Page 1

Instruction Manual

Form 5252

May 2013

627 Series

627 Series Pressure Reducing Regulators

WARNING

!

Failure to follow these instructions or

to properly install and maintain this

equipment could result in an explosion

and/or re causing property damage and

personal injury or death.

Fisher® regulators must be installed,

operated, and maintained in accordance

with federal, state, and local codes, rules

and regulations, and Emerson Process

Management Regulator Technologies, Inc.

(Regulator Technologies) instructions.

If the regulator vents gas or a leak

develops in the system, service to the unit

may be required. Failure to correct trouble

could result in a hazardous condition.

Call a gas service person to service the

unit. Only a qualied person must install

or service the regulator.

Introduction

Scope of the Manual

This manual provides instructions for the installation,

adjustment, maintenance, and parts ordering information

for the 627 Series regulators. These regulators are

usually shipped separate for line installation, although

sometimes they are shipped installed on other

equipment. Refer to the Instruction Manual of the other

equipment for installation and operating instructions.

Description

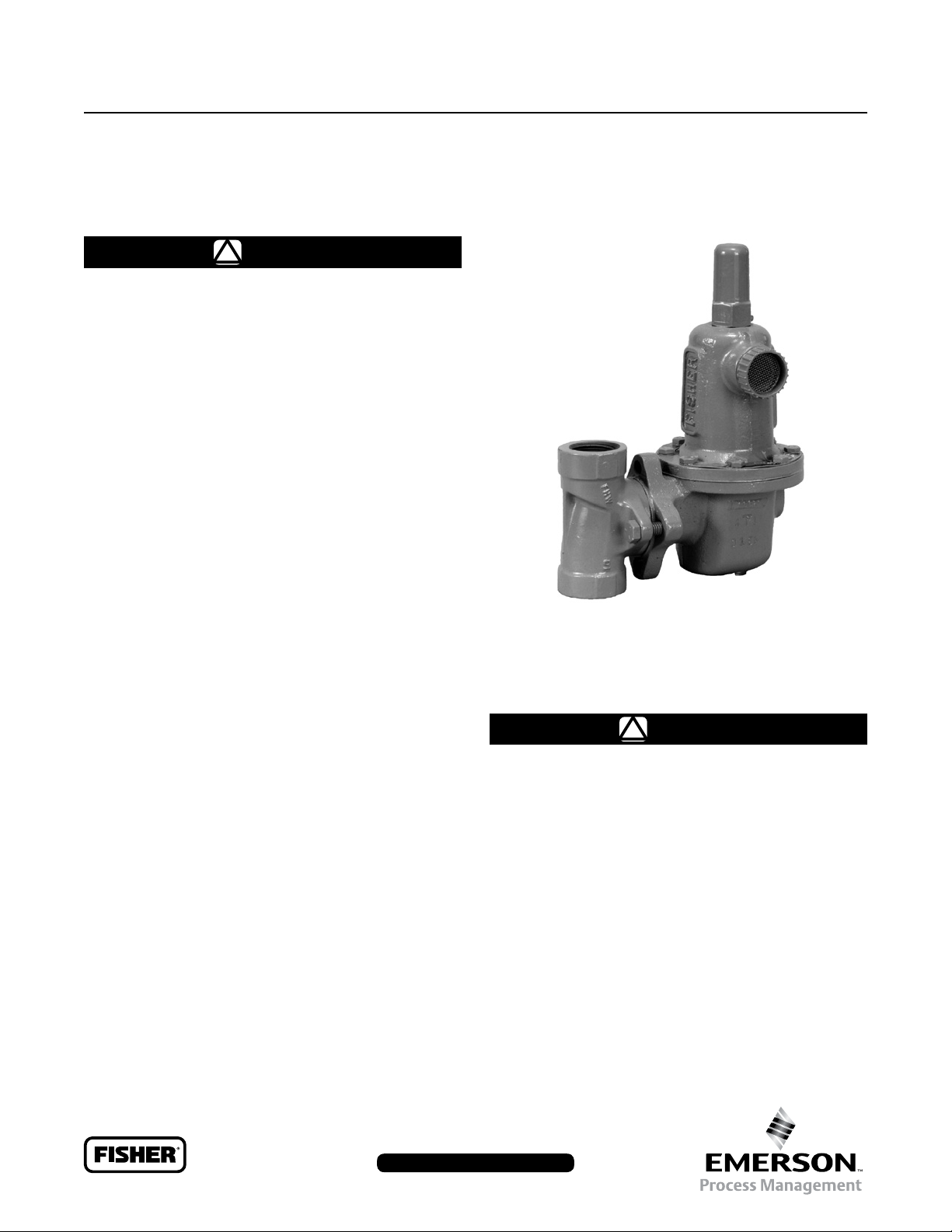

The 627 Series direct-operated pressure reducing

regulators (Figure 1) are for high and low pressure

systems. These regulators can be used with natural

gas, air, or a variety of other gases. Performance

characteristics vary according to construction.

W4793

Figure 1. Typical 627 Direct-Operated

Pressure Reducing Regulator

WARNING

!

Personal injury, property damage,

equipment damage, or leakage due to

escaping gas or bursting of pressurecontaining parts may result if this

regulator is overpressured or is installed

where service conditions could exceed

the limits given in the Specications

section, Tables 1, 2, 3, and 4, or where

conditions exceed any ratings of the

adjacent piping or piping connections.

To avoid such injury or damage, provide

pressure-relieving or pressure-limiting

devices (as required by the appropriate

code, regulation, or standard) to prevent

service conditions from exceeding

www.fisherregulators.com

D101328X012

Page 2

627 Series

Specications

The Specications section gives some general specications for the 627 Series regulators. The nameplates give

detailed information for a particular regulator as it comes from the factory.

Available Constructions

Type 627: Direct-operated pressure reducing

regulator equipped with a pitot tube for greater

regulated capacities (Figure 7).

Type 627R: Type 627 with internal relief and with

an open throat (Figure 8).

Type 627LR: Type 627R with light rate relief spring

(Figure 9).

Type 627M: Type 627 with a stem seal between

the body outlet pressure and diaphragm case.

Pressure is measured under the diaphragm

through the 1/4 NPT downstream control line

connection (Figure 10).

Type 627MR: Type 627M with internal relief

Maximum Body Outlet Pressure

(Types 627M, 627MR, and 627HM Only)

NPT Steel: 2000 psig / 138 bar

Flanged Steel: 1500 psig / 103 bar

Ductile Iron: 1000 psig / 69.0 bar

Orice Sizes

See Table 1

Internal Relief Performance

Type 627R: See Table 3

Type 627LR: See Table 4

Type 627MR: Limited by eld-installed control

line piping

Elastomer Temperature Capabilities

(Figure 11).

Type 627H: Type 627 with a diaphragm limiter to

deliver a higher outlet pressure (Figure 12).

Type 627HM: Type 627H with a stem seal

between the body outlet pressure and diaphragm

case. Pressure is measured under the diaphragm

through the 1/4 NPT downstream control line

connection (Figure 13).

MATERIAL

Nitrile (NBR)

Fluorocarbon (FKM)

Nylon (PA) Disk -40 to 180 -40 to 82

Neoprene (CR) for

Types 627H and 627HM only

Body Sizes and End Connection Styles

BODY SIZE

NPS DN

3/4 - - - - NPT

1 25

2 50

END CONNECTION STYLE

NPT, CL150 RF, CL300 RF,

CL600 RF, and Long Body

NPT, CL150 RF, CL300 RF,

CL600 RF, and Long Body

Maximum Inlet Pressure

(1)

(Body Rating)

CONSTRUCTION

AVAILABLE

All

NPT Stainless Steel: 2000 psig / 138 bar

Flanged Stainless Steel: 1440 psig / 99.3 bar

NPT Steel: 2000 psig / 138 bar

Flanged Steel: 1500 psig / 103 bar

Ductile Iron: 1000 psig / 69.0 bar

Maximum Valve Disk Inlet Pressure Rating

(1)

Nylon (PA) Disk: 2000 psig / 138 bar

Nitrile (NBR) Disk: 1000 psig / 69.0 bar

Fluorocarbon (FKM) Disk: 300 psig / 20.7 bar

Maximum Operating Inlet Pressure, Pressure

Differential, and Outlet Pressure Ranges

(1)

See Table 1 for pressures by orice size and

spring range

Maximum Spring and Diaphragm Casing Pressure

Flow Coefcients

See Table 5

IEC Sizing Coefcients

See Table 6

Pressure Registration

Type 627, 627H, 627R, or 627LR: Internal

Type 627M, 627HM, or 627MR: External through

1/4 NPT control line connection in the

diaphragm casing

De-Icer System

See Figure 3 and Type 627M Regulator De-Icer

System Application section

Relief Indicator

For Types 627R, 627LR, and 627MR

(see Figures 8, 9, and 11)

Spring Case Vent Connection

3/4 NPT with removable screened vent assembly

Approximate Weights

Ductile Iron, Steel, or Stainless Steel Casings:

10 pounds / 4 kg

(1)

Aluminum Casings: 6.3 pounds / 3 kg

See Table 2

1. The pressure/temperature limits in this Instruction Manual or any applicable standard limitation should not be exceeded.

2. Types 627, 627H, 627R, and 627LR are limited by maximum diaphragm casing pressure.

3. Stainless steel body is rated to -40°F / -40°C. Steel and Ductile Iron bodies are rated to -20°F / -29°C.

(1)(2)

(1)(3)

DISK/

DIAPHRAGM

Disk

Diaphragm

Disk

Diaphragm

Diaphragm -40 to 180 -40 to 82

TEMPERATURE

°F °C

-40 to 180 -40 to 82

0 to 180 -18 to 82

2

Page 3

627 Series

INLET PRESSURE

OUTLET PRESSURE

ATMOSPHERIC PRESSURE

ADJUSTING SCREW

A6557

INLET PRESSURE

OUTLET PRESSURE

ATMOSPHERIC PRESSURE

DIAPHRAGM

PUSHER POST

LEVER

CONTROL SPRING

STEM

VALVE DISK

ORIFICE

Figure 2. Type 627 Operational Schematic

those limits. The Type 627R, 627LR,

or 627MR regulator with internal relief

will provide downstream overpressure

protection within the limits given in

the Specications section, Tables 1, 2,

3, and 4. If these limits are exceeded,

additional downstream overpressure

protection must be provided by the user.

Additionally, physical damage to the

regulator could cause personal injury or

property damage due to escaping gas.

To avoid such injury or damage, install

the regulator in a safe location.

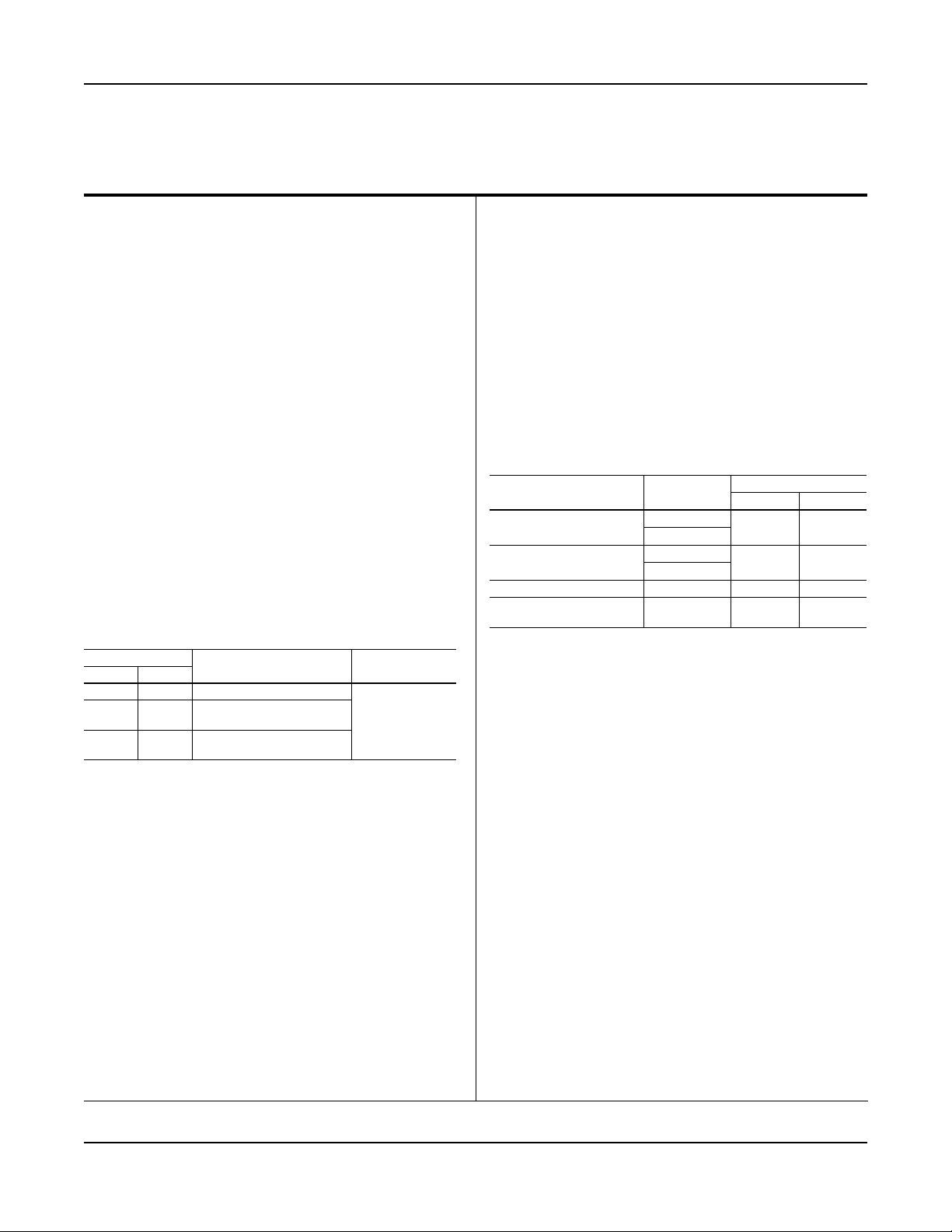

Principle of Operation

Refer to Figure 2. When downstream demand

decreases, the pressure under the diaphragm

increases. This pressure overcomes the regulator

setting (which is set by a spring). Through the action

of the pusher post assembly, lever, and valve stem

the valve disk moves closer to the orice and reduces

gas ow. If demand downstream increases, pressure

under the diaphragm decreases. Spring force pushes

the pusher post assembly downward and the valve

disk moves away from the orice.

Product Description

Types 627 and 627H Direct-Operated Pressure

Reducing Regulators—The Types 627 and 627H

regulators provide economical pressure reducing

control for a variety of residential, commercial, and

industrial applications. The regulator pitot tube located

in a high velocity stream provides dynamic boost that

compensates for outlet pressure drop.

Type 627 Long Body—The Type 627 Long Body

regulator can be used as a drop-in replacement for

existing Type 630 installations without the need to

modify piping.

Internal Relief for Type 627R, 627LR, or

627MR Regulator—The Type 627R internal relief

performance values were obtained by removing the

disk assembly from the regulator. For the Type 627R,

627LR, or 627MR regulator, the internal relief across

the diaphragm provides overpressure protection in

many applications. As outlet pressures build up above

the start-to-discharge point, the diaphragm moves off

the relief valve seat allowing the excess pressure to

bleed out through the screened vent.

For extra protection, should failure conditions exist

which would prevent normal operation of the regulator

3

Page 4

627 Series

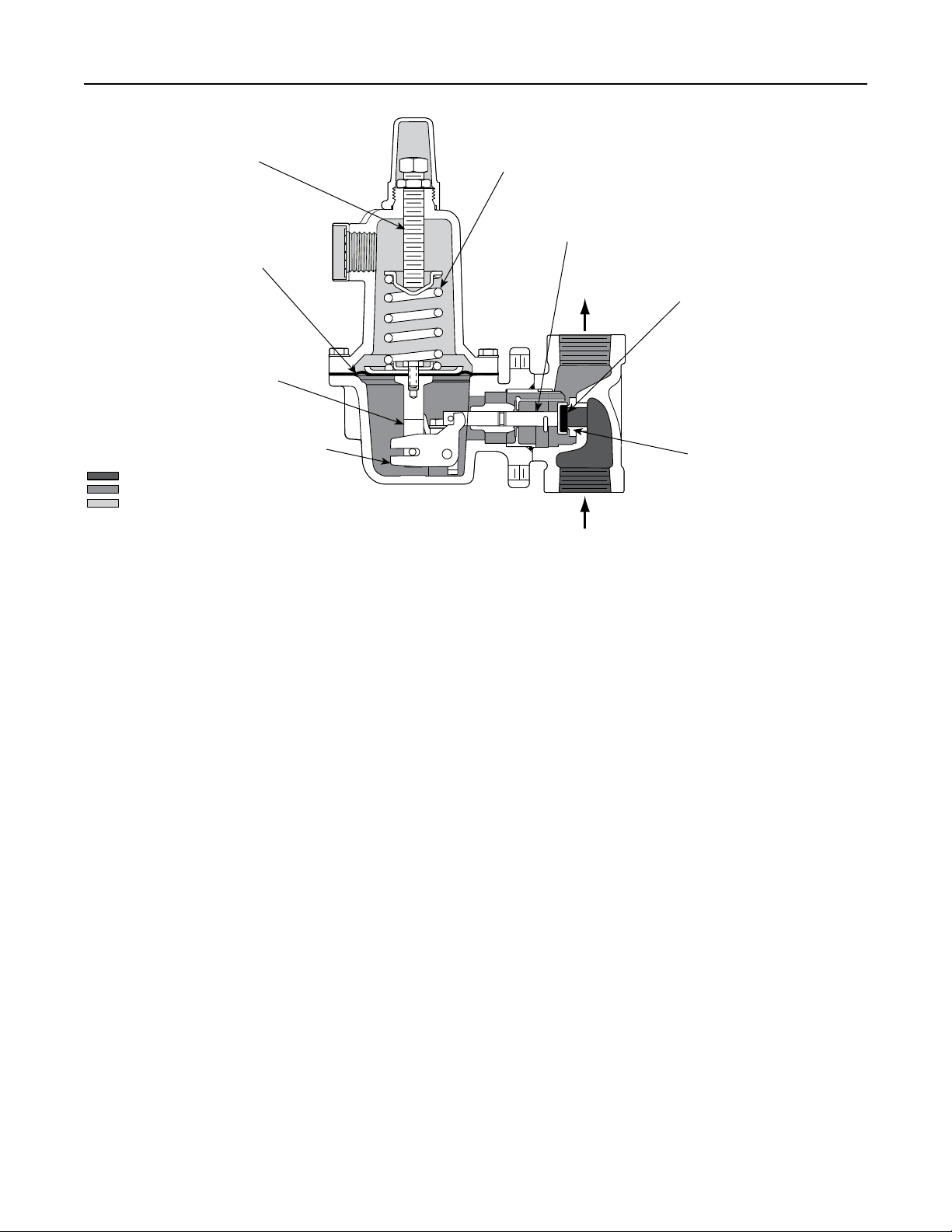

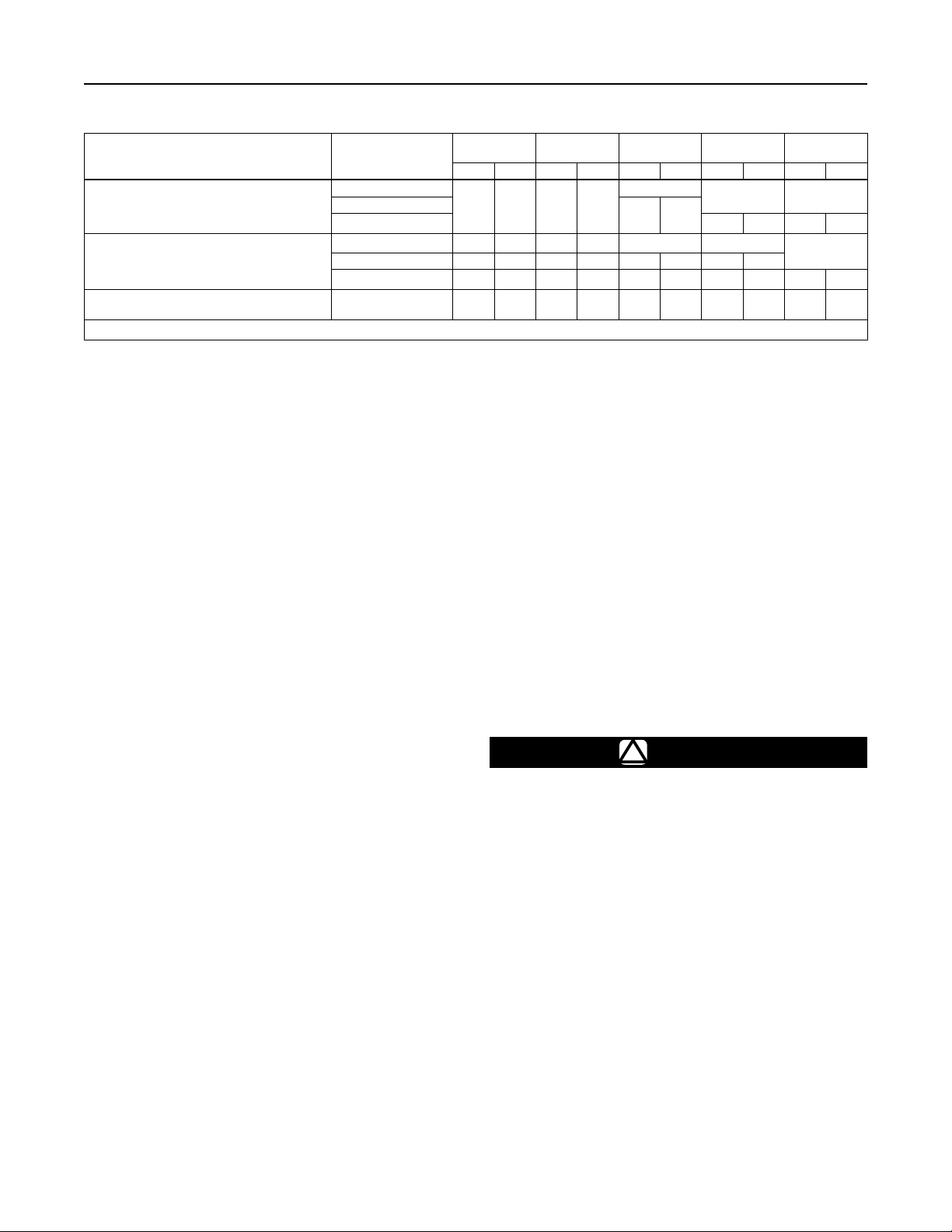

Table 1. Maximum Inlet Pressures and Outlet Pressure Ranges

OUTLET PRESSURE

TYPE

RANGE, SPRING PART

NUMBER, AND

COLOR CODE

(2)

5

to 20 psig /

0.34 to 1.4 bar

10B3076X012

Yellow

15 to 40 psig /

1.0 to 2.8 bar

10B3077X012

627

and

627M

(3)

Green

35 to 80 psig /

2.4 to 5.5 bar

10B3078X012

Blue

70 to 150 psig /

4.8 to 10.3 bar

10B3079X012

Red

(2)

5

to 20 psig /

0.34 to 1.4 bar

10B3076X012

Yellow

15 to 40 psig /

1.0 to 2.8 bar

10B3077X012

627R

Green

and

627MR

35 to 80 psig /

2.4 to 5.5 bar

10B3078X012

Blue

70 to 150 psig /

4.8 to 10.3 bar

10B3079X012

Red

15 to 40 psig /

1.0 to 2.8 bar

627LR

10B3077X012

Green

140 to 250 psig /

9.7 to 17.2 bar

10B3078X012

627H

and

627HM

(3)

Blue

240 to 500 psig /

16.5 to 34.5 bar

10B3079X012

Red

1. For inlet pressure in excess of 1000 psig / 69.0 bar, refer to the maximum body and disk pressure ratings in the Specications section.

2. For pressure settings under 10 psig / 0.69 bar, inlet pressure should be limited to approximately 100 psig / 6.9 bar so the setpoint adjustment can be obtained.

3. The unbalance forces change from the wide-open monitor mode to an active regulator mode such that the Type 627M or 627HM should have a 3/8 inch / 9.5 mm or larger orice.

- Shaded areas indicate that Fluorocarbon (FKM) and Nylon (PA) disk material are not available.

ORIFICE SIZE

Nylon (PA) Disk Nitrile (NBR) Disk Fluorocarbon (FKM) Disk

Inches mm psig bar psig bar psig bar

3/32

1/8

3/16

1/4

3/8

1/2

3/32

1/8

3/16

1/4

3/8

1/2

3/32

1/8

3/16

1/4

3/8

1/2

3/32

1/8

3/16

1/4

3/8

1/2

3/32

1/8

3/16

1/4

3/8

1/2

3/32

1/8

3/16

1/4

3/8

1/2

3/32

1/8

3/16

1/4

3/8

1/2

3/32

1/8

3/16

1/4

3/8

1/2

3/32

1/8

3/16

1/4

3/32

1/8

3/16

1/4

3/8

1/2

3/32

1/8

3/16

1/4

3/8

1/2

2.4

3.2

4.8

6.4

9.5

13

2.4

3.2

4.8

6.4

9.5

13

2.4

3.2

4.8

6.4

9.5

13

2.4

3.2

4.8

6.4

9.5

13

2.4

3.2

4.8

6.4

9.5

13

2.4

3.2

4.8

6.4

9.5

13

2.4

3.2

4.8

6.4

9.5

13

2.4

3.2

4.8

6.4

9.5

13

2.4

3.2

4.8

6.4

2.4

3.2

4.8

6.4

9.5

13

2.4

3.2

4.8

6.4

9.5

13

2000

1000

750

500

300

250

2000

1500

1000

750

500

300

2000

2000

1750

1500

1000

750

2000

2000

2000

1750

1250

750

2000

1000

750

500

300

200

2000

1500

1000

750

300

200

2000

1750

1000

750

300

200

2000

1000

500

300

200

200

2000

2000

1750

1500

1000

750

2000

2000

1750

1500

1000

750

MAXIMUM INLET PRESSURE

138

69.0

51.7

34.5

20.7

17.2

138

103

69.0

51.7

34.5

20.7

138

138

121

103

69.0

51.7

138

138

138

121

86.2

51.7

138

69.0

51.7

34.5

20.7

13.8

138

103

69.0

51.7

20.7

13.8

138

121

69.0

51.7

20.7

13.8

138

69.0

34.5

20.7

13.8

13.8

1000

1000

750

500

300

250

1000

1000

1000

750

500

300

1000

1000

1000

1000

1000

750

1000

1000

1000

1000

1000

750

1000

1000

750

500

300

200

1000

1000

1000

750

300

200

1000

1000

1000

750

300

200

1000

1000

500

300

200

200

1000

1000

750

500

138

138

121

103

69.0

51.7

138

138

121

103

69.0

51.7

1000

1000

1000

1000

750

500

1000

1000

1000

1000

1000

750

69.0

69.0

51.7

34.5

20.7

17.2

69.0

69.0

69.0

51.7

34.5

20.7

69.0

69.0

69.0

69.0

69.0

51.7

69.0

69.0

69.0

69.0

69.0

51.7

69.0

69.0

51.7

34.5

20.7

13.8

69.0

69.0

69.0

51.7

20.7

13.8

69.0

69.0

69.0

51.7

20.7

13.8

69.0

69.0

34.5

20.7

13.8

13.8

69.0

69.0

51.7

34.5

69.0

69.0

69.0

69.0

51.7

34.5

69.0

69.0

69.0

69.0

69.0

51.7

(1)

300

300

300

300

300

250

300

300

300

300

300

300

300

300

300

300

300

300

300

300

300

300

300

300

300

300

300

300

300

200

300

300

300

300

300

200

300

300

300

300

300

200

300

300

300

300

200

200

300

300

300

300

20.7

20.7

20.7

20.7

20.7

17.2

20.7

20.7

20.7

20.7

20.7

20.7

20.7

20.7

20.7

20.7

20.7

20.7

20.7

20.7

20.7

20.7

20.7

20.7

20.7

20.7

20.7

20.7

20.7

13.8

20.7

20.7

20.7

20.7

20.7

13.8

20.7

20.7

20.7

20.7

20.7

13.8

20.7

20.7

20.7

20.7

13.8

13.8

20.7

20.7

20.7

20.7

4

Page 5

627 Series

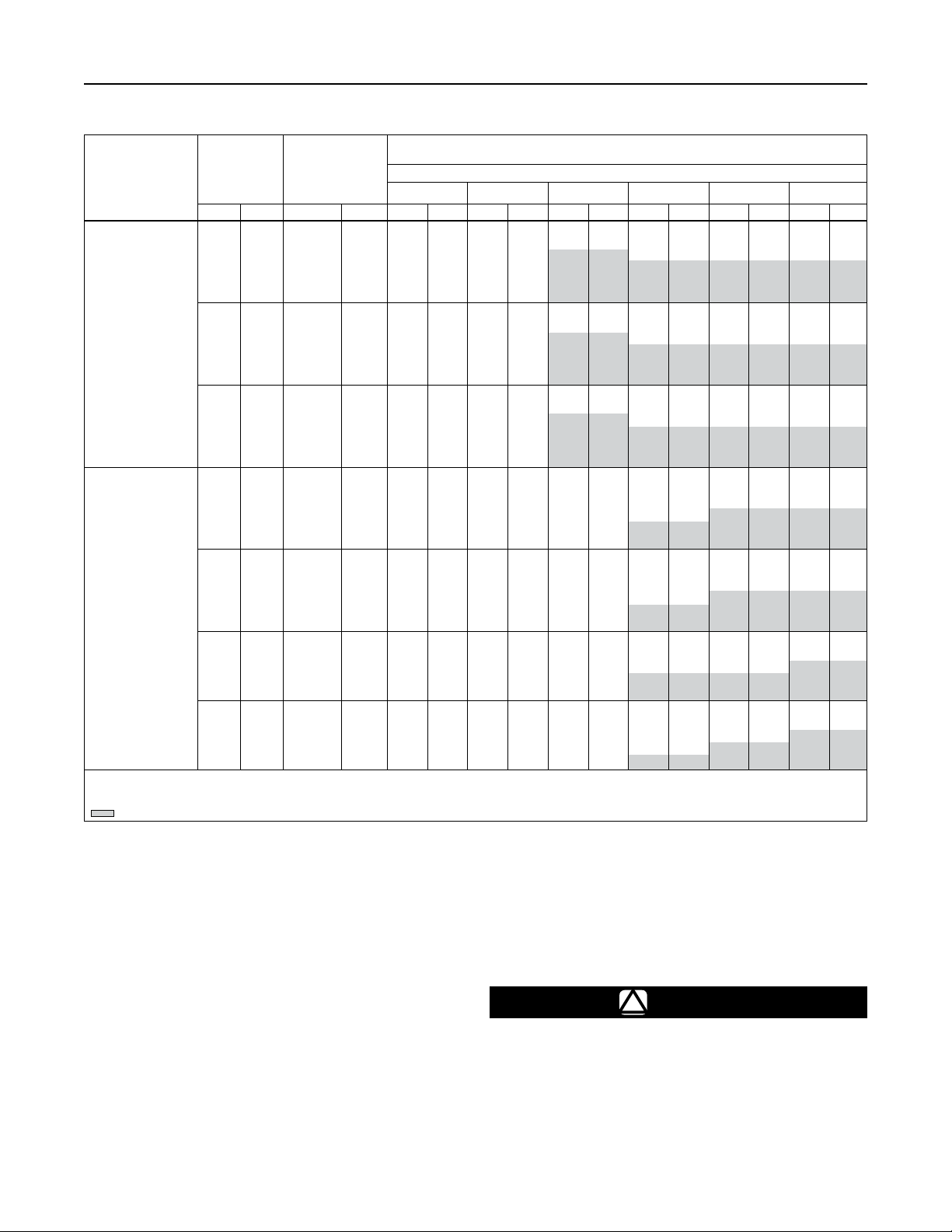

Table 2. Maximum Spring and Diaphragm Casing Pressure

MAXIMUM PRESSURE DESCRIPTION

Maximum pressure to spring and diaphragm

casings to prevent leak to atmosphere other than

relief action (internal parts damage may occur)

Maximum pressure to spring and diaphragm

casings to prevent burst of casings during

abnormal operation (leak to atmosphere and

internal parts damage may occur)

Maximum diaphragm casing overpressure (above

setpoint) to prevent damage to internal parts

1. If the spring case is pressurized, a metal adjusting screw cap is required. Contact your local Sales Ofce for details.

DIAPHRAGM

CASING MATERIAL

Die cast aluminum

Ductile iron

Steel or Stainless steel 250 17.2 800 55.2

Die cast aluminum 375 25.9 375 25.9 Not Available Not Available

Ductile iron 465 32.1 465 32.1 465 32.1 465 32.1

Steel or Stainless steel 1500 103 1500 103 1500 103 1500 103 1500 103

All materials 60 4.1 120 8.3 60 4.1 120 8.3 120 8.3

(for example, disk broken off or disk erosion), the

pusher post contacts the lever retainer causing the

relief valve assembly to open. Since the diaphragm

TYPE 627

psig bar psig bar psig bar psig bar psig bar

250 17.2 250 17.2

Perform steps 1 through 6 for all types of regulators:

1. Only personnel qualied through training and

continues to rise as downstream pressure builds, it

opens the relief valve; thereby, opening the valve.

This internal relief may be adequate for the application.

2. For a regulator that is shipped separately, make

Downstream Control Line for Type 627M, 627HM,

or 627MR Regulator—A Type 627M, 627HM, or

627MR regulator has a blocking throat stem seal

3. Ensure that all tubing and piping have been blown

with O-rings and a 1/4 NPT control line connection in

TYPES 627R

AND 627LR

experience should install, operate, or maintain

this regulator.

sure that there is no damage to or foreign material

in the regulator.

free of foreign debris.

the diaphragm case. A regulator with a downstream

control line is used for monitoring applications or

other applications where other equipment is installed

between the regulator and the pressure control point.

The stem seal separates the body outlet pressure

from the diaphragm case.

4. The regulator may be installed in any position as

long as the ow through the body is in the direction

indicated by the arrow cast on the body.

5. If continuous operation is required during

inspection or maintenance, install a three-valve

bypass around the regulator.

(1)

TYPE 627M TYPE 627MR

Not Available

250 17.2

Not Available Not Available

TYPES 627H

AND 627HM

Not Available

Installation

Regulator operation within ratings does not preclude

the possibility of damage from debris in the lines

or from external sources. A regulator should be

inspected for damage periodically and after any

overpressure condition. Key numbers referenced

in this section are shown in Figures 7 through 13.

Ensure that the operating temperature capabilities

listed in Specications section are not exceeded.

Note

If the regulator is shipped mounted on

another unit, install that unit according

to the appropriate Instruction Manual.

WARNING

!

A regulator may vent some gas to the

atmosphere. In hazardous or ammable

gas service, vented gas may accumulate

and cause personal injury, death, or

property damage due to re or explosion.

Vent a regulator in hazardous gas service

to a remote, safe location away from air

intakes or any hazardous area. The vent

line or stack opening must be protected

against condensation or clogging.

6. Position the body (key 1) and/or diaphragm spring

case (key 29) so it will not collect moisture or

debris into the screened vent. If the regulator

requires repositioning, refer to the Body Area

Maintenance Procedures and/or the Diaphragm

and Spring Case Area Maintenance Procedures

in the Maintenance section to reposition the

screened vent for the application.

5

Page 6

627 Series

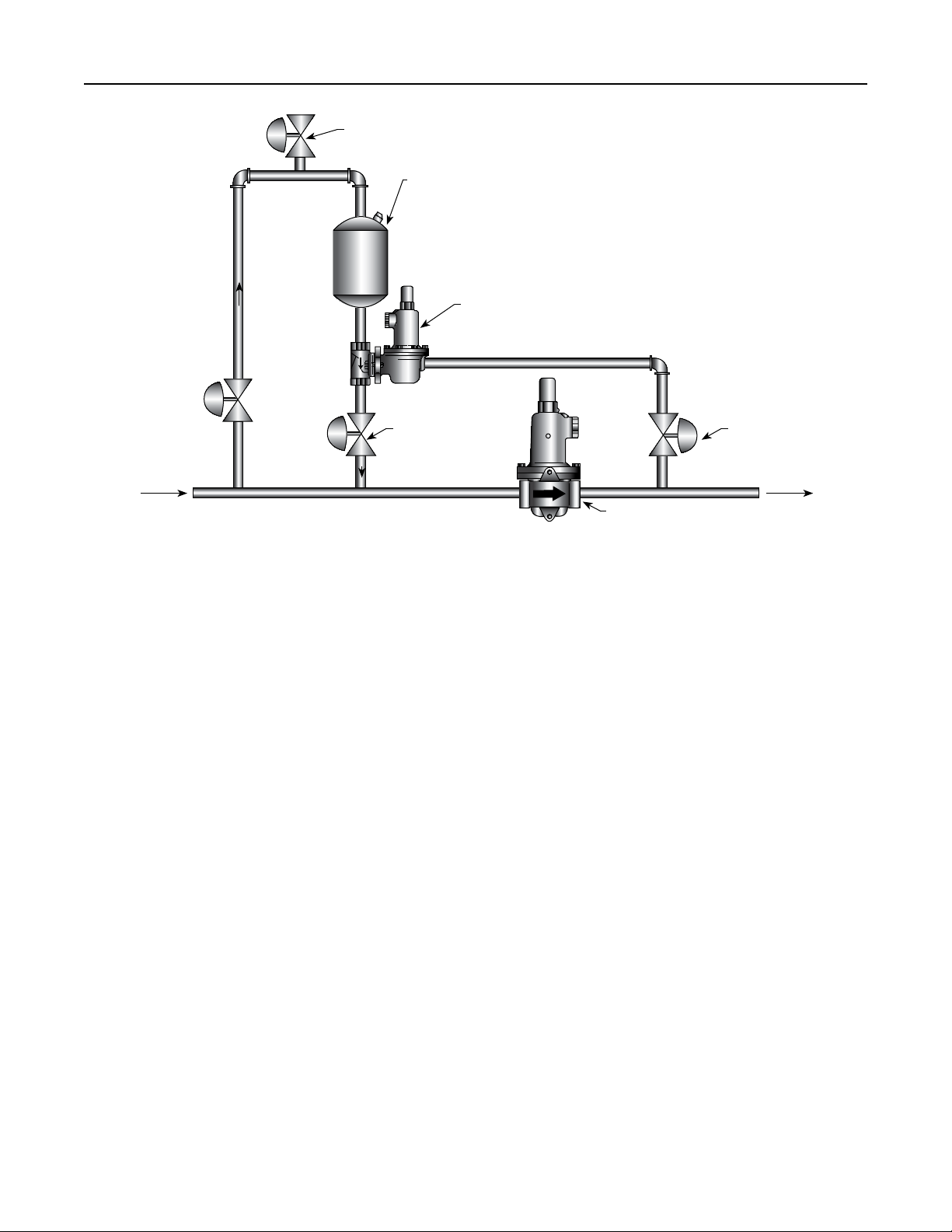

EQUALIZING LINE

VENT VALVE

GRAVITY FEED

ALCOHOL DRIP POT

TYPE 627M SET LOWER

THAN WORKING REGULATOR

CONTROL LINE

NEEDLE

VALV E

INLET

A3725

Figure 3. De-Icer System Operational Schematic

Perform steps 7 through 9 for Types 627M, 627HM,

and 627MR regulators only:

7. A Type 627M, 627HM, or 627MR regulator requires

a downstream control line. Install the control line

before putting the regulator into operation.

8. Ensure that the downstream control line piping

is at least 3/8 inch / 9.5 mm or larger outside

diameter tubing and connected to a straight

section of outlet piping 10 diameters downstream

of the regulator.

9. A hand valve should be installed in the control line.

This hand valve can be used to throttle down and

dampen outlet pulsations in control pressure which

may cause instability or cycling of the regulator.

Remote Vent Line Installation

All 627 Series regulators have a vent assembly

installed in the 3/4 NPT spring case vent opening.

The vent assembly can be removed to install a

remote vent line if necessary. Remote vent lines

must have the largest practical diameter. It should be

as short as possible with minimum number of bends

or elbows.

HAND

VALV E

WORKING REGULATOR

the vent or vent line and prevent proper operation of

the regulator. Periodically check the vent opening to

be sure it is not plugged with foreign debris.

Type 627M or 627HM Regulator

De-Icer System Application

For the Type 627M or 627HM regulator de-icer

system, refer to the application shown in Figure 3.

With a large pressure drop across the working

regulator, ice can form within this regulator. The

formation of ice decreases the size of the orice, so

the regulator is unable to supply enough ow to satisfy

the downstream demand. When the downstream

pressure falls below the outlet pressure setting of the

Type 627M or 627HM regulator, the disk assembly

of the Type 627M or 627HM regulator moves off its

orice, permitting alcohol to ow into the main gas

line. The alcohol carried to the main regulator by the

owstream prevents additional ice from forming on the

orice. When normal ow resumes, and as pressure

in the downstream system is restored, the Type 627M

or 627HM regulator shuts off.

Overpressure Protection

Protect the remote vent opening against entrance of

rain, snow, or any other foreign material that may plug

6

627 Series regulators have outlet pressure ratings that

are lower than their inlet pressure ratings. A pressure-

Page 7

627 Series

22.1

42.7

57.2

75.8

89.6

110

17.9

42.1

55.8

75.8

89.6

110

14.5

41.4

55.2

75.8

89.6

110

14.5

40.7

55.2

75.8

89.6

66.2

10.3

37.9

52.4

75.8

89.6

66.2

31.1

46.2

69.0

82.7

110

22.8

38.6

69.0

82.7

110

(1)

190

13.1

26.9

33.1

46.2

53.1

66.2

11.7

25.5

33.1

46.2

53.1

66.2

9.0

24.8

33.1

46.2

53.1

66.2

9.0

24.1

32.4

44.1

53.8

66.2

6.9

22.8

31.1

43.4

53.1

66.2

17.9

27.6

42.1

52.4

66.9

13.8

23.4

37.9

50.3

66.9

95

180

220

320

360

450

90

170

220

320

360

450

80

170

220

320

360

450

80

170

220

320

370

450

70

160

210

320

360

460

140

190

300

360

460

120

180

290

350

460

390

480

670

770

960

170

370

480

670

770

960

130

360

480

670

770

960

130

350

470

640

780

960

100

330

450

630

770

960

260

400

610

760

970

200

340

550

730

970

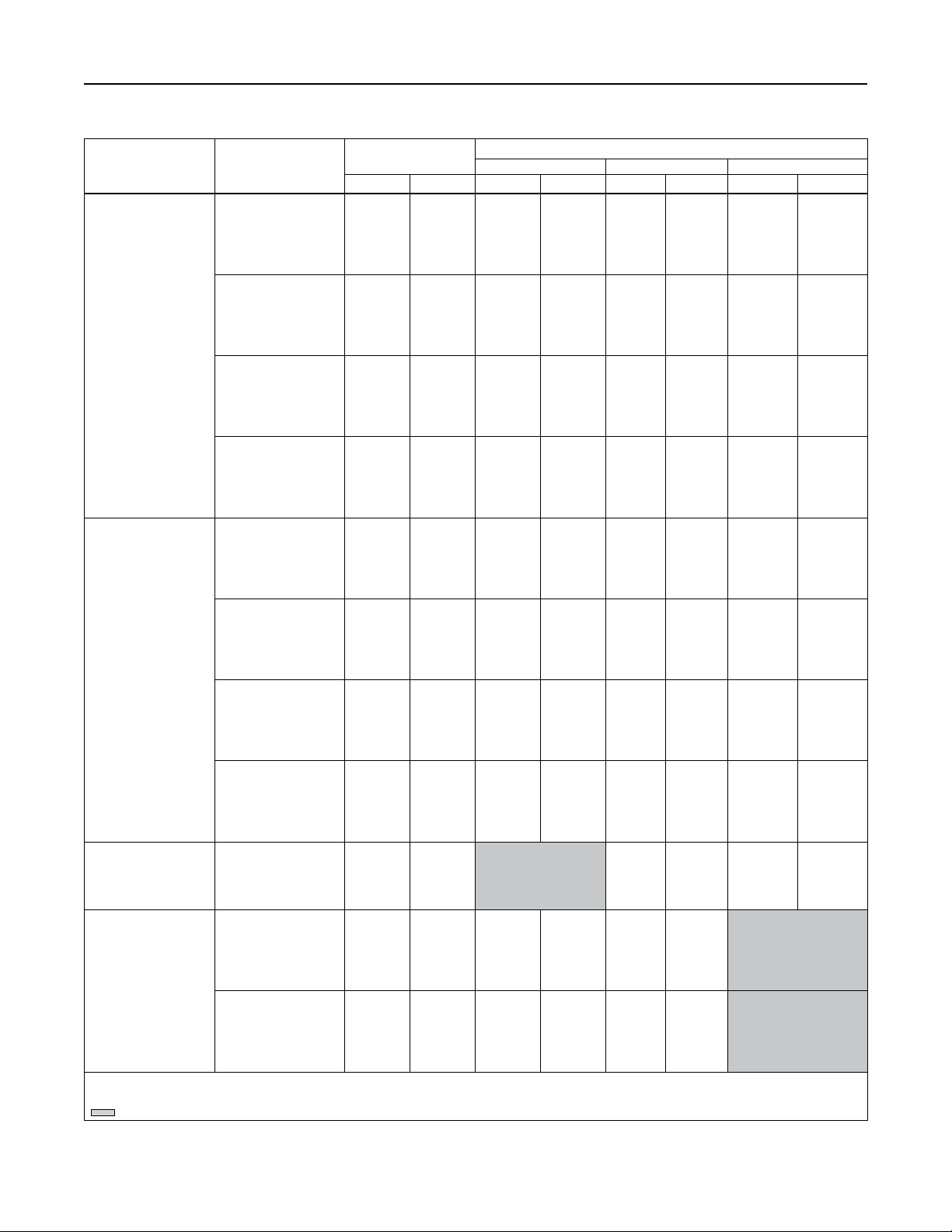

Table 3. Type 627R Internal Relief Performance

OUTLET

PRESSURE RANGE,

SPRING PART

NUMBER, AND

COLOR CODE

(3)

to 20 psig /

5

0.34 to 1.4 bar

10B3076X012

Yellow

15 to 40 psig /

1.0 to 2.8 bar

10B3077X012

Green

1. The internal relief performance values are obtained by removing the disk assembly.

2. For inlet pressures in excess of 1000 psig / 69.0 bar, refer to the maximum body and disk pressure ratings in the Specications section.

3. For pressure settings under 10 psig / 0.69 bar, inlet pressure should be limited to approximately 100 psig / 6.9 bar so the setpoint adjustment can be obtained.

- Shaded areas indicate maximum inlet pressures allowed during system malfunction only. Table 1 gives the maximum inlet pressure for normal regulator operation.

OUTLET

PRESSURE

SETTING

psig bar psig bar psig bar psig bar psig bar psig bar psig bar psig bar

10 0.69

15 1.0

20 1.4

15 1.0

1.4

20

30 2.1

40 2.8

MAXIMUM

ALLOWABLE

DOWNSTREAM

SYSTEM

PRESSURE

60

100

125

175

200

250

60

100

125

175

200

250

60

100

125

175

200

250

60

100

125

175

200

250

60

100

125

175

200

250

100

125

175

200

250

100

125

175

200

250

4.1

6.9

8.6

12.1

13.8

17.2

4.1

6.9

8.6

12.1

13.8

17.2

4.1

6.9

8.6

12.1

13.8

17.2

4.1

6.9

8.6

12.1

13.8

17.2

4.1

6.9

8.6

12.1

13.8

17.2

6.9

8.6

12.1

13.8

17.2

6.9

8.6

12.1

13.8

17.2

MAXIMUM INLET PRESSURE TO KEEP MAXIMUM ALLOWABLE DOWNSTREAM

3/32 / 2.4 1/8 / 3.2 3/16 / 4.8 1/4 / 6.4 3/8 / 9.5 1/2 / 13

1250

86.2

2000

138

2000

138

2000

138

2000

138

2000

138

1000

69.0

2000

138

2000

138

2000

138

2000

138

2000

138

850

58.6

2000

138

2000

138

2000

138

2000

138

2000

138

1000

69.0

2000

138

2000

138

2000

138

2000

138

2000

138

630

43.4

2000

138

2000

138

2000

138

2000

138

2000

138

2000

138

2000

138

2000

138

2000

138

2000

138

1500

103

2000

138

2000

138

2000

138

2000

138

SYSTEM PRESSURE FROM BEING EXCEEDED

Orice Size, Inches / mm

740

51.0

103

131

138

138

138

42.7

96.5

131

138

138

138

33.8

89.6

124

138

138

138

26.2

89.6

124

138

138

138

13.8

82.7

117

138

138

138

65.5

103

138

138

138

48.3

89.6

124

138

138

320

620

830

1100

1300

1600

260

610

810

1100

1300

1600

210

600

800

1100

1300

1600

210

590

800

1100

1300

1600

150

550

760

1100

1300

1600

450

670

1000

1200

1600

330

560

1000

1200

1600

1500

1900

2000

2000

2000

620

1400

1900

2000

2000

2000

490

1300

1800

2000

2000

2000

380

1300

1800

2000

2000

2000

200

1200

1700

2000

2000

2000

950

1500

2000

2000

2000

700

1300

1800

2000

2000

(2)

6.6

75

130

160

220

260

320

70

130

160

220

260

320

65

120

160

220

260

320

65

120

160

220

260

320

65

120

160

220

260

320

110

150

220

260

320

108

140

220

250

320

5.2

9.0

11.0

15.2

17.9

22.1

4.8

9.0

11.0

15.2

17.9

22.1

4.5

8.3

11.0

15.2

17.9

22.1

4.5

8.3

11.0

15.2

17.9

22.1

4.5

8.3

11.0

15.2

17.9

22.1

7.6

10.3

15.2

17.9

22.1

7.4

9.7

15.2

17.2

22.1

12.4

15.2

22.1

24.8

31.0

6.2

11.7

15.2

22.1

24.8

31.0

5.5

11.7

15.2

22.1

24.8

31.0

5.5

11.7

15.2

22.1

25.5

31.0

4.8

11.0

14.5

22.1

24.8

31.7

9.7

13.1

20.7

24.8

31.7

8.3

12.4

20.0

24.1

31.7

- continued -

relieving or pressure-limiting device must be provided

by the user for the Types 627, 627H, 627M, and

627HM regulators if the inlet pressure can exceed the

outlet pressure rating, since these regulators do not

have internal relief.

Types 627R and 627LR regulators provide internal

relief which limits the total outlet pressure buildup over

setpoint. Use Tables 3 and 4 to determine the total

outlet pressure. This internal relief may be adequate

for the application, if not, provide additional pressure

relief or a pressure-limiting device downstream.

Startup and Adjustment

Startup

WARNING

!

To avoid personal injury or property

damage due to explosion or damage to

regulator or downstream components

during startup, release downstream

7

Page 8

627 Series

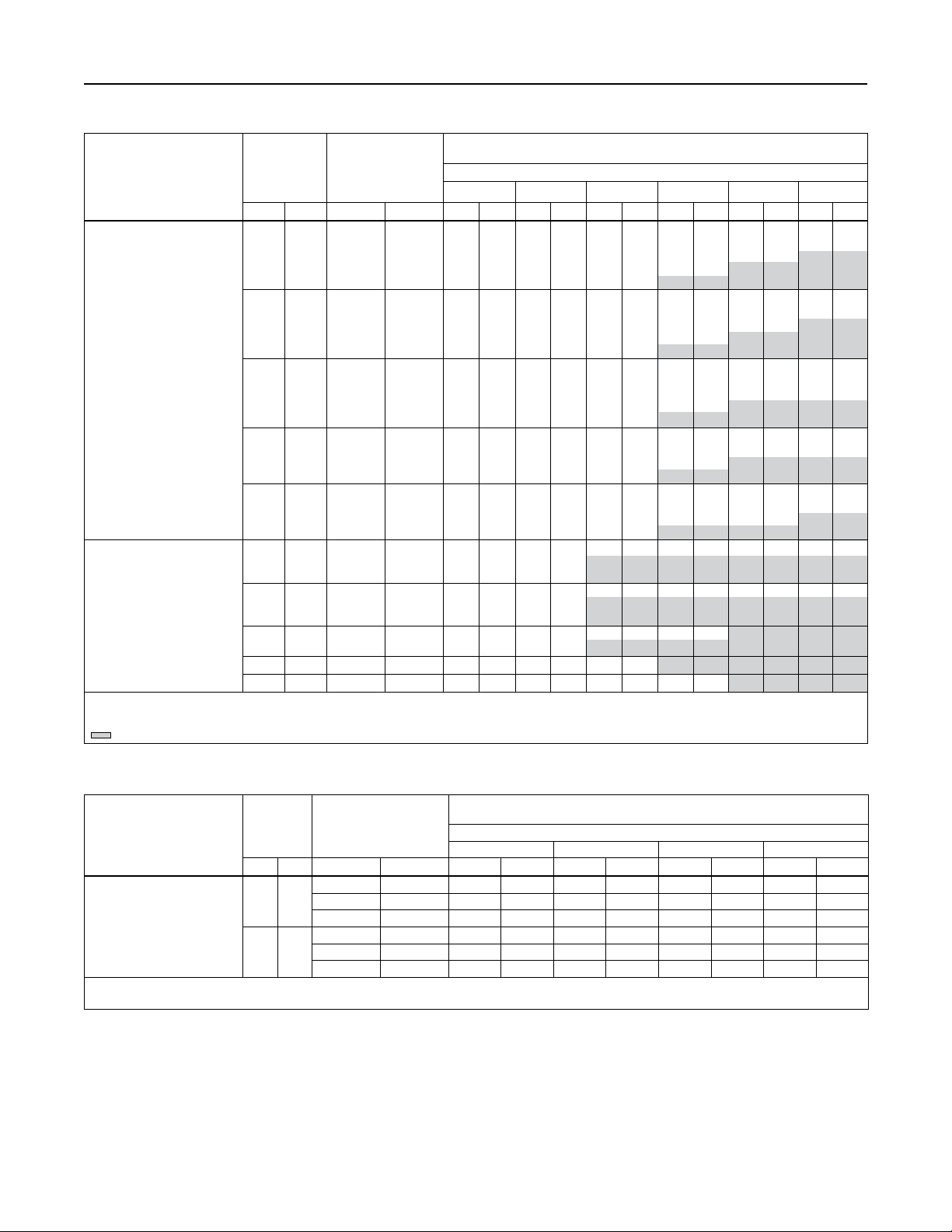

Table 3. Type 627R Internal Relief Performance

OUTLET PRESSURE RANGE,

SPRING PART NUMBER,

AND COLOR CODE

35 to 80 psig /

2.4 to 5.5 bar

10B3078X012

Blue

70 to 150 psig /

4.8 to 10.3 bar

10B3079X012

Red

1. The internal relief performance values are obtained by removing the disk assembly.

2. For inlet pressures in excess of 1000 psig / 69.0 bar, refer to the maximum body and disk pressure ratings in the Specications section.

3. For pressure settings under 10 psig / 0.69 bar, inlet pressure should be limited to approximately 100 psig / 6.9 bar so the setpoint adjustment can be obtained.

- Shaded areas indicate maximum inlet pressures allowed during system malfunction only. Table 1 gives the maximum inlet pressure for normal regulator operation.

OUTLET

PRESSURE

SETTING

psig bar psig bar psig bar psig bar psig bar psig bar psig bar psig bar

40 2.8

50 3.4

60 4.1

70 4.8

80 5.5

70 4.8

80 5.5

100 6.9

125 8.6 250 17.2 2000 138 1000 69.0 500 34.5 390 26.9 290 20.0 260 17.9

150 10.3 250 17.2 1200 82.7 260 17.9 260 17.9 260 17.9 260 17.9 260 17.9

MAXIMUM

ALLOWABLE

DOWNSTREAM

SYSTEM

PRESSURE

125

150

175

200

250

125

150

175

200

250

125

150

175

200

250

150

175

200

250

150

175

200

250

175

200

250

175

200

250

200

250

MAXIMUM INLET PRESSURE TO KEEP MAXIMUM ALLOWABLE DOWNSTREAM

3/32 / 2.4 1/8 / 3.2 3/16 / 4.8 1/4 / 6.4 3/8 / 9.5 1/2 / 13

8.6

2000

10.3

2000

12.1

2000

13.8

2000

17.2

2000

8.6

1400

10.3

2000

12.1

2000

13.8

2000

17.2

2000

8.6

10.3

12.1

13.8

17.2

10.3

12.1

13.8

17.2

10.3

12.1

13.8

17.2

12.1

13.8

17.2

12.1

13.8

17.2

13.8

17.2

900

1700

2000

2000

2000

1200

2000

2000

2000

800

1500

2000

2000

1900

2000

2000

1400

2000

2000

1500

2000

SYSTEM PRESSURE FROM BEING EXCEEDED

138

1100

138

1600

138

2000

138

2000

138

2000

96.5

820

138

1400

138

1900

138

2000

138

2000

62.1

450

117

1100

138

1700

138

2000

138

2000

82.7

850

138

1400

138

2000

138

2000

55.2

500

103

1200

138

1700

138

2000

131

600

138

1200

138

2000

96.5

250

138

960

138

2000

103

250

138

1600

(1)

(continued)

Orice Size, Inches / mm

75.8

500

750

980

1200

1600

400

650

700

1100

1500

270

540

780

1000

1400

430

670

920

1300

300

550

800

1200

400

630

1100

240

520

1000

240

770

34.5

51.7

67.6

82.7

110

27.6

44.8

48.3

75.8

103

18.6

37.2

53.8

69.0

96.5

29.6

46.2

63.4

89.6

20.7

37.9

55.2

82.7

27.6

43.4

75.8

16.5

35.9

69.0

16.5

53.1

110

138

138

138

56.5

96.5

131

138

138

31.0

75.8

117

138

138

58.6

96.5

138

138

34.5

82.7

117

138

41.4

82.7

138

17.2

66.2

138

17.2

110

300

440

580

720

940

230

370

530

670

920

190

300

470

610

880

250

400

550

830

200

330

480

770

260

380

680

200

330

620

230

520

20.7

30.3

40.0

49.6

64.8

15.9

25.5

36.5

46.2

63.4

13.1

20.7

32.4

42.1

60.7

17.2

27.6

37.9

57.2

13.8

22.8

33.1

53.1

17.9

26.2

46.9

13.8

22.8

42.7

15.9

35.9

140

170

230

290

340

450

150

210

270

330

430

190

250

310

420

170

230

280

400

160

210

270

390

200

250

360

190

240

350

210

320

(2)(3)

11.7

15.9

20.0

23.4

31.0

10.3

14.5

18.6

22.8

29.6

9.7

13.1

17.2

21.4

29.0

11.7

15.9

19.3

27.6

11.0

14.5

18.6

26.9

13.8

17.2

24.8

13.1

16.5

24.1

14.5

22.1

140

180

220

250

320

140

170

210

240

320

130

160

200

230

310

160

190

230

310

150

190

220

300

175

210

290

175

210

280

210

270

9.7

12.4

15.2

17.2

22.1

9.7

11.7

14.5

16.5

22.1

9.0

11.0

13.8

15.9

21.4

11.0

13.1

15.9

21.4

10.3

13.1

15.2

20.7

12.1

14.5

20.0

12.1

14.5

19.3

14.5

18.6

Table 4. Type 627LR Internal Relief Performance

OUTLET PRESSURE RANGE,

SPRING PART NUMBER,

AND COLOR CODE

15 to 40 psig /

1.03 to 2.8 bar

10B3077X012

Green

1. The internal relief performance values are obtained by removing the disk assembly.

2. For inlet pressures in excess of 1000 psig / 69.0 bar, refer to the maximum body and disk pressure ratings in the Specications section.

OUTLET

PRESSURE

SETTING

psig bar psig bar psig bar psig bar psig bar psig bar

30 2.1

40 2.8

MAXIMUM ALLOWABLE

DOWNSTREAM

SYSTEM PRESSURE

55 3.8 500 34.5 270 18.6 110 7.6 80 5.5

60 4.1 850 58.6 480 33.1 200 13.8 120 8.3

66 4.5 1000 69.0 660 45.5 290 20.0 175 12.1

66 4.5 380 26.2 190 13.1 85 5.9 80 5.5

70 4.8 700 48.3 370 25.5 150 10.3 115 7.9

75 5.2 1000 69.0 560 38.6 240 16.5 160 11.0

MAXIMUM INLET PRESSURE TO KEEP MAXIMUM ALLOWABLE

DOWNSTREAM SYSTEM PRESSURE FROM BEING EXCEEDED

3/32 / 2.4 1/8 / 3.2 3/16 / 4.8 1/4 / 6.4

(1)

Orice Size, Inches / mm

8

(2)

Page 9

627 Series

Table 5. Flow Coefcients

ORIFICE 3/4 NPT NPS 1 / DN 25 BODY NPS 2 / DN 50 BODY

Wide-Open

C

for

Inch mm

3/32 2.4 6.9 0.24 29.2 6.9 0.24 28.5 6.9 0.23 29.7

1/8 3.2 12.5 0.43 29.1 12.5 0.43 29.4 12.5 0.42 29.5

3/16 4.8 29 1.01 28.6 29 0.93 31.2 29 1.02 28.5

1/4 6.4 50 1.63 30.6 50 1.71 29.3 52 1.66 31.3

3/8 9.5 108 2.99 36.1 108 3.42 31.6 11 5 3.39 33.9

1/2 13 190 4.87 39.0 190 5.29 35.9 200 5.01 39.9

g

External

Relief Sizing

Wide-Open

Cv for

External

Relief Sizing

Wide-Open

C

1

Cg for

External

Relief Sizing

Wide-Open

Cv for

External

Relief Sizing

Table 6. IEC Sizing Coefcients

Wide-Open

C

1

Cg for

External

Relief Sizing

Wide-Open

Cv for

External

Relief Sizing

C

1

ORIFICE SIZE X

Inch mm 3/4 NPT Body NPS 1 / DN 25 Body NPS 2 / DN 50 Body

3/32 2.4 0.539 0.514 0.558

1/8 3.2 0.536 0.547 0.539 0.79

3/16 4.8 0.517 0.616 0.514 0.85

1/4 6.4 0.592 0.543 0.620 0.87

3/8 9.5 0.824 0.632 0.727 0.89

1/2 13 0.962 0.815 1.01 0.86

T

F

0.50

D

Table 7. Maximum Torque Values

KEY NUMBER

1. Refer to Figures 7 through 13 for key number locations.

(1)

2 Orice 25 34

3

18 Lever cap screw 7 9.5

22 Diaphragm connector nut 17 23

26 Guide retainer (for Types 627R, 627LR, and 627MR only) 3 4.1

37

46

Cap screw (with ductile iron or steel/stainless steel diaphragm casing) 25 34

Spring case cap screw (with aluminum or ductile iron diaphragm casing) 7 9.5

Spring case cap screw (with steel/stainless steel diaphragm casing) 35 47

pressure to prevent an overpressure

DESCRIPTION

Cap screw (with aluminum diaphragm casing) 16 22

Diaphragm cap screw (with Type 627 or 627M) 7 9.5

Diaphragm cap screw (with Type 627H or 627HM) 14 19

FOOT-POUNDS N•m

Adjustment

MAXIMUM TORQUE

condition on the diaphragm of

the regulator.

In order to avoid an overpressure

condition and possible equipment

damage, pressure gauges should

always be used to monitor pressures

during startup.

1. Slowly open the upstream shut-off valve.

The range of allowable pressure settings is marked on

the nameplate. If a pressure setting beyond this range

is necessary, substitute the appropriate regulator

control spring. Change the nameplate to indicate the

new pressure range.

Before increasing the setting, refer to Table 1, 2, 3, or 4.

Review the pressure limits for the control spring range

being used and be certain that the new pressure setting

2. Slowly open the downstream shut-off valve.

will not result in an overpressure condition.

F

0.85

L

3. Check all connections for leaks.

4. Make nal control spring adjustments

according to the adjustment procedures.

Note

Always use a pressure gauge to monitor

pressure when making adjustments.

9

Page 10

627 Series

Refer to Figures 7 through 13 for key number locations.

1. Remove the adjusting screw cap (key 36).

2. Loosen the locknut (key 34).

3. Increase the outlet pressure setting by turning the

adjusting screw (key 35) clockwise. Decrease the

outlet pressure setting by turning the adjusting

screw counterclockwise.

4. When the desired pressure is obtained, hold the

adjusting screw (key 35) in place and tighten the

locknut (key 34).

RELIEF

INDICATOR

CAP (KEY 49)

Shutdown

WARNING

!

To avoid personal injury or property

damage due to explosion or damage to

regulator or downstream components

during shutdown, release downstream

pressure to prevent an overpressure

condition on the diaphragm of

the regulator.

1. Close the nearest upstream shut-off valve.

2. Close the nearest downstream shut-off valve.

3. Open the vent valve between the regulator and

the downstream shut-off valve nearest to it.

4. For a Type 627, 627H, 627R, or 627LR regulator,

the regulator will open to release pressure between

the upstream shut-off valve and the regulator.

5. A Type 627M, 627HM, or 627MR regulator requires

venting the control line and downstream pressure

from the regulator before maintenance. The

pressure between these shut-off valves is released

through the open regulator because the disk

assembly remains open in response to the decrease

in control line pressure.

W4665

Figure 4. Relief Indicator

be inspected periodically and replaced as necessary

to ensure correct performance. The frequency of

inspection and replacement depends upon the severity

of conditions and the requirements of state and federal

laws. Normal wear of the orice and disk assembly is

accelerated with high pressure drops and with large

amounts of impurities in the owstream. Instructions

are given below for replacing the disk assembly,

orice, diaphragm, and O-rings. These procedures

may also be used for disassembly required for

inspection and replacement of other parts.

Problem Indication for Types 627R,

627LR, and 627MR Regulators

WARNING

!

Isolate the regulator from all pressure

to avoid personal injury and equipment

damage due to explosion or sudden

release of process pressure. Cautiously

release pressure from the regulator

before attempting disassembly.

Maintenance

Unless otherwise specied, the following maintenance

procedures apply to all types of regulators. For a

summary of maximum torque values required for all

types of regulators, refer to Table 7.

Due to normal wear, damage from external sources,

or debris in the air or gas line, regulator parts such

as the disk assembly, orice, and diaphragm must

10

The vent assembly is equipped with a relief indicator

(key 49, Figure 4). The cap for the relief indicator

snaps over the vent assembly opening. If the

relief valve opens wide, exhaust gas pops the cap

off the screen vent assembly opening indicating a

problem with the regulator. If the cap pops off, refer

to the shutdown and to the Body Area Maintenance

Procedures to inspect the disk assembly and orice.

If the disk assembly and orice are not damaged, refer

to the Diaphragm and Spring Case Area Maintenance

Procedures in this section.

Page 11

LEVER

(KEY 15)

DIAPHRAGM

CASING (KEY 5)

W4792

STEM (KEY 10)

STEM BACK-UP

RINGS

(KEY 12)

STEM O-RING

(KEY 11)

DIAPHRAGM CASING

O-RING (KEY 4)

STEM GUIDE

(KEY 8)

STABILIZER

(KEY 7)

TYPES 627, 627H, 627R, AND 627LR

BLOCKED THROAT

BACK-UP RINGS (KEY 45)

BLOCKED THROAT

(KEY 43)

BOOST BODY

(KEY 6)

HAIR PIN CLIP

(KEY 13)

DISK

ASSEMBLY

(KEY 9)

PITOT TUBE

AND TAB FOR

TYPE 627 ONLY

627 Series

BODY

(KEY 1)

CAP

SCREW

(KEY 3)

ORIFICE

(KEY 2)

W4791

TYPES 627M, 627HM, AND 627MR

Figure 5. Stem Assemblies

The disk assembly and orice can be inspected,

removed, and replaced without removing the regulator

body from the line connections. Refer to the Body

Area Maintenance Procedures.

Body Area Maintenance Procedures

These procedures are for gaining access to the disk

assembly, orice, diaphragm casing O-ring, and stem

assembly. All pressure must be released from the

diaphragm casing before performing these steps.

While using the following procedures, refer to

Figures 7 through 13 for key number locations.

Replacing the Disk Assembly or Orice

1. To inspect and replace the disk assembly (key 9)

or orice (key 2), remove the cap screws (key 3,

Figure 5), and separate the diaphragm casing

(key 5) from the body (key 1).

2. Inspect and, if necessary, remove the orifice

(key 2). If removed, coat the threads of the

replacement orifice with lubricant and torque to

25 foot-pounds / 34 N•m.

BLOCKED THROAT

O-RINGS (KEY 44)

3. Inspect the disk assembly (key 9) and, if necessary,

remove the hair pin clip (key 13) that holds the disk

assembly (key 9) in place. If replacing the disk

assembly is the only maintenance required, skip to

step 16.

Replacing the Stem Assembly

If it is necessary to perform maintenance on the stem

assembly, continue with steps 4 through 8 and 15

through 19 for Types 627, 627H, 627R, and 627LR

regulators, or steps 9 through 19 for Types 627M,

627HM, and 627MR regulators.

Perform steps 4 through 8 for Types 627, 627H,

627R, and 627LR Regulators only:

4. Use steps 5 through 8 to remove and replace the

stem assembly.

5. Remove the boost body (key 6), stabilizer (key 7),

and stem guide (key 8) from the diaphragm casing

(key 5). Unhook and remove the stem (key 10)

from the diaphragm casing (key 5).

6. Remove and inspect the diaphragm casing

O-ring (key 4, Figure 7, 8, 9, or 12) and replace

it if necessary.

11

Page 12

627 Series

DIAPHRAGM

(KEY 23)

W4668

W5433-1

RELIEF VALVE O-RING

(KEY 28)

PUSHER POST

(KEY 19)

RELIEF SEAL

RETAINER (KEY 47)

PUSHER POST

(KEY 19)

PUSHER POST

O-RING (KEY 52)

DIAPHRAGM CONNECTOR

ASSEMBLY (KEY 21)

TYPE 627, 627R, 627LR, 627M, OR 627MR

DIAPHRAGM

(KEY 23)

DIAPHRAGM

LIMITER (KEY 50)

DIAPHRAGM

HEAD (KEY 24)

DIAPHRAGM

HEAD CAP

SCREW (KEY 46)

DIAPHRAGM

HEAD (KEY 24)

DIAPHRAGM CONNECTOR

NUT (KEY 22)

LOWER SPRING

SEAT (KEY 31)

RELIEF VALVE

SPRING (KEY 27)

RELIEF SPRING

SEAT (KEY 25)

DIAPHRAGM LIMITER

O-RING (KEY 51)

GUIDE RETAINER

O-RING (KEY 48)

GUIDE RETAINER

(KEY 26)

TYPES 627H AND 627HM

Figure 6. Diaphragm Assemblies

7. Apply lubricant to a replacement diaphragm casing

O-ring (key 4, Figure 7, 8, 9, or 12) and install it onto

the boost body (key 6). Skip to step 14.

8. For the Type 627 or 627H regulators, be sure to

insert the pitot tube (tab) into the outlet side of the

body (see Figure 7 or 12). Skip to step 14.

Perform steps 9 through 19 for Types 627M,

627HM, and 627MR Regulators only:

9. Use steps 10 through 14 to remove and replace

the stem assembly.

10. To remove the blocked throat (key 43), insert a

screw driver blade into the groove provided in the

throat and pry it out of the diaphragm casing

(key 5). Inspect and replace parts as necessary.

11. Inspect and, if necessary, replace the blocked

throat O-rings (key 44, Figure 5) and back-up rings

(key 45, Figure 5).

12. Apply lubricant to replacement blocked throat

O-rings (key 44) and back-up rings (key 45).

13. Apply lubricant to the replacement stem O-ring

(key 11) and stem back-up rings (key 12) and

install them on the stem (key 10).

14. For assembly, lubricate the stem (key 10) and

insert the diaphragm casing (key 5) and hook it

on the lever (key 15).

15. Lubricate the contact points of the lever (key 15).

16. Insert parts into the diaphragm casing (key 5)

that were removed in steps 5 and 6 or step 10

(see Figure 5).

17. Install the disk assembly (key 9), line up the hole

in the disk assembly and stem (key 10) and insert

the hair pin clip (key 13).

18. Position the diaphragm casing (key 5) plus

attached parts in relation to the body (key 1) so

that they are correct for the application.

12

Page 13

627 Series

19. Secure the diaphragm casing (key 5) to the body

with the cap screws (key 3, Figure 5). For an

aluminum diaphragm casing, torque the cap screws

(key 3) to 16 foot-pounds / 22 N•m. For ductile iron

or steel diaphragm casings, torque the cap screws

(key 3) to 25 foot-pounds / 34 N•m.

20. It may be necessary to reposition the diaphragm

spring case to prevent rain, ice, and foreign

debris from entering the spring case. Refer to the

Diaphragm and Spring Case Area Maintenance

Procedures, steps 1, 2, and 21 through 25.

Diaphragm and Spring Case Area

Maintenance Procedures

These procedures are for gaining access to the control

spring, diaphragm assembly, and lever assembly. All

spring pressure must be released from the diaphragm

casing before these steps can be performed.

While using the following procedures, refer to

Figures 7 through 13 for key number locations.

1. Remove the adjusting screw cap (key 36), loosen

the lock nut (key 34), and turn the adjusting screw

(key 35) counterclockwise until all compression is

removed from the control spring (key 32).

2. Remove the spring case cap screws (key 37), the

nameplates, and lift off the spring case (key 29). If

changing the control spring (key 32) or repositioning

the spring case (key 29) is the only maintenance

required, install the replacement control spring

or rotate the spring case so it is correct for the

application. Skip to step 21. For diaphragm area

maintenance, continue with step 3.

3. Remove the diaphragm limiter O-ring and

diaphragm limiter (keys 51 and 50, on the

Type 627H or 627HM only). Remove the

diaphragm assembly by tilting it so that the pusher

post (key 19) slips off the lever (key 15).

4. If it is necessary to replace the lever assembly,

remove the lever cap screws (key 18).

5. Install the replacement lever (key 15) into the lever

retainer (key 16) by inserting the lever pin (key 17).

Secure the lever assembly into the diaphragm casing

with the cap screws (key 18) and torque the cap

screws to 7 foot-pounds / 9.5 N•m.

If it is necessary to perform maintenance on

the diaphragm assembly, continue with steps 6

through 11 and step 20 for Types 627, 627H,

627M, and 627HM regulators, or steps 12 through

19 for Types 627R, 627LR, and 627MR regulators.

Perform steps 6 through 11 for Types 627, 627H,

627M, and 627HM Regulators only:

6. For Types 627, 627H, 627M, and 627HM

regulators (Figures 5 and 6), use steps 7

through 11 to disassemble and reassemble the

diaphragm assembly.

7. Remove the diaphragm head cap screw (key 46),

lower spring seat (key 31, Type 627 or 627M only),

and diaphragm head (key 24). On the Type 627H

or 627HM, remove the pusher post O-rings

(key 52). Separate the diaphragm (key 23) from

the pusher post (key 19).

8. Install the diaphragm (key 23), in reverse order

in step 7, on the pusher post (key 19), insert and

nger tighten the diaphragm head cap screw

(key 46).

9. Hook the pusher post on the lever (key 15), then

turn the diaphragm (key 23) to match the holes in

the diaphragm with the holes in the spring casing.

10. Unhook the pusher post from the lever (key 15)

and torque the diaphragm head cap screw

(key 46) to 7 foot-pounds / 9.5 N•m for the

Type 627 or 627M. On the Type 627H or 627HM,

torque the diaphragm head cap screw to

14 foot-pounds / 19 N•m.

11. Hook the pusher post on the lever (key 15) and

check the hole alignment. If necessary, loosen the

cap screw (key 46) and reposition the diaphragm

(key 23) on the pusher post (key 19). Retorque

the screw (see step 10). Skip to step 20.

Perform steps 12 through 19 for Types 627R,

627LR, and 627MR Regulators only:

12. For Types 627R, 627LR, and 627MR

regulators (Figure 6), use steps 13 through

19 to disassemble and reassemble the

diaphragm assembly.

13. Remove the guide retainer (key 26) and separate

the diaphragm parts. Refer to Figure 6 for the

sequence of parts.

14. To remove the diaphragm (key 23), remove the

diaphragm connector nut (key 22) and lift off the

diaphragm head (key 24) and diaphragm (key 23)

from the connector assembly (key 21). Do not

attempt to disassemble the connector assembly

(key 21).

13

Page 14

627 Series

15. Position the replacement diaphragm (key 23)

on the connector assembly (key 21), install the

diaphragm head (key 24) and connector nut

(key 22), then torque to 17 foot-pounds / 23 N•m.

16. If necessary, replace the guide retainer O-ring

(key 48) and, set the guide retainer (key 26) aside,

ready for assembly.

17. On the pusher post (key 19) install the relief

seal O-ring (key 28) and apply lubricant. Also,

install the relief seal retainer (key 47), diaphragm

connector assembly (key 21, with attached parts)

relief spring (key 27), upper relief spring seat

(key 33), and guide retainer (key 26). Torque the

guide retainer (key 26) to 3 foot-pounds / 4.1 N•m.

18. Hook the pusher post (key 19) (with attached

parts) on the lever (key 15) to check the

alignment of the holes in the diaphragm with the

holes in the spring casing. If the holes do not

line up, unhook the pusher post from the lever,

hold the pusher post, and rotate the diaphragm

to the correct position.

19. Install the lower spring seat (key 31) over the relief

spring so it rests at on the connector nut (key 22).

20. Insert the diaphragm assembly into the diaphragm

casing (key 5) and hook the pusher post on the

lever (key 15).

21. Install the control spring (key 32) and upper spring

seat (key 33), and apply lubricant to the upper

spring seat (key 33).

22. Install the spring case (key 29) so that the

screened vent assembly (key 30) is in the correct

position for the application. Place the nameplates

over the screw holes, insert the spring case cap

screws (key 37), and nger tighten.

23. Screw in the adjusting screw (key 35) to put slack

into the diaphragm (key 23).

24. Using a crisscross pattern, nish tightening the

spring case cap screws (key 37) to 7 foot-pounds /

9.5 N•m of torque.

25. If necessary, refer to the installation and/or the

Startup and Adjustment procedures.

26. Install the adjusting locknut (key 34) after

regulator adjustment.

Parts Ordering

When corresponding with your local Sales Ofce about

this equipment, always reference the equipment serial

number or FS number that can be found on

the nameplate.

When ordering replacement parts, reference the key

number of each needed part as found in the following

parts list. Separate kits containing all recommended

spare parts are available.

Parts List

Note

In this parts list, parts marked NACE are

intended for corrosion-resistant service

as detailed in the NACE International

Standard MR0175.

Key Description Part Number

Type 627 Parts Kit with Aluminum/Nitrile (NBR) trim

(include keys 4, 9, 11, 12, and 23) R627X000A12

Type 627 Parts Kit with Stainless steel/

Nitrile (NBR) trim

(include keys 4, 9, 11, 12, and 23) R627X000S12

Type 627H Parts Kit with SST/Nylon (PA) trim R627HX00S12

Type 627R Parts Kit with Aluminum/

Nitrile (NBR) trim

(include keys 4, 9, 11, 12, 23, 28, and 48) R627RX00A12

Type 627R Parts Kit with Stainless steel/

Nitrile (NBR) trim

(include keys 4, 9, 11, 12, 23, 28, and 48) R627RX00S12

1 Body

Ductile iron

1000 psig / 69.0 bar maximum inlet pressure

3/4 NPT 30B3046X012

1 NPT 30B3048X012

2 NPT 30B3096X012

Ductile iron (Long Body)

1000 psig / 69.0 bar maximum inlet pressure

1 NPT 39B2451X012

2 NPT 39B0414X012

Steel

2000 psig / 138 bar maximum inlet pressure

3/4 NPT 30B3050X012

1 NPT 30B3051X012

2 NPT 30B7452X012

Steel (Long Body)

2000 psig / 138 bar maximum inlet pressure

1 NPT 39B0412X012

2 NPT 39B0415X012

Steel, CL600 RF anged

1500 psig / 103 bar maximum inlet pressure

NPS 1 / DN 25 40B6754X012

NPS 2 / DN 50 40B6756X012

Steel, CL300 RF anged

750 psig / 51.7 bar maximum inlet pressure

NPS 1 / DN 25 41B8978X012

NPS 2 / DN 50 41B8080X012

(1)

14

1. Bodies can be used for both standard and NACE constructions.

Page 15

627 Series

Key Description Part Number

1 Body

(1)

(continued)

Steel, CL150 RF anged

290 psig / 20.0 bar maximum inlet pressure

NPS 1 / DN 25 43B8656X022

NPS 2 / DN 50 44B0666X012

Steel, BWE

1000 psig / 69.0 bar maximum inlet pressure

NPS 1 / DN 25 33B6723X012

NPS 2 / DN 50 38B1688X012

Steel, PN 16/25/40 RF

580 psig / 40.0 bar maximum inlet pressure

NPS 1 / DN 25 44B0386X012

NPS 2 / DN 50 44B3342X012

Stainless Steel

(2)

, NPT

2000 psig / 138 bar maximum inlet pressure

3/4 NPT 30B3050X062

1 NPT 30B3051X092

2 NPT 30B7452X052

Stainless Steel

(2)

, CL150 RF anged

275 psig / 18.9 bar maximum inlet pressure

NPS 1 / DN 25 43B8656X052

NPS 2 / DN 50 44B0666X022

Stainless Steel

(2)

, CL300 RF anged

720 psig / 49.6 bar maximum inlet pressure

NPS 1 / DN 25 41B8978X072

NPS 2 / DN 50 41B8080X072

Stainless Steel

(2)

, CL600 RF anged

1440 psig / 99.2 bar maximum inlet pressure

NPS 1 / DN 25 40B6754X102

NPS 2 / DN 50 40B6756X062

Stainless Steel

(2)

, PN 16/25/40 RF

580 psig / 40.0 bar maximum inlet pressure

NPS 1 / DN 25 44B0386X032

NPS 2 / DN 50 44B3342X032

2* Orice

Aluminum

3/32 inch / 2.4 mm 0R044109022

1/8 inch / 3.2 mm 1A936709012

3/16 inch / 4.8 mm 00991209012

1/4 inch / 6.4 mm 0B042009012

3/8 inch / 9.5 mm 0B042209012

1/2 inch / 13 mm 1A928809012

303 Stainless steel

3/32 inch / 2.4 mm 0R044135032

1/8 inch / 3.2 mm 1A936735032

3/16 inch / 4.8 mm 00991235032

1/4 inch / 6.4 mm 0B042035032

3/8 inch / 9.5 mm 0B042235032

1/2 inch / 13 mm 1A928835032

316 Stainless steel, NACE construction only

3/32 inch / 2.4 mm 0R0441X0012

1/8 inch / 3.2 mm 1A9367X0022

3/16 inch / 4.8 mm 009912X0012

1/4 inch / 6.4 mm 0B0420X0012

3/8 inch / 9.5 mm 0B0422X0012

1/2 inch / 13 mm 1A9288X0012

3 Cap Screw (not shown), (2 required)

627 Series

For Ductile iron/Steel diaphragm case 1A560724052

For Aluminum diaphragm case

(not applicable for Types 627H and 627HM) 1A352524052

Type 627 Only

For Ductile iron/Steel diaphragm case 1A5607X0052

For Aluminum case with Steel diaphragm case 10A3869X012

For SST Case and body 1A5607X0052

For Aluminum Case and SST body 10A3869X022

Key Description Part Number

4* Diaphragm Case O-ring

Nitrile (NBR)

For Type 627, 627H, or 627R only 17A2325X022

Fluorocarbon (FKM)

For Types 627, 627R, and 627LR only 10A0037X012

5 Diaphragm Case

For Type 627, 627R, or 627LR

Aluminum without 1/8-inch / 3.2 mm gauge tap 40B3084X012

Aluminum with 1/8-inch / 3.2 mm gauge tap

for 627 Series (except Types 627H and 627HM) 11B5380X012

Ductile iron without 1/8-inch / 3.2 mm gauge tap 30B3053X012

Ductile iron with 1/8-inch / 3.2 mm gauge tap

for 627 Series (except Types 627H and 627HM) 31B0641X012

For Type 627, 627R, or 627LR

Steel 30B3104X012

Ductile iron with 1/4 NPT gauge tap for

627 Series (except Types 627H and 627HM) 39A5987X012

Steel with 1/4 NPT gauge tap for 627 Series

(except Type 627H) 30B8734X012

For Type 627M or 627MR

Ductile iron 39A5987X012

Steel 30B8734X012

For Type 627H, Steel 30B3104X012

For Type 627, Stainless steel 30B3104X082

For Type 627HM, Steel 30B8734X012

6 Boost Body (not for Type 627M, 627HM,

or 627MR), Delrin

®

For Type 627 or 627H 30B3056X012

For Type 627R or 627LR 30B3057X012

7 Stabilizer

Nitrile (NBR)

For Types 627, 627H, 627R, and 627LR only 10B3060X012

Fluorocarbon (FKM)

For Types 627, 627R, and 627LR only 10B3060X022

8 Stem Guide (for Types 627, 627H, 627R, and

627LR only), Powdered metal 20B3061X012

9* Disk Assembly (for all Orice Size)

Aluminum holder and Nitrile (NBR) disk 1C4248X0212

303 Stainless steel holder and Nitrile (NBR) disk 1C4248X0202

Aluminum holder and Nylon (PA) disk 1C4248X00A2

303 Stainless steel holder and Nylon (PA) disk 1C4248X0062

316 Stainless steel holder and Nylon (PA) disk 1C4248X0262

316 Stainless steel holder and Nitrile (NBR) disk 1C4248X0252

303 Stainless steel holder and

Fluorocarbon (FKM) disk 1C4248X0052

Aluminum holder and Fluorocarbon (FKM) disk 1C4248X0182

316 Stainless steel holder and

Fluorocarbon (FKM) disk 1C4248X0192

10 Stem

303 Stainless steel 10B3059X012

316 Stainless steel (NACE) 10B3059X022

11* Stem O-ring

Nitrile (NBR) 1D687506992

Fluorocarbon (FKM) For Types 627, 627R,

627LR, 627M, and 627MR only 1N430406382

12* Stem Back-up Ring,

Polytetrauoroethylene (PTFE) (2 required) 1K786806992

13 Hair Pin Clip, Stainless steel 10B3058X012

14 Drive Pin, Plated steel 1H3671X0012

15 Lever, Plated steel 20B3063X012

16 Lever Retainer, Plated steel 30B3097X012

17 Lever Pin

Stainless steel 10B3083X012

316 Stainless steel (NACE) 10B3083X022

*Recommended spare part.

1. Bodies can be used for both standard and NACE constructions.

2. Stainless steel body material can be used for applications in temperature ranges down to -40°F / -40°C and are only available for Types 627, 627R, and 627H.

Delrin® is a mark owned by E.I. du Pont de Nemours and Co.

15

Page 16

627 Series

Key Description Part Number

18 Lever Cap Screw (2 required)

Plated steel 10B7454X012

316 Stainless steel (NACE) 1B2905X0012

19 Pusher Post, Aluminum

For Type 627 or 627M 10B3098X012

For Type 627R, 627LR, or 627MR 10B3098X022

For Type 627H or 627HM,

416 Stainless steel 10B3098X032

Stainless steel (NACE) 10B3098X102

21 Diaphragm Connector (for Type 627R, 627LR,

or 627MR only), Stainless steel 28B8832X012

22 Diaphragm Connector Nut (for Type 627R, 627LR,

or 627MR only), Stainless steel 10B7449X012

23* Diaphragm

Nitrile (NBR)

For Type 627 or 627M with Aluminum or

Ductile iron diaphragm case 10B3069X012

For Type 627 or 627M with

Steel diaphragm case 10B8735X012

For Type 627R, 627LR, or 627MR with

Aluminum or Ductile iron diaphragm case 10B3068X012

For Type 627R, 627LR, or 627MR with

Steel diaphragm case 10B8736X012

For Type 627H or 627HM with Steel

diaphragm case (diaphragm is Neoprene (CR)

with Nylon (PA) fabric) 12B0178X012

Fluorocarbon (FKM)

For Types 627R, 627LR, and 627MR

with Steel case 10B8736X022

For Types 627 and 627M with Steel case 10B8735X042

For Types 627R, 627LR, and 627MR

with Ductile Iron and Aluminum Casing 10B3068X022

For Types 627 and 627M

with Ductile Iron and Aluminum Casing 10B3069X032

24 Diaphragm Head, Plated steel

For Type 627 or 627M, Plated steel 1D666428982

For Type 627R, 627LR, or 627MR, Plated steel 10B3071X012

For Type 627H or 627HM, 416 Stainless steel 12B0175X012

25 Relief Spring Seat (For Type 627R or

627MR only), Steel 10B7446X012

26 Guide Retainer (For Type 627R, 627LR, or

627MR only), Stainless steel 10B7450X012

27 Relief Spring (For Type 627R or 627MR only),

Plated steel 10B6757X012

For Type 627LR 1B541327022

28* Relief Seal O-ring

Nitrile (NBR)

For Type 627R, 627LR, or 627MR only 1J108506992

Fluorocarbon (FKM)

For Types 627R, 627LR, and 627MR only 1J1085X0042

29 Spring Case

For Type 627, 627R, or 627LR

Aluminum 40B3086X012

Ductile iron 30B3055X012

Steel 30B3102X012

Stainless steel (Types 627 and 627R only) 30B3102X092

29 Spring Case (continued)

For Type 627M or 627MR

Ductile iron 30B3055X012

Steel 30B3102X012

For Type 627H or 627HM

Steel 30B3102X012

Stainless steel (Type 627H only) 30B3102X092

Key Description Part Number

30 Screened Vent Assembly, Plastic 10B3093X012

31 Lower Spring Seat, Plated steel

For Type 627 or 627M 1D666625072

For Type 627R, 627LR, or 627MR 20B3073X012

32 Control Spring, Plated steel

5 to 20 psig / 0.34 to 1.4 bar, Yellow 10B3076X012

15 to 40 psig / 1.0 to 2.8 bar, Green 10B3077X012

35 to 80 psig / 2.4 to 5.5 bar, Blue 10B3078X012

70 to 150 psig / 4.8 to 10.3 bar, Red 10B3079X012

140 to 250 psig range / 9.7 to 17.2 bar, Blue,

used for Type 627H or 627HM 10B3078X012

240 to 500 psig range / 16.5 to 34.5 bar, Red,

used for Type 627H or 627HM 10B3079X012

33 Upper Spring Seat, Plated steel 1D667125072

34 Locknut, Plated steel 1D667728982

35 Adjusting Screw, Plated steel

For Type 627, 627M, 627H, or 627HM 10B3081X012

For Type 627R, 627LR, or 627MR 10B3080X012

36 Adjusting Screw Cap, Plastic 20B3082X012

37 Spring Case Cap Screw, Plated steel

(8 required)

For Aluminum or ductile iron diaphragm case 1A391724052

For Steel diaphragm case 1A368324052

For Stainless steel case and body 1A3683X0062

For Aluminum case and SST body 1A3917X0062

For Type 627H/HM, steel diaphragm case 1A346424052

For Type 627H, Stainless steel case and body 1A3464X0022

43 Blocked Throat (For Type 627M, 627HM, or

627MR only), Stainless steel 10B3085X012

44* Blocked Throat O-ring

Nitrile (NBR) For Type 627M, 627HM, or

627MR only (2 required) 1E264306992

Fluorocarbon (FKM)

For Types 627M and 627MR only 1E2643X0022

45* Blocked Throat Back-up Ring (For Type 627M,

627HM, or 627MR only), PTFE (2 required) 10B3106X012

46 Diaphragm Head Cap Screw, Steel

For Type 627 or 627M 1B290524052

For Type 627H or 627HM 1C379124052

47 Relief Seal Retainer (For Type 627R, 627LR, or

627MR only), Stainless steel 10B7445X012

48* Guide Retainer O-ring

Nitrile (NBR)

For Type 627R, 627LR, or 627MR only 1D682506992

Fluorocarbon (FKM)

For Types 627R, 627LR, and 627MR only 1N423906382

49 Relief Indicator (For Type 627R, 627LR, or

627MR only), Rubber (not shown) 30B3100X012

50 Diaphragm Limiter

(For Types 627H and 627HM only) 22B0176X012

51* Diaphragm Limiter O-ring

For Types 627H and 627HM only 1K877606992

52* Pusher Post O-ring (2 required)

For Types 627H and 627HM only 1C853806992

58 Pipe Plug, Zinc 1D8293T0022

67 Drive Screw, 18-8 Stainless steel 1A368228982

72 Pipe Plug, Zinc-plated steel 1A767524662

*Recommended spare part.

16

Page 17

627 Series

L1

36

L1

33

30

31

24

23

35

34

32

29

18

37

5

8

4

7

6

L2

46

19

15

L2

14

17

16

L2 L2

30B3092_G

APPLY LUBRICANT

L1 = MULTI-PURPOSE LITHIUM POLYMER TYPE GREASE

L2 = EXTREME LOW-TEMPERATURE BEARING GREASE

PARTS NOT SHOWN: 3

1. Lubricants must be selected such that they meet the temperature requirements.

(1)

Figure 7. Type 627 Regulator Assembly

11

12

10

L2

1

2

L1

9

13

17

Page 18

627 Series

49

25

48

31

24

23

L2

L1

30

27

22

21

29

34

36

35

33

26

32

18

37

5

8

4

7

6

1

L2

28

47

L1

19

15

14 17

16

L2 L2 L2

30B3089_G

APPLY LUBRICANT

L1 = MULTI-PURPOSE LITHIUM POLYMER TYPE GREASE

L2 = EXTREME LOW-TEMPERATURE BEARING GREASE

PARTS NOT SHOWN: 3

1. Lubricants must be selected such that they meet the temperature requirements.

(1)

Figure 8. Type 627R Regulator Assembly

11

12

10

L2

2

L1

9

13

18

Page 19

627 Series

49

48

31

24

23

L2

47

L1

30

27

22

21

28

29

34

36

35

33

26

32 18

37

5

8

4

7

6

1

2

L2

L1

19

15

L2

38B4843_C

APPLY LUBRICANT

L1 = MULTI-PURPOSE LITHIUM POLYMER TYPE GREASE

L2 = EXTREME LOW-TEMPERATURE BEARING GREASE

PARTS NOT SHOWN: 3

1. Lubricants must be selected such that they meet the temperature requirements.

(1)

14

17

Figure 9. Type 627LR Regulator Assembly

16

L2

10

L2

L1

9

13

19

Page 20

627 Series

36

L1

33

30

31

24

23

35

3234

29

18

37

5

44

L2

45

43

L1

46

19

15

14

L2

30B6433_E

APPLY LUBRICANT

L1 = MULTI-PURPOSE LITHIUM POLYMER TYPE GREASE

L2 = EXTREME LOW-TEMPERATURE BEARING GREASE

PARTS NOT SHOWN: 3

1. Lubricants must be selected such that they meet the temperature requirements.

(1)

17

16

L2

Figure 10. Type 627M Regulator Assembly

11

L2

12

10

L2

1

2

L1

9

13

20

Page 21

627 Series

49

25

48

31

24

23

L2

L1

30

27

22

21

29

34 36

35

33

26

32

18

37

5

44

45

43

1

L2

28

47

L1

19

15

14

L2

30B6434_E

APPLY LUBRICANT

L1 = MULTI-PURPOSE LITHIUM POLYMER TYPE GREASE

L2 = EXTREME LOW-TEMPERATURE BEARING GREASE

PARTS NOT SHOWN: 3

1. Lubricants must be selected such that they meet the temperature requirements.

(1)

Figure 11. Type 627MR Regulator Assembly

1617

L2 L2

11

12

2

L1

9

1310

L2

21

Page 22

627 Series

36

L1

33

30

24

37

23

35

34

32

29

52

51

18

5

8

4

7

6

50

L2

L1

46

19

15

14

17

16

L2

L2 L2

31B5374_D

APPLY LUBRICANT

L1 = MULTI-PURPOSE LITHIUM POLYMER TYPE GREASE

L2 = EXTREME LOW-TEMPERATURE BEARING GREASE

PARTS NOT SHOWN: 3

1. Lubricants must be selected such that they meet the temperature requirements.

(1)

11

12

10

L2

1

2

L1

9

13

22

Figure 12. Type 627H Regulator Assembly

Page 23

627 Series

36

L1

33

30

24

37

23

35

34

32

29

52

51

18

5

44

45

43

50

L2

L1

46

19

15

14

17

L2

31B9872_D

APPLY LUBRICANT

L1 = MULTI-PURPOSE LITHIUM POLYMER TYPE GREASE

L2 = EXTREME LOW-TEMPERATURE BEARING GREASE

PARTS NOT SHOWN: 3

1. Lubricants must be selected such that they meet the temperature requirements.

(1)

L2 L2 L2

16

11

12

10

1

2

L1

9

13

Figure 13. Type 627HM Regulator Assembly

23

Page 24

627 Series

Industrial Regulators

Emerson Process Management

Regulator Technologies, Inc.

USA - Headquarters

McKinney, Texas 75069-1872, USA

Tel: +1 800 558 5853

Outside U.S. +1 972 548 3574

Asia-Pacic

Shanghai 201206, China

Tel: +86 21 2892 9000

Europe

Bologna 40013, Italy

Tel: +39 051 419 0611

Middle East and Africa

Dubai, United Arab Emirates

Tel: +971 4811 8100

For further information visit www.fisherregulators.com

The Emerson logo is a trademark and service mark of Emerson Electric Co. All other marks are the property of their prospective owners. Fisher is a mark owned by Fisher Controls International LLC,

a business of Emerson Process Management.

The contents of this publication are presented for informational purposes only, and while every effort has been made to ensure their accuracy, they are not to be construed as warranties or

guarantees, express or implied, regarding the products or services described herein or their use or applicability. We reserve the right to modify or improve the designs or specications of such

products at any time without notice.