Page 1

Softing Linking Device

Manual for Configuration, Installation and Maintenance

V1.31

Date: July 24th, 2013

Softing Industrial Automation GmbH

Richard-Reitzner-Allee 6

85540 Haar

Germany

Phone (++49) 89 45656-0

Fax (++49) 89 45656-399

Copyright 2013 by Softing Industrial Automation GmbH

All rights reserved.

Page 2

© 2013 SOFTING Industrial Automation GmbH

No part of this document may be reproduced (printed material, photocopies, microfilm or other method) or

processed, copied or distributed using electronic systems in any form whatsoever without prior written permission

of SOFTING Industrial Automation GmbH.

The manufacturer reserves the right to make changes to the scope of supply as well as changes to technical data,

even without prior notice. A great deal of attention was given to the quality and functional integrity in designing,

manufacturing and testing the system. However, no liability can be assumed for potential errors that might exist or

for their effects. Should you find errors, please inform your distributor of the nature of these errors and the

circumstances under which they occur. We will be responsive to all reasonable ideas and will follow them up,

taking measures to improve the product if necessary.

We call your attention to the fact that the company name and trademark as well as product names are, as a rule,

protected by trademark, patent and product brand laws.

All rights reserved.

page 2 of 85 V1.31

Page 3

Softing Linking Device –

Manual for Configuration, Installation and Maintenance

Table of Contents

1 General Notes 7

1.1 Scope of Delivery 7

1.2 Safety Notes 7

1.3 Intended Use 7

1.4 System Requirements 7

1.4.1 Operating Systems 7

2 Hardware Installation 8

2.1 Overview Hardware – FG-110 FF 8

2.2 LED Block – Meaning 8

2.3 Power Supply 9

2.4 Ethernet Port 9

2.5 Modbus 10

2.5.1 MODBUS TCP 10

2.5.2 MODBUS serial (RS232 / RS485) 10

2.6 FF H1 fieldbus connection 11

2.7 FIM-110 FF - The pre-wired Installation of the FG-110 FF 11

2.8 Installation Overview 12

3 Ethernet Network Configuration 13

3.1 Linking Device IP address Configuration 13

3.2 PC IP address Configuration 13

4 Linking Device FG-110 FF - Internal Web Server 14

4.1 Homepage of the Linking Device FG-110 FF 14

4.2 Information 15

4.2.1 <Information><Contact> 15

4.2.2 <Information><Version> 15

4.2.3 <Information><Manual> 16

4.2.4 <Information><Notices> 17

4.3 <Diagnostics> 17

4.3.1 <Diagnostics><System> 17

4.3.2 <Diagnostics><Internet Protocol> 18

4.3.3 <Diagnostics><Fieldbus> 18

4.3.4 <Diagnostics><Advanced> 19

4.3.4.1 <Diagnostics><Advanced><Fieldbus Statistics> 19

4.3.4.2 <Diagnostics><Advanced><Modbus Statistics> 20

4.4 <Monitor> 22

4.4.1 <Monitor> <Point Pages> 22

4.4.2 <Monitor><Point Data> 23

V1.31 page 3 of 85

Page 4

Softing Linking Device –

Manual for Configuration, Installation and Maintenance

4.5 <Configuration> 23

4.5.1 <Configuration><Settings> 23

4.5.1.1 <Configuration><Settings><General Settings> 23

4.5.1.2 <Configuration><Settings><Internet Protocol> 25

4.5.1.3 <Configuration><Settings><LD Settings> 26

4.5.1.4 <Configuration><Settings><User Account> 27

4.5.2 <Configuration><System Maintenance> 28

4.5.2.1 <Configuration><System Maintenance><Restart> 28

4.5.2.2 <Configuration><System Maintenance><Firmware> 28

4.5.2.3 <Configuration><System Maintenance><System Backup> 29

4.5.2.4 <Configuration><System Maintenance><Time> 30

4.5.3 <Configuration><Page Options> 31

4.5.3.1 <Configuration><Page Options><Point Pages> 31

4.5.3.2 <Configuration><Page Options><Point Columns> 32

4.5.3.3 <Configuration><Page Options><Home Page> 33

4.5.4 <Configuration><Fieldbus> 34

4.5.4.1 <Configuration><Fieldbus><Devices> 34

4.5.4.2 <Configuration><Fieldbus><Blocks> 34

4.5.4.3 <Configuration><Fieldbus><H1 Parameter> 35

4.5.4.4 <Configuration><Fieldbus><HSE> 36

4.5.5 <Configuration><Modbus> 37

4.5.5.1 <Configuration><Modbus><Communication> 37

4.5.5.2 <Configuration><Modbus><Mapping> 38

4.5.5.3 <Configuration><Modbus><Import/Export> 38

5 FF-CONF Configure your plant 40

5.1 The screen FF-CONF and general descriptions 40

5.1.1 Caption 41

5.1.2 Main menu 41

5.1.2.1 Project 41

5.1.2.2 Edit 41

5.1.2.3 View 42

5.1.2.4 Build 42

5.1.2.5 Download 43

5.1.2.6 Online 44

5.1.2.7 Settings 44

5.1.2.8 Help 45

5.1.3 ToolBar - Icons you can use while working 45

5.1.4 Main view 45

5.1.4.1 <Network Configuration> 45

5.1.4.2 <Function Block Application> 46

5.1.4.3 Network Livelist 46

page 4 of 85 V1.3

Page 5

Softing Linking Device –

Manual for Configuration, Installation and Maintenance

5.1.4.4 Parameter View 46

5.1.4.5 Schedule View 46

5.1.5 The Trace Log 46

5.1.6 List and properties view 47

5.1.6.1 Device Types 47

5.1.6.2 Block Types 48

5.1.6.3 Devices 49

5.1.6.4 Blocks 50

5.1.6.5 Properties 50

5.1.7 Filtering the contents 51

5.2 General Information 51

5.2.1 Floating windows 51

5.2.2 Objects within the Network Configuration 52

5.2.3 Tag Names 52

5.2.4 Using the buttons of the objects 52

5.2.5 Using the context menu 53

5.3 Start FF-CONF 53

5.4 Managing the Device type library 54

5.5 Project handling 56

5.5.1 Create a New Project 56

5.5.2 Save project 57

5.5.3 Delete Project 57

5.6 Network configuration 58

5.6.1 Objects within the network configuration 58

5.6.2 Configure PC and Subnet 58

5.6.3 Add a Linking Device (HSE) 59

5.6.4 Add an H1 Link to a Linking Device 60

5.6.5 Add H1 Device (Field Device) to an H1 Link 61

5.7 Network Livelist 62

5.7.1 Set the online status 62

5.7.2 Display the Network Livelist 62

5.8 Function Block Application 65

5.8.1 New groups and applications (beside the Default Group and Application) 65

5.8.2 Configure the Function Block application 66

5.8.2.1 Devices first approach 66

5.8.2.2 Change tag names 67

5.8.2.3 Configure connections 68

5.8.2.4 Configure parameters 68

5.8.2.5 Change Block Tags 69

5.8.2.6 Changing parameters online 71

V1.31 page 5 of 85

Page 6

Softing Linking Device –

Manual for Configuration, Installation and Maintenance

5.8.2.7 Block types first approach 72

5.8.3 Schedule View 73

5.9 Handling Host devices 73

6 Error handling and troubleshooting 74

7 Appendix A - Bus Parameter Configuration 76

7.1 Bus parameters relevant for H1 devices 76

7.2 Bus parameters relevant for H1 Links 77

8 Glossary 79

8.1 General remarks of the user manual 79

8.2 Networking definitions 80

8.3 Fieldbus definitions 80

9 ATEX and IECex Certifications - Excerpt from the Instruction Manual 82

9.1 Preface 82

9.2 General Information on Explosion Protektion 82

9.3 Marking of equipment (type label) 82

9.4 General requirements 83

9.5 Commissioning, installation 83

9.6 Use 84

9.7 Maintenance and repair 84

Activity 85

9.8 Disposal 85

page 6 of 85 V1.3

Page 7

Softing Linking Device –

Manual for Configuration, Installation and Maintenance

General Notes

1 General Notes

Please read this document thoroughly from beginning to end before starting

installation to protect users from injury and to prevent misuse or damage to the

Linking Device.

1.1 Scope of Delivery

The scope of delivery for FIM-110 FF comprises the following parts:

● FG-110 FF Linking Device

● Up to 4 FF-H1 power supplies

● Up to 1 RS-232 / RS485 converter

● FF-Configuration Software

● Installation and operating guidelines (this document)

Please check whether the delivery is complete and free of defects before starting installation.

1.2 Safety Notes

Do not open the housing of the Linking Device FG-110 FF. It does not contain any parts that

need to be maintained or repaired by the user. In the event of a fault or defect, return the unit

to the vendor.

Opening the unit will void the warranty!

1.3 Intended Use

The Linking Device has been designed for use mainly in process control applications. For

use in hazardous areas, see appropriate chapter. The permissible ambient conditions given

in the Technical Data must be complied with.

The faultless and safe operation of the product requires proper transport, proper storage and

installation, and expert operation and maintenance in accordance with the manual.

1.4 System Requirements

1.4.1 Operating Systems

● Windows XP (Home or Professional)

● WIN 7 32 and 64 bit version

If the operating system requirement is not met, the setup will display a message and stop.

Software (not included in delivery):

● Mozilla Firefox 3.6

● Internet Explorer 8.0

● Google Chrome 10.0

V1.31 page 7 of 85

Page 8

Softing Linking Device –

Manual for Configuration, Installation and Maintenance

Hardware Installation

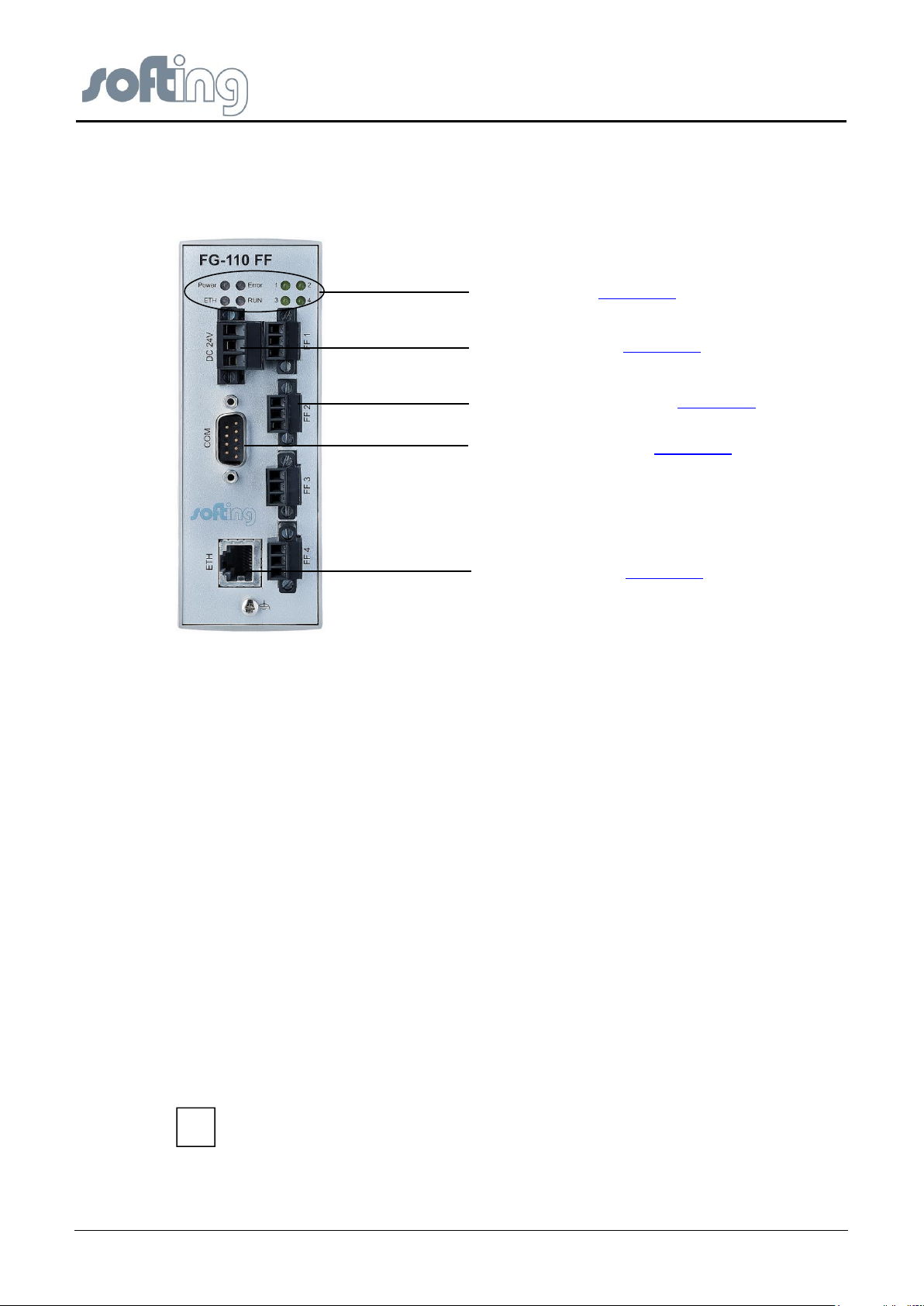

The LED may also light up if the bus has not been connected or is defective.

i

LED Block – see chapter 2.2

Power Supply – see chapter 2.3

Up to 4 H1 Segments – see chapter 2.6

Serial Port RS232 – see chapter 2.5

Ethernet Port – see chapter 2.4

2 Hardware Installation

2.1 Overview Hardware – FG-110 FF

Fig 2.1-1 Overview Hardware – FG-110 FF power and data connections

2.2 LED Block – Meaning

PWR

The "PWR" LED indicates the power supply status:

This green LED is on when the internal power supply is ensured. If this LED is off, the supply

voltage (24 V) is missing or the internal voltage generation is defective. In this case, the unit

needs to be returned to the manufacturer for repair.

LAN

The green "LAN" (Local Area Network) LED is on when proper communication (link

connection to a hub/switch/NIC) with the Ethernet is possible. It goes off temporarily during

transmission.

RUN

The "RUN" LED is available for application-specific purposes and is off by default.

ERROR

The "ERROR" LED is available for application-specific purposes and is off by default.

BUS

This green LED shows the bus activity of the FF H1 channel. The LED indicates the status

data exchange.

page 8 of 85 V1.3

Page 9

Softing Linking Device –

Manual for Configuration, Installation and Maintenance

Hardware Installation

L+

M

The starting current of the Linking Device may be up to 3A. The power supply

must provide this starting current in compliance with the voltage range to ensure a

safe start-up. Replacement Part for this connector is Phoenix Contact MSTB2,5/3STF-5,08 BK AU.

i

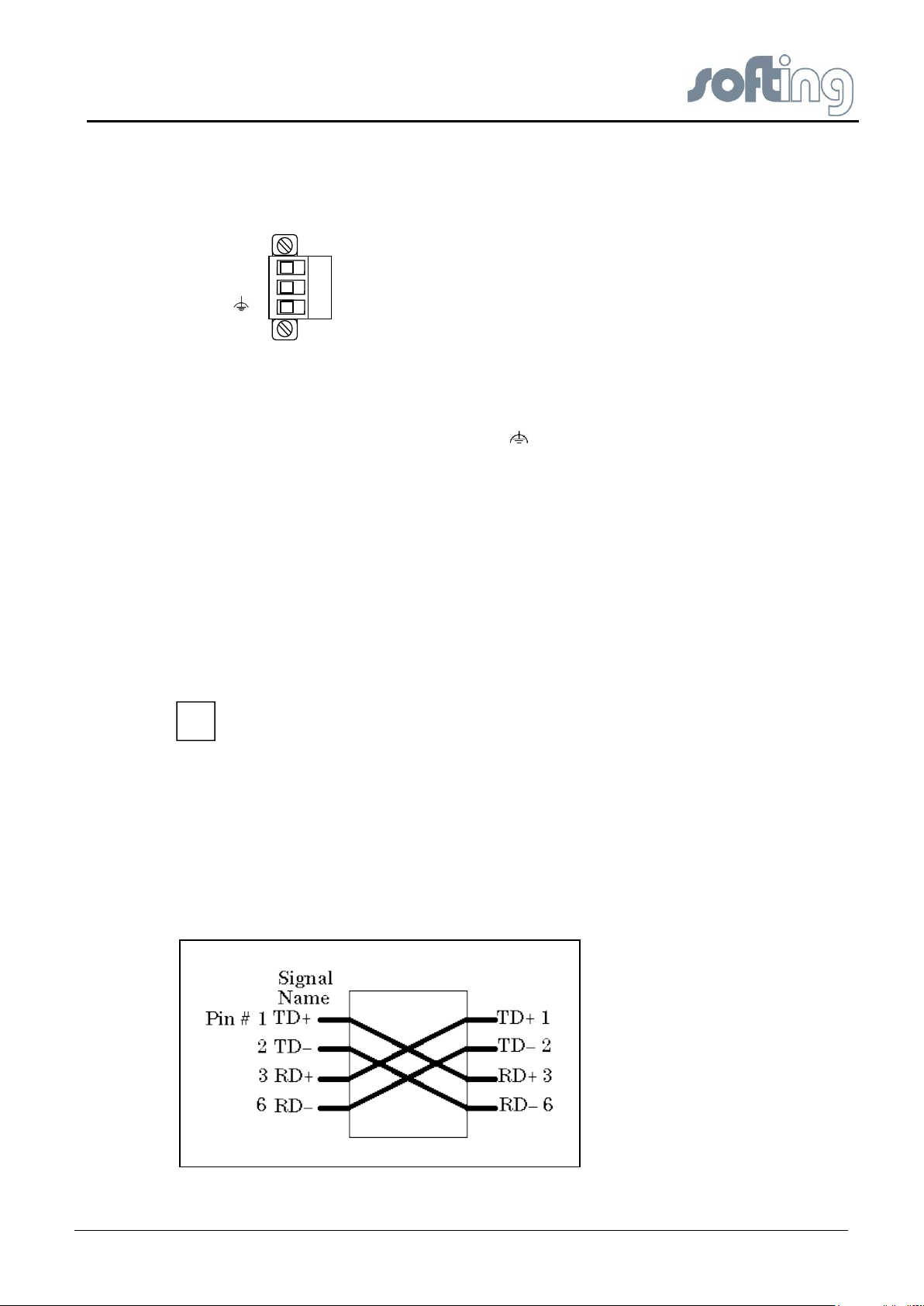

2.3 Power Supply

The Linking Device is powered by 24 V DC. The power supply plug connector is included in

the delivery. The power supply socket connector on the front panel is labeled DC 24V-.

Fig 2.3-1 Linking Device Power Supply

The two power supply terminals are labeled L+ and M. L+ must be connected to 24V and M

to 0V. The two terminals are provided with an internal reverse-polarity protection. The

functional ground terminal is labeled with the symbol and must be connected to the

protective ground. For use in an environment that is highly subject to electromagnetic

interference, an additional ground connection can be provided at the grounding screw below

the "LAN" connector.

Proper grounding is a prerequisite for compliance with the EMC directives and for ensuring

proper operation.

The power supply is connected to the plug connector via flexible wires with a cross section of

0.75 to 1.5 mm². The ground connection wire must have a cross section of 1.5 mm.

The Linking Device has an internal safety fuse which blows if an over voltage (of approx.

30V or higher) occurs in the power supply or if a fault occurs in the device. The safety fuse

can only be replaced by the device manufacturer.

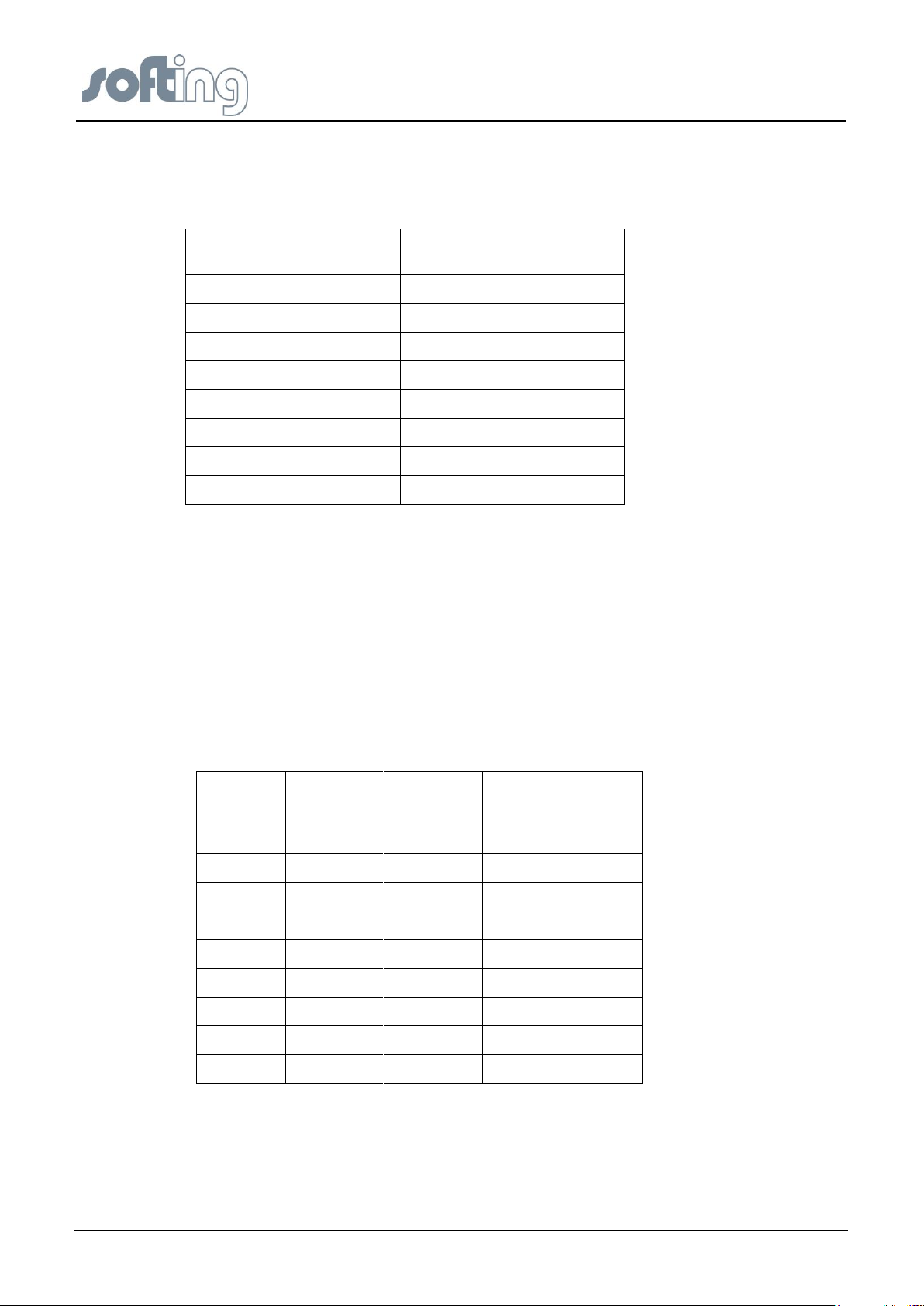

2.4 Ethernet Port

The Linking Device is equipped with one 10/100 Base-T Ethernet interface receptacle.

Connect the Linking Device to the PC that will be used for configuration, if it is possible using

an existing Ethernet Hub, Switch or Router. If you want to connect your PC to the Linking

Device directly do it with a crossover cable.

Fig 2.4-1 Crossover cable pinout

V1.31 page 9 of 85

Page 10

Softing Linking Device –

Manual for Configuration, Installation and Maintenance

Hardware Installation

Pin

MDI Signal Pinout

(Standard Ethernet Cable)

1

TD+

2

TD-

3

RD+

4

Not used

5

Not used

6

RD-

7

Not used

8

Not used

Pin #

Connector

1

Pin #

Connector 2

Signal

Description

1

1

Reserved

Do not connect

2 3 RXD

Receive Data

3 2 TXD

Transmit Data

4

4

Reserved

Do not connect

5 5 GND

Signal Ground

6

6

Reserved

Do not connect

7

7

Reserved

Do not connect

8

8

Reserved

Do not connect

9

9

Reserved

Do not connect

The Ethernet port corresponds to the standards IEEE 802.3 100BASE-TX/10BASE-T and

supports auto negotiation.

The pin assignment corresponds to MDI (Medium Dependent Interface).

Table 2.4-1 Ethernet Pins

2.5 Modbus

2.5.1 MODBUS TCP

The FG-110 FF is able to communicate with the HSE (High Speed Ethernet protocol of

Fieldbus Foundation) and Modbus TCP over the same Ethernet port.

2.5.2 MODBUS serial (RS232 / RS485)

The FG-110 FF provides a serial interface based on RS232.

The connection is made using a 9-pin male D-sub connector with the following pin layout:

Table 2.5-1 COM PIN Allocation

But mostly the units are connected to the Linking Device by the Interface RS485.

The FIM-110 FF offers a solution with a serial converter RS232 to RS485 (9185 see “Stahl

Manual”) of the company Stahl. For detailed information please follow the user guide of

page 10 of 85 V1.3

Page 11

Softing Linking Device –

Manual for Configuration, Installation and Maintenance

Hardware Installation

+

-

Stahl. You will find this manual on the CD-ROM or on the internet web page http://www.r-

stahl.com

2.6 FF H1 fieldbus connection

The fieldbus terminals are mounted in 4 sets of three terminals for the positive and negative

conductors and a shield (FF1 – FF4). Although the Linking Device is not polarity sensitive,

other components in the segment such as junction blocks may require correct polarity.

With 3-pole terminal blocks, up to 4 separate fieldbus segments can be connected. The FFH1 interfaces comply with type 114 of the FF physical layer profile, which is characterized by

● standard power signalling and voltage mode

● separately powered operation (galvanically isolated) no intrinsic safety

● the fieldbus cables +/- can be interchanged.

● wire diameter: 0.14 - 1.5 mm2, AWG 28-16

● replacement parts for the terminal block can be obtained from Phoenix-Contact

(http://www.phoenixcontact.com/) as part type MC 1,5/3-STF-3,81 BK AU.

Fig 2.6-1 Pin assignment 3-pole terminal block for FF H1 Connections

2.7 FIM-110 FF - The pre-wired Installation of the FG-110 FF

The FIM-110 FF has an IP-65 housing.

The upper cover provides access to single parts like

● the Linking Device FG-110 FF,

● the RS-232 / RS-485 converter,

● the fieldbus power conditioners/terminators,

● the power supply board and ground terminals.

The enclosure cover provides access to the terminal blocks. To open either cover of the

enclosure, use a ¼ inch blade screwdriver to remove the appropriate screw on the unhinged

side of the enclosure

The Linking Device is intended for mounting in a control cabinet. One of the favorite

possibilities is the FIM (SOFTING Foundation Fieldbus Interface Module FIM 110)

V1.31 page 11 of 85

Page 12

Softing Linking Device –

Manual for Configuration, Installation and Maintenance

Hardware Installation

Please ensure against the direct contact with the sunlight.

i

Fig 2.7-1 Mounting the Linking Device ready for use: the SOFTING Foundation Fieldbus Interface Module FIM 110

The Linking Device is convection-cooled. It therefore needs to be installed in such a way that

the ventilating ducts are at the top and bottom of the unit.

2.8 Installation Overview

The whole installation is wired as shown in the picture.

The network connectivity of the PC is part of the private Ethernet. The connectivity between

H1 Links and H1 Devices is realized by shielded twisted pair. The maximum distance

depends on the numbers of H1 Devices and other surrounding conditions, normally 1900 m.

page 12 of 85 V1.3

Page 13

Softing Linking Device –

Manual for Configuration, Installation and Maintenance

Ethernet Network Configuration

1

3.1

2

3.2

4

3 Ethernet Network Configuration

3.1 Linking Device IP address Configuration

The Linking Device is delivered with a pre-configured IP address 192.168.177.177. It must

be assigned an IP address from your LAN address range. Furthermore, subnet mask and

gateway IP address must be set.

To configure the Linking Device a private network between a PC and the Linking Device

must first be established. This can be done with a PC dedicated to the Linking Device or a

PC used for another purpose can be temporarily configured for the task. If a PC from another

network is used, carefully record the current IP address and other settings so the PC can be

returned to its original network when configuration of the Linking Device is finished. If using a

PC attached to another network, shut down the PC and remove it from the network before

proceeding to set up the Linking Device private network.

Please see the chapter <Configuration><Internet Protocol> and follow the instruction for the

IP configuration in the Linking Device.

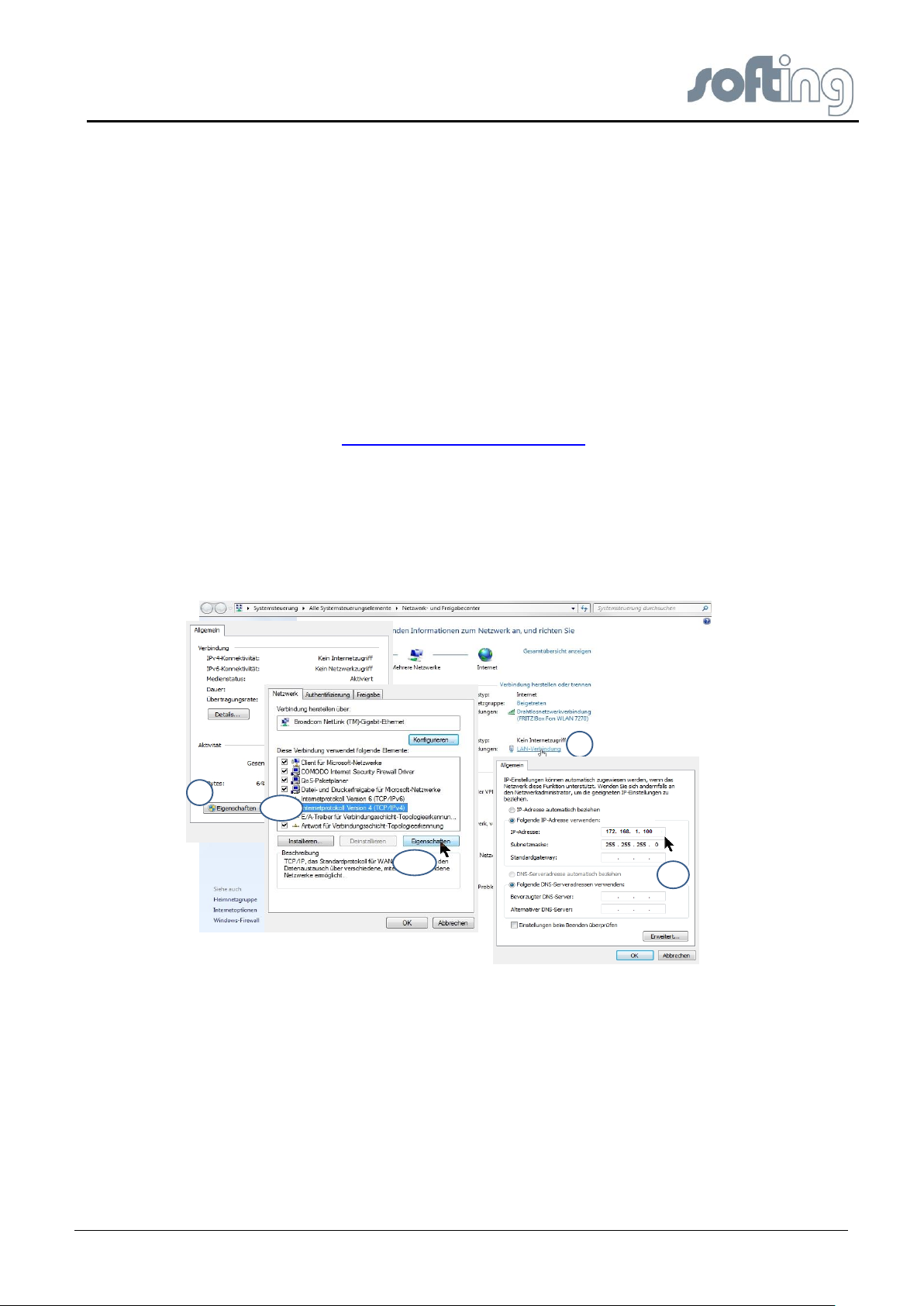

3.2 PC IP address Configuration

To install a private network on your PC please press the Microsoft Windows <Start> button

and choose <Control Panel><Network and Dial-up Connections>. The following screen

appears.

Fig 3.2-1: Configure IP address on PC

Follow the red numbered buttons. In the field IP address (4) fill in the IP address of the

subnet you have chosen. In this example we have chosen the address 192.168.1.10 as the

IP address for the PC.

Store the inputs with OK and close the window.

V1.31 page 13 of 85

Page 14

Softing Linking Device –

Manual for Configuration, Installation and Maintenance

Linking Device FG-110 FF - Internal Web Server

4 Linking Device FG-110 FF - Internal Web Server

The internal web server of the Linking Device FG-110 FF offers the possibilities to configure

the Linking Device (like IP address settings or Modbus mapping), to get diagnostic

information on the fieldbus or Modbus as well as to monitor process values of the connected

field devices.

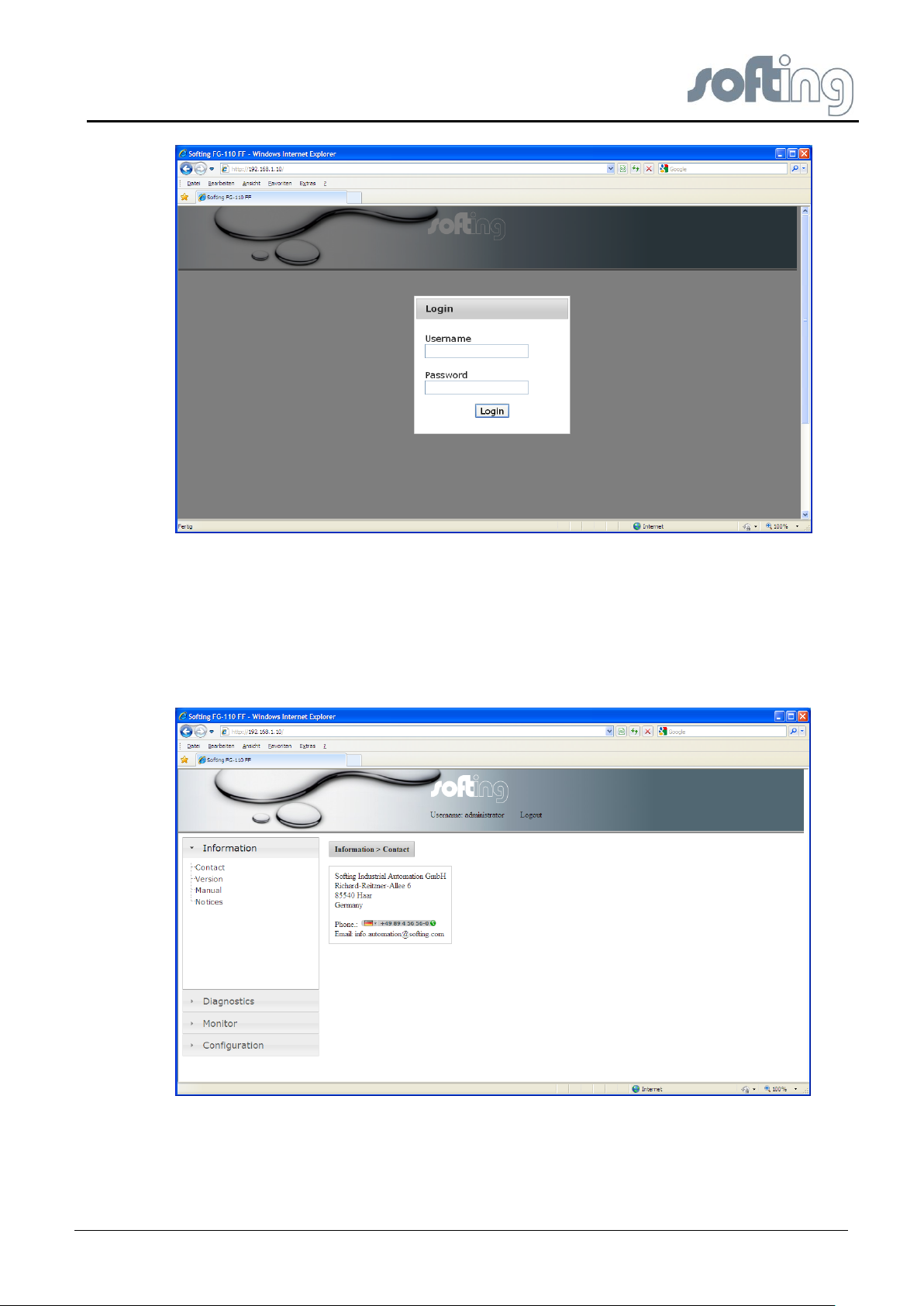

4.1 Homepage of the Linking Device FG-110 FF

The FG-110 FF web server application is optimized for Mozilla Firefox browser but it is also

possible to use Microsoft Internet Explorer.

When you start the web server the first time then please use the following default IP address,

login and password.

IP address: 192.168.1.10

Password: fgadmin

Login: administrator

After login was successful, the homepage screen of the Linking Device Web Site appears.

The screen is divided into three partitions. At the top of the screen you see the headline with

the input line for the http:// addresses (browser standard).

At the bottom left you see the headers of the main menu of the Linking Device Web Site

which will be described in detail in the following text. Next to the content menu listing you see

a free partition where the content of the single main menu items will be shown.

The headers of the main menu of the Linking Device Web Site are:

● Information

● Diagnostics

● Monitor

● Configuration

The submenu associated with each active menu opens automatically.

page 14 of 85 V1.3

Page 15

Softing Linking Device –

Manual for Configuration, Installation and Maintenance

Linking Device FG-110 FF - Internal Web Server

Fig 4.1-1 Starting Screen

4.2 Information

4.2.1 <Information><Contact>

When you click on <Information><Contact> you will see the contact address of Softing

Industrial Automation GmbH on the free partition on the right of the screen. This view is the

default Homepage.

Fig 4.2-1 Contact

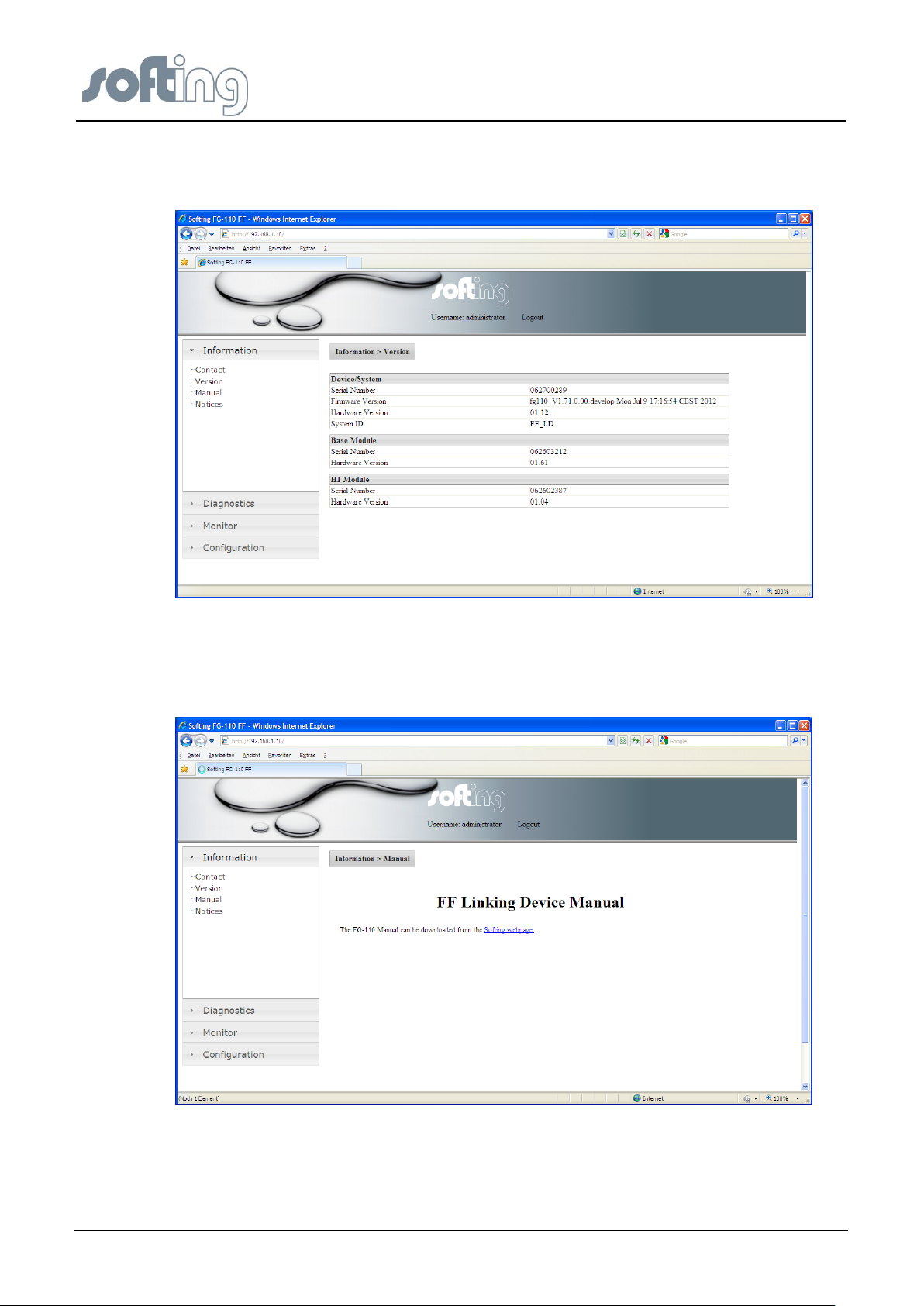

4.2.2 <Information><Version>

When you click on <Information><Version> you will see a large number of version numbers,

serial numbers and ID numbers of the connected devices in the in-house LAN on the free

V1.31 page 15 of 85

Page 16

Softing Linking Device –

Manual for Configuration, Installation and Maintenance

Linking Device FG-110 FF - Internal Web Server

right partition on the right of the screen. Here you can find the numbers of the several Linking

Device modules which are important for questions relating to the support of Softing Industrial

Automation GmbH.

Fig 4.2-2 Version

4.2.3 <Information><Manual>

Click on <Information><Manual> and you find a link to download the manual from the Softing

webpage

Fig 4.2-3 User Manual

page 16 of 85 V1.3

Page 17

Softing Linking Device –

Manual for Configuration, Installation and Maintenance

Linking Device FG-110 FF - Internal Web Server

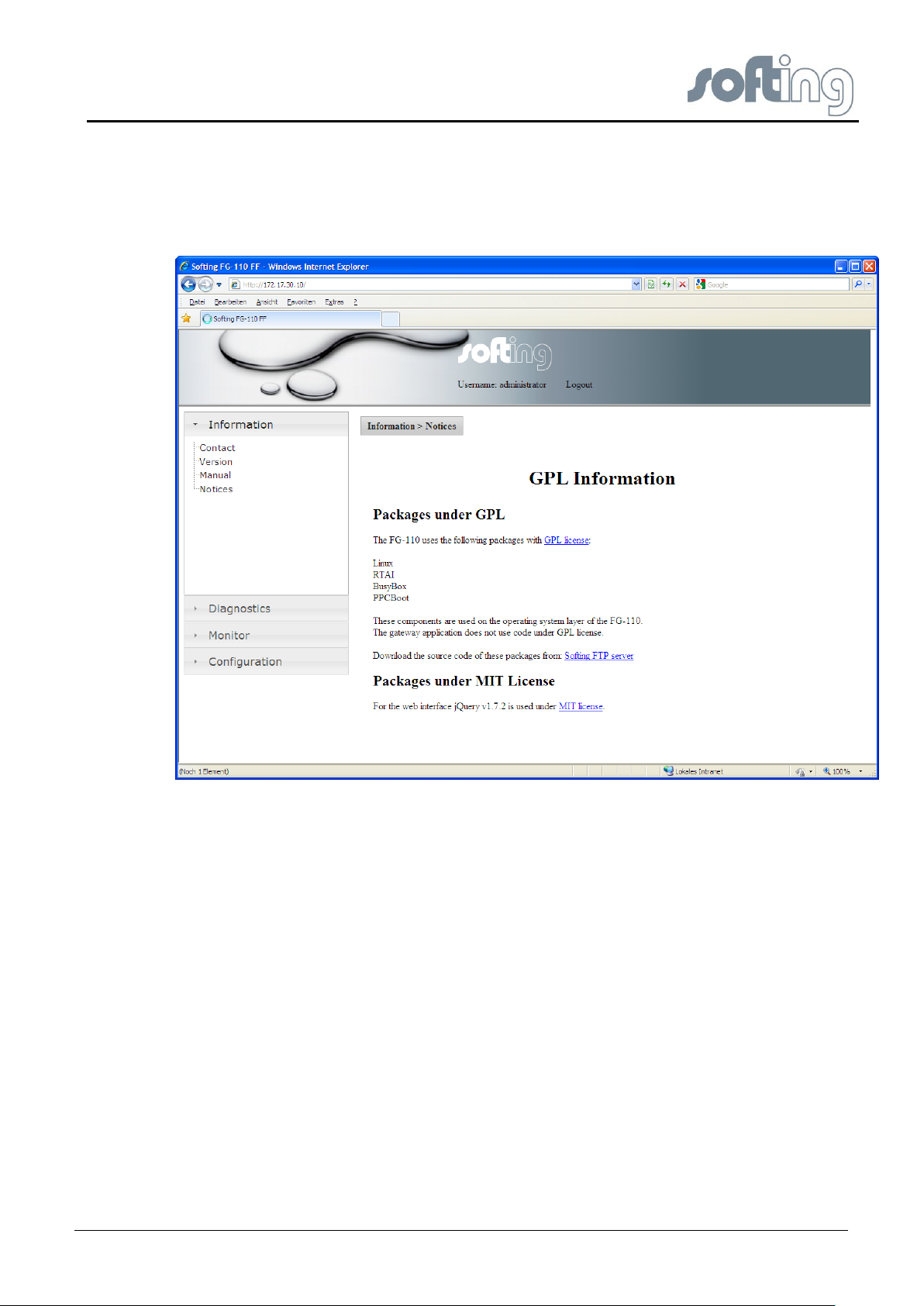

4.2.4 <Information><Notices>

Click on <Information><Notices> to obtain topical information about licenses which are used

in the Linking Device.

Fig 4.2-4 Actual information for the customer

4.3 <Diagnostics>

Under the menu item <Diagnostics> the headers <System>, <Internet Protocol>, <Fieldbus>

and <Advanced> are listed.

The tables listed under the menu item <Diagnostics> show the values in display mode.

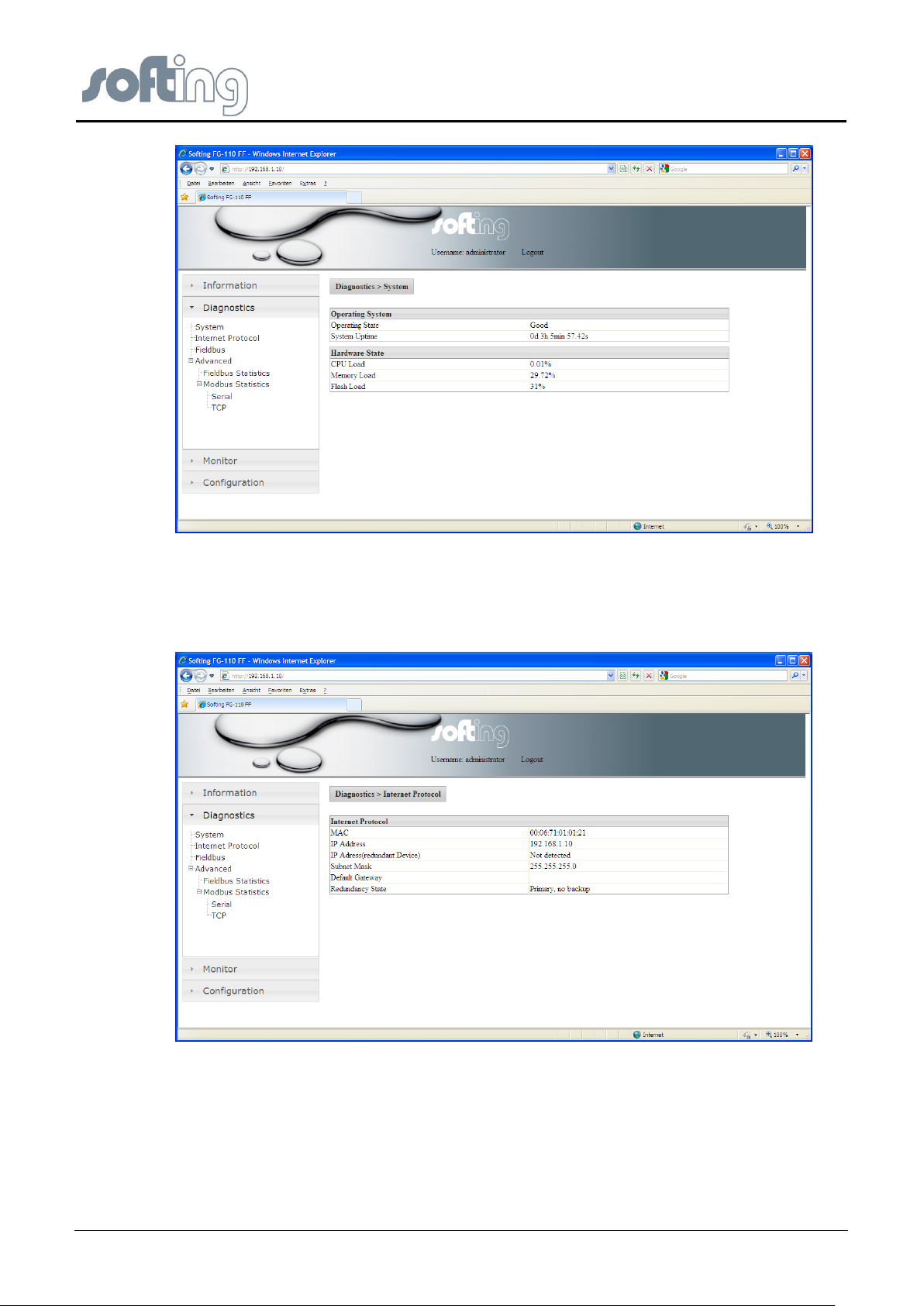

4.3.1 <Diagnostics><System>

The operating system and the application layer can be diagnosed.

The first table lists

● the Operating State,

● the System Uptime of the configured Linking Device Operating System.

The second table lists (in percent (%))

● the states of CPU Load,

● the Memory Load,

● the Flash Load of the configured Hardware.

The displayed data shows the usage rate of the system in %.

V1.31 page 17 of 85

Page 18

Softing Linking Device –

Manual for Configuration, Installation and Maintenance

Linking Device FG-110 FF - Internal Web Server

Fig 4.3-1 System - actual Information of the Linking Device state

4.3.2 <Diagnostics><Internet Protocol>

The table <Internet Protocol> lists the main information the system has got about the

connected subnet.

Fig 4.3-2 Data of the Internet protocol

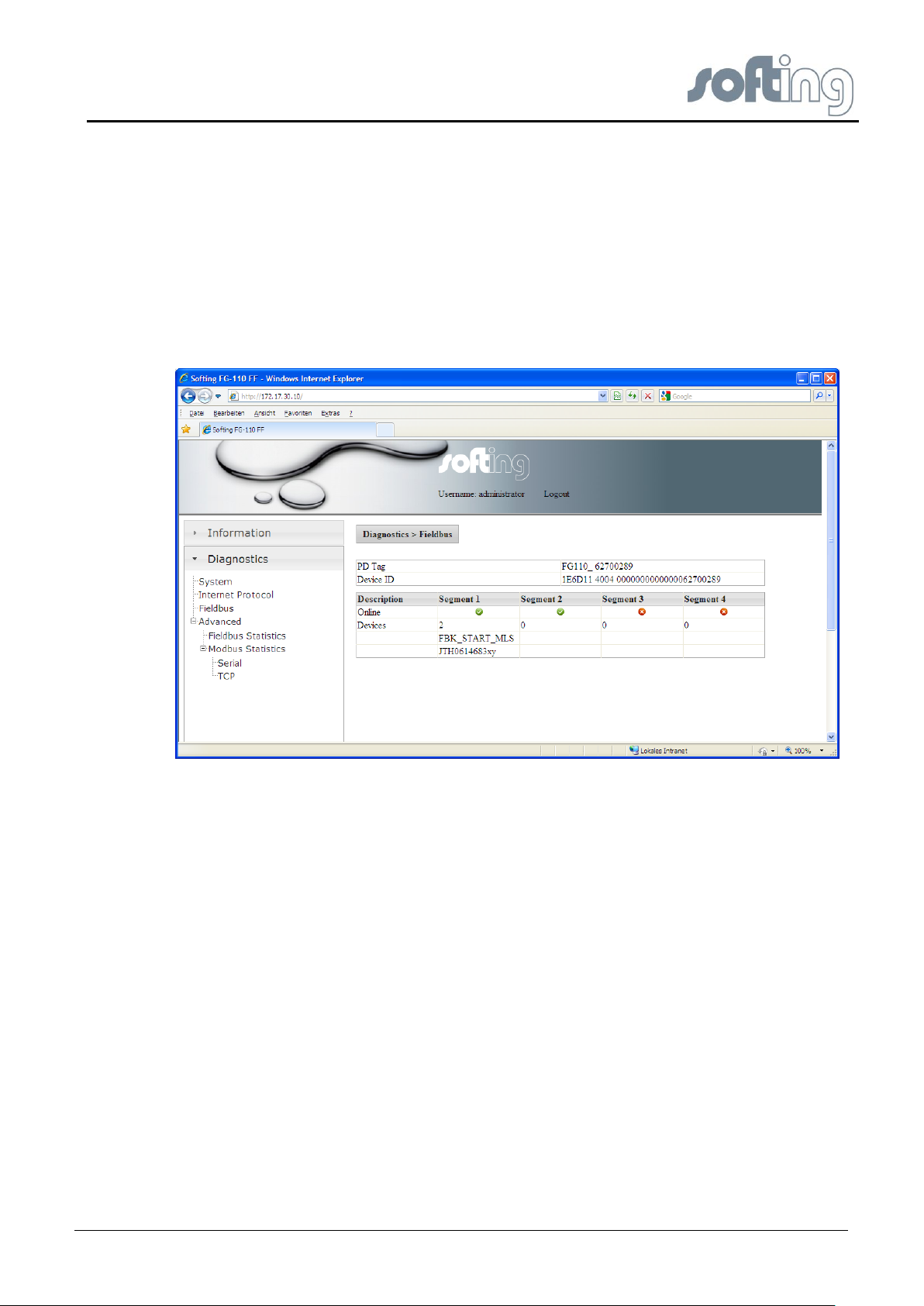

4.3.3 <Diagnostics><Fieldbus>

Fieldbus segment diagnostics are provided to give you a quick view of what is attached to

the Linking Device. It shows how many segments are active.

On the screen two tables are shown.

The first table shows the information about the Linking Device, the PD Tag as well as the

Device ID. The PD Tag can be modified in the Configuration page “LD Settings”.

page 18 of 85 V1.3

Page 19

Softing Linking Device –

Manual for Configuration, Installation and Maintenance

Linking Device FG-110 FF - Internal Web Server

Underneath it another table shows which segment (H1 Link) of the Linking Device (FG-110

FF) is occupied and how many FF-H1 devices are connected under each segment.

Additional, for each available FF-H1 device the tag name is shown. So, the this table provide

a simple live list of the FF-H1 network. Please note that this list will be updated just be

clicking on “Fieldbus” again.

For each Linking Device up to 4 H1 Links (segments) are available. And under each

segment H1 Link up to 16 devices H1 are possible.

(In this example: Segment 1 (H1 Link) from Linking Device HSE_ DEVICE_1 is occupied by

two connected devices (H1 Device), flagged with a green check mark. The segments 2-4

(H1 Links) are free, flagged with red buttons.

Fig 4.3-3 Shows the actual configuration – Linking Device and occupancy of the 4 H1 Links (Segments)

4.3.4 <Diagnostics><Advanced>

The menu item <Diagnostics><Advanced> therefore shows two different menu items.

● Fieldbus Statistics

● Modbus Statistics.

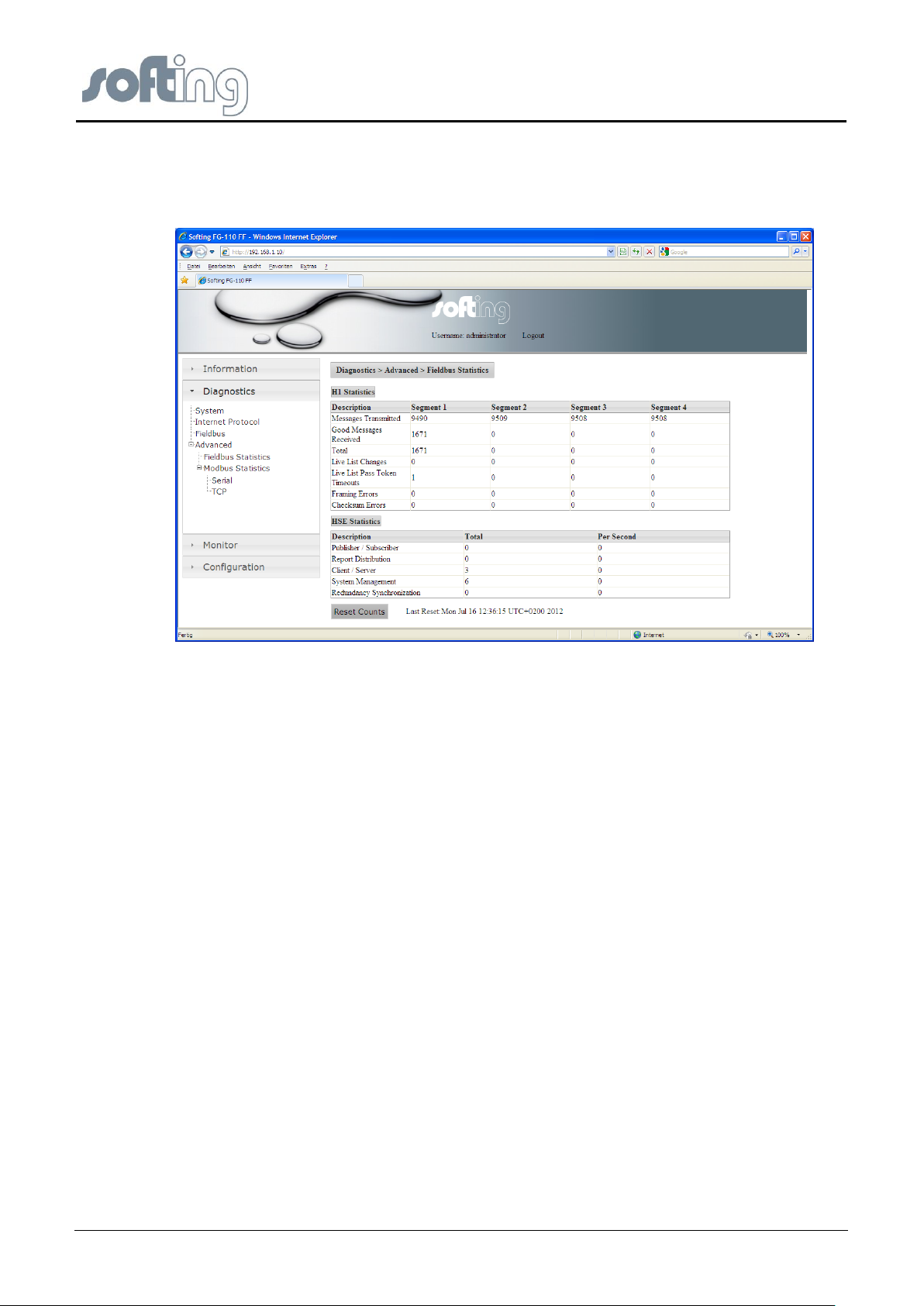

4.3.4.1 <Diagnostics><Advanced><Fieldbus Statistics>

The menu item <Fieldbus Statistics> shows two different tables. The values specified apply

to the time since the program has been started or the latest <Reset count>.

The first table shows statistical data for each single occupied segment of the H1 Device.

● Messages Transmitted:

Assumption of all the transmitted messages for each occupied segment

● Good Messages received:

Assumption of the good messages received at each occupied segment.

● Total: Number of total retries.

● Live List Changes: Number of total live list changes

● Live List Pass Token Timeouts: Number of pass token timeouts; Under good

conditions it should be “0”

V1.31 page 19 of 85

Page 20

Softing Linking Device –

Manual for Configuration, Installation and Maintenance

Linking Device FG-110 FF - Internal Web Server

● Framing Errors: Number of framing errors

● Checksum Errors: Number of checksum errors

Fig 4.3-4 Fieldbus Statistics (H1 and HSE)

The second table shows statistical data for each of the HSE Links.

● Publisher/Subscriber: Number of messages per second (average value)

● Report Distribution: Number of messages per second (average value)

● Client/Server: Number of messages per second (average value)

● System Management: Number of messages per second (average value)

● Redundancy Synchronization: Number of messages per second (average value)

Pressing the button <Reset count> sets the counter to zero. Recording of the statistical data

starts at the beginning.

You have to click<Fieldbus><Statistics> once again to see the new results.

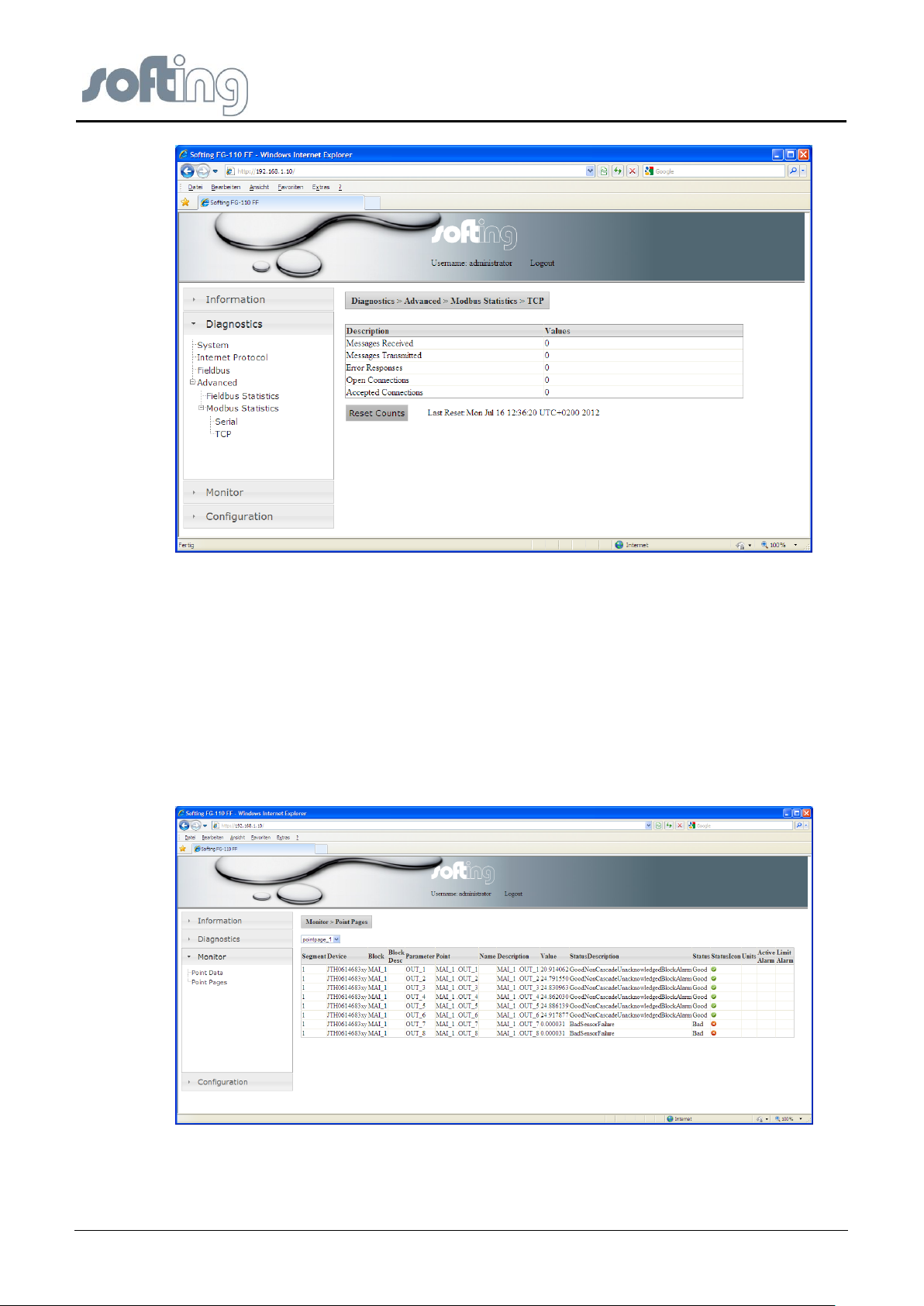

4.3.4.2 <Diagnostics><Advanced><Modbus Statistics>

The Modbus communications statistics provide information on the data and packets received

and transmitted by the Modbus slave interface. Select <Serial> if you want to monitor the

Modbus RTU link or <TCP> if you are monitoring the Modbus TCP/IP communications.

Therefore the Modbus may work with two different protocols. Menu item

<Diagnostics><Advanced> <Modbus Statistics> shows two different menu items.

● Serial

● TCP

page 20 of 85 V1.3

Page 21

Softing Linking Device –

Manual for Configuration, Installation and Maintenance

Linking Device FG-110 FF - Internal Web Server

<Diagnostics><Advanced><Modbus Statistics><Serial>

The menu item <Serial> shows statistical data of a Modbus connected on a serial interface.

First messages and CRC errors from received data are listed. Then messages and error

responses from the transmitted data are listed. RS232 needs a converting unit

RS232/RS485 and a separate data connection between Linking Device and Modbus.

The values specified apply to the time since the program has been started or the latest

<Reset count>.

Fig 4.3-5 Modbus Serial Statistics

Pressing the button <Reset count> sets all counters to zero. Recording of the statistical data

starts at the beginning.

You have to click<Modbus Statistics> <Serial> once again to see an update of the results.

<Diagnostics><Advanced><Modbus Statistics><TCP>

The menu item <TCP> shows statistical data of a Modbus connected using TCP. First

received and transmitted messages are listed. Then the error responses are counted. Finally

open and accepted connections are listed.

Pressing the button <Reset count> sets all counters to zero. Recording of the statistical data

starts at the beginning.

You have to click<Modbus Statistics> <TCP> once again to see an update of the results.

V1.31 page 21 of 85

Page 22

Softing Linking Device –

Manual for Configuration, Installation and Maintenance

Linking Device FG-110 FF - Internal Web Server

Fig 4.3-6 Modbus TCP Statistics

4.4 <Monitor>

Click <Monitor> Options to display the point pages and point data.

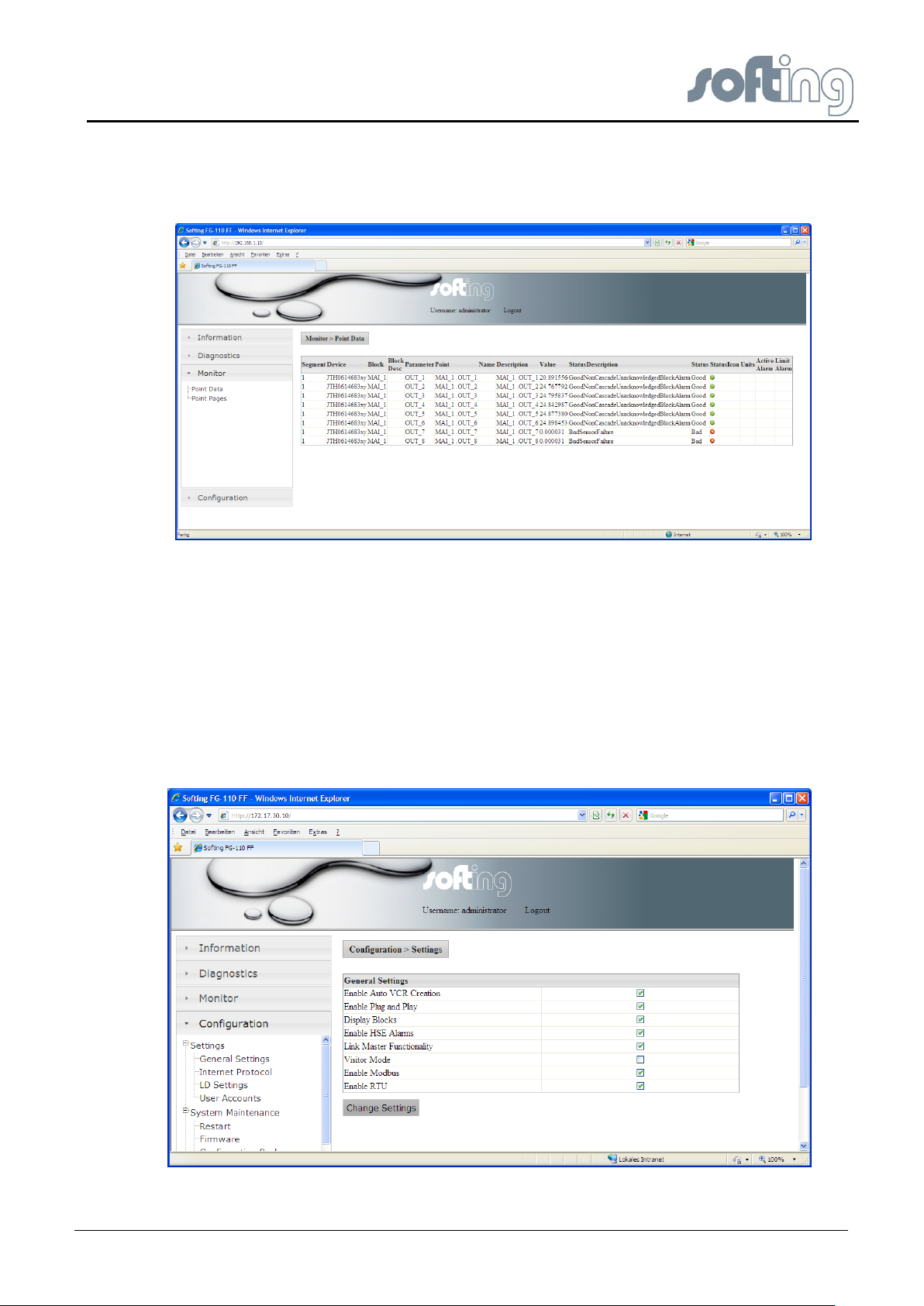

4.4.1 <Monitor> <Point Pages>

Point Pages provide a means to view the Process Value (PV) or Output of a Function Block

and its status on one or more web pages. Multiple pages can be configured to fit the

application and to keep track of the different parts of the plant.

First click <Point Pages> to select the desired part of data. It may be one or more rows or

sites.

Fig 4.4-1 Statistics of the H1 Devices for the selected page

page 22 of 85 V1.3

Page 23

Softing Linking Device –

Manual for Configuration, Installation and Maintenance

Linking Device FG-110 FF - Internal Web Server

4.4.2 <Monitor><Point Data>

Next click <Point Data> to see the details of all available point pages displayed for the

selected page.

Fig 4.4-2 Monitor Point Data – all Data of your plant will be shown

4.5 <Configuration>

The menu item <Configuration> is a very important item of the Linking Device web site. Here

the user with administrator rights has the possibility to change network parameters, configure

the point pages and perform Modbus mapping.

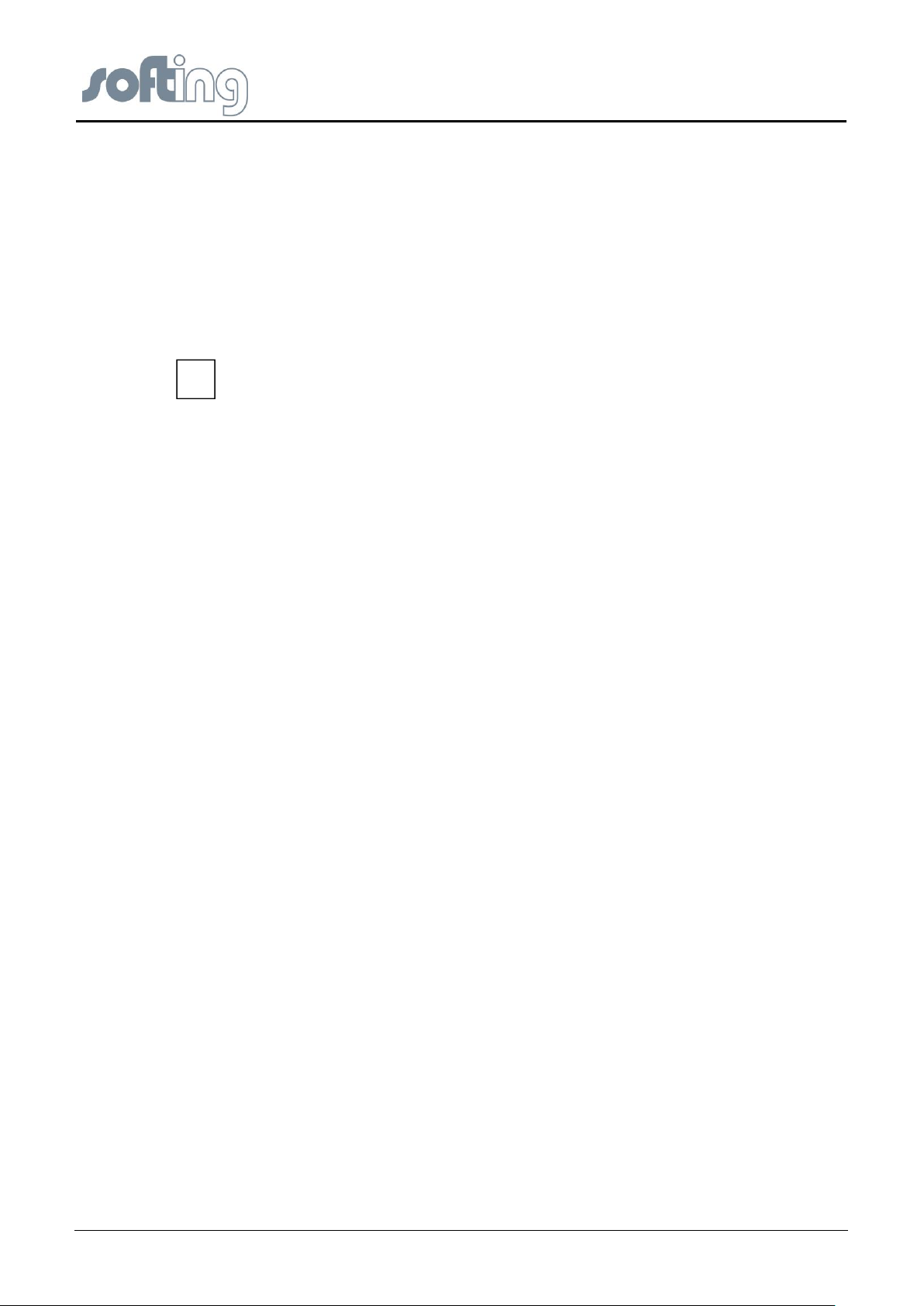

4.5.1 <Configuration><Settings>

4.5.1.1 <Configuration><Settings><General Settings>

Fig 4.5-1 General Settings of the Linking Device

V1.31 page 23 of 85

Page 24

Softing Linking Device –

Manual for Configuration, Installation and Maintenance

Linking Device FG-110 FF - Internal Web Server

Please note that the feature “Automatic VCR creation has to be enabled when the

tool FF_CONF is to be used for the Foundation fieldbus configuration

i

1.) Enable VCR Creation

If this feature is “on” then the Linking Device establishes the VCR connection by them self.

Please read in the software manual if it is necessary or not.

Some examples

Softing Configuration Tool (FF-CONF) --> On

Emerson AMS™ Software --> On

NI-FBUS Configuration Tool --> Off

2.) Enable Plug&Play

This feature makes sure that pre-configured device can be used without a configuration tool.

3.) Display Blocks

This feature enables or disables the point page functionality. The use of the point page

creates a lot of traffic of the FF-H1 network. If you don’t use this Monitor feature then you

can save more H1 bandwidth and faster reaction time over Modbus.

4.) Enable HSE Alarms

The Linking Device is able to use the already configured alarm VCR’s in the FF-H1 devices

or can established new one.

5.) Link Master Functionality

In case of visitor mode it can make sense to disable the Link Master functionality. If no Link

Master is available then a time-out will follow after 6 sec.

6.) Visitor Mode

When the Linking Device is in visitor mode it can be connected to a running FF-H1 network

with the FF-Host system without affecting the established communication.

7.) Enable Modbus

This button enables or disables Modbus TCP and RTU.

8.) Enable Modbus RTU

Modbus RTU runs over the same serial interface (RS232) which is necessary to establish an

application with HSE device redundancy. To use redundancy together with Modbus TCP the

feature “Modbus RTU” has to be disabled.

page 24 of 85 V1.3

Page 25

Softing Linking Device –

Manual for Configuration, Installation and Maintenance

Linking Device FG-110 FF - Internal Web Server

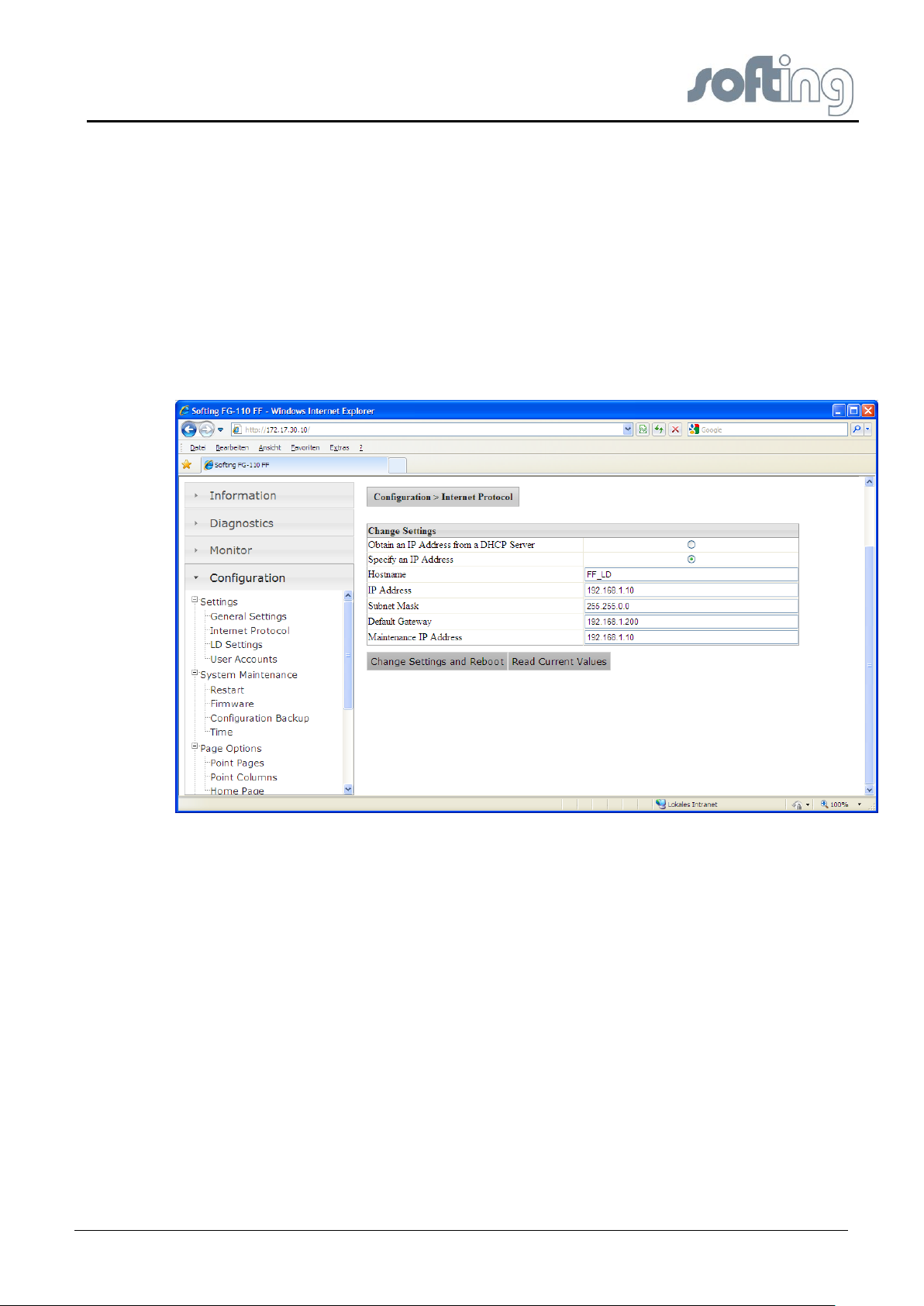

4.5.1.2 <Configuration><Settings><Internet Protocol>

The Linking Device is delivered in a default configuration. To change the default internet

protocol settings into assigned values of the chosen subnet in which the installation is

running you click <Configuration><Internet Protocol>.

A table which enables you to change settings appears.

First you can click a button to <obtain an IP address from a DHCP server>. When you click

this button the IP address is a random address chosen from the DHCP server. To find out

the IP address of the Linking Device you can use the tool “Search and Configure” (SAG.exe)

or the live list of the FF-CONF tool. Both tools are available on the CD-ROM or on the

Softing homepage.

Fig 4.5-1 Configure the Internet Protocol

To keep the systems under your control click the button <Specify an IP address>.

Underneath this button input fields become active to insert:

● Domain name: configurable name for the domain

● IP address: must be compatible with the subnet you choose for the PC setting, must

be present in any case.

● Net mask: default with 255.255.0.0, no change needed, must be present in any

case.

● Gateway: It is not necessary to configure a Default Gateway if the host and Linking

Device share the same network.

● Maintenance IP address: IP address of the connected PC in the same subnet.

The Maintenance IP Address is required to download the Linking Device firmware

from a maintenance server. The maintenance server is a TFTP server (Tiny File

Transfer Protocol) that contains an image of the flash memory content of the Linking

Device (it is also possible to download a file via the website). In that case it is not

necessary to install a maintenance server and to specify its address.

V1.31 page 25 of 85

Page 26

Softing Linking Device –

Manual for Configuration, Installation and Maintenance

Linking Device FG-110 FF - Internal Web Server

Do not access the web server of the Linking Device before the NEW

NETWORK SETTINGS or ERROR OCCURED message is displayed in

the browser window. If you do so, you will have to clear the cache of

your web browser after the boot process has finished, and then reestablish a connection to the web server of the Linking Device.

i

<Change Settings and Reboot>

When you click the button <Change Settings and Reboot> the web site shuts down and the

system reboots.

The input values will be checked for consistency. If the input values are not consistent, the

Linking Device will propose consistent values. You can use the proposed values by clicking

<yes> or keep the values you entered by selecting <no>.

The Linking Device will be rebooted after a few seconds and the new values will be

accepted.

If you change the IP address of the Linking Device, the IP connection between PC and

Linking Device will be lost. You have to use the new IP address to re-establish web access

to the Linking Device.

If all parameters are correct, the new values are accepted and displayed.

<Read Current Values>

If you changed some of the parameters and you are not sure of your changes, click the

button <Read Current Values>. Input fields which are already filled are shown again.

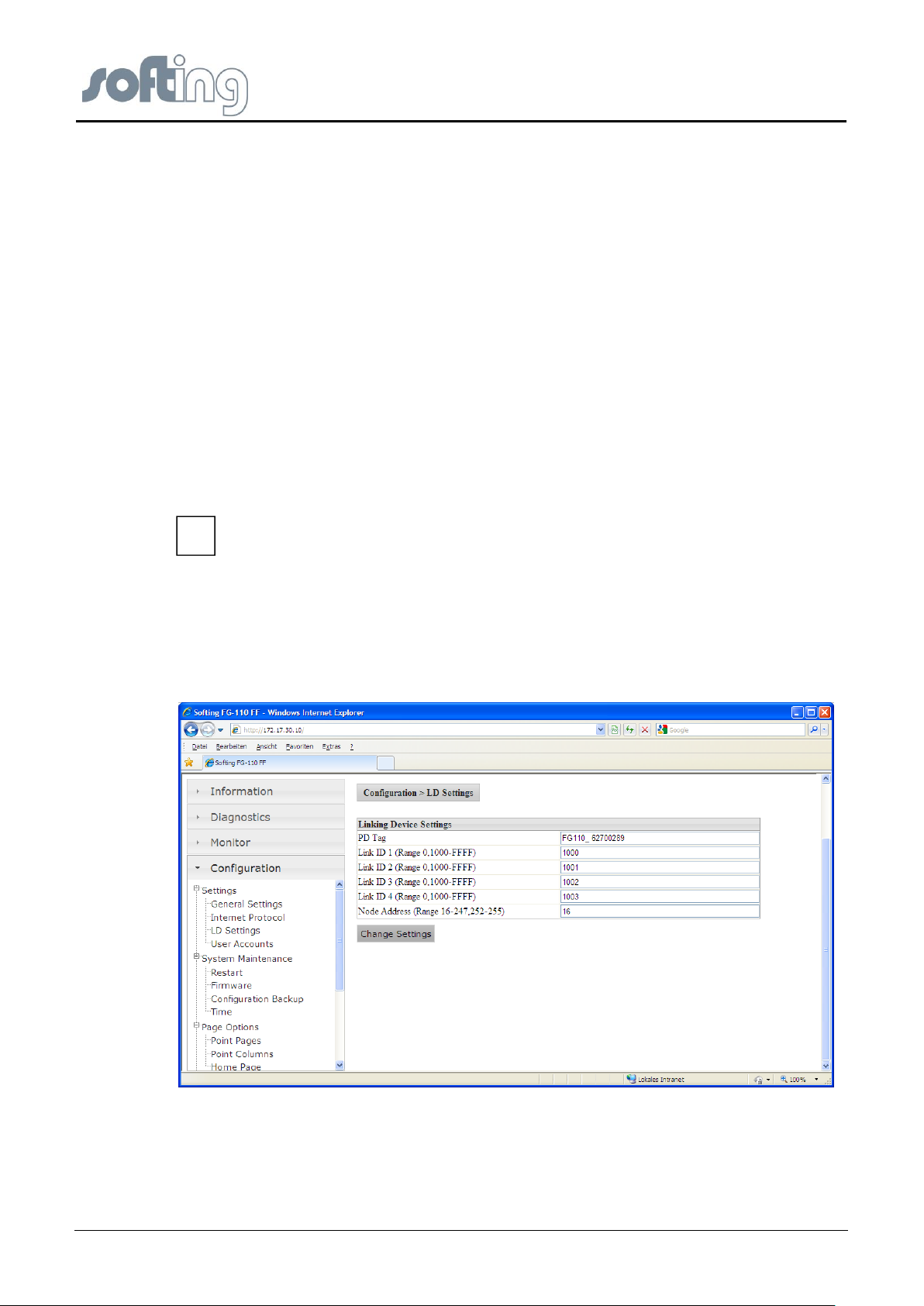

4.5.1.3 <Configuration><Settings><LD Settings>

Fig 4.5-2 Configuration of Linking Device Settings

Each Linking device gets a unique PD-Tag which includes the serial number.

The Webpage “LD-Settings” can be used to change the PD-Tag of the Linking device, the

Link ID as well as the Node Address of the H1 links.

page 26 of 85 V1.3

Page 27

Softing Linking Device –

Manual for Configuration, Installation and Maintenance

Linking Device FG-110 FF - Internal Web Server

4.5.1.4 <Configuration><Settings><User Account>

The Linking Device is shipped with default user password. Under this menu item you can

change the settings of the user passwords. Due to the jobs the user executes in this web site

there are several graduations for admission control.

The following standard logins and password are available.

Login: administrator Password: fgadmin

Login: maintenance Password: keepitgoing

Login: operator Password: runit

Login: executive Password: showme

These passwords can be configured with administrator rights.

Fig 4.5-3 Change user accounts – new Passwords

The following rights are connected to the pointed out roles:

The administrator can

● configure network settings (address, default)

● set passwords

● set time settings

● set home page options

● restart applications

in addition to all the functions of the other roles listed below.

The maintenance, executive and operator can just monitor the process values (point

pages) and the diagnostic. They have not access to all configuration sides.

V1.31 page 27 of 85

Page 28

Softing Linking Device –

Manual for Configuration, Installation and Maintenance

Linking Device FG-110 FF - Internal Web Server

You can install user passwords for four user groups. Fill in the new password and confirm

your input with a second input. The input mode is always the same for all user groups.

When you click the button <Change Password> the passwords will be changed and

activated the next time you enter the web site.

The administrator can modify any system or field device setting. Thus use caution when

changing the administrator password. If the administrator password is lost, you will not be

able to set up the Linking Device und and it is necessary for a staff member of Softing to

reset the password.

4.5.2 <Configuration><System Maintenance>

4.5.2.1 <Configuration><System Maintenance><Restart>

Restart causes the start of the program from the beginning with all settings stored last.

Fig 4.5-4 Restart of the HSE Device

Pressing the button <Restart now> causes another window to appear with the question

whether the restart of the device is desired. Seek the required file and

● Click <OK> to start the restart of the device.

Click <Cancel> to return the program to the beginning. Each setting is persistent.

4.5.2.2 <Configuration><System Maintenance><Firmware>

Clicking the button <seek> the Firmware Update page opens a file selector box to select the

firmware file to be downloaded. Click <Download Firmware and Reboot> to start the

download process. Firmware download and flash memory update take between one and two

minutes. You can observe the progress of the update process in the browser window.

During Reboot, the IP connection between PC and Linking Device will be lost.

Do not access the web server of the Linking Device before the SUCCESS message is

displayed in the browser window. If you do so, you will have to clear the cache of your web

browser after the boot process has finished, and then re-establish a connection to the web

server of the Linking Device.

The end of the boot process is indicated by a reboot of the Linking Device.

page 28 of 85 V1.3

Page 29

Softing Linking Device –

Manual for Configuration, Installation and Maintenance

Linking Device FG-110 FF - Internal Web Server

Please note that while the software download is running the connection between

the PC and the Linking Device will not be closed or the power supply of the

Linking Device disconnected. This can destroy the Linking Device.

i

Fig 4.5-5 Download Firmware and Reboot

After a new start the firmware stored in the chosen file is now valid for this configuration.

4.5.2.3 <Configuration><System Maintenance><System Backup>

Fig 4.5-6 Save your current system

V1.31 page 29 of 85

Page 30

Softing Linking Device –

Manual for Configuration, Installation and Maintenance

Linking Device FG-110 FF - Internal Web Server

Press the button <Save Configuration> another window appears on the screen which

enables you to search for a folder in your directory on your PC or external store media to

store the configuration you have created for the installation for future use.

With the button “Erase Configuration” the Linking device can be switched back to factory

default settings.

Erase causes the deletion of the valid configuration.

It is recommended that you erase the configuration part of the flash memory by checking

<Erase Configuration>. This will clear the FF configuration information (plant configuration),

but the IP configuration will not be changed.

Pressing the button <Erase Configuration> causes another window to appear with the

question whether the deletion of the configuration is desired.

● Click <OK> to start deletion of the configuration.

● Click <Cancel> returns the program to the beginning. Each setting is persistent.

If you erase the Linking Device configuration, the password will be reset to its default value.

4.5.2.4 <Configuration><System Maintenance><Time>

Click <Configuration><Time> to configure the system time.

The first table, Current Time, shows the current time on your PC, the time on the Softing

Linking Device. The difference between the current PC time and the time in the Linking

Device is shown in the field under it.

In the second table, Set Time, you can check a box Set with PC. After clicking the button

<Set Time> the current PC time and the time in the Linking Device will be synchronized and

shown in the table Current Time.

Fig 4.5-7 The possible opportunities to set time

page 30 of 85 V1.3

Page 31

Softing Linking Device –

Manual for Configuration, Installation and Maintenance

Linking Device FG-110 FF - Internal Web Server

If the Linking Device is connected to a network and if you want to use this feature, you can

select a timeserver at your facility or one near you geographically to ensure accurate time

adjustments. The device will function properly with this feature disabled but data time stamps

will be less accurate and time updates must be entered for each Linking Device. To use a

network time server, check the box <Network Time Protocol> (NTP), enter the IP address of

the time server and select the appropriate NTP packet version.

If a HSE SNTP server is configured then all other fields are greed out.

Alternately you can set the time manually. This is accomplished by checking the box

<Manual Entry>. This will enable you to enter information in the <Date> and <Time> fields.

In both cases you must confirm the input by clicking the button <Set Time>. Until then your

input will be activated.

4.5.3 <Configuration><Page Options>

Click <Configuration> <Page Options> to configure the Point Pages, the Point Columns and

the Home Page.

4.5.3.1 <Configuration><Page Options><Point Pages>

Point Pages provide a means to view the PV or Output of a Function Block and its status on

one or more web pages. Multiple pages can be configured to fit the application. Click

<Configuration> <Page Options> <Point Pages> to display the current list of Point Pages.

Fig 4.5-8 Create Pages to select information of your whole plant

With the button < >< > you can move the chosen point page so that the pages are sorted

in the order you desire.

To delete a point page which already exists, press the button <Delete> in the line of the point

page you want to erase.

To change the content of a listed point page, press the button <Edit> in the line where the

desired point page is listed.

V1.31 page 31 of 85

Page 32

Softing Linking Device –

Manual for Configuration, Installation and Maintenance

Linking Device FG-110 FF - Internal Web Server

Another window appears with a table where the valid Points for this point page are listed.

Over the table there is an input box with the name of the point page.

If you change this name you get a new point page with all the attributes of the chosen point

page.

The table below the page name has five columns. The first column is named “Point”. Under

this column, the possible Out-Blocks (AI Function Blocks) are listed. Beside the file name

you find a search field <…> for choosing another .out file from a file list.

The second column of the edit table is named “Name”. It can contain a name of the Function

Block.

The third column is named “Description”. In this field it is possible to type the description of

the Function Block.

In the next column “Up/Down” you can scroll the list. The last column “Delete” contains a

<Delete> button for each .out file in the table.

Under the table the buttons <Save Changes> and <New Point> are arranged. When you

press one of the buttons you can either save the changes of the point page or create a new

point.

Fig 4.5-9 Create a new Point or change pages

To save the changes click <Save Changes>.

To create a new Page click <New Point Page>. The input data of a new Point Page must be

treated in the same way as when existing Point Pages are changed.

After <Save Changes> and clicking <Point Pages> you see the data of all your pages again,

possibly including a new page. Without <Save Changes> the existing data remains

unmodified.

4.5.3.2 <Configuration><Page Options><Point Columns>

When you click <Configuration> <Page Options> <Point Columns> a table with various point

columns appears on the screen. A check mark in the check box right beside the point

columns enables the point columns. If the check box is empty the column is disabled and

does not appear in the point page. In this way you can build the format you need.

page 32 of 85 V1.3

Page 33

Softing Linking Device –

Manual for Configuration, Installation and Maintenance

Linking Device FG-110 FF - Internal Web Server

Fig 4.5-10 Select columns and save your selection

4.5.3.3 <Configuration><Page Options><Home Page>

When you click <Configuration><Page Options><Home Page> a table with four possibilities

for the first side of the homepage appears on the screen. You can choose between the

chapters “Information | Contact”, “Diagnostics | Fieldbus”, “Monitor | Point Monitor” or

“Monitor | Point Pages”.

Fig 4.5-11 Elect your homepage

V1.31 page 33 of 85

Page 34

Softing Linking Device –

Manual for Configuration, Installation and Maintenance

Linking Device FG-110 FF - Internal Web Server

The fields “Node” and “PD Tag” are input fields. In a connected system, the inputs

from here have an influence on the values in the FF-CONF Program. Press the

button <Set Tag> and the changed data appears as well in the FF-CONF

Program.

i

You choose the chapter for the start web side of the FG-110 FF with a click on the check box

beside the desired chapter.

When you press the button <Set Homepage> the input will be activated. The next start of the

web application will show you the selected page as your homepage. If you choose the

<Monitor><Point Monitor> you have to select the desired page. <Monitor><Point Pages>

shows you the desired page at once.

4.5.4 <Configuration><Fieldbus>

4.5.4.1 <Configuration><Fieldbus><Devices>

When you click <Configuration><Fieldbus><Devices> the table with the connected devices

to the Linking Device appears on the screen.

The table shows which segment from the Linking Device is occupied with how many devices.

The devices are indicated with their Node, their Device ID and their PD Tag.

Additionally there is information about the alarm VCR (VCR address) and the status of the

alarm (Alarm configured). When the alarm is configured ( ) then it can be used otherwise

there is a red dot ( ).

Fig 4.5-12 Change Node or PD Tag of your fieldbus devices

The fields “Segment” and “Device ID” are only display fields. No input is possible.

4.5.4.2 <Configuration><Fieldbus><Blocks>

In this site you see the blocks of all FF-H1 field devices which are connected to the Linking

Device.

Based on a possible large number of function block there are two filters:

- Segment: 1…4

page 34 of 85 V1.3

Page 35

Softing Linking Device –

Manual for Configuration, Installation and Maintenance

Linking Device FG-110 FF - Internal Web Server

- Device: Devices (PD Tags) on segment

In the table below is shown the function block type (Block Type), function block name (Block

Name) and the description.

With the “Enable” button can be selected if the bock will be displayed in Point Page Monitor

or not. By default only block with a block name are enabled.

Fig 4.5-13 Process the Block names or the Description of your Fieldbus Devices

If you designate the blocks (up to 32 ASCII-characters) it is useful – especially in large plants

– to assign self-explanatory names which say something about the location and define its

information (e.g. analog output, digital input). This facilitates control and assignment of the

displayed alerts or alarms.

4.5.4.3 <Configuration><Fieldbus><H1 Parameter>

Click <Configuration><Fieldbus><H1 Parameter> to define your parameters for the chosen

segment (H1 Link). With <Change Settings> you activate your inputs.

V1.31 page 35 of 85

Page 36

Softing Linking Device –

Manual for Configuration, Installation and Maintenance

Linking Device FG-110 FF - Internal Web Server

Please change these parameters only if you are absolutely sure it is necessary

and correct. Otherwise you will lose the Foundation fieldbus communication.

!

Fig 4.5-14 Change settings of the H1-Links

4.5.4.4 <Configuration><Fieldbus><HSE>

Click <Configuration><Fieldbus><HSE> to define your parameters for the Linking Device.

With <Change Settings> you activate your inputs.

Fig 4.5-15 Change settings of the Linking Device

page 36 of 85 V1.3

Page 37

Softing Linking Device –

Manual for Configuration, Installation and Maintenance

Linking Device FG-110 FF - Internal Web Server

4.5.5 <Configuration><Modbus>

The Linking Device allows traditional control systems access to modern fieldbus devices as

well as over the serial port RS485 and using TCP/IP. These control systems normally

include support for the Modbus communication protocol.

4.5.5.1 <Configuration><Modbus><Communication>

Click <Configuration><Modbus><Communication> to configure the Modbus Communication

settings. First check if the Modbus function is enabled and all parameters are set to a valid

value. Therefore consult the manual of your particular Modbus client and adjust the Modbus

configuration accordingly.

Most of these settings are self-explanatory and are related to configuring the serial port to

match the settings used by the Modbus Master.

If you are using Modbus TCP/IP over the Ethernet then the communication settings (baud

rate, parity, stop bits) can be ignored.

To apply the changes click <Change Settings>.

Fig 4.5-16 Change settings of the Modbus Communication

V1.31 page 37 of 85

Page 38

Softing Linking Device –

Manual for Configuration, Installation and Maintenance

Linking Device FG-110 FF - Internal Web Server

4.5.5.2 <Configuration><Modbus><Mapping>

Fig 4.5-17 Change settings of the Modbus Mapping

The functions of the Modbus mapping in the Linking Device are flexible enough to

accommodate most traditional control systems. The Modbus mapping table allows a user to

associate the output or input value of an AI or an AO Function Block with any traditional or

extended Modbus register. To add new entries click the button <New Entry>. Next type the

required Modbus register and assign the relevant process value (the out or in value of the

function block). When you have entered your entire data click the button <Change Mapping>

to apply the configuration. After a reload of the page you will see the new mapping entry.

On the FF H1 side 1 bit data length doesn’t exist. Therefore on the Modbus side the

Gateway doesn’t support Discrete Inputs and Coils.

4.5.5.3 <Configuration><Modbus><Import/Export>

To save the properties you have specified in Modbus Mapping use the function <Export>, if

you want to utilize an existing set of Modbus Mapping data use the function <Import>.

page 38 of 85 V1.3

Page 39

Softing Linking Device –

Manual for Configuration, Installation and Maintenance

Linking Device FG-110 FF - Internal Web Server

Fig 4.5-18 Import/Export of the Modbus Configuration

V1.31 page 39 of 85

Page 40

Softing Linking Device –

Manual for Configuration, Installation and Maintenance

FF-CONF Configure your plant

5 FF-CONF Configure your plant

By choosing the FF-CONFsetup.exe you will start the installation routine of the FF-CONF

program. To start FF-CONF it is not necessary to activate any network access, but without

network access online configuration is not necessary.

It is possible to create various configurations and store them in external files. FF-CONF is an

offline configuration tool and to build the Network Configuration it is not necessary to install

any fieldbus devices.

5.1 The screen FF-CONF and general descriptions

Below you see a screenshot of FF-CONF with most of the parts you will encounter while you

are working with FF-CONF. The numbers reference short explanations of the meaning and

will help you to find the particular description of the different specialist contents quickly.

5.1-1 An overview of the FF-CONF screen

The numbers on the screen will be described in the chapters 5.1.1 to 5.1.10

(1) Caption - FF-CONF, the active project, the status

(2) Main Menu – for details see chapter Main Menu

(3) Tool-Bar - Icons you can use while working. You save time using the offered functions

with one click.

(4) Main view tabs – the most important functions to build a configuration and to activate

the messaging between the blocks of the different devices.

(5) Main view, where you normally work after choosing a tab.

(6) The Trace Log shows error messages, warnings and information provided by FF-

CONF.

(7) List and properties view (items and icons) – List view icons provide a means for

handling device and block types and instances.

(8) List and properties view (contents) – show you the contents of the selected items (7) .

(9) Filtering the contents - Here you can set filters and select the contents shown in the

list view.

page 40 of 85 V1.3

Page 41

Softing Linking Device –

Manual for Configuration, Installation and Maintenance

FF-CONF Configure your plant

5.1.1 Caption

The caption shows the name FF-CONF, the file name of the active project and the program

status offline/online.

5.1.2 Main menu

In the maim menu you find the following items specially to administrate and to organize your

project. When you click on the right mouse button each of the items of the main menu allows

you to activate or deactivate the toolbar.

5.1.2.1 Project

5.1-2 Menu item Project

Here you can create a new project, open an available project, close, delete and save the

active project, rename the project (save as), save it as a template or view the properties of

the project in the right-hand part of your screen.

5.1.2.2 Edit

5.1-3 Edit

The functions of the item Edit are reserved for system-related functions.

V1.31 page 41 of 85

Page 42

Softing Linking Device –

Manual for Configuration, Installation and Maintenance

FF-CONF Configure your plant

5.1.2.3 View

5.1-4 View – shows you the displayed contents of the project

With <View> you can activate the desired contents like the Network Livelist, Schedule View

or intentionally hidden parts of the screen like Trace Log or previously activated views.

The tabs for the Network Configuration and the Function Block Application cannot be closed,

but can be brought to the foreground.

5.1.2.4 Build

The item Build consists of the two functions <Check All> und <Build All>. Both of the

functions can be done in the offline or online mode.

Fig 5.1-5 Build function

Check All

With the function <check all> the whole project is checked – network configuration as well as

function block application. This functionality can be used if you know that no download

domain can be built, for example due to missing device assignments. You see warnings and

errors in the Trace log.

page 42 of 85 V1.3

Page 43

Softing Linking Device –

Manual for Configuration, Installation and Maintenance

FF-CONF Configure your plant

Please use the download device functionality only if you are sure that the changes

will not affect other devices. Otherwise your system might not work correctly.

Inexperienced users of Foundation Fieldbus© are recommended to use

<download project>. Error messages are shown in the trace log view and will help

you to debug your control application.

!

!

Build All

<Build All> Build all first checks the configuration and then builds a download domain if there

are no error messages which prevent generation of the download domain.

A lot of information, warning and error codes are given in the Trace log. If the build all

function is done successfully you can download a device or the whole project.

5.1.2.5 Download

<Download> needs the online mode. You can download a device or the whole project.

5.1-6 Download device or project

Download Device

A single marked device can be downloaded after all the input and updates are checked for

correctness.

Download Project

All data of the project can be downloaded after all the input and updates are checked for

correctness. The download of the project transfers the download domain created by a build

from the PC to the Linking Device and the H1 Devices.

The trace log provides a lot of information. You can filter it by choosing only errors and

warnings (disable information).

After a successful download the units are fully operable.

V1.31 page 43 of 85

Page 44

Softing Linking Device –

Manual for Configuration, Installation and Maintenance

FF-CONF Configure your plant

5.1.2.6 Online

When FF-CONF is started with a new or an existent project FF-CONF is in mode offline. You

can configure devices or build your Function Block application in this mode. If you want to

see the real installation – the Network Livelist – you must change to the online mode. When

you open the livelist with <View> <Network Livelist> the program automatically changes to

online. The idea of this functionality is to change back to offline if the user does not need

online functionality. Online might need lots of performance.

5.1.2.7 Settings

The <tool settings> define the several conditions for the process which follows later,

especially storage location and data, as well as startup conditions and time cycles.

The <project settings> define information about the project like the time cycle for autosave or

the project description.

5.1-7 Tool and Project Settings

Tool Settings

5.1-8 Tool Settings – you can define a lot of properties

You define library and file locations, time cycles and enable/disable some functions.

<Project Settings>

5.1-9 Project Settings

page 44 of 85 V1.3

Page 45

Softing Linking Device –

Manual for Configuration, Installation and Maintenance

FF-CONF Configure your plant

Here you define the cycles of the auto save and the handling with Tag names. If you want to

add or to change the project description you can do it here even so the project exists.

5.1.2.8 Help

The Help function gives you information in different ways. You can call it by pressing the F1

button and you get the Help-Information for the current function you are working with. You

also can reach the Help function with the menu item Help.

Fig 5.1-10 The options of the Help function

5.1.3 ToolBar - Icons you can use while working

In this line 4 buttons are shown which can be used while FF-CONF is runing.

You can <Save Project>, start <Build All>, start <Download Project> and with the icon

<Online> you change offline/online. If you want to activate or deactivate the toolbar click the

right mouse button on any item of the main menu.

Fig 5.1-11 Activate or deactivate the ToolBar in any item of the main menu

5.1.4 Main view

Main view tabs (4) are the most important functions to build a configuration, to assign

configured devices of the <Network Configuration> with the <Network Livelist>, to configure

the <Function Block Application> and activate the messaging between the blocks of the

different devices.

Below you find a free space (5) where you normally work after you have chosen a tab.

5.1.4.1 <Network Configuration>

The tab <Network Configuration> is always unhidden. In the Network Configuration you

configure your network offline. The description of the devices must be allocated in the device

type library. Therefore see chapter Managing the Device Type Library.

To work faster you can use the offered icons:

to sort the devices, to assign and to download the project.

In the upper right corner of your working space you find two icons <Toggle drag> and

<Reset>. They allow you to relocate the devices shown in the working space and to reset to

the standard notification. First click <Toggle drag> and then to an object of the configuration.

Your mouse pointer changes to a cross and you can move the whole configuration picture

across your working space.

Fig 5.1-12 The icons <Toggle drag> and <Reset>

V1.31 page 45 of 85

Page 46

Softing Linking Device –

Manual for Configuration, Installation and Maintenance

FF-CONF Configure your plant

Fig 5.1-13 The changed mouse pointer allows you to move the whole configuration picture

5.1.4.2 <Function Block Application>

The tab <Function Block Application> is always active. Here you configure the

communication between the blocks of the H1 devices or the HSE Host. In Function Block

Application you can create different groups and applications to structure the whole plant and

its various areas.

5.1.4.3 Network Livelist

The Network Livelist shows you the currently active devices. To run your system it’s

necessary to assign configured and active devices of Network Configuration and Network

Livelist. How this is done is explained in detail in chapter Network Livelist.

In the Network Livelist you may sort the devices on PD Tags with the icon .

5.1.4.4 Parameter View

Parameter View shows you all parameters of each block as well as of the selected device as

of a block which is not associated with a device. You can change parameters if they are in

read/write mode.

5.1.4.5 Schedule View

Schedule View shows information about the cyclic behaviour of an H1 link. It lists all VCRs of

the LAS and the start time of the function blocks and their duration.

5.1.5 The Trace Log

Under the main view you see the partition for the Trace log. In the Trace log all information,

warnings and errors are listed while running the program. It shows the success of your

action. You can filter for each message type by activating the check box.

Here you see a screenshot with trace log after using the build function.

page 46 of 85 V1.3

Page 47

Softing Linking Device –

Manual for Configuration, Installation and Maintenance

FF-CONF Configure your plant

Fig 5.1-14 Example for Information and Warning in the Trace log

The source object of specific messages can be located by double clicking.

In this example the HSE Host device parameters are shown.

5.1.6 List and properties view

You choose the view to the contents of the available types of devices or blocks, the devices

or blocks or the properties of a selected field in the work space of an application (8). Under

the contents you find several icons which are different for each item to process a marked

content (7). Above you see the possibilities for filtering (9). The possibility of filtering is

different from item to item and is based on the contents.

5.1.6.1 Device Types

The device type view lists all devices in the device type library. Default device types are:

● FG 110 FF

● FG 100 FF

● FG 100 FF (Certified)

● HSE Host

The H1 Device Types have to be imported by the user.

V1.31 page 47 of 85

Page 48

Softing Linking Device –

Manual for Configuration, Installation and Maintenance

FF-CONF Configure your plant

Fig 5.1-15 Content of Device Types, the icons to process them and filters to select Device Types

Meaning of the icons below the contents:

● - to sort by Device Name

● - to import a new device,

● - to remove a marked device,

● and the count of total devices found.

5.1.6.2 Block Types

Fig 5.1-16 Content of Block Types, the icons to process them and filters to select Block Types

page 48 of 85 V1.3

Page 49

Softing Linking Device –

Manual for Configuration, Installation and Maintenance

FF-CONF Configure your plant

Meaning of the icons below the contents:

● - to sort by Manufacturer Name,

● and the count of total block types found.

5.1.6.3 Devices

Fig 5.1-17 Content of Devices, the icons to process them and filters to select Devices

Meaning of the icons below the contents:

● to sort by Manufacturer Name, Device Name, User Tag, PD Tag

● and tag list count.

V1.31 page 49 of 85

Page 50

Softing Linking Device –

Manual for Configuration, Installation and Maintenance

FF-CONF Configure your plant

5.1.6.4 Blocks

Fig 5.1-18 Content of Blocks, the icons to process them and filters to select Blocks

Meaning of the icons below the contents:

- to sort by Manufacturer Name,

- to look at FB Parameter View

● - to remove Function Block

● - to remove all unused Function Blocks

● - to copy and paste Function Blocks

The block view lists all explicitly and implicitly configured function blocks. The resource and

transducer blocks belong to the device and are not listed within the block list view.

5.1.6.5 Properties

If you choose the item properties you see the properties of any device or block that is

activated in any part of application. The properties of a selected object are displayed.

Properties View list of object types:

● Network configuration / livelist

● PC

● HSE subnet

● HSE devices (Linking Devices)

● H1 Links (Segments)

● H1 devices

● Function block application

● Group

● Application

● Block

page 50 of 85 V1.3

Page 51

Softing Linking Device –

Manual for Configuration, Installation and Maintenance

FF-CONF Configure your plant

Fig 5.1-19 The H1_Device_1 properties of the marked device are shown

5.1.7 Filtering the contents

Here you find the possibility to set filters and so you may select the contents shown in the list

view. The possibility of filtering is different from item to item and is based on the contents.

5.2 General Information

5.2.1 Floating windows

Fig 5.2-1 A special view to synchronize Network Configuration and Network Livelist in a very efficient method with

floating windows

Under the main menu item <View> <Reset Layout> the floating windows return to the default

view.

V1.31 page 51 of 85

Page 52

Softing Linking Device –

Manual for Configuration, Installation and Maintenance

FF-CONF Configure your plant

5.2.2 Objects within the Network Configuration

PC

Here you are working online or offline to build your Network Configuration and commission

your installation.

HSE Subnet

Ethernet component which corresponds with the Linking Device.

HSE Device

HSE Device or Linking Device. Field gateway to the H1 Links and the H1 devices.

H1 Link

The connective link between the HSE Device and the H1 Devices. It includes most of the

integrative functions of the field bus network. So the H1 Link object represents the port of

the linking device with the H1 VFD and the bus parameters common for every device on this

link.

H1 Device

Terminal with type information, network address, PD Tag and user tag. Details are provided

for each device in the properties view.

5.2.3 Tag Names

You find different tag names in FF-CONF. Nothing is prescribed for the User Tag. The string

specified with these tag names is unlimited.

If you see different tag names, please take into consideration that there is a difference

between user tags and FF PD tags. While user tags strings are not restricted in length and

character sets, FF PD tags are subject to the restrictions of the VisibleString data type within

FF-specs (32 ASCII characters).

As this might be inconvenient and if you don’t have any problems with the FF-restrictions,

you can enforce similarity between these tag names by selecting <Settings><Project

settings>and activate <Enforce PD tag same as User Tag>.

5.2.4 Using the buttons of the objects

Most of the objects offer the possibility to capture or to change the important data by clicking

the enclosed buttons. In the List View they allow you to build parts of the Network

Configuration. The current details are provided in the different chapters.

A double-click on the symbol of the objects of the Network Configuration or the Network

Livelist hides the units below or shows hidden units again. So you can select the units to

work with and get a better overview of this part of the installation.

page 52 of 85 V1.3

Page 53

Softing Linking Device –

Manual for Configuration, Installation and Maintenance

FF-CONF Configure your plant

Fig 5.2-2 Hide the units below with a double-click

Fig 5.2-3 Another double-click shows the hidden units

again

5.2.5 Using the context menu

Nearly all objects contain a context menu that allows you to do some of the steps to pattern

your Network Configuration or your Function Block Application. Examples are copy objects,

add and delete objects, the assign in the commissioning or set special parameters like in the

H1 Link.

Fig 5.2-4 For example the context menu of the H1 Link

5.3 Start FF-CONF

After correct installation you can start the program by clicking on

Start/Program…e.c..\Softing\FF-CONF\bin\FF-CONF.exe on your PC.

V1.31 page 53 of 85

Fig 5.3-1Start FF-CONF – Start Screen

Page 54

Softing Linking Device –

Manual for Configuration, Installation and Maintenance

FF-CONF Configure your plant

After a short time you see the screen to work with.

Fig 5.3-2 Basic screen to load an existent or a new project

The above screenshot shows the start screen of FF-CONF if you have never downloaded

device descriptions into the device library.

5.4 Managing the Device type library

HSE and H1 device types.

HSE device descriptions are preconfigured and cannot be changed. H1 device descriptions

can be added and removed. Each H1 device needs its special entry within the device type

library which must be notified before the Network Configuration can work successfully. A

device description has to be imported to the PC. You can add and delete single devices to

and from the device type library.

Before adding a device to the network configuration it has to be imported via the green

button. In the screen below you see the File selection dialog for importing a device

description.

While the .cff file is imported into the device type library possible error messages are shown

in the trace log. If there are any error messages, please contact the manufacturer of the

device for an update.

By selecting the cff-file, the information from associated .ffo and .sym files are imported as

well.

page 54 of 85 V1.3

Page 55

Softing Linking Device –

Manual for Configuration, Installation and Maintenance

FF-CONF Configure your plant

Fig 5.4-1 Select a .cff file for adding an H1 device to the list of Device Types.

The device library contains the description of H1 device types. The description of a device

(.cff-file, .ffo-file, .sym-file) is either part of the delivery of the H1 device or can be loaded

from fieldbus.org: http://www.fieldbus.org/index.php?option=com_mtree&Itemid=324

Remove a Device Type

To remove a device type from FF-CONF, select a device type within the list in the right-hand

partition of the screen (1). Click the button of the device type view (2). Acknowledge the

pop up window with <yes> (3) and the selected device type is deleted from the device type

list.

Fig 5.4-2 Remove a device type

V1.31 page 55 of 85

Page 56

Softing Linking Device –

Manual for Configuration, Installation and Maintenance

FF-CONF Configure your plant

Exception: HSE Devices cannot

be removed. You get the

notification:

!

5.5 Project handling

In the menu item <Network Configuration> you start the main configuration work of your

project.

5.5.1 Create a New Project

After the preliminaries you can start a new project.

Fig 5.5-1 Starting a new project

You choose <New> or <Open>.

New: The window (2) with the New Projects Dialog appears. Edit the project name and, if

desired, add a comment. Leave the window by pressing the <OK> button.

Open: You choose one of the shown projects to work with.

Fig 5.5-2 Open an existing project

page 56 of 85 V1.3

Page 57

Softing Linking Device –

Manual for Configuration, Installation and Maintenance

FF-CONF Configure your plant

5.5.2 Save project

You can save the project manually whenever you want. You have two options to do this:

Fig 5.5-3 Save your project manually

If you save your project at object time click the icon <save project> in the ToolBar.

Fig 5.5-4 Save your project with <save> or with <save as>

If you want to copy the project with a new name or to another folder use the function <save

as>.

In the <project settings> “autosave” you can define the auto save in any number of seconds

so that you save your project automatically after a short time of working.

Beside the autosave the project is saved on any “check”, “build” or “download”.

5.5.3 Delete Project

If you want to delete the current project you click the buttons <project> and <delete project>

in the upper left-hand corner of your screen.

Fig 5.5-5 Delete the current project

Of course you also can delete a non-current project with the functions of the operating

system.

V1.31 page 57 of 85

Page 58

Softing Linking Device –

Manual for Configuration, Installation and Maintenance

FF-CONF Configure your plant

5.6 Network configuration

The most important part of the project handling is the Network Configuration. You can

configure a network in two ways:

● You adapt the network configuration to the real existing installation,

● You configure a planned network without an existing installation and adapt it later. You

need only the offline status to do this.

Both ways have their advantages. The chosen way is to decide on your individual situation.

Of course it is possible to mix the procedure, e.g. you have some installed devices and you