Emerson DRS Installation Manual

Power Switching & Controls

For Business-Critical Continuity

DRS Series Surge Protective Device

Installation, Operation and Maintenance Manual

™

The Emerson Network Power DRS Series surge protective device is a high

quality, high energy surge current diversion system designed to protect

sensitive equipment from damaging transient voltage surges resulting

from load switching, lightning strikes and other sources. The DRS Series is a

modular product designed to be easily installed in existing AC panelboards

and control panels using standard DIN-rail mounting brackets.

The installer should perform the following steps to assure a quality installation.

Please read all instructions before starting the installation of this product.

These instructions do not replace national or local electrical codes.

INSTALLATION

Proper installation is required for maximum system performance. Read the

following information to assure a quality installation.

Environment – For use indoors, in an ambient temperature of -40°C to +85°C,

with a relative humidity of 0% to 95% (non-condensing).

Mounting – Unit mounts to standard 35mm symmetrical Din rail (EN50022/

DIN46277-3).

Connections – Unit should be connected in parallel with the power source

(see Diagram 1 on next page). The length of wire is critical to the performance of this device; therefore the connection wires should be as short as

possible. If installation cannot accommodate short wires the Kelvin method

of wiring should be used to improve performance of the SPD (see Diagram 2

on next page).

Wire Sizing/Routing – Wire connection terminals accept wire with the cross

sectional area of 6 - 35mm2. To reduce the wire impedance to surge currents

all conducts should be twisted together and routed in the same conduit raceway. All sharp bends in conductors should be avoided.

Over Current Protection – External over-current protection is required. A

50A rated fuse or a 32A circuit breaker is to precede the incoming terminals

of the SPD.

Remote Status Connections – Unit is provided with remote status contacts

located on the base of the device. The contacts may be wired using either the

normally open “NO” or normally closed positions depending whether there is

a need to monitor if the unit is in ok or failed status. After all modules are installed and operating normally the contacts are open. If modules are removed

or failed the contacts are closed (see Diagram 3 on next page).

OPERATION

This product is designed for years of trouble-free operation and requires

little or no operator intervention after installation. If a green indicator appears in the window of the module, the device is operating normally. If the

red indicator appears, the module has reduced protection and must be replaced. Prior to replacing module assure the voltage supplied to the unit is

correct and that the modules are not loose in the base causing a false failure.

Replacement modules are available for this device; see Part Numbering.

DIAGRAMS

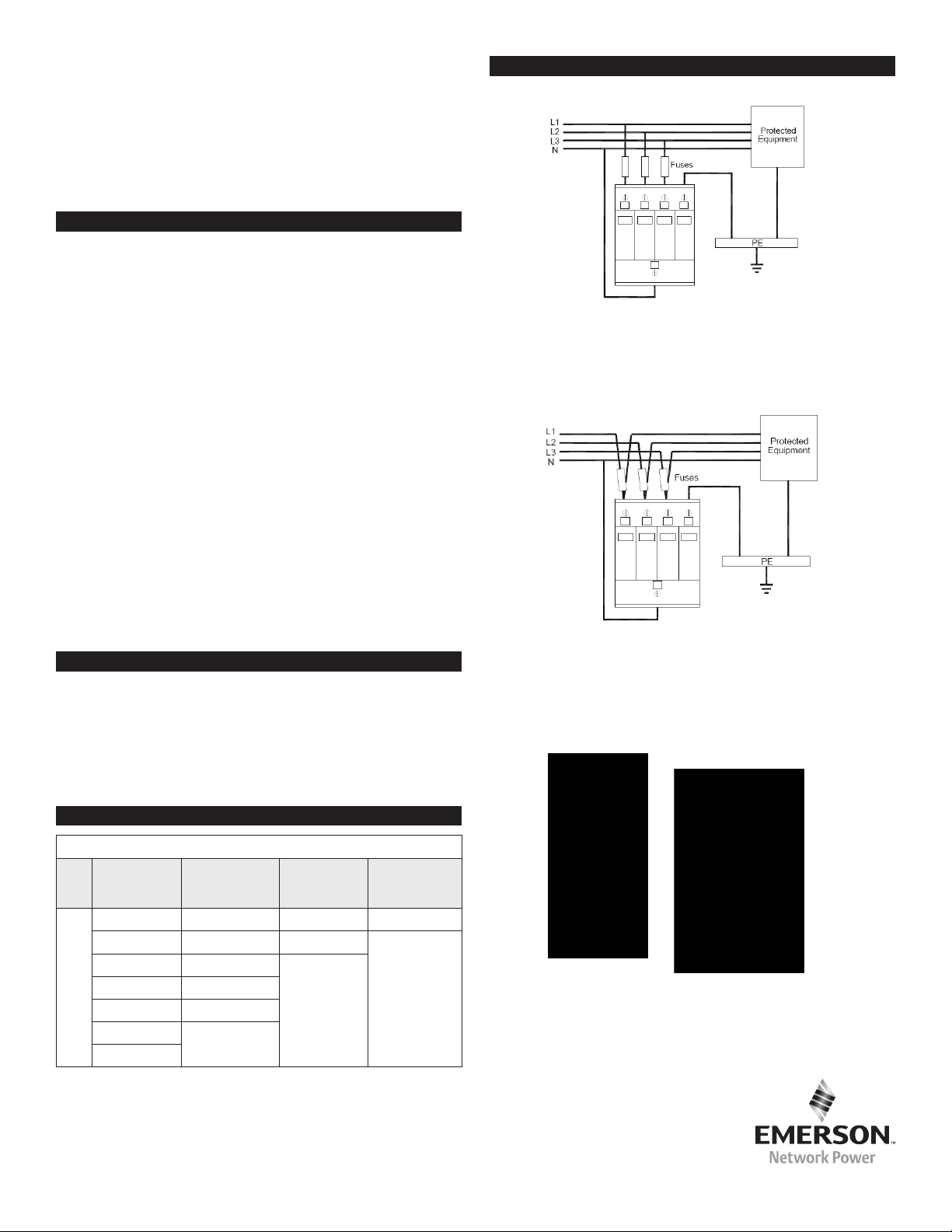

Diagram 1

Standard Connection

Diagram 2

Kelvin Connection

PART NUMBERING

Example: DRS27731

DRS

Nominal

Voltage

(Un) (XXX)

120 0 0 Q

230 1 1

240 2

277 3

346 4

480

600

# of Metal Ox-

ide Varistor

Modules* (X)

# of Gas Tube

Modules **

(X)

Highter Rated

Voltage***

(Optional)

* MOV modules are typically one module per phase and may be wired L-N, L-G or N-G

** Gas tube modules typically used in the N-G mode for type TT grounding systems.

*** Certain applications require higher rated components in order to survive frequent

voltage rises, in this case order a unit with a “Q” at the end of the part number.

Replacement modules available:

Order DRS + Un + M (for MOV) or G (for Gas tube) Example: DRS150M

Diagram 3

Remote Output

Loading...

Loading...