Page 1

026-1614 Rev 4 5-JAN-2013

E2 Installation and Operation Manual for RX Refrigeration,

BX HVAC, and CX Convenience Store Controllers

Applicable to E2 firmware versions 4.0 and above

Page 2

Page 3

Emerson Climate Technologies Retail Solutions

1065 Big Shanty Road NW,

Kennesaw, GA 30144, USA

Phone 770-425-2724

Fax 770-425-9319

E2 FIRMWARE VERSION

4.05F01

FCC COMPLIANCE NOTICE

This device complies with Part 15 of the FCC

lowing two conditions: (1) this device may not cause harmful interference, and (2) this

device

must accept any interference received, including interference that may cause

undesired operation.

CE COMPLIANCE NOTICE

Class A Product Information for E2 Controllers:

The Emerson Retail Solutions Einstein and E2 controllers are Class A

domestic environment this product may cause radio interference in which case the user

may be required to take adequate measures. This covers:

Rules. Operation is subject to the fol-

Suite 100

products. In a

• All E2 family product types: RX - Refrig

BX - Building/HVAC Controller (845-xxxx), CX- Convenience Store

Con

troller (845-xxxx), and all version models: (300, 400, 500).

eration Controller (845-xxxx),

Page 4

Page 5

TABLE OF CONTENTS

1 INTRODUCTION...................................................................................................................................................... 1-1

1.1 THE E2 REFRIGERATION CONTROLLER (RX)............................................................................................................ 1-1

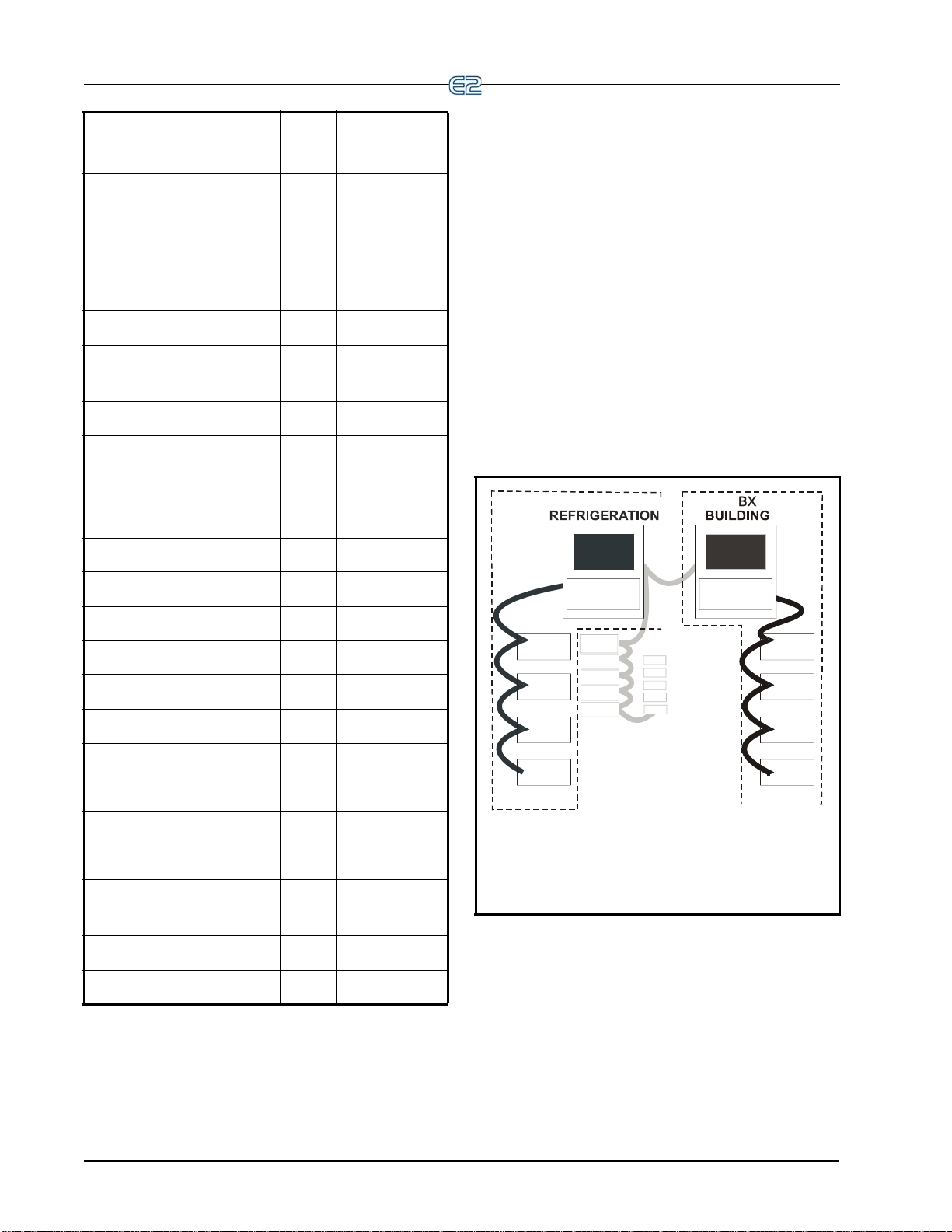

1.2 THE E2 BUILDING CONTROLLER (BX)...................................................................................................................... 1-2

1.3 THE E2 CONVENIENCE STORE CONTROLLER (CX)................................................................................................... 1-3

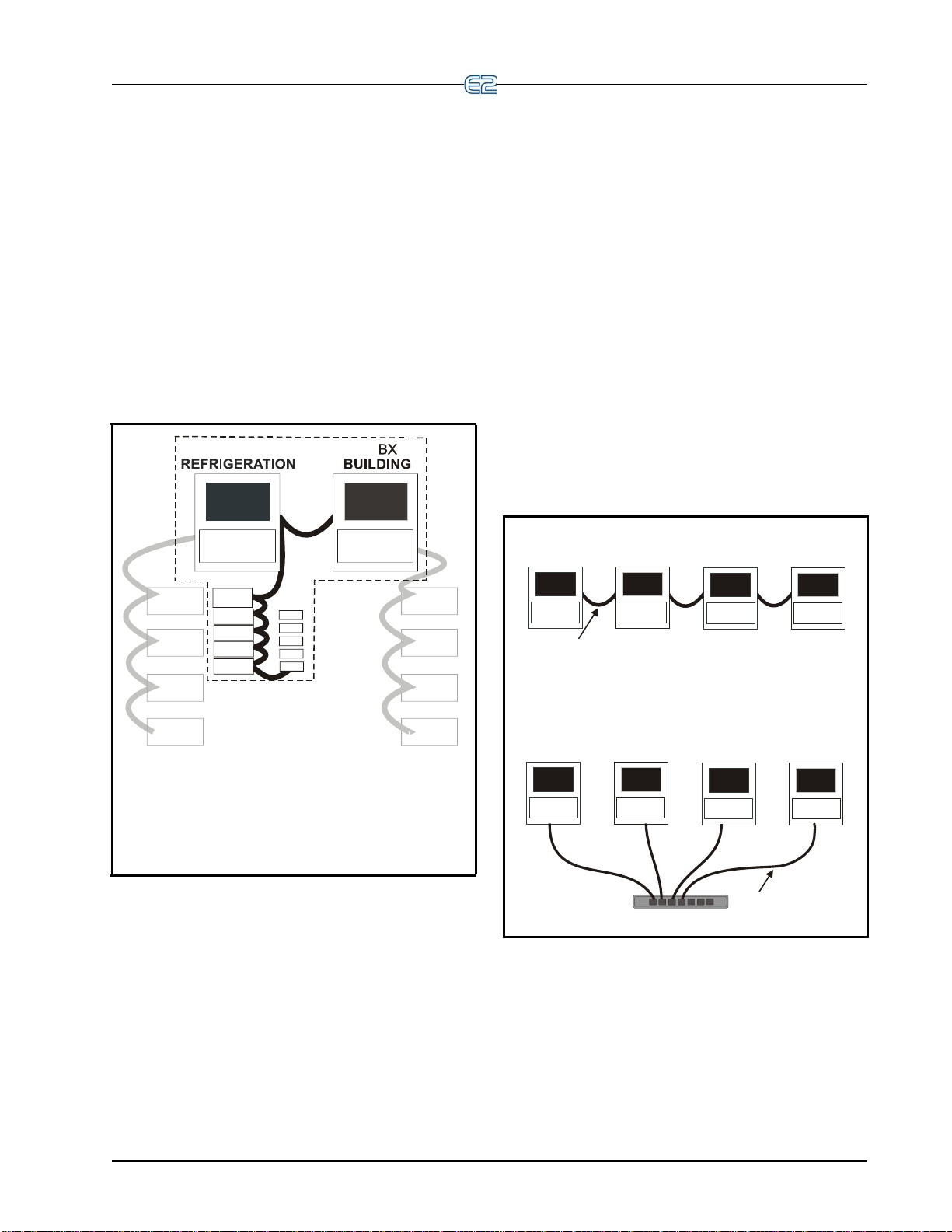

1.4 NETWORKING OVERVIEW.......................................................................................................................................... 1-4

1.4.1 E2 I/O Network .................................................................................................................................................. 1-4

1.4.2 The E2 Echelon Lonworks Network................................................................................................................... 1-5

1.4.3 Interconnection With Other E2s ........................................................................................................................ 1-5

1.5 DOCUMENTATION OVERVIEW ................................................................................................................................... 1-6

1.6 ON-LINE HELP SYSTEM OVERVIEW .......................................................................................................................... 1-7

1.7 SOFTWARE LICENSING............................................................................................................................................... 1-7

2 HARDWARE OVERVIEW...................................................................................................................................... 2-1

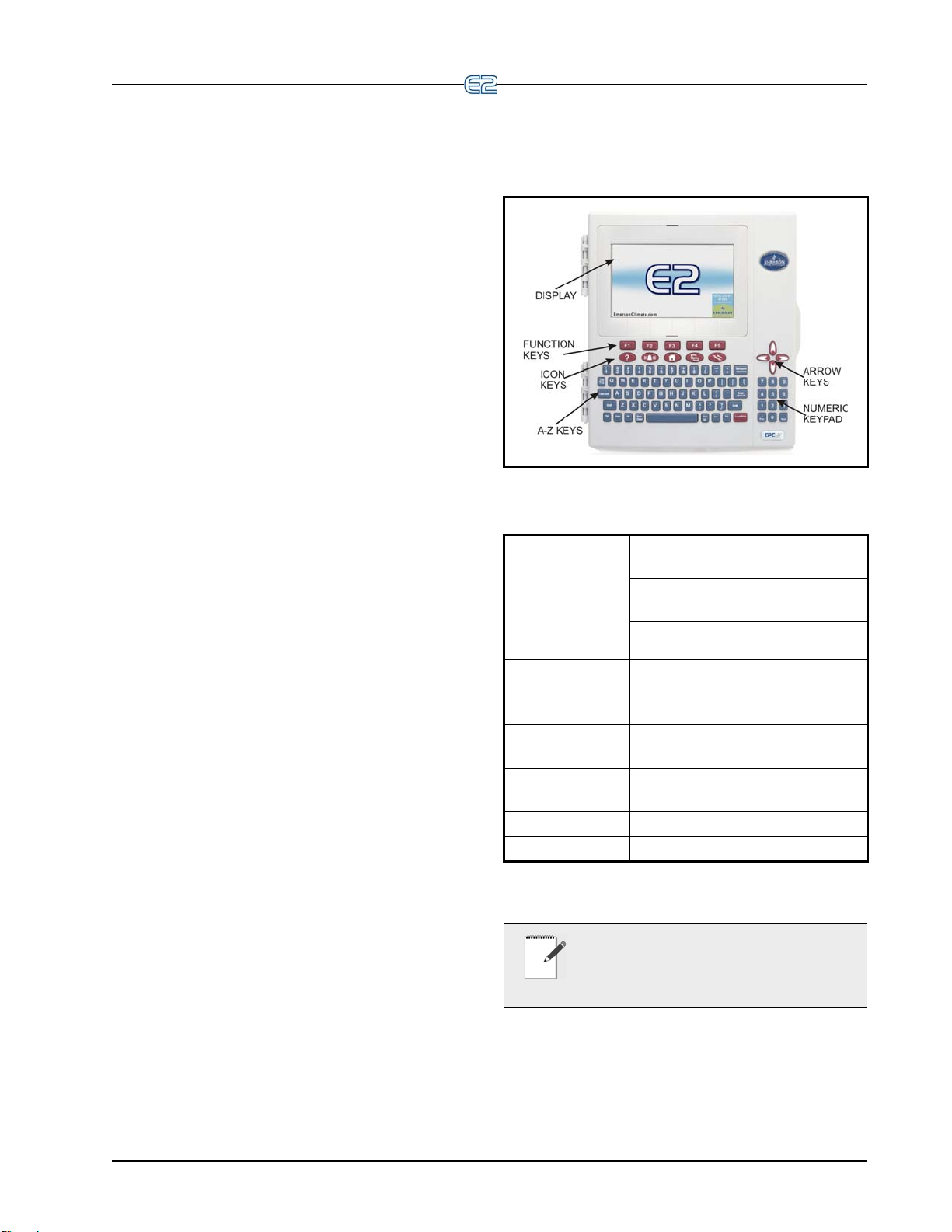

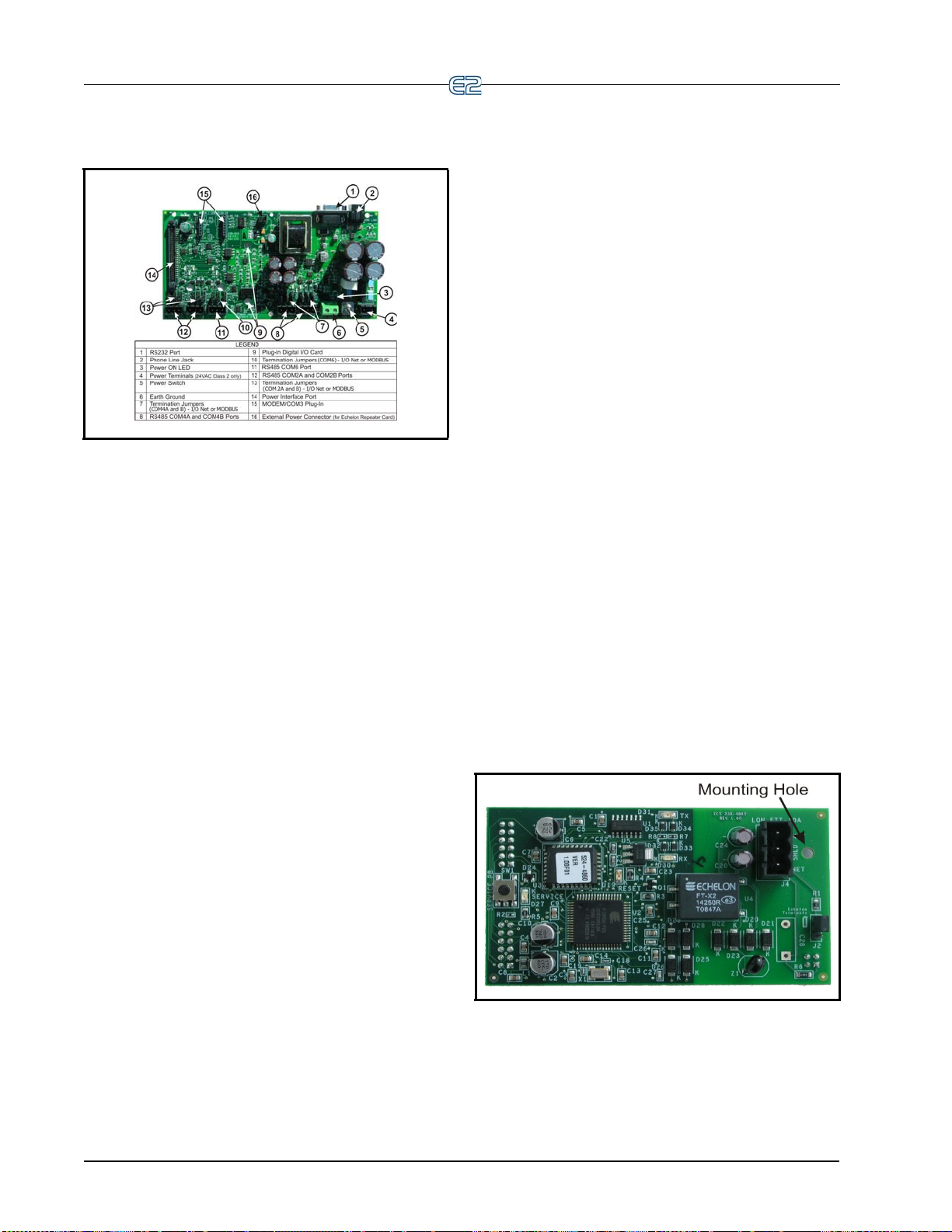

2.1 E2 HARDWARE .......................................................................................................................................................... 2-1

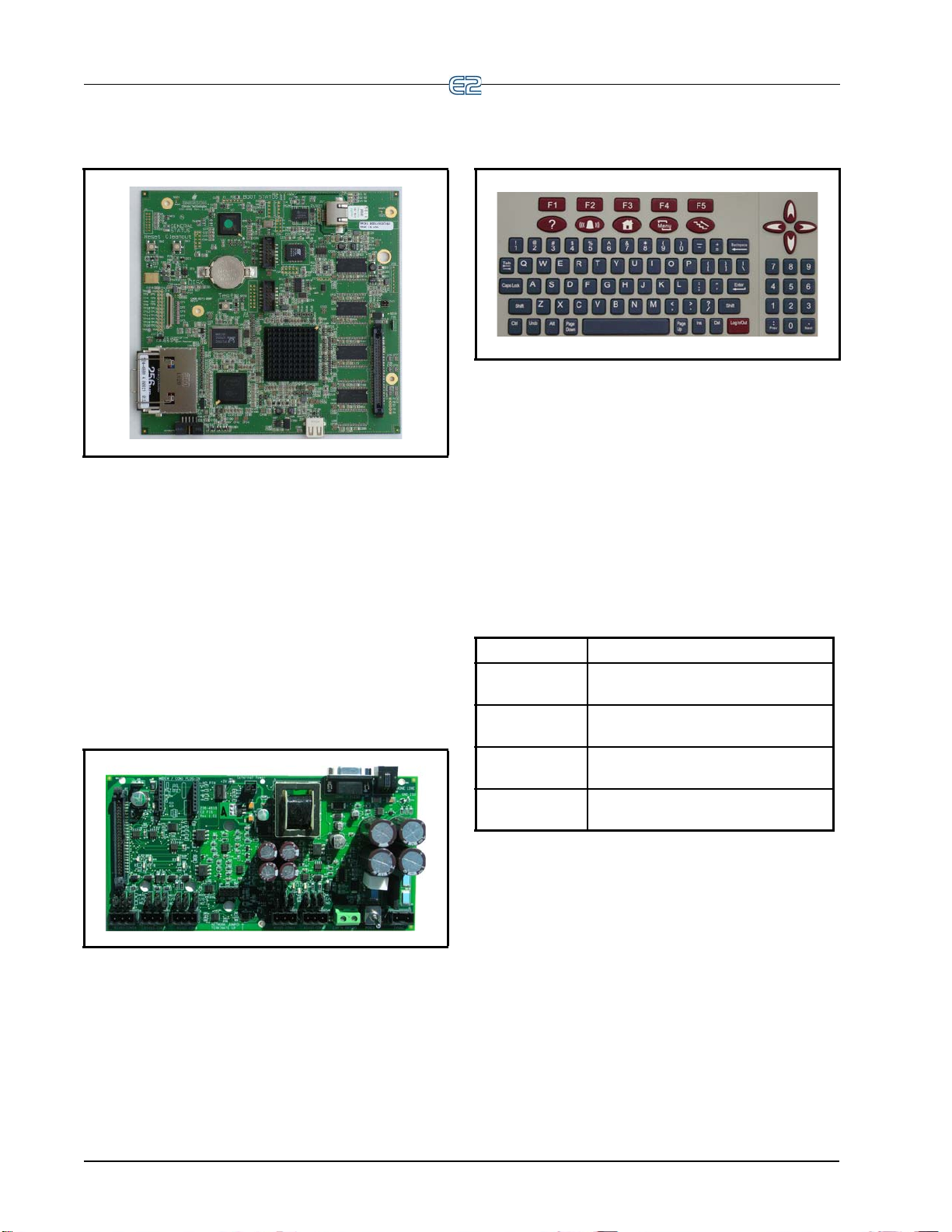

2.1.1 E2 Main Processor Board (CPU)...................................................................................................................... 2-2

2.1.2 E2 Processor Interface Board (PIB).................................................................................................................. 2-2

2.1.3 E2 Keypad.......................................................................................................................................................... 2-2

2.1.4 LEDs................................................................................................................................................................... 2-2

2.2 I/O NETWORK BOARDS AND PERIPHERALS............................................................................................................... 2-3

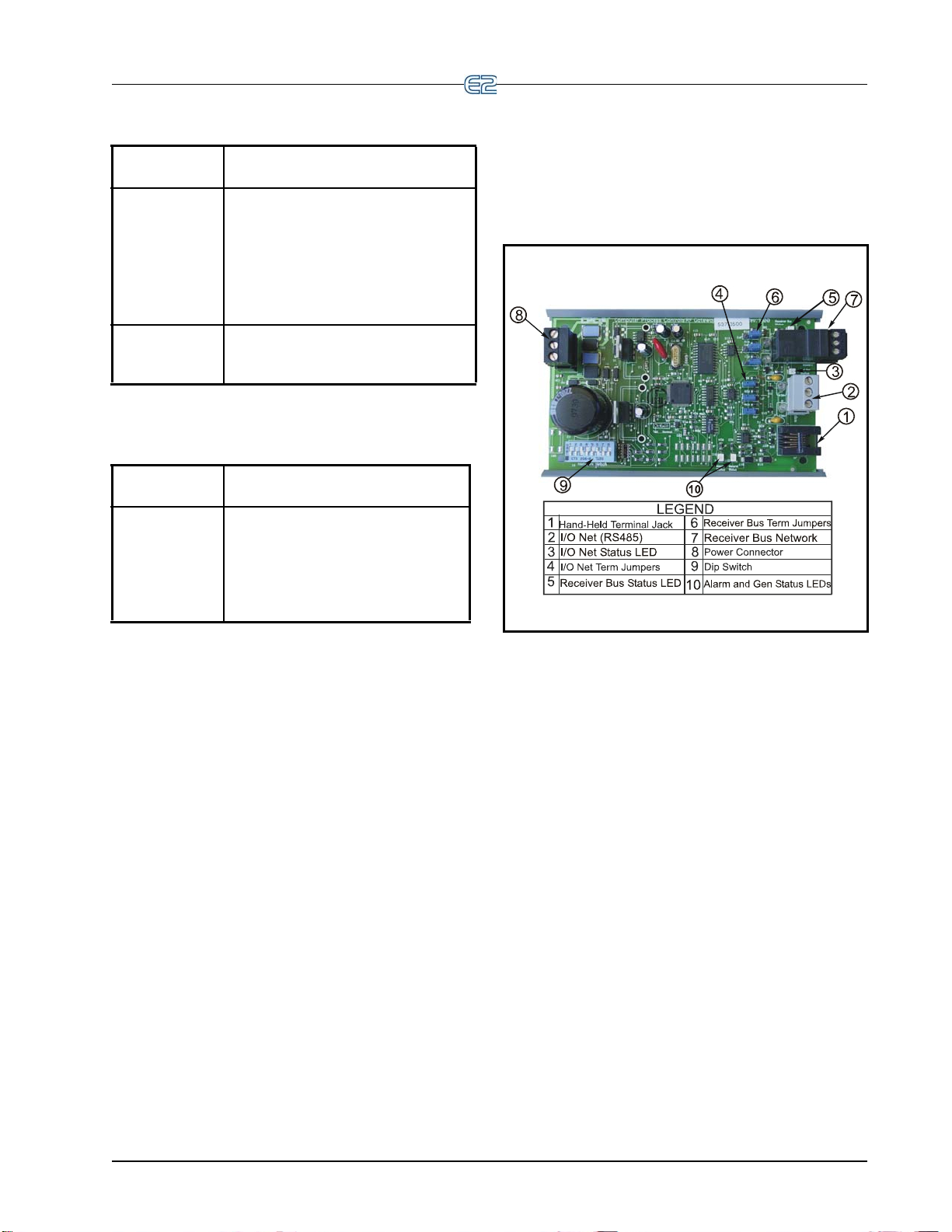

2.2.1 The Gateway Board ....................................................................... .................................................................... 2-3

2.2.2 MultiFlex Boards ............................................................................................................................................... 2-4

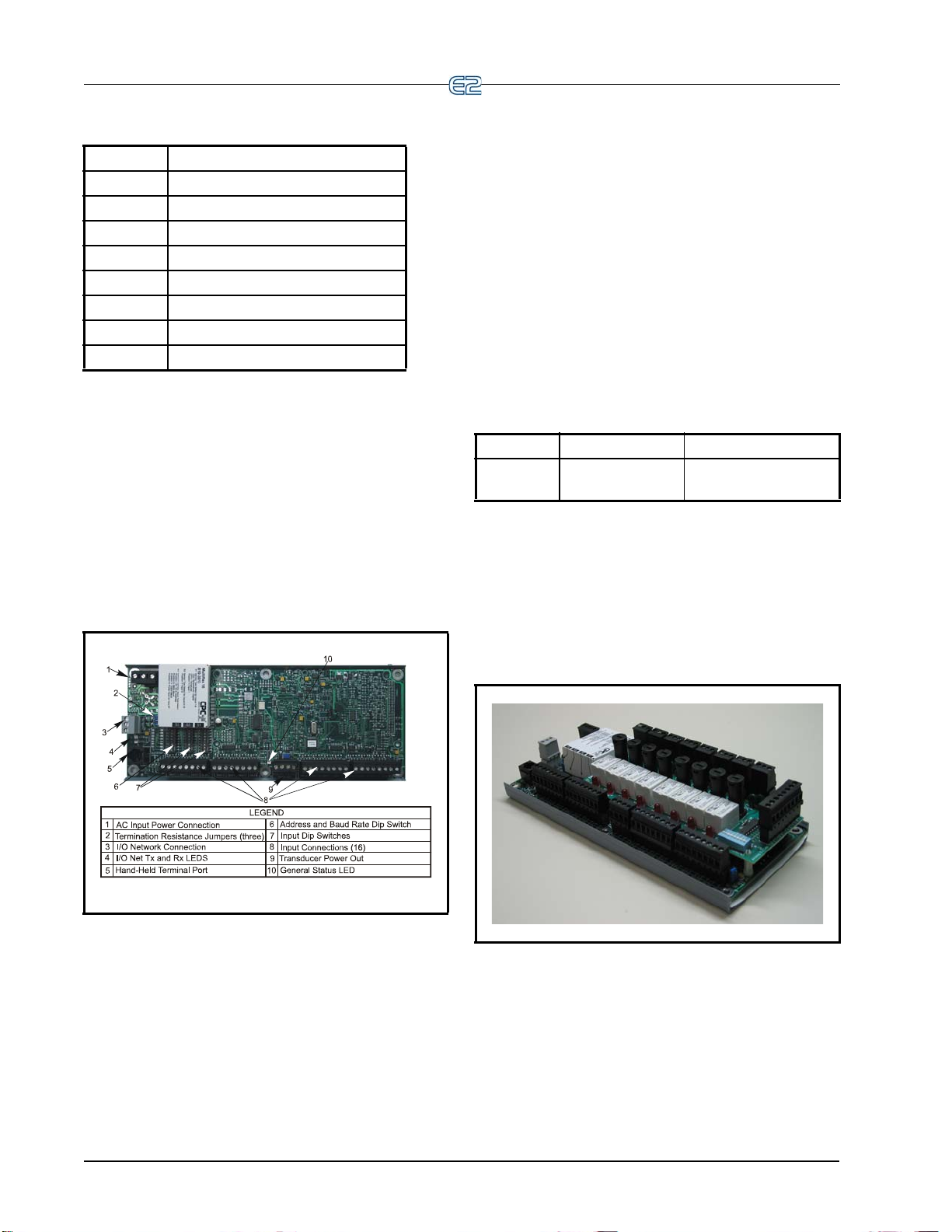

2.2.2.1 MultiFlex 16 Input Board ........................................................................................................................................ 2-4

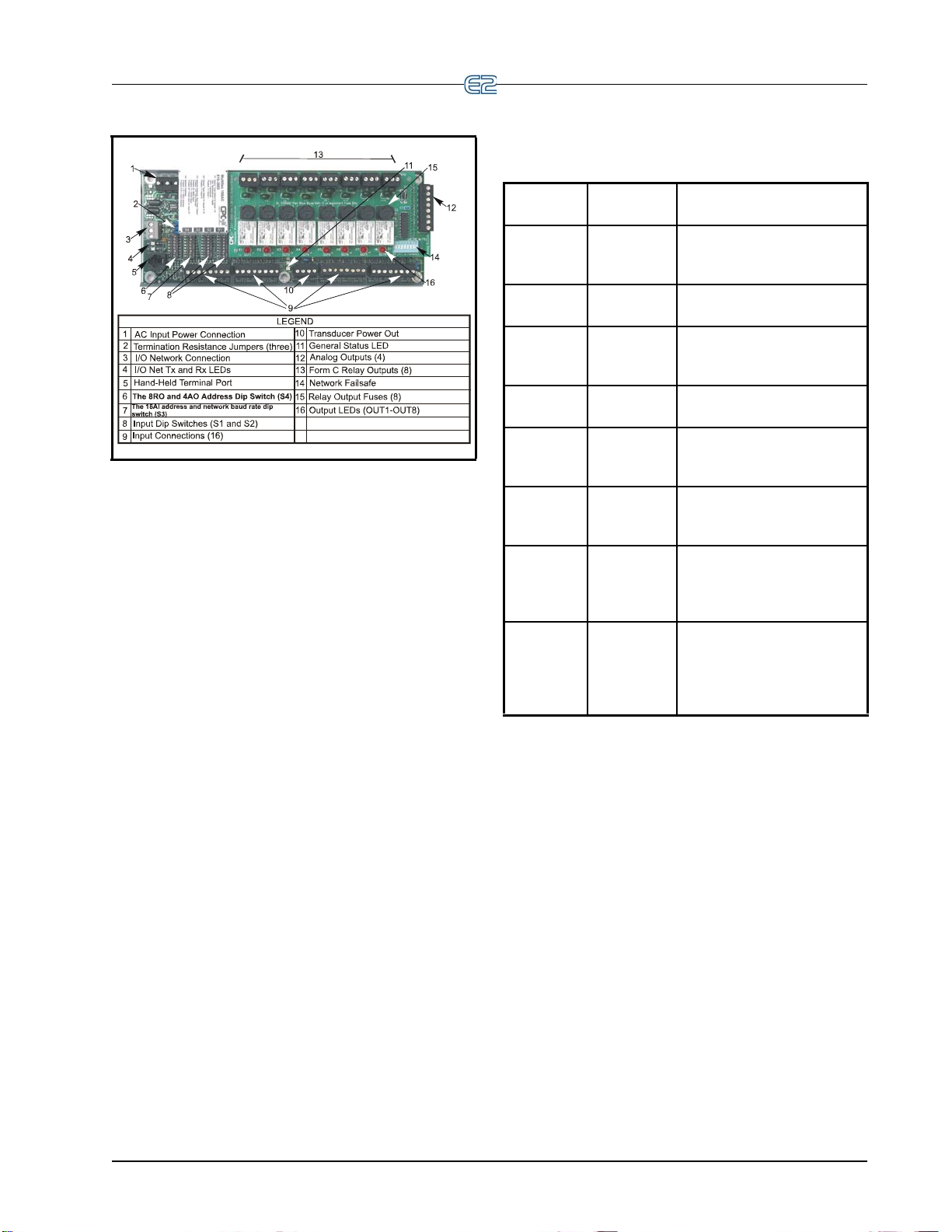

2.2.2.2 MultiFlex Combination Input/Output Boards .......................................................................................................... 2-4

2.2.2.3 MultiFlex CUB ........................................................................................................................................................ 2-6

2.2.2.4 MultiFlex RTU (BX and CX Only)......................................................................................................................... 2-6

2.2.2.5 MultiFlex Rooftop Control Board (RCB) (BX and CX Only) ................................................................................ 2-6

2.2.2.6 MultiFlex PAK Board......................... ............................. ............................. ........................................................... 2-6

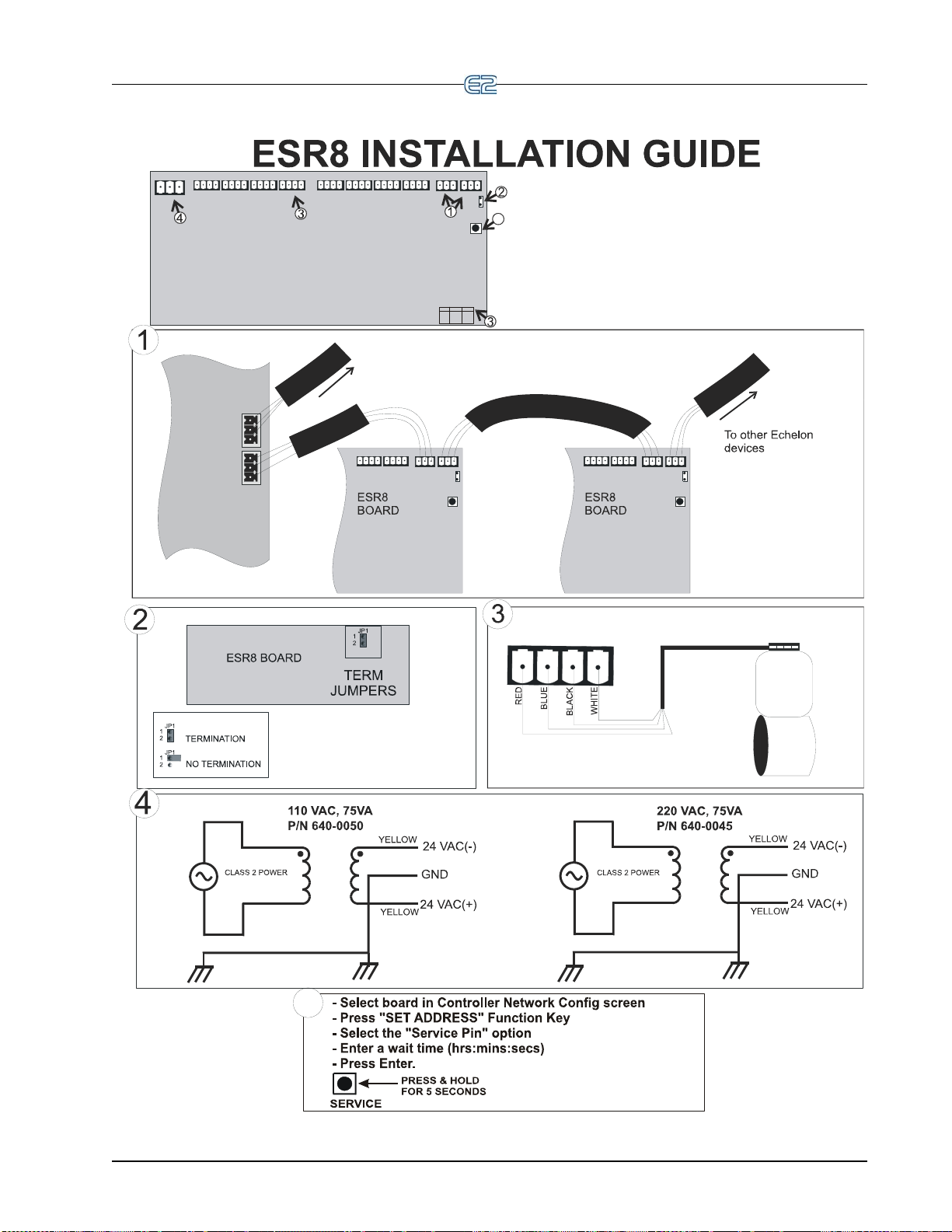

2.2.3 The MultiFlex ESR Board.................................................................................................................................. 2-7

2.2.4 Hand-held Terminal (P/N 814-3110)................................................................................................................. 2-7

2.2.5 The 8RO and 8ROSMT Relay Boards................................................................................................................ 2-8

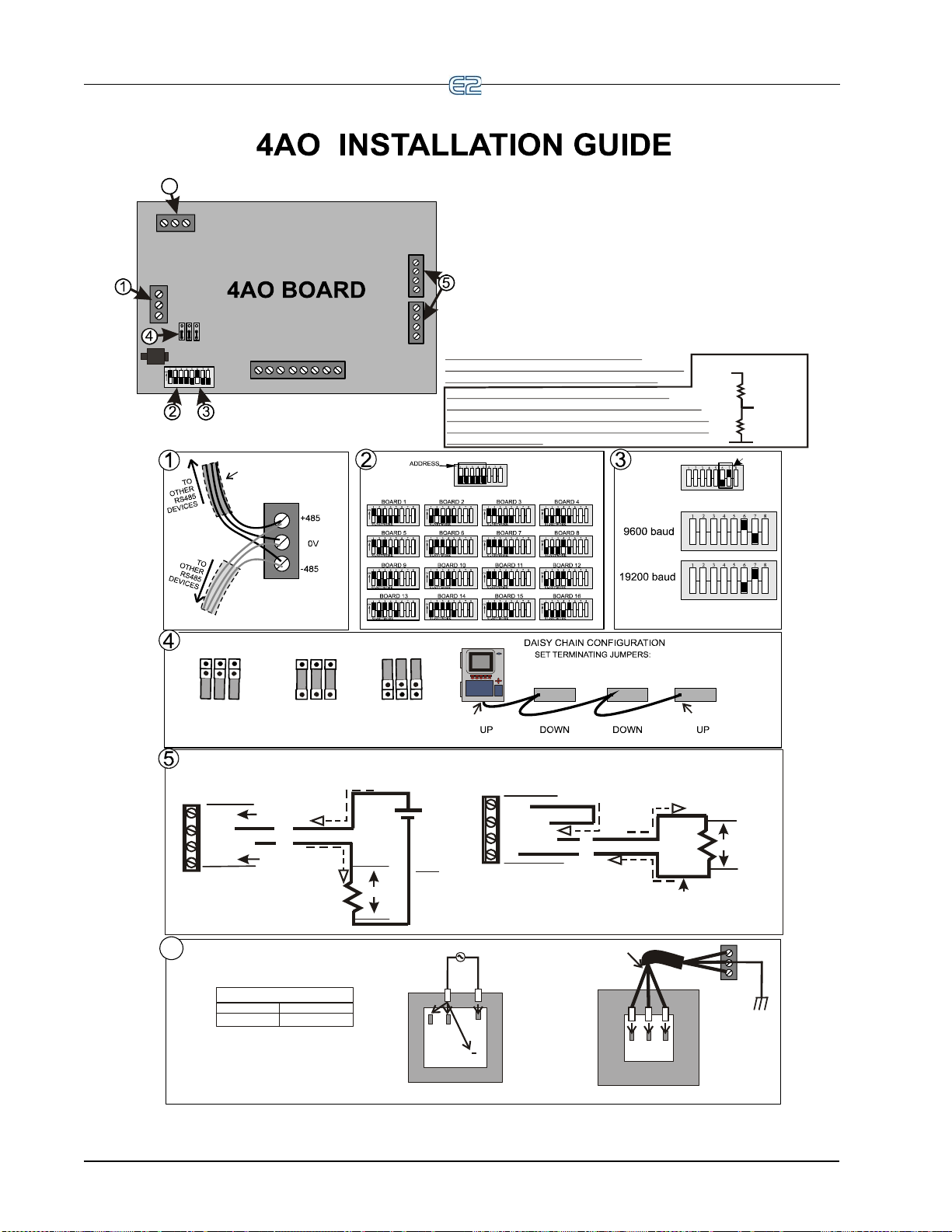

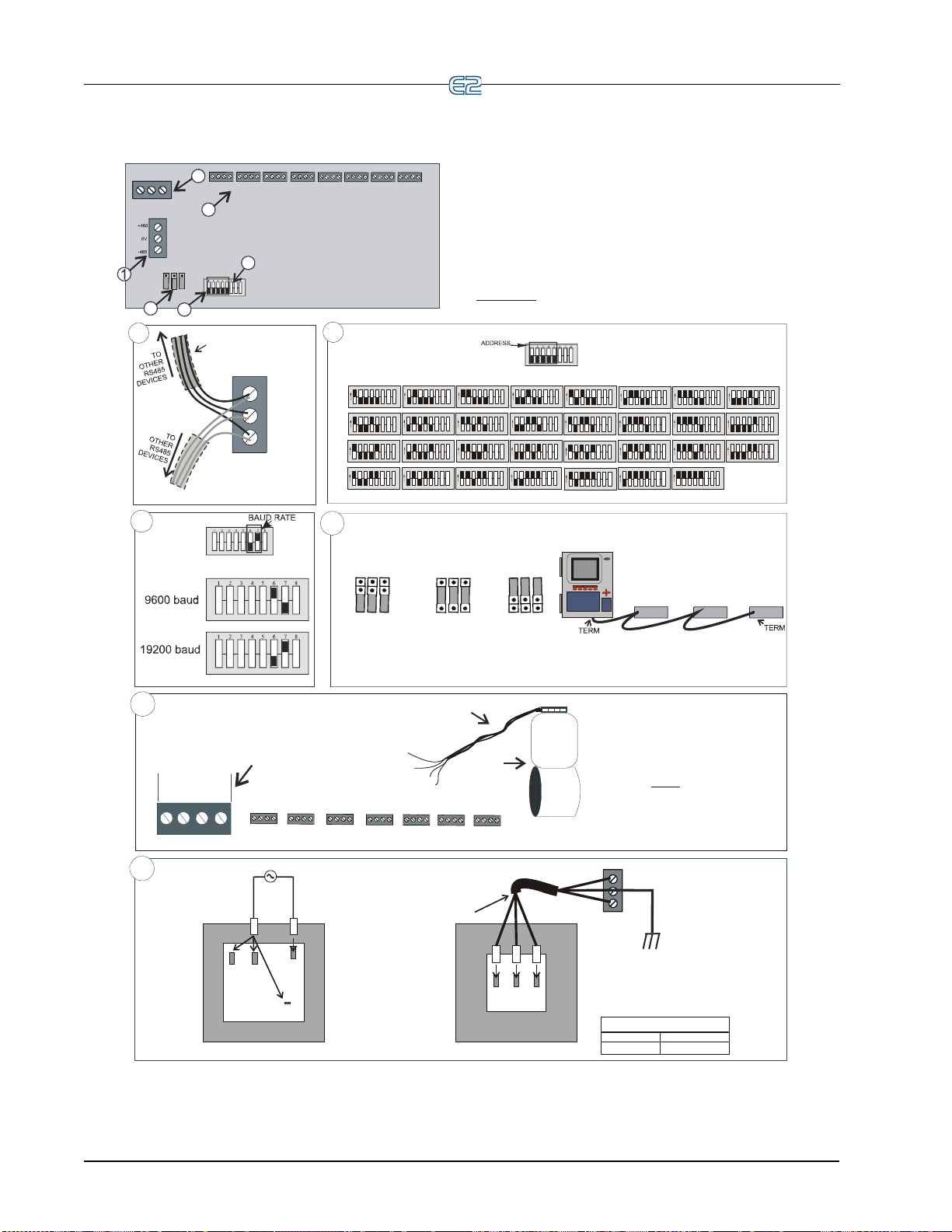

2.2.6 4AO Analog Output Board................................................................................................................................. 2-9

2.2.7 8DO Digital Output Board and PMAC II Anti-Sweat Controller ..................................................................... 2-9

2.3 ECHELON NETWORK BOARDS AND PERIPHERALS................................................................................................... 2-10

2.3.1 The 16AIe (Discontinued)................................................................................................................................ 2-10

2.3.2 The 8ROe (Discontinued)................................................................................................................................. 2-10

2.3.3 EC-2s................................................................................................................................................................ 2-11

2.3.4 CC-100 Case Controllers and CS-100 Case Circuit Controllers.................................................................... 2-11

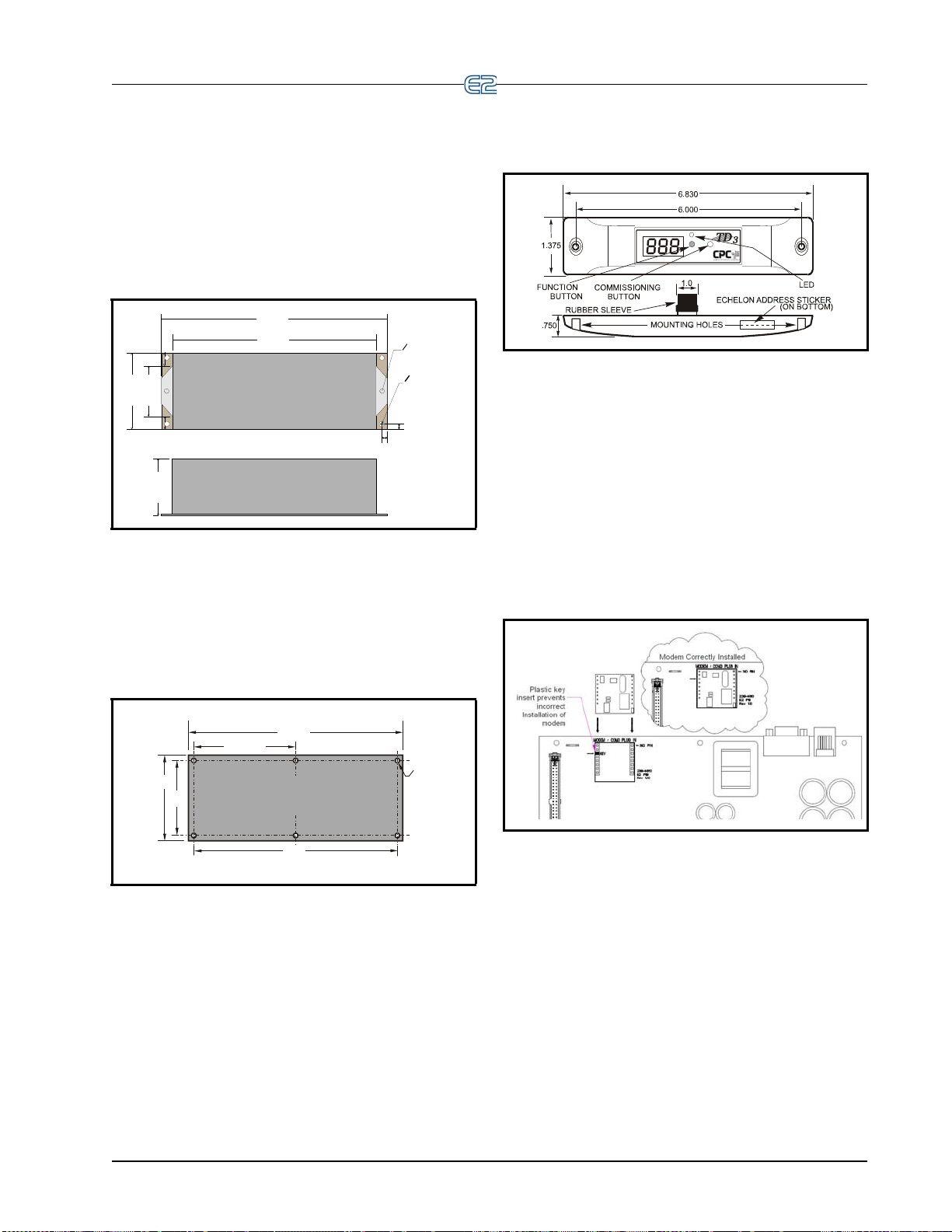

2.3.5 TD3 Temperature Display ............................................................................................................................... 2-12

2.3.6 Facility Status Display (FSD).......................................................................................................................... 2-12

3 MOUNTING............................................................................................................................................................... 3-1

3.1 MOUNTING THE E2.............................................................................................. ...................................................... 3-1

3.1.1 Standard Mount.................................................................................................................................................. 3-1

3.1.2 Recessed Mount.................................................................................................................................................. 3-1

3.1.3 Retrofit Mounting............................................................................................................................................... 3-2

3.1.4 Blank Face ......................................................................................................................................................... 3-3

3.2 MOUNTING I/O BOARDS............................................................................................................................................ 3-3

3.2.1 Single/Double Enclosures................................................................................................................................. 3-3

3.2.2 Boards Without Enclosures (Snap Track).......................................................................................................... 3-4

E2 RX/BX/CX I&O Manual Table of Contents • v

Page 6

3.3 ECHELON DEVICES .................................................................................................................................................... 3-5

3.3.1 CC-100 Case Controller and CS-100 Case Circuit Controller......................................................................... 3-5

3.3.2 MultiFlex ESR.................................................................................................................................................... 3-5

3.3.3 TD3..................................................................................................................................................................... 3-5

3.4 COM3 INTERNAL MODEM PLUG-IN CARD

(P/N 638-3362).................................................................................................................................................................. 3-5

3.4.1 Two-Channel and Four-Channel Repeaters ...................................................................................................... 3-6

3.4.1.1 Mounting Repeaters Overview ................................................................................................................................ 3-6

3.4.1.2 Mounting the Two-Channel Repeater...................................................................................................................... 3-6

3.4.1.3 Mounting the Four-Channel Repeater ..................................................................................................................... 3-6

3.5 SENSORS AND TRANSDUCERS.................................................................................................................................... 3-7

3.5.1 Pressure Transducers......................................................................................................................................... 3-7

3.5.1.1 Mounting.................................................................................................................................................................. 3-7

3.5.2 Inside Temperature Sensor................................................................................................................................. 3-7

3.5.2.1 Location ................................................................................................................................................................... 3-7

3.5.2.2 Mounting.................................................................................................................................................................. 3-7

3.5.3 Outside Temperature Sensor.............................................................................................................................. 3-7

3.5.3.1 Location ................................................................................................................................................................... 3-7

3.5.3.2 Mounting.................................................................................................................................................................. 3-7

3.5.4 Insertion Temperature Probe............................................................................................................................. 3-8

3.5.4.1 Location ................................................................................................................................................................... 3-8

3.5.4.2 Mounting.................................................................................................................................................................. 3-8

3.5.5 Supply and Return Air Sensors........................................................................................................................... 3-8

3.5.6 Refrigeration System Temperature Probes and Sensors.................................. .................................................. 3-8

3.5.6.1 Location ................................................................................................................................................................... 3-8

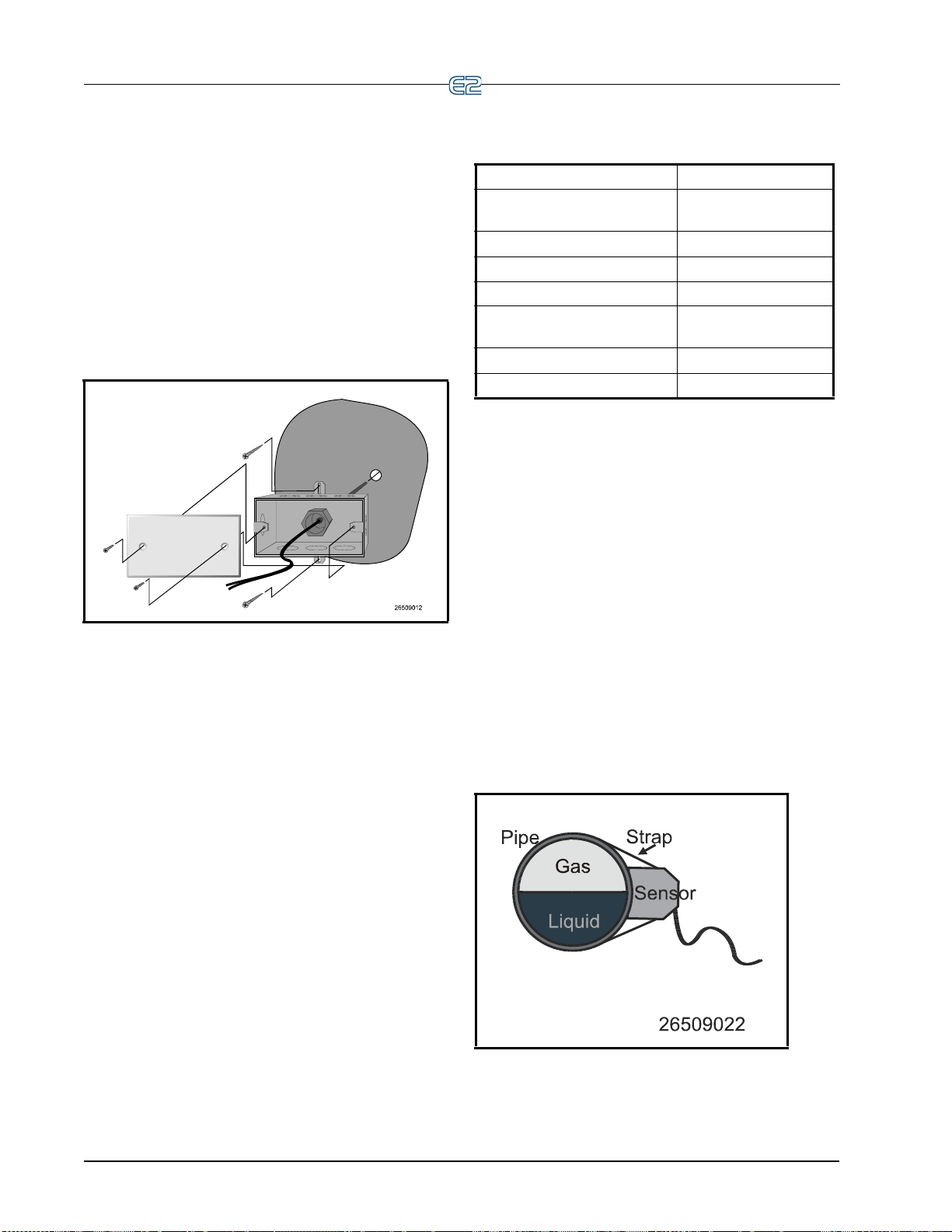

3.5.6.2 Mounting Bullet and Pipe Mount Sensors............................................................................................................... 3-8

3.5.7 Product Temperature Probes....................................................... ...................................................................... 3-9

3.5.8 Humidity Sensors and Humidistats.................................................................................................................... 3-9

3.5.8.1 Indoor RH Sensor .................................................................................................................................................... 3-9

3.5.8.2 Outdoor RH Sensors ................................................................................................................................................ 3-9

3.5.8.3 Duct-mounted Insertion RH Probe ...... ............................. ............................. ........................................................ 3-10

3.5.9 Dewpoint Probe................................................................................................................................................ 3-10

3.5.9.1 Location .................................................................................................................... ............................................. 3-10

3.5.9.2 Mounting..................................................................................................................... ........................................... 3-10

3.5.10 Light Level Sensor.......................................................................................................................................... 3-10

3.5.10.1 Location ............................................................................................................................................................... 3-10

3.5.10.2 Mounting.................................................................................................................................................. ............ 3-10

3.5.11 Liquid Level Sensors...................................................................................................................................... 3-11

3.5.12 Refrigerant Leak Detectors............................................................................................................................ 3-11

4 E2 HARDWARE SETUP.......................................................................................................................................... 4-1

4.1 SETTING UP THE E2 ................................................................................................................................................... 4-1

4.1.1 Enclosure............................................................................................................................................................ 4-1

4.1.2 Main Processor Board ..................................... ............................................. ..................................................... 4-1

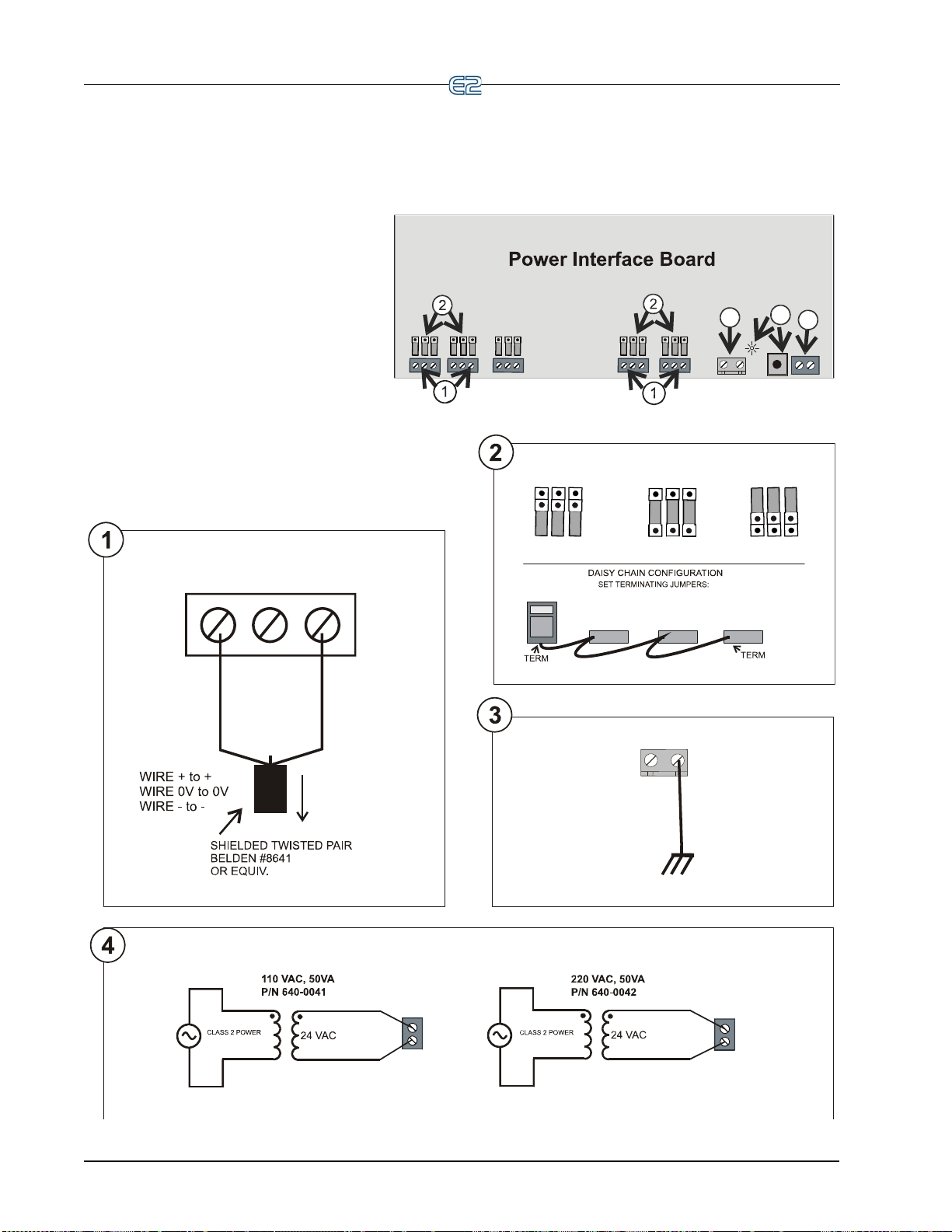

4.1.3 Power Interface Board (PIB)........................................................................ ..................................................... 4-2

4.2 POWERING THE E2..................................................................................................................................................... 4-2

4.2.1 RS485 Ports........................................................................................................................................................ 4-2

4.2.2 RS485 Termination Jumpers (MODBUS or I/O Net)......................................................................................... 4-2

4.2.3 Echelon Network Connect.................................................................................................................................. 4-2

4.2.4 Echelon Jumper.................................................................................................................................................. 4-2

4.3 ADD-ON E2 PERIPHERALS......................................................................................................................................... 4-2

4.3.1 Echelon Plug-In Card Kit

(P/N 638-4860) ............................................................................................................................................................. 4-2

4.3.2 COM3 RS232 Plug-In for External Modem (P/N 638-4875) ............................................................................ 4-3

4.3.3 COM3 Internal Modem Plug-In Card (P/N 638-3362) .................................................................................... 4-3

vi • Table of Contents 026-1614 Rev 4 5-JAN-2013

Page 7

4.3.4 Plug-In Digital I/O Network Card (P/N 638-4880)........................................................................................... 4-3

4.3.4.1 LEDs ........................................................................................................................................................................ 4-3

4.3.5 Plug-In Four-Channel Internal Repeater ............................................ .. ............................................................ 4-3

5 SERIAL CONFIGURATION................................................................................................................................... 5-1

5.1 OVERVIEW................................................................................................................................................................. 5-1

5.2 COM PORTS .............................................................................................................................................................. 5-1

5.3 SERIAL DEVICE AND SOFTWARE SETUP.................................................................................................................... 5-1

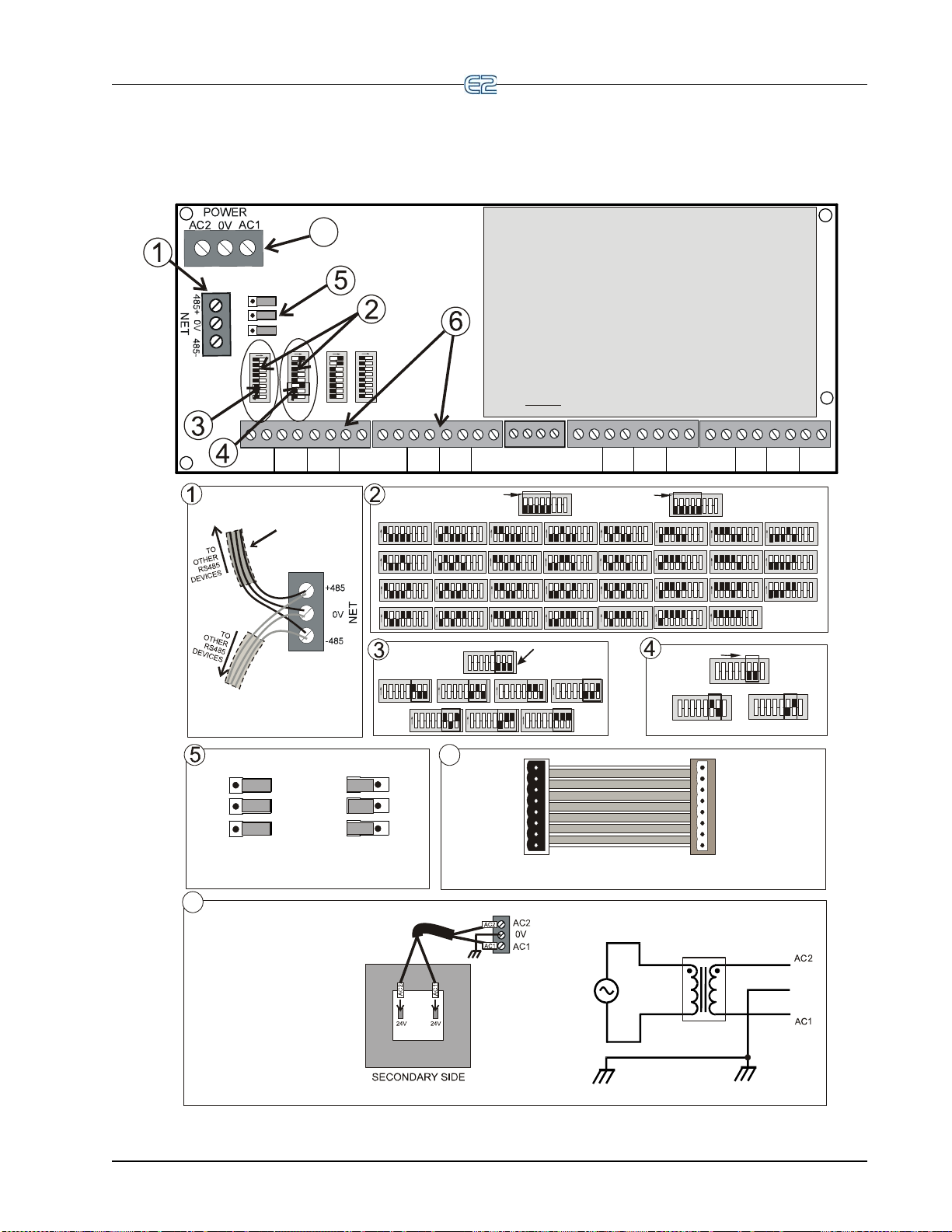

6 THE RS485 NETWORK AND HARDWARE SETUP.......................................................................................... 6-1

6.1 THE I/O NETWORK .................................................................................................................................................... 6-1

6.1.1 I/O Board Names and Terminology................................................................................................................... 6-1

6.1.2 MultiFlex-Plus (+) Board.................................................................................................................................. 6-2

6.1.2.1 Board Designation ................................................................................................................................................... 6-2

6.1.2.2 Board Calculations................................................................................................................................................... 6-2

6.1.3 Wiring Types...................................................................................................................................................... 6-2

6.1.4 The I/O Network Structure (Daisy Chains)........................................................................................................ 6-2

6.1.5 Network Noise Minimization.............................................................................................................................. 6-3

6.1.6 Network ID Numbers (Board Numbers) ............................................................................................................ 6-3

6.1.7 Setting the Baud Rate......................................................................................................................................... 6-3

6.1.8 Setting the Terminating and Biasing Jumpers................................................................................................... 6-4

6.1.9 Powering the I/O Boards................................................................................................................................... 6-4

6.1.9.1 Wiring Types ........................................................................................................................................................... 6-5

6.1.10 Board Installation............................................................................................................................................ 6-6

6.2 IMC/PRODIGY ROOFTOP UNIT CONTROLLERS.......................................................................................................... 6-6

6.3 MODBUS.................................................................................................................................................................. 6-6

6.3.1 Control Techniques Drive (VSD)....................................................................................................................... 6-6

6.3.2 Copeland Discus with CoreSense Diagnostics (ISD) ................................................ ........................................ 6-7

6.3.3 XR35CX, XR75CX, and XEV22 Case Controllers............................................................................................. 6-7

6.3.3.1 XR75CX-Case Display............................................................................................................................................ 6-7

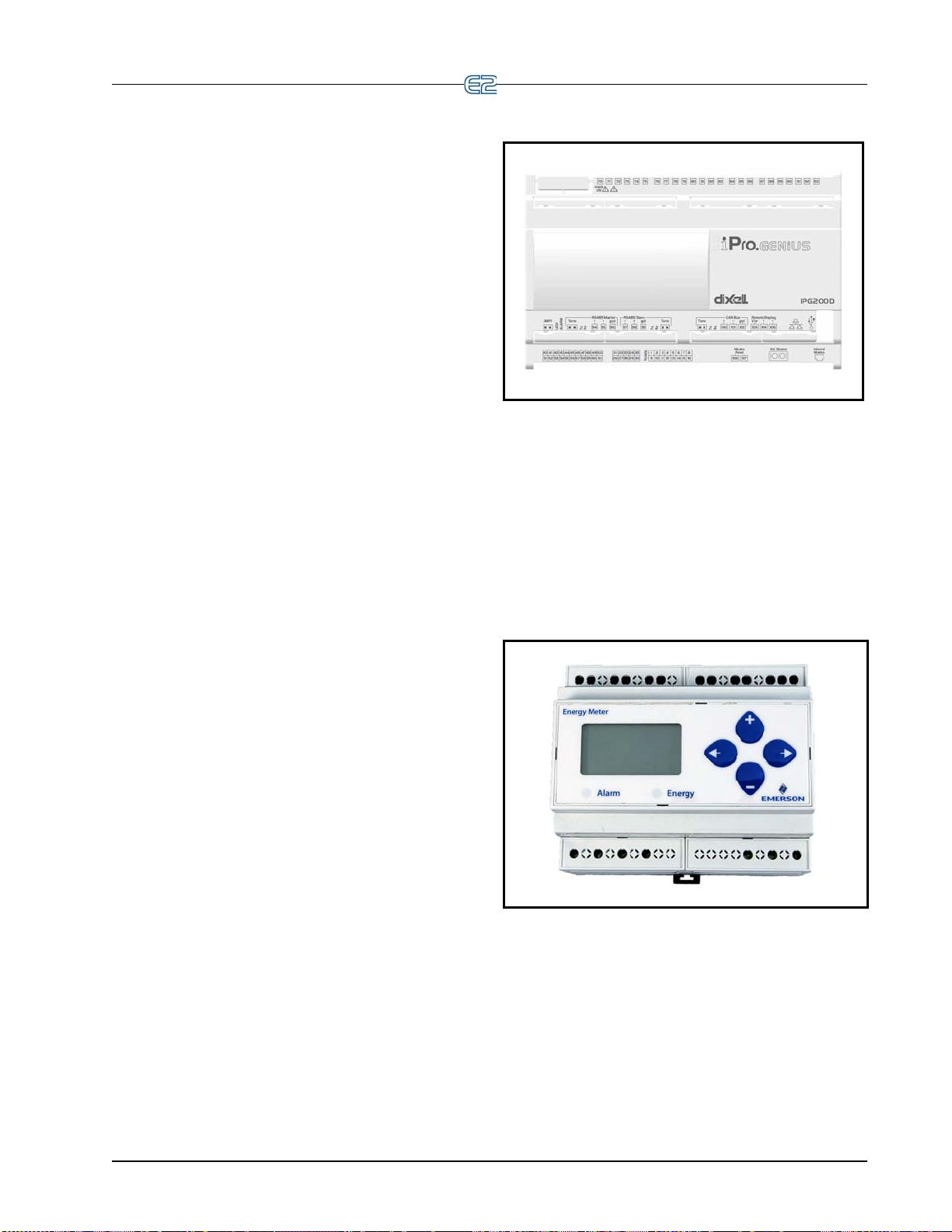

6.3.4 iPro DAC............................................................................................................................................................ 6-7

6.3.5 Energy Meter...................................................................................................................................................... 6-7

6.3.5.1 Overview.................................................................................................................................................................. 6-7

6.3.5.2 Supported System Types.......................................................................................................................................... 6-8

6.3.6 Modular Refrigerant Leak Detection Sensor (MRLDS) ................................................................................... 6-8

6.3.7 Copeland Discus with CoreSense Protection ................................................................................................... 6-8

6.3.8 Copeland CoreSense Communications.............................................................................................................. 6-8

6.3.9 Light Commercial Thermostat........................................................................................................................... 6-9

6.3.9.1 Thermostat Inputs .................................................................................................................................................... 6-9

6.3.9.2 Advisory and Alarms ............................................................................................................................................... 6-9

6.3.10 Refrigerant Leak Detection System (RLDS)................................................................................................... 6-11

6.3.10.1 Diagnostic Alarms ............................................................................................................................................... 6-12

6.3.11 Copeland Scroll – K5 Refrigeration Compressor.......................................................................................... 6-12

6.3.12 XM Series of Case Controllers...................................................................................................................... 6-12

6.3.12.1 XM670................................................................................................................................................................. 6-12

6.3.12.2 XM679................................................................................................................................................................. 6-12

6.3.12.3 XM678................................................................................................................................................................. 6-12

6.4 BACNET .................................................................................................................................................................. 6-13

6.4.1 BACnet Overview............................................................................................................................................. 6-13

6.4.2 BACnet Communication................................................................................................................................... 6-13

6.4.2.1 Master Slave Token Passing........................................................... ............................. .. . ....................................... 6-13

6.4.2.2 BACnet IP (Internet Protocol)............................................................................................................................... 6-14

6.4.2.3 Discovery ........................................................................................................................................... .................... 6-14

6.4.2.4 Client-Server.......................................................................................................................................................... 6-14

6.4.3 MS/TP Network Connection to E2................................................................................................................... 6-14

E2 RX/BX/CX I&O Manual Table of Contents • vii

Page 8

6.4.3.1 Add and Connect a BACnet Device ...................................................................................................................... 6-14

7 E2 ETHERNET PEER COMMUNICATIONS...................................................................................................... 7-1

7.1 ETHERNET IP CONFIGURATIONS................................................................................................................................ 7-1

7.2 HARDWARE SPECIFICATIONS..................................................................................................................................... 7-1

7.2.1 Components........................................................................................................................................................ 7-1

7.3 SOFTWARE SPECIFICATIONS ...................................................................................................................................... 7-2

7.4 ETHERNET NETWORK LAYOUTS ................................................................................................................................ 7-2

7.4.1 Closed Network Layout...................... ................................................................................................................ 7-2

7.4.2 Open Network Layout......................................................................................................................................... 7-3

7.5 SOFTWARE SETUP...................................................................................................................................................... 7-3

7.6 TROUBLESHOOTING ................................................................................................................................................... 7-4

8 ECHELON NETWORK AND HARDWARE SETUP........................................................................................... 8-1

8.1 OVERVIEW ................................................................................................................................................................. 8-1

8.2 WIRING TYPE............................................................................................................................................................. 8-1

8.3 ECHELON NETWORK STRUCTURING (DAISY-CHAINS).............................................................................................. 8-1

8.3.1 Maximum Number of Echelon Devices.............................................................................................................. 8-2

8.4 DEVICE TERMINATION............................................................................................................................................... 8-2

8.4.1 Using a Termination Block (P/N 535-2715) to Terminate a Daisy Chain................................................. ........ 8-3

8.5 WIRE RESTRICTIONS.................................................................................................................................................. 8-3

8.6 INSTALLING ECHELON DEVICES................................................................................................................................ 8-3

8.6.1 Powering Echelon Devices................................................................................................................................. 8-3

8.7 LEDS ......................................................................................................................................................................... 8-4

8.8 OPEN ECHELON DEVICE CONNECTIVITY................................................................................................................... 8-4

8.8.1 Configuring Echelon Devices............................................................................................................................. 8-4

8.8.1.1 Troubleshooting ....................................................................................................................................................... 8-5

9 INPUT AND OUTPUT SETUP................................................................................................................................ 9-1

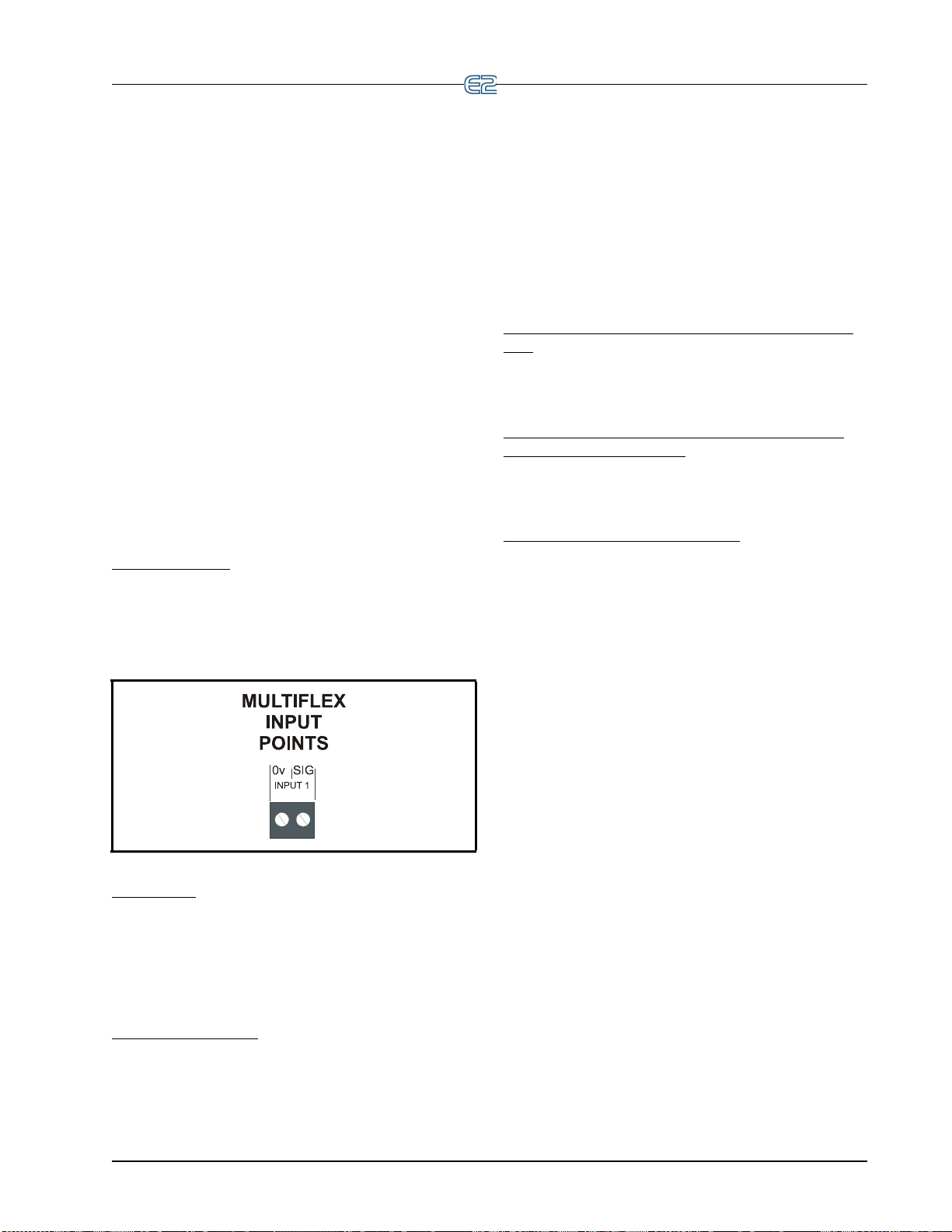

9.1 THE 16AI, 8IO, AND MULTIFLEX INPUTS ................................................................................................................. 9-1

9.1.1 Connecting Sensors to Input Boards.................................................................................................................. 9-1

9.1.1.1 Wiring ...................................................................................................................................................................... 9-1

9.1.1.2 Sensor Wiring Types................................................................................................................................................ 9-1

9.1.1.3 Input Type Dip Switches ......................................................................................................................................... 9-1

9.1.2 Power Connection.............................................................................................................................................. 9-2

9.1.3 Input Setup in E2................................................................................................................................................ 9-6

9.1.3.1 Configuring a Point from the Input Definitions/Status Screen................................................................................ 9-6

9.1.3.2 Using the Input Definitions/Status Screen............................................................................................................... 9-7

9.1.3.3 Setting Up Analog Inputs......................................................................................................................................... 9-7

9.1.3.4 Setting Up Digital Inputs......................................................................................................................................... 9-9

9.2 THE 8RO, 8IO, AND MULTIFLEX OUTPUTS ............................................................................................................ 9-10

9.2.1 Wiring Form C Contacts.................................................................................................................................. 9-10

9.2.2 MultiFlex Relay Outputs.................................................................................................................................. 9-10

9.2.3 Setting the Fail-Safe Dip Switch...................................................................................................................... 9-11

9.2.4 Relay Output Test Mode................................................................................................................................... 9-11

9.2.5 Wiring Outputs to Points................................................................................................................................. 9-12

9.2.6 The Output LED............................................................................................................................................... 9-12

9.2.7 Output Setup in E2 ........................................................................................................................................... 9-12

9.2.7.1 Configuring a Point from the Output Definitions/Status Screen ............ .. ................................ ............................. 9-12

9.2.7.2 Using the Output Definitions/Status Screen .......................................................................................................... 9-13

9.2.7.3 Setting Up Digital Outputs.............................................................................................................. ....................... 9-13

9.2.7.4 Setting Up Analog Outputs.................................................................................................................. .................. 9-14

9.3 CC-100 CASE CONTROLLERS.................................................................................................................................. 9-16

9.3.1 Inputs................................................................................................................................................................ 9-16

9.3.2 Power Module Wiring...................................................................................................................................... 9-17

viii • Table of Contents 026-1614 Rev 4 5-JAN-2013

Page 9

9.3.3 Valve Cable...................................................................................................................................................... 9-17

9.4

CCB CASE CONTROLLERS ...................................................................................................................................... 9-18

9.5 ESR8 AND MULTIFLEX ESR VALVE OUTPUT WIRING........................................................................................... 9-18

10 QUICK START...................................................................................................................................................... 10-1

10.1 LOGGING ON ......................................................................................................................................................... 10-1

10.2 CLEANING OUT THE CONTROLLER........................................................................................................................ 10-1

10.3 SETTING NUMBER OF NETWORK DEVICES............................................................................................................ 10-2

10.4 SETTING NUMBER OF APPLICATIONS .................................................................................................................... 10-3

10.5 THE MAIN STATUS (HOME) SCREEN..................................................................................................................... 10-3

10.5.1 Customizing the Home Screen....................................................................................................................... 10-3

10.6 COMMON SCREEN ELEMENTS ............................................................................................................................... 10-4

10.6.1 The Header..................................................................................................................................................... 10-4

10.6.1.1 Header Icons ........................................................................................................................................................ 10-4

10.6.2 The Function Keys ......................................................................................................................................... 10-4

10.6.3 The Help Line................................................................................................................................................. 10-4

10.7 SCREEN TYPES....................................................................................................................................................... 10-5

10.7.1 The Main Menu.............................................................................................................................................. 10-5

10.7.2 Status Screens ................................................................................................................................................ 10-5

10.7.3 The Actions Menu........................................................................................................................................... 10-6

10.7.4 The Setup Screens .......................................................................................................................................... 10-6

10.7.5 System Configuration Menu........................................ ................................................................................... 10-7

10.7.6 The System Information Menu ....................................................................................................................... 10-8

10.8 TIME/DATE SETUP................................................................................................................................................. 10-9

10.8.1 Setting the Time and Date.............................................................................................................................. 10-9

10.9 SET UP MODEM.............................................................................................................................................. ..... 10-10

10.10 SET UP TCP/IP.................................................................................................................................................. 10-11

10.11 SET UP NETWORK BAUD RATES......................................................... .......................................... ................... 10-12

10.11.1 COM1 Serial (RS232) Baud Rate .............................................................................................................. 10-12

10.11.2 I/O Network Baud Rate........................................................... ................................................................... 10-12

10.12 SET UP USER ACCESS ....................................................................................................................................... 10-13

10.12.1 Changing Required User Access Levels .................................................................................................... 10-14

10.12.2 Creating a New User Account ................................................................................................................... 10-14

10.12.3 Deleting a User.......................................................................................................................................... 10-14

10.13 SET UP I/O NETWORK ....................................................................................................................................... 10-15

10.13.1 Specify Number of Boards............................................................................................................... ........... 10-15

10.13.2 Checking Online Status.............................................................................................................................. 10-15

10.14 SET UP ECHELON NETWORK............................................................. .......................................... ...................... 10-16

10.14.1 Specifying Number of Devices ................................................................................................................... 10-16

10.14.2 Commissioning a Device............................................................................................................................ 10-16

10.14.2.1 The Service Button Method.................................................................................................................. ........... 10-17

10.14.2.2 The Manual ID Entry Method.......................................................................................................................... 10-18

10.15 LICENSE MANAGEMENT .................................................................................................................................... 10-19

10.15.1 Web Services.............................................................................................................................................. 10-20

10.16 SET UP ALARMING ............................................................................................................................................ 10-20

10.16.1 Specifying Alarm Reporting Types............................................................................................................. 10-21

10.16.1.1 The Display Line.......................................................................................................................... .................... 10-21

10.16.1.2 The Alarm Output...................................................................................................................... ...................... 10-21

10.16.1.3 Dial-Out ............................................................................................................................ ............................... 10-21

10.16.1.4 The Echelon Network (The Alarm Annunciator)............................................................................................ 10-21

10.16.2 Setting up an E2 to be an Alarm Annunciator ........................................................................................... 10-22

10.16.3 Alarm Dial-Out............................................................................................................... ........................... 10-22

10.16.4 Introduction: Alarm Reporting.................................................................................................................. 10-23

10.17 SET UP GLOBAL DATA...................................................................................................................................... 10-23

E2 RX/BX/CX I&O Manual Table of Contents • ix

Page 10

10.17.1 Priority Settings.......................................................................................................... ................................ 10-24

10.18

SET UP APPLICATIONS....................................................................................................................................... 10-25

10.18.1 Add/Delete an Application..................................................................................................... .................... 10-26

10.18.2 Using and Configuring a Setup Screen...................................................................................................... 10-26

10.18.2.1 The Edit Menu ...................................................................................................................... ........................... 10-27

10.18.2.2 Entering Setpoints............................................................................................................................................ 10-27

10.18.2.3 Navigating the Setup Screen............................................................................................ ............................. ... 10-27

10.18.3 Using the Help Key to get Property Help ............................................................................................ ...... 10-29

11 SOFTWARE OVERVIEW................................................................................................................................... 11-1

11.1 SUCTION GROUPS .................................................................................................................................................. 11-1

11.1.1 Introduction.................................................................................................................................................... 11-1

11.1.2 The (Standard) Suction Group Application ................................................................................................... 11-1

11.1.2.1 Overview of PID Control Strategy ...................................................................................................................... 11-1

11.1.2.2 Variable-Speed Compressors.................................................................................................. ............................ . 11-1

11.1.2.3 Floating Setpoint Control................................ ............................. .. ...................................................................... 11-1

11.1.3 The Enhanced Suction Group Application..................................................................................................... 11-1

11.1.3.1 Learning Mode.......................................................................................................... ............................. .............. 11-2

11.1.3.2 Circuit Load Analysis ........................ ............................. ............................. ........................... ............................. 11-2

11.1.3.3 The Control/Cycles Parameter............................................................................................................................. 11-2

11.1.3.4 Variable-Speed, Digital Scroll, and Digital Discus Compressor Support........................................................... 11-2

11.1.3.5 Floating Suction Control...................................................................................................................................... 11-2

11.1.4 Hardware Overview....................................................................................................................................... 11-2

11.2 CONDENSER CONTROL........................................................................................................................................... 11-3

11.2.1 Air Cooled Condensers .................................................................................................................................. 11-3

11.2.1.1 Air Cooled Strategy ............................................................................................................................................. 11-3

11.2.1.2 Temperature Differential Strategy....................................................................................................................... 11-3

11.2.2 Evaporative Condensers ................................................................................................................................ 11-4

11.2.3 Fan Control.................................................................................................................................................... 11-4

11.2.4 Condenser Split Mode.................................................................................................................................... 11-4

11.2.5 Fast Recovery................................................................................................................................................. 11-4

11.2.6 Hardware Overview....................................................................................................................................... 11-4

11.3 STANDARD CIRCUITS............................................................................................................................................. 11-5

11.3.1 Refrigeration Control..................................................................................................................................... 11-6

11.3.1.1 Temperature Monitor........................................................................................................................................... 11-6

11.3.1.2 Temperature Control............................................................................................................................................ 11-6

11.3.1.3 Line Up(ESR)/Defrost ....................................................................................................... ............................. ..... 11-6

11.3.1.4 Line Up(MFESR)/Defrost ................................................................................................................................... 11-6

11.3.2 Defrost Control .............................................................................................................................................. 11-6

11.3.2.1 Defrost States................................................................................................................... .................................... 11-6

11.3.2.2 Defrost Types....................................................................................................................................................... 11-6

11.3.2.3 Defrost Termination............................................................................................................................................. 11-7

11.3.2.4 Emergency Defrost ....................................................................................................................... ....................... 11-7

11.3.2.5 Hot Gas Defrost with ESR8 and MultiFlex ESR................................................................................................. 11-7

11.3.3 Clean and Door Switches............................................................................................................................... 11-7

11.3.3.1 Clean Switches................................................................................................................................ ..................... 11-7

11.3.3.2 Door Switches...................................................................................................................................................... 11-8

11.3.4 Fan Control.................................................................................................................................................... 11-8

11.3.5 The TD3 Temperature

Display ........................................................................................................................................................................ 11-8

11.3.6 The Control Link CD Case Display ............................................................................................................... 11-8

11.3.7 Wiring............................................................................................................................................................. 11-8

11.4 CASE CONTROL CIRCUITS ................................................................................................................................... 11-10

11.4.1 Overview.................................................................................................................... ................................... 11-10

11.4.2 Case Circuit Control Software Overview..................................................................................................... 11-10

11.4.2.1 Valve Control..................................................................................................................................................... 11-11

x • Table of Contents 026-1614 Rev 4 5-JAN-2013

Page 11

11.4.3 Refrigeration Control.............................................................................................................................. ..... 11-11

11.4.3.1 EEVs (Liquid Pulse and Liquid Stepper).................. .. ....................................................................................... 11-11

11.4.3.2 EEPRs (Suction Stepper) ............................................................................................................... .................... 11-12

11.4.4 Defrost Control.................................................................................................................. ......................... 11-12

11.4.4.1 Defrost States.................................................................................................................... ................................. 11-12

11.4.4.2 Defrost Types................................................................................................................................. .................... 11-12

11.4.4.3 Defrost Termination............................................................................................................................ ............... 11-13

11.4.4.4 Demand Defrost......................................................................................................................... ........................ 11-13

11.4.4.5 Emergency Defrost ........................................................................................................................ .................... 11-13

11.4.4.6 The WAIT State............................................................................................................................................... .. 11-13

11.4.5 Anti-Sweat Control....................................................................................................................................... 11-13

11.4.5.1 Dewpoint Input Sources................................................................................................................... .................. 11-14

11.4.6 Dual Temp Control ...................................................................................................................................... 11-14

11.4.7 Fan Control............................................................................................................................................. ..... 11-14

11.4.8 Light Control................................................................................................................................................ 11-14

11.4.9 Clean/Wash Mode........................................................................................................................................ 11-14

11.4.10 Walk-In Freezer Control ...................................................................................................... ...................... 11-15

11.4.11 Fail-Safe Mode.............................................................................................................................. ............. 11-15

11.4.11.1 Recoverable Sensor Failures............................................................................................................................ 11-15

11.4.12 Wiring.................................................................................................................................................... ..... 11-16

11.4.13 Setting Up An Individual Case Controller................................................................................................. 11-16

11.4.14 Associating Case Controllers with Case Circuit Control Applications..................................................... 11-16

11.5 LOGGING GROUPS ............................................................................................................................................... 11-16

11.5.1 Possible Data Errors .............................. ..................................................................................................... 11-17

11.5.2 Data Compression............................................................................................................... ......................... 11-17

11.5.2.1 Clipping................................................................................................................................... ........................... 11-17

11.5.2.2 Incompressible Data Types............................................................................................... ............................. .... 11-17

11.5.3 Base Log Group..................................................................................................................... ...................... 11-17

11.5.4 Setting Up Logging .............................................................................................................................. ........ 11-18

11.5.5 Logging Group Status Screen...................................................................................................................... 11-19

11.5.6 Log Reports.................................................................................................................................................. 11-19

11.5.6.1 Logging Group Report....................................................................................................................................... 11-19

11.5.6.2 Application Log Report .............................................. ................................................................................... .... 11-19

11.5.6.3 System Log Report ............................................................................................................................................ 11-20

11.6 AIR HANDLING UNITS (AHU).................................................... ........................................... .............................. 11-20

11.6.1 Overview ...................................................................................................................................................... 11-20

11.6.2 Temperature Control.................................................................................................................... ................ 11-20

11.6.3 Alternate Setpoints......................................................................................................... .............................. 11-20

11.6.4 Fan Control............................................................................................................................................. ..... 11-21

11.6.4.1 Single-Speed Fans................................................................................................................. ............................. 11-21

11.6.4.2 Two-Speed Fans................................................................................................................................................. 11-21

11.6.4.3 Variable-Speed Fans ...................................................................................................................................... .... 11-21

11.6.5 Economizer Control..................................................................................................................................... 11-22

11.6.5.1 Economization Enable............................................................................................................... ........................ 11-22

11.6.5.2 Economization Lockout Features ...................................................................................................................... 11-22

11.6.6 Digital Economizer Control......................................................................................................................... 11-22

11.6.7 Analog Economizer Control......................................................................................................................... 11-22

11.6.8 Dehumidification Control................................................................................................................. ........... 11-22

11.6.9 Curtailment .................................................................................................................................................. 11-23

11.6.10 Optimum Start/Stop (OSS) .................................................................................................................... ..... 11-23

11.6.11 Separate Setpoints...................................................................................................................................... 11-24

11.6.12 AHU Zone Control.................................................................................................... ................................. 11-24

11.6.13 Hardware Overview...................................................................................................................... ............. 11-24

11.7 ZONE CONTROL ................................................................................................................................................. .. 11-25

11.7.1 Overview ...................................................................................................................................................... 11-25

E2 RX/BX/CX I&O Manual Table of Contents • xi

Page 12

11.7.2 How Zones Work.......................................................................................................................................... 11-25

11.7.3 Applications That May Be Connected To Zones.......................................................................................... 11-26

11.7.3.1 MultiFlex RTU Board.. .. ............................. .. ............................. ........................................................................ 11-26

11.7.3.2 MultiFlex RCB Board........................................................................................................................................ 11-26

11.7.3.3 AHUs ................................................................................................................................................................. 11-27

11.7.4 Temperature Control.................................................................................................................................... 11-27

11.7.5 Zone Temperature........................................................................................................................................ 11-27

11.7.6 Economizer Control ..................................................................................................................................... 11-27

11.7.7 Economization Enable..................................................................................................................... ............ 11-27

11.7.8 The Effect of Enabling Economization......................................................................................................... 11-28

11.7.9 Dehumidification Control .................................................................................................. .......................... 11-28

11.7.10 The Zone Humidity Input............................................................................................................. ............... 11-28

11.7.11 The Effect of Enabling Dehumidification................................................................................. .................. 11-28

11.7.11.1 MultiFlex RTUs and RCBs.............................................................................................................................. 11-28

11.7.11.2 AHUs ........................................................................................................................... ............................. ....... 11-28

11.7.12 Optimum Start/Stop (OSS) ......................................................................................................................... 11-28

11.7.13 Losing Contact With Zone Applications..................................................................................................... 11-30

11.7.14 Stand-Alone MultiFlex RTUs..................................................................................................................... 11-30

11.7.15 MultiFlex RTU/ARTC and AHU Zone Association.................................................................................... 11-30

11.8 MULTIFLEX CUB BOARD.................................................................................................................................... 11-30

11.9 MULTIFLEX PAK BOARD.................................................................................................................................... 11-31

11.10 LIGHTING SCHEDULES ....................................................................................................................................... 11-31

11.10.1 Overview..................................................................................................................................................... 11-31

11.10.2 Functions of the Lighting Schedule Application ....................................................................................... . 11-32

11.10.3 Control Method Select................................................................................................................................ 11-32

11.10.4 Standard Control........................................................................................................................................ 11-32

11.10.4.1 The Light Level Interface Cell (LLEV INTERFACE).................................................. .................................. 11-32

11.10.4.2 The Schedule Interface Cell (SCHEDIF) . .................................................................................. ..................... 11-33

11.10.5 Alternate Control........................................................................................................... ............................. 11-33

11.10.5.1 Multi-Logic Combiner..................................................................................................................................... 11-33

11.10.5.2 Offset Solar Control......................................................................................................................... ................ 11-34

11.10.6 The Basic Schedule Cell..................................................................................................... ....................... 11-34

11.10.6.1 Slave Scheduling................................................................................................................ .............................. 11-34

11.10.7 The Min ON/OFF Cell............................................................................................................................... 11-34

11.10.8 The Proof Cell............................................................................................................................................ 11-34

11.10.9 Output Light Dimming .............................................................................................................................. 11-35

11.11 DEMAND CONTROL............................................................................................................................................ 11-35

11.11.1 Introduction to Demand Limit Control ...................................................................................................... 11-35

11.11.2 Demand Monitoring................................................................................................................................... 11-35

11.11.3 Load Shedding............................................................................................................................................ 11-36

11.11.3.1 Definition............................................................................................................................................. ............ 11-36

11.11.4 Shedding Levels.......................................................................................................................................... 11-36

11.11.5 Priority Levels........................................................................................................................................... 11-36

11.11.6 How Demand Control Uses Load Shedding ............................................................................................. 11-38

11.11.6.1 Power Monitoring Input..................................................................................................................... .. ............ 11-39

11.12 SENSOR CONTROL.............................................................................................................................................. 11-39

11.12.1 Overview..................................................................................................................................................... 11-39

11.12.2 Analog Sensor Control..................................................... .......................................... ................................ 11-39

11.12.3 Cut In/Cut Out Setpoint Control ................................................................................................................ 11-39

11.12.4 Digital Sensor Control.............................. ................................................................................................. 11-40

11.12.5 Logical Combination.................................................................................................................................. 11-40

11.13 LOOP/SEQUENCE CONTROL ............................................................................................................................... 11-40

11.13.1 Layout of the Loop/Sequence Control Application ................................................................................... . 11-40

11.13.1.1 Control Cells............................................................................................................................................... ..... 11-40

11.13.1.2 Output Cells .......................................................................................................... ............................. .............. 11-41

xii • Table of Contents 026-1614 Rev 4 5-JAN-2013

Page 13

11.13.1.3 Diagram.......................................................................................................................................................... .. 11-41

11.13.2 Loop/Sequence Control Cell Descriptions................................................................................................. 11-41

11.13.2.1 The Select Cell................................................................................................................................................. 11-41

11.13.2.2 The Setpoint Float Cell ......................................................................................................... ........................... 11-42

11.13.2.3 The PID Control Cell....................................................................................................................................... 11-42

11.13.2.4 The Filter Cell.................................................................................................................................................. 11-42

11.13.2.5 The Override Cell .......................................................................................................................................... .. 11-42

11.13.3 Output Cell Descriptions ........................................................................................................................... 11-42

11.13.3.1 The Sequencer Cell.......................................................................................................................................... 11-42

11.13.3.2 The PWM Cell................................................................................................................ ............................. .... 11-43

11.14 TIME SCHEDULING AND HOLIDAYS.............................................................. .......................................... ........... 11-43

11.14.1 How Schedules Work ................................................................................................................................. 11-43

11.14.1.1 Events............................................................................................................................................. .................. 11-43

11.14.1.2 Absolute and Relative Events .......................................................................................................................... 11-43

11.14.1.3 Temporary Schedule Events ........................ ............................. ....................................................................... 11-44

11.14.1.4 Overlapping...................................................................................................................................................... 11-44

11.14.1.5 Ranges........................................................................................................................................ ...................... 11-44

11.14.2 Holiday Schedules...................................................................................................................................... 11-44

11.15 POWER MONITORING......................................................................................................................................... 11-44

11.15.1 Overview ........................................................................................................................... ......................... 11-44

11.15.2 Logging ........................................................................................................................... ........................... 11-45

11.15.2.1 Power Monitoring Input.................................................................................................................... ............... 11-45

11.16 ANTI-SWEAT SETUP .......................................................................................................................................... 11-46

11.16.1 How Anti-Sweat Works ......................................................................................................................... ..... 11-46

11.17 HEAT/COOL CONTROL....................................................................................................................................... 11-46

11.17.1 Temperature Control....................................................................................................... ........................... 11-46

11.17.2 Unoccupied Hysteresis.............................................................................................................................. 11-47

11.17.3 Optimum Start/Stop (OSS)..................................... .................................................................................... 11-47

11.17.4 Setpoint Reset............................................................................................................... .............................. 11-47

11.17.5 Lead/Lag .................................................................................................................................................... 11-48