2

Travel Limit High 1‐2‐6‐7‐1

Travel Limit Low 1‐2‐6‐7‐2

Travel Setpoint 4

Function/Variable Fast‐Key Sequence

Tuning Hot Key

Tuning Set 1‐1‐2‐3‐1 or 1‐1‐1‐4‐1 or 1‐2‐6‐1

Valve Serial Number 1‐2‐3‐5

Valve Style 1‐2‐5‐3

Zero Control Signal 1‐2‐5‐4

1. Available only if the instrument has a transmitter and limit switches installed.

Diagnostic Messages The DVC2000 is constantly diagnosing itself for abnormal

conditions while powered up. The following messages will appear on the local user

interface if a fault condition exists (identified on the default screen by the alert

symbol

! ). Switch 1 ??? / Switch 2 ???: The alert symbol in conjunction with this

text indicates that limit switch circuit 1 is not powered, or at least one switch is enabled.

In order for either of the switches to work, switch circuit 1 must be powered. Switch 2

cannot work alone. To eliminate the alert symbol, you can either apply 5 to 30 VDC to

switch circuit 1 or disable both switches. Once switch circuit 1 is powered properly,

question marks (???) will indicate that the corresponding switch is disabled. Device

Locked by HART: Another HARTt host is communicating with the DVC2000. Typically

this means the instrument is “out of service”. In fw3 or later, clear this message by

holding down the left button while cycling power to the DVC2000. Check Supply: The

valve is not able to reach its target position due to insufficient supply pressure. This

error will most likely occur in conjunction with the Travel Deviation error. Travel

Deviation: This error message indicates that there is a difference between the input

signal (after characterization) and the actuator travel reading from the position feedback

element. The default setting is 7% travel deviation for 5 seconds. These settings can be

configured through a HART communicating host on any HC instrument or higher.

Possible sources of this error are insufficient air supply or excessive valve friction.

Check I/P Converter: A problem relating to the I/P converter has been detected.

Sources of this error include: DElectronics problems indicated by the drive current read

back being out of range. DLow supply pressure indicated by an active drive signal alert,

and DA stuck valve resulting in integrator wind‐up. Check Mounting: The valve

position feedback reading is valid, but it is outside the operating range. Sources of this

error include loose or bent mounting brackets or a misaligned magnet array. This error

does not identify faulty components, but rather faulty installation or alignment. This alert

is also called a Travel Sensor Failure. Shutdown Activated: This screen appears if

the positioner has shut down and no air is being delivered to the actuator. This indicates

that the valve is at it's fail‐safe position. An example of a source of this error is corrupt

firmware code upon start‐up. The factory setting default for this error is disabled. This

alert will only be enabled by actively configuring it with a HART based host. Replace

Main Board: A problem with the electronics has been detected. Sources of this error

may include hardware or firmware problems. If this error is detected the instrument may

be operational but performance will be degraded. FIELDVUE Instruments: Displayed

when there are no languages loaded on the DVC2000. Could occur during firmware

download. Pressure = ???: The actuator pressure reading is greater than 125% of the

configure maximum supply pressure. Reduce the supply pressure or stroke that valve

closed (air‐to‐open/fail close setup), eventually there will be a point where numerical

values appear.

Loading...

Loading...