Page 1

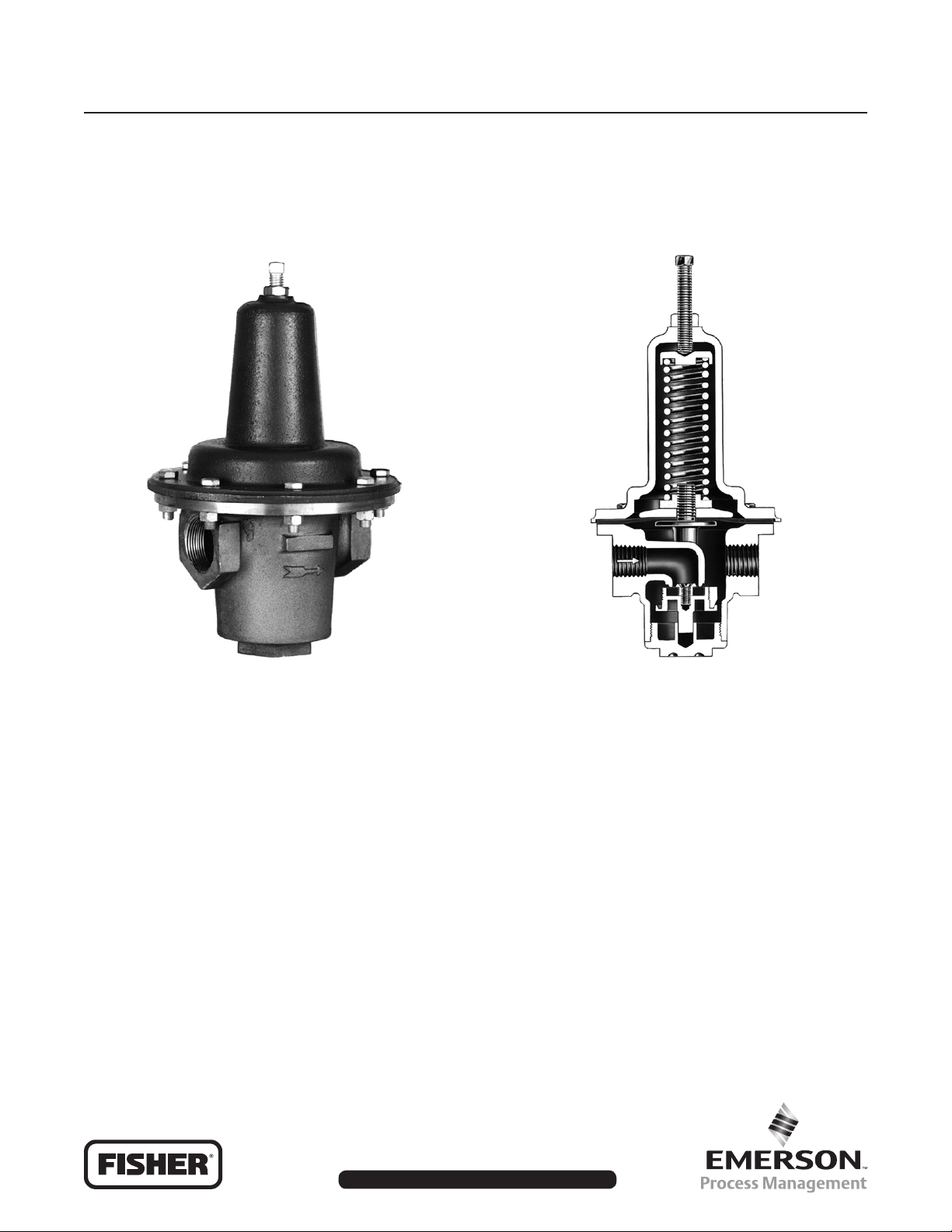

Type 75A Water Pressure Regulator

Bulletin 71.1:75A

August 2009

W2248

EXTERIOR

Figure 1. Type 75A Regulator

Introduction

The Type 75A regulator is designed to reduce

domestic or industrial water pressure, thus protecting

plumbing xtures and meters from high-pressure

surges. The Type 75A is self-contained, requiring no

external control line for operation.

Downstream pressure is directly registered under

the diaphragm. As the downstream pressure

increases, the diaphragm force overcomes the spring

W0057

SECTIONAL VIEW

FOR NPS 1/2, 3/4, 1, AND 1-1/2

(DN 15, 20, 25, AND 40) BODIES

compression, causes the valve disk to rise, and

reduces ow through the regulator.

If the downstream pressure decreases, the spring force

pushes the valve yoke and disk down to open the body

port. This permits increased ow and increases outlet

pressure to the desired level. The spring for each

regulator allows operation over an outlet pressure range

of 20 to 80 psig (1,4 to 5,5 bar). The outlet pressure

setting is easily changed by turning the adjusting screw.

D100116X012

www.emersonprocess.com/regulators

Page 2

Bulletin 71.1:75A

Specications

Body Size

NPS 1/2, 3/4, 1, and 1-1/2 (DN 15, 20, 25, and 40)

with integral cast seats

NPS 2 and 2-1/2 (DN 50 and 65) with

threaded-in seats

Maximum Inlet Pressure

(1)

200 psig (13,8 bar)

Outlet Pressure Ranges

20 to 80 psig (1,4 to 5,5 bar)

Maximum Allowable Outlet Pressure

(1)

10% above spring setting, or 5 psig (0,34 bar)

Minimum Operating Differential

5 psi (0,34 bar)

Maximum Operating Temperature

-20° to 150°F (-29° to 66°C)

Construction Materials

Body: Bronze

Spring Case: Cast iron

Threaded-in Orice (NPS 2 and 2-1/2

(DN 50 and 65) units only): Bronze

Valve Disk and Holder: Nitrile (NBR) and bronze

Diaphragm: Nitrile (NBR)

(1)

(1)

above setting, whichever is greater

1. The pressure/temperature limits in this bulletin or any applicable standard limitation should not be exceeded.

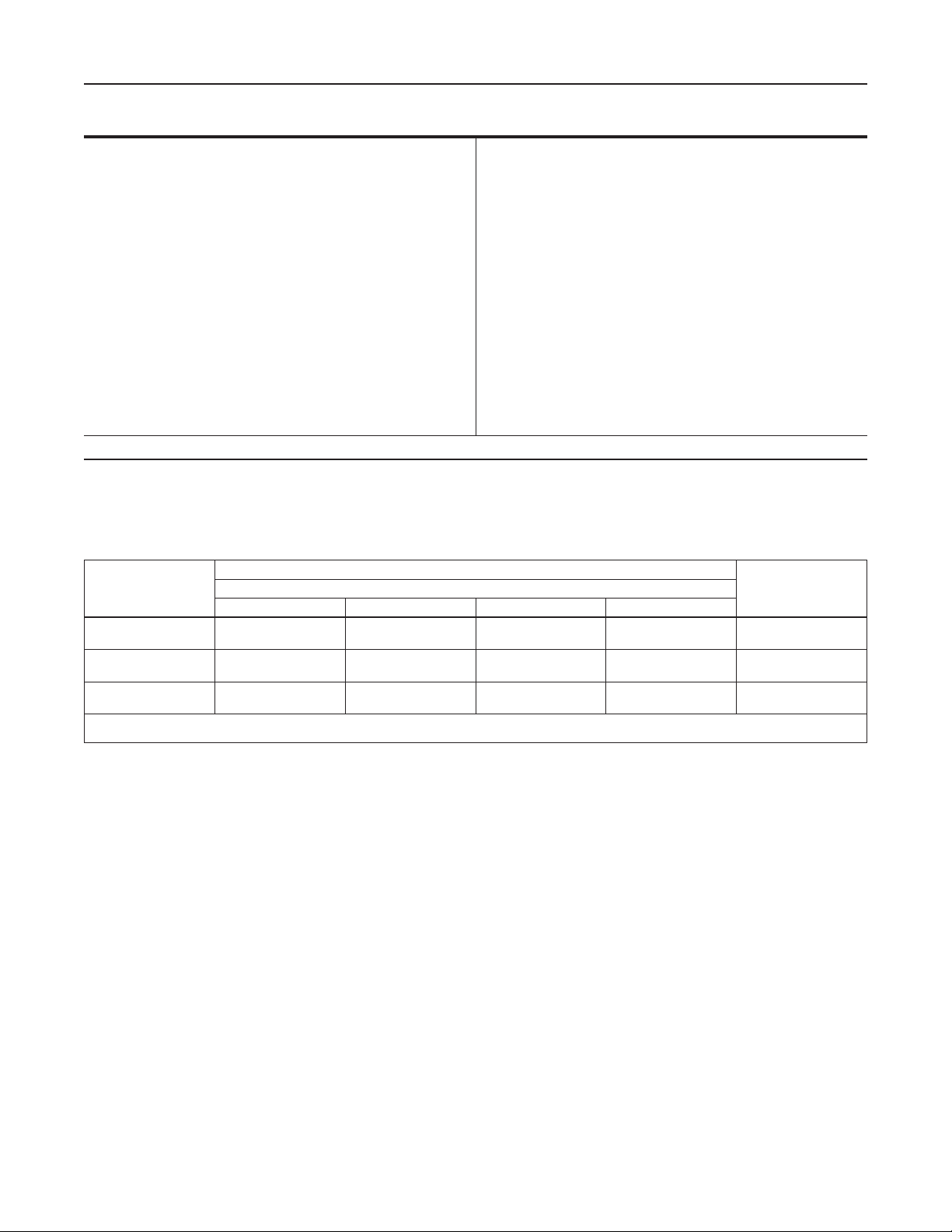

Table 1. Capacity Chart for Type 75A Regulator

CAPACITIES IN GPM (l/min) OF WATER

BODY SIZE, NPS (DN)

5 (0,34) 7 (0,48)

1/2 (15)

3/4 (20)

1 (25)

1-1/2 (40)

2 (50)

2-1/2 (65)

1. The 7 psig (0,48 bar) offset pressure and the related capacities are considered the upper limits of ows consistent with good piping practices and maximum uid velocities of

10 feet per second (3,05 m/s).

8 (30,3)

16 (60,6)

25 (94,6)

50 (189)

75 (284)

115 (435)

10 (37,9)

20 (75,7)

33 (125)

65 (246)

95 (360)

140 (530)

Droop, PSIG (bar)

(1)

10 (0,69) 15 (1,0)

14 (53,0)

28 (106)

45 (170)

85 (322)

125 (473)

185 (700)

19 (71,9)

40 (151)

60 (227)

115 (435)

175 (662)

260 (984)

WIDE-OPEN CV FOR

RELIEF SIZING

4.3

8.4

13.5

28.0

39.0

64.0

2

Page 3

Bulletin 71.1:75A

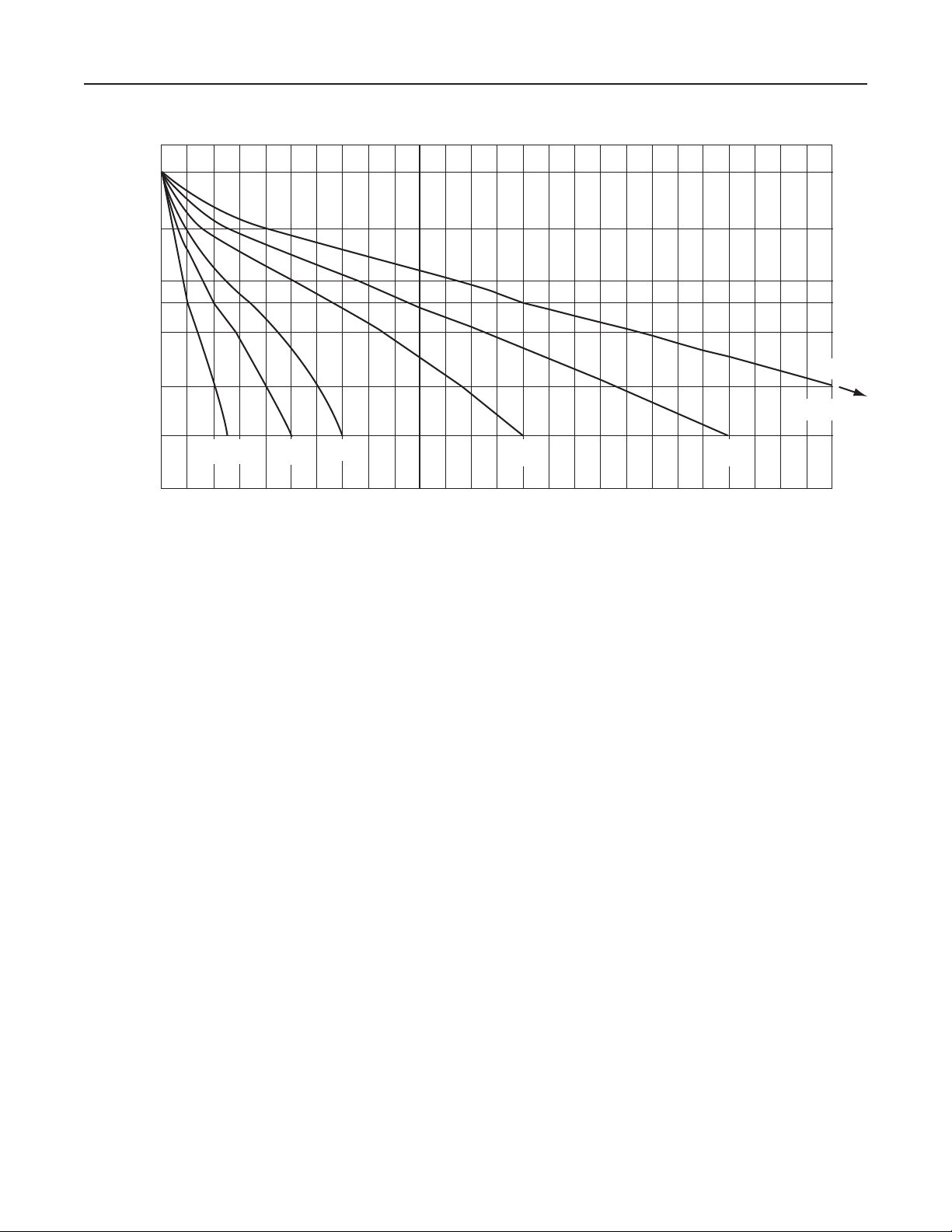

(+ 0,34)

+ 5

(0)

0

(- 0,34)

- 5

(-0,48)

- 7

(-0,69)

- 10

TO 320

(-1,0)

- 15

OFFSET, PSIG (bar)

(-1,4)

- 20

0 20 40 60 80 100 120 140 160 180 200 220 240 260

(0) (75,7) (151) (227) (303) (379) (454) (530) (606) (681) (757) (833) (908) (984)

NPS 1/2

(DN 15)

NPS 3/4

(DN 20)

NPS 1

(DN 25)

NPS 1-1/2

(DN 40)

NPS 2

(DN 50)

AT -20

NPS 2-1/2

(DN 65)

WATER FLOW, GPM (l/m)

Figure 2. Type 75A Sizing Curves

Overpressure Protection

As is the case with most regulators, Type 75A has

maximum inlet pressure ratings which exceed the

outlet pressure ratings. Overpressuring any regulating

equipment may be hazardous. If actual inlet pressure

can exceed the outlet pressure ratings, some type of

overpressure protection is needed.

Sizing Information

Flow capacity and the maximum permissible offset

pressure that the system can tolerate determine the

correct regulator size for your application. Consult the

Type 75A Sizing Curves (Figure 2) and the Capacity

Chart (Table 1) to size the regulator. Several choices

may provide the required ow rate.

For example, if desired water ow is 30 GPM

(114 l/m), the rst intersecting curve (Figure 2) is

that of the NPS 3/4 (DN 20) regulator. At that point,

offset is 11 psi (0,76 bar), which is outside the limits of

good piping practice. Moving upward again, the next

intersecting curve is that of the NPS 1 (DN 25) regulator.

Here, offset is 6 psi (0,41 bar). This rating is permissible

and the NPS 1 (DN 25) regulator is acceptable.

Ordering Information

In order to prevent delays in order processing, please

specify type numbers and regulator size clearly.

3

Page 4

Bulletin 71.1:75A

B

A

Figure 3. Dimensions

BODY SIZE,

NPS (DN)

1/2 (15)

3/4 (20)

1 (25)

1-1/2 (40)

2 (50)

2-1/2 (65)

E

D

C

A B C D E

9.75 (248)

11.25 (286)

12.25 (311)

13.62 (346)

18.62 (473)

19.12 (486)

DIMENSIONS, INCHES (mm)

7.12 (181)

8.38 (213)

9.12 (232)

9.88 (251)

13.88 (353)

14.12 (359)

4.31 (109)

5.44 (138)

6.62 (168)

8.19 (208)

9.38 (238)

9.38 (238)

3.75 (95)

4.25 (108)

4.75 (121)

5.88 (149)

6.38 (162)

7.75 (197)

1.88 (48)

2.12 (54)

2.38 (60)

2.94 (75)

3.19 (81)

3.88 (99)

Industrial Regulators

Emerson Process Management

Regulator Technologies, Inc.

USA - Headquarters

McKinney, Texas 75069-1872 USA

Tel: 1-800-558-5853

Outside U.S. 1-972-548-3574

Asia-Pacic

Shanghai, China 201206

Tel: +86 21 2892 9000

Europe

Bologna, Italy 40013

Tel: +39 051 4190611

Middle East and Africa

Dubai, United Arab Emirates

Natural Gas Technologies

Emerson Process Management

Regulator Technologies, Inc.

USA - Headquarters

McKinney, Texas 75069-1872 USA

Tel: 1-800-558-5853

Outside U.S. 1-972-548-3574

Asia-Pacic

Singapore, Singapore 128461

Tel: +65 6777 8211

Europe

Bologna, Italy 40013

Tel: +39 051 4190611

Gallardon, France 28320

Tel: +33 (0)2 37 33 47 00

TESCOM

Emerson Process Management

Tescom Corporation

USA - Headquarters

Elk River, Minnesota 55330-2445 USA

Tel: 1-763-241-3238

Europe

Selmsdorf, Germany 23923

Tel: +49 (0) 38823 31 0

Tel: +971 4811 8100

For further information visit www.emersonprocess.com/regulators

The Emerson logo is a trademark and service mark of Emerson Electric Co. All other marks are the property of their prospective owners. Fisher is a mark owned by Fisher Controls, Inc., a

business of Emerson Process Management.

The contents of this publication are presented for informational purposes only, and while every effort has been made to ensure their accuracy, they are not to be construed as warranties or

guarantees, express or implied, regarding the products or services described herein or their use or applicability. We reserve the right to modify or improve the designs or specications of such

products at any time without notice.

Emerson Process Management does not assume responsibility for the selection, use or maintenance of any product. Responsibility for proper selection, use and maintenance of any Emerson

Process Management product remains solely with the purchaser.

©Emerson Process Management Regulator Technologies, Inc., 1990; 2009 All Rights Reserved

Loading...

Loading...