Emerson FB1100 Instruction Manual

Emerson FB1100 Flow Computer Instruction Manual

Emerson FB1100 Flow Computer

Instruction Manual

D301752X012

February 2021

Remote Automation Solutions

Emerson FB1100 Flow Computer Instruction Manual

D301752X012

February 2021

Device Safety Considerations

Reading these Instructions

Before operating the device, read these instructions carefully and understand their safety implications. In some situations,

improperly using this device may result in damage or injury. Keep this manual in a convenient location for future reference.

Note that these instructions may not cover all details or variations in equipment or cover every possible situation regarding

installation, operation, or maintenance. Should problems arise that are not covered sufficiently in the text, immediately

contact Customer Support for further information.

Protecting Operating Processes

A failure of this device – for whatever reason -- may leave an operating process without appropriate protection and could result

in possible damage to property or injury to persons. To protect against this, you should review the need for additional backup

equipment or provide alternate means of protection (such as alarm devices, output limiting, fail-safe valves, relief valves,

emergency shutoffs, emergency switches, etc.). Contact Remote Automation Solutions for additional information.

Returning Equipment

If you need to return any equipment to Remote Automation Solutions, it is your responsibility to ensure that the equipment

has been cleaned to safe levels, as defined and/or determined by applicable federal, state and/or local law regulations or

codes. You also agree to indemnify Remote Automation Solutions and hold Remote Automation Solutions harmless from any

liability or damage which Remote Automation Solutions may incur or suffer due to your failure to ensure device cleanliness.

Grounding Equipment

Ground metal enclosures and exposed metal parts of electrical instruments in accordance with OSHA rules and regulations as

specified in Design Safety Standards for Electrical Systems, 29 CFR, Part 1910, Subpart S, dated: April 16, 1981 (OSHA rulings are

in agreement with the National Electrical Code). You must also ground mechanical or pneumatic instruments that include

electrically operated devices such as lights, switches, relays, alarms, or chart drives.

Important: Complying with the codes and regulations of authorities having jurisdiction is essential to ensuring personnel

safety. The guidelines and recommendations in this manual are intended to meet or exceed applicable codes and regulations.

If differences occur between this manual and the codes and regulations of authorities having jurisdiction, those codes and

regulations must take precedence.

Protecting from Electrostatic Discharge (ESD)

This device contains sensitive electronic components which be damaged by exposure to an ESD voltage. Depending on the

magnitude and duration of the ESD, it can result in erratic operation or complete failure of the equipment. Ensure that you

correctly care for and handle ESD-sensitive components.

System Training

A well-trained workforce is critical to the success of your operation. Knowing how to correctly install, configure, program,

calibrate, and trouble-shoot your Emerson equipment provides your engineers and technicians with the skills and confidence

to optimize your investment. Remote Automation Solutions offers a variety of ways for your personnel to acquire essential

system expertise. Our full-time professional instructors can conduct classroom training at several of our corporate offices, at

your site, or even at your regional Emerson office. You can also receive the same quality training via our live, interactive

Emerson Virtual Classroom and save on travel costs. For our complete schedule and further information, contact the Remote

Automation Solutions Training Department at 800-338-8158 or email us at education@emerson.com.

ii

Emerson FB1100 Flow Computer Instruction Manual

D301752X012

February 2021

Contents

Section 1: Introduction 1

Safety Labels ........................................................................................................................ 3

Features ............................................................................................................................... 3

Central Processing Unit (CPU) ............................................................................................... 4

1.3.1 Memory ................................................................................................................... 4

Explosion-proof Enclosure .................................................................................................... 4

1.4.1 Physical Security ....................................................................................................... 5

I/O ........................................................................................................................................ 6

Power Options...................................................................................................................... 6

Communications .................................................................................................................. 7

Human-Machine Interface (HMI) Module .............................................................................. 7

FBxWifi™ Communications .................................................................................................. 8

Software Tools ........................................................................................................... 9

Autonomous Measurement Mode .............................................................................. 9

RoHS2 Compliance .................................................................................................... 9

Section 2: Installation 11

2.1 Hazardous Locations .......................................................................................................... 11

2.2 Environmental Specifications ............................................................................................. 12

2.3 Required Tools ................................................................................................................... 12

2.4 Site Considerations ............................................................................................................ 13

2.5 General Wiring Guidelines .................................................................................................. 14

2.6 Front or Rear End Caps ....................................................................................................... 14

2.6.1 Removing/Replacing Retaining Clamp on End Caps ................................................ 14

2.6.2 Removing the Front or Rear End Caps ..................................................................... 15

2.6.3 Replacing the Front or Rear End Caps...................................................................... 16

2.7 Mounting the Enclosure ..................................................................................................... 16

2.7.1 Bolting Considerations ........................................................................................... 17

2.7.2 O-rings with Flange Adapters.................................................................................. 18

2.7.3 Direct Mount .......................................................................................................... 19

2.7.4 Indirect Mount ....................................................................................................... 19

2.7.5 Rotating the Housing ............................................................................................. 21

2.8 Grounding the Device ........................................................................................................ 22

2.9 Terminal Plate .................................................................................................................... 23

2.10 Power Modes ........................................................................................................... 24

2.10.1 Low Power Mode .................................................................................................. 24

2.10.2 Standard Power Mode .......................................................................................... 25

2.10.3 Notes on Battery Life ............................................................................................ 26

2.11 Connecting Power .................................................................................................... 26

2.11.1 Connecting DC Power .......................................................................................... 27

2.11.2 Connecting Battery Power .................................................................................... 27

2.12 Installing the Optional Solar Panel ............................................................................ 28

2.12.1 Attach Mounting Hardware to the Solar Panel ...................................................... 29

2.12.2 Mounting the Solar Panel (Integral Mount) ........................................................... 30

2.12.3 Mounting the Solar Panel (Remote Mount) ........................................................... 32

Contents iii

Emerson FB1100 Flow Computer Instruction Manual

D301752X012

February 2021

2.12.4 Connecting Solar Power ....................................................................................... 33

2.12.5 Adjusting the Optional Solar Panel Tilt Angle ........................................................ 34

2.13 Connecting Communication Ports ........................................................................... 35

2.13.1 Connecting to COM1 ............................................................................................ 36

2.13.2 Connecting to COM2 and COM3 .......................................................................... 37

2.14 Connecting the RTD ................................................................................................. 40

2.15 Wiring the Digital Output ......................................................................................... 41

Section 3: Operation 43

3.1 Powering Up/Powering Down the Device ........................................................................... 43

3.2 Establishing Communications ............................................................................................ 43

3.2.1 Communicating with the SCADA Host .................................................................... 43

3.2.2 Communicating with a Laptop Using One of the Serial Ports ................................... 44

3.2.3 Communicating with a Laptop Wirelessly with FBxWifi ........................................... 45

3.3 Communicating using the HMI Module .............................................................................. 45

Section 4: Service and Troubleshooting 49

4.1 Returning the Unit for Repairs ............................................................................................ 50

4.2 Interpreting the Status LEDs ............................................................................................... 51

4.3 Switch and Buttons ............................................................................................................ 53

4.4 Removing/Replacing the HMI Module ................................................................................ 53

4.5 Replacing the Main Battery Pack ......................................................................................... 54

4.6 Removing/Replacing the SRAM Battery .............................................................................. 57

4.7 Upgrading System Firmware .............................................................................................. 58

Appendix A: Special Instructions for Class I Division 2 Locations 61

Appendix B: Special Instructions for Class I Division 1 Locations 65

Appendix C: ATEX Non-Sparking Zone 2 Certifications 71

Appendix D: ATEX Flame-Proof Zone 1 Certifications 73

Appendix E: Autonomous Mode Requirements 75

Index 77

iv Contents

Section 1: Introduction

This section covers the following topics:

Safety Labels

Features

Central Processing Unit (CPU)

Explosion-proof Enclosure

I/O

Power Options

Communications

Human-Machine Interface (HMI) Module

FBxWifi™ Communications

Software Tools

Emerson FB1100 Flow Computer Instruction Manual

D301752X012

February 2021

Autonomous Measurement Mode

RoHS2 Compliance

The Emerson FB1100 Flow Computer measures pressure, differential pressure, and temperature

for a single meter run of natural gas. This manual describes how to install and configure the

Emerson FB1100 Flow Computer hardware.

™

For information on using the FBxConnect

accompanies FBxConnect.

configuration software, see the online help that

Introduction 1

Emerson FB1100 Flow Computer Instruction Manual

1

HMI module

2

Front end cap (cover)

3

Data plate

4

Rear end cap (cover)

5

Conduit fittings

6

Enclosure

7

Sensor module

D301752X012

February 2021

Figure 1-1: FB1100 Flow Computer

2 Introduction

Safety Labels

DANGER

WARNING

CAUTION

SAFETY FIRST

This product may display safety label(s) to identify potential hazards. The same types of notices

appear within the documentation. Whenever you see an exclamation point (!) enclosed within a

triangle (shown to the left), consult the documentation for additional safety information about the

hazard and how to avoid it. The labels used are:

Emerson FB1100 Flow Computer Instruction Manual

D301752X012

February 2021

MAY CAUSE DEATH

Observe all precautionary signs posted on the equipment.

Failure to do so may result in death or serious injury to personnel.

DANGER TO PERSONNEL AND EQUIPMENT

Observe all precautionary signs posted on the equipment.

Failure to do so may result in injury to personnel or cause damage to the equipment.

MAY CAUSE INJURY TO PERSONNEL OR DAMAGE EQUIPMENT.

Observe all precautionary signs posted on the equipment.

Failure to do so may result in injury to personnel or cause damage to the equipment.

Features

Introduction 3

General instructions and safety reminders.

The FB1100 Flow Computer includes the following key features:

Enclosure suitable for use in Class I Division 1 explosion proof and Ex db Zone 1 flame-proof

environments

Enclosure suitable for use in Class I Division 2 non-incendive and Ex nA Zone 2 non-sparking

environments

Integral multi-variable sensor for measurement of Pressure (P) and Differential Pressure (DP)

Connections for customer-supplied resistance temperature detector (RTD) for measurement

of temperature (T)

Single digital output

Emerson FB1100 Flow Computer Instruction Manual

Memory

Usage

8 MB SRAM

Holds in-use configuration, current state of all variables

Holds firmware image, historical logs, configuration backup (if saved to flash),

D301752X012

February 2021

Power from a DC power supply, a lithium battery, or an optional lead acid battery/solar panel

combination

Serial communication options for RS-232, RS-485 (2-wire), RS-485/422 (4-wire).

HMI module with optional display and back light for local operator interaction

Optional Wi-Fi

from a laptop without physical cable connection

Application software supports AGA3, AGA8, ISO 5167, ISO 6976, and API 21.1 calculations in

U.S., metric, or other natural gas standard units

Support for one-year autonomous measurement without external power (lithium battery

option)

®

transceiver (802.11 b/g) for field technician to access the flow computer

Central Processing Unit (CPU)

The flow computer’s CPU is a NXP® Kinetis® K61 series CPU with an ARM® Cortex® M4 processor

that operates at 4 to 60 MHz depending on the power mode. The CPU runs the Micrium operating

system.

1.3.1 Memory

The flow computer includes both static and flash memory.

Table 1-1: Memory

128 MB Flash

and the executing program

Explosion-proof Enclosure

The FB1100 Flow Computer includes an explosion-proof enclosure made of either aluminum or

stainless steel. The enclosure consists of the main housing, two threaded covers, and four conduit

entry points.

The four conduit entry points are ¾ in NPT pipe threaded holes that permit entry of field conduit

for I/O and communication wiring. ATEX installations use a ¾ in NPT to M20 thread reducer.

Unused apertures shall be closed with suitable blanking elements.

The FB1100 Flow Computer can operate in an unprotected outdoor environment. Wiring for I/O,

communications, and power enters the enclosure through the four conduit fittings with

appropriate protective seals and connects to the terminal plate.

The front end cap (cover) provides a viewing window for the HMI module. You can access the

terminal plate by removing the rear end cap (cover).

4 Introduction

The FB1100 Flow Computer has North American certification for Class I Division 1 Groups C and D

1

Retaining clamp (For ATEX & IEC approved products only)

2

Tie holes in end caps

3

Tie holes in coupling screws

(explosion proof) and Class I Division 2 Groups A, B, C and D (non-incendive) hazardous locations or

non-hazardous locations. See Appendix A and Appendix B for more information.

The FB1100 Flow Computer has European certification for EExd Zone 1 (flame-proof) and EExd

Zone 2 (non-sparking) hazardous locations or non-hazardous locations. See Appendix C and

Appendix D for more information.

Details on certification information are included on the data plate screwed to the top of the

enclosure.

1.4.1 Physical Security

The flow computer end caps include retaining clamps for ATEX/IEC applications. In addition, if local

regulations require it, you can wire a tamper-resistant seal using the tie holes located in the front

and rear end caps, and in the coupling screws.

Figure 1-2: Retaining Clamps and Tie Holes for Tamper-resistant Seals

Emerson FB1100 Flow Computer Instruction Manual

D301752X012

February 2021

Introduction 5

Emerson FB1100 Flow Computer Instruction Manual

Option

Usage

External DC Power

Lead Acid Battery Pack

6.0 Vdc

Lithium Battery Pack

10 Vdc

D301752X012

February 2021

I/O

The flow computer comes with base I/O from both the CPU and the built-in multi-variable (MV)

sensor. Base I/O consists of:

Pressure (P) input from the MV sensor

Differential pressure (DP) input from the MV sensor

Connections for temperature (T) input from a customer-supplied RTD

Single general purpose digital output (DO) - for use with an odorizer or other device

Power Options

You can power the flow computer using an external DC input, an internal battery, or an internal

rechargeable battery connected to a solar panel.

Important

Use only batteries supplied with the flow computer or sold by Emerson Remote Automation

Solutions as spare parts for this flow computer. If you substitute a battery you obtain elsewhere

will void your certification unless it is the identical part from the same manufacturer as that

supplied with the flow computer from Emerson.

you

Table 1-2: Power Options

Supply

5.7 Vdc to 30 Vdc external supply (Max power at 10 watts)

4.5Ah

Not suitable with ATEX or IECEx applications

Can be optionally charged by a 6-watt solar panel

41 Ah (approximate)

Not suitable with ATEX or IECEx applications

Required when using autonomous measurement mode

In autonomous measurement mode allows operation for one year

6 Introduction

Communications

Port

Type

Use

COM1 Serial communications

RS-232, RS-485 (2-wire), RS-485/422 (4-wire)

COM2 Serial communications

RS-232 or RS-485 (2-wire) communication to

COM3 Serial communications

RS-232 or RS-485 (2-wire) communication to

The flow computer includes three serial communication ports. The serial ports allow

communication using DNP3, Modbus, BSAP, and ROC protocols.

Table 1-3: Serial Ports

Software-selectable for RS-232, RS485 (2-wire), RS-485/422 (4-wire)

operation

4-wire

Software-selectable for RS-232, or

RS-485 (2-wire) operation

2-wire

Emerson FB1100 Flow Computer Instruction Manual

D301752X012

February 2021

communication to host or other devices. 4wire used with external radio.

host or other devices.

Software-selectable for RS-232, or

RS-485 (2-wire) operation

2-wire

host or other devices.

Human-Machine Interface (HMI) Module

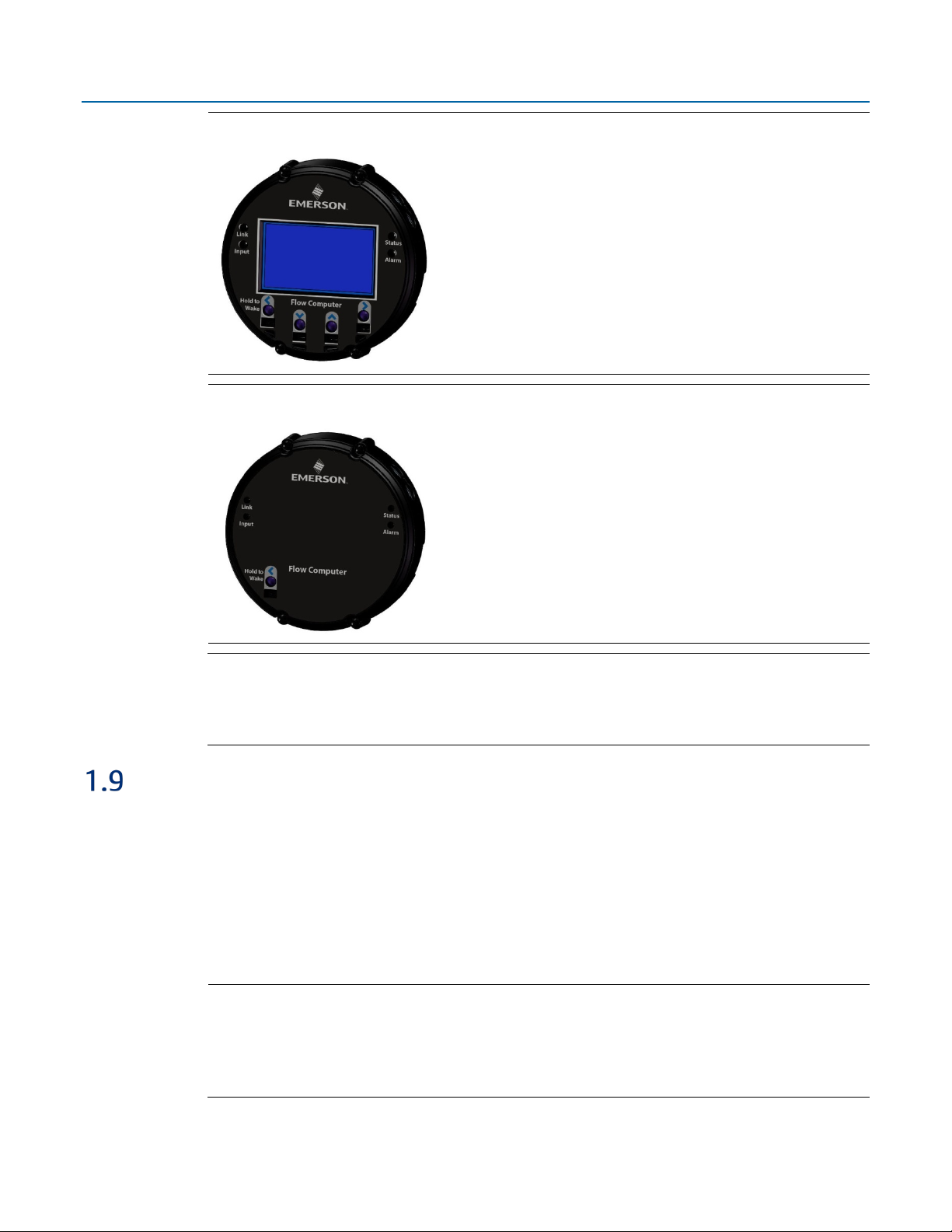

The flow computer includes an HMI module with an optional liquid crystal display (LCD) for local

operator access to the device. The LCD, if present, shows a series of menus that sequentially display

the current values of particular process variables. A configuration parameter in FBxConnect

determines whether you must log in first to view the menus. If required, you log in by selecting

alphanumeric characters by scrolling through a list until you select the correct character.

The HMI module includes four LEDs to provide status information. Units with the display include

four infrared (IR) buttons for operator interaction.

To conserve power, the HMI module enters sleep mode after a period of inactivity. Sleep mode

disables FBxWifi communication. In FBxConnect, you can configure the number of minutes of

inactivity triggering sleep mode through the LCD Sleep Time parameter. Setting this parameter to

0 disables sleep mode which keeps the HMI module on but uses significantly more power.

Introduction 7

Emerson FB1100 Flow Computer Instruction Manual

D301752X012

February 2021

Figure 1-3: HMI Module with LCD

Figure 1-4: HMI Module without LCD

Note

If your flow computer does not include the LCD option, you still have the status LEDs and a single IR

button for waking up the device (shown in Figure 1-4).

FBxWifi™ Communications

The flow computer has an optional Wi-Fi® transceiver (FBxWifi) that enables you to connect via a

laptop or tablet from some small distance away.

This capability allows an operator to potentially remain outside the hazardous location and still

communicate with the flow computer. The operator's laptop must have Wi-Fi capability, line-ofsight access to the HMI module, and must be loaded with FBxConnect configuration software.

Once connected, the operator can view process values, edit configuration parameters, and collect

logs.

Note

The FBxWifi electronics reside inside the HMI module. The HMI module must be awake to use

FBxWifi communications You can wake it up manually by holding a finger against the front cover

glass over the Hold to Wake button (the left-most button) for typically from five to ten seconds.

8 Introduction

Emerson FB1100 Flow Computer Instruction Manual

Software Tools

FBxConnect provides a series of wizards that allow you to perform configuration activities for the

flow computer. You connect a PC running FBxConnect to the flow computer using one of the

communication ports or through a wireless connection. You can then:

Set parameters within your application

Configure I/O channels

Specify the serial communication method for a port (RS-232 to RS-485) as needed

View or collect audit trail information such as alarm, event, or historical logs

Update system firmware

Autonomous Measurement Mode

You can configure the FB1100 Flow Computer to operate as a low power measurement device that

operates independently for one year. In this autonomous measurement mode, the flow computer

operates similarly to earlier generation chart recorders, collecting data from non-critical, low-flow

applications and storing it for later retrieval.

D301752X012

February 2021

Autonomous measurement mode supports collection of data from the multi-variable sensor and

RTD only. This mode requires the lithium battery pack; no external power supply is required.

You can interact with the device through the HMI module's infrared buttons or through a laptop

running FBxConnect. To maintain low power consumption for the battery, using this mode limits

you to 30 minutes of interaction per month.

See Appendix E for more information.

RoHS2 Compliance

Device with Integral MVS:

RoHS (2) EU Directive 2011/65/EU: This product may be considered out-of-scope when used for

the intended design purpose in a Large Scale Fixed Installation (LSFI).

Consult https://www.emerson.com/compliance for up-to-date product information.

Introduction 9

Emerson FB1100 Flow Computer Instruction Manual

D301752X012

February 2021

10 Introduction

Section 2: Installation

This section covers the following topics:

Hazardous Locations

Environmental Specifications

Required Tools

Site Considerations

General Wiring Guidelines

Front or Rear End Caps

Mounting the Enclosure

Grounding the Device

Terminal Plate

Power Modes

Emerson FB1100 Flow Computer Instruction Manual

D301752X012

February 2021

Connecting Power

Installing the Optional Solar Panel

Connecting Communication Ports

Connecting the RTD

Wiring the Digital Output

The flow computer ships from the factory fully assembled, except for the optional solar panel

assembly.

2.1 Hazardous Locations

The housing for the FB1100 Flow Computer is an explosion-proof case designed to operate in

hazardous locations.

For North America the FB1100 Flow Computer has certifications for Class I, Division 1 (Groups C &

D) explosion-proof, Class I Division 2 (Groups A, B, C & D) non-incendive, and non-hazardous

locations only. Appendix A contains special information for Class I Division 2 installations; Appendix B

contains special information for Class I Division 1 installations.

For Europe the FB1100 Flow Computer has certifications for Ex db Zone 1 flame-proof and for Ex nA

Zone 2 non-sparking installations and non-hazardous locations only. Appendix C contains special

information for Ex nA Zone 2 installations; Appendix D contains special information for Ex db Zone 1

installations.

All certifications are listed on the data plate located on the top of the device.

Installation 11

Emerson FB1100 Flow Computer Instruction Manual

Specification

Range

-40°C to +80 °C (-40 °F to +176 °F) - no battery, C1D1/C1D2

Maximum Process Connection

Humidity

5% to 95% non-condensing

Vibration

2g over 10 to 150 Hz; 1g over 150 to 200 Hz

Tool

Use

Torque wrench

For bolting/mounting the flow computer

3 mm hexagonal wrench

For screw for M4 x 0.7 end cap retaining clamp

9/16 in hexagonal wrench

For installing/removing ¾ in NPT conduit plugs

1 1/16 in combination wrench

For installing/removing ¾ in NPT to M20 thread

#1 Phillips-head screwdriver

For screws on HMI module

#2 Phillips-head screwdriver

For screws on other modules and boards

1/8 inch flat-head screwdriver

For 5.08 mm pitch terminal block connections

Laptop PC running Field Tools with FBxConnect

2.2 Environmental Specifications

This section summarizes the environmental specifications for the device. For full details, refer to

the product data sheet FB1100 Flow Computer (D301781X012).

Table 2-1: Environmental Specifications

-40°C to +80 °C (-40°F to +176 °F) - lead acid battery, C1D1/C1D2

Ambient Temperature

-40°C to +80 °C (-40 °F to +176 °F) - lithium battery, C1D1/C1D2

-40°C to +80 °C (-40 °F to +176 °F) - no battery, ATEX/IEC Ex db

-40°C to +80 °C (-40 °F to +176 °F) - no battery, ATEX/IEC Ex nA

D301752X012

February 2021

Temperature

2.3 Required Tools

Certain tools and equipment are required for installing and servicing the flow computer.

Table 2-2: Required Tools

2.5 mm hexagonal wrench For manipulating rotation set screw

120 °C (248 °F)

(ATEX required)

configuration software

12 Installation

reducer (ATEX required)

For software configuration

Emerson FB1100 Flow Computer Instruction Manual

2.4 Site Considerations

The flow computer must reside in an accessible location for configuration and service. Refer to the

dimensional drawings for information on the space required.

Ensure the installation location provides easy access to the HMI module.

If your unit includes the optional solar panel, ensure the installation location provides

sufficient space to mount the solar panel and adequate sunlight to charge the battery.

If your unit includes the optional FBxWifi ensure the installation location provides line-ofsight access to the transceiver.

Figure 2-1: FB1100 Flow Computer Dimensions – Multivariable Sensor

D301752X012

February 2021

Installation 13

2.5 General Wiring Guidelines

1

End Cap

2

Screw

3

Retaining Clamp

The flow computer’s pluggable terminal blocks use compression-type terminals that

accommodate wire between 28 and 12 AWG.

When making a connection, insert the bare end of the wire (approx. 1/4" max) into the clamp

adjacent to the screw and secure the screw.

To prevent shorts, ensure that no bare wire is exposed.

Allow some slack in the wire while making terminal connections. Slack makes the wires more

manageable and helps minimize mechanical strain on the terminal blocks.

Use twisted pair, shielded and insulated cable for communication and I/O wiring to minimize

signal errors caused by electromagnetic interference (EMI), radio frequency interference

(RFI), and transients. When using shielded cable, ground all shields at only one point in the

appropriate system. This prevents circulating ground current loops that can cause signal

errors.

2.6 Front or Rear End Caps

Emerson FB1100 Flow Computer Instruction Manual

D301752X012

February 2021

The flow computer includes two threaded covers (end caps). The front end cap includes a window

for viewing the HMI module; the rear end cap provides access to the terminal plate for power and

I/O wiring.

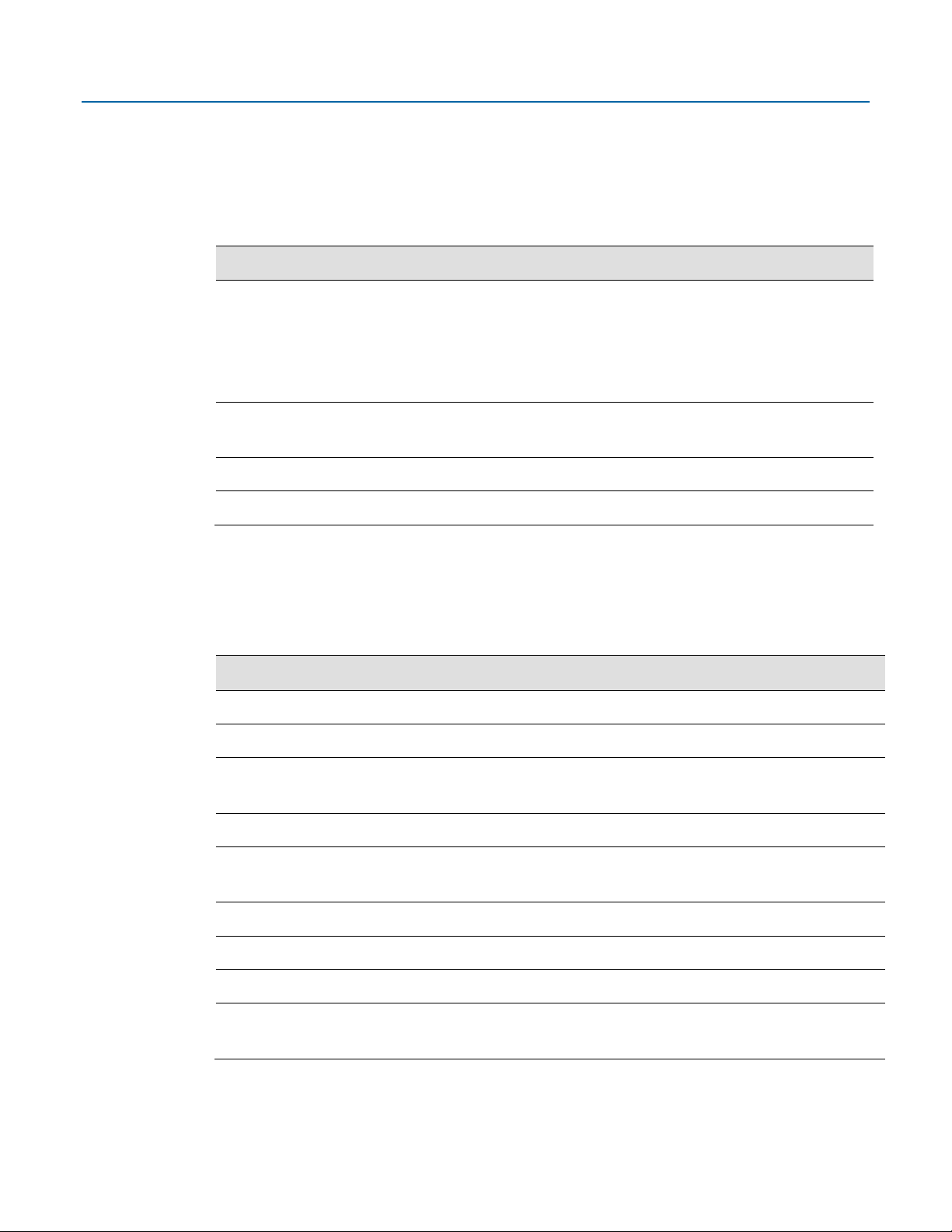

2.6.1 Removing/Replacing Retaining Clamp on End Caps

For flameproof ATEX/IEC applications, each end cap includes a retaining clamp which screws down

to prevent the end cap from being unscrewed.

Figure 2-2: Front End Cap with Retaining Clamp Fitted

14 Installation

Emerson FB1100 Flow Computer Instruction Manual

DANGER

D301752X012

February 2021

Figure 2-3. Retaining Clamp in Place

To loosen or tighten the screw, use a 3mm hexagonal wrench. When tightening, torque to 12 in-lbs

(1.4 N m).

Figure 2-4. Retaining Clamp and Screw

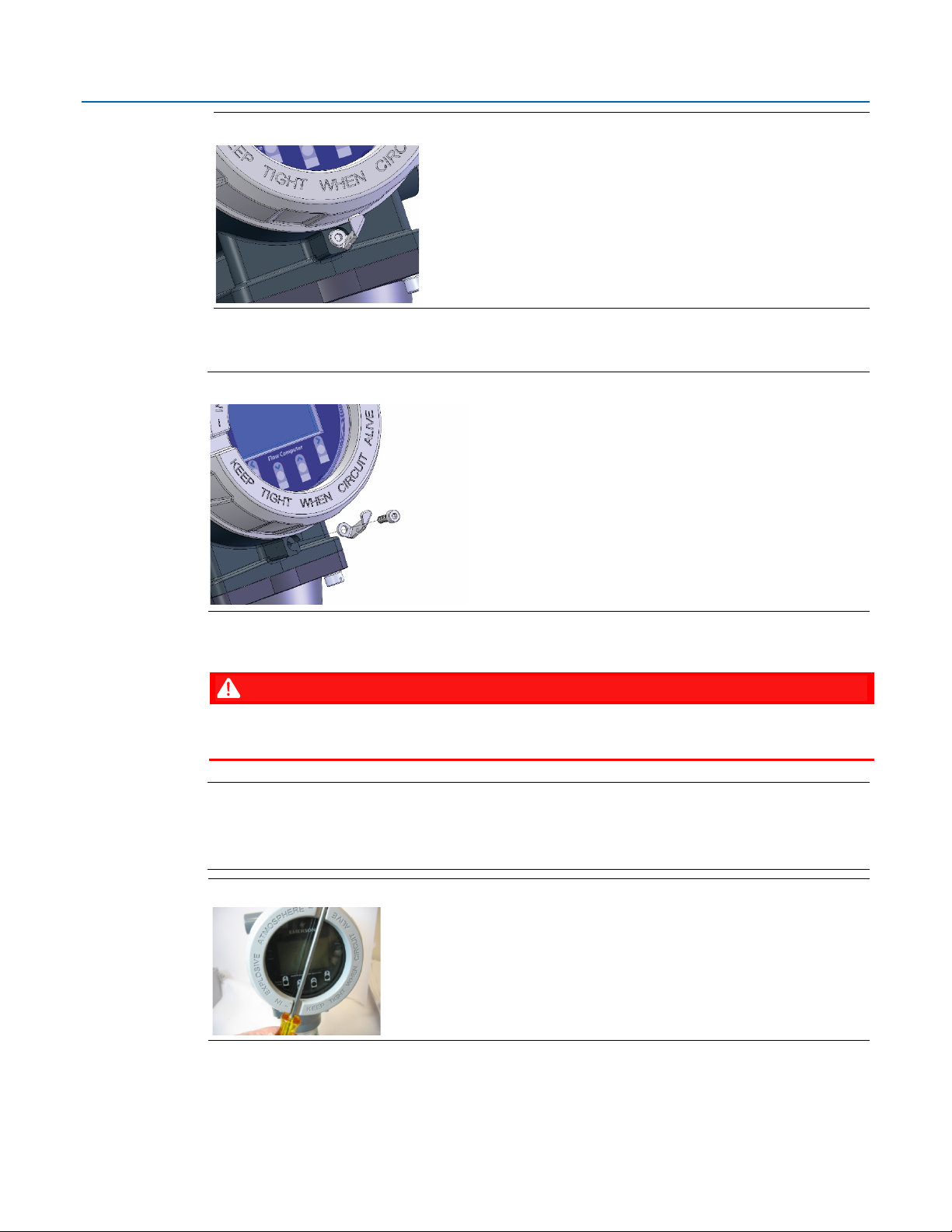

2.6.2 Removing the Front or Rear End Caps

EXPLOSION HAZARD: Never remove end cap(s) in a hazardous location. Removing end cap(s) in a

hazardous location could result in an explosion.

Note

If you need more leverage place a long screwdriver or other appropriate tool across the two

notches in the end cap to act as a pry bar (see Figure 2-5).

Figure 2-5: Removing or Tightening the End Cap with Long Screwdriver

Installation 15

Remove the retaining clamp (if present). (See Section 2.6.1.)

1.

Grasp the end cap (front or rear).

2.

Emerson FB1100 Flow Computer Instruction Manual

DANGER

D301752X012

February 2021

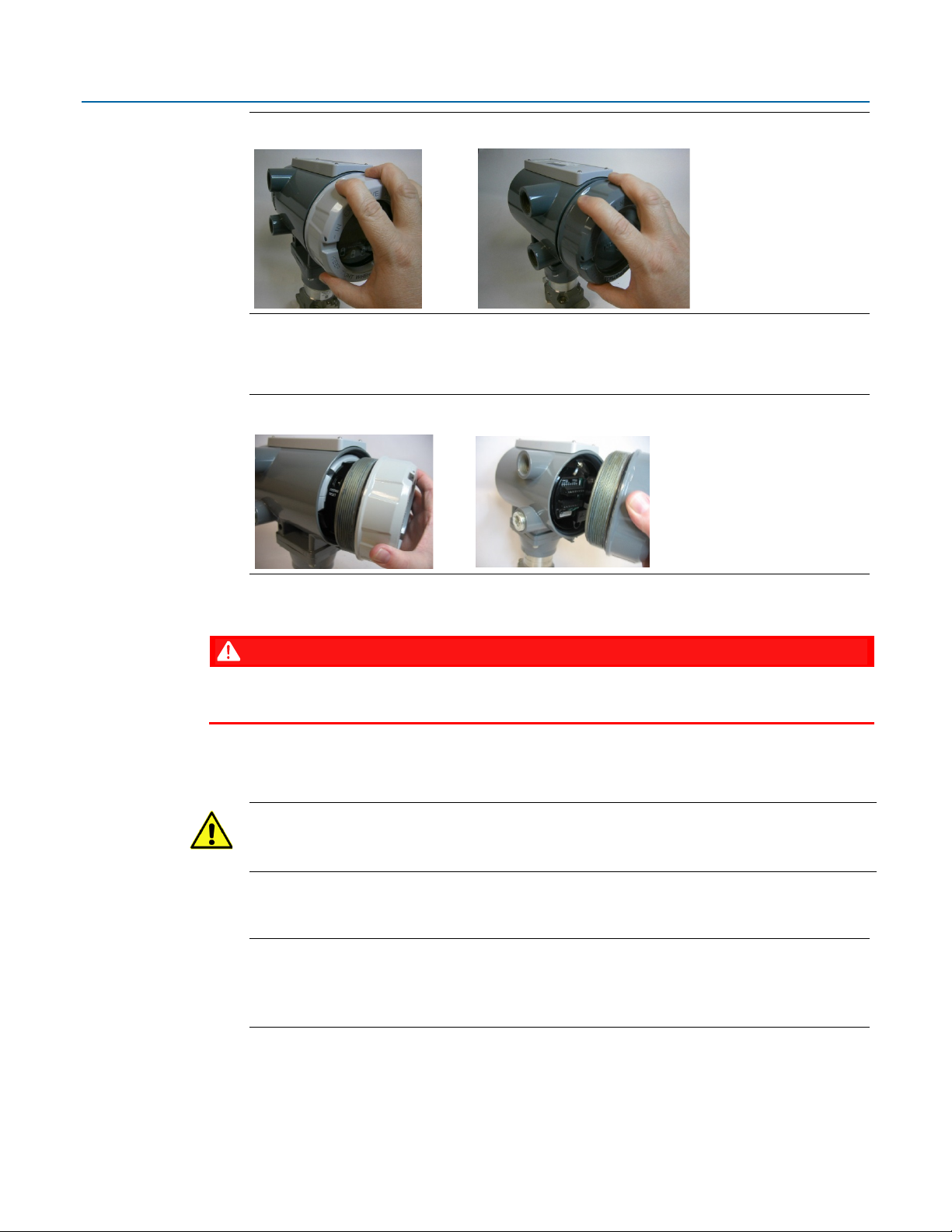

Figure 2-6: Front (left) and Rear (right) End caps

Unscrew the end cap turning it counter-clockwise until it comes off. Set it aside in a safe

3.

location.

Figure 2-7: Front (left) and Rear (right) End Caps Removal

2.6.3 Replacing the Front or Rear End Caps

EXPLOSION HAZARD: Ensure the area in which you perform this operation is non-hazardous.

Performing this operation in a hazardous area could result in an explosion.

Grasp the end cap (front or rear).

1.

2.

Carefully align the end cap threads with the threads of the enclosure.

Important

When replacing the rear end cap, ensure wires connecting to the terminal plate do not get

crimped or caught between the end cap threads and the enclosure.

3.

Screw the end cap clockwise (eight full turns) until it is tightly sealed to the enclosure.

Replace the retaining clamp (if required). (See Section 2.6.1.)

4.

Note

If you need more leverage place a long screwdriver or other appropriate tool across the two

notches in the end cap to act as a pry bar (see Figure 2-5).

2.7 Mounting the Enclosure

You can mount the flow computer either directly to a manifold on the pipeline or indirectly on a

two-inch pipe or pole.

16 Installation

Installations use either a traditional mounting kit or a coplanar mounting kit.

DANGER

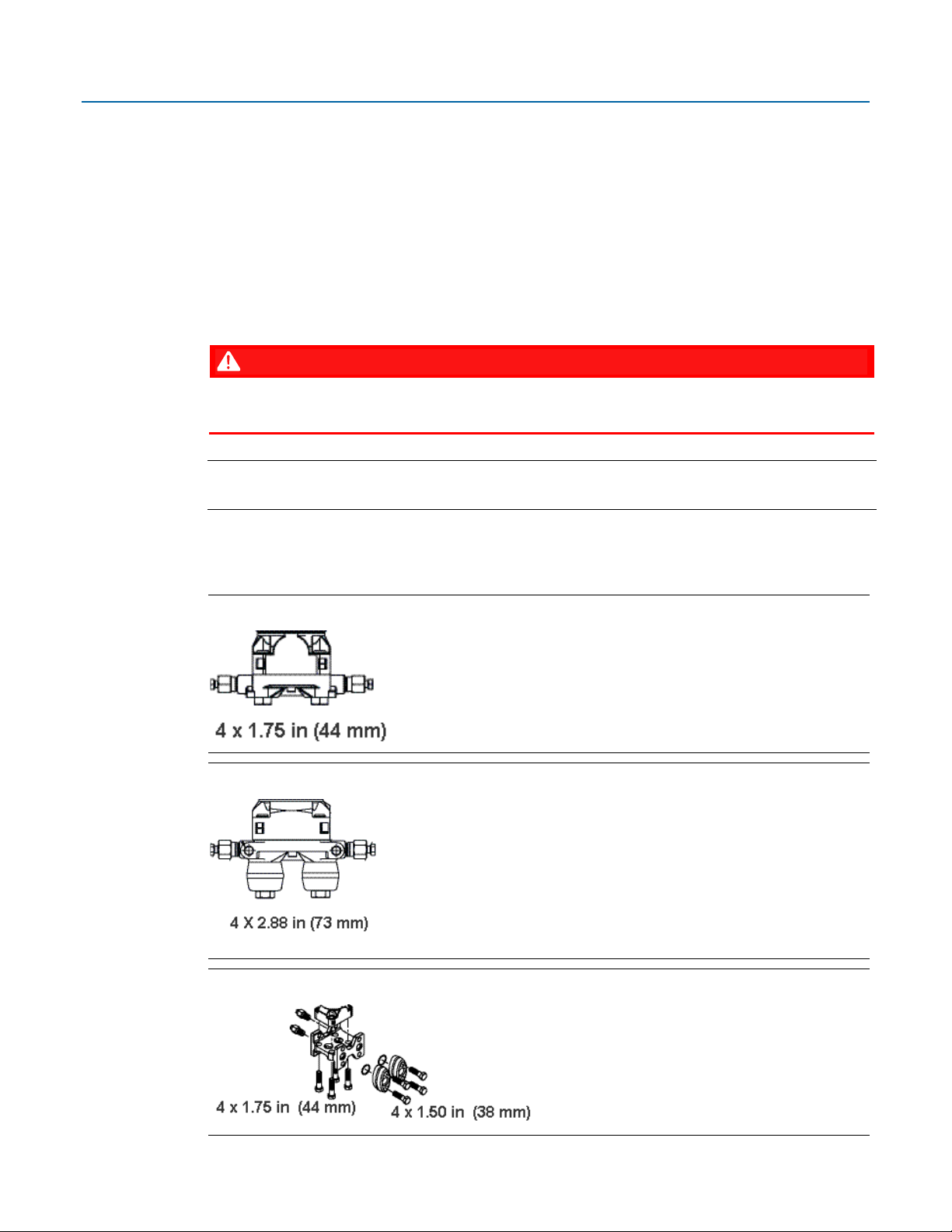

2.7.1 Bolting Considerations

If the flow computer installation requires assembly of a process flange, a manifold, or flange

adapters, follow these assembly guidelines to ensure a tight seal for optimal performance

characteristics of the flow computer.

Only use bolts supplied with the flow computer or sold by Emerson Remote Automation Solutions

as spare parts. Refer to the figure for common flow computer assemblies with the bolt length

required for proper flow computer installation.

Emerson FB1100 Flow Computer Instruction Manual

D301752X012

February 2021

EXPLOSION HAZARD: Ensure the area in which you perform this operation is non-hazardous.

Performing this operation in a hazardous area could result in an explosion.

Note

For all other manifolds, contact your local Emerson Sales office or Emerson Impact Partner.

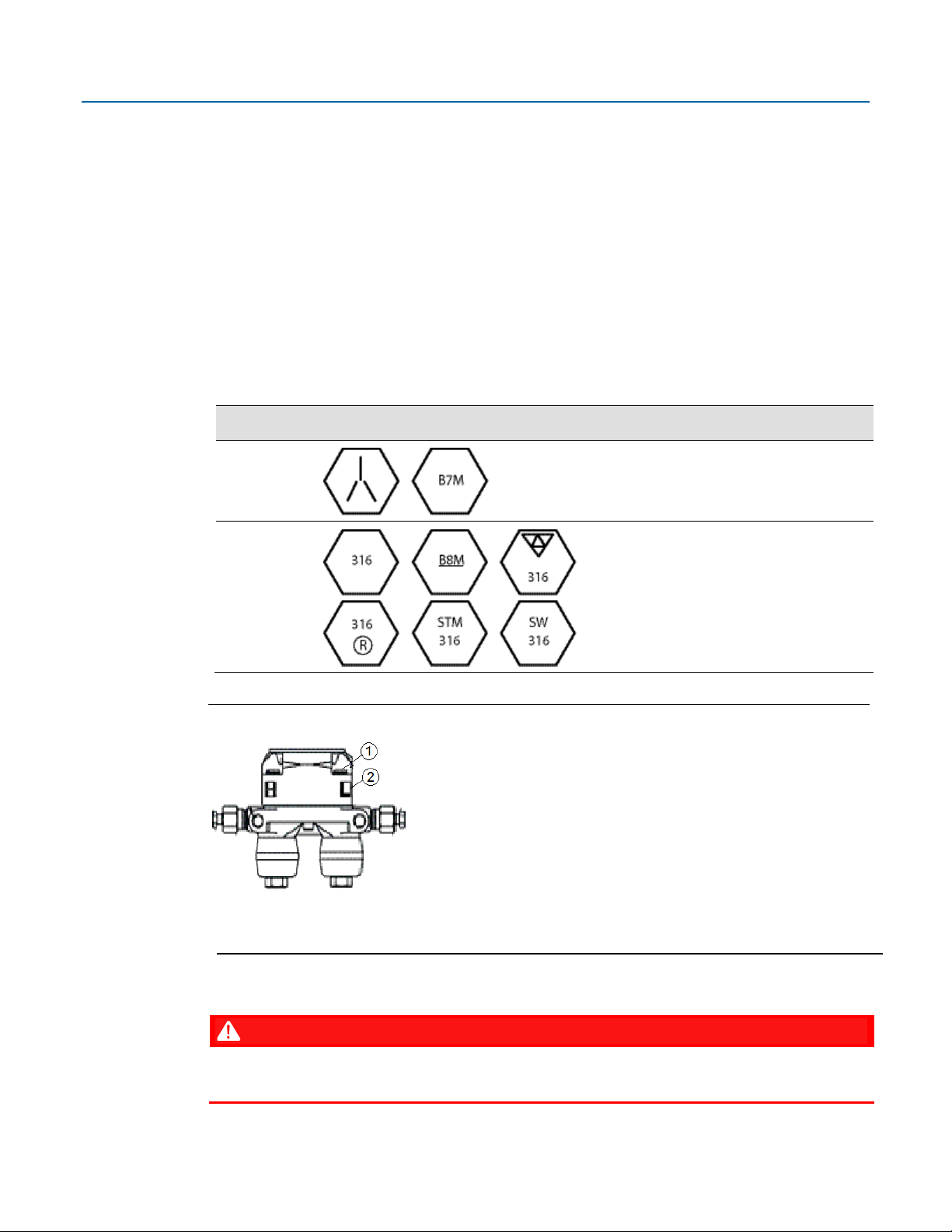

Bolts are typically carbon steel or stainless steel. Confirm the material by viewing the markings on

the head of the bolt and referencing the figure. If bolt material is not shown in the figure, contact

your local Emerson Remote Automation Solutions representative for more information.

Figure 2-8: Transmitter with Coplanar Flange

Figure 2-9: Transmitter with Coplanar Flange and Optional Flange Adapters

Installation 17

Figure 2-10: Transmitter with Traditional Flange and Optional Flange Adapters

Emerson FB1100 Flow Computer Instruction Manual

Bolt Material

Head markings

Initial Torque

Final Torque

1

Bolt

2

Sensor module

DANGER

Use the following bolt installation procedure:

Carbon steel bolts do not require lubrication. Stainless steel bolts are factory-coated with a

1.

lubricant to ease installation. Do not apply any additional lubricant when installing either

type of bolt.

Finger-tighten the bolts.

2.

Torque the bolts to the initial torque value using a crossing pattern. See Table 2-3 for initial

3.

torque value.

Torque the bolts to the final torque value using the same crossing pattern. See Table 2-3 for

4.

final torque value.

Verify that the flange bolts protrude through the sensor module before applying pressure.

5.

Table 2-3: Torque Values for the Flange and Flange Adapter Bolts

D301752X012

February 2021

Carbon

Steel (CS)

Stainless Steel

(SST)

Figure 2-11: Proper Bolt Installation

300 in. -lbs.

(33.9 N m)

150 in. -lbs.

(16.9 N m)

650 in. -lbs.

(73.4 N m)

300 in. -lbs.

(33.9 N m)

2.7.2 O-rings with Flange Adapters

18 Installation

Failure to install proper flange adapter O-rings may cause process leaks, which can result in death

or serious injury. Only use the O-ring that is designed for its specific flange adapter.

Emerson FB1100 Flow Computer Instruction Manual

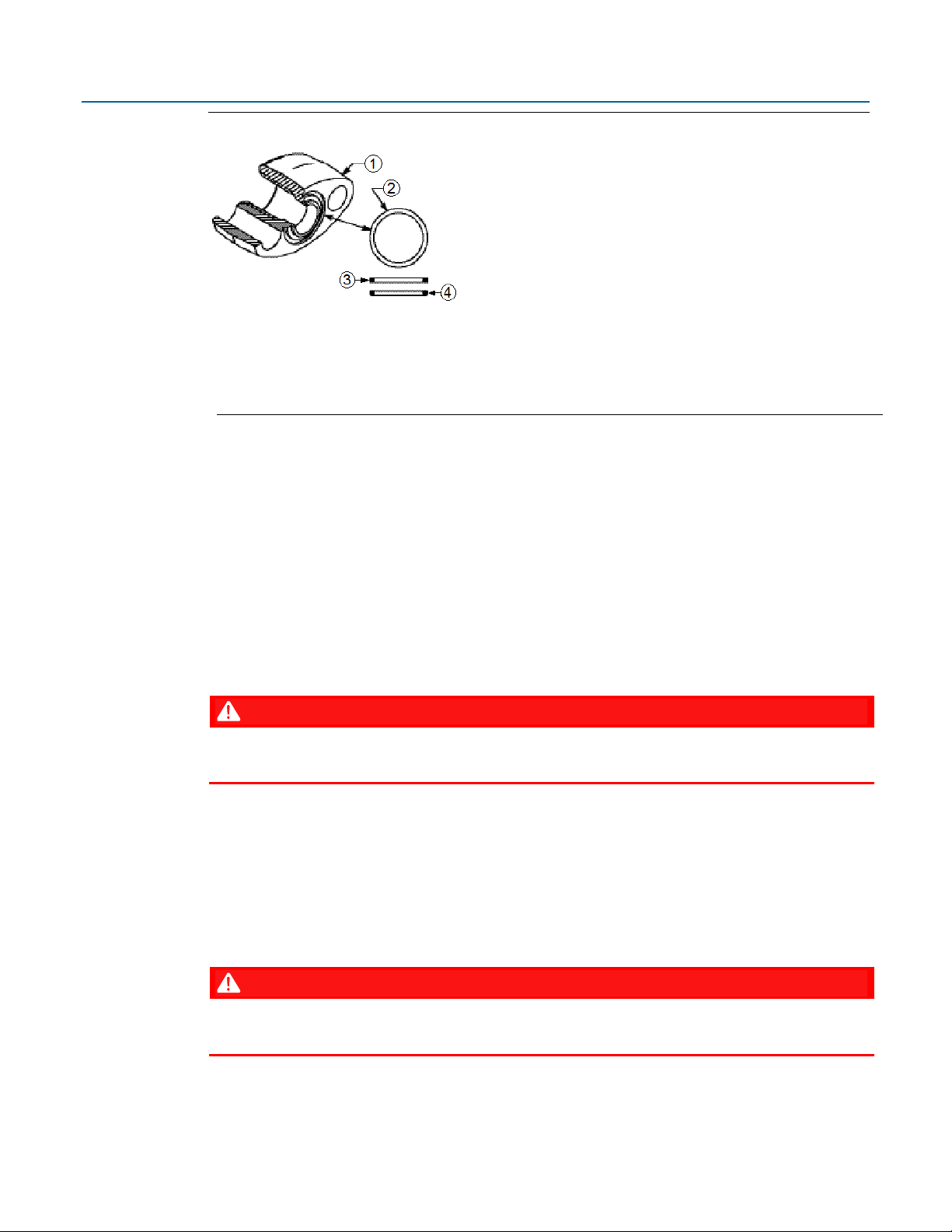

1

Flange

2

O-ring

3

Square PTFE-based profile

4

Round Elastomer profile

DANGER

DANGER

Figure 2-12: O-rings with Flange Adapters

Whenever the flange or adapters are removed, visually inspect the O-rings.

1.

Replace the O-rings if there are any signs of damage, such as nicks or cuts.

2.

If the O-rings are replaced, re-torque the flange bolts and alignment screws after installation

3.

to compensate for seating of the O-rings.

D301752X012

February 2021

2.7.3 Direct Mount

Direct mount installations use either a traditional mounting kit or a coplanar mounting kit. Mount

the flow computer directly to the natural gas pipeline only if the pipeline includes a process

manifold.

EXPLOSION HAZARD: Ensure the area in which you perform this operation is non-hazardous.

Performing this operation in a hazardous area could result in an explosion.

Place taps in the top or side of the line.

1.

Mount the flow computer beside or above the taps.

2.

2.7.4 Indirect Mount

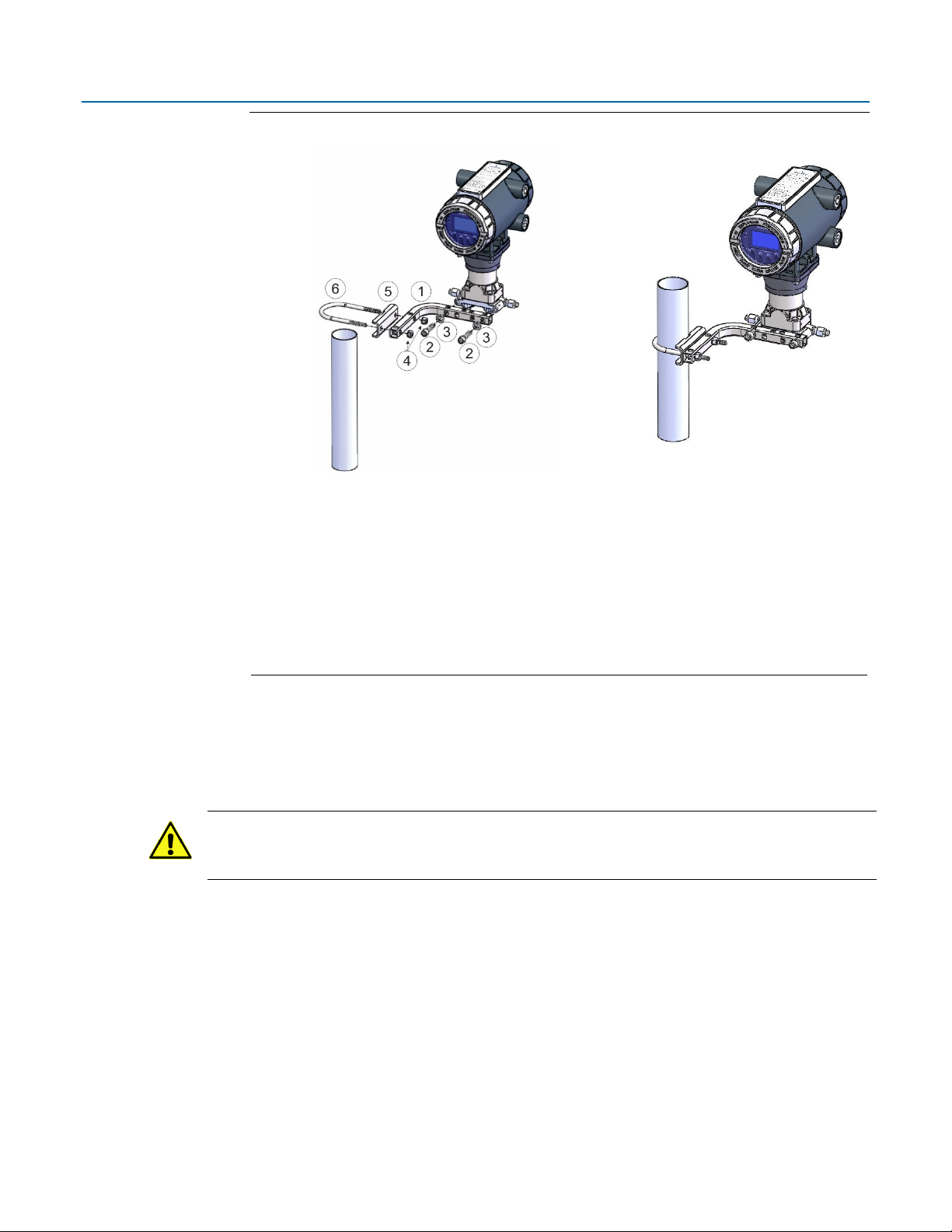

You can mount the flow computer to a two-inch pipe or pole. Indirect mount can use the coplanar,

or traditional flange mounting kits.

EXPLOSION HAZARD: Ensure the area in which you perform this operation is non-hazardous.

Performing this operation in a hazardous area could result in an explosion.

Installation 19

Emerson FB1100 Flow Computer Instruction Manual

1

2.0 in. pipe diam. U-bolt assembly (5/16-18 x 4.0 LG) with (2) nuts (item 3)

2

Mounting bracket

3

Apply Loctite® 222™ Low Strength Purple Threadlocker to nuts. Torque nuts to 30

4

7/16-20 x .625 cs/zinc cobalt screws (4). Torque to 30 in-lbs (3.4 N m)

Figure 2-13: Traditional Flange Mounting Kit

D301752X012

February 2021

in-lbs (3.4 N m)

20 Installation

Figure 2-14: Coplanar Mounting Kit

1

Tubular L-shaped bracket

2

3/8-16 x 1 ½ in socket head wire lockable screw (2) – Apply Killark® LUBG-6 Thread

Lubricant to threads. Torque screws to 30 in

3

Split 3/8 lock washer (2)

4

5/16-18 keps nut (2). Apply Loctite 222 Low Strength Purple Threadlocker to nuts.

Torque nuts to 30 in

5

U-bolt bracket

6

2-inch diameter pipe U-bolt

Emerson FB1100 Flow Computer Instruction Manual

D301752X012

February 2021

-lbs (3.4 N m)

2.7.5 Rotating the Housing

-lbs (3.4 N m)

To improve accessibility to the HMI module or to ease wiring, you can optionally rotate the

housing.

Important

Never rotate the housing more than 180 degrees from its original (as-shipped) position. Overrotation can break electronics within the unit.

Installation 21

Emerson FB1100 Flow Computer Instruction Manual

1

Set Screw (one each side)

DANGER

Figure 2-15: Housing Rotation Set Screw (1 each side)

D301752X012

February 2021

2.8 Grounding the Device

22 Installation

EXPLOSION HAZARD: Ensure the area in which you perform this operation is non-hazardous.

Performing this operation in a hazardous area could result in an explosion.

Loosen the two housing rotation set screws.

1.

Rotate the housing

2.

Re-tighten the two housing rotation set screws. Torque to 6 in-lbs. (0.7 N m).

3.

The flow computer includes a grounding lug on the terminal plate.

no more than 180 degrees from its original (as-shipped) position.

Loading...

Loading...