Page 1

RGB ELEKTRONIKA AGACIAK CIACIEK

SPÓŁKA JAWNA

Jana Dlugosza 2-6 Street

51-162 Wrocław

Poland

biuro@rgbelektronika.pl

+48 71 325 15 05

www.rgbautomatyka.pl

www.rgbelektronika.pl

DATASHEET

www.rgbautomatyka.pl

www.rgbelektronika.pl

OTHER SYMBOLS:

LX-400

LX400, LX 400, LX-400

EMERSON

Page 2

YOUR

PARTNER IN

MAINTENANCE

At our premises in Wrocław, we have a fully equipped servicing facility. Here we perform all the repair

works and test each later sold unit. Our trained employees, equipped with a wide variety of tools and

having several testing stands at their disposal, are a guarantee of the highest quality service.

OUR SERVICES

ENCODERS

SERVO

DRIVERS

LINEAR

ENCODERS

SERVO AMPLIFIERS

CNC

MACHINES

MOTORS

POWER

SUPPLIERS

OPERATOR

PANELS

CNC

CONTROLS

INDUSTRIAL

COMPUTERS

PLC

SYSTEMS

Repair this product with RGB ELEKTRONIKA

ORDER A DIAGNOSIS

∠

Buy this product at RGB AUTOMATYKA

BUY

∠

Page 3

User’s Guide

for the

LX

Brushless Servo Drives

Amplifier Models

LX-400, LX-700, LX-1100

Motor Models

DX-208, DX-316, DX-340

DX-455, DX-490, DX-4120

Artisan Scientific - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisan-scientific.com

Page 4

Artisan Scientific - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisan-scientific.com

Page 5

User’s Guide

for the

LX Series

Brushless Analog Servo Drives

LX400, LX-700, LX-1100

Information furnished by EMERSON EMC is believed to be

accurate and reliable. However, no responsibility is assumed by

EMERSON EMC for its use. EMERSON EMC reserves the right

to change the design or operation of the equipment described

herein and any associated motion products without notice.

EMERSON EMC also assumes no responsibility for any errors

that may appear in this document. Information in document is

subject to change without notice.

Part Number 400272-00 Rev: A.2

Date: 01/13/95j

Artisan Scientific - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisan-scientific.com

Section 1 – Page 1

Page 6

1 INTRODUCTION 1

2 INSTALLATION - MECHANICAL 2

3 INSTALLATION – ELECTRICAL 3

4 CONFIGURATION 4

5 START UP / CALIBRATIONS 5

6 SPECIAL APPLICATIONS 6

7 DIAGNOSTICS 7

8 APPENDICES 8

Artisan Scientific - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisan-scientific.com

Section 1 – Page 2

Page 7

1.1 Features of the LX Drives

1

Introduction

Ø Uses 96-264 VAC 50/60 Hz, single or

Ø Velocity or torque mode of control

3Ø, direct on-line power source

Ø 1 KW to 3 KW output power range Ø Limit switch inputs

Ø 10 lb.-in. to 100 lb.-in. (1.13 NM to 11.3

Ø Diagnostic LEDs

NM) matching motor series

Ø Resolver feedback tolerates shock and

high temperature

Ø Encoder simulation output for external

Ø Integral power supply minimizes

external wiring

Ø Backup logic supply input

position controller interface

Ø Personality module to maintain axis

Ø Integral brake available on motors

adjustments

Ø Sinusoidal commutation for smooth

motion

Ø Waterproof and connectorized

motors available

Ø Bus power sharing capability

Description

The LX Series of brushless servo drives is the latest in analog amplifier design from

Emerson EMC. The wide input voltage range and compact dimensions make it one of

the most versatile amplifiers available.

There are three amplifiers in the LX Series; the LX-400 (4.0 amps of continuous output

current), the LX-700 (7.0 amps of continuous output current) and the LX-1100 (10.9

amps of continuous output current). All three amplifiers have the same physical

dimensions.

Each LX Amplifier is matched with the proven reliable DX Brushless Servo motors.

When correctly matched, the LX Amplifier and DX Motor combinations offer continuous

torque output ratings of from 10 to 100 lb.-in.

The amplifiers incorporate pulse width modulated (PWM) design to provide efficient

power conversion. Sine wave commutation of the motor results in smooth rotation

across the full range of speed.

All LX Amplifiers are designed with their own power supply, heat sink, shunt resistor and

fan (when needed). This allows for simple installation and expansion.

Section 1 – Page 3

Artisan Scientific - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisan-scientific.com

Page 8

LX Amplifiers can be easily adjusted to operate with a variety of motors and controllers.

A personality module attached to the amplifier retains all adjustments. If an amplifier

needs to be replaced, the personality module can be removed and attached to a new

amplifier, thus alleviating the re-adjustment process.

Troubleshooting is aided through the use of status LEDs located on the front panel of

the amplifiers. The LEDs continually keep the operator informed of the status of the

amplifier at all times. In addition to the LED indications, fault conditions such as resolver

fault and motor over temperature are announced as a contact signal output which can

be monitored by a host controller.

Input power voltage can range from 96 to 264 VAC 50/60 Hz without jumper or switch

selection. A 230 VAC 50/60 Hz, 3Ø supply will deliver the maximum output power.

Optimum performance from a servo system is accomplished by carefully matching the

motor and amplifier. Emerson EMC’s DX Series of servo motors has been engineered

to compliment the LX servo amplifier, providing unparalleled reliability and performance.

The DX Motors are available in a number of configurations including connectorized or

waterproof (IP65) versions. Most motors are also available with a mechanical holding

brake.

NEMA motor face dimensions are available in addition to the metric dimensions on four

motor models to greatly simplify mounting to many standard reducers.

DXE-208 NEMA 23 compatible

DXE-316 NEMA 34 compatible

DXE-455 NEMA 56C

DXE-490 NEMA 143TC

DXE-4120 NEMA 143TC

The signal and power connections are conveniently located on the drive front panel to

simplify wiring in multi-axis applications.

Artisan Scientific - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisan-scientific.com

Section 1 – Page 4

Page 9

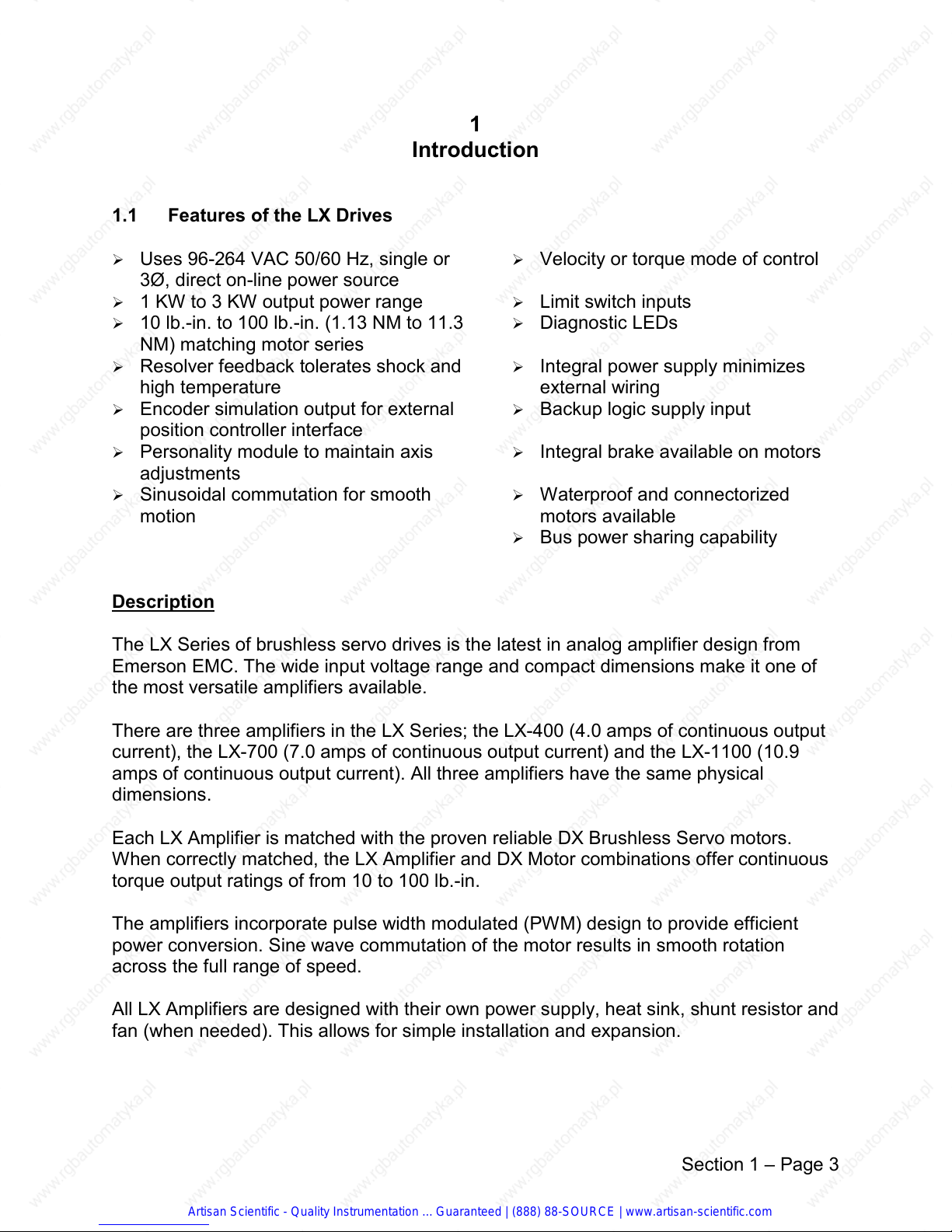

Figure 1.1 LX Drive, overall layout

Section 1 – Page 5

Artisan Scientific - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisan-scientific.com

Page 10

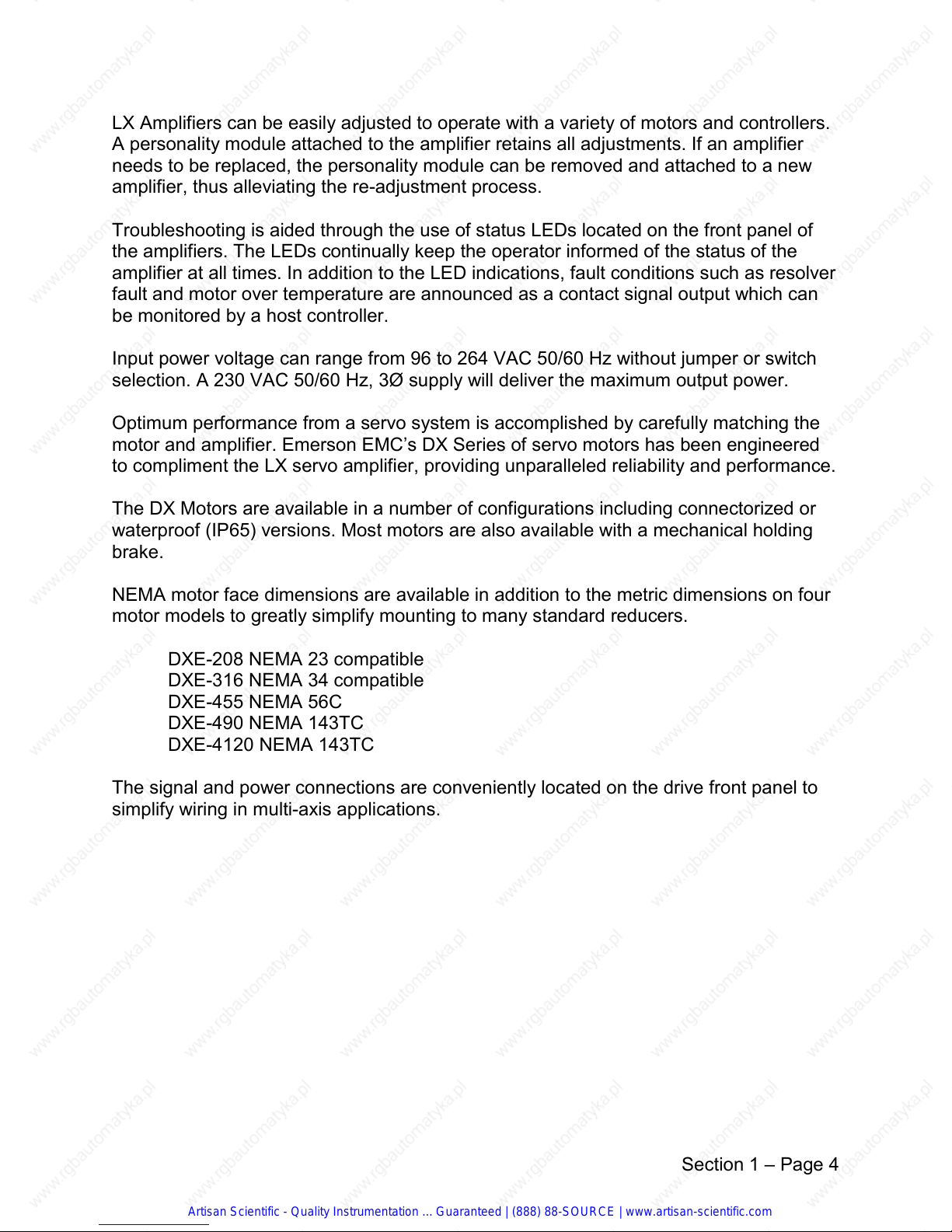

1.2 System Components

A complete LX package is made up of an LX amplifier, a DX motor and the appropriate

motor and resolver cables connected as shown in Figure 1.2. Cables are available from

Emerson for both the connectorized and non-connectorized motors. EMC designed

cables are recommended because they have been specially designed for the LX

amplifiers and will minimize installation problems. Table 1-A shows the available cables

and their application. For more information see Chapter 2.

Table 1-A – Motor Cabling

Motor Type Motor Model Motor Cable Resolver Cable

Waterproof Motors DXM/E-3xxW, 4xxW HPS-XXX (shielded)

250224-09

250036-00(non-

shielded)

Connectorized

DXM/E-3xxC, -455C ECM-XXX LCF-XXX

Motors

DXM/E-490C, -4120 ECL-XXX LCF-XXX

DXM/E-208 LCS-XXX

All cabling is PVC, rated for 105° C.

(XXX) is length in feet, consult an Emerson EMC application engineer for cabling

requirements over 100 ft.

Figure 1.2 Typical LX component configuration

Artisan Scientific - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisan-scientific.com

Section 1 – Page 6

Page 11

1.2.1 User Adjustments and Options

The amplifiers each have a personality module that is used to set up the drive for the

application as required. The drive features which are customized by the user on the

personality board include:

Continuous Current limit value

Maximum Speed Range (3000 / 6000 rpm)

Motor pole selection

Calibration adjustments

Limit Switch enable and polarity

Encoder output resolution

The Limit switch inputs and Emulates encoder outputs are standard on the LX, however

these features can be deleted when purchasing quantities of drives to further reduce

costs. See your Emerson Sales Representative for further details.

1.3 Basic Function and Operation

The amplifier is designed to operate in either a velocity command or current (torque)

mode with an analog ±10 volt command. The velocity command input is a true

differential input while the current command input is a single ended input that doubles

as the current demand output. This signal can be used as a master output in torque

helper applications as well as a test point for detecting the actual motor current required

in an application. For details about the current command mode see the “Special

Applications” section 6.

1.3.1 Feedback Signals

Speed and position feedback signals are accurately derived from the position

information coming from the resolver mounted on the motor shaft.

The derived tachometer signal is used by the amplifiers speed control circuitry and is

available as an analog signal output on the connection strip. This tachometer output

provides analog voltage proportional to the shaft speed with a range of ± 10V equal to ±

3000 / 6000 rpm.

Emulated encoder outputs with zero markers are provided on the standard LX amplifier

for use with position controllers.

1.3.2 Control Loops

The LX drive uses two high performance control loops (current and velocity) to control

the speed and torque of the motor. The “current loop” controls the current flowing into

the motor by comparing the current flowing in the motor to the current command from

the reference signal and correcting it to maintain the commanded current. The current

command can come from either an external controller or directly from the LX amplifiers

speed loop. The velocity loop controls the motor velocity by comparing the actual

Artisan Scientific - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisan-scientific.com

Section 1 – Page 7

Page 12

velocity of the motor to the velocity commanded by the drive and adjusting the current

command as needed to maintain the commanded velocity.

Velocity Loop

In the velocity loop circuit the error signal is processed by a P.I.D. (Proportional, Integral

and Derivative). The output of the P.I.D. filter is the current reference signal also

available for test on terminal 2 of the front connector. The voltage on this point is ± 10

VDC. At ± 10V the drive generates the maximum current in the designated direction.

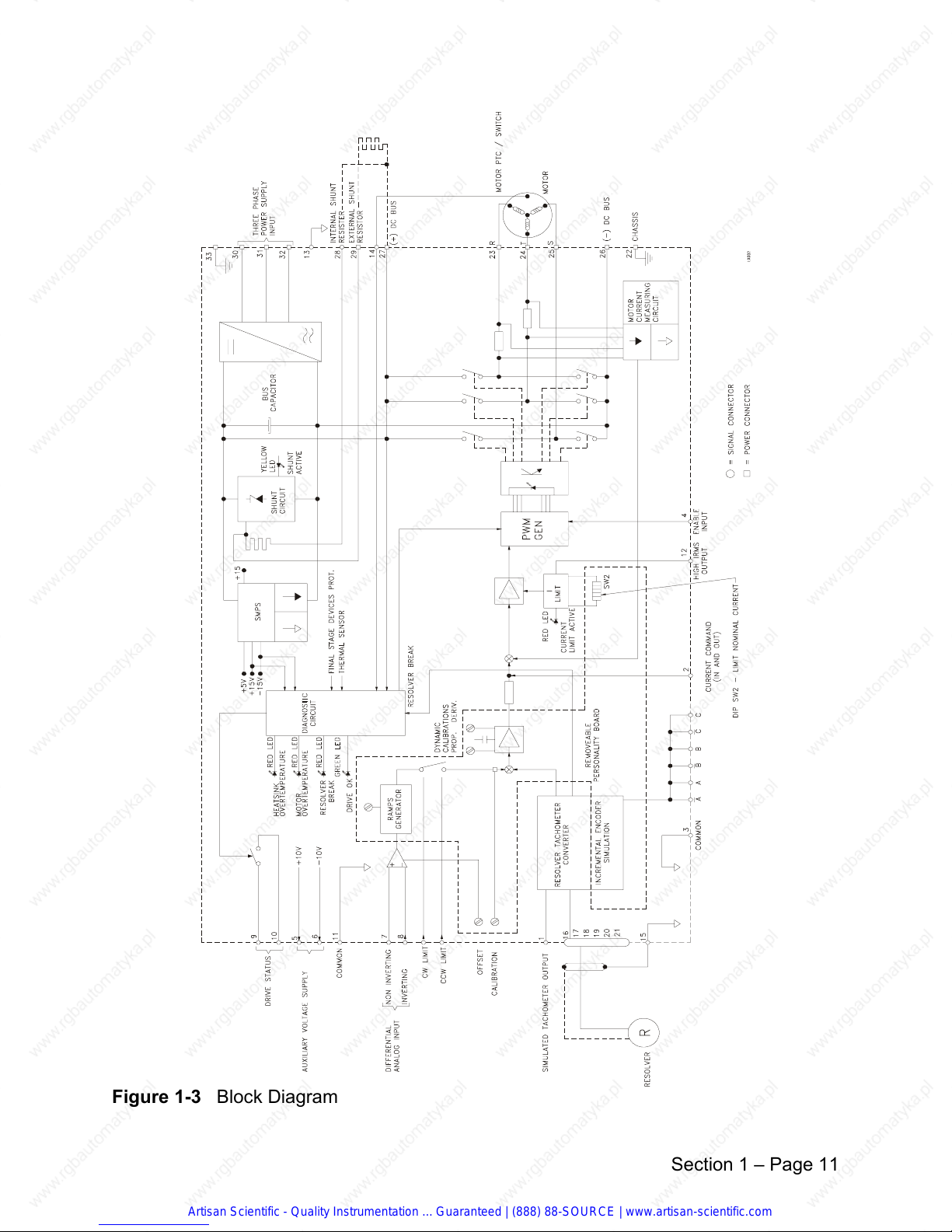

All the adjustments shown on the block diagram in Figure 1-3. Zero offset, proportional

gain, response, accel/decel ramp gradient and full scale speed are located on the

personality board and the potentiometers are accessible from the front panel.

Current Loop and Limiting

The current error signal is generated comparing the output of the current limiting stage

with the actual current in the motor. The current error signal is computed to generate

the PWM signals driving the IGBT final stage. In the block diagram in Figure 1-3, the

IGBT devices are shown as switches.

Current Limiting

In the current loop circuit there is a current limiting circuit referred to as Ixt, which

continuously monitors the current commanded and delivered into the motor.

The Ixt limiting circuit is not operational in the current command

mode. See Chapter 6 for details on implementing current command

mode.

This limiting circuit estimates the heating of the motor by continuously monitoring the

amount of current in the motor and the length of time this current has been flowing. The

limiting value is determined by the setting of dip switches on the personality board. If the

current requested exceeds the value set by the dip switches, the Ixt control circuit will

determine how long the commanded peak current will be allowed before limiting the

delivered current to the dip switch value. This current limiting is not a fault condition but

rather an Ixt current fold back limiting and is so indicated by the High Irms LED and

High Irms output. When the drive is in the Ixt limit status, the RED led (HIGH Irms) lights

and terminal 12 becomes open circuit. Once current fold back is engaged the drive will

continue in the limited current condition until the current commanded is reduced below

the dip switch level for length of time sufficient to reset the Ixt limiting circuitry. The

amount of time allowed above the continuous level before Ixt limiting varies is

dependent on the percent of RMS current the drive has been running. Peak current

availability is also dependent on the level of current demand below and the amount of

time below the dip switch level. In addition to the current foldback limiting, the LX

amplifiers also have short circuit protection. This prevents destruction of the amplifiers

due to short circuits either from a short that is applied while in operation or from a short

circuit in effect at power ON.

Artisan Scientific - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisan-scientific.com

Section 1 – Page 8

Page 13

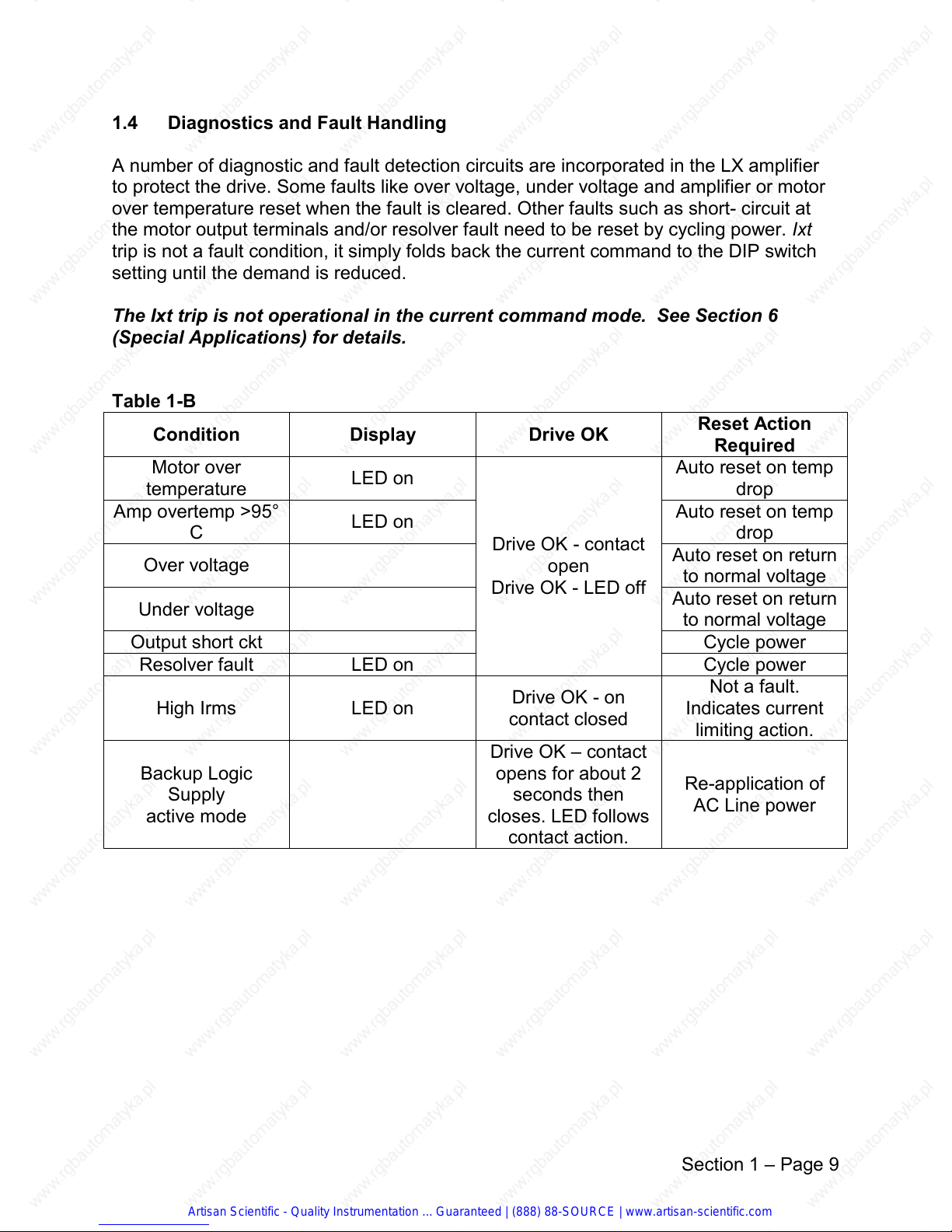

1.4 Diagnostics and Fault Handling

A number of diagnostic and fault detection circuits are incorporated in the LX amplifier

to protect the drive. Some faults like over voltage, under voltage and amplifier or motor

over temperature reset when the fault is cleared. Other faults such as short- circuit at

the motor output terminals and/or resolver fault need to be reset by cycling power. Ixt

trip is not a fault condition, it simply folds back the current command to the DIP switch

setting until the demand is reduced.

The Ixt trip is not operational in the current command mode. See Section 6

(Special Applications) for details.

Table 1-B

Condition Display Drive OK

Motor over

temperature

Amp overtemp >95°

C

LED on

LED on

Drive OK - contact

Over voltage

Drive OK - LED off

Under voltage

open

Reset Action

Required

Auto reset on temp

drop

Auto reset on temp

drop

Auto reset on return

to normal voltage

Auto reset on return

to normal voltage

Output short ckt Cycle power

Resolver fault LED on

High Irms LED on

Drive OK - on

contact closed

Cycle power

Not a fault.

Indicates current

limiting action.

Drive OK – contact

Backup Logic

Supply

active mode

opens for about 2

seconds then

closes. LED follows

Re-application of

AC Line power

contact action.

Artisan Scientific - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisan-scientific.com

Section 1 – Page 9

Page 14

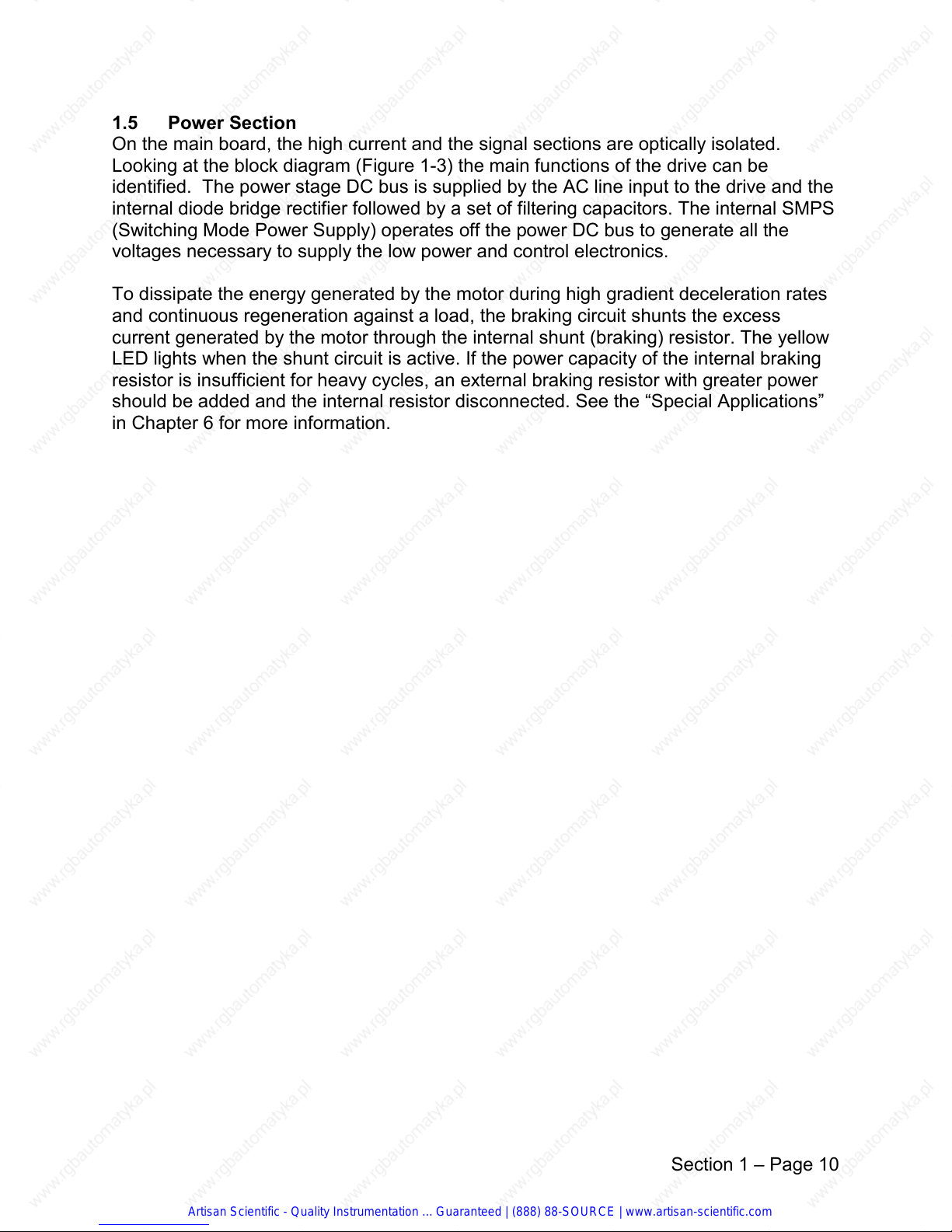

1.5 Power Section

On the main board, the high current and the signal sections are optically isolated.

Looking at the block diagram (Figure 1-3) the main functions of the drive can be

identified. The power stage DC bus is supplied by the AC line input to the drive and the

internal diode bridge rectifier followed by a set of filtering capacitors. The internal SMPS

(Switching Mode Power Supply) operates off the power DC bus to generate all the

voltages necessary to supply the low power and control electronics.

To dissipate the energy generated by the motor during high gradient deceleration rates

and continuous regeneration against a load, the braking circuit shunts the excess

current generated by the motor through the internal shunt (braking) resistor. The yellow

LED lights when the shunt circuit is active. If the power capacity of the internal braking

resistor is insufficient for heavy cycles, an external braking resistor with greater power

should be added and the internal resistor disconnected. See the “Special Applications”

in Chapter 6 for more information.

Artisan Scientific - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisan-scientific.com

Section 1 – Page 10

Page 15

Figure 1-3 Block Diagram

Section 1 – Page 11

Artisan Scientific - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisan-scientific.com

Page 16

2

INSTALLATION -- MECHANICAL

2.1 Installation

The following installation requirements, methods and procedures are provided to assure

reliable and trouble free installation of your Emerson MC LX Drive.

The methods and procedures are outlined on the following pages and include site

requirements, safety considerations, power and fusing requirements, wire and

transformer sizing, noise suppression, and I/O wiring.

2.2 Safety Considerations

The installer/user is responsible for incorporating appropriate safety features into the

equipment to prevent injury to personnel or damage to equipment.

The installer/user has the responsibility to comply with the safety requirements of the

system. This includes installing the system with an appropriate master interlock switch

for emergency shut down and using the proper wire and transformer sizes (if necessary)

to fit the system. This section will provide you with the information to complete a trouble

free installation.

WARNING!

The user is responsible for providing emergency interlock switches that will

remove AC power from the system any time the equipment is not running, or

when the emergency stop is activated. This is to eliminate the possibility of

electrocution or unwanted movement of the motor. The safety ground

connections should only be disconnected for servicing and only after all AC

power has been removed.

2.3 Selecting an Enclosure

The LX drive is designed for the industrial environment. However, no sophisticated

electronic system can tolerate certain atmospheric contaminants such as moisture, oils,

conductive dust, chemical contaminates and metallic particles. Therefore, if the drive is

going to be subjected to this type of environment it must be mounted vertically in a

NEMA type 12 enclosure.

Proper ventilation and filtering must also be provided. If the equipment environment is

above 50° C, cooling is mandatory. The amount of cooling depends on the size of the

enclosure, the thermal transfer of the enclosure to the ambient air and the amount of

power being dissipated inside the enclosure. Your enclosure supplier can assist you in

properly selecting an enclosure for your application.

Artisan Scientific - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisan-scientific.com

Section 2 – Page 1

Page 17

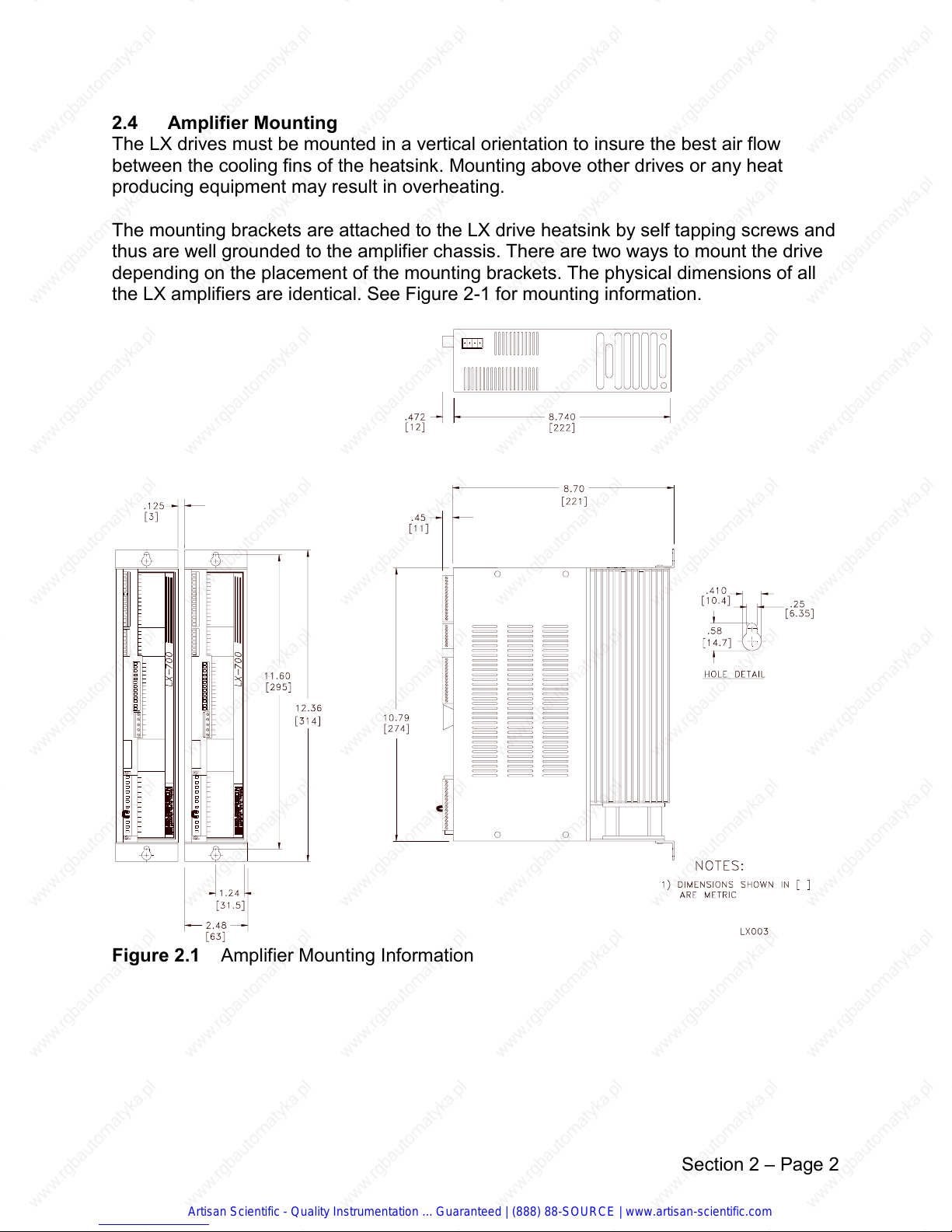

2.4 Amplifier Mounting

The LX drives must be mounted in a vertical orientation to insure the best air flow

between the cooling fins of the heatsink. Mounting above other drives or any heat

producing equipment may result in overheating.

The mounting brackets are attached to the LX drive heatsink by self tapping screws and

thus are well grounded to the amplifier chassis. There are two ways to mount the drive

depending on the placement of the mounting brackets. The physical dimensions of all

the LX amplifiers are identical. See Figure 2-1 for mounting information.

Figure 2.1 Amplifier Mounting Information

Artisan Scientific - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisan-scientific.com

Section 2 – Page 2

Page 18

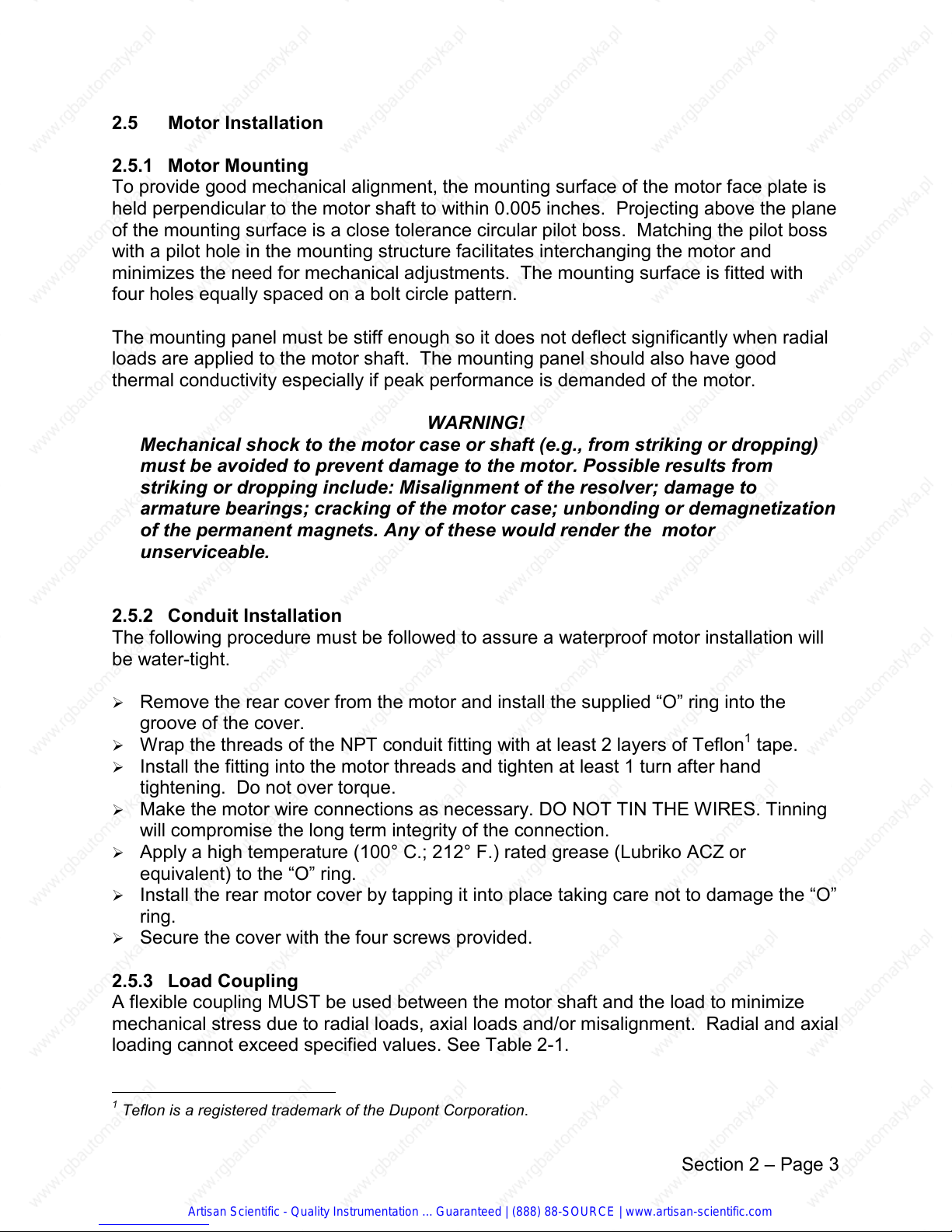

2.5 Motor Installation

2.5.1 Motor Mounting

To provide good mechanical alignment, the mounting surface of the motor face plate is

held perpendicular to the motor shaft to within 0.005 inches. Projecting above the plane

of the mounting surface is a close tolerance circular pilot boss. Matching the pilot boss

with a pilot hole in the mounting structure facilitates interchanging the motor and

minimizes the need for mechanical adjustments. The mounting surface is fitted with

four holes equally spaced on a bolt circle pattern.

The mounting panel must be stiff enough so it does not deflect significantly when radial

loads are applied to the motor shaft. The mounting panel should also have good

thermal conductivity especially if peak performance is demanded of the motor.

WARNING!

Mechanical shock to the motor case or shaft (e.g., from striking or dropping)

must be avoided to prevent damage to the motor. Possible results from

striking or dropping include: Misalignment of the resolver; damage to

armature bearings; cracking of the motor case; unbonding or demagnetization

of the permanent magnets. Any of these would render the motor

unserviceable.

2.5.2 Conduit Installation

The following procedure must be followed to assure a waterproof motor installation will

be water-tight.

Ø Remove the rear cover from the motor and install the supplied “O” ring into the

groove of the cover.

Ø Wrap the threads of the NPT conduit fitting with at least 2 layers of Teflon

Ø Install the fitting into the motor threads and tighten at least 1 turn after hand

1

tape.

tightening. Do not over torque.

Ø Make the motor wire connections as necessary. DO NOT TIN THE WIRES. Tinning

will compromise the long term integrity of the connection.

Ø Apply a high temperature (100° C.; 212° F.) rated grease (Lubriko ACZ or

equivalent) to the “O” ring.

Ø Install the rear motor cover by tapping it into place taking care not to damage the “O”

ring.

Ø Secure the cover with the four screws provided.

2.5.3 Load Coupling

A flexible coupling MUST be used between the motor shaft and the load to minimize

mechanical stress due to radial loads, axial loads and/or misalignment. Radial and axial

loading cannot exceed specified values. See Table 2-1.

1

Teflon is a registered trademark of the Dupont Corporation.

Artisan Scientific - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisan-scientific.com

Section 2 – Page 3

Page 19

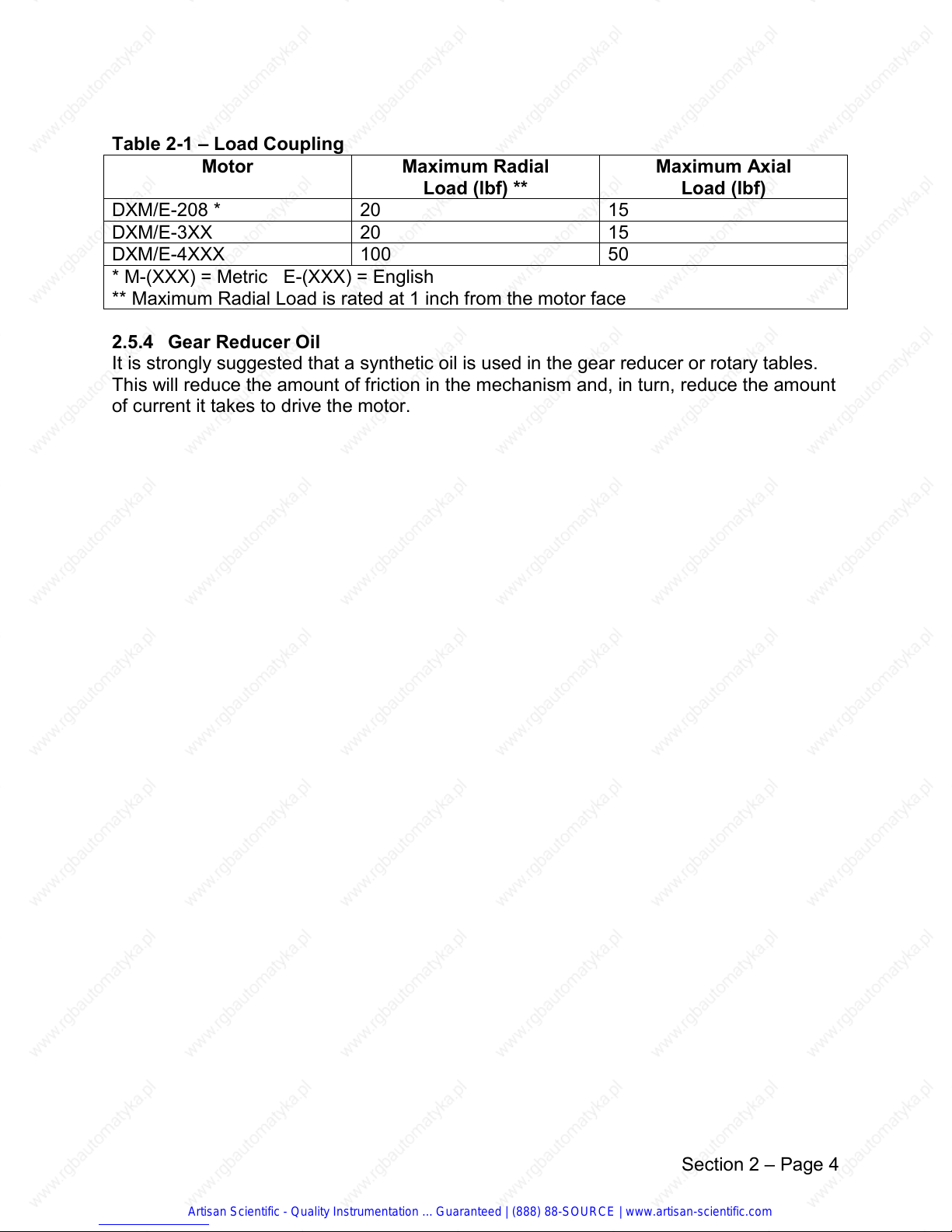

Table 2-1 – Load Coupling

Motor Maximum Radial

Load (lbf) **

Maximum Axial

Load (lbf)

DXM/E-208 * 20 15

DXM/E-3XX 20 15

DXM/E-4XXX 100 50

* M-(XXX) = Metric E-(XXX) = English

** Maximum Radial Load is rated at 1 inch from the motor face

2.5.4 Gear Reducer Oil

It is strongly suggested that a synthetic oil is used in the gear reducer or rotary tables.

This will reduce the amount of friction in the mechanism and, in turn, reduce the amount

of current it takes to drive the motor.

Artisan Scientific - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisan-scientific.com

Section 2 – Page 4

Page 20

3

INSTALLATION -- ELECTRICAL

3.1 Wiring

Wiring of any industrial equipment should be done with some consideration for future

troubleshooting and repair. It is a good idea that wiring be either color coded and/or

tagged with industrial wire tabs.

3.1.1 Interlocking

The user is responsible for emergency interlock switches. Any master interlock should

be wired to shut down AC power to all parts of the system. Your system should be

designed such that power is disconnected from the output loads any time the equipment

is not running or when the emergency stop is activated.

3.1.2 EMI/RFI Interference

If there is sensitive electronic equipment (digital computer, test equipment, etc.)

operating on the same AC power line as the Drive, additional EMI/RFI filtering may be

required to reduce the effects of conducted AC line noise.

3.1.3 Shielding Suggestions

Effects of electrical noise on the electronic equipment are greatly reduced when the

techniques outlined below are closely followed.

Ø Do not run low power control signals and high power wiring in the same raceway.

Ø If mixing wires cannot be avoided, then the low voltage control input and output

wiring must be shielded. The shield for these wires should be connected to ground

only at the source end of the signals.

Ø Do not connect both ends of a shielded cable to ground unless specified by the

manufacturer to do so. This may cause a ground loop condition which could cause

erratic equipment behavior and may be very difficult to locate.

Ø All the wires in the system must be kept as short as possible.

Artisan Scientific - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisan-scientific.com

Section 3– Page 1

Page 21

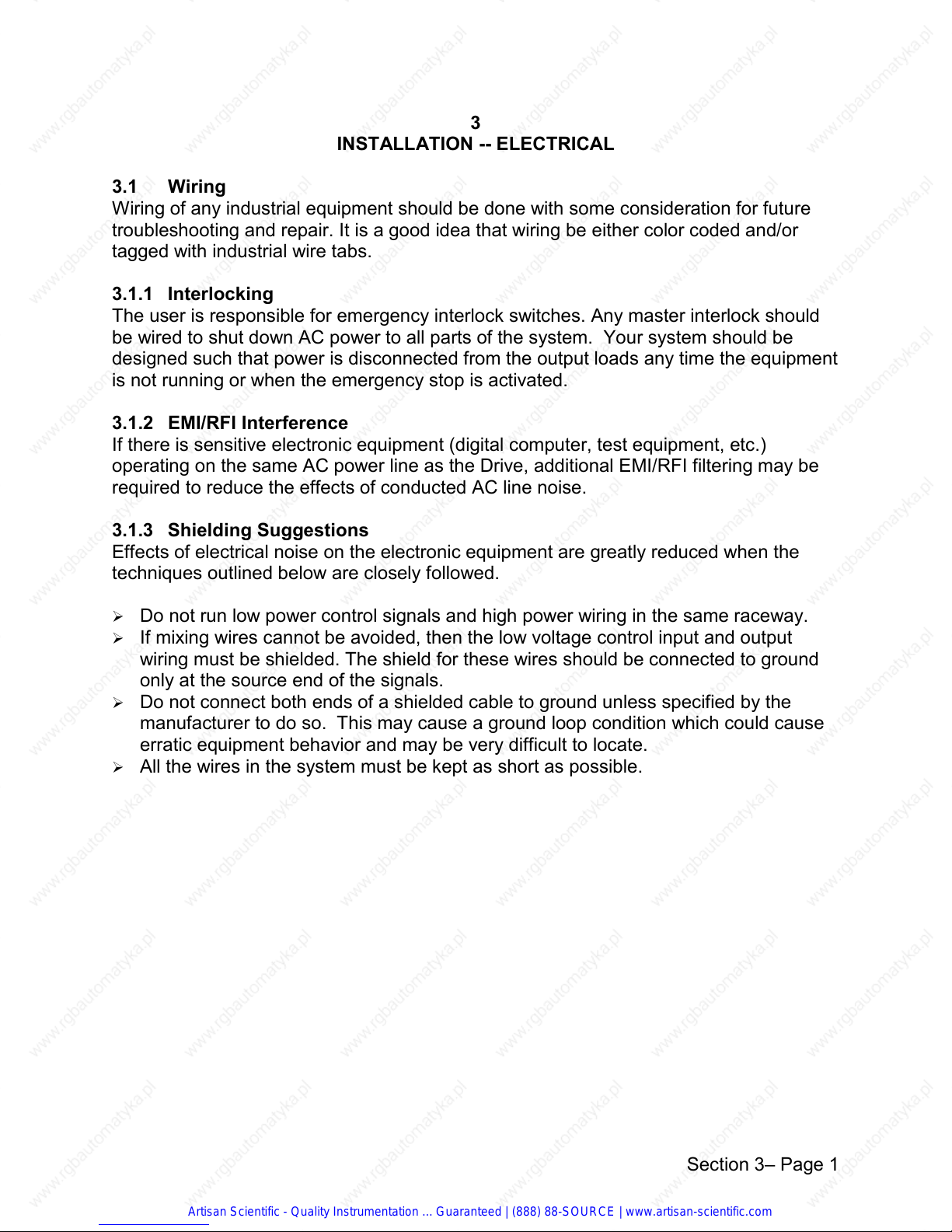

3.2 Magnetic Coil Noise

In the case of DC coils, a diode is installed across the coil in a direction that will cause

the voltage transient to be dissipated through the diode.

Figure 3.1 DC Coil Suppression

In the case of AC coils, a capacitor and resistor are installed across the coil to suppress

the unwanted transients.

Figure 3.2 AC Coil Suppression

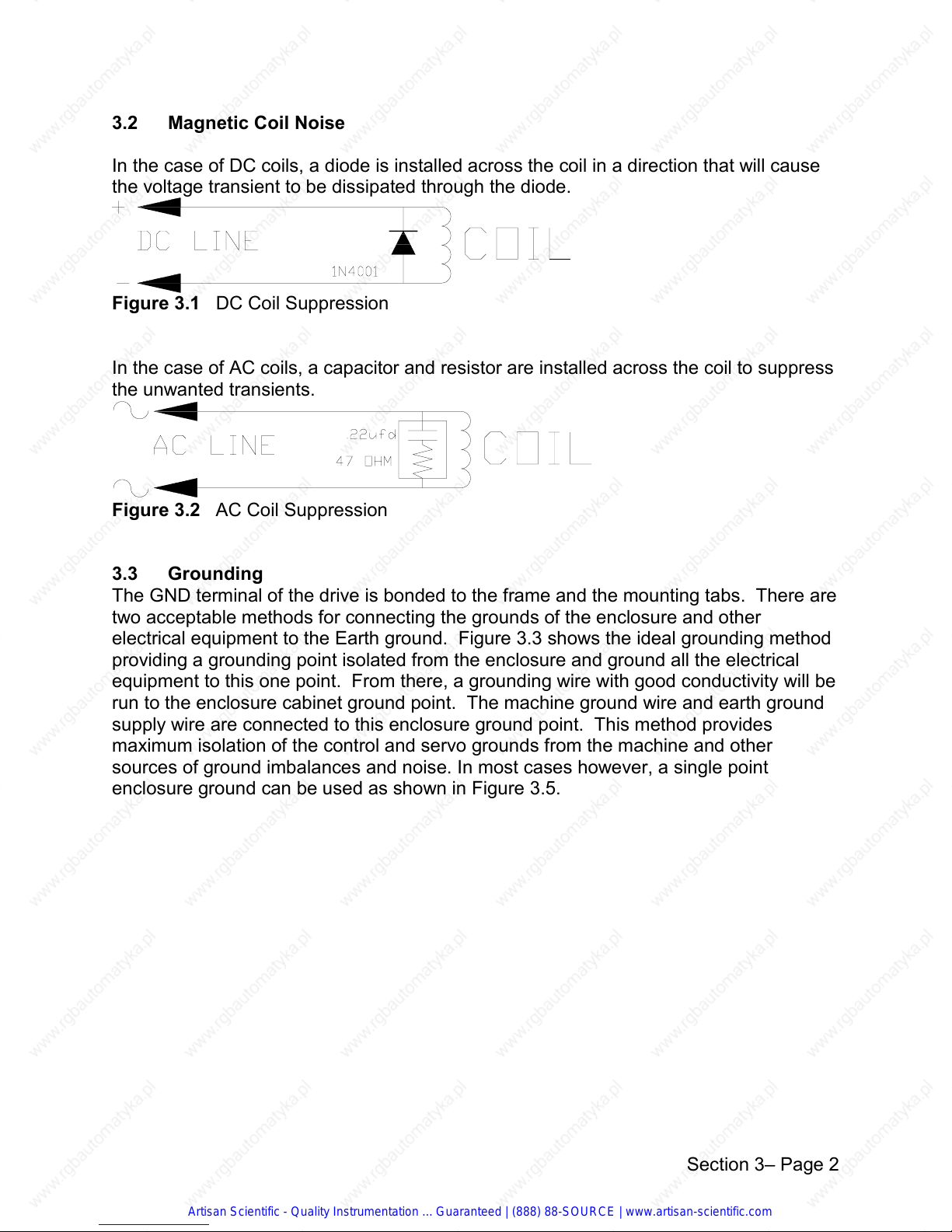

3.3 Grounding

The GND terminal of the drive is bonded to the frame and the mounting tabs. There are

two acceptable methods for connecting the grounds of the enclosure and other

electrical equipment to the Earth ground. Figure 3.3 shows the ideal grounding method

providing a grounding point isolated from the enclosure and ground all the electrical

equipment to this one point. From there, a grounding wire with good conductivity will be

run to the enclosure cabinet ground point. The machine ground wire and earth ground

supply wire are connected to this enclosure ground point. This method provides

maximum isolation of the control and servo grounds from the machine and other

sources of ground imbalances and noise. In most cases however, a single point

enclosure ground can be used as shown in Figure 3.5.

Artisan Scientific - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisan-scientific.com

Section 3– Page 2

Page 22

Figure 3.3 Ideal grounding example, schematic

Figure 3.4 Ideal grounding example, pictorial

Artisan Scientific - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisan-scientific.com

Section 3– Page 3

Page 23

Figure 3.5 Acceptable grounding example

3.4 AC Input

The drives are designed to operate on a 50/60 Hz, three phase AC power line. The AC

voltage of this power line must be within the specified range of 96-264 VAC. If at any

time the input line voltage falls below 96 VAC the drive will drop out the Drive OK output

contact and will disable the output bridge.

3.4.1 Single Phase Power

The LX drives will deliver maximum performance when operating on three phase,

however, 96 to 264 volt, 1Ø can be used with a derating factor.

Note: Consult Emerson EMC customer service if 1Ø power supply is used.

Artisan Scientific - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisan-scientific.com

Section 3– Page 4

Page 24

Table 3-A – Power Wiring and Fusing

Model MINIMUM WIRE SIZE AWG

1

FUSE RATING AMPS

LX-400 20 5

LX-700 18 8

LX-1100 16 12

1

Recommended fuse type is a LOW PEAK delayed action type fuse such as Bus brand

type LPN fuse. A standard rated delayed action or dual element fuse such as Bus

brand FRN may be used in lieu of the Low peak type fuse when availability dictates but

the level of drive protection afforded by the LPN fuse is better. In the case of a short

circuit in the drive, there will be fewer failed drive components if a low peak fuse is used

because it will blow before the currents reach a high level.

3.4.2 Transformer Power Supply

One 3Ø transformer may be used to supply more than one drive. The secondary

winding should be set up to supply the sum of the nominal current of the motors

connected. The transformer secondary must be a delta configuration or a WYE

configuration with a full current grounded neutral connection due to the harmonics

induced when supplying power to a rectified power supply. The type of primary winding

is immaterial.

Figure 3.6 Power supply example

Artisan Scientific - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisan-scientific.com

Section 3– Page 5

Page 25

The following formula can be used for transformer sizing. For each secondary winding,

the power in VA is:

Ps - (Paz * 1.5) * 1.73 / √ (n+2)

where:

Paz = (Vm1*Cm1 + Vm2* Cm2 + ............ +

Vmn*Cmn)

Vm = motor max speed in rad/sec (RPM/9.55)

Cm = nominal motor torque in Nm(lb-in/8.85)

1.73/√(n+2) = corrective factor when using more than one

drive supplied in parallel with n= number of drives.

The overall transformer power in VA is:

Pt = Ps1 + Ps2 ............ + Psn

where:

Ps1 = power of secondary winding 1

Ps2 = power of secondary winding 2

Psn = power of secondary winding n

Artisan Scientific - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisan-scientific.com

Section 3– Page 6

Page 26

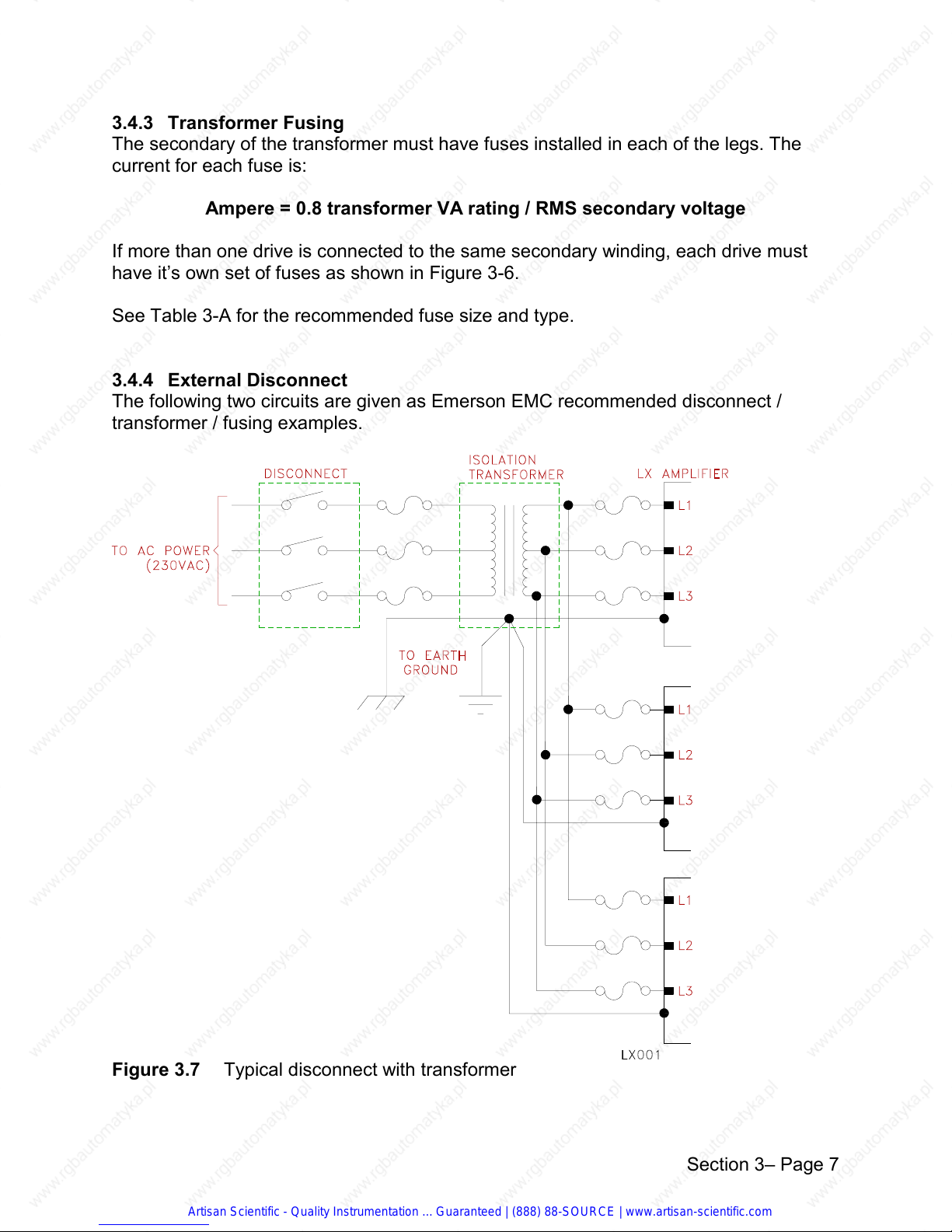

3.4.3 Transformer Fusing

The secondary of the transformer must have fuses installed in each of the legs. The

current for each fuse is:

Ampere = 0.8 transformer VA rating / RMS secondary voltage

If more than one drive is connected to the same secondary winding, each drive must

have it’s own set of fuses as shown in Figure 3-6.

See Table 3-A for the recommended fuse size and type.

3.4.4 External Disconnect

The following two circuits are given as Emerson EMC recommended disconnect /

transformer / fusing examples.

Figure 3.7 Typical disconnect with transformer

Artisan Scientific - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisan-scientific.com

Section 3– Page 7

Page 27

Figure 3.8 Typical disconnect without transformer

Section 3– Page 8

Artisan Scientific - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisan-scientific.com

Page 28

3.5 Motor Connections

DX motors are available in two different styles for most models; waterproof designated

by a W in the motor model number, and connectorized, designated by a C in the motor

model number. The waterproof type has been designed to meet IP65 waterproofing

standards. Cable entries are made through American National Standard Tapered Pipe

Threads (NPT) conduit holes. The connectorized type of motors come equipped with

one or two MS style multi-pin connectors. See Table 3-B for motor connector options.

Table 3-B – Motor Connector Options

DX MOTOR

MODEL

DX-208 YES (ONE) N/A

DX-316 YES (TWO) YES

DX-340 YES (TWO) YES

DX-455 YES (TWO) YES

DX-490 YES (TWO) YES

DX-4120 YES (TWO) YES

WITH MS STYLE

CONNECTORS

WITH NPT

HOLES

Note: Motors equipped with MS style connectors meet IP65 waterproofing

standards. However, the mating cables and connectors do not. If waterproofing

is required, motors with NPT conduit holes should be ordered.

3.5.1 Motor Thermal Protection

In each of the motors there is at least one level of thermal protection. Every motor

model has three 150° C thermal switches mounted directly within the motor windings.

The contacts are connected in series and are available via the motor connections for

controller sensing of motor temperature. The Waterproof motors also include a second

thermal switch which is electrically in series with the three winding sensors and is

mounted in the area of the user wiring terminal strips. This second thermal switch is set

to a lower temperature (80° C) to protect the lower temperature type PVC insulated

wiring that may be used for the motor connections. This lower temperature thermal

switch may be shunted out of the circuit by a jumper on the connection board when the

higher temperature connection wiring is used. All motor wiring supplied by Emerson

EMC is rated for at least 105° C., so the low temperature switch can be jumpered out.

The contacts remain closed as long as the temperature stays within operating range.

When the temperature exceeds the specification, the contacts will open. These

contacts are generally connected to the servo amplifier which shuts the amplifier off to

protect the motor from damage. The thermal switch contact ratings are 30VDC, 500

milliamps.

Artisan Scientific - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisan-scientific.com

Section 3– Page 9

Page 29

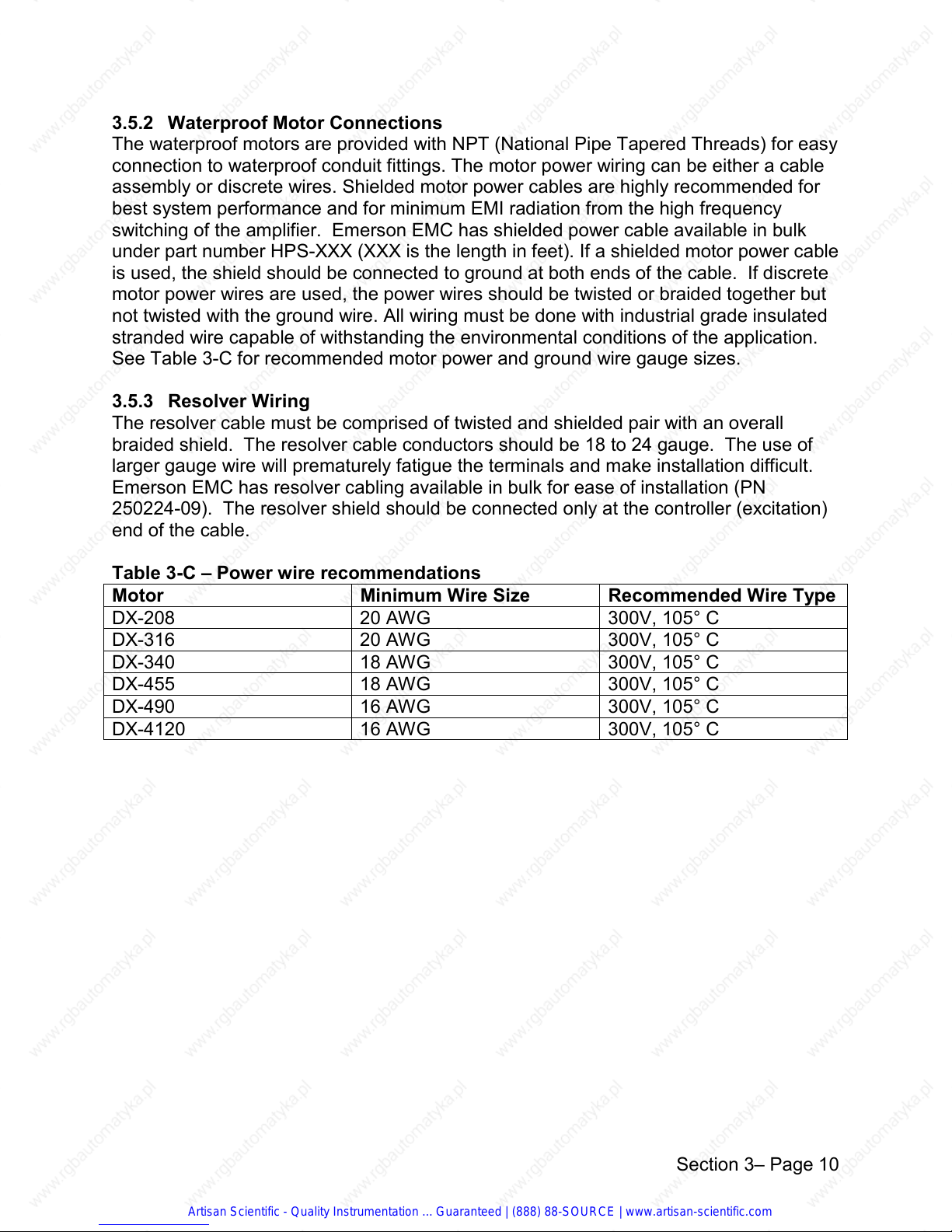

3.5.2 Waterproof Motor Connections

The waterproof motors are provided with NPT (National Pipe Tapered Threads) for easy

connection to waterproof conduit fittings. The motor power wiring can be either a cable

assembly or discrete wires. Shielded motor power cables are highly recommended for

best system performance and for minimum EMI radiation from the high frequency

switching of the amplifier. Emerson EMC has shielded power cable available in bulk

under part number HPS-XXX (XXX is the length in feet). If a shielded motor power cable

is used, the shield should be connected to ground at both ends of the cable. If discrete

motor power wires are used, the power wires should be twisted or braided together but

not twisted with the ground wire. All wiring must be done with industrial grade insulated

stranded wire capable of withstanding the environmental conditions of the application.

See Table 3-C for recommended motor power and ground wire gauge sizes.

3.5.3 Resolver Wiring

The resolver cable must be comprised of twisted and shielded pair with an overall

braided shield. The resolver cable conductors should be 18 to 24 gauge. The use of

larger gauge wire will prematurely fatigue the terminals and make installation difficult.

Emerson EMC has resolver cabling available in bulk for ease of installation (PN

250224-09). The resolver shield should be connected only at the controller (excitation)

end of the cable.

Table 3-C – Power wire recommendations

Motor Minimum Wire Size Recommended Wire Type

DX-208 20 AWG 300V, 105° C

DX-316 20 AWG 300V, 105° C

DX-340 18 AWG 300V, 105° C

DX-455 18 AWG 300V, 105° C

DX-490 16 AWG 300V, 105° C

DX-4120 16 AWG 300V, 105° C

Artisan Scientific - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisan-scientific.com

Section 3– Page 10

Page 30

Figure 3.9 DXM-3XXW motor wiring

Section 3– Page 11

Artisan Scientific - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisan-scientific.com

Page 31

Figure 3.10 DXM-4XX(X)W motor wiring

Section 3– Page 12

Artisan Scientific - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisan-scientific.com

Page 32

3.5.4 Connectorized Motor Wiring

Connectorized motors are equipped with two military style connectors for easy

connection and disconnect. This is especially useful for equipment that is disassembled

an reassembled many times. All the motor models except for the DX- 208 motor have

two connectors. One makes the motor power and ground connections and the other

makes the resolver and thermal switch connections. The connectors are different to

eliminate the possibility of incorrect connections. The LCF-XXX feedback cable makes

the resolver / thermal switch connection. The ECM- XXX and ECS-XXX cables make

the motor power, ground and brake connections (if required). The DX-208 motor is very

small and so is supplied with one integrated connector. The LCS-XXX cable includes

all the wiring for the DX-208 motor. The DX-208 motor is not available with a brake so

no brake wiring is included in the cable. The following figures show the wiring diagrams

for the ECM-XXX, ECL-XXX, LCS-XXX and LCF-XXX cables.

Table 3-D – Motor Cabling

Motor Type Motor Model Motor Cable Resolver Cable

Waterproof Motors DXM/E-3xxW, 4xxW HPS-XXX (shielded)

250224-09

250036-00(non-

shielded)

Connectorized

Motors

DXM/E-3xxC, -455C ECM-XXX LCF-XXX

DXM/E-490C, -4120 ECL-XXX LCF-XXX

DXM/E-208 LCS-XXX

All cabling is PVC, rated for 105° C.

(XXX) is length in feet, consult an Emerson EMC application engineer for cabling

requirements over 100 ft.

Cable Notes:

1. Applications that require LCS or LCF cables longer than 100 ft. should be

discussed with Emerson EMC’s Applications department.

2. As a general rule, the minimum cable bend radius is ten times the cable outer

diameter.

3. Motors with MS style connectors should be mounted with the connectors pointing

downward. This provides added protection against dust and water damage.

Artisan Scientific - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisan-scientific.com

Section 3– Page 13

Page 33

Figure 3.11 LCF-XXX Cable Wiring Diagram

Figure 3.12 ECM/ECL-XXX Cable Wiring Diagram

Figure 3.13 LCS-XXX Cable Wiring Diagram

Artisan Scientific - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisan-scientific.com

Section 3– Page 14

Page 34

3.6 Brake Motors

Brake motors are intended for applications where there is a load on the motor that must

be immovable with the power off. This is usually the case with vertical loads whether or

not they are counterbalanced. The motor brake will apply braking force with no power

applied to the brake connections and will disengage when the correct voltage is applied

to the motor brake terminals. See Figures 3-14, 3-15, 3-16 for connections to brake

motors of either waterproof or connectorized type.

Figure 3.14 Connectorized Motor Brake Connection

Section 3– Page 15

Artisan Scientific - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisan-scientific.com

Page 35

Figure 3.15 DXM-3XXW Motor Brake Connection

Figure 3.16 DXM-4XX(X)W Motor Brake Connection

Artisan Scientific - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisan-scientific.com

Section 3– Page 16

Page 36

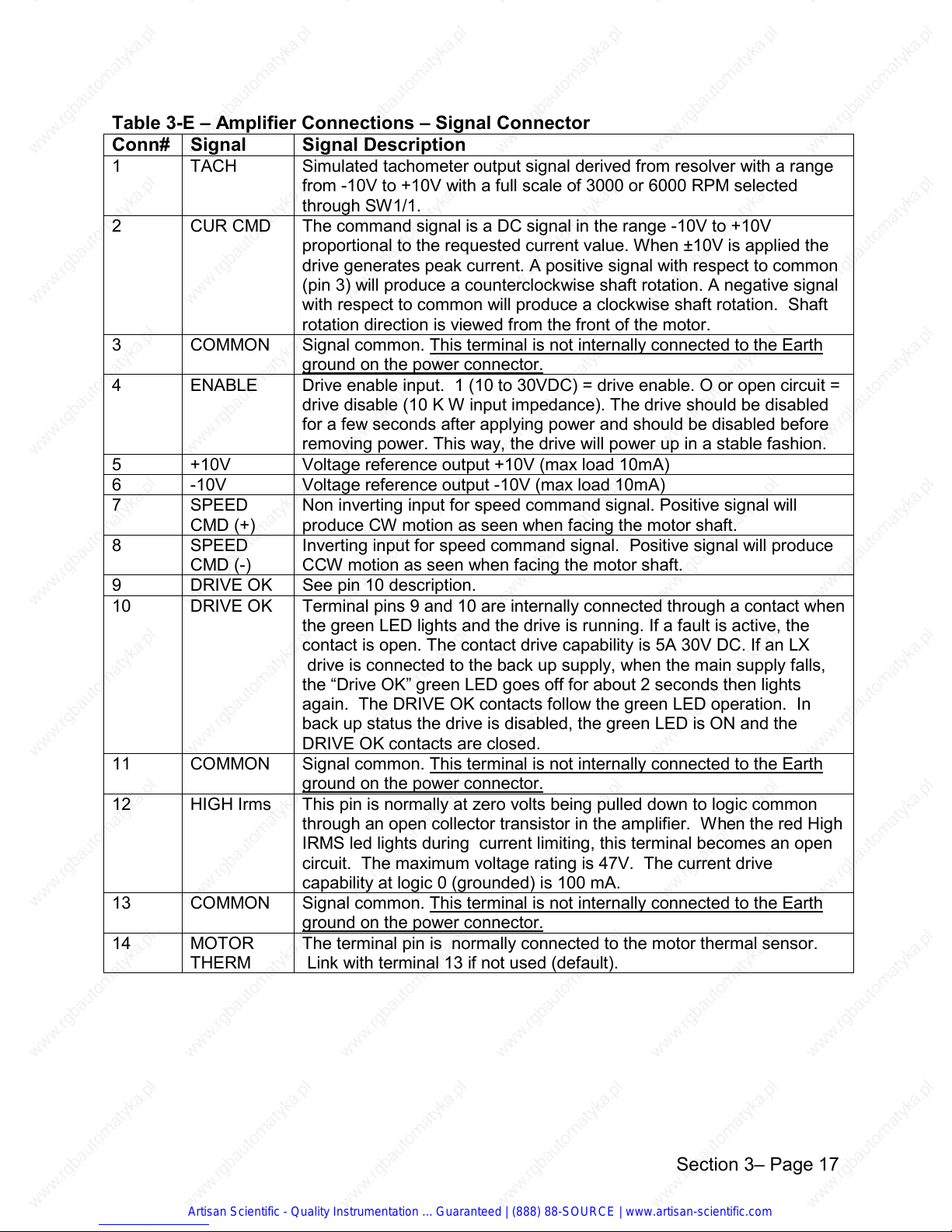

Table 3-E – Amplifier Connections – Signal Connector

Conn# Signal Signal Description

1 TACH Simulated tachometer output signal derived from resolver with a range

from -10V to +10V with a full scale of 3000 or 6000 RPM selected

through SW1/1.

2 CUR CMD The command signal is a DC signal in the range -10V to +10V

proportional to the requested current value. When ±10V is applied the

drive generates peak current. A positive signal with respect to common

(pin 3) will produce a counterclockwise shaft rotation. A negative signal

with respect to common will produce a clockwise shaft rotation. Shaft

rotation direction is viewed from the front of the motor.

3 COMMON Signal common. This terminal is not internally connected to the Earth

ground on the power connector.

4 ENABLE Drive enable input. 1 (10 to 30VDC) = drive enable. O or open circuit =

drive disable (10 K W input impedance). The drive should be disabled

for a few seconds after applying power and should be disabled before

removing power. This way, the drive will power up in a stable fashion.

5 +10V Voltage reference output +10V (max load 10mA)

6 -10V Voltage reference output -10V (max load 10mA)

7 SPEED

CMD (+)

8 SPEED

CMD (-)

9 DRIVE OK See pin 10 description.

10 DRIVE OK Terminal pins 9 and 10 are internally connected through a contact when

11 COMMON Signal common. This terminal is not internally connected to the Earth

12 HIGH Irms This pin is normally at zero volts being pulled down to logic common

13 COMMON Signal common. This terminal is not internally connected to the Earth

14 MOTOR

THERM

Non inverting input for speed command signal. Positive signal will

produce CW motion as seen when facing the motor shaft.

Inverting input for speed command signal. Positive signal will produce

CCW motion as seen when facing the motor shaft.

the green LED lights and the drive is running. If a fault is active, the

contact is open. The contact drive capability is 5A 30V DC. If an LX

drive is connected to the back up supply, when the main supply falls,

the “Drive OK” green LED goes off for about 2 seconds then lights

again. The DRIVE OK contacts follow the green LED operation. In

back up status the drive is disabled, the green LED is ON and the

DRIVE OK contacts are closed.

ground on the power connector.

through an open collector transistor in the amplifier. When the red High

IRMS led lights during current limiting, this terminal becomes an open

circuit. The maximum voltage rating is 47V. The current drive

capability at logic 0 (grounded) is 100 mA.

ground on the power connector.

The terminal pin is normally connected to the motor thermal sensor.

Link with terminal 13 if not used (default).

Artisan Scientific - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisan-scientific.com

Section 3– Page 17

Page 37

Table 3-F – Resolver Connector

Conn # Signal Signal Description

15 SHIELD Resolver cable shield. Do not connect anything else to this terminal.

It is electrically connected to logic common but has a dedicated

trace on the circuit board to minimize noise interference and

maximize shielding.

16 COS RET Cosine low signal coming from the resolver.

17 COS + Cosine high signal coming from the resolver.

18 SINE RET Sine low signal coming from the resolver.

19 SINE + Sine high signal coming from the resolver.

20 EXCIT RET Resolver excitation low signal.

21 EXCIT + Resolver excitation high signal.

Table 3-G – Personality Board Connector

Conn # Signal Signal Description

34 COMMON Logic common. This terminal is not internally connected to the Earth

ground on the power connector.

35 DR. OUT CW / CCW direction signal +15v = CW, 0v = CCW

36 PULSE OUT 2048 PPR 0v to +15V

37 A’

38 A

39 B’

40 B

41 Z’ Zero marker channel - 1 / rev 1

42 Z Zero marker channel - 1 / rev 1

43 CCW L.S. CCW limit switch input 10 to 30 volt. See DIP Switches for N.O. or

44 COMMON Common for N.O. CW limit switch. This terminal is not internally

45 CW L.S. CW limit switch input

46 COMMON Common for N.O. CCW limit switch. This terminal is not internally

1 The phase shift between channel A and B is 90° and the Z pulse is phased with the A pulse. Max

driving capability is 20 mA and each output can drive up to 10 line receiver devices with a maximum total

cable length of up to 5000 feet (1200 meters). If the encoder signal receiver is not terminated for RS422

signals, a termination resistor must be installed across each complementary signal pair to net 220W to

330W total resistance. These resistors must be installed at the point furthest from the signal source. The

termination resistance would be installed between the signal and common (ov).

Encoder Simulation Channels 128,

256, 512, 1024 lines/rev 1

1

1

5 volt, 20 milliamps

RS422 output drivers

N.C. polarity.

connected to the Earth ground on the power connector.

10 to 30 volt. See DIP Switches for N.O. or N.O. polarity.

connected to the Earth ground on the power connector.

Artisan Scientific - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisan-scientific.com

Section 3– Page 18

Page 38

Table 3-H – Power Connector

Conn # Signal Signal Description

22 MOTOR GND Chassis ground motor side. Connected internally to the Earth ground

terminal.

23 MOTOR

PHASE R

24 MOTOR

PHASE T

25 MOTOR

PHASE S

26 -DC BUS High power negative DC voltage.

27 + DC BUS High power positive DC voltage.

28 INT SHUNT This terminal pin is linked with terminal pin #27 to enable the internal

29 EXT SHUNT This terminal is used to drive an external brake resistor instead of

30 AC LINE 1 Phase 1 of the AC line.

31 AC LINE 2 Phase 2 of the AC line.

32 AC LINE 3 Phase 3 of the AC line.

33 EARTH GND Chassis ground power supply side. This is not connected to the logic

Motor power phase R.

Motor power phase T.

Motor power phase S.

brake resistor (default). If an external shunt is required, disconnect

this internal shunt resistor by removing the link between terminals 27

and 28. See the “Special Applications” section.

the internal one. The external brake resistor will be connected

between this terminal pin and pin#27. If an external shunt is

required, disconnect this internal shunt resistor by removing the link

between terminals 27 and 28. See Chapter 6.

side common. It is connected to the amplifier frame.

Artisan Scientific - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisan-scientific.com

Section 3– Page 19

Page 39

4

CONFIGURATION

4.1 Configuration Options

Drive configurations choices are made via the DIP switches mounted on a removable

personality board. Note that the OFF positions are all towards the connector on the

front of the personality board. The DIP switches control the following functions:

Ø SW1/1 Full scale speed selection 3000 RPM / 6000 RPM

Ø SW2 Nominal current limiting

Ø SW3 Motor poles selection

Ø SW1/2

Ø SW4

Ø SW5

1

Limit switch enable

1

Simulated encoder resolution selection

1

Limit switch polarity

NOTE: The personality boards for different size LX Amplifiers are not identical.

* A select resistor soldered into a header on the personality board is installed at the

factory which sets the gain windows for the range of motors normally used on that

amplifier.

Table 4-A – Standard Personality Board R22 Values

AMPLIFIERS MOTORS R22 RESISTOR VALUE

LX-400

LX-700

LX-1100

1

These functions can be deleted on special ordered; reduced cost drives.

2

Standard R22 value in the LX-700 is 82KΩ. A 47KΩ resistor and instructions for installation are included

with each LX-700 amplifier in the case of a DX-340 motor application.

DX-208

DX-316

DX-340

DX-455

DX-490

DX-4120

10 K Ω

47 K Ω2

82 K Ω

82 K Ω

2

Artisan Scientific - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisan-scientific.com

Section 4– Page 1

Page 40

4.2 Standard Motor Configurations

The LX amplifiers can be easily configured for DX motors supplied by Emerson EMC by

using the settings in the following table.

Table 4-B – Settings for DX Motors OFF=0 ON=1

(Tabel 4-B – Rev. 01/13/95j)

MOTOR

CURRENT

AMPS

2/1 2/2 2/3 2/4

LX AMP MOTOR

R22

ΩΩΩΩ

SW 3/1,2 SW 2/1-/4

# POLES

3/1 3/2

400

700

1100

DX-208 10K 4 1 0 2.16 0 0 0 0

DX-316 10K 6 0 1 2.97 0 1 1 0

DX-340 47K 6 0 1 6.14 1 0 1 0

DX-455 82K 6 0 1 7.32 1 1 1 1

DX-490 82K 6 0 1 10.99 1 1 1 1

DX-4120 82K 6 0 1 10.99 1 1 1 1

Figure 4.1 Personality Board Dip Switch Locations

Artisan Scientific - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisan-scientific.com

Section 4– Page 2

Page 41

4.3 Function Selections

This section covers the various optional functions and their selection.

4.3.1 Limit Switch Enable

OFF = function DISABLED (default) (0)

ON = function ENABLED (1)

SW1/2 enables the limit switch stop function. This function is normally used on limited

travel linear slide axes for over travel limit protection. When the CW limit is activated

the velocity command in that direction is clamped immediately to zero speed and will

not allow any more motion in that direction. The motor will be commanded to

decelerate at full amplifier capacity without any deceleration ramps even if a ramp has

been set into the accel/decel potentiometer. Motion in the opposite direction of the

activated switch will not be impeded i.e., CCW motion is not impeded with the CW limit

activated and vice versa. The position is not locked and the motor may drift + or -

depending on the Offset adjustment. The motor is not disabled but has full torque

capability and is holding zero speed. If the holding limit switch is released while a

speed command is applied, the motor will accelerate to the commanded speed at full

torque with no ramping even if a ramp has been set into the Acc/Dec potentiometer.

4.3.2 Limit Switch Polarity

With the limit switch function enabled, the activating logic is determined by DIP switches

SW5/1 and /2 allowing a choice between normally-open or normally-closed limit

switches.

SW5/1

SW5/2

ON = N.O limit switch application.

CCW rotation is disabled with a 0V (amplifier common) signal on

terminal #43 (CCW LIM. SW.). CCW rotation is enabled with terminal

#43 open.

OFF = N.C. limit switch application

CCW rotation is disabled with terminal #43 open (CCW LIM. SW.).

CCW rotation is enabled with a +1 to +30 volt signal applied.

ON = N.O. limit switch application.

CW rotation is disabled with an 0V (amplifier common) signal on

terminal #45 (CW LIM. SW.). CW rotation is enabled with terminal

#45 open.

OFF = N.C. limit switch application.

CW rotation is disabled with terminal #45 open (CW LIM. SW.).

CW rotation is enabled with a +1 to +30 volt signal applied.

Artisan Scientific - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisan-scientific.com

Section 4– Page 3

Page 42

4.3.3 Simulated Encoder Resolution

SW4 sets the simulated encoder resolution according to the following table. The default

position is 512 lines per revolution.

Table 4-C – Encoder Step/Revolution OFF = 0 ON = 1

SW4/1 SW4/2 ENCODER STEP/REVOLUTION

0 0 1024

0 1 512

1 0 256

1 1 128

4.4 Configuration Tables

This section covers the adjustments that are necessary when using a motor not covered

under the DX motor setup chart in Section 4.2.

4.4.1 Full Scale Speed

SW1/1 sets the full scale speed to match the control loop to the motor rated maximum

speed.

ON = 3000 RPM (default)

OFF = 6000 RPM

Artisan Scientific - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisan-scientific.com

Section 4– Page 4

Page 43

4.4.2 Motor Poles Selection

Switch SW3 sets the number of motor poles. The default setting is for a 6 pole motor.

Table 4-D – Motor Poles Selection OFF = 0 ON = 1

(Table 4-D – Rev. 01/13/95j)

SW3/1 SW3/2 MOTOR POLES

00 8

0 1 6

10 4

1 1 2

4.4.3 Continuous Current Adjustment

When continuous current of the motor is less than the continuous current of the drive, it

is possible to reduce the drive continuous current using the four SW2 switches with the

following logic.

Identify the required current level in Table 16 related to the LX drive model you are

using. Set the relevant SW2/ 1, 2, 3, 4 ON or OFF configuration.

Table 4-E – Nominal Current Adjustment OFF = 0 ON = 1

(Table 4-E – Rev. 01/13/95j)

SW2/1 SW2/2 SW2/3 SW2/4

0 0 0 0 2.16 3.78 5.67

0 0 0 1 2.30 4.02 6.02

0 0 1 0 2.43 4.25 6.38

0 0 1 1 2.57 4.49 6.73

0 1 0 0 2.70 4.73 7.09

0 1 0 1 2.84 4.96 7.44

0 1 1 0 2.97 5.20 7.80

0 1 1 1 3.11 5.43 8.15

1 0 0 0 3.24 5.67 8.51

1 0 0 1 3.38 5.91 8.86

1 0 1 0 3.51 6.14 9.21

1 0 1 1 3.65 6.38 9.57

1 1 0 0 3.78 6.62 9.92

1 1 0 1 3.92 6.85 10.28

1 1 1 0 4.05 7.09 10.63

1 1 1 1 4.19 7.32 10.99

LX-400

AMPS RMS

LX-700

AMPS RMS

LX-1100

AMPS RMS

Artisan Scientific - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisan-scientific.com

Section 4– Page 5

Page 44

5

START UP / CALIBRATION

This chapter will cover the steps necessary to correctly adjust an LX drive. In some

cases the most accurate adjustment requires some test equipment such as an

oscilloscope, tachometer or a voltmeter. The type of test equipment required is

dependent on the type of controller that is employed and the level of calibration

accuracy required for the application.

5.1 Drive Calibrations

Ø ZERO OFFSET Allows adjusting for input voltage offsets in the speed command

signal at zero speed (± 130 mV) to eliminate drift.

Ø CAL SPEED Adjusts the full scale speed command sensitivity. At fully CCW

the max speed will be achieved at 13 VDC command. At fully

CW the max speed will be achieved at 7 VDC command. The

speed range is set by dip switch SW1/1 - 3000/6000 RPM.

Ø RESPONSE Adjusts the derivative action. Turn CW to reduce the overshoot

and increase the PID filter derivative action. Too high an

adjustment will result in a high frequency oscillation on the

motor shaft and the possibility of overheating the motor. Too

high a setting will increase settling time to speed changes. Too

low a setting will result in slow response to load changes and

overshoot during quick speed changes.

Ø ACC/DEC Sets the motor acceleration/deceleration gradient. The range of

adjustment allows ramping to max. speed in 0-1 sec. with a ± 10

volt signal applied. Normal servo application requires full CCW

adjustment (zero ramping time).

Ø GAIN Proportional velocity gain control. Turn CW to increase the PID

filter proportional action. Too high an adjustment will cause a

medium frequency vibration on the motor shaft and possibility of

overheating a motor.

NOTE: THE PERSONALITY BOARDS FOR THE DIFFERENT

SIZE LX AMPLIFIERS ARE NOT ALL IDENTICAL

1

A select resistor soldered into a header on the personality board is installed at the

1

factory which sets the gain windows for the range of motors normally used on that

amplifier.

Section 5– Page 1

Artisan Scientific - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisan-scientific.com

Page 45

Table 5-A Personality Board R22 Selections

AMPLIFIERS NITIRS

LX-400

LX-700

LX-1100

DX-208

DX-316

DX-340

DX-455

DX-490

DX-4120

R22

RESISTOR VALUE

10 K Ω

47 K Ω**

82 K Ω

82 K Ω

**Standard R22 value in the LX-700 is 82 K Ω. The amplifier is shipped with a 47 K

Ω

resistor and instructions for installation in the case of a DX-340 motor application.

5.1.1 Zero Offset Adjust

The zero offset is factory set. The following instructions allow you to recalibrate the

offset when the LX is connected to a controller.

Open loop mode

The following instructions have to be executed with the position control in open loop or

the controller could interfere with the setting. If the controller cannot be set up in an

open loop configuration follow the instructions as described in Closed loop mode.

Ø Set up the controller to operate in open position loop mode. This will allow the motor

to rotate if there is an offset in the command signal.

Ø Adjust the command output signal offset before connecting to the LX drive.

Ø Connect the nulled command signal to terminals 7 and 8.

Ø Check that the limit switches are not engaged.

Ø Enable the drive and adjust the ZERO OFFSET potentiometer to stop the motor.

Ø Restore the original operation mode of the controller.

Closed loop mode

The easiest method of setting the Offset with a closed position loop is to monitor the

position controller analog command output with a voltmeter and adjust the Offset until

the voltage reads Zero ± 5 millivolts. If the position loop following error is visible on the

controller screen. With no command adjust the Offset until the following error is

minimized.

Artisan Scientific - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisan-scientific.com

Section 5– Page 2

Page 46

5.1.2. Cal. Speed Adjustment

This adjusts the command voltage input levels so they match the controllers output

levels. In other words, if the controller puts out 8.5 volts for a 3000 rpm command, the

drive must be adjusted to deliver 3000 rpm with an 8.5 volt command. The adjustment

range is from 75% to 140% of the DIP switch (SW1/1 setting) 3000 / 6000 rpm. The

adjustment procedure for the Cal. Speed is as follows:

Perform the Offset adjustment

If the position controller can be set up in an open position loop mode do so now

and follow step 1 through 5 to complete the calibration.

If the position controller cannot be set up in an open loop mode follow steps a.

through f.

Cal. Speed adjustment in open loop mode.

1. Apply 10% of the max command to pins 7 and 8.

2. Verify correct speed.

If the controller allows viewing the actual motor speed then monitor it and

adjust the Cal. Speed pot until the correct speed is observed ±5%. If the

controller doesn’t allow viewing the motor speed then use a tacho-meter on

the motor shaft or use the drive’s tach output signal. See Table 3-E.

3. Apply 25% of the max command and verify the speed per the above.

4. Continue increasing the command signal level in 25% increments and

verifying / adjusting Cal Speed until 100% command signal is achieved.

5. Follow the above procedure in the opposite motor direction to verify there is

no signal offset. Check for velocity offset. A difference of up to 5% between

CW & CCW is acceptable. Any more than 5% difference may indicate a

resolver phasing shift or a tachometer problem. The system will run but not at

optimum performance.

Cal. Speed Adjustment with closed position loop controller.

a. Adjust the position controller loop gain to a value below normal. This will

allow more accurate adjustment of the Cal. Speed setting.

b. Apply 10% of the max command to pins 7 and 8.

c. Verify correct speed.

If the controller allows viewing the following error, then monitor the following

error and adjust the Cal. Speed port until the correct amount of error is

observed. If the controller is designed with feed forward command, this

error should be near zero.

Artisan Scientific - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisan-scientific.com

Section 5– Page 3

Page 47

d. Apply 25% of the max command and verify the speed per the above.

e. Continue increasing the command signal level in 25% increments and

verifying / adjusting Cal Speed until 100% speed command is achieved .

f. Follow the above procedure in the opposite motor direction to check for

velocity offset.

5.1.3 Dynamic Calibration with Oscilloscope

The LX drives leave the factory with a default calibration. To most accurately adjust this

setting for your load you will need a low frequency function generator with an output

level between -3.5V and 3.5V and a dual trace storage oscilloscope. Remove the

controller signal cable from terminals 7 and 8. Connect the function generator

output to terminals 7 and 8 and set it per the following:

Ø Square wave

Ø Amplitude ± 2V (approximately 600 to 1200 rpm)

Ø Frequency 0.2 Hz (2.5 seconds each direction)

Ø The oscilloscope power cord must be grounded to the exact same point that the

amplifiers are grounded or a very inaccurate signal may be displayed

Ø Connect oscilloscope Channel A to terminal 1 (simulated tach signal)

Ø Connect oscilloscope Channel B to terminal 2 (current demand)

Ø Oscilloscope probes have to be grounded on terminal 11 of LX

Ø Connect the oscilloscope external trigger input to the function generator output

Ø Set oscilloscope for 1mV / div and for 20 mS / div scan time

WARNING! To avoid over travel interference on an axis with limited travel,

the stroke can be limited by either increasing the frequency of

the function generator or decreasing the amplitude. The

minimum signal amplitude that will allow a good calibration is

100mV pk to pk.

Refer to the following trace drawings to make the correct adjustments.

Artisan Scientific - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisan-scientific.com

Section 5– Page 4

Page 48

Start with the Gain adjustment and the Response pot fully CCW. The trace will probably

look like Figure 5.1. Turn the Gain CW until most of the instability is gone and the

Tach trace looks like Figure 5.2. Now turn the Response CW until the trace looks like

Figure 5.3. If the Response is turned too far CW the trace will look similar to Figure

5.4. This completes the oscilloscope calibration procedure.

Figure 5.1 Gain set too low. Figure 5.2 Gain set correctly,

Response not set.

Figure 5.3 Ideal gain setting. Figure 5.4 Response adjusted too high.

Artisan Scientific - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisan-scientific.com

Section 5– Page 5

Page 49

5.1.4 Dynamic Calibration without Oscilloscope

An acceptable calibration can normally be obtained by setting the calibration

potentiometers in the following fashion.

CAUTION!

THE FOLLOWING ADJUSTMENT PROCESS WILL CAUSE HIGH

FREQUENCY MOTOR INSTABILITY AND OSCILLATION FOR A SHORT

PERIOD OF TIME. VERIFY THAT THE LOAD WON’T BE DAMAGED BY THIS

MOTION.

Set the Acc/Dec pot to fully CCW. This completely eliminates the ramping.

Set the Response and Gain Pots to fully CCW.

Apply power to the amplifier.

Monitor the motor shaft rotation. Adjust the Offset pot until the motor shaft stops

rotating.

CAREFULLY!

Adjust the gain potentiometer CW until the motor just starts to buzz then quickly turn it

CCW until it stops buzzing, then turn it CCW (1) more turn.

CAREFULLY!

Adjust the response potentiometer CW until the motor just starts to buzz then quickly

turn it CCW until it stops buzzing, then turn it CCW (2) more turns.

Artisan Scientific - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisan-scientific.com

Section 5– Page 6

Page 50

6

SPECIAL APPLICATIONS

6.1 External Shunt Resistor

LX drives leave the factory with the internal shunt resistor enabled through an externally

wired jumper between terminal pins 27 and 28. If the power rating of the internal shunt

resistor is insufficient for heavy cycles an external shunt resistor with greater power

capacity should be added.

The internal shunt resistor capacity on all LX drives is 150 watts.

Figure 6.1 Internal shunt connection Figure 6.2 External shunt connection

(default).

To use an external shunt resistor:

1. Remove jumper between terminals 27 and 28.

2. Connect the external shunt resistor between terminals 27 and 29.

WARNING:

To avoid damaging the shunt driving circuit when using an external shunt

resistor:

Ø Remove the Internal Shunt jumper from the connection strip

Ø Do not use a resistor value less than 33

ΩΩΩΩ

Artisan Scientific - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisan-scientific.com

Section 6– Page 1

Page 51

6.2 Current Command Mode

LX drives can be operated in torque mode or current command mode using terminal pin

2 (CUR CMD) as an input for the current command signal. The command signal range

is ±10V. Terminal pin 2 is a bi-directional terminal with an input impedance of 20 kΩ .

Output impedance of the device driving the CUR CMD input must be 50W or less

(standard operating amp output). It serves as both an input for the current command

when operating in current command mode and an output for the current demand signal

generated by the speed loop when operating in velocity command mode.

When operating in current command, the Ixt limit circuit is not operational but the motor

current is still monitored. The High Irms output will go open circuit when the Ixt limit has

been reached and the High Irms LED will illuminate. The system controller must monitor

the High Irms output and reduce the current command when the voltage at that point is

high (not grounded to logic common)

Note: When operating an LX drive in torque mode, terminal pins 7 and 8 must

remain unconnected.

WARNING: NO AUTOMATIC CURRENT LIMITATION IS PERFORMED IN

CURRENT COMMAND MODE. It is the responsibility of the system

designer to implement current limitation by monitoring the high Irms

output.

6.2.1 Torque Helper Application

Torque helper applications can be easily implemented by interconnecting the drives to

share the same torque command from a master drive. To implement this, connect the

terminal pin 2 of the Lead drive (running in velocity mode) to the terminal pin 2 of the

Helper drive(s) (no connections to pins 7 & 8). This way the same current command is

being used by all the drives. Terminal pin 2 is a bi-directional terminal with an input

impedance of 20 kΩ.

Artisan Scientific - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisan-scientific.com

Section 6– Page 2

Page 52

6.3 Back Up Logic Supply

The connector on the top side of the drive provides a connection for an external multi

voltage power supply to maintain the encoder logic signals while the main power

is removed.

Note: If an LX drive is connected to the back up supply, when the main supply

falls below 96 VAC, the “Drive OK” green LED goes off for about 2

seconds then lights again. The drive status relays follows the green LED

operation. In back up status, the drive disabled, the green LED is ON and

the drive status relay contact is closed.

Figure 6.3 LX back up logic supply connection

Artisan Scientific - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisan-scientific.com

Section 6– Page 3

Page 53

7

DIAGNOSTICS

7.1 Diagnostics and Fault Handling

A number of diagnostic and fault detection circuits are incorporated in the LX amplifier

to protect the drive. Some faults like over “voltage”, “under voltage” and “amplifier or

motor over temperature” reset when the fault is cleared. Other faults such as “short-

circuit at the motor output terminals and/or resolver fault” need to be reset by cycling

power. Ixt trip is not a fault condition, it simply folds back the current command to the

DIP switch setting until the demand is reduced.

The lxt trip is not operational in the current command mode. See Section 6

(Special applications) for details.

Table 7-A

CONDITION DISPLAY DRIVE OK RESET ACTION REQUIRED

Motor Over temperature LED on Auto reset on Temp drop

Amp Overtemp >95°C

Over voltage

Under voltage Drive OK LED off

Output short Ckt Cycle power

Resolver Fault LED on Cycle power

High Irms LED on

Backup Logic Supply

active mode

LED on Auto reset on Temp drop

Drive OK contact open

Drive OK on, contact

closed

Drive OK contact opens

for about 2 seconds then

closes. LED follows

contact action.

Auto reset on return to normal

voltage

Auto reset on return to normal

voltage

Not a fault. Indicates current

limiting action.

Re-application of AC Line

power

Artisan Scientific - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisan-scientific.com

Section 7 – Page 1

Page 54

A

SPECIFICATIONS

A.1 LX Amplifier Mechanical Diagram

Artisan Scientific - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisan-scientific.com

Page 55

B. Amplifier Electrical Specifications

B.1 Amplifier Overview

UNITS LX-400 LX-700 LX-1100

Input power KVA 1.5 2.5 3.75

Input current Amps 4.5 7.5 11.2

Continuous output current Amps 4.0 7.0 10.9

Maximum output current Amps 8.0 14.0 22.0

Input voltage

Single of 3∅ 96 to 264 VAC, 47/63 Hz

Supply voltage

96V to 264VAC nominal RMS voltage direct on the main line or through a line

transformer.

Output current specification tolerance

± 10% of I max

Max voltage output of the amplifier between phases R,S,T

Supply voltage -10 VAC rms

Internal braking resistor capacity

33 Ω 150 Ω

External shunt resistor drive capacity

33 Ω 3300 watts

Analog command input

± 10V (10 kΩ input impedance)

Error amplifier temperature drift

1.3 uV/°C

Working temperature

-10 °C to +50 °C

Artisan Scientific - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisan-scientific.com

Page 56

B.2 User Adjustments

All adjustments are on the personality board

Ø Offset null

Ø Full scale speed

Ø Response

Ø Acc/Dec

Ø Gain

B.3 Diagnostic Annunciation

Ø N.O. relay contact output for drive O.K. monitoring

Ø Green LED for drive O.K. monitoring

Ø Red LED for resolver fault monitoring

Ø Red LED for heatsink over temperature

Ø Red LED for motor over temperature

Ø Red LED illuminates when Ixt current limiting is active

Ø Yellow LED illuminates when shunt circuit activates

B.4 Functions Enabled via Dip Switches

Ø Nominal current limiting

Ø Motor poles selection

Ø Speed scale selection

1

Ø

Limit switch enabling and polarity 1

1

Ø

Simulated encoder resolution

B.5 Protection and Diagnostics

Ø Resolver fault

Ø Current limiting to protect motor

Ø Drive O.K indication (LED and contact)

Ø Output short circuit Phase to phase or Grnd)

Ø Over temperature 95 °C on the heatsink

2

Ø

Under voltage 2 135 Vdc on the DC bus

Ø Over voltage 416 Vdc on the DC bus

The shunt circuit is automatically disabled when the input line power is lost while the DC

bus voltage not zero.

B.6 Personality Board Options

The standard LX amplifier contains the personality board with all options which include

the encoder and pulse / direction outputs along with the limit switch inputs. A reduced

cost version of the LX is available in quantity purchases which does not include these

connections or features.

1

These are available as ‘delete options’ at a reduced cost.

2

When under voltage is tripped, the optional external logic supply is automatically invoked. See

Chapter 6.

Artisan Scientific - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisan-scientific.com

Page 57

Artisan Scientific - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisan-scientific.com

Page 58

C. Combined Motor / Amplifier Characteristics

AMP

MODEL

LX-400 DXM/E-208 10 32 .60 .00010 5000 4.0

LX-700 DXM/E-340 40 115 1.50 .0014 3000 14.6

LX-1100 DXM/E-490 80 160 3.00 .0051 3000 37.0

MOTOR

MODEL

CONT.

TORQUE

lb–in

(Nm)

PEAK

TORQUE

lb- in

(Nm)

POWER

HP (kW)

INERTIA

lb-in-sec

(gm2)

2

MAX

SPEED

RPM

MOTOR

WT.

Lb

(kg)

(1.13) (3.62) (.45) (.0113) (1.81)

DXM/E-316 18 42 .76 .00052 4000 8.3

(2.00) (4.7) (.57) (.059) (3.8)

(4.5) (13.0) (1.10) (.158) (6.6)

DXM/E-455 60 125 2.14 .0026 3000 19.8

(6.80) (14.1) (1.60) (.294) (9.0)

(9.0) (18.1) (2.20) (.577) (16.8)

DXM/E-4120 100 200 2.90 .0074 3000 38.0

(11.3) (22.6) (2.10) (.837) (17.3)

Artisan Scientific - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisan-scientific.com

Page 59

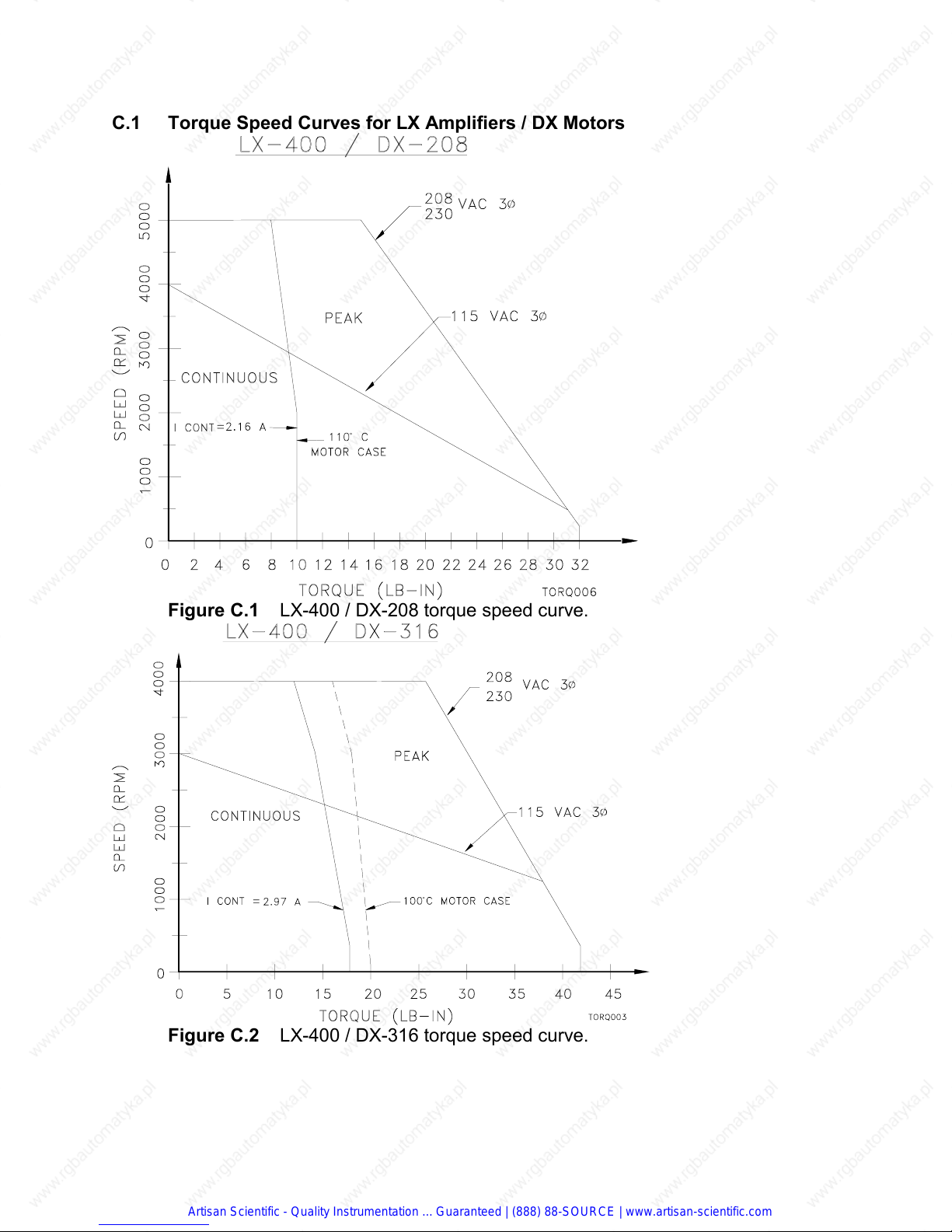

C.1 Torque Speed Curves for LX Amplifiers / DX Motors

Figure C.1 LX-400 / DX-208 torque speed curve.

Figure C.2 LX-400 / DX-316 torque speed curve.

Artisan Scientific - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisan-scientific.com

Page 60

Figure C.3 LX-700 / DX-340 torque speed curve.

Figure C.4 LX-700 / DX-455 torque speed curve.

Artisan Scientific - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisan-scientific.com

Page 61

Figure C.5 LX-1100 / DX-490 torque speed curve.

Figure C.6 LX-1100 / DX-4120 torque speed curve.

Artisan Scientific - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisan-scientific.com

Page 62

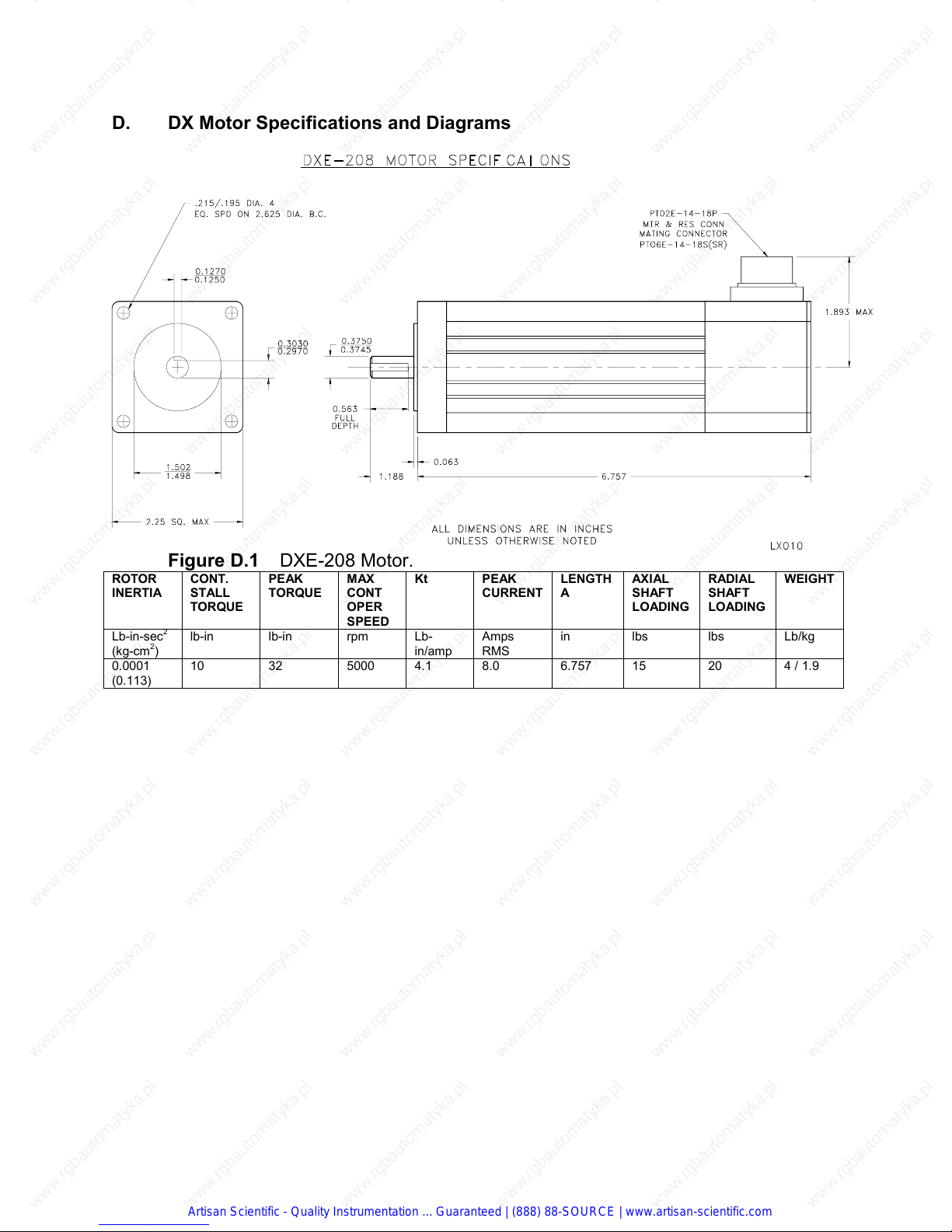

D. DX Motor Specifications and Diagrams

Figure D.1 DXE-208 Motor.

ROTOR

INERTIA

Lb-in-sec

(kg-cm2)

0.0001

(0.113)

CONT.

STALL

TORQUE

2

lb-in lb-in rpm Lb-

10 32 5000 4.1 8.0 6.757 15 20 4 / 1.9

PEAK

TORQUE

MAX

CONT

OPER

SPEED

Kt PEAK

in/amp

CURRENT

Amps

RMS

LENGTHAAXIAL

SHAFT

LOADING

in lbs lbs Lb/kg

RADIAL

SHAFT

LOADING

WEIGHT

Artisan Scientific - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisan-scientific.com

Page 63

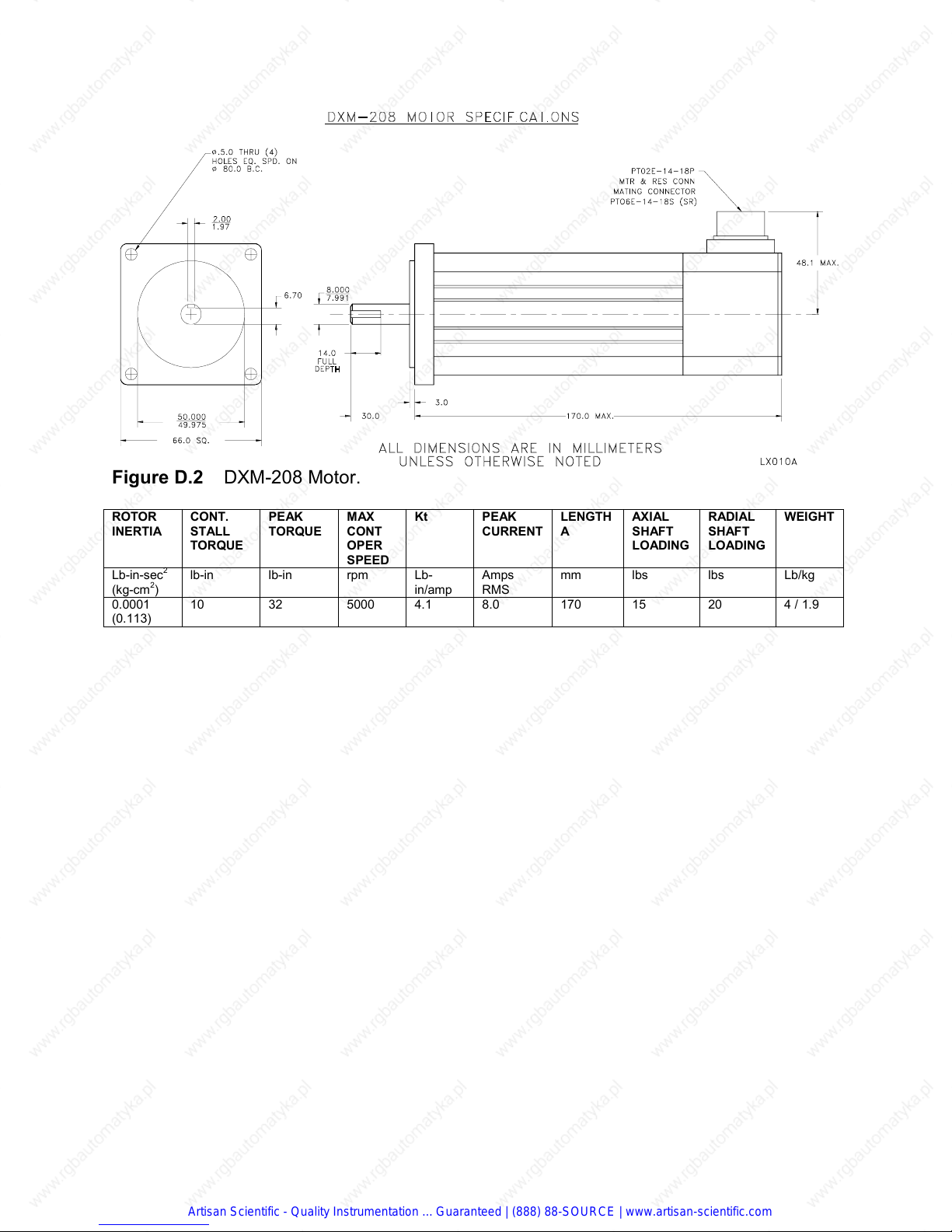

Figure D.2 DXM-208 Motor.

ROTOR

INERTIA

Lb-in-sec

(kg-cm2)

0.0001

(0.113)

CONT.

STALL

TORQUE

2

lb-in lb-in rpm Lb-

10 32 5000 4.1 8.0 170 15 20 4 / 1.9

PEAK

TORQUE

MAX

CONT

OPER

SPEED

Kt PEAK

in/amp

CURRENT

Amps

RMS

LENGTHAAXIAL

SHAFT

LOADING

mm lbs lbs Lb/kg

RADIAL

SHAFT

LOADING

WEIGHT

Artisan Scientific - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisan-scientific.com

Page 64

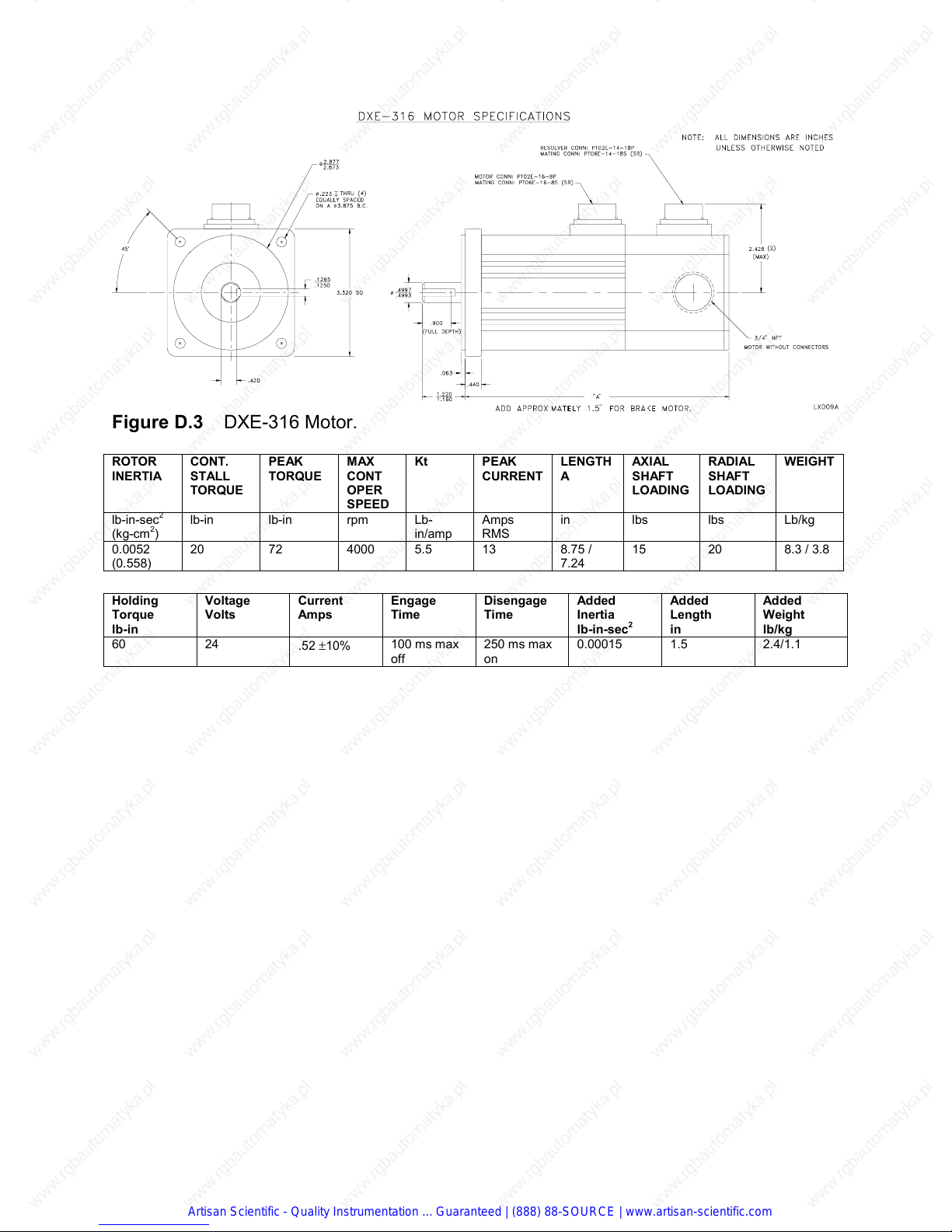

Figure D.3 DXE-316 Motor.

ROTOR

INERTIA

CONT.

STALL

TORQUE

2

lb-in-sec

lb-in lb-in rpm Lb-

(kg-cm2)

0.0052

20 72 4000 5.5 13 8.75 /

(0.558)

Holding

Torque

Voltage

Volts

lb-in

60 24

PEAK

TORQUE

Current

Amps

.52 ±10%

MAX

CONT

OPER

SPEED

Kt PEAK

in/amp

Engage

Time

100 ms max

off

CURRENT

Amps

LENGTHAAXIAL

SHAFT

LOADING

in lbs lbs Lb/kg

RADIAL

SHAFT

LOADING

WEIGHT

RMS

15 20 8.3 / 3.8

7.24

Disengage

Time

Added

Inertia

lb-in-sec

Added

Length

2

in

Added

Weight

lb/kg

250 ms maxon0.00015 1.5 2.4/1.1

Artisan Scientific - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisan-scientific.com

Page 65

Figure D.4 DXM-316/340 Motor.

ROTOR

INERTIA

CONT.

STALL

TORQUE

2

lb-in-sec

lb-in lb-in rpm Lb-

(kg-cm2)

0.0052

20 72 4000 5.5 13 223/184 15 20 8.3/3.8

(0.558)

0.0014

50 180 3000 8.3 21.7 301/260 15 20 14.6/6.7

(1.31)

Holding

Torque

Voltage

Volts

lb-in

60 24

PEAK

TORQUE

Current

Amps

.52 ±10%

MAX

CONT

OPER

SPEED

Kt PEAK

in/amp

DXM-316

DXM-340

Engage

Time

100 ms max

off

CURRENT

Amps

RMS

Disengage

Time

LENGTHAAXIAL

SHAFT

LOADING

Mm

NPT/CONN

lbs lbs Lb/kg

Added

Inertia

lb-in-sec

2