Page 1

Instruction Manual

Form 511

September 2009

Type 75A Water Pressure Regulator

Application

The Type 75A is designed to reduce domestic or

industrial water pressures to a constant pressure,

thus protecting plumbing xtures and meters from

high-pressure surges. As shown in Figure 1, it is selfcontained, requiring no external control line

for operation.

Installation

Check the unit for shipment damage. Clean all foreign

material from the pipelines and regulator interior.

Install the Type 75A in a horizontal line with the spring

case above or below the line, and with ow through

the regulator as indicated by the arrow cast on the

body. Coat the external threads with pipe compound

and draw up the connections tightly but not severely.

If a snap-acting valve (solenoid valve) is used in the

system, the snap-acting valve should be installed

upstream of the Type 75A. The Type 75A may be

damaged by high shutoff pressure if a snap-acting

valve is installed downstream.

Type 75A

Adjustment

One spring for each size regulator allows operation

over an outlet pressure range of 20 to 80 psi (1,4 to

5,5 bar). Maximum inlet pressure is 200 psi (13,8 bar).

Minimum operating differential pressure is 5 psi (0,34 bar).

To change the reduced pressure, loosen the adjusting

screw locknut (key 9) and turn the adjusting screw

(key 8) into the spring case to increase the reduced

pressure, or out of the case to decrease it. Re-tighten

the locknut.

www.emersonprocess.com/regulators

W0057-1

Figure 1. Type 75A Water Pressure Regulator

Maintenance

To replace the valve disk (key 13), unscrew the guide

plug (key 3) from the body. The valve disk holder

(key 5) may now be unscrewed from the yoke (key 4). Be

careful not to twist and rupture the diaphragm (key 12).

D100254X012

Page 2

Type 75A

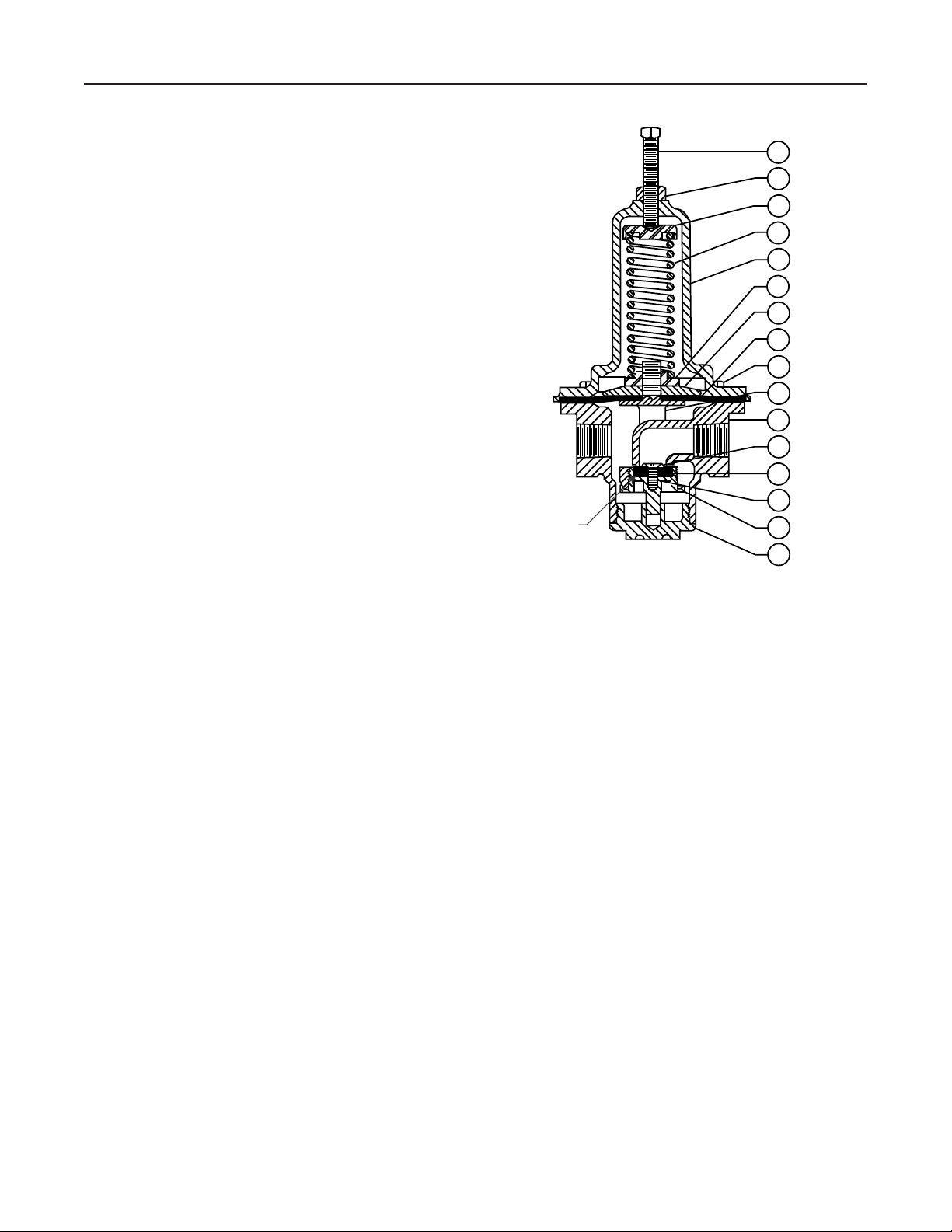

8

9

10

11

2

7

6

12

14

4

1

17

13

16

5

3

Note

A piece of hex bar stock can be drilled

out and slipped over the disk holder shaft

to t inside the holder. This simplies

removal of the holder from the yoke.

Use the following sizes of hex bar:

NPS 1/2 (DN 15) body – 7/8-inch (22 mm) hex;

NPS 3/4 (DN 20) body – 1-inch (25 mm) hex;

NPS 1 or 1-1/2 (DN 25 or 40) body –

1-1/4-inch (32 mm) hex; NPS 2 (DN 50)

body – 2-inch (51 mm) hex; NPS 2-1/2 (DN 65)

body – 2-1/2-inch (63 mm) hex.

To replace valve disk, unscrew the disk retaining screw

(key 16), remove old disk (key 13), apply gasket sealer

to new disk and install.

To replace the diaphragm, rst remove tension of the

regulator spring (key 11) by turning out the adjusting

screw (key 8). Remove the bolting that holds the spring

case (key 2) to the body and lift off the casing and

regulator spring. Unscrew the diaphragm nut (key 7)

and diaphragm head (key 6). Replace the diaphragm.

Parts Ordering

APPLY GASKALAC

20A5581-B

A0209

NPS 1/2, 3/4, 1, AND 1-1/2 BODY (DN 15, 20, 25, AND 40)

Figure 2. Type 75A Assemblies

When corresponding with your local Sales Ofce

or sales representative about this regulator, always

reference the type number which is found on the

nameplate (key 21).

When ordering replacement parts, reference the key

number of each needed part as found in the following

parts list.

Parts List

Key Description Part Number

1 Body

Bronze

NPS 1/2 (DN 15) 2A940812012

NPS 3/4 (DN 20) 2D226312012

NPS 1 (DN 25) 2V361512012

NPS 1-1/2 (DN 40) 3D174012012

NPS 2 (DN 50) 3D626712012

NPS 2-1/2 (DN 65) 3E231012012

2 Spring Case

Cast Iron

NPS 1/2 (DN 15) 1D878619042

NPS 3/4 (DN 20) 00085719042

NPS 1 (DN 25) 2A480119042

NPS 1-1/2 (DN 40) 3V361319042

NPS 2 and 2-1/2 (DN 50 and 65) 00132019042

Key Description Part Number

3 Guide Plug

Bronze

NPS 1/2 (DN 15) 0W099412012

NPS 3/4 (DN 20) 1A971912012

NPS 1 (DN 25) 1A950812012

NPS 1-1/2 (DN 40) 1A974612012

NPS 2 (DN 50) 1A975212012

NPS 2-1/2 (DN 65) 0D023212012

4 Valve Yoke

Bronze

NPS 1/2 (DN 15) 1A942712012

NPS 3/4 (DN 20) 1A945512012

NPS 1 (DN 25) 1A951412012

NPS 1-1/2 (DN 40) 2V361412012

NPS 2 (DN 50) 2V361612012

NPS 2-1/2 (DN 65) 2V361712012

5 Valve Disk Holder

Bronze

NPS 1/2 (DN 15) 1B590112012

NPS 3/4 (DN 20) 1B590212012

NPS 1 (DN 25) 1B867312012

NPS 1-1/2 (DN 40) 1B867712012

NPS 2 (DN 50) 1B867912012

NPS 2-1/2 (DN 65) 1B869812012

6 Diaphragm Head

NPS 1/2 (DN 15), Steel 1A941524092

NPS 3/4 (DN 20), Cast Iron 1A945619042

NPS 1 (DN 25), Cast Iron 1A950919052

NPS 1-1/2 (DN 40), Cast Iron 1V361219042

NPS 2 and 2-1/2 (DN 50 and 65), Cast Iron 1A975819042

2

Page 3

Type 75A

8

9

10

11

2

7

14

15

6

12

1

4

19

16

5

13

17

3

14

8

9

10

11

2

7

15

6

12

1

4

19

16

5

13

17

3

20

APPLY

GASKALAC

30A5582-A

A0211

NPS 2 (DN 50) BODY NPS 2-1/2 (DN 65) BODY

Figure 2. Type 75A Assemblies (continued)

Key Description Part Number

7 Diaphragm Nut

Steel

NPS 1/2 (DN 15) 1A941424092

NPS 3/4 (DN 20) 1E478524092

NPS 1 (DN 25) 1V361124092

NPS 1-1/2 (DN 40) 1A974824092

NPS 2 and 2-1/2 (DN 50 and 65) 1A982424092

8 Set Screw

Zinc-plated steel

NPS 1/2 (DN 15) 1C216032992

NPS 3/4 (DN 20) 1A514428992

NPS 1 and 1-1/2 (DN 25 and 40) 1F575328992

NPS 2 and 2-1/2 (DN 50 and 65) 1V360928982

9 Hex Nut

Brass

NPS 1/2 and 3/4 (DN 15 and 20) 1A518014012

NPS 1 and 1-1/2 (DN 25 and 40) 1A352414012

NPS 2 and 2-1/2 (DN 50 and 65) 1A599314012

10 Spring Seat

Steel

NPS 1/2 and 3/4 (DN 15 and 20) 1E478424092

NPS 1 (DN 25) 1V361024092

NPS 1-1/2 to 2-1/2 (DN 40 to 65) 1A975424092

11 Spring

Spring wire

NPS 1/2 (DN 15) 1V360527022

NPS 3/4 (DN 20) 1V360627142

NPS 1 (DN 25) 1V360727142

NPS 1-1/2 (DN 40) 1V360827142

NPS 2 and 2-1/2 (DN 50 and 65) 1C398227042

*Recommended spare part.

APPLY

GASKALAC

30A5580-A

A0212

Figure 2. Type 75A Assemblies (continued)

Key Description Part Number

12* Diaphragm

Neoprene (CR)

NPS 1/2 (DN 15) 1A941002112

NPS 3/4 (DN 20) 1A946102112

NPS 1 (DN 25) 1A951102112

NPS 1-1/2 (DN 40) 1A974302112

NPS 2 and 2-1/2 (DN 50 and 65) 1A975502112

13* Valve Disk

Nitrile (NBR)

NPS 1/2 (DN 15) 1C158203022

NPS 3/4 (DN 20) 1C158603022

NPS 1 (DN 25) 1C158703022

NPS 1-1/2 and 2 (DN 40 and 50) 1C158903022

NPS 2-1/2 (DN 65) 1C159803022

14 Cap Screw

Zinc-plated steel

NPS 1/2 (DN 15) (6 required) 1B720924052

NPS 3/4 (DN 20) (6 required) 1A352624052

NPS 1 (DN 25) (8 required) 1A368324052

NPS 1-1/2 (DN 40) (8 required) 1A353024052

NPS 2 (DN 50) (10 required) 1A569824052

NPS 2-1/2 (DN 65) (4 required) 1A582324052

15 Hex Nut

Zinc-plated steel

NPS 1/2 (DN 15) (6 required) 1A3915X0022

NPS 3/4 (DN 20) (6 required) 1A352724122

NPS 1 and 1-1/2 (DN 25 and 40) (8 required) 1A346524122

NPS 2 (DN 50) (10 required) 1A353724122

NPS 2-1/2 (DN 65) (6 required) 1A341224122

3

Page 4

Type 75A

Key Description Part Number

16 Machine Screw

Brass

NPS 1/2 (DN 15) 1A8991X0012

NPS 3/4 and 1 (DN 20 and 25) 0V070414012

NPS 1-1/2 and 2 (DN 40 and 50) 1D567314012

NPS 2-1/2 (DN 65) J17796X0012

17 Disk Retainer Washer

Brass

NPS 3/4 (DN 20) 0B078214012

NPS 1 (DN 25) 00147614012

NPS 1-1/2 and 2 (DN 40 and 50) 1A975014012

NPS 2-1/2 (DN 65) 0D023314012

*Recommended spare part.

Key Description Part Number

19* Orice

Bronze

NPS 2 (DN 50) 1A980512012

NPS 2-1/2 (DN 65) 1A981012012

20 Cap Screw

Zinc-plated steel

NPS 2-1/2 (DN 65) (6 required) 1A344424052

21 Nameplate (not shown) 11B6112X012

22 Drive Screw (not shown) 1A676728992

Industrial Regulators

Emerson Process Management

Regulator Technologies, Inc.

USA - Headquarters

McKinney, Texas 75069-1872 USA

Tel: 1-800-558-5853

Outside U.S. 1-972-548-3574

Asia-Pacic

Shanghai, China 201206

Tel: +86 21 2892 9000

Europe

Bologna, Italy 40013

Tel: +39 051 4190611

Middle East and Africa

Dubai, United Arab Emirates

Natural Gas Technologies

Emerson Process Management

Regulator Technologies, Inc.

USA - Headquarters

McKinney, Texas 75069-1872 USA

Tel: 1-800-558-5853

Outside U.S. 1-972-548-3574

Asia-Pacic

Singapore, Singapore 128461

Tel: +65 6777 8211

Europe

Bologna, Italy 40013

Tel: +39 051 4190611

Gallardon, France 28320

Tel: +33 (0)2 37 33 47 00

TESCOM

Emerson Process Management

Tescom Corporation

USA - Headquarters

Elk River, Minnesota 55330-2445 USA

Tel: 1-763-241-3238

Europe

Selmsdorf, Germany 23923

Tel: +49 (0) 38823 31 0

Tel: +971 4811 8100

For further information visit www.emersonprocess.com/regulators

The Emerson logo is a trademark and service mark of Emerson Electric Co. All other marks are the property of their prospective owners. Fisher is a mark owned by Fisher Controls, Inc., a

business of Emerson Process Management.

The contents of this publication are presented for informational purposes only, and while every effort has been made to ensure their accuracy, they are not to be construed as warranties or

guarantees, express or implied, regarding the products or services described herein or their use or applicability. We reserve the right to modify or improve the designs or specications of such

products at any time without notice.

Emerson Process Management does not assume responsibility for the selection, use or maintenance of any product. Responsibility for proper selection, use and maintenance of any Emerson

Process Management product remains solely with the purchaser.

©Emerson Process Management Regulator Technologies, Inc., 1945, 2009; All Rights Reserved

Loading...

Loading...