Page 1

Instruction Manual

HAS9xE-IM-A TEX

05/2007

Instruction Manual

CA T 100 & CAT 200

Continuous Analyzer T ransmitter

Addendum for Hazardous Area Applications

rd

3

Edition 05/2007

www.EmersonProcess.com

Page 2

CAT 100 & CA T 200 Addendum for

Hazardous Area Applications

ESSENTIAL INSTRUCTIONS

READ THIS P AGE BEFORE PROCEEDING!

Emerson Process Management (Rosemount Analytical) designs, manufactures and test s

its products to meet many national and international standards. Because these instruments

are sophisticated technical products, you MUST properly install, use, and maintain

them to ensure they continue to operate within their normal specifications. The following

instructions MUST be adhered to and integrated into your safety program when installing,

using and maintaining Emerson Process Management (Rosemount Analytical) products.

Failure to follow the proper instructions may cause any one of the following situations to

occur: Loss of life; personal injury; property damage; damage to this instrument; and warranty

invalidation.

• Read all instructions prior to installing, operating, and servicing the product.

• If you do not understand any of the instructions, contact your Emerson Process

Management (Rosemount Analytical) representative for clarification.

• Follow all warnings, cautions, and instructions marked on and supplied with the product.

Instruction Manual

HAS9XE-IM-ATEX

05/2007

• Inform and educate your personnel in the proper installation, operation, and

maintenance of the product.

• Install your equipment as specified in the Installation Instructions of the appropriate

Instruction Manual and per applicable local and national codes. Connect all products

to the proper electrical and pressure sources.

• T o ensure proper performance, use qualified personnel to install, operate, update, program,

and maintain the product.

• When replacement parts are required, ensure that qualified people use replacement parts

specified by Emerson Process Management (Rosemount Analytical). Unauthorized parts

and procedures can affect the product’s performance, place the safe operation of your

process at risk, and VOID YOUR W ARRANTY. Look-alike substitutions may result in fire,

electrical hazards, or improper operation.

• Ensure that all equipment doors are closed and protective covers are in place, except

when maintenance is being performed by qualified persons, to prevent electrical

shock and personal injury.

The information contained in this document is subject to change without notice. Misprints

reserved.

1st Edition 07/2004 2nd Edition 07/2005

3rd Edition 05/2007

© 2004-2007 by Emerson Process Management

Emerson Process Management

GmbH & Co. OHG

Industriestrasse 1

D-63594 Hasselroth

Germany

T +49 (0) 6055 884-0

F +49 (0) 6055 884-209

Internet: www.EmersonProcess.com

Page 3

Instruction Manual

HAS9xE-IM-ATEX

05/2007

This instruction manual provides information about installing, operating and

maintaining/servicing CAT series gas analyzers in hazardous (classied)

areas and shall be read in conjunction with the standard analyzer instruction

manual only!

This instruction manual covers all analyzer variations and and therefore may

describe congurations and/or options not part of your specic instrument.

The following denitions apply to WARNINGS, CAUTIONS and NOTES found

throughout this publication.

CAT

PREFACE

DEFINITIONS

Highlights an operation or

main tena n ce pro c edur e ,

practice, condition, statement, etc.

If not strictly observed, could

result in injury, death, or

long-term health hazards of

personnel.

NOTE

Highlights an essential operating

procedure, condition or statement.

Further graphical symbols may be used within this manual:

Elektrostatic discharge (ESD)

Explosion Hazard!

Highlights an operation or

main tena n ce proc edur e ,

practice, condition, statement, etc.

If not str i ctly obs erved ,

could result in damage to or

destruction of equipment, or

loss of effectiveness.

Heavy Instrument!

Harmful (to Health)!

All graphical symbols used in this product are from one or more of the following standards:

EN61010-1, IEC417, and ISO3864.

Emerson Process Management GmbH & Co. OHG S-1

Toxic!

Disconnect from Mains!

Page 4

Emerson Process Management GmbH & Co. OHGS-2

CAT

Instruction Manual

HAS9xE-IM-ATEX

05/2007

Safety Instructions

SAFETY INSTRUCTIONS

INTENDED USE STATEMENT

CAT series gas analyzers are intended to be used as analyzers for industrial purposes. They

must not be used in medical, diagnostic or life support applications, and no independent agency

certications or approvals are to be implied as covering such applications!

SAFETY SUMMARY

If this equipment is used in a manner not specied in these instructions, protective systems may

be impaired.

AUTHORIZED PERSONNEL

To avoid explosions, loss of life, personal injury and damage to this equipment and on-site property,

do not install, operate or service this instrument before reading and understanding this instruction

manual and receiving appropriate training. Save these instructions.

ADDITIONAL LITERATURE

This manual covers aspects specic for using CAT analyzers in hazardous (classied)

areas, only.

To install, start-up, operate and maintain/service the instrument in a safe manner it

is MANDATORY to read all additional instruction manuals shipped together with the

instrument!

The following instruction manuals are available and/or referenced within this manual at hand:

CAT 100:

HAS1xE-IM-HS Instruction manual BINOS 100 series

CAT 200:

HAS3xE-IM-HW Hardware instruction manual NGA MLT series

HAS3xE-IM-SW39 Instruction NGA MLT software V 3.9.x

(Software instruction manual depends on currently installed analyzer software

of the internal NGA MLT module)

Contact your local service center or sales ofce when missing documents. Save all instructions

for future use!

Page 5

Instruction Manual

HAS9xE-IM-ATEX

05/2007

Make sure to understand and observe all additional warnings given in

the assoziated analyzer instruction manual!

When installing these instruments all legislative requirements must

be taken into consideration! Take care of the special conditions given

within the instruction drawing in the manual on hand!

CAT

Safety Instructions

POSSIBLE HAZARDS

POSSIBLE EXPLOSION HAZARD

EXPLOSION HAZARD BY MODIFICATION

Any addition, substitution, or replacement of components installed on

or in this device, must be certied to meet the hazardous area classication that the device was certied to prior to any such component

addition, substitution, or replacement. In addition, the installation

of such device or devices must meet the requirements specied and

dened by the hazardous area classication of the unmodied device.

Any modications to the device not meeting these requirements, will

void the product certication(s).

PARTS INTEGRITY AND UPGRADES

Tampering with or unauthorized substitution of components may adversely

affect the safety of this instrument. Use only factory approved components

for repair.

Because of the danger of introducing additional hazards, do not perform

any unauthorized modication to this instrument.

Contact your local sales ofce for return Authorization.

Emerson Process Management GmbH & Co. OHG S-3

Page 6

Emerson Process Management GmbH & Co. OHGS-4

CAT

Instruction Manual

HAS9xE-IM-ATEX

05/2007

Safety Instructions

POSSIBLE EXPLOSION HAZARD

Do not open instrument when energized.

Ensure that external circuitry is disconnected or de-energized before

opening the instrument.

Ensure that all gas connections are made as labeled and are leak free.

Improper gas connections could result in explosion and death.

POSSIBLE EXPLOSION HAZARD

The CAT analyzer may utilize not only sample gas but one or more

pressurized carrier gases and/or calibration gases.

If an internal owmeter is not used, an external owmeter is required for

ow control. Legislative requirements and instructions for installation

in hazardous (classied) areas must be considered.

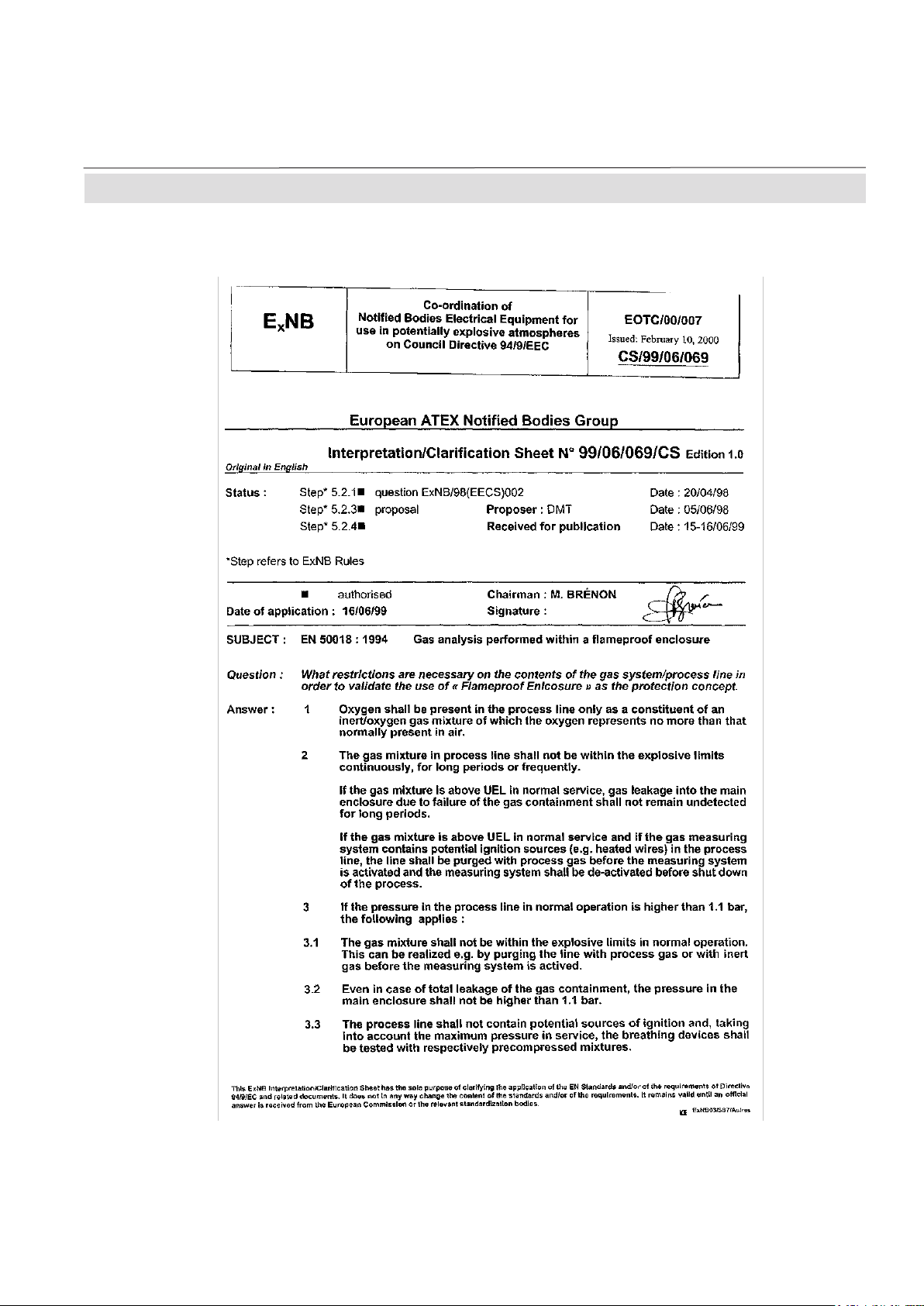

HOW TO STAY IN COMPLIANCE WITH THE

EUROPEAN DIRECTIVE 94/9/EC („ATEX“) WHEN PERFORMING

GAS ANALYSIS WITHIN A FLAMEPROOF ENCLOSURE.

Special conditions apply to using a ameproof enclosure analyzer under the scope of the

„European Directive for Equipment used in Explosive Atmosphere“ (Directive 94/9/EC; ATEX).

To stay compliant to the directive please consider the following clarication sheet released by

the European ATEX Notied Body Group:

Page 7

Instruction Manual

HAS9xE-IM-ATEX

05/2007

CAT

Safety Instructions

Emerson Process Management GmbH & Co. OHG S-5

Page 8

Emerson Process Management GmbH & Co. OHGS-6

CAT

Instruction Manual

HAS9xE-IM-ATEX

05/2007

Compliances

Compliances

This product is certied by several agencies for the use in hazardous (classied) areas. The

following certication marks show up on the product‘s nameplate label:

Zone classication:

USA Class I Zone 1, AEx d e m IIB + H2 T4 X

Canada Class I Zone 1, Ex d e m IIB + H2 T4 X

European Union ATEX, Category 2, Zone 1, Ex demb IIB + H2 T4 X

USA/Canada

Certied by the Canadian Standards Association, an „OSHA Nationally Recognized Testing

Laboratory“ (NRTL) for USA and Kanada. CSA certicate no.: 1477442.

European Union (EU)

Conforms with the provisions of the EMC Directive 89/336/EEC, Potentially Explosive Atmospheres Directive 94/9/EC and CE Directive 93/68/EEC.

EC ATEX Type Examination Certicate: LCIE 00 ATEX 6009 X.

EMERSON Process Management submitted samples for type examination of conformance to a

independent Notied Body (Laboratoire Central des Industries Electriques; LCIE), which issued

a type examination certicate.

Analyzer markings:

See appendix for a copy of the ATEX type examination certicate.

Page 9

Instruction Manual

HAS9xE-IM-ATEX

05/2007

Compliances

Special CSA approved versions with exten-

ded temperature range are available, too.

These versions show different markings:

CAT

Emerson Process Management GmbH & Co. OHG S-7

Page 10

CAT

Instruction Manual

HAS9xE-IM-ATEX

05/2007

Emerson Process Management GmbH & Co. OHGS-8

Page 11

Instruction Manual

HAS9xE-IM-ATEX

05/2007

CAT

Table of ConTenTs

Preface S-1

Denitions S-1

Safety Instructions S-2

Chapter 1 Installation 1-1

Chapter 2 Startup 2-1

Chapter 3 Service and Maintenance 3-1

APPENDIX A-1

A-1 EC Declaration of Conformity ...............................................................................A-2

A-2 EC Type Examination Certicates ........................................................................A-3

TOC-1Emerson Process Management GmbH & Co. OHG

Page 12

CAT

Instruction Manual

HAS9xE-IM-ATEX

05/2007

Table of Contenst

TOC-2 Emerson Process Management GmbH & Co. OHG

Page 13

Instruction Manual

HAS9xE-IM-ATEX

05/2007

Installing and wiring this instrument must comply with all relevant national

legislative requirements and regulations.

Consider all safety instructions within this on hand manual and all associated analyzer instruction manuals!

Take care of the special instructions at the installation drawing at the next

page!

CAT

CHAPTER 1

INSTALLATION

POSSIBLE EXPLOSION HAZARD

POSSIBLE EXPLOSION HAZARD

Installing this instrument requires opening the enclosure and working at

the open instrument. This is permitted only when both no hazardous atmosphere is present and the instrument and connected external circuitry are

de-energized!

Depending on the local regulation this may require a competent hot work

supervisor to ssue a hot work permit.

More detailled instructions about installing these instruments are given by the associated analyzer

instruction manual.

Emerson Process Management GmbH & Co. OHG 1-1

Page 14

CAT

Instruction Manual

HAS9xE-IM-ATEX

05/2007

1 Installation

3 signal cable glands

4 installation

drill-holes

A. Ex e junction box

B. Threads for cable glands for analog and digital

signal cables (M16 x 1,5)

C. 11 gas ttings (number depending on appli-

cation; ame arrestors inside gas inlets and

outlets).

D. Optional sample handling system, design

depending on applicational needs.

Note:

Junction box must be protected by fuse supply, which

has a breaking capacity adjusted to the short circuit

of the equipment (10 amps / 250 VAC).

Fig. 1: Installation drawing and

analyzer dimensions, inch (mm)

Emerson Process Management GmbH & Co. OHG1-2

Page 15

Instruction Manual

HAS9xE-IM-ATEX

05/2007

CHAPTER 2

STARTUP

Once the CAT analyzer is installed correctly

and in accordance to the instructions given

in chapter „Installation“ it is prepared for

startup.

POSSIBLE EXPLOSION HAZARD

Ensure all covers, plugs and housing parts are in place and secured

properly before supplying mains and signal voltages!

CAT

Ensure all requirements given

by the clarification sheet for

performing gas analysis within a

ameproof enclosure are considered BEFORE supplying gases

(see page S-6)!

This sheet gives instructions,

too, for the sequence of supplying gases during process and

analyzer startup .

After all safety aspects are followed and

checked the instrument may be powered and

operated according the instructions given in

the related instrument‘s instruction manual.

Emerson Process Management GmbH & Co. OHG 2-1

Page 16

CAT

Instruction Manual

HAS9xE-IM-ATEX

05/2007

2 Startup

Emerson Process Management GmbH & Co. OHG2-2

Page 17

Instruction Manual

HAS9xE-IM-ATEX

05/2007

Inspection, maintenance and service must be carried out considering

all related standards (e.g. EN 60079-17 “Inspection and maintenance of

electrical installations in hazardous areas (other than mines)”

CAT

CHAPTER 3

SERVICE AND MAINTENANCE

POSSIBLE EXPLOSION HAZARD

POSSIBLE EXPLOSION HAZARD

Service or replacement of safety related components or requiring to open

the instrument are permitted only if no hazardous atmosphere is present

and both the instrument and connected circuitry are de-energized!

Depending on the local regulation this may require a competent hot work

supervisor to ssue a hot work permit.

POSSIBLE EXPLOSION HAZARD

After maintenance or replacement of parts concerning explosion protection

an authority on explosion protection has to verify that the analyzer still meets

the requirements for explosion protection before it is switched on again.

Parts essential for explosion protection must not be repaired, they have to

be replaced if defective!

The authority has to issue a certicate for this and/or attach a test label to

the equipment before startup after maintenance or replacement of parts.

Emerson Process Management GmbH & Co. OHG 3-1

Page 18

CAT

Instruction Manual

HAS9xE-IM-ATEX

05/2007

3 Service and Maintenance

FLAMMABLE GASES - POSSIBLE EXPLOSION HAZARD

Leaks may cause explosion when measuring ammable gases!

When measuring ammable gases it is recommended to perform a leak test

on all gas paths, connections and components before startup or applying

power. Leak tests should be carried out on a 2 month‘s regular basis and

after repair/maintenance.

See the analyzer instruction manual for instructions on how to carry out

leak tests.

FLAMMABLE GASES - POSSIBLE EXPLOSION HAZARD

When measuring ammable gases it is recommended to purge the system

with air or an inert gas, e.g. nitrogen, prior to opening the enclosure.

Violation may cause an explotion!

More detailled instructions about servicing and maintaining CAT analyzers are subject of the

associated analyzer instruction manuals.

3-2

Emerson Process Management GmbH & Co. OHG

Page 19

Instruction Manual

HAS9xE-IM-ATEX

05/2007

APPENDIX

This chapter contains series CAT EC declarations

of conformity and EC type examination certicates.

CAT

Emerson Process Management GmbH & Co. OHG A-1

Page 20

Emerson Process Management GmbH & Co. OHGA-2

CAT

Instruction Manual

HAS9xE-IM-ATEX

05/2007

A-1 EC Declaration of Conformity

A-1 EC Declaration of Conformity

Page 21

Instruction Manual

HAS9xE-IM-ATEX

05/2007

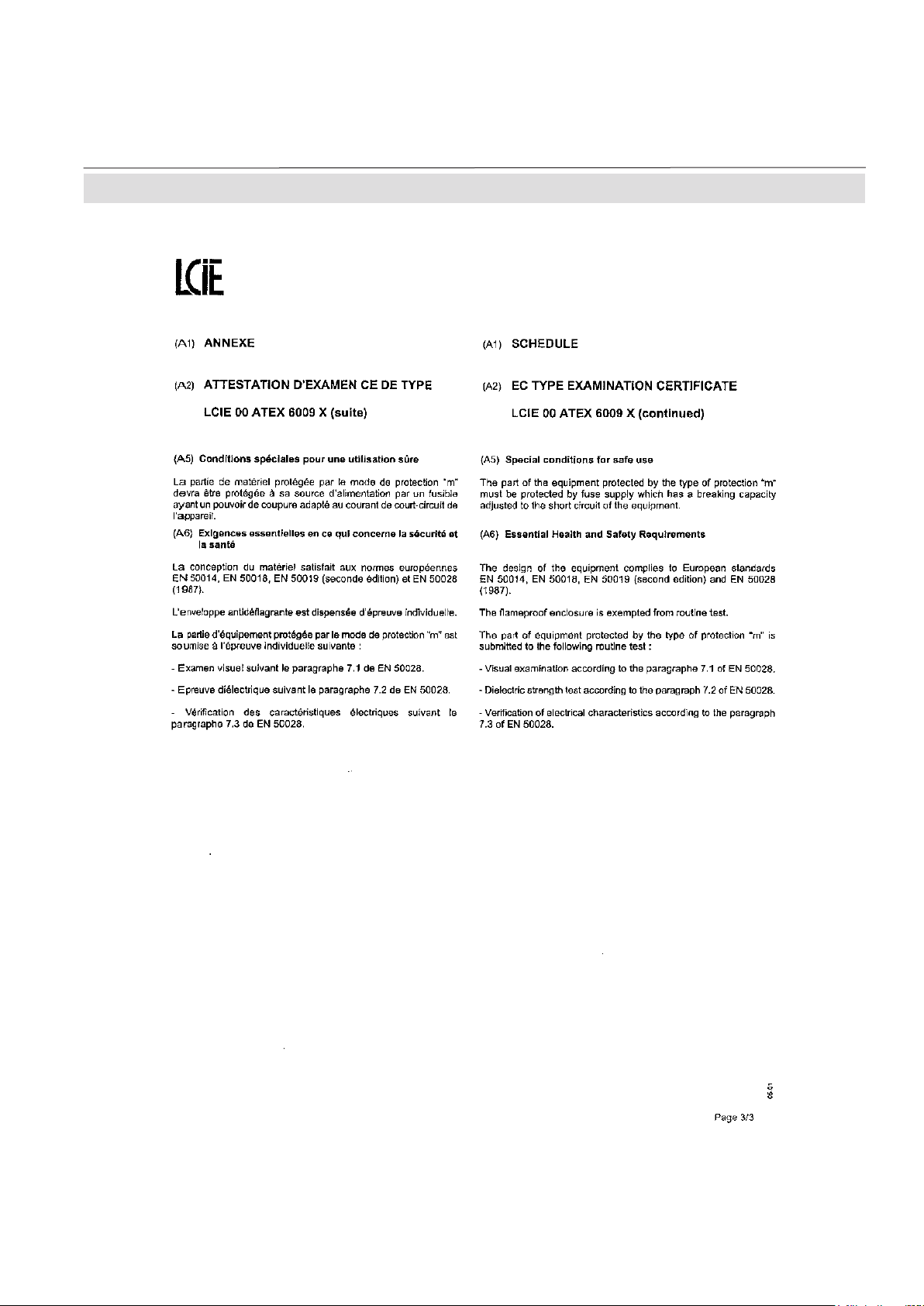

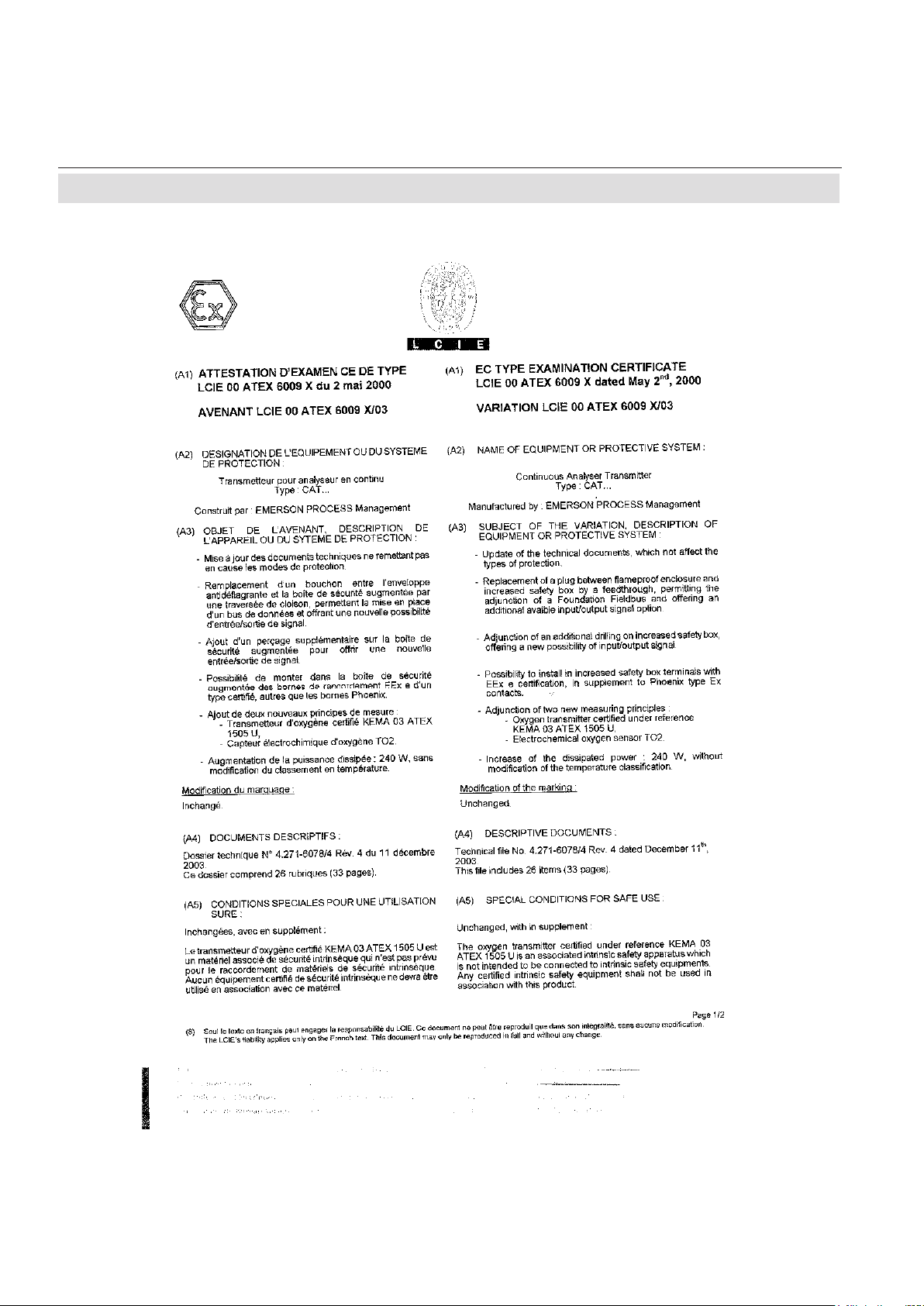

A-2 EC Type Examination Certicates

A-2 EC Type Examination Certicates

CAT

Emerson Process Management GmbH & Co. OHG A-3

Page 22

Emerson Process Management GmbH & Co. OHGA-4

CAT

Instruction Manual

HAS9xE-IM-ATEX

05/2007

A-2 EC Type Examination Certicates

Page 23

Instruction Manual

HAS9xE-IM-ATEX

05/2007

CAT

A-2 EC Type Examination Certicates

Emerson Process Management GmbH & Co. OHG A-5

Page 24

Emerson Process Management GmbH & Co. OHGA-6

CAT

Instruction Manual

HAS9xE-IM-ATEX

05/2007

A-2 EC Type Examination Certicates

Page 25

Instruction Manual

HAS9xE-IM-ATEX

05/2007

CAT

A-2 EC Type Examination Certicates

Emerson Process Management GmbH & Co. OHG A-7

Page 26

Emerson Process Management GmbH & Co. OHGA-8

CAT

Instruction Manual

HAS9xE-IM-ATEX

05/2007

A-2 EC Type Examination Certicates

Page 27

Instruction Manual

HAS9xE-IM-ATEX

05/2007

CAT

A-2 EC Type Examination Certicates

Emerson Process Management GmbH & Co. OHG A-9

Page 28

Emerson Process Management GmbH & Co. OHGA-10

CAT

Instruction Manual

HAS9xE-IM-ATEX

05/2007

A-2 EC Type Examination Certicates

Page 29

Instruction Manual

HAS9xE-IM-ATEX

05/2007

CAT

A-2 EC Type Examination Certicates

Emerson Process Management GmbH & Co. OHG A-11

Page 30

CAT

Instruction Manual

HAS9xE-IM-ATEX

05/2007

Emerson Process Management GmbH & Co. OHGA-12

Page 31

Instruction Manual

HAS9xE-IM-ATEX

05/2007

CAT

Page 32

CAT 100 & CAT 200 Addendum

WORLD HEADQUARTERS

ROSEMOUNT ANAL YTICAL EUROPE

Emerson Process Management

GmbH & Co. OHG

Industriestrasse 1

63594 Hasselroth

Germany

T 49 6055 884 0

F 49 6055 884209

Emerson Process Management

Rosemount Analytical Inc.

6565 P Davis Industrial Parkway

Solon, OH 44139 USA

T 440.914.1261

Toll Free in US and Canada 800.433.6076

F 440.914.1271

e-mail: gas.csc@EmersonProcess.com

www.raihome.com

GAS CHROMAT OGRAPHY CENTER

AND LATIN AMERICA

Emerson Process Management

Rosemount Analytical Inc.

11100 Brittmoore Park Drive

Houston, TX 77041

T 713 467 6000

F 713 827 3329

Instruction Manual

HAS9xE-IM-A TEX

05/2007

EUROPE, MIDDLE EAST AND AFRICA

Emerson Process Management

Shared Services Limited

Heath Place

Bognor Regis

West Sussex PO22 9SH

England

T 44 1243 863121

F 44 1243 845354

ASIA-PACIFIC

Emerson Process Management

Asia Pacific Private Limited

1 Pandan Crescent

Singapore 128461

Republic of Singapore

T 65 6 777 8211

F 65 6 777 0947

e-mail: analytical@ap.emersonprocess.com

© Emerson Process Management GmbH & Co. OHG 2007

Loading...

Loading...